Page 1

Integrated 2.5 GHz VCO

AD9518-1

Rev. C

Trademarks and registered trademarks are the property of their respective owners.

Fax: 781.461.3113 ©2007–2012 Analog Devices, Inc. All rights reserved.

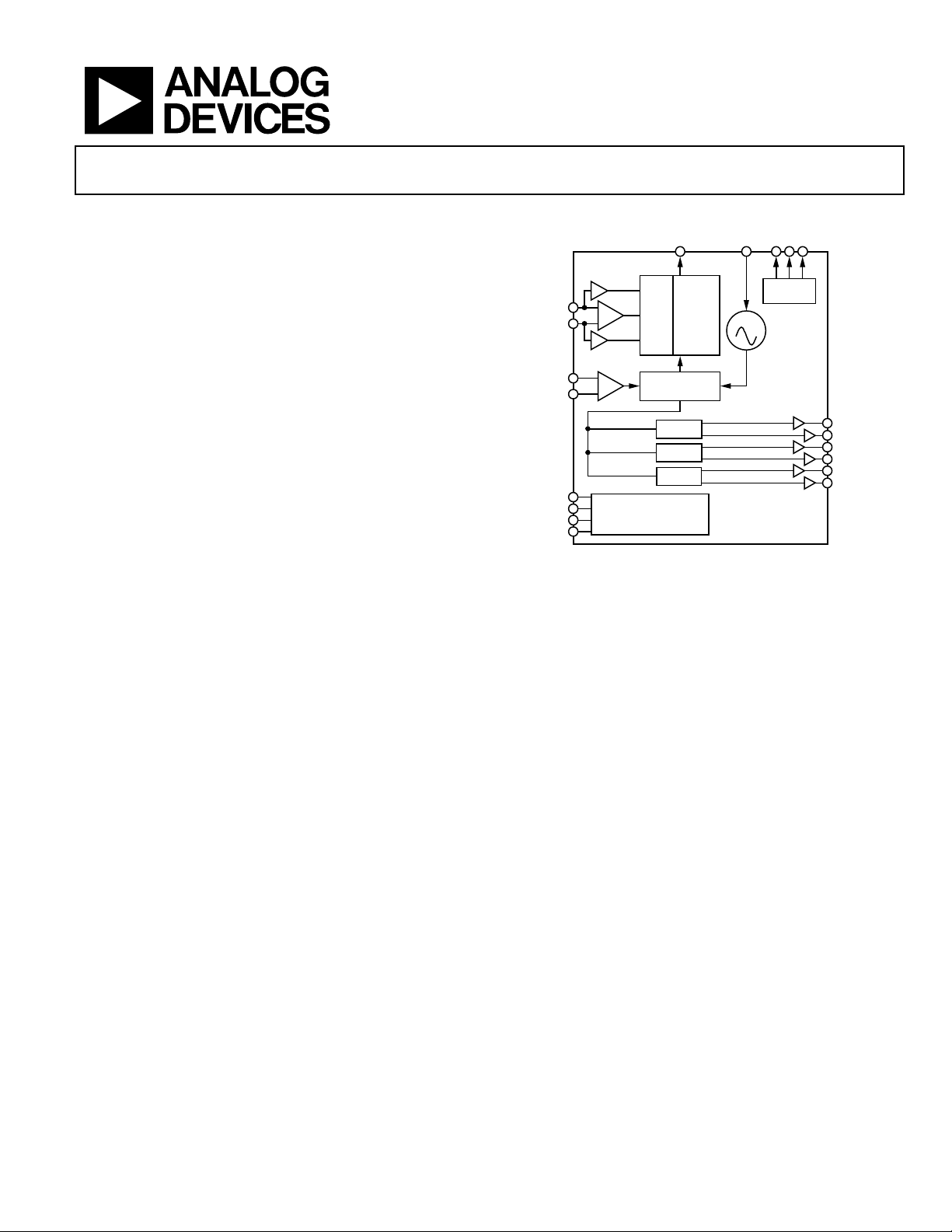

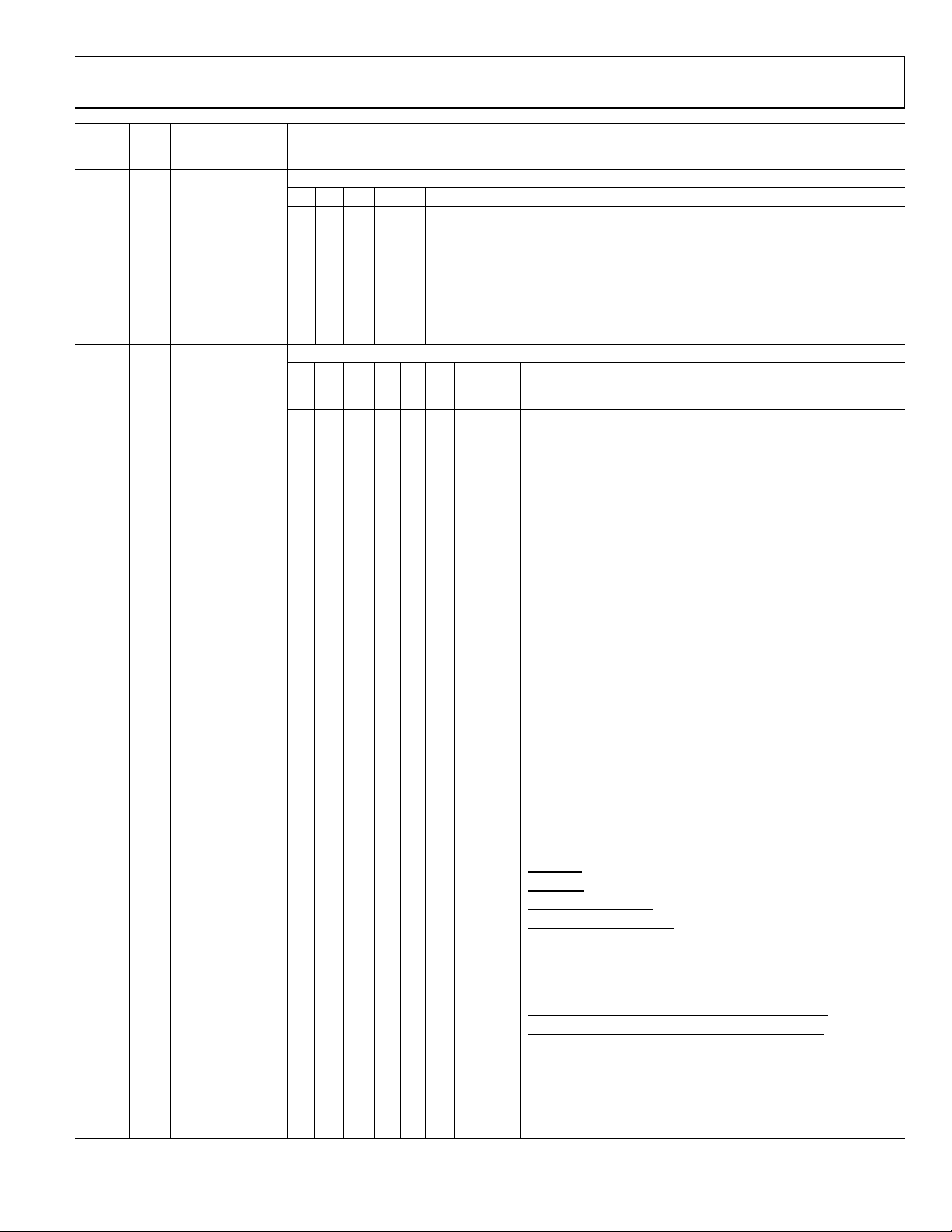

REFIN

REF1

REF2

CLK

LF

SWITCHOVER

AND MONITOR

PLL

DIVIDER

AND MUXs

CP

VCO

STATUS

MONITOR

LVPECL

LVPECL

SERIAL CONTROL PORT

AND

DIGITAL LOGIC

AD9518-1

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

DIV/Φ

DIV/Φ

DIV/Φ

LVPECL

06430-001

Data Sheet

FEATURES

Low phase noise, phase-locked loop (PLL)

On-chip VCO tunes from 2.30 GHz to 2.65 GHz

External VCO/VCXO to 2.4 GHz optional

1 differential or 2 single-ended reference inputs

Reference monitoring capability

Automatic revertive and manual reference

switchover/holdover modes

Accepts LVPECL, LVDS, or CMOS references to 250 MHz

Programmable delays in path to PFD

Digital or analog lock detect, selectable

3 pairs of 1.6 GHz LVPECL outputs

Each output pair shares a 1-to-32 divider with coarse

phase delay

Additive output jitter: 225 fs rms

Channel-to-channel skew paired outputs of <10 ps

Automatic synchronization of all outputs on power-up

Manual output synchronization available

Available in a 48-lead LFCSP

APPLICATIONS

Low jitter, low phase noise clock distribution

10/40/100 Gb/sec networking line cards, including SONET,

Synchronous Ethernet, OTU2/3/4

Forward error correction (G.710)

Clocking high speed ADCs, DACs, DDSs, DDCs, DUCs, MxFEs

High performance wireless transceivers

ATE and high performance instrumentation

GENERAL DESCRIPTION

The AD9518-11 provides a multi-output clock distribution

function with subpicosecond jitter performance, along with an

on chip PLL and VCO. The on-chip VCO tunes from 2.30 GHz to

2.65 GHz. Optionally, an external VCO/VCXO of up to 2.4 GHz

can be used.

The AD9518-1 emphasizes low jitter and phase noise to maximize

data converter performance, and it can benefit other applications

with demanding phase noise and jitter requirements.

The AD9518-1 features six LVPECL outputs (in three pairs).

The LVPECL outputs operate to 1.6 GHz.

For applications that require additional outputs, a crystal

reference input, zero-delay, or EEPROM for automatic

configuration at startup, the AD9520 and AD9522 are available.

6-Output Clock Generator with

FUNCTIONAL BLOCK DIAGRAM

Figure 1.

In addition, the AD9516 and AD9517 are similar to the AD9518

but have a different combination of outputs.

Each pair of outputs has dividers that allow both the divide

ratio and coarse delay (or phase) to be set. The range of division

for the LVPECL outputs is 1 to 32.

The AD9518-1 is available in a 48-lead LFCSP and can be

operated from a single 3.3 V supply. An external VCO, which

requires an extended voltage range, can be accommodated by

connecting the charge pump supply (VCP) to 5 V. A separate

LVPECL power supply can be from 2.5 V to 3.3 V (nominal).

The AD9518-1 is specified for operation over the industrial

range of −40°C to +85°C.

1

AD9518 is used throughout the data sheet to refer to all the members of the

AD9518 family. However, when AD9518-1 is used, it refers to that specific

member of the AD9518 family.

Information furnishe d by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Page 2

AD9518-1 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 3

Specifications ..................................................................................... 4

Power Supply Requirements ....................................................... 4

PLL Characteristics ...................................................................... 4

Clock Inputs .................................................................................. 6

Clock Outputs ............................................................................... 6

Timing Characteristics ................................................................ 6

Clock Output Additive Phase Noise (Distribution Only;

VCO Divider Not Used) .............................................................. 7

Clock Output Absolute Phase Noise (Internal VCO Used) .... 7

Clock Output Absolute Time Jitter (Clock Generation

Using Internal VCO) .................................................................... 8

Clock Output Absolute Time Jitter (Clock Cleanup Using

Internal VCO) ............................................................................... 8

Clock Output Absolute Time Jitter (Clock Generation

Using External VCXO) ................................................................ 8

Clock Output Additive Time Jitter (VCO Divider

Not Used) ....................................................................................... 9

Clock Output Additive Time Jitter (VCO Divider Used) ....... 9

Serial Control Port ..................................................................... 10

PD, SYNC

LD, STATUS, and REFMON Pins ............................................ 11

Power Dissipation ....................................................................... 11

Timing Diagrams ............................................................................ 12

Absolute Maximum Ratings .......................................................... 13

, and

RESET

Pins ..................................................... 10

Thermal Resistance .................................................................... 13

ESD Caution................................................................................ 13

Pin Configuration and Function Descriptions ........................... 14

Typical Performance Characteristics ........................................... 16

Terminology .................................................................................... 20

Detailed Block Diagram ................................................................ 21

Theory of Operation ...................................................................... 22

Operational Configurations ...................................................... 22

Digital Lock Detect (DLD) ....................................................... 30

Clock Distribution ..................................................................... 34

Reset Modes ................................................................................ 38

Power-Down Modes .................................................................. 38

Serial Control Port ......................................................................... 40

Serial Control Port Pin Descriptions ....................................... 40

General Operation of Serial Control Port ............................... 40

The Instruction Word (16 Bits) ................................................ 41

MSB/LSB First Transfers ........................................................... 41

Thermal Performance .................................................................... 44

Control Registers ............................................................................ 45

Control Register Map Overview .............................................. 45

Control Register Map Descriptions ......................................... 47

Applications Information .............................................................. 59

Frequency Planning Using the AD9518 .................................. 59

Using the AD9518 Outputs for ADC Clock Applications .... 59

LVPECL Clock Distribution ..................................................... 60

Outline Dimensions ....................................................................... 61

Ordering Guide .......................................................................... 61

Rev. C | Page 2 of 64

Page 3

Data Sheet AD9518-1

REVISION HISTORY

1/12—Rev. B to Rev. C

Change to 0x232 Description, Table 49 ........................................ 58

9/11—Rev. A to Rev. B

Changes to Applications and General Description Sections ....... 1

Change to CPRSET Pin Resistor Parameter, Table 1 .................... 4

Changes to Table 2 ............................................................................ 4

Change to Test Conditions/Comments Column of Output

Differential Voltage (V

) Parameter, Table 4 ............................... 5

OD

Change to Logic 1 Current and Logic 0 Current Parameters,

Tabl e 14 ............................................................................................. 10

Change to Test Conditions/Comments Column of LVPECL

Channel (Divider Plus Output Driver) Parameter, Table 16 ..... 11

Changes to Table 19 ........................................................................ 14

Changes to Captions, Figure 11 and Figure 16............................ 17

Added Figure 26, Renumbered Sequentially ............................... 19

Change to PLL External Loop Filter Section ............................... 27

Changes to Reference Switchover and Prescaler Sections ......... 28

Changes to Comments/Conditions Column, Table 27 .............. 29

Changes to Automatic/Internal Holdover Mode and

Frequency Status Monitors Sections ............................................. 32

Changes to VCO Calibration Section ........................................... 33

Changes to Clock Distribution Section ........................................ 34

Change to Write Section ................................................................. 40

Change to Figure 47 ........................................................................ 42

Changes to Table 41 ........................................................................ 44

Changes to Register Address 0x01C, Table 42 ............................ 45

Changes to Register Address 0x017, Bits[1:0] and

Register Address 0x018, Bits[2:0], Table 44 ................................. 50

Changes to Register Address 0x01C, Bits[5:1], Table 44 ............ 53

Change to Bit 5, Register Address 0x191, Register

Address 0x194, and Register Address 0x197, Table 46 ............... 56

Changes to LVPECL Clock Distribution Section ....................... 60

Updated Outline Dimensions and Changes to

Ordering Guide ............................................................................... 61

1/10—Rev. 0 to Rev. A

Added 48-Lead LFCSP Package (CP-48-8) .................... Universal

Changes to Features, Applications, and General Description ..... 1

Change to CPRSET Pin Resistor Parameter .................................. 4

Changes to V

Supply Parameter................................................. 11

CP

Changes to Table 18 ........................................................................ 13

Added Exposed Paddle Notation to Figure 4;

Changes to Table 19 ........................................................................ 14

Change to High Frequency Clock Distribution—CLK or

External VCO > 1600 MHz Section; Change to Table 21 .......... 22

Changes to Table 23 ........................................................................ 24

Change to Configuration and Register Settings Section ........... 25

Change to Phase Frequency Detector (PFD) Section ................ 26

Changes to Charge Pump (CP), On-Chip VCO, PLL

External Loop Filter, and PLL Reference Inputs Sections ......... 27

Change to Figure 31; Added Figure 32 ......................................... 27

Changes to Reference Switchover and Prescaler Sections ......... 28

Changes to A and B Counters Section and Table 27 .................. 29

Change to Holdover Section .......................................................... 31

Changes to VCO Calibration Section ........................................... 33

Changes to Clock Distribution Section ........................................ 34

Change to Table 32; Change to Channel Frequency

Division (0, 1, and 2) Section ........................................................ 35

Change to Write Section ................................................................ 40

Change to Figure 46 ........................................................................ 42

Added Thermal Performance Section; Added Table 41 ............ 44

Changes to 0x003 Register Address .............................................. 45

Changes to Table 43 ........................................................................ 47

Changes to Table 44 ........................................................................ 48

Changes to Table 45 ........................................................................ 55

Changes to Table 46 ........................................................................ 57

Changes to Table 47 ........................................................................ 58

Changes to Table 48 ........................................................................ 59

Added Frequency Planning Using the AD9518 Section ............ 60

Changes to LVDS Clock Distribution Section ............................ 61

Changes to Figure 52 and Figure 54; Added Figure 53 .............. 61

Added Exposed Paddle Notation to Outline Dimensions;

Changes to Ordering Guide ........................................................... 62

