Page 1

High-Speed Oversampling CMOS

ADC with 16-Bit Resolution

a

FEATURES

Monolithic 16-Bit, Oversampled A/D Converter

8 Oversampling Mode, 20 MSPS Clock

2.5 MHz Output Word Rate

1.01 MHz Signal Passband w/0.004 dB Ripple

Signal-to-Noise Ratio: 88.5 dB

Total Harmonic Distortion: –96 dB

Spurious Free Dynamic Range: 100 dB

Input Referred Noise: 0.6 LSB

Selectable Oversampling Ratio: 1, 2, 4, 8

Selectable Power Dissipation: 150 mW to 585 mW

85 dB Stopband Attenuation

0.004 dB Passband Ripple

Linear Phase

Single +5 V Analog Supply, +5 V/+3 V Digital Supply

Synchronize Capability for Parallel ADC Interface

Twos-Complement Output Data

44-Lead MQFP

at a 2.5 MHz Output Word Rate

AD9260

FUNCTIONAL BLOCK DIAGRAM

VINA

VINB

REF TOP

REF

BOTTOM

COMMON

MODE

VREF

SENSE

REFCOM

AVSS

AVDD

MULTIBIT

SIGMA-DELTA

MODULATOR

AD9260

REFERENCE

BUFFER

BANDGAP

REFERENCE

AVDD

AVSS

RESET/

AVSS

AVDD

12-BIT: 20MHz

16-BIT: 10MHz

16-BIT: 5MHz

16-BIT: 2.5MHz

BIAS

CIRCUIT

SYNC

DVSS DVDD

DIGITAL

DEMODULATOR

STAGE 1:2X

DECIMATION

FILTER

STAGE 2:2X

DECIMATION

FILTER

STAGE 3:2X

DECIMATION

FILTER

CLOCK

BUFFER

MODE

REGISTER

DRVSS

DRVDD

OUTPUT REGISTER

OUTPUT MODE MULTIPLEXER

OTR

BIT1–BIT16

DAV

READ

PRODUCT DESCRIPTION

The AD9260 is a 16-bit, high-speed oversampled analog-todigital converter (ADC) that offers exceptional dynamic range

over a wide bandwidth. The AD9260 is manufactured on an

advanced CMOS process. High dynamic range is achieved with

an oversampling ratio of 8× through the use of a proprietary

technique that combines the advantages of sigma-delta and

pipeline converter technologies.

The AD9260 is a switched-capacitor ADC with a nominal fullscale input range of 4 V. It offers a differential input with 60 dB

of common-mode rejection of common-mode signals. The signal range of each differential input is ±1 V centered on a 2.0 V

common-mode level.

The on-chip decimation filter is configured for maximum performance and flexibility. A series of three half-band FIR filter

stages provide 8× decimation filtering with 85 dB of stopband

attenuation and 0.004 dB of passband ripple. An onboard digital multiplexer allows the user to access data from the various

stages of the decimation filter.

The on-chip programmable reference and reference buffer amplifier are configured for maximum accuracy and flexibility. An

external reference can also be chosen to suit the user’s specific

dc accuracy and drift requirements.

MODECLKBIAS ADJUST

CS

The AD9260 operates on a single +5 V supply, typically consuming 585 mW of power. A power scaling circuit is provided

allowing the AD9260 to operate at power consumption levels as

low as 150 mW at reduced clock and data rates. The AD9260 is

available in a 44-lead MQFP package and is specified to operate

over the industrial temperature range.

PRODUCT HIGHLIGHTS

The AD9260 is fabricated on a very cost effective CMOS

process. High-speed, precision mixed-signal analog circuits are

combined with high-density digital filter circuits.

The AD9260 offers a complete single-chip 16-bit sampling

ADC with a 2.5 MHz output data rate in a 44-lead MQFP.

Selectable Internal Decimation Filtering—The AD9260

provides a high-performance decimation filter with 0.004 dB

passband ripple and 85 dB of stopband attenuation. The filter

is configurable with options for 1×, 2×, 4×, and 8× decimation.

Power Scaling—The AD9260 consumes a low 585 mW of power

at 16-bit resolution and 2.5 MHz output data rate. Its power

can be scaled down to as low as 150 mW at reduced clock rates.

Single Supply— Both of the analog and digital portions of the

AD9260 can operate off of a single +5 V supply simplifying

system power supply design. The digital logic will also accommodate a single +3 V supply for reduced power.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

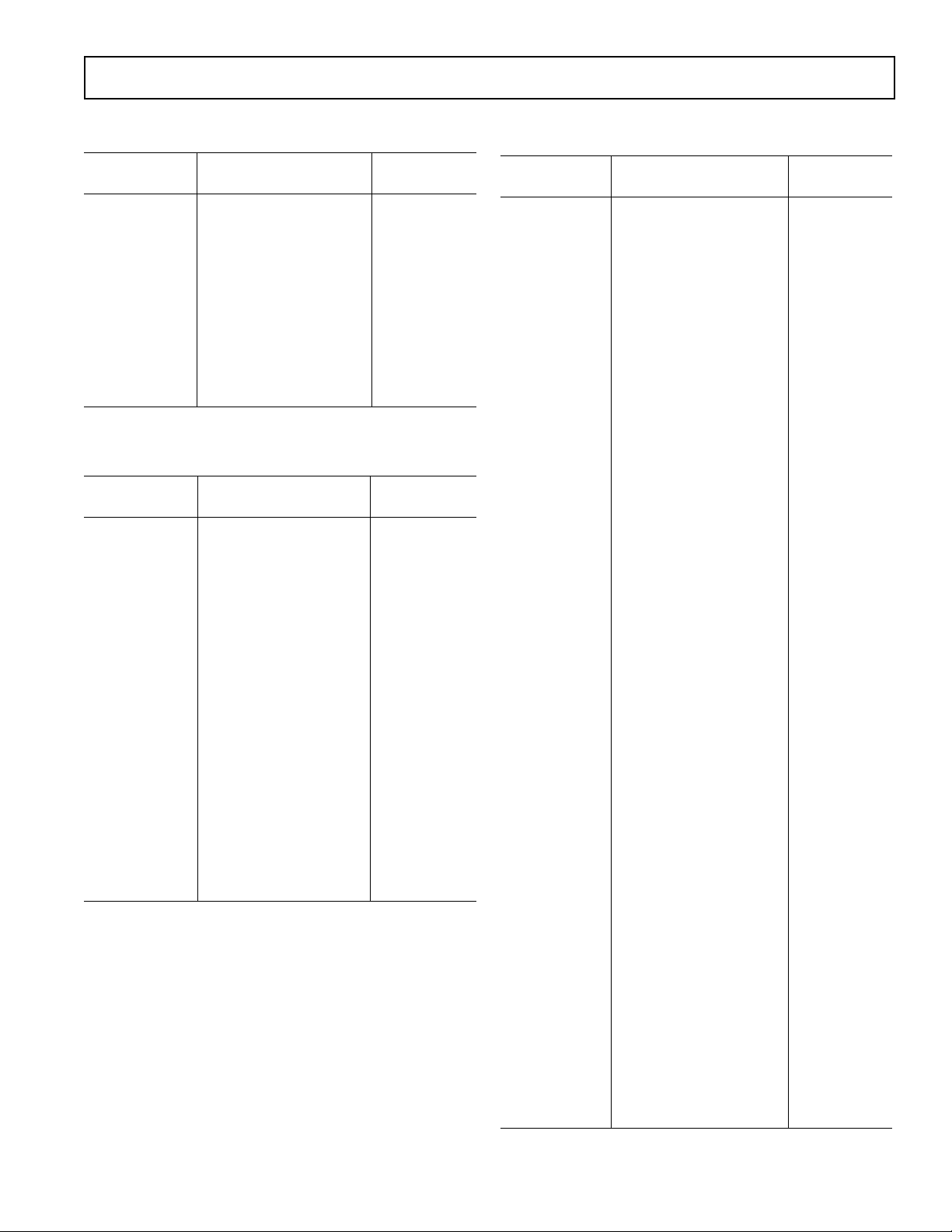

Page 2

AD9260–SPECIFICATIONS

CLOCK INPUT FREQUENCY RANGE

Parameter—Decimation Factor (N) AD9260 (8) AD9260 (4) AD9260 (2) AD9260 (1) Units

CLOCK INPUT (Modulator Sample Rate, f

)1111kHz min

CLOCK

20 20 20 20 MHz max

OUTPUT WORD RATE (FS = f

/N) 0.125 0.250 0.500 1 kHz min

CLOCK

2.5 5 10 20 MHz max

Specifications subject to change without notice

(AVDD = +5 V, DVDD = +3 V, DRVDD = +3 V, f

DC SPECIFICATIONS

P

arameter—Decimation Factor (N) AD9260 (8) AD9260 (4) AD9260 (2) AD9260 (1) Units

unless otherwise noted, R

BIAS

= 2 k)

= 20 MSPS, V

CLOCK

= +2.5 V, Input CML = 2.0 V T

REF

MIN

to T

RESOLUTION 16 16 16 12 Bits min

INPUT REFERRED NOISE (TYP)

1.0 V Reference 1.40 2.4 6.0 1.3 LSB rms typ

2.5 V Reference

1

0.68 (90.6) 1.2 (86) 3.7 (76) 1.0 (63.2) LSB rms typ (dB typ)

ACCURACY

Integral Nonlinearity (INL) ± 0.75 ± 0.75 ± 0.75 ± 0.3 LSB typ

Differential Nonlinearity (DNL) ±0.50 ± 0.50 ± 0.50 ± 0.25 LSB typ

No Missing Codes 16 16 16 12 Bits Guaranteed

Offset Error 0.9 (0.5) (0.5) (0.5) (0.5) % FSR max (typ @ +25°C)

Gain Error

Gain Error

2

3

2.75 (0.66) (0.66) (0.66) (0.66) % FSR max (typ @ +25°C)

1.35 (0.7) (0.7) (0.7) (0.7) % FSR max (typ @ +25°C)

TEMPERATURE DRIFT

Offset Error 2.5 2.5 2.5 2.5 ppm/°C typ

Gain Error

Gain Error

2

3

22 22 22 22 ppm/°C typ

7.0 7.0 7.0 7.0 ppm/°C typ

MAX

POWER SUPPLY REJECTION

AVDD, DVDD, DRVDD (+5 V ± 0.25 V) 0.06 0.06 0.06 0.06 % FSR max

ANALOG INPUT

Input Span

= 1.0 V 1.6 1.6 1.6 1.6 V p-p Diff. max

V

REF

= 2.5 V 4.0 4.0 4.0 4.0 V p-p Diff. max

V

REF

Input (VINA or VINB) Range +0.5 +0.5 +0.5 +0.5 V min

+AVDD – 0.5 +AVDD – 0.5 +AVDD – 0.5 +AVDD – 0.5 V max

Input Capacitance 10.2 10.2 10.2 10.2 pF typ

INTERNAL VOLTAGE REFERENCE

Output Voltage (1 V Mode) 1111 V typ

Output Voltage Error (1 V Mode) ± 14 ±14 ± 14 ±14 mV max

Output Voltage (2.5 V Mode) 2.5 2.5 2.5 2.5 V typ

Output Voltage Error (2.5 V Mode) ± 35 ± 35 ± 35 ± 35 mV max

Load Regulation

4

1 V REF 0.5 0.5 0.5 0.5 mV max

2.5 V REF 2.0 2.0 2.0 2.0 mV max

REFERENCE INPUT RESISTANCE 8888 kΩ

–2–

REV. B

Page 3

P

arameter—Decimation Factor (N) AD9260 (8) AD9260 (4) AD9260 (2) AD9260 (1) Units

POWER SUPPLIES

Supply Voltages

AVDD +5 +5 +5 +5 V (± 5%)

DVDD and DRVDD +5.5 +5.5 +5.5 +5.5 V max

+2.7 +2.7 +2.7 +2.7 V min

Supply Current

IAVDD 115 115 115 115 mA typ

134 mA max

IDVDD 12.5 10.3 6.5 2.4 mA typ

3.5 mA max

IDRVDD 0.450 0.850 1.7 2.6 mA typ

POWER CONSUMPTION 613 608 600 585 mW typ

630 mW max

NOTES

1

VINA and VINB Connect to DUT CML.

2

Including Internal 2.5 V reference.

3

Excluding Internal 2.5 V reference.

4

Load regulation with 1 mA load Current (in addition to that required by AD9260).

Specifications subject to change without notice.

