Page 1

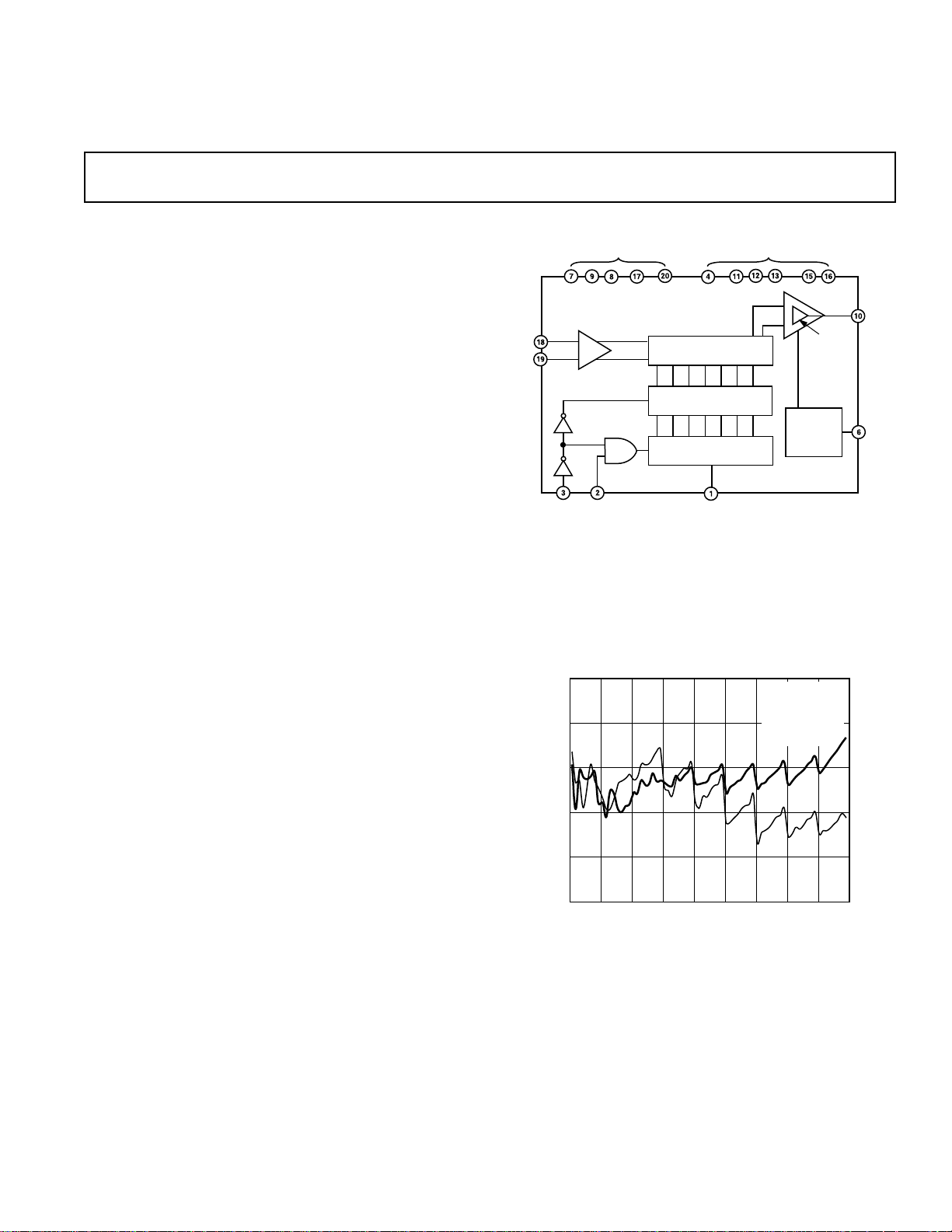

Gain Programmable

GAIN CONTROL – Decimal

DISTORTION – dBc

–90

0 8 16 24 32 40 48 56 64 72

–80

–70

–60

–50

–40

fO = 42MHz

V

IN

= 137mV p-p

(P

IN

= –15dBm)

(P

OUT

= 11dBm @

MAX GAIN)

HD3

HD2

a

FEATURES

Linear in dB Gain Response Over >53 dB Range

Drives Low Distortion >11 dBm Signal into 75 ⍀ Load:

–53 dBc SFDR at 42 MHz

Very Low Output Noise Level

Maintains Constant 75 ⍀ Output Impedance

Power-Up and Power-Down Condition

No Line Transformer Required

Upper Bandwidth: 235 MHz (Min Gain)

9 V Single Supply Operation

Power-Down Functionality

Supports SPI Interface

Low Cost

APPLICATIONS

Gain Programmable Line Driver

HFC High Speed Data Modems

Interactive CATV Set-Top Boxes

CATV Plant Test Equipment

General Purpose IF Variable Gain Block

VIN+

VIN–

CATV Line Driver

FUNCTIONAL BLOCK DIAGRAM

AD8321

INV

DATEN CLK

ATTENUATOR CORE

DATA LATCH

DATA SHIFT REGISTER

DATA SHIFT REGISTER

SDATA

AD8321

GNDVCC

PWR

AMP

REVERSE

AMP

POWER-

DOWN/

SWITCH

INTER

VOUT

PD

DESCRIPTION

The AD8321 is a low cost digitally controlled variable gain

amplifier optimized for coaxial line driving applications such as

cable modems that are designed to the DOCSIS* (upstream)

standard. An 8-bit serial word determines the desired output

gain over a 53.4 dB range, resulting in gain changes of 0.75 dB/

LSB.

The AD8321 comprises a digitally controlled variable attenuator

of 0 dB to –53.4 dB, which is preceded by a low noise, fixed

gain buffer and followed by a low distortion high power amplifier. The AD8321 accepts a differential or single-ended input

signal. The output is specified for driving a 75 Ω load, such as

coaxial cable, although the AD8321 is capable of driving other

loads. Performance of –53 dBc is achieved with an output level

up to 11 dBm at 42 MHz bandwidth using a 9 V supply.

A key performance and cost advantage of the AD8321 results

from the ability to maintain a constant 75 Ω output impedance

during power-up and power-down conditions. This eliminates

the need for external 75 Ω termination, resulting in twice the

effective output voltage when compared to a standard operational amplifier, thus eliminating the need for a transformer.

*Data-Over-Cable Service Interface Specifications

The AD8321 is packaged in a low cost 20-lead SOIC, operates

from a single +9 V supply, and has an operational temperature

range of –40°C to +85°C.

Figure 1. Harmonic Distortion vs. Gain Control

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

(@ VCC = +9 V, TA = +25ⴗC, VIN = 0.137 V p-p, single-ended input, RL = 75 ⍀, RIN =

AD8321–SPECIFICATIONS

75 ⍀ unless otherwise noted)

Parameter Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Specified AC Voltage Output = 11 dBm, Max Gain 0.137 V p-p

Noise Figure Max Gain, f = 10 MHz 15 dB

Input Resistance Single-Ended Input 820 Ω

Differential Input 900 Ω

Input Capacitance 2.0 pF

GAIN CONTROL INTERFACE

Gain Range 52.4 53.4 54.4 dB

Maximum Gain 25.25 26 26.75 dB

Minimum Gain –28.15 –27.4 –26.4 dB

Gain Scaling Factor 0.7526 dB/LSB

OUTPUT CHARACTERISTICS

Bandwidth (–3 dB) All Gain Codes 120 MHz

Bandwidth Roll-Off f = 65 MHz 0.8 dB

Bandwidth Peaking f = 65 MHz 0 dB

Output Offset Voltage All Gain Codes, Full Temperature Range ±30 mV

Output Noise Spectral Density Max Gain, f = 10 MHz 60 nV/√Hz

Min Gain, f = 10 MHz 20 nV/√Hz

Output Noise Temperature Sensitivity 0 ≤ T

≤ +70°C, Min Gain 0.02 nV/√Hz/°C

A

Power-Down Spectral Density 1 nV/√Hz

1 dB Compression Point Max Gain, f = 10 MHz +19.5 dBm

Output Impedance Power-Up and Power-Down 60 75 90 Ω

OVERALL PERFORMANCE

Worst Harmonic Distortion f = 42 MHz, P

f = 65 MHz, P

Distortion Temperature Sensitivity –40°C ≤ T

A

= 11 dBm, VCC = +9 V –53 dBc

OUT

= 11 dBm, VCC = +9 V –51 dBc

OUT

≤ +85°C 0.03 dBc/°C

Gain Accuracy f = 10 MHz, All Gain Codes ±0.2 dB

Gain Temperature Sensitivity 0 ≤ T

≤ +70°C 0.004 dB/°C

A

Output Settling to 1 mV

Gain Change @ T

Input Change Max Gain, V

= 1 Min to Max Gain, VIN = 0 V 60 ns

DATEN

= 0.15 V Step 30 ns

IN

Signal Feedthrough Power Down, 65 MHz, Min Gain –80 dBc

VIN = 0.137 V p-p

POWER CONTROL

Power-Down Settling Time to 1 mV Max Gain, V

Power-Up Settling Time to 1 mV Max Gain, V

Power-Up/Down Pedestal Offset Max Gain, V

= 0 40 ns

IN

= 0 300 ns

IN

= 0 ±30 mV

IN

Power-Up/Down Glitch Max Gain, VIN = 0 40 mV p-p

POWER SUPPLY

Quiescent Current Power-Up, V

= +9 V 82 90 97 mA

CC

Power-Down, VCC = +9 V 45 52 60 mA

Specifications subject to change without notice.

