Page 1

45 dB Digitally Controlled VGA

LF to 600 MHz

FEATURES

Digitally Controlled Variable Gain in 3 dB Steps

–5 dB to +40 dB (R

–10 dB to +35 dB (R

Less than 0.2 dB Flatness over a

= 1 k⍀)

L

= 200 ⍀)

L

+20 MHz Bandwidth

up to 380 MHz

4-Bit Parallel or 3-Wire Serial Interface

Differential 200 ⍀ Input and Output Impedance

Single 3.0 V–5.5 V Supply

Draws 37 mA at 5 V

Power-Down <1 mA Maximum

APPLICATIONS

Cellular/PCS Base Stations

IF Sampling Receivers

Fixed Wireless Access

Wireline Modems

Instrumentation

PRODUCT DESCRIPTION

The AD8369 is a high performance digitally controlled variable

gain amplifier (VGA) for use from low frequencies to a –3 dB

frequency of 600 MHz at all gain codes. The AD8369 delivers

excellent distortion performance: the two-tone, third-order

intermodulation distortion is –69 dBc at 70 MHz for a 1 V p-p

composite output into a 1 kW load. The AD8369 has a nominal

noise figure of 7 dB when at maximum gain, then increases with

decreasing gain.

Output IP3 is +19.5 dBm at 70 MHz into a

1 kW load and remains fairly constant over the gain range.

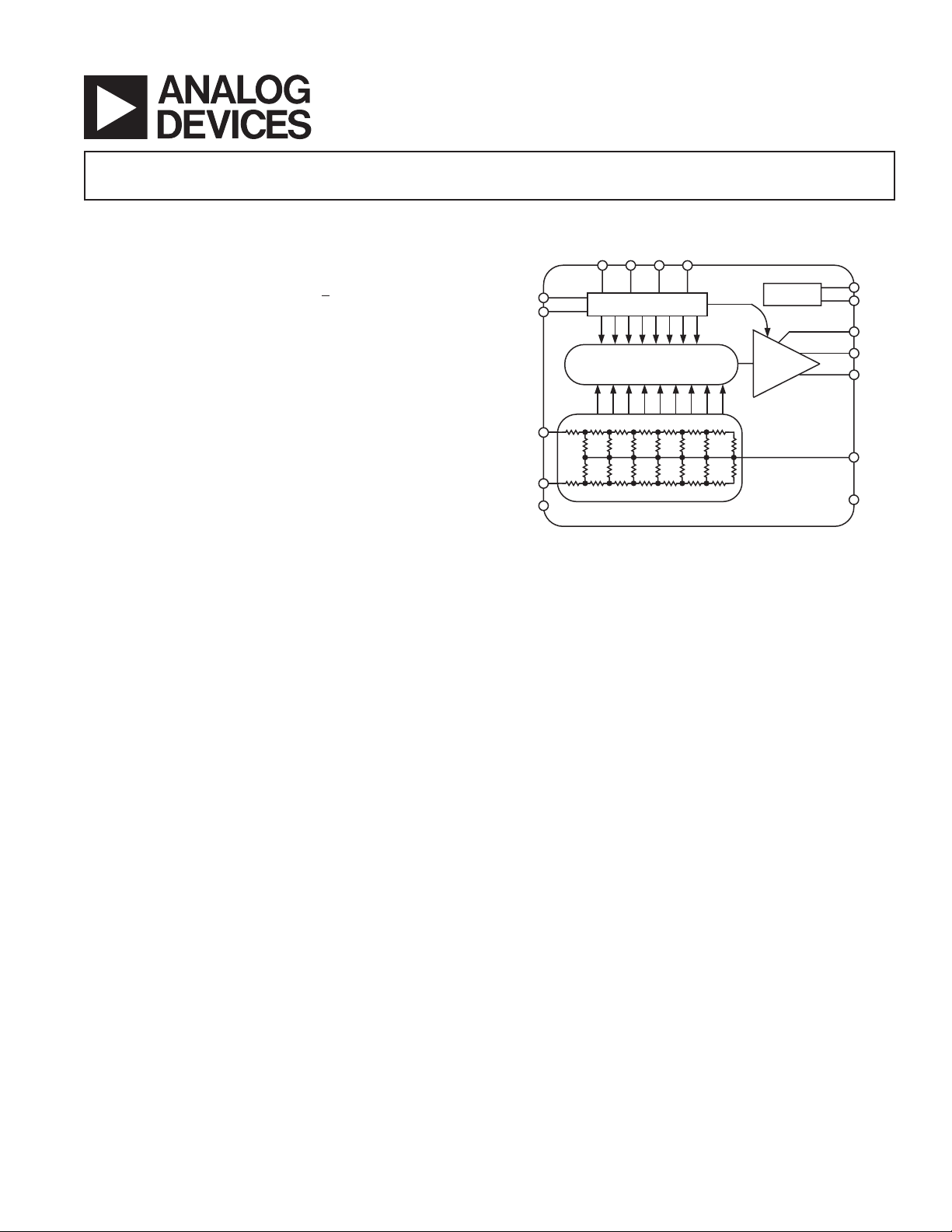

The signal input is applied to pins INHI and INLO. Variable gain

is achieved via two methods. The 6 dB gain steps are implemented

using a discrete X-AMP

®

structure, in which the input signal is

progressively attenuated by a 200 W R-2R ladder network that

also sets the input impedance; the 3 dB steps are implemented at

the output of the amplifier. This combination provides very

accurate 3 dB gain steps over a span of 45 dB. The output impedance is set by on-chip resistors across the differential output pins,

AD8369

*

FUNCTIONAL BLOCK DIAGRAM

BIT3 BIT0BIT2 BIT1

DENB

SENB

INHI

INLO

COMM

GAIN CODE DECODE

Gm CELLS

3dB STEP

BIAS

VPOS

PWUP

FILT

OPHI

OPLO

CMDC

COMM

OPHI and OPLO. The overall gain depends upon the source

and load impedances due to the resistive nature of the input and

output ports.

Digital control of the AD8369 is achieved using either a serial or

a parallel interface. The mode of digital control is selected by

connecting a single pin (SENB) to ground or the positive supply. Digital control pins can be driven with standard CMOS

logic levels.

The AD8369 may be powered on or off by a logic level applied

to the PWUP pin. For a logic high, the chip powers up rapidly

to its nominal quiescent current of 37 mA at 25ºC. When low,

the total dissipation drops to less than a few milliwatts.

The AD8369 is fabricated on an Analog Devices proprietary, high

performance 25 GHz silicon bipolar IC process and is available

in a 16-lead TSSOP package for the industrial temperature range

of –40∞C to +85∞C. A populated evaluation board is available.

*Patents Pending

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2002 Analog Devices, Inc. All rights reserved.

Page 2

(VS = 5 V, T = 25ⴗC, RS = 200 ⍀, RL = 1000 ⍀, Frequency = 70 MHz, at maximum gain,

AD8369–SPECIFICATIONS

unless otherwise noted.)

Parameter Conditions Min Typ Max Unit

OVERALL FUNCTION

Frequency Range 3 dB Bandwidth LF* 600 MHz

GAIN CONTROL INTERFACE

Voltage Gain Span 45 dB

Maximum Gain All bits high (1 1 1 1) 40 dB

Minimum Gain All bits low (0 0 0 0) –5 dB

Gain Step Size 3dB

Gain Step Accuracy

Over entire gain range, with respect to 3 dB step

± 0.05 dB

Gain Step Response Time Step = 3 dB, settling to 10% of final value 30 ns

INPUT STAGE

Input Resistance From INHI to INLO 200 W

From INHI to COMM, from INLO to COMM 100 W

Input Capacitance From INHI to INLO 0.1 pF

From INHI to COMM, from INLO to COMM 1.1 pF

Input Noise Spectral Density 2 nV/÷Hz

Input Common-Mode DC Voltage Measured at pin CMDC 1.7 V

Maximum Linear Input |V

INHI

– V

| at Minimum Gain 2.2 V

INLO

OUTPUT STAGE

Output Resistance From OPHI to OPLO 200 W

From OPHI to COMM, from OPLO to COMM 100 W

Output Capacitance From OPHI to OPLO 0.25 pF

From OPHI to COMM, from OPLO to COMM 1.5 pF

Common-Mode DC Voltage No input signal V

/2 V

S

Slew Rate Output step = 1 V 1200 V/ms

POWER INTERFACE

Supply Voltage 3.0 5.5 V

Quiescent Current PWUP high 37 42 mA

vs. Temperature –40∞C £ T

£ 85∞C52mA

A

Disable Current PWUP low 400 750 mA

vs. Temperature –40∞C £ TA £ 85∞C1mA

POWER UP INTERFACE Pin PWUP

Enable Threshold 1.0 V

Disable Threshold 2.2 V

Response Time Time delay following low to high transition 7 ms

on PWUP until output settles to within 10%

of final value

Input Bias Current PWUP = 5 V 160 mA

DIGITAL INTERFACE

Pins SENB, BIT0, BIT1, BIT2, BIT3,

and DENB

Low Condition 2.0 V

High Condition 3.0 V

Input Bias Current Low input 150 mA

Frequency = 10 MHz

Voltage Gain 40.5 dB

Gain Flatness Within ± 10 MHz of 10 MHz

+0.05* dB

Noise Figure 7.0 dB

Output IP3 f1 = 9.945 MHz, f2 = 10.550 MHz +22 dBV rms

+22 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 9.945 MHz, f2 = 10.550 MHz

V

– V

OPHI

Third-Order, V

= 1 V p-p composite –74 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –72 dBc

OPLO

= 1 V p-p –71 dBc

OPLO

P1dB For ± 1dB deviation from linear gain +3 dBV rms

+3 dBm

*The low frequency high-pass corner is determined by the capacitor on pin FILT, C

. See the Theory of Operation section for details.

