Page 1

Serial Digital Controlled

a

FEATURES

8-Bit Serial Gain Control

V/V/LSB Linear Gain Response

36 dB Gain Range

60.20 dB Gain Accuracy

Upper Bandwidth: 150 MHz

22 dBm 1 dB Compression Point (75 V)

Drives Low Distortion Signals into 75 V Load:

–57 dBc SFDR at 42 MHz and 12 dBm Out

–46 dBc SFDR at 42 MHz and 18 dBm Out

Single Supply Operation from 5 V to 12 V

Maintains 75 V Output Impedance

Power-Up and Power-Down Condition

Supports SPI Input Control Standard

APPLICATIONS

Coaxial Cable Driver

HFC Cable Telephony Systems

HFC High Speed Data Modems

Interactive Set-Top Boxes

PC Plug-In Modems

Interfaces with AD9853 I

High Performance Digitally Controlled Variable Gain

Block

2

C Controlled Digital Modulator

Variable Gain Line Driver

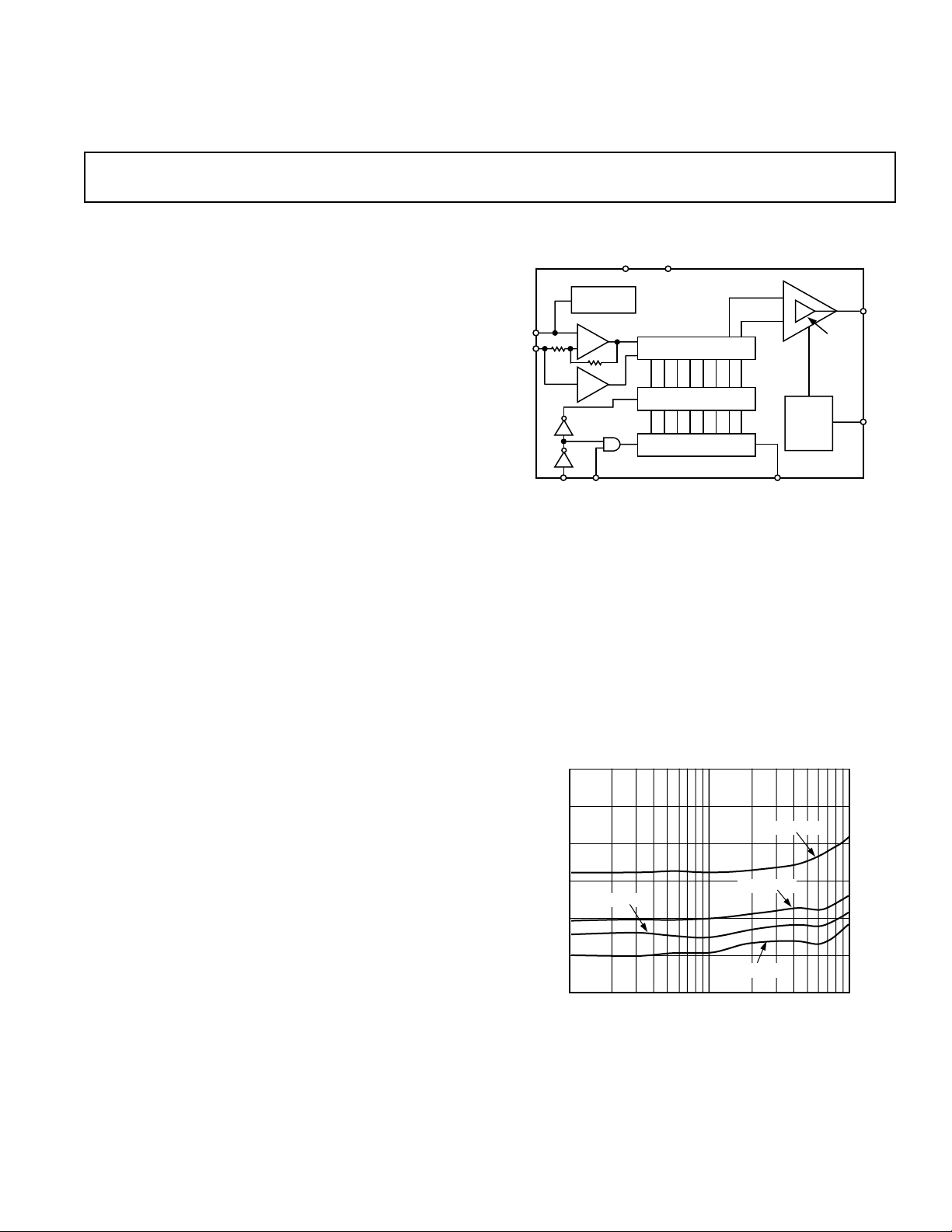

FUNCTIONAL BLOCK DIAGRAM

GNDVCC

REFERENCE

VREF

VIN

INV.

BUF.

DATEN CLK SDATA

AD8320

ATTENUATOR CORE

DATA LATCH

DATA SHIFT REGISTER

AD8320

PWR AMP

REVERSE

AMP

POWER-

DOWN/

SWITCH

INTER.

VOUT

PD

DESCRIPTION

The AD8320 is a digitally controlled variable gain amplifier

optimized for coaxial line driving applications. An 8-bit serial

word determines the desired output gain over a 36 dB range

(256 gain levels). The AD8320 provides linear gain response.

The AD8320 is made up of a digitally controlled variable attenuator of 0 dB to –36 dB, which is preceded by a low noise,

fixed gain buffer and followed by a low distortion high power

amplifier. The AD8320 has a 220 Ω input impedance and accepts a single-ended input signal with a specified analog input

level of up to 0.310 V p-p. The output is specified for driving a

75 Ω load, such as coaxial cable, although the AD8320 is capable of driving other loads. Distortion performance of –57 dBc

is achieved with an output level up to 12 dBm (3.1 V p-p) at

42 M H z, while –46 dBc distortion is achieved with an output

level up to 18 dBm (6.2 V p-p).

A key performance and cost advantage of the AD8320 results

from the ability to maintain a constant 75 Ω output impedance

during power-up and power-down conditions. This eliminates

the need for external 75 Ω back-termination, resulting in twice

the effective output voltage when compared to a standard operational amplifier. Additionally, the on-chip 75Ω termination

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

results in low glitch output during power-down and power-up

transitions, eliminating the need for an external switch.

The AD8320 is packaged in a 20-lead SOIC and operates from

a single +5 V through +12 V supply and has an operational

temperature range of –40°C to +85°C.