AC SPECIFICATIONS

(AVDD = +5 V, DVDD = +3 V, DRVDD = +3 V, f

unless otherwise noted, R

= 2 k)

BIAS

= 20 MSPS, V

CLOCK

= +2.5 V, Input CML = 2.0 V T

REF

Parameter—Decimation Factor (N) AD9260(8) AD9260(4) AD9260(2) AD9260(1) Units

DYNAMIC PERFORMANCE

INPUT TEST FREQUENCY: 100 kHz (typ)

Signal-to-Noise Ratio (SNR)

Input Amplitude = –0.5 dBFS 88.5 82 74 63 dB typ

Input Amplitude = –6.0 dBFS 82.5 78 68 58 dB typ

SNR and Distortion (SINAD)

Input Amplitude = –0.5 dBFS 87.5 82 74 63 dB typ

Input Amplitude = –6.0 dBFS 82 77.5 69 58 dB typ

Total Harmonic Distortion (THD)

Input Amplitude = –0.5 dBFS –96 –96 –97 –98 dB typ

Input Amplitude = –6.0 dBFS –93 –98 –96 –98 dB typ

Spurious Free Dynamic Range (SFDR)

Input Amplitude = –0.5 dBFS 100 98 98 88 dB typ

Input Amplitude = –6.0 dBFS 94 100 94 84 dB typ

INPUT TEST FREQUENCY: 500 kHz

Signal-to-Noise Ratio (SNR)

Input Amplitude = –0.5 dBFS 86.5 82 74 63 dB typ

80.5 dB min

Input Amplitude = –6.0 dBFS 82.5 77 68 58 dB typ

SNR and Distortion (SINAD)

Input Amplitude = –0.5 dBFS 86.0 81 74 63 dB typ

80.0 dB min

Input Amplitude = –6.0 dBFS 82.0 77 68 58 dB typ

Total Harmonic Distortion (THD)

Input Amplitude = –0.5 dBFS –97.0 –92 –89 –86 dB typ

–90.0 dB max

Input Amplitude = –6.0 dBFS –95.5 –96 –89 –86 dB typ

Spurious Free Dynamic Range (SFDR)

Input Amplitude = –0.5 dBFS 99.0 92 91 88 dB typ

90.0 dB max

Input Amplitude = –6.0 dBFS 98 100 91 82 dB typ

AD9260

to T

MIN

MAX

–3–REV. B

Page 4

AD9260–SPECIFICATIONS

AC SPECIFICATIONS (Continued)

Parameter—Decimation Factor (N) AD9260 (8) AD9260 (4) AD9260 (2) AD9260 (1) Units

DYNAMIC PERFORMANCE (Continued)

INPUT TEST FREQUENCY: 1.0 MHz (typ)

Signal-to-Noise Ratio (SNR)

Input Amplitude = –0.5 dBFS 85 82 74 63 dB typ

Input Amplitude = –6.0 dBFS 80 76 68 58 dB typ

SNR and Distortion (SINAD)

Input Amplitude = –0.5 dBFS 84.5 81 74 63 dB typ

Input Amplitude = –6.0 dBFS 80 76 69 58 dB typ

Total Harmonic Distortion (THD)

Input Amplitude = –0.5 dBFS –102 –96 –82 –79 dB typ

Input Amplitude = –6.0 dBFS –96 –94 –84 –77 dB typ

Spurious Free Dynamic Range (SFDR)

Input Amplitude = –0.5 dBFS 105 98 83 80 dB typ

Input Amplitude = –6.0 dBFS 98 96 87 80 dB typ

INPUT TEST FREQUENCY: 2.0 MHz (typ)

Signal-to-Noise Ratio (SNR)

Input Amplitude = –0.5 dBFS 82 74 63 dB typ

Input Amplitude = –6.0 dBFS 76 68 58 dB typ

SNR and Distortion (SINAD)

Input Amplitude = –0.5 dBFS 81 73 62 dB typ

Input Amplitude = –6.0 dBFS 76 69 58 dB typ

Total Harmonic Distortion (THD)

Input Amplitude = –0.5 dBFS –101 –80 –75 dB typ

Input Amplitude = –6.0 dBFS –95 –80 –76 dB typ

Spurious Free Dynamic Range (SFDR)

Input Amplitude = –0.5 dBFS 104 80 78 dB typ

Input Amplitude = –6.0 dBFS 100 83 79 dB typ

INPUT TEST FREQUENCY: 5.0 MHz (typ)

Signal-to-Noise Ratio (SNR)

Input Amplitude = –0.5 dBFS 59 dB typ

Input Amplitude = –6.0 dBFS 57 dB typ

SNR and Distortion (SINAD)

Input Amplitude = –0.5 dBFS 58 dB typ

Input Amplitude = –6.0 dBFS 57 dB typ

Total Harmonic Distortion (THD)

Input Amplitude = –0.5 dBFS –58 dB typ

Input Amplitude = –6.0 dBFS –67 dB typ

Spurious Free Dynamic Range (SFDR)

Input Amplitude = –0.5 dBFS 59 dB typ

Input Amplitude = –6.0 dBFS 70 dB typ

INTERMODULATION DISTORTION

1 = 475 kHz, fIN2 = 525 kHz –93 –91 –91 –83 dBFS typ

f

IN

fIN1 = 950 kHz, fIN2 = 1.050 MHz –95 –86 –85 –83 dBFS typ

DYNAMIC CHARACTERISTICS

Full Power Bandwidth 75 75 75 75 MHz typ

Small Signal Bandwidth (AIN = –20 dBFS) 75 75 75 75 MHz typ

Aperture Jitter 2222ps rms typ

Specifications subject to change without notice.

–4–

REV. B

Page 5

AD9260

DIGITAL FILTER CHARACTERISTICS

Parameter AD9260 Units

8× DECIMATION (N = 8)

Passband Ripple 0.00125 dB max

Stopband Attenuation 82.5 dB min

Passband 0 MHz min

0.605 × (f

Stopband 1.870 × (f

18.130 × (f

Passband/Transition Band Frequency

(–0.1 dB Point) 0.807 × (f

(–3.0 dB Point) 1.136 × (f

Absolute Group Delay

Group Delay Variation 0 µs max

Settling Time (to ±0.0007%)

1

1

13.55 × (20 MHz/f

24.2 × (20 MHz/f

4× DECIMATION (N = 4)

Passband Ripple 0.001 dB max

Stopband Attenuation 82.5 dB min

Passband 0 MHz min

1.24 × (f

Stopband 3.75 × (f

16.25 × (f

Passband/Transition Band Frequency

(–0.1 dB Point) 1.61 × (f

(–3.0 dB Point) 2.272 × (f

Absolute Group Delay

Group Delay Variation 0 µs max

Settling Time (to ±0.0007%)

1

1

2.90 × (20 MHz/f

5.05 × (20 MHz/f

2× DECIMATION (N = 2)

Passband Ripple 0.0005 dB max

Stopband Attenuation 85.5 dB min

Passband 0 MHz min

2.491 × (f

Stopband 7.519 × (f

12.481 × (f

Passband/Transition Band Frequency

(–0.1 dB Point) 3.231 × (f

(–3.0 dB Point) 4.535 × (f

Absolute Group Delay

Group Delay Variation 0 µs max

Settling Time (to ±0.0007%)

1

1

0.80 × (20 MHz/f

1.40 × (20 MHz/f

1× DECIMATION (N = 1)

Propagation Delay: t

PROP

13 ns max

Absolute Group Delay (225 × (20 MHz/f

NOTES

1

To determine “overall” Absolute Group Delay and/or Settling Time inclusive of delay from the sigma-delta modulator, add Absolute Group Delay and/or Settling

Time pertaining to specific decimation mode to the Absolute Group Delay specified in 1 × decimation.

Specifications subject to change without notice.

/20 MHz) MHz max

CLOCK

/20 MHz) MHz min

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz min

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz min

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

/20 MHz) MHz max

CLOCK

) µs max

CLOCK

) µs max

CLOCK

) µs max

CLOCK

) µs max

CLOCK

) µs max

CLOCK

) µs max

CLOCK

)) + t

CLOCK

PROP

ns max

–5–REV. B

Page 6

)

AD9260

–Digital Filter Characteristics

0

–20

–40

–60

MAGNITUDE – dB

–80

–100

–120

0 1.0

0.2 0.4 0.6 0.8

FREQUENCY (NORMALIZED TO

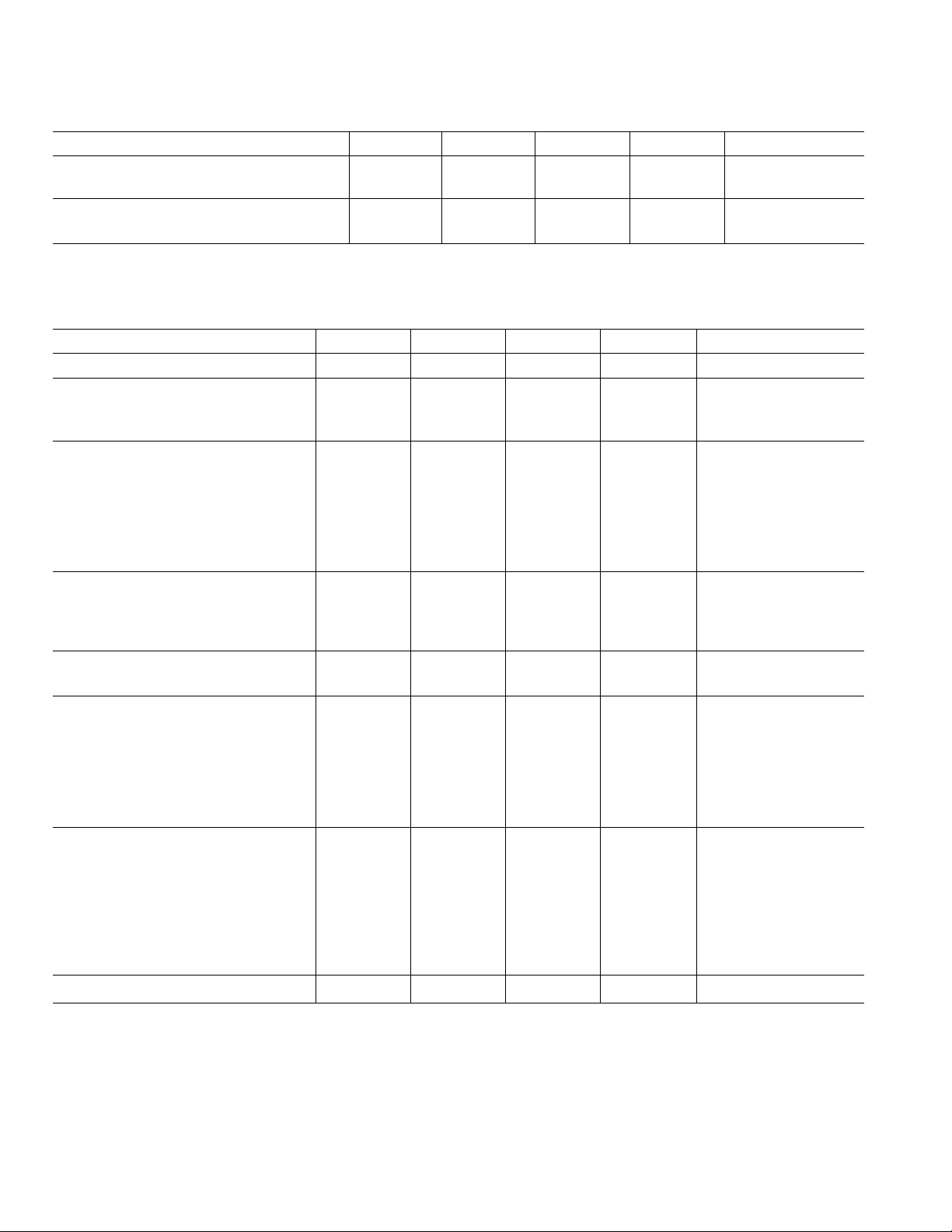

Figure 1a. 8× FIR Filter Frequency Response

0

–20

–40

–60

1.2

1.0

0.8

0.6

0.4

0.2

0

NORMALIZED OUTPUT RESPONSE

–0.2

–0.4

0 300200100

CLOCK PERIODS – RELATIVE TO CLK

400 500

Figure 1b. 8× FIR Filter Impulse Response

1.0

0.8

0.6

0.4

MAGNITUDE – dB

–80

–100

–120

0.2 0.4 0.6 0.8

0 1.0

FREQUENCY (NORMALIZED TO )

Figure 2a. 4× FIR Filter Frequency Response

0

–20

–40

–60

MAGNITUDE – dB

–80

–100

–120

0.2 0.4 0.6 0.8

0 1.0

FREQUENCY (NORMALIZED TO )