FILT

REV. 0–2–

Page 3

SPECIFICATIONS (Continued)

AD8369

Parameter Conditions Min Typ Max Unit

Frequency = 70 MHz

Voltage Gain 40.5 dB

Gain Flatness Within ± 20 MHz of 70 MHz ± 0.1 dB

Noise Figure 7.0 dB

Output IP3 f1 = 69.3 MHz, f2 = 70.7 MHz +19.5 dBV rms

+19.5 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 69.3 MHz, f2 = 70.7 MHz

– V

V

OPHI

Third-Order, V

= 1 V p-p composite –69 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –68 dBc

OPLO

= 1 V p-p –64 dBc

OPLO

P1dB For ± 1dB deviation from linear gain +3 dBV rms

+3 dBm

Frequency = 140 MHz

Voltage Gain 40.0 dB

Gain Flatness Within ± 20 MHz of 140 MHz ± 0.10 dB

Noise Figure 7.0 dB

Output IP3 f1 = 139.55 MHz, f2 = 140.45 MHz +17 dBV rms

+17 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 139.55 MHz, f2 = 140.45 MHz

– V

V

OPHI

Third-Order, V

= 1 V p-p composite –64 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –63 dBc

OPLO

= 1 V p-p –55 dBc

OPLO

P1dB For ± 1 dB deviation from linear gain +3 dBV rms

+3 dBm

Frequency = 190 MHz

Voltage Gain 39.7 dB

Gain Flatness Within ± 20 MHz of 190 MHz ± 0.1 dB

Noise Figure 7.2 dB

Output IP3 f1 = 189.55 MHz, f2 = 190.45 MHz +15.5 dBV rms

+15.5 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 189.55 MHz, f2 = 190.45 MHz

– V

V

OPHI

Third-Order, V

= 1 V p-p composite –61 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –57 dBc

OPLO

= 1 V p-p –51 dBc

OPLO

P1dB For ± 1dB deviation from linear gain +2 dBV rms

+2 dBm

Frequency = 240 MHz

Voltage Gain 39.3 dB

Gain Flatness Within ± 20 MHz of 240 MHz ± 0.1 dB

Noise Figure 7.2 dB

Output IP3 f1 = 239.55 MHz, f2 = 240.45 MHz +14 dBV rms

+14 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 239.55 MHz, f2 = 240.45 MHz

V

– V

OPHI

Third-Order, V

= 1 V p-p composite –58 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –50 dBc

OPLO

= 1 V p-p –49 dBc

OPLO

P1dB For ± 1 dB deviation from linear gain +1.5 dBV rms

+1.5 dBm

Frequency = 320 MHz

Voltage Gain 39.0 dB

Gain Flatness Within ± 20 MHz of 320 MHz ± 0.15 dB

Noise Figure 7.4 dB

Output IP3 f1 = 319.55 MHz, f2 = 320.45 MHz +11.5 dBV rms

+11.5 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 319.55 MHz, f2 = 320.45 MHz

V

– V

OPHI

Third-Order, V

= 1 V p-p composite –53 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –47 dBc

OPLO

= 1 V p-p –49 dBc

OPLO

P1dB For ± 1 dB deviation from linear gain +1.0 dBV rms

+1.0 dBm

REV. 0

–3–

Page 4

AD8369

SPECIFICATIONS (Continued)

Parameter Conditions Min Typ Max Unit

Frequency = 380 MHz

Voltage Gain 38.5 dB

Gain Flatness Within ± 20 MHz of 380 MHz ± 0.15 dB

Noise Figure 7.8 dB

Output IP3 f1 = 379.55 MHz, f2 = 380.45 MHz +8.5 dBV rms

+8.5 dBm

IMD

3

Harmonic Distortion Second-Order, V

f1 = 379.55 MHz, f2 = 380.45 MHz,

V

– V

OPHI

Third-Order, V

= 1 V p-p composite –47 dBc

OPLO

OPHI

OPHI

– V

– V

= 1 V p-p –45 dBc

OPLO

= 1 V p-p –49 dBc

OPLO

P1dB For ± 1 dB deviation from linear gain +0.5 dBV rms

+0.5 dBm

Specifications subject to change without notice.

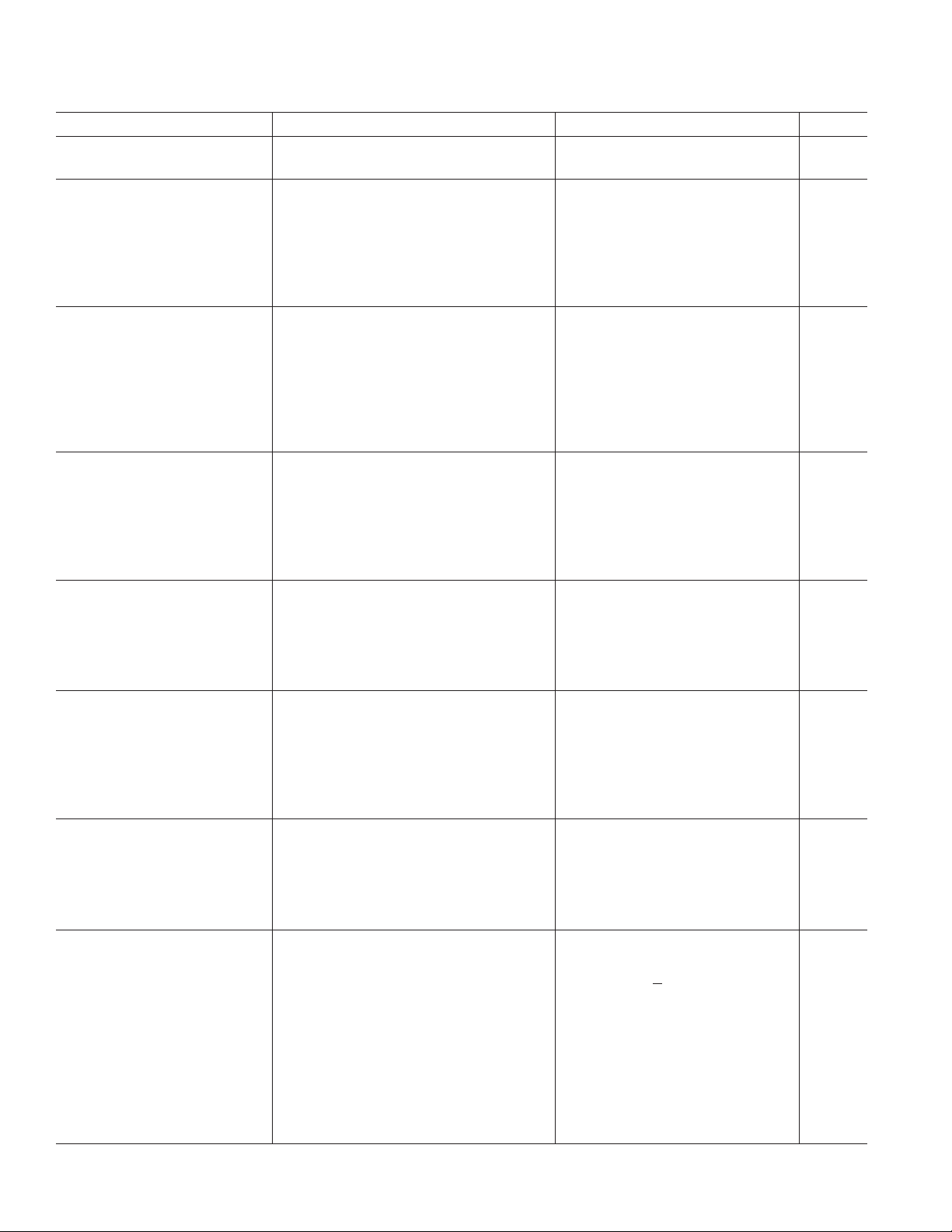

TIMING SPECIFICATIONS

SERIAL PROGRAMMING TIMING REQUIREMENTS

(VS = 5 V, T = 25∞C)

Parameter Typ Unit

Minimum Clock Pulsewidth (T

Minimum Clock Period (T

Minimum Setup Time Data vs. Clock (T

Minimum Setup Time Data Enable vs. Clock (T

Minimum Hold Time Clock vs. Data Enable (T

Minimum Hold Time Data vs. Clock (TDH)4ns

)10ns

PW

)20ns

CK

)2ns

DS

)2 ns

ES

)2 ns

EH

PARALLEL PROGRAMMING TIMING REQUIREMENTS

= 5 V, T = 25∞C)

(V

S

Parameter Typ Unit

Minimum Setup Time Data Enable vs. Data (T

Minimum Hold Time Data Enable vs. Data (T

Minimum Data Enable Width (TPW)4ns

T

T

DH

DS

DATA

(BIT 0)

CLOCK

(BIT 1)

DATA

ENABLE

(DEN B)

CLOCK

DISABLED

MSB MSB–1 MSB–2 LSB

T

PW

T

ES

DATA IS LATCHED ON LOW-TO-HIGH TRANSITION OF DENB

CLOCK

ENABLED

)2 ns

ES

)2 ns

EH

T

CK

T

EH

CLOCK

DISABLED

(NOT TO SCALE)

MSB

(BIT3)

MSB–1

(BIT2)

MSB–2

(BIT1)

LSB

(BIT0)

DENB

DATA IS LATCHED ON HIGH-TO-LOW

TRANSITION OF DENB

Serial Programming Timing

T

ESTEH

T

PW

(NOT TO SCALE)

Parallel Programming Timing

REV. 0–4–

Page 5

AD8369

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage VS, VPOS . . . . . . . . . . . . . . . . . . . . . . . . 5.5 V

PWUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

BIT0, BIT1, BIT2, BIT3, DENB, SENB . . . . . . V

Input Voltage, V

Input Voltage, V

Input Voltage, V

INHI

INHI

INHI

– V

or V

– V

................................

