Page 1

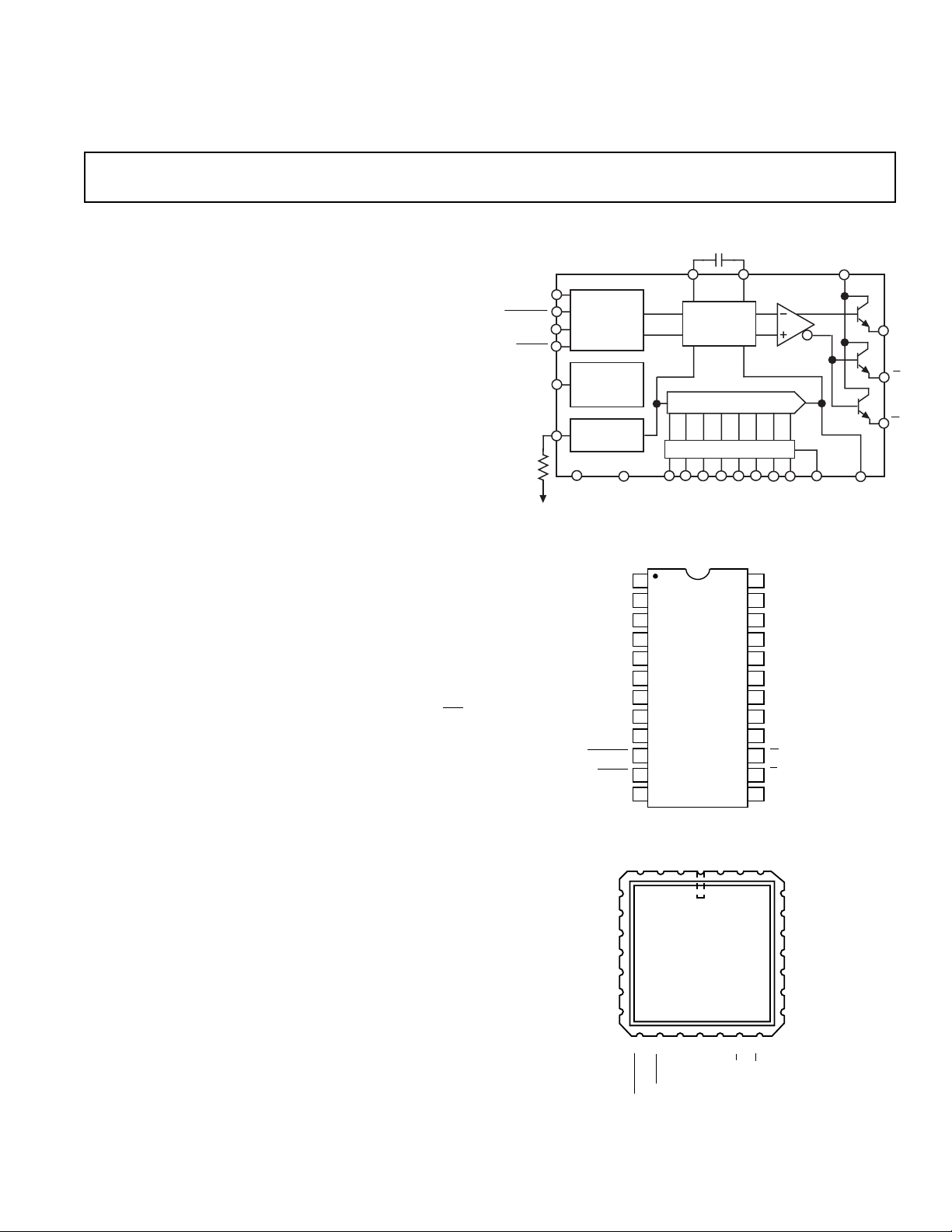

Digitally Programmable

DIFFERENTIAL

ANALOG

INPUT

STAGE

ECL

VOLTAGE

REFERENCE

REFERENCE

CURRENT

TIMING

CONTROL

CIRCUIT

OFFSET

ADJUST

LATCH

ENABLE

GROUND

ECL COMMON

Q

TRIGGER

RESET

ECL

REF

D0

(LSB)

C

S

+V

S

TRIGGER

RESET

Q

R

Q

INTERNAL DAC

TTL LATCHES

D

7

(MSB)

