Page 1

8-Bit

a

40 MSPS/60 MSPS/80 MSPS A/D Converter

FEATURES

8-Bit, Low Power ADC: 200 mW Typical

120 MHz Analog Bandwidth

On-Chip +2.5 V Reference and T/H

1 V p-p Analog Input Range

Single +5 V Supply Operation

+5 V or +3 V Logic Interface

Power-Down Mode: < 10 mW

Three Performance Grades (40 MSPS, 60 MSPS, 80 MSPS)

APPLICATIONS

Digital Communications (QAM Demodulators)

RGB & YC/Composite Video Processing

Digital Data Storage Read Channels

Medical Imaging

Digital Instrumentation

PRODUCT DESCRIPTION

The AD9057 is an 8-bit monolithic analog-to-digital converter

optimized for low cost, low power, small size, and ease of use.

With a 40 MSPS, 60 MSPS or 80 MSPS encode rates capability and full-power analog bandwidth of 120 MHz, the component is ideal for applications requiring excellent dynamic

performance.

To minimize system cost and power dissipation, the AD9057

includes an internal +2.5 V reference and a track-and-hold

circuit. The user must provide only a +5 V power supply and an

encode clock. No external reference or driver components are

required for many applications.

The AD9057’s encode input is TTL/CMOS compatible and the

8-bit digital outputs can be operated from +5 V or +3 V supplies.

A power-down function may be exercised to bring total consumption to < 10 mW. In power-down mode the digital outputs

are driven to a high impedance state.

Fabricated on an advanced BiCMOS process, the AD9057 is

available in a space saving 20-lead surface mount plastic package (20 SSOP) and is specified over the industrial (–40°C to

+85°C) temperature range.

AD9057

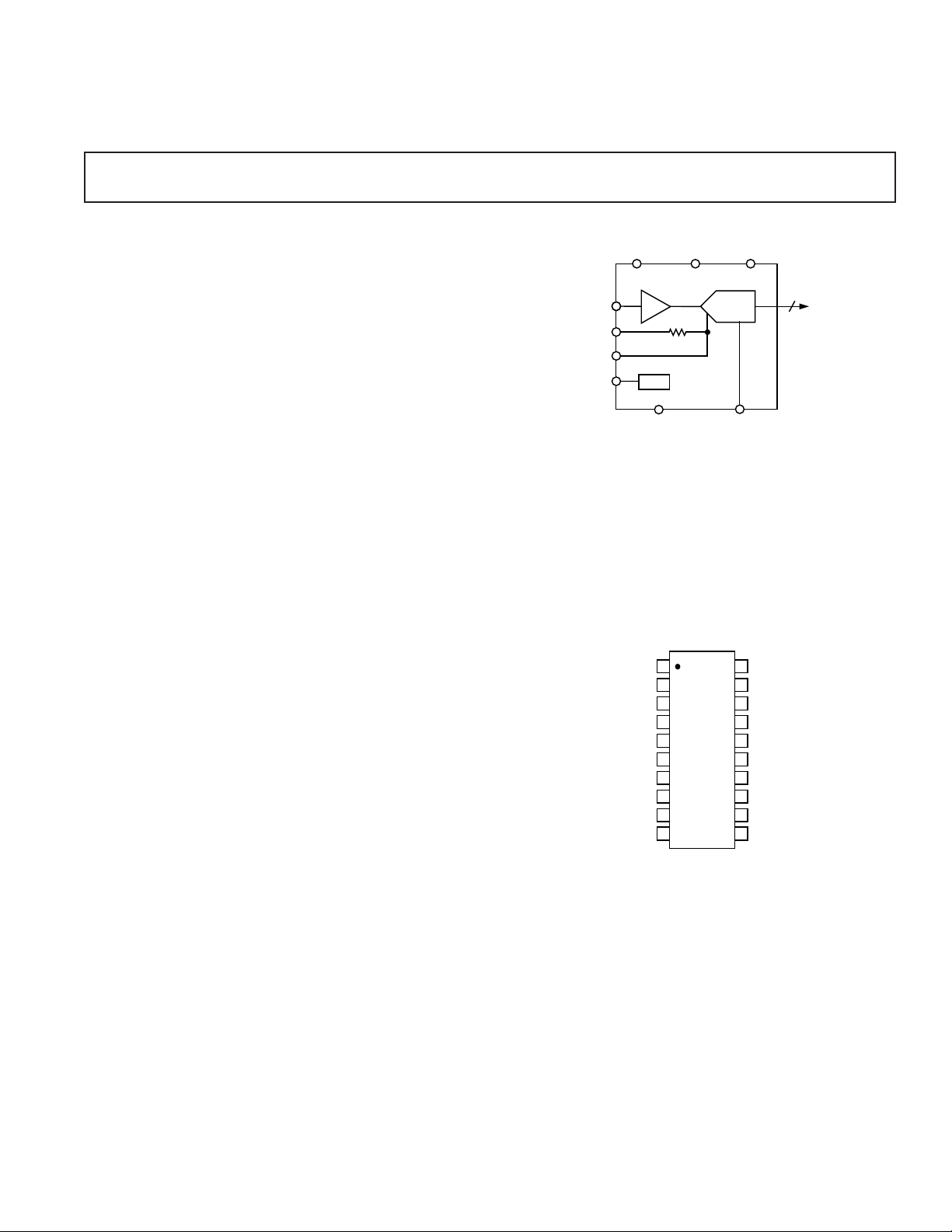

FUNCTIONAL BLOCK DIAGRAM

V

AIN

BIAS OUT

VREF IN

VREF OUT

Customers desiring multichannel digitization may consider the

AD9059, a dual 8-bit, 60 MSPS monolithic based on the

AD9057 ADC core. The AD9059 is available in a 28-lead surface mount plastic package (28 SSOP) and is specified over the

industrial temperature range.

