Datasheet AD824AR-3V, AD824AR-16, AD824AR-14-3V, AD824AR-14, AD824AR Datasheet (Analog Devices)

...Page 1

Single Supply, Rail-to-Rail

1

2

14

13

5

6

7

10

9

8

3

4

12

11

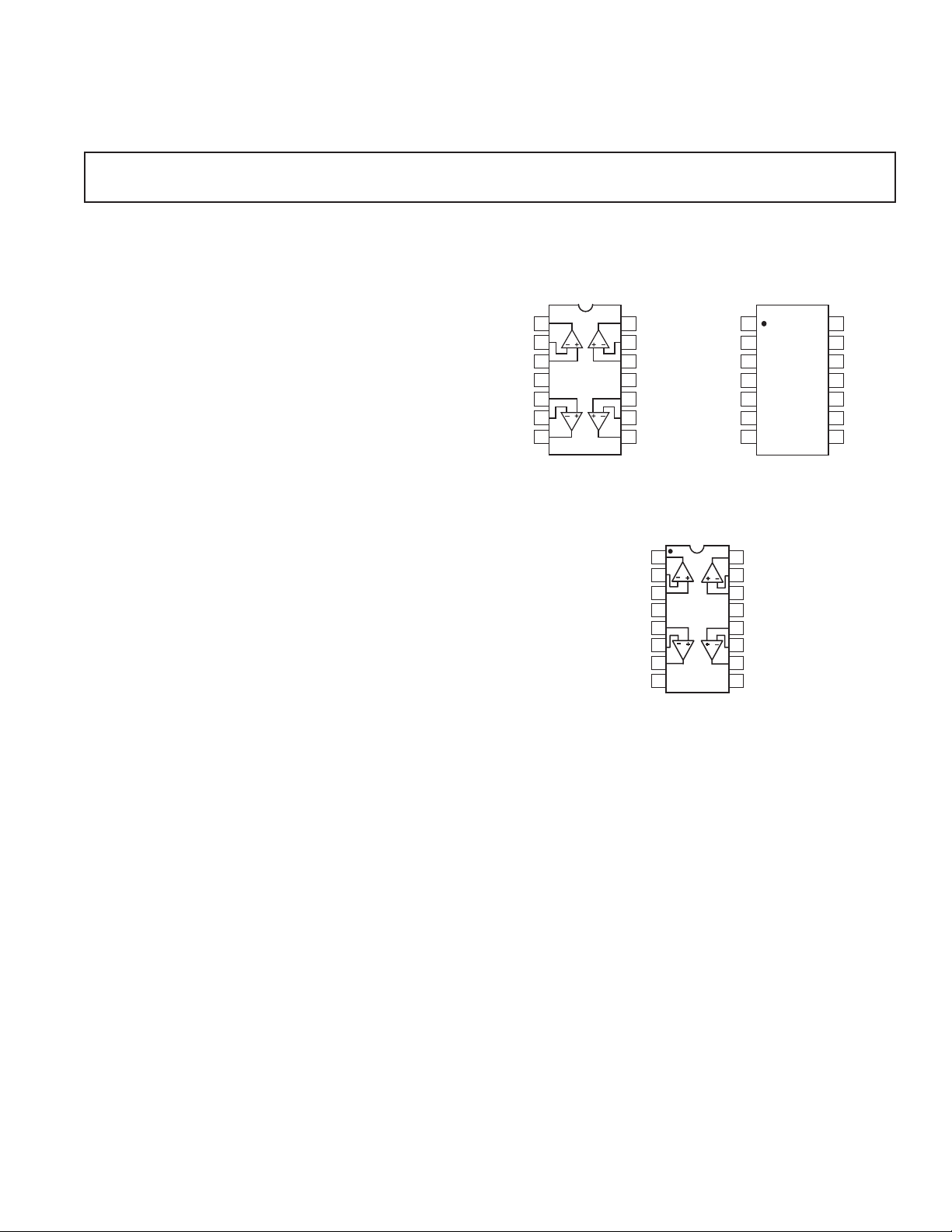

TOP VIEW

AD824

OUT A

–IN A

+IN A

V+

+IN B

–IN B

OUT B

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

a

FEATURES

Single Supply Operation: 3 V to 30 V

Very Low Input Bias Current: 2 pA

Wide Input Voltage Range

Rail-to-Rail Output Swing

Low Supply Current: 500 A/Amp

Wide Bandwidth: 2 MHz

Slew Rate: 2 V/s

No Phase Reversal

APPLICATIONS

Photo Diode Preamplifier

Battery Powered Instrumentation

Power Supply Control and Protection

Medical Instrumentation

Remote Sensors

Low Voltage Strain Gage Amplifiers

DAC Output Amplifier

GENERAL DESCRIPTION

The AD824 is a quad, FET input, single supply amplifier, featuring rail-to-rail outputs. The combination of FET inputs and

rail-to-rail outputs makes the AD824 useful in a wide variety of

low voltage applications where low input current is a primary

consideration.

The AD824 is guaranteed to operate from a 3 V single supply

up to ±15 V dual supplies.

Fabricated on ADI’s complementary bipolar process, the AD824

has a unique input stage that allows the input voltage to safely

extend beyond the negative supply and to the positive supply

without any phase inversion or latchup. The output voltage

swings to within 15 mV of the supplies. Capacitive loads to

350 pF can be handled without oscillation.

The FET input combined with laser trimming provides an input

that has extremely low bias currents with guaranteed offsets

below 300 µV. This enables high accuracy designs even with

high source impedances. Precision is combined with low

noise, making the AD824 ideal for use in battery powered

medical equipment.

Low Power, FET-Input Op Amp

AD824

PIN CONFIGURATIONS

14-Lead Epoxy DIP

(N Suffix)

16-Lead Epoxy SO

(R Suffix)

OUT A

1

–IN A

2

+IN A

3

V+

4

AD824

5

+IN B

–IN B

6

OUT B

7

8

NC

NC = NO CONNECT

Applications for the AD824 include portable medical equipment,

photo diode preamplifiers and high impedance transducer

amplifiers.

The ability of the output to swing rail-to-rail enables designers

to build multistage filters in single supply systems and maintain

high signal-to-noise ratios.

The AD824 is specified over the extended industrial (–40°C to

+85°C) temperature range and is available in 14-pin DIP and

narrow 14-lead and 16-lead SO packages.

