Page 1

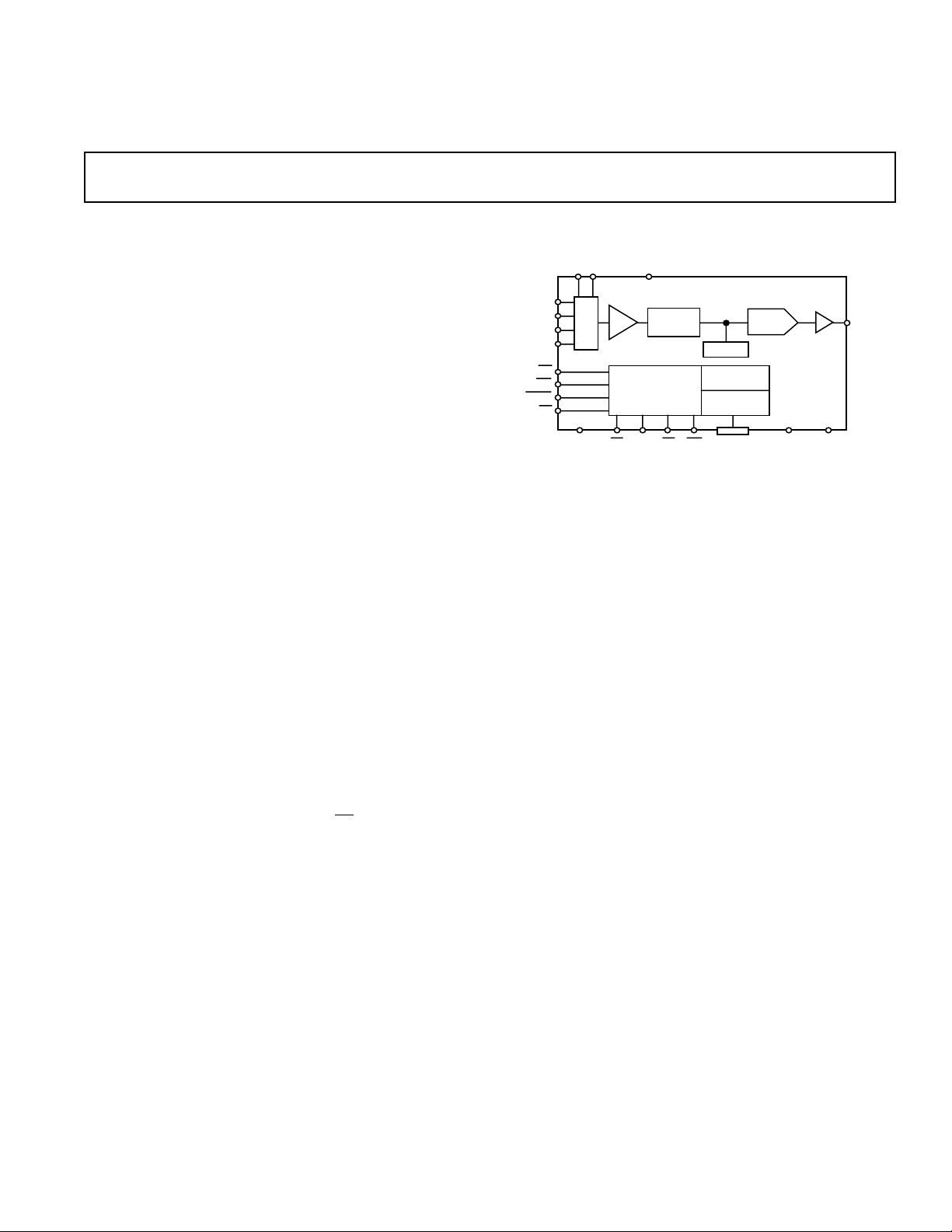

8-Bit, 4-Channel Data

V

OUT

DGND

AG

DACAGADC

DATA I/O

(8 BITS)

M

U

X

T/H

8-BIT ADC

1.25 REF

8-BIT

DAC

RS

INT

BUSY

ST

DAC REG

ADC REG

CONTROL LOGIC

A0 A1

VDD (+5.0V)

RD WRCLK CS

AD8401

V

A

IN

V

B

IN

V

C

IN

V

D

IN

a

FEATURES

2 ms ADC with T/H

4-Channel MUX

AD899 Compatible

+5 Volt Operation

On-Chip Reference

4 ms Voltage Output DAC

Fast Bus Access Time—75 ns

APPLICATIONS

Servo Controls

Digitally Controlled Calibration

Process Control Equipment

GENERAL DESCRIPTION

The AD8401 is a complete data acquisition and control system

containing ADC, DAC, 4-channel MUX, and internal voltage

reference. Built using CBCMOS, this monolithic circuit offers

the user a complete system with very high package density and

reliability.

