Page 1

Wideband, High Output Current,

a

FEATURES

AC PERFORMANCE

Gain Bandwidth Product: 80 MHz (Gain = 2)

Fast Settling: 100 ns to 0.01% for a 10 V Step

Slew Rate: 375 V/s

Stable at Gains of 2 or Greater

Full Power Bandwidth: 6.0 MHz for 20 V p-p

DC PERFORMANCE

Input Offset Voltage: 1 mV max

Input Offset Drift: 14 V/ⴗC

Input Voltage Noise: 9 nV/√Hz typ

Open-Loop Gain: 90 V/mV into a 500 ⍀ Load

Output Current: 100 mA min

Quiescent Supply Current: 14 mA max

APPLICATIONS

Line Drivers

DAC and ADC Buffers

Video and Pulse Amplifiers

Available in Plastic DIP, Hermetic Metal Can,

Hermetic Cerdip, SOIC and LCC Packages and in

Chip Form

MIL-STD-883B Parts Available

Available in Tape and Reel in Accordance with

EIA-481A Standard

PRODUCT DESCRIPTION

The AD842 is a member of the Analog Devices family of wide

bandwidth operational amplifiers. This device is fabricated using

Analog Devices’ junction isolated complementary bipolar (CB)

process. This process permits a combination of dc precision and

wideband ac performance previously unobtainable in a monolithic op amp. In addition to its 80 MHz gain bandwidth, the

AD842 offers extremely fast settling characteristics, typically

settling to within 0.01% of final value in less than 100 ns for a

10 volt step.

The AD842 also offers a low quiescent current of 13 mA, a high

output current drive capability (100 mA minimum), a low input

voltage noise of 9 nV√Hz and a low input offset voltage (1 mV

maximum).

The 375 V/µs slew rate of the AD842, along with its 80 MHz

gain bandwidth, ensures excellent performance in video and

pulse amplifier applications. This amplifier is ideally suited for

use in high frequency signal conditioning circuits and wide

bandwidth active filters. The extremely rapid settling time of

the AD842 makes this amplifier the preferred choice for data

acquisition applications which require 12-bit accuracy. The

*Covered by U.S. Patent Nos. 4,969,823 and 5,141,898.