14-Lead Epoxy SO

(R Suffix)

1

OUT A

2

–IN A

3

+IN A

V+

+IN B

–IN B

OUT B

4

5

6

7

16

15

14

13

12

11

10

9

AD824

TOP VIEW

(Not to Scale)

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

NC

14

13

12

11

10

9

8

OUT D

–IN D

+IN D

V–

+IN C

–IN C

OUT C

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

Page 2

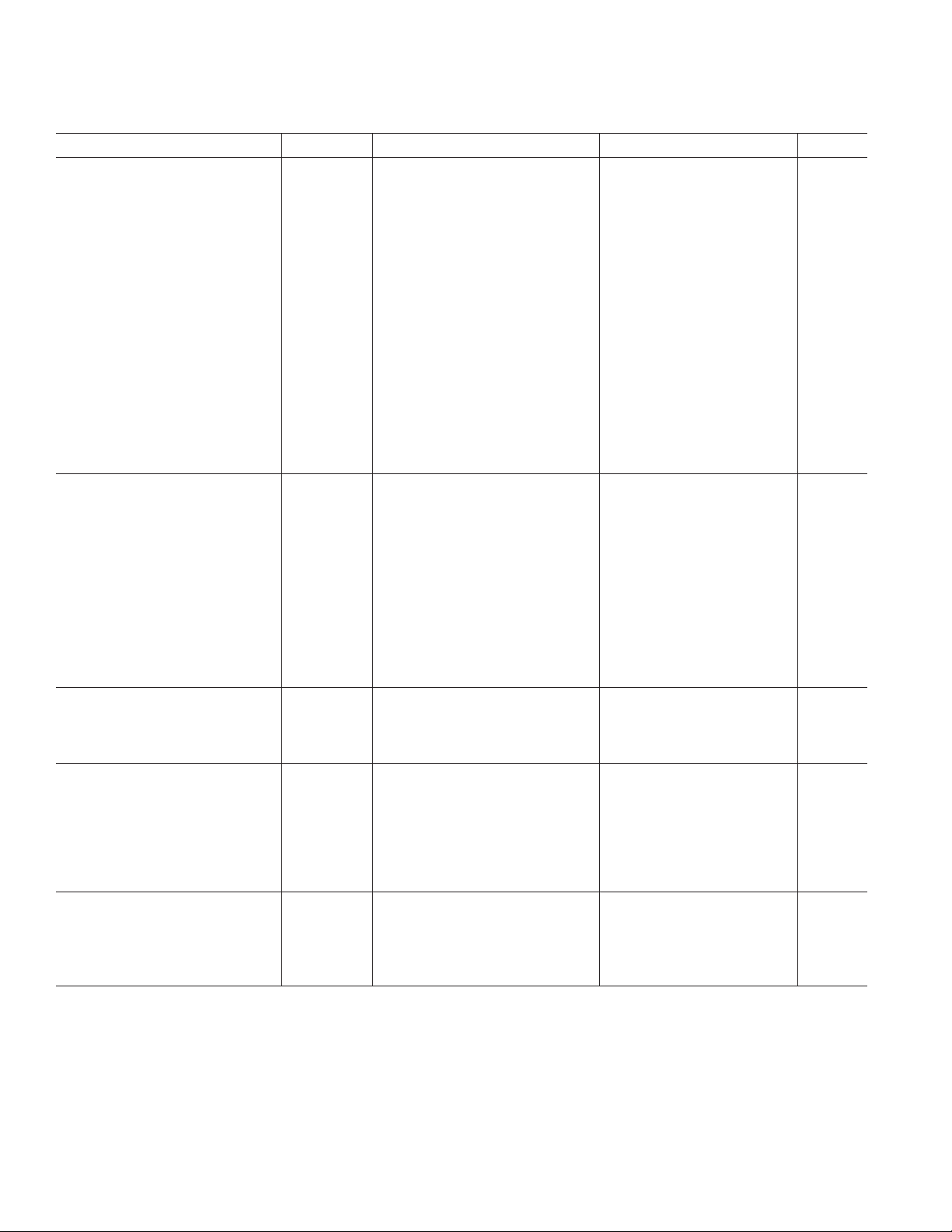

AD824–SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

(@ VS = 5.0 V, VCM = 0 V, V

= 0.2 V, TA = 25C unless otherwise noted)

OUT

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage AD824A V

Input Bias Current I

Input Offset Current I

B

OS

OS

T

to T

MIN

T

MIN

T

MIN

to T

to T

MAX

MAX

MAX

0.1 1.0 mV

1.5 mV

212pA

300 4000 pA

210pA

300 pA

Input Voltage Range –0.2 3.0 V

Common-Mode Rejection Ratio CMRR V

Input Impedance 10

Large Signal Voltage Gain A

VO

= 0 V to 2 V 66 80 dB

CM

= 0 V to 3 V 60 74 dB

V

CM

T

MIN

to T

MAX

60 dB

13

储3.3 Ω储pF

VO = 0.2 V to 4.0 V

R

= 2 kΩ 20 40 V/mV

L

R

= 10 kΩ 50 100 V/mV

L

= 100 kΩ 250 1000 V/mV

R

L

T

MIN

to T

= 100 kΩ 180 400 V/mV

MAX, RL

Offset Voltage Drift ∆VOS/∆T2µV/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