PIN CONFIGURATION

PWRDN

VREF OUT

VREF IN

BIAS OUT

ENCODE

D

+2.5V

GND

V

AIN

V

GND

AD9057

1kΩ

GND

1

2

3

4

5

D

6

7

8

D

9

10

(Not to Scale)

PWRDN V

ADCT/H

ENCODE

AD9057

TOP VIEW

20

19

18

17

16

15

14

13

12

11

DD

D0 (LSB)

D1

D2

D3

GND

V

DD

D4

D5

D6

D7 (MSB)

8

D7–D0

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1997

Page 2

AD9057–SPECIFICA TIONS

(VD = +5 V, VDD = +3 V; external reference)

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Units

Test AD9057BRS-40 AD9057BRS-60 AD9057BRS-80

RESOLUTION 8 8 8 Bits

DC ACCURACY

Differential Nonlinearity +25°C I 0.75 1.9 0.75 1.9 0.75 1.9 LSB

Full VI 2.0 2.0 2.0 LSB

Integral Nonlinearity +25°C I 0.75 1.9 0.75 1.9 0.75 1.9 LSB

Full VI 2.0 2.0 2.0 LSB

No Missing Codes Full VI GUARANTEED GUARANTEED GUARANTEED

Gain Error

Gain Tempco

1

1

+25°C I –6 –2.5 +6 –6 –2.5 +6 –6 –2.5 +6 % FS

Full VI –8 +8 –8 +8 –8 +8 % FS

Full V ±70 ±70 ±70 ppm/°C

ANALOG INPUT

Input Voltage Range

(Centered at +2.5 V) +25°C V 1.0 1.0 1.0 V p-p

Input Offset Voltage +25°C I –15 ±0 +15 –15 ±0 +15 –15 ±0 +15 mV

Full VI –25 +25 –25 +25 –25 +25 mV

Input Resistance +25°C V 150 150 150 kΩ

Input Capacitance +25°CV222pF

Input Bias Current +25°CI 616 616 616µA

Full VI 25 25 25 µA

Analog Bandwidth +25°C V 120 120 120 MHz

BANDGAP REFERENCE

Output Voltage Full VI 2.4 2.5 2.6 2.4 2.5 2.6 2.4 2.5 2.6 V

Temperature Coefficient Full V ±10 ±10 ±10 ppm/°C

SWITCHING PERFORMANCE

Maximum Conversion Rate Full VI 40 60 80 MSPS

Minimum Conversion Rate Full IV 5 5 5 MSPS

Aperture Delay (t

Aperture Uncertainty (Jitter) +25°C V 5 5 5 ps, rms

Output Valid Time (t

) +25°C V 2.7 2.7 2.7 ns

A

2

)

V

Full IV 4.0 6.6 4.0 6.6 4.0 6.6 ns

Output Propagation Delay (tPD)2Full IV 11.5 18.0 9.5 14.2 8.0 11.3 ns

DYNAMIC PERFORMANCE

3

Transient Response +25°CV999ns

Overvoltage Recovery Time +25°CV999ns

Signal-to-Noise Ratio (SINAD)

(With Harmonics)

= 10.3 MHz +25°C I 42 45.5 42 45 41.5 45 dB

f

IN

= 76 MHz +25°C V 44.0 43.5 43.5 dB

f

IN

Effective Number of Bits

= 10.3 MHz +25°C I 6.7 7.2 6.7 7.2 6.6 7.2 Bits

f

IN

= 76 MHz +25°C V 7.0 6.9 6.9 Bits

f

IN

Signal-to-Noise Ratio (SNR)

(Without Harmonics)