9/07—Revision 0: Initial Version

Rev. C | Page 3 of 64

Page 4

AD9518-1 Data Sheet

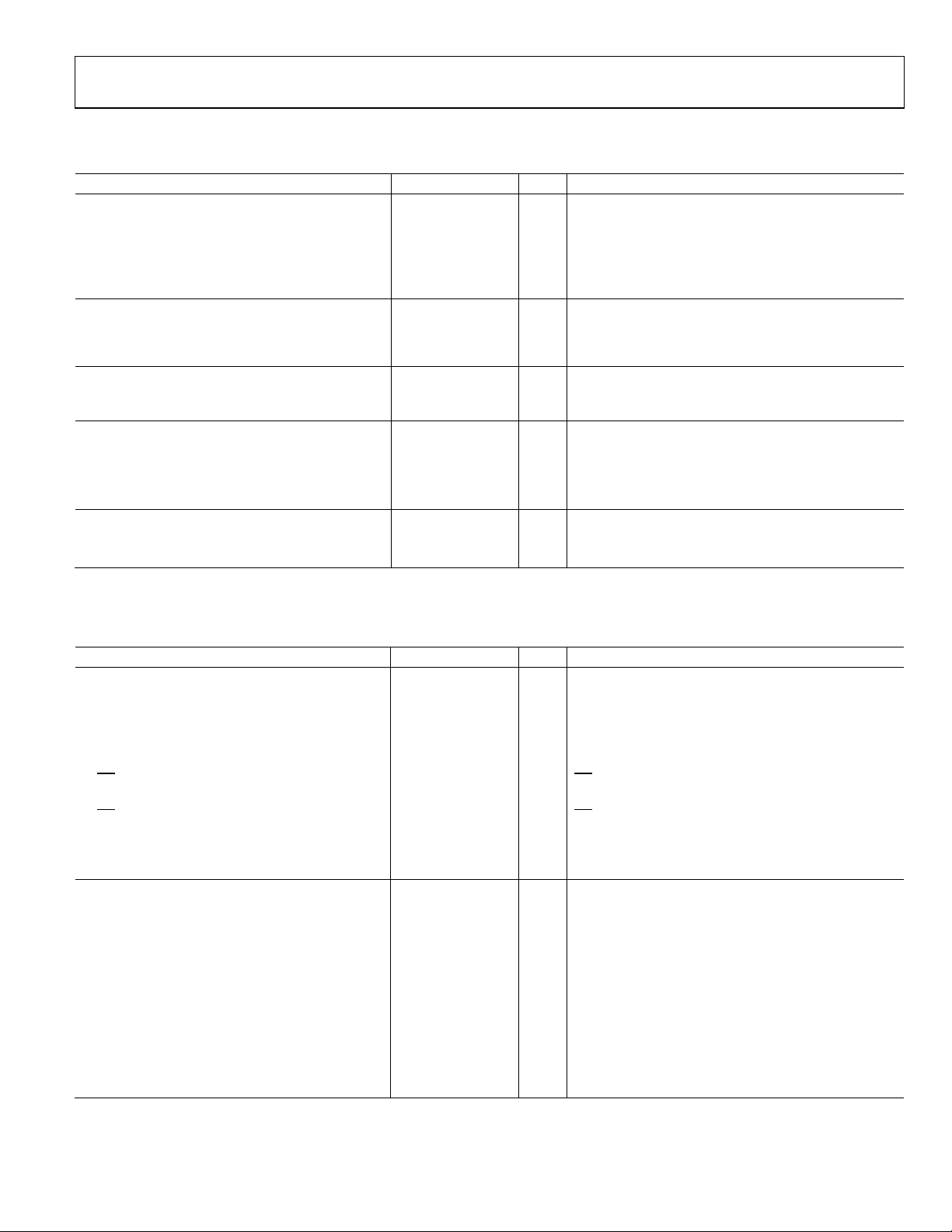

REFERENCE INPUTS

Input Sensitivity

250 mV p-p

PLL figure of merit (FOM) increases with increasing slew rate

SPECIFICATIONS

Typical values are given for VS = V

Minimum and maximum values are given over full V

POWER SUPPLY REQUIREMENTS

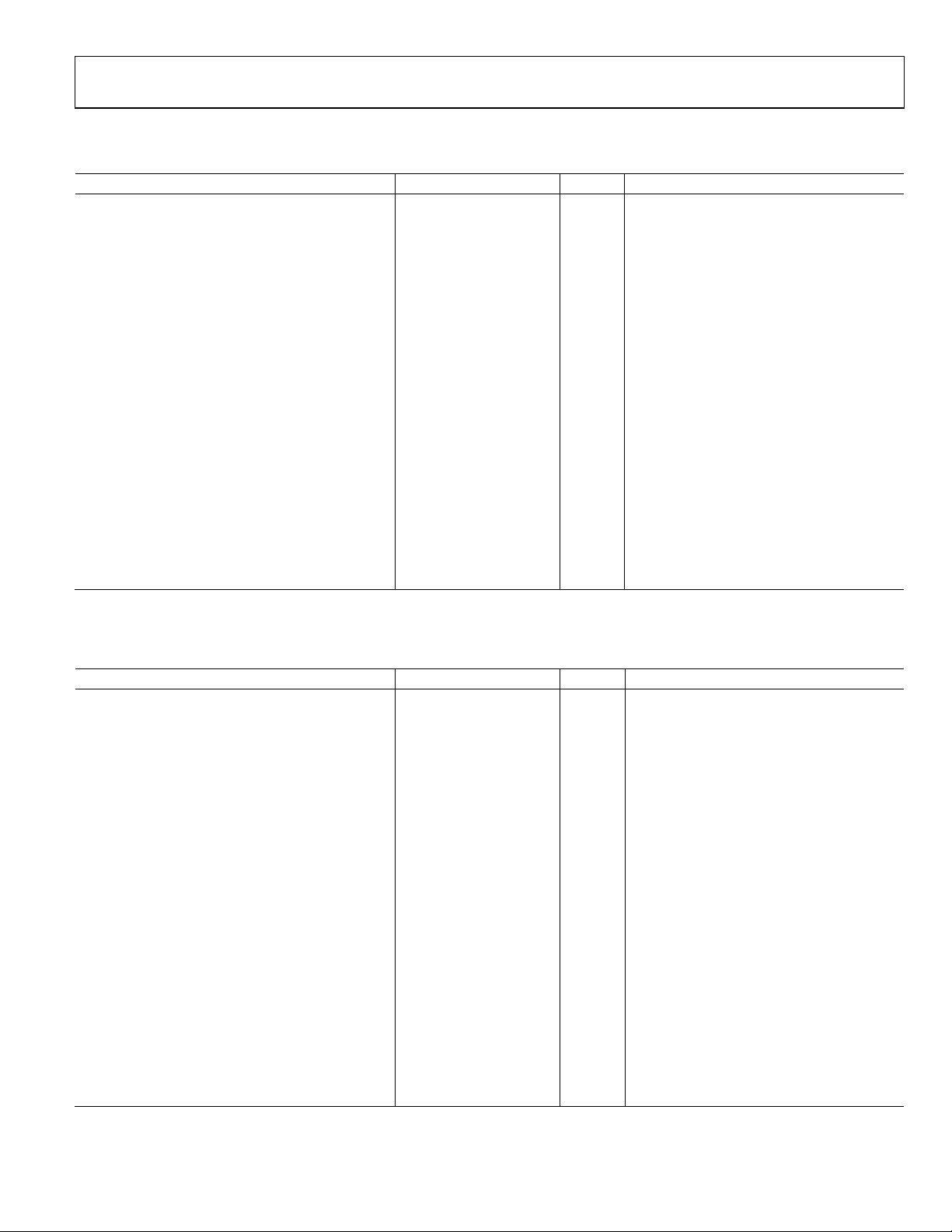

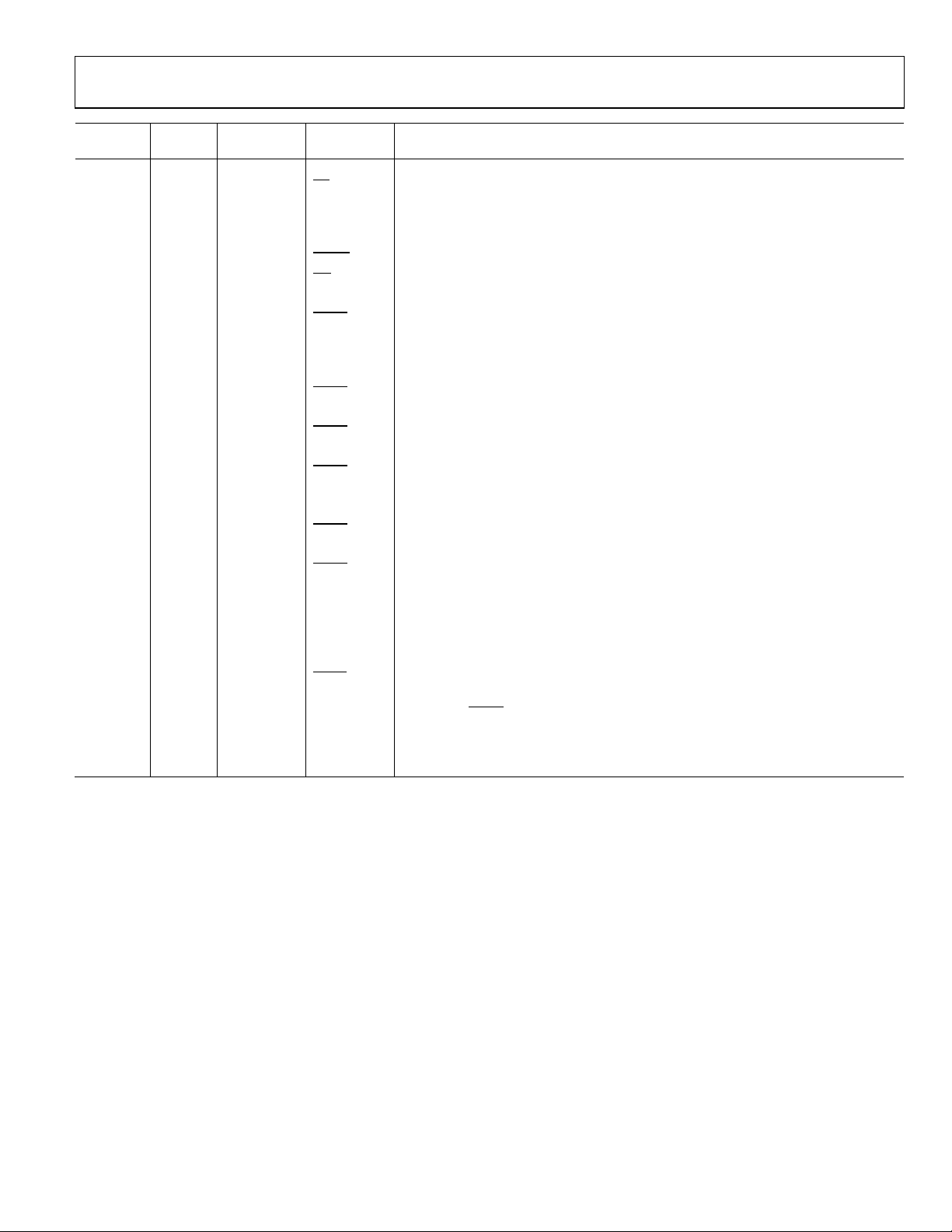

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

VS 3.135 3.3 3.465 V 3.3 V ± 5%

V

2.375 VS V Nominally 2.5 V to 3.3 V ± 5%

S_LVPE CL

VCP VS 5.25 V Nominally 3.3 V to 5.0 V ± 5%

RSET Pin Resistor 4.12 kΩ Sets internal biasing currents; connect to ground

CPRSET Pin Resistor 2.7 5.1 10 kΩ Sets internal CP current range, nominally 4.8 mA (CP_lsb = 600 µA);

BYPASS Pin Capacitor 220 nF Bypass for internal LDO regulator; necessary for LDO stability;

PLL CHARACTERISTICS

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

VCO (ON-CHIP)

Frequency Range 2300 2650 MHz See Figure 11

VCO Gain (K

Tuning Voltage (VT) 0.5 VCP − 0.5 V VCP ≤ VS when using internal VCO; outside of this range, the CP

Frequency Pushing (Open-Loop) 1 MHz/V

Phase Noise at 100 kHz Offset −105 dBc/Hz f = 2475 MHz

Phase Noise at 1 MHz Offset −124 dBc/Hz f = 2475 MHz

) 50 MHz/V See Figure 6

VCO

= 3.3 V ± 5%; VS ≤ VCP ≤ 5.25 V; TA = 25°C; R

S_ LVPE CL

and TA (−40°C to +85°C) variation.

S

= 4.12 kΩ; CP

SET

= 5.1 kΩ, unless otherwise noted.

RSET

actual current can be calculated by CP_lsb = 3.06/CPRSET;

connect to ground

connect to ground

spurs may increase due to CP up/down mismatch

Differential Mode (REFIN,

REFIN

)

Differential mode (can accommodate single-ended input by

Input Frequency 0 250 MHz Frequencies below about 1 MHz should be dc-coupled; be careful

Self-Bias Voltage, REFIN 1.35 1.60 1.75 V Self-bias voltage of REFIN1

Self-Bias Voltage,

REFIN

1.30 1.50 1.60 V

Input Resistance, REFIN 4.0 4.8 5.9 kΩ

Input Resistance,

REFIN

4.4 5.3 6.4 kΩ

Dual Single-Ended Mode (REF1, REF2) Two single-ended CMOS-compatible inputs

Input Frequency (AC-Coupled) 20 250 MHz Slew rate > 50 V/µs

Input Frequency (DC-Coupled) 0 250 MHz Slew rate > 50 V/µs; CMOS levels

Input Sensitivity (AC-Coupled) 0.8 V p-p Should not exceed VS p-p

Input Logic High 2.0 V

Input Logic Low 0.8 V

Input Current −100 +100 µA

Pulse Width High/Low 1.8 ns This value determines the allowable input duty cycle and is the

Input Capacitance 2 pF

PHASE/FREQUENCY DETECTOR (PFD)

PFD Input Frequency 100 MHz Antibacklash pulse width = 1.3 ns, 2.9 ns

45 MHz Antibacklash pulse width = 6.0 ns

Antibacklash Pulse Width 1.3 ns Register 0x017[1:0] = 01b

2.9 ns Register 0x017[1:0] = 00b; Register 0x017[1:0] = 11b

6.0 ns Register 0x017[1:0] = 10b

Rev. C | Page 4 of 64

ac grounding undriven input)

to match V

(self-bias voltage)

CM

(see Figure 10); the input sensitivity is sufficient for ac-coupled

LVPECL and LVDS signals

Self-bias voltage of

Self-biased

Self-biased

1

1

REFIN

1

amount of time that a square wave is high/low

Each pin, REFIN/

REFIN

(REF1/REF2)

Page 5

Data Sheet AD9518-1

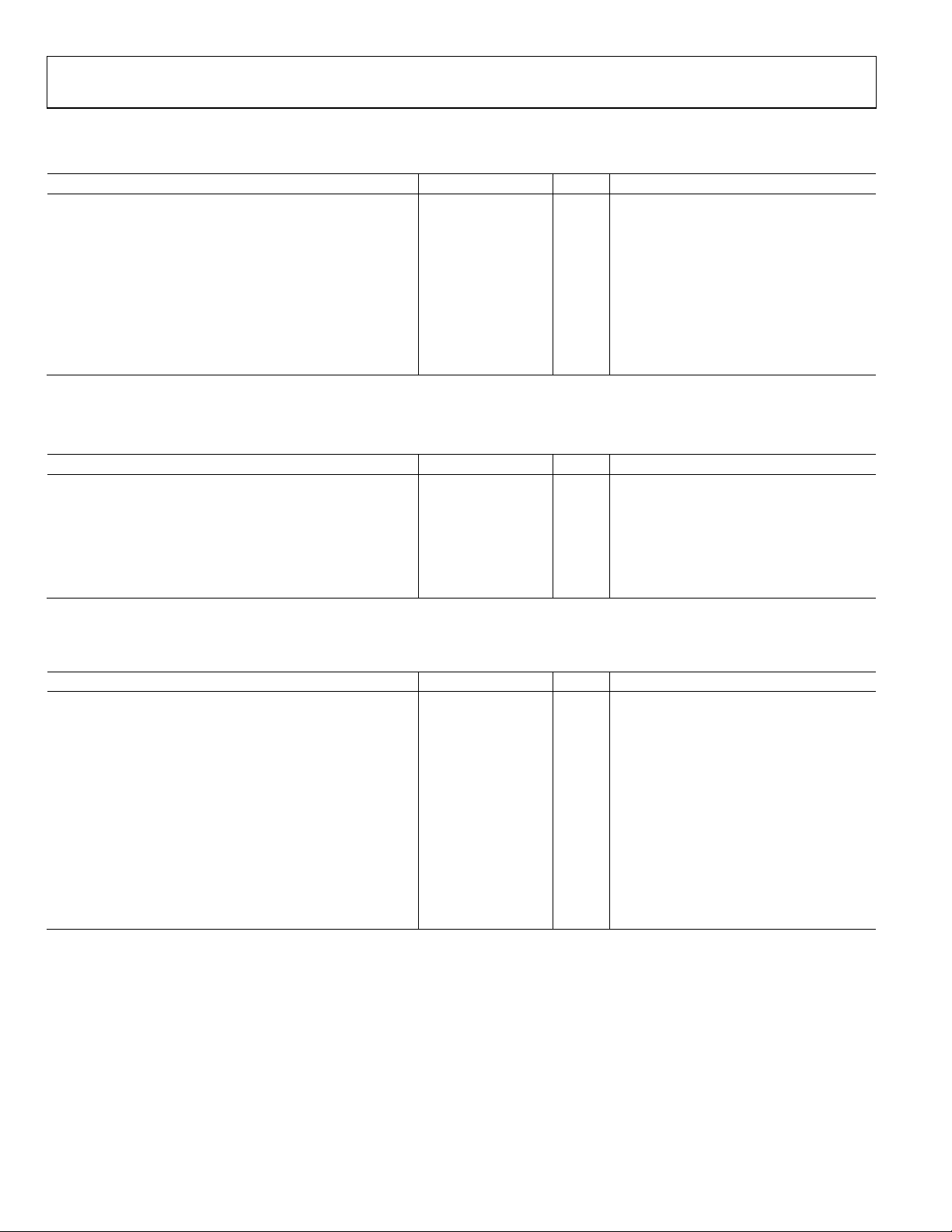

Sink-and-Source Current Matching

2 % 0.5 < CPV < VCP − 0.5 V

P = 1 FD

300

MHz

P = 2 DM (2/3)

200

MHz

Prescaler Output Frequency

300

MHz

A, B counter input frequency (prescaler input frequency divided

110

880 ps

At 50 MHz PFD Frequency

−143 dBc/Hz

High Range (ABP 1.3 ns, 2.9 ns)

7.5 ns

Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 0b

High Range (ABP 1.3 ns, 2.9 ns)

15 ns

Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 0b

Parameter Min Typ Max Unit Test Conditions/Comments

CHARGE PUMP (CP) CPV is CP pin voltage; VCP is charge pump power supply voltage

ICP Sink/Source Programmable

High Value 4.8 mA With CP

Low Value 0.60 mA

Absolute Accuracy 2.5 % CPV = VCP/2 V

CP

Range 2.7/10 kΩ

RSET

ICP High Impedance Mode Leakage 1 nA

ICP vs. CPV 1.5 % 0.5 < CPV < VCP − 0.5 V

ICP vs. Temperature 2 % CPV = VCP/2 V

PRESCALER (PART OF N DIVIDER)

See the

Prescaler Input Frequency

P = 2 FD 600 MHz

P = 3 FD 900 MHz

P = 4 DM (4/5) 1000 MHz

P = 8 DM (8/9) 2400 MHz

P = 16 DM (16/17) 3000 MHz

P = 32 DM (32/33) 3000 MHz

by P)

PLL DIVIDER DELAYS Register 0x019: R, Bits[5:3]; N, Bits[2:0] (see Table 44)

000 Off ps

001 330 ps

010 440 ps

011 550 ps

100 660 ps

101 770 ps

= 5.1 kΩ

RSET

VCXO/VCO Feedback Divider N—P, A, B, R section

111 990 ps

NOISE CHARACTERISTICS

In-Band Phase Noise of the Charge

Pump/Phase Frequency Detector

(In-Band Is Within the LBW of the PLL)

The PLL in-band phase noise floor is estimated by measuring the

in-band phase noise at the output of the VCO and subtracting

20 log(N) (where N is the value of the N divider)

At 500 kHz PFD Frequency −165 dBc/Hz

At 1 MHz PFD Frequency −162 dBc/Hz

At 10 MHz PFD Frequency −151 dBc/Hz

PLL Figure of Merit (FOM) −220 dBc/Hz Reference slew rate > 0.25 V/ns; FOM + 10 log(f

PFD

mation of the PFD/CP in-band phase noise (in the flat region) inside

the PLL loop bandwidth; when running closed-loop, the phase

noise, as observed at the VCO output, is increased by 20 log(N)

PLL DIGITAL LOCK DETECT WINDOW2 Signal available at LD, STATUS, and REFMON pins

when selected by appropriate register settings

Required to Lock (Coincidence of Edges) Selected by Register 0x017[1:0] and Register 0x018[4]

Low Range (ABP 1.3 ns, 2.9 ns) 3.5 ns Register 0x017[1:0] = 00b, 01b,11b; Register 0x018[4] = 1b

High Range (ABP 6.0 ns) 3.5 ns Register 0x017[1:0] = 10b; Register 0x018[4] = 0b

To Unlock After Lock (Hysteresis)2

Low Range (ABP 1.3 ns, 2.9 ns) 7 ns Register 0x017[1:0] = 00b, 01b, 11b; Register 0x018[4] = 1b

High Range (ABP 6.0 ns) 11 ns Register 0x017[1:0] = 10b; Register 0x018[4] = 0b

1

REFIN and

2

For reliable operation of the digital lock detect, the period of the PFD frequency must be greater than the unlock-after-lock time.

REFIN

self-bias points are offset slightly to avoid chatter on an open input condition.

) is an approxi-

Rev. C | Page 5 of 64

Page 6

AD9518-1 Data Sheet

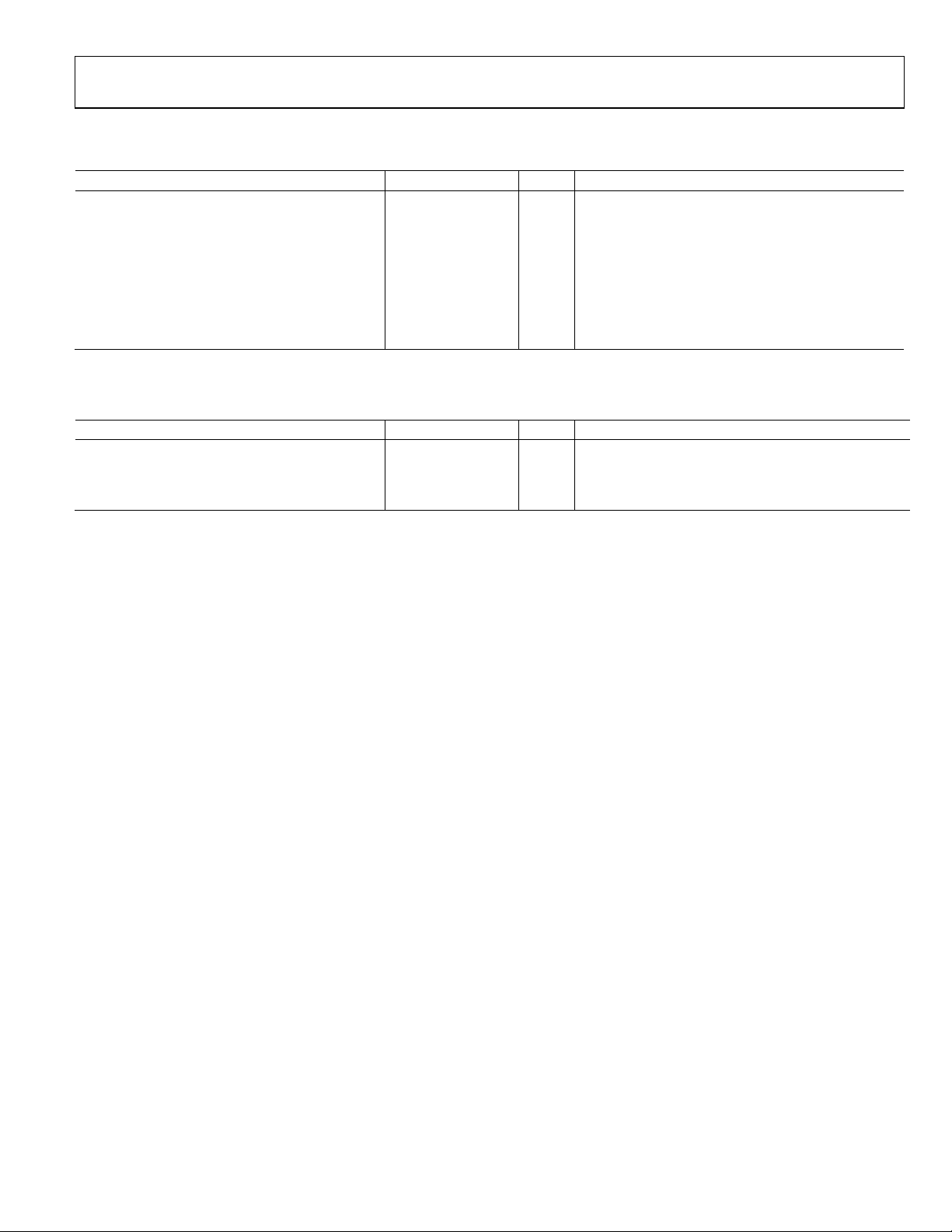

CLOCK INPUTS (CLK,

)

Differential input

Input Capacitance

2

pF

V

−

V

−

V

−

CLOCK INPUTS

Table 3.

Parameter Min Typ Max Unit Test Conditions/Comments

CLK

Input Frequency 01 2.4 GHz High frequency distribution (VCO divider)

01 1.6 GHz Distribution only (VCO divider bypassed)

Input Sensitivity, Differential 150 mV p-p Measured at 2.4 GHz; jitter performance is

improved with slew rates > 1 V/ns

Input Level, Differential 2 V p-p Larger voltage swings may turn on the protection

diodes and may degrade jitter performance

Input Common-Mode Voltage, VCM 1.3 1.57 1.8 V Self-biased; enables ac coupling

Input Common-Mode Range, V

Input Sensitivity, Single-Ended 150 mV p-p CLK ac-coupled;

Input Resistance 3.9 4.7 5.7 kΩ Self-biased

1

Below about 1 MHz, the input should be dc-coupled. Care should be taken to match VCM.

CLOCK OUTPUTS

Table 4.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL CLOCK OUTPUTS Termination = 50 Ω to VS − 2 V

OUT0, OUT1, OUT2, OUT3, OUT4, OUT5 Differential (OUT,

Output Frequency, Maximum 2950 MHz Using direct to output; see Figure 16 for peak-to-peak

Output High Voltage (VOH)

Output Low Voltage (VOL)

Output Differential Voltage (VOD) 550 790 980 mV

1.3 1.8 V With 200 mV p-p signal applied; dc-coupled

CMR

ac-bypassed to RF ground

CLK

)

OUT

V

S_LVPECL

1.12

S_LVPECL

2.03

−

V

S_LVPECL

0.98

S_LVPECL

1.77

−

V

S_LVPECL

0.84

S_LVPECL

1.49

−

V

V

differential amplitude

This is VOH − VOL for each leg of a differential pair for

default amplitude setting with driver not toggling; the

peak-to-peak amplitude measured using a differential

probe across the differential pair with the driver toggling

is roughly 2× these values (see Figure 16

over frequency)

for variation

TIMING CHARACTERISTICS

Table 5.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL Termination = 50 Ω to VS − 2 V; level = 810 mV

Output Rise Time, tRP 70 180 ps 20% to 80%, measured differentially

Output Fall Time, tFP 70 180 ps 80% to 20%, measured differentially

PROPAGATION DELAY, t

OUTPUT

High Frequency Clock Distribution

Configuration

Clock Distribution Configuration 773 933 1090 ps See Figure 30

Variation with Temperature 0.8 ps/°C

OUTPUT SKEW, LVPECL OUTPUTS1

LVPECL Outputs That Share the Same

Divider

LVPECL Outputs on Different Dividers 13 40 ps

All LVPECL Outputs Across Multiple Parts 220 ps

1

This is the difference between any two similar delay paths while operating at the same voltage and temperature.