D

1

AD9500

C

EXT

R

SET

R

S

–V

S

–V

S

D2D3D4D5D

6

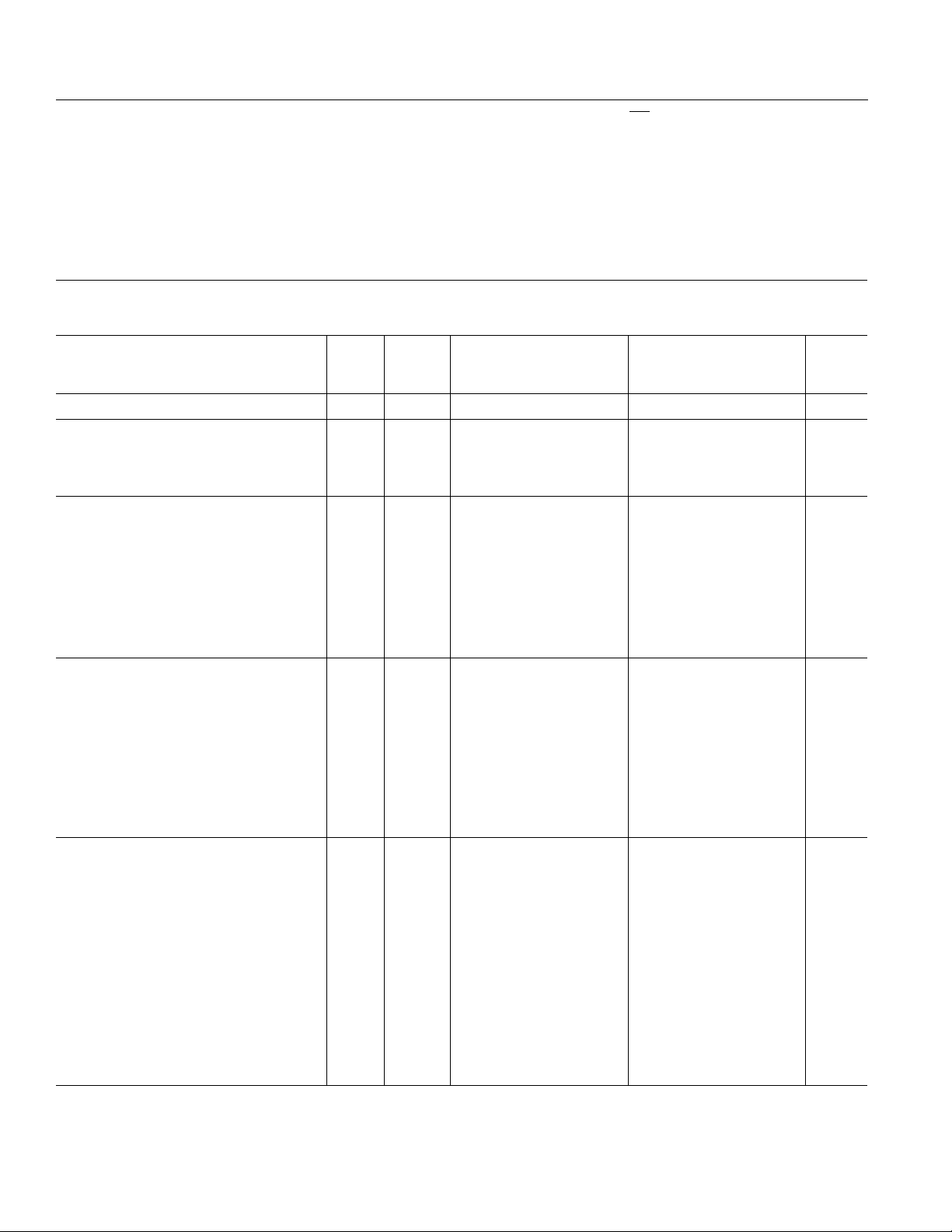

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

TOP VIEW

(Not to Scale)

D

4

D7 (MSB)

ECL

REF

OFFSET ADJUST

C

S

+V

S

D

3

D

2

D

1

D0 (LSB)

LATCH ENABLE

GROUND

R

S

–V

S

ECL COMMON

Q

TRIGGER

RESET

TRIGGER

RESET

Q

R

Q

AD9500

D

5

D

6

TOP VIEW

(Not to Scale)