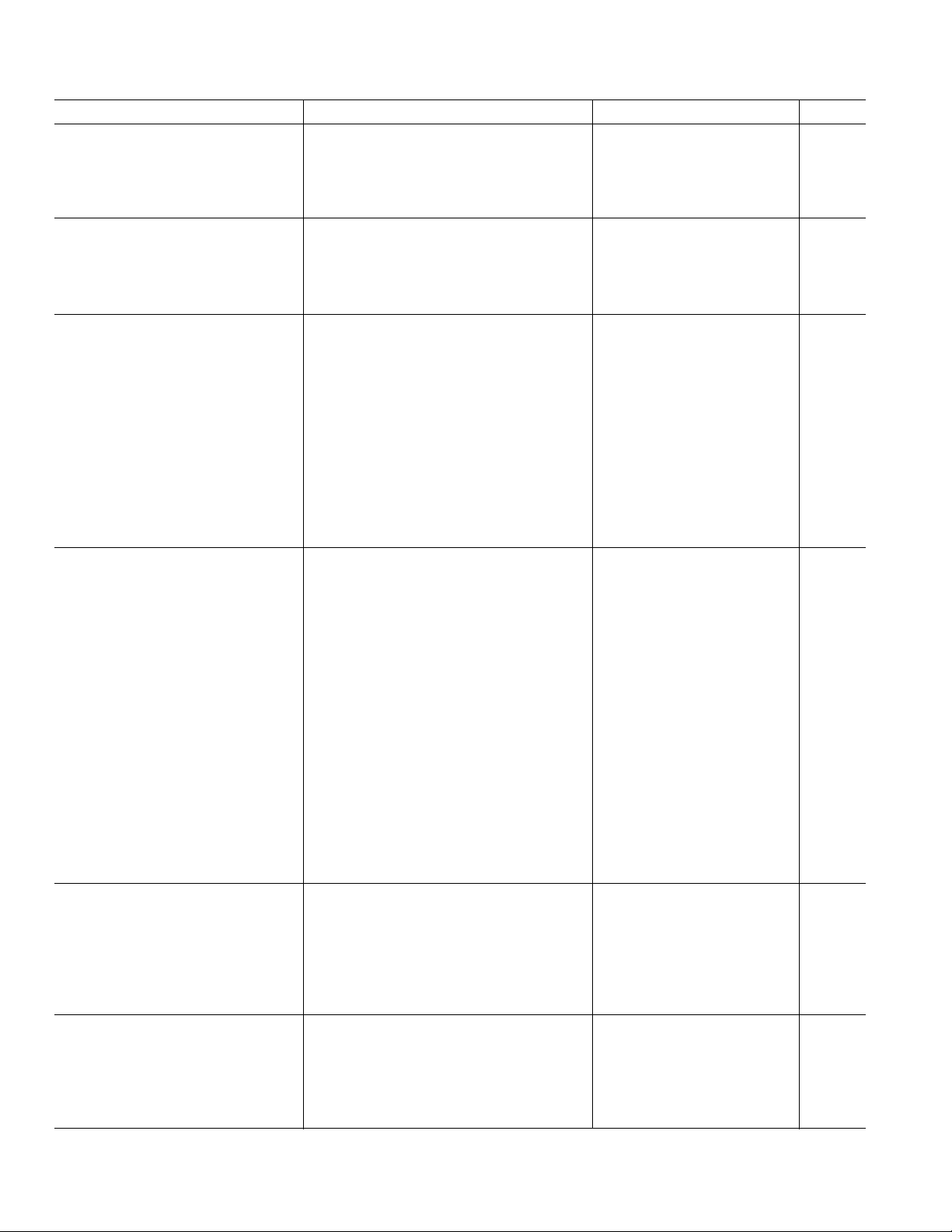

220

230

PO = 18dBm

240

250

PO = 8dBm

260

DISTORTION – dBc

270

280

1

FREQUENCY – MHz

PO = 12dBm

PO = 4dBm

10 100

Figure 1. Worst Harmonic Distortion vs. Frequency for

Various Output Levels at V

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

= 12 V

CC

Page 2

(@ VCC = 12 V, TA = +258C, VIN = 0.310 V p-p, RL = 75 V, RS = 75 V unless

AD8320–SPECIFICA TIONS

otherwise noted)

Parameter Conditions Min Typ Max Units

INPUT CHARACTERISTICS

Full-Scale Input Voltage Max Gain, P

Max Gain, P

= 18 dBm, VCC = 12 V 0.310 V p-p

OUT

= 12 dBm, VCC = 5 V 0.155 V p-p

OUT

Input Resistance 220 Ω

Input Capacitance 2.0 pF

GAIN CONTROL INTERFACE

Gain Range 36 dB

Full Scale (Max) Gain 26 (20) dB (V/V)

Gain Offset (Min) Gain –10.0 (0.316) dB (V/V)

Gain Scaling Factor 0.077 V/V/LSB

OUTPUT CHARACTERISTICS

Bandwidth (–3 dB) All Gain Codes 150 MHz

Bandwidth Roll-Off F = 65 MHz 0.7 dB

Bandwidth Peaking F = 65 MHz 0 dB

Output Offset Voltage All Gain Codes ± 40 mV

Output Offset Drift Full Temperature Range ±0.25 mV/°C

Output Noise Spectral Density Max. Gain, Frequency = 10 MHz 73 nV/√Hz

Min. Gain, Frequency = 10 MHz 53 nV/√ Hz

PD = 0, Frequency = 10 MHz 4.5 nV/√Hz

1 dB Compression Point V

= 12 V 22.5 dBm

CC

V

= 5 V 16 dBm

CC

Output Impedance Power Up and Power Down 65 75 85 Ω

Overload Recovery Max Gain, VIN = 500 mV p-p 40 ns

OVERALL PERFORMANCE

Worst Harmonic Distortion F = 42 MHz, P

F = 42 MHz, P

F = 42 MHz, P

F = 65 MHz, P

F = 65 MHz, P

F = 65 MHz, P

3rd Order Intercept F = 42 MHz, P

F = 42 MHz, P

F = 65 MHz, P

F = 65 MHz, P

= 12 dBm, VCC = 12 V –57.0 –52.0 dBc

OUT

= 12 dBm, VCC = 5 V –43.0 –39.0 dBc

OUT

= 18 dBm, VCC = 12 V –46.0 –42.0 dBc

OUT

= 12 dBm, VCC = 12 V –57.0 –52.0 dBc

OUT

= 12 dBm, VCC = 5 V –42.5 –39.0 dBc

OUT

= 18 dBm, VCC = 12 V –43.0 –40.0 dBc

OUT

= 18 dBm, VCC = 12 V 34 dBm

OUT

= 12 dBm, VCC = 5 V 32 dBm

OUT

= 18 dBm, VCC = 12 V 32.5 dBm

OUT

= 12 dBm, VCC = 5 V 28.5 dBm

OUT

Full-Scale (Max Gain) Accuracy F = 10 MHz ± 0.1 dB

Gain Offset (Min Gain) Accuracy F = 10 MHz ± 0.2 dB

Gain Accuracy F = 10 MHz, All Gain Codes –0.75 ±0.2 0.75 dB

Gain Drift Full Temperature Range ±0.5 mdB/°C

Gain Variation w/Supply V

= +5 V to 12 V 35 mdB/V

CC

Output Settling to 1 mV

Gain Change @ T

= 1 Min to Max Gain, VIN = 0.31 V p-p 30 ns

DATEN

Input Change Max Gain, VIN = 0 V to 0.31 V p-p 25 ns

POWER CONTROL

Power-Down Settling Time to 1 mV Max Gain, V

Power-Up Settling Time to 1 mV Max Gain, V

Power-Down Pedestal Offset Max Gain, V

= 0 45 ns

IN

= 0 65 ns

IN

= 0 ±30 mV

IN

Spectral Output Leakage F (PD) = 400 Hz @ 15% Duty Cycle –70 dBm

5 MHz ≤ F ≤ 65 MHz

Maximum Reverse Power PD = 0 5 dBm

POWER SUPPLY

Specified Operating Range +5 +12 V

Quiescent Current PD = 1, V

Power Down PD = 0, V

Power Up, V

= +12 V PD = 1, VCC = +12 V 97 105 mA

CC

= +5 V 80 85 mA

CC

= +5 V 25 30 mA

CC

Power Down, VCC =+12 V PD = 0, VCC = +12 V 32 37 mA

–2–

REV. 0

Page 3

AD8320

LOGIC INPUTS (TTL/CMOS Logic)

(DATEN, CLK, SDATA, 5 V ≤ VCC ≤ 12 V; Full Temperature Range)