Open-Loop Impedance Z

OH

OL

SC

OUT

I

= 20 µA 4.975 4.988 V

SOURCE

to T

T

MIN

I

SOURCE

T

MIN

I

SINK

T

MIN

I

SINK

T

MIN

MAX

= 2.5 mA 4.80 4.85 V

to T

MAX

= 20 µA1525mV

to T

MAX

= 2.5 mA 120 150 mV

to T

MAX

4.97 4.985 V

4.75 4.82 V

20 30 mV

140 200 mV

Sink/Source ±12 mA

to T

T

MIN

MAX

±10 mA

f = 1 MHz, AV = 1 100 Ω

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 12 V 70 80 dB

T

Supply Current/Amplifier I

SY

to T

MIN

T

MIN

to T

MAX

MAX

66 dB

500 600 µA

DYNAMIC PERFORMANCE

Slew Rate SR RL = 10 kΩ, AV = 1 2 V/µs

Full-Power Bandwidth BW

Settling Time t

S

P

1% Distortion, VO = 4 V p-p 150 kHz

V

= 0.2 V to 4.5 V, to 0.01% 2.5 µs

OUT

Gain Bandwidth Product GBP 2 MHz

Phase Margin φo No Load 50 Degrees

Channel Separation CS f = 1 kHz, RL = 2 kΩ –123 dB

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 2 µV p-p

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 16 nV/√Hz

f = 1 kHz 0.8 fA/√Hz

Total Harmonic Distortion THD f = 10 kHz, RL = 0, AV = +1 0.005 %

–2–

REV. B

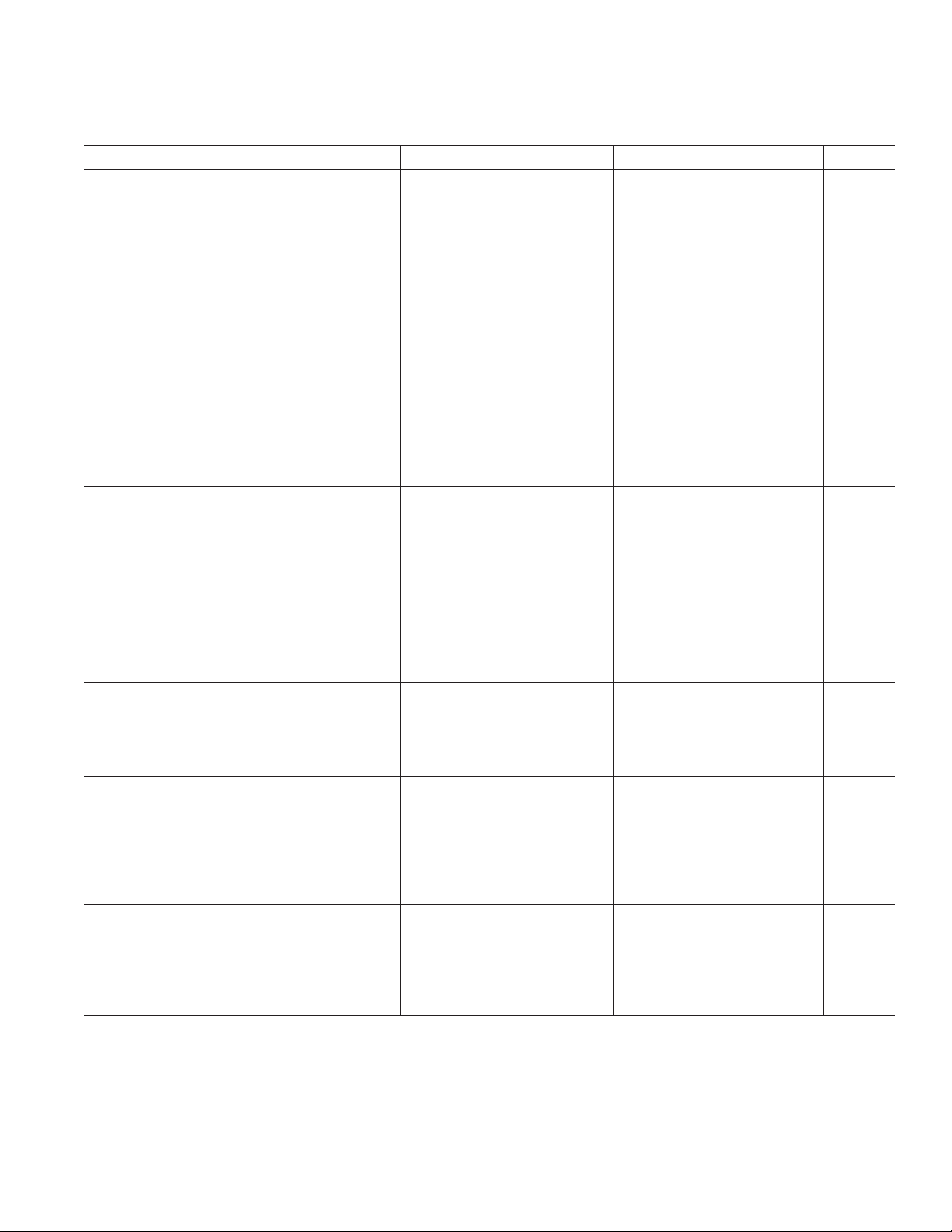

Page 3

AD824

ELECTRICAL SPECIFICATIONS

(@ VS = 15.0 V, V

= 0 V, TA = 25C unless otherwise noted)

OUT

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage AD824A V

Input Bias Current I

Input Offset Current I

OS

B

I

B

OS

to T

T

MIN

MAX

VCM = 0 V 4 35 pA

T

to T

MIN

MAX

VCM = –10 V 25 pA

T

to T

MIN

MAX

0.5 2.5 mV

0.6 4.0 mV

500 4000 pA

320 pA

500 pA

Input Voltage Range –15 13 V

Common-Mode Rejection Ratio CMRR V

Input Impedance 10

Large Signal Voltage Gain A

VO

= –15 V to 13 V 70 80 dB

CM

T

MIN

to T

MAX

66 dB

13

储3.3 Ω储pF

Vo = –10 V to +10 V;

R

= 2 kΩ 12 50 V/mV

L

= 10 kΩ 50 200 V/mV

R

L

R

= 100 kΩ 300 2000 V/mV

L

T

MIN

to T

= 100 kΩ 200 1000 V/mV

MAX, RL

Offset Voltage Drift ∆VOS/∆T2µV/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

