Page 1

Low Jitter Clock Generator with

14 LVPECL/LVDS/HSTL/29 LVCMOS Outputs

FEATURES

Output frequency: <1 MHz to 1 GHz

Start-up frequency accuracy: <±100 ppm (determined by

VCXO reference accuracy)

Zero delay operation

Input-to-output edge timing: <150 ps

Dual VCO dividers

14 outputs: configurable LVPECL, LVDS, HSTL, and LVCMOS

14 dedicated output dividers with jitter-free adjustable delay

Adjustable delay: 63 resolution steps of ½ period of VCO

output divider

Output-to-output skew: <50 ps

Duty cycle correction for odd divider settings

Automatic synchronization of all outputs on power-up

Absolute output jitter: <150 fs at 122.88 MHz

Integration range: 12 kHz to 20 MHz

Broadband timing jitter: 124 fs

Digital lock detect

Nonvolatile EEPROM stores configuration settings

SPI- and I²C-compatible serial control port

Dual PLL architecture

PLL1

Low bandwidth for reference input clock cleanup with

external VCXO

Phase detector rate of 300 kHz to 75 MHz

Redundant reference inputs

Auto and manual reference switchover modes

Revertive and nonrevertive switching

Loss of reference detection with holdover mode

Low noise LVCMOS output from VCXO used for RF/IF

synthesizers

PLL2

Phase detector rate of up to 250 MHz

Integrated low noise VCO

APPLICATIONS

LTE and multicarrier GSM base stations

Wireless and broadband infrastructure

Medical instrumentation

Clocking high speed ADCs, DACs, DDSs, DDCs, DUCs, MxFEs

Low jitter, low phase noise clock distribution

Clock generation and translation for SONET, 10Ge, 10G FC,

and other 10 Gbps protocols

Forward error correction (G.710)

High performance wireless transceivers

ATE and high performance instrumentation

AD9523-1

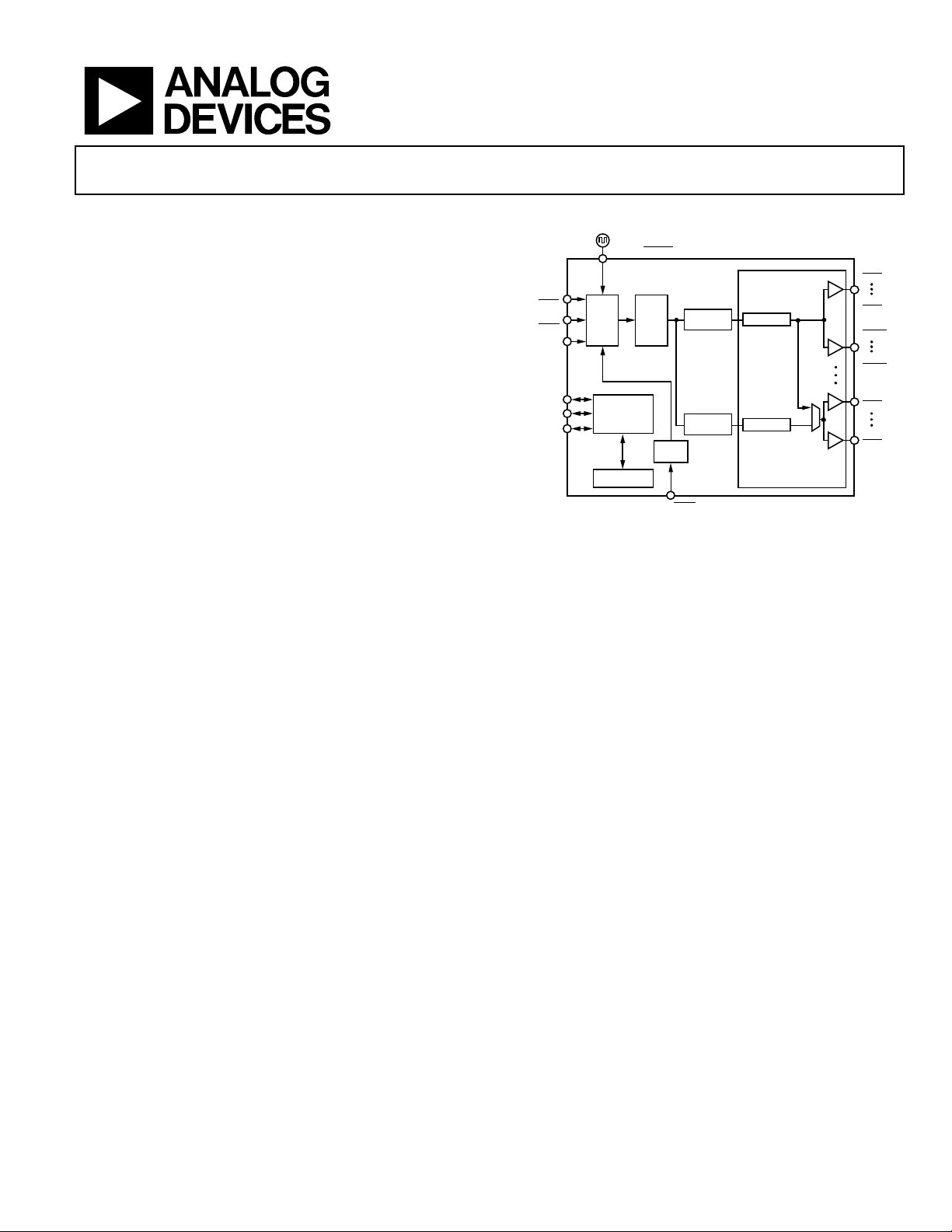

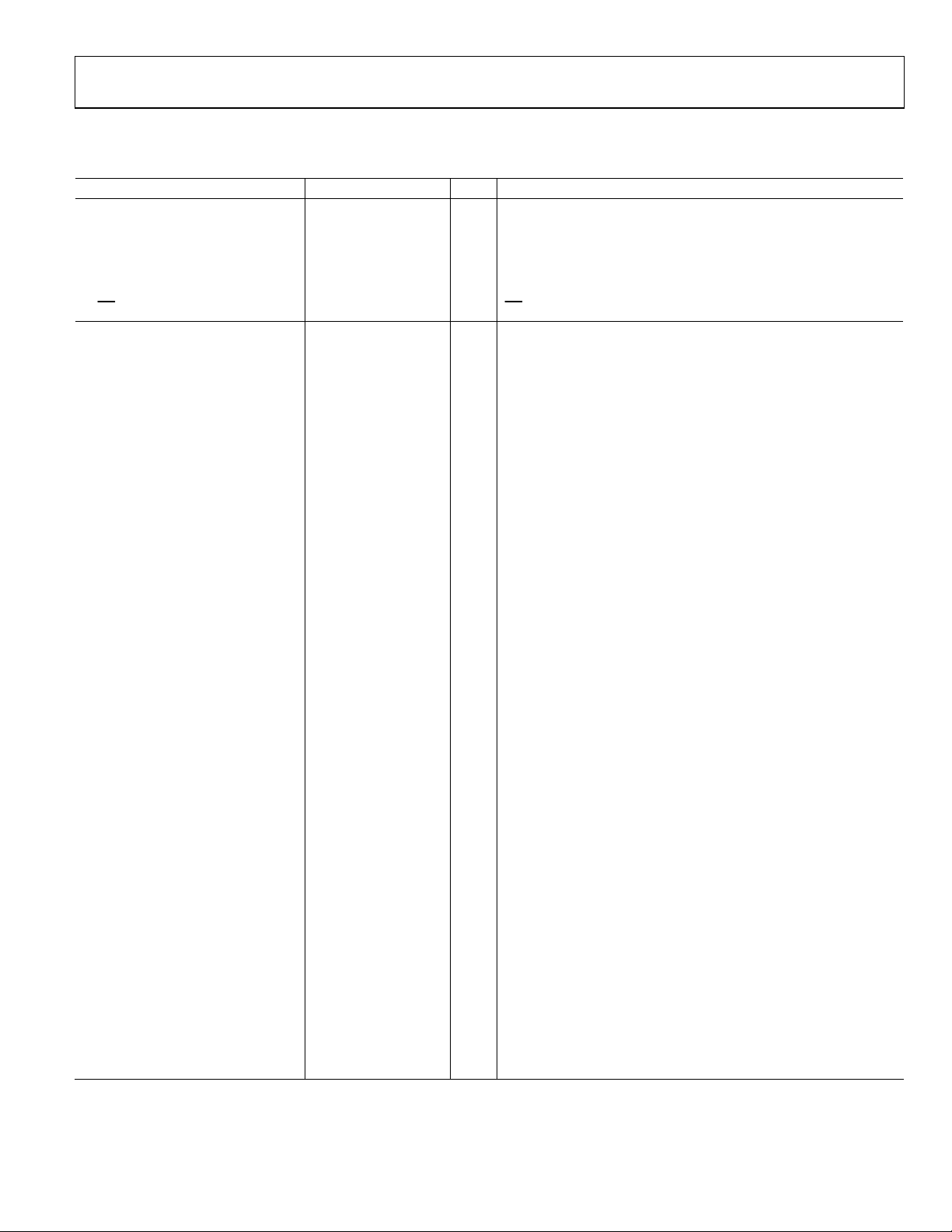

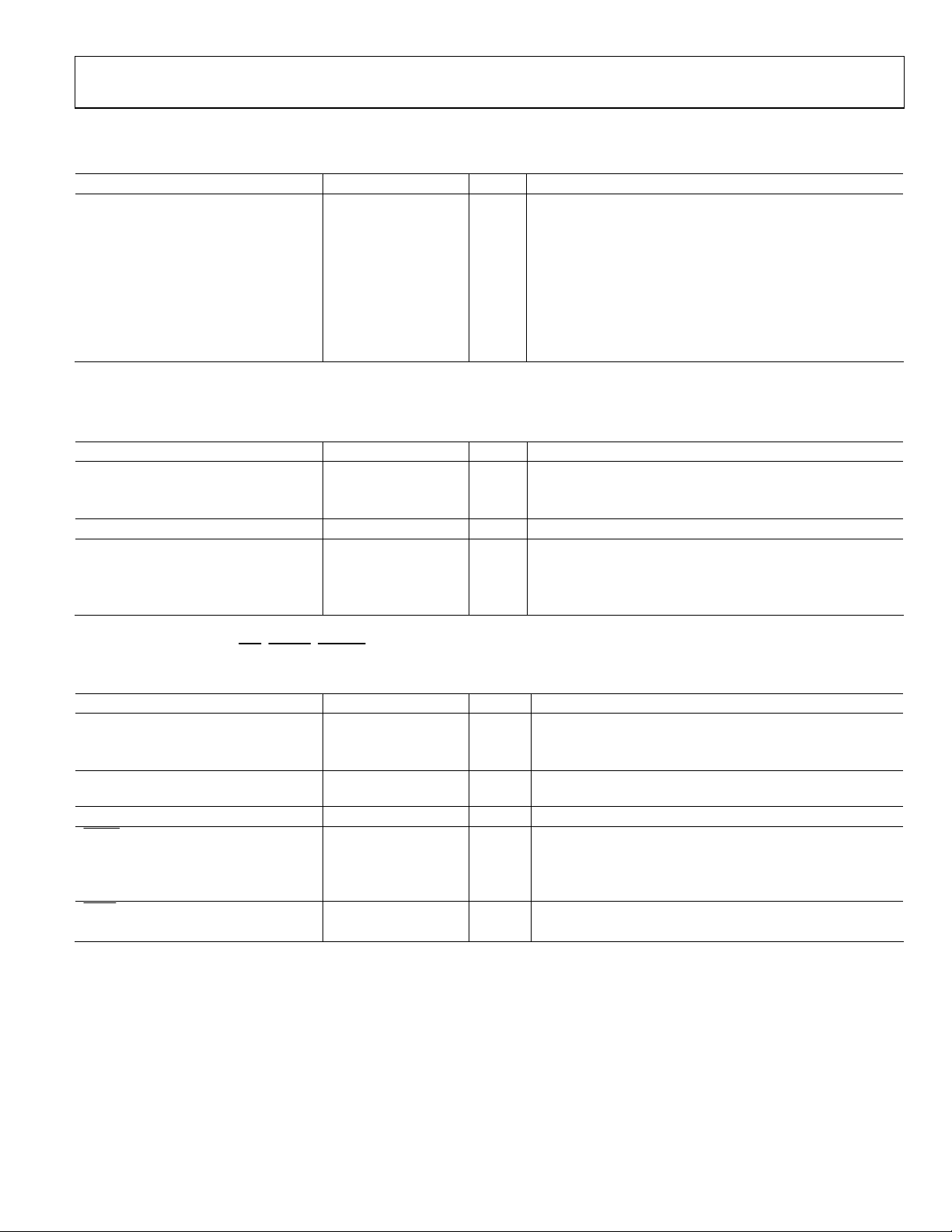

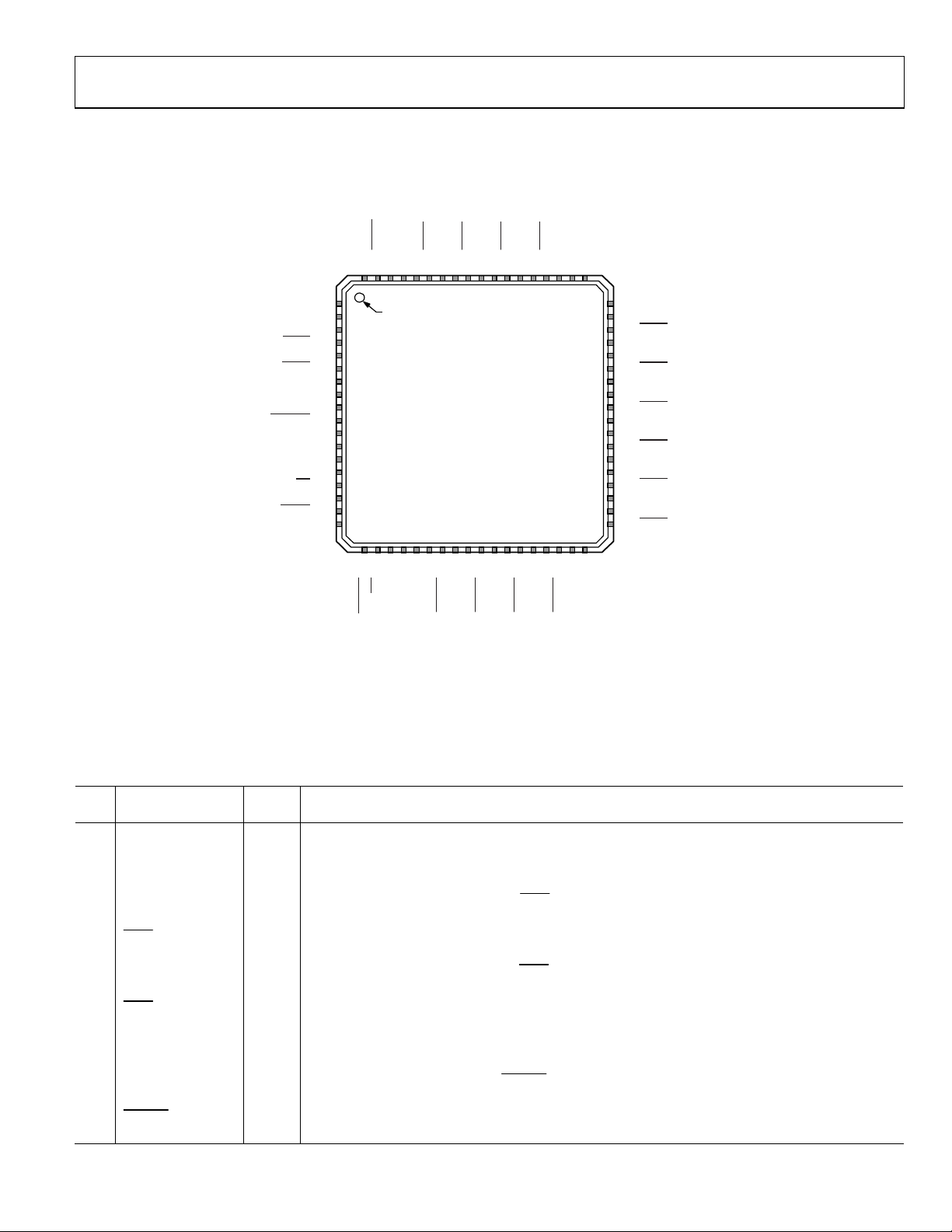

FUNCTIONAL BLOCK DIAGRAM

OSC_IN, OSC_IN

AD9523-1

REFA,

REFA

REFB,

REFB

REF_TEST

SCLK/SCL

SDIO/ SDA

SDO

PLL1

CONTROL

INTERFACE

(SPI AND I

EEPROM

2

PLL2

C)

ZERO

DELAY

ZD_IN, ZD_IN

DIVIDE- BY-

3, 4, 5

DIVIDE- BY-

3, 4, 5

Figure 1.