= 10.3 MHz +25°C I 43 46.5 43 46 42.5 46 dB

f

IN

= 76 MHz +25°C V 45.5 45 45 dB

f

IN

2nd Harmonic Distortion

= 10.3 MHz +25°C I –50 –62 –50 –62 –50 –62 dBc

f

IN

= 76 MHz +25°C V –54 –54 –54 dBc

f

IN

3rd Harmonic Distortion

= 10.3 MHz +25°C I –46 –60 –46 –60 –46 –60 dBc

f

IN

= 76 MHz +25°C V –54 –54 –54 dBc

f

IN

Two Tone Intermodulation

Distortion (IMD) +25°C V –52 –52 –52 dBc

Differential Phase +25°C V 0.8 0.8 0.8 Degrees

Differential Gain +25°C V 1.0 1.0 1.0 %

DIGITAL INPUTS

Logic “1” Voltage Full VI 2.0 2.0 2.0 V

Logic “0” Voltage Full VI 0.8 0.8 0.8 V

Logic “1” Current Full VI ±1 ±1 ±1 µA

Logic “0” Current Full VI ±1 ±1 ±1 µA

Input Capacitance +25°C V 4.5 4.5 4.5 pF

Encode Pulse Width High (t

) +25°C IV 9.0 166 6.7 166 5.5 166 ns

EH

Encode Pulse Width Low (tEL) +25°C IV 9.0 166 6.7 166 5.5 166 ns

–2–

REV. B

Page 3

AD9057

Parameter Temp Level Min Typ Max Min Typ Max Min Typ Max Units

Test AD9057BRS-40 AD9057BRS-60 AD9057BRS-80

DIGITAL OUTPUTS

Logic “1” Voltage (V

= +3 V) Full VI 2.95 V

DD

Logic “1” Voltage (VDD = +5 V) Full IV 4.95 V

Logic “0” Voltage Full VI 0.05 V Output Coding

Offset Binary Code

POWER SUPPLY

V

Supply Current (VD = +5 V) Full VI 36 48 38 48 40 51 mA

D

VDD Supply Current (VDD = +3 V)4Full VI 4.0 6.5 5.5 6.5 7.4 8.8 mA

Power Dissipation

5, 6

Full VI 192 260 205 260 220 281 mW

Power-Down Dissipation Full VI 6 10 6 10 6 10 mW

Power Supply Rejection Ratio

(PSRR) +25°C I 15 15 15 mV/V

NOTES

1

Gain error and gain temperature coefficient are based on the ADC only (with a fixed +2.5 V external reference).

2

tV and tPD are measured from the 1.5 V level of the ENCODE to the 10%/90% levels of the digital output swing. The digital output load during test is not to exceed

an ac load of 10 pF or a dc current of ±40 µA.

3

SNR/harmonics based on an analog input voltage of –0.5 dBFS referenced to a 1.0 V full-scale input range.

4

Digital supply current based on VDD = +3 V output drive with <10 pF loading under dynamic test conditions.

5

Power dissipation is based on specified encode and 10.3 MHz analog input dynamic test conditions (V

6

Typical thermal impedance for the RS style (SSOP) 20-pin package: θJC = 46°C/W, θCA = 80°C/W, θJA = 126°C/W.

= +5 V ± 5%, VDD = +3 V ± 5%).

D

Specifications subject to change without notice.

