Page 1

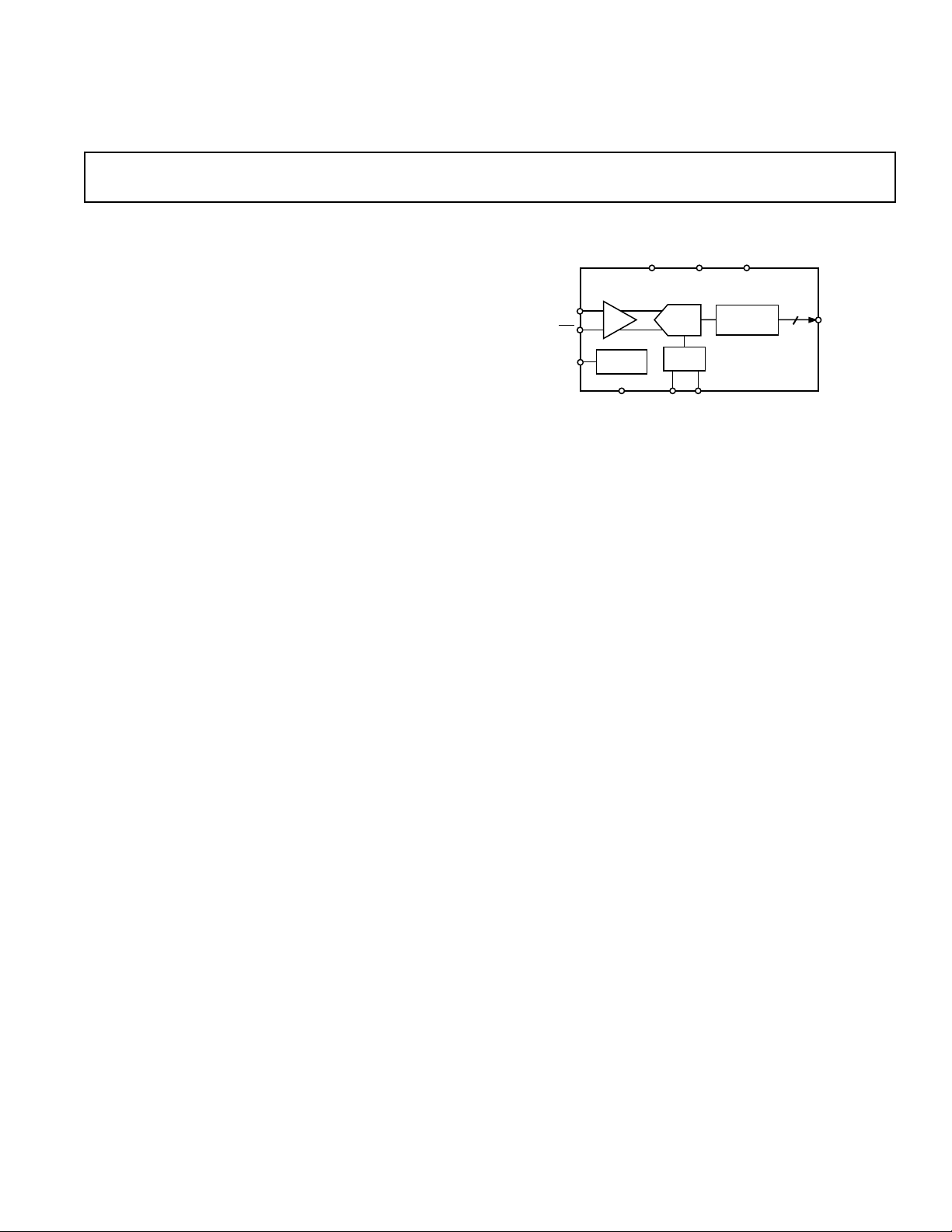

8-Bit, 50 MSPS/80 MSPS/100 MSPS

REF

TIMING

V

D

PWRDWN

V

DD

A

IN

GND

REF

OUT

REF

IN

ADC

OUTPUT

STAGING

ENCODE

AD9283

8

D7–D0

T/H

A

IN

a

FEATURES

8-Bit, 50, 80 and 100 MSPS ADC

Low Power: 90 mW at 100 MSPS

On-Chip Reference and Track/Hold

475 MHz Analog Bandwidth

SNR = 46.5 dB @ 41 MHz at 100 MSPS

1 V p-p Analog Input Range

Single +3.0 V Supply Operation (2.7 V–3.6 V)

Power-Down Mode: 4.2 mW

APPLICATIONS

Battery Powered Instruments

Hand-Held Scopemeters

Low Cost Digital Oscilloscopes

GENERAL DESCRIPTION

The AD9283 is an 8-bit monolithic sampling analog-to-digital

converter with an on-chip track-and-hold circuit and is optimized for low cost, low power, small size and ease of use. The

product operates at a 100 MSPS conversion rate, with outstanding dynamic performance over its full operating range.

