Page 1

16-Channel, 8-Bit

a

FEATURES

16 Independently Addressable Voltage Outputs

Full-Scale Set by External Reference

2 µs Settling Time

Double Buffered 8-Bit Parallel Input

High Speed Data Load Rate

Data Readback

Operates from Single +5 V

Optional ±6 V Supply Extends Output Range

APPLICATIONS

Phased Array Ultrasound & Sonar

Power Level Setting

Receiver Gain Setting

Automatic Test Equipment

LCD Clock Level Setting

GENERAL DESCRIPTION

The AD8600 contains 16 independent voltage output digital-toanalog converters that share a common external reference input

voltage. Each DAC has its own DAC register and input register

to allow double buffering. An 8-bit parallel data input, four address pins, a

digital interface.

The AD8600 is constructed in a monolithic CBCMOS process

which optimizes use of CMOS for logic and bipolar for speed

and precision. The digital-to-analog converter design uses voltage mode operation ideally suited to single supply operation.

The internal DAC voltage range is fixed at DACGND to V

The voltage buffers provide an output voltage range that approaches ground and extends to 1.0 V below V

reference voltage values and digital inputs will settle within

±1 LSB in 2 µs.

Data is preloaded into the input registers one at a time after the

internal address decoder selects the input register. In the write

mode (R/

the positive edge of the

be used to load the data. After changes have been submitted to

the input registers, the DAC registers are simultaneously updated by a common load

put voltages simultaneously appear on all 16 outputs.

CS select, a LD, EN, R/W, and RS provide the

.