Figure 3a. 2× FIR Filter Frequency Response

1.2

1.2

0.2

0

NORMALIZED OUTPUT RESPONSE

–0.2

10 100 11020 30 40 50 60 70 80 90

0

CLOCK PERIODS – RELATIVE TO CLK

Figure 2b. 4× FIR Filter Impulse Response

1.0

0.8

0.6

0.4

0.2

0

NORMALIZED OUTPUT RESPONSE

–0.2

0

5

CLOCK PERIODS – RELATIVE TO CLK

Figure 3b. 2× FIR Filter Impulse Response

201510

–6–

REV. B

Page 7

AD9260

Table I. Integer Filter Coefficients for First Stage Decimation

Filter (23-Tap Halfband FIR Filter)

Lower Upper Integer

Coefficient Coefficient Value

H(1) H(23) –1

H(2) H(22) 0

H(3) H(21) 13

H(4) H(20) 0

H(5) H(19) –66

H(6) H(18) 0

H(7) H(17) 224

H(8) H(16) 0

H(9) H(15) –642

H(10) H(14) 0

H(11) H(13) 2496

H(12) 4048

Table II. Integer Filter Coefficients for Second Stage Decimation Filter (43-Tap Halfband FIR Filter)

Lower Upper Integer

Coefficient Coefficient Value

H(1) H(43) 3

H(2) H(42) 0

H(3) H(41) –12

H(4) H(40) 0

H(5) H(39) 35

H(6) H(38) 0

H(7) H(37) –83

H(8) H(36) 0

H(9) H(35) 172

H(10) H(34) 0

H(11) H(33) –324

H(12) H(32) 0

H(13) H(31) 572

H(14) H(30) 0

H(15) H(29) –976

H(16) H(28) 0

H(17) H(27) 1680

H(18) H(26) 0

H(19) H(25) –3204

H(20) H(24) 0

H(21) H(23) 10274

H(22) 16274

NOTE: The composite filter undecimated coefficients (i.e.,

impulse response) in the 4× decimation mode can be determined

by convolving the first stage filter taps with a “zero stuffed”

version of the second stage filter taps (i.e., insert one zero between samples). Similarly, the composite filter coefficients in the

8× decimation mode can be determined by convolving the taps

of the composite 4× decimation mode (as previously determined) with a “zero stuffed” version of the third stage filter taps

(i.e., insert three zeros between samples).

Table III. Integer Filter Coefficients for Third Stage Decimation Filter (107-Tap Halfband FIR Filter)

Lower Upper Integer

Coefficient Coefficient Value

H(1) H(107) –1

H(2) H(106) 0

H(3) H(105) 2

H(4) H(104) 0

H(5) H(103) –2

H(6) H(102) 0

H(7) H(101) 3

H(8) H(100) 0

H(9) H(99) –3

H(10) H(98) 0

H(11) H(97) 1

H(12) H(96) 0

H(13) H(95) 3

H(14) H(94) 0

H(15) H(93) –12

H(16) H(92) 0

H(17) H(91) 27

H(18) H(90) 0

H(19) H(89) –50

H(20) H(88) 0

H(21) H(87) 85

H(22) H(86) 0

H(23) H(85) –135

H(24) H(84) 0

H(25) H(83) 204

H(26) H(82) 0

H(27) H(81) –297

H(28) H(80) 0

H(29) H(79) 420

H(30) H(78) 0

H(31) H(77) –579

H(32) H(76) 0

H(33) H(75) 784

H(34) H(74) 0

H(35) H(73) –1044

H(36) H(72) 0

H(37) H(71) 1376

H(38) H(70) 0

H(39) H(69) –1797

H(40) H(68) 0

H(41) H(67) 2344

H(42) H(66) 0

H(43) H(65) –3072

H(44) H(64) 0

H(45) H(63) 4089

H(46) H(62) 0

H(47) H(61) –5624

H(48) H(60) 0

H(49) H(59) 8280

H(50) H(58) 0

H(51) H(57) –14268

H(52) H(56) 0

H(53) H(55) 43520

H(54) 68508

–7–REV. B

Page 8

AD9260–SPECIFICATIONS

DIGITAL SPECIFICATIONS

(AVDD = +5 V, DVDD = +5 V, T

MIN

to T

unless otherwise noted)

MAX

Parameter AD9260 Units

1

CLOCK

AND LOGIC INPUTS

High-Level Input Voltage

(DVDD = +5 V) +3.5 V min

(DVDD = +3 V) +2.1 V max

Low-Level Input Voltage

(DVDD = +5 V) +1.0 V min

(DVDD = +3 V) +0.9 V max

High-Level Input Current (V

Low-Level Input Current (V

= DVDD) ± 10 µA max

IN

= 0 V) ± 10 µA max

IN

Input Capacitance 5 pF typ

LOGIC OUTPUTS (with DRVDD = 5 V)

High-Level Output Voltage (I

High-Level Output Voltage (I

Low-Level Output Voltage

Low-Level Output Voltage (I

= 50 µA) +4.5 V min

OH

= 0.5 mA) +2.4 V min

OH

2

(IOL = 0.3 mA) +0.4 V max

= 50 µA) +0.1 V max

OL

Output Capacitance 5 pF typ

LOGIC OUTPUTS (with DRVDD = 3 V)

High-Level Output Voltage (I

= 50 µA) +2.4 V min

OH

Low-Level Output Voltage (IOL = 50 µA) +0.7 V max

NOTES

1

Since CLK is referenced to AVDD, +5 V logic input levels only apply.

2

The AD9260 is not guaranteed to meet VOL = 0.4 V max for standard TTL load of IOL = 1.6 mA.

Specifications subject to change without notice.

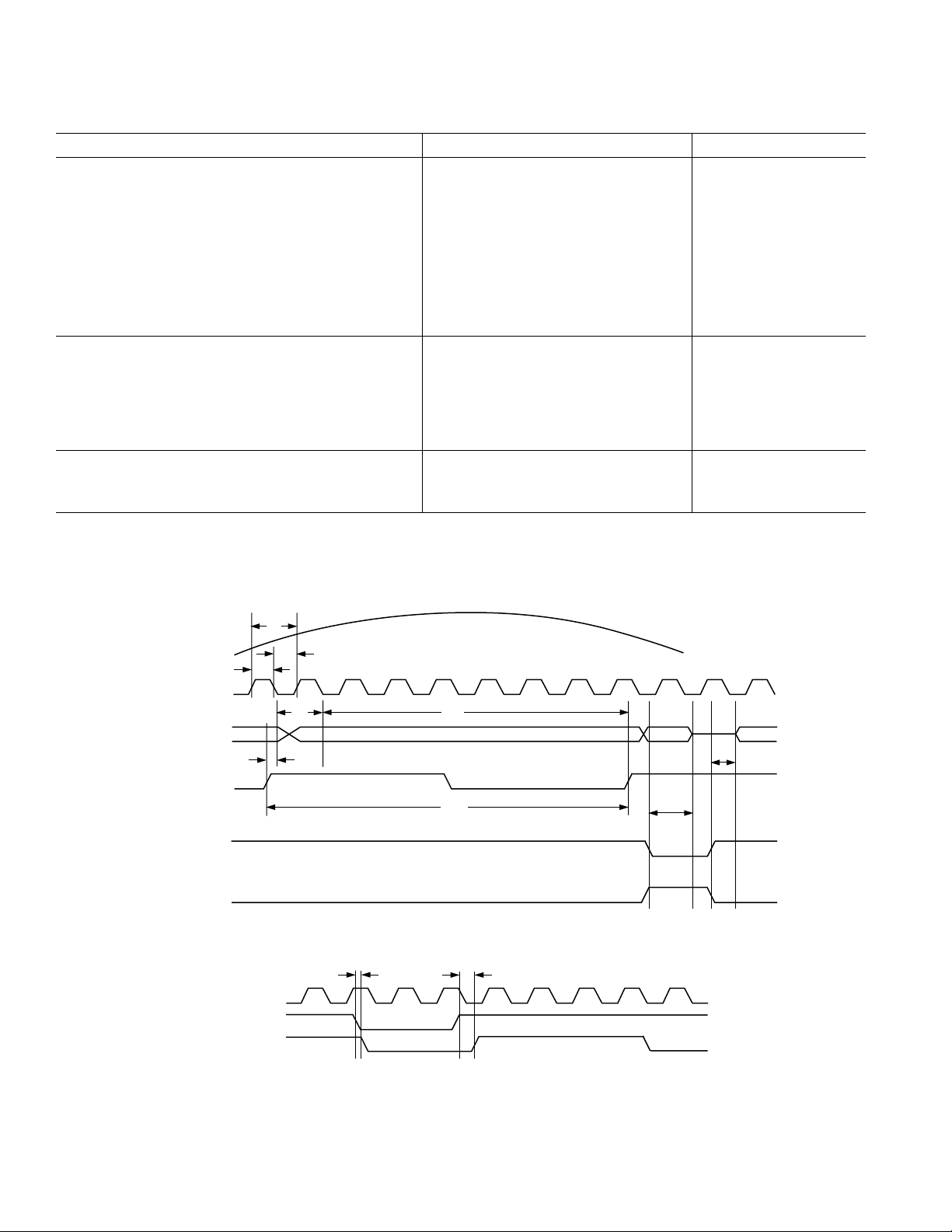

ANALOG INPUT

INPUT CLOCK

DATA OUTPUT

DAV

READ

CS

S1

t

CH

t

H

INPUT CLOCK

RESET

DAV

S2

t

C

t

CL

t

t

DAV

DS

t

OE

t

OD

t

DI

Figure 4a. Timing Diagram

t

RES-DAV

t

CLK-DAV

Figure 4b.

RESET

Timing Diagram

–8–

REV. B

Page 9

AD9260

WARNING!

ESD SENSITIVE DEVICE

SWITCHING SPECIFICATIONS

(AVDD = +5 V, DVDD = +5 V, CL = 20 pF, T

MIN

to T

unless otherwise noted)

MAX

Parameters Symbol AD9260 Units

Clock Period t

Data Available (DAV) Period t

Data Invalid t

Data Setup Time t

Clock Pulsewidth High t

Clock Pulsewidth Low t

Data Hold Time t

RESET to DAV Delay t

CLOCK to DAV Delay t

Three-State Output Disable Time t

Three-State Output Enable Time t

Specifications subject to change without notice.

C

DAV

DI

DS

CH

CL

H

RES–DAV

CLK–DAV

OD

OE

ABSOLUTE MAXIMUM RATINGS*

With

Respect

Parameter to Min Max Units

AVDD AVSS –0.3 +6.5 V

DVDD DVSS –0.3 +6.5 V

AVSS DVSS –0.3 +0.3 V

AVDD DVDD –6.5 +6.5 V

DRVDD DRVSS –0.3 +6.5 V

DRVSS AVSS –0.3 +0.3 V

REFCOM AVSS –0.3 +0.3 V

CLK, MODE, READ,

Model Range Description Option*

AD9260AS –40°C to +85°C 44-Lead MQFP S-44

AD9260EB Evaluation Board

*S = Metric Quad Flatpack.

THERMAL CHARACTERISTICS

Thermal Resistance

44-Lead MQFP

θ

= 53.2°C/W

JA

= 19°C/W

θ

JC

50 ns min

tC × Mode ns min

40% t

t

–tH–t

DAV

DAV

DI

ns max

ns min

22.5 ns min

22.5 ns min

3.5 ns min

10 ns typ

15 ns typ

8 ns typ

45 ns typ

ORDERING GUIDE

Temperature Package Package

CS, RESET DVSS –0.3 DVDD + 0.3 V

Digital Outputs DRVSS –0.3 DRVDD

+ 0.3 V

VINA, VINB,

CML, BIAS AVSS –0.3 AVDD

VREF AVSS –0.3 AVDD

SENSE AVSS –0.3 AVDD

+ 0.3 V

+ 0.3 V

+ 0.3 V

CAPB, CAPT AVSS –0.3 AVDD + 0.3 V

Junction Temperature +150 °C

Storage Temperature –65 +150 °C

Lead Temperature

(10 sec) +300 °C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum ratings

for extended periods may effect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9260 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–9–REV. B

Page 10

AD9260

DEFINITIONS OF SPECIFICATION

INTEGRAL NONLINEARITY (INL)

INL refers to the deviation of each individual code from a line

drawn from “negative full scale” through “positive full scale.”

The point used as “negative full scale” occurs 1/2 LSB before

the first code transition. “Positive full scale” is defined as a

level 1 1/2 LSB beyond the last code transition. The deviation

is measured from the middle of each particular code to the true

straight line.

DIFFERENTIAL NONLINEARITY (DNL, NO MISSING

CODES)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. Guaranteed

no missing codes to 14-bit resolution indicates that all 16384

codes, respectively, must be present over all operating ranges.

NOTE: Conventional INL and DNL measurements don’t really

apply to Σ∆ converters: the DNL looks continually better if

longer data records are taken. For the AD9260, INL and DNL

numbers are given as representative.