EXPLANATION OF TEST LEVELS

Test Level Description

I 100% Production Tested

II 100% Production Tested at +25°C and Sample

Tested at Specified Temperatures

III Sample Tested Only

IV Parameter is Guaranteed by Design and Char-

acterization Testing

V Parameter is a Typical Value Only

VI 100% Production Tested at +25°C; Guaran-

teed by Design and Characterization Testing

for Industrial Temperature Range

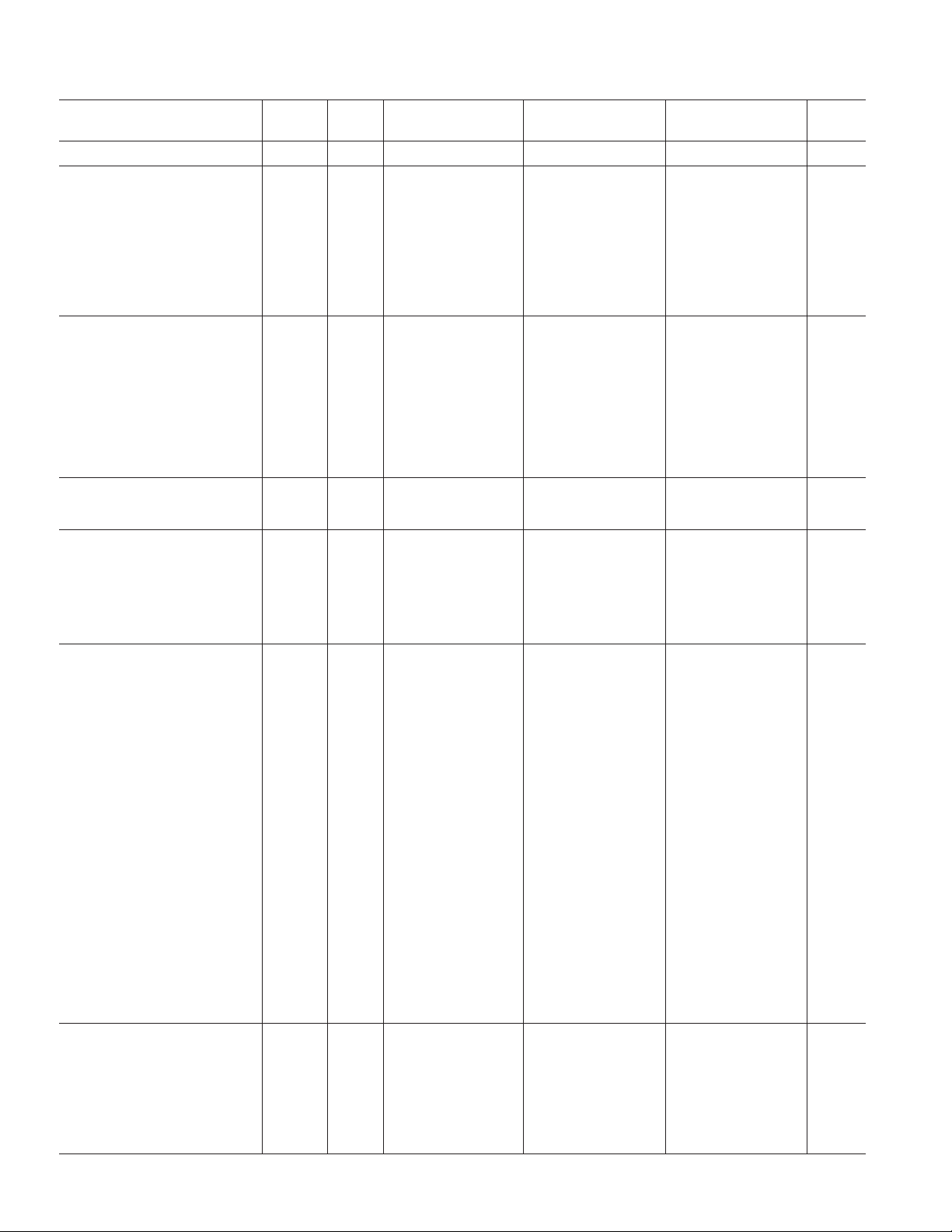

AIN

ENCODE

DIGITAL

OUTPUTS

N

N + 1

t

A

t

EH

N – 3 N – 2 N – 1 N N + 1 N + 2

N + 2

t

EL

N + 3

N + 4

t

V

t

PD

N + 5

REV. B

t

APERTURE DELAY

A

t

PULSE WIDTH HIGH

EH

t

PULSE WIDTH LOW

EL

t

V

OUTPUT VALID TIME

t

PD

OUTPUT PROP DELAY

Figure 1. Timing Diagram

–3–

MIN TYP MAX

2.7 ns

166 ns

166 ns

6.6 ns

4.0 ns

9.5 ns

Page 4

AD9057

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

VD, VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7 V

Analog Inputs . . . . . . . . . . . . . . . . . . . . –0.5 V to V

Digital Inputs . . . . . . . . . . . . . . . . . . . . –0.5 V to V

V

Input . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to VD + 0.5 V

REF

+ 0.5 V

D

+ 0.5 V

DD

Digital Output Current . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Operating Temperature . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . +175°C