Parameter Min Typ Max Units

Logic “1” Voltage 2.1 5.0 V

Logic “0” Voltage 0 0.8 V

Logic “1” Current (V

Logic “0” Current (V

Logic “1” Current (V

Logic “0” Current (V

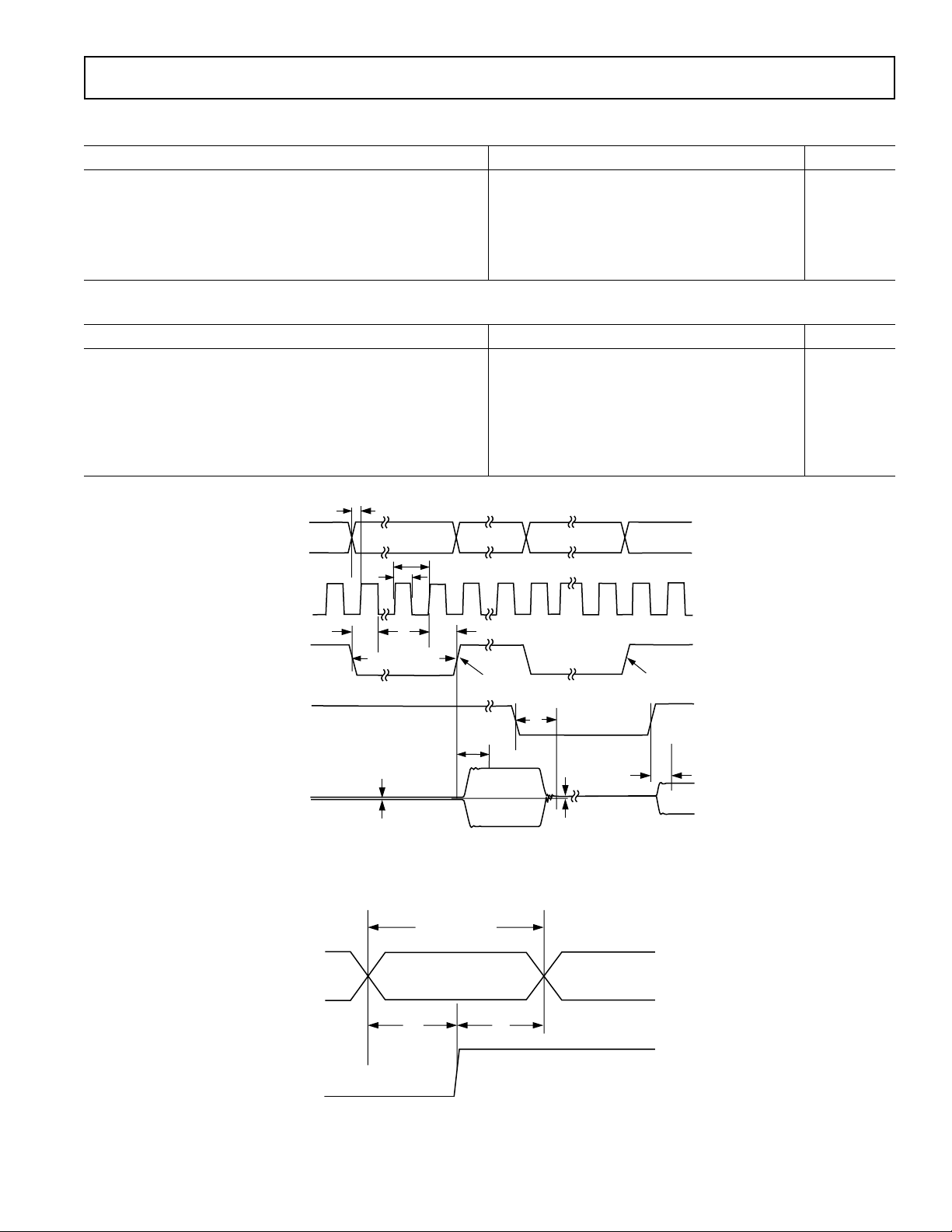

TIMING REQUIREMENTS

= 5 V) CLK, SDATA, DATEN 020nA

INH

= 0 V) CLK, SDATA, DATEN –450 –75 nA

INL

= 5 V) PD 0 190 µA

INH

= 0 V) PD –320 –70 µA

INL

(Full Temperature Range, VCC Supply Range, TR = TF = 4 ns, F

= 8 MHz unless otherwise noted.)

CLK

Parameter Min Typ Max Units

Clock Pulse Width (T

Clock Period (T

C

Setup Time SDATA vs. Clock (T

Setup Time DATEN vs. Clock (T

Hold Time SDATA vs. Clock (T

Hold Time DATEN vs. Clock (T

) 12.0 ns

WH

) 32.0 ns

) 6.5 ns

DS

) 17.0 ns

ES

) 5.0 ns

DH

) 3.0 ns

EH

Input Rise and Fall Times, SDATA, DATEN, Clock (TR, TF)10ns

T

DS

SDATA

CLK

VALID DATA WORD G1

MSB. . . .LSB

T

C

T

WH

VALID DATA WORD G2

DATEN

PD

ANALOG

OUTPUT

T

ES

8 CLOCK CYCLES

SIGNAL AMPLITUDE (p-p)

T

EH

GAIN TRANSFER (G1)

T

Figure 2. Serial Interface Timing

VALID DATA BIT

MSB

T

CLK

MSB-1 MSB-2

DS

GAIN TRANSFER (G2)

T

OFF

GS

T

ON

PEDESTAL

T

DH

Figure 3.

–3–REV. 0

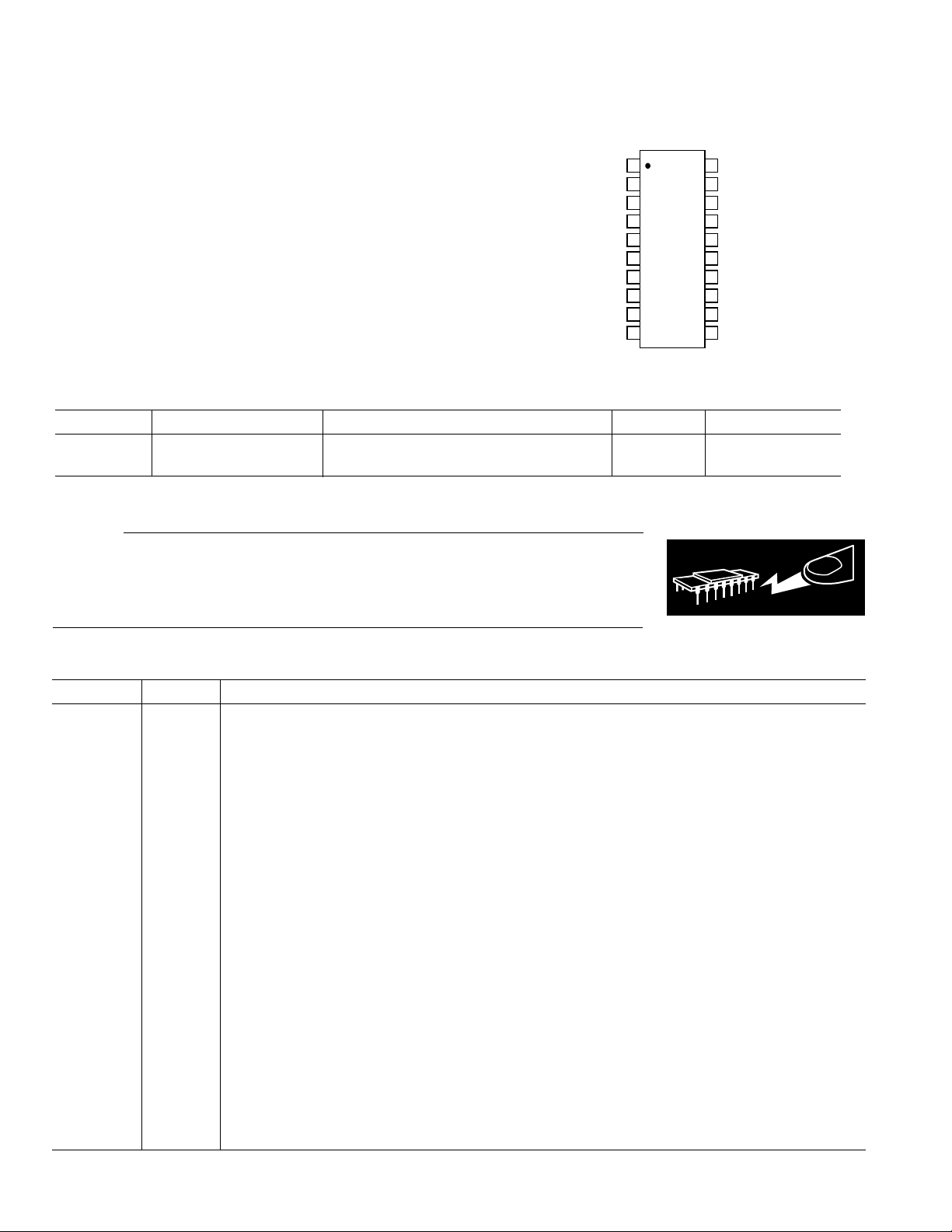

Page 4

AD8320

TOP VIEW

(Not to Scale)

20

19

18

17

16

15

14

13

12

11

1

2

3

4

5

6

7

8

9

10

AD8320

VOUT

VCC

VCC

CLK

DATEN

GND

VCC

PD

VOCM

GND

GND

VIN

VREF

VCC

BYP

GND

GND

SDATA

VCC

GND

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage +V

S

PIN CONFIGURATION

Pins 7, 8, 9, 17, 20 . . . . . . . . . . . . . . . . . . . –0.8 V to +13 V

Input Voltages

Pins 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±3 V

Pins 1, 2, 3, 6 . . . . . . . . . . . . . . . . . . . . . . . . –0.8 V to +5 V

Internal Power Dissipation

Small Outline (RP) . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3 W

Operating Temperature Range . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, Soldering 60 seconds . . . . . . . . . . +300°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Model Temperature Range Package Description u

JA

Package Option

AD8320ARP –40°C to +85°C 20-Lead Thermally Enhanced Power SOIC* 53°C/W RP-20

AD8320-EB Evaluation Board

*Shipped in tubes (38 pieces/tube) and dry packed per J-STD-020.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

WARNING!

Although the AD8320 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ESD SENSITIVE DEVICE

PIN FUNCTION DESCRIPTIONS

Pin Function Description

1 SDATA Serial Data Input. This digital input allows for an 8-bit serial (gain) word to be loaded into the internal

register with the MSB (most significant bit) first.

2 CLK Clock Input. The clock port controls the serial attenuator data transfer rate to the 8-bit master-slave

register. A Logic 0 to 1 transition latches the data bit and a 1 to 0 transfers the data bit to the slave.

This requires the input serial data word to be valid at or before this clock transition.

3 DATEN Data Enable Low Input. This port controls the 8-bit parallel data latch and shift register. A Logic 0 to 1

transition transfers the latched data to the attenuator core (updates the gain) and simultaneously inhibits serial data transfer into the register. A 1 to 0 transition inhibits the data latch (holds the previous

gain state) and simultaneously enables the register for serial data load.