The converter is a successive approximation ADC with T/H,

and is capable of operating with conversion times as short as

2 µs. Analog input bandwidth is 200 kHz, and DAC output volt-

age settling time is less than 4 µs, making the AD8401 capable

of controlling servo loops with speed and precision.

The 8-bit data interface provides both read and write operation

for parallel bus interfaces to microcontrollers and DSP processors. An external 5 MHz clock sets the 2 µs conversion rate.

Slower clocks reduce the conversion time and the internal power

dissipation. The standard control lines: Reset, Busy, Interrupt,

Read and Write complete the handshaking signals for microprocessor communication. A start trigger

cise sampling intervals in synchronous sampling applications.

ST input allows pre-

Acquisition System

AD8401

FUNCTIONAL BLOCK DIAGRAM

The input multiplexer addressing is designed for direct interface

to the AD899 hard-disk drive, read-channel device with no extra

hardware or special software. Analog input range levels are likewise compatible with the AD899.

The AD8401 is designed to operate from a single +5 volt supply, which will give an ADC input range of 0 V to 3.0 V, and

DAC output range of 0 V to 2.5 V.

The AD8401 is offered in the SOIC-28 surface mount package,

and is guaranteed to operate over the extended industrial temperature range of –40°C to +85°C.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

AD8401–SPECIFICA TIONS

ADC ELECTRICAL CHARACTERISTICS

(@ VDD = +5.0 V 6 5%, AG

unless otherwise noted)

DAC

= AG

= 0.0 V; f

ADC

= 5 MHz; –408C ≤ TA ≤ +858C,

CLK

Parameter Symbol Conditions Min Typ Max Units

STATIC PERFORMANCE

Resolution N 8 Bits

Total Unadjusted Error TUE ±3 LSB

Relative Accuracy INL –1 +1 LSB

Differential Nonlinearity DNL –1 +1 LSB

Offset Error V

Full-Scale Error A

∆Full-Scale/∆V

DD

OSE

E

TA = +25°C –4 +4 LSB

T

= Full Temp Range –6 +6 LSB

A

TA = +25°C –4 +4 LSB

T

= Full Temp Range –6 +6 LSB

A

TA = +25°C 1 LSB

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio SNR 44 dB

Total Harmonic Distortion THD 48 dB

Intermodulation Distortion IMD 60 dB

Frequency Response 0 to 200 kHz 0.1 dB

Track/Hold Acquisition Time t

AQ

200 ns

ANALOG INPUTS (Applies to Inputs A, B. C, D)

Unipolar Input Range V

Input Current I

Input Capacitance C

IN

IN

IN

03V

–500 +500 µA

10 pF

LOGIC INPUTS

Clock Input Current Low I

Clock Input Current High I

Input Leakage Current I

CKL

CKH

L

LOGIC OUTPUTS (Applies to Outputs DB0–DB7,

Logic Output Low Voltage V

Logic Output High Voltage V

Output Leakage Current I

Output Capacitance C

CONVERSION TIME t

Specifications subject to change without notice.

OL

OH

OZ

OZ

C

VIN = 0 V 1.6 mA

VIN = V

DD

40 µA

CS, RD, RS, ST 10 µA

INT, BUSY)

IOL = 1.6 mA 0.4 V

IOH = 200 µA 4.0 V

CS = 1 (Except INT & BUSY)10µA

CS = 1 (Except INT & BUSY)10pF

External Clock 2 µs

Table I. Multiplexer Address Input Decode

A1 A0 Input Selected

00V

01V

10V

11V

A

IN

B

IN

C

IN

D

IN

–2–

REV. 0

Page 3

AD8401

DAC ELECTRICAL CHARACTERISTICS

(@ VDD = +5.0 V 6 5%, AG

to AG

; –408C ≤ TA ≤ +858C, unless otherwise noted)

DAC

DAC

= AG

= 0.0 V; RL = 2 kV, CL = 100 pF

ADC

Parameter Symbol Conditions Min Typ Max Units

STATIC PERFORMANCE

Resolution N 8 Bits

Total Unadjusted Error TUE ±2 LSB

Relative Accuracy INL –1 +1 LSB

Differential Nonlinearity DNL –1 +1 LSB

Offset Error V

Full-Scale Error A

∆Full-Scale/∆V

DD

OSE

E

TA = +25°C –2 +2 LSB

T

= Full Temp Range –2.5 +2.5 LSB

A

TA = +25°C –3 +3 LSB

T

= Full Temp Range –4 +4 LSB

A

TA = +25°C –0.5 +0.5 LSB

Load Regulation at Full-Scale –0.2 +0.2 LSB

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio SNR 44 dB

Total Harmonic Distortion THD 48 dB

ANALOG OUTPUT

Output Voltage Range OVR 0 +2.5 V

LOGIC INPUTS (Applies to DB0–DB7, CS, WR, RD, RS)

