Page 1

a

RAMP

RAMP

CLOCK

R

SET

CAL IN

8-BIT

DATA

SEM/DEM

LEM/TEM

RETRACE

REF

DAC

OUTPUT

LOGIC

PWM

OUT

CAL

DAC

INTERNAL

TIMING

L

A

T

C

H

L

A

T

C

H

AD9561

CAL

OUT

CAL

OUT

Pulse Width Modulator

AD9561

FEATURES

60 MHz Pulse Rate

8-Bit Resolution

Center, Left or Right Justify

Low Power: 700 mW typical

Minimum Pulse Width: <5 ns

Maximum PW: 100 % Full-scale

APPLICATIONS

Laser Printers

Digital Copiers

Color Copiers

GENERAL DESCRIPTION

The AD9561 is a second generation high speed, digitally

programmable pulse width modulator (PWM). Output pulse

width is proportional to an 8-bit DATA input value. Two

additional control inputs determine if the pulse is placed at the

beginning, middle or end of the clock period. Pulse width and

placement can be changed every clock cycle up to 60 MHz.

Pulse width modulation is a well proven method for controlling

gray scale and resolution enhancement in scanning laser print

engines. Modulating pulse width provides the most cost

effective method for continuous tone reproduction and resolu-

tion enhancement in low-to-moderate cost scanning electro-

photographic systems.

The AD9561 uses precision analog circuits to control dot size

so that near-photographic quality images are practical without

the high frequency clock signals required by all digital approaches.

The AD9561 has improved features and performance over its

predecessor, the AD9560. An improved ramp topology enables

control of pulse width through 100% of the dot clock period as

opposed to 95% for the AD9560. This enables smooth transi-

tion across dot boundaries for line screen applications.