ZERO ERROR

The major carry transition should occur for an analog value

1/2 LSB below VINA = VINB. Zero error is defined as the

deviation of the actual transition from that point.

GAIN ERROR

The first code transition should occur at an analog value

1/2 LSB above negative full scale. The last transition should

occur at an analog value 1 1/2 LSB below the nominal full scale.

Gain error is the deviation of the actual difference between first

and last code transitions and the ideal difference between first

and last code transitions.

TEMPERATURE DRIFT

The temperature drift for zero error and gain error specifies the

maximum change from the initial (+25°C) value to the value at

or T

T

MIN

POWER SUPPLY REJECTION

MAX

.

The specification shows the maximum change in full scale from

the value with the supply at the minimum limit to the value with

the supply at its maximum limit.

APERTURE JITTER

Aperture jitter is the variation in aperture delay for successive

samples and is manifested as noise on the input to the A/D.

SIGNAL-TO-NOISE AND DISTORTION (S/N+D, SINAD)

RATIO

S/N+D is the ratio of the rms value of the measured input signal

to the rms sum of all other spectral components below the

Nyquist frequency, including harmonics but excluding dc.

The value for S/N+D is expressed in decibels.

EFFECTIVE NUMBER OF BITS (ENOB)

For a sine wave, SINAD can be expressed in terms of the number of bits. Using the following formula,

N = (SINAD – 1.76)/6.02

it is possible to get a measure of performance expressed as N,

the effective number of bits.

Thus, effective number of bits for a device for sine wave inputs

at a given input frequency can be calculated directly from its

measured SINAD.

TOTAL HARMONIC DISTORTION (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of the measured input signal and

is expressed as a percentage or in decibels.

SIGNAL-TO-NOISE RATIO (SNR)

SNR is the ratio of the rms value of the measured input signal to

the rms sum of all other spectral components below the Nyquist

frequency, excluding the first six harmonics and dc. The value

for SNR is expressed in decibels.

SPURIOUS FREE DYNAMIC RANGE (SFDR)

SFDR is the difference in dB between the rms amplitude of the

input signal and the peak spurious signal.

TWO-TONE SFDR

The ratio of the rms value of either input tone to the rms value

of the peak spurious component. The peak spurious component

may or may not be an IMD product. May be reported in dBc

(i.e., degrades as signal level is lowered), or in dBFS (always

related back to converter full scale).

–10–

REV. B

Page 11

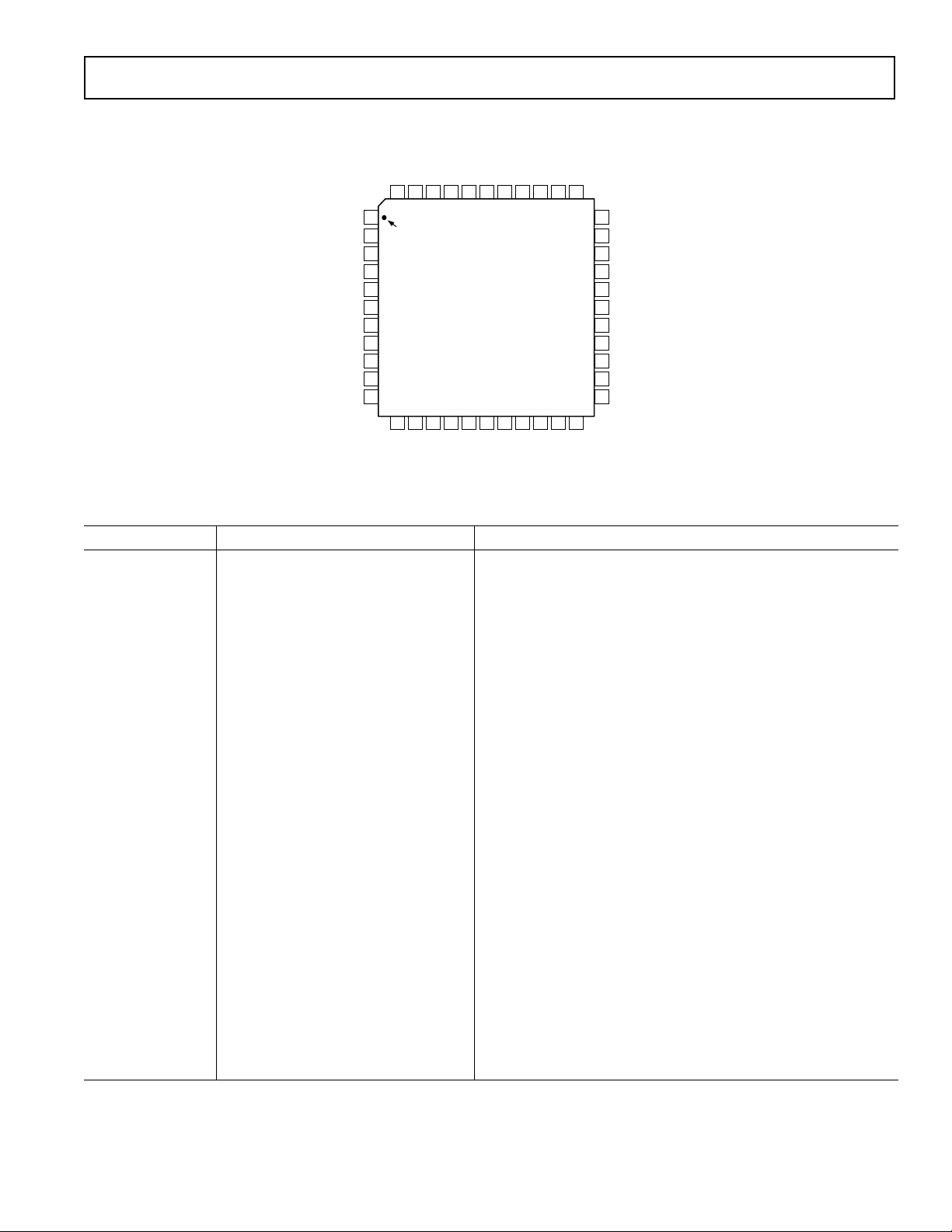

PIN CONFIGURATION

AD9260

VINB

42

BIT11

NC

VINA

CML

40 39 3841

AD9260

TOP VIEW

(Not to Scale)

BIT8

BIT9

BIT10

AVSS

BIT7

CAPT

BIT6

CAPB

BIT5

BIAS

BIT4

MODE

33

32

31

30

29

28

27

26

25

24

23

BIT3

REFCOM

VREF

SENSE

RESET

AVSS

AVDD

CS

DAV

OTR

BIT1 (MSB)

BIT2

DVSS

AVSS

DVDD

AVDD

DRVSS

DRVDD

CLK

READ

(LSB) BIT16

BIT15

BIT14

NC

AVDD

4344 36 35 3437

1

PIN 1

IDENTIFIER

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18 19 20 21 2 2

BIT12

BIT13

NC = NO CONNECT

PIN FUNCTION DESCRIPTIONS

Pin No. Name Description

1 DVSS Digital Ground.

2, 29, 38 AVSS Analog Ground.

3 DVDD +3 V to +5 V Digital Supply.

4, 28, 44 AVDD +5 V Analog Supply.

5 DRVSS Digital Output Driver Ground.

6 DRVDD +3 V to +5 V Digital Output Driver Supply.

7 CLK Clock Input.

8 READ Part of DSP Interface—Pull Low to Disable Output Bits.

9 BIT16 Least Significant Data Bit (LSB).

10–23 BIT15–BIT2 Data Output Bit.

24 BIT1 Most Significant Data Bit (MSB).

25 OTR Out of Range—Set When Converter or Filter Overflows.

26 DAV Data Available.

27 CS Chip Select (CS): Active LOW.

30 RESET RESET: Active LOW.

31 SENSE Reference Amplifier SENSE: Selects REF Level.

32 VREF Input Span Select Reference I/O.

33 REFCOM Reference Common.

34 MODE Mode Select—Selects Decimation Mode.

35 BIAS Power Bias.

36 CAPB Noise Reduction Pin—Decouples Reference Level.

37 CAPT Noise Reduction Pin—Decouples Reference Level.

39 CML Common-Mode Level (AVDD/2.5).

40, 43 NC No Connect (Ground for Shielding Purposes).

41 VINA Analog Input Pin (+).

42 VINB Analog Input Pin (–).

–11–REV. B

Page 12

AD9260

–Typical Performance Characteristics

(AVDD = DVDD = DRVDD = +5.0 V, 4 V Input Span, Differential DC Coupled Input with CML = 2.0 V, f

= 20 MSPS, Full Bias)

CLOCK

0

100kHz INPUT

–20

–40

–60

–80

dB BELOW FULL SCALE

–100

–120

0

0.4 0.6 0.8

FREQUENCY – MHz

20MHz CLOCK

8 DECIMATION

THD: –96dB

1.0

1.20.2

Figure 5. Spectral Plot of the AD9260 at 100 kHz Input,

20 MHz Clock, 8

0

–20

–40

–60

–80

dB BELOW FULL SCALE

–100

–120

0

×

OSR (2.5 MHz Output Data Rate)

100kHz INPUT

20MHz CLOCK

4 DECIMATION

THD: –98dB

0.5

1 1.5 2 2.5

FREQUENCY – MHz

Figure 6. Spectral Plot of the AD9260 at 100 kHz Input,

×

20 MHz Clock, 4

OSR (5 MHz Output Data Rate)

0

–20

–40

–60

–80

dB BELOW FULL SCALE

–100

–120

1

02

3456 78910

FREQUENCY – MHz

100kHz INPUT

20MHz CLOCK

1 DECIMATION

THD: –98dB

Figure 8. Spectral Plot of the AD9260 at 100 kHz Input,

20 MHz Clock, Undecimated (20 MHz Output Data Rate)

110

106

102

98

WORST CASE SPUR – dBFS

94

90

–12dBFS/TONE

–6.5dBFS/TONE

–26dBFS/TONE

0.20

–46dBFS/TONE

0.4 0.6 1

FREQUENCY – MHz

0.8

Figure 9. Dual Tone SFDR vs. Input Frequency (F1 = F2,

– F2, Span = 10% Center Frequency, Mode = 8×)

(F

1

0

–20

–40

–60

–80

dB BELOW FULL SCALE

–100

–120

0

1 1.5 2 2.5 3 3.5 4 4.5

FREQUENCY – MHz

100kHz INPUT

20MHz CLOCK

2 DECIMATION

THD: –98dB

50.5

Figure 7. Spectral Plot of the AD9260 at 100 kHz Input,

×

20 MHz Clock, 2

OSR (10 MHz Output Data Rate)