Logic Input Low Voltage V

Logic Input High Voltage V

Input Leakage Current I

Input Capacitance C

IL

IH

L

IL

2.4 V

–10 10 µA

0.8 V

10 pF

AC CHARACTERISTICS

Voltage Output Settling Time t

Positive Full-Scale Change t

Negative Full-Scale Change t

S

POS

NEG

To ±1/2 LSB of Final Value 2 4 µs

10% to 90% 1 2 µs

90% to 10% 2 4 µs

DAC Glitch Impulse 15 nV s

Digital Feedthrough 1 nV s

VIN to V

Isolation f = 50 kHz 60 dB

OUT

POWER REQUIREMENTS

Positive Supply Current I

Specifications subject to change without notice.

DD

No Load 13 mA

REV. 0

–3–

Page 4

AD8401

DGND

10pF

3kΩ

DBN

DBN

10pF

3kΩ

+5V

DGND

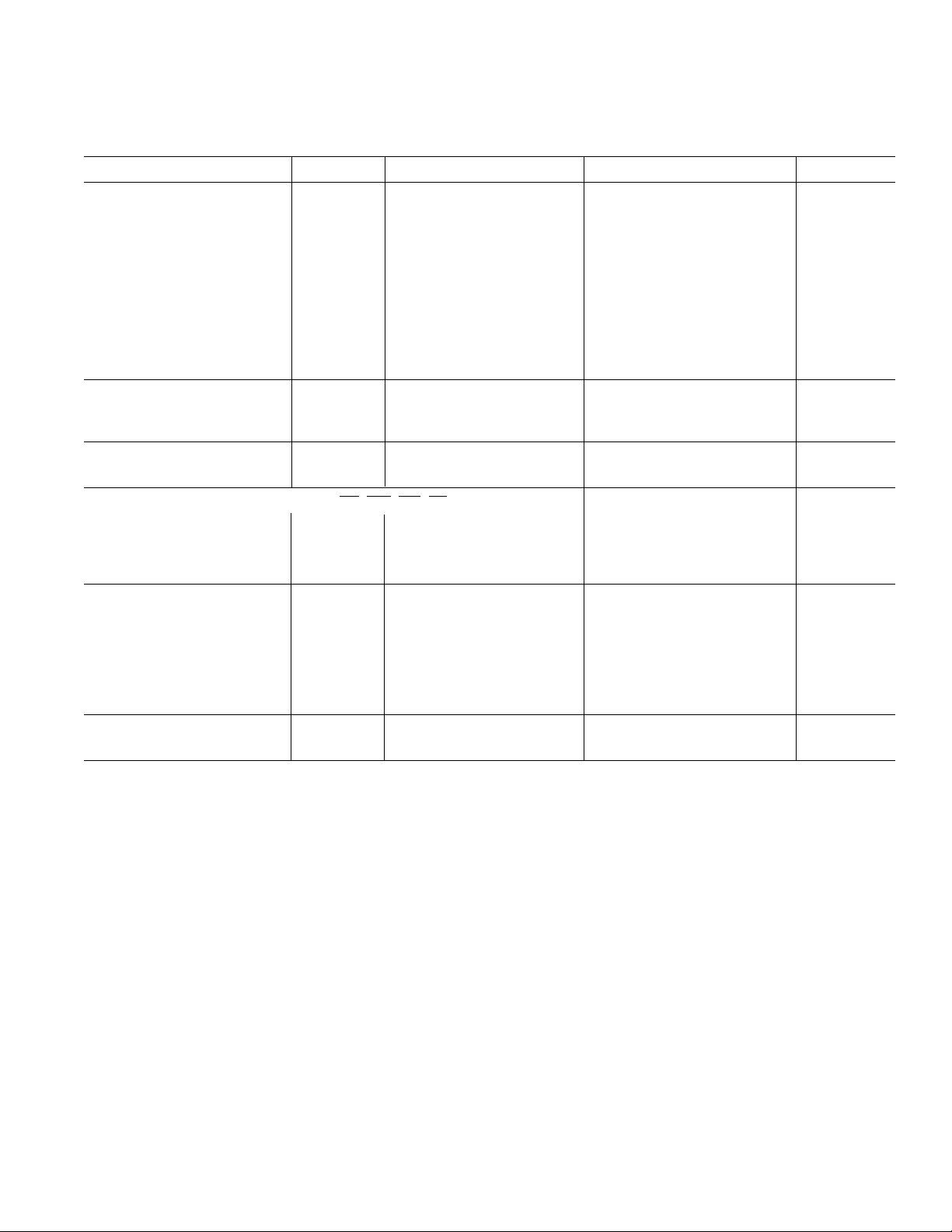

TIMING ELECTRICAL SPECIFICATIONS

Parameters

1, 2, 3

(@ VDD = +5.0 V 6 5%, AG

unless otherwise noted)

Symbol Condition Min Typ Max Units

DAC

= AG

= 0.0 V; f

ADC

= 5 MHz; –408C ≤ TA ≤ +858C,

CLK

DAC TIMING (See Figure 8 Timing Diagram)

WR Pulse Width t

CS to WR Setup Time t

CS to WR Hold Time t

Data Setup Time t

Data Hold Time t

1

2

3

4

5

50 ns

0ns

0ns

60 ns

0ns

ADC TIMING (See Figures 6 and 7 Timing Diagrams)

ST Pulse Width t

ST to BUSY Delay t

BUSY to INT Delay t

BUSY to CS Delay t

CS to RD Setup Time t

RD Pulse Width

4

CS to RD Hold Time t

Data Access after

Data Access after

Bus Relinquish after

RD t

RD t

RD t

RD to INT Delay t

RD to BUSY Delay t

Data Valid after

BUSY t

Data Valid after BUSY t

NOTES

1

All input control signals are specified with tR = tF = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

2

t13 and t17 are measured with the load circuits of Figure 1 and defined as the time required for an output to cross either 0.8 V or 2.4 V.

3

t14 is defined as the time required for the data line to change 0.5 V when loaded with the circuit of Figure 2.

4

t15 is determined by t13.

DBN

3kΩ

CL

DGND

+5V

3kΩ

DBN

CL

DGND

6

7

8

9

10

t

11

12

13

13

14

15

16

17

17

CL = 20 pF 10 75 ns

CL = 100 pF 10 135 ns

CL = 20 pF 90 ns