Maximum Case Temperature . . . . . . . . . . . . . . . . . . +150°C

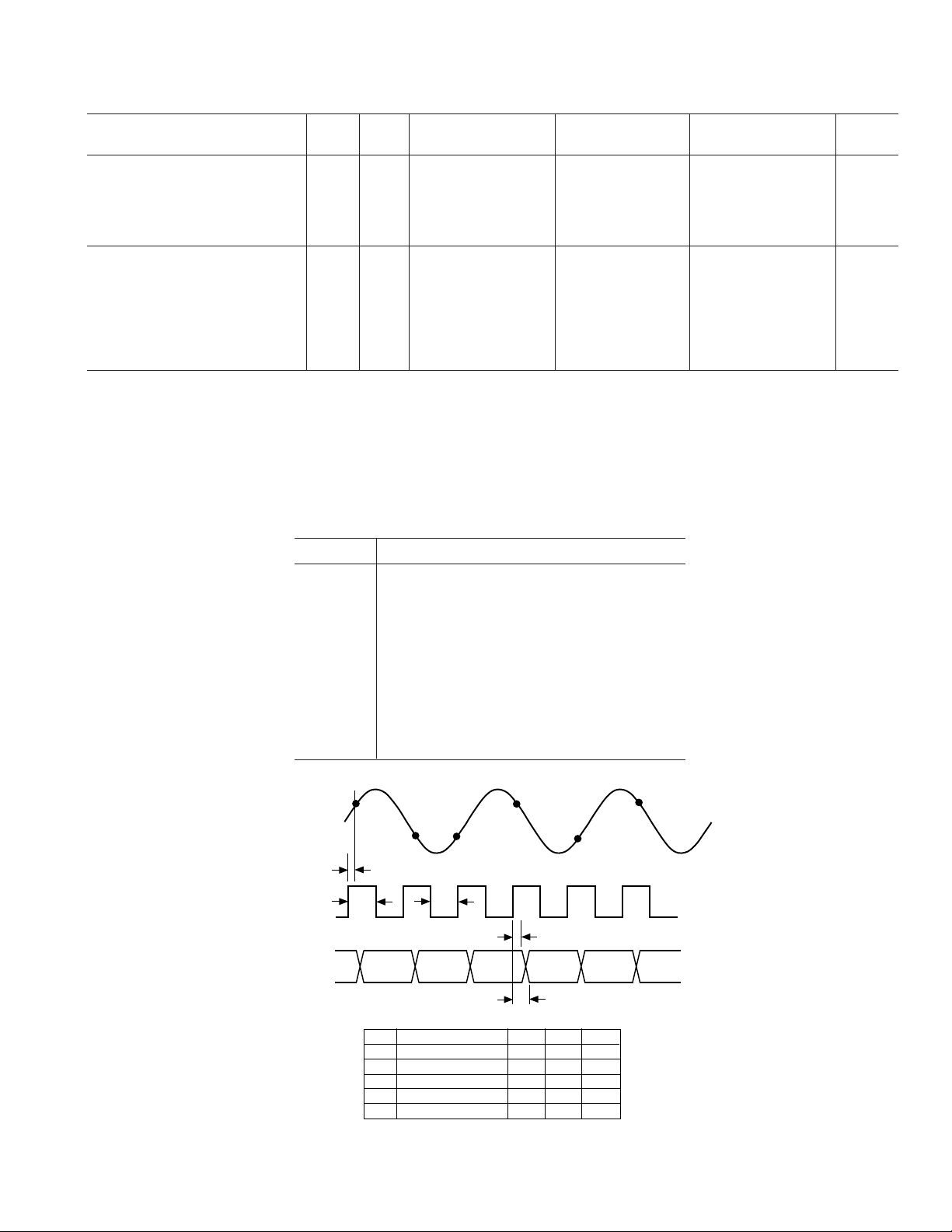

ORDERING GUIDE

Temperature

Model Range Package Option*

AD9057BRS–40, –60, –80 –40° C to +85°C RS-20

AD9057/PCB +25°C Evaluation Board

*RS = Shrink Small Outline (SSOP).

Table I. Digital Coding (VREF = +2.5 V)

Analog Input Voltage Level Digital Output

3.0 V Positive Full Scale 1111 1111

2.502 V Midscale +1/2 LSB 1000 0000

2.498 V Midscale –1/2 LSB 0111 1111

2.0 Negative Full Scale 0000 0000

PIN DESCRIPTIONS

Pin No. Name Function

1 PWRDN Power-Down Function Select;

Logic HIGH for Power-Down

Mode (Digital Outputs Go to

High Impedance State).

2 VREF OUT Internal Reference Output

(+2.5 V typ); Bypass with

0.1 µF to Ground.

3 VREF IN Reference Input for ADC (+2.5

V typ, ±10%).

4, 9, 16 GND Ground (Analog/Digital).

5, 8 V

D

Analog +5 V Power Supply.

6 BIAS OUT Bias Pin for AC Coupling

(1 kΩ to REF IN).

7 AIN Analog Input for ADC.

10 ENCODE Encode Clock for ADC (ADC

Samples on Rising Edge of

ENCODE).

11–14, 17–20 D7–D4, D3–D0 Digital Outputs of ADC.

15 V

DD

Digital Output Power Supply.

Nominally +3 V to +5

V.

PIN CONFIGURATION

PWRDN

VREF OUT

VREF IN

GND

BIAS OUT

AIN

GND

ENCODE

V

D

V

D

1

2

3

4

AD9057

5

TOP VIEW

(Not to Scale)

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

D0 (LSB)

D1

D2

D3

GND

V

DD

D4

D5

D6

D7 (MSB)

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9057 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–4–

REV. B

Page 5

Typical Performance Characteristics–AD9057

ANALOG INPUT FREQUENCY – MHz

dB

–30

–70

0 16020 40 60 80 100 120 140

–35

–50

–55

–60

–65

–40

–45

ENCODE = 60MSPS

AIN = –0.5dBFS

3RD HARMONIC

2ND HARMONIC

0

–10

–20

–30

–40

dB

–50

–60

–70

–80

–90

030

Figure 2. Spectral Plot 60 MSPS, 10.3 MHz

0

ENCODE = 60MSPS

ANALOG IN = 76MHz, –0.5dBFS

–10

SINAD = 44.9dB

ENOB = 7.16 BITS

–20

SNR = 45.2dB

–30

–40

dB

–50

–60

–70

–80

–90

030

ENCODE = 60MSPS

ANALOG IN = 10.3MHz, –0.5dBFS

SINAD = 46.1dB

ENOB = 7.36 BITS

SNR = 46.5dB

FREQUENCY – MHz

FREQUENCY – MHz

Figure 5. Harmonic Distortion vs. AIN Frequency

0

–10

–20

–30

–40

dB

–50

–60

–70

–80

–90

03010 20

ENCODE = 60MSPS

F1 IN = 9.5MHz @ –7.0dBFS

F2 IN = 9.9MHz @ –7.0dBFS

2F1 - F2 = –52.0dBc

2F2 - F1 = –53.0dBc

FREQUENCY – MHz

Figure 3. Spectral Plot 60 MSPS, 76 MHz

48

46

44

42

40

dB

REV. B

ENCODE = 60MSPS

38

AIN = –0.5dBFS

36

34

32

30

0 16020 40 60 80 100 120 140

ANALOG INPUT FREQUENCY – MHz

Figure 4. SINAD/SNR vs. AIN Frequency

SINAD

SNR

–5–

Figure 6. Two-Tone Intermodulation Distortion

54

48

42

36

30

dB

AIN = 10.3MHz, –0.5dBFS

24

18

12

0

5 10 20304050607080 90

ENCODE RATE – MSPS

SNR

SINAD

Figure 7. SINAD/SNR vs. Encode Rate

Page 6

AD9057–

Typical Performance Characteristics

350

300

250

200

mW

150

100

AIN = 10.3MHz, –0.5dBFS

50

0

5 10 2030405060708090

ENCODE RATE – MSPS

VDD = +5V

VDD = +3V

Figure 8. Power Dissipation vs. Encode Rate

46.5

46.0

45.5

45.0

44.5

44.0

dB

43.5

43.0

42.5

42.0

41.5

–45 9002570

ENCODE = 60MSPS

AIN = 10.3MHz, –0.5dBFS

TEMPERATURE – °C

SNR

SINAD

12

11

10

9.5

9.0

8.5

– ns

PD

t

8.0

7.5

7.0

6.5

6.0

–45 9002570

Figure 11. t

46.5

46

45.5

45

44.5

dB

44

43.5

43

42.5

5.8 9.28.35

VDD = +3V

VDD = +5V

TEMPERATURE – °C

vs. Temperature/Supply (VDD = +3 V/+5 V)

