Page 1

Octal 8-Bit TrimDAC

DAC 8

V

OUT

V

REFH

V

REFL

.

.

.

.

.

.

AD8801/AD8803

V

REFL

V

REFH

O1

O8

SHDNRS

CS

CLK

SDI

GND

V

DD

8

8

8

88

8

3

DAC

SELECT

11-BIT

SERIAL

LATCH

D

CK

RS

1

8

ADDRESS

8-BIT

LATCH

CK

RS

8-BIT

LATCH

CK RS

DAC 1

V

OUT

V

REFH

V

REFL

a

FEATURES

Low Cost

Replaces Eight Potentiometers

Eight Individually Programmable Outputs

Three-Wire Serial Input

Power Shutdown ≤ 25 mW Including I

Midscale Preset, AD8801

Separate V

Range Setting, AD8803

REFL

+3 V to +5 V Single Supply Operation

APPLICATIONS

Automatic Adjustment

Trimmer Potentiometer Replacement

Video and Audio Equipment Gain and Offset Adjustment

Portable and Battery Operated Equipment

GENERAL DESCRIPTION

The AD8801/AD8803 provides eight digitally controlled dc

voltage outputs. This potentiometer divider TrimDAC

replacement of the mechanical trimmer function in new designs.

The AD8801/AD8803 is ideal for dc voltage adjustment

applications.

Easily programmed by serial interfaced microcontroller ports,

the AD8801 with its midscale preset is ideal for potentiometer

replacement where adjustments start at a nominal value. Applications such as gain control of video amplifiers, voltage controlled frequencies and bandwidths in video equipment,

geometric correction and automatic adjustment in CRT computer graphic displays are a few of the many applications ideally

suited for these parts. The AD8803 provides independent control of both the top and bottom end of the potentiometer divider

allowing a separate zero-scale voltage setting determined by the

V

pin. This is helpful for maximizing the resolution of de-

REFL

vices with a limited allowable voltage control range.

See the AD8802/AD8804 for a twelve channel version of this product.

TrimDAC is a registered trademark of Analog Devices, Inc.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

