Page 1

Low Noise,

–

A

Data Sheet

FEATURES

Low noise: 2.7 nV/√Hz @ f = 10 kHz

Low offset voltage: 250 μV max over V

Offset voltage drift: 0.4 μV/°C typ and 2.3 μV/°C max

Bandwidth: 28 MHz

Rail-to-rail input/output

Unity gain stable

2.7 V to 5.5 V operation

−40°C to +125°C operation

Qualified for automotive applications (AD8656)

APPLICATIONS

ADC and DAC buffers

Audio

Industrial controls

Precision filters

Digital scales

Automotive collision avoidance

PLL filters

GENERAL DESCRIPTION

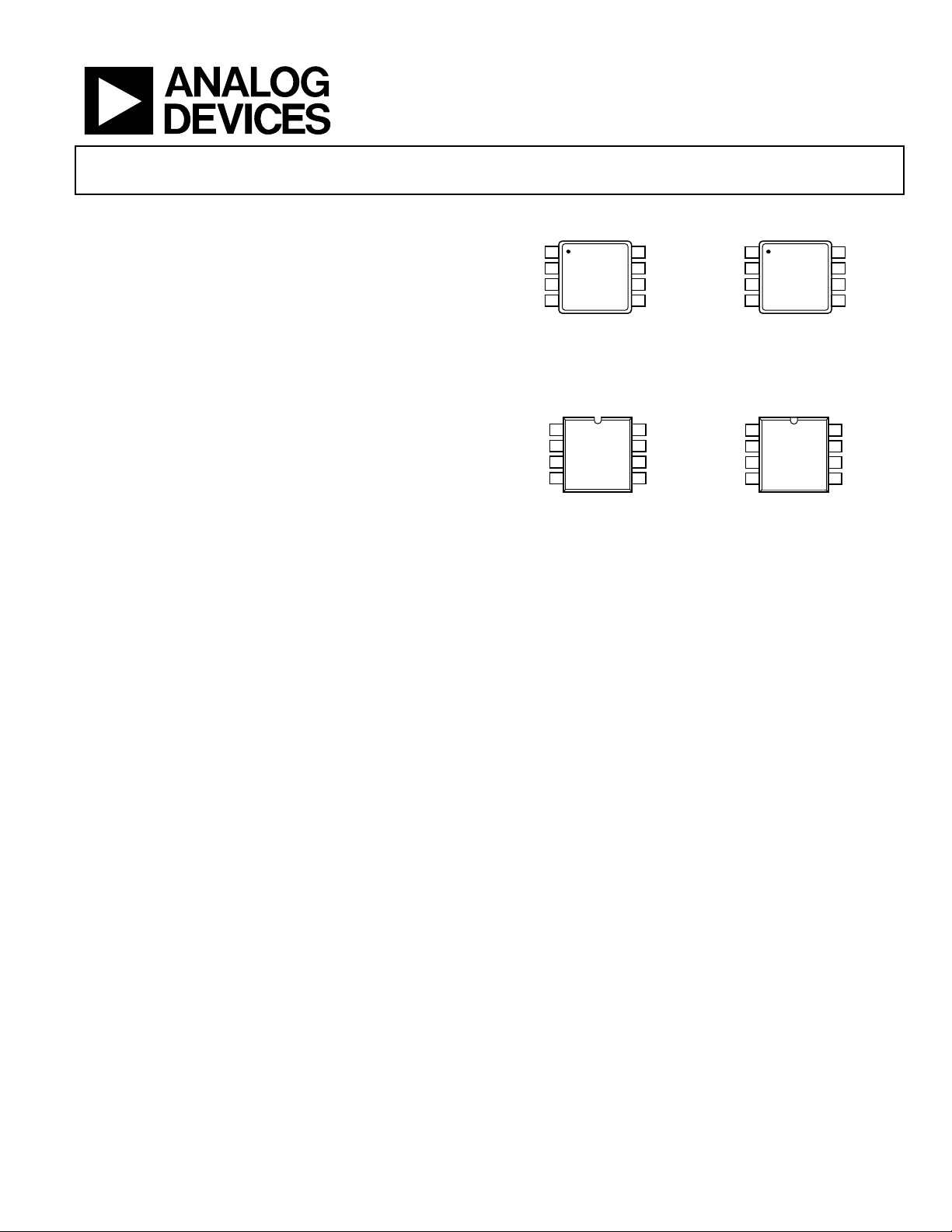

CM

1

NC

IN

2

+IN

3

(Not to Scale)

V–

4

NC = NO CONNECT

Figure 1. AD8655

8-Lead MSOP (RM-8)

NC

1

–IN

2

3

+IN

(Not to Scale)

4

V–

NC = NO CONNECT

Figure 3. AD8655

8-Lead SOIC (R-8)