4, 11, 12,

13, 15, 16 GND Common External Ground Reference.

5 VOCM VCC/2 Reference Pin. A dc output reference level that is equal to 1/2 of the supply voltage (VCC).

This port should be externally ac decoupled (0.1µF cap).

6 PD Power-Down Low Logic Input. A Logic 0 powers down (shuts off) the power amplifier disabling the

output signal and enabling the reverse amplifier. A Logic 1 enables the output power amplifier and

disables the reverse amplifier.

7, 8, 9, 17, 20 VCC Common Positive External Supply Voltage.

10 VOUT Output Signal Port. DC biased to approximately VCC/2.

14 BYP Internal Bypass. This pin must be externally ac decoupled (0.1 µF cap).

18 VREF Input Reference Voltage (typically 1.9 V at 27°C). This port should be externally ac decoupled

19 VIN Analog Voltage Input Signal Port. DC biased to VREF voltage.

(0.1 µF cap).

–4–

REV. 0

Page 5

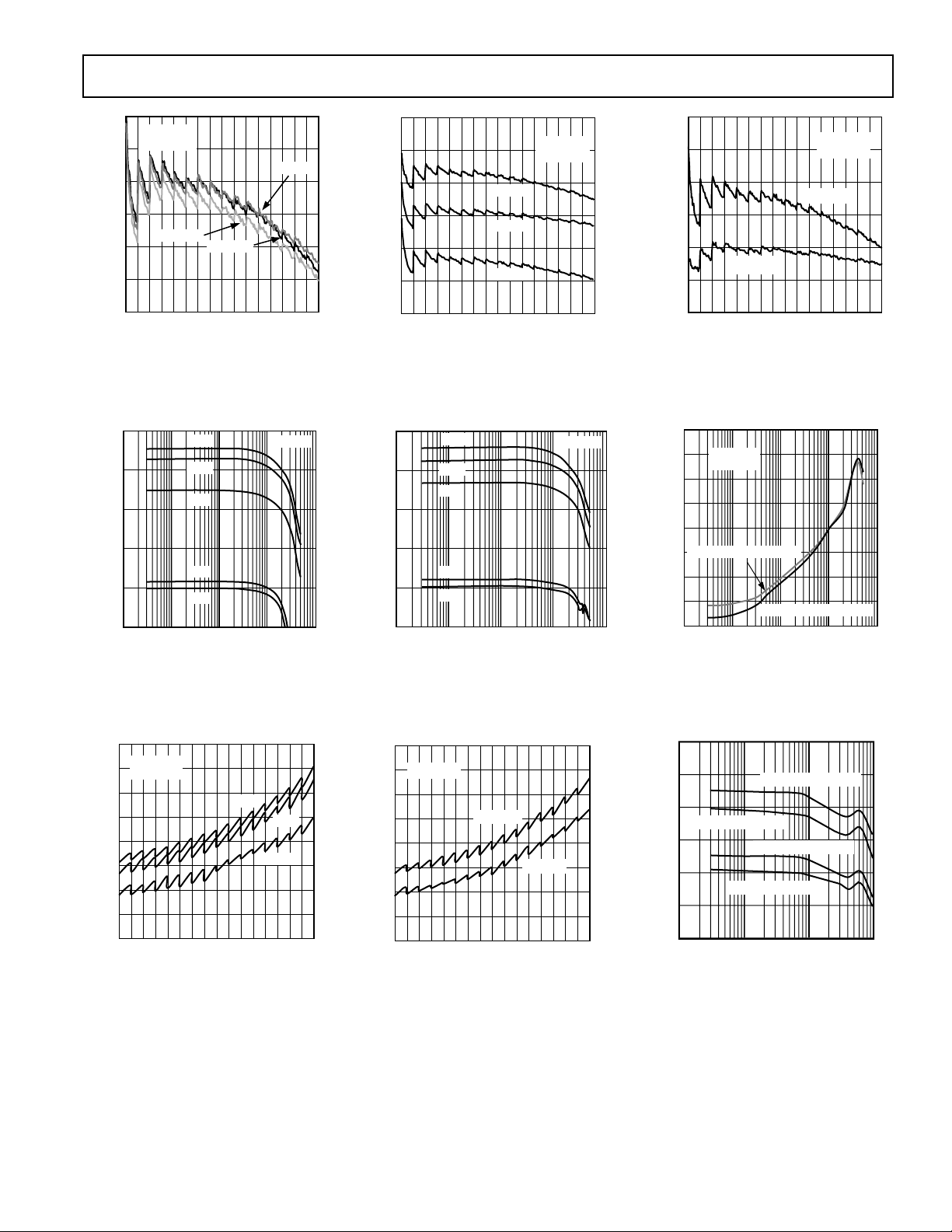

T ypical Performance Characteristics–AD8320

GAIN CONTROL – Decimal

GAIN ERROR – dB

0.45

0

0

20.30

20.15

20.45

64 128 192 256

0.15

F = 10MHz

T = +258C

VCC = 5V

VCC = 12V

0.30

FREQUENCY – Hz

220

100k 1G1M 10M 100M

290

VCC = 12V, PIN = 28dBm

FEEDTHROUGH – dB

VCC = 5V, PIN = 214dBm

MAX GAIN

PD = 0V

230

240

250

260

270

280

2100

0.3

VCC = 12V

F = 10MHz

0.2

0.1

0

20.1

GAIN ERROR – dB

20.2

20.3

T = 2408C

0

GAIN CONTROL – Decimal

T = +858C

64 128 192

T = +258C

256

Figure 4. Gain Error vs. Gain Control

at Various Temperatures

30

20

10

0

GAIN – dB

210

255D

170D

85D

01D

00D

VCC = 5V

0.6

0.3

0

20.3

GAIN ERROR – dB

20.6

20.9

21.2

0

GAIN CONTROL – Decimal

64 128 192 256

VCC = 12V

T = +258C

10MHz

42MHz

65MHz

Figure 5. Gain Error vs. Gain Control

at Various Frequencies

30

20

10

GAIN – dB

0

210

255D

170D

85D

01D

00D

VCC = 12V

Figure 6. Gain Error vs. Gain Control

at Different Supply Voltages

220

100k 1G1M 10M 100M

Figure 7. AC Response

80

F = 10MHz

75

V

CC

70

65

60

55

50

OUTPUT NOISE – nV/!Hz

45

40

064

Figure 10. Output Referred Noise vs.

Gain Control at Various Temperatures

REV. 0

FREQUENCY – Hz

= 12V

+858C

128 192

GAIN CONTROL – Decimal

+258C

2408C

256

220

100k 1G1M 10M 100M

FREQUENCY – Hz

Figure 8. AC Response

80

F = 10MHz

75

70

65

60

55

50

OUTPUT NOISE – nV/!Hz

45

40

064

VCC = 12V

VCC = 5V

GAIN CONTROL – Decimal

128 192

256

Figure 11. Output Referred Noise vs.

Gain Control at Different Supply

Voltages

–5–

Figure 9. Input Signal Feedthrough

vs. Frequency

90

80

70

MAX GAIN, VCC = 5V

60

50

OUTPUT NOISE – nV/!Hz

40

30

100k

MAX GAIN, VCC = 12V

MIN GAIN, VCC = 12V

MIN GAIN, VCC = 5V

1M

FREQUENCY – Hz

10M 100M

Figure 12. Output Referred Noise vs.