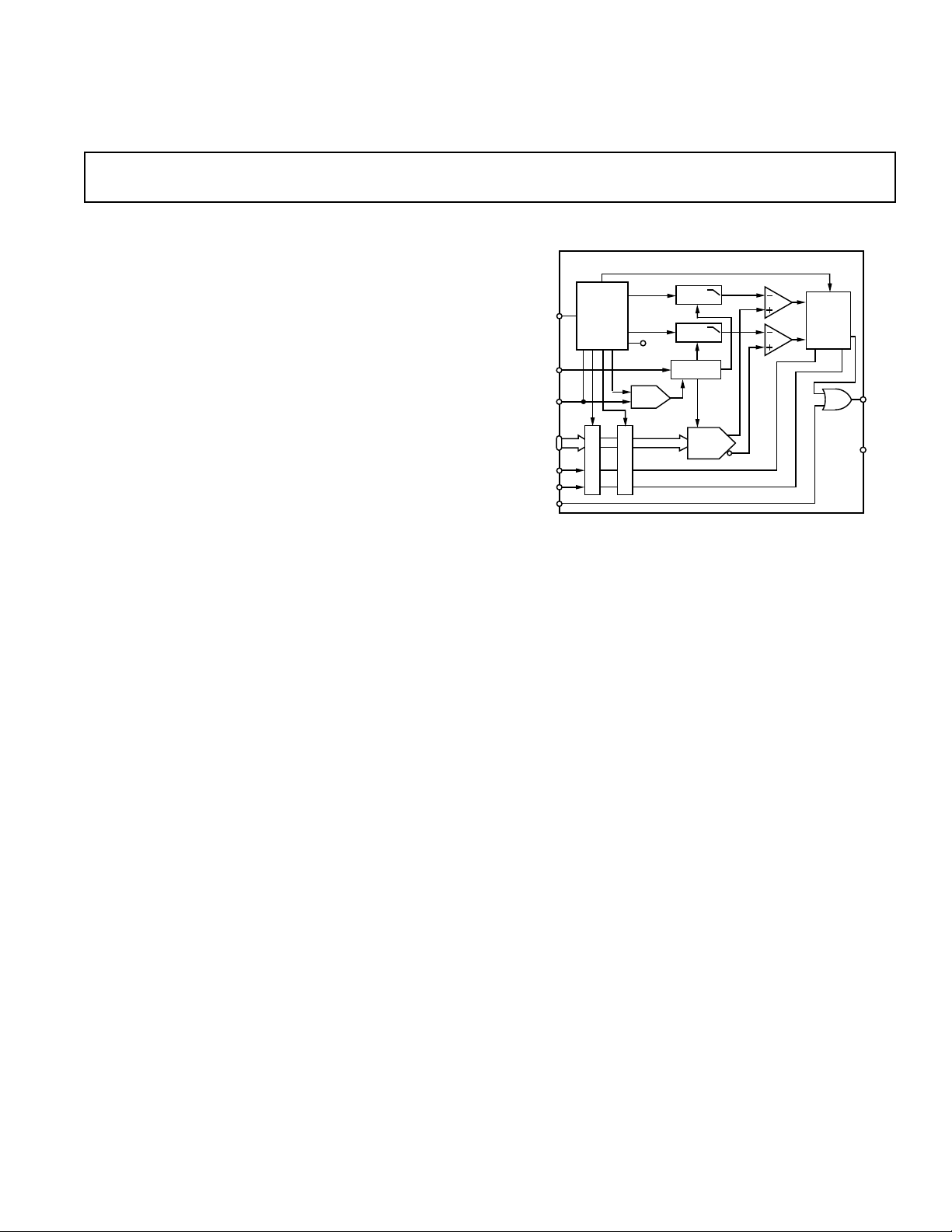

FUNCTIONAL BLOCK DIAGRAM

Additionally, input data setup and hold time are symmetrical at

2 ns each, simplifying interface to the system bus.

Finally, chip design and pinout are optimized to decrease

sensitivity of analog circuits to digital coupling. (See layout

section for detailed recommendations for optimum results.)

Inputs are TTL or CMOS compatible, and outputs are CMOS

compatible. The AD9561JR is packaged in a 28-lead plastic

SOIC. It is rated over the commercial temperature range, 0°C

to +70°C.

HIGHLIGHTS

1. 60 MHz native printer clock rate.

2. Single +5 V power supply.

3. On-chip Autocalibration.

4. Pulse placement flexibility.

5. High resolution: 256 pulse widths.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1996

Page 2

AD9561–SPECIFICATIONS

(+VS = +5 V; R

= 715 V, CLOCK = 20 MHz unless otherwise noted)

SET

AD9561JR

Parameter Temp Min Typ Max Units

RESOLUTION 8 Bits

ACCURACY (@ 20 MHz)

Differential Nonlinearity +25°C ±0.5 ±2 LSB

Integral Linearity

Odd/Even Pulse Mismatch

1

2

+25°C ± 1.5 ±4 LSB

+25°C ±0.75 LSB

DIGITAL INPUTS

Logic “1” Voltage Full 2.0 V

Logic “0” Voltage Full 0.8 V

Input Current Full ±1 µA

Input Capacitance

+25°C

5pF

Data Setup Time Full 2.0 0.3 ns

Data Hold Time Full 2.0 0.3 ns

Minimum Clock Pulse Width (HIGH) Full 6 ns

DYNAMIC PERFORMANCE

Maximum Trigger Rate Full 60 MHz

Minimum Propagation Delay (t

Minimum Propagation Delay TC Full 60 ps/°C

Output Pulse Width @ Code 25

Output Pulse Width @ Code 255 Full 100 % Clock

Output Rise Time

Output Fall Time

5, 6

5, 6

PD

3

)

4

+25°C122028ns

Full 5 ns

Full 1.8 3 ns

Full 1.8 3 ns

RETRACE Propagation Delay Full 6 ns

PWM OUTPUT

Logic “1” Voltage

Logic “0” Voltage

5, 6

5, 6

Full 4.6 V

Full 0.4 V

CAL OUT

Logic “1” Voltage Full 4.6 V

Logic “0” Voltage Full 0.4 V

POWER SUPPLY

7

Positive Supply Current (+5.0 V) Full 140 170 mA

Power Dissipation Full 700 850 mW

Power Reduce Current Full 70 85 mA

Power Reduce Dissipation Full 350 425 mW

Power Supply Rejection Ratio

Propagation Delay Sensitivity (TEM)

NOTES

1

Best Fit between codes 25 and 230. INL is very layout sensitive.