Open-Loop Impedance Z

OH

OL

SC

OUT

I

= 20 µA 14.975 14.988 V

SOURCE

T

to T

MIN

I

SOURCE

T

MIN

I

SINK

T

MIN

I

SINK

T

MIN

Sink/Source, T

MAX

= 2.5 mA 14.80 14.85 V

to T

MAX

= 20 µA –14.985 –14.975 V

to T

MAX

= 2.5 mA –14.88 –14.85 V

to T

MAX

MIN

to T

MAX

14.970 14.985 V

14.75 14.82 V

–14.98 –14.97 V

–14.86 –14.8 V

±8 ± 20 mA

f = 1 MHz, AV = 1 100 Ω

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 15 V 70 80 dB

T

Supply Current/Amplifier I

SY

to T

MIN

MAX

VO = 0 V 560 625 µA

T

to T

MIN

MAX

68 dB

675 µA

DYNAMIC PERFORMANCE

Slew Rate SR RL = 10 kΩ, AV = 1 2 V/µs

Full-Power Bandwidth BW

Settling Time t

S

P

1% Distortion, VO = 20 V p-p 33 kHz

V

= 0 V to 10 V, to 0.01% 6 µs

OUT

Gain Bandwidth Product GBP 2 MHz

Phase Margin φo 50 Degrees

Channel Separation CS f = 1 kHz, RL =2 kΩ –123 dB

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 2 µV p-p

Voltage Noise Density e

Current Noise Density i

n

n

Total Harmonic Distortion THD f =10 kHz, V

f = 1 kHz 16 nV/√Hz

f = 1 kHz 1.1 fA/√Hz

= 3 V rms,

O

RL = 10 kΩ 0.005 %

REV. B

–3–

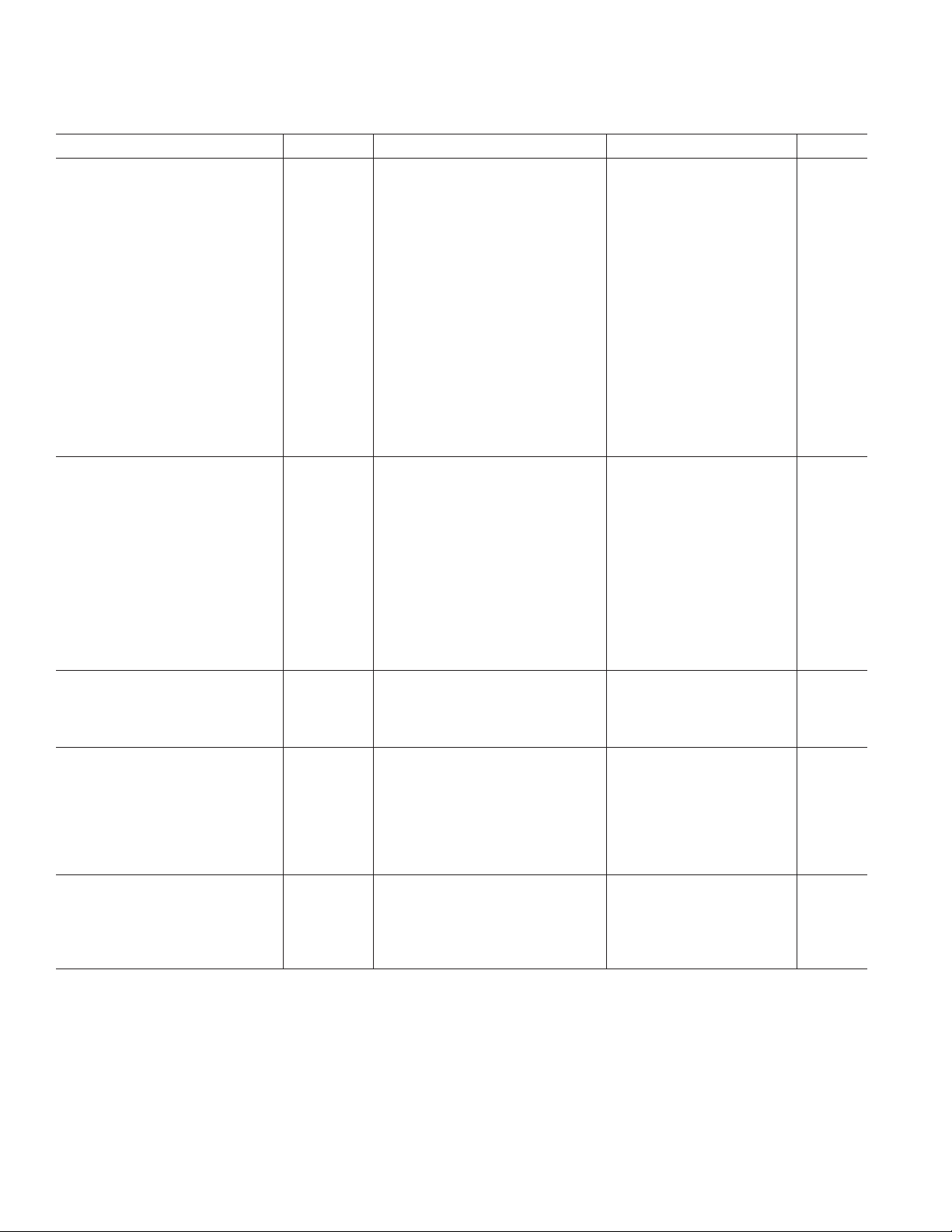

Page 4

AD824–SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

(@ VS = 3.0 V, VCM = 0 V, V

= 0.2 V, TA = 25C unless otherwise noted)