–12–

0

DUAL-TONE TEST

f1 = 1.0MHz

–20

f2 = 975kHz

20MHz CLOCK

–40

8 DECIMATION

IM3: –94dB

–60

–80

dB BELOW FULL SCALE

–100

–120

0

0.4 0.6 0.8 1

FREQUENCY – MHz

1.20.2

Figure 10. Two-Tone Spectral Performance of the

AD9260 Given Inputs at 975 kHz and 1.0 MHz, 20 MHz

×

Clock, 8

Decimation

REV. B

Page 13

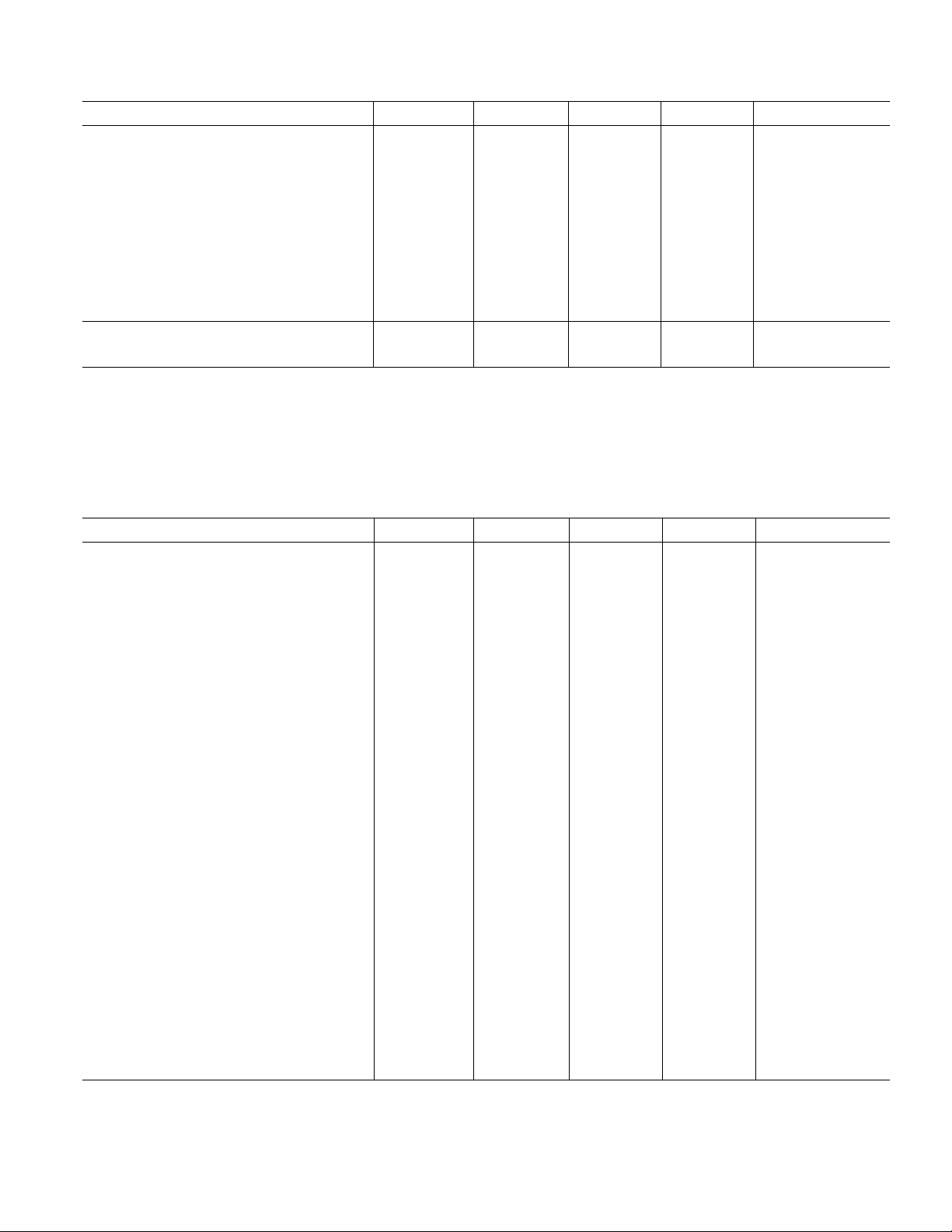

Typical AC Characterization Curves vs. Decimation Mode

INPUT FREQUENCY – MHz

0.1 10

SINAD – dBFS

1

60

1 MODE

2 MODE

4 MODE

8 MODE

65

70

75

80

85

90

55

50

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, Differential DC Coupled Input with CML = 2 V, AIN = 0.5 dBFS Full Bias)

90

AD9260

85

80

75

70

SINAD – dBFS

65

60

55

50

0.1 10

INPUT FREQUENCY – MHz

8 MODE

4 MODE

1

Figure 11. SINAD vs. Input Frequency (f

–50

–60

–70

–80

THD – dBFS

–90

–100

–110

0.1 10

8 MODE

1

INPUT FREQUENCY – MHz

2 MODE

4 MODE

Figure 12. THD vs. Input Frequency (f

2 MODE

1 MODE

= 20 MSPS)

CLOCK

1 MODE

= 20 MSPS)

CLOCK

1

Figure 14. SINAD vs. Input Frequency (f

–70

–75

–80

–85

–90

–95

–100

THD – dBFS

–105

–110

–115

–120

0.1 10

8 MODE

INPUT FREQUENCY – MHz

Figure 15. THD vs. Input Frequency (f

4 MODE

1

CLOCK

1 MODE

2 MODE

CLOCK

= 10 MSPS)

= 10 MSPS)

1

–50

–60

–70

–80

SFDR – dBFS

–90

–100

–110

8 MODE

0.1 10

INPUT FREQUENCY – MHz

Figure 13. SFDR vs. Input Frequency (f

1

8× SINAD performance limited by noise contribution of input differential op

amp driver.

–70

1 MODE

2 MODE

4 MODE

1

= 20 MSPS)

CLOCK

–75

–80

–85

–90

–95

–100

SFDR – dBFS

–105

–110

–115

–120

0.1 10

8 MODE

1

INPUT FREQUENCY – MHz

2 MODE

4 MODE

Figure 16. SFDR vs. Input Frequency (f

1 MODE

CLOCK

= 10 MSPS)

–13–REV. B

Page 14

AD9260

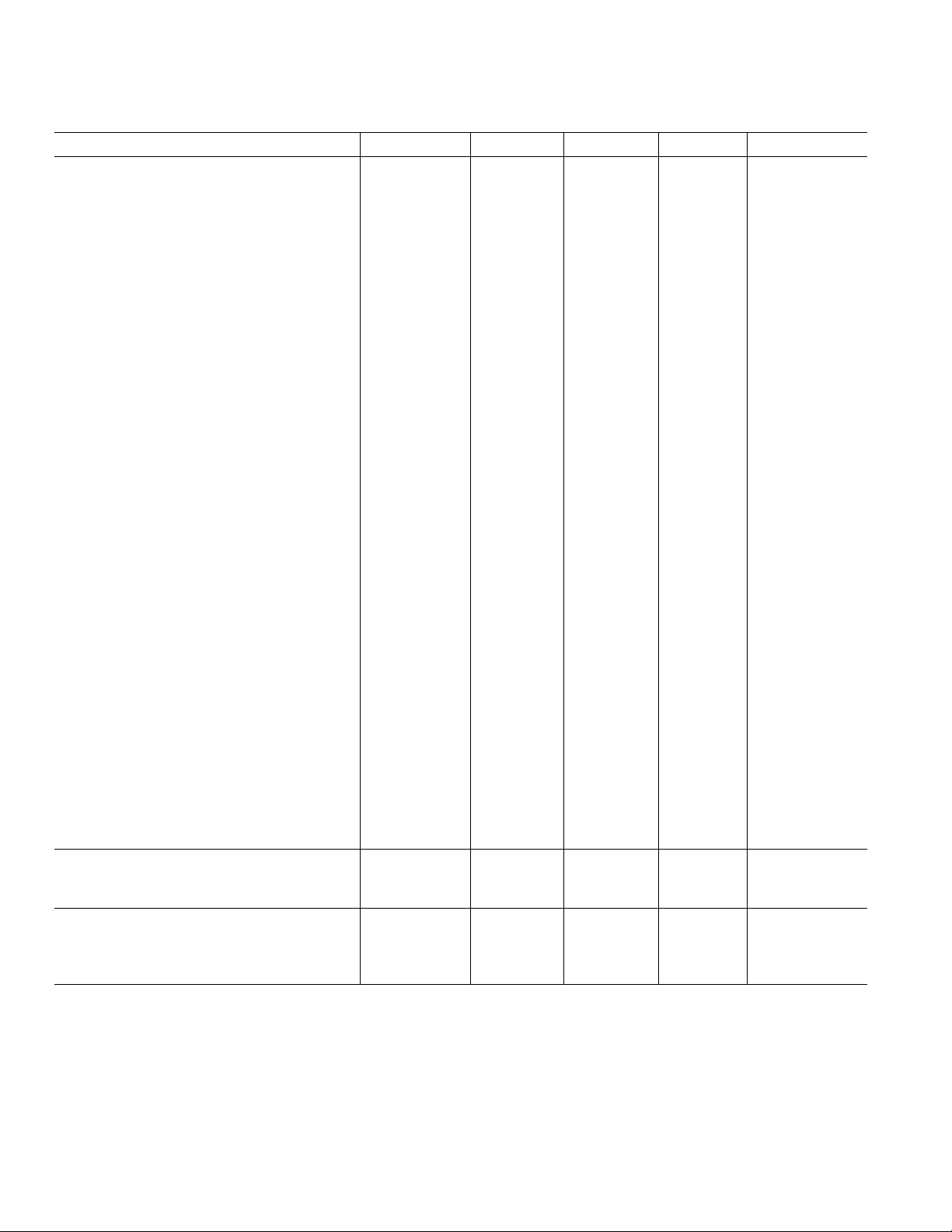

Typical AC Characterization Curves for 8 Mode

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, Differential DC Coupled Input with CML = 2 V, Full Bias)

90

90

85

–0.5dBFS

80

75

SINAD – dB

70

65

60

–6.0dBFS

–20dBFS

0.1

INPUT FREQUENCY – MHz

Figure 17. SINAD vs. Input Frequency (f

–70

–75

–80

–85

–90

THD – dB

–95

–100

–105

–110

–20dBFS

–0.5dBFS

–6.0dBFS

0.1

INPUT FREQUENCY – MHz

Figure 18. THD vs. Input Frequency (f

= 20 MSPS)

CLOCK

= 20 MSPS)

CLOCK

85

80

75

SINAD – dB

70

65

60

–70

–75

–80

–85

–90

THD – dB

–95

–100

–105

0.1

INPUT FREQUENCY – MHz

0.1

INPUT FREQUENCY – MHz

1

1

Figure 20. SINAD vs. Input Frequency (f

1

Figure 21. THD vs. Input Frequency (f

–0.5dBFS

–6.0dBFS

–20dBFS

= 10 MSPS)

CLOCK

–20dBFS

–6.0dBFS

–0.5dBFS

= 10 MSPS)

CLOCK

1

1

1

105

100

–0.5dBFS

–6.0dBFS

–20dBFS

INPUT FREQUENCY – MHz

= 20 MSPS)

CLOCK

1

95

SFDR – dBc

90

85

80

0.1

Figure 19. SFDR vs. Input Frequency (f

1

SINAD performance limited by noise contribution of input differential op amp

driver.

–14–

105

100

–6.0dBFS

95

–0.5dBFS

SFDR – dBc

90

85

80

0.1

INPUT FREQUENCY – MHz

–20dBFS

Figure 22. SFDR vs. Input Frequency (f

= 10 MSPS)

CLOCK

1

REV. B

Page 15

Typical AC Characterization Curves for 4 Mode

INPUT FREQUENCY – MHz

0.1

1

SFDR – dBc

–0.5dBFS

–6.0dBFS

–20dBFS

110

105

95

90

80

100

85

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, Differential DC Coupled Input with CML = 2 V, Full Bias)

90

90

AD9260

85

80

75

70

SINAD – dB

65

60

55

50

0.1 10

–0.5dBFS

–6.0dBFS

–20dBFS

INPUT FREQUENCY – MHz

1

Figure 23. SINAD vs. Input Frequency (f

–70

–75

–80

–85

–90

THD – dB

–95

–100

–105

–110

0.1 10

Figure 24. THD vs. Input Frequency (f

–20dBFS

–0.5dBFS

–6.0dBFS

INPUT FREQUENCY – MHz

1

CLOCK

= 20 MSPS)

CLOCK

= 20 MSPS)

85

–0.5dBFS

80

–6.0dBFS

75

SINAD – dB

70

65

–20dBFS

60

0.1

INPUT FREQUENCY – MHz

Figure 26. SINAD vs. Input Frequency (f

–70

–75

–80

–85

–90

THD – dB

–95

–6.0dBFS

–100

–105

–110

0.1

INPUT FREQUENCY – MHz

Figure 27. THD vs. Input Frequency (f

–0.5dBFS

CLOCK

= 10 MSPS)

CLOCK

–20dBFS

= 10 MSPS)

1

1

110

105

100

95

SFDR – dBc

90

85

80

0.1 10

Figure 25. SFDR vs. Input Frequency (f

INPUT FREQUENCY – MHz

1

–0.5dBFS

–6.0dBFS

–20dBFS

CLOCK

= 20 MSPS)

Figure 28. SFDR vs. Input Frequency (f

–15–REV. B

= 10 MSPS)

CLOCK

Page 16

AD9260

Typical AC Characterization Curves for 2 Mode

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, Differential DC Coupled Input with CML = 2 V, Full Bias)

80

80

75

70

65

SINAD – dB

60

55

50

0.1 10

INPUT FREQUENCY – MHz

1

Figure 29. SINAD vs. Input Frequency (f

–60

–65

–70

–0.5dBFS

THD – dB

–75

–80

–85

–90

–95

–6.0dBFS

–5.0dBFS

–6.0dBFS

–20dBFS

CLOCK

–20dBFS

= 20 MSPS)

75

70

65

SINAD – dB

60

55

50

0.1 10

INPUT FREQUENCY – MHz

1

–0.5dBFS

–6.0dBFS

–20dBFS

Figure 32. SINAD vs. Input Frequency (f

–60

–65

–70

–75

THD – dB

–80

–85

–90

–0.5dBFS

–95

–20dBFS

–6.0dBFS

= 10 MSPS)

CLOCK

–100

0.1 10

INPUT FREQUENCY – MHz

1.0

Figure 30. THD vs. Input Frequency (f

100

95

90

–6.0dBFS

85

SFDR – dBc

80

75

70

0.1 10

–0.5dBFS

1

INPUT FREQUENCY – MHz

Figure 31. SFDR vs. Input Frequency (f

= 20 MSPS)