. . . . . . . . . . . . . . . . . . . . . . . . 4 V

INLO

with respect to COMM . . 4.5 V

INLO

with respect to COMM

INLO

COMM – 200 mV

+ 200 mV

S

+ 200 mV

S

Internal Power Dissipation . . . . . . . . . . . . . . . . . . . . . 265 mW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150∞C/W

JA

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 125∞C

Operating Temperature Range . . . . . . . . . . . .–40∞C to +85∞C

Storage Temperature Range . . . . . . . . . . . . . –65∞C to +150∞C

Lead Temperature Range (soldering 60 sec) . . . . . . . to 300∞C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other condition s above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD8369ARU –40ºC to +85ºC Tube, 16-Lead TSSOP RU-16

AD8369ARU-REEL7 –40ºC to +85ºC 7" Tape and Reel

AD8369EVAL Evaluation Board

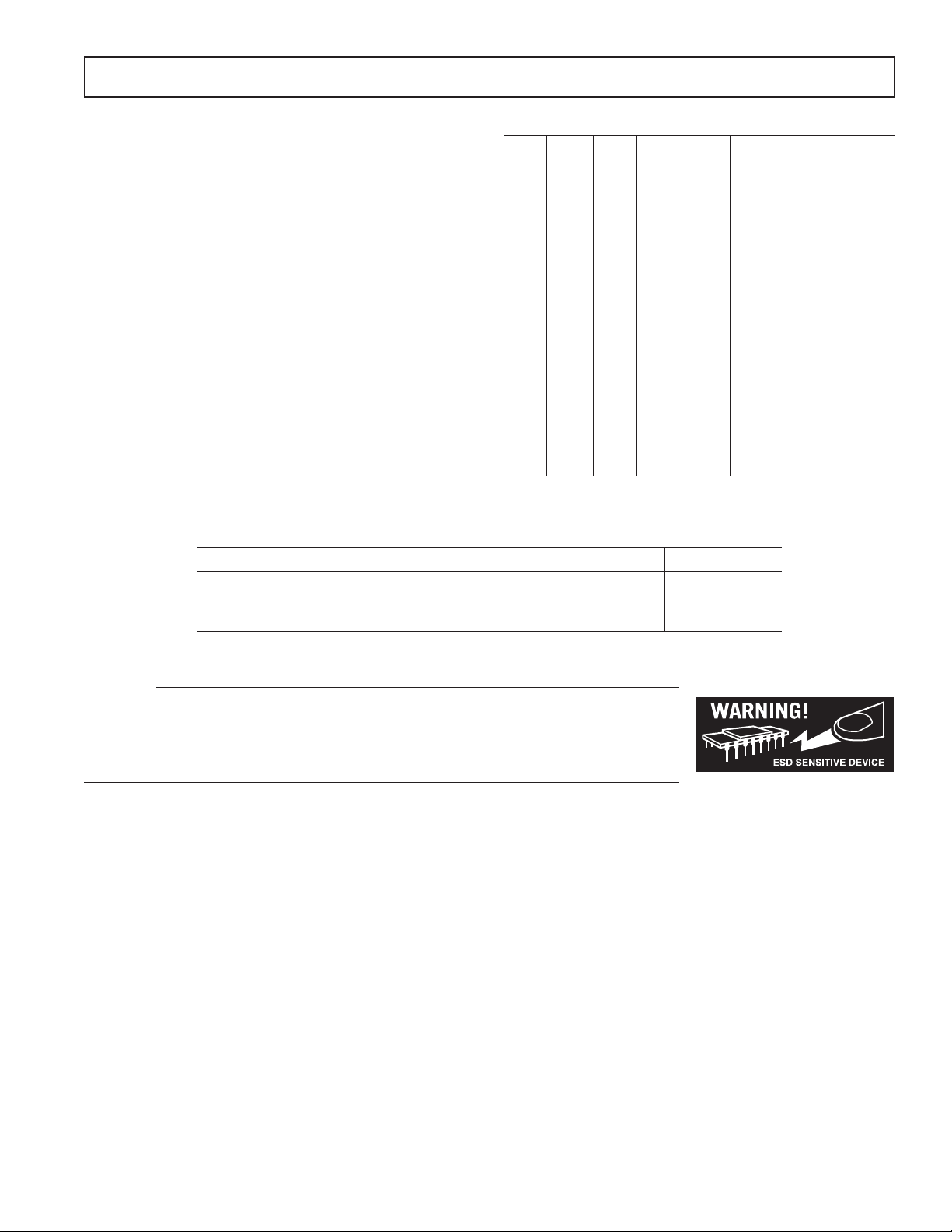

Table I. Typical Voltage Gain vs. Gain Code (VS = 5 V, f = 70 MHz)

Typical Typical

Gain Gain (dB) Gain (dB)

Code BIT3 BIT2 BIT1 BIT0 RL = 1 k⍀ RL = 200 ⍀

00000–5 –10

10001–2 –7

200101 –4

300114 –1

401007 2

5010110 5

6011013 8

7011116 11

8100019 14

9100122 17

10 1 01025 20

11 1 01128 23

12 1 10031 26

13 1 10134 29

14 1 11037 32

15 1 11140 35

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD8369 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. 0

–5–

Page 6

AD8369

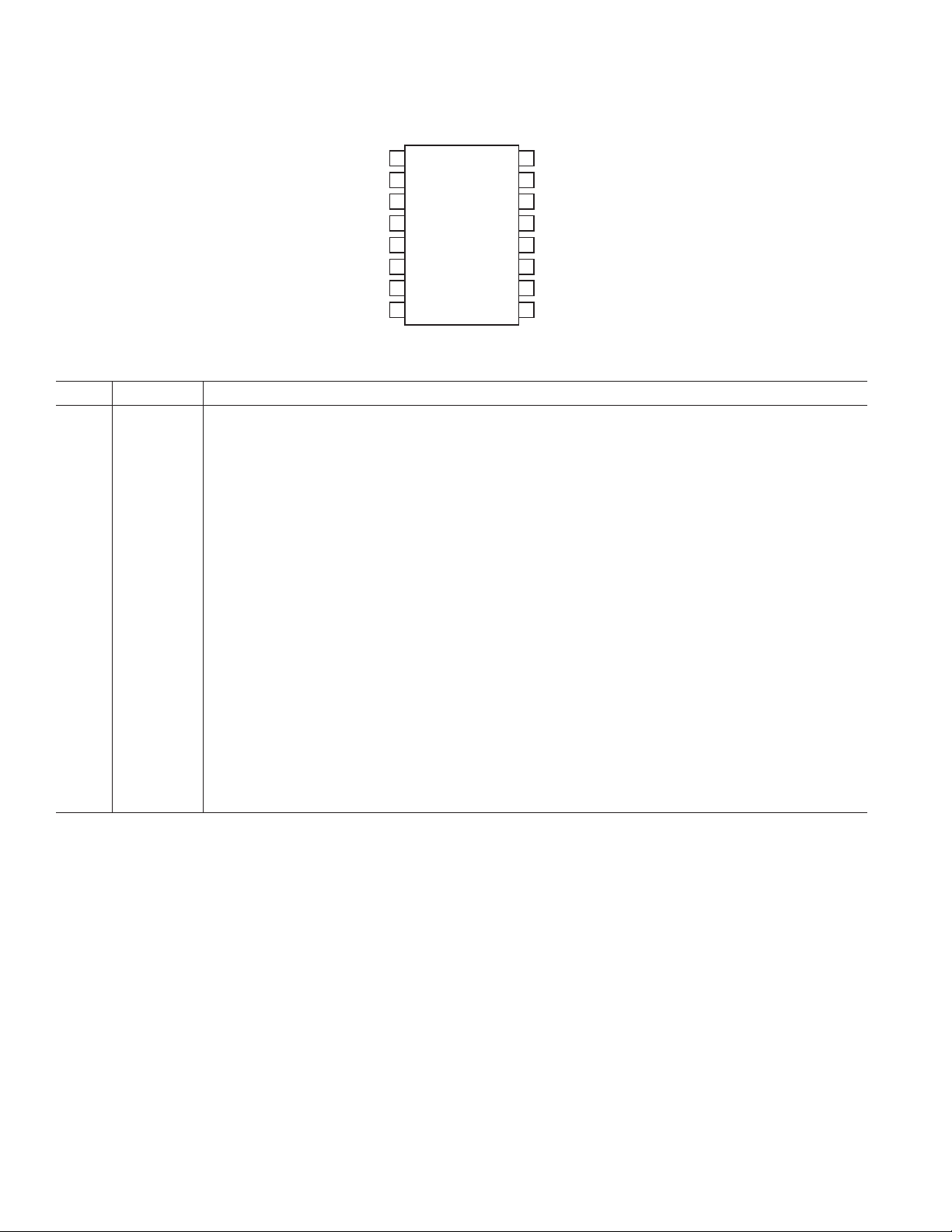

PIN CONFIGURATION

16

INLO

1

2

COMM

AD8369

3

BIT0

BIT1

BIT2

BIT3

DENB

OPLO OPHI

4

5

6

7

8

TOP VIEW

(Not To Scale)

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1 INLO Balanced Differential Input. Internally biased, should be ac-coupled.

2 COMM Device Common. Connect to low impedance ground.

3 BIT0 Gain Selection Least Significant Bit. Used as DATA input signal when in serial mode of operation.

4 BIT1 Gain Selection Control Bit. Used as CLOCK input pin when in serial mode of operation.

5 BIT2 Gain Selection Control Bit. Inactive when in serial mode of operation.

6 BIT3 Gain Selection Most Significant Bit. Inactive when in serial mode of operation.

7 DENB Data Enable Pin. Writes data to register. See Timing Specifications for details.

8 OPLO Balanced Differential Output. Biased to midsupply, should be ac-coupled.

9 OPHI Balanced Differential Output. Biased to midsupply, should be ac-coupled.

10 CMDC Common-Mode Decoupling Pin. Connect bypass capacitor to ground for additional common-mode supply

decoupling beyond the existing internal decoupling.

11 FILT High-Pass Filter Connection. Used to set high-pass corner frequency.

12 SENB Serial or Parallel Interface Select. Connect SENB to VPOS for serial operation. Connect SENB to COMM

for parallel operation.

13 VPOS Positive Supply Voltage, V

= +3 V to +5.5 V.