Frequency

Page 6

AD8320

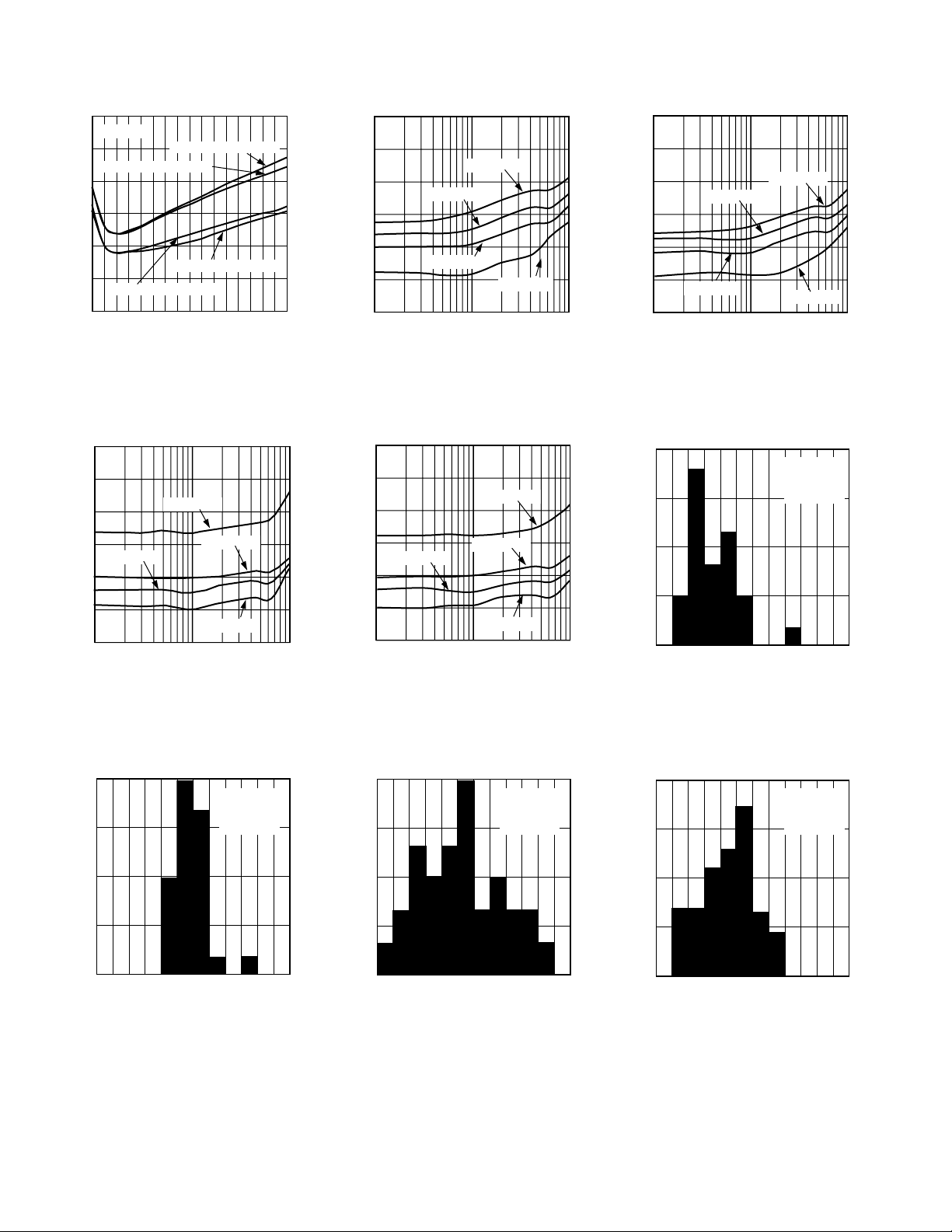

230

VCC = 12V

240

F = 42MHz, PO = 18dBm

250

260

270

DISTORTION – dBc

280

F = 65MHz, PO = 12dBm

290

0 64 128 192 256

F = 65MHz, PO = 18dBm

F = 42MHz, PO = 12dBm

GAIN CONTROL – Decimal

Figure 13. Worst Harmonic Distortion vs. Gain Control

220

230

240

250

PO = 8dBm

260

DISTORTION – dBc

270

280

1 10 100

PO = 18dBm

PO = 12dBm

PO = 4dBm

FREQUENCY – MHz

Figure 16. Worst Harmonic Distortion vs. Frequency for Various Output

Levels at VCC = 10 V

220

230

240

250

260

DISTORTION – dBc

270

280

1 10 100

PO = 12dBm

PO = 10dBm

PO = 8dBm

PO = 4dBm

FREQUENCY – MHz

Figure 14. Worst Harmonic Distortion vs. Frequency for Various Output

Levels at VCC = 5 V

220

230

240

250

PO = 8dBm

260

DISTORTION – dBc

270

280

1

FREQUENCY – MHz

PO = 18dBm

PO = 12dBm

PO = 4dBm

10 100

Figure 17. Worst Harmonic Distortion vs. Frequency for Various Output

Levels at VCC = 12 V

220

230

240

250

260

DISTORTION – dBc

270

280

1 10 100

PO = 10dBm

PO = 8dBm

FREQUENCY – MHz

PO = 12dBm

PO = 4dBm

Figure 15. Worst Harmonic Distortion vs. Frequency for Various Output

Levels at VCC = 6 V

40

30

20

PERCENTAGE

10

0

247

HARMONIC DISTORTION – dBc

246 245 244 243

VCC = 12V

= 18dBm

P

O

F = 42MHz

N = 30

Figure 18. Distribution of Worst Harmonic Distortion

40

30

20

PERCENTAGE

10

0

245

HARMONIC DISTORTION 2 dBc

244 243 242 241

VCC = 12V

P

= 18dBm

O

F = 65MHz

N = 30

Figure 19. Distribution of Worst Harmonic Distortion

20

VCC = 12V

P

= 12dBm

O

15

10

PERCENTAGE

5

0

259

HARMONIC DISTORTION 2 dBc

258 257 256 255

F = 42MHz

N = 30

Figure 20. Distribution of Worst Harmonic Distortion

–6–

30.0

22.5

15.0

PERCENTAGE

7.5

0

244

HARMONIC DISTORTION 2 dBc

243 242 241 240

VCC = 5V

P

= 12dBm

O

F = 65MHz

N = 30

Figure 21. Distribution of Worst Harmonic Distortion

REV. 0

Page 7

AD8320

FREQUENCY – MHz

45

1 10 100

35

30

3RD ORDER INTERCEPT – dBm

40

25

VCC = 12V

PO = 12dBm

20

PO = 18dBm

235

F = 42MHz, VCC = 5V, PO = 12dBm

240

245

250

F = 65MHz

V

= 12V

250

DISTORTION 2 dBc

255

260

265

250 225

F = 42MHz

V

= 12V

CC

= 18dBm

P

O

F = 65MHz, VCC = 12V, PO = 12dBm

075

TEMPERATURE 2 8C

CC

250

= 18dBm

P

O

25 50 100

Figure 22. Harmonic Distortion vs.

Temperature

VCC = 12V

= 310mV p-p

V

IN

MIN GAIN

F = 10MHz

20

PO = 18dBm

MAX GAIN

VCC = 12V

42.041.2 42.4 42.8

–20

– dBm

OUT

P

–40

–60

–80

0

41.6

FREQUENCY – MHz

Figure 23. Two-Tone Intermodulation Distortion

VCC = 12V

= 310mV p-p

V

IN

MAX GAIN

F = 10MHz

Figure 24. Third Order Intercept vs.

Frequency

30

27

24

21

GAIN – dB

CL = 22pF

CL = 100pF

VCC = 5V

MAX GAIN

CL = 0pF

CL = 150pF

FREQUENCY – Hz

20mV

12.5nsec

Figure 25. Transient Response

12.5nsec1.2V

Figure 26. Transient Response

18

15

100k 1G1M 10M 100M

Figure 27. AC Response for Various

Capacitive Loads

30

VCC = 5V

MAX GAIN

F = 1MHz

CL = 0pF

OUTPUT VOLTAGE – Volts

500mV

TIME – Seconds

CL = 22pF

CL = 100pF

CL = 150pF

5nsec

Figure 28. Transient Response for

Various Capacitive Loads

27

24

21

GAIN – dB

18

15

100k 1G1M 10M 100M

CL = 22pF

CL = 100pF

CL = 150pF

FREQUENCY – Hz

Figure 29. AC Response for Various

Capacitive Loads

VCC = 12V

MAX GAIN

CL = 0pF

VCC = 12V

MAX GAIN

F = 1MHz

CL = 0pF

1V

CL = 22pF

CL = 100pF

CL = 150pF

5nsec

Figure 30. Transient Response for

Various Capacitive Loads

–7–REV. 0

Page 8

AD8320

100mV

V

OUT

5V

5V

VCC = 12V

MAX GAIN

V

= 0V p-p

IN

PD

75nsec

Figure 31. Power-Up/Power-Down

Glitch

2.50V

V

OUT

V

IN

5V1V

VCC = 12V

F = 40MHz

MAX GAIN

20nsec

Figure 34. Overload Recovery

5mV

V

OUT

5V

5V

VCC = 12V

MAX GAIN

V

= 0V p-p

IN

CLK

DATEN

250nsec

Figure 32. Clock Feedthrough

2.00V

V

OUT

V

IN

250mV

VCC = 12V, F = 40MHz

MAX GAIN

20nsec

Figure 35. Output Settling Time Due

to Input Change

1.25V

V

OUT

V

IN

5V500mV

VCC = 5V

F = 40MHz

MAX GAIN

20nsec

Figure 33. Overload Recovery

2.50V

V

5V

OUT

DATEN

VCC = 12V, F = 40MHz

MIN TO MAX GAIN

V

= .310V p-p

IN

20nsec

Figure 36. Output Settling Time Due

to Gain Change

80

70

60

50

INPUT IMPEDANCE – V

40

100k 1G1M 10M 100M

FREQUENCY – Hz

VCC = 5V

= 115V

R

T

Figure 37. Input Impedance vs.