–2–

REV. 0

Page 3

AD8321

LOGIC INPUTS (TTL/CMOS Logic)

(DATEN, CLK, SDATA, VCC = +9 V; Full Temperature Range)

Parameter Min Typ Max Units

Logic “1” Voltage 2.1 5.0 V

Logic “0” Voltage 0 0.8 V

Logic “1” Current (V

Logic “0” Current (V

Logic “1” Current (V

Logic “0” Current (V

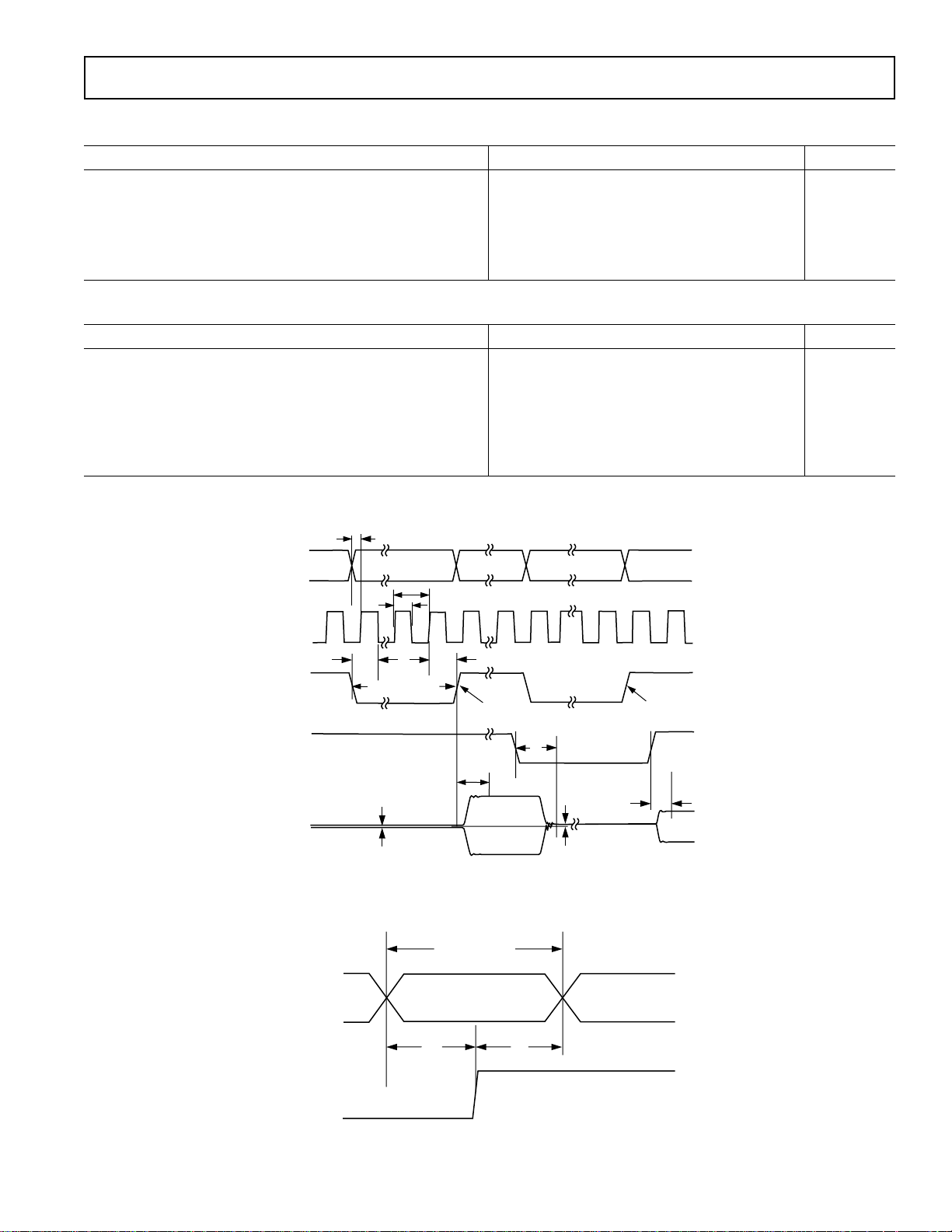

TIMING REQUIREMENTS

= 5 V) CLK, SDATA, DATEN 020nA

INH

= 0 V) CLK, SDATA, DATEN –600 –100 nA

INL

= 5 V) PD 50 190 µA

INH

= 0 V) PD –250 –30 µA

INL

(Full Temperature Range, VCC = +9 V, TR = TF = 4 ns, f

= 8 MHz unless otherwise noted.)

CLK

Parameter Min Typ Max Units

Clock Pulsewidth (T

Clock Period (T

Setup Time SDATA vs. Clock (T

Setup Time DATEN vs. Clock (T

Hold Time SDATA vs. Clock (T

Hold Time DATEN vs. Clock (T

) 16.0 ns

WH

) 32.0 ns

C

) 5.0 ns

DS

) 15.0 ns

ES

) 5.0 ns

DH

) 3.0 ns

EH

Input Rise and Fall Times, SDATA, DATEN, Clock (TR, TF)10ns

T

DS

SDATA

CLK

VALID DATA WORD G1

MSB. . . .LSB

T

C

T

WH

VALID DATA WORD G2

DATEN

PD

ANALOG

OUTPUT

T

ES

8 CLOCK CYCLES

SIGNAL AMPLITUDE (p-p)

Figure 2. Serial Interface Timing

SDATA

MSB

CLK

T

EH

GAIN TRANSFER (G1)

T

GS

VALID DATA BIT

MSB-1 MSB-2

T

DS

T

T

DH

OFF

PEDESTAL

GAIN TRANSFER (G2)

T

ON

Figure 3. SDATA Timing

–3–REV. 0

Page 4

AD8321

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage +V

S

Pins 7, 8, 9, 17, 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . +11 V

Input Voltages

Pins 18, 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.5 V

Pins 1, 2, 3, 6 . . . . . . . . . . . . . . . . . . . . . . –0.8 V to +5.5 V

Internal Power Dissipation

Small Outline (R) . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.90 W

Operating Temperature Range . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, Soldering 60 seconds . . . . . . . . . . +300°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

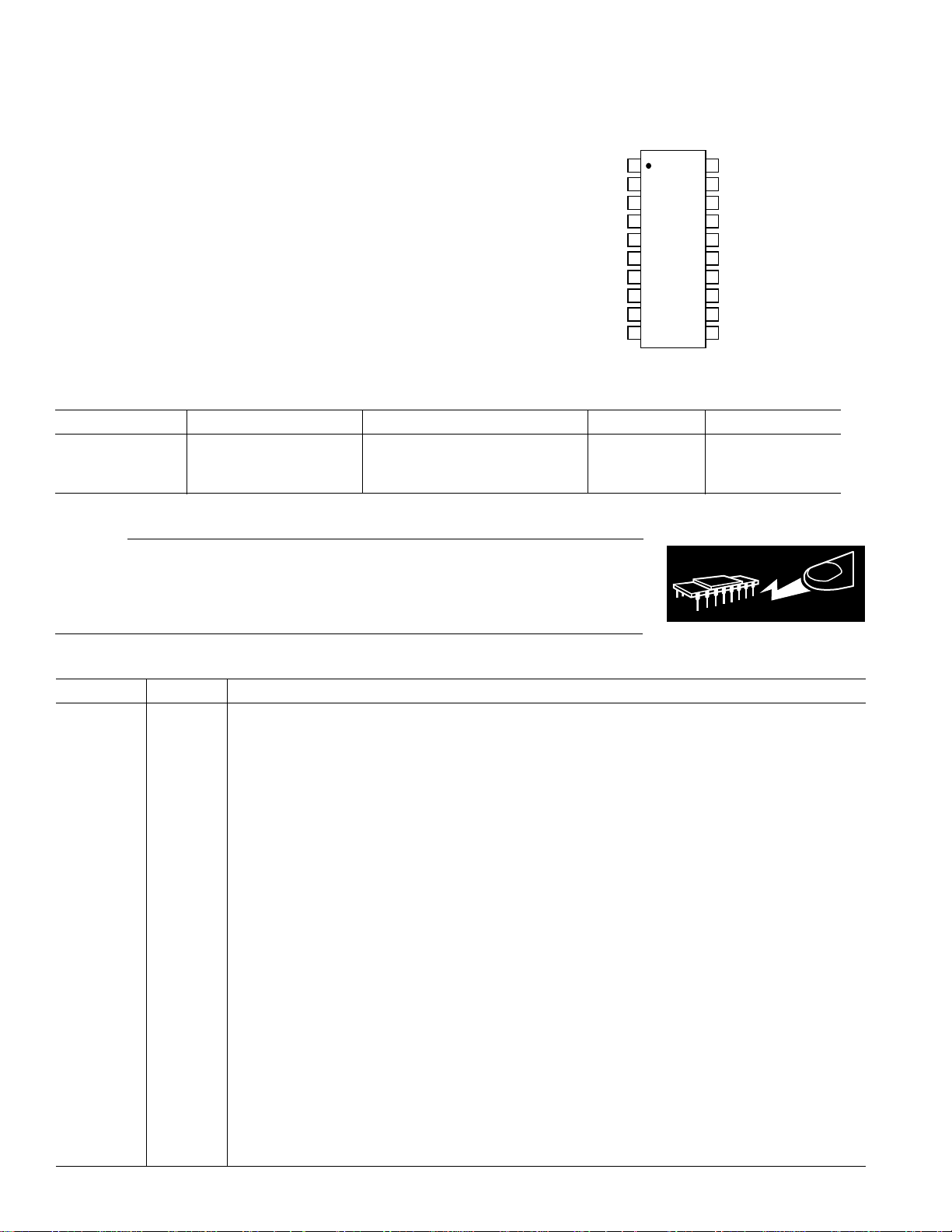

PIN CONFIGURATION

SDATA

CLK

DATEN

GND

BYP1

PD

VCC

VCC

VCC

VOUT

1

2

3

4

5

AD8321

TOP VIEW

6

(Not to Scale)

7

8

9

10

20

VCC

19

VIN–

18

VIN+

17

VCC

16

GND

15

GND

14

BYP2

13

GND

12

GND

11

GND

ORDERING GUIDE

Model Temperature Range Package Description

JA

Package Option

AD8321AR –40°C to +85°C 20-Lead SOIC 58°C/W* R-20

AD8321AR-REEL –40°C to +85°C 20-Lead SOIC 58°C/W* R-20

AD8321-EVAL Evaluation Board

*Thermal Resistance measured on SEMI standard 4-layer board.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

WARNING!

Although the AD8321 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ESD SENSITIVE DEVICE

PIN FUNCTION DESCRIPTIONS

Pin Function Description

1 SDATA Serial Data Input. This digital input allows for an 8-bit serial (gain) word to be loaded into the internal

register with the MSB (most significant bit) first.

2 CLK Clock Input. The clock port controls the serial attenuator data transfer rate to the 8-bit master-slave

register. A Logic 0-to-1 transition latches the data bit and a 1-to-0 transfers the data bit to the slave.