CLOCK

–20dBFS

= 20 MSPS)

CLOCK

–100

0.1 10

INPUT FREQUENCY – MHz

1

Figure 33. THD vs. Input Frequency (f

100

95

–6.0dBFS

90

–0.5dBFS

85

SFDR – dBc

80

75

70

0.1 10

INPUT FREQUENCY – MHz

1

–20dBFS

Figure 34. SFDR vs. Input Frequency (f

= 10 MSPS)

CLOCK

= 10 MSPS)

CLOCK

–16–

REV. B

Page 17

Typical AC Characterization Curves for 1 Mode

INPUT FREQUENCY – MHz

0.1 10

SINAD – dB

1

–0.5dBFS

–6.0dBFS

–20dBFS

70

65

60

55

50

45

40

INPUT FREQUENCY – MHz

0.1 10

THD – dBc

1

–0.5dBFS

–6.0dBFS

–20dB

–60

–70

–80

–85

–90

–95

–100

–75

–65

–55

INPUT FREQUENCY – MHz

0.1 10

SFDR – dBc

1

–6.0dBFS

–20dBFS

95

85

75

70

65

60

50

80

90

55

–0.5dBFS

100

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, Differential DC Coupled Input with CML = 2 V, Full Bias)

70

65

–0.5dBFS

60

AD9260

55

SINAD – dB

50

45

40

0.1 10

–6.0dBFS

–20dBFS

1

INPUT FREQUENCY – MHz

Figure 35. SINAD vs. Input Frequency (f

–55

–60

–65

–70

–75

–80

THD – dB

–85

–90

–95

–100

0.1 10

–20dBFS

1

INPUT FREQUENCY – MHz

–0.5dBFS

Figure 36. THD vs. Input Frequency (f

= 20 MSPS)

CLOCK

–6.0dBFS

= 20 MSPS)

CLOCK

Figure 38. SINAD vs. Input Frequency (f

Figure 39. THD vs. Input Frequency (f

CLOCK

= 10 MSPS)

CLOCK

= 10 MSPS)

100

95

90

85

80

75

70

SDFR – dBc

65

60

55

50

0.1 10

Figure 37. SFDR vs. Input Frequency (f

–0.5dBFS

–6.0dBFS

–20dBFS

INPUT FREQUENCY – MHz

1

= 20 MSPS)

CLOCK

Figure 40. SFDR vs. Input Frequency (f

= 10 MSPS)

CLOCK

–17–REV. B

Page 18

AD9260

Typical AC Characterization Curves

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, AIN = –0.5 dBFS, Differential DC Coupled Input with CML = 2 V)

100

95

90

85

80

75

70

SFDR – dBFS

65

60

55

50

QUARTER BIAS

52

CLOCK FREQUENCY – MHz

10 15 20

FULL BIAS

HALF BIAS

Figure 41. SFDR vs. Clock Rate (fIN = 100 kHz in 8× Mode)

100

80

60

FULL BIAS

HALF BIAS

–60

–65

–70

–75

–80

THD – dBc

–85

–90

–95

–100

1.0

1.2

1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

COMMON MODE INPUT LEVEL – Volts

F

F

IN

Figure 44. THD vs. Common-Mode Input Level (CML)

–40

–50

–60

FS = 10MHz

= 1MHz, 2 MODE

IN

= 100kHz, 8 MODE

FS = 20MHz

SFDR – dBFS

40

20

0

5

10 15 25

CLOCK FREQUENCY – MHz

QUARTER BIAS

20

Figure 42. SFDR vs. Clock Rate (fIN = 500 kHz in 4× Mode)

100

FULL BIAS

80

60

SFDR – dBFS

40

20

0

5

HALF BIAS

QUARTER BIAS

10 15 25

CLOCK FREQUENCY – MHz

20

Figure 43. SFDR vs. Clock Rate (fIN = 1.0 MHz in 2× Mode)

CMR – dB

–70

–80

–90

Figure 45. CMR vs. Input Frequency (V

100k 10M1M10k1k

INPUT FREQUENCY – Hz

CML

Mode)

100

4V SPAN SNR-8 MODE

95

90

85

SFDR – dBFS

80

75

0

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

FREQUENCY – MHz

4V SPAN SFDR-2 MODE

1.6V SPAN SNR-8 MODE

1.6V SPAN SFDR-2 MODE

Figure 46. 4 V vs. 1.6 V Span SNR/SFDR (f

FS = 5MHz

100M

= 2 V p-p, 1

= 20 MSPS)

CLOCK

×

–18–

REV. B

Page 19

AD9260

20MSPS-dBFS

FULL BIAS

AIN – dBFS

WORST SPUR – dBc and dBFS

–60

50

70

80

90

100

110

120

–50 –40 –30 –20 –10 0

10MSPS-dBc

HALF BIAS

10MSPS-dBFS

HALF BIAS

20MSPS-dBc

FULL BIAS

60

FULL BIAS-dBFS

AIN – dBFS

WORST SPUR – dBc and dBFS

–60

50

70

80

90

100

110

120

–50 –40 –30 –20 –10 0

60

HALF BIAS-dBFS

HALF BIAS-dBc

FULL BIAS-dBc

AIN – dBFS

WORST SPUR – dBc and dBFS

–60

50

70

80

90

100

110

120

–50 –40 –30 –20 –10 0

60

dBc

dBFS

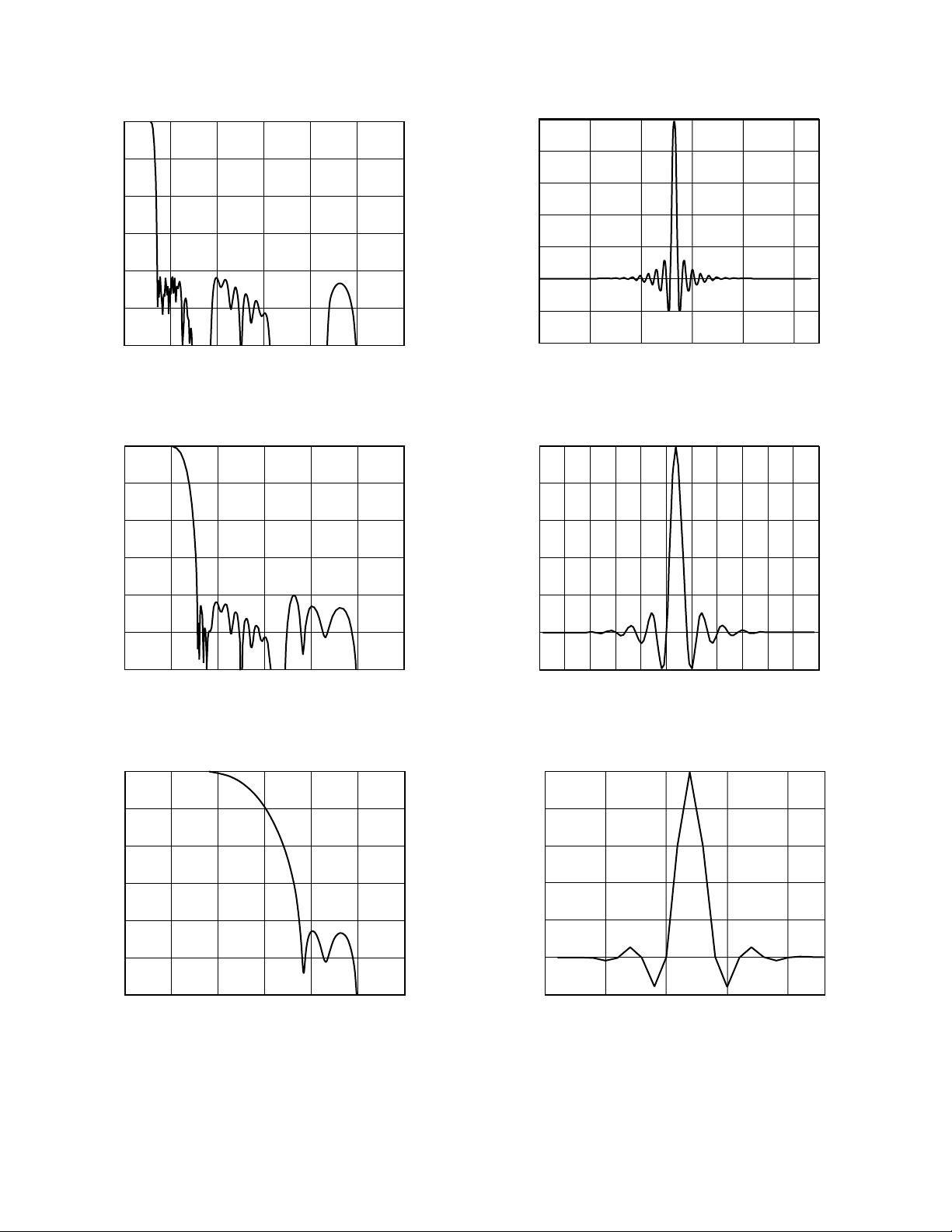

Additional AC Characterization Curves

(AVDD = DVDD = DRVDD = +5 V, 4 V Input Span, AIN = –0.5 dBFS, Differential DC Coupled Input with CML = 2 V, Full Bias, unless otherwise noted)

120

115

110

105

100

SFDR – dBFS

95

90

85

80

–50

–45 –40 –35 –30 –25 –20 –15 –10 –5 0

20 MSPS

FULL BIAS

AIN – dBFS

20 MSPS

HALF BIAS

10 MSPS

HALF BIAS

10 MSPS

FULL BIAS

Figure 47. Single-Tone SFDR vs. Amplitude (fIN =100 kHz,

×

Mode)

8

110

105

100

95

SFDR – dBFS

90

20 MSPS

FULL BIAS

10 MSPS

HALF BIAS

10 MSPS

FULL BIAS

Figure 50. Two-Tone SFDR (F1 = 475 kHz, F2 = 525 MHz,

×

Mode)

8

85

80

–50

–45 –40 –35 –30 –25 –20 –15 –10 –5 0

AIN – dBFS

Figure 48. Single-Tone SFDR vs. Amplitude (fIN =1.0 MHz,

×

Mode)

2

110

10 MSPS

105

100

95

SFDR – dBFS

90

85

80

–50

Figure 49. Single-Tone SFDR vs. Amplitude (fIN = 500 kHz,

2

×

Mode)

HALF BIAS

20 MSPS

FULL BIAS

–45 –40 –35 –30 –25 –20 –15 –10 –5 0

AIN – dBFS

10 MSPS

FULL BIAS

Figure 51. Two-Tone SFDR (F1 = 0.95 kHz, F2 = 1.05 MHz,

×

Mode 20 MSPS)

8

Figure 52. Two-Tone SFDR (F1 = 1.9 MHz, F2 = 2.1 MHz,

4

×

Mode 20 MSPS)

–19–REV. B

Page 20

AD9260

+

–

5B

+

V

IN

–

5B

DAC1

INT1

+

–

5B

DAC2

INT2

SHUFFLE

5B

ADC

DAC

M

CONTROL/TEST

LOGIC

BANDGAP

REFERENCE

REFERENCE

BUFFER

OUT

Figure 53. Simplified Block Diagram

THEORY OF OPERATION

The AD9260 utilizes a new analog-to-digital converter architecture to combine sigma-delta techniques with a high-speed,

pipelined A/D converter. This topology allows the AD9260 to

offer the high dynamic range associated with sigma-delta converters while maintaining very wide input signal bandwidth

(1.25 MHz) at a very modest 8× oversampling ratio. Figure 53

provides a block diagram of the AD9260. The differential

analog input is fed into a second order, multibit sigma-delta

modulator. This modulator features a 5-bit flash quantizer and

5-bit feedback. In addition, a 12-bit pipelined A/D quantizes

the input to the 5-bit flash to greater accuracy. A special digital

modulation loop combines the output of the 12-bit pipelined

A/D with the delayed output of the 5-bit flash to produce the

equivalent response of a second order loop with a 12-bit

quantizer and 12-bit feedback. The combination of a second

order loop and multibit feedback provides inherent stability:

the AD9260 is not prone to idle tones or full-scale idiosyncracies sometimes associated with higher order single bit sigmadelta modulators.

The output of this 12-bit modulator is fed into the digital decimation filter. The voltage level on the MODE pin establishes

the configuration for the digital filter. The user may bring the

data out undecimated (at the clock rate), or at a decimation

factor of 2×, 4×, or a full 8×. The spectra for these four cases

are shown in Figures 5, 6, 7 and 8, all for a 100 kHz full-scale

input and 20 MHz clock. The spectra of the undecimated

output clearly shows the second order shaping characteristic of

the quantization noise as it rises at frequencies above 1.25 MHz.