8 OUTPUTS

6 OUTPUTS

14-CLOCK

DISTRIBUTI ON

GENERAL DESCRIPTION

The AD9523-1 provides a low power, multi-output, clock

distribution function with low jitter performance, along with an

on-chip PLL and VCO with two VCO dividers. The on-chip VCO

tunes from 2.94 GHz to 3.1 GHz.

The AD9523-1 is defined to support the clock requirements for

long term evolution (LTE) and multicarrier GSM base station

designs. It relies on an external VCXO to provide the reference

jitter cleanup to achieve the restrictive low phase noise requirements necessary for acceptable data converter SNR performance.

The input receivers, oscillator, and zero delay receiver provide

both single-ended and differential operation. When connected

to a recovered system reference clock and a VCXO, the device

generates 14 low noise outputs with a range of 1 MHz to 1 GHz,

and one dedicated buffered output from the input PLL (PLL1).

The frequency and phase of one clock output relative to another

clock output can be varied by means of a divider phase select

function that serves as a jitter-free, coarse timing adjustment

in increments that are equal to half the period of the signal

coming out of the VCO.

An in-package EEPROM can be programmed through the serial

interface to store user-defined register settings for power-up

and chip reset.

OUT0,

OUT0

OUT3,

OUT3

OUT10,

OUT10

OUT13,

OUT13

OUT4,

OUT4

OUT9,

OUT9

09278-001

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010–2011 Analog Devices, Inc. All rights reserved.

Page 2

AD9523-1

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Conditions..................................................................................... 3

Supply Current.............................................................................. 3

Power Dissipation......................................................................... 5

REFA

REFA,

ZD_IN

OSC_CTRL Output Characteristics .......................................... 6

REF_TEST Input Characteristics............................................... 6

PLL1 Output Characteristics ...................................................... 7

OUT0,

Characteristics .............................................................................. 7

Timing Alignment Characteristics............................................. 8

Jitter and Noise Characteristics .................................................. 9

PLL2 Characteristics .................................................................... 9

Logic Input Pins—PD,

REF_SEL........................................................................................ 9

Status Output Pins—STATUS1, STATUS0 ............................. 10

Serial Control Port—SPI Mode................................................ 10

Serial Control Port—IC Mode................................................ 11

Absolute Maximum Ratings.......................................................... 12

Thermal Resistance .................................................................... 12

ESD Caution................................................................................ 12

Pin Configuration and Function Descriptions........................... 13

Typical Performance Characteristics ........................................... 16

, REFB,

Input Characteristics...................................................... 6

OUT0

REFB

to OUT13,

SYNC, RESET

, OSC_IN,

OUT13

Distribution Output

OSC_IN

, EEPROM_SEL,

, and ZD_IN,

Input/Output Termination Recommendations.......................... 19

Terminology.................................................................................... 20

Theory of Operation ...................................................................... 21

Detailed Block Diagram ............................................................ 21

Overview ..................................................................................... 21

Component Blocks—Input PLL (PLL1).................................. 22

Component Blocks—Output PLL (PLL2) .............................. 23

Clock Distribution ..................................................................... 25

Zero Delay Operation................................................................ 27

Serial Control Port ......................................................................... 28

SPI/IC Port Selection................................................................ 28

IC Serial Port Operation.......................................................... 28

SPI Serial Port Operation.......................................................... 31

SPI Instruction Word (16 Bits)................................................. 32

SPI MSB/LSB First Transfers .................................................... 32

EEPROM Operations..................................................................... 35

Writing to the EEPROM ........................................................... 35

Reading from the EEPROM ..................................................... 35

Programming the EEPROM Buffer Segment......................... 36

Power Dissipation and Thermal Considerations....................... 38

Clock Speed and Driver Mode ................................................. 38

Evaluation of Operating Conditions........................................ 38

Thermally Enhanced Package Mounting Guidelines............ 39

Control Registers............................................................................ 40

Control Register Map ................................................................ 40

Control Register Map Bit Descriptions................................... 45

Outline Dimensions....................................................................... 58

Ordering Guide .......................................................................... 58

REVISION HISTORY

3/11—Rev. A to Rev. B

Added Table Summary, Table 8 ...................................................... 7

Changes to Figure 24...................................................................... 21

Changes to EEPROM Operations Section and Writing to the

EEPROM Section............................................................................ 35

Changes to Addr (Hex) 0x01A, Bits[4:3], Table 30.................... 40

Changes to Bits[4:3], Table 40....................................................... 47

Rev. B | Page 2 of 60

12/10—Rev. 0 to Rev. A

Changes to General Description Section .......................................1

Changes to Frequency Range, Table 11 ..........................................9

Changes to PLL2 General Description Section.......................... 23

Changes to Table 47, Address 0x0F3, Bit 1 ................................. 48

10/10—Revision 0: Initial Version

Page 3

AD9523-1

SPECIFICATIONS

f

= 122.88 MHz single-ended, REFA and REFB on differential at 30.72 MHz, f

VCXO

Typical is given for VDD = 3.3 V ± 5%, and T

T

(−40°C to +85°C) variation, as listed in Tabl e 1.

A

= 25°C, unless otherwise noted. Minimum and maximum values are given over the full VDD and

A

CONDITIONS

Table 1.

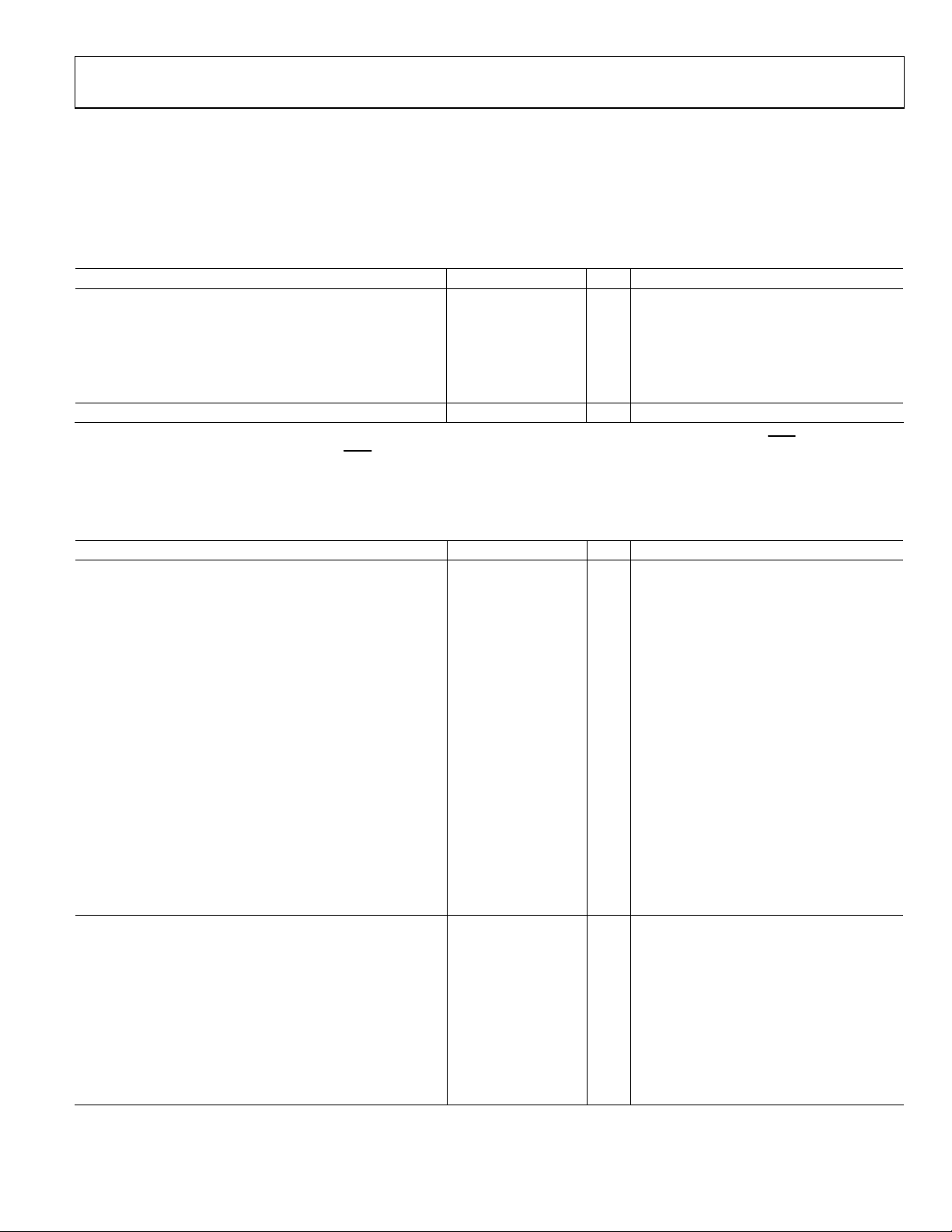

Parameter Min Typ Max Unit Test Conditions/Comments

SUPPLY VOLTAGE

VDD3_PLL, Supply Voltage for PLL1 and PLL2 3.135 3.3 3.465 V 3.3 V ± 5%

VDD3_VCO, Supply Voltage for VCO 3.135 3.3 3.465 V 3.3 V ± 5%

VDD3_REF, Supply Voltage Clock Output Drivers Reference 3.135 3.3 3.465 V 3.3 V ± 5%

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 3.135 3.3 3.465 V 3.3 V ± 5%

VDD1.8_OUT[x:y],1 Supply Voltage Clock Dividers 1.768 1.8 1.832 V 1.8 V ± 5%

TEMPERATURE RANGE, TA −40 +25 +85 °C

1

x and y are the pair of differential outputs that share the same power supply. For example, VDD3_OUT[0:1] is Supply Voltage Clock Output OUT0,

respectively) and Supply Voltage Clock Output OUT1,

OUT1

(Pin 65 and Pin 64, respectively).

SUPPLY CURRENT

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

SUPPLIES OTHER THAN CLOCK OUTPUT DRIVERS

VDD3_PLL, Supply Voltage for PLL1 and PLL2 37 41.9 mA Decreases by 9 mA typical if REFB is turned off

VDD3_VCO, Supply Voltage for VCO and VCO Divider M1 70 75.8 mA All outputs use VCO Divider M1

VDD3_REF, Supply Voltage Clock Output Drivers Reference

VCO Divider M1 Enabled

LVPECL Mode, LVDS Mode 4 5.1 mA

HSTL Mode, CMOS Mode 3 3.6 mA

VCO Divider M2 Enabled

LVPECL Mode, LVDS Mode 26 30.1 mA

HSTL Mode, CMOS Mode 24.5 28.6 mA

VDD1.8_OUT[x:y],1 Supply Voltage Clock Dividers 3.2 5.8 mA Current for each divider: f = 122.88 MHz

VDD1.8_OUT[x:y],1 Supply Voltage Clock Dividers 6.4 12 mA Current for each divider: f = 983.04 MHz

CLOCK OUTPUT DRIVERS—LOWER POWER MODE OFF Channel x control register, Bit 4 = 0

LVDS Mode, 7 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 11.5 13.2 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 40 45 mA f = 983.04 MHz

LVDS Mode, 3.5 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 6.5 7.5 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 23 26.3 mA f = 983.04 MHz

LVPECL Mode

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 13 14.4 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 41 46.5 mA f = 983.04 MHz

= 2949.12 MHz, doubler is on, unless otherwise noted.

VCO

OUT0

(Pin 68 and Pin 67,

Use VCO Divider M1; only one output driver

is turned on; for each additional output that

is turned on, the current increments by 1.2 mA

maximum

Use VCO Divider M1; values are independent

of the number of outputs turned on

Use VCO Divider M2; only one output driver

is turned on; for each additional output that

is turned on, the current increments by 1.2 mA

maximum

Use VCO Divider M2; values are independent

of the number of outputs turned on

Rev. B | Page 3 of 60

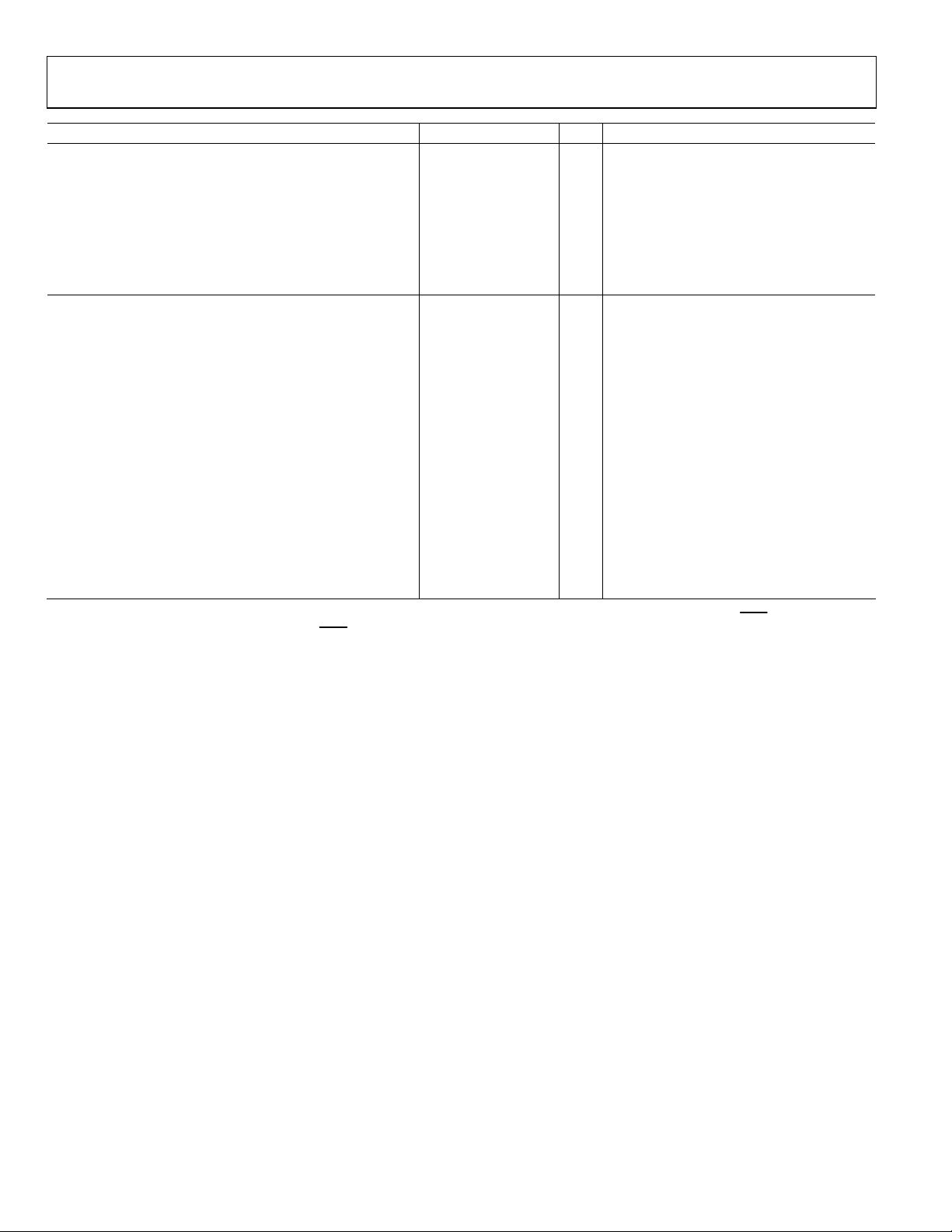

Page 4

AD9523-1

Parameter Min Typ Max Unit Test Conditions/Comments

HSTL Mode, 16 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 20 24.2 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 50 59.1 mA f = 983.04 MHz

HSTL Mode, 8 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 14 16.7 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 42.5 49 mA f = 983.04 MHz

CMOS Mode (Single-Ended)

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 2 2.4 mA f = 15.36 MHz, 10 pF Load

CLOCK OUTPUT DRIVERS—LOWER POWER MODE ON Channel x control register, Bit 4 = 1

LVDS Mode, 7 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 10 10.8 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 27 29.8 mA f = 983.04 MHz

LVDS Mode, 3.5 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 6.5 7.5 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 23 26.3 mA f = 983.04 MHz

LVPECL Mode

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 11 12.4 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 28 31.2 mA f = 983.04 MHz

HSTL Mode, 16 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 20 24.3 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 50 59.1 mA f = 983.04 MHz

HSTL Mode, 8 mA

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 11 12.7 mA f = 122.88 MHz

VDD3_OUT[x:y],1 Supply Voltage Clock Output Drivers 27 31.8 mA f = 983.04 MHz

1

x and y are the pair of differential outputs that share the same power supply. For example, VDD3_OUT[0:1] is Supply Voltage Clock Output OUT0,

respectively) and Supply Voltage Clock Output OUT1,

OUT1

(Pin 65 and Pin 64, respectively).