This requires the input serial data word to be valid at or before this clock transition.

3 DATEN Data Enable Low Input. This port controls the 8-bit parallel data latch and shift register. A Logic 0-to-

1 transition transfers the latched data to the attenuator core (updates the gain) and simultaneously

inhibits serial data transfer into the register. A 1-to-0 transition inhibits the data latch (holds the previous gain state) and simultaneously enables the register for serial data load.

4, 11, 12,

13, 15, 16 GND Common External Ground Reference.

5 BYP1 V

/2 Reference Pin. A dc output reference level that is equal to 1/2 of the supply voltage (VCC). This

CC

port should be externally ac-decoupled (0.1 µF capacitor). For external use of this reference voltage,

buffering is required.

6 PD Power-Down Low Logic Input. A Logic 0 powers down (shuts off) the power amplifier disabling the

output signal and enabling the reverse amplifier. A Logic 1 enables the output power amplifier and

disables the reverse amplifier.

7, 8, 9, 17, 20 VCC Common Positive External Supply Voltage.

10 VOUT Output Signal Port. DC-biased to approximately V

CC

/2.

14 BYP2 Internal Bypass. This pin must be externally ac-decoupled (0.1 µF cap).

18 VIN+ Noninverting Input. DC-biased to approximately V

/2. For single-ended inverting operation, use

CC

0.1 µF decoupling capacitor between VIN+ and ground.

19 VIN– Inverting Input. DC-biased to approximately V

/2. Should be ac-coupled with a 0.1 µF capacitor.

CC

–4–

REV. 0

Page 5

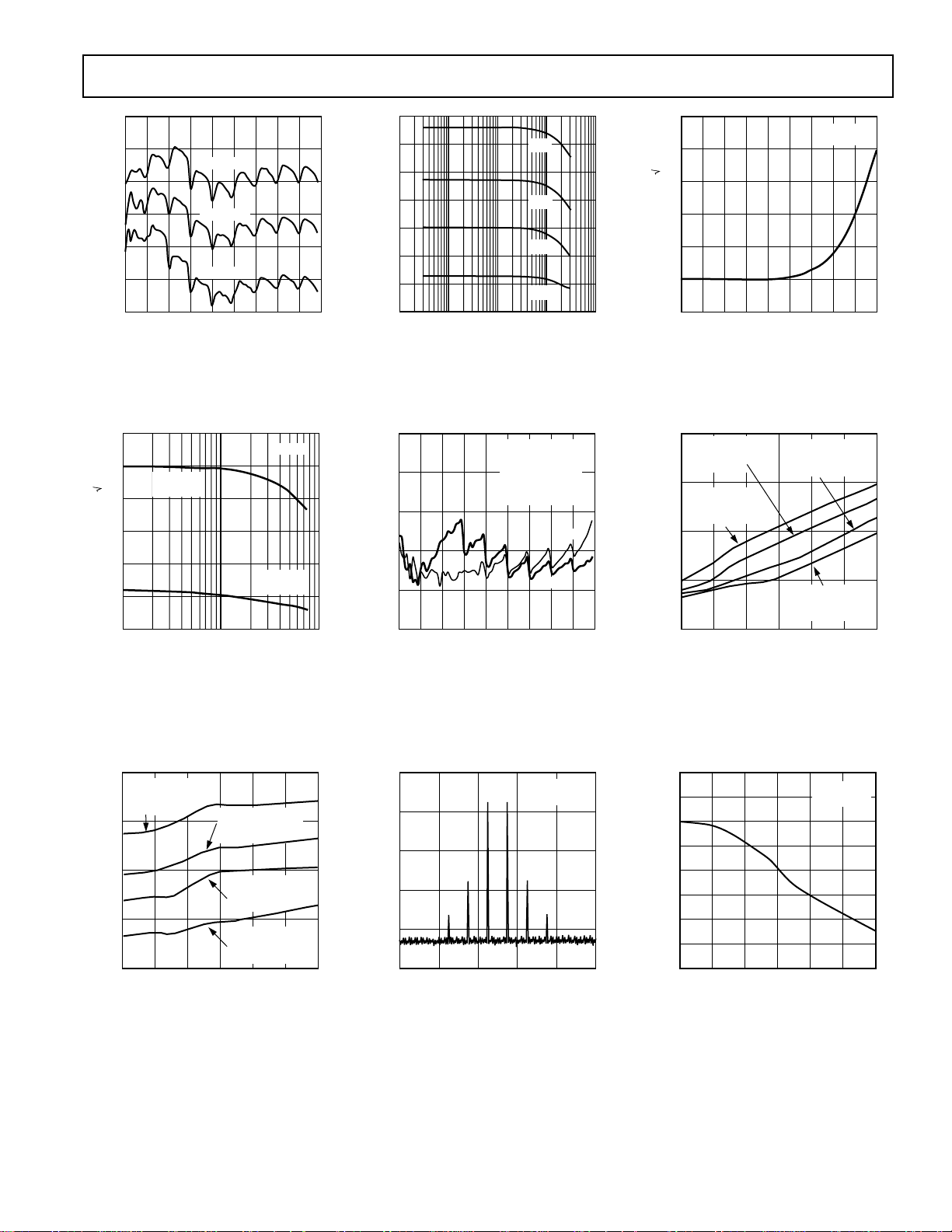

Typical Performance Characteristics–AD8321

FREQUENCY – MHz

3RD ORDER INTERCEPT – dBm

5

22

23

24

25

27

PO = 11dBm

MAX GAIN

26

15 25

35 45

55

28

29

30

65

0.6

0.3

0

–0.3

–0.6

GAIN ERROR – dB

–0.9

–1.2

08

f = 10MHz

f = 42MHz

f = 65MHz

16 24 32 40 48 56 64 72

GAIN CONTROL – Decimal

Figure 4. Gain Error vs. Gain Control

70

PD = 1

60

50

40

30

OUTPUT NOISE – nV/ Hz

20

10

MAX GAIN

(71D)

MIN GAIN

(00D)

1 10 100

FREQUENCY – MHz

Figure 7. Output Referred Noise vs.

Frequency

30

–10

GAIN – dB

–20

–30

–40

20

10

0

0.1

1 10 100

FREQUENCY – MHz

71D

46D

23D

00D

Figure 5. AC Response

–30

–40

–50

–60

DISTORTION – dBc

–70

–80

0816

GAIN CONTROL – Decimal

fO = 65MHz

= 0.137V p-p

V

IN

(P

= –15dBm)

IN

(P

= 11dBm @

OUT

MAX GAIN)

HD2

24 40 48 56 64 72

32

Figure 8. Harmonic Distortion vs.

Gain Control

HD3

1000

70

60

50

40

30

OUTPUT NOISE – nV/ Hz

20

10

08

16 24 32 40 48 56 64 72

GAIN CONTROL – Decimal

f = 10MHz

PD =1

Figure 6. Output Referred Noise vs.

Gain Control

–47

PIN = –14dBm

= 12dBm @

(P

OUT

MAX GAIN)

–50

PIN = –13dBm

= 13dBm @

(P

OUT

MAX GAIN)

–53

DISTORTION – dBc

–56

–59

5 15 25 45 55 65

FUNDAMENTAL FREQUENCY – MHz

PIN = –15dBm

(P

OUT

MAX GAIN)

PIN = –17dBm

(P

OUT

MAX GAIN)

35

= 11dBm @

= 9dBm @

Figure 9. Second Order Harmonic

Distortion vs. Frequency for Various

Input Levels

–47

PIN = –13dBm

(P

MAX GAIN)

–50

–53

DISTORTION – dBc

–56

–59

5 15 25 45 55 65

Figure 10. Third Order Harmonic

Distortion vs. Frequency for Various

Input Levels

REV. 0

= 13dBm @

OUT

FUNDAMENTAL FREQUENCY – MHz

PIN = –14dBm

= 12dBm @

(P

OUT

MAX GAIN)

PIN = –15dBm

= 11dBm @

(P

OUT

MAX GAIN)

PIN = –17dBm

= 9dBm @

(P

OUT

MAX GAIN)

35

20

0

–20

– dBm

OUT

–40

P

–60

–80

41.0

41.4 41.8 42.2 42.6 43.0

FREQUENCY – MHz

PO = 11dBm

MAX GAIN

Figure 11. Two-Tone Intermodulation Distortion

–5–

Figure 12. Third Order Intercept vs.