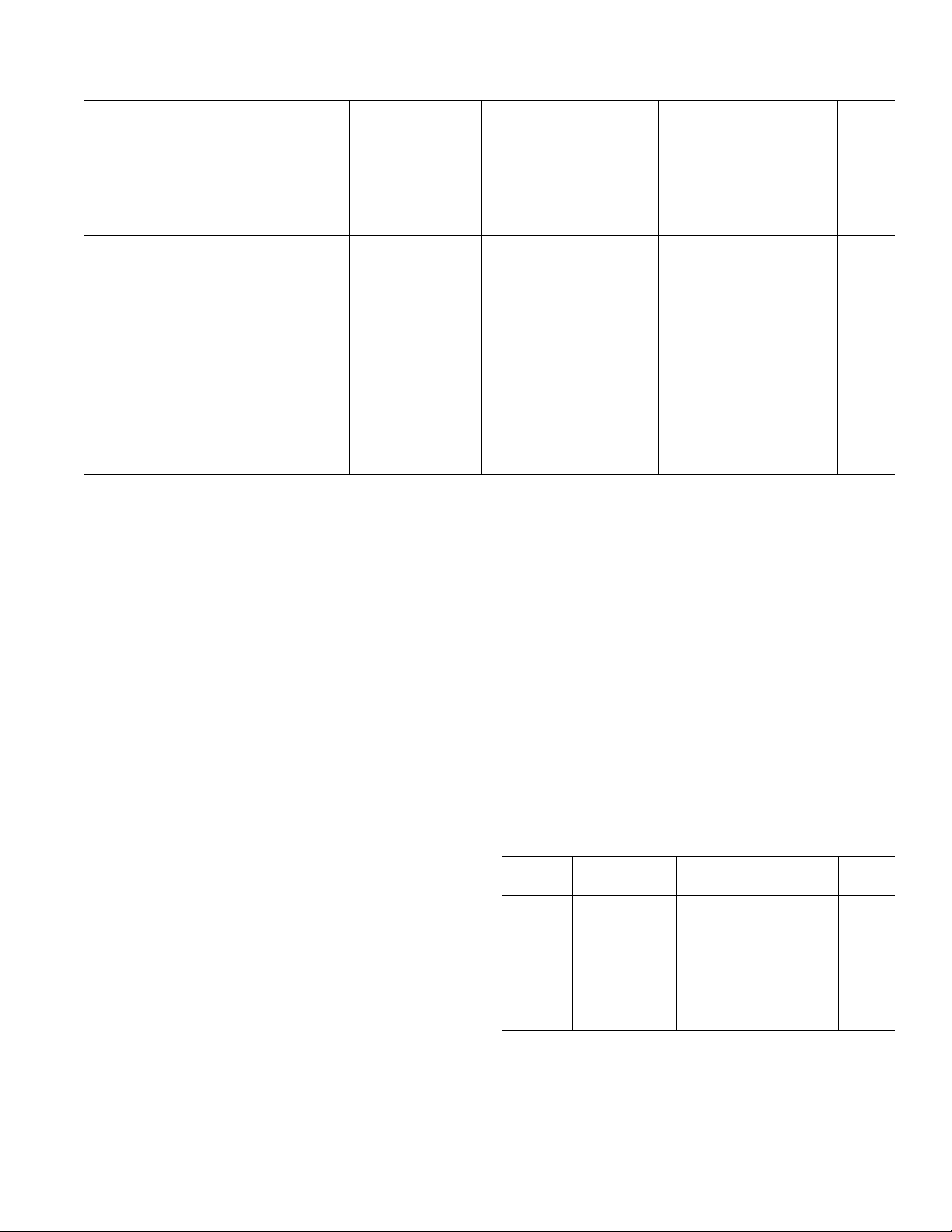

4 3 2 1 282726

12 13

14 15

16 17 18

25

24

23

22

21

20

19

5

6

7

8

9

10

11

LATCH ENABLE

GROUND

ECL COMMON

OFFSET ADJUST

TRIGGER

D7 (MSB)

ECL

REF

C

S

+V

S

Q

Q

R

RESET

TRIGGER

RESET

Q

NC

D

6

NC

NC

NC

AD9500

D

5

D

4

D

3

D

2

D

1

D0 (LSB)

R

S

–V

S

a

FEATURES

10 ps Delay Resolution

2.5 ns to 10 s Full-Scale Range

Fully Differential Inputs

Separate Trigger and Reset Inputs

Low Power Dissipation—310 mW

MIL-STD-883 Compliant Versions Available

APPLICATIONS

ATE

Pulse Deskewing

Arbitrary Waveform Generators

High Stability Timing Source

Multiple Phase Clock Generators

GENERAL DESCRIPTION

The AD9500 is a digitally programmable delay generator, which

provides programmed delays, selected through an 8-bit digital

code, in resolutions as small as 10 ps. The AD9500 is constructed in a high performance bipolar process, designed to

provide high speed operation for both digital and analog circuits.

The AD9500 employs differential TRIGGER and RESET

inputs which are designed primarily for ECL signal levels but

function with analog and TTL input levels. An onboard ECL

reference midpoint allows both of the inputs to be driven by

either single ended or differential ECL circuits. The AD9500

output is a complementary ECL stage, which also provides a

parallel output circuit to facilitate reset timing implementations.

The digital control data is passed to the AD9500 through a

transparent latch controlled by the LATCH ENABLE signal. In

the transparent mode, the internal DAC of the AD9500 will

attempt to follow changes at the inputs. The LATCH ENABLE

is otherwise used to strobe the digital data into the AD9500

latches.

The AD9500 is available as an industrial temperature range

device, –25°C to +85°C, and as an extended temperature range

device, –55°C to +125°C. Both grades are packaged in a 24-lead

cerdip (0.3" package width), as well as 28-leaded and leadless

surface mount packages. The AD9500 is available in versions

compliant with MIL-STD-883. Refer to the Analog Devices

Military Products Databook or current AD9500/883B data

sheet for detailed specifications.

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Q

Delay Generator

AD9500

FUNCTIONAL BLOCK DIAGRAM

PIN CONFIGURATIONS

R

NC = NO CONNECT

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD9500–SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

1

Positive Supply Voltage (+VS) . . . . . . . . . . . . . . . . . . . . . +7 V

Negative Supply Voltage (–V

) . . . . . . . . . . . . . . . . . . . . –7 V

S

ECL COMMON to Ground Differential . . . . –2.0 V to +5.0 V

Digital Input Voltage Range . . . . . . . . . . . . . –3.5 V to +5.0 V

Trigger/Reset Input Voltage Range . . . . . . . . . . . . . . . ±5.0 V

Trigger/Reset Differential Voltage . . . . . . . . . . . . . . . . . .5.0 V

Minimum R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 Ω

SET

Digital Output Current (

Offset Adjust Current (Sinking) . . . . . . . . . . . . . . . . . . . 4 mA

) . . . . . . . . . . . . . . . . . . . . 2 mA

Q

R

Operating Temperature Range

AD9500BP/BQ . . . . . . . . . . . . . . . . . . . . . –25°C to +85°C

AD9500TE/TQ . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . .+175°C

Lead Soldering Temperature (10 sec) . . . . . . . . . . . . .+300°C

Digital Output Current (Q and Q) . . . . . . . . . . . . . . . 30 mA

ELECTRICAL CHARACTERISTICS

2

(Supply Voltages +VS = +5.0 V, VS = –5.2 V; C

= 0 pF; R

EXT

= 500 ⍀ unless otherwise noted)