OUT0

(Pin 68 and Pin 67,

Rev. B | Page 4 of 60

Page 5

AD9523-1

POWER DISSIPATION

Table 3.

Parameter Min Typ Max Unit Test Conditions/Comments

POWER DISSIPATION Does not include power dissipated in termination resistors

Typical Configuration 898 984.7 mW

PD, Power-Down

74 98.2 mW

INCREMENTAL POWER DISSIPATION

Base Typical Configuration 393 434.7 mW

Switched to One Input,

−28.5 −8 mW Running at 30.72 MHz

Reference Single-Ended Mode

Switched to Two Inputs,

26 44.6 mW Running at 30.72 MHz

Reference Differential Mode

Switched to Two Inputs,

−27.5 −5.1 mW Running at 30.72 MHz

Reference Single-Ended Mode

VCO Divider M2 76 88.3 mW Incremental power increase VCO Divider M2 (OUT4) from base typical

Output Distribution, Driver On Incremental power increase (OUT1) from base typical

LVDS Mode

3.5 mA 29 34.8 mW Single 3.5 mA LVDS output at 122.88 MHz

88 105.6 mW Single 3.5 mA LVDS output at 983.04 MHz

7 mA 43 50 mW Single 7 mA LVDS output at 122.88 MHz

141 164 mW Single 7 mA LVDS output at 983.04 MHz

LVPECL Mode 46 51 mW Single LVPECL output at 122.88 MHz

144 159 mW Single LVPECL output at 983.04 MHz

HSTL Mode

8 mA 44 51 mW Single 8 mA HSTL output at 122.88 MHz

143 165 mW Single 8 mA HSTL output at 983.04 MHz

16 mA 48 55 mW Single 16 mA HSTL output at 122.88 MHz

153 176 mW Single 16 mA HSTL output at 983.04 MHz

CMOS Mode 6.6 7.9 mW Single 3.3 V CMOS output at 15.36 MHz

9.9 11.9 mW Dual complementary 3.3 V CMOS output at 15.36 MHz

9.9 11.9 mW Dual in-phase 3.3 V CMOS output at 15.36 MHz

Output Distribution, Driver On Lower power mode on, (Channel x control register, Bit 4 = 1)

LVDS Mode

3.5 mA 28.5 33.6 mW Single 3.5 mA LVDS output at 122.88 MHz

88 105.6 mW Single 3.5 mA LVDS output at 983.04 MHz

7 mA 37 42.9 mW Single 7 mA LVDS output at 122.88 MHz

98 113.7 mW Single 7 mA LVDS output at 983.04 MHz

LVPECL Mode 40.5 46 mW Single LVPECL output at 122.88 MHz

100 110 mW Single LVPECL output at 983.04 MHz

HSTL Mode

8 mA 34 39.1 mW Single 8 mA HSTL output at 122.88 MHz

94 108.1 mW Single 8 mA HSTL output at 983.04 MHz

16 mA 48 55.2 mW Single 16 mA HSTL output at 122.88 MHz

153 176 mW Single 16 mA HSTL output at 983.04 MHz

Clock distribution outputs running as follows: 7 LVPECL at 122.88 MHz,

3 LVDS (3.5 mA) at 61.44 MHz, 3 LVDS (3.5 mA) at 245.76 MHz, 1 singleended CMOS 10 pF load at 122.88 MHz, 1 differential input reference

at 30.72 MHz; f

= 122.88 MHz, f

VCXO

= 2949.12 MHz, VCO Divider M1

VCO

at 3, and VCO Divider M2 is off; PLL2 BW = 530 kHz

PD pin pulled low, with typical configuration conditions

Absolute total power with clock distribution; 1 LVPECL output (OUT0)

running at 122.88 MHz; 1 differential input reference at 30.72 MHz;

= 122.88 MHz, f

f

VCXO

= 2949.12 MHz, VCO Divider M1 at 3; VCO

VCO

Divider M2 is off

Rev. B | Page 5 of 60

Page 6

AD9523-1

REFA, REFA, REFB, REFB, OSC_IN, OSC_IN, AND ZD_IN, ZD_IN INPUT CHARACTERISTICS

Table 4.

Parameter Min Typ Max Unit Test Conditions/Comments

DIFFERENTIAL MODE

Input Frequency Range 400 MHz

Input Slew Rate (OSC_IN) 400 V/µs

Common-Mode Internally

Generated Input Voltage

Input Common-Mode Range 1.025 1.475 V For dc-coupled LVDS (maximum swing)

Differential Input Voltage,

Sensitivity Frequency < 250 MHz

Differential Input Voltage,

Sensitivity Frequency > 250 MHz

Differential Input Resistance 4.8 kΩ

Differential Input Capacitance 1 pF

Duty Cycle

Pulse Width Low 1 ns

Pulse Width High 1 ns

CMOS MODE, SINGLE-ENDED INPUT

Input Frequency Range 250 MHz

Input High Voltage 2.0 V

Input Low Voltage 0.8 V

Input Capacitance 1 pF

Duty Cycle

Pulse Width Low 1.6 ns

Pulse Width High 1.6 ns

0.6 0.7 0.8 V

100 mV p-p

200 mV p-p

Minimum limit imposed for jitter

performance

Capacitive coupling required; can

accommodate single-ended input

by ac grounding of unused input;

instantaneous voltage on either pin

must not exceed the 1.8 V dc supply rails

Capacitive coupling required; can

accommodate single-ended input

by ac grounding of unused input;

instantaneous voltage on either pin

must not exceed the 1.8 V dc supply rails

Duty cycle limits are set by pulse width

high and pulse width low

Duty cycle limits are set by pulse width

high and pulse width low

OSC_CTRL OUTPUT CHARACTERISTICS

Table 5.

Parameter Min Typ Max Unit Test Conditions/Comments

OUTPUT VOLTAGE

High VDD3_PLL − 0.15 V R

Low 150 mV

LOAD

> 20 kΩ

REF_TEST INPUT CHARACTERISTICS

Table 6.

Parameter Min Typ Max Unit Test Conditions/Comments

REF_TEST INPUT

Input Frequency Range 250 MHz

Input High Voltage 2.0 V

Input Low Voltage 0.8 V

Rev. B | Page 6 of 60

Page 7

AD9523-1

PLL1 OUTPUT CHARACTERISTICS

Table 7.

Parameter1 Min Typ Max Unit Test Conditions/Comments

MAXIMUM OUTPUT FREQUENCY 250 MHz

Rise Time/Fall Time (20% to 80%) 387 665 ps 15 pF load

Duty Cycle 45 50 55 % f = 250 MHz

OUTPUT VOLTAGE HIGH Output driver static

VDD3_PLL − 0.25 V Load current = 10 mA

VDD3_PLL − 0.1 V Load current = 1 mA

OUTPUT VOLTAGE LOW Output driver static

0.2 V Load current = 10 mA

0.1 V Load current = 1 mA

1

CMOS driver strength: strong (see Table 52).

OUT0, OUT0 TO OUT13, OUT13 DISTRIBUTION OUTPUT CHARACTERISTICS

Duty cycle performance is specified with the invert divider bit set to 1, and the divider phase bits set to 0.5. (For example, for Channel 0,

0x190[7] = 1 and 0x192[7:2] = 1.)

Table 8.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL MODE

Maximum Output Frequency 1 GHz Minimum VCO/maximum dividers

Rise Time/Fall Time (20% to 80%) 117 147 ps 100 Ω termination across output pair

Duty Cycle 47 50 52 % f < 500 MHz

43 48 52 % f = 500 MHz to 800 MHz

40 49 54 % f = 800 MHz to 1 GHz

Differential Output Voltage Swing 643 775 924 mV

Common-Mode Output Voltage VDD – 1.5 VDD − 1.4 VDD − 1.25 V Output driver static

SCALED HSTL MODE, 16 mA

Maximum Output Frequency 1 GHz Minimum VCO/maximum dividers

Rise Time/Fall Time (20% to 80%) 112 141 ps 100 Ω termination across output pair

Duty Cycle 47 50 52 % f < 500 MHz

44 48 51 % f = 500 MHz to 800 MHz

40 49 54 % f = 800 MHz to 1 GHz

Differential Output Voltage Swing 1.3 1.6 1.7 mV Nominal supply

Supply Sensitivity 0.6

Common-Mode Output Voltage VDD − 1.76 VDD − 1.6 VDD − 1.42 V

LVDS MODE, 3.5 mA

Maximum Output Frequency 1 GHz

Rise Time/Fall Time (20% to 80%) 138 161 ps 100 Ω termination across output pair

Duty Cycle 48 51 53 % f < 500 MHz

43 49 53 % f = 500 MHz to 800 MHz

41 49 55 % f = 800 MHz to 1 GHz

Differential Output Voltage Swing

Balanced 247 454 mV

Unbalanced 50 mV

Common-Mode Output Voltage 1.125 1.375 V Output driver static

Common-Mode Difference 50 mV

Short-Circuit Output Current 3.5 24 mA Output driver static

Rev. B | Page 7 of 60

mV/

mV

Magnitude of voltage across pins; output

driver static

Change in output swing vs.

VDD3_OUT[x:y] (∆V

Voltage swing between output pins;

output driver static

Absolute difference between voltage

swing of normal pin and inverted pin

Voltage difference between output pins;

output driver static

/∆VDD3)

OD

Page 8

AD9523-1

Parameter Min Typ Max Unit Test Conditions/Comments

CMOS MODE

Maximum Output Frequency 250 MHz

Rise Time/Fall Time (20% to 80%) 387 665 ps 15 pF load

Duty Cycle 45 50 55 % f = 250 MHz

Output Voltage High Output driver static

VDD − 0.25 V Load current = 10 mA

VDD − 0.1 V Load current = 1 mA

Output Voltage Low Output driver static

0.2 V Load current = 10 mA

0.1 V Load current = 1 mA

TIMING ALIGNMENT CHARACTERISTICS

Table 9.

Parameter Min Typ Max Unit Test Conditions/Comments

OUTPUT TIMING SKEW

Between Outputs in Same Group1

LVPECL, HSTL, and LVDS

Between LVPECL, HSTL, and

30 183 ps

LVDS Outputs

CMOS

Between CMOS Outputs 100 300 ps Single-ended, true phase, high-Z mode

Mean Delta Between Groups1 50

Adjustable Delay 0 63 Steps Resolution step; for example, 8 × 0.5/1 GHz

Resolution Step 500 ps ½ period of 1 GHz

Zero Delay

Between Input Clock Edge on

150 500 ps

REFA or REFB to ZD_IN Input

Clock Edge, External Zero

Delay Mode

1

There are three groups of outputs. They are as follows: the top outputs group, consisting of OUT0, OUT1, OUT2, and OUT3; the right outputs group, consisting of

OUT4, OUT5, OUT6, OUT7, OUT8, and OUT9; and the bottom outputs group, consisting of OUT10, OUT11, OUT12, and OUT13.

Delay off on all outputs; maximum

deviation between rising edges of outputs;

all outputs are on, unless otherwise noted

PLL1 settings: PFD = 7.68 MHz, ICP = 63.5 µA,

= 10 kΩ, antibacklash pulse width is

R

ZERO

at maximum, BW = 40 Hz, REFA and

ZD_IN are set to differential mode

Rev. B | Page 8 of 60

Page 9

AD9523-1

JITTER AND NOISE CHARACTERISTICS

Table 10.

Parameter Min Typ Max Unit Test Conditions/Comments

OUTPUT ABSOLUTE RMS TIME JITTER

LVPECL Mode, HSTL Mode, LVDS Mode

109 fs Integrated BW = 200 kHz to 5 MHz

115 fs Integrated BW = 200 kHz to 10 MHz

150 fs Integrated BW = 12 kHz to 20 MHz

177 fs Integrated BW = 10 kHz to 61 MHz

187 fs Integrated BW = 1 kHz to 61 MHz

124 fs Integrated BW = 1 MHz to 61 MHz

PLL2 CHARACTERISTICS

Table 11.

Parameter Min Typ Max Unit Test Conditions/Comments

VCO (ON CHIP)

Frequency Range 2940 3100 MHz

Gain 45 MHz/V

PLL2 FIGURE OF MERIT (FOM) −226 dBc/Hz

MAXIMUM PFD FREQUENCY

Antibacklash Pulse Width

Minimum and Low 250 MHz

Maximum and High 125 MHz

Application example based on a typical setup (see Table 3);

f = 122.88 MHz

LOGIC INPUT PINS—PD, SYNC, RESET, EEPROM_SEL, REF_SEL

Table 12.

Parameter Min Typ Max Unit Test Conditions/Comments

VOLTAGE

Input High 2.0 V

Input Low 0.8 V

INPUT LOW CURRENT ±80 ±250 µA

CAPACITANCE 3 pF

RESET TIMING

Pulse Width Low 50 ns

Inactive to Start of Register

Programming

SYNC TIMING

Pulse Width Low 1.5 ns High speed clock is the CLK input signal

100 ns

The minus sign indicates that, due to the internal pull-up

resistor, current is flowing out of the AD9523-1

Rev. B | Page 9 of 60

Page 10

AD9523-1

STATUS OUTPUT PINS—STATUS1, STATUS0

Table 13.

Parameter Min Typ Max Unit Test Conditions/Comments

VOLTAGE

Output High 2.94 V

Output Low 0.4 V

SERIAL CONTROL PORT—SPI MODE

Table 14.

Parameter Min Typ Max Unit Test Conditions/Comments

CS (INPUT)

Voltage

Input Logic 1 2.0 V

Input Logic 0 0.8 V

Current

Input Logic 1 30 µA

Input Logic 0 −110 µA

Input Capacitance 2 pF

SCLK (INPUT) IN SPI MODE

Voltage

Input Logic 1 2.0 V

Input Logic 0 0.8 V

Current

Input Logic 1 240 µA

Input Logic 0 1 µA

Input Capacitance 2 pF

SDIO (WHEN INPUT IS IN BIDIRECTIONAL MODE)

Voltage

Input Logic 1 2.0 V

Input Logic 0 0.8 V

Current

Input Logic 1 1 µA

Input Logic 0 1 µA

Input Capacitance 2 pF

SDIO, SDO (OUTPUTS)

Output Logic 1 Voltage 2.7 V

Output Logic 0 Voltage 0.4 V

TIMING

Clock Rate (SCLK, 1/t

Pulse Width High, t

Pulse Width Low, t

) 25 MHz

SCLK

8 ns

HIGH

12 ns

LOW

SDIO to SCLK Setup, tDS 3.3 ns

SCLK to SDIO Hold, tDH 0 ns

SCLK to Valid SDIO and SDO, tDV 14 ns

CS to SCLK Setup, tS

CS to SCLK Setup and Hold, tS, tC

CS Minimum Pulse Width High, t

PWH

CS has an internal 40 kΩ pull-up resistor

The minus sign indicates that, due to the

internal pull-up resistor, current is flowing out

of the AD9523-1

SCLK has an internal 40 kΩ pull-down resistor

in SPI mode but not in I2C mode

10 ns

0 ns

6 ns

Rev. B | Page 10 of 60

Page 11

AD9523-1

SERIAL CONTROL PORT—I²C MODE

VDD = VDD3_REF, unless otherwise noted.

Table 15.

Parameter Min Typ Max Unit Test Conditions/Comments

SDA, SCL (WHEN INPUTTING DATA)

Input Logic 1 Voltage 0.7 × VDD V

Input Logic 0 Voltage 0.3 × VDD V

Input Current with an Input Voltage Between

0.1 × VDD and 0.9 × VDD

Hysteresis of Schmitt Trigger Inputs 0.015 × VDD V

Pulse Width of Spikes That Must Be

Suppressed by the Input Filter, t

SPIKE

SDA (WHEN OUTPUTTING DATA)

Output Logic 0 Voltage at 3 mA Sink Current 0.4 V

Output Fall Time from VIH

MIN

to VIL

MAX

with

a Bus Capacitance from 10 pF to 400 pF

TIMING

Clock Rate (SCL, f

) 400 kHz

I2C

Bus Free Time Between a Stop and Start

Condition, t

IDLE

Setup Time for a Repeated Start Condition,

t

SET; STR

Hold Time (Repeated) Start Condition, t

Setup Time for a Stop Condition, t

Low Period of the SCL Clock, t

High Period of the SCL Clock, t

SCL, SDA Rise Time, t

SCL, SDA Fall Time, t

Data Setup Time, t

Data Hold Time, t

20 + 0.1 C

RISE

20 + 0.1 C

FAL L

100 ns

SET; DAT

100 880 ns

HLD; DAT

Capacitive Load for Each Bus Line, C

1

CB is the capacitance of one bus line in picofarads (pF).