, CLK-TO-LVPECL

PECL

835 995 1180 ps See Figure 28

5 15 ps

Rev. C | Page 6 of 64

Page 7

Data Sheet AD9518-1

CLK-TO-LVPECL ADDITIVE PHASE NOISE

Distribution section only; does not include

At 100 MHz Offset

−149

dBc/Hz

VCO = 2.3 GHz; Output = 2.3 GHz

CLOCK OUTPUT ADDITIVE PHASE NOISE (DISTRIBUTION ONLY; VCO DIVIDER NOT USED)

Table 6.

Parameter Min Typ Max Unit Test Conditions/Comments

PLL and VCO

CLK = 1 GHz, Output = 1 GHz Input slew rate > 1 V/ns

Divider = 1

At 10 Hz Offset −109 dBc/Hz

At 100 Hz Offset −118 dBc/Hz

At 1 kHz Offset −130 dBc/Hz

At 10 kHz Offset −139 dBc/Hz

At 100 kHz Offset −144 dBc/Hz

At 1 MHz Offset −146 dBc/Hz

At 10 MHz Offset −147 dBc/Hz

CLK = 1 GHz, Output = 200 MHz Input slew rate > 1 V/ns

Divider = 5

At 10 Hz Offset −120 dBc/Hz

At 100 Hz Offset −126 dBc/Hz

At 1 kHz Offset −139 dBc/Hz

At 10 kHz Offset −150 dBc/Hz

At 100 kHz Offset −155 dBc/Hz

At 1 MHz Offset −157 dBc/Hz

>10 MHz Offset −157 dBc/Hz

CLOCK OUTPUT ABSOLUTE PHASE NOISE (INTERNAL VCO USED)

Table 7.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL ABSOLUTE PHASE NOISE Internal VCO; direct to LVPECL output

VCO = 2.65 GHz; Output = 2.65 GHz

At 1 kHz Offset −46 dBc/Hz

At 10 kHz Offset −76 dBc/Hz

At 100 kHz Offset −104 dBc/Hz

At 1 MHz Offset −123 dBc/Hz

At 10 MHz Offset −140 dBc/Hz

At 40 MHz Offset −146 dBc/Hz

VCO = 2.475 GHz; Output = 2.475 GHz

At 1 kHz Offset −47 dBc/Hz

At 10 kHz Offset −77 dBc/Hz

At 100 kHz Offset −105 dBc/Hz

At 1 MHz Offset −124 dBc/Hz

At 10 MHz Offset −141 dBc/Hz

At 40 MHz Offset −146 dBc/Hz

At 1 kHz Offset −54 dBc/Hz

At 10 kHz Offset −78 dBc/Hz

At 100 kHz Offset −106 dBc/Hz

At 1 MHz Offset −125 dBc/Hz

At 10 MHz Offset −141 dBc/Hz

At 40 MHz Offset −146 dBc/Hz

Rev. C | Page 7 of 64

Page 8

AD9518-1 Data Sheet

LVPECL OUTPUT ABSOLUTE TIME JITTER

Application example based on a typical

77 fs rms

Integration BW = 200 kHz to 10 MHz

CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK GENERATION USING INTERNAL VCO)

Table 8.

Parameter Min Ty p Max Unit Test Conditions/Comments

setup where the reference source is clean,

so a wider PLL loop bandwidth is used;

reference = 15.36 MHz; R = 1

VCO = 2.46 GHz; LVPECL = 491.52 MHz; PLL LBW = 55 kHz 142 fs rms Integration BW = 200 kHz to 10 MHz

370 fs rms Integration BW = 12 kHz to 20 MHz

VCO = 2.46 GHz; LVPECL = 122.88 MHz; PLL LBW = 55 kHz 145 fs rms Integration BW = 200 kHz to 10 MHz

356 fs rms Integration BW = 12 kHz to 20 MHz

VCO = 2.46 GHz; LVPECL = 61.44 MHz; PLL LBW = 55 kHz 195 fs rms Integration BW = 200 kHz to 10 MHz

402 fs rms Integration BW = 12 kHz to 20 MHz

CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK CLEANUP USING INTERNAL VCO)

Table 9.

Parameter Min Ty p Max Unit Test Conditions/Comments

LVPECL OUTPUT ABSOLUTE TIME JITTER Application example based on a typical

setup where the reference source is jittery,

so a narrower PLL loop bandwidth is used;

reference = 10.0 MHz; R = 20

VCO = 2.49 GHz; LVPECL = 622.08 MHz; PLL LBW = 125 Hz 745 fs rms Integration BW = 12 kHz to 20 MHz

VCO = 2.49 GHz; LVPECL = 155.52 MHz; PLL LBW = 125 Hz 712 fs rms Integration BW = 12 kHz to 20 MHz

VCO = 2.46 GHz; LVPECL = 122.88 MHz; PLL LBW = 125 Hz 700 fs rms Integration BW = 12 kHz to 20 MHz

CLOCK OUTPUT ABSOLUTE TIME JITTER (CLOCK GENERATION USING EXTERNAL VCXO)

Table 10.

Parameter Min Ty p Max Unit Test Conditions/Comments

LVPECL OUTPUT ABSOLUTE TIME JITTER Application example based on a typical

setup using an external 245.76 MHz VCXO

(Toyocom TCO-2112); reference = 15.36 MHz;

R = 1

LVPECL = 245.76 MHz; PLL LBW = 125 Hz 54 fs rms Integration BW = 200 kHz to 5 MHz

109 fs rms Integration BW = 12 kHz to 20 MHz

LVPECL = 122.88 MHz; PLL LBW = 125 Hz 79 fs rms Integration BW = 200 kHz to 5 MHz

114 fs rms Integration BW = 200 kHz to 10 MHz

163 fs rms Integration BW = 12 kHz to 20 MHz

LVPECL = 61.44 MHz; PLL LBW = 125 Hz 124 fs rms Integration BW = 200 kHz to 5 MHz

176 fs rms Integration BW = 200 kHz to 10 MHz

259 fs rms Integration BW = 12 kHz to 20 MHz

Rev. C | Page 8 of 64

Page 9

Data Sheet AD9518-1

LVPECL OUTPUT ADDITIVE TIME JITTER

Distribution section only; does not include PLL and

CLOCK OUTPUT ADDITIVE TIME JITTER (VCO DIVIDER NOT USED)

Table 11.

Parameter Min Typ Max Unit Test Conditions/Comments

VCO; uses rising edge of clock signal

CLK = 622.08 MHz; LVPECL = 622.08 MHz;

Divider = 1

CLK = 622.08 MHz; LVPECL = 155.52 MHz;

Divider = 4

CLK = 1.6 GHz; LVPECL = 100 MHz; Divider = 16 215 fs rms Calculated from SNR of ADC method; DCC not used

CLK = 500 MHz; LVPECL = 100 MHz; Divider = 5 245 fs rms Calculated from SNR of ADC method; DCC on

CLOCK OUTPUT ADDITIVE TIME JITTER (VCO DIVIDER USED)

Table 12.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL OUTPUT ADDITIVE TIME JITTER Distribution section only; does not include PLL and VCO;

CLK = 2.4 GHz; VCO DIV = 2; LVPECL = 100 MHz;

Divider = 12; Duty-Cycle Correction = Off

40 fs rms BW = 12 kHz to 20 MHz

80 fs rms BW = 12 kHz to 20 MHz

for even divides

uses rising edge of clock signal

210 fs rms Calculated from SNR of ADC method

Rev. C | Page 9 of 64

Page 10

AD9518-1 Data Sheet

(INPUT)

CS has an internal 30 kΩ pull-up resistor

Input Logic 0 Voltage

0.8 V

Input Capacitance

2

pF

to SCLK Setup and Hold, tS, tH

2

ns

Logic 0 Current

110 µA

Capacitance

2

pF

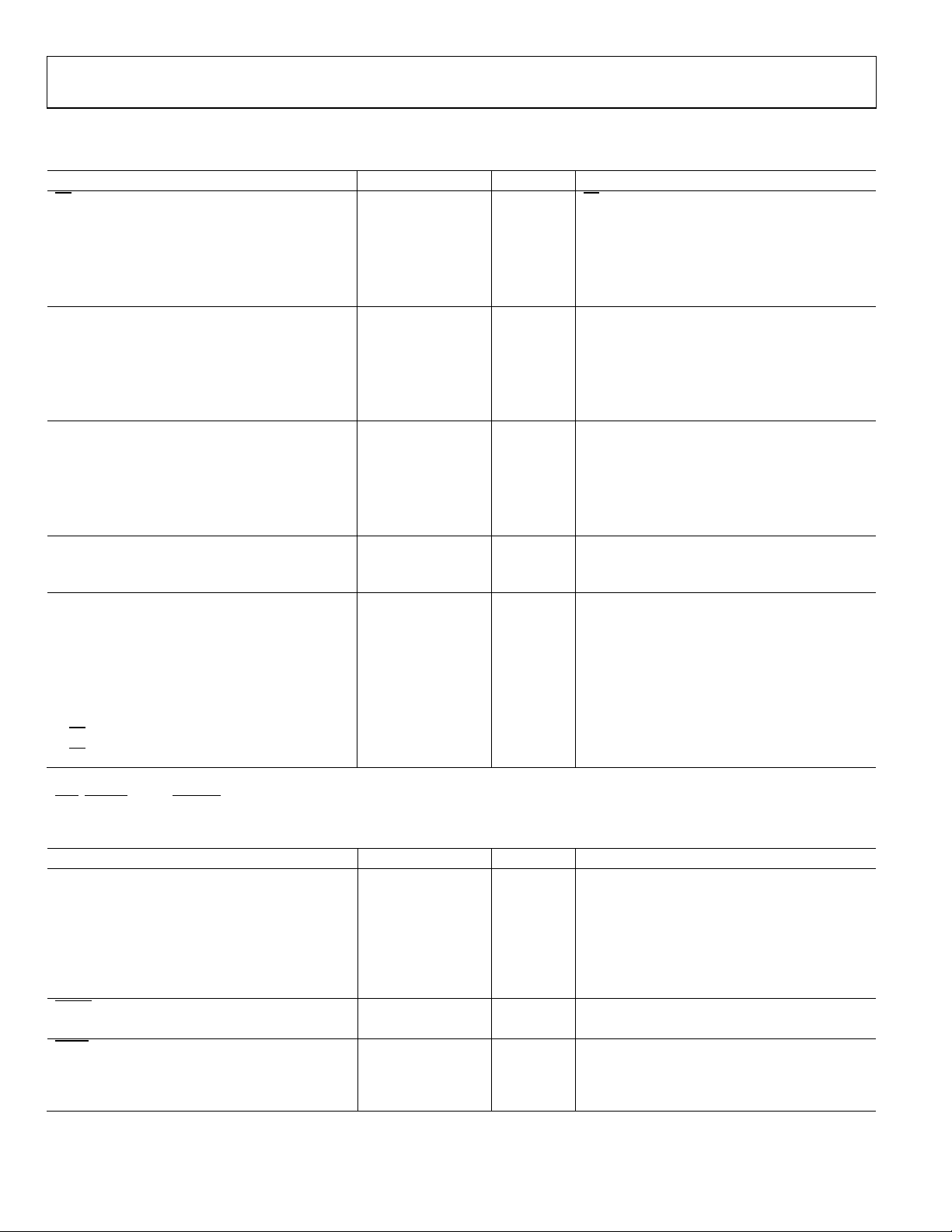

SERIAL CONTROL PORT

Table 13.

Parameter Min Typ Max Unit Test Conditions/Comments

CS

Input Logic 1 Voltage 2.0 V

Input Logic 0 Voltage 0.8 V

Input Logic 1 Current 3 µA

Input Logic 0 Current 110 µA

Input Capacitance 2 pF

SCLK (INPUT) SCLK has an internal 30 kΩ pull-down resistor

Input Logic 1 Voltage 2.0 V

Input Logic 1 Current 110 µA

Input Logic 0 Current 1 µA

Input Capacitance 2 pF

SDIO (WHEN INPUT)

Input Logic 1 Voltage 2.0 V

Input Logic 0 Voltage 0.8 V

Input Logic 1 Current 10 nA

Input Logic 0 Current 20 nA

SDIO, SDO (OUTPUTS)

Output Logic 1 Voltage 2.7 V

Output Logic 0 Voltage 0.4 V

TIMING

Clock Rate (SCLK, 1/t

Pulse Width High, t

Pulse Width Low, t

SDIO to SCLK Setup, tDS 2 ns

SCLK to SDIO Hold, tDH 1.1 ns

SCLK to Valid SDIO and SDO, tDV 8 ns

CS

Minimum Pulse Width High, t

CS

PD

,

SYNC

, AND

) 25 MHz

SCLK

16 ns

HIGH

16 ns

LOW

3 ns

PWH

RESET

PINS

Table 14.

Parameter Min Ty p Max Unit Test Conditions/Comments

INPUT CHARACTERISTICS These pins each have a 30 kΩ internal pull-up

resistor

Logic 1 Voltage 2.0 V

Logic 0 Voltage 0.8 V

Logic 1 Current 1 µA

TIMING

RESET

Pulse Width Low 50 ns

TIMING

SYNC

Pulse Width Low 1.5 High speed

High speed clock is CLK input signal

clock

cycles

Rev. C | Page 10 of 64

Page 11

Data Sheet AD9518-1

OUTPUT CHARACTERISTICS

When selected as a digital output (CMOS); there are other

Capacitance

3

pF

On-chip capacitance; used to calculate RC time constant

POWER DELTAS, INDIVIDUAL FUNCTIONS

Power delta when a function is enabled/disabled

LD, STATUS, AND REFMON PINS

Table 15.

Parameter Min Typ Max Unit Test Conditions/Comments

modes in which these pins are not CMOS digital outputs;

see

Table 44, Register 0x017, Register 0x01A, and

Register 0x01B

Output Voltage High (VOH) 2.7 V

Output Voltage Low (VOL) 0.4 V

MAXIMUM TOGGLE RATE 100 MHz Applies when mux is set to any divider or counter output,

or PFD up/down pulse; also applies in analog lock detect

mode; usually debug mode only; beware that spurs may

couple to output when any of these pins are toggling

ANALOG LOCK DETECT

for analog lock detect readback; use a pull-up resistor

REF1, REF2, AND VCO FREQUENCY STATUS MONITOR

Normal Range 1.02 MHz Frequency above which the monitor always indicates the

presence of the reference

Extended Range (REF1 and REF2 Only) 8 kHz Frequency above which the monitor always indicates the

presence of the reference

LD PIN COMPARATOR

Trip Point 1.6 V

Hysteresis 260 mV

POWER DISSIPATION

Table 16.

Parameter Min Typ Max Unit Test Conditions/Comments

POWER DISSIPATION, CHIP

Power-On Default 0.76 1.0 W No clock; no programming; default register values;

does not include power dissipated in external resistors

Full Operation 1.1 1.7 W PLL on; internal VCO = 2476 MHz; VCO divider = 2;

all channel dividers on; six LVPECL outputs at 619 MHz;

does not include power dissipated in external resistors

Power-Down 75 185 mW

PD

Power-Down, Maximum Sleep 31 mW

PD

VCP Supply 4 4.8 mW PLL operating; typical closed-loop configuration

VCO Divider 30 mW VCO divider bypassed

REFIN (Differential) 20 mW All references off to differential reference enabled

REF1, REF2 (Single-Ended) 4 mW All references off to REF1 or REF2 enabled; differential

VCO 70 mW CLK input selected to VCO selected

PLL 75 mW PLL off to PLL on, normal operation; no reference

Channel Divider 30 mW Divider bypassed to divide-by-2 to divide-by-32

LVPECL Channel (Divider Plus Output Driver) 160 mW No LVPECL output on to one LVPECL output on,