DD

and I

REF

®

allows

with Power Shutdown

AD8801/AD8803

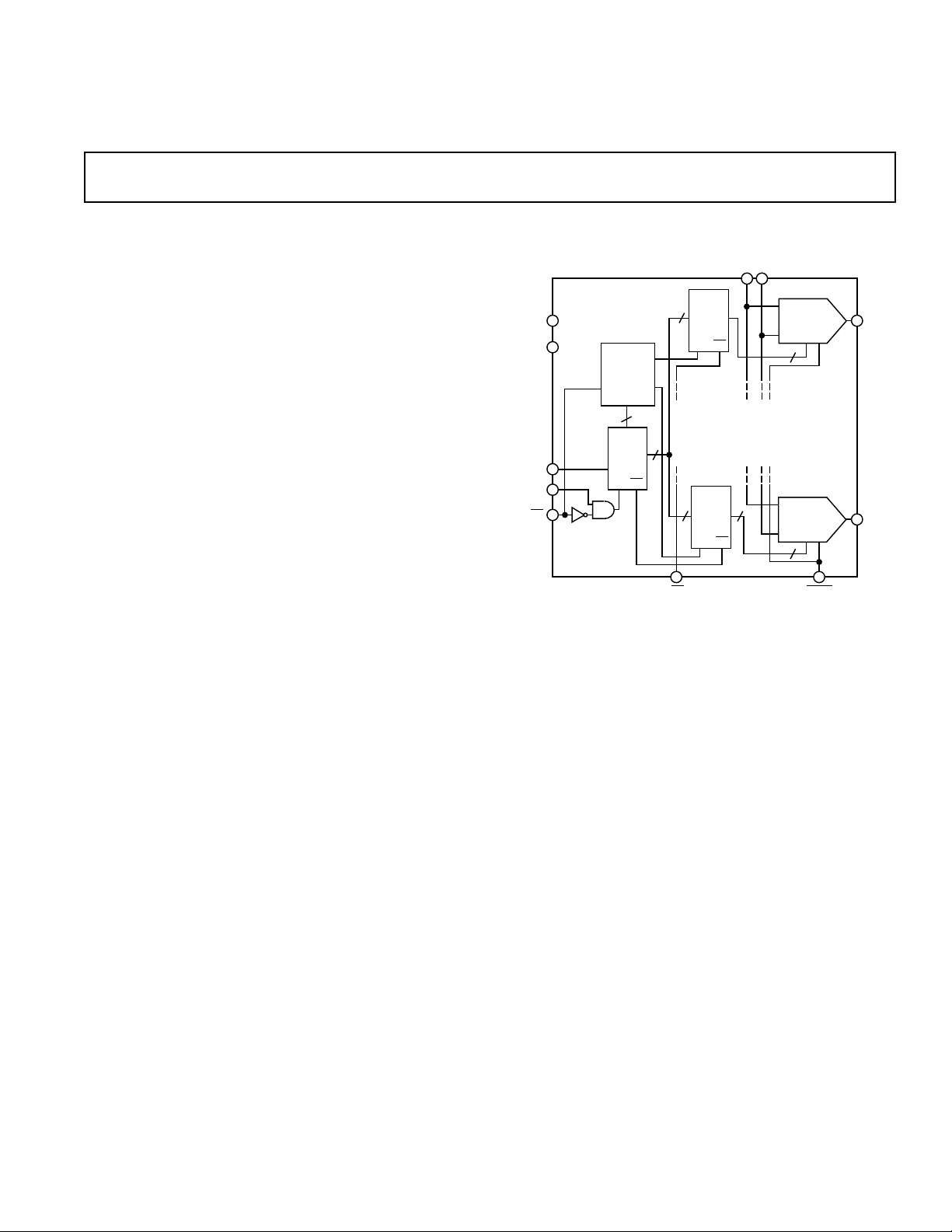

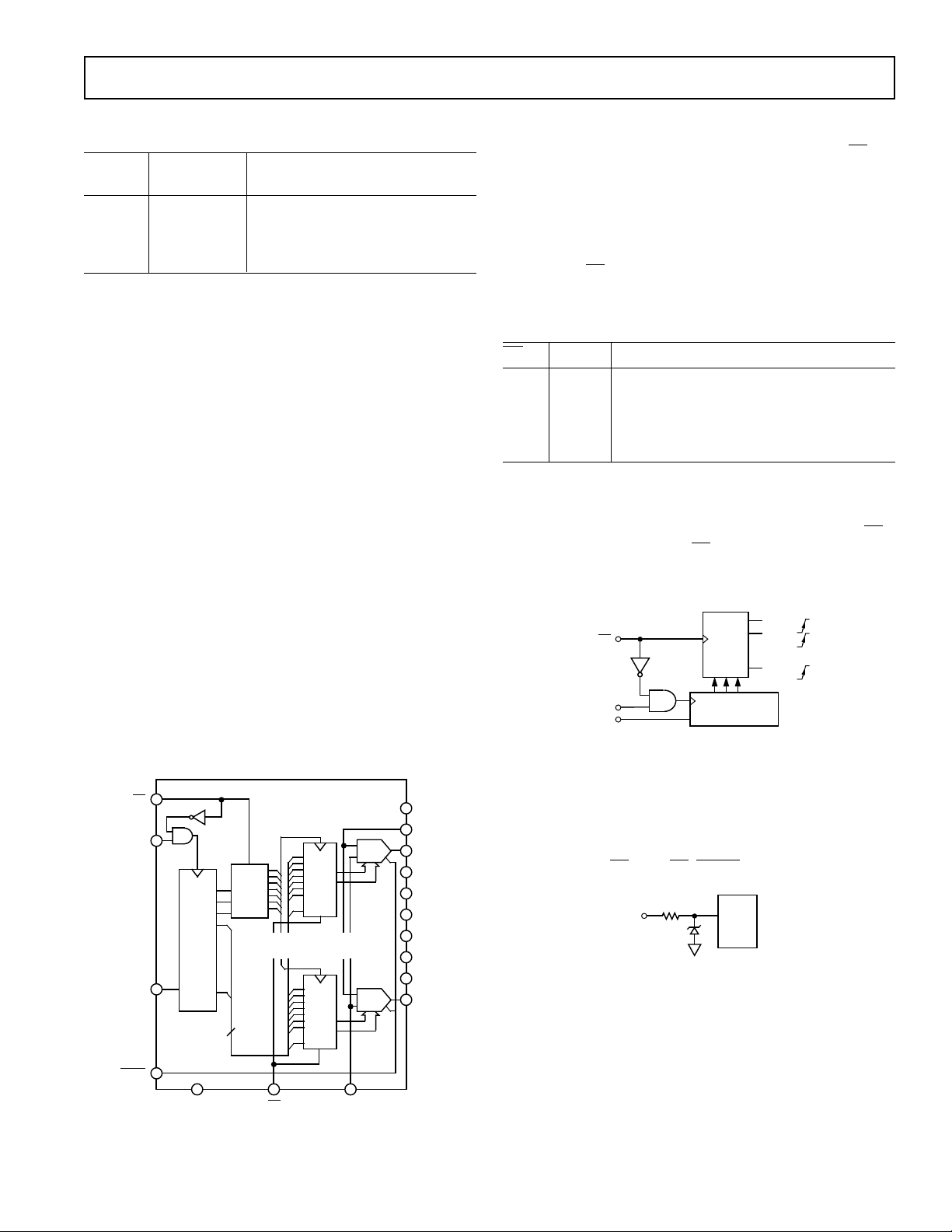

FUNCTIONAL BLOCK DIAGRAM

(DACs 2–7 Omitted for Clarity)

Internally the AD8801/AD8803 contain eight voltage output

digital-to-analog converters, sharing a common reference voltage input.

Each DAC has its own DAC register that holds its output state.

These DAC registers are updated from an internal serial-to-parallel shift register that is loaded from a standard three-wire serial

input digital interface. Eleven data bits make up the data word

clocked into the serial input register. This data word is decoded

where the first 3 bits determine the address of the DAC register

to be loaded with the last 8 bits of data. The AD8801/AD8803

consumes only 5 µA from 5 V power supplies. In addition, in

shutdown mode reference input current consumption is also reduced to 5 µA while saving the DAC latch settings for use after

return to normal operation.

The AD8801/AD8803 is available in 16-pin plastic DIP and the

1.5 mm height SO-16 surface mount packages.

© Analog Devices, Inc., 1995

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

AD8801/AD8803–SPECIFICATIONS

(VDD = +3 V 6 10% or +5 V 6 10%, V

≤ TA ≤ +858C unless otherwise noted)

= +VDD, V

REFH

= 0 V, –408C

REFL

Parameter Symbol Conditions Min Typ1Max Units

STATIC ACCURACY

Specifications Apply to All DACs

Resolution N 8 Bits

Integral Nonlinearity Error INL –1.5 ±1/2 +1.5 LSB

Differential Nonlinearity DNL Guaranteed Monotonic –1 ±1/4 +1 LSB

Full-Scale Error G

Zero-Code Error V

DAC Output Resistance R

Output Resistance Match ∆R/R

REFERENCE INPUT

Voltage Range

Input Resistance R

Reference Input Capacitance

2

3

V

V

C

C

FSE

ZSE

OUT

REFH

REFL

REFH

REF0

REF1

O

Pin Available on AD8803 Only 0 V

Digital Inputs = 55H, V

REFH

= V

DD

Digital Inputs All Zeros 25 pF

Digital Inputs All Ones 25 pF

–4 –2.8 +0.5 LSB

–0.5 ±0.1 +0.5 LSB

358 kΩ

1%

0V

DD

DD

V

V

2kΩ

DIGITAL INPUTS

Logic High V

Logic Low V

Logic High V

Logic Low V

Input Current I

Input Capacitance

POWER SUPPLIES

3

4

Power Supply Range V

Supply Current (CMOS) I

Supply Current (TTL) I

Shutdown Current I

Power Dissipation P

IH

IL

IH

IL

IL

C

IL

Range 2.7 5.5 V

DD

DD

DD

REFH

DISS

Power Supply Sensitivity PSRR V

Power Supply Sensitivity PSRR VDD = 3 V ± 10%, V

DYNAMIC PERFORMANCE

V

Settling Time (Positive or Negative) t

OUT

3

S

VDD = +5 V 2.4 V

VDD = +5 V 0.8 V

VDD = +3 V 2.1 V

VDD = +3 V 0.6 V

VIN = 0 V or +5 V ±1 µA

5pF

VIH = VDD or VIL = 0 V 0.01 5 µA

VIH = 2.4 V or VIL = 0.8 V, VDD= +5.5 V 1 4 mA

SHDN = 0 0.01 5 µA

VIH = VDD or VIL = 0 V, VDD = +5.5 V 27.5 µW

= 5 V ± 10%, V

DD

= +4.5 V 0.001 0.002 %/%

REFH

= +2.7 V 0.01 %/%

REFH

±1/2 LSB Error Band 0.6 µs

Crosstalk CT See Note 5, f = 100 kHz 50 dB

SWITCHING CHARACTERISTICS

Input Clock Pulse Width tCH, t

Data Setup Time t

Data Hold Time t

CS Setup Time t

CS High Pulse Width t

Reset Pulse Width t

CLK Rise to

CS Rise Hold Time t

CS Rise to Next Rising Clock t

NOTES

1

Typical values represent average readings measured at +25 °C.

2

V

can be any value between GND and VDD, for the AD8803 V

REFH

3

Guaranteed by design and not subject to production test.

4

Digital Input voltages VIN = 0 V or VDD for CMOS condition. DAC outputs unloaded. P

5

Measured at a V

6

See timing diagram for location of measured values. All input control voltages are specified with tR = tF = 2 ns (10% to 90% of VDD) and timed from a voltage

level of 1.6 V.

Specifications subject to change without notice.

pin where an adjacent V

OUT

3, 6

CL

DS

DH

CSS

CSW

RS

CSH

CS1

pin is making a full-scale voltage change.

OUT

Clock Level High or Low 15 ns

can be any value between GND and VDD.

REFL

is calculated from (IDD × VDD).

DISS

5ns

5ns

10 ns

10 ns

60 ns

15 ns

10

ns

–2–

REV. A

Page 3

AD8801/AD8803

V

REFH

O1

V

DD

RS

O4

SHDN

CS

O6

O5

SDI

O2

O3

O8

O7

GND CLK

1

2

16

15

5

6

7

12

11

10

3

4

14

13

89

TOP VIEW

(Not to Scale)

AD8801

V

REFH

O1

V

DD

O8

O4

SHDN

CS

O5

SDI

CLK

O2

O3

O7

O6

GND V

REFL

1

2

16

15

5

6

7

12

11

10

3

4

14

13

89

TOP VIEW

(Not to Scale)

AD8803

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

(TA = +25°C, unless otherwise noted)

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3, +8 V

V

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 V, V

REFX

Outputs (Ox) to GND . . . . . . . . . . . . . . . . . . . . . . . . 0 V, V

Digital Input Voltage to GND . . . . . . . . . . . . . . . . . . 0 V, V

DD

DD

DD

Operating Temperature Range . . . . . . . . . . . . .–40°C to +85°C

Maximum Junction Temperature (T

MAX) . . . . . . . . +150°C

J

Storage Temperature . . . . . . . . . . . . . . . . . . .–65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . +300°C