CL = 100 pF 135 ns

40 ns

0ns

0ns

75 ns

0ns

10 70 ns

110 ns

30 ns

85 ns

110 ns

a. High Z to V

OH

b. High Z to V

OL

Figure 1. Load Circuits for Data Access Time Test

a. V

OH

Figure 2. Load Circuits for Bus Relinquish Time Test

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . +8 V

Input Voltages . . . . . . . . . . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

Output Short-Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Package Power Dissipation . . . . . . . . . . . . . . (T

Thermal Resistance θ

JA

28-Lead SOIC (R) . . . . . . . . . . . . . . . . . . . . . . . . . 53°C/W

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range (T

max) . . . . –65°C to +150°C

J

Lead Temperature Range (Soldering, 60 sec) . . . . . . +300°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

max–TA)/θ

J

JA

Model* Range Description Option

AD8401AR –40°C to +85°C 28-Lead SOIC SOL-28

AD8401Chips +25°C Die

*The AD8401 contains 1257 transistors.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8401 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

–4–

precautions are recommended to avoid performance degradation or loss of functionality.

to High Z

b. VOL to High Z

ORDERING GUIDE

Temperature Package Package

WARNING!

ESD SENSITIVE DEVICE

REV. 0

Page 5

AD8401

1

23

5

6

7

8

9

10

11 12 13 14 15 16 17

18

19

20

21

22

23

24

25

2627

Die Size 91 X 121 mil = 11,011 sq mil

28

PIN CONFIGURATION

1

V

DD

2

AG

DAC

3

V

OUT

4

NC

5

A1

6

RS

7

DB7

DB6

DB5

DB4

DB3

DB2

DGND

DB1

AD8401AR

Top View

8

(Not to Scale)

9

10

11

12

13

14

NC = NO CONNECT

A0

28

27

VINA

26

VINB

25

VINC

24

VIND

23

AG

ADC

22

CLK

21

INT

20

BUSY

ST

19

RD

18

17

CS

16

WR

15

DB0

DICE CHARACTERISTICS

PIN DESCRIPTIONS

Pin# Name Description

1V

2AG

3V

DD

DAC

OUT

Positive Supply. Nominal value +5 volts. This pad requires 2 bonds for die assembly.

The substrate is common with V

DD

.