The on-chip decimation filter provides excellent stopband rejection to suppress any stray input signal between 1.25 MHz and

18.75 MHz, substantially easing the requirements on any antialiasing filter for the analog input path. The decimation filters

are integrated with symmetric FIR filter structures, providing a

linear phase response and excellent passband flatness.

16

3B

ADC3BDAC

–D

Z

HALF-BAND

DECIMATION FILTER STAGE 1

HALF-BAND

DECIMATION FILTER STAGE 2

HALF-BAND

DECIMATION FILTER STAGE 3

OUTPUT BITS

+

4

–

3B

ADC3BDAC

PIPELINE CORRECTION LOGIC

++

DIFFERENTIATOR

C

OUT

LSB

8 LSBs

+

4

–

4B

ADC

The digital output driver register of the AD9260 features both

READ and CHIP SELECT pins to allow easy interfacing. The

digital supply of the AD9260 is designed to operate over a

2.7 V to 5.25 V supply range, though 3 V supplies are recommended to minimize digital noise on the board. A DATA

AVAILABLE pin allows the user to easily synchronize to the

converter’s decimated output data rate. OUT-OF-RANGE

(OTR) indication is given for an overflow in the pipelined A/D

converter or digital filters. A RESETB function is provided to

synchronize the converter’s decimated data and clear any overflow condition in the analog integrators.

An on-chip reference and reference buffer are included on the

AD9260. The reference can be configured in either a 2.5 V

mode (providing a 4 V pk-pk differential input full scale), a 1 V

mode (providing a 1.6 V pk-pk differential input full scale), or

programmed with an external resistor divider to provide any

voltage level between 1 V and 2.5 V. However, optimum noise and

distortion performance for the AD9260 can only be achieved with a

2.5 V reference as shown in Figure 46.

For users wishing to operate the part at reduced clock frequencies, the bias current of the AD9260 is designed to be scalable.

This scaling is accomplished through use of the proper external

resistor tied to the BIAS pin: the power can be reduced roughly

proportionately to clock frequency by as much as 75% (for clock

rates of 5 MHz). Refer to Figures 41–43 and 47–51 for characterization curves showing performance tradeoffs.

ANALOG INPUT AND REFERENCE OVERVIEW

Figure 54, a simplified model of the AD9260, highlights the

relationship between the analog inputs, VINA, VINB and the

reference voltage VREF. Like the voltage applied to the top of

the resistor ladder in a flash A/D converter, the value VREF

defines the maximum input voltage to the A/D converter. An

internal reference buffer in the AD9260 scales the reference

voltage VREF before it is applied internally to the AD9260

–20–

REV. B

Page 21

AD9260

A/D core. The scale factor of this reference buffer is 0.8. Consequently, the maximum input voltage to the A/D core is +0.8 ×

VREF. The minimum input voltage to the A/D core is automatically defined to be –0.8 × VREF. With this scale factor, the

maximum differential input span of 4 V p-p is obtained with a

VREF voltage of 2.5 V. A smaller differential input span may be

obtained by using a VREF voltage of less than 2.5 V at the

expense of ac performance (refer to Figure 46).

+0.8VREF

VINA

16

VINB

+

–

A/D CORE

–0.8VREF

Figure 54. Simplified Input Model

INPUT SPAN

The AD9260 is implemented with a differential input structure.

This structure allows the common-mode level (average voltage

of the two input pins) of the input signal to be varied independently of the input span of the converter over a wide range, as

shown in Figure 44. Specifically, the input to the A/D core is

the difference of the voltages applied at the VINA and VINB

input pins. Therefore, the equation,

VCORE = VINA–VINB (1)

defines the output of the differential input stage and provides

the input to the A/D core.

The voltage, VCORE, must satisfy the condition,

–0.8 × VREF ≤ VCORE ≤ +0.8 × VREF (2)

where VREF is the voltage at the VREF pin.

INPUT COMPLIANCE RANGE

In addition to the limitations on the differential span of the

input signal indicated in Equation 2, an additional limitation is

placed on the inputs by the analog input structure of the AD9260.

The analog input structure bounds the valid operating range for

VINA and VINB. The condition,

AVSS +0.5 V < VINA < AVDD – 0.5 V

AVSS +0.5 V < VINB < AVDD + 0.5 V

(3)

where AVSS is nominally 0 V and AVDD is nominally +5 V,

defines this requirement. Thus the valid inputs for VINA and

VINB are any combination that satisfies both Equations 2 and

3. Note, the clock clamping method used in the differential

driver circuit shown in Figure 57 is sufficient for protecting the

AD9260 in an undervoltage condition.

For additional information showing the relationships between

VINA, VINB, VREF and the digital output of the AD9260, see

Table V.

Refer to Table IV for a summary of the various analog input

and reference configurations.

ANALOG INPUT OPERATION

The analog input structure of the AD9260 is optimized to meet

the performance requirements for some of the most demanding

communication and data acquisition applications. This input

structure is composed of a switched-capacitor network that

samples the input signal applied to pins VINA and VINB on

every rising edge of the CLK pin. The input switched capacitors are charged to the input voltage during each period of

CLK. The resulting charge, q, on these capacitors is equal to

C × V

, where C is the input capacitor. The change in charge

IN

on these capacitors, delta q, as the capacitors are charged from a

previous sample of the input signal to the next sample, is approximated in the following equation,

delta q ~ C × deltaV

where V

V

N–2

represents the present sample of the input signal and

N

represents the sample taken two clock cycles earlier. The

= C × (VN – V

N

) (4)

N–2

average current flow into the input (provided from an external

source) is given in the following equation,

I = delta q/T ~ C × (V

where T represents the period of CLK and f

N

– V

N–2

) × f

CLOCK

represents the

CLOCK

(5)

frequency of CLK. Equations 4 and 5 provide simplifying approximations of the operation of the analog input structure of

the AD9260. A more exact, detailed description and analysis of

the input operation is provided below.

SS3

SS1

VINA

CPA1

SS2

VINB

CPA2

CPB1

CPB2

CS1

CS2

SH3

SH4

SH1

SS4

SH2

ANALOG

MODULATOR

Figure 55. Detailed Analog Input Structure

Figure 55 illustrates the analog input structure of the AD9260.

For the moment, ignore the presence of the parasitic capacitors

CPA and CPB. The effects of these parasitic capacitors will be

discussed near the end of this section. The switched capacitors,

CS1 and CS2, sample the input voltages applied on pins VINA

and VINB. These capacitors are connected to input pins VINA

and VINB when CLK is low. When CLK rises, a sample of the

input signal is taken on capacitors CS1 and CS2. When CLK is

high, capacitors CS1 and CS2 are connected to the Analog

Modulator. The modulator precharges capacitors CS1 and CS2

to minimize the amount of charge required from any circuit

used in combination with the AD9260 to drive input pins VINA

and VINB. This reduces the input drive requirements of the

analog circuitry driving pins VINA and VINB. The Analog

Modulator precharges the voltages across capacitors CS1 and

CS2, approximately equal to a delayed version of the input

signal. When capacitors CS1 and CS2 are connected to input

pins VINA and VINB, the differential charge, Q(n), on these

capacitors is given in the following equation,

Q(n) = q1 – q2 = CS × VCORE (6)

–21–REV. B

Page 22

AD9260

where q1 and q2 are the individual charges stored on capacitors

CS1 and CS2 respectively, and CS is the capacitance value of

CS1 and CS2. When capacitors CS1 and CS2 are connected to

the Analog Modulator during the preceding “precharge” clock

phase, the capacitors are precharged equal to an approximation

of a previous sample of the input signal. Consequently the

differential charge on these capacitors while CLK is high is

given in the following equation,

Q(n–1) = CS × VCORE(delay) + CS × Vdelta (7)

where VCORE(delay) is the value of VCORE sampled during a

previous period of CLK, and Vdelta is the sigma-delta error

voltage left on the capacitors. Vdelta is a natural artifact of the

sigma-delta feedback techniques utilized in the Analog Modulator of the AD9260. It is a small random voltage term that

changes every clock period and varies from 0 to ±0.05 × VREF.

The analog circuitry used to drive the input pins of the AD9260

must respond to the charge glitch that occurs when capacitors

CS1 and CS2 are connected to input pins VINA and VINB. This

circuitry must provide additional charge, qdelta, to capacitors

CS1 and CS2, which is the difference between the precharged

value, Q(n–1), and the new value, Q(n), as given in the following equation,

Qdelta = Q(n) – Q(n–1) (8)

Qdelta = CS × [VCORE–VCORE(delay) + Vdelta] (9)

DRIVING THE INPUT

Transient Response

The charge glitch occurs once at the beginning of every period

of the input CLK (falling edge), and the sample is taken on

capacitors CS1 and CS2 exactly one-half period later (rising

edge). Figure 56 presents a typical input waveform applied to

input Pins VINA and VINB of the AD9260.

TRACK SAMPLE TRACK SAMPLE TRACK SAMPLE TRACK SAMPLE

CLOCK

VINA-VINB

Figure 56. Typical Input Waveform

Figure 56 illustrates the effect of the charge glitch when a source

with nonzero output impedance is used to drive the input pins.

This source must be capable of settling from the charge glitch in

one-half period of the CLK. Unfortunately, the MOS switches

used in any CMOS-switched capacitor circuit (including those

in the AD9260) include nonlinear parasitic junction capacitances connected to their terminals. Figure 55 also illustrates

the parasitic capacitances, Cpa1, Cpb1, Cpa2 and Cpb2, associated with the input switches.

Parasitic capacitor Cpa1 and Cpa2 are always connected to Pins

VINA and VINB and therefore do not contribute to the glitch

energy. Parasitic capacitors Cpb1 and Cpb2, on the other hand,

cause a charge glitch that adds to that of input capacitors CS1

and CS2 when they are connected to input Pins VINA and

VINB. The nonlinear junction capacitance of Cpb1 and Cpb2

cause charge glitch energy that is nonlinearily related to the

input signal. Therefore, linear settling is difficult to achieve

unless the input source completely settles during one-half

period of CLK. A portion of the glitch impulse energy “kicked”

back at the source is not linearly related to the input signal.

Therefore, the best way to ensure that the input signal settles

linearly is to use wide bandwidth circuitry, which settles as

completely as possible from the glitch during one-half period of

the CLK.

The AD9260 utilizes a proprietary clock-boosted boot-strapping

technique to reduce the nonlinear parasitic capacitances of the

internal CMOS switches. This technique improves the linearity

of the input switches and reduces the nonlinear parasitic capacitance. Thus, this technique reduces the nonlinear glitch energy.

The capacitance values for the input capacitors and parasitic

capacitors for the input structure of the AD9260, as illustrated

in Figure 55, are listed as follows.

CS = 3.2 pF, Cpa = 6 pF, Cpb = 1 pF (where CS is the capacitance value of capacitors CS1 and CS2, Cpa is the value of

capacitors Cpa1 and Cpa2, and Cpb is the value of capacitors

Cpb1 and Cpb2). The total capacitance at each input pin is

= CS + Cpa + Cpb = 10.2 pF.

C

IN

Input Driver Considerations

The optimum noise and distortion performance of the AD9260 can

ONLY be achieved when the AD9260 is driven differentially with a

4 V input span . Since not all applications have a signal precon-

ditioned for differential operation, there is often a need to perform a single-ended-to-differential conversion. In the case of the

AD9260, a single-ended-to-differential conversion is best realized

using a differential op amp driver. Although a transformer will

perform a similar function for ac signals, its usefulness is precluded by its inability to directly drive the AD9260 and thus the

additional requirement of an active low noise, low distortion

buffer stage.

Single-Ended-to-Differential Op Amp Driver

There are two single-ended-to-differential op amp driver circuits useful for driving the AD9260. The first circuit, shown in

Figure 57, uses the AD8138 and represents the best choice in

most applications. The AD8138 is a low-distortion differential

ADC driver designed to convert a ground-referenced singleended input signal to a differential output signal with a specified

common-mode level for dc-coupling applications. It is capable

of maintaining the typical THD and SFDR performance of the

AD9260 with only a slight degradation in its noise performance

in the 8× mode (i.e., SNR of 85 dB–86 dB).

In this application, the AD8138 is configured for unity gain and

its common-mode output level is set to 2.5 V (i.e., VREF of the

AD9260) to maximize its output headroom while operating from a

single supply. Note, single-supply operation has the benefit of

not requiring an input protection network for the AD9260 in

dc-coupled applications. A simple R-C network at the output is

used to filter out high-frequency noise from the AD8138. Recall,

the AD9260’s small signal bandwidth is 75 MHz, hence any

noise falling within the baseband bandwidth of the AD9260

defined by its sample and decimation rate, as well as “images”

of its baseband response occurring at multiples of the sample

rate, will degrade its overall noise performance.