SET

–25ⴗC to +85ⴗC –55ⴗC to +125ⴗC

Test AD9500BP/BQ AD9500TE/TQ

Parameter Level Temp Min Typ Max Min Typ Max Units

RESOLUTION 8 8 Bits

ACCURACY

3

Differential Linearity I +25°C 0.5 0.5 LSB

Integral Linearity I +25°C 1.0 1.0 LSB

Monotonicity I +25°C Guaranteed Guaranteed

DIGITAL INPUT

Logic “1” Voltage VI Full 2.0 2.0 V

Logic “0” Voltage VI Full 0.8 0.8 V

Logic “1” Current VI Full 5 5 µA

Logic “0” Current VI Full 5 5 µA

Digital Input Capacitance VI +25°C 5.5 5.5 pF

Data Setup Time

Data Hold Time

Latch Pulsewidth (t

RESET/TRIGGER INPUTS

4

5

) V +25°C 3.0 3.0 ns

LPW

6

V +25°C 0.4 0.75 0.4 0.75 ns

V +25°C 0.4 0.75 0.4 0.75 ns

TRIGGER Input Voltage Range IV Full –2.5; 4.5 –2.5; 4.5 V

RESET Input Voltage Range IV Full –2.5; 2.0 –2.5; 2.0 V

Differential Switching Voltage IV Full 40 300 40 300 mV

Input Bias Current I +25°C 4050 4050µA

VI Full 75 75 µA

Input Resistance IV +25°C4 4 kΩ

Input Capacitance IV +25°C 6.5 7.25 6.5 7.25 pF

Minimum Input Pulsewidth

t

, t

TPW

RPW

DYNAMIC PERFORMANCE

Maximum Trigger Rate IV +25°C 60 60 MHz

Minimum Propagation Delay (t

Minimum Propagation Delay TC V Full 7.5 7.5 ps/°C

Full-Scale Range TC

9

Delay Uncertainty (Jitter) V +25°C10 10 ps

Reset Propagation Delay (t

Reset-to-Trigger Holdoff (t

Trigger-to-Reset Holdoff (t

Minimum Output Pulsewidth V +25°C 3.3 3.3 ns

Output Rise Time

Output Fall Time

7

7

Delay Coefficient Settling Time (t

Linear Ramp Settling Time (t

7

8

)

PD

10

)

RD

11

)

THO

12

)

RHO

DAC

) V +25°C22 22 ns

LRS

V +25°C 2.0 2.0 ns

I +25°C 5.4 6.4 7.4 5.4 6.4 7.4 ns

V Full 0.5 0.5 ps/°C

I +25°C 5.4 6.4 7.4 5.4 6.4 7.4 ns

IV +25°C 0.2 0 0.2 0 ns

IV +25°C 2.0 1.5 2.0 1.5 ns

I +25°C 2.0 2.0 ns

I +25°C 2.0 2.0 ns

13

)

V +25°C29 29 ns

REV. D–2–

Page 3

AD9500

–25ⴗC to +85ⴗC –55ⴗC to +125ⴗC

Test AD9500BP/BQ AD9500TE/TQ

Parameter Level Temp Min Typ Max Min Typ Max Units

SUPPORT FUNCTIONS

ECL

ECL

REF

Voltage Drift

REF

14

Offset Adjust Range V Full –2 –2 mA

DIGITAL OUTPUTS

7

Logic “1” Voltage VI Full –1.1 –1.1 V

Logic “0” Voltage VI Full –1.5 –1.5 V

POWER SUPPLY

15

Positive Supply Current (+5.0 V) I +25°C 2428 2428mA

Negative Supply Current (–5.2 V) I +25°C 3742 3742mA

Nominal Power Dissipation V +25°C 312 312 mW

Power Supply Rejection Ratio

16

Full-Scale Range Sensitivity I +25°C 70 300 70 300 ps/V

Minimum Propagation Delay

Sensitivity I +25°C 150 500 150 500 ps/V

NOTES

1

Absolute maximum ratings are limiting values, to be applied individually, and beyond which serviceability of the circuit may be impaired. Functional operability under

any of these conditions is not necessarily implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

2

Typical thermal impedance

24-Lead Cerdip θ

28-Leadless PLCC (Plastic) θ

28-Leaded Ceramic LCC θ

3

R

= 10 kΩ (Full-scale delay = 100 ns).

SET

4

The digital data inputs must remain stable for the specified time prior to the LATCH ENABLE signal.

5

The digital data inputs must remain stable for the specified time after the LATCH ENABLE signal.

6

The TRIGGER and RESET inputs are differential and must be driven relative to one another. Both of these inputs are ECL compatible, but can also be used with

TTL logic families in a limited fashion.

7

Outputs terminated through 50 Ω resistors to –2.0 V.