2

According to the original I2C specification, an I2C master must also provide a minimum hold time of 300 ns for the SDA signal to bridge the undefined region of the SCL

falling edge.

HLD; STR

SET; STP

1.3 µs

LOW

0.6 µs

HIGH

1

400 pF

B

−10 +10 µA

50 ns

1

20 + 0.1 C

250 ns

B

Note that all I

(0.3 × VDD) and VIL

VIH

MIN

1.3 µs

0.6 µs

0.6 µs

After this period, the first clock pulse is

generated

0.6 µs

1

300 ns

B

1

300 ns

B

This is a minor deviation from the original I²C

specification of 0 ns minimum2

2

C timing values are referred to

levels (0.7 × VDD)

MAX

Rev. B | Page 11 of 60

Page 12

AD9523-1

ABSOLUTE MAXIMUM RATINGS

Table 16.

Parameter Rating

VDD3_PLL, VDD3_REF, VDD3_OUT[x:y],

−0.3 V to +3.6 V

LDO_VCO to GND

REFA, REFA, REFB, REFB to GND

SCLK/SCL, SDIO/SDA, SDO, CS to GND

OUT0, OUT0, OUT1, OUT1, OUT2, OUT2,

OUT3, OUT3

, OUT4, OUT4, OUT5, OUT5,

−0.3 V to +3.6 V

−0.3 V to +3.6 V

−0.3 V to +3.6 V

OUT6, OUT6, OUT7, OUT7, OUT8, OUT8,

OUT9, OUT9

, OUT10, OUT10, OUT11,

OUT11, OUT12, OUT12, OUT13, OUT13

to GND

SYNC, RESET, PD, REF_SEL to GND

−0.3 V to +3.6 V

STATUS0, STATUS1 to GND −0.3 V to +3.6 V

SP0, SP1, EEPROM_SEL to GND −0.3 V to +3.6 V

VDD1.8_OUT[x:y], LDO_PLL1, LDO_DIV_M1

2 V

to GND

Junction Temperature1 115°C

Storage Temperature Range −65°C to +150°C

Lead Temperature (10 sec) 300°C

1

See Table 17 for θJA.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

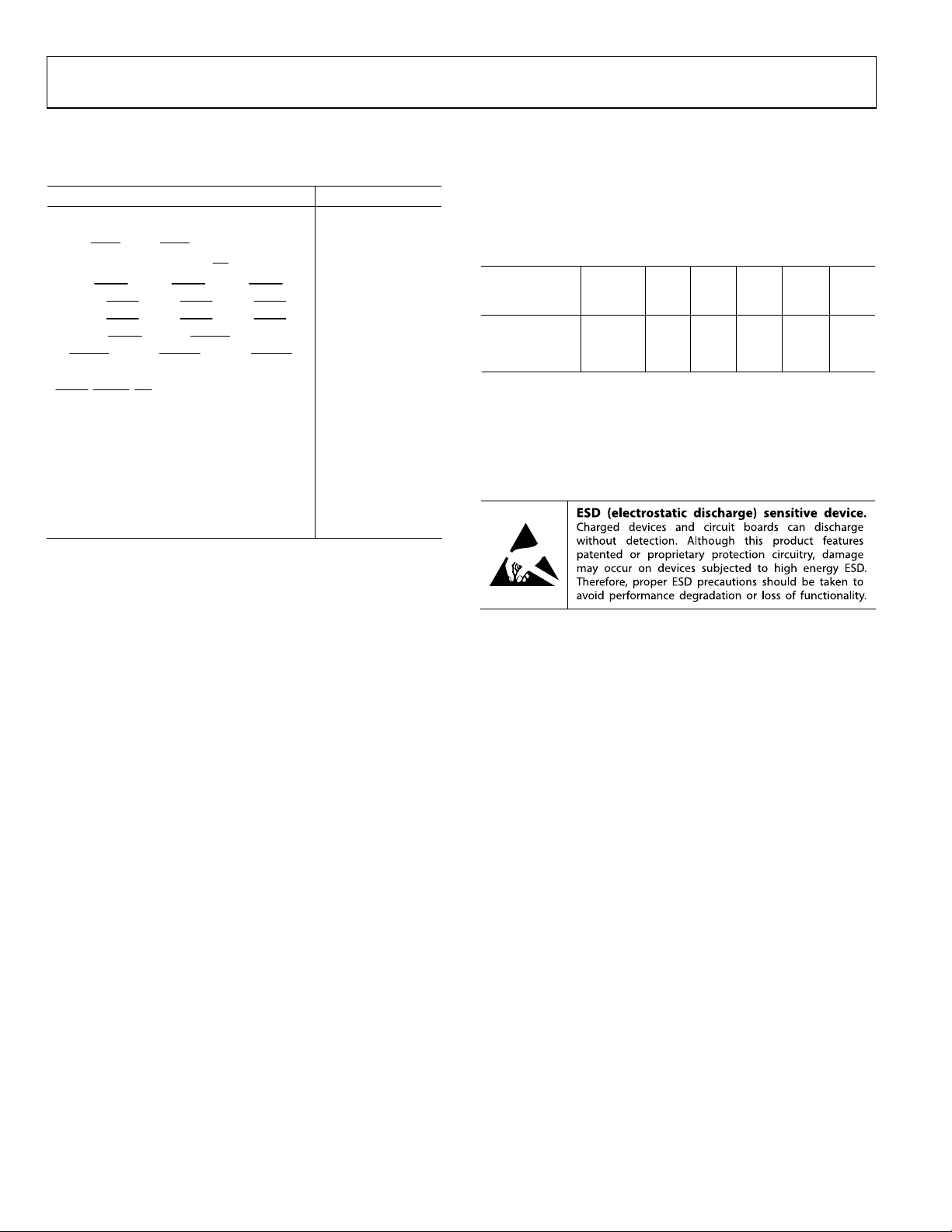

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 17. Thermal Resistance

Package Type

72-Lead LFCSP,

10 mm ×

10 mm

1

Per JEDEC 51-7, plus JEDEC 51-5 2S2P test board.

2

Per JEDEC JESD51-2 (still air) or JEDEC JESD51-6 (moving air).

3

Per MIL-Std 883, Method 1012.1.

4

Per JEDEC JESD51-8 (still air).

Additional power dissipation information can be found in the

Power Dissipation and Thermal Considerations section.

ESD CAUTION

Airflow

Velocity

(m/sec) θ

1, 2

1, 3

θ

JA

JC

1, 4

θ

JB

1, 2

Ψ

Unit

JT

0 21.3 1.7 12.6 0.1 °C/W

1.0 20.1 0.2 °C/W

2.5 18.1 0.3 °C/W

Rev. B | Page 12 of 60

Page 13

AD9523-1

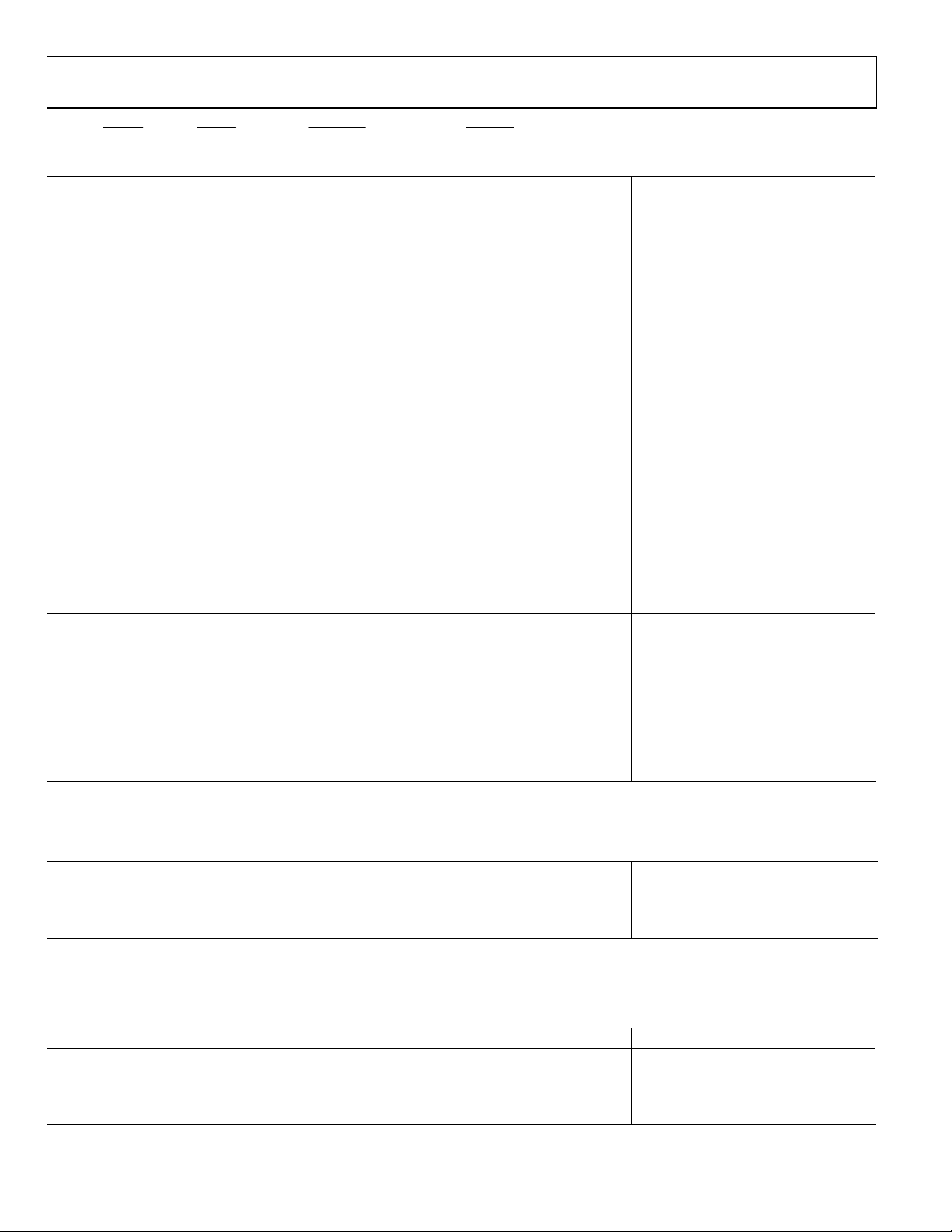

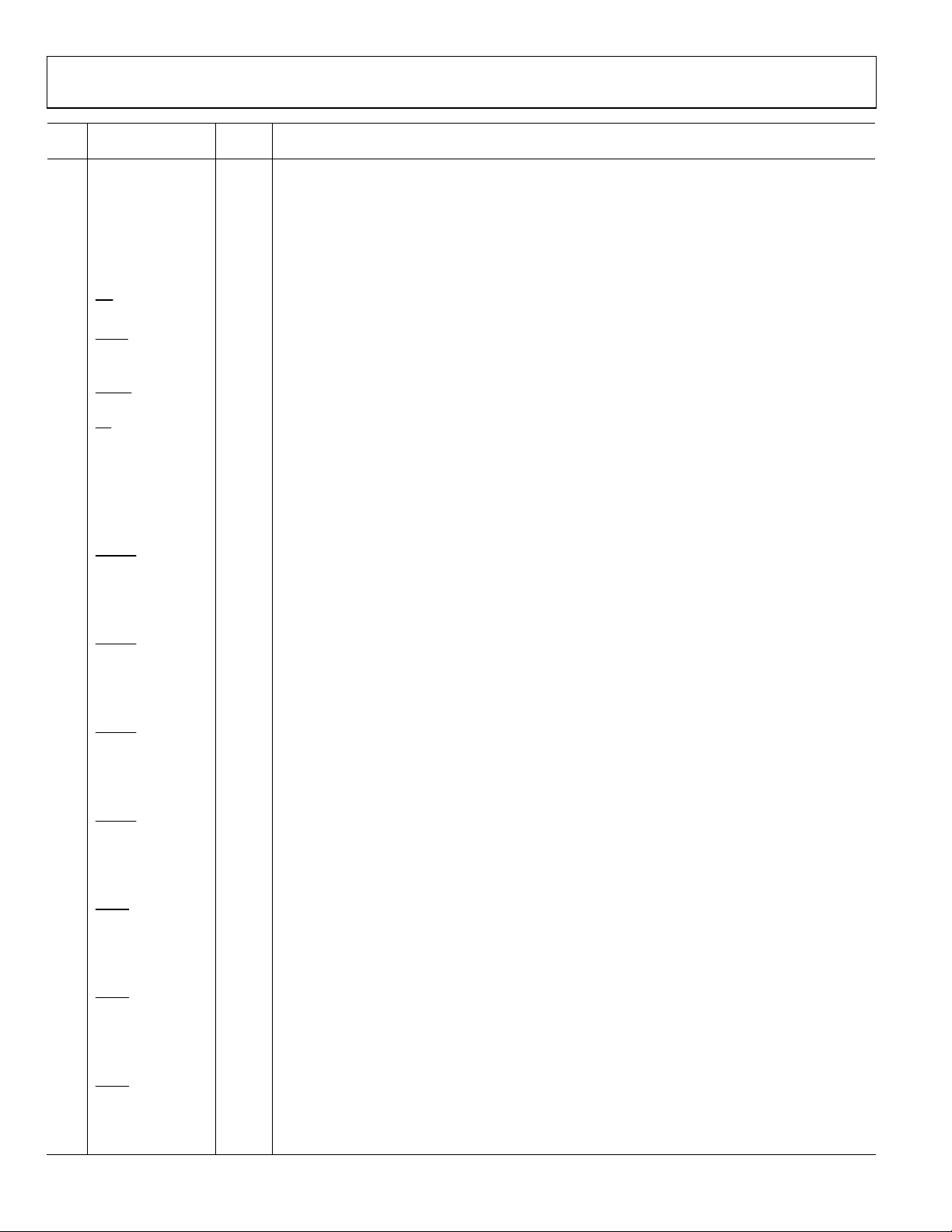

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

PLL1_OUT

ZD_IN

ZD_IN

VDD1.8_OUT[0:1]

OUT0

OUT0

VDD3_OUT[0:1]

OUT1

OUT1

VDD1.8_OUT[2:3]

OUT2

OUT2

VDD3_OUT[2:3]

OUT3

OUT3

EEPROM_SEL

STATUS0/SP0

STATUS1/SP1

7271706968676665646362616059585756

55

REFA

REFA

REFB

REFB

PD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17SYNC

18VDD3_REF

PIN 1

INDICATOR

AD9523-1

TOP VIEW

(Not to Scale)

192021222324252627282930313233

CS

SDO

OUT13

RESET

SDIO/SDA

SCLK/SCL

OUT13

REF_TEST

VDD3_OUT[12:13]

OUT11

OUT12

OUT11

OUT12

VDD1.8_OUT[12:13]

34

OUT10

VDD3_OUT[10: 11]

54

VDD1.8_OUT[4:5]

53

OUT4

52

OUT4

51

VDD3_OUT[4:5]

50

OUT5

49

OUT5

48

VDD1.8_OUT[6:7]

47

OUT6

46

OUT6

45

VDD3_OUT[6:7]

44

OUT7

43

OUT7

42

VDD1.8_OUT[8:9]

41

OUT8

40

OUT8

39

VDD3_OUT[8:9]

38

OUT9

37

OUT9

35OUT10

36VDD1.8_OUT [10: 11]

LDO_PLL1

VDD3_PLL

LF1_EXT_CAP

OSC_CTRL

OSC_IN

OSC_IN

LF2_EXT_CAP

LDO_VCO

VDD3_VCO

LDO_DIV_M1

REF_SEL

NOTES

1. THE EXPOSED PADDLE IS THE GROUND CONNECTION ON THE CHIP. IT MUST BE SOLDERED

TO THEANALOG GROUND OF THE PCB TO ENSURE PROPER FUNCTIONALITY

AND HEAT DISSIPATION, NOISE, AND MECHANICAL STRENGTH BENEFITS.