Frequency

Page 6

AD8321

34

30

26

GAIN – dB

22

18

14

1 10 100

FREQUENCY – MHz

MAX GAIN

= 11dBm

P

O

CL = 10pF

CL = 0pF

CL = 20pF

CL = 50pF

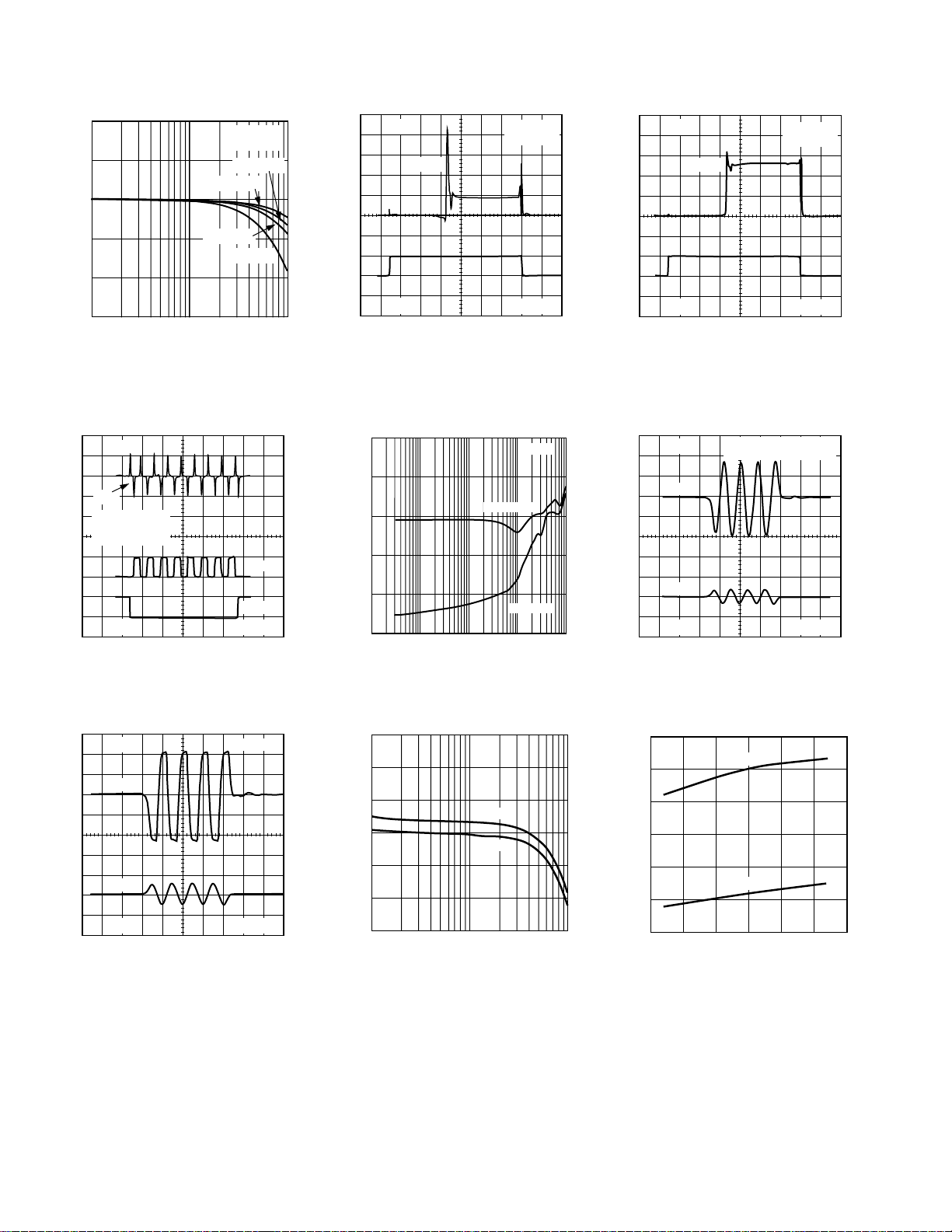

Figure 13. AC Response for Various

Capacitor Loads

7.5mV

V

OUT

VIN = 0V p-p

MAX GAIN

tr(CLK) = 3ns

CLK

DATEN

5V

150ns

Figure 16. Clock Feedthrough

5mV

5V

V

OUT

MIN GAIN

V

= 0V p-p

IN

PD

75ns

Figure 14. Power Up/Power Down

Glitch

0

–20

–40

–60

FEEDTHROUGH – dB

–80

–100

0.1

1 10 100

FREQUENCY – MHz

PD = 0

MAX GAIN

MIN GAIN

1000

Figure 17. Input Signal Feedthrough

vs. Frequency

15mV

5V

V

OUT

MAX GAIN

= 0V p-p

V

IN

PD

75ns

Figure 15. Power Up/Power Down

Glitch

0.75V

V

OUT

V

IN

200mV

MAX GAIN

V

= 0V p-p – 0.137V p-p

IN

30ns

Figure 18. Output Settling Time Due

to Input Change

1.5V

V

V

OUT

IN

0.5V

MAX GAIN

30ns

Figure 19. Overload Recovery

90

85

80

75

70

IMPEDANCE – V

65

60

1 10 100

PD = 0

PD = 1

FREQUENCY – MHz

Figure 20. Output Impedance vs.

Frequency

100

90

80

– mA

70

CC

+I

60

50

40

–50

–25 0 25

PD =1

PD = 0

50 75 100

TEMPERATURE – 8C

Figure 21. Supply Current vs.

Temperature

–6–

REV. 0

Page 7

AD8321

OPERATIONAL DESCRIPTION

The AD8321 is a digitally controlled variable gain power ampli-

fier that is optimized for driving a 75 Ω cable. As a multifunc-

tional bipolar device on a single silicon die, it incorporates all

the analog features necessary to accommodate reverse path

(upstream) high speed (5 MHz to 65 MHz) cable data modem

requirements. The AD8321 has an overall gain range of approximately 53 dB and is capable of greater than 100 MHz

operation at output signal levels exceeding 12 dBm. Overall,

when considering the device’s wide gain range, low distortion,

wide bandwidth and variable load drive, the device can be used

in many variable gain block applications.

GNDVCC

PWR

AMP

REVERSE

AMP

POWER-

DOWN/

SWITCH

INTER

VOUT

PD

VIN+

VIN–

INV

DATEN CLK

AD8321

ATTENUATOR CORE

DATA SHIFT REGISTER

DATA SHIFT REGISTER

DATA LATCH

SDATA

Figure 22. Functional Block Diagram

The digitally programmable gain is controlled by the three-wire

“SPI” compatible inputs. These inputs are called SDATA

(serial data input port), DATEN (data enable low input port)

and CLK (clock input port). See Pin Function Descriptions

and Functional Block diagram. The AD8321 is programmed by

an 8-bit “attenuator” word. When a standard 8-bit word is

used, the first data bit MSB will be shifted out of the 7-bit shift

register during the eighth rising CLK edge. The lower seven

bits will then be loaded into the AD8321’s digital decode section when the DATEN input is taken high.

The gain of the AD8321 is linear in steps of 0.7526 dB. The

gain transfer function starts at –27.43 dB (at decimal code 0)

and increases 0.7526 dB/LSB. The gain increases up to decimal

code 71. At this point the gain is at its maximum level of 26 dB.

If a decimal word between 71 and 127 is entered, the gain is no

longer incremented and stays at 26 dB. Since the MSB of an 8-bit

word is a “don’t care” bit, at decimal code 128, the AD8321’s

gain returns to its minimum value. The gain vs. gain control

relationship repeats itself as shown in Figure 23 for the upper

127 codes.

The gain transfer function is as follows:

= 26 dB – ((71 – CODE) × 0.7526 dB) for CODE ≤ 71

A

V

A

= 26 dB for 71 ≤ CODE ≤ 127

V

= 26 dB + ((199 – CODE) × 0.7526 dB) for 128 ≤

A

V

CODE ≤ 199

A

= 26 dB for 199 ≤ CODE ≤ 255

V

where CODE is the decimal equivalent of the 8-bit word loaded in

the AD8321’s data latch (see Figure 23).

30

20

10

0

GAIN – dB

–10

–20

–30

32 22419216012864 96

0 256

GAIN CODE – Decimal

Figure 23. Linear-In dB Gain vs. Gain Control

The AD8321 is composed of four analog functions in the

power-up or forward mode. The input amplifier (preamp) which

can be used single-endedly or differentially and provides a maximum of 12 dB of attenuation. If the input is used in the differential configuration, it is imperative that the input signals are

180 degrees out of phase and of equal amplitudes. This will

ensure the proper gain accuracy and harmonic performance.

The preamp stage drives a vernier stage that provides the fine

tune gain adjustment. The 0.7526 dB step resolution is implemented in this stage. After the vernier stage, a DAC provides the

bulk of the AD8321’s attenuation (six bits or 36 dB). The signals

in the preamp and vernier gain blocks are differential to improve the PSRR and linearity. A single-ended current is fed

from the DAC into the output stage, which amplifies this cur-

rent to the appropriate level necessary to drive a 75 Ω load. The

output stage utilizes negative feedback to implement a

75 Ω output impedance. This eliminates the need for an external 75 Ω matching resistor needed in typical video (or video

filter) termination requirements.

–7–REV. 0

Page 8

AD8321

The attenuation setting in the AD8321 is determined by the

8-bit word in the data latch. The SDATA load sequence is

initiated by a falling edge on DATEN. The gain control data

(SDATA) is serially loaded (MSB first) into the 7-bit shift register

at each rising edge of the clock. See Figure 24. While DATEN

is low, the data latch holds the previous data word allowing the

attenuation level to remain unchanged. After eight clock cycles

the new data word is fully loaded and DATEN is switched high.

This enables the data latch and the loaded register data is passed to

the attenuator with the updated gain value. Also at this DATEN

transition, the internal clock is disabled, thus inhibiting new

serial input data.

The power amplifier has two basic modes of operation. A forward mode (or power-up mode) and a reverse mode (or powerdown) mode. In the power-up mode (PD = 1), the power

amplifier stage is enabled and the AD8321 has a maximum gain

of 20 V/V or 26 dB (into 75 Ω). With a total attenuation of

53.43 dB in the DAC, vernier and preamp, the AD8321’s total

gain range is 26 dB to –27.43 dB. In both the forward or reverse

mode the single-ended output signal maintains a dc level of

/2. This dc output level provides for optimum large signal

V

CC

linearity.

In the power-down mode (PD = 0), the power amplifier is

turned off and a “reverse” amplifier (the inner triangle in Figure

22) is enabled. During this 1-to-0 transition, the output power

is disabled. This assures that S11 and S22 remain approximately

equal to zero thus minimizing line reflections. In the time domain, as PD switches states, a transitional glitch and pedestal

offset results (See Figures 14 and 15). These anomalies have

been minimized by temperature compensated internal circuitry

and laser trimming. The powered down supply current drops to

52 mA versus 90 mA in the power-up mode.

APPLICATIONS

General Application

The AD8321 is primarily intended for use as the return path

(also called upstream path) Power Amplifier (PA) or line driver

in cable modem applications. Upstream data is modulated in

either QPSK or QAM format. This is done either in DSP or by

a dedicated QPSK/QAM modulator such as the AD9853 or

other modem/modulator chip. The amplifier receives its input

signal either from the dedicated QPSK/QAM modulator or from

a DAC. In both cases, the signal must be low-pass filtered before being applied to the line driving amplifier. Because the

distance to the central office varies from cable modem subscriber to subscriber, resulting in various line losses, signals from

various subscribers will require attenuation while others may

require gain. As a result, the AD8321 line driver is required to

vary its output applying attenuation or gain as needed so that all

signals arriving at the central office are of the same amplitude.

DOCSIS (Data Over Cable Service Interface Specifications)

requires a cable modem output signal ranging in power from a

minimum of 8 dBmV to a maximum of 58 dBmV. In cable

modem applications where DOCSIS compliance is desired, the

AD8321 amplifier must be used in conjunction with a 75 Ω

matching attenuator connected between the AD8321 output

and the low-pass input port of the diplexer. See the schematic in

Figure 28. The matching attenuator is used to achieve DOCSIScompliant noise levels at the lower end of the AD8321 output

power range. The insertion loss of a diplexer is typically less

than 1 dB. As a result of these combined losses, the PA line

driver must be capable of delivering sufficient power into a 75 Ω

load while maintaining reasonable distortion performance at the

output of the modem. (See sections containing “DOCSIS” for

further information. All references to DOCSIS pertain to

SP-RFI-I04-980724 entitled Radio Frequency Interface

Specification.)