REV. E

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Fast Settling Op Amp

AD842*

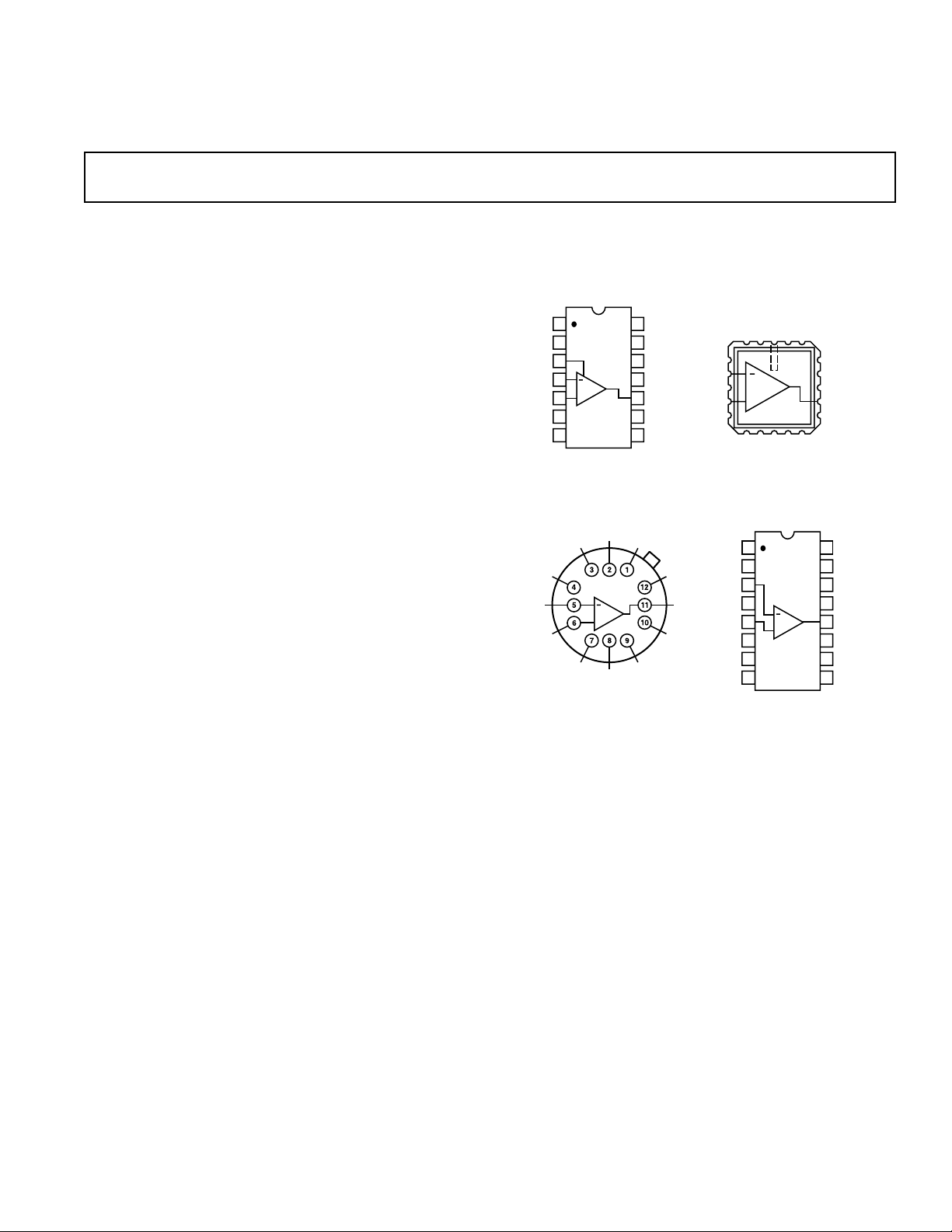

CONNECTION DIAGRAMS

Plastic DIP (N) Package

and

Cerdip (Q) Package

NC

NC

BALANCE

–INPUT

+INPUT

NC

1

AD842

2

3

4

+

5

6

V–

7

TOP VIEW

NC = NO CONNECT

14

NC

13

BALANCE

12

NC

11

V+

10

OUTPUT

9

NC

8

NC

TO-8 (H) Package

NC

BALANCE

BALANCE

NC

V+

AD842

–INPUT

+INPUT

NC

NOTE: CAN BE TIED TO V+

NC = NO CONNECT

+

NC

TOP VIEW

OUTPUT

V–

NC

AD842 is also appropriate for other applications such as high

speed DAC and ADC buffer amplifiers and other wide bandwidth circuitry.

APPLICATION HIGHLIGHTS

1. The high slew rate and fast settling time of the AD842 make

it ideal for DAC and ADC buffers amplifiers, lines drivers

and all types of video instrumentation circuitry.

2. The AD842 is a precision amplifier. It offers accuracy to

0.01% or better and wide bandwidth; performance previously

available only in hybrids.

3. Laser-wafer trimming reduces the input offset voltage of

1 mV max, thus eliminating the need for external offset

nulling in many applications.

4. Full differential inputs provide outstanding performance in

all standard high frequency op amp applications where the

circuit gain will be 2 or greater.

5. The AD842 is an enhanced replacement for the HA2542.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

LCC (E) Package

BALANCE

NC

BALANCE

NC

3212019

NC

4

–IN

5

NC

6

+IN

NC

+

7

AD842

8

9

101112

S

NC

NCNCNC

–V

NC = NO CONNECT

SOIC (R-16) Package

1

NC

–INPUT

+INPUT

–V

NC

NC

S

NC

2

AD842

3

4

5

+

6

7

8

TOP VIEW

NC = NO CONNECT

BALANCE

NC

13

NC

18

17

+V

16

NC

OUTPUT

15

14

NC

16

NC

15

BALANCE

14

+V

13

NC

12

OUTPUT

11

NC

10

NC

9

NC

S

S

Page 2

AD842–SPECIFICATIONS

Model AD842J/JR

(@ +25ⴗC and ⴞ15 V dc, unless otherwise noted)