2

Due to linearity mismatch in dual ramps.

3

Measured from rising edge of clock to transition of Codes 0 to 255.

4

Minimum pulse width (at 20 MHz) limited by rise time. Pulse width for Code 25 will be greater when CLOCK < 20 MHz.

5

Output load = 10 pF and 2 mA source/sink.

6

Load conditions to test output drive capability. Linearity will degrade with either capacitive or current loading. Best linearity obtained driving a single CMOS input.

7

All performance specifications valid when supply maintained at +5 V, ±5%.

8

Tested from +4.75 V to +5.25 V.

Specification subject to change without notice.

8

+25°C 1.5 ns/V

–2–

REV. 0

Page 3

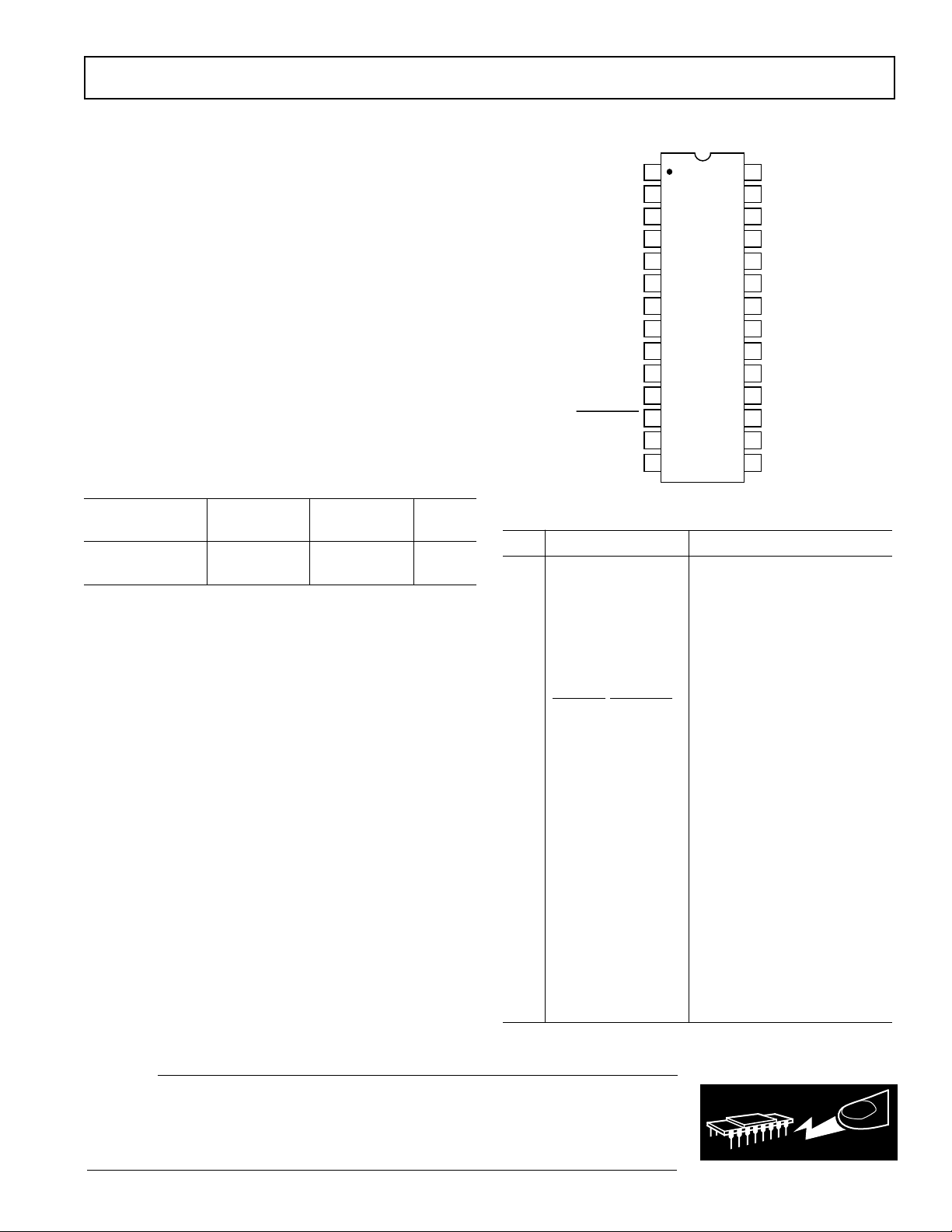

AD9561

28

27

26

22

21

20

19

18

17

25

24

23

TOP VIEW

(Not to Scale)