Precision CMOS Amplifier

AD8655/AD8656

PIN CONFIGURATIONS

8

AD8655

TOP VIEW

AD8655

TOP VIEW

NC

V+

7

OUT

6

NC

5

05304-048

NC

8

V+

7

6

OUT

5

NC

05304-049

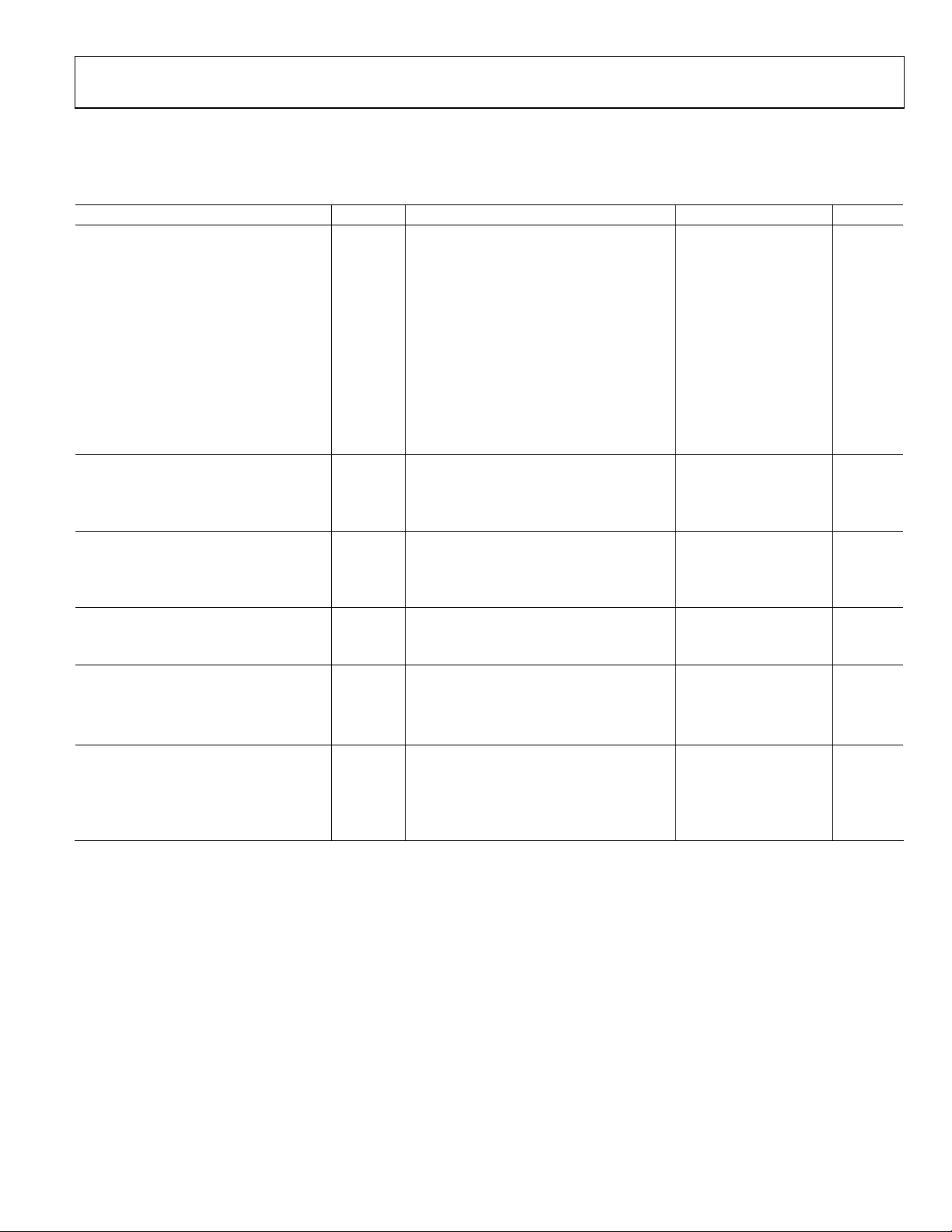

1

OUT

–IN A

2

+IN A

3

V–

4

Figure 2. AD8656

8-Lead MSOP (RM-8)

OUT A

1

2

–IN A

+IN A

3

V–

4

Figure 4. AD8656

8-Lead SOIC (R-8)

AD8656

TOP VIEW

(Not to Scale)

AD8656

TOP VIEW

(Not to Scale)

8

7

6

5

8

7

6

5

V+

OUT B

–IN B

+IN B

V+

OUT B

–IN B

+IN B

05304-059

05304-060

The AD8655/AD8656 are the industry’s lowest noise, precision

CMOS amplifiers. They leverage the Analog Devices DigiTrim®

technology to achieve high dc accuracy.

The AD8655/AD8656 provide low noise (2.7 nV/√Hz @ 10 kHz),

low THD + N (0.0007%), and high precision performance

(250 μV max over V

) to low voltage applications. The ability

CM

to swing rail-to-rail at the input and output enables designers

to buffer analog-to-digital converters (ADCs) and other wide

dynamic range devices in single-supply systems.

The high precision performance of the AD8655/AD8656

improves the resolution and dynamic range in low voltage

applications. Audio applications, such as microphone pre-amps

and audio mixing consoles, benefit from the low noise, low

distortion, and high output current capability of the AD8655/

AD8656 to reduce system level noise performance and maintain

audio fidelity. The high precision and rail-to-rail input and

output of the AD8655/AD8656 benefit data acquisition, process

controls, and PLL filter applications.

The AD8655/AD8656 are fully specified over the −40°C to

+125°C temperature range. The AD8655/AD8656 are available

in Pb-free, 8-lead MSOP and SOIC packages.

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devi ces for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2005–2011 Analog Devices, Inc. All rights reserved.

Page 2

AD8655/AD8656

TABLE OF CONTENTS

Specifications..................................................................................... 3

Data Sheet

Driving Capacitive Loads.......................................................... 16

Absolute Maximum Ratings............................................................ 5

ESD Caution.................................................................................. 5

Typical Performance Characteristics............................................. 6

Theory of Operation ...................................................................... 15

Applications..................................................................................... 16

Input Overvoltage Protection................................................... 16

Input Capacitance....................................................................... 16

REVISION HISTORY

9/11—Rev. A to Rev. B

Changes to Features Section............................................................ 1

Updated Outline Dimensions....................................................... 19

Changes to Ordering Guide.......................................................... 19

Added Automotive Products Section .......................................... 19

6/05—Rev. 0 to Rev. A

Added AD8656 ...................................................................Universal

Added Figure 2 and Figure 4........................................................... 1

Changes to Specifications................................................................ 3

Changed Caption of Figure 12 and Added Figure 13.................. 7

Replaced Figure 16 ...........................................................................7

Changed Caption of Figure 37 and Added Figure 38................ 11

Replaced Figure 47 .........................................................................13

Added Figure 55.............................................................................. 14

Changes to Ordering Guide.......................................................... 18

Layout, Grounding, and Bypassing Considerations.................. 18

Power Supply Bypassing............................................................ 18

Grounding................................................................................... 18