S

14 PWUP Power-Up Pin. Connect PWUP to VPOS to power up the device. Connect PWUP to COMM to power-down.

15 COMM Device Common. Connect to a low impedance ground.

16 INHI Balanced Differential Input. Internally biased, should be ac-coupled.

INHI

15

COMM

14

PWUP

13

VPOS

12

SENB

11

FILT

10

CMDC

9

REV. 0–6–

Page 7

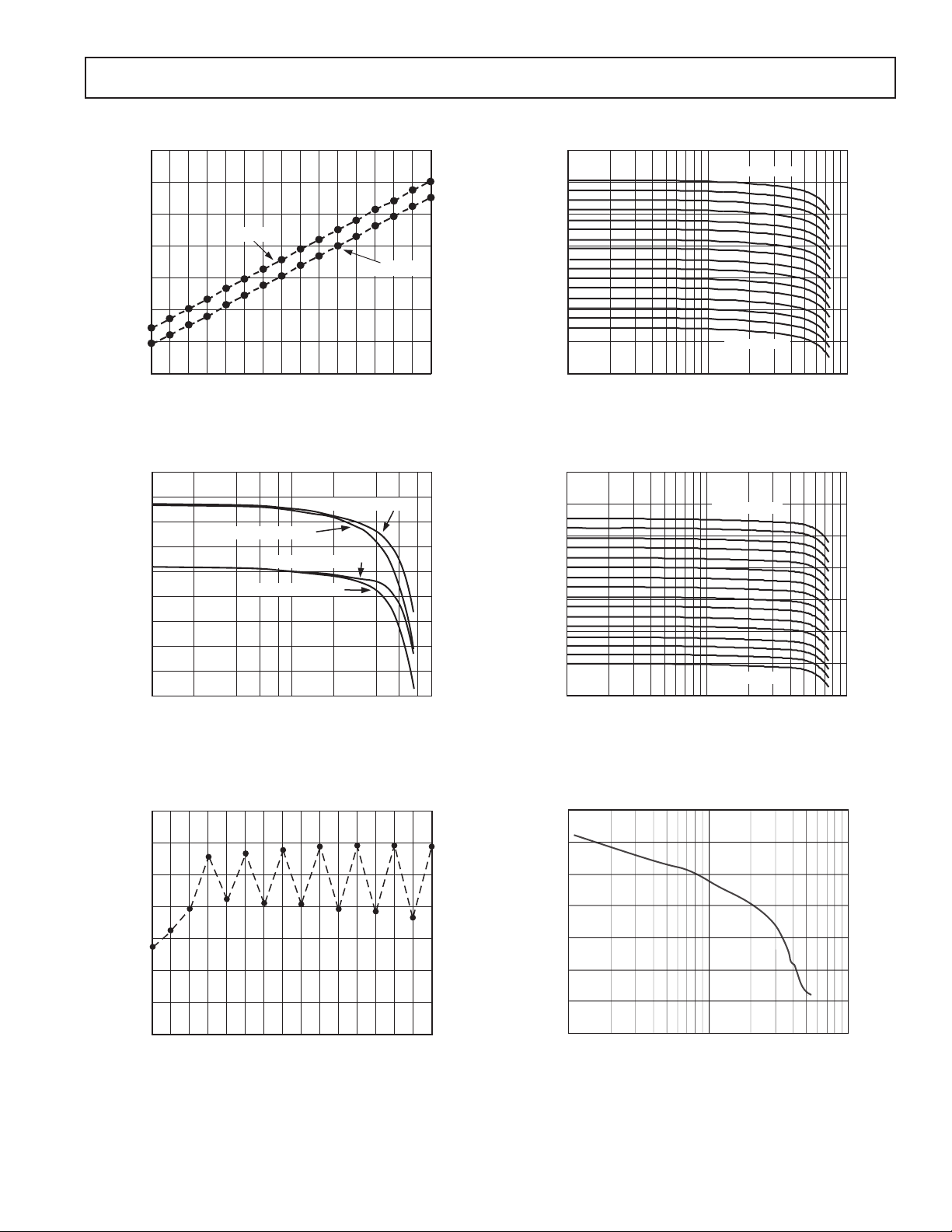

Typical Performance Characteristics–AD8369

FREQUENCY – MHz

10

OUTPUT IP3 – dBm

100 1000

35

30

25

20

10

0

15

5

OUTPUT IP3 – dBV rms

28

23

18

13

3

–7

8

–2

(VS = 5 V, T = 25ⴗC, RS = 200 ⍀, Maximum gain, unless otherwise noted.)

50

40

30

20

10

GAIN – dB

0

ⴚ10

ⴚ20

01

23456 78 910

RL = 1k⍀

GAIN CODE

TPC 1. Gain vs. Gain Code at 70 MHz

43

41

39

37

35

33

GAIN – dB

31

29

27

25

10

VS = 3V, RL = 1k⍀

VS = 3V, RL = 200⍀

FREQUENCY – MHz

VS = 5V, RL = 1k⍀

VS = 5V, RL = 200⍀

100 1000

RL = 200⍀

11 12 13 14 15

50

40

30

20

10

GAIN – dB

0

ⴚ10

ⴚ20

10

FREQUENCY – MHz

GAIN CODE 15

GAIN CODE 0

100 1000

TPC 4. Gain vs. Frequency by Gain Code, RL = 1 k

50

40

30

20

10

GAIN – dB

0

ⴚ10

ⴚ20

10

FREQUENCY – MHz

GAIN CODE 15

GAIN CODE 0

100 1000

W

TPC 2. Maximum Gain vs. Frequency by RL and

Supply Voltage

28

26

24

22

OUTPUT IP3 – dBm

18

16

14

23456 78 9102011 12 13 14 15

01

GAIN CODE

TPC 3. Output IP3 vs. Gain Code at 70 MHz, VS = 5 V,

= 200

R

L

W

REV. 0 –7–

21

19

17

15

13

11

OUTPUT IP3 – dBV rms

9

7

TPC 5. Gain vs. Frequency by Gain Code, RL = 200

TPC 6. Output IP3 vs. Frequency, VS = 5 V, RL = 200

Maximum Gain

W

W

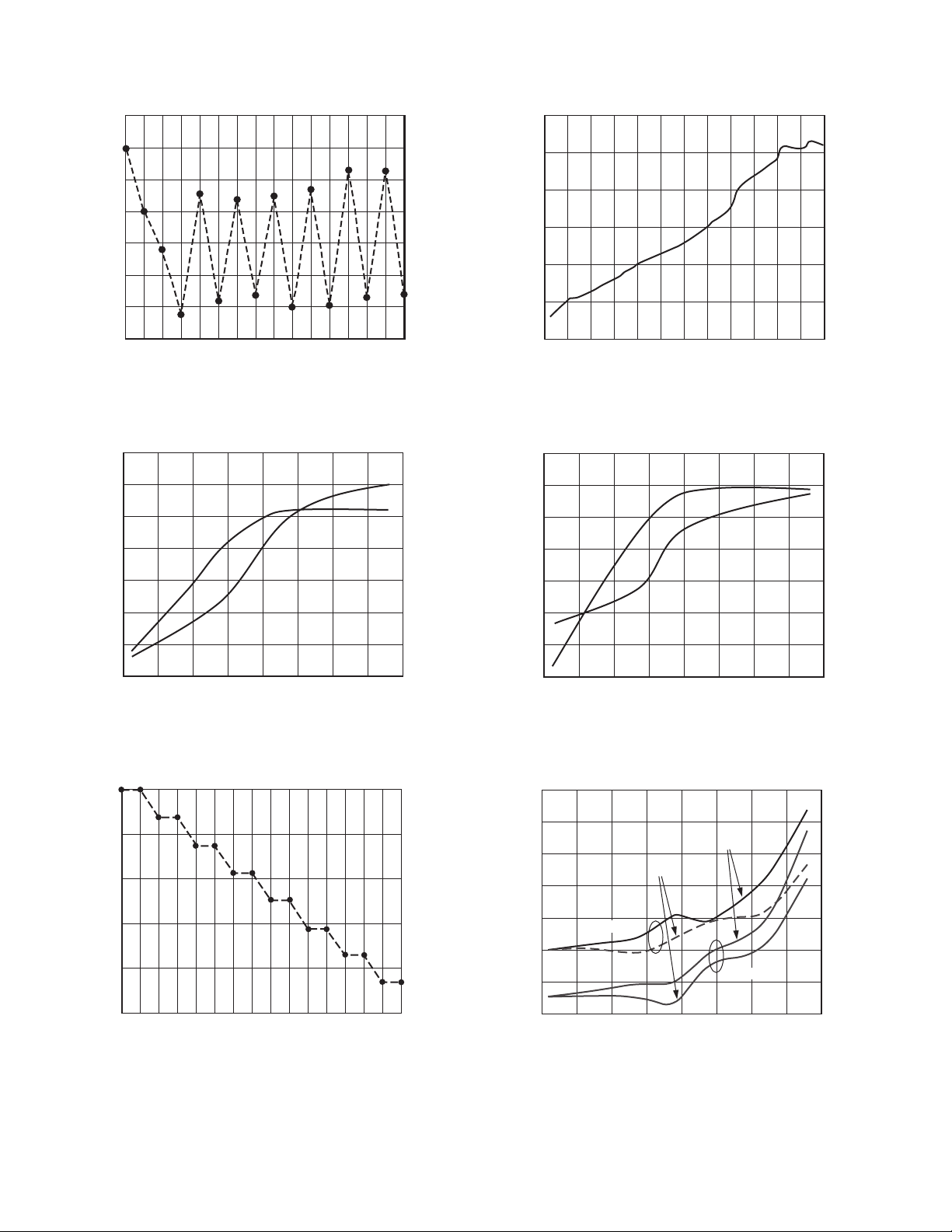

Page 8

AD8369

–63

–64

–65

–66

–67

OUTPUT IMD – dBc

–68

–69

–70

4

0

3215678

GAIN CODE

91011121314 15

TPC 7. Two-Tone, IMD3 vs. Gain Code at 70 MHz,

V

OPHI

ⴚ40

ⴚ45

ⴚ50

ⴚ55

ⴚ60

– V

= 1 V p-p, VS = 5 V, RL = 1 k

OPLO

HD

3

HD

2

W

–20

–30

–40

–50

–60

OUTPUT IMD – dBc

–70

–80

0

200

15010050 250 300 350 400

FREQUENCY – MHz

TPC 10. Two-Tone IMD3 vs. Frequency V

VS = 5 V, RL = 1 kW, Maximum Gain

ⴚ35

ⴚ40

ⴚ45

ⴚ50

ⴚ55

HD

3

HD

2

450 500 550 600

– V

OPHI

OPLO

= 1 V p-p,

ⴚ65

HARMONIC DISTORTION – dBc

ⴚ70

ⴚ75

050

TPC 8. Harmonic Distortion at V

Frequency, V

50

40

30

20

NOISE FIGURE – dB

10

0

01

100 150 200 250 300 350 400

FREQUENCY – MHz

– V

= 5 V, RL = 1 kW, Maximum Gain

S

23456 78 910

OPHI

GAIN CODE

OPLO

11 12 13 14 15

= 1 V p-p vs.