1

2

3

7

8

9

10

11

12

4

5

6

13

14

16

15

AD9561

OUT

V

DD

D2

D1

GND

V

DD

RETRACE

CAL START

V

DD

GND

D0 (LSB)

LEM/TEM

SEM/DEM

GND

D3

D4

D5

V

DD

GND

V

DD

CAL OUT

GND

D7(MSB)

CLOCK

GND

R

SET

D6

PWR REDUCE

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

PIN CONFIGURATION

Positive Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . +7 V

Digital Input Voltage Range . . . . . . . . . . . . . . . –0.5 V to V

Minimum R

Digital Output Current (Sourcing)

Digital Output Current (Sinking)

Operating Temperature Range

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Ω

SET

2

. . . . . . . . . . . . . . . 10 mA

2

. . . . . . . . . . . . . . . . 10 mA

3

. . . . . . . . . . . . . 0°C to +70°C

DD

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . .+150°C

Lead Soldering Temperature (10 sec)

NOTES

1

Absolute maximum ratings are limiting values, to be applied individually, and

beyond which serviceability may be impaired. Functional operation under any of

these conditions is not necessarily implied.

2

CAL OUT should drive a single TTL or CMOS input.

3

Typical Thermal Impedance:

28-lead SOIC (plastic) θJA = 71.4 °C/W; θJC = 23°C/W.

4

When soldering surface mount packages in vapor phase equipment, temperature

should not exceed 220°C for more than one minute.

4

. . . . . . . . . . . .+300°C

ORDERING GUIDE

Temperature Package Package

PIN DESCRIPTIONS

Model Range Description Option

Pin Name Description

AD9561JR 0°C to +70°C 28-Lead SOIC R-28

AD9561JR-REEL* 0°C to +70°C 28-Lead SOIC R-28

*Tape and Reel ordered in multiples of 1000 ICs.

1–5 D3–D7 Digital Data Bits, D7 Is MSB

6 CLOCK Clock Input

7V

DD

8 GND Ground Return

9V

DD

10 GND Ground Return

11 CAL OUT Calibration Complete Output

12

POWER REDUCE Place AD9561 in Sleep Mode

13 GND Ground Return

14 R

SET

15 GND Ground Return

16 V

DD

17 CAL START Initiates Calibration Cycle

18 RETRACE Force Output High

19 V

DD

20 GND Ground Return

21 OUT Modulated Pulse Out

22 GND Ground Return

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9561 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

23 V

DD

24 LEM/TEM Controls Leading (1) or

25 SEM/DEM Controls Single (1) or Dual (0)

26–28 D0–D2 Digital Data Bits, D0 is LSB

–3–

+5 V Supply

+5 V Supply

Ramp Current Set Resistor

+5 V Supply

+5 V Supply

+5 V Supply

Trailing (0) Edge Modulation

Edge Modulation

Page 4

AD9561

LEADING EDGE

MODULATION

TRAILING EDGE

MODULATION

DUAL EDGE

MODULATION

CLOCK

N

N+1 N+1

THEORY OF OPERATION

General

The AD9561 is a mixed signal IC designed to provide highspeed pulse width modulation in laser printers and copiers. It

uses high performance analog circuits to achieve high resolution

pulse control without requiring the excessively high clock rates

of an all digital solution.

Because of the sensitivity of analog circuits to digital crosstalk,

PCB layout is critical for achieving optimum results. Please read the

layout section at the end of this data sheet and follow suggestions

completely for best performance.