1

AD842K AD842S

2

Conditions Min Typ Max Min Typ Max Min Typ Max Units

INPUT OFFSET VOLTAGE

3

T

MIN–TMAX

0.5 1.5 0.3 1.0 0.5 1.5 mV

2.5/3 1.5 3.5 mV

Offset Drift 14 14 14 µV/°C

INPUT BIAS CURRENT 4.2 8 3.5 5 4.2 8 µA

T

MIN–TMAX

10 612µA

Input Offset Current 0.1 0.4 0.05 0.2 0.1 0.4 µA

T

MIN–TMAX

0.5 0.3 0.6 µA

INPUT CHARACTERISTICS Differential Mode

Input Resistance 100 100 100 kΩ

Input Capacitance 2.0 2.0 2.0 pF

INPUT VOLTAGE RANGE

Common Mode ⴞ10 ⴞ10 ⴞ10 V

Common-Mode Rejection V

= ±10 V 86 115 90 115 86 115 dB

CM

T

MIN–TMAX

80 86 80 dB

INPUT VOLTAGE NOISE f = 1 kHz 9 9 9 nV/√Hz

Wideband Noise 10 Hz to 10 MHz 28 28 28 µV rms

OPEN-LOOP GAIN V

= ±10 V

O

R

≥ 500 Ω 40/30 90 50 90 40 90 V/mV

LOAD

T

MIN–TMAX

20/15 25 20 V/mV

OUTPUT CHARACTERISTICS

Voltage R

Current V

≥ 500 Ω ⴞ10 ⴞ10 ⴞ10 V

LOAD

= ±10 V 100 100 100 mA

OUT

Open Loop 5 5 5 Ω

FREQUENCY RESPONSE

Gain Bandwidth Product V

Full Power Bandwidth

Rise Time

Overshoot

Slew Rate

5

5

5

Settling Time

4

5

= 90 mV 80 80 80 MHz

OUT

VO = 20 V p-p

R

≥ 500 Ω 4.7 6 4.7 6 4.7 6 MHz

LOAD

A

= –2 10 10 10 ns

VCL

A

= –2 20 20 20 %

VCL

A

= –2 300 375 300 375 300 375 V/µs

VCL

10 V Step

to 0.1% 80 80 80 ns

to 0.01% 100 100 100 ns

Differential Gain f = 4.4 MHz 0.015 0.015 0.015 %

Differential Phase f = 4.4 MHz 0.035 0.035 0.035 Degree

POWER SUPPLY

Rated Performance ±15 ± 15 ±15 V

Operating Range ⴞ5 ⴞ18 ⴞ5 ⴞ18 ⴞ5 ⴞ18 V

Quiescent Current 13/14 14/16 13 14 13 14 mA

Power Supply Rejection Ratio V

TEMPERATURE RANGE

Rated Performance

6

T

MIN–TMAX

= ±5 V to ±18 V 86 100 90 105 86 100 dB

S

T

MIN–TMAX

80 86 80 dB

0 +75 0 +75 –55 +125 °C

16/19.5 16 19 mA

PACKAGE OPTIONS

Plastic (N-14) AD842JN AD842KN

Cerdip (Q-14) AD842JQ AD842KQ AD842SQ, AD842SQ/883B

SOIC (R-16) AD842JR-16

Tape and Reel AD842JR-16-REEL

AD842JR-16-REEL7

TO-8 (H-12A) AD842JH AD842KH AD842SH

LCC (E-20A) AD842SE/883B

Chips AD842JCHIPS AD842SCHIPS

NOTES

1

AD842JR specifications differ from those of the AD842JN, JQ and JH due to the thermal characteristics of the SOIC package.

2

Standard Military Drawing available 5962-8964201xx

2A – (SE/883B); XA – (SH/883B); CA – (SQ/883B).

3

Input offset voltage specifications are guaranteed after 5 minutes at TA = +25°C.

4

Full power bandwidth = slew rate/2 π V

5

Refer to Figures 22 and 23.

6

“S” grade T

All min and max specifications are guaranteed. Specifications shown in boldface are tested on all production units.