REF

. Changes in

CC

W low) data is latched into the input register during

EN pulse. Pulses as short as 40 ns can

EN × LD strobe. The new analog out-

Multiplying DAC

AD8600*

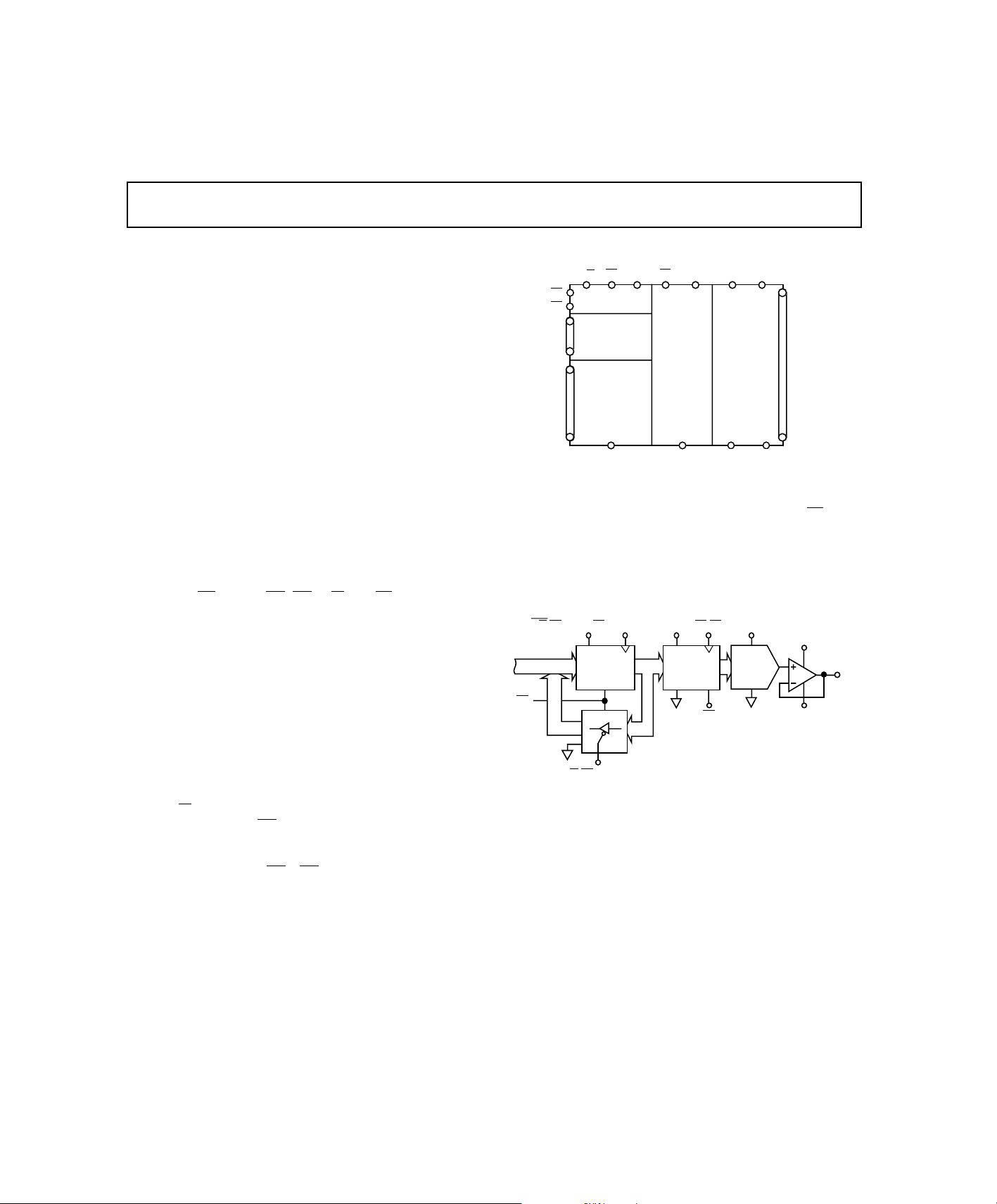

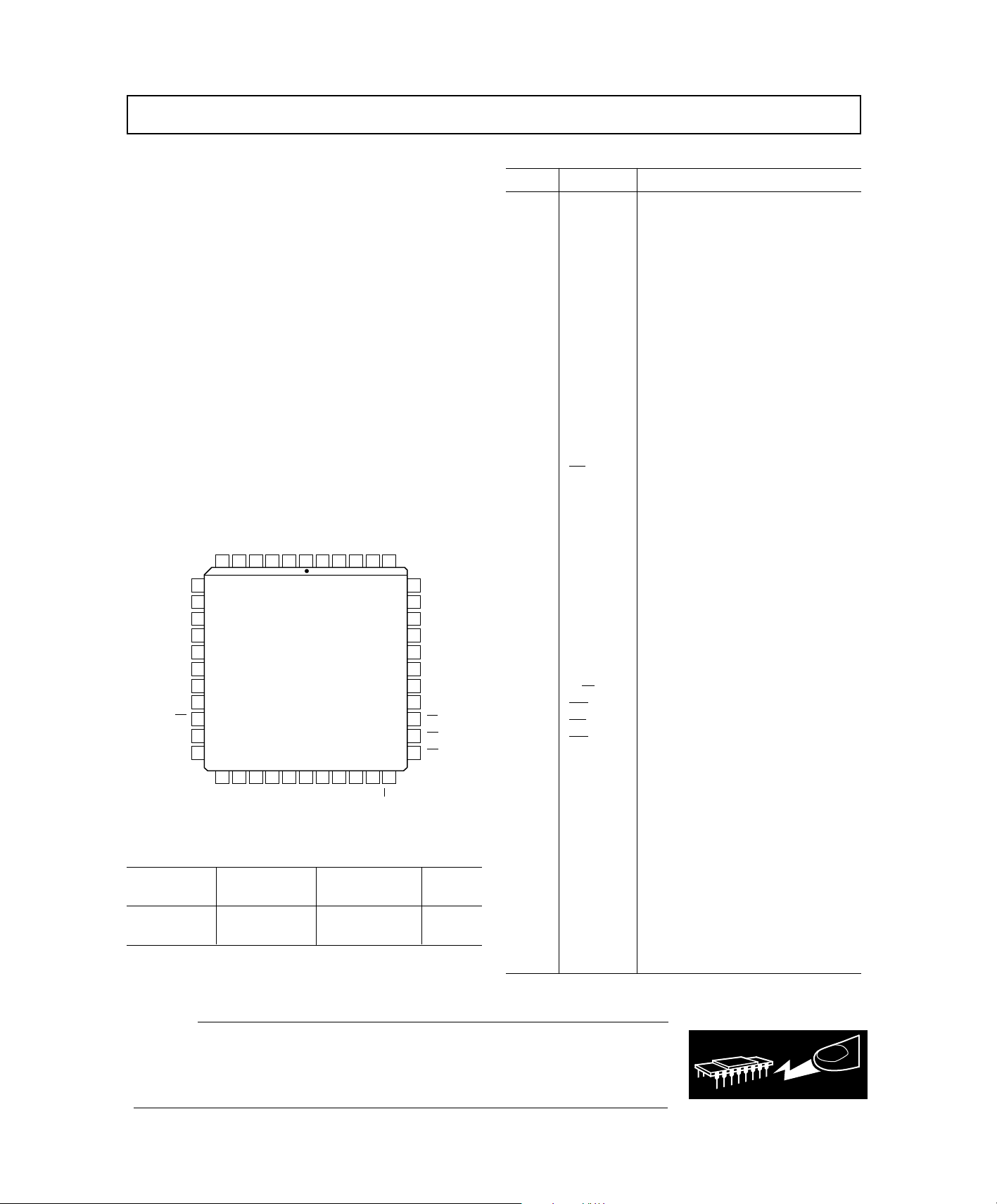

FUNCTIONAL BLOCK DIAGRAM

V

RS

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

CS

EN

A3

A2

A1

A0

R/W

CONTROL

ADDRESS

REGISTERS

LOGIC

DECODE

16 x 8

INPUT

D

GND1

DD1

At system power up or during fault recovery the reset (RS) pin

forces all DAC registers into the zero state which places zero

volts at all DAC outputs.

The AD8600 is offered in the PLCC-44 package. The device is

designed and tested for operation over the extended industrial

temperature range of –40°C to +85°C.