Leakage Currents........................................................................ 18

Outline Dimensions .......................................................................19

Ordering Guide .......................................................................... 19

Automotive Products ................................................................. 19

4/05—Revision 0: Initial Version

Rev. B | Page 2 of 20

Page 3

Data Sheet

AD8655/AD8656

SPECIFICATIONS

VS = 5.0 V, VCM = VS/2, TA = 25°C, unless otherwise specified.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage VOS V

−40°C ≤ TA ≤ +125°C 550 μV

Offset Voltage Drift

ΔV

OS

/ΔT

Input Bias Current IB 1 10 pA

−40°C ≤ TA ≤ +125°C 500 pA

Input Offset Current IOS 10 pA

−40°C ≤ TA≤ +125°C 500 pA

Input Voltage Range 0 5 V

Common-Mode Rejection Ratio CMRR VCM = 0 V to 5 V 85 100 dB

Large Signal Voltage Gain AVO V

−40°C ≤ TA ≤ +125°C 95 dB

OUTPUT CHARACTERISTICS

Output Voltage High VOH I

Output Voltage Low VOL I

Output Current I

V

OUT

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 5.0 V 88 105 dB

Supply Current/Amplifier ISY V

−40°C ≤ TA ≤ +125°C 5.3 mA

INPUT CAPACITANCE CIN

Differential 9.3 pF

Common-Mode 16.7 pF

NOISE PERFORMANCE

Input Voltage Noise Density en f = 1 kHz 4

f = 10 kHz 2.7

Total Harmonic Distortion + Noise THD + N G = 1, RL = 1 kΩ, f = 1 kHz, VIN = 2 V p-p 0.0007 %

FREQUENCY RESPONSE

Gain Bandwidth Product GBP 28 MHz

Slew Rate SR RL = 10 kΩ 11 V/μs

Settling Time ts To 0.1%, VIN = 0 V to 2 V step, G = +1 370 ns

Phase Margin CL = 0 pF 69 degrees

= 0 V to 5 V 50 250 μV

CM

−40°C ≤ T

= 0.2 V to 4.8 V, RL = 10 kΩ, VCM = 0 V 100 110 dB

O

= 1 mA; −40°C ≤ TA ≤ +125°C 4.97 4.991 V

L

= 1 mA; −40°C ≤ TA ≤ +125°C 8 30 mV

L

OUT

= 0 V 3.7 4.5 mA

O

≤ +125°C 0.4 2.3 μV/°C

A

= ±0.5 V ±220 mA

nV/√Hz

nV/√Hz

Rev. B | Page 3 of 20

Page 4

AD8655/AD8656

Data Sheet

VS = 2.7 V, VCM = VS/2, TA = 25°C, unless otherwise specified.

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage VOS V

= 0 V to 2.7 V 44 250 μV

CM

−40°C ≤ TA ≤ +125°C 550 μV

Offset Voltage Drift

ΔV

OS

/ΔT

−40°C ≤ T

≤ +125°C 0.4 2.0 μV/°C

A

Input Bias Current IB 1 10 pA

−40°C ≤ TA ≤ +125°C 500 pA

Input Offset Current IOS 10 pA

−40°C ≤ TA ≤ +125°C 500 pA

Input Voltage Range 0 2.7 V

Common-Mode Rejection Ratio CMRR VCM = 0 V to 2.7 V 80 98 dB

Large Signal Voltage Gain AVO V

= 0.2 V to 2.5 V, RL = 10 kΩ, VCM = 0 V 98 dB

O

−40°C ≤ TA ≤ +125°C 90 dB

OUTPUT CHARACTERISTICS

Output Voltage High VOH I

Output Voltage Low VOL I

Output Current I

V

OUT

= 1 mA; −40°C ≤ TA ≤ +125°C 2.67 2.688 V

L

= 1 mA; −40°C ≤ TA ≤ +125°C 10 30 mV

L

= ±0.5 V ±75 mA

OUT

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 5.0 V 88 105 dB

Supply Current/Amplifier ISY V

= 0 V 3.7 4.5 mA

O

−40°C ≤ TA ≤ +125°C 5.3 mA

INPUT CAPACITANCE CIN

Differential 9.3 pF

Common-Mode 16.7 pF

NOISE PERFORMANCE

Input Voltage Noise Density en f = 1 kHz 4.0

f = 10 kHz 2.7

nV/√Hz

nV/√Hz

Total Harmonic Distortion + Noise THD + N G = 1, RL = 1kΩ, f = 1 kHz, VIN = 2 V p-p 0.0007 %

FREQUENCY RESPONSE

Gain Bandwidth Product GBP 27 MHz

Slew Rate SR RL = 10 kΩ 8.5 V/μs

Settling Time ts To 0.1%, VIN = 0 to 1 V step, G = +1 370 ns

Phase Margin CL = 0 pF 54 degrees

Rev. B | Page 4 of 20

Page 5

Data Sheet

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Supply Voltage 6 V

Input Voltage VSS − 0.3 V to VDD + 0.3 V

Differential Input Voltage ±6 V

Output Short-Circuit Duration

to GND

Electrostatic Discharge (HBM) 3.0 kV

Storage Temperature Range

R, RM Packages

Junction Temperature Range

R, RM Packages

Lead Temperature

(Soldering, 10 sec)

Indefinite

−65°C to +150°C

−65°C to +150°C

260°C

AD8655/AD8656

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 4.

Package Type θ

8-Lead MSOP (RM) 210 45 °C/W

8-Lead SOIC (R) 158 43 °C/W

1

θJA is specified for worst-case conditions; that is, θJA is specified for a device

soldered in the circuit board for surface-mount packages.