SDATA

CLK

DATEN

ANALOG

OUTPUT

VALID DATA WORD G1

T

ES

PD

SIGNAL AMPLITUDE (p-p)

T

DS

MSB. . . .LSB

T

C

8 CLOCK CYCLES

T

WH

T

EH

GAIN TRANSFER (G1)

T

GS

VALID DATA WORD G2

T

OFF

PEDESTAL

Figure 24. Serial Interface Timing

GAIN TRANSFER (G2)

T

ON

–8–

REV. 0

Page 9

AD8321

Basic Connection

Figure 25 shows the basic schematic for operating the AD8321

in single-ended inverting mode. To operate in inverting mode,

connect the input signal through an ac coupling capacitor to

VIN–; VIN+ should be decoupled to ground with a 0.1 µF

capacitor. Because the amplifier operates from a single supply,

and the differential input pins are biased to approximately

/2, the differential inputs must be ac-coupled using 0.1 µF

V

CC

capacitors. For operation in the noninverting mode, the VIN–

pin should be decoupled to ground via a 0.1 µF capacitor, with

the input signal being fed to the AD8321 through the (ac-coupled)

VIN+ pin. Inverting mode should be chosen if the AD8321 is

being used as a drop-in replacement for the AD8320 (the

AD8321 predecessor). Balanced differential inputs to the

AD8321 may also be applied at an amplitude that is one-half

the specified single-ended input amplitude. See the Differential

Inputs section for more on this mode of operation.

Power Supply and Decoupling

The AD8321 should be powered with a good quality (i.e., low

noise) single supply of 9 V. Although the AD8321 circuit will

function at voltages lower than 9 V, optimum performance will

not be achieved at lower supply settings. Careful attention must

be paid to decoupling the power supply pins. A 10 µF capacitor

located in near proximity to the AD8321 is required to provide

good decoupling for lower frequency signals. In addition, and

more importantly, five 0.1 µF decoupling capacitors should be

located close to each of the five power supply pins (7, 8, 9, 17

and 20). A 0.1 µF capacitor must also be connected to the pins

labeled BYP1 and BYP2 (Pins 5 and 14) to provide decoupling

to internal nodes of the device. All six ground pins should be

connected to a common low impedance ground plane.

Input Bias, Impedance and Termination

On the input side, the VIN+ and VIN– have a dc bias level

equal to (V

/2)–0.2 V. The input signal must therefore be ac-

CC

coupled before being applied to either input pin. The input

impedance, when operated in single-ended mode is roughly

820 Ω (900 Ω in differential mode). An external shunt resistance (R1) to ground of 82.5 Ω is required to create a singleended input impedance of close to 75 Ω. If single-ended 50 Ω

termination is required, a 53.6 Ω shunt resistor may be used.

Differential input operation may be achieved by using a shunt

resistor of 41 Ω to ground on each of the inputs, or 82.6 Ω

across the inputs resulting in a differential input impedance of

approximately 75 Ω. Note: to avoid dc loading of either the

VIN+ or VIN– pin, the ac-coupling capacitor must be placed

between the input pin(s) and the shunt resistor(s). Refer to the

Differential Inputs section for more details on this mode of

operation.

Output Bias, Impedance and Termination

On the output side, the VOUT pin is also dc-biased to VCC/2 or

midway between the supply voltage and ground. The output

signal must therefore be ac-coupled before being applied to the

load. The dc-bias voltage is available on the BYP1 and BYP2

pins (Pins 5 and 14 respectively) and can be used in dc-biasing

schemes. These nodes must be decoupled to ground using a

0.1 µF capacitor as shown in Figure 25. If the BYP1 and/or

BYP2 voltages are used externally, they should be buffered.

External back termination resistors are not required when using

the AD8321. The output impedance of the AD8321 is 75 Ω and

is maintained dynamically. This on chip back termination is

maintained regardless of whether the amplifier is in forward

transmit mode or reverse powered down mode. If the output

signal is being evaluated on 50 Ω test equipment such as a spectrum analyzer, a 75 Ω to 50 Ω adapter (commonly called a mini-

mum loss pad) should be used to maintain a properly matched

circuit.

VCC

+9V

INPUT

10mF

82.5V

DATEN

SDATA

C7

C8

C9

C6

0.1mF

0.1mF

VCC VCC

C2

0.1mF

VIN+

C1

0.1mF

VIN–

R1

DATEN

CLK

PD

AD8321

CLK

0.1mF

VCC

ATTENUATOR

DATA LATCH

SDATA

C10

0.1mF

VCC

CORE

DATA SHIFT

REGISTER

0.1mF

C11

VCC

C4

0.1mF

BYP1

C5

0.1mF

POWER-

DOWN/

SWITCH

INTER

GNDGNDGNDGNDGND

BYP2

VOUT

Ce

0.1mF

TO

DIPLEXER

R

= 75V

IN

Figure 25. Basic Connection for Single-Ended Inverting Operation

–9–REV. 0

Page 10

AD8321

Varying the Gain and SPI Programming

The gain of the AD8321 can be varied over a range of 53 dB

from approximately –27 dB to +26 dB, in increments of approximately 0.7526 dB per LSB. Programming the gain of the

AD8321 is accomplished using conventional Serial Peripheral

Interface or SPI protocol. Three digital lines, DATEN, CLK

and SDATA, are used to stream eight bits of data into the serial

shift register of the AD8321. Changing the state of the DATEN

port from Logic 1-to-0 starts the load sequence by activating the

CLK line. No changes in output signal are realized during this

transition. Subsequently, any data applied to SDATA is clocked

into the serial shift register Most Significant Bit (MSB) first and

on the rising edge of each CLK pulse. The AD8321 may be

programmed to deliver maximum gain (+26 dB) at decimal

code 71. As a result, only the last seven bits of a typical 8-bit

SPI word effect the gain resulting in the gain response depicted

in Figure 22. Since the SPI codes from 0 through 71 appear

digitally identical to codes 128 through 199 for all bits except

the MSB, the AD8321 repeats the gain vs. decimal code response twice in the 256 available codes (see Operational Description for gain equations and Figure 23 for Gain Response).

The MSB of a typical SPI word (i.e., the first data bit presented

to the SDATA line after the DATEN transition from logic 1 to

0 and prior to the rising edge of the first clock pulse) is disregarded or ignored. Data enters the serial shift register through

the SDATA port on the rising edge of the next seven CLK

pulses. Returning the DATEN line to Logic 1 latches the content of the shift register into the attenuator core resulting in a

well controlled change in output signal level. The timing diagram for AD8321’s serial interface is shown in Figure 24.

Gain Dependence on Load Impedance

The AD8321 has a dynamic output impedance of 75 Ω. This

dynamic output impedance is trimmed to provide a maximum

gain of +26 dB when loaded with 75 Ω. Operating the AD8321

at load impedances other than 75 Ω will only change the gain of

the AD8321 while the specified gain range of 53 dB is unchanged.

Varying the load impedance will result in 6 dB of additional gain

when R

R

LOAD

approaches infinity. The relationship between

LOAD

and gain is depicted in Figure 26 and is described by the

following equation:

Gain (dB) = [20 log ((2 × R

LOAD

)/(R

+75))]+(26–(0.7526 ×

LOAD

(71-Code)))

35

30

25

20

Between Burst On/Off Transients, Asynchronous PowerDown and DOCSIS

A 42% reduction in consumed power may be achieved asynchronously by applying Logic 0 to PD Pin 6 activating the onchip “reverse amplifier.” The supply current is then reduced to

approximately 52 mA and the modem can no longer transmit in

the upstream direction. The on-chip reverse amplifier is de-

signed to reduce “between burst noise” and maintain a 75 Ω

source impedance to the low pass port of the modem’s diplexer

while minimizing power consumption. Changing the logic level

applied to the PD pin will result in a Burst On/Off Transient at

the output of the AD8321. The transient results from switching

between the forward transmit amplifier and the powered down

(reverse) amplifier. Although the resulting transient meets the

DOCSIS transient amplitude requirements at maximum gain, it

is the lower gain range (i.e., 8 dBmV to 31 dBmV) where the

AD8321 may exceed the 7 mV maximum. The diplexer may

further reduce the glitch amplitude. An external RF switch, such

as Alpha Industries AS128-73 GaAs 2 Watt High Linearity

SPDT RF switch, may be used to further reduce the spurious

emissions, improve the isolation between the cable plant and the

upstream line driver and switch in a 75 Ω back termination

required to maintain proper line termination to the LP port of

the diplexer (see Figure 28).

Noise and DOCSIS

One of the most difficult issues facing designers of DOCSIS

compliant modems is maintaining a quiet output from the PA

during times when no information is being transmitted upstream. In addition, maintaining proper signal-to-noise ratios

serves to ensure the quality of transmitted data. This is extremely

critical when the output signal of the modem is set to the minimum DOCSIS specified output level or 8 dBmV. The AD8321

output noise spectral density at minimum gain (or 8 dBmV) is

20 nV/√Hz measured at 10 MHz. Considering the “Spurious

Emissions in 5 MHz to 42 MHz” of Table 4–8 in DOCSIS, the

calculated noise power in dBmV for 160 K sym/sec is:

20 20 160 3 60 41 5

log / .nV Hz E or dBmV

2

×+

+−

Comparing the computed noise power to the signal at 8 dBmV

yields –49.5 dBc or 3.5 dB higher than the required –53 dBc in

DOCSIS Table 4–8. An attenuator designed to match the

AD8321 75 Ω source to the 75 Ω load may be required. Refer-

ring to the schematic of Figure 28 and the evaluation board

silkscreen of Figure 31, the matching attenuator is comprised of

the three resistors referred to as Rc, Rd and Re. Select the attenuation level from Table I such that noise floor is reduced to

levels specified in DOCSIS.

15

GAIN – dB

10

5

0

0 500

R

LOAD

– V

Figure 26. Maximum Gain vs. R

400300200100

LOAD

Table I.