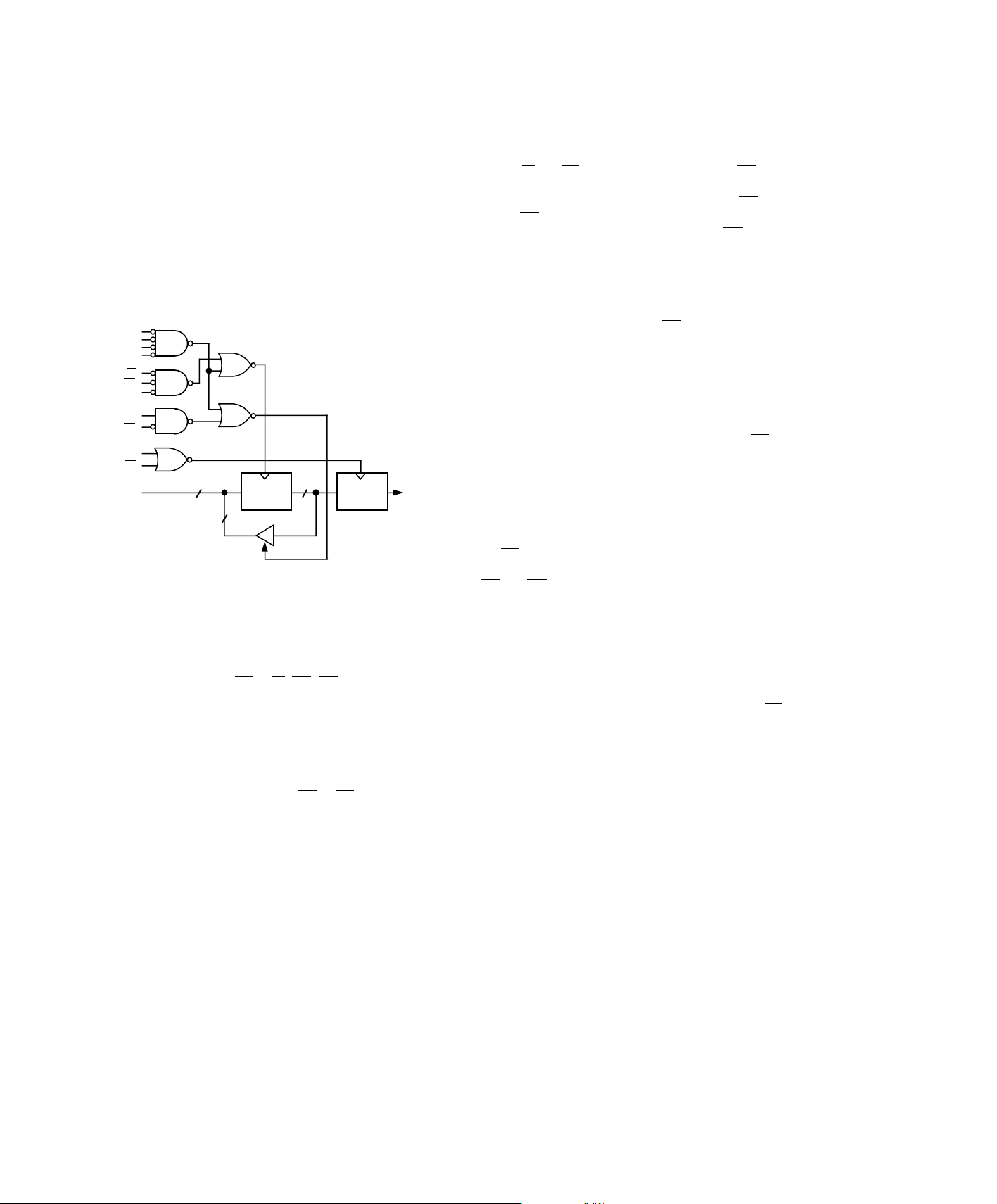

R/

W•CS•ADDR•EN

DB7...DB0

RS

D

GND1

R/W•CS•ADDRESS

V

INPUT

REGISTER

DD1

Figure 1. Equivalent DAC Channel

V

LD

DD2VREFVCC

16 x 8

DAC

REGISTERS

AD8600

D

GND2

V

DD2

DAC

REGISTER

D

GND2

LD•EN

RS

8-BIT

DAC

DACGND

DACGND

16

V

REF

R-2R

DAC

O0

O1

O2

O3

O4

O5

O6

O7

O8

S

O9

O10

O11

O12

O13

O14

O15

V

EE

V

CC

O

X

V

EE

*Patent pending.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

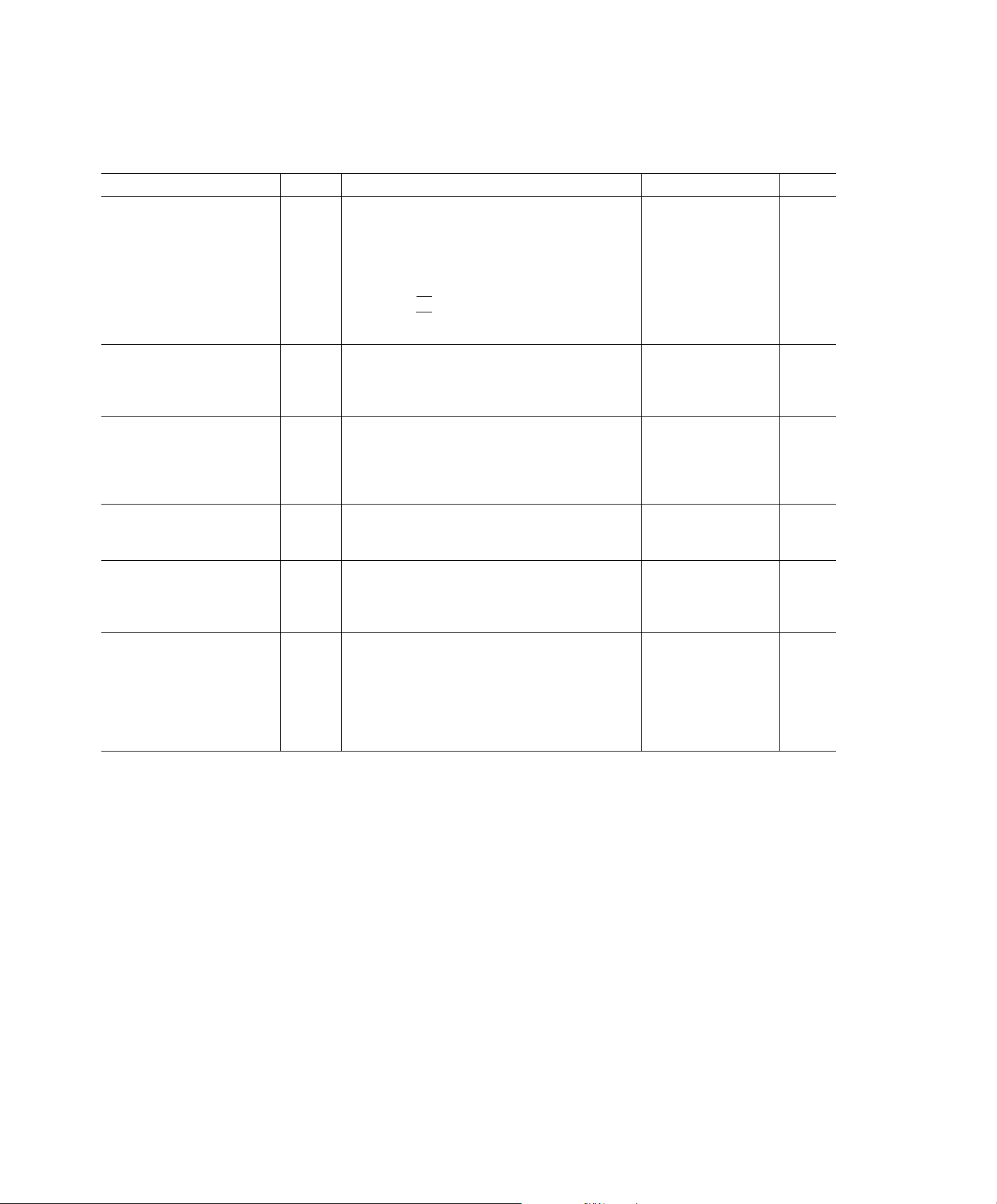

AD8600–SPECIFICATIONS

(@ V

= V

SINGLE SUPPLY

DD1

= VCC = +5 V ± 5%, V

DD2

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

Resolution N 8 Bits

Relative Accuracy

2

Differential Nonlinearity

Full-Scale Voltage V

Full-Scale Tempco TCV

Zero Scale Error V

Reference Input Resistance R

ANALOG OUTPUT

Output Voltage Range

Output Current I

Capacitive Load C

1

2

2

INL –1 ±1/2 +1 LSB

DNL Guaranteed Monotonic –1 ±1/4 +1 LSB

FS

ZSE

V

ZSE

REF

OVR

OUT

L

Data = FF

Data = FF

FS

Data = 00H, RS = “0,” TA= +25°C +3.5 LSB

Data = 00H, RS = “0” +5 LSB

Data = AB

V

SS

= +2.5 V 0.000 2.500 V

REF

Data = 80

No Oscillation 50 pF

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Logic Input Current I

Logic Input Capacitance

3

IL

IH

IL

C

IL

LOGIC OUTPUTS

Logic Out High Voltage V

Logic Out Low Voltage V

AC CHARACTERISTICS

3

Slew Rate SR For ∆V

Voltage Output Settling Time

Voltage Output Settling Time2t

OH

OL

2

t

S1

S2

IOH = –0.4 mA 3.5 V

IOL = 1.6 mA 0.4 V

REF

±1 LSB of Final Value, Full-Scale Data Change 2 µs

±1 LSB of Final Value, ∆V

POWER SUPPLIES

V

Positive Supply Current I

Logic Supply Currents I

Power Dissipation P

CC

DD1&2

DISS

= 5 V, VIL = 0 V, No Load 24 35 mA

IH

V

= 5 V, VIL = 0 V, No Load 0.1 mA

IH

V

= 5 V, VIL = 0 V, No Load 120 175 mW

IH

Power Supply Sensitivity PSS ∆VCC = ±5% 0.007 %/%

Logic Power Supply Range V

Positive Power Supply Range3V

NOTES

1

When V

2

Single supply operation does not include the final 2 LSBs near analog ground. If this performance is critical, use a negative supply (VEE) pin of at least –0.7 V to

–5.25 V. Note that for the INL measurement zero-scale voltage is extrapolated using codes 7

3

Guaranteed by design not subject to production test.

Specifications subject to change without notice.

= 2.500 V, 1 LSB = 9.76 mV.

REF

DDR

CCR

= 0 V, V

EE

H

H

H

H

= +2.500 V, –40°C ≤ TA ≤ +85°C, unless otherwise noted)

REF

2.480 2.490 2.500 V

±20 ppm/°C

1.2 2 kΩ

±2mA

0.8 V

2.4 V

10 µA

10 pF

or FS Code Change 4 7 V/µs

= 1 V, Data = FF

REF

H

2 µs

4.75 5.25 V

to 8010.