1

θJC Unit

JA

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. B | Page 5 of 20

Page 6

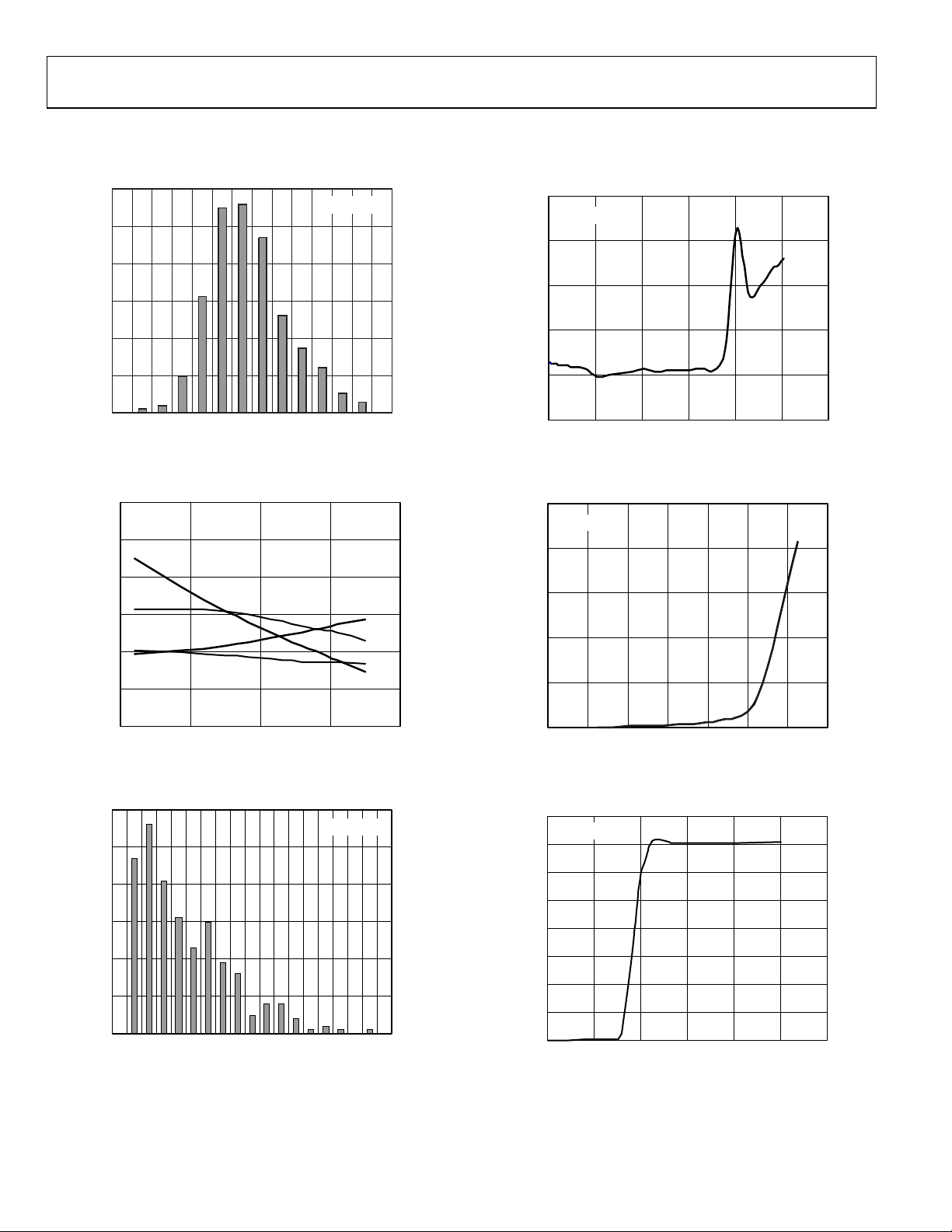

AD8655/AD8656

TYPICAL PERFORMANCE CHARACTERISTICS

60

VS = ±2.5V

50

40

30

20

NUMBER OF AMPLIFIERS

10

Data Sheet

20

VS = ±2.5V

10

0

(μV)

OS

V

–10

–20

0

–150 –100 –50 0 50 100 150

(μV)

V

OS

Figure 5. Input Offset Voltage Distribution

150.0

100.0

50.0

(μV)

0.0

OS

V

–50.0

–100.0

–150.0

–50 0 50

TEMPERATURE (°C)

Figure 6. Input Offset Voltage vs. Temperature

60

50

40

30

VS = ±2.5V

100 150

VS = ±2.5V

05304-001

05304-002

–30

01234

COMMON-MODE VOLTAGE (V)

Figure 8. Input Offset Voltage vs. Common-Mode Voltage

250

VS = ±2.5V

200

150

IB (pA)

100

50

0

0 20 40 60 80 100 120 140

TEMPERATURE (°C)

Figure 9. Input Bias Current vs. Temperature

4.0

VS = ±2.5V

3.5

3.0

2.5

2.0

56

05304-004

05304-005

20

NUMBER OF AMPLIFIERS

10

0

0 0.2 0.4 0.6 0.8 1.0 1.2

|TCV

Figure 7. |TC V

| (μV/°C)

OS

| Distribution

OS

1.4 1.6

05304-003

Rev. B | Page 6 of 20

1.5

SUPPLY CURRENT (mA)

1.0

0.5

0

012 34

SUPPLY VOLTAGE (V)

Figure 10. Supply Current vs. Supply Voltage

56

05304-006

Page 7

Data Sheet

4.5

VS = ±2.5V

4.0

3.5

3.0

(V)

OH

V

4.996

4.994

4.992

4.990

4.988

AD8655/AD8656

VS = ±2.5V

LOAD CURRENT = 1mA

SUPPLY CURRENT (mA)

2.5

2.0

–50 0 50

TEMPERATURE (°C)

100 150

Figure 11. Supply Current vs. Temperature

2500

VS = ±2.5V

2000

1500

V

OH

1000

V

OL

500

DELTA SWING FROM SUPPLY (mV)

0

0 50 100 150 200

CURRENT LOAD (mA)

250

Figure 12. AD8655 Output Voltage to Supply Rail vs. Current Load

10000

1000

VS = ±2.5V

05304-007

05304-008

4.986

4.984

4.982

–50 0 50

TEMPERATURE (°C)