Rc (⍀) Rd (⍀) Re (⍀) Attenuation (dB)

1304 8.65 1304 –1

654.3 17.42 654.3 –2

432 26.1 432 –3

331.5 35.75 331.5 –4

–10–

REV. 0

Page 11

AD8321

Distortion and DOCSIS

Care must be taken when selecting attenuation levels specified

in Table I as the output signal from the AD8321 must compensate for the losses resulting from any added attenuation as well

as the insertion losses associated with the diplexer. An increase

in input signal becomes apparent at the upper end of the gain

range and will be needed to achieve the 58 dBmV at the modem output. The insertion losses of the diplexer may vary,

depending on the quality of the diplexer and whether the frequency of operation is in near proximity to the cut-off frequency of the low-pass filter. Figures 9 and 10 show the

expected second and third harmonic distortion performance vs.

fundamental frequency at various input power levels. These

graphs indicate the worst harmonic levels exhibited over the

entire output range of the AD8321 (i.e., –27 dB to +26 dB).

Figures 9 and 10 are useful when it is necessary to determine

inband harmonic levels (5 MHz to 42 MHz or 5 MHz to

65 MHz). Harmonics that are higher in frequency, as compared

to the cutoff frequency of the low-pass filter of the diplexer, will

be further suppressed by the stop band attenuation level of the

LP filter in the diplexer. Designers must balance the need to

improve noise performance by adding attenuation with the

resulting need for increased signal amplitude while maintaining

DOCSIS specified distortion performance.

Evaluation Board Features and Operation

The AD8321 evaluation board (p/n AD8321-EVAL) and companion software program written in Microsoft Visual Basic are

available through Analog Devices, Inc. and can be used to

control the AD8321 Variable Gain Upstream Power Amplifier

via the parallel port of a PC. This evaluation package provides a

convenient way to program the gain/attenuation of the AD8321

without the addition of any external glue logic. AD8321-EVAL

has been developed to facilitate the use of the AD8321 in an

application targeted at DOCSIS compliance. A low cost Alpha

Industries AS128-73 GaAs 2 Watt High Linearity SPDT RF

switch (referred to as SWb) is included on the evaluation board

(see Figure 28) along with accommodations for a user specified

75 Ω matching attenuator (See Table I for a table of resistor

values of attenuators ranging from –1 dB to –4 dB). The

AD8321 DATEN, CLK and SDATA digital lines are programmed according to the gain setting and mode of operation

selected using the Windows

®

interface of the control software

(see Figure 30). The serial interface of the AD8321 is addressed through the parallel port of a PC using four or more

bits (plus ground). Two additional bits from the parallel port

are used to control the RF switch(s). This software programs

the AD8321 gain or attenuation, incorporates asynchronous

control of the power-down feature (PD Pin 6) as well as asynchronous control of the Alpha Industries RF switch(es) AS128-

73.* A standard printer cable is used to feed the necessary data

to the AD8321-EVAL board. These features allow the designer

to fully develop and evaluate the upstream signal path beginning at the input to the PA.

Windows is a registered trademark of Microsoft Corporation.

*Alpha Industries @ www.alphaind.com

Overshoot on PC Printer Ports

The data lines on some PC parallel printer ports have excessive

overshoot. Overshoot presented to the CLK pin (TP7 on the

evaluation board) may cause communications problems. The

evaluation board layout was designed to accommodate a series

resistor and shunt capacitor (R6 and C12) if required to filter or

condition the CLK data.

Between Burst Transient Reduction

In order to reduce the amplitude of the “Burst On/Off Transient” glitch at the output of the AD8321, when switching from

forward transmit mode to reverse powered down mode, position

the SWb switch in Figure 28 to position “a” before changing the

logic applied to PD Pin 6 of the AD8321 from Logic 1-to-0

(and also 0-to-1). Use the “Enable Output Switch” feature in

the evaluation board control software (see Figure 31) to select

the appropriate position of the AS128-73 switch. A check in this

box enables the switch to pass upstream data to the output of

the evaluation board. The AS128-73 produces a glitch of approximately 5 mV p-p regardless of the AD8321 gain setting.

The AD8321-EVAL board comes with resistors and capacitors

installed on the logic lines controlling the RF switch (R8, R9,

C16, C17). These values were selected to reduce the glitch

amplitude to DOCSIS acceptable levels and may be modified if

required. The SPDT function of the AS128-73 RF switch accommodates the need to maintain proper termination when the

diplexer is disconnected from the output of the AD8321. The

AD8321-EVAL board accommodates the needed back termination (refer to the Cb and Rb of the evaluation circuit).

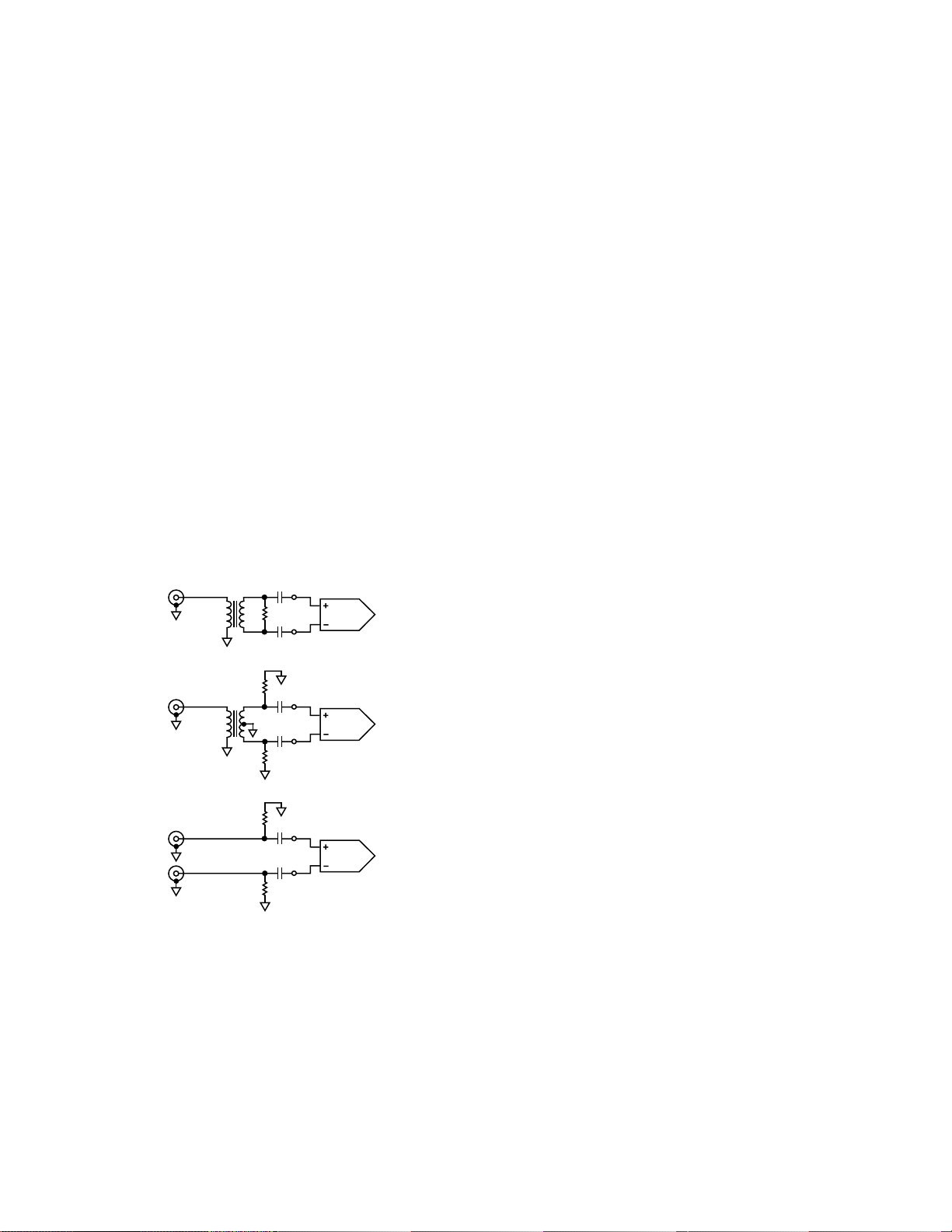

Differential Inputs

When evaluating the AD8321 in differential input mode, termination resistor(s) should be selected and applied such that the

combined resistance of the termination resistor(s) and the input

impedance of the AD8321 results in a match between the signal

source impedance and the input impedance of the AD8321. The

evaluation board is designed to accommodate Mini-Circuits T16T-KK81 1:1 transformer for the purposes of converting a

single-ended (i.e., ground referenced) input signal to differential inputs. The following paragraphs identify three options for

providing differential input signals to the AD8321 evaluation

board. Option 1 uses a transformer to produce a truly differential input signal. The termination resistor(s) specified in Option

1 and 2 may also be used without the transformer if a differential signal source is available. Option 2 uses a transformer andproduces ground referenced input signals that are separated in

phase by 180°. Option 3 relies on differential signals provided

by the user and does not employ a transformer for single-todifferential conversion.

Differential Input Option 1: Install the Mini-Circuits T1-6TKK81 1:1 transformer in the T1 location of the evaluation

board. Jumpers J1, J2 and J3 should be applied pointing in the

direction of the transformer. A differential input termination

resistor of 82.5 Ω can be used in the R3 position. This value

should be used when the single-ended input signal has a source

impedance of 75 Ω. In this configuration, the input signal must

be applied to the VIN+/DIFF IN port of the evaluation board.

An open circuit is required in R1, R2 and J4 positions resulting

in a 75 Ω differential input termination to the AD8321. If a

50 Ω single-ended input source is applied to the VIN+/DIFF IN

port, the R3 value should be 53.6 Ω.

–11–REV. 0

Page 12

AD8321

Differential Input Option 2: Install the Mini-Circuits T1-6TKK81 1:1 transformer in the T1 location of the evaluation

board. Jumpers J1, J2 and J3 should be applied pointing in the

direction of the transformer. Apply an open circuit in the R3

position while J4 is applied connecting the center-tap of the

secondary to ground. A 41 Ω resistor should be used between

each input and ground at R1 and R2. This option will also

result in a 75 Ω differential input termination to the AD8321.

If a 50 Ω single-ended input source is applied to the VIN+/

DIFF IN port, the R1 and R2 values should be 26.7 Ω.