10

V

DD

7.0 V

–2–

REV. 0

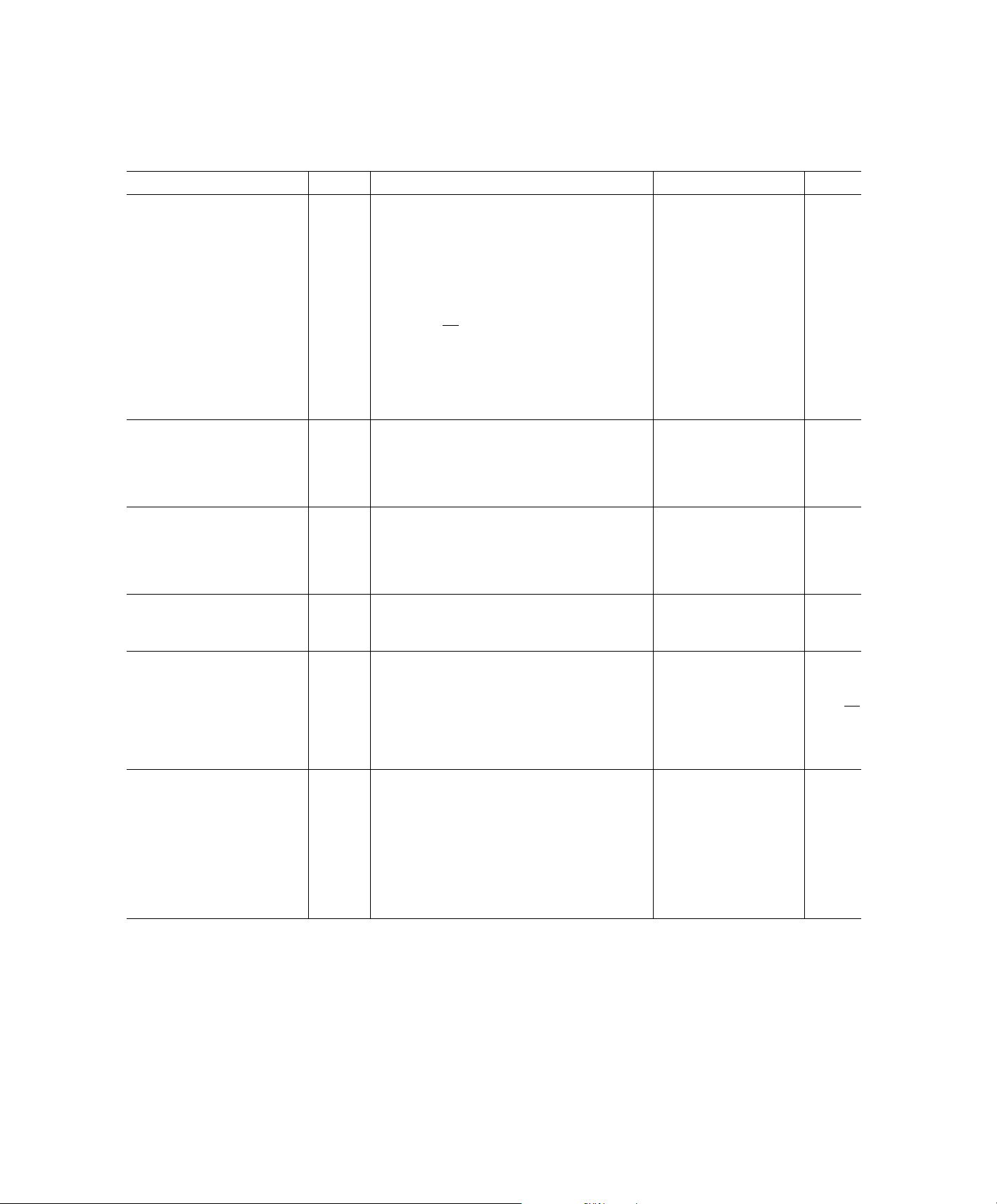

Page 3

AD8600

(@ V

= V

DUAL SUPPLY

DD1

= VCC = +5 V ± 5%, V

DD2

Parameter Symbol Condition Min Typ Max Units

STATIC PERFORMANCE

1

Resolution N 8 Bits

Total Unadjusted Error TUE All Other DACs Loaded with Data = 55

Relative Accuracy INL –1 ±1/2 +1 LSB

Differential Nonlinearity DNL Guaranteed Monotonic –1 ±1/4 +1 LSB

Full-Scale Voltage V

Full-Scale Voltage Error V

FS

FSE

Full-Scale Tempco TCV

Zero Scale Error V

Zero Scale Error V

Zero Scale Error V

ZSE

ZSE

ZSE

Zero Scale Tempco TCV

Reference Input Resistance R

Reference Input Capacitance2C

REF

REF

Data = FFH, V

Data = FFH, V

Data = FFH, V

FS

Data = 00H, RS = “0,” TA = +25°C–2±1+2 mV

Data = 00H, All Other DACs Data = 00

Data = 00H, All Other DACs Data = 55

Data = 00H, VCC = +5 V, VEE = –5 V ±10 µV/°C

ZS

Data = AB

Data = AB

ANALOG OUTPUT

V

Output Voltage Range OVR

Output Voltage Range

Output Current I

Capacitive Load

2

2

OVR

OUT

C

L

1

2

= +3.5 V 0.000 3.500 V

REF

V

= V

CC

Data = 80

No Oscillation 50 pF

LOGIC INPUTS

Logic Input Low Voltage V

Logic Input High Voltage V

Logic Input Current I

Logic Input Capacitance

2

IL

IH

IL

C

IL

LOGIC OUTPUTS

Logic Out High Voltage V

Logic Out Low Voltage V

AC CHARACTERISTICS

2

OH

OL

IOH = –0.4 mA 3.5 V

IOL = 1.6 mA 0.4 V

Reference In Bandwidth BW –3 dB Frequency, V

Slew Rate SR For ∆ V

Voltage Noise Density e

Digital Feedthrough FT Digital Inputs to DAC Outputs 10 nVs

Voltage Output Settling Time

Voltage Output Settling Time3t

N

3

t

S1

S2

f = 1 kHz, V

±1 LSB of Final Value, FS Data Change 1 2 µs

±1 LSB of Final Value, ∆V

POWER SUPPLIES

V

Positive Supply Current I

Negative Supply Current I

Logic Supply Currents I

Power Dissipation

4

CC

EE

DD1&2

P

DISS

= 5 V, VIL = 0 V, VEE = –5 V, No Load 22 35 mA

IH

V

= 5 V, VIL = 0 V, VEE = –5 V, No Load 22 35 mA

IH

V

= 5 V, VIL = 0 V, VEE = –5 V, No Load 0.1 mA

IH

V

= 5 V, VIL = 0 V, VEE = –5 V, No Load 225 350 mW

IH

Power Supply Sensitivity PSS ∆ VCC & ∆VEE = ±5% 0.007 %/%

Logic Power Supply Range V

Pos Power Supply Range

Neg Power Supply Range

NOTES

1

When V

2

Guaranteed by design not subject to production test.

3

Settling time test is performed using RL = 50 kΩ and CL = 35 pF.

4

Power Dissipation is calculated using 5 V × (IDD + |ISS| + I

Specifications subject to change without notice.

= +3.500 V, 1 LSB = 13.67 mV.

REF

2

2

V

V

DDR

CCR

EER

DD1

= –5 V ± 5%, V

EE

REF

REF

REF

H

H

= +7 V, V

DD2

H

= +3.5 V 3.473 3.486 3.500 V

= +3.5 V –1 +1 LSB

= +3.5 V ±20 ppm/°C

EE

= +3.500 V, –40°C ≤ TA ≤ +85°C, unless otherwise noted)

REF

H

H

H

–1 ±3/4 +1 LSB

–1 +1 LSB

±1/2 LSB

1.2 2 kΩ

= –0.7 V, V

= 5 V 0.000 5.000 V

REF

±2mA

240 pF

0.8 V

2.4 V

10 µA

10 pF

= 2.5 VDC + 0.1 V

or FS Code Change 4 7 V/µs

REF

REF

= 0 V 46 nV/√Hz

REF

= 1 V, Data = FF

REF

AC

500 kHz

H

12 µs

4.75 5.25 V

V

DD

7.0 V

–5.25 0.0 V

+ I

).

DD2

REV. 0

–3–

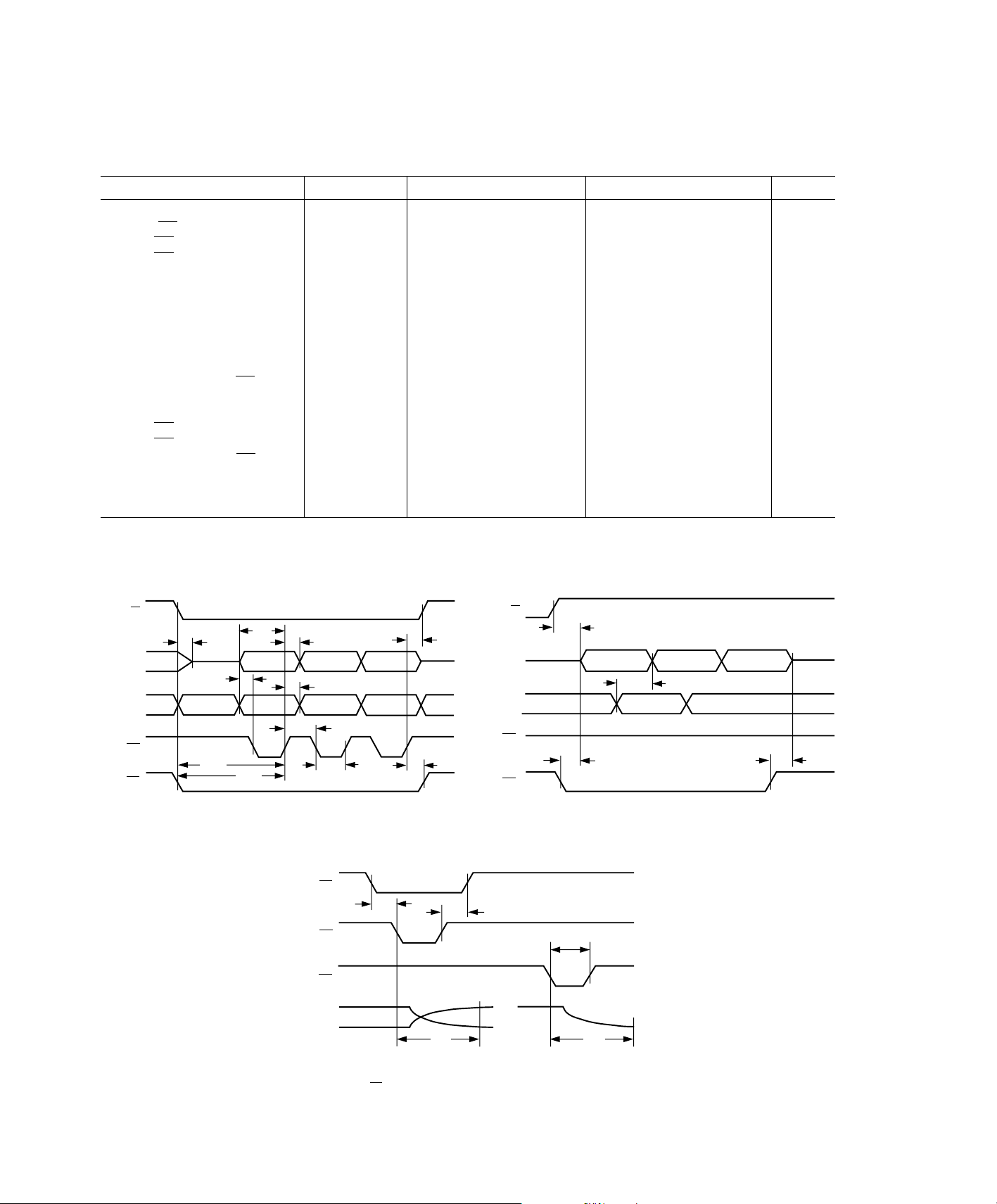

Page 4

AD8600

(@ V

= V

= VCC = +5 V ± 5%, V

DD2

ELECTRICAL CHARACTERISTICS

DD1

unless otherwise noted)

Parameter Symbol Condition Min Typ Max Units

INTERFACE TIMING

Clock (EN) Frequency f

EN) High Pulse Width t

Clock (

EN) LowPulse Width t

Clock (

Data Setup Time t

Data Hold Time t

Address Setup Time t

Address Hold Time t

Valid Address to Data Valid t

Load Enable Setup Time t

Load Enable Hold Time t

Read/Write to Clock (

Read/Write to DataBus Hi-Z t

Read/Write to DataBus Active t

EN) to Read/Write t

Clock (

EN) to Chip Select t

Clock (

Chip Select to Clock (

Chip Select to Data Valid t

Chip Select to DataBus Hi-Z t

Reset Pulse Width t

NOTES

1

Guaranteed by design not subject to production test.