LVPECL Driver 90 mW Second LVPECL output turned on, same channel

pin pulled low; does not include power dissipated

PD

in terminations

pin pulled low; PLL power-down, Register 0x010[1:0] =

PD

01b; SYNC power-down, Register 0x230[2] = 1b; REF for

distribution power-down, Register 0x230[1] = 1b

reference not enabled

enabled

independent of frequency

Rev. C | Page 11 of 64

Page 12

AD9518-1 Data Sheet

K

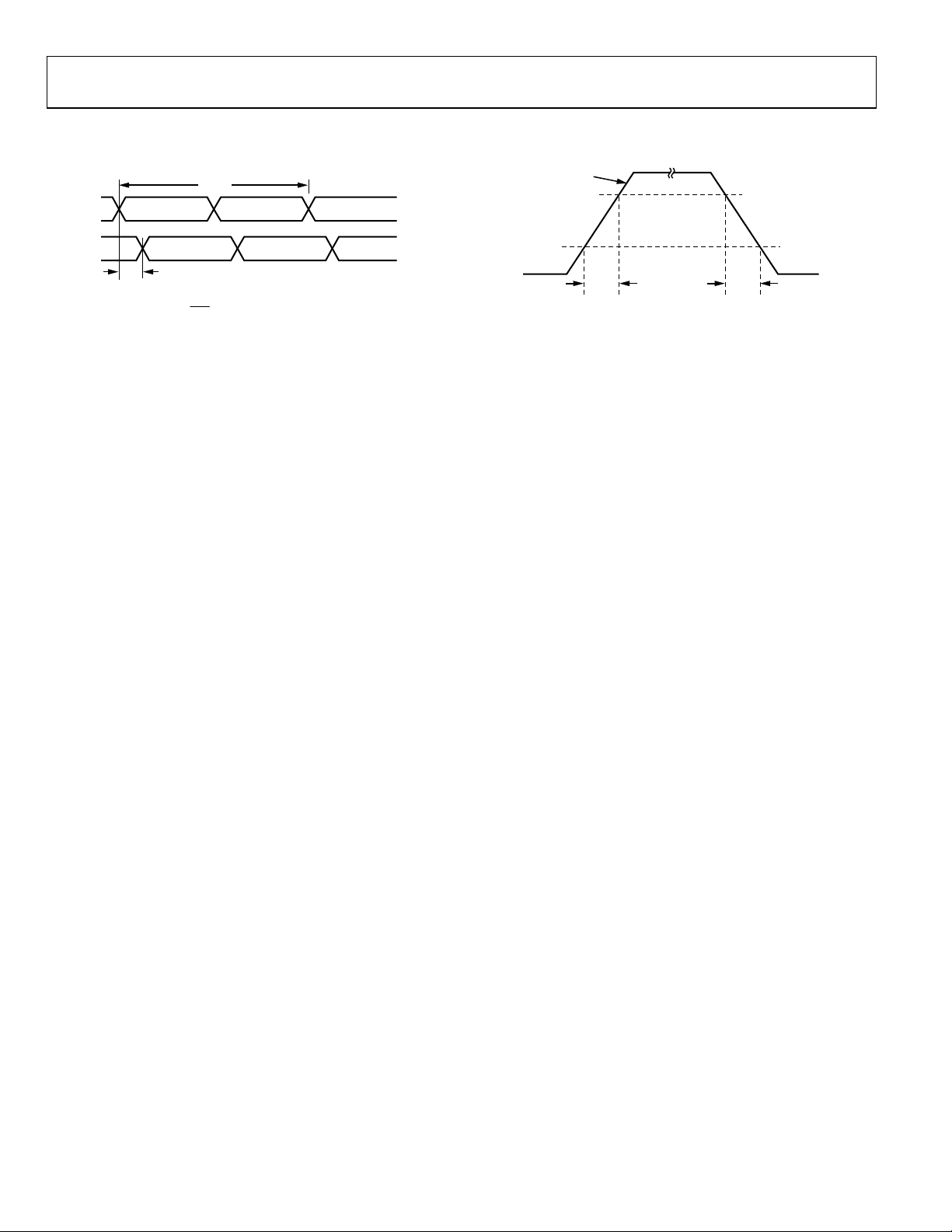

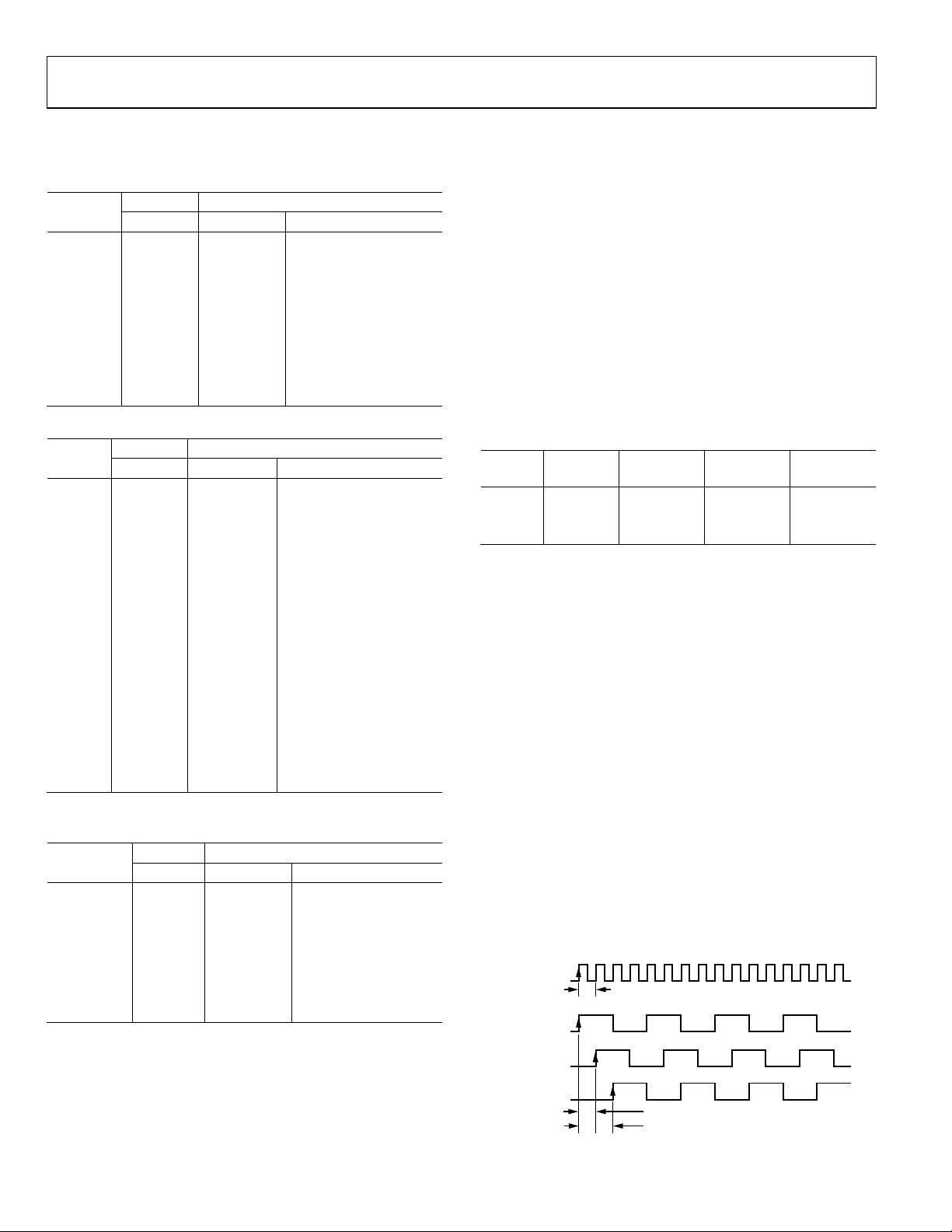

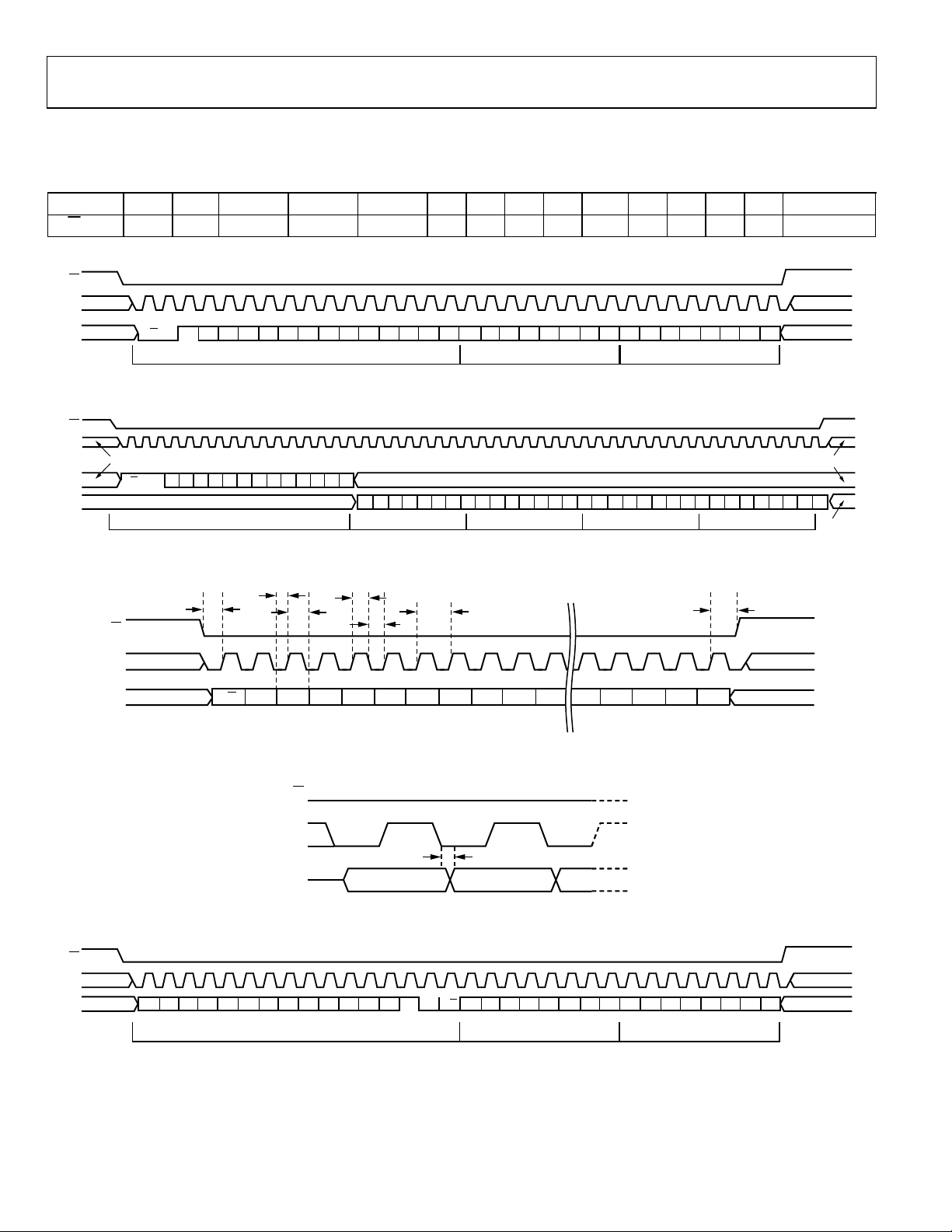

TIMING DIAGRAMS

t

CLK

CL

t

PECL

Figure 2. CLK/

CLK

to Clock Output Timing, DIV = 1

06430-060

DIFFERENTIAL

80%

20%

Figure 3. LVPECL Timing, Differential

LVPECL

t

RP

t

FP

06430-061

Rev. C | Page 12 of 64

Page 13

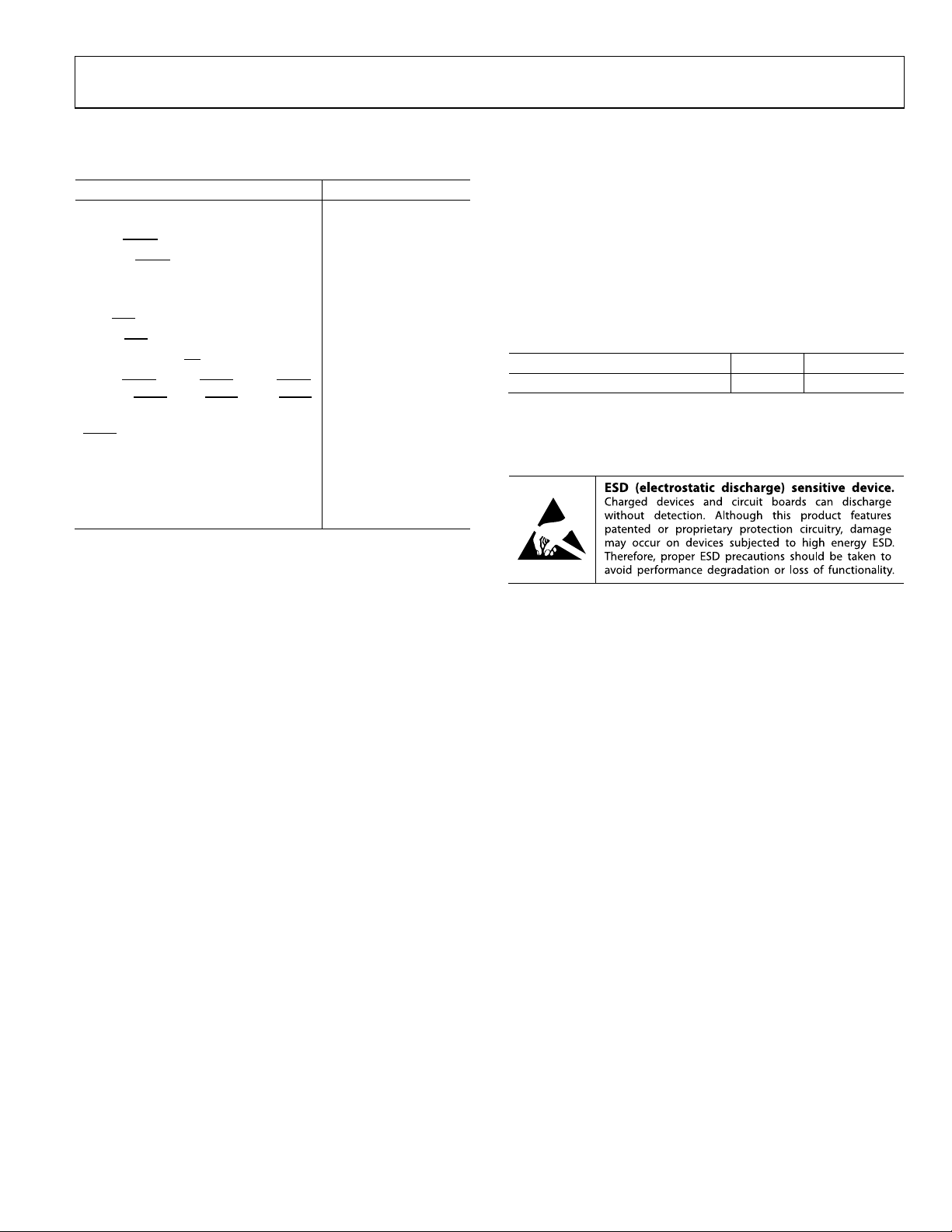

Data Sheet AD9518-1

VCP to GND

−0.3 V to +5.8 V

ABSOLUTE MAXIMUM RATINGS

Table 17.

Parameter Rating

VS, VS_LVPECL to GND −0.3 V to +3.6 V

REFIN,

REFIN to

RSET to GND −0.3 V to VS + 0.3 V

CPRSET to GND −0.3 V to VS + 0.3 V

CLK,

CLK to

SCLK, SDIO, SDO, CS to GND −0.3 V to VS + 0.3 V

OUT0,

OUT3,

to GND

SYNC

REFMON, STATUS, LD to GND −0.3 V to VS + 0.3 V

Junction Temperature1 150°C

Storage Temperature Range −65°C to +150°C

Lead Temperature (10 sec) 300°C

1

See Table 18 for θJA.

to GND −0.3 V to VS + 0.3 V

REFIN

−3.3 V to +3.3 V

REFIN

to GND −0.3 V to VS + 0.3 V

CLK

−1.2 V to +1.2 V

CLK

, OUT1,

OUT0

,OUT4,

OUT3

to GND −0.3 V to VS + 0.3 V

OUT1

OUT4

, OUT2,

, OUT5,

OUT2

OUT5

,

−0.3 V to VS + 0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

Table 18.

Package Type1 θJA Unit

48-Lead LFCSP 24.7 °C/W

1

Thermal impedance measurements were taken on a 4-layer board in still air

in accordance with EIA/JESD51-2.

ESD CAUTION

Rev. C | Page 13 of 64

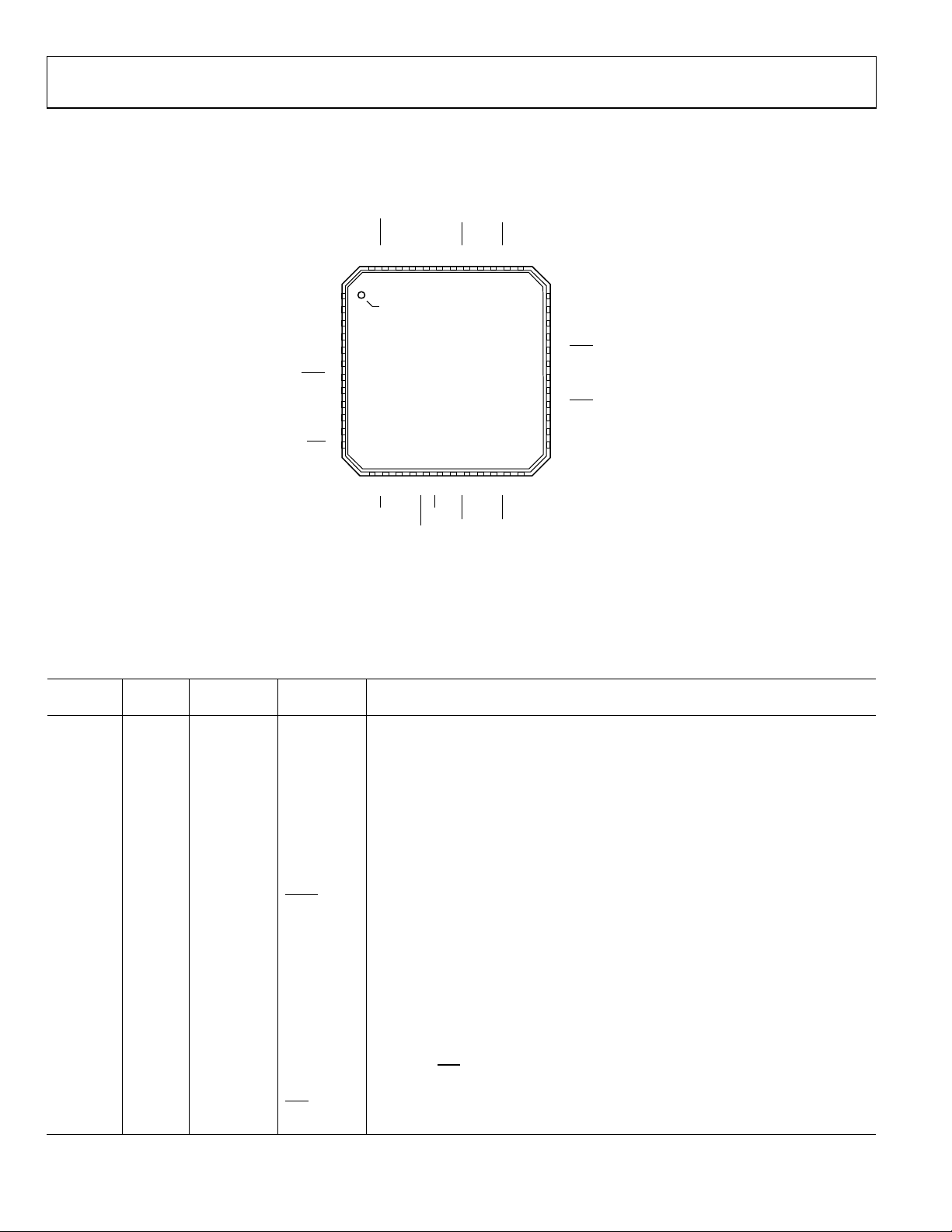

Page 14

AD9518-1 Data Sheet

13141516171819

2021222324

SCLK

CS

SDO

SDIO

RESET

PD

OUT4

OUT4

VS_LVPECL

OUT5

OUT5

VS

4847464544434241403938

37

REFIN (REF1)

REFIN (REF2)

CPRSETVSRSETVSOUT0

OUT0

VS_LVPECL

OUT1

OUT1

VS

1

2

3

4

5

6

7

8

9

10

11

12

35

36

34

33

32

31

30

29

28

27

26

25

AD9518-1

TOP VIEW

(Not to S cale)

PIN 1

INDICATOR

CP

STATUS

CLK

VCP

REFMON

LD

BYPASS

VS

REF_SEL

LF

SYNC

CLK

OUT3

OUT2

VS

VS

VS_LVPECL

VS_LVPECL

OUT3

OUT2

NC

GND

VS

GND

06430-003

NOTES

1. NC = NO CONNECT.

2. THE EXTERNAL PADDLE ON THE BOTTOM OF THE PACKAGE MUST BE

CONNECTED T O GROUND FO R P ROPER OPERAT ION.

11 I Differential

CLK

Along with

, this is the self-biased differential input for the clock distribution section.

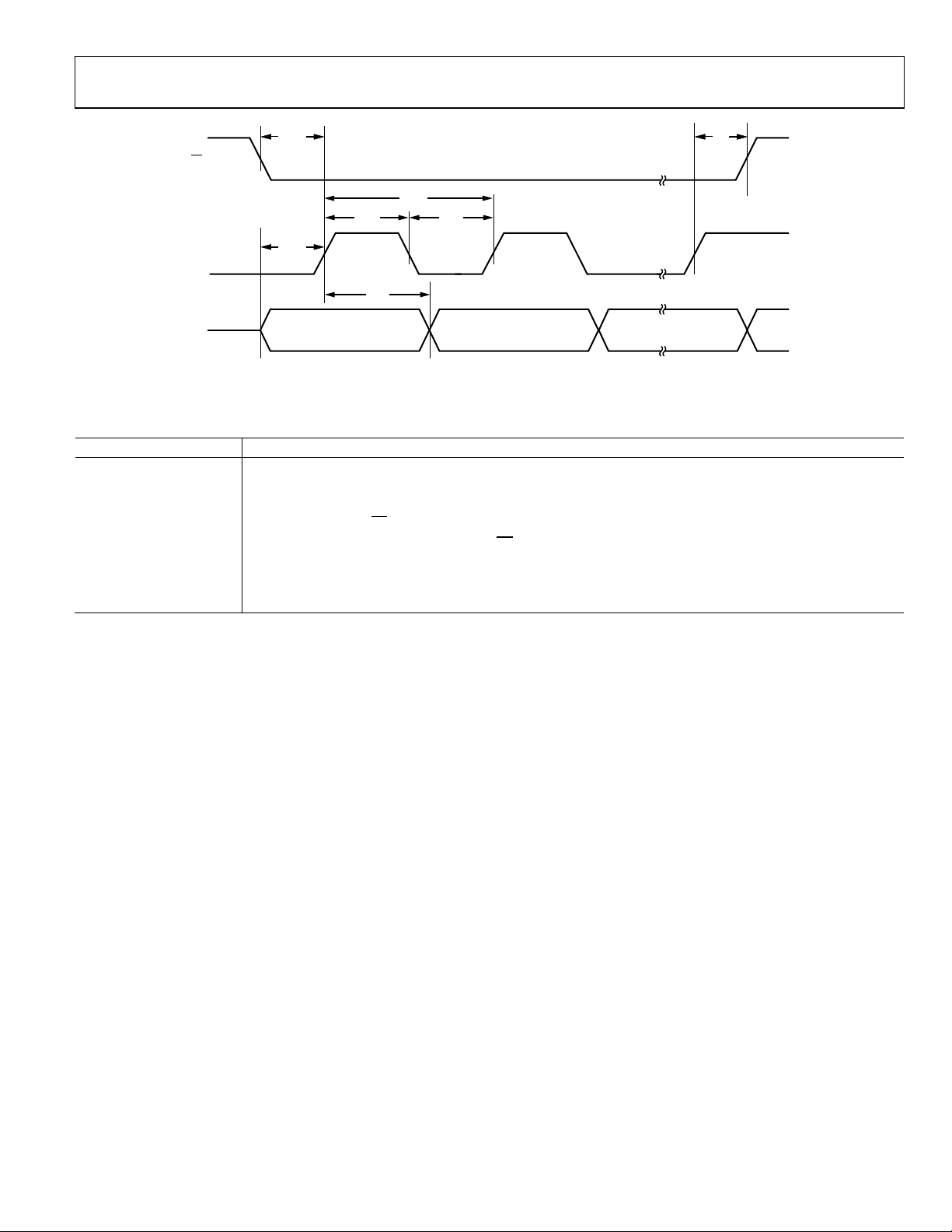

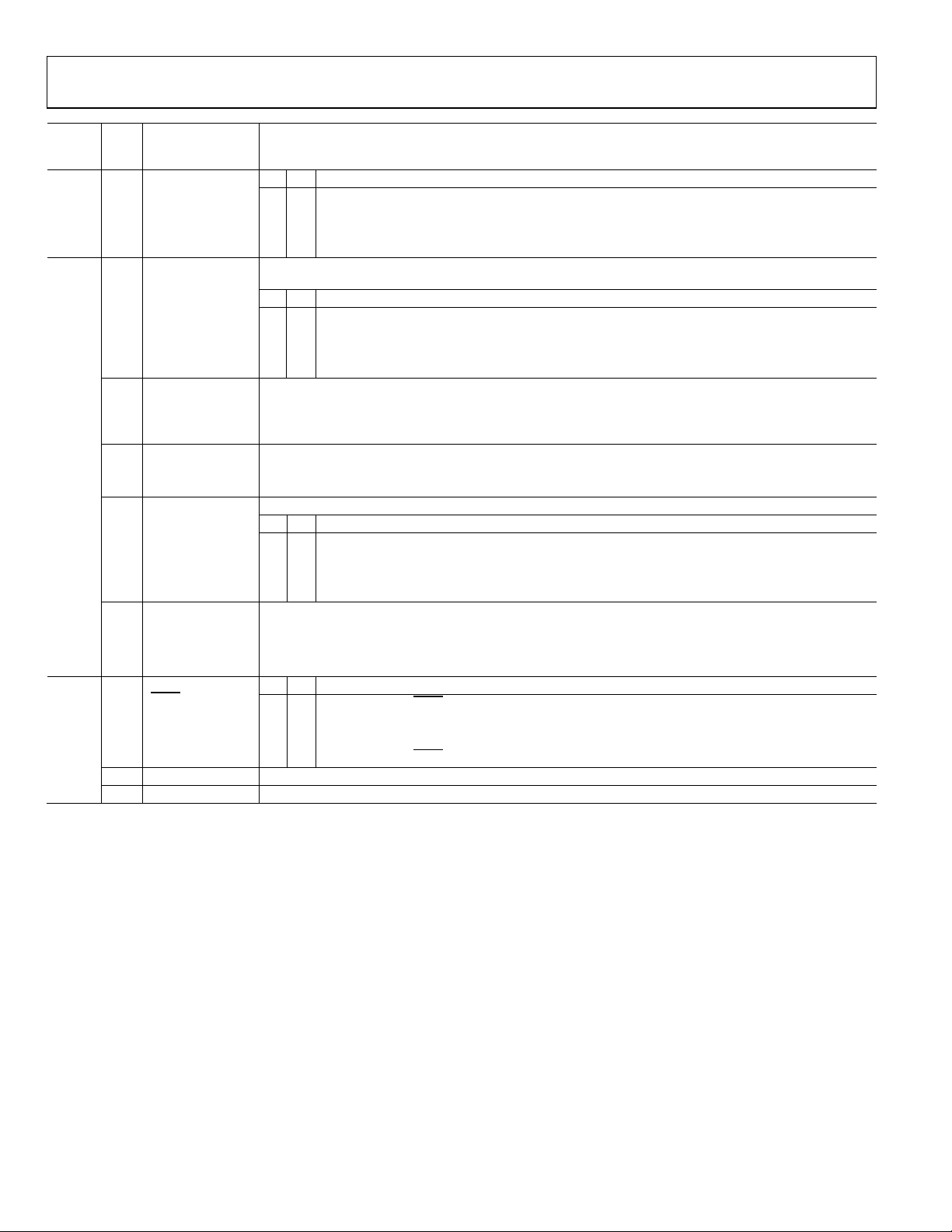

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Table 19. Pin Function Descriptions

Input/

Pin No.

Output Pi n Type Mnemonic Description

1 O 3.3 V CMOS REFMON Reference Monitor (Output). This pin has multiple selectable outputs; see Table 44,

2 O 3.3 V CMOS LD Lock Detect (Output). This pin has multiple selectable outputs; see Table 44,

3 I Power VCP Power Supply for Charge Pump (CP). VS ≤ VCP ≤ 5.0 V. This pin is usually 3.3 V for most

4 O CP Charge Pump (Output). Connects to external loop filter.

5 O 3.3 V CMOS STATUS Status (Output). This pin has multiple selectable outputs; see Table 44, Register 0x017.

6 I 3.3 V CMOS REF_SEL Reference Select. Selects REF1 (low) or REF2 (high). This pin has an internal 30 kΩ

7 I 3.3 V CMOS

8 I Loop filter LF Loop Filter (Input). Connects to VCO control voltage node internally.

9 O Loop filter BYPA SS This pin is for bypassing the LDO to ground with a capacitor.

10, 24, 25,

I Power VS 3.3 V Power Pins.

26, 35, 37,

43, 45

SYNC

clock input

12 I Differential

clock input

Along with CLK, this is the self-biased differential input for the clock distribution section.