8

Program Delay = 0.0 ps (Digital Data = 00H). In Operation, any programmed delays are in addition to the Minimum Propagation Delay.

9

Change in total delay through AD9500, exclusive of changes in minimum propagation delay tPD.

10

Measured from the 50% transition point of the reset signal input, to the 50% transition point of the resetting output.

11

Minimum time from falling edge of RESET to triggering input, to ensure a valid output event.

12

Minimum time from triggering event to rising edge of RESET, to ensure a valid output event.

13

Measured from the LATCH ENABLE input to the point when the AD9500 becomes 8-bit accurate again, after a full-scale change in the programmed delay.

14

Standard 10K and 10KH ECL families operate with a 1.1 mV/°C drift by design.

15

Supply voltages should remain stable within ±5% for normal operation.

16

Measured at ±5% of –V

Specifications subject to change without notice.

and +VS.

S

= 56°C/W; θJC = 16°C/W

JA

= 60°C/W; θJC = 22°C/W

JA

= 69°C/W; θJC = 25°C/W

JA

IV +25°C –1.4 –1.3 –1.2 –1.4 –1.3 –1.2 V

V Full 1.1 1.1 mV/°C

VI Full 30 30 mA

VI Full 44 44 mA

EXPLANATION OF TEST LEVELS

Test Level

I – 100% production tested.

II – 100% production tested at +25°C, and sample tested at

specified temperatures.

III – Periodically sample tested.

IV – Parameter is guaranteed by design and characterization

testing.

V – Parameter is a typical value only.

VI – All devices are 100% production tested at +25°C. 100%

production tested at temperature extremes for extended

temperature devices; sample tested at temperature extremes for commercial/industrial devices.

REV. D

ORDERING GUIDE

Temperature Package Package

Model Ranges Descriptions Options

AD9500BP –25°C to +85°C 28-Leadless PLCC (Plastic),

Industrial Temperature P-28A

AD9500BQ –25°C to +85°C 24-Lead Cerdip,

Industrial Temperature Q-24

AD9500TE –55°C to +125°C 28-Leaded LCC,

Extended Temperature E-28A

AD9500TQ –55°C to +125°C 24-Lead Cerdip,

Extended Temperature Q-24

–3–

Page 4

AD9500

PIN FUNCTION DESCRIPTIONS

Pin Name Description

D

4–D6

D

(MSB) One of eight digital inputs used to set the programmed delay. D7 (MSB) is the most significant bit of the

7

ECL

REF

OFFSET ADJUST The OFFSET ADJUST is used to adjust the minimum propagation delay (t

C

S

+V

S

TRIGGER Noninverted input of the edge-sensitive differential trigger input stage. The output at Q will be delayed by

TRIGGER Inverted input of the edge-sensitive differential trigger input stage. The output at Q will be delayed by the

RESET Inverted input of the level-sensitive differential reset input stage. The output at Q will be reset after a signal

RESET Noninverted input of the level-sensitive differential reset input stage. The output at Q will be reset after a

Q One of two complementary ECL outputs. A “triggering” event at the inputs will produce a logic HIGH on

Q One of two complementary ECL outputs. A “triggering” event at the inputs will produce a logic LOW on

Q

R

ECL COMMON The collector common for the ECL output stage. The collector common may be tied to +5.0 V, but nor-

–V

S

R

S

GROUND The ground return for the TTL and analog inputs.

LATCH ENABLE Transparent TTL latch control line. A logic HIGH on the LATCH ENABLE freezes the digital code at the

D

(LSB) One of eight digital inputs used to set the programmed delay. D0 (LSB) is the least significant bit of the

0

D3–D

1

One of eight digital inputs used to set the programmed delay.

digital input word.

ECL midpoint reference, nominally –1.3 V. Use of the ECL

allows either of the TRIGGER or RESET

REF

inputs to be configured for single-ended ECL inputs.

), by pulling or pushing a

PD

small current out of or into the pin.

CS allows the full-scale range to be extended by using an external timing capacitor. The value of C

connected between C

See R

S

(C

INTERNAL

= 10 pF).

and +V

S

, may range from no external capacitance to 0.1 µF+.

S

EXT

,

Positive supply terminal, nominally +5.0 V.

the programmed delay, after the triggering event. The programmed delay is set by the digital input word.

The TRIGGER input must be driven in conjunction with the TRIGGER input.

programmed delay, after the triggering event. The programmed delay is set by the digital input word. The

TRIGGER input must be driven in conjunction with the TRIGGER input.

is received at the reset inputs. In the “minimum configuration,” the minimum output pulsewidth will be

equal to the “reset propagation delay,” t

. The RESET input must be driven in conjunction with the

RD

RESET input.

signal is received at the reset inputs. In the “minimum configuration,” the minimum output pulsewidth will

be equal to the “reset propagation delay,” t

. The RESET input must be driven in conjunction with the

RD

RESET input.

the Q output. A “resetting” event at the inputs will produce a logic LOW on the Q output.

the Q output. A “resetting” event at the inputs will produce a logic HIGH on the Q output.

output is parallel to the Q output. The

Q

R

ing output pulsewidths. A “triggering” event at the inputs will produce a logic LOW on the

“resetting” event at the inputs will produce a logic HIGH on the

output is typically used to drive delaying circuits for extend-

Q

R

output.