2

All logic input signals have maximum rise and fall times of 2 ns.

Specifications subject to change without notice.

1, 2

CLK

CH

CL

DS

DH

AS

AH

AD

LS

EN)t

EN)t

LH

RWC

RWZ

RWD

TWH

TCH

CSC

CSD

CSZ

RS

Data Loading 12.5 MHz

= –5 V, V

EE

= +3.500 V, –40°C ≤ TA ≤ +85°C,

REF

40 ns

40 ns

40 ns

10 ns

0ns

0ns

160 ns

0ns

0ns

30 ns

120 ns

120 ns

0ns

0ns

30 ns

120 ns

150 ns

25 ns

R/W

DATA

ADDR

EN

CS

t

RWZ

t

t

RWC

AS

t

DS

t

CSC

Figure 2. Write Timing

R/W

t

TWH

t

DH

t

AH

t

CH

t

CL

t

TCH

HIGH-Z

DATA

ADDR

EN

CS

HIGH -Z

t

t

RWD

CSD

t

AD

t

CSZ

Figure 3. Readback Timing

LD

t

LS

EN

RS

OUT

t

LH

t

RS

t

S1

t

S1

Figure 4. Write to DAC Register & Voltage Output Settling

Timing (CS= High, Prevents Input Register Changes)

–4–

REV. 0

Page 5

AD8600

ABSOLUTE MAXIMUM RATINGS

(TA= +25°C unless otherwise noted)

V

(Digital Supply) to GND . . . . . . . . . . . . . .–0.3 V, +7 V

DD1

(DAC Buffer/Driver Supply) . . . . . . . . . . . . –0.3 V, +7 V

V

DD2

(Analog Supply) to GND . . . . . . . . . . . . . . . –0.3 V, +7 V

V

CC

(Analog Supply) to GND . . . . . . . . . . . . . . . +0.3 V, –7 V

V

EE

to GND . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

V

REF

to V

V

DD2

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

V

OUT

Short Circuit Duration

V

OUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–0.3 V

REF

to GND or Power Supplies

1

. . . . . . . . . . . . . . .

Digital Input/Output Voltage to GND . . . –0.3 V, V

Thermal Resistance–Theta Junction-to-Ambient (θ

+ 0.3 V

CC

CC

Continuous

+ 0.3 V

DD

)

JA

PLCC-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47°C/W

– T

Package Power Dissipation . . . . . . . . . . . . . . . . (T

Maximum Junction Temperature T

max . . . . . . . . . . . 150°C

J

)/θ

J

A

JA

Operating Temperature Range . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300°C

NOTE

1

No more than four outputs may be shorted to power or GND simultaneously.

PIN CONFIGURATION

CC

DD2

DGND2

V

V

43

25 28

26

A2

A0

A1

EE

V

O8

404142

O9

39

38

O10

O11

37

O12

36

35

O13

34

O14

33

O15

32

DGND1

31

LD

30

CS

29

EN

27

A3

R/W

O6

7

8

O5

9

O4

10

O3

O2

11

O1

12

13

O0

V

14

DD1

RS

15

DB0

16

DB1

17

NC = NO CONNECT

O7

DB2

EE

V

DB3

CC

V

DB4

REF

NC

DACGND

V

3

AD8600

TOP VIEW

(Not to Scale)

21 24

22182019

23

DB7

DB5

DB6

4412645

ORDERING GUIDE

Package Package

Model Temperature Description Option

AD8600AP –40°C to +85°C 44-Lead PLCC P-44A

AD8600Chips +25°C Die*

*For die specifications contact your local Analog Devices sales office.

The AD8600 contains 5782 transistors.

PIN DESCRIPTION

Pin No. Name Description

1 NC No Connection

2V

REF

Reference input voltage common

to all DACs.

3 DACGND DAC Analog Ground Return. Sets

analog zero-scale voltage.

4V

5V

CC

EE

Output Amplifier Positive Supply

Output Amplifier Negative Supply

6 O7 DAC Channel Output No. 7

7 O6 DAC Channel Output No. 6

8 O5 DAC Channel Output No. 5

9 O4 DAC Channel Output No. 4

10 O3 DAC Channel Output No. 3

11 O2 DAC Channel Output No. 2

12 O1 DAC Channel Output No. 1

13 O0 DAC Channel Output No. 0

14 V

15

DD1

RS Active Low Reset Input Pin

Digital Logic Power Supply

16 DB0 Data Bit Zero I/O (LSB)

17 DB1 Data Bit I/O

18 DB2 Data Bit I/O

19 DB3 Data Bit I/O

20 DB4 Data Bit I/O

21 DB5 Data Bit I/O

22 DB6 Data Bit I/O

23 DB7 Most Significant Data Bit I/O (MSB)

24 A0 Address Bit Zero (LSB)

25 A1 Address Bit

26 A2 Address Bit

27 A3 Most Significant Addr Bit (MSB)

28 R/

29

30

31

W Read/Write Select Control Input

EN Active Low Enable Clock Strobe

CS Chip Select Input

LD DAC Register Load Strobe

32 DGND1 Digital Ground Input No. 1

33 O15 DAC Channel Output No. 15

34 O14 DAC Channel Output No. 14

35 O13 DAC Channel Output No. 13

36 O12 DAC Channel Output No. 12

37 O11 DAC Channel Output No. 11

38 O10 DAC Channel Output No. 10

39 O9 DAC Channel Output No. 9

40 O8 DAC Channel Output No. 8

41 V

42 V

EE

CC

Output Amplifier Negative Supply

Output Amplifier Positive Supply

43 DGND2 Digital Ground Input No. 2

44 V

DD2

DAC Analog Supply Voltage

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8600 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

–5–

WARNING!

ESD SENSITIVE DEVICE

Page 6

AD8600

TRANSFER EQUATIONS

Output Voltage

V

Oi= D ×

REF

256

where i is the DAC channel number and D is the decimal value

of the DAC register data.

Table I. Truth Table

EN R/W CS LD RS Operation

Write to DAC Register

– X H L H Update DAC Register

L X H – H Update DAC Register

+ X H L H Latches DAC Register

L X H + H Latches DAC Register

L L L L H DAC Register Transparent

Write to Input Register

L L L H H Load Data to Input Register at

Decoded Address

+ L L H H Latches Data in Input Register at

Decoded Address

L L + H H Latches Data in Input Register at

Decoded Address

Readback Input Registers

X H L H H Input Register Readback (Data

Access)

X H + H H Hi-Z Readback Disconnects from

Bus

X X H X X Hi-Z on Data Bus

Reset

X X X X L Clear All Registers to Zero,

= 0 V

V

OUT

X X H H + Latches All Registers to Zero

LX LH +

CS = Low; Input Register Ready

R/W, DAC Register Latched

for

to Zero

NOTES

1

+ symbol means positive edge of control input line.

2

– symbol means negative edge of control input line.

Decoded DAC Register

Oi= A

where A is the decimal value of the decoded address bits A3,

A2, A1, A0 (LSB).

Address,

vation of the active low

ent when

the decoded input register. When the load strobe

CS, R/W and data inputs should be stable prior to acti-

EN input. Input registers are transpar-

EN is low. When EN returns high, data is latched into

LD and EN

pins are active low, all input register data is transferred to the

DAC registers. The DAC registers are transparent while they

are enabled.