The AD9561 was designed to facilitate either higher effective

resolution or photo-realistic image reproduction on low cost

laser print platforms. Its 8-bit pulse width resolution and pulse

positioning capabilities combine to offer the highest level of gray

shading and resolution enhancement flexibility available. It

also includes an autocalibration circuit to minimize external

components, and eliminates an extra burden on the system

microprocessor.

The Functional Block Diagram illustrates the analog content,

comprising ramp generators, DACs and comparators that

generate a series of pulses. These pulses are combined in the

output logic to form PWM OUT pulses whose width is proportional to the 8-bit DATA and whose position is determined by

the SEM/DEM and LEM/TEM inputs.

The AD9561 employs a proprietary ramp topology that

eliminates the loss of dynamic range at the ends of the ramp.

The Functional Block Diagram is shown for illustration purposes

only and does not represent the actual implementation.

Modulation Modes

Positioning the width controlled pulses at the beginning, middle

or end of the CLOCK period, as shown in Figure 2, adds

significantly to the flexibility of the AD9561. This is accomplished through control bit SEM/DEM and LEM/TEM. These

acronyms represent Single-Edge Modulation/Dual-Edge

Modulation and Leading-Edge Modulation/Trailing-Edge

Modulation. SEM/DEM and LEM/TEM are collectively

identified as CONTROL.

DATA

CONTROL

OUTPUT

FF, XX

00, XX C0, 10 C0, 0X C0, 0X 80, 0X 40, 0X 00, XX C0, 0X E0, 11 FF, XX

100%

DNC

PULSE N

0%

DNC

PULSE

N+1

75%

TEM

75%

DEM

75%

DEM

50%

DEM

25%

DEM0%DNC

75%

DEM

87%

LEM

Figure 1. Pulse Pattern Example

Figure 2. Modulation Modes

Pulse positioning within the CLOCK period is defined by the

following table:

Table I. Truth Table

SEM/DEM LEM/TEM Alignment

1 1 LEM

1 0 TEM

0 X DEM

Single-Edge Modulation offers two options in which one edge is

modulated while the other remains fixed relative to the CLOCK.

For Leading-Edge Modulation, the rising edge of the pulse is

delayed from the leading edge of the CLOCK proportional to

DATA, and the falling edge remains fixed at the end of the

CLOCK period. This may also be called “right-hand justified.”

Similarly, Trailing-Edge Modulation has the rising edge fixed

on the beginning of the CLOCK period and the falling edge

delayed proportional to DATA. This can be called “left-hand

justified.”

Dual-Edge Modulation is often called “center justified” because

the delay of both edges varies relative to the CLOCK. With

increasing values for DATA, pulse width increases with its

center remaining constant proportional to the CLOCK.

Like DATA, modulation control inputs SEM/DEM, and

LEM/TEM can be updated at the CLOCK rate up to 60 MHz.

–4–

REV. 0

Page 5

AD9561

t

AC

CAL START

CAL OUT

1µs MIN

Pulse Pattern Example

Figure 1 at the top of the previous page illustrates the PWM

OUT of the AD9561 with various DATA and CONTROL

inputs. The DATA format is Binary. In the Pulse Pattern

Example, the Hexadecimal format is used, i.e., FF

represents

H

decimal 255.

The top line shows the CLOCK; the second shows DATA and

CONTROL inputs, which are latched on the rising edge of

CLOCK. The third line shows the resulting pulse.

The AD9561 DATA and CONTROL inputs are double

latched. The OUTPUT pulse labeled “Pulse N” results from

DATA and CONTROL values latched in by the first CLOCK,

illustrating the one CLOCK period timing delay.

The CONTROL value number for pulse one is shown as xx.

This means the value is not important because a 100% pulse

will be output for any CONTROL value for DATA value 255 or

FF

. Likewise, OUTPUT Pulse N is noted as 100% DNC (do

H

not care), also noting that CONTROL value is unimportant.

The fourth DATA/CONTROL value is C0/0X. This indicates

that the level for LEM/TEM is unimportant when SEM/DEM is

logic Level “0”.