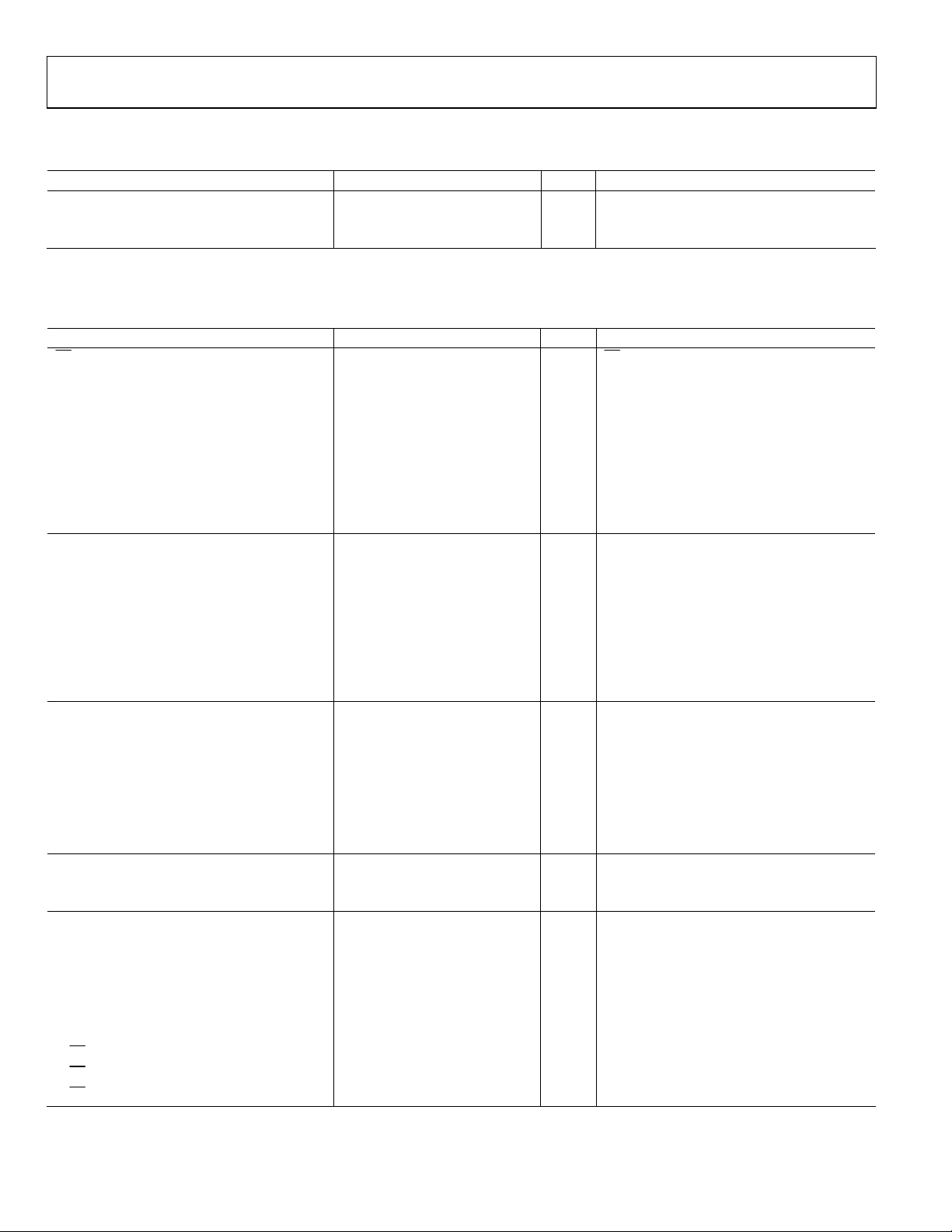

Figure 2. Pin Configuration

09278-002

Table 18. Pin Function Descriptions

Pin

No. Mnemonic Type

1 LDO_PLL1 P/O

1

Description

1.8 V Internal LDO Regulator Decoupling Pin for PLL1. Connect a 0.47 F decoupling capacitor from

this pin to ground. Note that for best performance, the LDO bypass capacitor must be placed in close

proximity to the device.

2 VDD3_PLL P 3.3 V Supply PLL1 and PLL2. Use the same supply as VCXO.

3 REFA I

Reference Clock Input A. Along with REFA

, this pin is the differential input for the PLL reference.

Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

4

REFA

I

Complementary Reference Clock Input A. Along with REFA, this pin is the differential input for the

PLL reference. Alternatively, this pin can be programmed as a single-ended 3.3V CMOS input.

5 REFB I

Reference Clock Input B. Along with REFB

, this pin is the differential input for the PLL reference.

Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

6

REFB

I

Complementary Reference Clock Input B. Along with REFB, this pin is the differential input for the PLL

reference. Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

7 LF1_EXT_CAP O PLL1 External Loop Filter Capacitor. Connect this pin to ground.

8 OSC_CTRL O Oscillator Control Voltage. Connect this pin to the voltage control pin of the external oscillator.

9 OSC_IN I

PLL1 Oscillator Input. Along with OSC_IN

, this pin is the differential input for the PLL reference.

Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

10

OSC_IN

I

Complementary PLL1 Oscillator Input. Along with OSC_IN, this pin is the differential input for the PLL

reference. Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

Rev. B | Page 13 of 60

Page 14

AD9523-1

Pin

No. Mnemonic Type

11 LF2_EXT_CAP O PLL2 External Loop Filter Capacitor Connection. Connect capacitor to this pin and the LDO_VCO pin.

12 LDO_VCO P/O

13 VDD3_VCO P 3.3 V Supply for VCO and VCO M1 Divider.

14 LDO_DIV_M1 P/O

15

PD

16 REF_SEL I Reference Input Select. This pin has an internal 40 kΩ pull-down resistor.

17

SYNC

18 VDD3_REF P 3.3 V Supply for Output Clock Drivers Reference and VCO Divider M2.

19

20

RESET

CS

21 SCLK/SCL I

22 SDIO/SDA I/O Serial Control Port Bidirectional Serial Data In/Data Out for SPI Mode (SDIO) or I²C Mode (SDA).

23 SDO O

24 REF_TEST I Test Input to PLL1 Phase Detector.

25

OUT13

26 OUT13 O

27 VDD3_OUT[12:13] P 3.3 V Supply for Output 12 and Output 13 Clock Drivers.

28

OUT12

29 OUT12 O

30 VDD1.8_OUT[12:13] P 1.8 V Supply for Output 12 and Output 13 Clock Dividers.

31

OUT11

32 OUT11 O

33 VDD3_OUT[10:11] P 3.3 V Supply for Output 10 and Output 11 Clock Drivers.

34

OUT10

35 OUT10 O

36 VDD1.8_OUT[10:11] P 1.8 V Supply for Output 10 and Output 11 Clock Dividers.

37

OUT9

38 OUT9 O

39 VDD3_OUT[8:9] P 3.3 V Supply for Output 8 and Output 9 Clock Drivers.

40

OUT8

41 OUT8 O

42 VDD1.8_OUT[8:9] P 1.8 V Supply for Output 8 and Output 9 Clock Dividers.

43

OUT7

44 OUT7 O

1

Description

2.5 V LDO Internal Regulator Decoupling Pin for VCO. Connect a 0.47 F decoupling capacitor from

this pin to ground. Note that, for best performance, the LDO bypass capacitor must be placed in close

proximity to the device.

1.8 V LDO Regulator Decoupling Pin for VCO Divider M1. Connect a 0.47 F decoupling capacitor

from this pin to ground. Note that, for best performance, the LDO bypass capacitor must be placed

in close proximity to the device.

I Chip Power-Down, Active Low. This pin has an internal 40 kΩ pull-up resistor.

I

Manual Synchronization. This pin initiates a manual synchronization and has an internal 40 kΩ pullup resistor.

I

Digital Input, Active Low. Resets internal logic to default states. This pin has an internal 40 kΩ pull-up

resistor.

I Serial Control Port Chip Select, Active Low. This pin has an internal 40 kΩ pull-up resistor.

2

Serial Control Port Clock Signal for SPI Mode (SCLK) or I

C Mode (SCL). Data clock for serial program-

ming. This pin has an internal 40 kΩ pull-down resistor in SPI mode but is high impedance in I²C mode.

Serial Data Output. Use this pin to read data in 4-wire mode (high impedance in 3-wire mode). There

is no internal pull-up/pull-down resistor on this pin.

O

Complementary Square Wave Clocking Output 13. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 13. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 12. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 12. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 11. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 11. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 10. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 10. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 9. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 9. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 8. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 8. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 7. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 7. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

Rev. B | Page 14 of 60

Page 15

AD9523-1

Pin

No. Mnemonic Type

45 VDD3_OUT[6:7] P 3.3 V Supply for Output 6 and Supply Output 7 Clock Drivers.

46

OUT6

47 OUT6 O

48 VDD1.8_OUT[6:7] P 1.8 V Supply for Output 6 and Output 7 Clock Dividers.

49

OUT5

50 OUT5 O

51 VDD3_OUT[4:5] P 3.3 V Supply for Output 4 and Output 5 Clock Drivers.

52

OUT4

53 OUT4 O

54 VDD1.8_OUT[4:5] P 1.8 V Supply for Output 4 and Output 5 Clock Dividers.

55 STATUS1/SP1 I/O

56 STATUS0/SP0 I/O

57 EEPROM_SEL I

58

OUT3

59 OUT3 O

60 VDD3_OUT[2:3] P 3.3 V Supply for Output 2 and Output 3 Clock Drivers.

61

OUT2

62 OUT2 O

63 VDD1.8_OUT[2:3] P 1.8 V Supply for Output 2 and Output 3 Clock Dividers.

64

OUT1

65 OUT1 O

66 VDD3_OUT[0:1] P 3.3 V Supply for Output 0 and Output 1 Clock Drivers.

67

OUT0

68 OUT0 O

69 VDD1.8_OUT[0:1] P 1.8 V Supply for Output 0 and Output 1 Clock Dividers.

70 ZD_IN I

71

ZD_IN

72 PLL1_OUT O

EP EP, GND GND

1

P = power, I = input, O = output, I/O = input/output, P/O = power/output, GND = ground.

1

Description

O

Complementary Square Wave Clocking Output 6. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 6. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 5. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 5. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 4. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 4. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

Lock Detect and Other Status Signals (STATUS1)/I

down resistor.

Lock Detect and Other Status Signals (STATUS0)/I

down resistor.

EEPROM Select. Setting this pin high selects the register values stored in the internal EEPROM to be

loaded at reset and/or power-up. Setting this pin low causes the AD9523-1 to load the hard-coded

default register values at power-up/reset. This pin has an internal 40 kΩ pull-down resistor.

O

Complementary Square Wave Clocking Output 3. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 3. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 2. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 2. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 1. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 1. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

O

Complementary Square Wave Clocking Output 0. This pin can be configured as one side of

a differential LVPECL/LVDS/HSTL output or as a single-ended CMOS output.

Square Wave Clocking Output 0. This pin can be configured as one side of a differential LVPECL/

LVDS/HSTL output or as a single-ended CMOS output.

External Zero Delay Clock Input. Along with ZD_IN

reference. Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

I

Complementary External Zero Delay Clock Input. Along with ZD_IN, this pin is the differential input

for the PLL reference. Alternatively, this pin can be programmed as a single-ended 3.3 V CMOS input.

Single-Ended CMOS Output from PLL1. This pin has settings for weak and strong in Register 0x1BA,

Bit 4 (see Table 52).

Exposed Paddle. The exposed paddle is the ground connection on the chip. It must be soldered

to the analog ground of the PCB to ensure proper functionality and heat dissipation, noise, and

mechanical strength benefits.