OUT

Parameter Symbol Conditions Min Typ Max Unit

INPUT CHARACTERISTICS

Offset Voltage AD824A -3 V V

Input Bias Current I

Input Offset Current I

B

OS

OS

T

to T

MIN

T

MIN

T

MIN

to T

to T

MAX

MAX

MAX

0.2 1.0 mV

1.5 mV

212pA

250 4000 pA

210pA

250 pA

Input Voltage Range 0 1 V

Common-Mode Rejection Ratio CMRR V

Input Impedance 10

Large Signal Voltage Gain A

VO

= 0 V to 1 V 58 74 dB

CM

T

MIN

to T

MAX

56 dB

13

储3.3 Ω储pF

VO = 0.2 V to 2.0 V

R

= 2 kΩ 10 20 V/mV

L

= 10 kΩ 30 65 V/mV

R

L

R

= 100 kΩ 180 500 V/mV

L

T

MIN

to T

= 100 kΩ 90 250 V/mV

MAX, RL

Offset Voltage Drift ∆VOS/∆T2µV/°C

OUTPUT CHARACTERISTICS

Output Voltage High V

Output Voltage Low V

Short Circuit Limit I

Open-Loop Impedance Z

I

OH

OL

SC

SC

OUT

I

= 20 µA 2.975 2.988 V

SOURCE

T

to T

MIN

I

SOURCE

T

MIN

I

SINK

T

MIN

I

SINK

T

MIN

MAX

= 2.5 mA 2.8 2.85 V

to T

MAX

= 20 µA1525mV

to T

MAX

= 2.5 mA 120 150 mV

to T

MAX

2.97 2.985 V

2.75 2.82 V

20 30 mV

140 200 mV

Sink/Source ±8mA

Sink/Source, T

MIN

to T

MAX

±6mA

f = 1 MHz, AV = 1 100 Ω

POWER SUPPLY

Power Supply Rejection Ratio PSRR VS = 2.7 V to 12 V, 70 dB

Supply Current/Amplifier I

SY

to T

T

MIN

MAX

VO = 0.2 V, T

MIN

to T

MAX

66 dB

500 600 µA

DYNAMIC PERFORMANCE

Slew Rate SR RL =10 kΩ, AV = 1 2 V/µs

Full-Power Bandwidth BW

Settling Time t

S

P

1% Distortion, VO = 2 V p-p 300 kHz

V

= 0.2 V to 2.5 V, to 0.01% 2 µs

OUT

Gain Bandwidth Product GBP 2 MHz

Phase Margin φo 50 Degrees

Channel Separation CS f = 1 kHz, RL = 2 kΩ –123 dB

NOISE PERFORMANCE

Voltage Noise en p-p 0.1 Hz to 10 Hz 2 µV p-p

Voltage Noise Density e

Current Noise Density i

n

n

f = 1 kHz 16 nV/√Hz

0.8 fA/√Hz

Total Harmonic Distortion THD f = 10 kHz, RL = 0, AV = +1 0.01 %

–4–

REV. B

Page 5

AD824

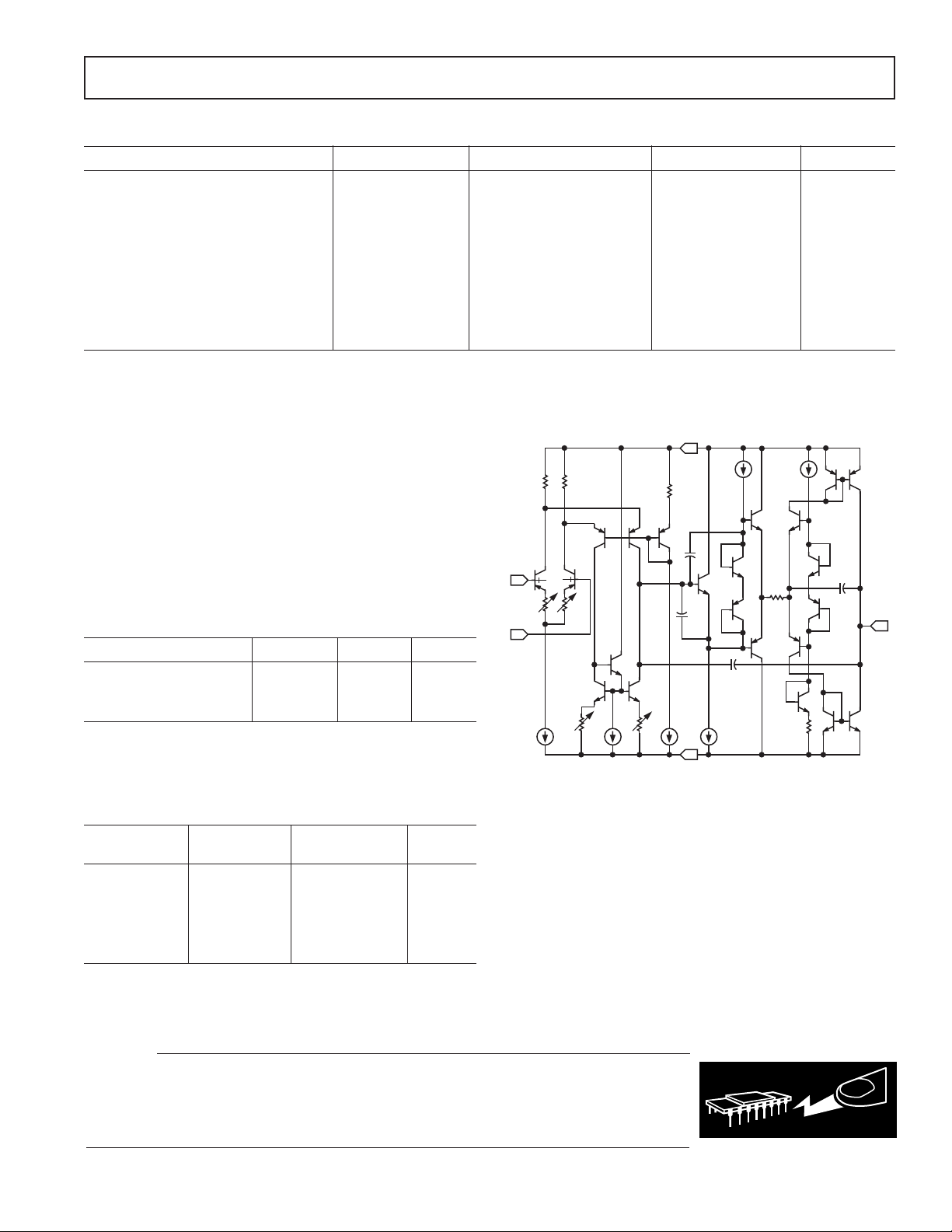

R1 R2

+IN

J1 J2

R13

–IN

R15

Q4

Q5

Q6

R9

I5

V

CC

C3

Q7

C2

Q22

Q19

Q21 Q27

Q18 Q29

Q20

Q23

R7

C4

V

OUT

Q24 Q25

Q31

Q28

R17

Q26

C1

I4I3I2I1

R12 R14

Q2

Q8

Q3

V

EE

I6

WAFER TEST LIMITS

(@ VS = 5.0 V, VCM = 0 V, TA = 25C unless otherwise noted)

Parameter Symbol Conditions Limit Unit

Offset Voltage V

Input Bias Current I

Input Offset Current I

Input Voltage Range V

OS

B

OS

CM

Common-Mode Rejection Ratio CMRR V

= 0 V to 2 V 66 dB min

CM

1.0 mV max

12 pA max

20 pA

–0.2 to 3.0 V min

Power Supply Rejection Ratio PSRR V = + 2.7 V to +12 V 70 µV/V

Large Signal Voltage Gain A

Output Voltage High V

Output Voltage Low V

Supply Current/Amplifier I

NOTE

Electrical tests and wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed for

standard product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

ABSOLUTE MAXIMUM RATINGS

1

VO

OH

OL

SY

RL = 2 kΩ 15 V/mV min

I

= 20 µA 4.975 V min

SOURCE

I

= 20 µA25 mV max

SINK

VO = 0 V, RL = ∞ 600 µA max

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . –V

– 0.2 V to +V

S

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ± 30 V

Output Short Circuit Duration to GND . . . . . . . . . Indefinite

Storage Temperature Range

N, R Package . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Operating Temperature Range

AD824A . . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature Range

N, R Package . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . . 300°C

Package Type θ

2

JA

θ

JC

Units

14-Pin Plastic DIP (N) 76 33 °C/W

14-Pin SOIC (R) 120 36 °C/W

16-Pin SOIC (R) 92 27 °C/W

NOTES

1

Absolute maximum ratings apply to packaged parts unless otherwise noted.

2

θJA is specified for the worst case conditions, i.e., θ

for P-DIP packages; θJA is specified for device soldered in circuit board for SOIC

package.

is specified for device in socket

JA

Figure 1. Simplified Schematic of 1/4 AD824

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD824AN* –40°C to +85°C 14-Pin Plastic DIP N-14

AD824AR –40°C to +85°C 14-Pin SOIC R-14

AD824AR-3V –40°C to +85°C 14-Pin SOIC R-14

AD824AR-14 –40°C to +85°C 14-Pin SOIC R-14

AD824AR-14-3V –40°C to +85°C 14-Pin SOIC R-14

AD824AR-16 –40°C to +85°C 16-Pin SOIC R-16

*Not for new designs. Obsolete April 2002.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD824 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. B

–5–

WARNING!