100 150

Figure 14. Output Voltage Swing High vs. Temperature

12

LOAD CURRENT = 1mA

V

= ±2.5V

S

10

8

(mV)

OL

V

6

4

2

–50 0 50

TEMPERATURE (°C)

100 150

Figure 15. Output Voltage Swing Low vs. Temperature

120

100

80

VS = ±2.5V

= 28mV

V

IN

= 1MΩ

R

L

= 47pF

C

L

05304-009

05304-010

100

10

V

OL

DELTA SWING FROM SUPPLY (mV)

V

OH

1

0.1 1 10

CURRENT LOAD (mA)

Figure 13. AD8656 Output Swing vs. Current Load

100 1000

05304-056

Rev. B | Page 7 of 20

60

CMRR (dB)

40

20

0

100 1k 10k

Figure 16. CMRR vs. Fre quency

FREQUENCY (Hz)

100k 10M

1M

05304-011

Page 8

AD8655/AD8656

110.00

107.00

104.00

VS = ±2.5V

V

= 0V

CM

100

Hz 1/2)

√

Data Sheet

VS = ±2.5V

101.00

CMRR (dB)

98.00

95.00

92.00

–50 0 50

TEMPERATURE (°C)

Figure 17. Large Signal CMRR vs. Temperature

100

80

60

PSRR (dB)

40

20

0

100 1k 10k 100k 1M

+PSRR

–PSRR

FREQUENCY (Hz)

Figure 18. Small Signal PSSR vs. Frequency

110.00

108.00

VS = ±2.5V

100 150

VS = ±2.5V

V

= 50mV

IN

R

= 1M

Ω

L

CL = 47pF

10M 100M

05304-012

05304-013

10

VOLTAGE NOISE DENSITY (nV/

1

1 10 100 1k

FREQUENCY (Hz)

Figure 20. Voltage Noise Density vs. Frequency

VS = ±2.5V

Vn (p-p) = 1.23μV

1

500nV/DIV

1s/DIV

Figure 21. Low Frequency Noise (0.1 Hz to 10 Hz).

T

V

IN

V

OUT

VS = ±2.5V

C

= 50pF

L

GAIN = +1

10k 100k

05304-019

05304-020

106.00

2

PSRR (dB)

104.00

102.00

100.00

–50 0 50

Figure 19. Large Signal PSSR vs. Temperature

TEMPERATURE (°C)

100 150

05304-014

1V/DIV

20μs/DIV

Figure 22. No Phase Reversal

05304-021

Rev. B | Page 8 of 20

Page 9

Data Sheet

120

100

80

60

VS = ±2.5V

= 11.5pF

C

LOAD

PHASE MARGIN = 69°

–45

–90

AD8655/AD8656

6

5

4

VS = ±2.5V

V

= 5V

IN

G = +1

40

GAIN (dB)

20

0

–20

–40

10k 100k 1M

FREQUENCY (Hz)

10M 100M

Figure 23. Open-Loop Gain and Phase vs. Frequency

140.00

130.00

120.00

(dB)

VO

A

100.00

VS = ±2.5V

R

= 10kΩ

L

110.00

90.00

–50 0 50

TEMPERATURE (°C)

Figure 24. Large Signal Open-Loop Gain vs. Temperature

50

40

30

–225

100 150

VS = ±2.5V

R

= 1M

Ω

L

CL = 47pF

–135

–180

PHASE SHIFT (Degrees)

05304-015

05304-016

3

OUTPUT (V)

2

1

0

10k 100k 1M

FREQUENCY (Hz)

Figure 26. Maximum Output Swing vs. Frequency

VS = ±2.5V

C

= 100pF

L

GAIN = +1

V

= 4V

IN

2

(1V/DIV)

OUT

V

TIME (10μs/DIV)

Figure 27. Large Signal Response

T

VS = ±2.5V

C

= 100pF

L

G = +1

05304-018

10M

T

05304-022

20

10

0

CLOSED-LOOP GAIN (dB)

–10

–20

1k 10k 100k 1M

FREQUENCY (Hz)

Figure 25. Closed-Loop Gain vs. Frequency

2

(100mV/DIV)

OUT

V

10M 100M

05304-017

TIME (1μs/DIV)

05304-023

Figure 28. Small Signal Response

Rev. B | Page 9 of 20

Page 10

AD8655/AD8656

–

30

VS = ±2.5V

V

= 200mV

IN

25

20

15

OVERSHOOT %

10

5

–OS

+OS

100

VS = ±2.5V

G = +100

10

1

OUTPUT IMPEDANCE (Ω)

G = +10

Data Sheet

G = +1

0

0 50 100 150 200 250 300 350

CAPACITANCE (pF)

Figure 29. Small Signal Overshoot vs. Load Capacitance

300mV

0V

0V

–2.5V

T

V

IN

1

2

V

OUT

VS = ±2.5V

= 300mV

V

IN

GAIN = –10

RECOVERY TIME = 240ns

400ns/DIV

Figure 30. Negative Overload Recovery Time

T

1

0V

300mV

2.5V

V

IN

V

OUT

V

= ±2.5V

S

= 300mV

V

IN

GAIN = –10

RECOVERY TIME = 240ns

05304-024

05304-025

0.1

100 1k 10k 100k 1M 10M 100M

FREQUENCY (Hz)

Figure 32. Output Impedance vs. Frequency

80

70

60

50

40

30

NUMBER OF AMPLIFIERS

20

10

0

–150 –125 –100 –75 –50 –25 0

25 50 75 100 125 150

V

(μV)

OS

VS = ±1.35V

Figure 33. Input Offset Voltage Distribution

60

40

20

(μV)

OS

V

0

VS = ±1.35V

05304-027

05304-028

2

0V

400ns/DIV

05304-026

Figure 31. Positive Overload Recovery Time

–20

–40

–50 0 50 100 150

TEMPERATURE (°C)