Package Power Dissipation . . . . . . . . . . . . .(T

Thermal Resistance θ

JA,

MAX – TA)/θ

J

JA

SOIC (SO-16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60°C/W

P-DIP (N-16) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57°C/W

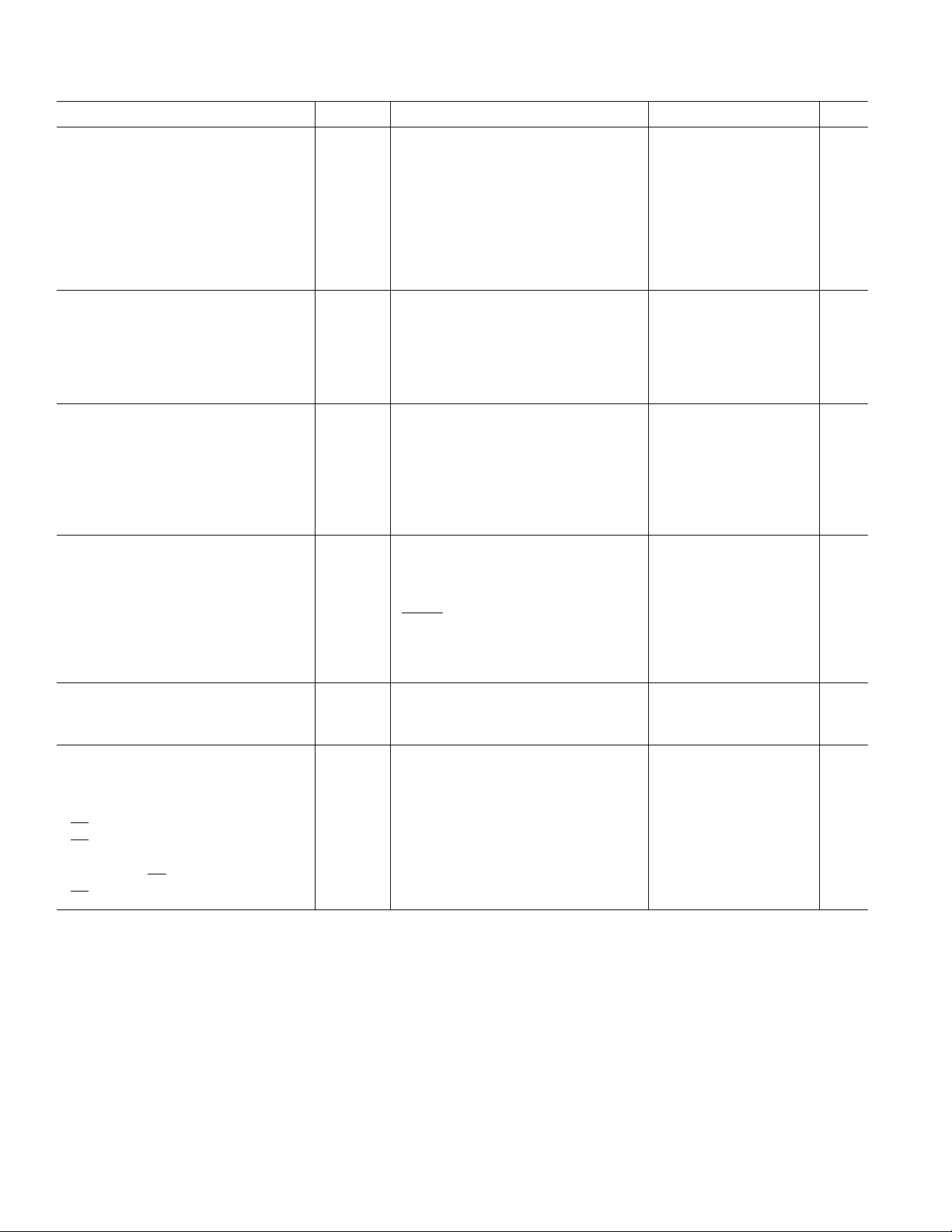

AD8801 PIN DESCRIPTIONS

Pin Name Description

1V

2 O1 DAC Output #1, Addr = 000

3 O2 DAC Output #2, Addr = 001

4 O3 DAC Output #3, Addr = 010

5 O4 DAC Output #4, Addr = 011

Common DAC Reference Input

REFH

2

2

2

2

6 SHDN Reference input open circuit, active low, all

DAC outputs open circuit. DAC latch settings

maintained.

7

CS Chip Select Input, active low. When CS returns

high, data in the serial input register is decoded

based on the address bits and loaded into the tar-

get DAC register.

8 GND Ground

9 CLK Serial Clock Input, Positive Edge Triggered

10 SDI Serial Data Input

11 O5 DAC Output #5, Addr = 100

12 O6 DAC Output #6, Addr = 101

13 O7 DAC Output #7, Addr = 110

14 O8 DAC Output #8, Addr = 111

2

2

2

2

15 RS Asynchronous preset to midscale output setting,

16 V

active low. Loads all DAC latches with 80

Positive power supply, specified for operation at

DD

.

H

both +3 V and +5 V.

ORDERING GUIDE

Package Package

Model FTN Temperature Description Option

AD8801AN

AD8801AR

RS –40°C to +85°C PDIP-16 N-16

RS –40°C to +85°C SO-16 R-16A

AD8803AN REFL –40°C to +85°C PDIP-16 N-16

AD8803AR REFL –40°C to +85°C SO-16 R-16A

AD8803 PIN DESCRIPTIONS

Pin Name Description

1V

2 O1 DAC Output #1, Addr = 000

3 O2 DAC Output #2, Addr = 001

4 O3 DAC Output #3, Addr = 010

5 O4 DAC Output #4, Addr = 011

Common High-Side DAC Reference Input

REFH

2

2

2

2

6 SHDN Reference inputs open circuit, active low, all

DAC outputs open circuit. DAC latch settings

maintained.

7

CS Chip Select Input, active low. When CS returns

high, data in the serial input register is decoded

based on the address bits and loaded into the tar-

get DAC register.

8 GND Ground

9V

Common Low-Side DAC Reference Input

REFL

10 CLK Serial Clock Input, Positive Edge Triggered

11 SDI Serial Data Input

12 O5 DAC Output #5, Addr = 100

13 O6 DAC Output #6, Addr = 101

14 O7 DAC Output #7, Addr = 110

15 O8 DAC Output #8, Addr = 111

16 V

Positive power supply, specified for operation at

DD

2

2

2

2

both +3 V and +5 V.

PIN CONFIGURATIONS

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although these devices feature proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

REV. A

precautions are recommended to avoid performance degradation or loss of functionality.