ESD SENSITIVE DEVICE

Page 6

AD824

–Typical Performance Characteristics

1µs50mV

VS = 15V

NO LOAD

45

90

135

180

80

60

40

GAIN – dB

20

0

100 10M1k 10k 100k 1M

100

90

10

0%

TPC 1. Open-Loop Gain/Phase and Small Signal

Response, V

= ±15 V, No Load

S

PHASE – Degrees

1µs50mV

VS = 5V

NO LOAD

45

90

135

180

80

60

40

GAIN – dB

20

0

100 10M1k 10k 100k 1M

100

90

10

0%

TPC 3. Open-Loop Gain/Phase and Small Signal

Response, V

= 5 V, No Load

S

PHASE – Degrees

80

60

40

GAIN – dB

20

0

100 10M1k 10k 100k 1M

100

90

10

0%

1µs50mV

VS = 15V

= 100pF

C

L

45

90

135

180

PHASE – Degrees

GAIN – dB

–20

60

40

20

0

100

90

10

0%

VS = 5V

= 220pF

C

L

45

90

135

180

PHASE – Degrees

10M1k 10k 100k 1M

1µs50mV

TPC 2. Open-Loop Gain/Phase and Small Signal

Response, V

= ±15 V, CL = 100 pF

S

–6–

TPC 4. Open-Loop Gain/Phase and Small Signal

Response, V

= 5 V, CL = 220 pF

S

REV. B

Page 7

AD824

1µs50mV

VS = 3V

NO LOAD

45

90

135

180

10M1k 10k 100k 1M

GAIN – dB

–20

60

40

20

0

100

90

10

0%

TPC 5. Open-Loop Gain/Phase and Small Signal

Response, V

= 3 V, No Load

S

PHASE – Degrees

t

100

90

10

0%

t

10.810

100

90

10

0%

TPC 7. Slew Rate, RL = 10k

9.950

2µs5V

2µs5V

µs

µs

GAIN – dB

–20

= 3V

60

40

20

0

V

S

CL = 220pF

45

90

135

180

PHASE – Degrees

100

90

V

OUT

10

0%

5V

100µs

TPC 8. Phase Reversal with Inputs Exceeding Supply by 1 V

10M1k 10k 100k 1M

0.8

0.7

0.6

100

90

10

0%

1µs50mV

0.5

0.4

0.3

0.2

OUTPUT TO RAIL – Volts

0.1

0

1 10m5 10 50 100 500 1m 5m

LOAD CURRENT – A

SOURCE

SINK

TPC 6. Open-Loop Gain/Phase and Small Signal

Response, V

= 3 V, CL = 220 pF

S

REV. B

TPC 9. Output Voltage to Supply Rail vs. Sink and Source

Load Currents

–7–

Page 8

AD824

–TYPICAL PERFORMANCE CHARACTERISTICS

14

COUNT = 60

12

60

40

20

NOISE DENSITY – nV/ Hz

5 10 15 20

3V VS 15V

FREQUENCY – kHz

TPC 10. Voltage Noise Density

0.1

RL = 0

A

0.010

THD+N – %

0.001

0.0001

20 100 1k 10k 20k

VS = +3

VS = +5

VS = 15

FREQUENCY – Hz

V

= +1

10

8

6

4

NUMBER OF UNITS

2

0

–2.5 2.5–2.0 –1.5 –1.0 –0.5 0 0.5 1.0 1.5 2.0

OFFSET VOLTAGE DRIFT

TPC 13. TC VOS Distribution, –55°C to +125°C, VS = 5, 0

150

125

100

75

50

25

0

INPUT OFFSET CURRENT – pA

–25

–60 140–40 –20 0 20 40 60 80 100 120

TEMPERATURE – C

VS = 5, 0

TPC 11. Total Harmonic Distortion

280

240

200

160

120

NUMBER OF UNITS

80

40

0

–0.5 0.5–0.4 –0.3 –0.2 –0.1 0 0.1 0.2 0.3 0.4

OFFSET VOLTAGE – mV

COUNT = 860

TPC 12. Input Offset Distribution, VS = 5, 0

TPC 14. Input Offset Current vs. Temperature

100k

VS = 5, 0

10k

1k

100

10

INPUT BIAS CURRENT – pA

1

20 14040 60 80 100 120

TEMPERATURE – C

TPC 15. Input Bias Current vs. Temperature

–8–

REV. B

Page 9

120

FREQUENCY – Hz

1k

INPUT VOLTAGE NOISE – nV/√Hz

100

1

1 100k10 100 1k 10k

10

100

80

60

40

20

COMMON-MODE REJECTION – dB

0

10 10M100 1k 10k 100k 1M

FREQUENCY – Hz

AD824

TPC 16. Common-Mode Rejection vs. Frequency

–40

–60

–80

THD – dB

–100

–120

100 100k1k 10k

FREQUENCY – Hz

TPC 17. THD vs. Frequency, 3 V rms

100

80

100

80

TPC 19. Input Voltage Noise Spectral Density vs.

Frequency

120

100

80

60

40

20

POWER SUPPLY REJECTION – dB

0

10 10M100

1k 10k 100k 1M

FREQUENCY – Hz

TPC 20. Power Supply Rejection vs. Frequency

30

25

60

40

20

OPEN-LOOP GAIN – dB

0

–20

10 10M100

TPC 18. Open-Loop Gain and Phase vs. Frequency

REV. B

15V

3, 0V

1k 10k 100k 1M

FREQUENCY – Hz

60

40

20

0

–20

PHASE MARGIN – Degrees

–9–

20

15

10

OUTPUT VOLTAGE – Volts

5

0

1k 1M3k

10k 30k 100k 300k

INPUT FREQUENCY – Hz

TPC 21. Large Signal Frequency Response

Page 10

AD824

–80

–90

–100

–110

CROSSTALK – dB

–120

–130

–140

10 100

1k 10k 100k

FREQUENCY – Hz

TPC 22. Crosstalk vs. Frequency

10k

1k

100

10

1

OUTPUT IMPEDANCE –

.1

1 TO 4

1 TO 2

1 TO 3

100

90

10

0%

TPC 25. Large Signal Response

2750

2500

2250

2000

1750

1500

SUPPLY CURRENT – µA

1250

5µs5V

VS = 15V

VS = 3, 0

.01

10 10M100

1k 10k 100k 1M

FREQUENCY – Hz

TPC 23. Output Impedance vs. Frequency, Gain = +1

500ns20mV

100

90

10

0%

TPC 24. Small Signal Response, Unity Gain Follower,

储

100 pF Load

10k

1000

–60 140–40

–20 0 20 40 60 80 100 120

TEMPERATURE – C

TPC 26. Supply Current vs. Temperature

1000

VS = 15V

V

= 3, 0

S

100

V

– V

OL

S

10

OUTPUT SATURATION VOLTAGE – mV

0

0.01 10.00.10 1.0

VS – V

OH

LOAD CURRENT – mA

TPC 27. Output Saturation Voltage

–10–

REV. B

Page 11

AD824

APPLICATION NOTES

INPUT CHARACTERISTICS

In the AD824, n-channel JFETs are used to provide a low

offset, low noise, high impedance input stage. Minimum input

common-mode voltage extends from 0.2 V below –V

than +V

. Driving the input voltage closer to the positive rail will

S

to 1 V less

S

cause a loss of amplifier bandwidth.

The AD824 does not exhibit phase reversal for input voltages

up to and including +V

AD824 voltage follower to a 0 V to 5 V (+V

. Figure 2a shows the response of an

S

) square wave input.

S

The input and output are superimposed. The output tracks the

input up to +V

without phase reversal. The reduced bandwidth

S

above a 4 V input causes the rounding of the output wave form.

For input voltages greater than +V

, a resistor in series with

S

the AD824’s noninverting input will prevent phase reversal at

the expense of greater input voltage noise. This is illustrated in

Figure 2b.

2µs1V

100

90

10

GND

0%

1V

(a)

10µs1V

+V

GND

1V

100

90

S

10

0%

1V

(b)

R

V

IN

Figure 2. (a) Response with RP = 0; V

+5V

P

V

OUT

from 0 to +V

IN

S

(b) VIN = 0 to + VS + 200 m V

= 0 to + V

V

OUT

RP = 49.9 k

S

Ω

Since the input stage uses n-channel JFETs, input current

during normal operation is positive; the current flows out from

the input terminals. If the input voltage is driven more positive

than +V

– 0.4 V, the input current will reverse direction as

S

internal device junctions become forward biased. This is

illustrated in TPC 8.

A current-limiting resistor should be used in series with the

input of the AD824 if there is a possibility of the input voltage

exceeding the positive supply by more than 300 mV or if an

input voltage will be applied to the AD824 when ± V

= 0. The

S

amplifier will be damaged if left in that condition for more than

10 seconds. A 1 kΩ resistor allows the amplifier to withstand up

to 10 V of continuous overvoltage and increases the input voltage noise by a negligible amount.

Input voltages less than –V

are a completely different story.

S

The amplifier can safely withstand input voltages 20 V below

the minus supply voltage as long as the total voltage from the

positive supply to the input terminal is less than 36 V. In addition,

the input stage typically maintains picoamp level input currents

across that input voltage range.

OUTPUT CHARACTERISTICS

The AD824’s unique bipolar rail-to-rail output stage swings

within 15 mV of the positive and negative supply voltages. The

AD824’s approximate output saturation resistance is 100 Ω for

both sourcing and sinking. This can be used to estimate output

saturation voltage when driving heavier current loads. For

instance, the saturation voltage will be 0.5 V from either supply

with a 5 mA current load.

For load resistances over 20 kΩ, the AD824’s input error

voltage is virtually unchanged until the output voltage is driven

to 180 mV of either supply.

If the AD824’s output is overdriven so as to saturate either of

the output devices, the amplifier will recover within 2 µs of its

input returning to the amplifier’s linear operating region.

Direct capacitive loads will interact with the amplifier’s effective

output impedance to form an additional pole in the amplifier’s

feedback loop, which can cause excessive peaking on the pulse

response or loss of stability. Worst case is when the amplifier is

used as a unity gain follower. TPC 4 and 6 show the AD824’s

pulse response as a unity gain follower driving 220 pF. Configurations with less loop gain, and as a result less loop bandwidth,

will be much less sensitive to capacitance load effects. Noise

gain is the inverse of the feedback attenuation factor provided

by the feedback network in use.

Figure 3 shows a method for extending capacitance load drive

capability for a unity gain follower. With these component values, the circuit will drive 5,000 pF with a 10% overshoot.