Analog Ground for the DAC. There is a separate analog ground for the ADC.

Voltage Output from the DAC.

4 NC No Connect.

5 A1 Address Input that controls multiplexer. See Table I for address decode.

6 RESET (

7–12, 14, 15 DB7 to DB0 Digital I/O Lines. DB7 (7) is the Most Significant Bit (MSB), for both the ADC and

13 DGND Digital Ground.

16

17

18

19

20

21

22 CLK External Clock Input Pin. Accepts a TTL or 5 V CMOS input logic levels.

23 AG

27–24 V

28 A0 Address input that controls multiplexer. See Table I for address decode.

REV. 0

RS) Active Low Digital Input that clears the DAC register to zero, setting the DAC to mini-

mum scale. It also asynchronously clears the

INT line of the ADC.

the DAC, and DB0 (15) is the Least Significant Bit (LSB).

WR Rising Edge Triggered Write Input. Used to load data into the DAC register.

CS Chip Select. Active Low Input

RD Active Low Read Input. When this input is active, ADC data can be read from the

ST Falling Edge Triggered Start Input. Used for applications requiring precise sample tim-

BUSY ADC Active Low, Status Output. When the ADC is performing a conversion, the

part.

RD going low starts the ADC conversion.

ing. The falling edge of

gated by

CS.

ST starts the conversion and sets the BUSY low. The ST is not

BUSY output is low.

INT Active Low Output. The Interrupt output notifies the system that the ADC has com-

ADC

A, B, C, D Four Analog Inputs

IN

pleted its conversion.

INT goes high on the rising edge of CS or RD. It will also be

forced high when RESET is asserted.

Analog ADC Ground

–5–

Page 6

AD8401

V

IN

CLK

BUSY

CS , RD

OR ST

100ns

TYP

50ns TYP

MSB DECISION

DB7

LSB DECISION

DB0

t

x

50ns TYP

OPERATION

The AD8401 is a complete data acquisition and control system.

It contains the DAC, a four channel input multiplexer, a track/

hold, an ADC, as well as an internal bandgap reference. It interfaces to the microcontroller via an 8-bit digital I/O port.

D/A CONVERTER SECTION

The DAC is an 8-bit voltage mode DAC with an output that

swings from AG

to the 1.25 volt bandgap voltage. It uses an

DAC

R-2R ladder fed by PNP current sources which allow the output

to swing to ground so that the DAC operates in a unipolar mode.

AMPLIFIER SECTION

The DAC’s output is buffered by an internal high speed op

amp. The op amps output range is set at 0 V to 2.5 V. The op

amp has a 500 ns typical settling time to 0.2% for positive

slewing signals. There are differences in settling time for negative slewing signals. Signals going to zero volts will settle slightly

slower to ground than is seen in the positive direction.

V

DD

20Ω

V

AG

OUT

DAC

20Ω

n-CH

Figure 3. Equivalent Amplifier Output Stage

Current sinking capability is also limited near zero volts in single

supply operation. Figure 3 provides an equivalent amplifier output stage schematic.

Figure 4 shows the wave forms for a conversion cycle. The track

and hold begins holding the input voltage V

approximately

IN

50 ns after the falling edge of the Start command. The MSB decision is made approximately 50 ns after the second falling edge

of the CLK. If t

the CLK will be seen as the first falling clock edge. If t

is greater than 50 ns, then the falling edge of

X

is less

X

than 50 ns, the first MSB conversion will not occur until one

clock cycle later. The following bits will each be converted in a

similar manner 50 ns after each CLK edge until all eight bits

have been converted. After the end of conversion the contents of

the ADC SAR register are transferred to the output data latch,

the track and hold is returned to the track mode,

INT goes low

and the SAR is reset.

Figure 4. Operating Waveforms Using the External Clock

ANALOG INPUT

The analog inputs of the AD8401 are fed into resistor voltage

divider networks with a typical value of 8.5 kΩ. The amplifiers

driving these inputs must have an output resistance low enough

to drive these nodes without losing accuracy. Taps from the

voltage dividers are connected to the track and hold amplifier by

the multiplexer switches.

INTERNAL REFERENCE

An on-chip bandgap is provided as a voltage reference to both

the DAC and the ADC. This reference is internal to the

AD8401 and is not accessible to the user. It is laser trimmed for

both absolute accuracy and temperature coefficients. The reference is internally buffered by a separate control amplifier for both

the DAC and ADC to improve isolation between the converters.

DIGITAL I/O

The 8-bit parallel data I/O port on the AD8401 provides access

to both the DAC and the ADC. This port is TTL/CMOS compatible with three-state outputs that are ESD protected.