2

C Address (SP1). This pin has an internal 40 kΩ pull-

2

C Address (SP0). This pin has an internal 40 kΩ pull-

, this pin is the differential input for the PLL

Rev. B | Page 15 of 60

Page 16

AD9523-1

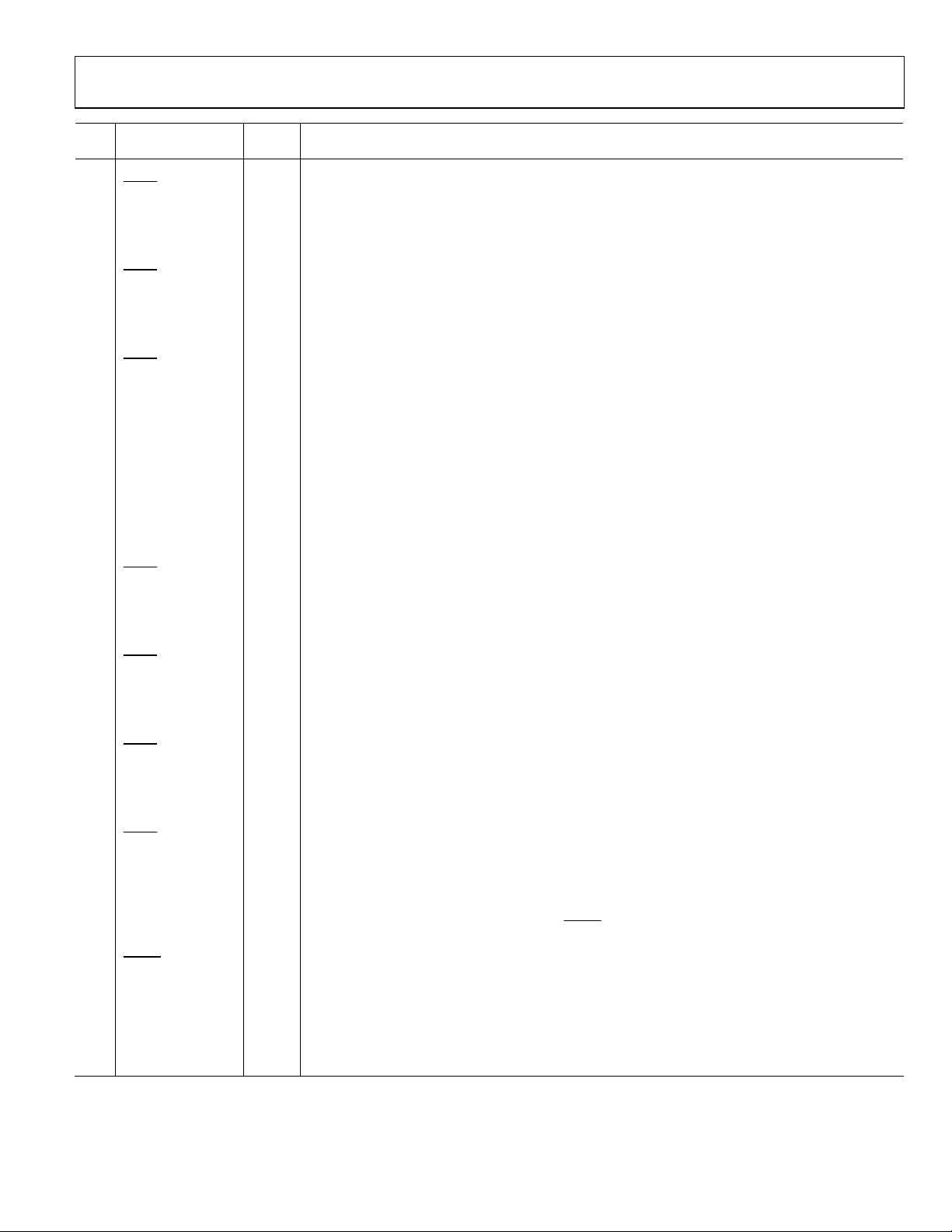

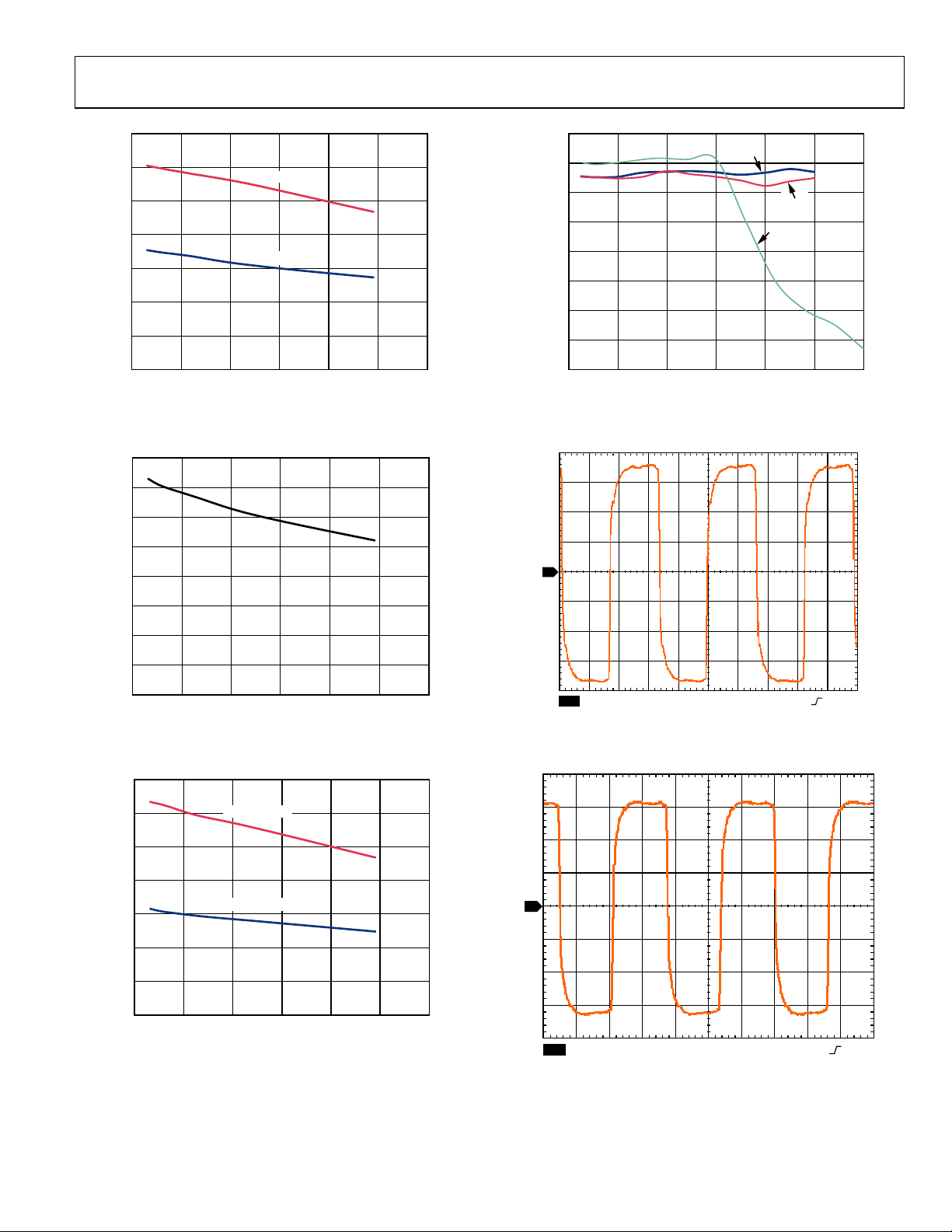

TYPICAL PERFORMANCE CHARACTERISTICS

f

= 122.88 MHz, REFA differential at 30.72 MHz, f

VCXO

60

50

40

HSTL = 16mA

= 2949.12 MHz, and doubler is off, unless otherwise noted.

VCO

45

40

35

30

30

CURRENT (mA)

20

10

0

0 200 400 600 800 1000 1200

HSTL = 8mA

FREQUENCY (MHz)

Figure 3. VDD3_OUT[x:y] Current (Typical) vs. Frequency;

HSTL Mode at 16 mA and 8 mA

45

40

35

30

25

20

CURRENT (mA)

15

10

5

0

0 200 400 600 800 1000 1200

LVD S = 7mA

LVD S = 3 .5m A

FREQUENC Y (MHz)

Figure 4. VDD3_OUT[x:y] Current (Typical) vs. Frequency;

LVDS Mode at 7 mA and 3.5 mA

25

20

CURRENT (mA)

15

10

5

0

0 200 400 600 800 1000 1200

09278-003

FREQUE NCY (MHz )

09278-005

Figure 5. VDD3_OUT[x:y] Current (Typical) vs. Frequency, LVPECL Mode

35

30

25

20

15

CURRENT (mA)

10

5

0

0 100 200 300 400 500 600

09278-004

FREQUENCY (MHz)

20pF

10pF

2pF

09278-006

Figure 6. VDD3_OUT[x:y] Current (Typical) vs. Frequency;

CMOS Mode at 20 pF, 10 pF, and 2 pF Load

Rev. B | Page 16 of 60

Page 17

AD9523-1

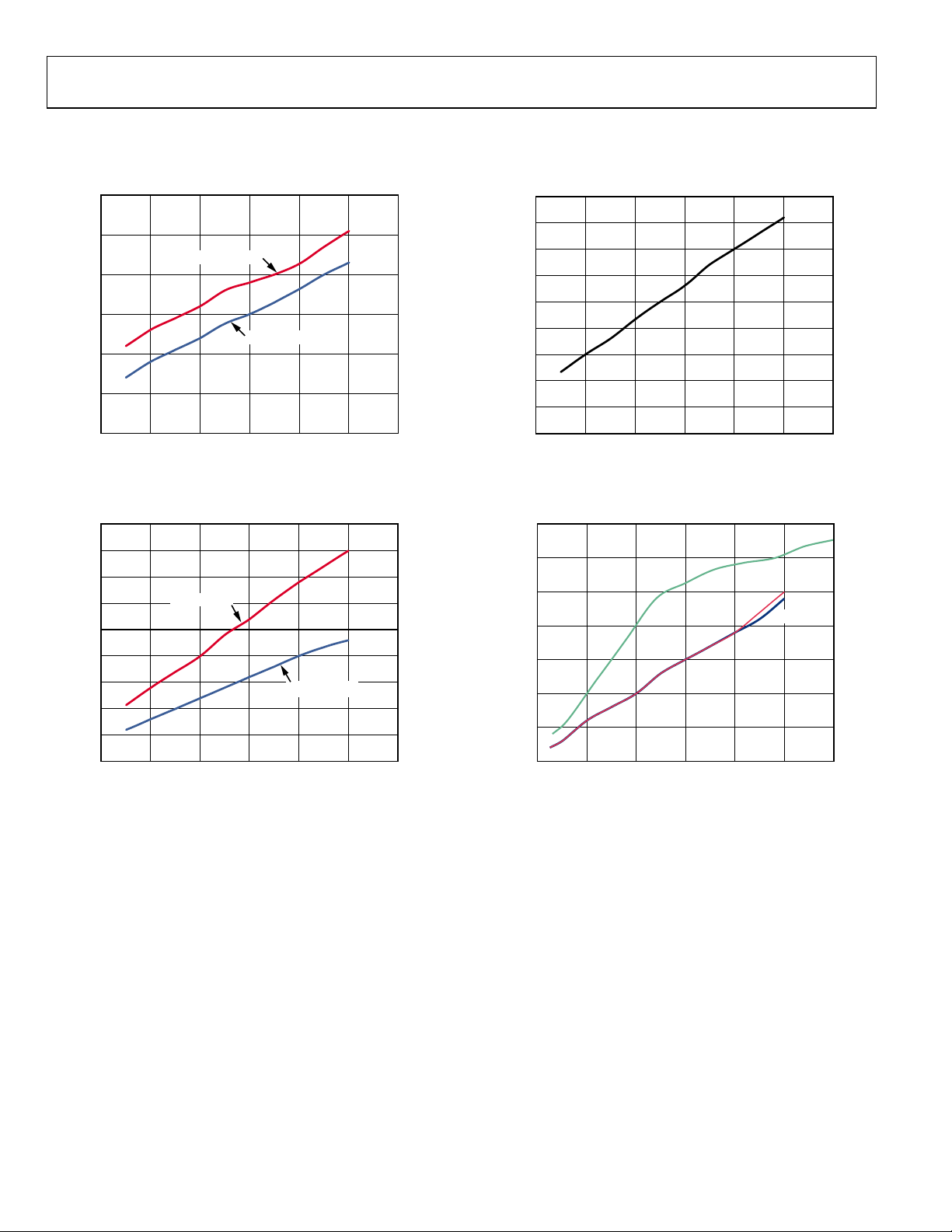

A

A

3.5

3.0

2.5

2.0

L SWING (V p-p)

1.5

1.0

DIFFERENTI

0.5

HSTL = 16mA

HSTL = 8mA

4.0

3.5

3.0

2.5

2.0

1.5

AMPLITUDE (V)

1.0

0.5

2pF

10pF

20pF

0

0 200 400 600 800 1000 1200

FREQUENC Y (MHz)

Figure 7. Differential Voltage Swing vs. Frequency;

HSTL Mode at 16 mA and 8 mA

1.6

1.4

1.2

1.0

0.8

L SWING (V p-p)

0.6

0.4

DIFFERENTI

0.2

0

0 200 400 600 800 1000 1200

FREQUENCY (MHz)

Figure 8. Differential Voltage Swing vs. Frequency, LVPECL Mode

1.4

1.2

LVD S = 7 mA

0

0 100 200 300 400 500 600

09278-007

FREQUENCY (MHz)

09278-010

Figure 10. Amplitude vs. Frequency and Capacitive Load;

CMOS Mode at 2 pF, 10 pF, and 20 pF Load

1

CH1 200mV 2. 5ns/DIV

09278-008

40.0GS/s

A CH1 104mV

09278-013

Figure 11. Output Waveform (Differential), LVPECL at 122.88 MHz

1.0

0.8

0.6

0.4

DIFFERENTIAL SWING (V p-p)

0.2

0

0 200 400 600 800 1000 1200

LVDS = 3.5mA

FREQUENCY (MHz)

Figure 9. Differential Voltage Swing vs. Frequency;

09278-009

1

CH1 500mV Ω 2.5ns/DIV

40.0GS/s

A CH1 80mV

Figure 12. Output Waveform (Differential), HSTL at 16 mA, 122.88 MHz

09278-049

LVDS Mode at 7 mA and 3.5 mA

Rev. B | Page 17 of 60

Page 18

AD9523-1

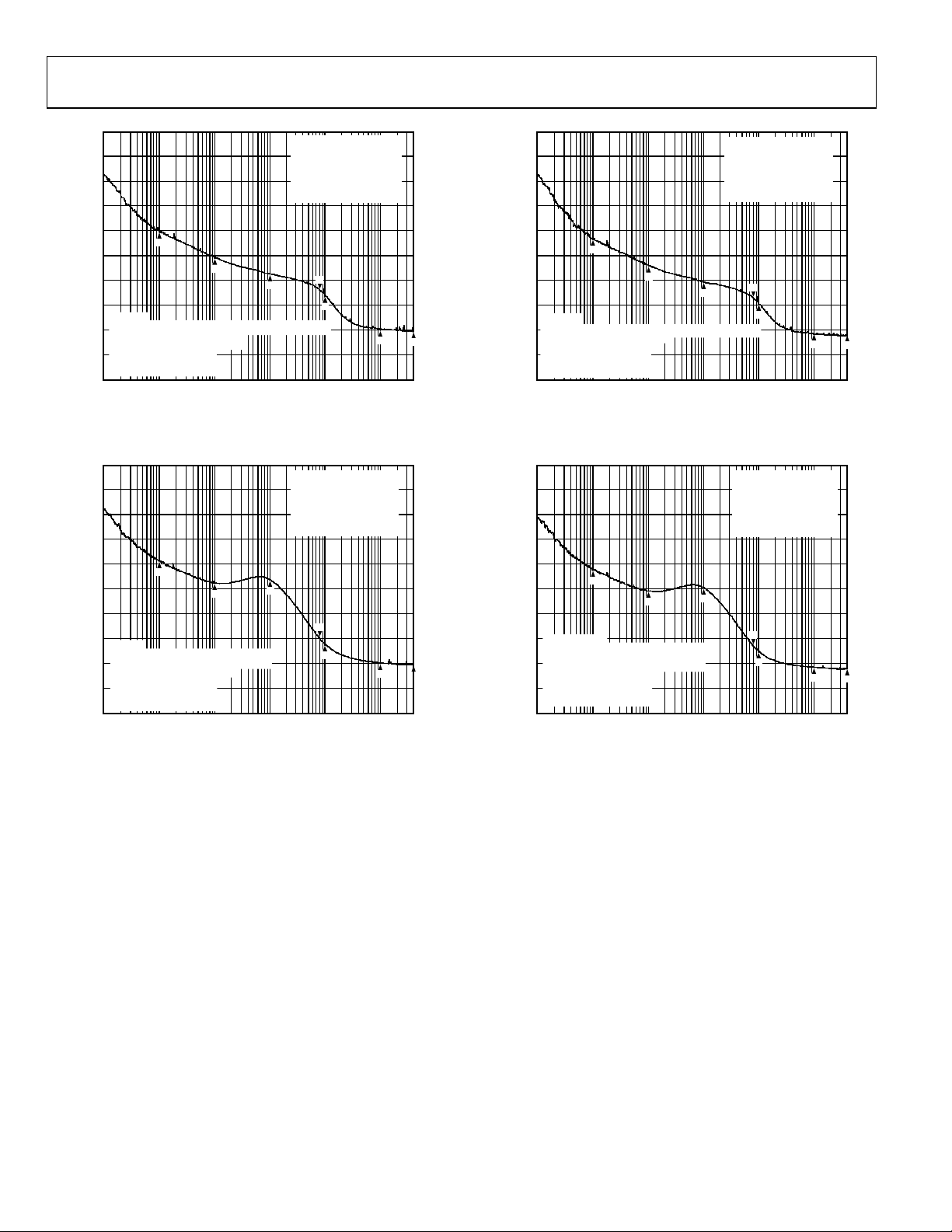

–

–

–

–

80

–90

–100

1: 1kHz, –120.0dBc/Hz

2: 10kHz, –130.6dBc/Hz

3: 100kHz, –137.4dBc/Hz

4: 1MHz, –145.7dBc/Hz

5: 10MHz, –159.6dBc/Hz

6: 40MHz, –160.3dBc/Hz

7: 800kHz, –143.7dBc/Hz

–110

–120

–130

–140

–150

PHASE NOISE (dBc/Hz)

–160

–170

–180

100 1k 10k 100k 1M 10M

1

2

3

NOISE:

ANALYSIS RANGE x: START 10kHz TO STO P 40MHz

INTG NOISE: –78.1dBc/40MHz

RMS NOI SE: 175.4 µRAD

10.0mdeg

RMS JITTER: 151.4fsec

RESIDUAL FM: 2. 1kHz

7

FREQUENCY (Hz)

Figure 13. Phase Noise, Output = 184.32 MHz

(VCXO = 122.88 MHz, Crystek VCXO CVHD-950); Doubler On

4

5

6

09278-113

80

–90

–100

1: 1kHz, –123.1dBc/Hz

2: 10kHz, –133.8dBc/Hz

3: 100kHz, –140.5dBc/Hz

4: 1MHz, –149.0Bc/Hz

5: 10MHz, –161.5dBc/Hz

6: 40MHz, –162.1dBc/Hz

7: 800kHz, –146.9dBc/Hz

–110

–120

–130

–140

–150

PHASE NOISE (dBc/Hz)

NOISE:

ANALYSIS RANGE x: START 1 0kHz TO STOP 40MHz

–160

INTG NOISE: –81.0dBc/40MHz

RMS NOISE: 126.6µRAD

7.3mdeg

–170

RMS JITTER: 164.0fsec

RESIDUAL FM: 1.7kHz

–180

100 1k 10k 100k 1M 10M

1

2

3

FREQUENCY (Hz)

Figure 15. Phase Noise, Output = 122.88 MHz

(VCXO = 122.88 MHz, Crystek VCXO CVHD-950); Doubler On

7

4

5

6

09278-014

80

–90

–100

1: 1kHz, –118.3dBc/Hz

2: 10kHz, –127.5dBc/Hz

3: 100kHz, –126.0dBc/Hz

4: 1MHz, –151.8dBc/Hz

5: 10MHz, –159.6dBc/Hz

6: 40MHz, –160.3dBc/Hz

7: 800kHz, –149.5dBc/Hz

–110

–120

–130

1

2

3

–140

–150

PHASE NOISE (dBc/Hz)

NOISE:

ANALYSIS RANGE x: START 10k Hz

–160

INTG NOISE: –73.1dBc/40MHz

RMS NOISE: 312.0µRAD

17.9mdeg

–170

RMS JITTER: 269.4fsec

RESIDUAL FM: 2. 0kHz

–180

100 1k 10k 100k 1M 10M

TO STOP 40MHz

FREQUENCY (Hz)

Figure 14. Phase Noise, Output = 184.32 MHz

(VCXO = 122.88 MHz, Crystek VCXO CVHD-950); Doubler On;

Optimized for Low 800 kHz Offset Noise

80

–90

–100

1: 1kHz, –122.0Bc/Hz

2: 10kHz, –130.7dBc/Hz

3: 100kHz, –129.3dBc/Hz

4: 1MHz, –154.9dBc/Hz

5: 10MHz, –161.5dBc/Hz

6: 40MHz, –162.1dBc/Hz

7: 800kHz, –152.7dBc/Hz

–110

–120

–130

PHASE NOISE (dBc/Hz)

–140

–150

–160

7

4

5

6

–170

–180

100 1k 10k 100k 1M 10M

09278-012

1

2

NOISE:

ANALYSIS RANGE x: START 10kHz

INTG NOISE: –76.3dBc/40MHz

RMS NOISE: 217.0µRAD

12.4mdeg

RMS JITTER: 281.1fsec

RESIDUAL FM: 1.6kHz

TO STOP 40M Hz

FREQUENCY (Hz)

3

7

4

5

6

09278-015

Figure 16. Phase Noise, Output = 122.88 MHz

(VCXO = 122.88 MHz, Crystek VCXO CVHD-950); Doubler On;

Optimized for Low 800 kHz Offset Noise

Rev. B | Page 18 of 60

Page 19

AD9523-1

INPUT/OUTPUT TERMINATION RECOMMENDATIONS

AD9523-1

LVD S

OUTPUT

Figure 17. AC-Coupled LVDS Output Driver

AD9523-1

LVD S

OUTPUT

Figure 18. DC-Coupled LVDS Output Driver

AD9523-1

LVP ECL -

COMPATIBLE

OUTPUT

Figure 19. AC-Coupled LVPECL Output Driver

0.1µF

0.1µF

100Ω

0.1µF

0.1µF

100Ω

100Ω

HIGH

IMPEDANCE

INPUT

HIGH

IMPEDANCE

INPUT

HIGH

IMPEDANCE

INPUT

DOWNSTREAM

DEVICE

DOWNSTREAM

DEVICE

DOWNSTREAM

DEVICE

AD9523-1

HSTL

OUTPUT

09278-142

0.1µF

100Ω

0.1µF

HIGH

IMPEDANCE

INPUT

DOWNSTREAM

DEVICE

09278-046

Figure 21. AC-Coupled HSTL Output Driver

AD9523-1

HSTL

OUTPUT

09278-143

100Ω

Figure 22. DC-Coupled HSTL Output Driver

100Ω

1

(OPTIONAL

09278-044

1

RESISTOR VALUE DEPENDS UPON

REQUIRED TERMINATION OF SOURCE.