The ADC requires only a single 3.0 V (2.7 V to 3.6 V) power

supply and an encode clock for full performance operation. No

external reference or driver components are required for many

applications. The digital outputs are TTL/CMOS compatible

and a separate output power supply pin supports interfacing

with 3.3 V or 2.5 V logic.

3 V A/D Converter

AD9283

FUNCTIONAL BLOCK DIAGRAM

The encoder input is TTL/CMOS compatible. A power-down

function may be exercised to bring total consumption to

4.2 mW. In power-down mode, the digital outputs are driven

to a high impedance state.

Fabricated on an advanced CMOS process, the AD9283 is

available in a 20-lead surface mount plastic package (SSOP)

specified over the industrial temperature range (–40°C to +85°C).

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

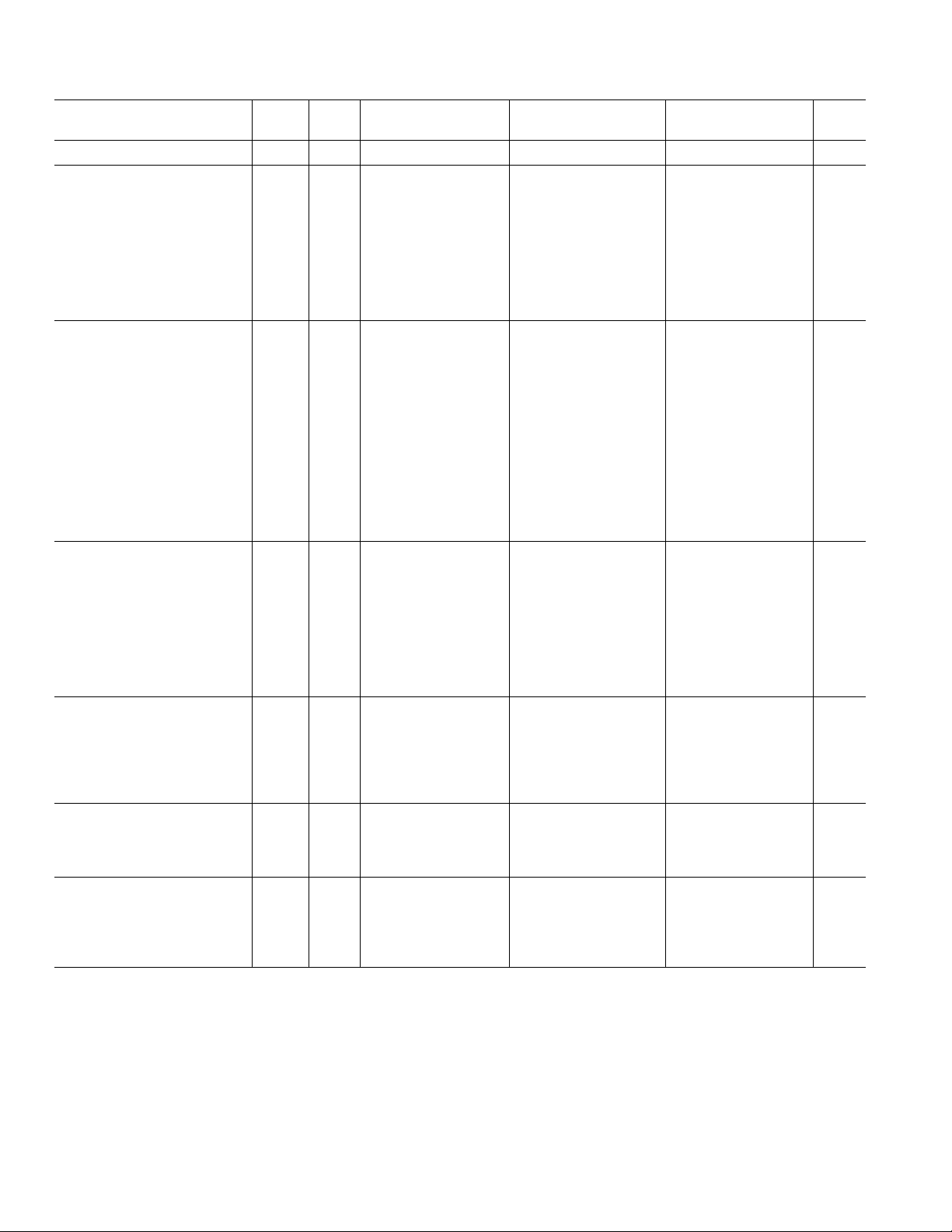

AD9283–SPECIFICATIONS

(VDD = 3.0 V, VD = 3.0 V; single-ended input; external reference, unless otherwise noted)