Figure 34. Input Offset Voltage vs. Temperature

05304-029

Rev. B | Page 10 of 20

Page 11

Data Sheet

80

70

VS = ±1.35V

AD8655/AD8656

10000

VS =±1.35V

60

50

40

30

NUMBER OF AMPLIFIERS

20

10

0

0 0.2 0.4 0.6 0.8

4.5

VS = ±1.35V

4.0

3.5

3.0

SUPPLY CURRENT (mA)

2.5

|TCV

Figure 35. |TCV

1.0 1.2 1.4 1.6

| (μV/°C)

OS

| Distribution

OS

05304-030

1000

100

V

10

OL

DELTA OUTPUT FROM SUPPLY (mV)

1

0.1 1 10

V

OH

CURRENT LOAD (mA)

Figure 38. AD8656 Output Swing vs. Current Load

2.698

2.694

2.690

(V)

2.686

OH

V

2.682

2.678

VS = ±1.35V

LOAD CURRENT = 1mA

05304-057

100

2.0

–50 0 50 100 150

TEMPERATURE (°C)

Figure 36. Supply Current vs. Temperature

1400

VS = ±1.35V

1200

1000

800

) (mV)

OUT

-V

600

SY

(V

400

200

0

020406080

LOAD CURRENT (mA)

V

OH

V

OL

100 120

Figure 37. AD8655 Output Voltage to Supply Rail vs. Load Current

05304-031

05304-050

2.674

–50 0 50 100 150

TEMPERATURE (°C)

Figure 39. Output Voltage Swing High vs. Temperature

14

VS = ±1.35V

LOAD CURRENT = 1mA

12

10

8

(mV)

OL

V

6

4

2

–50 0 50 100 150

TEMPERATURE (°C)

Figure 40. Output Voltage Swing Low vs. Temperature

05304-032

05304-033

Rev. B | Page 11 of 20

Page 12

AD8655/AD8656

–

T

V

IN

V

OUT

2

1V/DIV

35

VS = ±1.35V

G = +1

C

= 50pF

L

30

25

20

15

OVERSHOOT %

10

5

VS = ±1.35V

V

= 200mV

IN

–OS

+OS

Data Sheet

(500mV/DIV)

V

OUT

2

Figure 41. No Phase Reversal

VS = ±1.35V

= 50pF

C

L

GAIN = +1

TIME (10μs/DIV)

Figure 42. Large Signal Response

T

20μs/DIV

T

VS = ±1.35V

= 100pF

C

L

GAIN = +1

05304-047

05304-042

0

0 50 100 150 200 250 300 350

CAPACITANCE (pF)

Figure 44. Small Signal Overshoot vs. Load Capacitance

T

200mV

0V

0V

–1.35V

1

2

V

IN

V

OUT

VS = ±1.35V

V

= 200mV

IN

GAIN = –10

RECOVERY TIME = 180ns

400ns/DIV

Figure 45. Negative Overload Recovery Time

T

1

0V

200mV

V

IN

VS = ±1.35V

= 200mV

V

IN

GAIN = –10

RECOVERY TIME = 200ns

05304-044

05304-045

(100mV/DIV)

V

OUT

2

TIME (1μs/DIV)

05304-043

Figure 43. Small Signal Response

1.35V

0V

V

2

OUT

400ns/DIV

Figure 46. Positive Overload Recovery Time

05304-046

Rev. B | Page 12 of 20

Page 13

Data Sheet

120

100

80

VS = ±1.35V

= 28mV

V

IN

= 1MΩ

R

L

= 47pF

C

L

120

100

AD8655/AD8656

VS = ±1.35V

C

= 11.5pF

LOAD

PHASE MARGIN = 54°

80

60

–45

–90

60

CMRR (dB)

40

20

0

100 1k 10k

Figure 47. CMRR vs. Fre quency

102.00

98.00

94.00

CMRR (dB)

90.00

86.00

–50 0 50

Figure 48. Large Signal CMRR vs. Temperature

100

80

60

+PSRR

–PSRR

FREQUENCY (Hz)

TEMPERATURE (°C)

100k 1M

VS = ±1.35V

100 150

VS = ±1.35V

= 50mV

V

IN

= 1MΩ

R

L

= 47pF

C

L

05304-034

05304-035

40

GAIN (dB)

20

0

–20

–40

10k 100k 1M

FREQUENCY (Hz)

10M 100M

Figure 50. Open-Loop Gain and Phase vs. Frequency

130.00

120.00

110.00

(dB)

VO

A

100.00

90.00

80.00

–50 0 50

TEMPERATURE (°C)

Figure 51. Large Signal Open-Loop Gain vs. Temperature

50

40

30

20

–135

–180

–225

VS = ±1.35V

R

= 10kΩ

L

100 150

VS = ±1.35V

R

= 1M

Ω

L

CL = 47pF

PHASE SHIFT (Degrees)

05304-036

05304-037

PSRR (dB)

40

20

0

100 1k 10k 100k

Figure 49. Small Signal PSSR vs. Frequency

FREQUENCY (Hz)

1M 100M10M

05304-040

Rev. B | Page 13 of 20

10

0

CLOSED-LOOP GAIN (dB)

–10

–20

1k 10k 100k 1M

FREQUENCY (Hz)

Figure 52. Closed-Loop Gain vs. Frequency

10M 100M

05304-038

Page 14

AD8655/AD8656

Data Sheet

3.0

2.5

VS = 1.35V

V

= 2.7V

IN

2.0

G = +1

NO LOAD

1.5

OUTPUT (V)

1.0

0.5

0

10k 100k 1M

FREQUENCY (Hz)

Figure 53. Maximum Output Swing vs. Frequency

1000

VS = ±1.35V

100

G = +100

10

G = +10

G = +1

10M

05304-039

0

–20

50mV p-p

–40

–60

–80

–100

CHANNEL SEPERATION (dB)