CLK

Figure 4. Pin Configuration

Register 0x01B.

Register 0x01A.

applications; but if a 5 V external VCXO is used, this pin should be 5 V.

pull-down resistor.

Manual Synchronizations and Manual Holdover. This pin initiates a manual

synchronization and is used for manual holdover. Active low. This pin has an internal

30 kΩ pull-up resistor.

This pin has 31 pF of internal capacitance to ground, which may influence the loop

filter design for large loop bandwidths.

CLK

This pin can be left floating if internal VCO is used.

This pin can be left floating if internal VCO is used.

Rev. C | Page 14 of 64

Page 15

Data Sheet AD9518-1

20 O LVPECL

LVPECL Output; One Side of a Differential LVPECL Output.

Input/

Pin No.

13 I 3.3 V CMOS SCLK Serial Control Port Data Clock Signal.

14 I 3.3 V CMOS

15 O 3.3 V CMOS SDO Serial Control Port. Unidirectional serial data output.

16 I/O 3.3 V CMOS SDIO Serial Control Port. Bidirectional serial data input/output.

17 I 3.3 V CMOS

18 I 3.3 V CMOS

19 O LVPECL OUT4 LVPECL Output; One Side of a Differential LVPECL Output.

21, 30, 31,

40

22 O LVPECL OUT5 LVPECL Output; One Side of a Differential LVPECL Output.

23 O LVPECL

27, 34 GND GND Ground. See the description for EPAD.

28 O LVPECL

29 O LVPECL OUT3 LVPECL Output; One Side of a Differential LVPECL Output.

32 O LVPECL

33 O LVPECL OUT2 LVPECL Output; One Side of a Differential LVPECL Output.

36 NC No Connection.

38 O LVPECL

39 O LVPECL OUT1 LVPECL Output; One Side of a Differential LVPECL Output.

41 O LVPECL

42 O LVPECL OUT0 LVPECL Output; One Side of a Differential LVPECL Output.

44 O Current set

46 O Current set

47 I Reference

48 I Reference

EPAD GND GND Ground. The external paddle on the bottom of the package must be connected to

Output Pi n Type Mnemonic Description

Serial Control Port Chip Select, Active Low. This pin has an internal 30 kΩ pull-up

CS

resistor.

Chip Reset, Active Low. This pin has an internal 30 kΩ pull-up resistor.

RESET

Chip Power Down, Active Low. This pin has an internal 30 kΩ pull-up resistor.

PD

OUT4

I Power VS_LVPECL Extended Voltage 2.5 V to 3.3 V LVPECL Power Pins.

LVPECL Output; One Side of a Differential LVPECL Output.

OUT5

LVPECL Output; One Side of a Differential LVPECL Output.

OUT3

LVPECL Output; One Side of a Differential LVPECL Output.

OUT2

LVPECL Output; One Side of a Differential LVPECL Output.

OUT1

LVPECL Output; One Side of a Differential LVPECL Output.

OUT0

RSET Resistor connected here sets internal bias currents. Nominal value = 4.12 kΩ.

resistor

CPRSET Resistor connected here sets the CP current range. Nominal value = 5.1 kΩ.

resistor

(REF2) Along with REFIN, this is the self-biased differential input for the PLL reference.

REFIN

input

REFIN (REF1) Along with

input

Alternatively, this pin is a single-ended input for REF2.

, this is the self-biased differential input for the PLL reference.

REFIN

Alternatively, this pin is a single-ended input for REF1.

ground for proper operation.

Rev. C | Page 15 of 64

Page 16

AD9518-1 Data Sheet

0 500 1000 1500 2000 2500 3000

CURRENT (mA)

FREQUENCY (MHz)

300

100

120

140

160

180

200

220

240

260

280

3 CHANNELS—6 LV P E CL

3 CHANNELS—3 LV P E CL

2 CHANNELS—2 LV P E CL

1 CHANNEL—1 LVP E CL

06430-007

65

35

40

45

50

55

60

2.3 2.72.62.52.4

K

VCO

(MHz/V)

VCO FREQ UE NCY ( GHz)

06430-010

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0 0.5 1.0 1.5 2.0 2.5 3.0

CURRENT FROM CP P IN (mA)

VOLTAGE ON CP PIN (V)

PUMP DOWN PUMP UP

06430-011

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0 0.5 1.0 1.5 2.0 3.0 4.02.5 3.5 5.04.5

CURRENT FROM CP P IN (mA)

VOLTAGE ON CP PIN (V)

PUMP DOWN PUMP UP

06430-012

–140

–145

–150

–155

–160

–165

–170

0.1 1 10010

PFD PHASE NO ISE REFERRED TO PFD INP UT

(dBc/Hz)

PFD FREQUENCY (MHz)

06430-013

–210

–224

–222

–220

–218

–216

–214

–212

0 2.52.01.51.00.5

PLL FIGURE OF MERIT (dBc/Hz)

SLEW RATE (V/ns)

06430-136

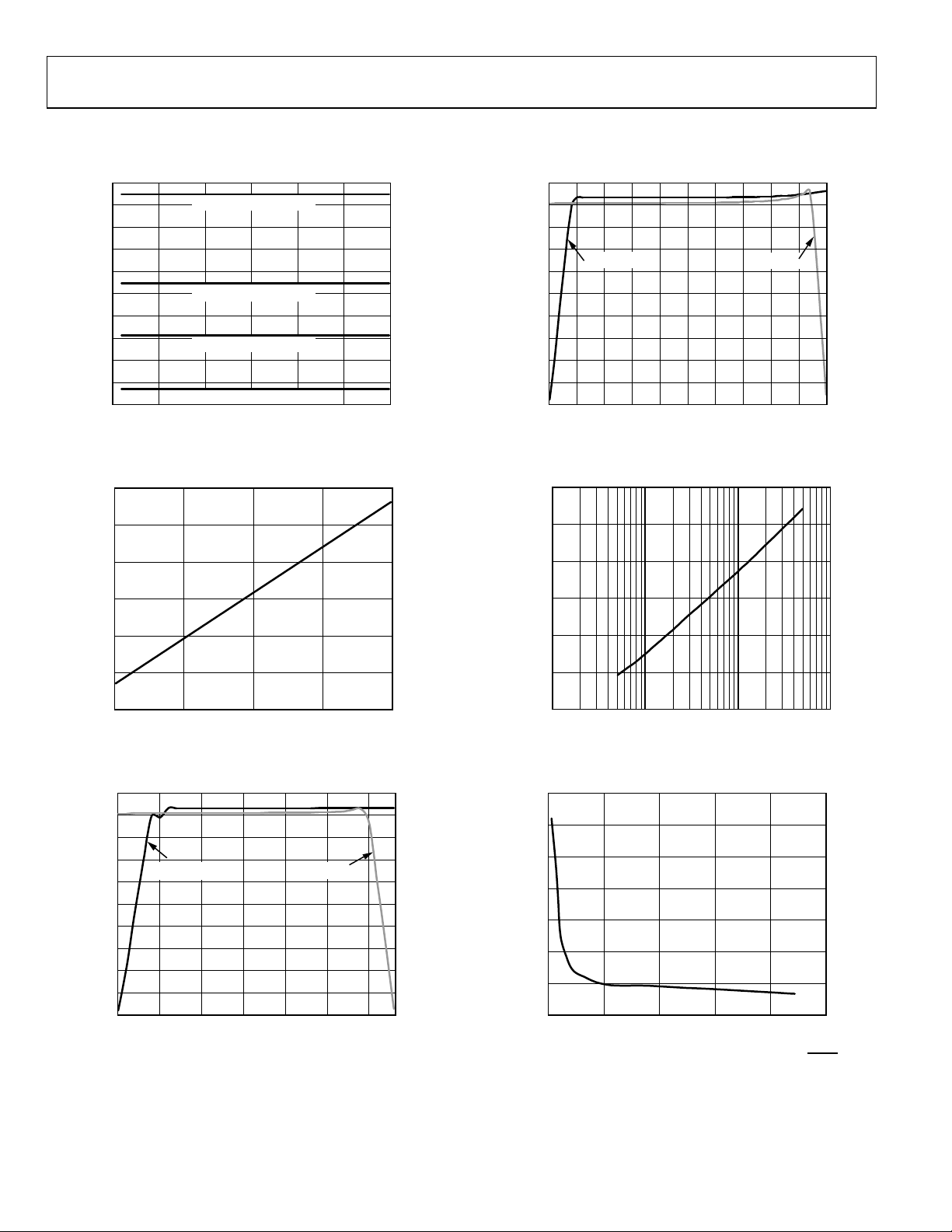

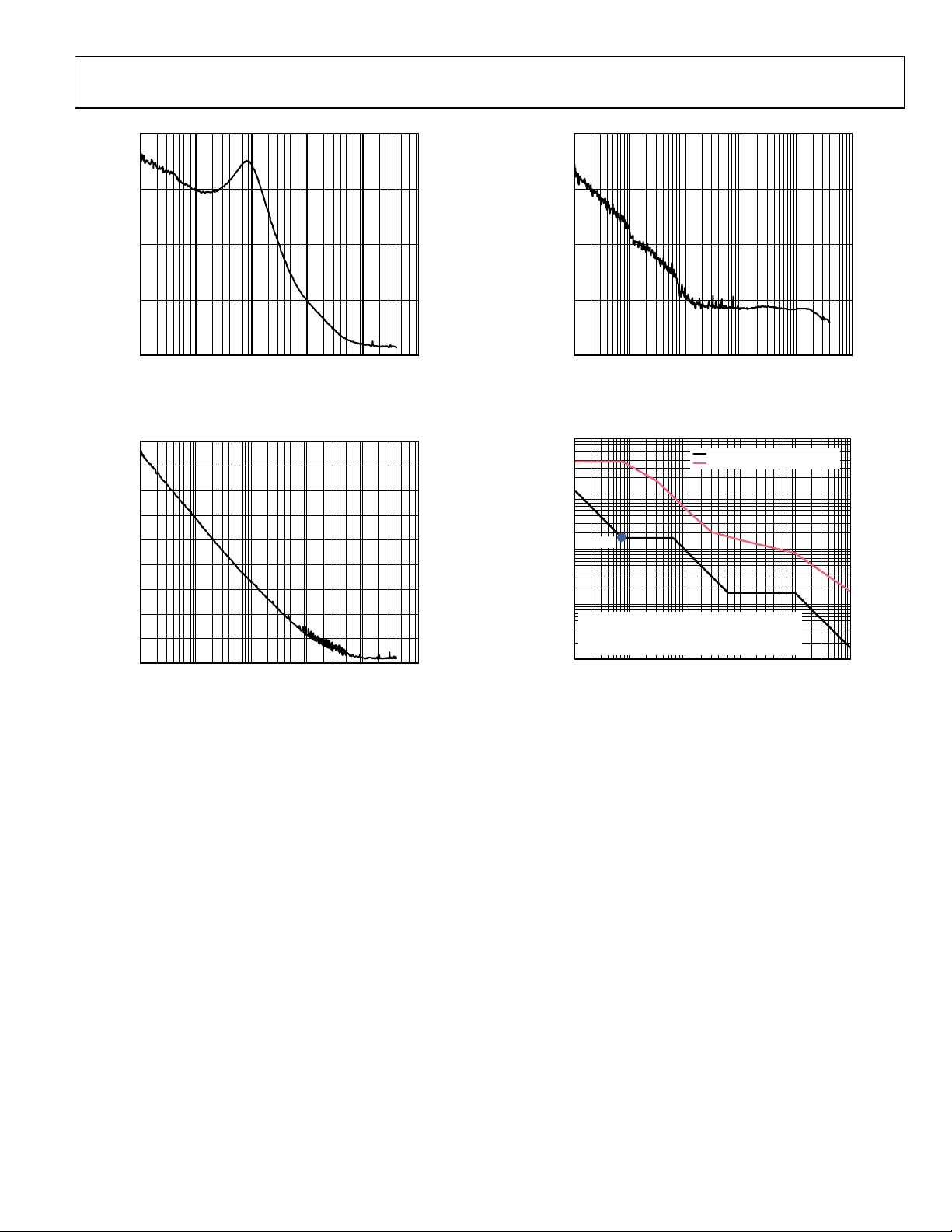

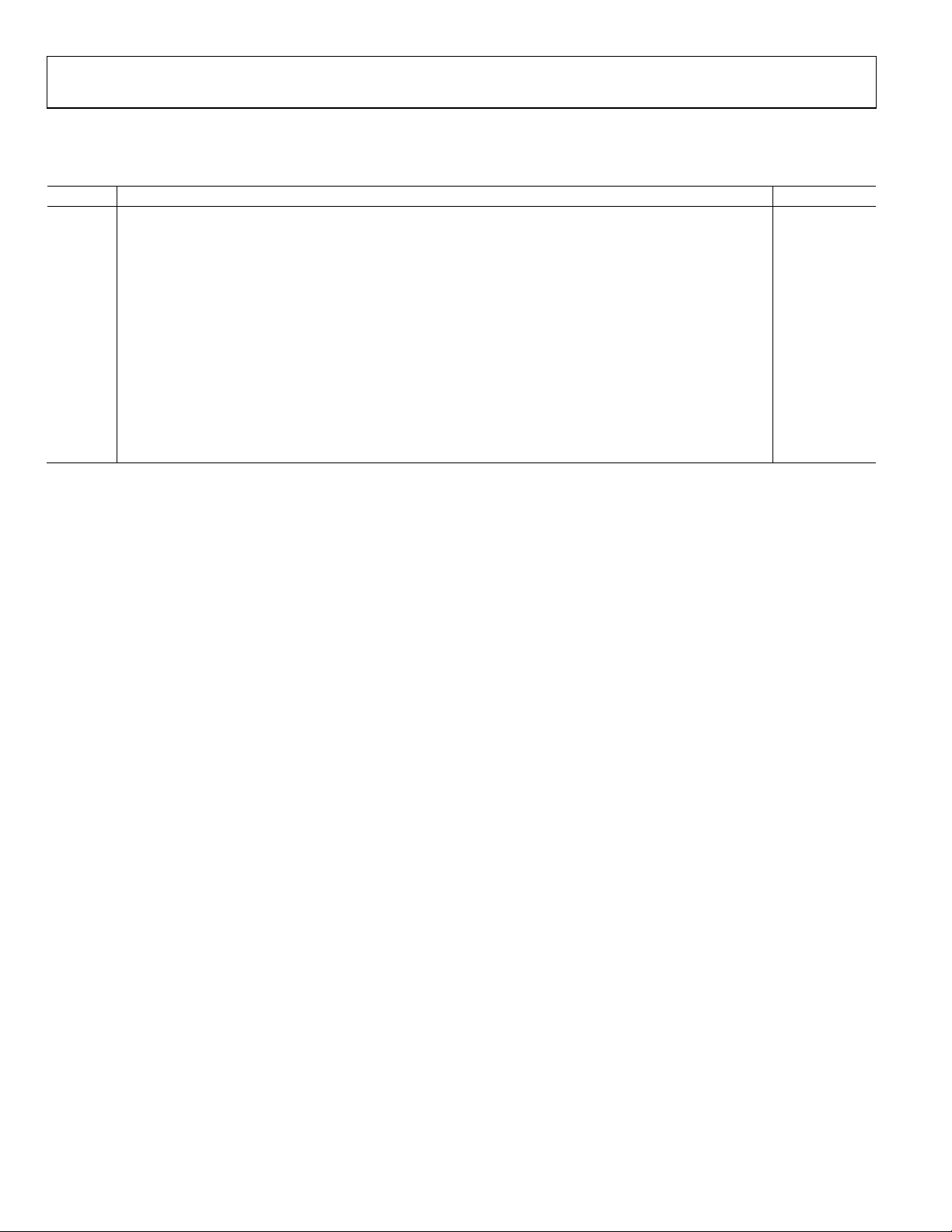

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 5. Current vs. Frequency, Direct to Output, LVPECL Outputs

Figure 6. K

vs. VCO Frequency

VCO

Figure 8. Charge Pump Characteristics at VCP = 5.0 V

Figure 9. PFD Phase Noise Referred to PFD Input vs. PFD Frequency

Figure 7. Charge Pump Characteristics at VCP = 3.3 V

Figure 10. PLL Figure of Merit (FOM) vs. Slew Rate at REFIN/

REFIN

Rev. C | Page 16 of 64

Page 17

Data Sheet AD9518-1

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

2.3 2.4 2.5 2.6 2.7

VCO TUNING VOLTAGE (V)

FREQUENCY ( GHz)

06430-138

–110

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

10

0

CENTER 122.88MHz SPAN 50 M Hz5MHz/DIV

RELATIVE POWER (dB)

06430-137

–110

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

10

0

CENTER 122.88MHz SPAN 1MHz100kHz/DIV

RELATIVE POWER (dB)

06430-135

1.0

0.6

0.2

–0.2

–0.6

–1.0

0 252015105

DIFFERENTIAL OUTPUT (V)

TIME (ns)

06430-014

1.0

0.6

0.2

–0.2

–0.6

–1.0

0 21

DIFFERENTIAL OUTPUT (V)

TIME (ns)

06430-015

1600

800

1000

1200

1400

0 321

DIFFERENTIAL SWING (mV p-p)

FREQUENCY ( GHz)

06430-020

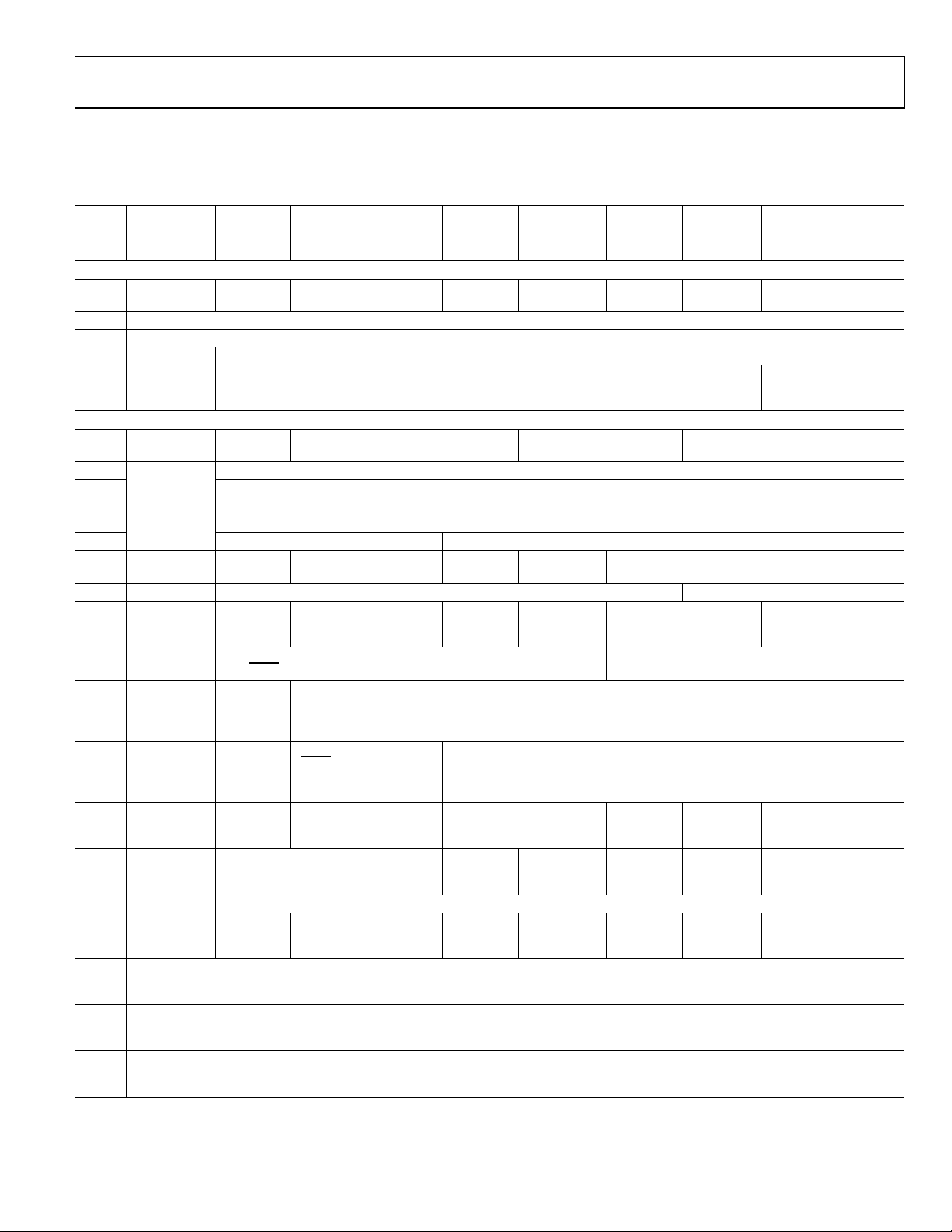

Figure 11. VCO Tuning Voltage vs. Frequency

(Note that VCO calibration centers the dc tuning voltage

for the PLL setup that is active during calibration.)