Test AD9283BRS-100 AD9283BRS-80 AD9283BRS-50

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Units

RESOLUTION 8 8 8 Bits

DC ACCURACY

Differential Nonlinearity +25°CI ±0.5 +1.25 ±0.5 +1.25 ±0.5 +1.25 LSB

Full VI +1.50 +1.50 +1.50 LSB

Integral Nonlinearity +25°C I –1.25 ±0.75 +1.25 –1.25 ±0.75 +1.25 –1.25 ± 0.75 +1.25 LSB

Full VI +2.25 +1.50 +1.50 LSB

No Missing Codes Full VI Guaranteed Guaranteed Guaranteed

Gain Error

Gain Tempco

1

1

+25°CI –6 ±2.5 +6 –6 ±2.5 +6 –6 ±2.5 +6 % FS

Full VI –8 +8 –8 +8 –8 +8 % FS

Full VI 80 80 80 ppm/°C

ANALOG INPUT

Input Voltage Range

(With Respect to A

) Full V ±512 ±512 ±512 mV p-p

IN

Common-Mode Voltage Full V ±200 ±200 ±200 mV

Input Offset Voltage +25°C I –35 ±10 35 –35 ±10 35 –35 ±10 35 mV

Full VI ±40 ±40 ±40 mV

Reference Voltage Full VI 1.2 1.25 1.3 1.2 1.25 1.3 1.2 1.25 1.3 V

Reference Tempco Full VI ±130 ±130 ±130 ppm/°C

Input Resistance +25°C I 7 10 13 7 10 13 7 10 13 kΩ

Full VI 5 16 5 16 5 16 kΩ

Input Capacitance +25°CV222pF

Full VI µA

Analog Bandwidth, Full Power +25°C V 475 475 475 MHz

SWITCHING PERFORMANCE

Maximum Conversion Rate Full VI 100 80 50 MSPS

Minimum Conversion Rate +25°CIV111MSPS

Encode Pulsewidth High (t

Encode Pulsewidth Low (t

Aperture Delay (t

) +25°CV000ns

A

Aperture Uncertainty (Jitter) +25°C V 5 5 5 ps rms

Output Valid Time (t

) +25°C IV 4.3 1000 5.0 1000 8.0 1000 ns

EH

) +25°C IV 4.3 1000 5.0 1000 8.0 1000 ns

EL

2

)