Differential Input Option 3: A differential input may be applied to both VIN– and VIN+ inputs of the evaluation board. In

this example, no transformer is employed. Jumpers J1, J2 and J3

are installed in line with the input signals. Select the differential

input termination configuration of either Option 1 or Option 2.

Apply Option 1 resistor value to R3 for a true differential input

or apply Option 2 values to R1 and R2 to produce ground refer-

enced inputs that are separated in phase by 180°. If the differential input signal source impedance is anything other than 75 Ω

or 50 Ω, calculate the appropriate value according to the equa-

tions below:

For Option 1 Configurations:

Desired Input Impedance = R3储900

For Option 2 and 3 (R1 = R2 = R):

Desired Input Impedance = 2 × (R储450)

DIFF IN

T1

OPTION 1 DIFFERENTIAL INPUT TERMINATION

DIFF IN

T1

OPTION 2 DIFFERENTIAL INPUT TERMINATION

VIN+

VIN–

OPTION 3 DIFFERENTIAL INPUT TERMINATION

R3

R2

R1

R2

R1

AD8321

AD8321

AD8321

Figure 27. Differential Input Termination Options

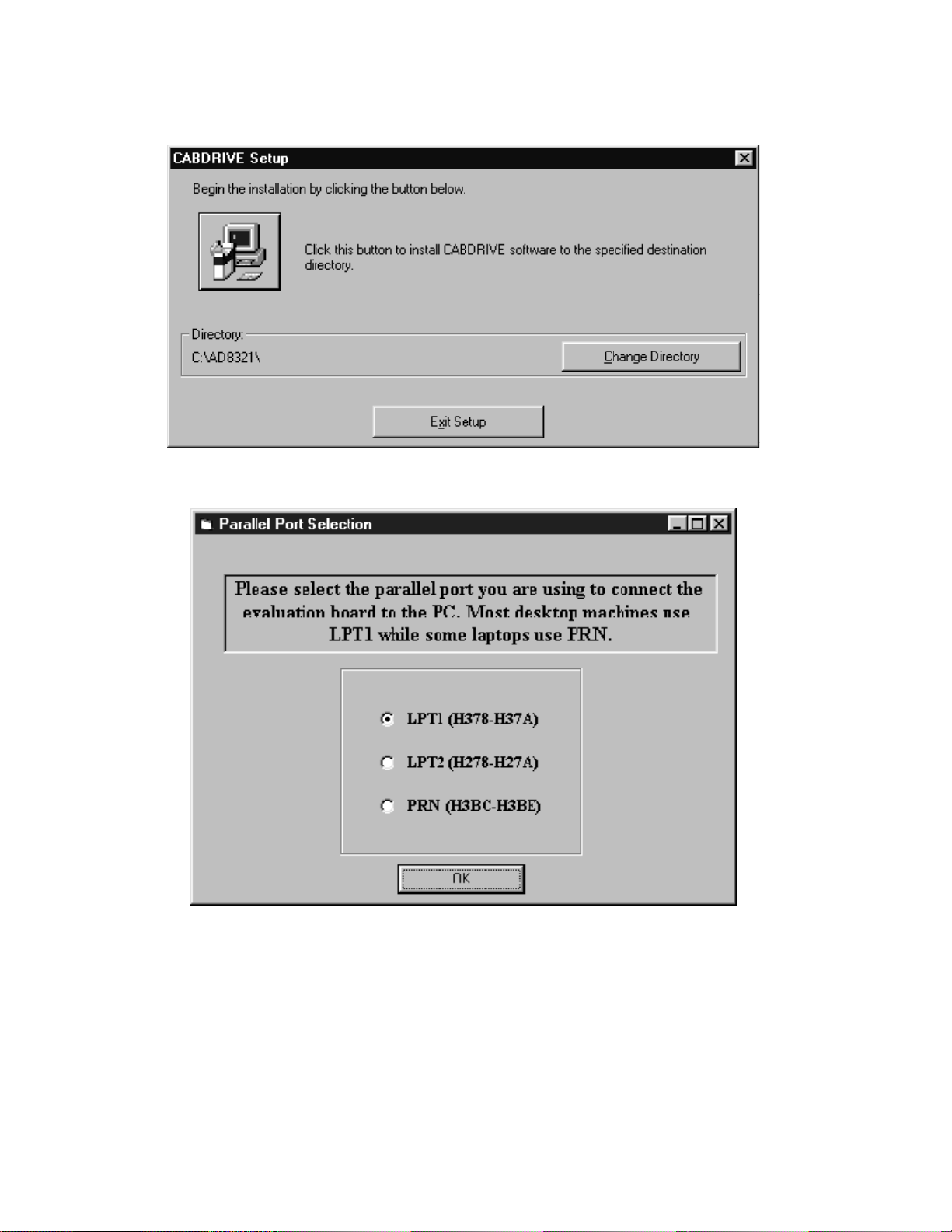

Controlling the Evaluation Board from a PC

The AD8321-EVAL package comes with the circuit described

by Figure 28 and includes a –2 dB attenuator (reference Rc, Rd

and Re) and the control software allowing the user to program

the gain/attenuation of the AD8321 via a standard printer cable

connected to the parallel port of a PC.

Install Software

To install the “CABDRIVE” software that controls the AD8321EVAL evaluation circuit, close all Windows applications and

select the “SETUP” file located on Disk 1 of the AD8321EVAL software. Follow the on screen instructions (see Figure

29) and insert Disk 2 when prompted to do so. Enter the path

of the directory into which the control software will be installed.

Select the button in the upper left corner to begin the installation of “CABDRIVE” software into the specified directory.

Running the Software

To invoke the control software, select the “Ad8321” icon from

the directory containing the installed software. After invoking

the control software, choose the appropriate printer port from

the display portrayed in Figure 30.

Controlling the Gain/Attenuation of AD8321

The AD8321 control panel has four different functions. The

slide bar controls the gain/attenuation of the AD8321. Adjust

the slider to the gain/attenuation displayed in units of dB. The

additional displays show the selection in units of Volts (output)/

Volts (input), and the corresponding control codes in decimal,

binary and hexadecimal. (See Figure 31.)

“POWER UP” and “POWER DOWN”

The buttons marked “Power Up” and “Power Down” select

the mode of operation of the AD8321. The “Power Up” button

puts the AD8321 in forward transmit mode feeding the conditioned signal to the VOUT port on the evaluation board. Conversely, the “Power Down” button selects the reverse mode

where the forward signal transmission is disabled and the low

noise reverse amplifier actively maintains a 75 Ω back termina-

tion. These features may be selected asynchronously (at any

time). (See the section on Between Burst Transient Reduction

for more specific details.)

Enable Output Switch

An Alpha Industries AS128-73 GaAs 2W Hi Linearity switch is

installed on a standard AD8321-EVAL circuit and is controlled

by the check box on the control panel portrayed in Figure 31.

This feature is intended to remove the output of the AD8321

from the VOUT port prior to using the “Power Up” and

“Power Down” feature described above. This application circuit

may be used to reduce any transients created between bursts to

DOCSIS compliant levels. (See the section on Between Burst

Transient Reduction for more specific details.)

–12–

REV. 0

Page 13

VIN–

J3

82.5V

P1–5

P1–6

P1–2

P1–3

P1– 8

P1–7

R1

TP1

10mF

C1

0.1mF

VCC

SDATA

CLK

DATEN

PD

C15

0.1mF

GND

C

X

V1

V2

R8

1kV

R9

1kV

V

CT

VCC

TP6

TP7

TP8

TP9

TP5

TP4

C6

0.1mF

R6

C16

10mF

C16

1000pF

C17

1000pF

TPc

C12

1000pF

Jb

AD8321

1

AD8321

2

3

TPa

Cc

0.1mF

4

5

6

7

8

9

10

C4

C7

C8

C9

C10

20

19

18

17

16

15

14

13

12

11

C11

C5

Rc Re

C2

0.1mF

Cd

TPd

0.1mF

Rd

Cb

0.1mF

NOTE:

BYPASS CAPACITORS

C4, C5, C7, C8, C9, C10, C11 ARE

0.1mF.

AS128-73

SWb

V1

b

V2

Rb

75V

TP12

TPe

TP13

Vct

Rf

10kV

Ce

0.1mF

TO

DIPLEXER

Figure 28. AD8321-EVAL Schematic of Single-Ended Inverting Input, Upstream PA Driver Solution Using AD8321,

Matching Attenuator and Alpha Industries AS128-73 RF Switch

–13–REV. 0

Page 14

AD8321

EVALUATION BOARD FEATURES AND OPERATION

Figure 29. Evaluation Board Software Installation

Figure 30. Evaluation Board Control Software

–14–

REV. 0

Page 15

AD8321

Figure 31. Screen Display of Windows-Based Control Software

–15–REV. 0

Page 16

AD8321

Figure 32. Evaluation Board Silkscreen (Component Side)