PD

SNR

SINAD

ENCODE = 60MSPS

AIN = 10.3MHz, –05dBFS

ENCODE HIGH PULSE WIDTH –

10 10.96.7 7.5

ns

Figure 9. SINAD/SNR vs. Temperature

0

–0.2

–0.4

–0.6

–0.8

–1.0

GAIN ERROR – %

–1.2

–1.4

–1.6

–1.8

–45 9002570

TEMPERATURE – °C

Figure 10. ADC Gain vs. Temperature (with External

+2.5 V Reference)

Figure 12. SINAD/SNR vs. Encode Pulse Width

0

–1

–2

–3

–4

–5

–6

ADC GAIN – dB

–7

–8

–9

–10

1 10 100

ENCODE = 60MSPS

AIN = –0.5dBFS

2 5 20 50 200 500

ANALOG FREQUENCY – MHz

Figure 13. ADC Frequency Response

–6–

REV. B

Page 7

AD9057

THEORY OF OPERATION

The AD9057 combines Analog Devices’ proprietary MagAmp

gray code conversion circuitry with flash converter technology to

provide a high performance, low cost ADC. The design architecture ensures low power, high speed, and 8-bit accuracy. A

single-ended TTL/CMOS compatible ENCODE input controls

ADC timing for sampling the analog input pin and strobing the

digital outputs (D7–D0). An internal voltage reference (VREF

OUT) may be used to control ADC gain and offset or an external reference may be applied.

The analog input signal is buffered at the input of the ADC and

applied to a high speed track-and-hold. The T/H circuit holds

the analog input value during the conversion process (beginning

with the rising edge of the ENCODE command). The T/H’s

output signal passes through the gray code and flash conversion

stages to generate coarse and fine digital representations of the

held analog input level. Decode logic combines the multistage

data and aligns the 8-bit word for strobed outputs on the rising

edge of the ENCODE command. The MagAmp/Flash architecture of the AD9057 results in three pipeline delays for the output data.

USING THE AD9057

Analog Inputs

The AD9057 provides a single-ended analog input impedance of

150 kΩ. The input requires a dc bias current of 6 µA (typical)

centered near +2.5 V (±10%). The dc bias may be provided by

the user or may be derived from the ADC’s internal voltage

reference. Figure 14 shows a low cost dc bias implementation

allowing the user to capacitively couple ac signals directly into

the ADC without additional active circuitry. For best dynamic

performance, the VREF OUT pin should be decoupled to

ground with a 0.1 µF capacitor (to minimize modulation of

the reference voltage) and the bias resistor should be approximately 1 kΩ. A 1 kΩ bias resistor (±20%) is included within

the AD9057 and may be used to reduce application board size

and complexity.

+5V

2

REF OUT

REF IN

0.1µF

0.1µF

VIN

(1V p-p)

3

6

BIAS OUT

AIN

7

1kΩ

AD9057

Figure 14. Capacitively Coupled AD9057

Figure 15 shows typical connections for high performance dc

biasing using the ADC’s internal voltage reference. All components may be powered from a single +5 V supply (in the example

analog input signals are referenced to ground).

+5V

2

REF OUT

3

REF IN

AIN

7

AD9057

VIN

(–0.5V TO +0.5V)

1kΩ

+5V

10kΩ

AD8041

1kΩ

10kΩ

0.1µF

Figure 15. DC Coupled AD9057 (Inverted VIN)

Voltage Reference

A stable and accurate +2.5 V voltage reference is built into the

AD9057 (VREF OUT). The reference output may be used to

set the ADC gain/offset by connecting VREF OUT to VREF IN.

The internal reference is capable of providing 300µA of drive

current (for dc biasing the analog input or other user circuitry).

Some applications may require greater accuracy, improved

temperature performance, or gain adjustments which cannot be

obtained using the internal reference. An external voltage may

be applied to the VREF IN with VREF OUT disconnected for

gain adjustment of up to ±10% (the VREF IN pin is internally

tied directly to the ADC circuitry). ADC gain and offset will

vary simultaneously with external reference adjustment with a

1:1 ratio (a 2% or 50 mV adjustment to the +2.5 V reference

varies ADC gain by 2% and ADC input range center offset by

50 mV). Theoretical input voltage range versus reference input

voltage may be calculated from the following equations:

V

(p-p) = VREF IN/2.5

RANGE

V

MIDSCALE

V

TOP-OF-RANGE

V

BOTTOM-OF-RANGE

= VREF IN

= VREF IN + V

= VREF IN – V

RANGE

RANGE

/2

/2

Digital Logic (+5 V/+3 V Systems)

The digital inputs and outputs of the AD9057 can easily be

configured to interface directly with +3 V or +5 V logic systems.

The ENCODE and power-down (PWRDN) inputs are CMOS

stages with TTL thresholds of 1.5 V, making the inputs compatible with TTL, +5 V CMOS, and +3 V CMOS logic families.