)

Figure 23. REFx, VCXO, and Zero Delay Input Differential Mode

HIGH

IMPEDANCE

INPUT

0.1µF

SELF-BIASED

0.1µF

DOWNSTREAM

DEVICE

AD9523-1

REF, VCXO,

ZERO DELAY

INPUTS

09278-047

09278-048

AD9523-1

LVP ECL -

COMPATIBLE

OUTPUT

100Ω

Figure 20. DC-Coupled LVPECL Output Driver

IMPEDANCE

HIGH

INPUT

DOWNSTREAM

DEVICE

09278-045

Rev. B | Page 19 of 60

Page 20

AD9523-1

TERMINOLOGY

Phase Jitter and Phase Noise

An ideal sine wave can be thought of as having a continuous

and even progression of phase with time from 0° to 360° for

each cycle. Actual signals, however, display a certain amount

of variation from ideal phase progression over time. This

phenomenon is called phase jitter. Although many causes can

contribute to phase jitter, one major cause is random noise,

which is characterized statistically as being Gaussian (normal)

in distribution.

This phase jitter leads to a spreading out of the energy of the

sine wave in the frequency domain, producing a continuous

power spectrum. This power spectrum is usually reported as

a series of values whose units are dBc/Hz at a given offset in

frequency from the sine wave (carrier). The value is a ratio

(expressed in decibels) of the power contained within a 1 Hz

bandwidth with respect to the power at the carrier frequency.

For each measurement, the offset from the carrier frequency is

also given.

It is meaningful to integrate the total power contained within

some interval of offset frequencies (for example, 10 kHz to

10 MHz). This is called the integrated phase noise over that

frequency offset interval and can be readily related to the time

jitter due to the phase noise within that offset frequency interval.

Phase noise has a detrimental effect on the performance of ADCs,

DACs, and RF mixers. It lowers the achievable dynamic range of

the converters and mixers, although they are affected in somewhat

different ways.

Time Jitter

Phase noise is a frequency domain phenomenon. In the time

domain, the same effect is exhibited as time jitter. When observing

a sine wave, the time of successive zero crossings varies. In a square

wave, the time jitter is a displacement of the edges from their

ideal (regular) times of occurrence. In both cases, the variations in

timing from the ideal are the time jitter. Because these variations

are random in nature, the time jitter is specified in seconds root

mean square (rms) or 1 sigma of the Gaussian distribution.

Time jitter that occurs on a sampling clock for a DAC or an

ADC decreases the signal-to-noise ratio (SNR) and dynamic

range of the converter. A sampling clock with the lowest possible

jitter provides the highest performance from a given converter.

Additive Phase Noise

Additive phase noise is the amount of phase noise that is

attributable to the device or subsystem being measured.

The phase noise of any external oscillators or clock sources is

subtracted. This makes it possible to predict the degree to which

the device impacts the total system phase noise when used in

conjunction with the various oscillators and clock sources, each

of which contributes its own phase noise to the total. In many

cases, the phase noise of one element dominates the system

phase noise. When there are multiple contributors to phase

noise, the total is the square root of the sum of squares of the

individual contributors.

Additive Time Jitter

Additive time jitter is the amount of time jitter that is attributable to

the device or subsystem being measured. The time jitter of any

external oscillators or clock sources is subtracted. This makes

it possible to predict the degree to which the device impacts the

total system time jitter when used in conjunction with the various

oscillators and clock sources, each of which contributes its own

time jitter to the total. In many cases, the time jitter of the external

oscillators and clock sources dominates the system time jitter.

Rev. B | Page 20 of 60

Page 21

AD9523-1

THEORY OF OPERATION

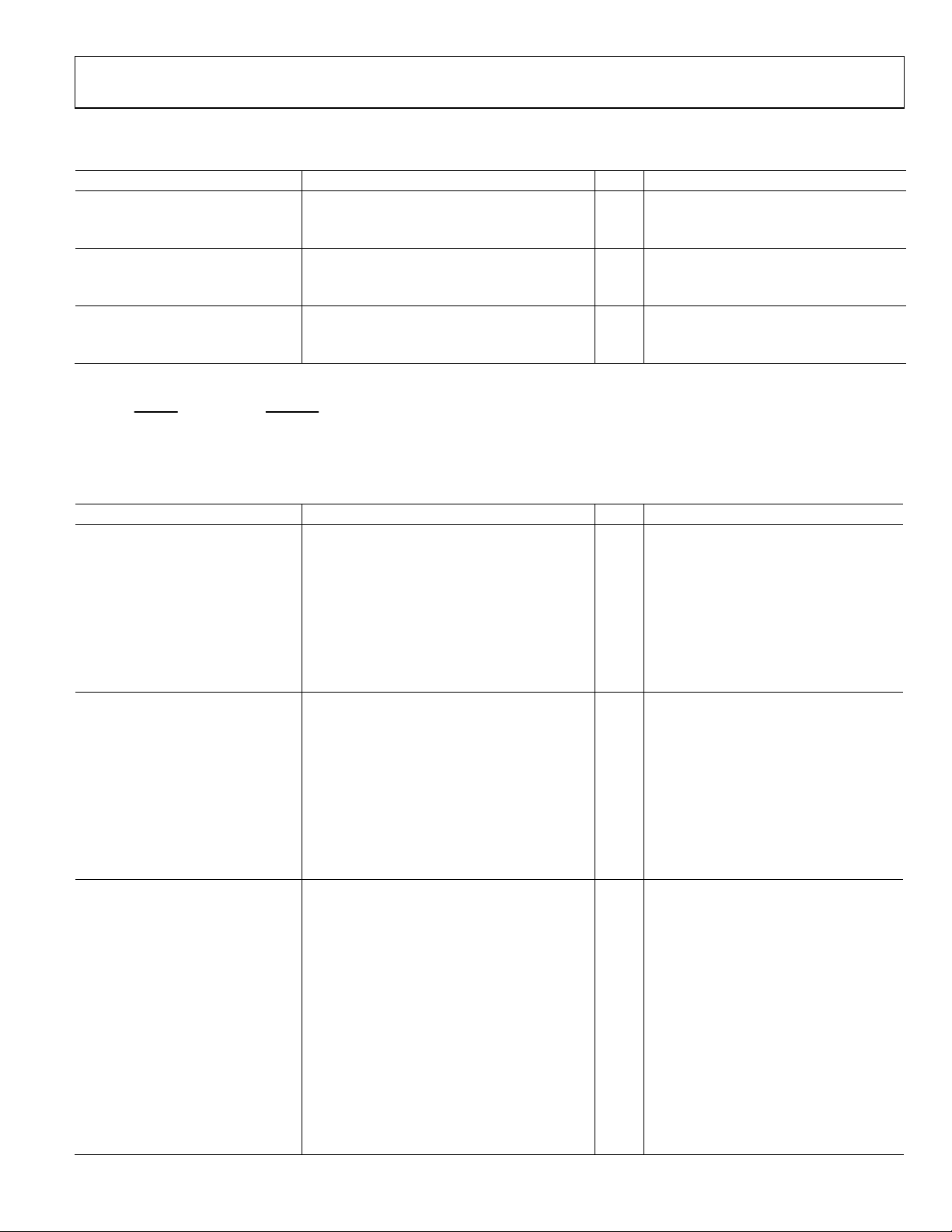

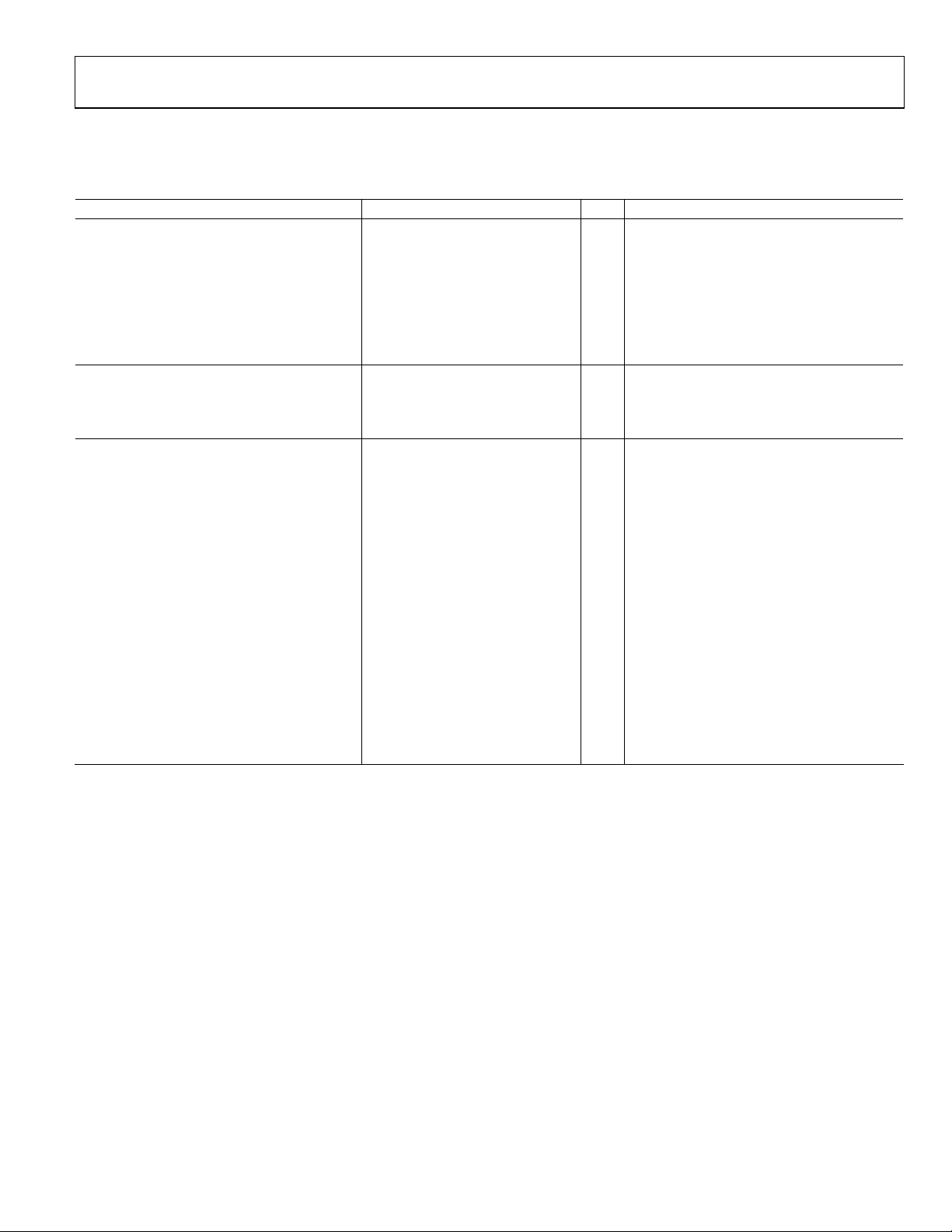

DETAILED BLOCK DIAGRAM

VDD3_PLL

VCXO

LDO_PLL1 LDO_VCO

OSC_CTRL O SC_IN

PLL1_OUT

STATUS0/

SP0

STATUS1/

SP1

LF2_EXT_CAPLF1_EXT_CAP

VDD1.8_OUT[x:y]

VDD3_OUT[x:y]

REFA

REFA

REF_SEL

REFB

REFB

REF_TEST

SDIO/SDA

SDO

SCLK/SCL

RESET

EEPROM_SEL

∆t

EDGE

÷D

SELECT

∆t

EDGE

÷D

SELECT

STATUS MONI TOR

LOCK DETECT/

SERIAL PORT

LOCK

÷N1

DETECT

P

F

D

LOOP

FILTER

CHARGE

PUMP

PLL1

÷R1

SWITCH-

OVER

CONTROL

÷R1

÷R1

CONTROL

CS

PD

INTERFACE

(SDI AND I

EEPROM

2

C)

÷D1

÷R2 ×2

PLL2

ADDRESS

LOCK

DETECT

P

F

D

CHARGE

PUMP

÷N2

LOOP

FILTER

VCO

M1

M2

FANOUT

FANOUT

(TEST PATH)

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

∆t

EDGE

÷D

SELECT

∆t

÷D

EDGE

SELECT

∆t

EDGE

÷D

SELECT

∆t

EDGE

÷D

SELECT

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

∆t

÷D

EDGE

SELECT

AD9523-1

OUT13

OUT13

OUT12

OUT12

OUT11

OUT11

OUT10

OUT10

OUT9

OUT9

OUT8

OUT8

OUT7

OUT7

OUT6

OUT6

OUT5

OUT5

OUT4

OUT4

OUT3

OUT3

OUT2

OUT2

OUT1

OUT1

OUT0

OUT0

ZD_IN

ZD_IN

LDO_DIV_M I

Figure 24. Top Level Diagram

OVERVIEW

The AD9523-1 is a clock generator that employs integer-N-based

phase-locked loops (PLL). The device architecture consists of two

cascaded PLL stages. The first stage, PLL1, consists of an integer

division PLL that uses an external voltage-controlled crystal

oscillator (VCXO) from 15 MHz to 250 MHz. PLL1 has a narrowloop bandwidth that provides initial jitter cleanup of the input

reference signal. The second stage, PLL2, is a frequency

multiplying PLL that translates the first stage output frequency

to a range of 2.94 GHz to 2.96 GHz. PLL2 incorporates an

integer-based feedback divider that enables integer frequency

multiplication. Programmable integer dividers (1 to 1024) follow

PLL2, establishing a final output frequency of 1 GHz or less.

The AD9523-1 includes reference signal processing blocks that

enable a smooth switching transition between two reference inputs.

This circuitry automatically detects the presence of the reference

input signals. If only one input is present, the device uses it as

the active reference. If both are present, one becomes the active

reference and the other becomes the backup reference. If the active

reference fails, the circuitry automatically switches to the backup

reference (if available), making it the new active reference.

Rev. B | Page 21 of 60

VDD3_VCO

SYNC

09278-020

A register setting determines what action to take if the failed

reference is once again available: either stay on Reference B or

revert to Reference A. If neither reference is usable, the AD9523-1

supports a holdover mode. A reference select pin (REF_SEL,

Pin 16) is available to manually select which input reference is

active (see Tab l e 4 2). The accuracy of the holdover is dependent

on the external VCXO frequency stability at half supply voltage.