Table II. Address Decode Table

A3 A2 A1 A0 Addr DAC

(MSB) (LSB) Code Updated

(Binary) (Hex)

0000 0 O0

0001 1 O1

0010 2 O2

0011 3 O3

0100 4 O4

0101 5 O5

0110 6 O6

0111 7 O7

1000 8 O8

1001 9 O9

1010 A O10

1011 B O11

1100 C O12

1101 D O13

1110 E O14

1111 F O15

–6–

REV. 0

Page 7

Typical Performances Characteristics–AD8600

125–25–50

8

–4

–2

0

4

1007550250

TEMPERATURE – °C

ZERO-SCALE – mV

VCC = +5V

V

EE

= –5V

V

REF

= 3.5V

+1/2

–1/2

+1/2

LINEARITY ERROR – LSB

–1/2

DACs 00–07 SUPERIMPOSED

0

VCC = +5V

V

EE

V

REF

T

A

0

DACs 08–015 SUPERIMPOSED

DIGITAL INPUT CODE – Decimal

= –5V

= +3.5V

= +25°C

Figure 5. Linearity Error vs.

Digital Code

15

VCC = +5V

V

= –5V

EE

10

RS = 0

5

0

– mA

OUT

–5

I

–10

–15

–4 –3 –2 0–1 1 2 3 4

V

– Volts

OUT

3.50

3.49

3.48

FULL-SCALE OUTPUT – Volts

3.47

2560 19212864

Figure 6. Full-Scale Voltage vs.

Temperature

4

3

2

1

OUTPUT AMPLITUDE – Volts

0

VCC = +5V

VEE = –5V

V

= 3.5V

REF

TEMPERATURE – °C

VCC = +5V

V

= –5V

EE

V

= 3.5V

REF

TIME – 250ns/DIV

125–25–50 1007550250

Figure 7. Zero-Scale Voltage vs.

Temperature

100

VCC = +5V

= –5V

V

80

60

40

20

NOISE VOLTAGE DENSITY – nV/√Hz

EE

V

= 0V

REF

= +25°C

T

A

0

10

100

FREQUENCY – Hz

10k1k

Figure 8. Output Current vs.

Voltage

–5

–10

GAIN – dB

–15

1k

VIN = 100mV p-p + 2.5V

CODE = FF

TA = +25°C

H

10k 10M1M100k

FREQUENCY – Hz

DC

GAIN

00

–45

PHASE

–90

Figure 11. Gain & Phase vs.

Frequency

Figure 9. Full-Scale Settling Time

0

–20

–40

–60

FEEDTHROUGH – dB

PHASE – Degrees

–80

–100

100

VIN = 2V p-p + 1V

RS = 0

T

= +25°C

A

1k 100k10k

FREQUENCY – Hz

Figure 12. AC Feedthrough vs.

Frequency

Figure 10. Voltage Noise Density vs.

Frequency

60

DC

50

40

PSRR – dB

30

20

∆VCC = 100mV p-p

T

= +25°C

A

CODE = 00

VEE = –5V

FREQUENCY – Hz

H

1k

10k10010 100k

Figure 13. PSRR vs. Frequency

REV. 0

–7–

Page 8

AD8600

20

19

18

17

SUPPLY CURRENT – mA

16

15

VCC = +5V

= –5V

V

EE

V

= 3.5V

REF

TEMPERATURE – °C

χ + 3σ

χ

χ − 3σ

125–50–75 10025 50–25 0 75

Figure 14. Supply Current vs. Temperature Figure 15. Output Voltage Drift

Operation

The AD8600 is a 16-channel voltage output, 8-bit digital to

analog converter. The AD8600 operates from a single +5 V

supply, or for a wider output swing range, the part can operate

from dual supplies of ±5 V or ±6 V or a single supply of +7 V.

The DACs are based upon a unique R-2R ladder structure*

that removes the possibility of current injection from the reference to ground during code switching. Each of the 8-bit DACs

has an output amplifier to provide 16 low impedance outputs.

With a single external reference, 16 independent dc output levels can be programmed through a parallel digital interface. The

interface includes 4 bits of address (A0–A3), 8 bits of data

(DB0–DB7), a read/write select pin (R/

EN), a DAC register load strobe (LD), and a chip select

strobe (

CS). Additionally a reset pin (RS) is provided to asynchro-

pin (

W), an enable clock

nously reset all 16 DACs to 0 V output.

D/A Converter Section

The internal DAC is an 8-bit voltage mode device with an output that swings from DACGND to the external reference voltage, V

. The equivalent schematic of one of the DACs is

REF

shown in Figure 16. The DAC uses an R-2R ladder to ensure

accuracy and linearity over the full temperature range of the part.

The switches shown are actually N and P-channel MOSFETs to

allow maximum flexibility and range in the choice of reference

V

REF

DACGND

TO 15

DACs

R

R

V

R

R

R

R

R

R

R

R

2R

R

*R = 30kΩ

TYPICALLY

OUT

Figure 16. Equivalent Schematic of Analog Channel

voltage. The switches’ low ON resistance and matching is important in maintaining the accuracy of the R-2R ladder.

5

VCC = +5V

4

3

2

1

0

–1

–2

–3

CHANGE IN ZERO SCALE – mV

–4

–5

= –5V

V

EE

V

= 3.5V

REF

CODE = 00

T = HOURS OF OPERATION AT +125°C

H

χ + 3σ

χ

χ − 3σ

12002000 1000600 800400

Accelerated by Burn-In

Amplifier Section

The output of the DAC ladder is buffered by a rail-to-rail output amplifier. This amplifier is configured as a unity gain follower as shown in Figure 16. The input stage of the amplifier

contains a PNP differential pair to provide low offset drift and

noise. The output stage is shown in Figure 17. It employs

complementary bipolar transistors with their collectors connected to the output to provide rail-to-rail operation. The NPN

transistor enters into saturation as the output approaches the

negative rail. Thus, in single supply, the output low voltage is

limited by the saturation voltage of the transistor. For the transistors used in the AD8600, this is approximately 40 mV. The

AD8600 was not designed to swing to the positive rail in contrast to some of ADI’s other DACs (for example, the AD8582).

The output stage of the amplifier is actually capable of swinging

to the positive rail, but the input stage limits this swing to approximately 1.0 V below V

CC

.

V

CC

V

OUT

V

EE

Figure 17. Equivalent Analog Output Circuit

During normal operation, the output stage can typically source

and sink ±1 mA of current. However, the actual short circuit

current is much higher. In fact, each DAC is capable of sourcing 20 mA and sinking 8 mA during a short condition. The

absolute maximum ratings state that, at most, four DACs can

be shorted simultaneously. This restriction is due to current

densities in the metal traces. If the current density is too high,

voltage drops in the traces will cause a loss in linearity performance for the other DACs in the package. Thus to ensure longterm reliability, no more than four DACs should be shorted

simultaneously.

*Patent Pending.

–8–

REV. 0

Page 9

Power Supply and Grounding Considerations

The low power consumption of the AD8600 is a direct result of

circuit design optimizing using a CBCMOS process. The overall power dissipation of 120 mW translates to a total supply current of only 24 mA for 16 DACs. Thus, each DAC consumes

only 1.5 mA. Because the digital interface is comprised entirely

of CMOS logic, the power dissipation is dependent upon the

logic input levels. As expected for CMOS, the lowest power

dissipation is achieved when the input level is either close to

ground or +5 V. Thus, to minimize the power consumption,

CMOS logic should be used to interface to the AD8600.

The AD8600 has multiple supply pins. V

the output amplifiers’ positive supply, and V

(Pins 4 and 42) is

CC

(Pins 5 and 41)

EE

the amplifiers’ negative supply. The digital input circuitry is

powered by V

2R ladder switches are powered by V

(Pin 14), and finally the DAC register and R-

DD1

(Pin 44). To minimize

DD2

noise feedthrough from the supplies, each supply pin should be

decoupled with a 0.1 µF ceramic capacitor close to the pin.

When applying power to the device, it is important for the digital supply, V

for V

to remain less than 0.3 V above V

REF

, to power on before the reference voltage and

DD2

during normal

DD2

operation. Otherwise, an inherent diode will energize, and it

could damage the AD8600.

In order to improve ESD resistance, the AD8600 has several

ESD protection diodes on its various pins. These diodes shunt

ESD energy to the power supplies and protect the sensitive active circuitry. During normal operation, all the ESD diodes are

reversed biased and do not affect the part. However, if overvoltages occur on the various inputs, these diodes will energize. If

the overvoltage is due to ESD, the electrical spike is typically

short enough so that the part is not damaged. However, if the

overvoltage is continuous and has sufficient current, the part

could be damaged. To protect the part, it is important not to

forward bias any of the ESD protection diodes during normal

operation or during power up. Figure 18 shows the location of

these diodes. For example, the digital inputs have diodes connected to V

and from DGND1. Thus, the voltage on any

CC

digital input should never exceed the analog supply or drop below ground, which is also indicated in the absolute maximum

ratings.