V

Full VI 2.0 3.0 2.0 3.0 2.0 3.0 ns

Output Propagation Delay (tPD)2Full VI 4.5 7.0 4.5 7.0 4.5 7.0 ns

DIGITAL INPUTS

Logic “1” Voltage Full VI 2.0 2.0 2.0 V

Logic “0” Voltage Full VI 0.8 0.8 0.8 V

Logic “1” Current Full VI ±1 ±1 ±1 µA

Logic “0” Current Full VI ±1 ±1 ±1 µA

Input Capacitance +25°C V 2.0 2.0 2.0 pF

DIGITAL OUTPUTS

Logic “1” Voltage Full VI 2.95 2.95 2.95 V

Logic “0” Voltage Full VI 0.05 0.05 0.05 V

Output Coding Offset Binary Code Offset Binary Code Offset Binary Code

POWER SUPPLY

Power Dissipation

3, 4

Full VI 90 120 90 115 80 100 mW

Power-Down Dissipation Full VI 4.2 7 4.2 7 4.2 7 mW

Power Supply Rejection Ratio

(PSRR) +25°C I 18 18 18 mV/V

–2– REV. B

Page 3

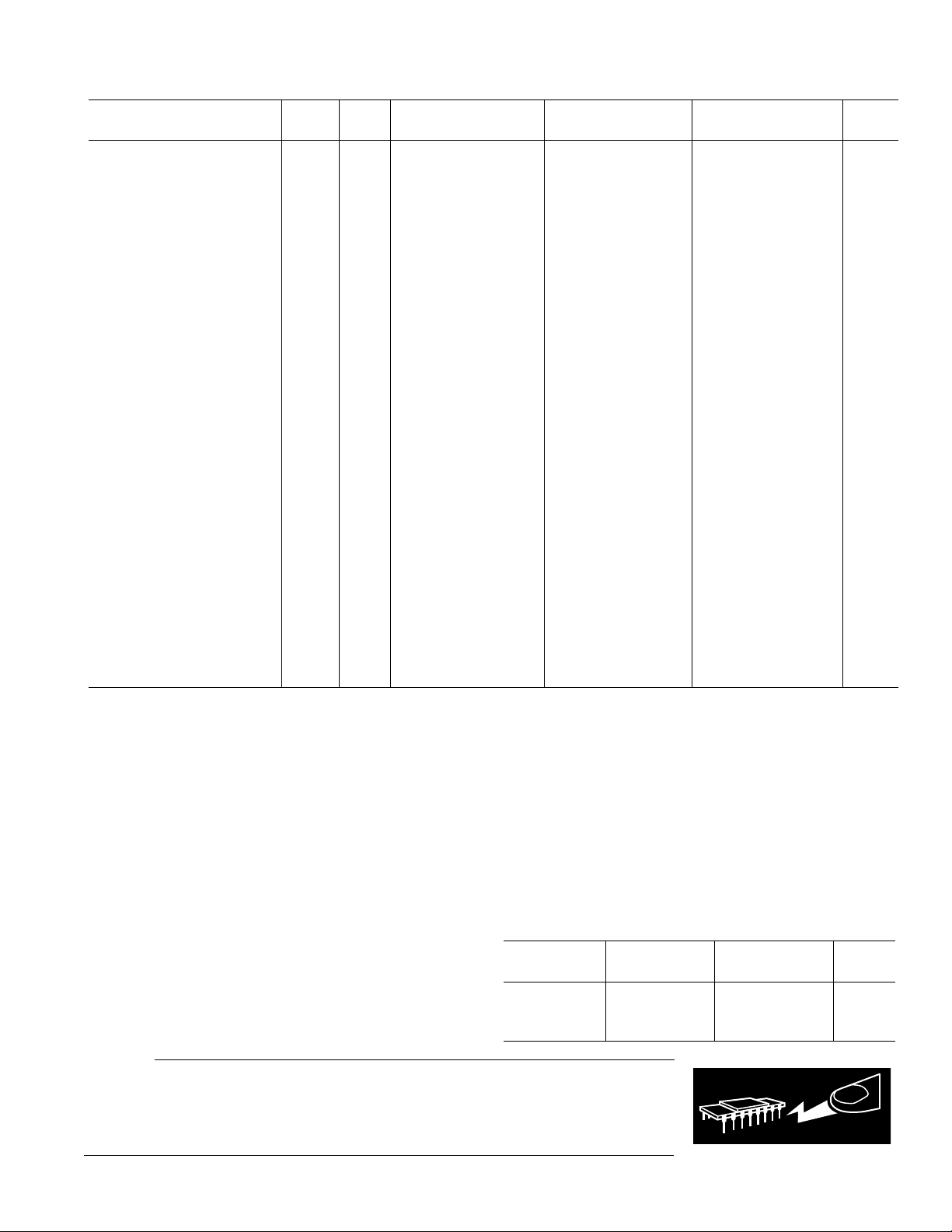

AD9283

WARNING!

ESD SENSITIVE DEVICE

Test AD9283BRS-100 AD9283BRS-80 AD9283BRS-50

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Units

DYNAMIC PERFORMANCE

Transient Response +25°CV 2 2 2 ns

Overvoltage Recovery Time +25°CV 2 2 2 ns

Signal-to-Noise Ratio (SNR)

(Without Harmonics)

= 10.3 MHz +25°C I 46.5 47 44 47 dB

f

IN

= 27 MHz +25°C I 46.5 44 47 47 dB

f

IN

= 41 MHz +25°C I 43.5 46.5 47 dB

f

IN

= 76 MHz +25°C V 46.0 dB

f

IN

Signal-to-Noise Ratio (SINAD)

(With Harmonics)