–3–

Page 4

AD8801/AD8803

OCTAL 8-BIT TRIMDAC, WITH SHUTDOWN

1

V

SDI

CLK

CS

OUT

A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

0

1

0

1

0

+5V

0V

DAC REGISTER LOAD

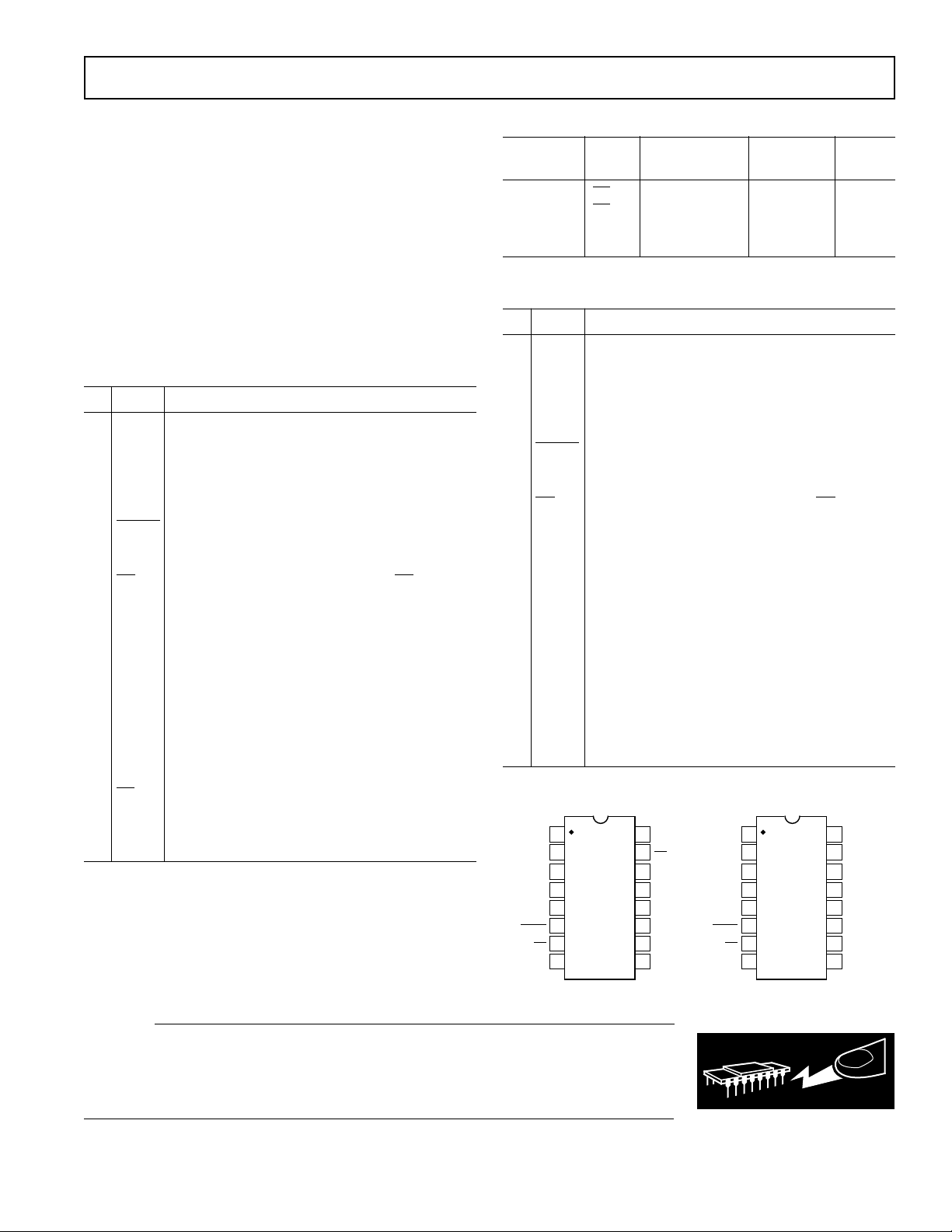

Figure 2a. Timing Diagram

DETAIL SERIAL DATA INPUT TIMING (RS = "1")

SDI

1

(DATA

CLK

CS

V

OUT

AX OR D

0

IN)

1

0

t

CSS

1

0

+5V

0V

AX OR D

X

t

CH

X

t

DS

t

DH

t

t

CSH

CL

±1 LSB ERROR BAND

Figure 2b. Detail Timing Diagram

RESET TIMING

1

RS

0

+5V

V

OUT

2.5V

t

RS

t

S

±1 LSB ERROR BAND

following address assignments for the ADDR decode which determines the location of DAC register receiving the serial register data in bits B7 through B0:

DAC # = A2 × 4 + A1 × 2 + A0 + 1

DAC outputs can be changed one at a time in random sequence. The fast serial-data loading of 33 MHz makes it possible

to load all eight DACs in as little time as 3 µs (12 × 8 × 30 ns).

The exact timing requirements are shown in Figure 2.

The AD8801 offers a midscale preset activated by the

RS pin

simplifying initial setting conditions at first power up. The

AD8803 has both a V

REFH

and a V

pin to establish indepen-

REFL

dent positive full-scale and zero-scale settings to optimize resolution. Both parts offer a power shutdown

SHDN that places

the DAC structure in a zero power consumption state resulting

in only leakage currents being consumed from the power supply,

V

inputs, and all 8 outputs. In shutdown mode the DACx

t

CS1

REF

latch settings are maintained. When returning to operational

mode from power shutdown the DAC outputs return to their

previous voltage settings.

V

REFH

DAC

REGISTER

TO OTHER DACS

P CH

N CH

D7

D6

D0

.

.

.

.

.

.

MSB

O

2R

2R

X

R

R

.

.

.

t

CSW

t

S

±1 LSB

±1 LSB

Figure 2c. Reset Timing Diagram

Table I. Serial-Data Word Format

ADDR DATA

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB MSB LSB

2102928272625242322212

0

OPERATION

The AD8801/AD8803 provides eight channels of programmable

voltage output adjustment capability. Changing the programmed

output voltage of each TrimDAC is accomplished by clocking in

an 11-bit serial data word into the SDI (Serial Data Input) pin.

The format of this data word is three address bits, MSB first,

followed by eight data bits, MSB first. Table I provides the serial register data word format. The AD8801/AD8803 has the

2R

2R

V

GND

REFL

LSB

Figure 3. AD8801/AD8803 Equivalent TrimDAC Circuit

PROGRAMMING THE OUTPUT VOLTAGE

The output voltage range is determined by the external reference connected to V

REFH

and V

pins. See Figure 3 for a

REFL

simplified diagram of the equivalent DAC circuit. In the case of

the AD8801, its V

therefore cannot be offset. V

is internally connected to GND and

REFL

can be tied to VDD and V

REFH

REFL

can be tied to GND establishing a basic rail-to-rail voltage output programming range. Other output ranges are established by

the use of different external voltage references. The general

transfer equation that determines the programmed output

voltage is:

V

(Dx) = (Dx)/256 × (V

O

REFH

– V

REFL

) + V

REFL

(1)

where Dx is the data contained in the 8-bit DACx latch.

–4–

REV. A

Page 5

AD8801/AD8803

LOGIC

100Ω

For example, when V

= +5 V and V

REFH

= 0 V the follow-

REFL

ing output voltages will be generated for the following codes:

DVOXOutput State

(V

= +5 V, V

REFH

REFL

= 0 V)

255 4.98 V Full-Scale

128 2.50 V Half-Scale (Midscale Reset Value)

1 0.02 V 1 LSB

0 0.00 V Zero-Scale

REFERENCE INPUTS (V

REFH

, V

REFL

)

The reference input pins set the output voltage range of all eight

DACs. In the case of the AD8801 only the V

pin is avail-

REFH

able to establish a user designed full-scale output voltage. The

external reference voltage can be any value between 0 and V

DD

but must not exceed the VDD supply voltage. In the case of the

AD8803, which has access to the V

which establishes the

REFL

zero-scale output voltage, any voltage can be applied between

0 V and V

V

REFH

. V

DD

can be smaller or larger in voltage than

REFL

since the DAC design uses fully bidirectional switches as

shown in Figure 3. The input resistance to the DAC has a code

dependent variation that has a nominal worst case measured at

55

, which is approximately 2 kΩ. When V

H

V

, the REFL reference must be able to sink current out of

REFL

is greater than

REFH

the DAC ladder, while the REFH reference is sourcing current

into the DAC ladder. The DAC design minimizes reference

glitch current maintaining minimum interference between DAC

channels during code changes.

DAC OUTPUTS (O1–O8)

The eight DAC outputs present a constant output resistance of

approximately 5 kΩ independent of code setting. The distribution of R

from DAC to DAC typically matches within ±1%.

OUT

However, device to device matching is process lot dependent

having a ±20% variation. The change in R

with temperature

OUT

has a 500 ppm/°C temperature coefficient. During power shutdown all eight outputs are open circuited.