–16–

REV. 0

Page 17

AD8321

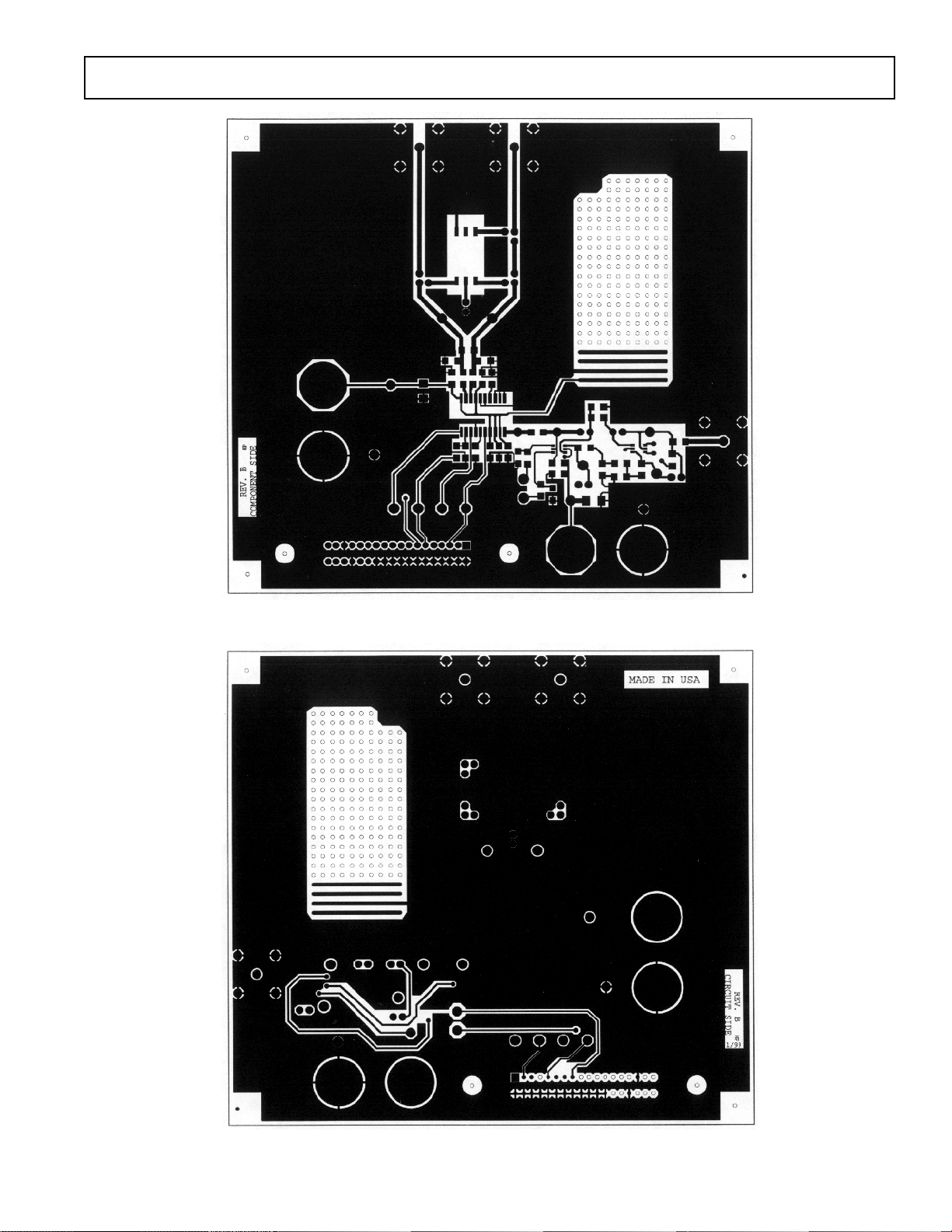

Figure 33. Evaluation Board Layout (Component Side)

Figure 34. Evaluation Board Layout (Solder Side)

–17–REV. 0

Page 18

AD8321

EVALUATION BOARD BILL OF MATERIALS

AD8321 Evaluation Board Rev. B SINGLE- ENDED INVERTING INPUT March 17, 1999

Qty. Description Vendor Ref Desc.

210µF 16 V. 1350 size tantalum chip capacitor ADS# 4-7-6 C6 & C14

14 0.1 µF 50 V. 1206 size ceramic chip capacitor ADS# 4-5-18 C1–C5, C7–C11, Cb–e

3 1,000 pF 50 V. 1206 size ceramic chip capacitor ADS# 4-5-20 C12, C16 & C17

1 82.5 Ω 1% 1/8 W. 1206 size chip resistor D -K # P 82.5 FCT-ND R1

30 Ω 5% 1/8 W. 1206 size chip resistor ADS# 3-18- 88 R2 & R6, Ca

2 1.00 kΩ 1% 1/8 W. 1206 size chip resistor ADS# 3-18-11 R8 & 9

1 75.0 Ω 1% 1/8 W. 1206 size chip resistor ADS# 3-18-145 Rb

2 649 Ω 1% 1/8 W. 1206 size chip resistor D -K # P 649 FCT-ND Rc & Re

1 10.0 kΩ 1% 1/8 W. 1206 size chip resistor ADS# 3-18-119 Rf

1 17.4 Ω 1% 1/8 W. 1206 size chip resistor D -K # P17.4 FCT-ND Rd

1 Alpha # AS 128-73 GaAs Hi Linearity switch Alpha # AS 128-73 SWb

2 Pink Test Point ADS# 12-18-63 TPc & TPd

1 Blue Test Point [Vct] ADS# 12-18-62 TP14

6 Grey Test Point [Bus lines] ADS# 12-18-64 TP6–TP9, TP12 & TP13

2 Yellow Test Point [INPUTS] ADS# 12-18-32 TP1 & TP2

3 Orange Test Point [OUTPUTS] ADS# 12-18-60 TPa, TPb & TPe

1 Red Test Point [DUT VCC] ADS# 12-18-43 TP4

2 Black Test Point [GND] ADS# 12-18-44 TP5 & TP15

2 2 pin .1 inch ctr. shunt Berg # 65474 - 001 ADS# 11-2-38 J3 & Jb

5 2 pin .1 inch ctr. male Header Berg # 69157 - 102 ADS# 11-2-37 J3, Ja, Jb, Jc, Jd

2 75 Ω right-angle BNC Telegartner # J01003A1949 Comp. Mktg. Services INPUTS, OUTPUT

1 Conn. 36 pin Centronics Right Angle ADS# 12-3-50 P1

4 5-way Metal Binding Post ADS# 12-7-7 DUT VCC, GND, Vct

1 AD8321 AR ADS# AD8321AR D.U.T.

1 AD8321 REV. B Evaluation PC board E.M.C. Evaluation PC board

4 #4 - 40 × 1/4 inch ss panhead machine screw ADS# 30-1-1

4 #4 - 40 × 3/4 inch long aluminum round stand-off ADS# 30-16-3

2 # 2 - 56 × 3/8 inch ss panhead machine screw ADS# 30-1-17 (p1 hardware)

2 # 2 steel flat washer ADS# 30-6-6 (p1 hardware)

2 # 2 steel internal tooth lockwasher ADS# 30-5-2 (p1 hardware)

2 # 2 ss hex. machine nut ADS# 30-7-6 (p1 hardware)

Optional Components J1, J2, J4, R3, Ra, SWa, T1, +VIN+

–18–

REV. 0

Page 19

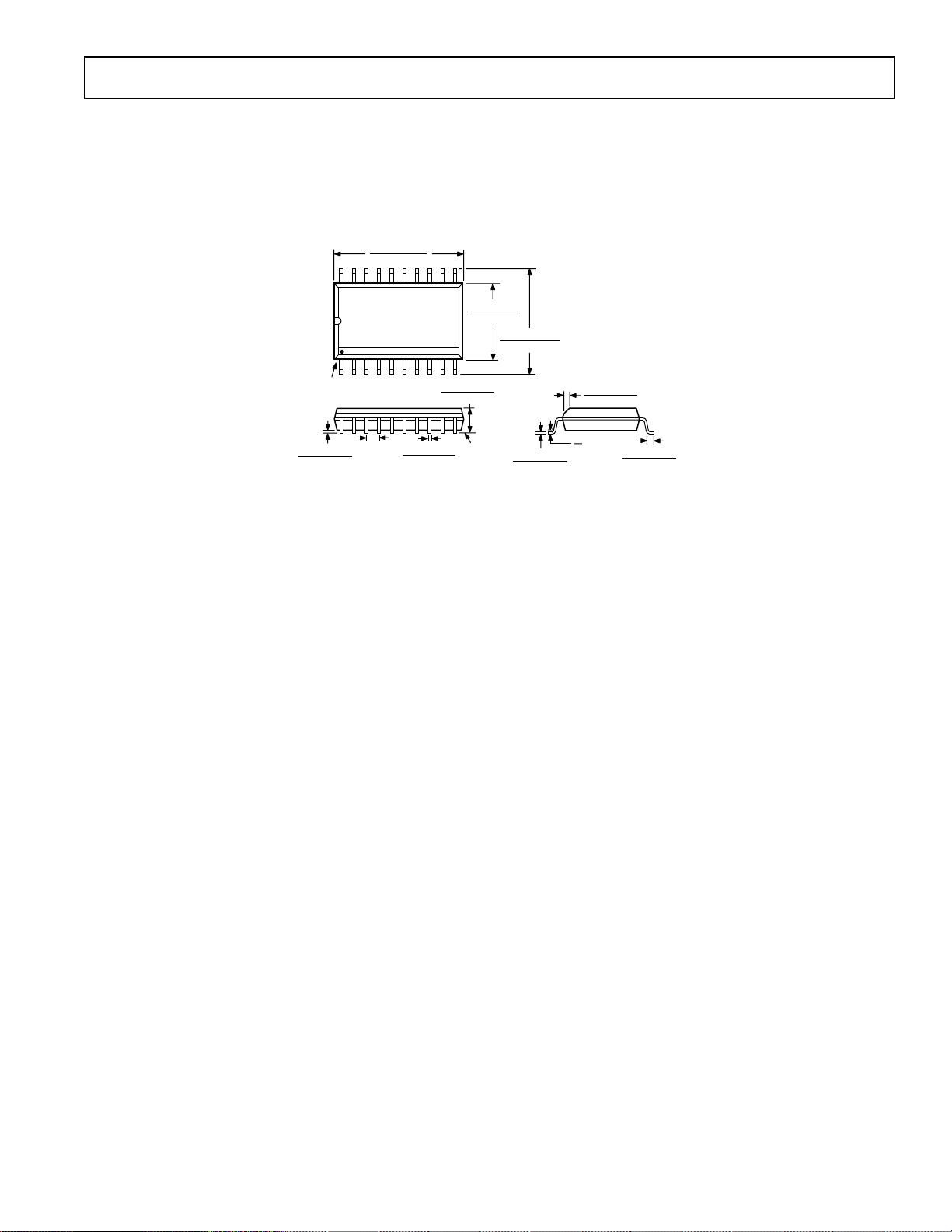

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Small Outline Package

(R-20)

0.5118 (13.00)

0.4961 (12.60)

AD8321

20 11

PIN 1

0.0118 (0.30)

0.0040 (0.10)

0.0500

(1.27)

BSC

0.1043 (2.65)

0.0926 (2.35)

0.0192 (0.49)

0.0138 (0.35)

0.2992 (7.60)

0.2914 (7.40)

101

SEATING

PLANE

0.4193 (10.65)

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.0291 (0.74)

0.0098 (0.25)

88

08

C3557–8–4/99

3 458

0.0500 (1.27)

0.0157 (0.40)

PRINTED IN U.S.A.

–19–REV. 0

Loading...

Loading...