= 10.3 MHz +25°C I 45 47 43.5 46.5 dB

f

IN

= 27 MHz +25°C I 45.5 43.5 46.5 46 dB

f

IN

= 41 MHz +25°C I 42.5 45 42 dB

f

IN

= 76 MHz +25°C V 42.5 dB

f

IN

Effective Number of Bits

= 10.3 MHz +25°C I 7.3 7.5 7.6 Bits

f

IN

= 27 MHz +25°C I 7.4 7.5 7.5 Bits

f

IN

= 41 MHz +25°C I 7.3 7.5 Bits

f

IN

= 76 MHz +25°C V 6.9 Bits

f

IN

2nd Harmonic Distortion

= 10.3 MHz +25°C I 57 60 55 60 dBc

f

IN

= 27 MHz +25°C I 60 55 60 56 dBc

f

IN

= 41 MHz +25°C I 50 58 55 dBc

f

IN

= 76 MHz +25°CV 46 dBc

f

IN

3rd Harmonic Distortion

= 10.3 MHz +25°C I 54.5 70 55 70 dBc

f

IN

= 27 MHz +25°C I 55 55 62.5 60 dBc

f

IN

= 41 MHz +25°C I 47 52.5 60 dBc

f

IN

= 76 MHz +25°CV 53 dBc

f

IN

Two-Tone Intermod Distortion

(IMD)

f

= 10.3 MHz +25°C V 52 52 52 dBc

IN

NOTES

1

Gain error and gain temperature coefficient are based on the ADC only (with a fixed 1.25 V external reference).

2

tV and tPD are measured from the 1.5 V level of the ENCODE input to the 50%/50% levels of the digital outputs swing. The digital output load during test is not to

exceed an ac load of 10 pF or a dc current of ± 40 µA.

3

Power dissipation measured with encode at rated speed and a dc analog input.

4

Typical thermal impedance for the RS style (SSOP) 20-lead package: θJC = 46°C/W, θCA = 80°C/W, θJA = 126°C/W.

5

SNR/harmonics based on an analog input voltage of –0.7 dBFS referenced to a 1.024 V full-scale input range.

Specifications subject to change without notice.

5

ABSOLUTE MAXIMUM RATINGS*

VD, VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +4 V

Analog Inputs . . . . . . . . . . . . . . . . . . . . –0.5 V to V

Digital Inputs . . . . . . . . . . . . . . . . . . . –0.5 V to V

VREF IN . . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to V

+ 0.5 V

D

+ 0.5 V

DD

+ 0.5 V

D

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Operating Temperature . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . +175°C

Maximum Case Temperature . . . . . . . . . . . . . . . . . . +150°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions outside of those indicated in the operation

sections of this specification is not implied. Exposure to absolute maximum

ratings for extended periods may affect device reliability.

ORDERING GUIDE

Temperature Package Package

Model Ranges Descriptions Options

AD9283BRS

-50, -80, -100 –40°C to +85°C 20-Lead SSOP RS-20

AD9283/PCB +25°C Evaluation Board

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9283 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. B

Page 4

AD9283

EXPLANATION OF TEST LEVELS

Test Level

I 100% production tested.

II 100% production tested at +25°C and sample tested at

specified temperatures.

III Sample tested only.

IV Parameter is guaranteed by design and characterization

testing.

V Parameter is a typical value only.

VI 100% production tested at +25°C; guaranteed by design

and characterization testing for industrial temperature

range; 100% production tested at temperature extremes for

military devices.

PIN CONFIGURATION

VREF IN

GND

A

A

GND

1

2

3

4

5

V

D

6

IN

7

IN

8

V

D

9

10

PWRDWN

VREF OUT

ENCODE

Table I. Output Coding (VREF = +1.25 V)

Step AIN–A

IN

255 0.512 1111 1111

• ••

• ••

128 0.002 1000 0000

127 –0.002 0111 1111

• ••

• ••

0 –0.512 0000 0000

20

D0 (LSB)

19

D1

18

D2

17

D3

16

15

14

13

12

11

GND

V

DD

D4

D5

D6

D7 (MSB)

AD9283

TOP VIEW

(Not to Scale)

Digital Output

PIN FUNCTION DESCRIPTIONS

Pin Number Name Function

1 PWRDWN Power-down function select; Logic HIGH for power-down mode (digital outputs go to

high impedance state).

2 VREF OUT Internal Reference Output (+1.25 V typ); Bypass with 0.1 µF to Ground.

3 VREF IN Reference Input for ADC (+1.25 V typ).

4, 9, 16 GND Ground.

5, 8 V

6A

D

IN

Analog +3 V Power Supply.

Analog Input for ADC (Can be left open if operating in single-ended mode, but recom-

mend connection to a 0.1 µF capacitor and a 25 Ω resistor in series to ground for better

input matching).

7A

IN

Analog Input for ADC

10 ENCODE Encode Clock for ADC (ADC samples on rising edge of ENCODE).

11–14, 17–20 D7–D4, D3–D0 Digital Outputs of ADC.