Any of the divider settings are programmable via the serial

programming port, enabling a wide range of input/output

frequency ratios under program control. The dividers also

include a programmable delay to adjust timing of the output

signals, if required.

The output is compatible with LVPECL, LVDS, or HSTL logic

levels (see the Input/Output Termination Recommendations

section); however, the AD9523-1 is implemented only in CMOS.

The loop filters of each PLL are integrated and programmable.

Only a single external capacitor for each of the two PLL loop

filters is required.

The AD9523-1 operates over the extended industrial temperature

range of −40°C to +85°C.

Page 22

AD9523-1

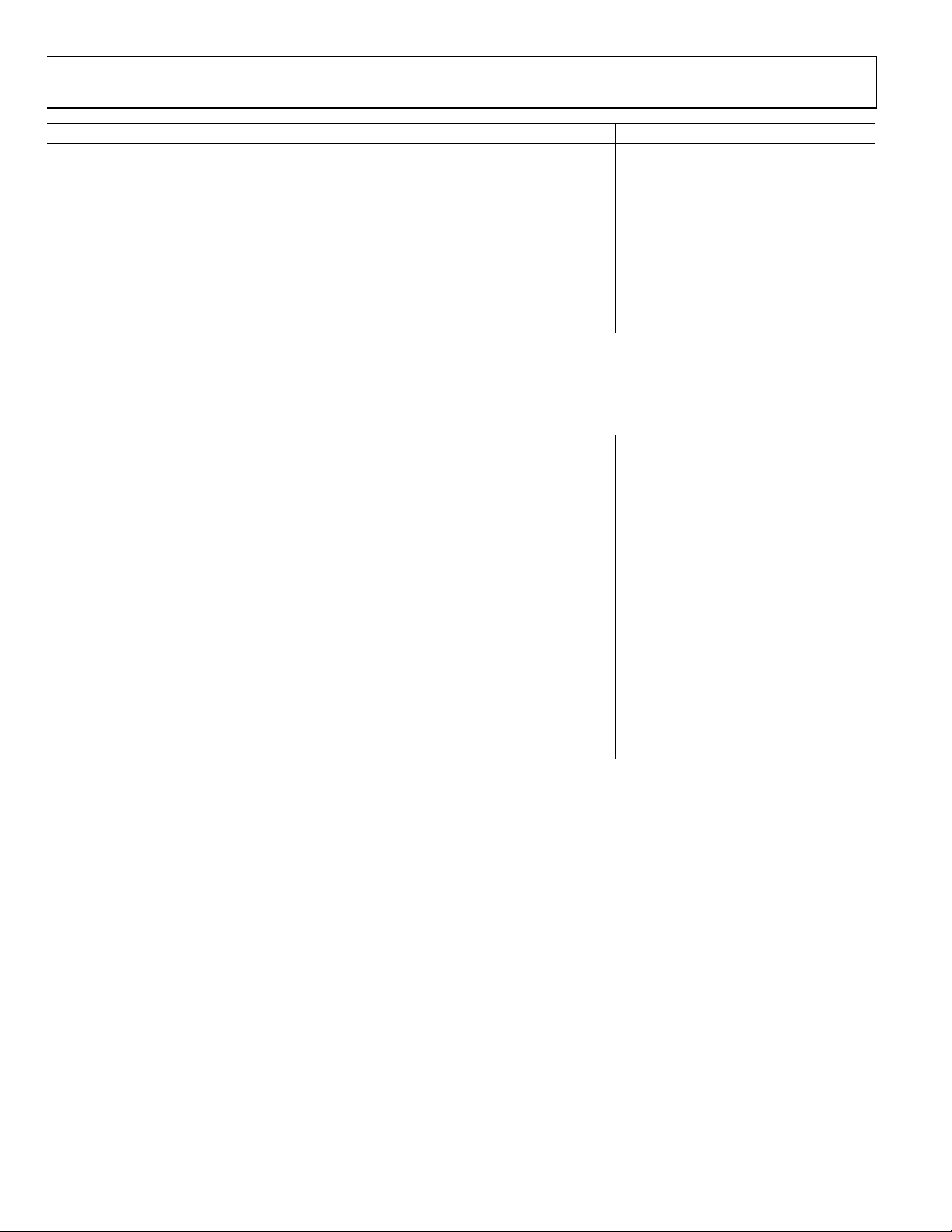

COMPONENT BLOCKS—INPUT PLL (PLL1)

PLL1 General Description

Fundamentally, the input PLL (referred to as PLL1) consists of

a phase-frequency detector (PFD), charge pump, passive loop filter,

and an external VCXO operating in a closed loop (see Figure 26).

PLL1 has the flexibility to operate with a loop bandwidth of

approximately 10 Hz to 100 Hz. This relatively narrow loop

bandwidth gives the AD9523-1 the ability to suppress jitter that

appears on the input references (REFA and REFB). The output

of PLL1 then becomes a low jitter phase-locked version of the

reference input system clock.

PLL1 Reference Clock Inputs

The AD9523-1 features two separate differential reference clock

inputs, REFA and REFB. These inputs can be configured to

operate in full differential mode or single-ended CMOS mode.

In differential mode, these pins are internally self-biased. If

REFA

REFA or REFB is driven single-ended, the unused side (

REFB

) should be decoupled via a suitable capacitor to a quiet

ground. shows the equivalent circuit of REFA or REFB.

Figure 23

It is possible to dc-couple to these inputs, but the dc operation

point should be set as specified in the tables.

Specifications

To operate either the REFA input or the REFB input in 3.3 V

CMOS mode, the user must set Bit 5 or Bit 6, respectively, in

Register 0x01A (see Tabl e 4 0 ). The single-ended inputs can be

driven by either a dc-coupled CMOS level signal or an ac-coupled

sine wave or square wave.

The differential reference input receiver is powered down when

the differential reference input is not selected, or when the PLL

is powered down. The single-ended buffers power down when

the PLL is powered down, when their respective individual powerdown registers are set, or when the differential receiver is selected.

The REFB R divider uses the same value as the REFA R divider

unless Bit 7, the enable REFB R divider independent division

control bit in Register 0x01C, is programmed as shown in Tab le 4 2 .

,

PLL1 Loop Filter

The PLL1 loop filter requires the connection of an external

capacitor from LF1_EXT_CAP (Pin 7) to ground. The value of the

external capacitor depends on the use of an external VCXO and

the configuration parameters, such as input clock rate and desired

bandwidth. Normally, a 0.3 µF capacitor allows the loop bandwidth

to range from 10 Hz to 100 Hz and ensures loop stability over

the intended operating parameters of the device (see Tabl e 43 for

R

values).

ZERO

LF1_EXT_CAP LDO_PLL1

AD9523-1

R

ZERO

CHARGE

PUMP

C

POLE1

R

C

POLE2

POLE2

BUFFER

OSC_CTRL

1kΩ

0.3µF

Figure 25. PLL1 Loop Filter

Table 19. PLL1 Loop Filter Programmable Values

R

C

R

C

ZERO

(kΩ)

POLE1

(nF)

POLE2

(kΩ)

POLE2

(nF)

LF1_EXT_CAP1

(μF)

883 1.5 fixed 165 fixed 0.337 fixed 0.3

677

341

135

10

External

1

External loop filter capacitor.

An external R-C low-pass filter should be used at the OSC_CTRL

output. The values shown in Figure 25 add an additional low-pass

pole at ~530 Hz. This R-C network filters the noise associated with

the OSC_CTRL buffer to achieve the best noise performance at the

1 kHz offset region.

09278-022

LF1_EXT_CAP

REFA

REFA

REF_SEL

REFB

REFB

REF_TEST

DIVIDE-BY1, 2, ... 1023

DIVIDE-BY1, 2, ... 1023

3.3V CMOS

OR 1.8V

DIFFERENTI AL

DIVIDE- BY-

1, 2, ...63

1.8V LDO

VDD3_PLL LDO_PLL1

SWITCH-

OVER

CONTROL

P

F

D

CHARGE

0.5µA LSB

R

ZERO

PUMP

7 BITS,

C

POLE1

DIVIDE-BY-

1, 2, ... 1023

AD9523-1

R

C

POLE2

POLE2

OSC_CTRL

VCXO

OSC_IN

09278-021

Figure 26. Input PLL (PLL1) Block Diagram

Rev. B | Page 22 of 60

Page 23

AD9523-1

PLL1 Input Dividers

Each reference input feeds a dedicated reference divider block.

The input dividers provide division of the reference frequency

in integer steps from 1 to 1023. They provide the bulk of the

frequency prescaling that is necessary to reduce the reference

frequency to accommodate the bandwidth that is typically

desired for PLL1.

PLL1 Reference Switchover

The reference monitor verifies the presence/absence of the

prescaled REFA and REFB signals (that is, after division by the

input dividers). The status of the reference monitor guides the

activity of the switchover control logic. The AD9523-1 supports

automatic and manual PLL reference clock switching between

REFA (the REFA and

REFB

pins). This feature supports networking and infrastructure

REFA

pins) and REFB (the REFB and

applications that require redundant references.

There are several configurable modes of reference switchover. The

manual switchover is achieved either via a programming register

setting or by using the REF_SEL pin. The automatic switchover

occurs when REFA disappears and there is a reference on REFB.

The reference automatic switchover can be set to work as follows:

• Nonrevertive: stay on REFB. Switch from REFA to REFB

when REFA disappears, but do not switch back to REFA

if it reappears. If REFB disappears, then go back to REFA.

• Revert to REFA. Switch from REFA to REFB when REFA

disappears. Return to REFA from REFB when REFA returns.

See Tab le 4 2 for the PLL1 miscellaneous control register bit

settings.

PLL1 Holdover

In the absence of both input references, the device enters holdover mode. Holdover is a secondary function that is provided

by PLL1. Because PLL1 has an external VCXO available as a

frequency source, it continues to operate in the absence of the

input reference signals. When the device switches to holdover,

the charge pump tristates. The device continues operating in this

mode until a reference signal becomes available. Then the device

exits holdover mode, and PLL1 resynchronizes with the active

reference. In addition to tristate, the charge pump can be forced

to VCC/2 during holdover (Register 0x01C, Bit 6; see Tabl e 42 ).

COMPONENT BLOCKS—OUTPUT PLL (PLL2)

PLL2 General Description

The output PLL (referred to as PLL2) consists of an optional

input reference doubler, reference divider, phase-frequency

detector (PFD), a partially integrated analog loop filter (see

Figure 27), an integrated voltage-controlled oscillator (VCO),

and a feedback divider. The VCO produces a nominal 3.0 GHz

signal with an output divider that is capable of division ratios of

3, 4, and 5.

The PFD of the output PLL drives a charge pump that increases,

decreases, or holds constant the charge stored on the loop filter

capacitors (both internal and external). The stored charge results

in a voltage that sets the output frequency of the VCO. The

feedback loop of the PLL causes the VCO control voltage to

vary in a way that phase locks the PFD input signals.

The gain of PLL2 is proportional to the current delivered by

the charge pump. The loop filter bandwidth is chosen to reduce

noise contributions from PLL sources that could degrade phase

noise requirements.

The output PLL has a VCO with multiple bands spanning a range

of 2.94 GHz to 3.1 GHz. However, the actual operating frequency

within a particular band depends on the control voltage that

appears on the loop filter capacitor. The control voltage causes

the VCO output frequency to vary linearly within the selected

band. This frequency variability allows the control loop of the

output PLL to synchronize the VCO output signal with the

reference signal applied to the PFD. Typically, the device

automatically selects the appropriate band as part of its

calibration process (invoked via the VCO control register

at Address 0x0F3, shown in Tab l e 4 7 ).

PLL1_OUT

DIVIDE-BY -

1, 2, 4, 8, 16

R2

DIVIDE-BY-

1, 2, 3...31

×2

AD9523-1

VDD3_PLL

PLL CORE

PFD

1.9V

LF2_EXT_CAP

R

ZERO

CHARGE PUMP

7 BITS, 3.5µ A LSB

A/B

COUNTERS

Figure 27. Output PLL (PLL2) Block Diagram

Rev. B | Page 23 of 60

LDO_VCO

C

POLE1

N DIVIDER

C

POLE2

R

POLE2

DIVIDE-BY -4

PRESCALER

LDO LDO

PLL_1.8V

DIVIDE-BY -

3, 4, 5,

DIVIDE-BY -

3, 4, 5,

VDD3_REF

LDO_DIV_M1VDD3_VCO

M1

TO DIST/

RESYNC

M2

TO DIST/

RESYNC

09278-023

Page 24

AD9523-1

Input 2× Frequency Multiplier

The 2× frequency multiplier provides the option to double the

frequency at the PLL2 input. This allows the user to take advantage

of a higher frequency at the input to the PLL (PFD) and, thus,

allows for reduced in-band phase noise and greater separation

between the frequency generated by the PLL and the modulation

spur associated with PFD. However, increased reference spur

separation results in harmonic spurs, introduced by the frequency

multiplier, that increase as the duty cycle deviates from 50% at the

OSC_IN inputs. As such, beneficial use of the frequency multiplier

is application-specific. Typically, a VCXO with proper interfacing

has a duty cycle that is approximately 50% at the OSC_IN inputs.

Note that the maximum output frequency of the 2× frequency

multipliers must not exceed the maximum PFD rate that is

specified in Tabl e 11 .

PLL2 Feedback Divider

PLL2 has a feedback divider (N divider) that enables it to provide

integer frequency up-conversion.

bination of a prescaler (P) and two counters, A and B.

divider value is

The PLL2 N divider is a com-

The total

N = (P × B) + A

where P = 4.

The feedback divider is a dual modulus prescaler architecture, with

a nonprogrammable P that is equal to 4. The value of the B counter

can be from 3 to 63, and the value of the A counter can be from 0 to 3.

However, due to the architecture of the divider, there are constraints,

as listed in

Tabl e 45 .

PLL2 Loop Filter

The PLL2 loop filter requires the connection of an external

capacitor from LF2_EXT_CAP (Pin 11) to LDO_VCO (Pin 12),

as illustrated in Figure 27. The value of the external capacitor

depends on the operating mode and the desired phase noise

performance. For example, a loop bandwidth of approximately

500 kHz produces the lowest integrated jitter. A lower bandwidth

produces lower phase noise at 1 MHz but increases the total

integrated jitter.

Table 20. PLL2 Loop Filter Programmable Values

R

C

R

C

ZERO

(Ω)

3250 48 900 Fixed at 16 Typical at 1000

3000 40 450

2750 32 300

2500 24 225

2250 16

2100 8

2000 0

1850

1

External loop filter capacitor.

POLE1

(pF)

POLE2

(Ω)

POLE2

(pF)

LF2_EXT_CAP1

(pF)

VCO Divider M1 and VCO Divider M2

The VCO dividers provide frequency division between the internal

VCO and the clock distribution. Each VCO divider can be set to

divide by 3, 4, or 5. When the AD9523-1 is used without any

zero delay feedback (internal or external), the phase relationship

between the reference inputs and the outputs is a function of

the phase relationship between the OSC input and the reference

inputs. Because the VCO divider is not reset by

SYNC

, there is

an additional phase variability of up to x VCO periods, where

x = VCO divider setting.

VCO Calibration

The AD9523-1 on-chip VCO must be manually calibrated to

ensure proper operation over process and temperature. This is

accomplished by setting the calibrate VCO bit (Register 0x0F3,

Bit 1) to 1. (This bit is not self-clearing.) The setting can be

performed as part of the initial setup before executing the

IO_Update bit (Register 0x234, Bit 0 = 1). A readback bit, VCO

calibration in progress (Register 0x22D, Bit 0), indicates when

a VCO calibration is in progress by returning a logic true (that is,

Bit 0 = 1). If the EEPROM is in use, setting the calibrate VCO bit

to 1 before saving the register settings to the EEPROM ensures

that the VCO calibrates automatically after the EEPROM has

loaded. After calibration, it is recommended that a sync be initiated

(see the Clock Distribution Synchronization section).

Note that the calibrate VCO bit defaults to 0. This bit must

change from 0 to 1 to initiate a calibration sequence. Therefore,

any subsequent calibrations require the following sequence:

1. Register 0x0F3, Bit 1 (calibrate VCO bit) = 0

2. Register 0x234, Bit 0 (IO_Update bit) = 1

3. Register 0x0F3, Bit 1 (calibrate VCO bit) = 1

4. Register 0x234, Bit 0 (IO_Update bit) = 1

VCO calibration is controlled by a calibration controller that

runs off the VCXO input clock. The calibration requires that

PLL2 be set up properly to lock the PLL2 loop and that the

VCXO clock be present.