Frequency

90

VCC = 5V, PD = 0

80

70

VCC = 12V, PD = 0

60

OUTPUT IMPEDANCE – V

50

100k 1M 10M 100M

VCC = 5V, PD = 1

VCC = 12V, PD = 1

FREQUENCY – Hz

Figure 38. Output Impedance vs.

Frequency

120

0

–50 –25

VCC = 12V, PD = 1

VCC = 5V, PD = 1

VCC = 12V, PD = 0

VCC = 5V, PD = 0

0 25 50 75 100

TEMPERATURE – 8C

100

80

60

40

SUPPLY CURRENT – mA

20

Figure 39. Supply Current vs.

Temperature

–8–

REV. 0

Page 9

–16

GAIN – Code – Decimal

–8

0 25632

GAIN – dB

64 96 128 160 192 224

24

8

0

32

16

AV = 20 3 LOG10 (0.316 + 0.077 3 CODE)

OPERATIONAL DESCRIPTION

The AD8320 is a digitally controlled variable gain power amplifier that is optimized for driving 75 Ω cable. A multifunctional

bipolar device on single silicon, it incorporates all the analog

features necessary to accommodate reverse path (upstream) high

speed (5 MHz to 65 MHz) cable data modem and cable telephony requirements. The AD8320 has an overall gain range of

36 dB (–10 dB to 26 dB) and is capable of greater than 100MHz

of operation at output signal levels exceeding 18 dBm. Overall,

when considering the device’s wide gain range, low distortion,

wide bandwidth and variable load drive, the device can be used

in many variable gain block applications.

The digitally programmable gain is controlled by the three wire

“SPI” compatible inputs. These inputs are called SDATA

(serial data input port), DATEN (data enable low input port)

and CLK (clock input port). See Pin Function Descriptions and

Functional Block diagram. The AD8320 is programmed by an

8-bit “attenuator” word. These eight bits determine the 256

programmable gain settings. See attenuator core description

below. The gain is linear in V/V/LSB and can be described by

the following equation:

A

= 0.316 + 0.077 × Code (RL = 75 Ω)

V

where code is the decimal equivalent of the 8-bit word. For example, if all 8 bits are at a logic “1,” the decimal equivalent is

255 and A

equals 19.95 V/V or 26 dB. The gain scaling factor

V

is 0.077 V/V/LSB, with an offset of 0.316 V/V (–10.0dB). Figure 40 shows the linear gain versus decimal code and Figure 41

shows the gain in dB versus decimal code. Note the nonlinearity that results when viewed in dB versus code. The dB step

size increases as the attenuation increases (i.e., gain decreases)

and reaches a maximum step size of approximately 1.9dB (gain

change between 01 and 00 decimal).

22

20

18

AV = 0.316 + 0.077 3 CODE

16

14

12

10

8

GAIN – V/V

6

4

2

0

–2

0 25632

64 96 128 160 192 224

POWER-UP

POWER-DOWN

GAIN – Code – Decimal

Figure 40. Linear Gain vs. Gain Control

The AD8320 is composed of three analog functions in the powerup or forward mode (Figure 42). The input inverter/buffer

amplifier provides single-ended to differential output conversion. The output signals are nominally 180 degrees out of phase

and equal in amplitude with a differential voltage gain of 2 (6 dB).

Maintaining close to 180 degrees and equal amplitude is required for proper gain accuracy of the attenuator core over the

specified operating frequency. The input buffer/inverter also

provides equal dc voltages to the core inputs via the internal

reference. This is required to ensure proper core linearity over

the full specified power supply range (5 V to 12V).

–9–REV. 0

AD8320

Figure 41. Log Gain vs. Gain Control

The attenuator core can be viewed as eight binarily weighted

(differential in–differential out) transconductance (gm) stages

with the “in phase” current outputs of all eight stages connected

in parallel to their respective differential load resistors (not

shown). The core differential output signals are also 180 degrees

out of phase and equal in amplitude. The input stages are likewise parallel, connected to the inverting input amplifier and

buffer outputs as shown. Nine bits plus of accuracy is achieved

for all gain settings over the specified frequency, supply voltage

and temperature range. The actual total core GM × RL attenuation is determined by which combination of binarily weighted

gm stages are selected by the data latch. With 8 bits, 256 levels

of attenuation can be programmed. This results in a 36dB

attenuation range (0 dB to –36 dB). See gain equation above.

GNDVCC

REFERENCE

VREF

VIN

INV.

BUF.

DATEN CLK SDATA

AD8320

ATTENUATOR CORE

DATA LATCH

DATA SHIFT REGISTER

Figure 42. Functional Block Diagram

To update the AD8320 gain, the following digital load sequence

is required. The attenuation setting is determined by the 8-bit

word in the data latch. This 8-bit word is serially loaded (MSB

first) into the shift register at each rising edge of the clock. See

Figure 43. During this data load time (T), DATEN is low and

the data latch is latched holding the previous (T– 1) data word

keeping the attenuation level unchanged. After eight clock

cycles the new data word is fully loaded and DATEN is

switched high. This enables the data latch (becomes transparent) and the loaded register data is passed to the attenuator with

the updated gain value. Also at this DATEN transition, the

internal clock is disabled, thus inhibiting new serial input data.

PWR AMP

REVERSE

POWER–

DOWN

SWITCH

INTER.

VOUT

AMP

PD

Page 10

AD8320

SDATA

CLK

T

DS

VALID DATA WORD G1

MSB. . . .LSB

T

C

T

WH

VALID DATA WORD G2

DATEN

PD

ANALOG

OUTPUT

T

ES

8 CLOCK CYCLES

SIGNAL AMPLITUDE (p-p)

T

EH

GAIN TRANSFER (G1)

T

GS

Figure 43. Serial Interface Timing

The power amplifier has two basic modes of operation; forward

or power-up mode and reverse or power-down mode. In the

power-up mode (PD = 1), the power amplifier stage is enabled

and the differential output core signal is amplified by 20dB.

With a core attenuation range of 0 dB to –36 dB and 6dB of

input gain, the overall AD8320 gain range is 26 dB to –10dB.

In this mode, the single-ended output signal maintains a dc

level of VCC/2. This dc output level provides for optimum large

signal linearity and allows for dc coupling the output if necessary. The output stage is unique in that it maintains a dynamic

output impedance of 75 Ω. This allows for a direct 75 Ω cable

connection and results in 6 dB of added load power versus using

a series 75 Ω back-termination resistor as required with traditional low output impedance amplifiers. The power amplifier

will also drive lower or higher output loads, although the device’s

gain (not gain range) will change accordingly (see Applications

section).

In the power-down mode (PD = 0), the power amplifier is turned

off and a “reverse” amplifier (the inner triangle in Figure 42) is

enabled. During this 1 to 0 transition, the output power amplifier’s

input stage is also disabled, resulting in no forward output signal

(S21 is 0), although the attenuator core and input amplifier/

buffer signals are not affected (S11 ≈ 0). The function of the

reverse amplifier is to maintain 75 Ω and VCC/2 at the output

port (VOUT) during power-down. This is required to minimize

line reflections (S22 ≈ 0) and ensures proper filter operation for

any forward mode device sharing the same bus (i.e., in a multiplexed configuration). (See Applications section.) In the time

domain, as PD switches states, a transitional glitch and pedestal

offset results. (See Figures 31 and 43.) The powered down

supply current drops to 32 mA versus 97 mA (V

= 12 V) in

CC

power-up mode.

Generally, using the power-down low input (PD) for switching

allows for multiple devices to be multiplexed via splitters (N-1

off, 1 on) and reduces overall total power consumption as required for cable data applications. For cable telephony, the

power-down current generally needs to be much lower during

GAIN TRANSFER (G2)

T

OFF

T

ON

PEDESTAL

what is referred to as sleep and standby modes, and VCC supply

switching via PFETS or equivalent, as described in the applications section, would be required.

APPLICATIONS

The AD8320 is primarily intended to be used as the return path

(also called upstream path) line driver in cable modem and

cable telephony applications. Data to be transmitted is modulated in either QPSK or QAM format. This is done either in

DSP or by a dedicated QPSK/QAM modulator such as the

AD9853.

The amplifier receives its input signal either from the dedicated

QPSK/QAM modulator or from a DAC. In both cases, the

signal must be low-pass filtered before being applied to the line

driving amplifier.

CENTRAL

OFFICE

75V

AD9853

TO MODEM

RECEIVE

CIRCUITRY

7TH ORDER

ELLIPTIC

LOW PASS

FILTER

SUBSCRIBER

DIPLEXER

AD8320

Figure 44. Block Diagram of Cable Modem’s Upstream

Driver Section

The amplifier drives the line through a diplexer. The insertion

loss of a diplexer is typically –3 dB. As a result, the line driver

must deliver a power level roughly 3 dB greater than required by

the applicable cable modem standard so that diplexer losses are

canceled out.