Specifications subject to change without notice.

specifications are tested with automatic test equipment at TA = –55°C and TA = +125°C.

MIN–TMAX

PEAK

.

–2–

REV. E

Page 3

AD842

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation

2

1

Plastic (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 W

Cerdip (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 W

TO-8 (H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 W

SOIC (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 W

LCC (E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 W

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . ±6 V

Storage Temperature Range

Q, H, E . . . . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

N, R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –65°C to +125°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +175°C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . +300°C

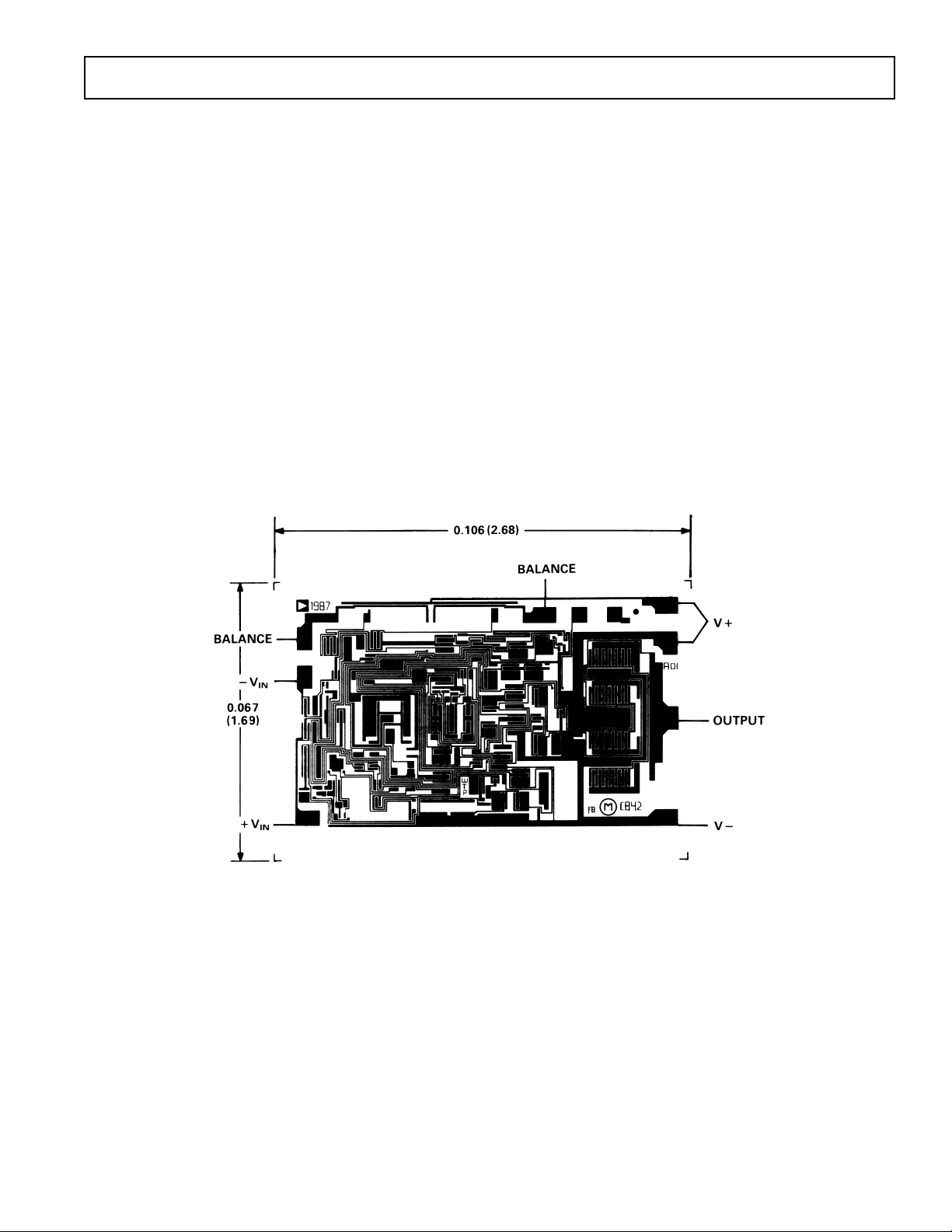

METALIZATION PHOTOGRAPH

Contact factory for latest dimensions.