TPC 9. Noise Figure vs. Gain Code at 70 MHz, VS = 5 V,

= 200

R

L

W

ⴚ60

HARMONIC DISTORTION – dBc

ⴚ65

ⴚ70

050

TPC 11. Harmonic Distortion at V

Frequency, V

8.0

7.8

7.6

7.4

7.2

NOISE FIGURE – dB

7.0

6.8

6.6

050

100 150 200 250 300 350 400

FREQUENCY – MHz

– V

= 5 V, RL = 200 W, Maximum Gain

S

RL = 1k⍀

100 150 200 250 300 350 400

FREQUENCY – MHz

OPHI

5V

3V

RL = 200⍀

TPC 12. Noise Figure vs. Frequency by RL and

Supply Voltage at Maximum Gain

= 1 V p-p vs.

OPLO

REV. 0–8–

Page 9

AD8369

FREQUENCY – MHz

10

P1dB – dBm

100 1000

0

1

2

3

4

5

6

7

8

9

P1dB – dBV rms

–7

–6

–5

–4

–3

–2

–1

0

1

2

9.0

8.5

8.0

7.5

7.0

6.5

6.0

P1dB – dBm

5.5

5.0

4.5

4.0

01

23456 78 91011 12 13 14 15

GAIN CODE

TPC 13. Output P1dB vs. Gain Code at 70 MHz,

= 5 V, RL = 200

V

S

80

70

60

50

40

CMRR – dB

30

20

10

W

2.0

1.5

1.0

0.5

0

–0.5

–1.0

P1dB – dBV rms

–1.5

–2.0

–2.5

–3.0

TPC 16. Output P1dB vs. Frequency, VS = 5 V,

= 200 W, Maximum Gain

R

L

ⴚ40

ⴚ50

ⴚ60

ⴚ70

ⴚ80

REVERSE ISOLATION – dB

ⴚ90

0

10

100 1000

FREQUENCY – MHz

TPC 14. Common-Mode Rejection Ratio vs. Frequency

at Maximum Gain, V

= 5 V, RL = 200 W (Refer to

S

Appendix for Definition)

250

R

200

RESISTANCE – ⍀

150

100

10

TPC 15. Equivalent Input Resistance and

Capacitance vs. Frequency at Maximum Gain

REV. 0

INHI

INLO

FREQUENCY – MHz

100

C

1000

0.75

0.50

0.25

0

CAPACITANCE – pF

–9–

ⴚ100

10

100 1000

FREQUENCY – MHz

TPC 17. Reverse Isolation vs. Frequency at

Maximum Gain, V

= 5 V, RL = 200 W (Refer to

S

Appendix for Definition)

250

200

⍀

RESISTANCE –

150

100

10

OPHI

OPLO

FREQUENCY – MHz

R

C

100

TPC 18. Equivalent Output Resistance and

Capacitance vs. Frequency at Maximum Gain

1000

0.75

0.50

0.25

0

CAPACITANCE – pF

Page 10

AD8369

90

GAIN

15

60

10MHz

380MHz

500MHz

300

30

0

330

180

150

210

120

GAIN CODES

0, 1, AND 9

240

CODE

750MHz

270

TPC 19. Differential Input Reflection Coefficient,

S

, ZO = 50 W Differential, Selected Gain Codes

11

DIFFERENTIAL OUTPUT

250mV/VERTICAL DIVISION

ZERO

AVERAGE OF 128 SAMPLES

90

GAIN

CODE

15

500MHz

60

30

10MHz

0

380MHz

330

300

180

150

210

120

GAIN CODES

0, 1, AND 9

240

750MHz

270

TPC 22. Differential Output Reflection Coefficient,

S

, ZO = 50 W Differential, Selected Gain Codes

22

INPUT = 250mV p-p, 10MHz

OVERDRIVE

ZERO

OUTPUT

1V/VERTICAL

DIVISION

RECOVERY

BIT 0

2V/VERTICAL DIVISION

GND

TIME – 20ns/DIV

TPC 20. Gain Step Time Domain Response, 3 dB Step,

VS = 5 V, RL = 1 kW, Parallel Transparent Mode

DIFFERENTIAL OUTPUT

ZERO

GND

70MHz, 750mV/DIV

PWUP 2V/VERTICAL DIVISION

TIME – 2s/DIV

TPC 21. PWUP Time Domain Response,

Maximum Gain, V

= 5 V, RL = 1 k

S

W

BIT 3

2V/VERTICAL DIVISION

GND

TIME – 1s/DIV

TPC 23. Overdrive Recovery, Maximum Gain,

VS = 5 V, RL = 1 kW, Parallel Transparent Mode

DIFFERENTIAL

OUTPUT

ZERO

GND

TIME – 20s/DIV

200mV/DIV

INPUT

2mV/DIV

TPC 24. Pulse Response, Maximum Gain, VS = 5 V,

= 1 k

R

W

L

REV. 0–10–

Page 11

2.0

FREQUENCY – MHz

10

GAIN ERROR – dB

100 1000

0.5

0

1.0

1.5

2.0

ⴚ0.5

ⴚ1.0

ⴚ1.5

ⴚ2.0

ⴚ40ⴗC

ⴙ85ⴗC

GAIN ERROR AT ⴚ40ⴗC AND ⴙ85ⴗC

WITH RESPECT TO ⴙ25ⴗC. DATA BASED

ON 45 PARTS FROM TWO BATCH LOTS.

FREQUENCY – MHz

10

GAIN ERROR – dB

100 1000

0.5

0

1.0

1.5

2.0

ⴚ0.5

ⴚ1.0

ⴚ1.5

ⴚ2.0

GAIN ERROR AT ⴚ40ⴗC AND ⴙ85ⴗC

WITH RESPECT TO ⴙ25ⴗC. DATA BASED

ON 45 PARTS FROM TWO BATCH LOTS.

ⴚ40ⴗC

ⴙ85ⴗC

FREQUENCY – MHz

10

P1dB – dBm

100 1000

0

6

10

–2

2

4

8

ⴙ85ⴗC

ⴚ40ⴗC

ⴙ25ⴗC

P1dB – dBV rms

–7

–1

3

–9

–5

–3

1

1.5

1.0

AD8369

0.5

0

ⴚ0.5

GAIN ERROR – dB

ⴚ1.0

GAIN ERROR AT ⴚ40ⴗC AND ⴙ85ⴗC

ⴚ1.5

WITH RESPECT TO ⴙ25ⴗC. DATA BASED

ON 45 PARTS FROM TWO BATCH LOTS.

ⴚ2.0

10

FREQUENCY – MHz

ⴚ40ⴗC

ⴙ85ⴗC

100 1000

TPC 25. Gain Error Due to Temperature Change vs.

Frequency, 3 Sigma to Either Side of Mean, V

= 5 V,

S

RL = 1 kW, Maximum Gain

2.0

1.5

1.0

0.5

0

ⴚ0.5

GAIN ERROR – dB

ⴚ1.0

GAIN ERROR AT ⴚ40ⴗC AND ⴙ85ⴗC

ⴚ1.5

WITH RESPECT TO ⴙ25ⴗC. DATA BASED

ON 45 PARTS FROM TWO BATCH LOTS.

ⴚ2.0

10

FREQUENCY – MHz

ⴚ40ⴗC

ⴙ85ⴗC

100 1000

TPC 28. Gain Error Due to Temperature Change

vs. Frequency, 3 Sigma to Either Side of Mean,

V

= 5 V, RL = 200 W, Maximum Gain

S

TPC 26. Gain Error Due to Temperature Change vs.

Frequency, 3 Sigma to Either Side of Mean, V

RL = 1 kW, Maximum Gain

35

30

25

20

15

OUTPUT IP3 – dBm

10

TPC 27. IP3 vs. Frequency by Temperature, VS = 5 V,

RL = 200 W, Maximum Gain

REV. 0

–40ⴗC

+85ⴗC

FREQUENCY – MHz

5

0

10

100

+25ⴗC

= 3 V,

S

1000

28

23

18

13

8

OUTPUT IP3 – dBV rms

3

–2

–7

–11–

TPC 29. Gain Error Due to Temperature Change

vs. Frequency, 3 Sigma to Either Side of Mean,

= 3 V, RL = 200 W, Maximum Gain

V

S

TPC 30. Output P1dB vs. Frequency by Temperature,

VS = 5 V, RL = 200 W, Maximum Gain

Page 12

AD8369

60

50

40

30

PA RT COUNT

20

10

0

3.06

3.08

GAIN STEP SIZE – dB/CODE

3.10 3.12 3.14

SAMPLE FROM

ONE BATCH LOT

TPC 31. Distribution of Gain Step Size, 70 MHz,

V

= 5 V

S

18

16

14

12

10

8

PA RT COUNT

6

4

2

0

–73 –72 –71 –70 –69 –68 –67 –66 –65 –64 –63 –62

–74

IMD – dBc

SAMPLE FROM

TWO BATCH LOTS

TPC 32. Distribution of IMD3, 70 MHz, RL = 1 kW,

V

OPHI

– V

= 1 V p-p Composite, VS = 5 V,

OPLO

Maximum Gain

40

35

30

25

20

PA RT COUNT

15

10

5

0

3.16

3.18 3.20 3.22

GAIN STEP SIZE – dB/CODE

SAMPLE FROM

ONE BATCH LOT

TPC 34. Distribution of Gain Step Size, 320 MHz,

V

= 5 V

S

26

24

22

20

18

16

14

12

10

PA RT COUNT

8

6

4

2

0

–58

–57 –56

–53 –52–55 –54 –51 –50 –49 –48

IMD – dBc

SAMPLE FROM

TWO BATCH LOTS

TPC 35. Distribution of IMD3, 320 MHz, RL = 1 kW,

V

OPHI

– V

= 1 V p-p Composite, VS = 5 V,

OPLO

Maximum Gain

3000

2500

2000

1500

1000

GROUP DELAY – ps

500

0

0

3V, RL = 1k⍀

5V, RL = 1k⍀

3V, RL = 200⍀

5V, RL = 200⍀

400

300200100 500 600 700 800

FREQUENCY – MHz

TPC 33. Group Delay vs. Frequency by RL and

Supply Voltage at Maximum Gain

1600

1400

1200

1000

800

GROUP DELAY – ps

600

400

0

100 200 300 400 500 600 700 800

FREQUENCY – MHz

ALL GAIN CODES

REPRESENTED

TPC 36. Group Delay vs. Frequency by Gain Code,

VS = 5 V, RL = 1 kW, Maximum Gain

REV. 0–12–

Page 13

DIGITAL

INHI

CMDC

INLO

100

90

80

70

60

50

40

PSSR – dB

30

20

10

0

10

100 1000

FREQUENCY – kHz

TPC 37. Power Supply Rejection Ratio, VS = 5 V,

R

= 1 kW, Maximum Gain

L

GAIN STEP SELECTION

Gm CELLS

~

FIXED

GAIN

V

S

2

– 0.7

20pF

3dB SWITCHED

ATTENUATOR

BIAS

10000

AD8369

V

S

OPHI

100⍀

V

/2

S

V

S

100⍀

V

/2

S

OPLO

22pF

Figure 1. General Block Diagram, Control and Signal Paths Are Differential

THEORY OF OPERATION

The AD8369 is a digitally controlled fully differential VGA

based on a variation of Analog Devices’ patented X-AMP architecture (Figure 1). It provides accurate gain control over a 45 dB

span with a constant –3 dB bandwidth of 600 MHz.