Selecting R

SET

Because the AD9561 must provide full range coverage of the

CLOCK pulse period, the ramp time must be matched to the

CLOCK period. All components for the ramp generators, except

R

, are integrated in the AD9561.

SET

, is selected by the user to set the ramp time close to the

R

SET

CLOCK period. The ramps are generated by constant current

sources charging on-chip capacitors.

R

can be chosen in the range from 226 Ω for 60 MHz

SET

operation to 16.5 kΩ for 1 MHz. Because the absolute value of

the on-chip capacitor can vary by ± 20%, the autocalibration

circuit is included to fine tune the matching of the ramp time to

the CLOCK period.

100

where F is the CLOCK frequency in Hz. The resistor value

determined by the equation will generate a current near centerrange of the autocalibration circuit.

Autocalibration

The AD9561 should be calibrated when power is applied to the

system or after a power reduce cycle.

Figure 4. Autocalibration Timing

Autocalibration is initiated by applying a pulse of 1 µs minimum

duration to Pin 17, CAL START. The CLOCK pulse should be

applied continuously during calibration. As Figure 4 shows, the

initial state of CAL OUT is not known.

During the CAL IN pulse, all internal logic is initialized for

calibration and proper synchronization once calibration is

complete; the falling edge of CAL IN initiates the Auto-CAL

cycle.

Auto-CAL is not affected by the code applied to the DATA or

CONTROL inputs. However, to assure that no pulses are

generated during calibration, it is suggested that all digital

inputs be held at Logic “0.”

On the falling edge of CAL IN, the ramp’s slope is set as slow as

possible for the current R

. Figure 4 shows the RAMP slope

SET

increasing as autocalibration adds small incremental currents,

until it crosses the internal REF LO before the end of the

CLOCK period.

RAMP

END OF CLOCK CYCLE

10

CLOCK FREQUENCY – MHz

1

0201

Figure 3. R

SET

Figure 3 shows approximate values for R

R

– kΩ

SET

Values vs. CLOCK Frequency

SET

10

over the operating

frequency range. The following equation should be used to

determine R

REV. 0

SET

:

30.2068 ×10

R =

1.04414

F

9

REF LO

TIME

RAMP

Figure 5. Autocalibration Conceptual

The calibration current is incremented on each 32nd CLOCK

pulse until the full-scale ramp time is equal to the period of the

CLOCK. Cal Complete is detected and CAL OUT goes high

when the ramp crosses REF LO before it is reset by the next

CLOCK. With a maximum of 64 incremental increases, the

maximum autocalibration time, t

equation:

tAC=

where: FC = CLOCK frequency in Hertz

, can be calculated by the

AC

32×64

F

C

–5–

Page 6

AD9561

This yields the maximum time from the trailing edge of CAL IN

to the rising edge of CAL OUT. As an example, the maximum

time required for auto-calibration for a system with clock frequency

of 20 MHz is 102.4 ms plus the width of the CAL IN pulse.

Power Reduce

The POWER REDUCE function permits the user to power

down all nonessential circuits when the printer is not active.

Applying a Logic “0” to POWER REDUCE decreases the

power supply requirement by approximately half.

APPLICATIONS

DATA Timing

Input DATA to the AD9561 is double latched. As a result of the

internal timing, the OUTPUT is delayed more than one clock

period from its corresponding DATA word. Figure 6 illustrates

timing of DATA and CONTROL inputs relative to the CLOCK.

CLOCK

DATA

CONTROL

SETUP

HOLD

Figure 6. DATA and CONTROL Timing

The DATA and CONTROL inputs to the AD9561 are standard master-slave latches. Inputs are latched in on the rising

edge of the CLOCK with 2 ns Set-Up time and 2 ns Hold time.

This is a design improvement over the AD9560 meant to

simplify interfacing the AD9561 to digital processing circuits.

A propagation delay exists between the CLOCK and OUTPUT

pulses. The minimum propagation delay can be observed when

alternating between codes 0 (00

hexadecimal) and 255 (FF

H

H

hexadecimal). This delay is due in part to normal circuit

propagation; the remainder is due to time required to implement the proprietary ramp function. OUTPUT pulse transitions will typically occur 22 ns after the rising edge of CLOCK.