Dimensions shown in inches and (mm).

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Maximum internal power dissipation is specified so that TJ does not exceed

+150°C at an ambient temperature of +25°C.

Thermal Characteristics:

S

Plastic Package 30°C/W 100°C/W

Cerdip Package 30°C/W 110°C/W 38°C/W

TO-8 Package 30°C/W 100°C/W 27°C/W

16-Lead SOIC Package 30°C/W 100°C/W

20-Lead LCC Package 35°C/W 150°C/W

Recommended Heat Sink: Aavid Engineering© #602B

θ

JC

θ

JA

θ

SA

–3–REV. E

Page 4

AD842

–Typical Characteristics

(at +25ⴗC and VS = ⴞ15 V, unless otherwise noted)

20

15

V

IN

10

5

INPUT COMMON-MODE RANGE – Volts

0

05 20

SUPPLY VOLTAGE – ⴞVolts

10 15

Figure 1. Input Common-Mode

Range vs. Supply Voltage

18

16

14

12

QUIESCENT CURRENT – mA

20

15

10

5

OUTPUT VOLTAGE SWING – Volts

0

05 20

SUPPLY VOLTAGE – ⴞ Volts

ⴞ V

OUT

10 15

Figure 2. Output Voltage Swing

vs. Supply Voltage

–5

–4

–3

INPUT BIAS CURRENT – A

30

25

20

15

10

5

OUTPUT VOLTAGE SWING – Volts p-p

0

10 100 10k

ⴞ 15V SUPPLIES

1k

LOAD RESISTANCE – ⍀

Figure 3. Output Voltage Swing

vs. Load Resistance

100

10

1

0.1

OUTPUT IMPEDANCE – ⍀

10

05 20

SUPPLY VOLTAGE – ⴞ Volts

10 15

Figure 4. Quiescent Current vs.

Supply Voltage

18

17

16

15

14

13

12

QUIESCENT CURRENT – mA

11

10

–60 –40 140

–20 0 20 40 60 80 100 120

TEMPERATURE – ⴗC

Figure 7. Quiescent Current vs.

Temperature

–2

–60 –40 140

–20 0 20 40 60 80 100 120

TEMPERATURE – ⴗC

Figure 5. Input Bias Current vs.

Temperature

300

275

250

225

200

175

–OUTPUT CURRENT

150

125

SHORT CIRCUIT CURRENT LIMIT – mA

100

–60 –40 140

+ OUTPUT CURRENT

–20020 40 60 80 100 120

AMBIENT TEMPERATURE – ⴗC

Figure 8. Short-Circuit Current

Limit vs. Temperature

0.01

10k 100k 100M

1M 10M

FREQUENCY – Hz

Figure 6. Output Impedance vs.

Frequency

85

80

75

70

GAIN BANDWIDTH – MHz

65

–60 –40 140

–20020 40 60 80 100 120

TEMPERATURE – ⴗC

Figure 9. Gain Bandwidth Product

vs. Temperature

–4–

REV. E

Page 5

AD842

120

100

80

60

40

OPEN-LOOP GAIN – dB

20

0

100 1k 100M

500⍀ LOAD

10k 100k 1M 10M

FREQUENCY – Hz

Figure 10. Open-Loop Gain and

Phase Margin vs. Frequency

120

100

80

CMR – dB

60

40

20

1k 10k 100M100k 1M 10M

FREQUENCY – Hz

VS = ⴞ 15V

V

= 1V p-p

CM

+ 25ⴗC

Figure 13. Common-Mode

Rejection vs. Frequency

100

80

60

40

20

0

110

105

100

500⍀ LOAD

95

OPEN-LOOP GAIN – dB

PHASE MARGIN – Degrees

90

05 20

SUPPLY VOLTAGE – ⴞV

10 15

Figure 11. Open-Loop Gain vs.