The 3 dB gain steps can be controlled by a user-selectable

parallel- or serial-mode digital interface. A single pin (SENB)

selects the mode. The AD8369 is designed for optimal

operation when used in a fully differential system, although

single-ended operation is also possible. Its nominal input and

output impedances are 200 W.

Input Attenuator and Output 3 dB Step

The AD8369 is comprised of a seven-stage R-2R ladder network (eight taps) and a selected Gm stage followed by a

fixed-gain differential amplifier. The ladder provides a total

attenuation of 42 dB in 6 dB steps. The full signal is applied to

amplifier using the first tap; at the second tap, the signal

the

is 6 dB lower and so on. A further 3dB interpolating gain step is

introduced at the output of the fixed gain amplifier, providing

the full 45 dB of gain span.

Fixed Gain Amplifier

The fixed gain amplifier is driven by the tap point of the R-2R

ladder network via the selected Gm cell. The output stage is a

complementary pair of current sources, loaded with internal

100 W resistors to ac ground which provides a 200 W differential

output impedance. The low frequency gain of the AD8369

can be approximated by the equation:

V

OUT L

V

IN

06

.

Ê

Á

Ë

200

200

Ê

ˆ

R

Á

˜

Á

R=+

¯

L

Ë

ˆ

1

˜

˜

-

15

n

()

¯

2

where RL is the external load resistor in ohms and n is the gain

code; 0 is the minimum gain code and 15 is the maximum gain

code. The external load, which is in parallel combination with

the internal 200 W output resistor, affects the overall gain and

peak output swing. Note that the external load has no effect on the

gain step size.

Input and Output Interfaces

The dc working points of the differential input and output interfaces of the AD8369 are internally biased. The inputs INHI and

INLO are biased to a diode drop below V

/2 (~1.7 V for a 5 V

S

positive supply) to meet isolation and headroom constraints,

while the outputs OPHI and OPLO are centered on the supply

midpoint, V

/2, to provide the maximum output swing.

S

The internal VS/2 reference and the CMDC reference are buffered and decoupled to ground via internal capacitors. The

input bias voltage, derived from this VS/2 reference, is brought

REV. 0

–13–

Page 14

AD8369

DENB

SENB

B A

MUX

B A

MUX

B A

MUX

B A

MUX

SHIFT

REGISTER

A/B

SHIFT

REGISTER

SHIFT

REGISTER

SHIFT

REGISTER

BIT0

(DATA)

BIT1

(CLOCK)

BIT2 BIT3

GAIN CONTROL REGISTER

(LATCH)

TO GAIN CONTROL SECTION

BIT0 BIT1 BIT2 BIT3

T/H

out to pin CMDC for decoupling to ground. An external

capacitor from CMDC to COMM of 0.01 mF or more is

recommended to lower the input common-mode impedance of

the AD8369 and improve single-ended operation.

Signals must be ac-coupled at the input, either via a pair of

capacitors or a transformer. These may not be needed when the

source has no dc path to ground, such as a SAW filter. The

output may need dc blocking capacitors when driving dcgrounded loads, but it can be directly coupled to an ADC,

provided that the common-mode levels are compatible.

The input and output resistances form a high-pass filter in combination with any external ac-coupling capacitors that should

be chosen to minimize signal roll-off at low frequencies. For

example, using input-coupling capacitors of 0.1 mF, each driving

a 100 W input node (200 W differential), the –3 dB high-pass

corner frequency is at:

p()()

210 100

It is important to note that the input and output resistances are

subject to process variations of up to ± 20%. This will affect the

high-pass corner frequencies and the overall gain when driven

from, or loaded by, a finite impedance (see the Reducing Gain

Sensitivity to Input and Output Impedance Variation section).

Noise and Distortion

It is a common aspect of this style of VGAs, however implemented, that the effective noise figure worsens as the gain is

reduced. The AD8369 uses a fixed gain amplifier, having a certain

invariant noise spectral density, preceded by an attenuator.

Thus, the noise figure increases simply by 6 dB per tap point,

from a starting point of 7 dB at full gain.

However, unlike voltage-controlled amplifiers that must necessarily invoke nonlinear elements in the signal path, the distortion

in a step-gain amplifier can be very low and is essentially independent of the gain setting. Note that the postamplifier 3 dB step

does not affect the noise performance, but it has some bearing

on the output third-order intercept (OIP3). See TPCs 3 and 9.

Offset Control Loop

The AD8369 uses a control loop to null offsets at the input. If

left uncorrected, these offsets, in conjunction with the gain of

the AD8369, would reduce the available voltage swing at the

output. The control loop samples the differential output voltage error and feeds nulling currents back into the input stage.

The nominal high-pass corner frequency of this loop is internally set to 520 kHz, but it is subject to process variations of

up to ± 20%. This corner frequency can be reduced by adding

an external capacitor from the FILT pin to ground, in parallel

to an internal 30 pF capacitor. For example, an external capacitor of 0.1 mF would lower the high-pass corner by a factor of

30/100,030, to approximately 156 Hz. This frequency

be chosen to be at least one decade below the lowest component of interest in the input spectrum.

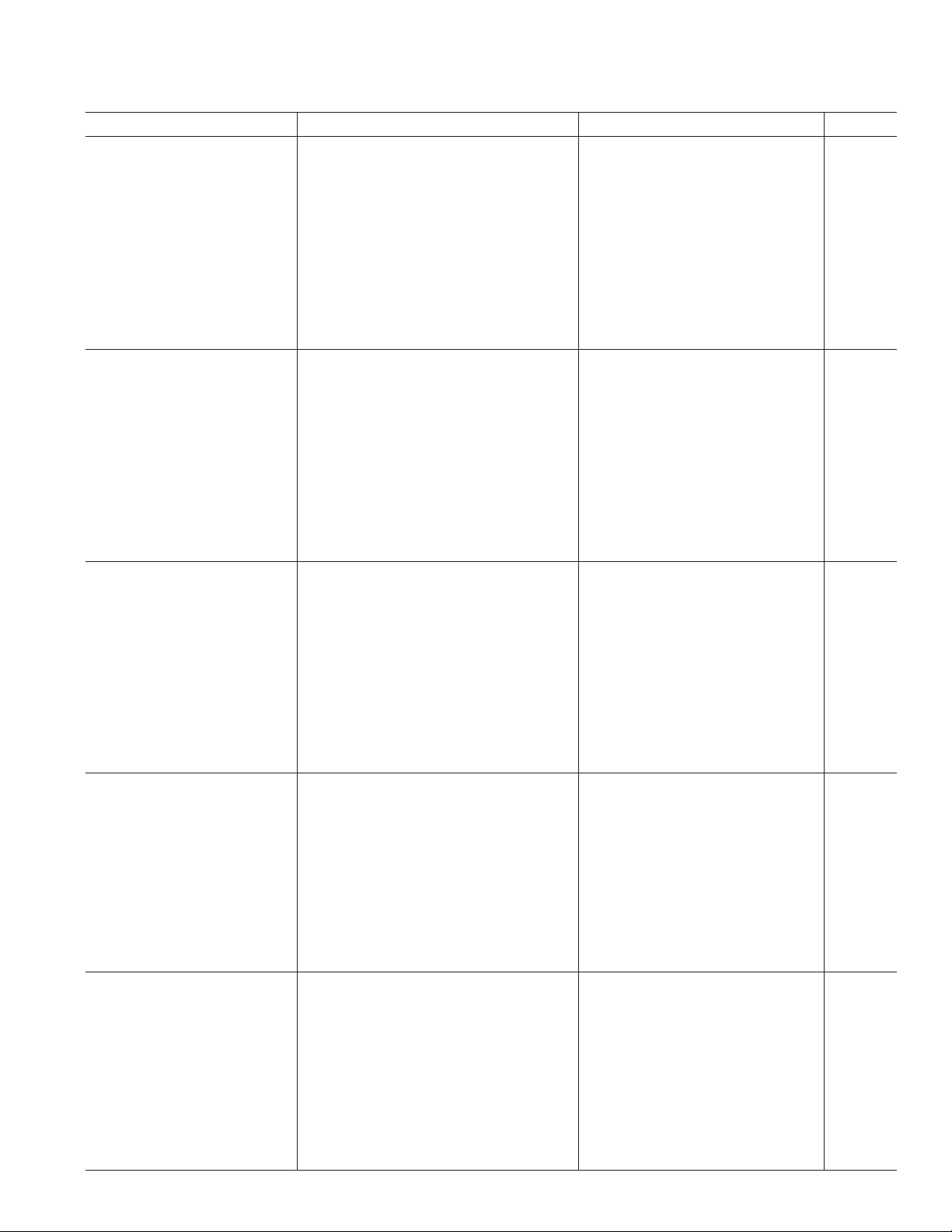

Digital Control

The gain of the AD8369 is controlled via a serial or parallel

interface, as shown in Figure 2. Serial or parallel operation is

selected via the SENB pin. Setting SENB to a logic low (< V

selects parallel operation, while a logic high on SENB (> V

selects serial operation. The AD8369 has two control registers, the

gain control register and the shift register. The gain control register

is a latch that holds the data that sets the amplifier gain. The

shift registers are composed of four flip-flops that accept the

serial data stream.