–22–

REV. B

Page 23

AD9260

499

499 50

+5V

100pF

AD8138

50

499

100pF

C

S

C

S

VINA

AD9260

VINB

VREF

0.1F10F

VIN

499

Figure 57. AD8138 Single-Ended Differential ADC Driver

The second driver circuit, shown in Figure 58, can provide slightly

enhanced noise performance relative to the AD8138, assuming

low-noise, high-speed op amps are used. This differential op amp

driver circuit is configured to convert and level-shift a 2 V p-p

single-ended, ground-referenced signal to a 4 V p-p differential

signal centered at the common-mode level of the AD9260. The

circuit is based on two op amps that are configured as matched

unity gain difference amplifiers. The single-ended input signal is

applied to opposing inputs of the difference amplifiers, thus

providing differential outputs. The common-mode offset voltage

is applied to the noninverting resistor leg of each difference amplifier providing the required offset voltage. This offset voltage is

derived from the common-mode level (CML) pin of the AD9260

via a low output impedance buffer amplifier capable of driving a

1 µF capacitive load. The common-mode offset can be varied

over a 1.8 V to 2.5 V span without any serious degradation in

distortion performance as shown in Figure 44, thus providing

some flexibility in improving output compression distortion from

some ± 5 op amps with limited positive voltage swing.

To protect the AD9260 from an undervoltage fault condition

from op amps specified for ±5 V operation, two 50 Ω series

resistors and a diode to AGND are inserted between each op

amp output and the AD9260 inputs. The AD9260 will inherently

be protected against any overvoltage condition if the op amps

share the same positive power supply (i.e., AVDD) as the AD9260.

Note, the gain accuracy and common-mode rejection of each difference amplifier in this driver circuit can be enhanced by using

a matched thin-film resistor network (i.e., Ohmtek ORNA5000F)

for the op amps. Resistor values should be 500 Ω or less to maintain the lowest possible noise.

The noise performance of each unity gain differential driver

circuit is limited by its inherent noise gain of two. For unity gain

op amps ONLY, the noise gain can be reduced from two to one

R

V

-VIN

CML

50

R

C

C

R

R

C

C

100pF

F

C

V

-VIN

CML

F

100pF

C

50

C

D

100pF

0.1F

50

50

AD817

1.0F

VINA

AD9260

VINB

CML

VIN

R

R

R

R

Figure 58. DC-Coupled Differential Driver with

Level-Shifting

beyond the input signals passband by adding a shunt capacitor,

C

, across each op amp’s feedback resistor. This will essentially

F

establish a low-pass filter which reduces the noise gain to one

beyond the filter’s f

input signal to f

–3 dB

while simultaneously bandlimiting the

–3 dB

. Note, the pole established by this filter can

also be used as the real pole of an antialiasing filter. Since the

noise contribution of two op amps from the same product family

are typically equal but uncorrelated, the total output-referred

noise of each op amp will add root-sum square leading to a

further 3 dB degradation in the circuit’s noise performance.

Further out-of-band noise reduction can be realized with the

addition of single-ended and differential capacitors, C

and CD.

S

The distortion and noise performance of the two op amps

within the signal path are critical in achieving the AD9260’s

optimum performance. Low noise op amps capable of providing

greater than 85 dB THD at 1 MHz while swinging over a 1 V to

3 V range are a rare commodity, yet should only be considered.

The AD9632 op amp was found to provide superb distortion

performance in this circuit due to its ability to maintain excellent distortion performance over a wide bandwidth while swinging over a 1 V to 3 V range. Since the AD9632 is gain-of-two or

greater stable, the use of the noise reduction shunt capacitors

discussed above was prohibited thus degrading its noise performance slightly (1 dB–2 dB) when compared to the OPA642.

Note, the majority of the AD9260 test and characterization data

presented in this data sheet was taken using the AD9632 op

amp in this dc coupled driver circuit. This driver circuit is also

provided on the AD9260 evaluation board since the AD8138

was unreleased at that time.

Table IV. Reference Configuration Summary

Reference Input Span (VINA–VINB) Required VREF

Operating Mode (V p-p) (V) Connect To

INTERNAL 1.6 1 SENSE VREF

INTERNAL 4.0 2.5 SENSE REFCOM

INTERNAL 1.6 ≤ SPAN ≤ 4.0 and 1 ≤ VREF ≤ 2.5 and R1 VREF and SENSE

SPAN = 1.6 × VREF VREF = (1+R1/R2) R2 SENSE and REFCOM

EXTERNAL 1.6 ≤ SPAN ≤ 4.0 1 ≤ VREF ≤ 2.5 SENSE AVDD

VREF EXT. REF.

–23–REV. B

Page 24

AD9260

The outputs of each op amp are ac coupled via a small series

resistor and capacitor (i.e., 50 Ω and 0.1 µF) to the respective

inputs of the AD9260. Similar to the dc coupled driver, further

out-of-band noise reduction can be realized with the addition of

100 pF single-ended and differential capacitors, CS and CD.

The lower-cutoff frequency of this ac coupled circuit is determined by R

level pin, CML, of the AD9260 for proper biasing of the inputs.

Although the OPA642 was found to provide the lowest overall

noise and distortion performance (i.e., 88.8 dB and 96 dB

THD @ 100 kHz), the AD8055 (or dual AD8056) suffered

only a 0.5 dB to 1.5 dB degradation in overall performance. It

is worth noting that given the high-level of performance attainable

by the AD9260, special consideration must be given to both the

quality of the test equipment and test setup in its evaluation.

Common-Mode Level

The CML pin is an internal analog bias point used internally by

the AD9260. This pin must be decoupled to analog ground

with at least a 0.1 µF capacitor as shown in Figure 59. The dc

level of CML is approximately AVDD/2.5. This voltage should

be buffered if it is to be used for any external biasing.

Note: the common-mode voltage of the input signal applied to

the AD9260 need not be at the exact same level as CML. While

this level is recommended for optimal performance, the AD9260 is

tolerant of a range of input common-mode voltages around

AVDD/2.5.

REFERENCE OPERATION

The AD9260 contains an onboard bandgap reference and internal reference buffer amplifier. The onboard reference provides a

pin-strappable option to generate either a 1 V or 2.5 V output.

With the addition of two external resistors, the user can generate

reference voltages other than 1 V and 2.5 V. Another alternative is to use an external reference for designs requiring enhanced accuracy and/or drift performance. See Table IV for a

summary of the pin-strapping options for the AD9260 reference

configurations. Note, the optimum noise and distortion can only be

achieved with a 2.5 V reference.

Figure 60 shows a simplified model of the internal voltage reference of the AD9260. A pin-strappable reference amplifier

buffers a 1 V fixed reference. The output from the reference

amplifier, A1, appears on the VREF pin and MUST be decoupled with 0.1 µF and 10 µF capacitor to REFCOM. The

voltage on the VREF pin determines the full-scale input span of

the A/D. This input span equals:

The voltage appearing at the VREF pin, as well as the state of

the internal reference amplifier, A1, are determined by the voltage appearing at the SENSE pin. The logic circuitry contains

two comparators that monitor the voltage at the SENSE pin.

The comparator with the lowest set point (approximately 0.3 V)

and CC in which RC is tied to the common-mode

C

0.1F

CML

AD9260

Figure 59. CML Decoupling

Full-Scale Input Span = 1.6 × VREF

TO A/D

6.25k

6.25k

DISABLE

–

1V

AD9260

DISABLE

A1

5k

A2

5k

A2

+

LOGIC

A1

LOGIC

CAPT

CAPB

VREF

7.5k7.5k

SENSE

5k

REFCOM

Figure 60. Simplified Reference

controls the position of the switch within the feedback path of

A1. If the SENSE pin is tied to REFCOM, the switch is connected to the internal resistor network, thus providing a VREF

of 2.5 V. If the SENSE pin is tied to the VREF pin via a short

or resistor, the switch is connected to the SENSE pin. A short

will provide a VREF of 1.0 V while an external resistor network

will provide an alternative VREF SPAN between 1.0 V and

2.5 V. The external resistor network may, for example, be

implemented as a resistor divider circuit. This divider circuit

could consist of a resistor (R1) connected between VREF and

SENSE and another resistor (R2) connected between SENSE

and REFCOM. The other comparator controls internal circuitry that will disable the reference amplifier if the SENSE pin

is tied to AVDD. Disabling the reference amplifier allows the

VREF pin to be driven by an external voltage reference.

The reference buffer circuit, level shifts the reference to an

appropriate common-mode voltage for use by the internal circuitry. The on-chip buffer provides the low impedance necessary for driving the internal switched capacitor circuits and

eliminates the need for an external buffer op amp.

The actual reference voltages used by the internal circuitry of

the AD9260 appear on the CAPT and CAPB pins. If VREF is

configured for 2.5 V, thus providing a 4 V full-scale input span,

the voltages appear at CAPT and CAPB are 3.0 V and 1.0 V

respectively. For proper operation when using the internal or an

external reference, it is necessary to add a capacitor network to

decouple the CAPT and CAPB pins. Figure 61 shows the recommended decoupling network. This capacitive network performs the following three functions: (1) along with the reference

amplifier, A2, it provides a low source impedance over a large

frequency range to drive the A/D internal circuitry, (2) it provides the necessary compensation for A2, and (3) it bandlimits

the noise contribution from the reference. The turn-on time of

the reference voltage appearing between CAPT and CAPB is

approximately 15 ms and should be evaluated in any powerdown mode of operation.

–24–

REV. B

Page 25

AD9260

0.1F

AD9260

V

REF

+

10F

SENSE

REFCOM

CAPT

0.1F

CAPB

0.1F

+

10F

0.1

F

Figure 61. Recommended Reference Decoupling Network

DIGITAL INPUTS AND OUTPUTS

Digital Outputs

The AD9260 output data is presented in a twos complement

format. Table V indicates the output data formats for various

input ranges and decimation modes. A straight binary output

data format can be created by inverting the MSB.

Table V. Output Data Format

Input (V) Condition (V) Digital Output

8 Decimation Mode

VINA–VINB < –0.8 × VREF 1000 0000 0000 0000

VINA–VINB = –0.8 × VREF 1000 0000 0000 0000

VINA–VINB = 0 0000 0000 0000 0000

VINA–VINB = +0.8 × VREF – 1 LSB 0111 1111 1111 1111

VINA–VINB >= + 0.8 × VREF 0111 1111 1111 1111

4 Decimation Mode

VINA–VINB < –0.825 × VREF 1000 0001 0001 1100

VINA–VINB = –0.825 × VREF 1000 0001 0000 1100

VINA–VINB = 0 0000 0000 0000 0000

VINA–VINB = +0.825 × VREF – 1 LSB 0111 1110 1110 0011

VINA–VINB >= + 0.825 × VREF 0111 1110 1110 0011

2 Decimation Mode

VINA–VINB < –0.825 × VREF 1000 0000 0100 0001

VINA–VINB = –0.825 × VREF 1000 0000 0100 0001

VINA–VINB = 0 0000 0000 0000 0000

VINA–VINB = +0.825 × VREF – 1 LSB 0111 1111 1011 1110

VINA–VINB >= + 0.825 × VREF 0111 1111 1011 1110

The slight different ± full-scale input voltage conditions and

their corresponding digital output code for the 4× and 2× decimation modes can be attributed to the different digital scaling

factors applied to each of the AD9260’s FIR decimation stages

for filter optimization purposes. Thus, a + full-scale reading of

0111 1111 1111 1111 and – full-scale reading of 1000 0000

0000 0000 is unachievable in the 2× and 4× decimation mode.

As a result, a digital overrange condition can never exist in the

2× and 4× decimation mode and thus OTR being set high indicates an overrange condition in the analog modulator.

The output data format in 1× decimation differs from that in 2×,

4× and 8× decimation modes. In 1× decimation mode the output data remains in a twos complement format, but the digital

numbers are scaled by a factor of 7/128. This factor of 7/128 is

the product of an internal scale factor of 7/8 in the analog modulator and a 1/16 scale factor caused by LSB justification of the

12-bit modulator data.

CS AND READ PINS

The CS and READ pins control the state of the output data

pins (BIT1–BIT16) on the AD9260. The CS pin is active low

and the READ pin is active high. When CS and READ are

both active the ADC data is driven on the output data pins,

otherwise the output data pins are in a high-impedance (Hi-Z)

–25–REV. B

state. Table VI indicates the relationship between the CS and

READ pins and the state of Pins Bit 1–Bit 16.

Table VI. CS and READ Pin Functionality

CS READ Condition of Data Output Pins

Low Low Data Output Pins in Hi-Z State

Low High ADC Data on Output Pins

High Low Data Output Pins in Hi-Z State

High High Data Output Pins in Hi-Z State

DAV PIN

The DAV pin indicates when the output data of the AD9260 is