Q

R

output. A

Q

R

mally it is tied to the circuit ground for standard ECL outputs.

Negative supply terminal, nominally –5.2 V.

RS is the reference current setting terminal. An external setting resistor, R

determines the internal reference current. See C

–V

S

(250 Ω ≤ R

S

≤ 50 kΩ).

SET

, connected between RS and

SET

logic inputs. A logic LOW on the LATCH ENABLE allows the internal current levels to be continuously

updated through the logic inputs D

thru D7.

0

digital input word.

One of eight digital inputs used to set the programmed delay.

–4–

REV. D

Page 5

AD9500

DIE LAYOUT

Figure 1. System Timing Diagram

MECHANICAL INFORMATION

Die Dimensions . . . . . . . . . . . . . . . 104 ⫻ 103 ⫻ 18 (max) mils

Pad Dimensions . . . . . . . . . . . . . . . . . . . . . . . 4 ⫻ 4 (min) mils

Metalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum

Backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . None

Substrate Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–V

Passivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Oxynitride

Die Attach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gold Eutectic

Bond Wire . . . . . . . . 1.25 mil, Aluminum; Ultrasonic Bonding

S

or 1 mil, Gold; Gold Ball Bonding

REV. D

–5–

Page 6

AD9500

Figure 2. Input/Output Circuits

–6–

REV. D

Page 7

INSIDE THE AD9500

The heart of the AD9500 is the linear ramp generator. A triggering event at the input of the AD9500 initiates the ramp cycle.

As the ramp voltage falls, it will eventually go below the threshold set up by the internal DAC (digital-to-analog converter). A

comparator monitors both the linear ramp voltage and the DAC

threshold level. The output of the comparator serves as the

output for the AD9500, and the interval from the trigger until

the output switches is the total delay time of the AD9500.

The total delay through the AD9500 is made up of two components. The first is the full-scale programmed delay, t

determined by R

SET

and C

. The second component of the

EXT

D (max)

,

total delay is the minimum propagation delay through the

AD9500 (t

). The full-scale delay is variable from 2.5 ns to

PD

greater than 1 ms. The internal DAC is capable of generating

256 separate programmed delays within the full-scale range (this

gives 10 ps increments for a 2.5 ns full-scale setting).

The actual programmed delay is directly related to both the

digital control data (digital data to the internal DAC) and the

RC time constant established by R

SET

and C

. The specific

EXT

relationship is as follows:

Total Delay = Minimum Propagation Delay +

Programmed Delay

= t

+ (digital value/256) R

PD

SET

(C

+ 10 pF)

EXT

Figure 3. Typical Programmed Delay Ranges

The internal DAC determines the programmed delay by way of

the threshold level at its output. The LATCH ENABLE control

for the onboard latch is active (latches) logic “HIGH.” In the

logic “LOW” state, the latch is transparent, and the internal

DAC will attempt to follow changes at the digital data inputs.

Both the LATCH ENABLE control and the data inputs are

TTL compatible. The internal DAC may be updated at any

time, but full timing accuracy may not be attained unless triggering events are held off until after the DAC settling time

).

(t

DAC

AD9500

Figure 4. Internal Timing Diagram

On resetting, the ramp voltage held in the timing capacitor

+ 10 pF) is discharged. The AD9500 discharges the bulk

(C

EXT

of the ramp voltage very quickly, but to maintain absolute accuracy, subsequent triggering events should be held off until after

the linear ramp settling time (t

high frequency triggering at a constant rate will not be affected

by the slight settling errors since they will be constant for fixed

reset-to-trigger cycles.

The RESET and TRIGGER inputs of the AD9500 are differential and must be driven relative to one another. Accordingly, the

TRIGGER and RESET inputs are ideally suited for analog or

complementary input signals. Single-ended ECL input signals

can be accommodated by using the ECL midpoint reference

(ECL

) to drive one side of the differential inputs.

REF

The output of the AD9500 consists of both Q and Q driver

stages, as well as the

extending the output pulsewidth. In the most direct reset con-

output which is used primarily for

Q

R

figuration, either the Q or the Q output is tied to the respective

RESET input. This generates a delayed output pulse with a

duration equal to the reset delay time (t

6 ns. Note that the reset delay time (t

very small programmed delay settings. The duration of the

output pulse can be extended by driving the reset inputs with the

output through an RC network (see “Extended Output

Q

R

Pulsewidth” application). Using the

reset circuit avoids loading the Q or Q outputs.

Values in the specification table are based on 5 ns FSR test

conditions. Nearly all dynamic specifications degrade for longer

full scales. For details of performance change, request the application note “Using Digitally Programmable Delay Generators.”

). Applications which employ

LRS

) of approximately

RD

) becomes extended for

RD

output to drive the

Q

R

REV. D

–7–

Page 8

AD9500

APPLICATIONS

The AD9500 is a very versatile device that is not difficult to use.

Essentially there are only a few basic configurations which can

be extended into a number of applications. The TRIGGER and

RESET inputs of the AD9500 can be treated as single ended, or

as differential, which allows the AD9500 to operate with a wide

range of signal sources. The output pulse from the AD9500 can

be reset in one of two ways, either immediately by driving the

RESET inputs with the output itself, or in a delayed mode.