Figure 12. PFD/CP Spurs; 122.88 MHz; PFD = 15.36 MHz;

LBW = 55 kHz; I

= 4.8 mA; f

CP

= 2.46 GHz

VCO

Figure 14. LVPECL Output (Differential) at 100 MHz

Figure 15. LVPECL Output (Differential) at 1600 MHz

Figure 13. Output Spectrum, LVPECL; 122.88 MHz; PFD = 15.36 MHz;

LBW = 55 kHz; I

= 4.8 mA; f

CP

= 2.46 GHz

VCO

Figure 16. LVPECL Differential Swing vs. Frequency,

Using a Differential Probe Across the Output Pair

Rev. C | Page 17 of 64

Page 18

AD9518-1 Data Sheet

–70

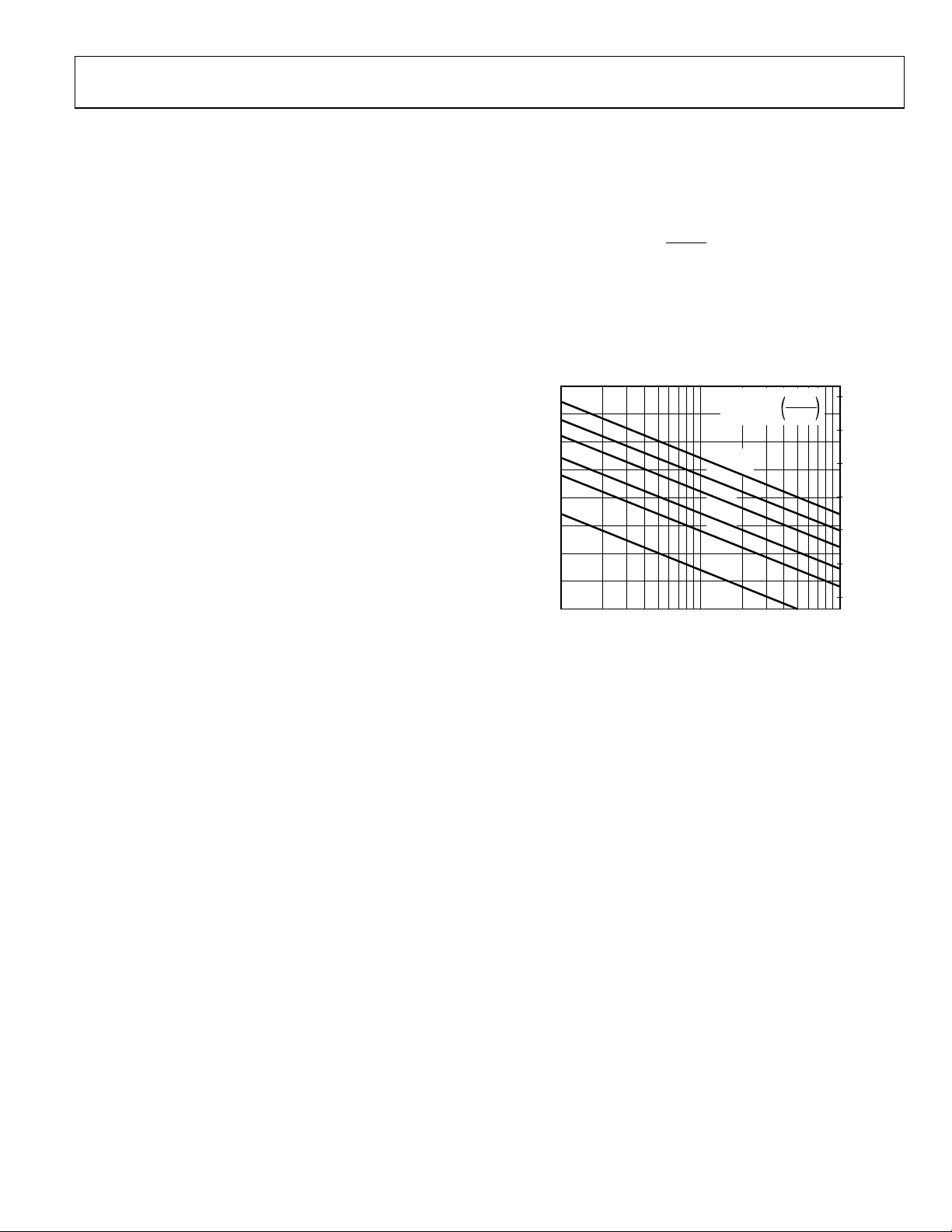

–80

–90

–100

–110

–120

–130

–140

–150

10k 100M10M1M100k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-023

–70

–80

–90

–100

–110

–120

–130

–140

–150

10k 100M10M1M100k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-024

–70

–80

–90

–100

–110

–120

–130

–140

–150

10k 100M10M1M100k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-025

–120

–130

–125

–135

–140

–145

–150

–155

–160

10 100M10M1M100k10k1k100

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-026

–110

–120

–130

–140

–150

–160

10 100M10M1M100k10k1k100

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-027

–100

–110

–120

–130

–140

–150

10 100M10M1M100k10k1k100

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-128

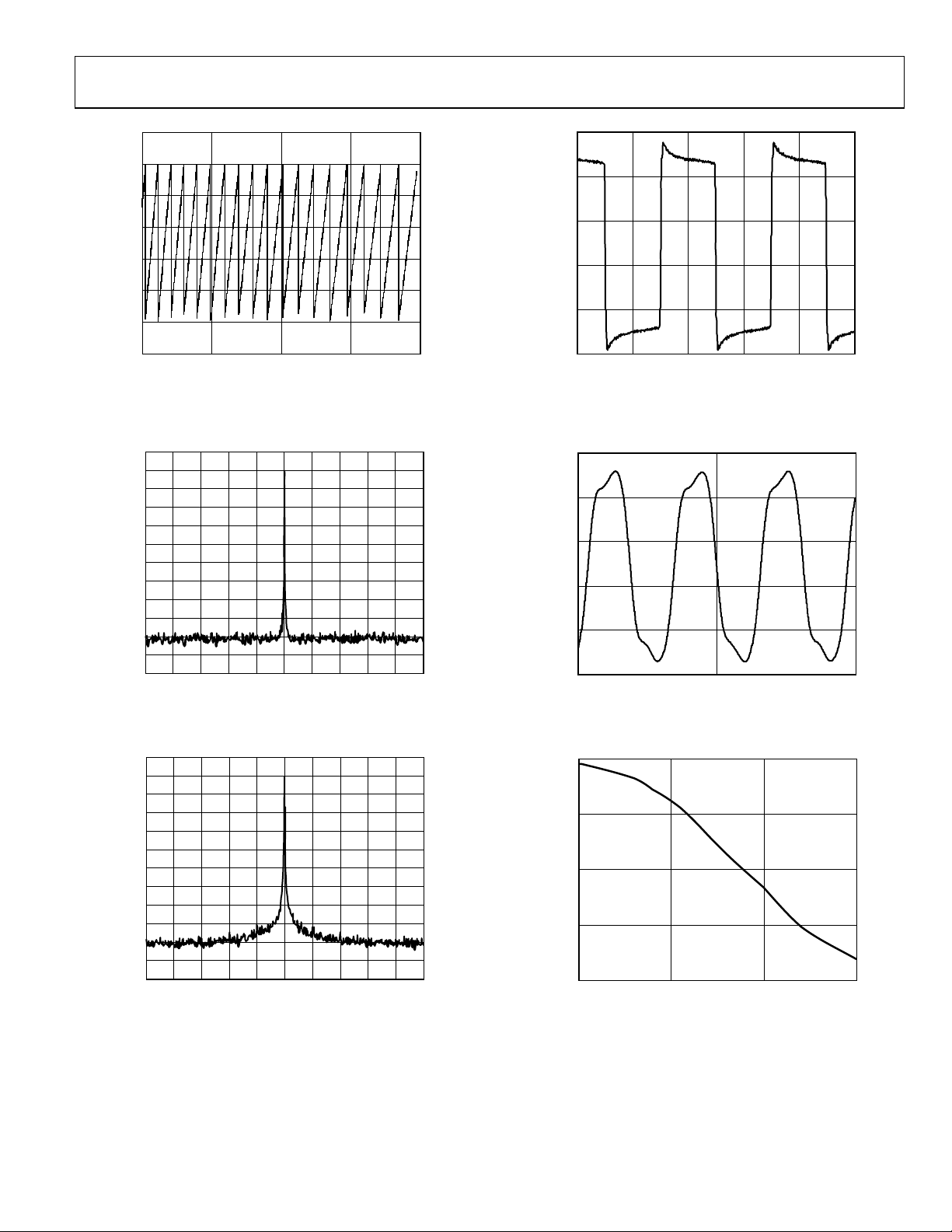

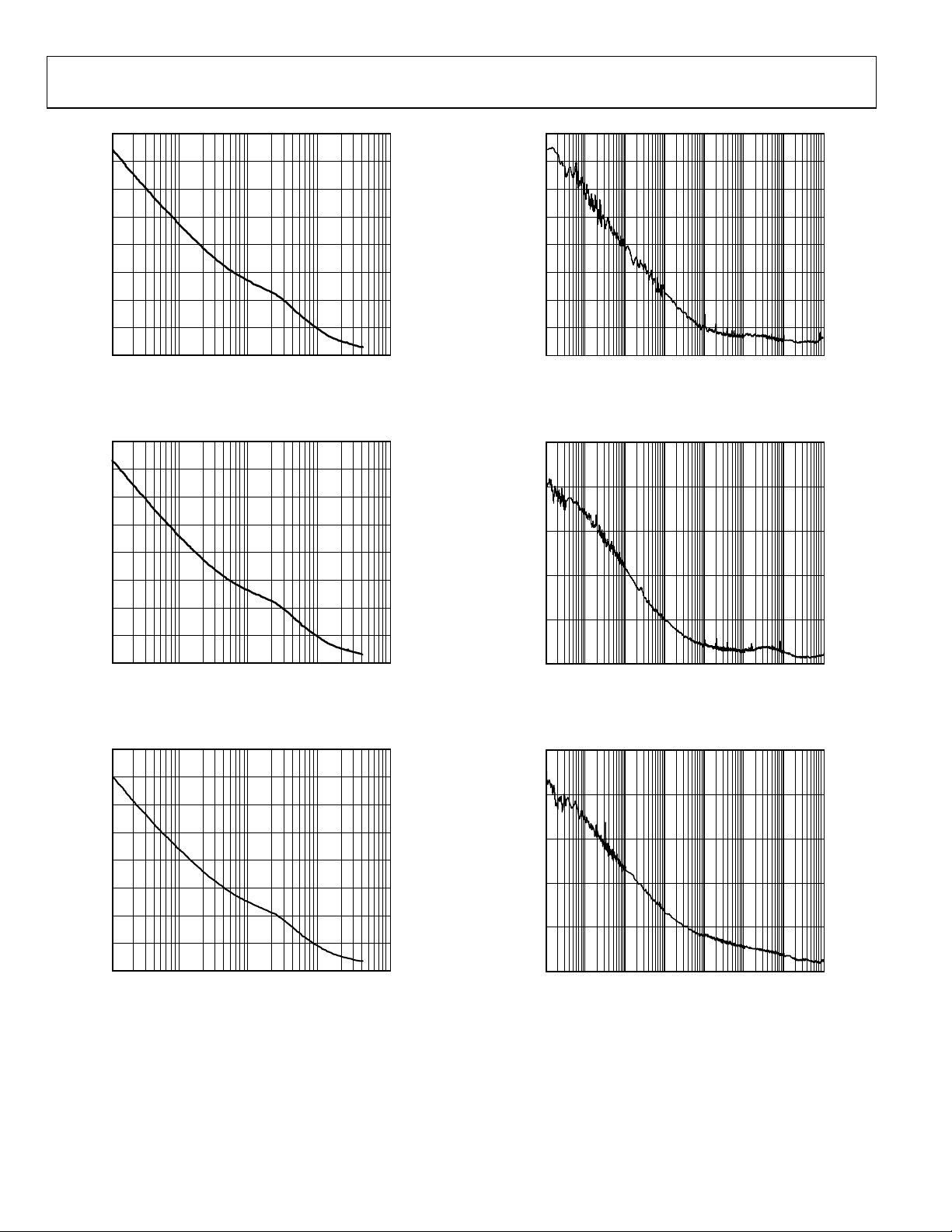

Figure 17. Internal VCO Phase Noise (Absolute) Direct to LVPECL at 2650 MHz

Figure 18. Internal VCO Phase Noise (Absolute) Direct to LVPECL at 2475 MHz

Figure 20. Phase Noise (Additive) LVPECL at 245.76 MHz, Divide-by-1

Figure 21. Phase Noise (Additive) LVPECL at 200 MHz, Divide-by-5

Figure 19. Internal VCO Phase Noise (Absolute) Direct to LVPECL at 2300 MHz

Figure 22. Phase Noise (Additive) LVPECL at 1600 MHz, Divide-by-1

Rev. C | Page 18 of 64

Page 19

Data Sheet AD9518-1

–120

–160

–150

–140

–130

1k 100M10M1M100k10k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-141

–70

–80

–90

–100

–110

–120

–130

–140

–150

–160

1k 100M10M1M100k10k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-139

–120

–160

–150

–140

–130

1k 100M10M1M100k10k

PHASE NOISE (dBc/Hz)

FREQUENCY ( Hz )

06430-140

1000

100

10

1

0.1

0.01 0.1 1 10 100 1000

INPUT JITTER AMPLITUDE (UI p-p)

JITTER F RE QUENCY (kHz)

06430-148

OC-48 OBJECTIVE MASK

AD9518

NOTE: 375UI M AX AT 10Hz OFFS E T IS THE

MAXIMUM JITTER THAT CAN BE

GENERATED BY THE TEST EQUIPMENT.

FAILURE POINT IS GREATER THAN 375UI .

f

OBJ

Figure 23. Phase Noise (Absolute) Clock Generation; Internal VCO at

2.4576 GHz; PFD = 15.36 MHz; LBW = 55 kHz; LVPECL Output = 122.88 MHz

Figure 24. Phase Noise (Absolute) Clock Cleanup; Internal VCO at 2.488 GHz;

PFD = 19.44 MHz; LBW = 12.8 kHz; LVPECL Output = 155.52 MHz

Figure 25. Phase No ise (Absolute); External VCXO (Toyocom TCO-2112) at

245.76 MHz; PFD = 15.36 MHz; LBW = 25 0 Hz; LVPECL Output = 245.76 MHz

Figure 26. GR-253 Jitter Tolerance Plot

Rev. C | Page 19 of 64

Page 20

AD9518-1 Data Sheet

TERMINOLOGY

Phase Jitter and Phase Noise

An ideal sine wave can be thought of as having a continuous

and even progression of phase with time from 0° to 360° for

each cycle. Actual signals, however, display a certain amount

of variation from ideal phase progression over time. This

phenomenon is called phase jitter. Although many causes can

contribute to phase jitter, one major cause is random noise,

which is characterized statistically as being Gaussian (normal)

in distribution.

This phase jitter leads to a spreading out of the energy of the

sine wave in the frequency domain, producing a continuous

power spectrum. This power spectrum is usually reported as a

series of values whose units are dBc/Hz at a given offset in

frequency from the sine wave (carrier). The value is a ratio

(expressed in dB) of the power contained within a 1 Hz

bandwidth with respect to the power at the carrier frequency.

For each measurement, the offset from the carrier frequency is

also given.

It is meaningful to integrate the total power contained within

some interval of offset frequencies (for example, 10 kHz to

10 MHz). This is called the integrated phase noise over that

frequency offset interval and can be readily related to the time

jitter due to the phase noise within that offset frequency interval.

Phase noise has a detrimental effect on the performance of

ADCs, DACs, and RF mixers. It lowers the achievable dynamic

range of the converters and mixers, although they are affected

in somewhat different ways.

Time Jitter

Phase noise is a frequency domain phenomenon. In the time

domain, the same effect is exhibited as time jitter. When

observing a sine wave, the time of successive zero crossings

varies. In a square wave, the time jitter is a displacement of the

edges from their ideal (regular) times of occurrence. In both

cases, the variations in timing from the ideal are the time jitter.

Because these variations are random in nature, the time jitter is

specified in units of seconds root mean square (rms) or 1 sigma

of the Gaussian distribution.

Time jitter that occurs on a sampling clock for a DAC or an

ADC decreases the signal-to-noise ratio (SNR) and dynamic

range of the converter. A sampling clock with the lowest possible

jitter provides the highest performance from a given converter.

Additive Phase Noise

Additive phase noise is the amount of phase noise that can be

attributed to the device or subsystem being measured. The phase

noise of any external oscillators or clock sources is subtracted.

This makes it possible to predict the degree to which the device

impacts the total system phase noise when used in conjunction

with the various oscillators and clock sources, each of which

contributes its own phase noise to the total. In many cases, the

phase noise of one element dominates the system phase noise.

When there are multiple contributors to phase noise, the total

is the square root of the sum of squares of the individual

contributors.

Additive Time Jitter

Additive time jitter is the amount of time jitter that can be

attributed to the device or subsystem being measured. The time

jitter of any external oscillators or clock sources is subtracted. This

makes it possible to predict the degree to which the device impacts

the total system time jitter when used in conjunction with the

various oscillators and clock sources, each of which contributes

its own time jitter to the total. In many cases, the time jitter of

the external oscillators and clock sources dominates the system

time jitter.

Rev. C | Page 20 of 64

Page 21

Data Sheet AD9518-1

V

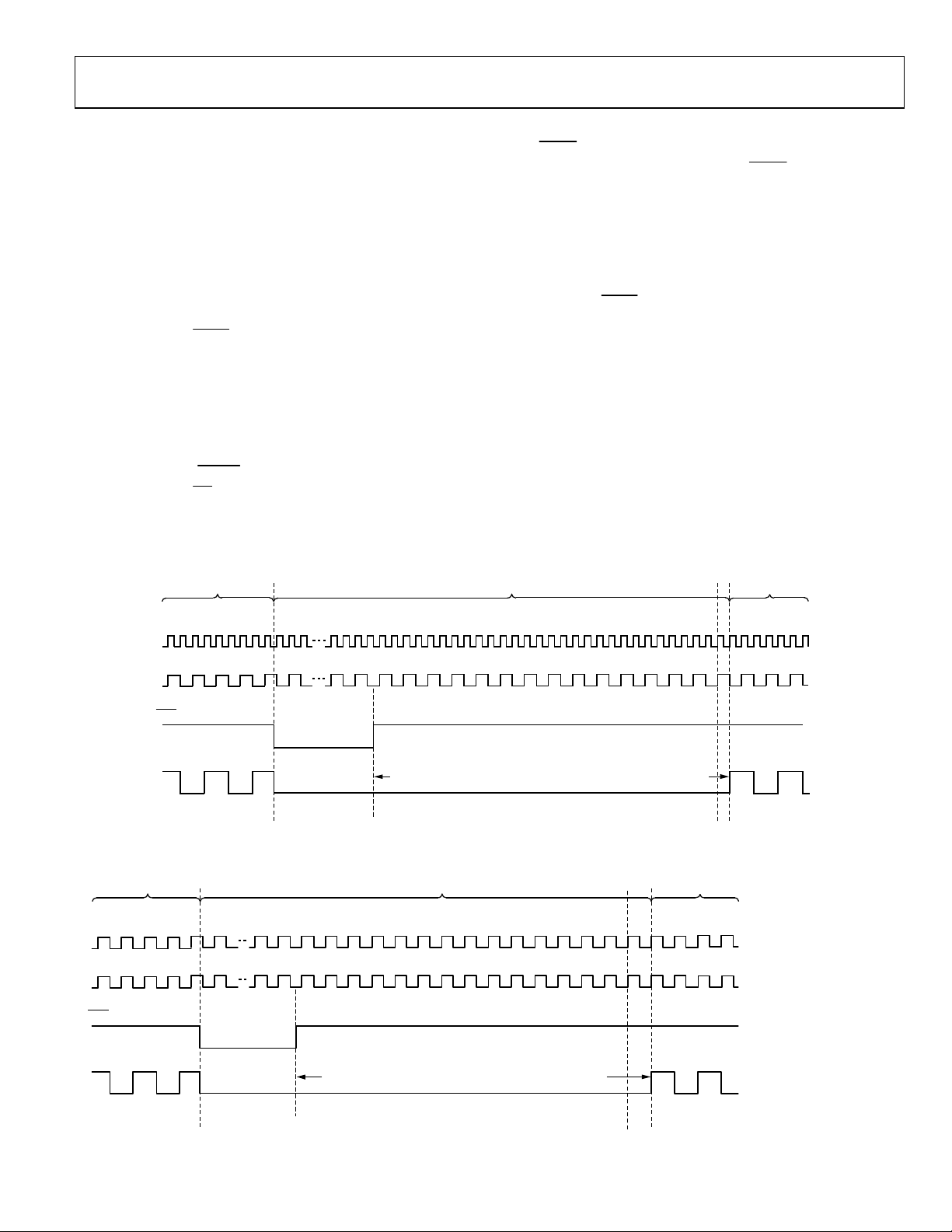

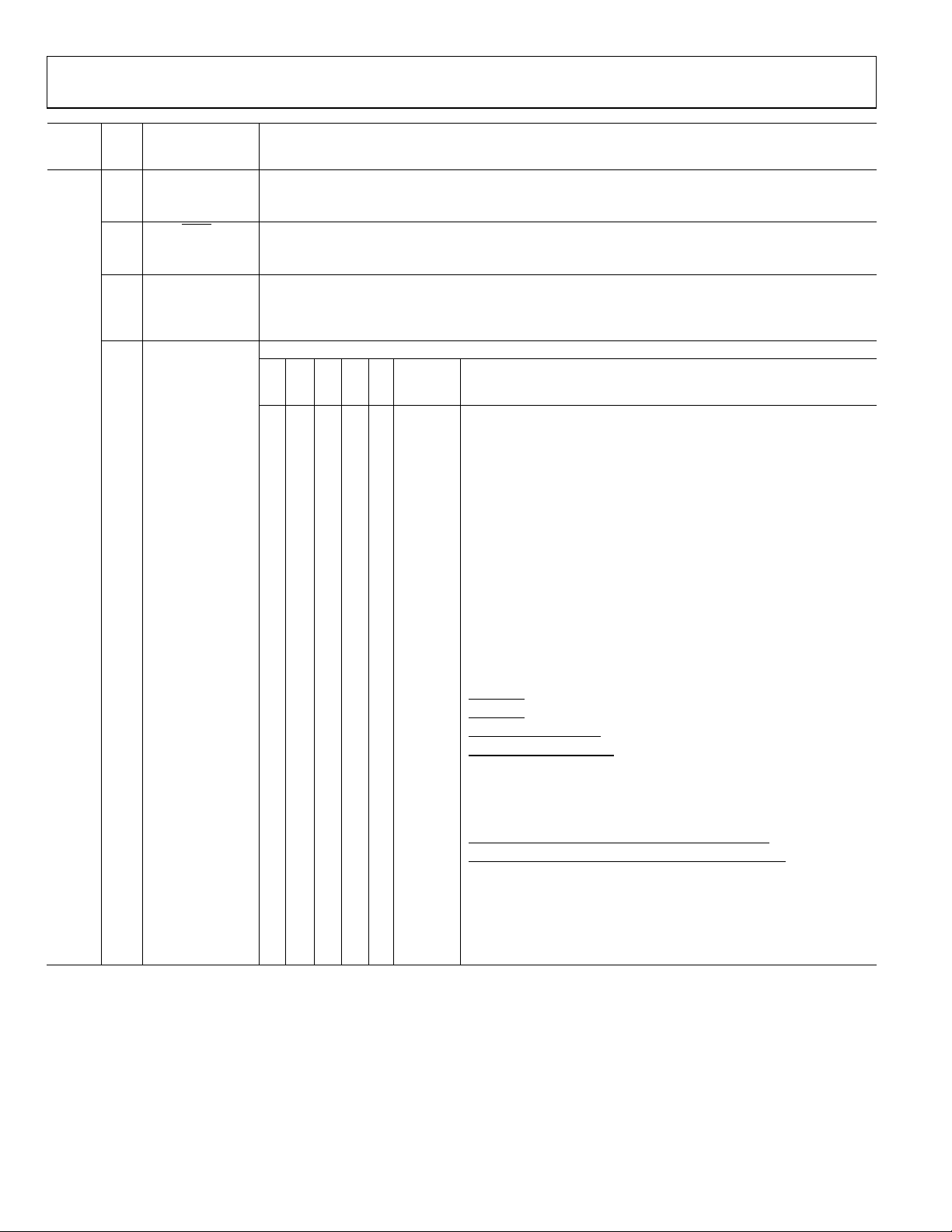

DETAILED BLOCK DIAGRAM

REFIN (REF 1)

REFIN (REF 2)

BYPASS

CLK

CLK

SYNC

RESET

SCLK

SDIO

SDO

REF1

REF2

LF

PD

CS

REF_ SEL CPRSETVCP

REFERENCE

SWITCHOVER

STATUS

STATUS

LOW DROPOUT

REGULATOR (LDO)

VCO

DIGITAL

LOGIC

SERIAL

CONTROL

PORT

AD9518-1

S GND RSE T

DISTRIBUTI ON

REFERENCE

R

DIVIDER

VCO STATUS

P, P + 1

PRESCALER

DIVIDE BY

2, 3, 4, 5, OR 6

01

N DIVIDER

A/B

COUNTERS

Figure 27. Detailed Block Diagram

REFMO N

PROGRAMMABLE

R DELAY

PROGRAMMABLE

N DELAY

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

LOCK

DETECT

PHASE

FREQUENCY

DETECT OR

PLL

REFERENCE

CHARGE

PUMP

HOLD

LVPECL

LVPECL

LVPECL

LD

CP

STATUS

OUT0

OUT0

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

OUT4

OUT4

OUT5

OUT5

06430-002

Rev. C | Page 21 of 64

Page 22

AD9518-1 Data Sheet

0x1E0[2:0] = 010b

Set VCO divider = 4.