As with all high speed data converters, the encode signal should

be clean and jitter free to prevent degradation of ADC dynamic

performance.

The AD9057’s digital outputs will also interface directly with

+5 V or +3 V CMOS logic systems. The voltage supply pin

(V

) for these CMOS stages is isolated from the analog V

DD

D

voltage supply. By varying the voltage on this supply pin the

digital output HIGH level will change for +5 V or +3 V systems.

Optimum SNR is obtained running the outputs at +3 V. Care

should be taken to isolate the V

supply voltage from the +5 V

DD

analog supply to minimize digital noise coupling into the ADC.

REV. B

–7–

Page 8

AD9057

The AD9057 provides high impedance digital output operation

when the ADC is driven into power-down mode (PWRDN,

logic HIGH). A 200 ns (minimum) power-down time should be

provided before a high impedance characteristic is required at

the outputs. A 200 ns power-up period should be provided to

ensure accurate ADC output data after reactivation (valid output

data is available three clock cycles after the 200 ns delay).

Timing

The AD9057 is guaranteed to operate with conversion rates

from 5 MSPS to 80 MSPS depending on grade. The ADC is

designed to operate with an encode duty cycle of 50%, but performance is insensitive to moderate variations. Pulse width variations of up to ±10% (allowing the encode signal to meet the

minimum/maximum HIGH/LOW specifications) will cause no

degradation in ADC performance (see Figure 1 timing diagram).

Power Dissipation

The power dissipation of the AD9057 is specified to reflect a

typical application setup under the following conditions: analog

input is –0.5 dBFS at 10.3 MHz, V

is +5 V, VDD is +3 V, and

D

digital outputs are loaded with 7 pF typical (10 pF maximum).

The actual dissipation will vary as these conditions are modified

in user applications. Figure 8 shows typical power consumption

for the AD9057 versus ADC encode frequency and V

supply

DD

voltage.

A power-down function allows users to reduce power dissipation

when ADC data is not required. A TTL/CMOS HIGH signal

(PWRDN) shuts down portions of the ADC and brings total

power dissipation to less than 10 mW. The internal bandgap

voltage reference remains active during power-down mode to

minimize ADC reactivation time. If the power-down function is

not desired, Pin 1 should be tied to ground.

APPLICATIONS

The wide analog bandwidth of the AD9057 makes it attractive

for a variety of high performance receiver and encoder applications. Figure 16 shows two ADCs in a typical low cost I & Q

demodulator implementation for cable, satellite, or wireless

LAN modem receivers. The excellent dynamic performance of

the ADC at higher analog input frequencies and encode rates

empowers users to employ direct IF sampling techniques (refer

to Figure 3 spectral plot). IF sampling eliminates or simplifies

analog mixer and filter stages to reduce total system cost and

power.

AD9057

AD9057

VCO

IF IN

90

VCO

BPF

°

BPF

Figure 16. I & Q Digital Receiver

The high sampling rate and analog bandwidth of the AD9057

are ideal for computer RGB video digitizer applications. With a

full-power analog bandwidth of 2× the maximum sampling

rate, the ADC provides sufficient pixel to pixel transient settling time to ensure accurate 60 MSPS video digitization. Figure 17 shows a typical RGB video digitizer implementation for

the AD9057.

RED

GREEN

BLUE

H-SYNC

AD9057

AD9057

AD9057

PLL

8

8

8

PIXEL CLOCK

Figure 17. RGB Video Encoder

Evaluation Board

The AD9057/PCB evaluation board provides an easy to use

analog/digital interface for the 8-bit, 60 MSPS ADC. The

board includes typical hardware configurations for a variety of

high speed digitization evaluations. On board components

include the AD9057 (in the 20-pin SSOP package), an optional

analog input buffer amplifier, a digital output latch, board

timing drivers, an analog reconstruction digital-to-analog converter, and configurable jumpers for ac coupling, dc coupling,

and power-down function testing. The board is configured at

shipment for dc coupling using the AD9057’s internal voltage

reference.

For dc coupled analog input applications, amplifier U2 is configured to operate as a unity gain inverter with adjustable offset

for the analog input signal. For full-scale ADC drive the analog

input signal should be 1 V p-p into 50 Ω (R1) referenced to

ground (0 V). The amplifier offsets the analog signal by

+VREF (+2.5 V typical) to center the voltage for proper ADC

input drive. For dc coupled operation, connect E1 to E2 (analog input to R2) and E11 to E12 (amplifier output to analog

input of AD9057) using the board jumper connectors. DC

offset of the analog input signal can be modified by adjusting

potentiometer R10.

For ac coupled analog input applications, amplifier U2 is

removed from the analog signal path. The analog signal is

coupled into the input of the AD9057 through capacitor C2.

The ADC pulls analog input bias current from the VREF IN

voltage through the 1 kΩ resistor internal to the AD9057

(BIAS OUT). The analog input signal to the board should be

1 V p-p into 50 Ω (R1) for full-scale ADC drive. For ac

coupled operation, connect E1 to E3 (analog input A to C2

feedthrough capacitor) and E10 to E12 (C2 to the analog input

and internal bias resistor) using the board jumper connectors.