–120

–140

10 100 1k

+2.5V

V+

+

V

A

IN

V–

–

–2.5V

Figure 55. Channel Separation vs. Frequency

R1

10k

Ω

R2

100

V–

B

V

OUT

V+

10k

FREQUENCY (Hz)

100k 1M 10M 100M

VS =±2.5V

V

= 50mV

Ω

IN

05304-058

OUTPUT IMPEDANCE (Ω)

1

0.1

100 1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

05304-041

Figure 54. Output Impedance vs. Frequency

Rev. B | Page 14 of 20

Page 15

Data Sheet

THEORY OF OPERATION

The AD8655/AD8656 amplifiers are voltage feedback, rail-torail input and output precision CMOS amplifiers, which operate

from 2.7 V to 5.0 V of power supply voltage. These amplifiers

use the Analog Devices DigiTrim technology to achieve a

higher degree of precision than is available from most CMOS

amplifiers. DigiTrim technology, used in a number of ADI

amplifiers, is a method of trimming the offset voltage of the

amplifier after it is packaged. The advantage of post-package

trimming is that it corrects any offset voltages caused by the

mechanical stresses of assembly.

AD8655/AD8656

The AD8655/AD8656 can be used in any precision op amp

application. The amplifier does not exhibit phase reversal for

common-mode voltages within the power supply. The

AD8655/AD8656 are great choices for high resolution data

acquisition systems with voltage noise of 2.7 nV/√Hz and

THD + Noise of –103 dB for a 2 V p-p signal at 10 kHz. Their

low noise, sub-pA input bias current, precision offset, and high

speed make them superb preamps for fast filter applications.

The speed and output drive capability of the AD8655/AD8656

also make them useful in video applications.

The AD8655/AD8656 are available in standard op amp pinouts,

making DigiTrim completely transparent to the user. The input

stage of the amplifiers is a true rail-to-rail architecture, allowing

the input common-mode voltage range of the amplifiers to

extend to both positive and negative supply rails. The openloop gain of the AD8655/AD8656 with a load of 10 kΩ is

typically 110 dB.

Rev. B | Page 15 of 20

Page 16

AD8655/AD8656

APPLICATIONS

INPUT OVERVOLTAGE PROTECTION

The internal protective circuitry of the AD8655/AD8656 allows

voltages exceeding the supply to be applied at the input. It is

recommended, however, not to apply voltages that exceed the

supplies by more than 0.3 V at either input of the amplifier. If a

higher input voltage is applied, series resistors should be used to

limit the current flowing into the inputs. The input current

should be limited to less than 5 mA.

The extremely low input bias current allows the use of larger

resistors, which allows the user to apply higher voltages at the

inputs. The use of these resistors adds thermal noise, which

contributes to the overall output voltage noise of the amplifier.

For example, a 10 kΩ resistor has less than 12.6 nV/√Hz of

thermal noise and less than 10 nV of error voltage at room

temperature.

INPUT CAPACITANCE

Along with bypassing and ground, high speed amplifiers can be

sensitive to parasitic capacitance between the inputs and ground.

For circuits with resistive feedback network, the total capacitance,

whether it is the source capacitance, stray capacitance on the

input pin, or the input capacitance of the amplifier, causes a

breakpoint in the noise gain of the circuit. As a result, a

capacitor must be added in parallel with the gain resistor to

obtain stability. The noise gain is a function of frequency and

peaks at the higher frequencies, assuming the feedback capacitor is selected to make the second-order system critically

damped. A few picofarads of capacitance at the input reduce

the input impedance at high frequencies, which increases the

amplifier’s gain, causing peaking in the frequency response or

oscillations. With the AD8655/AD8656, additional input

damping is required for stability with capacitive loads greater

than 200 pF with direct input to output feedback. See the

Driving Capacitive Loads section.

DRIVING CAPACITIVE LOADS

Although the AD8655/AD8656 can drive capacitive loads up to

500 pF without oscillating, a large amount of ringing is present

when operating the part with input frequencies above 100 kHz.

This is especially true when the amplifiers are configured in

positive unity gain (worst case). When such large capacitive

loads are required, the use of external compensation is highly

recommended. This reduces the overshoot and minimizes

ringing, which, in turn, improves the stability of the

AD8655/AD8656 when driving large capacitive loads.

Data Sheet

One simple technique for compensation is a snubber that

consists of a simple RC network. With this circuit in place,

output swing is maintained, and the amplifier is stable at all

gains. Figure 57 shows the implementation of a snubber, which

reduces overshoot by more than 30% and eliminates ringing.

Using a snubber does not recover the loss of bandwidth

incurred from a heavy capacitive load.

VS = ±2.5V

A

= 1

V

C

= 500pF

L

VOLTAGE (100mV/DIV)

TIME (2μs/DIV)

Figure 56. Driving Heavy Capacitive Loads Without Compensation

V

CC

+

V–

V+

–

+

–

200mV

Figure 57. Snubber Network

VS = ±2.5V

A

= 1

V

R

= 200Ω

S

= 500pF

C

S

C

= 500pF

L

VOLTAGE (100mV/DIV)

Figure 58. Driving Heavy Capacitive Loads Using a Snubber Network

500pF

V

EE

TIME (10μs/DIV)

200Ω

500pF

05304-052

05304-051

05304-053

Rev. B | Page 16 of 20

Page 17

Data Sheet

THD Readings vs. Common-Mode Voltage

Total harmonic distortion of the AD8655/AD8656 is well below

0.0007% with a load of 1 kΩ. This distortion is a function of the

circuit configuration, the voltage applied, and the layout, in

addition to other factors.