Supply Voltage

30

25

20

15

10

OUTPUT VOLTAGE – Volts p-p

5

0

1M 10M 100M

FREQUENCY – Hz

Figure 14. Large Signal Frequency

Response

RL = 1kV

+25ⴗC

V

= ⴞ15V

S

120

100

80

60

40

20

POWER SUPPLY REJECTION – dB

0

100 1k 100M

+ SUPPLY

– SUPPLY

10k 100k 1M 10M

FREQUENCY – Hz

Figure 12. Power Supply Rejection

vs. Frequency

10

8

V

ⴞ

6

4

2

0.1%

0

–2

–4

–6

OUTPUT SWING FROM 0 TO

–8

–10

30 40 110

0.01%

0.1%

0.01%

50 60 70 80 90 100

SETTLING TIME – ns

Figure 15. Output Swing and

Error vs. Settling Time

–80

–90

–100

–110

–120

HARMONIC DISTORTION – dB

–130

–140

100 1k 100k10k

3RD HARMONIC

FREQUENCY – Hz

2ND HARMONIC

3V RMS

R

= 1k⍀

L

Figure 16. Harmonic Distortion vs.

Frequency

50

40

30

20

INPUT VOLTAGE – nV Hz

10

0

10 100 10M

1k 10k 100k 1M

FREQUENCY – Hz

Figure 17. Input Voltage vs.

Frequency

550

500

450

400

350

SLEW RATE – Vs

300

250

–60 –40 140

–20020 40 60 80 100 120

TEMPERATURE – ⴗC

Figure 18. Slew Rate vs.

Temperature

–5–REV. E

Page 6

AD842

HP3314A

FUNCTION

GENERATOR

OR

EQUIVALENT

RIN =

499⍀

49.9⍀

332⍀

R

= 1k⍀

F

+V

–

AD842

+

–V

0.1F

S

2.2F

V

OUT

0.1F

2.2F

S

499⍀

Figure 19a. Inverting Amplifier

Configuration (DIP Pinout)

RF = 205⍀

0.1F

+V

S

2.2F

–

100⍀

49.9⍀

AD842

+

–V

0.1F

2.2F

S

IN

V

OUT

499⍀

HP3314A

FUNCTION

GENERATOR

OR

EQUIVALENT

R1 = 205⍀

V

Figure 20a. Noninverting Amplifier

Configuration (DIP Pinout)

Figure 19b. Inverter Large Signal

Pulse Response

Figure 20b. Noninverting Large

Signal Pulse Response

Figure 19c. Inverter Small Signal

Pulse Response

Figure 20c. Noninverting Small

Signal Pulse Response

–6–

REV. E

Page 7

OFFSET NULLING

The input offset voltage of the AD842 is very low for a high

speed op amp, but if additional nulling is required, the circuit

shown in Figure 21 can be used.

AD842 SETTLING TIME

Figures 22 and 24 show the settling performance of the AD842

in the test circuit shown in Figure 23.

Settling time is defined as:

The interval of time from the application of an ideal step

function input until the closed-loop amplifier output has

entered and remains within a specified error band.

This definition encompasses the major components which comprise settling time. They include (1) propagation delay through

the amplifier; (2) slewing time to approach the final output value;

(3) the time of recovery from the overload associated with slewing and (4) linear settling to within the specified error band.

Expressed in these terms, the measurement of settling time is

obviously a challenge and needs to be done accurately to assure

the user that the amplifier is worth consideration for the

application.

+V

0.1F

S

10k ⍀

2.2F

0.1F

2.2F

–V

S

OUTPUT

R

L

INPUT

–

AD842

+

Figure 21. Offset Nulling (DIP Pinout)

AD842

ERROR

AMP

(ⴛ15)

HP6263

DDD5109

FLAT-TOP

PULSE

GENERATOR

499⍀ 1k⍀

499⍀ 1k⍀

50⍀

499⍀

+15V

AD842

–15V

0.1F

2.2F

0.1F

2.2F

Figure 23. Settling Time Test Circuit

Figure 23 shows how measurement of the AD842’s 0.01% settling in 100 ns was accomplished by amplifying the error signal

from a false summing junction with a very high-speed proprietary hybrid error amplifier specially designed to enable testing

of small settling errors. The device under test was driving a

300 Ω load. The input to the error amp is clamped in order to

avoid possible problems associated with the overdrive recovery

of the oscilloscope input amplifier. The error amp gains the

error from the false summing junction by 15, and it contains a

gain vernier to fine trim the gain.