Because the distance to the central office varies from subscriber

to subscriber, signals from different subscribers will be attenuated by differing amounts. As a result, the line driver is required

to vary its gain so that all signals arriving at the central office

have the same amplitude.

–10–

REV. 0

Page 11

AD8320

Basic Connection

Figure 45 shows the basic schematic for operating the AD8320.

Because the amplifier operates from a single supply, the input

signal must be ac-coupled using a 0.1 µF capacitor. The input

pin has a bias level of about 1.9 V. This bias level is available on

the VREF pin (Pin 18) and can be used to externally bias signals

if dc-coupling is desired. Under all conditions, a 0.1 µF decoupling

capacitor must be connected to the VREF pin. If the VREF voltage is to be used externally, it should be buffered first.

The VIN pin of the AD8320 (Pin 19) has an input impedance

of 220 Ω. Typically, in video applications, 75 Ω termination is

favored. As a result, an external shunt resistance (R1) to ground

of 115 Ω is required to create an overall input impedance of

75 Ω. If 50 Ω termination is required, a 64.9Ω shunt resistor

should be used. Note, to avoid dc loading of the VIN pin, the

ac-coupling capacitor should be placed between the input pin

and the shunt resistor as shown in Figure 45.

On the output side, the VOUT pin also has a dc bias level. In

this case the bias level is midway between the supply voltage and

ground. The output signal must therefore be ac-coupled before

being applied to the load. The dc bias voltage is available on the

VOCM pin (Pin 5) and can be used in dc-coupled applications.

This node must be decoupled to ground using a 0.1 µF capaci-

tor. If the VOCM voltage is to be used externally, it should be

buffered.

Since the AD8320 has a dynamic output impedance of 75Ω, no

external back termination resistor is required. If the output

signal is being evaluated on 50 Ω test equipment such as a spectrum analyzer, a 75 Ω to 50 Ω adapter (commonly called a pad)

should be used to maintain a properly matched circuit.

Varying the Gain

The gain of the AD8320 can be varied over a range of 36dB,

from –10 dB to +26 dB, by varying the 8-bit gain setting word.

The timing diagram for AD8320’s serial interface is shown in

Figure 43.

The write cycle to the device is initiated by the falling edge of

DATEN. This is followed by eight clock pulses that clock in the

control word. Because the clock signal is level triggered, data is

effectively clocked on the falling edge of CLK.

After the control word has been clocked in, the DATEN line

goes back high, allowing the gain to be updated (this takes

about 30 ns).

The relationship between gain and control word is given by the

equation:

Gain (V/V) = 0.077 × Code + 0.316

where code is the decimal equivalent of the gain control word

(0 to 255).

The gain in dB is given by the equation:

Gain (dB) = 20 log

(0.077 × Code + 0.316)

10

The digital interface also contains an asynchronous power-down

mode. The normally high PD line can be pulled low at any time.

This turns off the output signal after 45 ns, and reduces the

quiescent current to between 25 mA and 32mA (depending

upon the power supply voltage). In this mode, the programmed

gain is maintained.

Clock Line Feedthrough

Clock feedthrough results in a 5 mV p-p signal appearing superimposed on the output signal (see Figure 32). If this impinges

upon the dynamic range of the application, the clock signal

should be noncontinuous, i.e., should only be turned on for

eight cycles during programming.

Power Supply and Decoupling

The AD8320 should be powered with a good quality (i.e., low

noise) single supply of between +5 V and +12 V. In order to

achieve an output power level of +18 dBm (6.2 V p-p) into

+5V TO +12V

C12

0.1mF

INPUT

R1*

115V

*FOR A 75V INPUT

IMPEDANCE

SDATA

DATEN

CLK

PD

VCC

10mF

C1

0.1mF

C3

C7

0.1mF

VREF

VIN

DATEN

C6

0.1mF

VCC

REFERENCE

C5

CLK

C4

0.1mF

VCC

VCC VCC VCC GND BYP

AD8320

ATTENUATOR CORE

DATA LATCH

DATA SHIFT REGISTER

0.1mF

C2

C11

0.1mF

SDATA GNDGND GND GND GND

0.1mF

POWER-

DOWN

/

SWITCH

INTER.

VOUT

VOCM

PD

C10

0.1mF

TO DIPLEXER

RIN = 75V

C8

0.1mF

Figure 45. Basic Connection

–11–REV. 0

Page 12

AD8320

75 Ω, a supply voltage of at least +10 V is required. To achieve

a signal level of +12 dBm (about 3.1 V p-p) into 75Ω, a minimum supply level of +5 V is required. However, for the lowest

possible distortion, the power supply voltage should be raised as

high as possible. In varying the power supply from +5 V to

+12 V, the quiescent current increases from 80 mA to 97 mA.

Careful attention must be paid to decoupling the power supply

pins. A 10 µF capacitor, located fairly close to the device, is

required to provide good decoupling for lower frequency signals.

In addition, five 0.1 µF decoupling capacitors should be located

close to each of the five power supply pins (7, 8, 9, 17 and 20).

A 0.1 µF capacitor must also be connected to the pin labeled

BYP (Pin 14), to provide decoupling to an internal node of the

device. All six ground pins should be connected to a low impedance ground plane.

Alternative Power-Down Mode

As previously mentioned, the AD8320 can be put into a low

power sleep mode by pulling the PD pin low. If lower power

consumption is required during power-down mode, an alternative

scheme can be used as shown in Figure 46.

VCC+12V

POWER-

DOWN

PD

DATEN

CLK

SDATA

PD

AD8320

14

0.1mF

G

GND

*

S

D

VCC

75V

IRLML5103

VOUT

VOCM

0.01mF

0.1mF

AS103

SEE TEXT)

(

J2

0.1mF

VOUT

J1

VDD

+5V

0.1mF

J3

0.1mF

75V

V1V2

A HEXFET power MOSFET (International Rectifier part number IRLML5103) is used to turn on and off the current to the

supply pins of the AD8320. Under normal operating conditions,

the gate (labeled POWER-DOWN) should be grounded. Pulling the gate to within 2 V of the supply will open the switch and

reduce the current to the amplifier to zero.

In cable modem and cable telephony applications the modem

must always present an output impedance of 75 Ω to the line.

This forces the line driver to always present a 75 Ω impedance

to the diplexer. In this application, a single pole double throw

RF switch (AS103, Alpha Semiconductor) is used to switch in

an external 75 Ω impedance when the AD8320 is turned off.

This resistor then mimics the dynamic output impedance of the

AD8320. TTL or CMOS logic can be used to drive the two

voltages driving the RF switch (V1 and V2).

Before the AD8320 is turned back on again, the gain needs to

be set to a known level. This can be done by holding the PD pin

of the AD8320 low after POWER-DOWN has gone high. While

PD is held low, the 8-bit serial data stream can be clocked into

the AD8320. During this time the quiescent current will increase to 32 mA. However, this time period can be as small as

about 1 µs. In this mode the output settles about 45 ns after the

rising edge of PD.

Alternatively, if DATEN is held low as the AD8320 is powered

on, the device will power up in minimum gain. In this mode, the

output settles after about 200 µs. Note that for both cases, the

capacitor on VOCM has been reduced from 0.1 µF to 0.01 µF

to facilitate a faster turn-on time. All other capacitors in the

circuit should be connected as shown in Figure 45.

V2

V1

*ADDITIONAL PINS AND DECOUPLING CAPACITORS

OMITTED FOR CLARITY

POWER-

DOWN

V1

V2

PD

DATEN

CLK

SDATA

OUTPUT

QUIESCENT

CURRENT

10–12V

0V

3–5V

0V

3–5V

0V

0V

97mA

0mA 32mA

97mA

Figure 46. Alternative Power-Down Mode with Timing

–12–

REV. 0

Page 13

+5V

AD603*

REFIN

AGND

DATA

CLK

ENABLE

PD

11dBmV

DGND

VIN

15V

PD

VDD

AD7801*

CS D0–D7WR LDAC

CLR

D0–D7

CLK

VIN

COMM

8

74HCT164*

AB

1.5V

1kV

100V

GPOS

VPOS

GNEG

+0.5V

VNEG

–5V

FBDK

VOUT

41dBmV

Figure 47. Enhanced Dynamic Range Circuit

Enhanced Dynamic Range Application

The AD8320 can be combined with the AD603 to give additional dynamic range as shown in Figure 47. The AD603 is a

voltage controlled variable gain amplifier. The gain of the AD603 is

determined by the difference in voltage between the GPOS and

GNEG pins. This differential voltage has a range of ± 0.5 V. In

this example, the voltage on GNEG is tied to +0.5 V. As the

voltage on GPOS is varied from 0 V to 1 V, the gain of the AD603

changes from –10 dB to +30 dB with a slope of 25 mV/dB (i.e.,

linear in dB). The gain control voltage is supplied by the AD7801

DAC. The output voltage of the DAC (0 V to +2.5V) is divided

down to fit the 0 V to 1 V range of the AD603 using a resistor

attenuator network.