+2.5V

–

AD8655

+

–2.5V

V

IN

Figure 59. THD + N Test Circuit

V

OUT

R

L

05304-054

AD8655/AD8656

1.0

0.5

SWEEP 1:

= 2V p-p

V

IN

0.2

0.1

0.05

0.02

0.01

%

0.005

0.002

0.001

0.0005

0.0002

0.0001

= 10kΩ

R

L

SWEEP 2

SWEEP 1

20 100 1k 10k 80k50 500 5k 50k200 2k 20k

Hz

Figure 60. THD + Noise vs. Frequency

SWEEP 2:

V

= 2V p-p

IN

= 1kΩ

R

L

05304-055

Rev. B | Page 17 of 20

Page 18

AD8655/AD8656

LAYOUT, GROUNDING, AND BYPASSING CONSIDERATIONS

POWER SUPPLY BYPASSING

Power supply pins can act as inputs for noise, so care must be

taken to apply a noise-free, stable dc voltage. The purpose of

bypass capacitors is to create low impedances from the supply

to ground at all frequencies, thereby shunting or filtering most

of the noise. Bypassing schemes are designed to minimize the

supply impedance at all frequencies with a parallel combination

of capacitors with values of 0.1 μF and 4.7 μF. Chip capacitors

of 0.1 μF (X7R or NPO) are critical and should be as close as

possible to the amplifier package. The 4.7 μF tantalum capacitor

is less critical for high frequency bypassing, and, in most cases,

only one is needed per board at the supply inputs.

GROUNDING

A ground plane layer is important for densely packed PC

boards to minimize parasitic inductances. This minimizes

voltage drops with changes in current. However, an understanding of where the current flows in a circuit is critical to

implementing effective high speed circuit design. The length

of the current path is directly proportional to the magnitude

of parasitic inductances, and, therefore, the high frequency

impedance of the path. Large changes in currents in an

inductive ground return create unwanted voltage noise.

LEAKAGE CURRENTS

Poor PC board layout, contaminants, and the board insulator

material can create leakage currents that are much larger than

the input bias current of the AD8655/AD8656. Any voltage

differential between the inputs and nearby traces creates leakage

currents through the PC board insulator, for example, 1 V/100

GΩ = 10 pA. Similarly, any contaminants on the board can

create significant leakage (skin oils are a common problem).

To significantly reduce leakage, put a guard ring (shield) around

the inputs and input leads that are driven to the same voltage

potential as the inputs. This ensures there is no voltage potential

between the inputs and the surrounding area to create any

leakage currents. To be effective, the guard ring must be driven

by a relatively low impedance source and should completely

surround the input leads on all sides, above and below, by using

a multilayer board.

The charge absorption of the insulator material itself can also

cause leakage currents. Minimizing the amount of material

between the input leads and the guard ring helps to reduce the

absorption. Also, using low absorption materials, such as

Teflon® or ceramic, may be necessary in some instances.

Data Sheet

The length of the high frequency bypass capacitor leads is

critical, and, therefore, surface-mount capacitors are recommended. A parasitic inductance in the bypass ground trace

works against the low impedance created by the bypass

capacitor. Because load currents flow from the supplies, the

ground for the load impedance should be at the same physical

location as the bypass capacitor grounds. For larger value

capacitors intended to be effective at lower frequencies, the

current return path distance is less critical.

Rev. B | Page 18 of 20

Page 19

Data Sheet

OUTLINE DIMENSIONS

5.00(0.1968)

4.80(0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES)ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

85

1

1.27 (0.0500)

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012-AA

Figure 61. 8-Lead Standard Small Outline Package [SOIC_N]

Dimensions shown in millimeters and (inches)

6.20 (0.2441)

5.80 (0.2284)

4

BSC

0.51 (0.0201)

0.31 (0.0122)

Narrow Body (R-8)

1.75 (0.0688)

1.35 (0.0532)

8°

0°

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

1.27 (0.0500)

0.40 (0.0157)

45°

012407-A

3.20

3.00

2.80

PIN 1

IDENTIFIER

0.95

0.85

0.75

0.15

0.05

COPLANARITY

AD8655/AD8656

3.20

3.00

2.80

8

5

5.15

4.90

1

0.65 BSC

0.10

COMPLIANT TO JEDEC STANDARDS MO-187-AA

Figure 62. 8-Lead Mini Small Outline Package [MSOP]

4.65

4

15° MAX

6°

0°

0.23

0.09

0.40

0.25

1.10 MAX

(RM-8)

Dimensions shown in millimeters

0.80

0.55

0.40

10-07-2009-B

ORDERING GUIDE

1, 2

Model

AD8655ARZ −40°C to +125°C 8-Lead SOIC_N R-8

AD8655ARZ-REEL −40°C to +125°C 8-Lead SOIC_N R-8

AD8655ARZ-REEL7 −40°C to +125°C 8-Lead SOIC_N R-8

AD8655ARMZ-REEL −40°C to +125°C 8-Lead MSOP RM-8 A0D

AD8655ARMZ −40°C to +125°C 8-Lead MSOP RM-8 A0D

AD8656ARZ −40°C to +125°C 8-Lead SOIC_N R-8

AD8656ARZ-REEL −40°C to +125°C 8-Lead SOIC_N R-8

AD8656ARZ-REEL7 −40°C to +125°C 8-Lead SOIC_N R-8

AD8656ARMZ −40°C to +125°C 8-Lead MSOP RM-8 A0S

AD8656ARMZ-REEL −40°C to +125°C 8-Lead MSOP RM-8 A0S

AD8656WARMZ-REEL −40°C to +125°C 8-Lead MSOP RM-8 A0S

1

Z = RoHS Compliant Part.

2

W = Qualified for Automotive Applications.

Temperature

Range Package Description Package Option Branding

AUTOMOTIVE PRODUCTS

The AD8656W model is available with controlled manufacturing to support the quality and reliability requirements of automotive

applications. Note that these automotive models may have specifications that differ from the commercial models; therefore, designers

should review the Specifications section of this data sheet carefully. Only the automotive grade product shown is available for use in

automotive applications. Contact your local Analog Devices account representative for specific product ordering information and to

obtain the specific Automotive Reliability reports for this model.

.

Rev. B | Page 19 of 20

Page 20

AD8655/AD8656

NOTES

Data Sheet

©2005–2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05304-0-9/11(B)

Rev. B | Page 20 of 20

Loading...

Loading...