AD8600

V

V

CC

DD2

ALL DIGITAL INPUTS

(A0–A3, DB0–DB7)

W, CS, EN, LD, RS )

(R/

DGND1

V

REF

DACGND

Figure 18. ESD Protection Diode Locations

Attention should be paid to the ground pins of the AD8600 to

ensure that noise is not introduced to the output. The pin labeled DACGND (Pin 3) is actually the ground for the R-2R

ladder, and because of this, it is important to connect this pin to

a high quality analog ground. Ideally, the analog ground should

be an actual ground plane. This helps create a low impedance,

low noise ground to maintain accuracy in the analog circuitry.

The digital ground pins (DGND1 at Pin 32 and DGND2 at

Pin 43) provide the ground reference for the internal digital circuitry and latches. The first thought may be to connect both of

these pins to the system digital ground. However, this is not the

best choice because of the high noise typically found on a

system’s digital ground. This noise can feed through to the output through the DAC’s ground pins. Instead, DGND1 and

DGND2 should be connected to the analog ground plane. The

actual switching current in these pins is small and should not

degrade the analog ground.

5 V Output Swing

The output swing is limited to 1.0 V below the positive supply.

This gives a maximum output of +4.0 V on a +5 V supply. To

increase the output range, the analog supply, V

ladder supply, V

output of +5 V with a 5 V reference. V

, can be increased to +7 V. This allows an

DD2

DD1

+5 V to ensure that the input logic levels do not change.

Reference Input Considerations

The AD8600 is designed for one reference to drive all 16 DACs.

The reference pin (V

) is connected directly to the R-2R lad-

REF

ders of each DAC. With 16 DACs in parallel, the input impedance is typically 2 kΩ and a minimum of 1.2 kΩ. The input

resistance is code dependent. Thus, the chosen reference device

must be able to drive this load. Some examples of +2.5 V references that easily interface to the AD8600 are the REF43,

AD680, and AD780. The unique architecture ensures that the

reference does not have to supply “shoot through” current,

which is a condition in some voltage mode DACs where the reference is momentarily connected to ground through the CMOS

switches. By eliminating this possibility, all 16 DACs in the

AD8600 can easily be driven from a single reference.

, and the DAC

CC

should remain at

REV. 0

–9–

Page 10

AD8600

Interface Timing and Control

The AD8600 employs a double buffered DAC structure with

each DAC channel having a unique input register and DAC register as shown in the diagram entitled “Equivalent DAC Channel” on the first page of the data sheet. This structure allows

maximum flexibility in loading the DACs. For example, each

DAC can be updated independently, or, if desired, all 16 input

registers can be loaded, followed by a single

LD strobe to update all 16 DACs simultaneously. An additional feature is the

ability to read back from the input register to verify the DAC’s

data.

A0

A1

N1

A2

R/W

EN

CS

R/W

CS

LD

EN

D7–D0

A3

N2

N3

N4

N5

N6

8

INPUT

REGISTER

READ BACK

88

DAC

REGISTER

R-2R

LADDER

Figure 19. Logic Interface Circuit for DAC Channel 0

The interface logic for a single DAC channel is shown in Figure

19. This figure specifically shows the logic for Channel 0; however, by changing the address input configuration to gate N1,

the other 15 channels are achieved. All of the logic for the

AD8600 is level sensitive and not edge triggered. For example,

if all the control inputs (

CS, R/W, EN, LD) are low, the input

and DAC registers are transparent and any change in the digital

inputs will immediately change the DAC’s R-2R ladder.

Table I details the different logic combinations and their effects.

Chip Select (

CS), Enable (EN) and R/W must be low to write

the input register. During this time that all three are low, any

data on DB7–DB0 changes the contents of the input register.

This data is not latched until either

EN or CS returns high.

The data setup and hold times shown in the timing diagrams

must be observed to ensure that the proper data is latched into

the input register.

To load multiple input registers in the fastest time possible,

W and CS should remain low, and the EN line be used

both R/

to “clock” in the data. As the write timing diagram shows, the

address should be updated at the same time as

EN returns high, valid data must be present for a time

Before

equal to the data setup time (t

the data Hold Time (t

DH

), and after EN returns high,

DS

) must be maintained. If these mini-

EN goes low.

mum times are violated, invalid data may be latched into the input register. This cycle can be repeated 16 times to load all of

the DACs. The fastest interface time is equal to the sum of the

low and high times (t

minimum of 80 ns. Because the

and tCH) for the EN input, which gives a

CL

EN input is used to clock in

the data, it is often referred to as the clock input, and the timing

specifications give a maximum clock frequency of 12.5 MHz,

which is just the reciprocal of 80 ns.

After all the input registers have been loaded, a single load

strobe will transfer the contents of the input registers to the

DAC registers.

address or data on the inputs could change, then

EN must also be low during this time. If the

CS should be

high during this time to ensure that new data is not loaded into

an input register. Alternatively, a single DAC can be updated

by first loading its input register and then transferring that to the

DAC register without loading the other 15 input registers.

The final interface option is to read data from the DAC’s input

registers, which is accomplished by setting R/

CS low. Read back allows the microprocessor to verify that

ing

W high and bring-

correct data has been loaded into the DACs. During this time

EN and LD should be high. After a delay equal to t

RWD

, the

data bus becomes active and the contents of the input register

are read back to the data pins, DB0–DB7. The address can be

changed to look at the contents of all the input registers. Note

that after an address change, the valid data is not available for a

time equal to t

. The delay time is due to the internal

AD

readback buffers needing to charge up the data bus (measured

with a 35 pF load). These buffers are low power and do not

have high current to charge the bus quickly. When

CS returns

high, the data pins assume a high impedance state and control

of the data lines or bus passes back to the microprocessor.

–10–

REV. 0

Page 11

AD8600

DB0–DB7

A0–A3

LD

EN

R/

W

CS

DGND1, DGND2

DACGND

8

4

DIGITAL GROUND ANALOG GROUND

AD8600

MOTOROLA

68HC11

PC0–PC7

PB0–PB3

PB4

PB5

PB6

PB7

GND

Unipolar Output Operation

The AD8600 is configured to give unipolar operation. The fullscale output voltage is equivalent to the reference input voltage

minus 1 LSB. The output is dependent upon the digital code

and follows Table III. The actual numbers given for the analog

output are calculated assuming a +2.5 V reference.

Table III. Unipolar Code Table

DAC

Binary Input

MSB LSB Analog Output

1 1 1 1 1 1 1 1 +V

1 0 0 0 0 0 0 1 +V

1 0 0 0 0 0 0 0 +V

0 1 1 1 1 1 1 1 +V

0 0 0 0 0 0 0 1 +V

0 0 0 0 0 0 0 0 +V

(255/256) = +2.49 V

REF

(129/256) = +1.26 V

REF

(128/256) = +1.25 V

REF

(127/256) = +1.24 V

REF

(001/256) = +0.01 V

REF

(000/256) = +0.00 V

REF

Bipolar Output Operation

The AD8600 can be configured for bipolar operation with the

addition of an op amp for each output as shown in Figure 20.

The output will now have a swing of ± V

, as detailed in Table

REF

IV. This modification is only needed on those channels that require bipolar outputs. For channels which only require unipolar

output, no external amplifier is needed. The OP495 quad amplifier is chosen for the external amplifier because of its low

power, rail-to-rail output swing, and DC accuracy. Again, the

values calculated for the analog output are based upon an assumed +2.5 V reference.