+V

S

0.01F

8

V

IN

1/4

AD824

4

–V

20k

0.01F

S

20pF

100

V

OUT

C

L

Figure 3. Extending Unity Gain Follower Capacitive Load

Capability Beyond 350 pF

REV. B

–11–

Page 12

AD824

APPLICATIONS

Single Supply Voltage-to-Frequency Converter

The circuit shown in Figure 4 uses the AD824 to drive a low

power timer, which produces a stable pulse of width t

. The

1

positive going output pulse is integrated by R1-C1 and used as

one input to the AD824, which is connected as a differential

integrator. The other input (nonloading) is the unknown voltage,

VIN. The AD824 output drives the timer trigger input, closing

the overall feedback loop.

10V

C5

0.1F

3

0V TO 2.5V

FULL SCALE

REF02

2

V

6

5

4

499k, 1%

R1

499k, 1%

0.01F, 2%

U4

= 5V

REF

CMOS

**

R

R2

SCALE

10k

74HCO4

4

0.01F, 2%

U1

1/4

U3B U3A

32 1

C1

AD824B

C2

NOTES

= VIN/(VREF t1), t1 = 1.1 R3 C6

f

OUT

= 25kHz fS AS SHOWN.

* = 1% METAL FILM, <50ppm/C TC

** = 10%, 20T FILM, <100ppm/C TC

t

= 33s FOR f

1

OUT

U2

CMOS 555

THR

6

TR

2

DIS

7

48

RV+

GND

1

R3*

116k

C6

390pF

5%

(NPO )

= 20kHz @ VIN = 2.0V

OUT

CV

0.1F

C3

0.1F

C4

OUT2

OUT1

3

5

Figure 4. Single Supply Voltage-to-Frequency Converter

Typical AD824 bias currents of 2 pA allow megaohm-range

source impedances with negligible dc errors. Linearity errors on

the order of 0.01% full scale can be achieved with this circuit.

This performance is obtained with a 5 V single supply, which

delivers less than 3 mA to the entire circuit.

Single Supply Programmable Gain Instrumentation Amplifier

The AD824 can be configured as a single supply instrumentation amplifier that is able to operate from single supplies down

to 3 V or dual supplies up to ±15 V. AD824 FET inputs’ 2 pA

bias currents minimize offset errors caused by high unbalanced

source impedances.

An array of precision thin-film resistors sets the in amp gain to

be either 10 or 100. These resistors are laser-trimmed to ratio

match to 0.01% and have a maximum differential TC of 5 ppm/°C.

Table I. AD824 In Amp Performance

Parameters VS = 3 V, 0 V VS = 5 V

CMRR 74 dB 80 dB

Common-Mode

Voltage Range –0.2 V to +2 V –5.2 V to +4 V

3 dB BW, G = 10 180 kHz 180 kHz

G = 100 18 kHz 18 kHz

t

SETTLING

2 V Step (VS = 0 V, 3 V) 2 µs

5 V (V

= ±5 V) 5 µs

S

Noise @ f = 1 kHz, G = 10 270 nV/√Hz 270 nV/√Hz

G = 100 2.2 µV/√Hz 2.2 µV/√Hz

5µs

100

90

10

0%

1V

Figure 5a. Pulse Response of In Amp to a 500 mV p-p

Input Signal; V

V

REF

V

IN1

V

IN2

90kR29kR31kR41kR59kR690k

G = 10 G = 100 G = 10G = 100

R

P

1k

R

1k

(G = 10) V

(G = 100) V

FOR R1 = R6, R2 = R5 AND R3 = R4

R1

= 5 V, 0 V; Gain = 10

S

+V

S

0.1F

2

1

1/4

AD824

3

P

= (V

OUT

= (V

– V

IN1

IN1

OUT

) (1+ ) + V

IN2

– V

) (1+ ) + V

IN2

6

AD824

5

R6

R4 + R5

R5 + R6

R4

1/4

OHMTEK

PART # 1043

7

V

11

REF

REF

OUT

Figure 5b. A Single Supply Programmable

Instrumentation Amplifier

–12–

REV. B

Page 13

AD824

3.3/5V

3.3/5V

R1

50k

R2

50k

A1

3

2

4

1

11

0.1F

FALSE GROUND (FG)

A4

12

13

14

SAMPLE/

HOLD

A3

10

9

8

A2

5

6

7

15

14

16

10

9

11

AD824B

3.3/5V

ADG513

R5

2k

AD824C

+

–

V

OUT

CH

C

500pF

FG

4

5

8

6

7

2

3

1

AD824A

AD824D

R4

2k

FG

13

500pF

FG

A1

A2

A3

A4

3 Volt, Single Supply Stereo Headphone Driver

The AD824 exhibits good current drive and THD+N performance, even at 3 V single supplies. At 1 kHz, total harmonic

distortion plus noise (THD+N) equals –62 dB (0.079%) for a

300 mV p-p output signal. This is comparable to other single

supply op amps that consume more power and cannot run on 3 V

power supplies.

In Figure 6, each channel’s input signal is coupled via a 1 µF

Mylar capacitor. Resistor dividers set the dc voltage at the

noninverting inputs so that the output voltage is midway between

the power supplies (1.5 V). The gain is 1.5. Each half of the

AD824 can then be used to drive a headphone channel. A 5 Hz

high-pass filter is realized by the 500 µF capacitors and the

headphones, which can be modeled as 32 ohm load resistors to

ground. This ensures that all signals in the audio frequency

range (20 Hz–20 kHz) are delivered to the headphones.

3V

0.1F

L

R

CHANNEL 1

CHANNEL 2

1F

MYLAR

95.3k

1F

MYLAR

95.3k

47.5k

47.5k

AD824

AD824

10k

10k

AD824

AD824

1/4

1/4

1/4

1/4

4.99k

4.99k

0.1F

500F

HEADPHONES

32 IMPEDANCE

500F

of 4.5 V can be used to drive an A/D converter front end. The

other half of the AD824 is configured as a unity-gain inverter

and generates the other bridge input of –4.5 V. Resistors R1 and

R2 provide a constant current for bridge excitation. The AD620

low power instrumentation amplifier is used to condition the

differential output voltage of the bridge. The gain of the AD620

is programmed using an external resistor R

49.4 kΩ

G =

R

G

and determined by:

G

+ 1

A 3.3 V/5 V Precision Sample-and-Hold Amplifier

In battery-powered applications, low supply voltage operational

amplifiers are required for low power consumption. Also, low

supply voltage applications limit the signal range in precision

analog circuitry. Circuits like the sample-and-hold circuit shown

in Figure 8, illustrate techniques for designing precision analog

circuitry in low supply voltage applications. To maintain high

signal-to-noise ratios (SNRs) in a low supply voltage application

requires the use of rail-to-rail, input/output operational amplifiers. This design highlights the ability of the AD824 to operate

rail-to-rail from a single 3 V/5 V supply, with the advantages of

high input impedance. The AD824, a quad JFET-input op amp,

is well suited to S/H circuits due to its low input bias currents

(3 pA, typical) and high input impedances (3 × 10

13

Ω, typical).

The AD824 also exhibits very low supply currents so the total

supply current in this circuit is less than 2.5 mA.