THEORY OF OPERATION

OPERATIONAL CONFIGURATIONS

The AD9518 can be configured in several ways. These

configurations must be set up by loading the control registers

(see Table 42 and Table 43 through Ta ble 49). Each section or

function must be individually programmed by setting the

appropriate bits in the corresponding control register or registers.

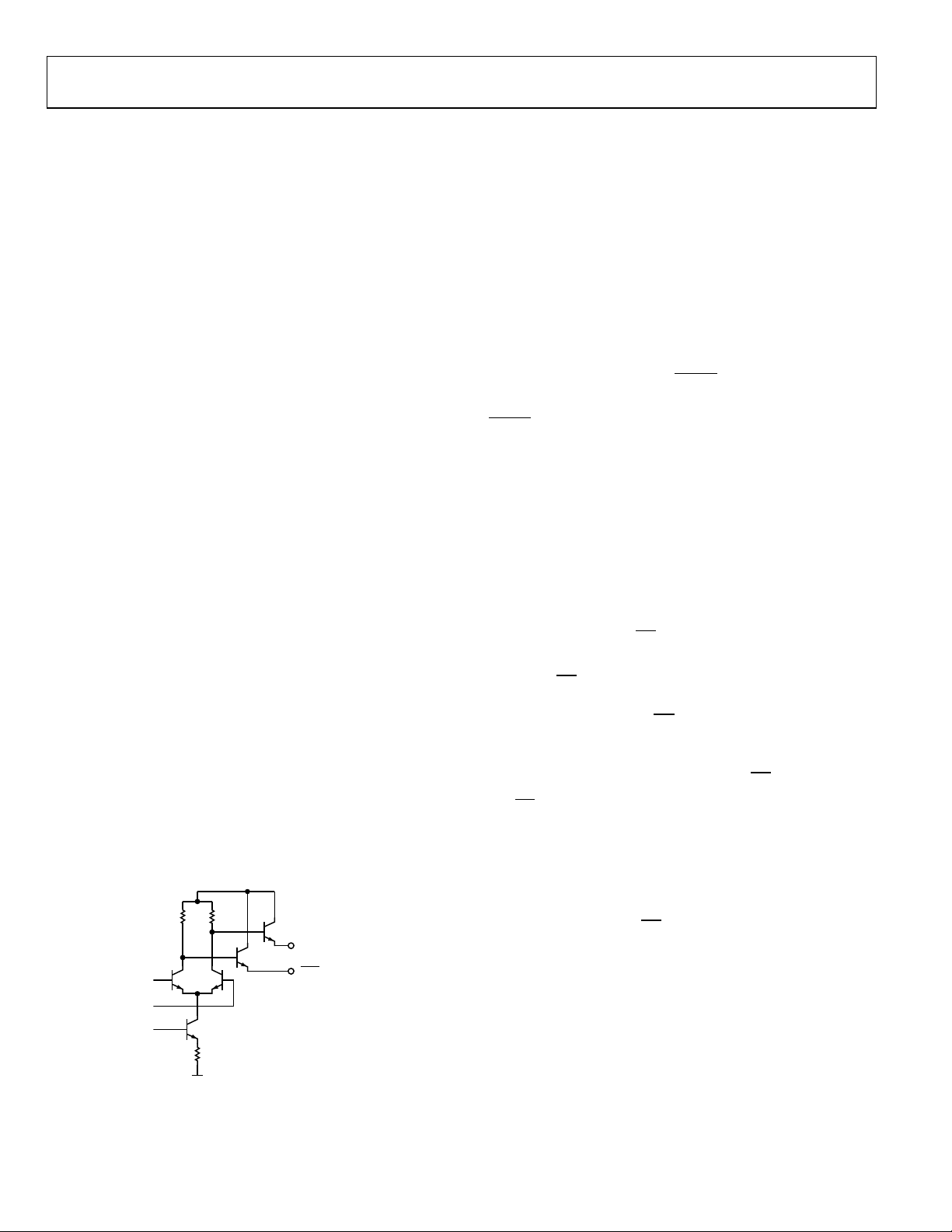

High Frequency Clock Distribution—CLK or External VCO > 1600 MHz

The AD9518 power-up default configuration has the PLL

CLK

powered off and the routing of the input set so that the CLK/

input is connected to the distribution section through the VCO

divider (divide-by-2/divide-by-3/divide-by-4/ divide-by-5/divideby-6). This is a distribution-only mode that allows for an external

input up to 2.4 GHz (see Table 3). The maximum frequency that

can be applied to the channel dividers is 1600 MHz; therefore,

higher input frequencies must be divided down before reaching

the channel dividers. This input routing can also be used for lower

input frequencies, but the minimum divide is 2 before the channel

dividers.

When the PLL is enabled, this routing also allows the use of the

PLL with an external VCO or VCXO with a frequency of less

than 2400 MHz. In this configuration, the internal VCO is not

used and is powered off. The external VCO/VCXO feeds

directly into the prescaler.

The register settings shown in Table 20 are the default values of

these registers at power-up or after a reset operation. If the

contents of the registers are altered by prior programming after

power-up or reset, these registers can also be set intentionally to

these values.

After the appropriate register values are programmed,

Register 0x232 must be set to 0x01 for the values to take effect.

Table 20. Default Settings of Some PLL Registers

Register Function

0x010[1:0] = 01b PLL asynchronous power-down (PLL off).

0x1E1[0] = 0b Use the VCO divider.

0x1E1[1] = 0b CLK selected as the source.

When using the internal PLL with an external VCO, the PLL

must be turned on.

Table 21. Settings When Using an External VCO

Register Function

0x010[1:0] = 00b PLL normal operation (PLL on).

0x010 to 0x01D PLL settings. Select and enable a

reference input; set R, N (P, A, B), PFD

polarity, and I

loop configuration.

0x1E1[1] = 0b CLK selected as the source.

An external VCO requires an external loop filter that must be

connected between CP and the tuning pin of the VCO. This

loop filter determines the loop bandwidth and stability of the

PLL. Make sure to select the proper PFD polarity for the VCO

being used.

Table 22. Setting the PFD Polarity

Register Function

0x010[7] = 0b PFD polarity positive (higher control

voltage produces higher frequency).

0x010[7] = 1b PFD polarity negative (higher control

voltage produces lower frequency).

, according to the intended

CP

Rev. C | Page 22 of 64

Page 23

Data Sheet AD9518-1

V

REFIN (REF 1)

REFIN (REF 2)

BYPASS

CLK

CLK

PD

SYNC

RESET

SCLK

SDIO

SDO

CS

REF1

REF2

REGULATOR (LDO)

LF

REF_ SEL CPRSETVCP

REFERENCE

SWITCHOVER

STATUS

STATUS

LOW DROPOUT

VCO

DIGITAL

LOGIC

SERIAL

CONTRO L

PORT

S GND RSET

DISTRIBUTION

REFERENCE

R

DIVIDE R

VCO STATUS

P, P + 1

PRESCALER

DIVIDE BY

2, 3, 4, 5, OR 6

01

N DIVIDER

A/B

COUNTERS

REFMON

PROGRAMMABLE

R DELAY

PROGRAMMABLE

N DELAY

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

LOCK

DETECT

PHASE

FREQUENCY

DETECTOR

AD9518-1

PLL

REFERENCE

CHARGE

PUMP

HOLD

LVPECL

LVPECL

LVPECL

LD

CP

STATUS

OUT0

OUT0

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

OUT4

OUT4

OUT5

OUT5

Figure 28. High Frequency Clock Distribution or External VCO > 1600 MHz

06430-029

Rev. C | Page 23 of 64

Page 24

AD9518-1 Data Sheet

V

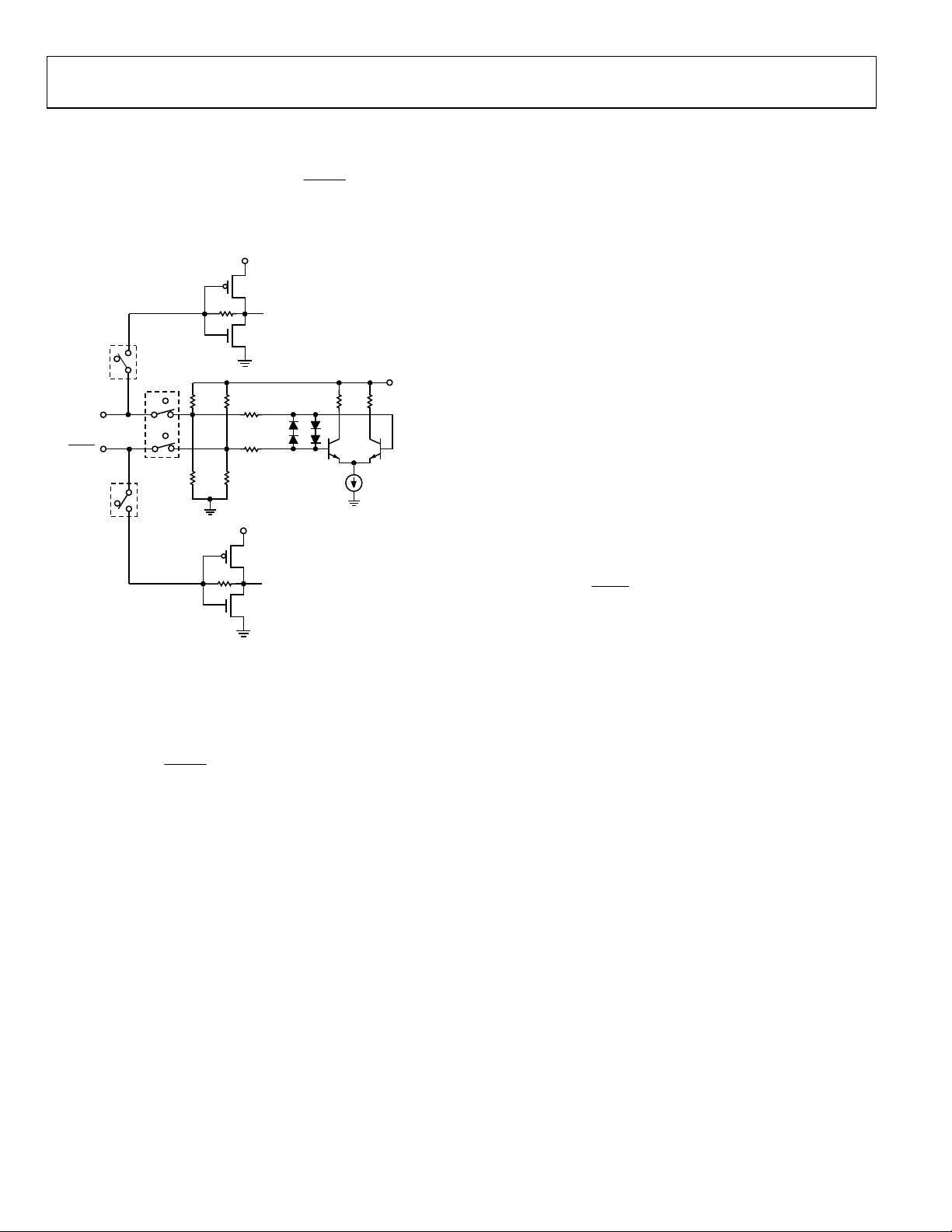

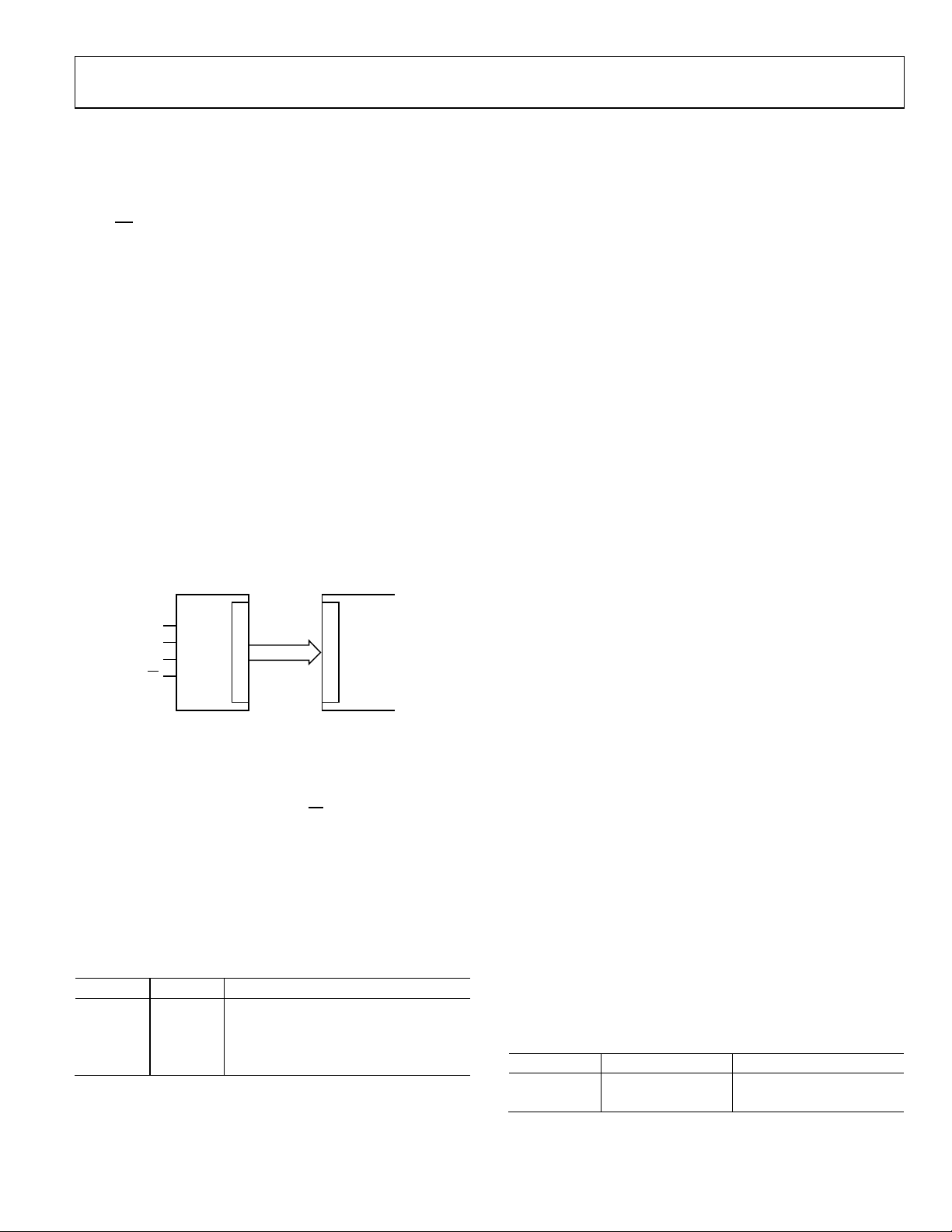

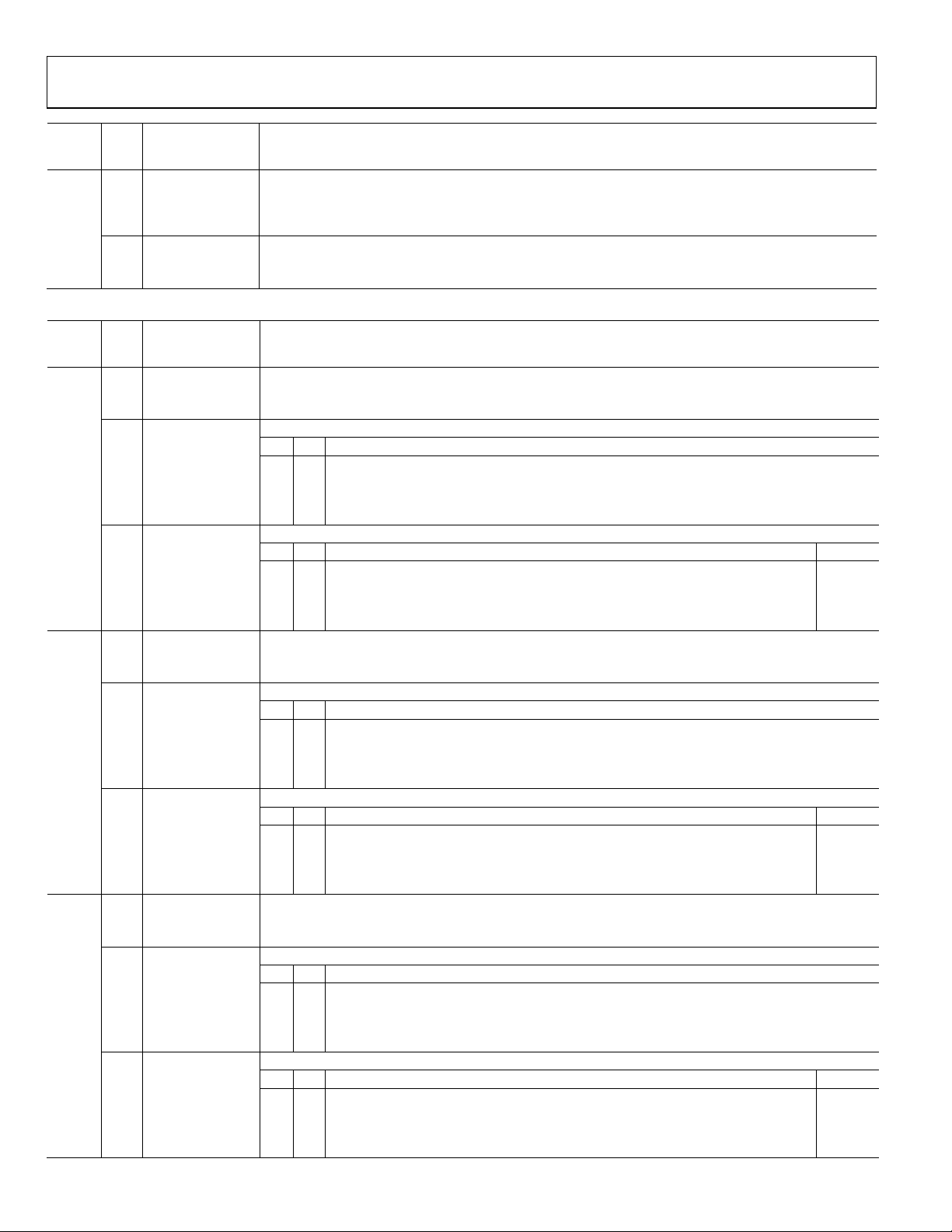

Internal VCO and Clock Distribution

When using the internal VCO and PLL, the VCO divider must

be employed to ensure that the frequency presented to the channel

dividers does not exceed their specified maximum frequency of

1600 MHz (see Table 3). The internal PLL uses an external loop

filter to set the loop bandwidth. The external loop filter is also

crucial to the loop stability.

When using the internal VCO, it is necessary to calibrate the

VCO (Register 0x018[0]) to ensure optimal performance.

For internal VCO and clock distribution applications, use the

register settings that are shown in Table 23.

REFIN ( REF1)

REFIN ( REF2)

BYPASS

CLK

CLK

PD

SYNC

RESET

SCLK

SDIO

SDO

CS

REF1

REF2

REGULATOR ( LDO)

LF

REF_ SEL CPRSETVCP

REFERENCE

SWITCHOVER

STATUS

STATUS

LOW DROPOUT

VCO

DIGITAL

LOGIC

SERIAL

CONTROL

PORT

AD9518-1

S GND RSET

DISTRIBUTI ON

REFERENCE

R

DIVIDER

VCO STATUS

P, P + 1

PRESCALER

DIVIDE BY

2, 3, 4, 5, OR 6

01

N DIVIDER

A/B

COUNTERS

Figure 29. Internal VCO and Clock Distribution

Table 23. Settings When Using an Internal VCO

Register Function

0x010[1:0] = 00b PLL normal operation (PLL on).

0x010 to 0x01D PLL settings. Select and enable a reference

input; set R, N (P, A, B), PFD polarity, and I

according to the intended loop configuration.

0x018[0] = 0b,

0x232[0] = 1b

Reset VCO calibration. This process is not

required the first time after power-up, but it

must be performed subsequently.

0x1E0[2:0] Set VCO divider to divide-by-2, divide-by-3,

divide-by-4, divide-by-5, or divide-by-6.

0x1E1[0] = 0b Use VCO divider as the source for the

distribution section.

0x1E1[1] = 1b Select VCO as the source.

0x018[0] = 1b,

Initiate VCO calibration.

0x232[0] = 1b

REFMON

LOCK

DETECT

PROGRAMMABLE

R DELAY

PROGRAMMABLE

N DELAY

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

PHASE

FREQUENCY

DETECTOR

PLL

REFERENCE

CHARGE

PUMP

HOLD

LVPECL

LVPECL

LVPECL

LD

CP

STATUS

OUT0

OUT0

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

OUT4

OUT4

OUT5

OUT5

CP

06430-030

Rev. C | Page 24 of 64

Page 25

Data Sheet AD9518-1

V

REFIN (REF1)

REFIN (REF2)

BYPASS

CLK

CLK

PD

SYNC

RESET

SCLK

SDIO

SDO

CS

REF1

REF2

REGULATOR ( LDO)

LF

REF_ SEL CPRSETVCP

REFERENCE

SWITCHOVER

STATUS

STATUS

LOW DROPOUT

VCO

DIGITAL

LOGIC

SERIAL

CONTROL

PORT

S GND RSET

DISTRIBUTI ON

REFERENCE

R

DIVIDER

VCO STATUS

P, P + 1

PRESCALER

DIVIDE BY

2, 3, 4, 5, OR 6

01

N DIVIDER

A/B

COUNTERS

REFMON

PROGRAMMABLE

R DELAY

PROGRAMMABLE

N DELAY

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

DIVIDE BY

1 TO 32

LOCK

DETECT

PHASE

FREQUENCY

DETECT OR

AD9518-1

PLL

REFERENCE

CHARGE

PUMP

HOLD

LVPECL

LVPECL

LVPECL

LD

CP

STATUS

OUT0

OUT0

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

OUT4

OUT4

OUT5

OUT5

Figure 30. Clock Distribution or External VCO < 1600 MHz

Clock Distribution or External VCO < 1600 MHz

When the external clock source to be distributed or the external

VCO/VCXO is less than 1600 MHz, a configuration that bypasses

the VCO divider can be used. This configuration differs from the

High Frequency Clock Distribution—CLK or External VCO >

1600 MHz section only in that the VCO divider (divide-by-2/

divide-by-3/divide-by-4/divide-by-5/divide-by-6) is bypassed.