Figure 24 shows the “long term” stability of the settling characteristics of the AD842 output after a 10 V step. There is no

evidence of settling tails after the initial transient recovery time.

The use of a junction isolated process, together with careful

layout, avoids these problems by minimizing the effects of transistor isolation capacitance discharge and thermally induced

shifts in circuit operating points. These problems do not occur

even under high output current conditions.

499⍀

TEK

7A13

TEK

7A16

TEK

7603

OSCILLOSCOPE

FET PROBE

TEK P6201

Figure 22. 0.01% Settling Time

–7–REV. E

Page 8

AD842

GROUNDING AND BYPASSING

In designing practical circuits with the AD842, the user must

remember that whenever high frequencies are involved, some

Figure 24. AD842 Settling Demonstrating No Settling

Tails

special precautions are in order. Circuits must be built with

short interconnect leads. Large ground planes should be used

whenever possible to provide a low resistance, low inductance

circuit path, as well as minimizing the effects of high frequency

coupling. Sockets should be avoided because the increased

interlead capacitance can degrade bandwidth.

Feedback resistors should be of low enough value to assure that

the time constant formed with the circuit capacitances will not

limit the amplifier performance. Resistor values of less than

5 kΩ are recommended. If a larger resistor must be used, a small

(<10 pF) feedback capacitor connected in parallel with the feedback resistor, R

, may be used to compensate for these stray

F

capacitances and optimize the dynamic performance of the

amplifier in the particular application.

Power supply leads should be bypassed to ground as close as

possible to the amplifier pins. A 2.2 µF capacitor in parallel with

a 0.1 µF ceramic disk capacitor is recommended.

CAPACITIVE LOAD DRIVING ABILITY

Like all wideband amplifiers, the AD842 is sensitive to capacitive loading. The AD842 is designed to drive capacitive loads of

up to 20 pF without degradation of its rated performance. Capacitive loads of greater than 20 pF will decrease the dynamic

performance of the part although instability should not occur

unless the load exceeds 100 pF.

2.2F

+V

S

0.1F

V

IN

TERMINATION

RESISTOR FOR

INPUT SIGNAL

+

AD842

–

–V

0.1F

2.2F

S

USING A HEAT SINK

The AD842 draws less quiescent power than most precision

high speed amplifiers and is specified for operation without a

heat sink. However, when driving low impedance loads, the current to the load can be 10 times the quiescent current. This will

create a noticeable temperature rise. Improved performance can

be achieved by using a small heat sink such as the Aavid Engineering #602B.

TERMINATED LINE DRIVER

The AD842 is optimized for high speed line driver applications.

Figure 25 shows the AD842 driving a doubly terminated cable

in a gain-of-2 follower configuration. The AD842 maintains a

typical slew rate of 375 V/µs, which means it can drive a ±10 V,

6.0 MHz signal or a ±3 V, 19.9 MHz signal.

The termination resistor, R

, (when equal to the characteristic

T

impedance of the cable) minimizes reflections from the far end

of the cable. A back-termination resistor (R

, also equal to the

BT

characteristic impedance of the cable) may be placed between

the AD842 output and the cable in order to damp any stray

signals caused by a mismatch between R

and the cable’s char-

T

acteristic impedance. This will result in a “cleaner” signal. With

this circuit, the voltage on the line equals V

of V

is dropped across RBT.

OUT

because one half

IN

The AD842 has ±100 mA minimum output current and, therefore, can drive ±5 V into a 50 Ω cable.

The feedback resistors, R1 and R2, must be chosen carefully.

Large value resistors are desirable in order to limit the amount

of current drawn from the amplifier output. But large resistors

can cause amplifier instability because the parallel resistance

R1储R2 combines with the input capacitance (typically 2–5 pF) to

create an additional pole. Also, the voltage noise of the AD842

is equivalent to a 5 kΩ resistor, so large resistors can significantly increase the system noise. Resistor values of 1 kΩ or 2 kΩ

are recommended.