The data format is binary. This data coding applies to both the

DAC and the ADC. See the applications information section.

ADC SECTION

A fast successive approximation ADC is used to attain a conversion time of 2 microseconds. Start of conversion is initiated by

CS and RD. Following a Start command the BUSY signal will

become active and another Start command should not be given

until the conversion is complete.

The RESET (

INT (Interrupt or conversion complete) which normally goes

active low at the end of a conversion will be forced high by

RESET asynchronously.

RS) input does not affect A/D conversion, but the

V

IN

VIND

5kΩ

A

5kΩ

3.57kΩ

MUX

3.57kΩ

AGADC

T/H

Figure 5. Equivalent Analog Input Circuit

TRACK-AND-HOLD AMPLIFIER

Following the resistive divider at the input of the AD8401 is a

track-and-hold amplifier that captures input signals accurately

up to the 200 kHz Nyquist frequency of the ADC. To attain this

performance the T/H amplifier must have a much greater bandwidth than the signal of interest. Because of this the user must

be careful to band limit the input signal to avoid aliasing high

frequency components and noise into the passband.

The track-and-hold amplifier is internally controlled by the Start

command and is not directly available to the user. After the

Start command signal the track-and-hold is placed into the hold

mode; it returns to the track mode after the conversion is

complete.

–6–

REV. 0

Page 7

BUSY

t

10

INT

t

16

t

15

CS

t

14

t

8

t

17

RD

DATA NEW DATA

HIGH Z

OLD DATA

t

12

t

11

t

9

t

13

CLOCK

The AD8401 uses an external clock that is TTL or 5 V CMOS

compatible. The external clock speed is 5 MHz and the duty

cycle may vary from 30% to 70%. The external clock can be

continuously operated between conversions.

DIGITAL INTERFACE: ADC TIMING AND CONTROL

Two basic ADC operating modes are available with the

AD8401. The first mode uses the Start (

synchronized A/D conversion. As soon as the

the T/H switches from tracking to the hold mode capturing the

present analog input-voltage sample. With the T/H holding the

analog sample the successive-approximation analog-to-digital

conversion is completed on that sample value. At the end of

conversion the T/H returns to the tracking mode. This mode of

conversion is ideal for digital signal processing applications

where precise interval sampling is necessary to minimize errors

due to sampling uncertainty or jitter. A precise clock source can

be used to drive the

ST input.

The second mode of conversion is started by the

puts going low, after which the

cessor into a WAIT state until end of conversion. Mode 2 is

asserted by connecting the

ST pin to logic high. The major advantage of this interface is that a single Read Instruction will

start and complete a new analog-to-digital conversion without

the need for carefully tailored software delays that often are not

portable when software routines are taken to a different processor running at a different clock speed.

t

6

ST

t

7

BUSY

INT

CS

RD

DATA

t

CONVERT

t

8

t

9

Figure 6. Mode 1, ADC Interface Timing

Mode 1 Interface

As shown in Figure 6, the falling edge of the ST pulse initiates a

conversion and puts the T/H amplifier into the hold mode. The

BUSY signal goes low during the whole A/D conversion time

and returns high signaling end of conversion. The

be used to interrupt the microprocessor. When the microprocessor performs a READ to access the AD8401 data, the rising

edges of

timing specification. INT can also be used to externally trigger a

pulse that activates the

a buffer or First In First Out FIFO memory. The microprocessor can then load a series of readings from this buffer memory at

a convenient time. Care must be taken not to have the

high when

operate properly. Also triggering the

fore conversion is complete will cause erroneous readings.

REV. 0

CS or RD will reset the INT output to high after the t

CS and RD and places the new data into

RD is brought low; otherwise, the AD8401 will not

ST) pin to trigger a

ST pin is asserted,

RD and CS in-

BUSY line puts the micropro-

t

15

t

10

t

13

t

11

DATA VALIDHIGH Z

t

12

t

14

INT line can

ST input

ST line a second time be-

AD8401

Figure 7. Mode 2, ADC Interface Timing

Mode 2 Interface

This interface mode can be used with microprocessors that can

be put into a WAIT state for at least 2 microseconds. The

pin must be tied to logic high for proper operation. The microprocessor begins a conversion by executing a READ instruction

that asserts the

dress. The AD8401

microprocessor’s READY (or WAIT) line into a WAIT state.

The analog input signal is captured by the T/H on the falling

edge of

the

BUSY line returns high, and then the µP completes its

READ of the new data now on the digital output port of the

AD8401. Note that while conversion is in progress the ADC

places the results from the last conversion (Old Data) on the

data bus. The Figure 7 timing diagram details the applicable

timing specification requirements.