This limits the frequency of the clock source to <1600 MHz (due

to the maximum input frequency allowed at the channel dividers).

Configuration and Register Settings

For clock distribution applications where the external clock is

less than 1600 MHz, use the register settings shown in Table 24.

Table 24. Settings for Clock Distribution < 1600 MHz

Register Function

0x010[1:0] = 01b PLL asynchronous power-down (PLL off)

0x1E1[0] = 1b

Bypass the VCO divider as source for

distribution section

0x1E1[1] = 0b CLK selected as the source

When using the internal PLL with an external VCO of <1600 MHz,

the PLL must be turned on.

Rev. C | Page 25 of 64

06430-028

Table 25. Settings for Using Internal PLL with External VCO <

1600 MHz

Register Function

0x1E1[0] = 1b

Bypass the VCO divider as source for distribution

section

0x010[1:0] = 00b

PLL normal operation (PLL on), along with

other appropriate PLL settings in Register 0x010

to Register 0x01D

An external VCO/VCXO requires an external loop filter that

must be connected between CP and the tuning pin of the

VCO/VCXO. This loop filter determines the loop bandwidth

and stability of the PLL. Make sure to select the proper PFD

polarity for the VCO/VCXO being used.

Table 26. Setting the PFD Polarity

Register Function

0x010[7] = 0b

PFD polarity positive (higher control voltage

produces higher frequency)

0x010[7] = 1b

PFD polarity negative (higher control voltage

produces lower frequency)

After the appropriate register values are programmed,

Register 0x232 must be set to 0x01 for the values to take effect.

Page 26

AD9518-1 Data Sheet

VCPV

Phase-Locked Loop (PLL)

REF_SEL

SGND

RSET

REFMO N

CPRSET

N DIVIDER

DIST

REF

R DIVIDER

A/B

COUNTERS

0

1

REFIN ( REF1)

REFIN ( REF2)

BYPASS

CLK

CLK

REGULATOR (LDO)

LF

REFERENCE

SWITCHOVER

REF1

REF2

LOW DROPOUT

VCO

STATUS

STATUS

P, P + 1

PRESCALER

DIVIDE BY

2, 3, 4, 5, OR 6

01

Figure 31. PLL Functional Blocks

The AD9518 includes an on-chip PLL with an on-chip VCO.

The PLL blocks can be used either with the on-chip VCO to

create a complete phase-locked loop, or with an external VCO

or VCXO. The PLL requires an external loop filter, which

usually consists of a small number of capacitors and resistors.

The configuration and components of the loop filter help to

establish the loop bandwidth and stability of the operating PLL.

The AD9518 PLL is useful for generating clock frequencies

from a supplied reference frequency. This includes conversion

of reference frequencies to much higher frequencies for subsequent

division and distribution. In addition, the PLL can be exploited

to clean up jitter and phase noise on a noisy reference. The exact

choices of PLL parameters and loop dynamics are very application

specific. The flexibility and depth of the AD9518 PLL allow the

part to be tailored to function in many different applications

and signal environments.

Configuration of the PLL

The AD9518 allows flexible configuration of the PLL,

accommodating various reference frequencies, PFD comparison

frequencies, VCO frequencies, internal or external VCO/VCXO,

and loop dynamics. This is accomplished by the various settings

that include the R divider, the N divider, the PFD polarity (only

applicable to external VCO/VCXO), the antibacklash pulse width,

the charge pump current, the selection of internal VCO or

external VCO/VCXO, and the loop bandwidth. These are

PROGRAMMABLE

R DELAY

PROGRAMMABLE

N DELAY

VCO STATUS

managed through programmable register settings (see Table 42

and Table 44) and by the design of the external loop filter.

Successful PLL operation and satisfactory PLL loop performance

are highly dependent upon proper configuration of the PLL

settings. The design of the external loop filter is crucial to the

proper operation of the PLL. A thorough knowledge of PLL

theory and design is helpful.

ADIsimCLK™ (V1.2 or later) is a free program that can help

with the design and exploration of the capabilities and features

of the AD9518, including the design of the PLL loop filter. It is

available at www.analog.com/clocks.

Phase Frequency Detector (PFD)

The PFD takes inputs from the R counter and N counter and

produces an output proportional to the phase and frequency

difference between them. The PFD includes a programmable

delay element that controls the width of the antibacklash pulse.

This pulse ensures that there is no dead zone in the PFD transfer

function and minimizes phase noise and reference spurs. The

antibacklash pulse width is set by Register 0x017[1:0].

An important limit to keep in mind is the maximum frequency

allowed into the PFD, which in turn determines the correct

antibacklash pulse setting. The antibacklash pulse setting is

specified in the phase/frequency detector parameter of Table 2.

LOCK

DETECT

PHASE

FREQUENCY

DETECTOR

PLL

REF

HOLD

CHARGE PUMP

LD

CP

STATUS

06430-064

Rev. C | Page 26 of 64

Page 27

LF

VCO

CHARGE

PUMP

CP

BYPASS

C1 C2 C3

R1

31pF

R2

C

BP

= 220nF

AD9518-1

06430-065

CLK/CLK

EXTERNAL

VCO/VCXO

CHARGE

PUMP

CP

C1 C2 C3

R1

R2

AD9518-1

06430-265

Data Sheet AD9518-1

Charge Pump (CP)

The charge pump is controlled by the PFD. The PFD monitors

the phase and frequency relationship between its two inputs, and

tells the CP to pump up or pump down to charge or discharge the

integrating node (part of the loop filter). The integrated and

filtered CP current is transformed into a voltage that drives the

tuning node of the internal VCO through the LF pin (or the tuning

pin of an external VCO) to move the VCO frequency up or down.

The CP can be set (Register 0x010[6:4]) for high impedance

(allows holdover operation), for normal operation (attempts to

lock the PLL loop), for pump up, or for pump down (test modes).

The CP current is programmable in eight steps from (nominally)

600 µA to 4.8 mA. The exact value of the CP current LSB is set

by the CPRSET resistor, which is nominally 5.1 kΩ. If the value

of the resistor connected to the CP_RSET pin is doubled, the

resulting charge pump current range becomes 300 µA to 2.4 mA.

On-Chip VCO

The AD9518 includes an on-chip VCO that covers the frequency

range shown in Tabl e 2. The calibration procedure ensures that

the VCO operating voltage is centered for the desired VCO

frequency. The VCO must be calibrated when the VCO loop is

first set up, as well as any time the nominal VCO frequency

changes. However, once the VCO is calibrated, the VCO has

sufficient operating range to stay locked over temperature and

voltage extremes without needing additional calibration. See the

VCO Calibration section for more information.

The on-chip VCO is powered by an on-chip, low dropout (LDO),

linear voltage regulator. The LDO provides some isolation of

the VCO from variations in the power supply voltage level.

The BYPASS pin should be connected to ground by a 220 nF

capacitor to ensure stability. This LDO employs the same

technology used in the anyCAP® line of regulators from Analog

Devices, Inc., making it insensitive to the type of capacitor used.

Driving an external load from the BYPASS pin is not supported.

Note that the reference input signal must be present and the

VCO divider must not be static during VCO calibration.

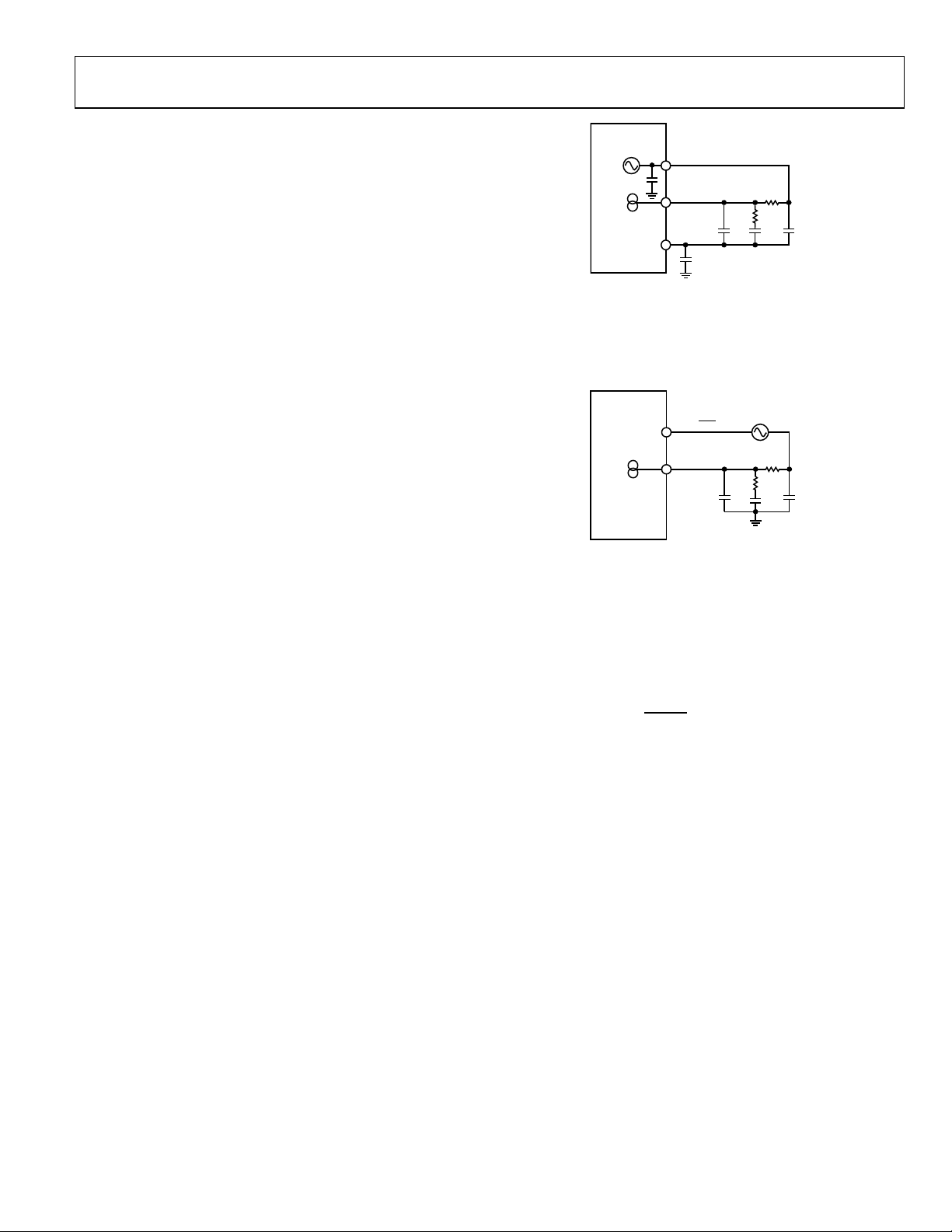

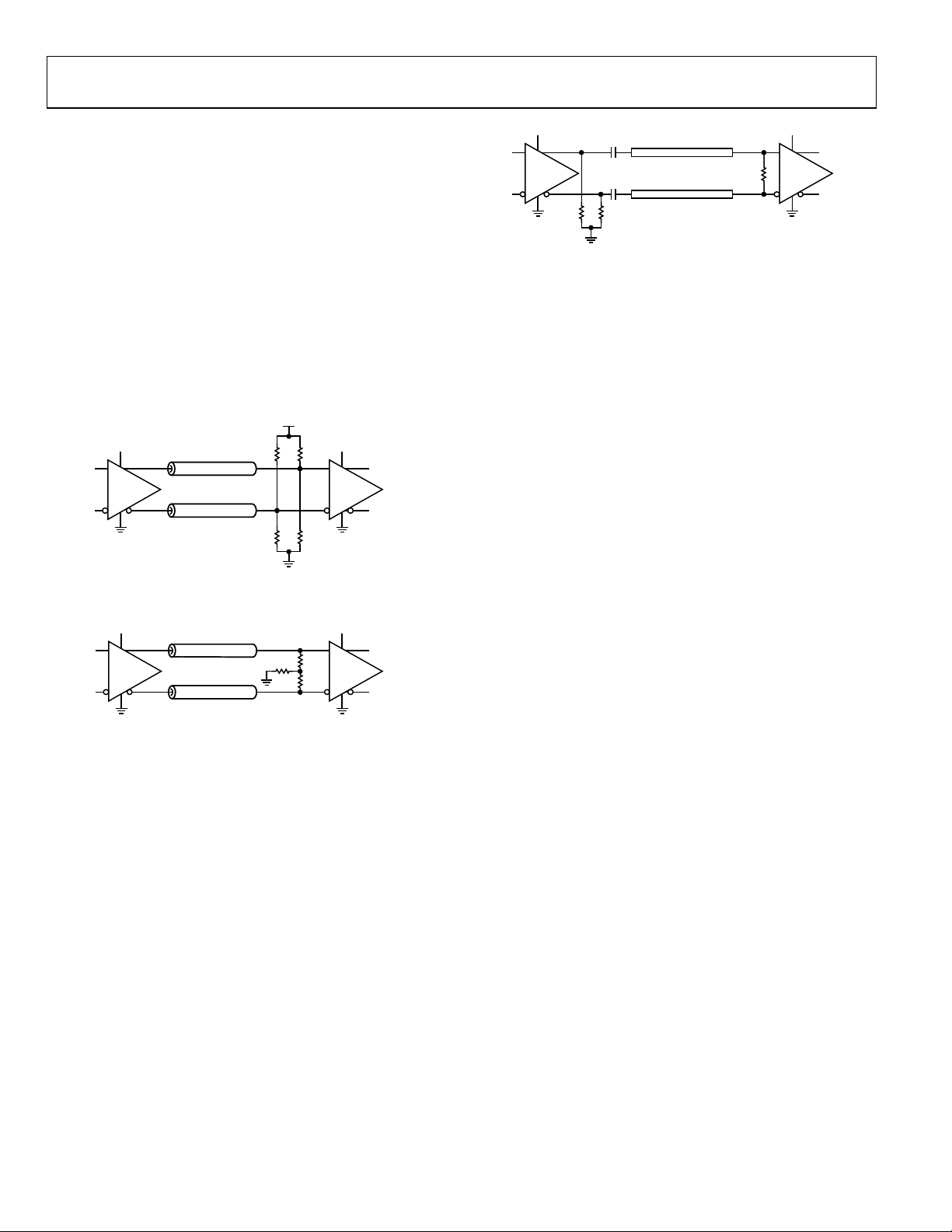

PLL External Loop Filter

When using the internal VCO, the external loop filter should

be referenced to the BYPASS pin for optimal noise and spurious

performance. An example of an external loop filter for a PLL

that uses the internal VCO is shown in Figure 32. The thirdorder design that is shown in Figure 32 usually offers the best

performance. A loop filter must be calculated for each desired

PLL configuration. The values of the components depend upon the

VCO frequency, the K

, the PFD frequency, the CP current, the

VCO

desired loop bandwidth, and the desired phase margin. The loop

filter affects the phase noise, loop settling time, and loop stability.

A basic knowledge of PLL theory is helpful for understanding loop

filter design. ADIsimCLK can help with the calculation of a loop

Rev. C | Page 27 of 64

filter according to the application requirements.

Figure 32. Example of External Loop Filter for a PLL Using the Internal VCO

When using an external VCO, the external loop filter should be

referenced to ground. See Figure 33 for an example of an external

loop filter for a PLL using an external VCO. For more information

on suggested loop filters, see the UG-075 User Guide.

Figure 33. Example of External Loop Filter for a PLL Using an External VCO

PLL Reference Inputs

The AD9518 features a flexible PLL reference input circuit that

allows either a fully differential input or two separate single-ended

inputs. The input frequency range for the reference inputs is

specified in Ta bl e 2. Both the differential and the single-ended

inputs are self-biased, allowing for easy ac coupling of input signals.

The differential input and the single-ended inputs share the

two pins, REFIN and

REFIN

(REF1 and REF2, respectively).

The desired reference input type is selected and controlled by

Register 0x01C (see Table 42 and Table 44).

When the differential reference input is selected, the self-bias

level of the two sides is offset slightly (~100 mV, see Table 2) to

prevent chattering of the input buffer when the reference is slow

or missing. This increases the voltage swing that is required of the

driver and overcomes the offset. The differential reference input

can be driven by either ac-coupl ed LVDS or ac-coupled LVPECL

signals.

The single-ended inputs can be driven by either a dc-coupled

CMOS level signal or an ac-coupled sine-wave or square wave.

Each single-ended input can be independently powered down

when not needed to increase isolation and reduce power. Either

a differential or a single-ended reference must be specifically

enabled. All PLL reference inputs are off by default.

The differential reference input is powered down whenever the

PLL is powered down, or when the differential reference input

is not selected. The single-ended buffers power down when the

PLL is powered down, and when their individual power down

registers are set. When the differential mode is selected, the

single-ended inputs are powered down.

Page 28

AD9518-1 Data Sheet

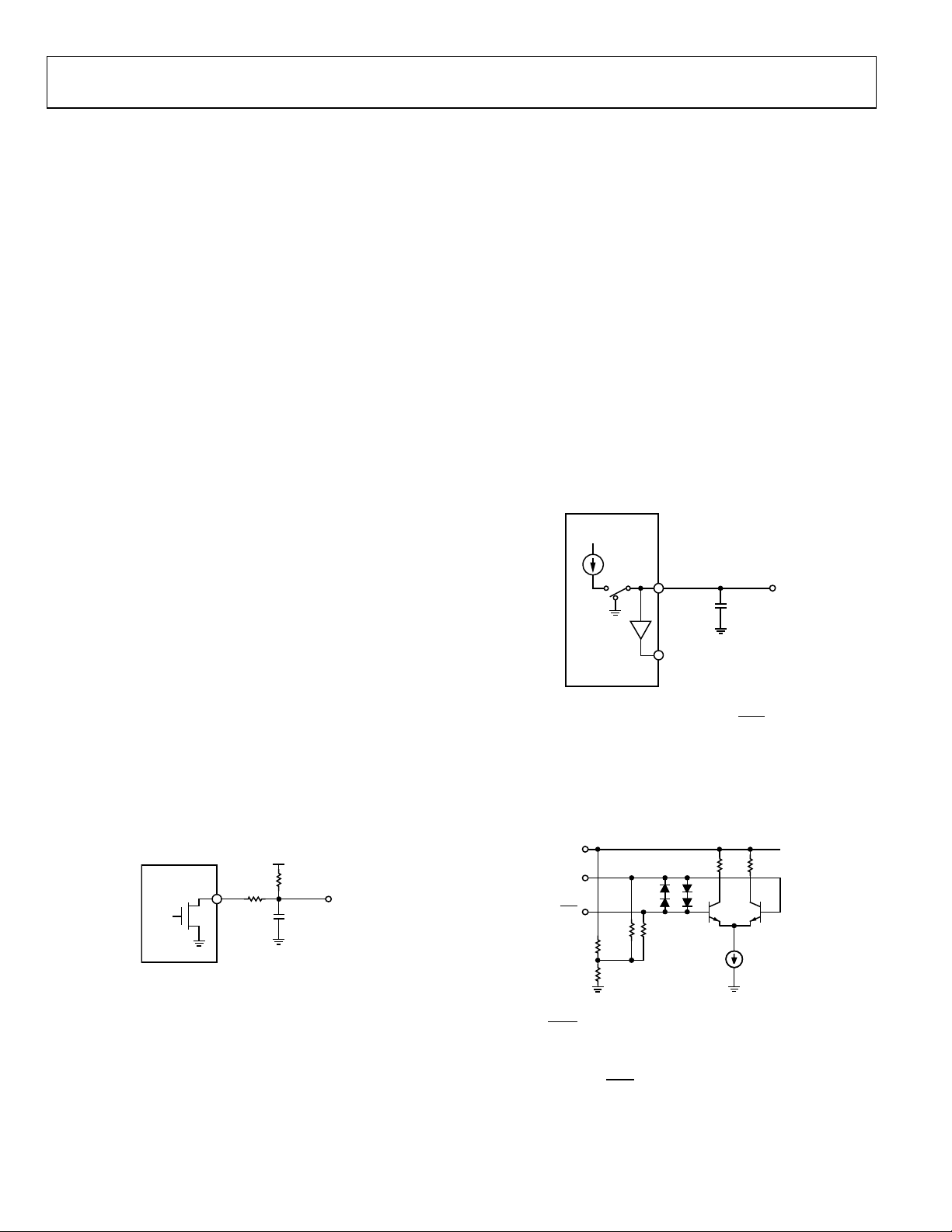

V

In differential mode, the reference input pins are internally selfbiased so that they can be ac-coupled via capacitors. It is possible

to dc couple to these inputs. If the differential REFIN is driven

by a single-ended signal, the unused side (

REFIN

) should be

decoupled via a suitable capacitor to a quiet ground. Figure 34

shows the equivalent circuit of REFIN.

S

85kΩ

REF1

V

S

REFIN

REFIN

REF2

10kΩ 12kΩ

150Ω

150Ω

10kΩ 10kΩ

V

S

85kΩ

Figure 34. REFIN Equivalent Circuit

06430-066

Reference Switchover

The AD9518 supports dual single-ended CMOS inputs, as well

as a single differential reference input. In the dual single-ended

reference mode, the AD9518 supports automatic and manual

PLL reference clock switching between REF1 (on Pin REFIN)

and REF2 (on Pin

REFIN

). This feature supports networking

and other applications that require smooth switching of redundant

references. When used in conjunction with the automatic holdover

function, the AD9518 can achieve a worst-case reference input

switchover with an output frequency disturbance as low as 10 ppm.

When using reference switchover, the single-ended reference

inputs should be dc-coupled CMOS levels and never be allowed

to go to high impedance. If these inputs are allowed to go to high

impedance, noise may cause the buffer to chatter, causing

a false detection of the presence of a reference.

Reference switchover can be performed manually or automatically. Manual switchover is performed either through

Register 0x01C or by using the REF_SEL pin. Manual switchover

requires the presence of a clock on the reference input that is

being switched to, or that the deglitching feature be disabled

(Register 0x01C[7]). The reference switching logic fails if this

condition is not met, and the PLL does not reacquire.

Automatic revertive switchover relies on the REFMON pin to

indicate when REF1 disappears. By programming Register 0x01B =

0xF7 and Register 0x01C = 0x26, the REFMON pin is programmed

to be high when REF1 is invalid, which commands the switch to

REF2. When REF1 is valid again, the REFMON pin goes low, and