If termination is not used, cables appear as capacitive loads and

can be decoupled from the AD842 by a resistor in series with

the output.

50⍀ OR 75⍀

R

R1

CABLE

ST

R

T

RT = RST = CABLE CHARACTERISTIC

IMPEDANCE

R2

Figure 25. Line Driver Configuration

–8–

REV. E

Page 9

OVERDRIVE RECOVERY

50⍀

AD842

+V

S

0.1F

2.2F

–V

S

0.1F

2.2F

+

–

1k⍀

OUTPUT

HP3314A

PULSE GENERATOR

OR EQUIVALENT

1s, ⴞ1V SQUARE

WAVE INPUT

Figure 26 shows the overdrive recovery capability of the AD842.

Typical recovery time is 80 ns from negative overdrive and

400 ns from positive overdrive.

Figure 26. Overdrive Recovery

AD842

Figure 27. Overdrive Recovery Test Circuit

–9–REV. E

Page 10

AD842

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

PIN 1

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

16 9

PIN 1

0.050 (1.27)

14-Lead Plastic Package

(N-14)

0.795 (20.19)

0.725 (18.42)

14

17

0.100 (2.54)

0.022 (0.558)

0.014 (0.356)

8

BSC

0.070 (1.77)

0.045 (1.15)

16-Lead SOIC Package

(R-16)

0.4133 (10.50)

0.3977 (10.00)

0.2992 (7.60)

0.2914 (7.40)

81

0.1043 (2.65)

BSC

0.0926 (2.35)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.4193 (10.65)

0.3937 (10.00)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.0291 (0.74)

0.0098 (0.25)

0.195 (4.95)

0.115 (2.93)

ⴛ 45ⴗ

14-Lead Cerdip Package

(Q-14)

0.005 (0.13) MIN 0.098 (2.49) MAX

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

14

1

PIN 1

0.785 (19.94) MAX

0.023 (0.58)

0.014 (0.36)

0.100

(2.54)

BSC

8

0.310 (7.87)

0.220 (5.59)

7

0.060 (1.52)

0.015 (0.38)

0.070 (1.78)

0.030 (0.76)

0.150

(3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15°

0°

0.015 (0.38)

0.008 (0.20)

20-Terminal Leadless Ceramic Chip Carrier Package

(E-20A)

0.200 (5.08)

BSC

R TYP

0.075

(1.91)

REF

0.055 (1.40)

0.045 (1.14)

REF

19

18

14

13

20

1

BOTTOM

VIEW

0.150 (3.81)

0.100 (2.54) BSC

3

4

0.050 (1.27)

8

BSC

9

45° TYP

BSC

0.015 (0.38)

MIN

0.028 (0.71)

0.022 (0.56)

0.358 (9.09)

0.342 (8.69)

SQ

0.100 (2.54)

0.064 (1.63)

0.358

(9.09)

MAX

SQ

0.088 (2.24)

0.054 (1.37)

0.095 (2.41)

0.075 (1.90)

0.011 (0.28)

0.007 (0.18)

0.075 (1.91)

C1195c–0–3/00 (rev. E)

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

SEATING

PLANE

0.0125 (0.32)

0.0091 (0.23)

0.181 (4.60)

0.148 (3.76)

0.615 (15.62)

0.592 (15.04)

0.040 (1.02) MAX

0.045 (1.14)

0.000 (0.00)

8ⴗ

0ⴗ

0.555 (14.10)

0.545 (13.84)

0.0500 (1.27)

0.0157 (0.40)

12-Lead Metal Can Package

(TO-8 Style)

REFERENCE PLANE

0.375 (9.53)

MIN

0.050 (1.27) MAX

0.400

(10.16)

BSC

0.019 (0.48)

0.016 (0.41)

0.021 (0.53)

0.016 (0.41)

BASE & SEATING PLANE

0.200 (5.08)

BSC

6

5

4

0.037 (0.94)

0.026 (0.66)

879

10

11

12

12 3

0.100 (2.54)

BSC

0.036 (0.91)

0.026 (0.66)

0.200

(5.08)

BSC

PRINTED IN U.S.A.

–10–

REV. E

Loading...

Loading...