DIGITAL INTERFACE: DAC TIMING AND CONTROL

Table II shows the truth table for DAC operation. The internal

8-bit DAC register contents are loaded from the data bus when

both

WR and CS are asserted. The DAC register determines the

D/A converter analog-output voltage. The

tive edge triggered input that loads the bus data into the DAC

register subject to the data setup and data hold timing requirements. When

will not change with changing data bus values. Figure 8 provides

the detail timing diagram for write cycle operation.

CS WR RS DAC Function

H H H No Effect

L L H No Effect

L ` H DAC Register Updated

` L H DAC Register Updated

X X L DAC Register Loaded with all Zeros

15

DATA VALID DATA

–7–

CS and RD pins at the AD8401’s decoded ad-

BUSY output then goes low, forcing the

RD. When the conversion is complete (8 clocks later),

WR input is a posi-

CS and WR are low, the DAC register contents

Table II. DAC Register Logic

CS

t

2

WR

t

1

t

4

Figure 8. Write Cycle Timing

ST

t

3

t

5

Page 8

AD8401

RESET

CS

WR

DAC REGISTER

D0 D7

INPUT DATA

TO DAC LADDER

120

0

4.5

30

10

–3.5

20

–4.5

60

40

50

70

80

90

110

100

3.52.51.50.5–0.5–1.5–2.5

FULL SCALE ERROR – LSB

UNITS

SS = 300 UNITS TA = +25°C

An active low pulse, at any time, on the RESET pin asynchronously forces all DAC register bits to zero. The DAC output

voltage becomes zero volts and stays at that value until a new

data word is loaded into the DAC register with a new

mand. The equivalent input logic for the DAC register loading

is shown in Figure 9.