CS

CLK

SDI

D

D10

SER

REG

ADDR

D9

D8

D7

.

.

.

D0

8

EN

DEC

...

...

...

AD8801/AD8803

D7

DAC

REG

#1

D0

D7

DAC

REG

#8

D0

DAC

DAC

R

..

..

..

DAC

R

V

DD

V

REFH

1

8

O1

O2

O3

O4

O5

O6

O7

O8

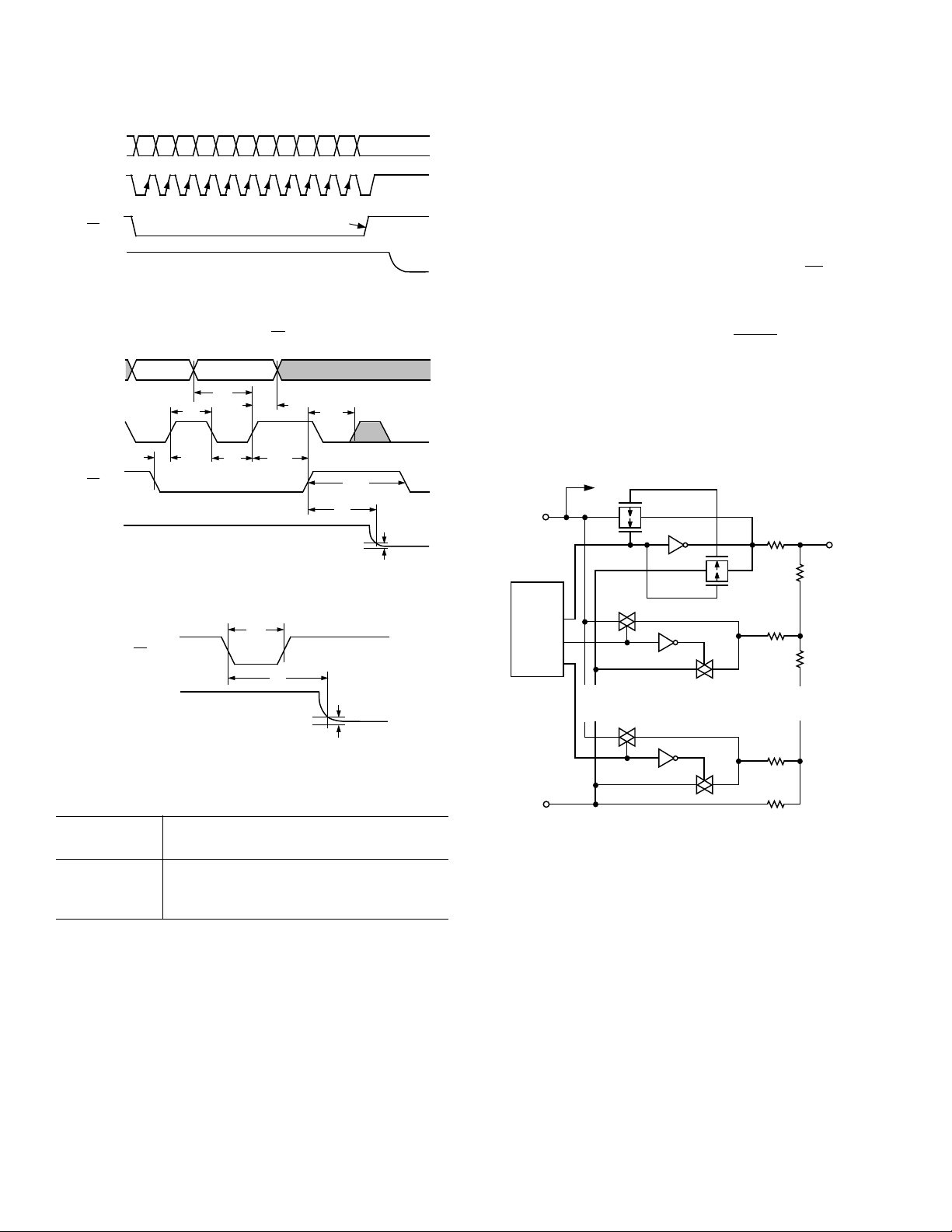

DIGITAL INTERFACING

The AD8801/AD8803 contains a standard three-wire serial input control interface. The three inputs are clock (CLK),

CS and

serial data input (SDI). The positive-edge sensitive CLK input

requires clean transitions to avoid clocking incorrect data into

the serial input register. Standard logic families work well. If

mechanical switches are used for product evaluation, they

should be debounced by a flip-flop or other suitable means. Figure 4 block diagram shows more detail of the internal digital circuitry. When

CS is taken active low, the clock can load data into

the serial register on each positive clock edge, see Table II.

Table II. Input Logic Control Truth Table

CS CLK Register Activity

1 X No effect.

0 P Shifts Serial Register one bit loading the

next bit in from the SDI pin.

P X Data is transferred from the serial register

to the decoded DAC register. See Figure 5.

NOTE: P = positive edge, X = don’t care.

The data setup and data hold times in the specification table

determine the data valid time requirements. The last 11 bits of

the data word entered into the serial register are held when

returns high. At the same time

CS goes high it gates the address

CS

decoder which enables one of the eight positive edge triggered

DAC registers, see Figure 5 detail.

DAC 1

SERIAL

DAC 2

.

.

.

DAC 8

CS

CLK

SDI

ADDR

DECODE

REGISTER

Figure 5. Equivalent Control Logic

The target DAC register is loaded with the last eight bits of the serial data word completing one DAC update. Eight separate 11-bit

data words must be clocked in to change all eight output settings.

All digital inputs are protected with a series input resistor and

parallel Zener ESD structure shown in Figure 6. This applies to

digital input pins

CS, SDI, RS, SHDN, CLK.

Figure 6. Equivalent ESD Protection Circuit

Digital inputs can be driven by voltages exceeding the AD8801/

AD8803 V

value. This allows 5 V logic to interface directly to

DD

the part when it is operated at 3 V.

SHDN

REV. A

GND

RS

(AD8801 ONLY) (AD8803 ONLY)