The onboard reference voltage may be used to drive the ADC

or an external reference may be applied. To use the internal

voltage reference, connect E6 to E5 (VREF OUT to VREF

IN). To apply an external voltage reference, connect E4 to E5

(external reference from the REF banana jack to VREF IN).

The external voltage reference should be +2.5 V ± 10%.

–8–

REV. B

Page 9

AD9057

The power-down function of the AD9057 can be exercised

through a board jumper connection. Connect E7 to E9 (+5 V to

PWRDN) for power-down operation. For normal operation,

connect E8 to E9 (ground to PWRDN).

The encode signal source should be TTL/CMOS compatible

and capable of driving a 50 Ω termination (R7). The digital

outputs of the AD9057 are buffered through latches on the

evaluation board (U3) and are available for the user at connector Pins 30–37. Latch timing is derived from the ADC ENCODE clock and a digital clocking signal is provided for the

board user at connector Pins 2 and 21.

An onboard reconstruction digital-to-analog converter is

available for quick evaluations of ADC performance using an

+V

D

ENCODE

PWRDN

Digital Inputs

oscilloscope or spectrum analyzer. The DAC converts the

ADC’s digital outputs to an analog signal for examination at

the DAC OUT connector. The DAC is clocked at the ADC

ENCODE frequency. The AD9760 is a 10-bit/100 MSPS single

+5 V supply DAC. The reconstruction signal facilitates quick

system troubleshooting or confirmation of ADC functionality

without requiring external digital memory, timing, or display

interfaces. The DAC can be used for limited dynamic testing,

but customers should note that test results will be based on the

combined performance of the ADC and DAC (the best ADC

performance will be recognized by evaluating the digital outputs

of the ADC directly).

+V

D

AIN

500Ω

Analog Input

V

REFIN

, +3V TO +5V

+V

DD

D0–D7

Digital Outputs

+V

D

V

REFOUT

Output V

V

REF

Figure 18. Equivalent Circuits

V

REFIN

Bias Output

V

REFIN

1kΩ

REF

+V

D

Input

BIAS OUT

+V

D

3kΩ

2.5kΩ

REV. B

–9–

Page 10

AD9057

ANALOG IN

R1

50Ω

J7, V

E2

E1

DD

BNC

J1

E7

+5V

J6, REF

C17

DIS

+V

DD

NC

S

R7

50Ω

0.1µF

8

7

6

5

500Ω

R4

2kΩ

1

2

4

5

12

13

9

10

R10

U4

74AC00

U4

74AC00

U4

74AC00

U4

74AC00

R5

2kΩ

R6

10Ω

U2

ENCODE

C10

0.1µF

AD8041Q

1

NC

2

3

4

–V

BNC

J3

+

S

R3

1kΩ

C11

10µF

V

R2

1kΩ

E3

GND

E4

E5

E6

C1

E12

C2

0.1µF

GND

GND

0.1µF

E11

E10

3

6

11

8

E9

E8

+5V

+5V

PWRDN

1

PWRDN

2

REF OUT

3

REF IN

4

GND

5

V

D

6

BIAS OUT

7

AIN

8

V

D

9

GND

10

ENC

ANALOG

RECONSTRUCT

DAC OUT

(LSB) D0

(MSB) D7

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

GND

GND

BNC

J2

GND

V

10

D1

D2

D3

DD

D4

D5

D6

1

DB9

2

DB8

3

DB7

4

DB6

5

DB5

6

DB4

7

DB3

8

DB2

9

DB1

DB0

50Ω

20

D0

19

D1

18

D2

17

D3

16

GND

15

V

DD

14

D4

13

D5

12

D6

11

D7

28

CLK

(MSB)

(LSB)

IOUT

AB

22 21

R8

DAC

AD9760AR

DVDD

AVDD

COMP2

COMP1

FSADJ

REFIO

REFLO

SLEEP

R11

50Ω

C37DRPF

P2

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

U3

74ACQ574

9

D7

8

D6

7

D5

6

D4

5

D3

4

D2

3

D1

2

D0

27

24

23

19

18

17

16

15

8D

7D

6D

5D

4D

3D

2D

1D

+5V

+5V

CK

8Q

7Q

6Q

5Q

4Q

3Q

2Q

1Q

OE

111

C13

0.1µF

PWRDN

12

13

14

15

16

17

18

19

C18

0.1µF

R9

2kΩ

+5V

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

C19

0.1µF

J4, GND

J5, +5V

DECOUPLING CAPS

C3

0.1µF

C4

0.1µF

C7

0.1µF

C5

0.1µF

C8

0.1µF

C14

0.1µF

+

C9

0.1µF

C12

10µF

Figure 19. Evaluation Board Schematic

–10–

REV. B

Page 11

AD9057

REV. B

Figure 20. Evaluation Board Layout

–11–

Page 12

AD9057

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead SSOP

(RS-20)

0.295 (7.50)

0.271 (6.90)

20 11

0.311 (7.9)

0.301 (7.64)

0.078 (1.98)

0.068 (1.73)

0.008 (0.203)

0.002 (0.050)

PIN 1

0.0256

(0.65)

BSC

101

0.07 (1.78)

0.066 (1.67)

SEATING

PLANE

0.212 (5.38)

0.205 (5.21)

0.009 (0.229)

0.005 (0.127)

8°

0°

C2156b–2–4/97

0.037 (0.94)

0.022 (0.559)

–12–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...