1

7

–

= kHz

16

Figure 2. Digital Interface Block Diagram

In parallel operation, the 4-bit parallel data is placed on pins

BIT3 through BIT0 and passed along to the gain control register

via the mux. Data is latched into the gain control register on the

falling edge of the input to DENB, subject to meeting the specified setup and hold times. If this pin is held high (> V

/2), any

S

changes in the parallel data will result in a change in the gain,

after propagation delays. This is referred to as the transparent

mode of operation. If DENB is held low, the last 4-bit word in

the gain control register will remain latched regardless of the signals

at the data inputs.

In serial operation, the BIT0 pin is used for data input while the

BIT1 pin is the clock input. Data is loaded into the serial shift

registers on the rising edge of the clock when DENB is low.

Given the required setup and hold times are observed, four rising

edge transitions of the clock will fully load the shift register. On

the rising edge of DENB, the 4-bit word in the shift register is

passed into the gain control register. While this pin is held high,

the clock input to the shift registers is turned off. Once DENB is

taken low, the shift register clock is again enabled and the last 4-bit

word prior to enabling the clock will be latched into the gain

control registers. This enables the loading of a new 4-bit gain

control word without interruption of the signal path. Only when

DENB goes high is data transferred from the shift registers to the

gain control registers. If no connections are made to the digital

control pins, internal 40 kW resistors pull these pins to levels

that set the AD8369 to its minimum gain condition.

At power-up or chip enable, if the AD8369 is in parallel mode

and DENB is held low, the gain control register will come up in

an indeterminate state. To avoid this, DENB should be held

high with valid data present during power-up when operating in

should

the parallel mode. In serial mode, the data in the gain control

interface powers up with a random gain code independent of

S

/2)

S

the DENB pin. Serial mode operation requires at least four

clock cycles and the transition of DENB from low to high for

/2)

valid data to be present at the gain control register.

REV. 0–14–

Page 15

AD8369

V

S

3V TO 5.5V

0.1F

INⴙ

50⍀ TX LINE

TC4-1W

0.1F

0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

R

L

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

Figure 3. Basic Connections

BASIC CONNECTIONS

Figure 3 shows the minimum connections required for basic

operation of the AD8369. Supply voltages of between +3 V and

+5.5 V are permissible. The supply to the VPOS pin should be

decoupled with at least one low inductance surface-mount ceramic

capacitor of 0.1 mF placed as close as possible to the device. More

effective decoupling is provided by placing a 100 pF capacitor in

parallel and including a 4.7 W resistor in series with the supply.

Attention should be paid to voltage drops. A ferrite bead is a

better choice than the resistor where a smaller drop is required.

Input-Output Interface

A broadband 50 W input termination can be achieved by

using a 1:2 turns-ratio transformer, as shown in Figure 3.

This also can be used to convert a single-ended input signal

to a balanced differential form at the inputs of the AD8369.

As in all high frequency applications, the trace impedance

should be maintained right up to the input pins by careful

design of the PC board traces, as described in the PCB

Layout Considerations section.

Reducing Gain Sensitivity to Input and Output Impedance Variation

The lot-to-lot variations in gain mentioned previously can, in

principle, be eliminated by adjustments to the source and load.

Define a term as a function of the input and output resistances

of the AD8369 and the source and load resistances presented to it:

RR

RR

=

a

SOURCE INPUT

OUTPUT LOAD

()

=

a

()

0.1F

0.1F

0.1F

910111213141516

R

AD8369

OPLO

87654321

0.1F

CONTROL INTERFACE

L

In general, there is a loss factor, 1/(1+ ), at each interface so

the

overall gain reduction due to source and output loading is

40 log10 (1 + ). In this case, the input and output loss factors

are 0.8 (1.94 dB) at each interface so the overall gain is

reduced by 3.88 dB.

Operation from a Single-Sided Source

While there are distinct benefits of driving the AD8369 with a

well-balanced input, in terms of distortion and gain conformance at high frequencies, satisfactory operation will often be

possible when a single-sided source is ac-coupled directly to pin

INHI, and pin INLO is ac-grounded via a second capacitor. This

mode of operation takes advantage of the good HF common-mode

rejection of the input system. The capacitor values are, as always,

selected to ensure adequate transmission at low frequencies.

0.1F

0.1F

OPLO

0.1F

910111213141516

R

L

87654321

0.1F

50⍀

SOURCE

V

S

0.1F

0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

AD8369

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

0.1F

For a 50 W source, = 0.25. Then the load resistance for zero

sensitivity to variations must be 800 W. Put more simply:

RRRR

()()

SOURCE LOAD INPUT OUTPUT

=

()( )

= 200

2

REV. 0

CONTROL INTERFACE

Figure 4. Single-Ended-to-Differential Application Example

–15–

Page 16

AD8369

For example, suppose the input signal in Figure 4 is a 140 MHz

sinusoid from a ground-referenced 50 W source. The 0.1 mF

coupling capacitors present a very low reactance at this frequency

(11 mW) so that essentially all of the ac voltage is delivered to the

differential inputs of the AD8369. It will be apparent that, in

addition to the use of adequate coupling capacitance, the external

capacitor used to extend the low frequency range of the offset

control loop, C

, must also be large enough to prevent the

FILT

offset control loop from attempting to track the ac signal fluctuations.

V

S

0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

AD8369

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

0.1F

0.1F

OPLO

CONTROL INTERFACE

Figure 5. AD8369 to ADC Interface

0

–10

–20

–30

–40

–50

– dBFS

OUT

–60

P

–70

–80

–90

–100

51015202530

0

ADC OUTPUT FREQUENCY – MHz

70MHz – 1dBFS

HD2 = –83dBc

HD3 = –80dBc

SNR = 51dB

Figure 6. Single-Tone 70 MHz, –1 dBFS

0

–10

–20

–30

–40

–50

– dBFS

OUT

–60

P

–70

–80

–90

–100

0

–7dBFS

–72.5dBFS

51015202530

ADC OUTPUT FREQUENCY – MHz

Interfacing to an ADC

The AD8369 can be used to effectively increase the dynamic

range of an ADC in a direct IF sampling receiver application.

Figure 5 provides an example of an interface to an ADC designed

for an IF of 70 MHz. It comprises a low-pass filter that attenuates

harmonics while providing an impedance transformation from

200 W to 1 kW. This impedance transformation allows the AD8369

to operate much below its peak output swing in the pass band,

which significantly reduces distortion.

270nH

0.1F

910111213141516

6.8pF 15pF

87654321

0.1F

270nH

ADC

1k⍀

A high performance 14-bit ADC, the AD6645, is used for illustrative purposes and is sampling at 64 MSPs with a full-scale

input of 2.2 V p-p. Typically, an SNR of 51 dB and an SFDR of

almost –90 dBFS are realized by this configuration. Figure 6 shows

an FFT of the AD8369 delivering a single tone at –1 dBFS (that

is, 2 V p-p) at the input of the ADC with an HD2 of –83 dBc and

HD3 of –80 dBc. Figure 7 shows that the two-tone, third-order

intermodulation distortion level is –65.5 dBc.

PCB Layout Considerations

Each input and output pin of the AD8369 presents 100 W

rela

tive to their respective ac grounds. To ensure that signal

integrity is not seriously impaired by the printed circuit board, the

relevant connection traces should provide a characteristic

impedance of 100 W to the ground plane. This can be achieved

through proper layout. Figure 8 shows the cross section of a PC

board and Table II shows the dimensions that will provide a

100 W line impedance.

Table II. Dimensions Required for 100 W Characteristic

Impedance Microstrip Line in FR-4

(FR-4) 4.6

r

W22 mils

H53 mils

T 2.1 mils

Figure 7. Two-Tone, 70 MHz, 70.3 MHz, –7 dBFS

REV. 0–16–

Page 17

AD8369

Key considerations when laying out an RF trace with a controlled

impedance include:

•

Space the ground plane to either side of the signal trace at least

3 line-widths away to ensure that a microstrip (vertical dielectric) line is formed, rather than a coplanar (lateral dielectric)

waveguide.

•

Ensure that the width of the microstrip line is constant and

that there are as few discontinuations (component pads, etc.)

as possible along the length of the line. Width variations

cause impedance discontinuities in the line and may result

in unwanted reflections.

•

Do not use silkscreen over the signal line; this will alter the

line impedance.

•

Keep the length of the input and output connection lines as

short as possible.

SW 2

PWDN

13

2

C5

0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

L

C8

1nF

AD8369

R60⍀R70⍀R80⍀R90⍀R10

INⴙ

INⴚ

J1

J2

LATCH

TC4-1W

0⍀

PWUP

V

S

C4

1nF

INHI

T1

R2

0⍀

R1

R

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

1nF

C3

3W 3WW

T

H

⑀

r

Figure 8. Cross-Sectional View of a PC Board

The AD8369 contains both digital and analog sections. Care

should be taken to ensure that the digital and analog sections

are adequately isolated on the PC board. The use of separate

ground planes for each section connected at only one point via a

ferrite bead inductor will ensure that the digital pulses do not

adversely affect the analog section of the AD8369.

R5

OPEN

C7

C8

0.1F

1nF

0⍀

910111213141516

OPLO

87654321

C2

1nF

1nF

C1

R11

0⍀

T2

TC4-1W

R12

0⍀

OUTⴙ

J6

OUTⴚ

J7

REV. 0

CLOCK

DATA

C9

OPEN

R3

1k⍀

31012498761152 131

15 22 2416 21201918 231714 25

R13

1k⍀

R4

1k⍀

D-SUB 25 PIN MALE

25 8 11

1

3467 10912

Figure 9. Evaluation Board Schematic

–17–

SW3

V

SW4

14

28

4

S

V

S

A

3

2

SW1

B

1

Page 18

AD8369

Evaluation Board

The evaluation board allows for quick testing of the AD8369

using standard 50 W test equipment. The schematic is shown in

Figure 9. Transformers T1 and T2 are used to transform 50 W

source and load impedances to the desired 200 W reference level.

This allows for broadband operation of the device without the need

to pay close attention to impedance matching (see Table III).

Evaluation Board Software

The evaluation board comes with the AD8369 control software

that allows for serial gain control from most computers. The

evaluation board is connected via a cable to the parallel port of

the computer. By simply adjusting the slider bar in the control

software, the gain code is automatically updated to the AD8369.

On some older PCs, it may be necessary to use 5 kW pull-up

resistors to VPOS on DATA, CLOCK, and LATCH depending

upon the capabilities of the port transceiver.