MINIMUM CONFIGURATION

The minimum configuration uses only one of the TRIGGER

inputs. The other is connected to the ECL reference midpoint,

ECL

. This allows the AD9500 to be triggered with standard

REF

10K or 10KH ECL signals. Once a triggering event occurs, the

Q output will go into the logic HIGH state, and the Q output

will go into the logic LOW state after the programmed delay.

The Q output is then used to drive the RESET input, causing

the AD9500 to reset itself. The result is a delayed output pulse

which is only as wide as the reset propagation delay (t

RD

).

the Q and the Q outputs are completely free for other uses. Q

has limited current drive; the minimum resistance for R

should

D

be 4 kΩ.

Figure 6. Extended Output Pulsewidth Configuration

MULTICHANNEL DESKEWING

Perhaps the most appropriate use of the AD9500 is in multiple

delay matching applications. Slight differences in impedance

and cable length can create large timing skews within a highspeed system. Much of this skew can be eliminated by running

each signal through an AD9500. With one line used as a standard, the programmed delays of the other AD9500s are adjusted

to eliminate the timing skews. With the very fine timing adjustments possible from the AD9500 (as small as 10 ps), nearly any

high-speed system should be able to automatically adjust itself

to extremely tight tolerances.

Figure 5. Single Input–Minimum Timing Configuration

EXTENDED OUTPUT PULSEWIDTHS

The extended pulse configuration is similar to the minimum

configuration. The difference here is that the output pulsewidth

has been extended. Operation is identical in terms of triggering

the AD9500; the functional difference is in the resetting circuit.

In this case the

through a resistor/capacitor charging network. The charging

output is used to drive the RESET input

Q

R

network will cause the signal at the RESET input to fall more

slowly, which will extend the output pulsewidth. An added

benefit of the extended pulsewidth configurations is that both

–8–

Figure 7. Multiple Delay Matching

REV. D

Page 9

AD9500

MEASURING UNKNOWN DELAYS

Two AD9500s can be combined to measure delays with a high

degree of precision. One AD9500 is set with little or no programmed delay, and its output is used to drive the unknown

delay circuit, which in turn drives the input of a “D” type flipflop. The second AD9500 is triggered along with the first, and

its output provides a clocking signal for the flip-flop. The programmed delay of the second AD9500 is then varied to detect

the output edge from the unknown delay circuit.

Detecting the output edge is relatively straightforward. If the

programmed delay through the second AD9500 is too long, the

flip-flop output will be at logic HIGH. If, on the other hand, the

programmed delay through the second AD9500 is too short, the

flip-flop output will be at logic LOW. When the programmed

delay is properly adjusted, the flip-flop will likely bounce between logic HIGH and logic LOW. The digital code value used

to create the second programmed delay is a direct indication of

the delay through the unknown circuit. The most accurate results can only be attained by calibrating the system without the

unknown delay circuit in place.

Figure 8. Measuring Unknown Delays

equals the DAC threshold. By varying the DAC threshold level

and adjusting the second AD9500 programmed delay, a point

by point reconstruction of the ac waveform can be created.

Figure 9. Measuring AC Waveforms

PROGRAMMABLE OSCILLATOR

Another interesting use of the AD9500 is in a digitally programmable oscillator. The highly accurate delays generated by the

AD9500 can be exploited to create a ring oscillator with variable

duty cycle. The delayed output of the first AD9500 is used to

drive the TRIGGER input of the second AD9500. The output

of the second AD9500, in turn, is used to drive the TRIGGER

input of the first AD9500. Together the two devices will alternately trigger each other creating two pulse chains on the outputs.

The total delay through both AD9500s combined, determines

the period of the oscillation frequency. The duty cycle can be

controlled by using the outputs to drive the SET and RESET

inputs of a flip-flop. The total delay through the first AD9500

will control the flip-flop logic LOW output pulsewidth, and the

second AD9500 will control the flip-flop logic HIGH output

pulsewidth.

MEASURING HIGH SPEED AC WAVEFORMS

The same circuitry used to measure unknown delays can be

extended to measure the time response of high speed ac waveforms. With the addition of a digital-to-analog converter and an

analog comparator, the circuit functions very much like the

previous application. The DAC sets a threshold level which

drives one of the differential comparator inputs. The other comparator input is driven by the device under test (DUT). The

output of the first AD9500 causes the DUT to produce an

output. The second AD9500, which is also triggered along with

the first AD9500, strobes the comparator latch enable.