Figure 6. 3 Volt Single Supply Stereo Headphone Driver

Low Dropout Bipolar Bridge Driver

The AD824 can be used for driving a 350 ohm Wheatstone

bridge. Figure 7 shows one half of the AD824 being used to

buffer the AD589—a 1.235 V low power reference. The output

+V

S

REV. B

49.9k

+1.235V

AD589

10k

1%

10k

1%

1/4

1/4

AD824

AD824

26.4k, 1%

350 350

10k

1%

1/4

1/4

AD824

AD824

Figure 7. Low Dropout Bipolar Bridge Driver

R1

20

350 350

–4.5V

R2

20

TO A/D CONVERTER

REFERENCE INPUT

3

AD824

R

G

2

+V

S

–V

S

0.1F

GND

0.1F

–V

S

+V

AD620

4

–V

S

7

5

V

REF

S

6

Figure 8. 3.3 V/5.5 V Precision Sample and Hold

In many single supply applications, the use of a false ground

generator is required. In this circuit, R1 and R2 divide the

+5V

1F

1F

–5V

supply voltage symmetrically, creating the false ground voltage

at one-half the supply. Amplifier A1 then buffers this voltage

creating a low impedance output drive. The S/H circuit is configured in an inverting topology centered around this false

ground level.

–13–

Page 14

AD824

A design consideration in sample-and-hold circuits is voltage

droop at the output caused by op amp bias and switch leakage

currents. By choosing a JFET op amp and a low leakage CMOS

switch, this design minimizes droop rate error to better than

0.1 µV/µs in this circuit. Higher values of CH will yield a lower

droop rate. For best performance, C

and C2 should be poly-

H

styrene, polypropylene or Teflon capacitors. These types of

capacitors exhibit low leakage and low dielectric absorption. Additionally, 1% metal film resistors were used throughout the design.

In the sample mode, SW1 and SW4 are closed, and the output

= –VIN. The purpose of SW4, which operates in parallel

is V

OUT

with SW1, is to reduce the pedestal, or hold step, error by

injecting the same amount of charge into the noninverting input

of A3 that SW1 injects into the inverting input of A3. This

creates a common-mode voltage across the inputs of A3 and is

then rejected by the CMR of A3; otherwise, the charge injection

from SW1 would create a differential voltage step error that

would appear at V

. The pedestal error for this circuit is

OUT

less than 2 mV over the entire 0 V to 3.3 V/5 V signal range.

Another method of reducing pedestal error is to reduce the pulse

amplitude applied to the control pins. In order to control the

ADG513, only 2.4 V are required for the “ON” state and

0.8 V for the “OFF” state. If possible, use an input control

signal whose amplitude ranges from 0.8 V to 2.4 V instead of a

full range 0 V to 3.3 V/5 V for minimum pedestal error.

Other circuit features include an acquisition time of less than

3 µs to 1%; reducing C

and C2 will speed up the acquisition

H

time further, but an increased pedestal error will result. Settling

time is less than 300 ns to 1%, and the sample-mode signal BW

is 80 kHz.

The ADG513 was chosen for its ability to work with 3 V/5 V

supplies and for having normallyopen and normallyclosed precision CMOS switches on a dielectrically isolated process. SW2 is

not required in this circuit; however, it was used in parallel with

SW3 to provide a lower R

analog switch.

ON

–14–

REV. B

Page 15

AD824

* AD824 SPICE Macro-model 9/94, Rev. A *

ARG/ADI

*

* Copyright 1994 by Analog Devices, Inc.

*

* Refer to “README.DOC” file for License Statement.

Use of this model indicates your acceptance with

the terms and provisions in the License Statement. *

* Node assignments

* noninverting input

* | inverting input

* | | positive supply

* | | | negative supply

* | | | | output

* | | | | |

.SUBCKT AD824

1 2 99 50 25

*

* INPUT STAGE & POLE AT 3.1 MHz

*

R3 5 99

1.193E3

R4 6 99

1.193E3

CIN 1 2

4E-12

C2 5 6

19.229E-12

I1 4 50 108E-6

IOS 1 2

1E-12

EOS 7 1

POLY(1) (12,98) 100E-6 1

J1 4 2 5

JX

J2 4 7 6

JX

*

* GAIN STAGE & DOMINANT POLE

*

EREF 98

0 (30,0) 1

R5 9 98

2.205E6

C3 9 25

54E-12

G1 98 9

(6,5) 0.838E-3

V1 8 98

-1

V2 98 10

-1

D1 9 10

DX

D2 8 9

DX

*

* COMMON-MODE GAIN NETWORK WITH ZERO AT 1 kHz *

R21 11 12

1E6

R22 12 98

100

C14 11 12

159E-12

E13 11 98

POLY(2) (2,98) (1,98) 0 0.5 0.5

*

* POLE AT 10 MHz

*

R23 18 98

1E6

C15 18 98

15.9E-15

G15 98 18

(9,98) 1E-6

*

* OUTPUT STAGE

*

ES 26 98

(18,98) 1

RS 26 22

500

IB1 98 21

2.404E-3

IB2 23 98

2.404E-3

D10 21 98

DY

D11 98 23

DY

C16 20 25

2E-12

C17 24 25

2E-12

DQ197 20

DQ

Q2 20 21

22 NPN

Q3 24 23

22 PNP

DQ224 51

DQ

Q5 25 20

97 PNP 20

Q6 25 24

51 NPN 20

VP 96 97

0

VN 51 52

0

EP 96 0

(99,0) 1

EN 52 0

(50,0) 1

R25 30 99

5E6

R26 30 50

5E6

FSY1 99

0 VP 1

FSY2 0

50VN 1

DC1 25 99

DX

DC2 50 25

DX

*

* MODELS USED

*

.MODEL JX NJF(BETA=3.2526E-3 VTO=-2.000 IS=2E-12) .MODEL

NPN NPN(BF=120 VAF=150 VAR=15 RB=2E3

+ RE=4 RC=550 IS=1E-16)

.MODEL PNP PNP(BF=120 VAF=150 VAR=15 RB=2E3 + RE=4

RC=750 IS=1E-16)

.MODEL DX D(IS=1E-15)

.MODEL DY D()

.MODEL DQ D(IS=1E-16)

.ENDS AD824

REV. B

–15–

Page 16

AD824

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

PIN 1

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

14-Pin Plastic (N) Package

(N-14)

0.795 (20.19)

0.725 (18.42)

14

1

0.100 (2.54)

0.022 (0.558)

0.014 (0.356)

BSC

0.070 (1.77)

0.045 (1.15)

8

0.280 (7.11)

0.240 (6.10)

7

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

16

1

PIN 1

0.195 (4.95)

0.115 (2.93)

0.4133 (10.50)

0.3977 (10.00)

0.050 (1.27)

BSC

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

16-Pin SOIC Package

(R-16)

9

0.2992 (7.60)

0.2914 (7.40)

8

0.1043 (2.65)

0.0926 (2.35)

0.4193 (10.65)

0.3937 (10.00)

0.3444 (8.75)

0.3367 (8.55)

14

1

0.050 (1.27)

BSC

0.0291 (0.74)

0.0098 (0.25)

14-Pin SOIC (R) Package

(R-14)

8

0.2440 (6.20)

0.2284 (5.80)

7

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

45

SEATING

PLANE

0.0099 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8

0

0.0500 (1.27)

0.0160 (0.41)

45

C00875–0–1/02(B)

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

SEATING

PLANE

0.0125 (0.32)

0.0091 (0.23)

8

0

0.0500 (1.27)

0.0157 (0.40)

Revision History

Location Page

Data Sheet changed from REV. A to REV. B.

Edits to ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 3

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Deleted DICE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PRINTED IN U.S.A.

–16–

REV. B

Loading...

Loading...