It is necessary to set SW3 on the evaluation board to “SER” for

the control software to function normally.

A screen shot of the evaluation software interface is shown in

Figure 11.

Figure 10. Evaluation Board Layout

Figure 11. Evaluation Software Interface

REV. 0–18–

Page 19

AD8369

Table III. AD8369 Evaluation Board Configuration Options

Component Function Default Condition

VPOS, GND Supply and Ground Vector Pins Not Applicable

SW1 Data Enable: Set to Position A when in serial mode of operation, set to Position B Not Applicable

when in parallel mode of operation.

SW2 Device Enable: When in the PWDN position, the PWUP pin will be connected to Not Applicable

ground and the AD8369 will be disabled. The device is enabled when the switch is

in the PWUP position, connecting the PWUP pin to VPOS.

SW3, R5 Serial/Parallel Selection. The device will respond to serial control inputs from Not Applicable

connector P1 when the switch is in the SER position. Parallel operation is achieved R5 = Open (Size 0603)

when in the PAR position. Device can be hardwired for parallel mode of operation by

placing the 0 W resistor in position R5.

SW4 Parallel Interface Control. Used to hardwire BIT0 through BIT3 to the desired gain Not Applicable

code when in parallel mode of operation. The switch functions as a hexadecimal

to binary encoder (Gain Code 0 = 0000, Gain Code 15 = 1111).

J1, J2, J6, J7 Input and Output Signal Connectors. These SMA connectors provide a convenient Not Applicable

way to interface the evaluation board with 50 W test equipment.

C1, C2, C3, C4 AC-Coupling Capacitors. Provides ac-coupling of the input and output signals. C1, C2, C3, C4

= 1 nF (Size 0603)

T1, T2 Impedance Transformers. Used to transform the 200 W input and output T1, T2 = TC4-1W

impedance to 50 W. (MiniCircuits)

R1, R2, R11, R12 Single-Ended or Differential. R2 and R11 are used to ground the center tap of R1, R2, R11, R12

the secondary windings on transformers T1 and T2. R1 and R12 should be used = 0 W (Size 0603)

to ground J2 and J7 when used in single-ended applications. R1 and R12 should be

removed for differential operation.

R6, R7, R8, R9, R10 Control Interface Resistors. Simple series resistors for each control interface signal. R6, R7, R8, R9,

R10 = 0 W (Size 0603)

C5, C6, C8 Power Supply Decoupling. Nominal supply decoupling consists of a 0.1 mF capacitor C5 = 0.1 mF (Size 0603)

to ground followed by a 1 nF capacitor to ground positioned as close to the device C6 = C8 = 1 nF

as possible. C8 provides additional decoupling of the input common-mode voltage. (Size 0603)

C7 High-Pass Filter Capacitor. Used to set high-pass corner frequency of output. C7 = 0.1 mF (Size 0603)

C9 Clock Filter Capacitor. May be required with some printer ports to minimize overshoot. C9 = Open (Size 0603)

The clock waveform may be smoothed using a simple filter network established by

R7 and C9. Some experimentation may be necessary to determine optimum values.

REV. 0

–19–

Page 20

AD8369

APPENDIX

Characterization Equipment

Two sets of automated characterization equipment were used to

obtain the majority of the information contained in this data sheet.

An Agilent N4441A Balanced Measurement System was used to

obtain the gain, phase, group delay, reverse isolation, CMRR,

and s-parameter information. Except for the s-parameter information, T-attenuator pads were used to match the 50 W impedance of

the ports of this instrument to the AD8369.

An Anritsu MS4623B “Scorpion” Vector Network Analyzer was

used to obtain nonlinear measurements IMD

, IP3, and P1dB

3

through matching baluns and attenuator networks.

Definitions of Selected Parameters

Common-mode rejection ratio (TPC 14) has been defined for

this characterization effort as:

Differential Mode forwardgain

Common Mode forwardgain

-

,

-

,

where the numerator is the gain into a differential load at the

output due to a differential source at the input and the denominator is the gain into a common-mode load at the output due to a

common-mode source at the input. In terms of mixed-mode

s-parameters, this equates to:

SDD

SCC2121

Reverse isolation (TPC 17) is defined as SDD12.

More information on mixed-mode s-parameters can be obtained

in the a reference by Bockelman, D.E. and Eisenstadt, W.R.,

Combined Differential and Common-Mode Scattering Parameters:

Theory and Simulation. IEEE Transactions on Microwave Theory

and Techniques, v 43, n 7, 1530 (July 1995).

Composite Waveform Assumption

The nonlinear two-tone measurements made for this data sheet,

i.e., IMD

and IP3, are based on the assumption of a fixed value

3

composite waveform at the output, generally 1 V p-p. The frequencies of interest dictate the use of RF test equipment and

because this equipment is generally not designed to work in

units of volts, but rather watts and dBm, an assumption was

made to simplify equipment setup and operation.

Two sinusoidal tones can be represented as:

Vft

11

Vft

22

2=

sin p

()

2=

sin

p

()

The average voltage of one tone is:

T

11

2

Vdt

=

1

2

T

0

()

Ú

where T is the period of the waveform. The average voltage of the

two-tone composite signal is:

T

1

VVdt

()

Ú

T

0

2

+

12

=

1

So each tone contributes 1/÷2 to the average composite amplitude in terms of voltage. It can be shown that the average

power of this composite waveform is two times greater, or 3dB,

than that of the single tone. This principle can be used to set

correct input amplitudes from generators scaled in dBm and

is correct if the two tones are of equal amplitude and are not

farther than 1 percent apart in frequency.

69.8⍀

69.8⍀

V

S

69.8⍀

10nF0.1F

10nF69.8⍀

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

R

L

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

PORT1 PORT2

PORT3 PORT4

AGILENT N4441A

(ALL PORTS 50⍀)

0.1F

AD8369

RL= 200⍀ DIFFERENTIAL: R1 = 69.8⍀, R2 = 69.8⍀

1nF

CONTROL INTERFACE

= 1000⍀ DIFFERENTIAL: R1 = 475⍀, R2 = 52.3⍀

R

L

910111213141516

OPLO

87654321

Figure 12. Balanced Measurement System Setup

10nF

10nF

R1

R1

R2

R2

REV. 0–20–

Page 21

AD8369

V

S

10nF0.1F

0.1F

1nF

MINI-CIRCUITS

TC4-1W

V

MINI-CIRCUITS

TC4-1W

OPLO

10nF

910111213141516

MINI-CIRCUITS

TC4-1W

87654321

10nF

10nF

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

R

L

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

SOURCE

OUTPUT

AD8369

ANRITSU MS4623B VNA

CONTROL INTERFACE

RECEIVER

INPUT

Figure 13. Vector Network Analyzer Setup (200 W)

S

10nF

INHI

10nF0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

0.1F

AD8369

1nF

10nF

910111213141516

604⍀

237⍀4120⍀

MINI-CIRCUITS

TC4-1W

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

ANRITSU MS4623B VNA

SOURCE

OUTPUT

RECEIVER

OPLO

CONTROL INTERFACE

INPUT

Figure 14. Vector Network Analyzer Setup (1 kW)

87654321

10nF

604⍀

REV. 0

–21–

Page 22

AD8369

–19dB

LPF

–12dB

RF OUT

R & S SMT-03

SIGNAL GENERATOR

MACOM

ETC1-1-13

100nF

100nF

AD8351

V

S

100nF

100nF

191⍀

191⍀

162⍀

162⍀

5.0V

100nF

113⍀

113⍀

100nF

1nF0.1F

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

Figure 15. Harmonic Distortion Setup

AD8369

0.1F

V

S

1nF

OPLO

87654321

100nF

910111213141516

TEK P6248

DIFF

R

L

PROBE

100nF

TEK 1103

PROBE

POWER

SUPPLY

R & S

FSEA30

SPECTRUM

ANALYZER

R & S SMT-03

SIGNAL GENERATOR

RF OUT

–34dBm AT 70MHz

MINI-CIRCUITS

TC4-1W

PICOSECOND

PULSE LABS

PULSE GENERATOR

V

5.0V

S

1nF0.1F

10nF

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

R

L

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

50⍀

AD8369

0.1F

V

S

1nF

OPLO

10nF

910111213141516

87654321

10nF

604⍀

604⍀

AGILENT INFINIUM

DSO

237⍀4120⍀

MINI-CIRCUITS

TC4-1W

Figure 16. Gain Step Response Setup

REV. 0–22–

Page 23

AD8369

AGILENT 8112A

PULSE

GENERATOR

R & S SMT-03

SIGNAL GENERATOR

RF OUT

PULSE IN

MINI-CIRCUITS

TC4-1W

SPLITTER

0⍀

10nF

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

0⍀

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

C2

Figure 17. Pulse Response Setup

AD8369

2F10F

0.1F

V

S

1nF

910111213141516

OPLO

87654321

V

5.0V

S

100nF

100nF

TEK TDS 5104 DSO

1000⍀

TEK P6248

DIFF

PROBE

TEK 1103

PROBE

POWER

SUPPLY

R & S SMT-03

SIGNAL GENERATOR

RF OUT

–20dBm AT 10MHz

MINI-CIRCUITS

TC4-1W

PICOSECOND

PULSE LABS

PULSE GENERATOR

V

5.0V

S

1nF0.1F

10nF

PWUP VPOS SENB FILT CMDC OPHI

COMM

INHI

R

L

INLO DENBCOMM BIT0 BIT1 BIT2 BIT3

10nF

AD8369

50⍀

V

S

0.1F

1nF

910111213141516

OPLO

87654321

10nF

10nF

604⍀

604⍀

AGILENT INFINIUM

DSO

237⍀4120⍀

MINI-CIRCUITS

TC4-1W

Figure 18. Overdrive Response Setup

REV. 0

–23–

Page 24

AD8369

OUTLINE DIMENSIONS

16-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-16)

Dimensions shown in millimeters

5.10

5.00

4.90

0.15

0.05

4.50

4.40

4.30

PIN 1

16

0.65

BSC

COPLANARITY

COMPLIANT TO JEDEC STANDARDS MO-153AB

0.10

0.30

0.19

9

81

1.20

MAX

6.40

BSC

SEATING

PLANE

0.20

0.09

C03029–0–11/02(0)

0.75

8ⴗ

0ⴗ

0.60

0.45

–24–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...