15 V

DD

Digital output power supply. Nominally +2.5 V to +3.6 V.

–4– REV. B

Page 5

AD9283

OUT

V

DD

33.3kV

A

IN

14.3kV

A

ENCODE

D7–D0

SAMPLE N

IN

t

A

t

EH

SAMPLE N+1

t

EL

DATA N–4 DATA N–3 DATA N–2 DATA N–1 DATA N DATA N+1

Figure 2. Equivalent Analog Input Circuit

1/

SAMPLE N+2

fS

SAMPLE N+3

Figure 1. Timing Diagram

V

DD

33.3kV

A

IN

14.3kV

SAMPLE N+4

t

PD

SAMPLE N+5

t

V

Figure 5. Equivalent Digital Output Circuit

V

D

V

BIAS

REF IN

Figure 3. Equivalent Reference Input Circuit

V

D

ENCODE

Figure 4. Equivalent Encode Input Circuit

V

D

OUT

Figure 6. Equivalent Reference Output Circuit

–5–REV. B

Page 6

AD9283

FREQUENCY – A

IN

10 20 30 40 50 60 80 100

70

65

dB

45

40

30

55

50

60

2ND

3RD

35

ENCODE = 100 MSPS

FREQUENCY

0

–10

–90

dB

–50

–60

–70

–80

–30

–40

–20

ENCODE = 100 MSPS

A

IN

1 = 9MHz

A

IN

2 = 10MHz

IMD = 52dBc

FREQUENCY

10 20 30 40 50 60 80 90

55

dB

45

40

35

30

50

100

SNR

SINAD

ENCODE = 100 MSPS

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

FREQUENCY

ENCODE = 100 MSPS

A

= 10.3MHz

IN

SNR = 46.5dB

SINAD = 45dB

2nd = 57dBc

3rd = 54.5dBc

Figure 7. Spectrum: fS = 100 MSPS, fIN = 10.3 MHz

0

ENCODE = 100 MSPS

–10

A

= 41MHz

IN

SNR = 46.5dB

–20

SINAD = 45dB

2nd = 58dBc

–30

3rd = 52.5dBc

–40

dB

–50

–60

–70

–80

–90

Figure 8. Spectrum: fS = 100 MSPS, fIN = 40 MHz

0

ENCODE = 100 MSPS

–10

A

= 76MHz

IN

SNR = 46dB

–20

SINAD = 42.5dB

2nd = 46dBc

–30

3rd = 53dBc

–40

dB

–50

–60

–70

–80

–90

Figure 9. Spectrum: fS = 100 MSPS, fIN = 76 MHz

Figure 10. Harmonic Distortion vs. AIN Frequency

FREQUENCY

Figure 11. Two-Tone Intermodulation Distortion

FREQUENCY

Figure 12. SINAD/SNR vs. AIN Frequency

–6– REV. B

Page 7

AD9283

ENCODE RATE

10 20 30 40 50 60 70 80

120

POWER – mW

40

20

0

80

60

100

90 100

AIN = 10.3MHz

TEMPERATURE – 8C

–40 –20 0 20 40 60 80

49

48

dB

44

46

45

47

–60 100

SINAD

SNR

CODE

1.00

0.75

LSB

–0.25

–0.50

–0.75

–1.00

0.25

0.00

0.50

49

48

47

46

dB

45

44

43

10 100

SNR

SINAD

20 30 40 50 60 70 80 90

ENCODE RATE

AIN = 10.3MHz

Figure 13. SINAD/SNR vs. Encode Rate

dB

60

50

SNR

40

30

SINAD

ENCODE = 100 MSPS

AIN = 10.3MHz

Figure 16. Analog Power Dissipation vs. Encode Rate

20

10

0

6.5 6 4.5 4

7 5.5 5 3.5 3

ENCODE PULSEWIDTH HIGH – ns

Figure 14. SINAD/SNR vs. Encode Pulsewidth High

0.5

0.0

–0.5

–1.0

–1.5

–2.0

–2.5

dB

–3.0

–3.5

–4.0

–4.5

–5.0

–5.5

0

100 200 300 400 500

Figure 15. ADC Frequency Response: fS = 100 MSPS

BANDWIDTH – MHz

Figure 17. SINAD/SNR vs. Temperature

600

Figure 18. Differential Nonlinearity

–7–REV. B

Page 8

AD9283

2.0

1.5

1.0

0.5

0.0

LSB

–0.5

–1.0

–1.5

–2.0

CODE

Figure 19. Integral Nonlinearity

APPLICATIONS

Theory of Operation

The analog signal is applied differentially or single-endedly to

the inputs of the AD9283. The signal is buffered and fed forward to an on-chip sample-and-hold circuit. The ADC core

architecture is a bit-per-stage pipeline type converter utilizing

switch capacitor techniques. The bit-per-stage blocks determine

the 5 MSBs and drive a FLASH converter to encode the 3 LSBs.