Figure 4. Block Diagram

V

REFL

–5–

Page 6

TEMPERATURE – °C

I

DD

SUPPLY CURRENT – µA

100k

0.001

–55 125–35 –15 5 25 45 65 85 105

10k

10

1

0.1

0.01

1k

100

VDD = +5.5V

LOGIC = +2.4V

ALL DIGITAL PINS

TIED TOGETHER

VDD = +5.5V

LOGIC = +5.5V

ALL DIGITAL PINS

TIED TOGETHER

AD8801/AD8803–Typical Performance Characteristics

1

VDD = +5V

= +5V

V

0.75

REFH

= 0V

V

REFL

0.5

0.25

0

INL – LSB

–0.25

–0.5

–0.75

–1

0 25632 64 96 128 160 192 224

CODE – Decimal

Figure 7. INL vs. Code

1

VDD = +5V

= +5V

V

0.75

REFH

= 0V

V

REFL

0.5

0.25

0

DNL – LSB

–0.25

–0.5

–0.75

–1

0 25664 128 192

TA = –40°C, +25°C, +85°C

CODE – Decimal

TA = +85°C

= +25°C

T

A

= –40°C

T

A

200

VDD = +5V

= +2V

V

REFH

= 0V

V

REFL

ALL OTHER DACS SET

150

TO ZERO SCALE

T

= +25°C

A

100

CURRENT – µA

REF

I

50

0

0 25632

64 96 128 160 192 224

CODE – Decimal

Figure 10. Input Reference Current vs. Code

10k

1k

100

SHUTDOWN CURRENT – nA

10

REF

I

0

–35 255–15–55

TEMPERATURE – °C

65 1251058545

VDD = +5.5V

= 0V

V

REF

VDD = +5.5V

= +5.5V

V

REF

Figure 8. Differential Nonlinearity Error vs. Code

1200

VDD = +4.5V

1080

960

840

720

600

480

FREQUENCY

260

240

120

Figure 9. Total Unadjusted Error Histogram

= +4.5V

V

REF

= 0V

V

REFL

= +25°C

T

A

SS = 2446 PCS

0

–3.4 –2.5–3.3 –3.2 –3.1 –3.0 –2.9 –2.8 –2.7 –2.6

TOTAL UNADJUSTED ERROR – LSB

–6–

Figure 11. Shutdown Current vs. Temperature

Figure 12. Supply Current vs. Temperature

REV. A

Page 7

AD8801/AD8803

10

0%

100

90

OUTPUT1: OOH → FF

H

TIME – 0.2µs/DIV

OUTPUT2 – 10mV/DIV

VDD = +5V

V

REF

= +2V

f = 500kHz

10

0%

100

90

OUTPUT1: 7FH → 80

H

VDD = +5V

V

REF

= +2V

TIME – 0.2µs/DIV

OUT1

10mV/DIV

CS

5V/DIV

100

10

1.0

0.1

0.01

SUPPLY CURRENT – mA

DD

I

0.001

0.0001

0.50

21.51

LOGIC INPUT VOLTAGE – Volts

VDD = +3V

2.5

TA = +25°C

ALL DIGITAL INPUTS

TIED TOGETHER

VDD = +5V

53 4.543.5

Figure 13. Supply Current vs. Logic Input Voltage

80

60

40

PSRR – dB

VDD = +5V ±0.5V

V

REFH

CODE = 80

TA = +25°C

= +2V

P

H

Figure 16. Adjacent Channel Clock Feedthrough

20

0

100 100k10k1k10

FREQUENCY – Hz

Figure 14. Power Supply Rejection vs. Frequency

VDD = +5V

= +2V

V

100

90

2V

OUT1

0V

10

5V

0%

0%

CS

0V

TIME – 1µs/DIV

Figure 15. Large-Signal Settling Time

REF

Figure 17. Midscale Transition

0.01

VDD = +4.5V

= +4.5V

V

REF

SS = 162 PCS

0.005

0

–0.005

CHANGE IN ZERO-SCALE ERROR – LSB

–0.01

= 0V

V

REFL

0 600

150 300 450

HOURS OF OPERATION AT 150°C

Figure 18. Zero-Scale Error Accelerated by Burn-In

REV. A

–7–

Page 8

AD8801/AD8803

AD8801/

AD8803

V

DD

DGND

10µF

0.1µF

+

+5V

0.04

x + 2σ

0.02

0

–0.02

CHANGE IN FULL-SCALE ERROR – LSB

–0.04

0 600150 300 450

x

x – 2σ

HOURS OF OPERATION AT 150°C

VDD = +4.5V

= +4.5V

V

REF

SS = 162 PCS

Figure 19. Full-Scale Error Accelerated by Burn-In

APPLICATIONS

Supply Bypassing

Precision analog products, such as the AD8801/AD8803, require a well filtered power source. Since the AD8801/AD8803

operate from a single +3 V to +5 V supply, it seems convenient

to simply tap into the digital logic power supply. Unfortunately,

the logic supply is often a switch-mode design, which generates

noise in the 20 kHz to 1 MHz range. In addition, fast logic gates

can generate glitches hundred of millivolts in amplitude due to

wiring resistances and inductances.

If possible, the AD8801/AD8803 should be powered directly

from the system power supply. This arrangement, shown in Figure 21, will isolate the analog section from the logic switching

transients. Even if a separate power supply trace is not available,

however, generous supply bypassing will reduce supply-line induced errors. Local supply bypassing consisting of a 10 µF tan-

talum electrolytic in parallel with a 0.1 µF ceramic capacitor is

recommended (Figure 22).

TTL/CMOS

LOGIC

CIRCUITS

+5V

POWER SUPPLY

+

TANT

10µF

0.1µF

AD8801/

AD8803

Figure 21. Use Separate Traces to Reduce Power Supply

Noise

1.0

0.5

0

–0.5

INPUT RESISTANCE DRIFT – kΩ

–1.0

0 600150 300 450

x + 2σ

x

x – 2σ

HOURS OF OPERATION AT 150°C

VDD = +4.5V

= +4.5V

V

REF

CODE = 55

SS = 162 PCS

H

Figure 20. REF Input Resistance Accelerated by Burn-In

Figure 22. Recommended Supply Bypassing for the

AD8801/AD8803

Buffering the AD8801/AD8803 Output

In many cases, the nominal 5 kΩ output impedance of the

AD8801/AD8803 is sufficient to drive succeeding circuitry. If a

lower output impedance is required, an external amplifier can

be added. Several examples are shown in Figure 23. One amplifier of an OP291 is used as a simple buffer to reduce the output

resistance of DAC A. The OP291 was chosen primarily for its

rail-to-rail input and output operation, but it also offers operation to less than 3 V, low offset voltage, and low supply current.

The next two DACs, B and C, are configured in a summing arrangement where DAC C provides the coarse output voltage

setting and DAC B can be used for fine adjustment. The insertion of R1 in series with DAC B attenuates its contribution to

the voltage sum node at the DAC C output.

–8–

REV. A

Page 9

AD8801/AD8803

O1

O2

O3

O4

O5

O6

O7

O8

SDI

SCLK

RESET

SHDN

CS

VDD V

REFH

GND

AD8801

+5V

P3.0

P3.1

P1.3

P1.2

P1.1

SERIAL DATA SHIFT REGISTER

RxD

TxD

SHIFT CLOCK

1.11.21.3

PORT 1

SBUF

8051 µC

0.1µF 10µF

+

+5V

V

REFHVDD

V

REFL

V

H

V

L

V

H

V

L

V

H

V

L

AD8801/

AD8803

GND

DIGITAL INTERFACING

OMITTED FOR CLARITY

R1

100kΩ

OP291

SIMPLE BUFFER

0V TO 5V

SUMMER CIRCUIT

WITH FINE TRIM

ADJUSTMENT

Figure 23. Buffering the AD8801/AD8803 Output

Increasing Output Voltage Swing

An external amplifier can also be used to extend the output voltage swing beyond the power supply rails of the AD8801/AD8803.

This technique permits an easy digital interface for the DAC,

while expanding the output swing to take advantage of higher

voltage external power supplies. For example, DAC A of Figure 24 is configured to swing from –5 V to +5 V. The actual

output voltage is given by:

Microcomputer Interfaces

The AD8801/AD8803 serial data input provides an easy interface to a variety of single-chip microcomputers (µCs). Many µCs

have a built-in serial data capability that can be used for communicating with the DAC. In cases where no serial port is provided, or it is being used for some other purpose (such as an

RS-232 communications interface), the AD8801/AD8803 can

easily be addressed in software.

Eleven data bits are required to load a value into the AD8801/

AD8803 (3 bits for the DAC address and 8 bits for the DAC

value). If more than 11 bits are transmitted before the Chip Select input goes high, the extra (i.e., the most-significant) bits are

ignored. This feature is valuable because most µCs only transmit

data in 8-bit increments. Thus, the µC will send 16 bits to the

DAC instead of 11 bits. The AD8801/AD8803 will only respond to the last 11 bits clocked into the SDI input, however, so

the serial data interface is not affected.

An 8051 µC Interface

A typical interface between the AD8801/AD8803 and an 8051

µC is shown in Figure 25. This interface uses the 8051’s internal

serial port. The serial port is programmed for Mode 0 operation, which functions as a simple 8-bit shift register. The 8051’s

Port3.0 pin functions as the serial data output, while Port3.1

serves as the serial clock.