It may vary from 10 ns–35 ns over temperature.

Transfer Function

Output pulse width increases with increasing DATA values. As

the heavy line of Figure 7 shows, the transfer function of the

AD9561 is slightly nonideal.

100

80

60

40

PULSE WIDTH – Percentage

20

An ideal transfer would give 0% (or 0 ns) pulse width for a Code 0.

As the code is incremented in steps of one, the pulse width would

increase by 0.39% until it reached 100% for Code 255.

When operating at high clock rates, several of the most narrow

pulses do not reach valid logic Level “1” because of finite rise

time. For example, at 20 MHz, a 1.95% pulse (code 5 or 05

)

H

would have an expected pulse width of 1 ns. Because the rise

time is typically 1.5 ns, this pulse will not reach a full output

level. Therefore, depending on the clock rate, the lowest set of

codes produces a series of triangle waves increasing in width

and amplitude until a pulse of approximately 3 ns–5 ns reaches

a proper logic level. Thus, the transfer is flat until about

3 ns–5 ns pulse width (number of codes varies as a function of

CLOCK frequency).

Because of the new ramp topology in the AD9561, the transfer

function extends slightly greater than 100% (typically 102%) of

the clock period. This has the effect of creating smooth transitions

at the CLOCK period boundaries instead of the discontinuities

produced by the AD9560.

t

CLOCK

t

PD

(RIGHT JUSTIFIED)

LEM

t

CLOCK

t

CLOCK

TEM

(LEFT JUSTIFIED)

t

CLOCK

DEM

(CENTER JUSTIFIED)

Figure 8. Dot Clock Period Transitions

As shown in Figure 8, a Leading Edge Modulated pulse followed

by a Trailing Edge Modulated pulse will stay high from the rising

edge of the first pulse to the falling edge of the second. This is

due to Code 255 being designed to be typically 102% of the

CLOCK period. (Dashed lines indicate where transitions

would occur if the code for the following or preceding period

were 0.) Likewise, no gap occurs for maximum width Trailing

Edge Modulation to max pulse width for Dual Edge Modulation. Because the ending and starting characteristics of all

modes are symmetrical, any combination of pulses that ends at

the boundary of the first period and starts at the boundary of

the second period will produce a continuous pulse across the

boundary.

For the purposes of printing text, or any time absolute white or

black is required, 0 is decoded and a 100% LOW is output in

the next CLOCK cycle. Similarly, 255 is detected and the next

pulse is 100% HIGH.

Retrace

The RETRACE function permits driving the output to a

constant Logic High. For laser printer applications, applying a

logic “1” to RETRACE holds the laser on during the retrace

period so end of scan can be detected. Returning it to Logic

Low gives control back to the input data bits D0–D7.

0

025

12.5

128

CODE

255

Figure 7. Pulse Width Transfer Function

–6–

REV. 0

Page 7

AD9561

Grounding and Bypassing

Because the AD9561 uses analog circuits to achieve its superb

gray scale resolution, caution must be exercised when incorporating it into the mostly digital controller card for a printer.

Achieving the accuracy designed into the AD9561 requires that

interference due to improper grounding, power supply noise and

digital coupling be minimized by following good layout practices.

It is strongly urged that all following recommendations be

followed.

Factory characterization proves that a single ground plane

dedicated to the AD9561 is most effective. This is atypical of

many mixed signal circuits that use separate analog and digital

grounds. Due to the operating speed of the AD9561, separate

grounds result in erratic performance, which is eliminated by

using a single isolated ground plane. This is because the DATA

“low” value can be different from the ground value of the

AD9561. All pins on the AD9561 labeled GROUND should

be connected to the single dedicated ground plane. For best

results, it is suggested that this plane be in the first interior layer

under the IC. To assure logic level compatibility from the drive

circuits to the AD9561, a single connection to the board’s main

ground is necessary.

The connection between the dedicated ground plane and the

board’s main ground should be parallel to the path of the digital

signals interfacing to the AD9561. High frequency return current

seeks the path most parallel to the signal current. Whenever a

parallel path does not exist, ground bounce results.