If the DUT output is greater than the DAC threshold when the

comparator is latched, the comparator output will be at logic

HIGH. If the output is below the DAC threshold, the comparator will be at logic LOW. The programmed delay setting of the

second AD9500 is adjusted to the point where the DUT output

Figure 10. Ring Oscillator

REV. D

–9–

Page 10

AD9500

LAYOUT CONSIDERATIONS

The AD9500 is a precision timing device, and as such high

frequency design techniques must be employed to achieve the

best performance. The use of a low impedance ground plane is

particularly important. Ideally the ground plane should be on

the component side of the layout and extend under the

AD9500, to shield it from system timing signals. Sockets pose a

special problem for a circuit like the AD9500 because of the

additional inter-lead capacitance they create. If sockets must be

used, pin sockets are generally preferred. Power supply decou-

pling is also critical to a high-speed design; a 0.1 µF ceramic

capacitor and a 0.01 µF mica capacitor for both power supplies

should be very effective. DAC threshold stability can be improved

by decoupling the OFFSET ADJUST pin to +5.0 V (note that this

will lengthen the DAC settling time, t

DELAY OFFSET ADJUSTMENTS

DAC

)

As the full-scale delay is increased, a component of the minimum propagation delay also increases. This is caused by the

additional time required by the ramp (now with a much “flatter”

slope) to fall below the DAC threshold corresponding to the

minimum propagation delay (t

). One means of decreasing the

PD

minimum propagation delay (when the full-scale delay, set by

R

SET

and C

is large) is to offset the internal DAC threshold

EXT

toward the initial ramp levels, thus reducing the time for the

internal ramp to cross the threshold once the AD9500 is triggered.

GENERAL PERFORMANCE ENHANCEMENTS

High speed operation is generally more consistent if C

EXT

is

kept small (i.e., no external capacitor) to maintain small discharge time constants. Integral linearity, however, benefits from

larger values of C

by buffering small system spikes and

EXT

surges. Another means of improving integral linearity is to draw

a small current (≈200 µA) out of the OFFSET ADJUST pin

with a 47 kΩ pull-down resistor. This has the effect of moving

the internal DAC reference levels into a relatively more linear

region of the ramp. This technique is generally only useful for

small full-scale delay configurations. Its use with larger full-scale

delays will extend the minimum propagation delay (t

). A pull-

PD

up resistor to +5.0 V creates the opposite effect by reducing the

minimum propagation delay (t

reset propagation delay (t

) at the expense of increased

PD

) and degraded linearity (see OFF-

RD

SET matching circuit).

Caution should be used when applying high slew rate data at the

inputs of the AD9500. For data inputs with slew rates in excess

of 1 V/ns, a 100 Ω series resistor should be utilized in the data

path.

An external DAC can be used with the AD9500 for increased

resolution and higher update rates. For the most part, a standard ECL DAC, operating between +5.0 V and ground, should

work with the AD9500. The output of the external DAC must

be connected to the OFFSET ADJUST pin of the AD9500 with

the internal DAC turned off (D

thru D7 at logic LOW). For

0

normal operation, the external DAC output should range from

0 mA to –2 mA (sinking).

Figure 11. The Offset Adjust Pin Can Be Used to Match

Several AD9500s

The DAC levels are offset toward the initial ramp level by injecting a small current into the offset adjust pin. Note, however,

that the ramp start-up region is less linear than the later portions

of the ramp, which is the primary reason for the built-in offset.

If the minimum propagation delay is kept above 5 ns (the linear

portion of the ramp), no significant degradation in linearity

should result. This concept can be extended to match the actual

propagation delays of several AD9500s, by injecting or sinking

a small current (<2 mA) into or out of each of the OFFSET

ADJUST pins.

–10–

Figure 12. Operation with External DAC

REV. D

Page 11

OUTLINE DIMENSIONS

1

28

5

11

12

18

26

BOTTOM

VIEW

19

4

25

0.028 (0.71)

0.022 (0.56)

45° TYP

0.015 (0.38)

MIN

0.055 (1.40)

0.045 (1.14)

0.050

(1.27)

BSC

0.075

(1.91)

REF

0.011 (0.28)

0.007 (0.18)

R TYP

0.095 (2.41)

0.075 (1.90)

0.150

(3.51)

BSC

0.300 (7.62)

BSC

0.200

(5.08)

BSC

0.075

(1.91)

REF

0.458 (11.63)

0.442 (11.23)

SQ

0.458

(11.63)

MAX

SQ

0.100 (2.54)

0.064 (1.63)

0.088 (2.24)

0.054 (1.37)

Dimensions shown in inches and (mm).

24-Lead Cerdip

(Q-24)

0.005 (0.13) MIN 0.098 (2.49) MAX

AD9500

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

24

1

PIN 1

0.023 (0.58)

0.014 (0.36)

1.280 (32.51) MAX

0.100 (2.54)

BSC

28-Leaded LCC

(E-28A)

13

12

0.070 (1.78)

0.030 (0.76)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15°

0°

C1137d–0–4/99

0.015 (0.38)

0.008 (0.20)

REV. D

0.048 (1.21)

0.042 (1.07)

0.048 (1.21)

0.042 (1.07)

0.020

(0.50)

R

4

5

IDENTIFIER

TOP VIEW

(PINS DOWN)

11

12

0.456 (11.58)

0.450 (11.43)

0.495 (12.57)

0.485 (12.32)

28-Leadless PLCC

(P-28A)

0.056 (1.42)

0.042 (1.07)

26

25

PIN 1

0.050

(1.27)

BSC

19

18

SQ

SQ

–11–

0.180 (4.57)

0.165 (4.19)

0.110 (2.79)

0.085 (2.16)

0.025 (0.63)

0.015 (0.38)

0.021 (0.53)

0.013 (0.33)

0.032 (0.81)

0.026 (0.66)

0.040 (1.01)

0.025 (0.64)

0.430 (10.92)

0.390 (9.91)

PRINTED IN U.S.A.

Loading...

Loading...