Where D is the DAC input value (i.e., 0 to 255). This circuit

can be combined with the “fine/coarse” circuit of Figure 23 if,

for example, a very accurate adjustment around 0 V is desired.

tion, which increases the available output swing to +10 V. The

DAC B of Figure 24 is in a noninverting gain of two configurafeedback resistors can be adjusted to provide any scaling of the

output voltage, within the limits of the external op amp power

supplies.

REV. A

OUT

A

B

= 1+

V

REFH

V

REFL

R

100kΩ

V

+5V

V

DD

AD8801/

AD8803

GND

R

Figure 24. Increasing Output Voltage Swing

D

F

S

R

S

OP193

×

×5V

()

256

R

100kΩ

+5V

–5V

+12V

100kΩ

100kΩ

–5V

F

–5V TO +4.98V

OP191

0V TO +10V

Figure 25. Interfacing the 8051 µC to an AD8801/AD8803,

Using the Serial Port

When data is written to the Serial Buffer Register (SBUF, at

Special Function Register location 99

), the data is automati-

H

cally converted to serial format and clocked out via Port3.0 and

Port3.1. After 8 bits have been transmitted, the Transmit Interrupt flag (SCON.1) is set and the next 8 bits can be transmitted.

The AD8801 and AD8803 require the Chip Select to go low at

the beginning of the serial data transfer. In addition, the SCLK

input must be high when the Chip Select input goes high at the

end of the transfer. The 8051’s serial clock meets this requirement, since Port3.1 both begins and ends the serial data in the

high state.

Software for the 8051 Interface

A software routine for the AD8801/AD8803 to 8051 interface is

shown in Listing 1. The routine transfers the 8-bit data stored at

data memory location DAC_VALUE to the AD8801/AD8803

DAC addressed by the contents of location DAC_ADDR.

–9–

Page 10

AD8801/AD8803

;

; This subroutine loads an AD8801/AD8803 DAC from an 8051 microcomputer,

; using the 8051’s serial port in MODE 0 (Shift Register Mode).

; The DAC value is stored at location DAC_VAL

; The DAC address is stored at location DAC_ADDR

;

; Variable declarations

;

PORT1 DATA 90H ;SFR register for port 1

DAC_VALUE DATA 40H ;DAC Value

DAC_ADDR DATA 41H ;DAC Address

SHIFT1 DATA 042H ;high byte of 16-bit answer

SHIFT2 DATA 043H ;low byte of answer

SHIFT_COUNT DATA 44H ;

;

ORG 100H ;arbitrary start

DO_8801: CLR SCON.7 ;set serial

CLR SCON.6 ; data mode 0

CLR SCON.5

CLR SCON.1 ;clr transmit flag

ORL PORT1.1,#00001110B ;/RS, /SHDN, /CS high

CLR PORT1.1 ;set the /CS low

MOV SHIFT1,DAC_ADDR ;put DAC value in shift register

ACALL BYTESWAP ;

MOV SBUF,SHIFT2 ;send the address byte

ADDR_WAIT: JNB SCON.1,ADDR_WAIT ;wait until 8 bits are sent

CLR SCON.1 ;clear the serial transmit flag

MOV SHIFT1,DAC_VALUE ;send the DAC value

ACALL BYTESWAP ;

MOV SBUF,SHIFT2 ;

VALU_WAIT: JNB SCON.1,VALU_WAIT ;wait again

CLR SCON.1 ;clear serial flag

SETB PORT1.1 ;/CS high, latch data

RET ; into AD8801

;

BYTESWAP: MOV SHIFT_COUNT,#8 ;Shift 8 bits

SWAP_LOOP: MOV A,SHIFT1 ;Get source byte

RLC A ;Rotate MSB to carry

MOV SHIFT1,A ;Save new source byte

MOV A,SHIFT2 ;Get destination byte

RRC A ;Move carry to MSB

MOV SHIFT2,A ;Save

DJNZ SHIFT_COUNT,SWAP_LOOP ;Done?

RET

END

Listing 1. Software for the 8051 to AD8801/AD8803 Serial Port Interface

–10–

REV. A

Page 11

AD8801/AD8803

The subroutine begins by setting appropriate bits in the Serial

Control register to configure the serial port for Mode 0 operation. Next the DAC’s Chip Select input is set low to enable the

AD8801/AD8803. The DAC address is obtained from memory

location DAC_ADDR, adjusted to compensate for the 8051’s

serial data format, and moved to the serial buffer register. At

this point, serial data transmission begins automatically. When

all 8 bits have been sent, the Transmit Interrupt bit is set, and

the subroutine then proceeds to send the DAC value stored at

location DAC_VALUE. Finally the Chip Select input is returned high, causing the appropriate AD8801/AD8803 output

voltage to change, and the subroutine ends.

The 8051 sends data out of its shift register LSB first, while the

AD8801/AD8803 require data MSB first. The subroutine therefore includes a BYTESWAP subroutine to reformat the data.

This routine transfers the MSB-first byte at location SHIFT1 to

an LSB-first byte at location SHIFT2. The routine rotates the

MSB of the first byte into the carry with a Rotate Left Carry instruction, then rotates the carry into the MSB of the second byte

with a Rotate Right Carry instruction. After 8 loops, SHIFT2

contains the data in the proper format.

; This 8051 µC subroutine loads an AD8801 or AD8803 DAC with an 8-bit value,

; using the 8051’s parallel port #1.

; The DAC value is stored at location DAC_VALUE

; The DAC address is stored at location DAC_ADDR

;

; Variable declarations

PORT1 DATA 90H ;SFR register for port 1

DAC_VALUE DATA 40H ;DAC Value

DAC_ADDR DATA 41H ;DAC Address (0 through 7)

LOOPCOUNT DATA 43H ;COUNT LOOPS

;

ORG 100H ;arbitrary start

LD_8803: ORL PORT1,#11110000B ;set CLK, /CS and /SHDN high,

CLR PORT1.5 ;Set Chip Select low

MOV LOOPCOUNT,#3 ;Address is 3 bits

MOV A,DAC_ADDR ; Get DAC address

RR A ; Rotate the DAC

RR A ;address to the Most

RR A ;Significant Bits (MSBs)

ACALL SEND_SERIAL ;Send the address

MOV LOOPCOUNT,#8 ;Do 8 bits of data

MOV A,DAC_VALUE

ACALL SEND_SERIAL ;Send the data

SETB PORT1.5 ;Set /CS high

RET ;DONE

The BYTESWAP routine in Listing 1 is convenient because the

DAC data can be calculated in normal LSB form. For example,

producing a ramp voltage on a DAC is simply a matter of repeatedly incrementing the DAC_VALUE location and calling

the LD_8801 subroutine.

If the µC’s hardware serial port is being used for other purposes,

the AD8801/AD8803 can be loaded by using the parallel port.

A typical parallel interface is shown in Figure 26. The serial data

is transmitted to the DAC via the 8051’s Port1.7 output, while

Port1.6 acts as the serial clock.

Software for the interface of Figure 26 is contained in Listing 2. The

subroutine will send the value stored at location DAC_VALUE to

the AD8801/AD8803 DAC addressed by location DAC_ADDR.

The program begins by setting the AD8801/AD8803’s Serial

Clock and Chip Select inputs high, then setting Chip Select low

to start the serial interface process. The DAC address is loaded

into the accumulator and three Rotate Right shifts are performed. This places the DAC address in the 3 MSBs of the accumulator. The address is then sent to the AD8801/AD8803 via

the SEND_SERIAL subroutine. Next, the DAC value is loaded

into the accumulator and sent to the AD8801/AD8803. Finally,

the Chip Select input is set high to complete the data transfer.