CLOCK, DATA and CONTROL signal traces should run

from the drive logic to the AD9561 in a group parallel to the

connection between the system ground and the AD9561

ground. Using more than one signal plane will permit these

traces to be as close to the ground interconnection as possible.

This results in lowest impedance ground return and minimum

ground interference due to digital switching.

Attention to subtle layout characteristics can yield significant

improvement in performance of high speed mixed signal ICs.

The AD9561 pinouts were chosen for maximum isolation of

sensitive pins such as R

. The Pin 1 end of the IC should be

SET

oriented toward the source of the high speed digital inputs.

This will help assure that these signal runs are short, with

essentially the same length, thus having equal propagation

delays. Most importantly, it will facilitate orienting traces to

minimize coupling.

High speed digital traces including DATA, CLOCK, SEM/

DEM, LEM/TEM and the OUTPUT should not pass under the

body of the IC. The CLOCK, in particular, should enter

perpendicular to the IC.

For best results, the OUTPUT trace should exit perpendicular

to the IC and pass through a via to a signal layer under the

ground plane. This trace or any resistor or other component

of the output circuit should not be parallel to R

as electro-

SET

magnetic coupling can occur, causing the ramp current reference

to be noisy and linearity to deteriorate.

Optimally, R

should be a chip resistor located on the same

SET

side of the board as the AD9561. It should be located close to

Pin 14, without being close to the other IC pins. R

SET

should

be on the top of the board with the AD9561 with no vias to add

stray reactance and additional coupling paths.

To reiterate the key layout considerations, high speed

digital traces should not be located near the R

SET

pin or

under the center of the IC body.

A final interface consideration relates to rise/fall time of

the high speed signals. Some logic families have rise and

fall times as fast as 2 V/ns. This can result in on-chip

parasitic coupling of these signals into the analog section.

The undesirable effect can be eliminated by inserting

series resistors in the DATA, SEM/DEM and LEM/

TEM connections. These resistors, in conjunction with the

capacitance of the input pin and bond pad, will form a low

pass filter to limit slew rate of the signals. The value of

these resistors should be chosen based on trading off slower

rise and fall time to possible interference to set up and hold

times for faster clock rates.

Power supply noise can also disrupt the linear circuits of

the AD9561. Since switching power supplies are becoming

the norm in most systems, caution should be exercised to

minimize switching noise reaching the AD9561. The IC is

designed for maximum power supply rejection. However,

frequency content of switching supply noise often exceeds

the frequency range of highest rejection. The preferred

method would be to use a linear regulator from a higher

supply voltage. If this is not practical, insert a ferrite bead

in series with the supply connection. If possible, a V

DD

plane or a substantial width trace should connect VDD to

Pin 7 first and then connect to each of the other V

DD

pins

with wide traces. Thorough decoupling will complete a low

pass filter for the supply.

All V

connections should be connected together. 0.1 µF

DD

chip capacitors should be connected as closely as possible

to each V

pin to the dedicated ground plane. Laboratory

DD

results indicate that performance is maximized when these

chip capacitors are mounted on the same side of the PC

card as the AD9561. If mounting chip components on the

same side as the AD9561 is not a preferred manufacturing

method, due consideration is encouraged to make an exception, at least in the case of R

and as many decoupling

SET

capacitors as practical. Additionally, a 10 µF tantalum

capacitor should decouple the supply on the AD9561 side

of the regulator or ferrite bead, also to the dedicated

ground plane.

For a recommended layout, see the AD9561/PCB data

sheet. A copy can be obtained by calling Applications

Support at 1-800-ANALOGD.

REV. 0

–7–

Page 8

AD9561

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead SOIC

(R-28)

0.7125 (18.10)

0.6969 (17.70)

28 15

141

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

C2938–6–12/96

0.0118 (0.30)

0.0040 (0.10)

PIN 1

0.0500

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

0.1043 (2.65)

0.0926 (2.35)

SEATING

PLANE

0.0125 (0.32)

0.0091 (0.23)

0.0291 (0.74)

0.0098 (0.25)

0.0500 (1.27)

8°

0°

0.0157 (0.40)

x 45°

–8–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...