Each of the 5 MSB stages provides sufficient overlap and error

correction to allow optimization of performance with respect to

comparator accuracy. The output staging block aligns the data,

carries out the error correction and feeds the data to the eight

output buffers. The AD9283 includes an on-chip reference

(nominally 1.25 V) and generates all clocking signals from one

externally applied encode command. This makes the ADC easy

to interface with and requires very few external components for

operation.

ENCODE Input

The ENCODE input is fully TTL/CMOS compatible with a

nominal threshold of 1.5 V. Care was taken on the chip to

match clock line delays and maintain sharp clock logic transitions. Any high speed A/D converter is extremely sensitive to

the quality of the sampling clock provided by the user. This

ADC uses an on-chip sample-and-hold circuit which is essentially a mixer. Any timing jitter on the ENCODE will be combined with the desired signal and degrade the high frequency

performance of the ADC. The user is advised to give commensurate thought to the clock source.

Analog Input

The analog input to the ADC is fully differential and both inputs are internally biased. This allows the most flexible use of ac

or dc and differential or single-ended input modes. For peak

performance the inputs are biased at 0.3 × V

. See the specifi-

D

cation table for allowable common-mode range when dc coupling the input. The inputs are also buffered to reduce the load

the user needs to drive. For best dynamic performance, the

impedances at A

and AIN should be matched. The importance

IN

of this increases with sampling rate and analog input frequency.

The nominal input range is 1.024 V p-p.

Digital Outputs

The digital outputs are TTL/CMOS compatible. The output

buffers are powered from a separate supply, allowing adjustment

of the output voltage swing to ease interfacing with 2.5 V or

3.3 V logic. The AD9283 goes into a low power state within two

clock cycles following the assertion of the PWRDWN input.

PWRDWN is asserted with a logic high. During power-down

the outputs transition to a high impedance state. The time it

takes to achieve optimal performance after disabling the powerdown mode is approximately 15 clock cycles. Care should be

taken when loading the digital outputs of any high speed ADC.

Large output loads create current transients on the chip that can

degrade the converter’s performance.

Voltage Reference

A stable and accurate 1.25 V voltage reference is built into the

AD9283 (VREF OUT). In normal operation, the internal reference is used by strapping Pins 2 and 3 of the AD9283 together.

The input range can be adjusted by varying the reference voltage applied to the AD9283. No degradation in performance

occurs when the reference is adjusted ±5%. The full-scale range

of the ADC tracks reference voltage changes linearly. Whether

used or not, the internal reference (Pin 2) should be bypassed

with a 0.1 µF capacitor to ground.

Timing

The AD9283 provides latched data outputs with four pipeline

delays. Data outputs are available one propagation delay (t

PD

)

after the rising edge of the encode command (Figure 1. Timing

Diagram). The minimum guaranteed conversion rate to the

ADC is 1 MSPS. The dynamic performance of the converter

will degrade at encode rates below this sample rate.

Evaluation Board

The AD9283 evaluation board offers an easy way to test the

AD9283. It only requires a 3 V supply, an analog input and

encode clock to test the AD9283. The board is shipped with the

100 MSPS grade ADC.

The analog input to the board accepts a 1 V p-p signal centered

at ground. J1 should be used (Jump E3–E4, E18–E19) to drive

the ADC through Transformer T1. J2 should be used for singleended input drive (Jump E19–E21).

Both J1 and J2 are terminated to 50 Ω on the PCB. Each analog

path is ac-coupled to an on-chip resistor divider which provides

the required dc bias.

A (TTL/CMOS Level) sample clock is applied to connector

J3 which is terminated through 50 Ω on the PCB. This clock is

buffered by U5 which also provides the clocks for the 574

latches, DAC, and the off-card latch clock CLKCON. (Timing

can be modified at E17.)

There is a reconstruction DAC (AD9760) on the PCB. The

DAC is on the board to assist in debug only—the outputs

should not be used to measure performance of the ADC.