SEND_SERIAL: RLC A ;Move next bit to carry

MOV PORT1.7,C ;Move data to SDI

CLR PORT1.6 ;Pulse the

SETB PORT1.6 ; CLK input

DJNZ LOOPCOUNT,SEND_SERIAL ;Loop if not done

RET;

END

Listing 2. Software for the 8051 to AD8801/AD8803 Parallel Port Interface

REV. A

–11–

Page 12

AD8801/AD8803

+5V

VDD V

8051 µC

REFH

AD8803

GND

V

O1

O2

O3

O4

O5

O6

O7

O8

REFL

PORT 1

P1.7

P1.6

P1.5

P1.4

1.51.61.7

1.4

SDI

CLK

CS

SHDN

Figure 26. An AD8801/AD8803-8051 µC Interface Using

Parallel Port 1

Unlike the serial port interface of Figure 25, the parallel port interface only transmits 11 bits to the AD8801/AD8803. Also, the

BYTESWAP subroutine is not required for the parallel interface, because data can be shifted out MSB first. However, the

results of the two interface methods are exactly identical. In

most cases, the decision on which method to use will be determined by whether or not the serial data port is available for

communication with the AD8801/AD8803.

An MC68HC11-to-AD8801/AD8803 Interface

Like the 8051, the MC68HC11 includes a dedicated serial data

port (labeled SPI). The SPI port provides an easy interface to

the AD8801/AD8803 (Figure 27). The interface uses three lines

of Port D for the serial data, and one or two lines from Port C

to control the

SHDN and RS (AD8801 only) inputs.

MC68HC11

*

MOSI

(PD3)

SCK

(PD4)

SS

(PD5)

PC0

PC1

*ADDITIONAL PINS OMITTED FOR CLARITY

AD8801/

AD8803*

SDI

CLK

CS

SHDN

RS (AD8801 ONLY)

Figure 27. An AD8801/AD8803-to-MC68HC11 Interface

A software routine for loading the AD8801/AD8803 from a

68HC11 evaluation board is shown in Listing 3. First, the

MC68HC11 is configured for SPI operation. Bits CPHA and

CPOL define the SPI mode wherein the serial clock (SCK) is

high at the beginning and end of transmission, and data is valid

on the rising edge of SCK. This mode matches the requirements

of the AD8801/AD8803. After the registers are saved on the

stack, the DAC value and address are transferred to RAM and

the AD8801/AD8803’s

CS is driven low. Next, the DAC’s address byte is transferred to the SPDR register, which automatically initiates the SPI data transfer. The program tests the SPIF

bit and loops until the data transfer is complete. Then the DAC

value is sent to the SPI. When transmission of the second byte is

complete,

CS is driven high to load the new data and address

into the AD8801/AD8803.

–12–

REV. A

Page 13

AD8801/AD8803

*

* AD8801/AD8803 to M68HC11 Interface Assembly Program

*

* M68HC11 Register definitions

*

PORTC EQU $1003 Port C control register

* “0,0,0,0;0,0,RS/, SHDN/”

DDRC EQU $1007 Port C data direction

PORTD EQU $1008 Port D data register

* “0,0,/CS,CLK;SDI,0,0,0”

DDRD EQU $1009 Port D data direction

SPCR EQU $1028 SPI control register

* “SPIE,SPE,DWOM,MSTR;CPOL,CPHA,SPR1,SPR0”

SPSR EQU $1029 SPI status register

* “SPIF,WCOL,0,MODF;0,0,0,0”

SPDR EQU $102A SPI data register; Read-Buffer; Write-Shifter

*

* SDI RAM variables: SDI1 is encoded from 0 (Hex) to 7 (Hex)

* SDI2 is encoded from 00 (Hex) to FF (Hex)

* AD8801/3 requires two 8-bit loads; upper 5 bits

* of SDI1 are ignored. AD8801/3 address bits in last

* three LSBs of SDI1.

*

SDI1 EQU $00 SDI packed byte 1 “0,0,0,0;0,A2,A1,A0”

SDI2 EQU $01 SDI packed byte 2 “DB7,DB6,DB5,DB4;DB3,DB2,DB1,DB0”

*

* Main Program

*

ORG $C000 Start of user’s RAM in EVB

INIT LDS #$CFFF Top of C page RAM

*

* Initialize Port C Outputs

*

LDAA #$03 0,0,0,0;0,0,1,1

* /RS-Hi, /SHDN-Hi

STAA PORTC Initialize Port C Outputs

LDAA #$03 0,0,0,0;0,0,1,1

STAA DDRC /RS and /SHDN are now enabled as outputs

*

* Initialize Port D Outputs

*

LDAA #$20 0,0,1,0;0,0,0,0

* /CS-Hi,/CLK-Lo,SDI-Lo

STAA PORTD Initialize Port D Outputs

LDAA #$38 0,0,1,1;1,0,0,0

STAA DDRD /CS,CLK, and SDI are now enabled as outputs

*

* Initialize SPI Interface

*

LDAA #$53

STAA SPCR SPI is Master,CPHA=0,CPOL=0,Clk rate=E/32

*

* Call update subroutine

*

BSR UPDATE Xfer 2 8-bit words to AD8402

JMP $E000 Restart BUFFALO

*

* Subroutine UPDATE

*

UPDATE PSHX Save registers X, Y, and A

REV. A

–13–

Page 14

AD8801/AD8803

PSHY

PSHA

*

* Enter Contents of SDI1 Data Register

*

LDAA $0000 Hi-byte data loaded from memory

STAA SDI1 SDI1 = data in location 0000H

*

* Enter Contents of SDI2 Data Register

*

LDAA $0001 Low-byte data loaded from memory

STAA SDI2 SDI2 = Data in location 0001H

*

LDX #SDI1 Stack pointer at 1st byte to send via SDI

LDY #$1000 Stack pointer at on-chip registers

*

* Reset AD8801 to one-half scale (AD8803 does not have a Reset input)

*

BCLR PORTC,Y $02 Assert /RS

BSET PORTC,Y $02 De-assert /RS

*

* Get AD8801/03 ready for data input

*

BCLR PORTD,Y $20 Assert /CS

*

TFRLP LDAA 0,X Get a byte to transfer via SPI

STAA SPDR Write SDI data reg to start xfer

*

WAIT LDAA SPSR Loop to wait for SPIF

BPL WAIT SPIF is the MSB of SPSR

* (when SPIF is set, SPSR is negated)

INX Increment counter to next byte for xfer

CPX #SDI2+1 Are we done yet ?

BNE TFRLP If not, xfer the second byte

*

* Update AD8801 output

*

BSET PORTD,Y $20 Latch register & update AD8801

*

PULA When done, restore registers X, Y & A

PULY

PULX

RTS ** Return to Main Program **

Listing 3. AD8801/AD8803 to MC68HC11 Interface Program Source Code

–14–

REV. A

Page 15

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Pin Plastic DIP Package (N-16)

0.840 (21.33)

0.745 (18.93)

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

16

18

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

9

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

16-Pin Narrow Body SOIC Package (R-16A)

0.195 (4.95)

0.115 (2.93)

0.015 (0.381)

0.008 (0.204)

AD8801/AD8803

16 9

PIN 1

1

0.0098 (0.25)

0.0040 (0.10)

0.0500

(1.27)

BSC

0.3937 (10.00)

0.3859 (9.80)

0.0192 (0.49)

0.0138 (0.35)

8

0.1574 (4.00)

0.1497 (3.80)

0.2440 (6.20)

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0099 (0.25)

0.0075 (0.19)

8°

0°

0.0196 (0.50)

0.0099 (0.25)

0.0500 (1.27)

0.0160 (0.41)

x 45°

REV. A

–15–

Page 16

C2026–18–4/95

–16–

PRINTED IN U.S.A.

Loading...

Loading...