V

REF

R1

10k

R1

10k

Table IV. Bipolar Code Table

DAC

Binary Input

MSB LSB Analog Output

1 1 1 1 1 1 1 1 +2 V

1 0 0 0 0 0 0 1 +2 V

1 0 0 0 0 0 0 0 +2 V

0 1 1 1 1 1 1 1 +2 V

0 0 0 0 0 0 0 1 +2 V

0 0 0 0 0 0 0 0 +2 V

(255/256) – V

REF

(129/256) – V

REF

(128/256) – V

REF

(127/256) – V

REF

(001/256) – V

REF

(000/256) – V

REF

= +2.49 V

REF

= +0.02 V

REF

= +0.00 V

REF

= –0.02 V

REF

= –2.48 V

REF

= –2.50 V

REF

Interfacing to the 68HC11 Microcontroller

The 68HC11 is a popular microcontroller from Motorola,

which is easily interfaced to the AD8600. The connections between the two components are shown in Figure 21. Port C of

the 68HC11 is used as a bidirectional input/output data port to

write to and read from the AD8600. Port B is used for addressing and control information. The bottom 4 LSBs of Port B are

the address, and the top 4 MSBs are the control lines (

LD, CS,

EN, and R/W). The microcode for the 68 HC11 is shown in

Figure 22. The comments in the program explain the function

of each step. Three routines are included in this listing: read

from the AD8600, write to the AD8600, and a continuous loop

that generates a saw-tooth waveform. This loop is used in the

application below.

REV. 0

+5V

V

REF

AD8600

OUT

1/4

OP495

ø

–5V

Figure 20. Circuit for Bipolar Output Operation

V

OUT

Figure 21. Interfacing the 68HC11 to the AD8600

–11–

Page 12

AD8600

* This program contains subroutines to read and write

* to the AD8600 from the 68HC11. Additionally, a ramp

* program has been included, to continuously ramp the

* output giving a triangle wave output.

*

* The following connections need to be made:

* 68HC11 AD8600

* GND DGND1,2

* PC0-PC7 DB0–DB7 respectively, data port

* PB0-PB3 A0–A3 respectively, address port

* PB4 LD

* PB5 EN

* PB6 R/W

* PB7 CS

*

portc equ $1003 define port addresses

portb equ $1004

ddrc equ $1007

*

org $C000

read lds #$CFFF subroutine to read from AD8600

*

ldaa #$00 initialize port c to 00000000

staa ddrc configures PC0-PC7 as inputs.

*

ldx #$00 points to DAC address in 68HC11 memory

ldaa 0,x put the address in the accumulator

adda #$70 add the control bits to the address

* R/W, LD, EN are high, CS is low.

staa portb output control and address on port b.

*

inx points to memory location to store the data

ldaa portc read data from DAC

staa 0,x Store this data in memory at address “x”

*

ldy #$1000

bset portb,y $f0 Set CS, LD, EN high

jmp $e000 Return to BUFFALO

*

*

write lds #$cfff routine to write to AD8600

ldaa #$ff initialize port c to 11111111

staa ddrc configures PC0-PC7 as outputs.

*

ldx #$00 points to DAC address in 68HC11 mem

ldaa 0,x puts the address in the accumulator

adda #$30 set CS, R/W low and LD, EN high

staa portb output to portb for control and address

*

inx points to memory location to store the data

ldaa 0,x load the data into the accumulator

staa portc write the data to the DAC

*

ldy #$1000

bclr portb,y $30 Set LD, EN low to latch data

bset portb,y $b0 Bring LD, EN, CS high, write is complete

*

jmp $e000 Return to BUFFALO

*

*

ramp lds #$cfff routine to generate a triangle wave

ldaa #$ff configure port c as outputs

–12–

REV. 0

Page 13

staa ddrc

*

ldx #$00 set x to point to the DAC address

ldaa 0,x load the address from 68HC11 mem

staa portb set the address on portb

* LD, CS, EN, R/W are all low for

* transparent DAC loading

ldab #$ff set accumulator b to 255

*

loop ldaa #$00 start the triangle wave at zero

staa portc write the data to the AD8600

*

load inca increase the data by one

staa portc send the new data to the AD8600

cba compare a to b

bne load we haven’t reached 255 yet

jmp loop we have reached 255, so start over

Figure 22. 68HC11 Microcode to Interface to the AD8600.

AD8600

Time Dependent Variable Gain Amplifier Using the AD600

The AD8600 is ideal for generating a control signal to set the

gain of the AD600, a wideband, low noise variable gain amplifier. The AD600 (and similar parts such as the AD602 and

AD603) is often used in ultrasound applications, which require

the gain to vary with time. When a burst of ultrasound is applied, the reflections from near objects are much stronger than

from far objects. To accurately resolve the far objects, the gain

must be greater than for the near objects. Additionally, the signals take longer to reach the ultrasound sensor when reflected

from a distant object. Thus, the gain must increase as the time

increases.

The AD600 requires a dc voltage to adjust its gain over a

40 dB range. Since it is a dual, the two variable gain amplifiers

can be cascaded to achieve 80 dB of gain. The AD8600 is used

to generate a ramped output to control the gain of the AD600.

The slope of the ramp should correspond to the time delay

of the ultrasound signal. Since ultrasound applications often

require multiple channels, the AD8600 is ideal for this

application.

The circuit to achieve a time dependent variable gain amp is

shown in Figure 23. The AD600’s gain is controlled by differential inputs, C1LO and C1HI, with a gain constant of

32 dB/V. Thus for 40 dB of gain, the differential control input

needs to be 1.25 V. In this application, the C1LO input is set at

the midscale voltage of 0.625 V, which is generated by a simple

voltage divider from the REF43. The AD8600’s output is divided in half, generating a 0 V to 1.25 V ramp, and then applied

to C1HI. This ramp sweeps the gain from 0 dB to 40 dB.

+5V

VCC, V

2

DD1

AD8600

V

REF

2

+2.5V

DIGITAL

CONTROL

+5V

46

REF43

, V

DD2

ULTRASOUND

O

ø

13

V

IN

(FROM

SENSOR)

R1

10k

10k

R2

A1LO

0V – 1.25V

C1

100pF

2

A1HI

3

4

GAT11C1LO

R3

30k

C1HI

16

+5V

AD600

–5V

0.625V

R4

10k

V

POS

13

V

OUT

14

A1OP

15

A1CM

12

Figure 23. Ultrasound Amplifier with Digitally Controlled

Variable Gain

REV. 0

–13–

Page 14

AD8600

200ns/DIV200ns/DIV

V

OUT

50mV/DIV

The functionality of this circuit is shown in the scope photo in

Figure 24 The top trace is the control ramp, which goes from

0 V to 1.25 V. The bottom trace is the output of the AD600.

The input is actually a 12 mV p-p, 10 kHz sine wave. Thus, the

bottom trace shows the envelop of this waveform to illustrate

the increase in gain as time progresses. This ramp was generated under control of the 68HC11 using the “ramp” subroutine

as mentioned above. The slope of the ramp can easily be

lengthened by adding some delay in the loop, or the slope can

be increased by stepping by 2 or more LSBs instead of the current 1 LSB changes.

GAIN

CONTROL

1V/DIV

AD600

OUTPUT

0.2V/DIV

200µs/DIV

Glitch Impulse

A specification of interest in many DAC applications is the

glitch impulse. This is the amount of energy contained in any

overshoot when a DAC changes at its major carry transition, in

other words, when the DAC switches from code 01111111 to

code 10000000. This point is the most demanding because all

of the R-2R ladder switches are changing state. The AD8600’s

glitch impulse is shown in Figure 25. Calculating the value of

the glitch is accomplished by calculating the area of the pulse,

which for the AD8600 is: Glitch Impulse = (1/2) × (100 mV) ×

(200 ns) = 10 nV sec.

Figure 24. Time Dependent Gain of the AD600

Figure 25. Glitch Impulse

–14–

REV. 0

Page 15

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

44-Lead Plastic Lead Chip Carrier (PLCC) Package

(P-44A)

0.180 (4.57)

0.165 (4.19)

40

39

29

28

0.110 (2.79)

0.085 (2.16)

0.025 (0.63)

0.015 (0.38)

0.021 (0.53)

0.013 (0.33)

0.032 (0.81)

0.026 (0.66)

0.050

(1.27)

BSC

0.040 (1.01)

0.025 (0.64)

0.048 (1.21)

0.042 (1.07)

0.020

(0.50)

0.048 (1.21)

0.042 (1.07)

6

7

17

18

R

PIN 1

IDENTIFIER

TOP VIEW

0.656 (16.66)

0.650 (16.51)

0.695 (17.65)

0.685 (17.40)

0.056 (1.42)

0.042 (1.07)

SQ

SQ

0.63 (16.00)

0.59 (14.99)

AD8600

REV. 0

–15–

Page 16

AD8600

C1921–18–7/94

–16–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...