TYPICAL PERFORMANCE CHARACTERISTICS

1.0

VDD = +5V

T

0.5

0

= +25°C

A

WR com-

Figure 9. Equivalent DAC Register Control Logic

–0.5

LINEARITY ERROR – LSB

–0.1

0

DIGITAL INPUT CODE – DECIMAL

19212864

Figure 10. ADC Linearity Error vs. Digital Code

1.0

VDD = +5V

= +25°C

T

A

0.5

0

–0.5

LINEARITY ERROR – LSB

–0.1

0

Figure 11. DAC Linearity Error vs. Digital Code

DIGITAL INPUT CODE – DECIMAL

19212864

256

256

–8–

Figure 12. ADC Full-Scale Error Histogram

2.5

2.0

1.5

1.0

0.5

0

–0.5

–1.0

–1.5

ADC FULL-SCALE ERROR – LSB

–2.0

–2.5

–3.0

TEMPERATURE – °C

VDD = +5V

100–25–50 7550250

Figure 13. ADC Full-Scale Error vs. Temperature

REV. 0

Page 9

240

220

200

180

160

140

120

UNITS

100

80

60

40

20

0

–3–4 43210–1–2

FULL SCALE ERROR – LSB

TA = +25°C

SS = 300 UNITS

Figure 14. DAC Full-Scale Error Histogram

3.0

2.5

2.0

1.5

1.0

0.5

0

–0.5

–1.0

DAC FULL SCALE ERROR – LSB

–1.5

–2.0

–2.5

TEMPERATURE – °C

x +3σ

x

x – 3σ

VDD = +5V

AD8401

VDD = +5V

2.5

2.0

1.5

1.0

0.5

OUTPUT VOLTAGE – Volts

0

Figure 17. DAC Output Swing vs. Load Resistance

100–25–50 7550250

Figure 18. DAC Output Slew Rate Positive Transition

= +25°C

T

A

RL TO V

100 10k1k 100k10

LOAD RESISTANCE – Ω

3

2

100

90

1

0

5V

0

10

5V

0%

DATA

0

1V

5V

V

OUT

WR

TIME – 1µs/DIV

RL TO GND

DD

5V

0

1µS5V

Figure 15. DAC Full-Scale Error vs. Temperature

4

3

2

1

0

–1

–2

–3

DAC FULL SCALE OUT CHANGE – LSB

–4

–5

BURN-IN TIME @ 150°C – HOURS

x +3σ

x

x – 3σ

VDD = +5V

SS = 135 UNITS

5001000 400300200

Figure 16. DAC Full-Scale Out Change vs Time

Accelerated by Burn-In

3

100

90

2

1

0

5V

10

0

0%

DATA

0

1V

5V

V

OUT

WR

1µS5V

TIME – 1µs/DIV

5V

0

Figure 19. DAC Output Slew Rate Negative Transition

REV. 0

–9–

Page 10

AD8401

500mV

100

90

– 0.5V /DIV

OUT

V

10

0%

Figure 20. DAC Output Swing with Capacitive Load

VDD = +5V

TA = +25°C

CL = 1000pF

20µS

TIME – 20µs /DIV

10.0

9.5

9.0

8.5

8.0

7.5

SUPPLY CURRENT – mA

7.0

6.5

6.0

VDD = +5.25V

VDD = +4.75V

TEMPERATURE – °C

VIN = +2.4V

Figure 21. Supply Current vs. Temperature

100–25–50 7550250

60

40

20

POWER SUPPLY REJECTION – dB

0

1k 10k 1M100k

FREQUENCY – Hz

TA = +25°C

OUTPUT = FULL SCALE

V

= 5V ± 200mV

DD

Figure 22. Power Supply Rejection Ratio vs. Frequency

–10–

REV. 0

Page 11

AD8401

OUTPUT

CODE

FULL SCALE

TRANSITION

123 FS

FS – 1LSB

V

IN

INPUT VOLTAGE – LSBs

1LSB = FS

256

11111111

11111110

11111101

00000011

00000010

00000001

00000000

APPLICATIONS INFORMATION

The software programming needs to format data as defined by

the transfer equations and Code Tables that follow.

DAC Transfer Equation

V

OUT

=2.500 ×

D

256

=2.500 ×

255

for a 2.50 V full scale

256

where D is the decimal value 0 through 255 of the 8-bit data

word.

Table III. DAC Unipolar Code

Nominal

Analog

DAC Register Contents General Transfer

Decimal Binary Equation Output V

255 1111 1111

129 1000 0001

128 1000 0000

127 0111 1111

1 0000 0001

0 0000 0000

2.500 ×

2.500 ×

2.500 ×

2.500 ×

2.500 ×

2.500 ×

255

256

129

256

128

256

127

256

1

256

0

256

2.490 V

1.260 V

1.250 V

1.240 V

0.010 V

0.000 V

OUT

The nominal output voltages listed in the Code Table are subject to the static performance specifications. The INL, ZeroScale and Full-Scale errors describe the total specified variation

that will be encountered from part to part. One LSB of error for

the 2.5 V FS range is 9.766 millivolts (= 2.50/256).

Although separate AGNDs exist for both the DAC and ADC to

minimize crosstalk, writing data to the DAC while the ADC is

performing a conversion may result in an incorrect conversion

from the ADC due to signal interaction between the DAC and

ADC. Therefore, to ensure correct operation of the ADC, the

DAC register should not be updated while the ADC is converting.

The AD8401 is configured for an input range of +3.0 volts Full

Scale. The nominal transfer characteristic for this range is plotted in Figure 23. The output coding is natural binary with one

LSB equal to 11.72 millivolts. Note that the first code transition

between 0 LSB and 1 LSB occurs at 5.8 mV, one half of the

11.72 mV LSB step size. The last code transition occurs at Full

Scale minus 1.5 LSBs, which is a 2.982 V input.

The AD8401 is easily interfaced to most microprocessors by using either address bits or address decode to select the appropriate multiplexer channel. Figure 24 shows how easily the AD8401

interfaces to the AD899. No additional hardware is required.

REV. 0

Figure 23. ADC 0 V to +3 V Input Transfer Characteristic

–11–

Page 12

AD8401

ADDRESS BUS

T/H

VDD (+5.0V)

DGND

AD8401

8-BIT ADC

CONTROL LOGIC

ST

RD

CLOCK

1.25V REF

CS

WR

8-BIT DAC

DAC REG

ADC REG

DATA I/O

(8 BITS)

AG

DAC

AG

V

ADC

A1 A0

AD899

A1

A0

A

B

C

D

VINA

VINB

VINC

VIND

RESET

INT

BUSY

Figure 24. AD8401 Interface to the AD899 Read-Channel Hard Disk Drive Circuit

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead Wide-Body SO

(SOL-28)

0.7125 (18.10)

0.6969 (17.70)

OUT

C1857–18–10/93

28 15

PIN 1

0.0500

0.0118 (0.30)

0.0040 (0.10)

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

141

0.1043 (2.65)

0.0926 (2.35)

SEATING

PLANE

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.0125 (0.32)

0.0091 (0.23)

0.3937 (10.00)

0.0291 (0.74)

0.0098 (0.25)

0.0500 (1.27)

8°

0°

0.0157 (0.40)

x 45°

PRINTED IN U.S.A.

–12–

REV. 0

Loading...

Loading...