–8– REV. B

Page 9

AD9283

Figure 20. Printed Circuit Board Top Side Silkscreen

Figure 21. Printed Circuit Board Bottom Side Silkscreen

Figure 22. Printed Circuit Board Top Side Copper

Figure 23. Printed Circuit Board “Split” Power Layer

–9–REV. B

Page 10

AD9283

Figure 24. Printed Circuit Board Ground Layer

EVALUATION BOARD BILL OF MATERIALS — GS01717

# QTY REFDES DEVICE PACKAGE VALUE

1 15 C1, C4–C17 Ceramic Cap 0603 0.1 µF

2 4 C18–C21 Tantalum Cap BCAPTAJD 10 µF

3 24 E1–E6, E8–E10, E12–E19,

E21, E34–E39 W-HOLE

4 4 J1, J2, J3, J5 Connector SMB

5 1 P1 5-Pin Connector Wieland Connector

6 1 P2 37-Pin Connector AMP-747462-2

7 5 R4, R9, R10, R21, R22 Resistor 1206 50

8 1 R7 Resistor 1206 25

9 1 R23 Resistor 1206 2K

10 1 T1 Transformer Mini-Circuits T1-1T-KK81

11 1 U1 AD9283 SSOP-20

12 1 U3 AD9760 SOIC-28

13 1 U4 74ACQ574 SOIC-20

14 1 U5 SN74LVC86 SO14

Figure 25. Printed Circuit Board Bottom Side Copper

(P/N #25.602.2553.0 Top

P/N #Z5.530.0525.0 Bottom)

–10– REV. B

Page 11

123456789

C21

10mF

VDAC

C20

10mF

VDL

C19

10mF

VD

C18

10mF

VA

PWDN

E8

E9

VA

P1

CLKCON

VDL

C16

0.1mF

201918171615141312

VCC

U4

74ACQ574

OUT_END0D1D2D3D4D5D6D7

123456789

20

19

18

D0

D1

U1

AD9283

PWDN

REFOUT

1

2

3

E1 E2

E5E6

E10

VDL VDAC

12345

VA VD GND

101112131415161718192021222324252627282930313233343536

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

CLKLAT

C11

0.1mF

Q0Q1Q2Q3Q4Q5Q6

VD

C9

0.1mF

17

16

15

D2

REFIN

C5

D3

GND

4

0.1mF

5

GND

VA

VDD

AIN

6

C1

0.1mF

11

Q7

CLOCK

GND

10

14

13

12

D4

D5

D6

AIN

VA1

VA

8

C4

C8

VA

T1

J1

GND

9

0.1mF

0.1mF

C6

321

456

E4

E3

0.1mF

7

E38

E39

C10

E37

E35

0.1mF

CLKDAC

28272625242322212019181716

CLK

U3

AD9760

DB9

123456789

DA7

C13

U5

R9

50V

E36

E34

11

D7

10

ENC

R7

25V

C7

0.1mF

C17

0.1mF

E19

E18

E21

J2

R4

50V

37

VDAC

DVDD

DCOM

DB8

DB7

DA6

DA5

0.1mF

VCC

SN74LVC86

J3

VDAC

P2

C37DRPF

J5

0.1mF

AVDD

COMP2

DB5

DB4

DA3

DA2

VDL

4A4Y3B

ENC

R10

C14

IOUTA

IOUTB

DB3

DB2

DA1

DA0

VDL

E13

E14

CLKLAT

CLKCON

E17E15

VDL

50V

0.1mF

ACOM

DB1

E12

3A

E16

C15

NC5

DB6

DA4

131412111098

4B

1B1A1Y2A2B2YGND

2134567

R21

50V

R22

50V

VDAC

FSADJ

COMP1

DB0

NC1

101112

CLKDAC

3Y

AD9283

R23

2kV

C12

15

REFIO

SLEEP

REFLO

NC2

NC3

NC4

14

13

0.1mF

Figure 26. Printed Circuit Board Schematic

–11–REV. B

Page 12

AD9283

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Shrink Small Outline Package (SSOP)

(RS-20)

0.295 (7.50)

0.271 (6.90)

20 11

C3389b–0–9/99

0.311 (7.9)

0.301 (7.64)

0.078 (1.98)

0.068 (1.73)

0.008 (0.203)

0.002 (0.050)

PIN 1

0.0256

(0.65)

BSC

101

0.07 (1.78)

0.066 (1.67)

SEATING

PLANE

0.212 (5.38)

0.205 (5.21)

0.009 (0.229)

0.005 (0.127)

8°

0°

0.037 (0.94)

0.022 (0.559)

–12–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...