In order that the same gain control word can be used for both

the AD603 and the AD8320, the serial data stream is converted

to the parallel format of the AD7801 DAC using a serial-toparallel shift register. The rising edge of the enable pulse simultaneously updates both amplifiers.

As the control word is varied from 00Dec to 255Dec, the gain of

the signal chain varies from –26 dB to +50 dB (there is 6 dB of

attenuation between AD603 and AD8320). In practice, this

circuit is not usable at the lower end of the gain range due to the

small input signal (11 dBmV or about 10 mV p-p). Figure 48

shows the spectrum of the output signal at a frequency of

42 MHz and an output level of 61 dBmV (3.1 V p-p, max gain).

The gain vs. code transfer function of the two amplifiers along

with the overall gain is shown in Figure 49. The overall gain

transfer function combines a linear in dB transfer function with

a linear in Volts/Volt transfer function. It is clear from Figure 49

that the overall gain transfer function can be considered to be

approximately linear in dB over the top 50 dB of its range.

AD8320

TO MODEM

RECEIVE

CHANNEL

DIPLEXER

+12V

AD8320*

0.1mF

220V

20pF

75V

220V

*ADDITIONAL PINS AND

DECOUPLING CAPACITORS

OMITTED FOR CLARITY

61dBmV

Figure 48. Output Spectrum of Enhanced Dynamic Range

Circuit (Output Level = 61 dBmV, Frequency = 42 MHz)

60

50

40

30

20

GAIN

–10

–20

–30

10

0

41 61 81 101 121 141

0 16121

GAIN CONTROL WORD – Decimal

AD603

Figure 49. Gain Transfer Function of Enhanced Dynamic

Range Circuit

58dBmV

75V

AD8320/AD603

AD8320

181 201 221 241

–13–REV. 0

Page 14

AD8320

Varying Gain by Varying Load Impedance

As already mentioned, the AD8320 has a dynamic output impedance of 75 Ω. The specified gain range assumes that the

output is terminated with a 75 Ω load impedance. Varying the

load impedance allows the gain to be varied, up to a maximum

of twice the specified gain (for R

= `). The variation in gain

L

with load resistance is shown in Figure 50 for the case of a gain

control word of 255Dec (i.e., max gain).

32

30

28

26

GAIN – dB

24

22

20

0 100

Figure 50. Gain vs. R

R

LOAD

(Gain Control Word = 255Dec)

LOAD

1000 10000

– V

The gain can be described by the following equation:

AV=20log

2R

10

R

LOAD

LOAD

()

+75

0.316 +0.077 ×Code

where Code is the decimal equivalent of the 8-bit word.

Evaluation Board

A two layer evaluation board for the AD8320 is available (part

number AD8320-EB). This board has been carefully laid out

and tested to demonstrate the specified high speed performance

of the device. Figure 51 shows the schematic of the evaluation

board. The silkscreen for the component side layer is shown in

Figure 52. The layout of the board is shown in Figure 53 and

Figure 54.

The evaluation board package includes a fully populated board

with BNC-type connectors along with Windows

®

-based software for controlling the board from a PC’s printer port via a

standard printer cable.

A prototyping area is provided to allow for additional circuitry

on the board. The single supply and ground to the board are

brought over to this area and are available on two strips. There

are also two extra strips available on the prototyping area which

can be used for additional power supplies.

The board should be powered with a good quality (i.e., low

noise) single supply of between +5 V and +12 V. Extensive

decoupling is provided on the board. A 10 µF capacitor, located

fairly close to the device, provides good decoupling for lower

frequency signals. In addition, and more importantly, five

0.1 µF decoupling capacitors are located close to each of the

five power supply pins (7, 8, 9, 17 and 20).

Controlling the Evaluation Board from a PC

The evaluation board ships with Windows-based control software. A standard printer cable can be used to connect the

evaluation board to a PC’s printer port (also called parallel

port). The cable length should be kept to less than about 5 feet.

The wiring of a standard printer cable, with respect to the signal lines that are used in this application, is shown in Figure 55.

Although the software controls the evaluation board via the

PC’s parallel port, the AD8320 digital interface is serial. Three

of the parallel port’s eight bits (and one digital ground line) are

used to implement this serial interface. A fourth bit is used to

control the PD pin.

VCC

VREF

INPUT

TP2

115V

C7

10mF

C12

0.1mF

TP1

C1

0.1mF

R1

0.1mF

VREF

VIN

C9

OPTIONAL

C6

0.1mF

VCC

REFERENCE

CLK

Figure 51. Evaluation Board Schematic

All trademarks are the property of their respective holders.

C5

C4

0.1mF

VCC VCC VCC VCC GND BYP

0.1mF

C2

C11

0.1mF

AD8320

ATTENUATOR CORE

DATA LATCH

DATA SHIFT REGISTER

SDATA

R4

0

562 16, 19-30, 33

36-PIN CENTRONICS CONNECTOR

GND GNDGND GND GND

DATEN

3

–14–

C3

0.1mF

POWER-

DOWN

/

SWITCH

INTER

VOUT

VOCM

PD

C10

0.1mF

TP4

TP3

C8

0.1mF

OUTPUT

VOCM

REV. 0

Page 15

AD8320

The control software requires Windows 3.1 or later to operate.

To install the software, insert the disk labeled “Disk # 1 of 2” in

the PC and run the file called SETUP.EXE. Additional installation instructions will be given on-screen. Before beginning installation, it i s important to close any other Windows applications

that are running.

When you launch the installed control software from Windows,

you will be asked to select the printer port you are using. Most

modern PCs have only one printer port, usually called LPT1.

However, some laptop computers use the PRN port.

Figure 56 shows the main screen of the control software. Using

the slider, you can set any gain in the AD8320’s 36 dB range.

The gain is displayed on-screen in dB and V/V. The 8-bit gain

setting byte is also displayed, in binary, hexadecimal and decimal.

Each time the slider is moved, the software automatically sends

and latches the required 8-bit data stream to the AD8320. You

can power down or reset the device simply by clicking the

appropriate buttons. The software also offers one volatile storage location that can be used to store a particular gain. This

functions in the same way as the memory on a pocket calculator.

Overshoot on PC Printer Ports’ Data Lines

The data lines on some printer ports have excessive overshoot.

Overshoot on the pin used as the serial clock (Pin 6 on the DSub-25 connector) can cause communication problems. This

overshoot can be eliminated by applying mild filtering to the

CLK line on the evaluation board. This can be done by putting

a small series resistor on the CLK line, combined with a

capacitor to ground. Pads are provided (C9, R4) on the component side of the evaluation board to allow easy insertion of

these devices. Determining the size of these values will take

some experimentation. Depending upon the overshoot from the

printer port, this capacitor may need to be as large as 0.01µF,

while the resistor is typically in the 50 Ω to 100Ω range.

Figure 52. Evaluation Board Silkscreen (Component Side)

–15–REV. 0

Page 16

AD8320

Figure 53. Evaluation Board Layout (Component Side)

–16–

REV. 0

Page 17

AD8320

Figure 54. Evaluation Board Layout (Solder Side)

36 PIN CENTRONICS

1

19

36

18

SIGNAL D-SUB-25 36-PIN CENTRONICS

DATEN 23

PD 31

DATA 5 5

CLK 6 2

DGND 25 16, 19–30, 33

EVALUATION BOARD PC

D-SUB 25 PIN (MALE)

1

14

25

13

DATEN

PD

SDATA

CLK

GND

Figure 55. Interconnection Between AD8320EB and PC Printer Port

–17–REV. 0

Page 18

AD8320

Figure 56. Screen Display of Windows-Based Control Software

–18–

REV. 0

Page 19

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Thermally Enhanced Power Small Outline Package

(RP-20)

0.5118 (13.00)

0.4961 (12.60)

AD8320

0.2992 (7.60)

0.2914 (7.40)

PIN 1

0.0118 (0.30)

0.0040 (0.10)

STANDOFF

20

1

0.0500

(1.27)

BSC

HEAT

SINK

0.3340 (8.61)

0.3287 (8.35)

0.0201 (0.51)

0.0130 (0.33)

11

0.1890 (4.80)

0.1791 (4.55)

10

0.1043 (2.65)

0.0926 (2.35)

SEATING

PLANE

0.4193 (10.65)

0.3937 (10.00)

8°

0°

0.0500 (1.27)

0.0057 (0.40)

0.0295 (0.75)

0.0098 (0.25)

x 45°

–19–REV. 0

Page 20

C3167–8–1/98

–20–

PRINTED IN U.S.A.

Loading...

Loading...