Page 1

LED Driver/Monitor

FEATURES

PWM input for LED brightness control

Open LED detection

Latch-off overcurrent protection

Constant voltage regulated output

Supply range: 9 V to 27 V

Regulated voltage range: 12.5 V to 27 V

Operating current: 300 µA

Shutdown current: 10 µA

Temperature range −40°C to +125°C

8-lead MSOP package

GENERAL DESCRIPTION

The AD8240 LED driver/monitor, in combination with an

external transistor, supplies a constant 12 V to drive LED

lamps. This allows cost-effective LED lamp monitoring and

short-circuit protection. The output is regulated at 12 V when

the supply voltage is between 12.5 V and 27 V.

A CMOS compatible, level-dependent, digital input can be used

for PWM control of the LED brightness. V

the PWM input is high and turned off when the input is low.

The AD8240 is designed to work with a PWM frequency up

to 500 Hz, and a typical PWM range from 5% to 95%.

Open LED detection is accomplished by measuring the change

in LED lamp current caused by an open LED(s) through the use

of an internal high-side current-sense amplifier that amplifies

the voltage across an external current shunt. The voltage across

the shunt resistor is amplified to a level that can be measured by

a microcontroller A/D converter or a comparator. The ability to

measure the change in LED lamp current is the key benefit of

constant-voltage LED lamp driving.

The output is current-limited by latching off the output voltage

when the current reaches a preset level. The current limit is set

by selecting the value of the external current shunt that causes

the output of the sense amplifier to slightly exceed the 5 V

reference level when the current exceeds a maximum level.

When the sense amplifier output exceeds 5 V, it trips an internal

comparator that causes the driver to latch off the output voltage.

The latch is reset during the next PWM cycle. The overcurrent

condition can also be detected by a microcontroller or external

comparator by measuring the sense amplifier output.

is turned on when

O

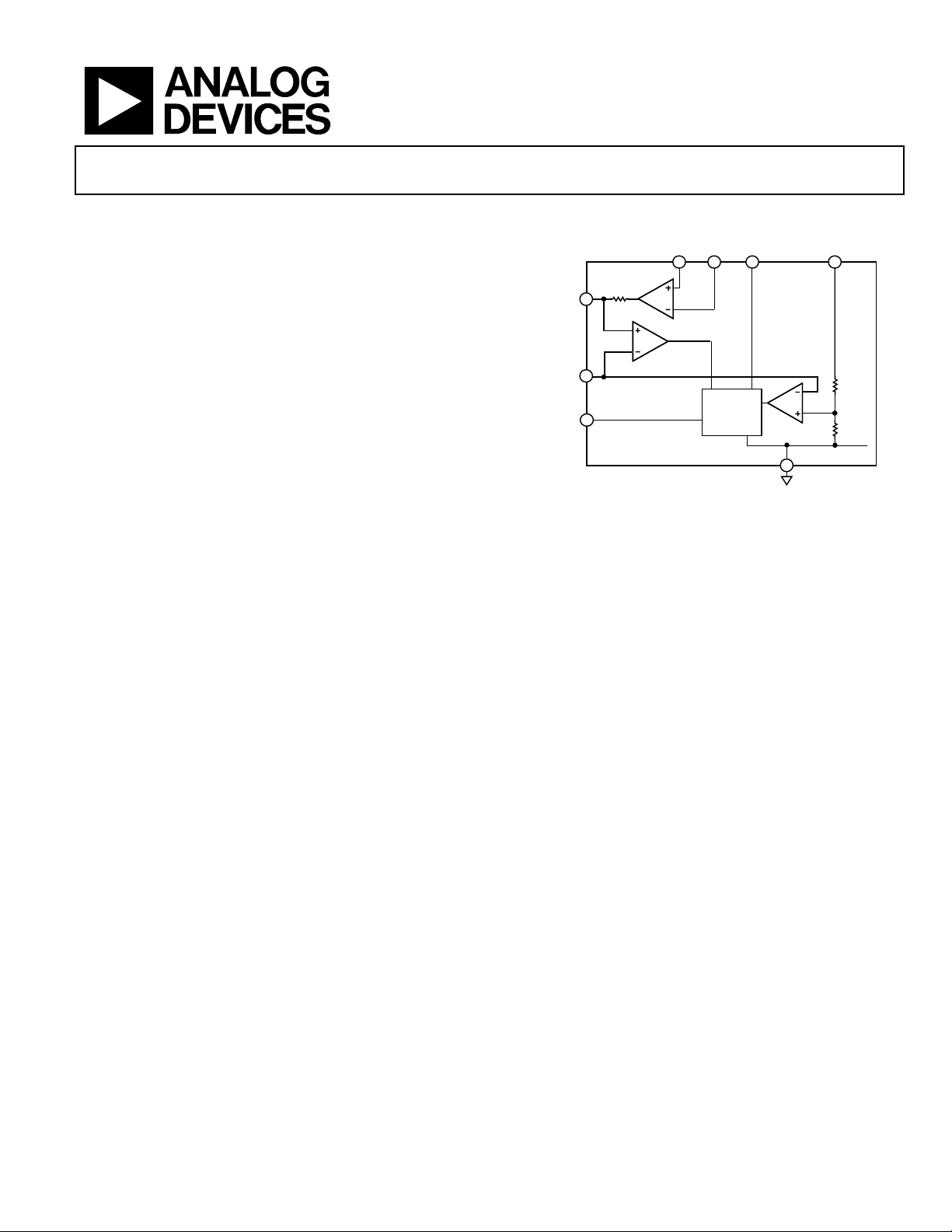

AD8240

FUNCTIONAL BLOCK DIAGRAM

V

P

L

U

S

SHUNT

BASE

6

LATCH-OFF

DRIVER

7

V

SENSE

REFERENCE

PWM

5

R

SENSE

1

10k

Ω

5V

2

3

AD8240

Figure 1.

PRODUCT HIGHLIGHTS

1. Partial LED lamp failure detection.

Allows for compliance with automotive regulations

for turn signal functionality detection and minimum

brightness, as well as running/brake light minimum

brightness compliance.

2. Current limiting/latch-off protection.

Limiting and latching off the LED current protects vehicle

wiring and prevents lamp damage

3. PWM input.

Provides brightness control.

4. Constant voltage output.

Saves cost by minimizing wiring and system design

complexity.

5. Drives an external transistor for low power operation.

Providing for an external power transistor allows the

AD8240 to be a low cost solution in a small package. A

more efficient design is made possible when the system

designer can select a power device with specifications

that match the application requirements.

6. Linear regulation.

Minimizes EMI, which allows faster system integration,

qualification, and time to market. Additionally, costs are

reduced by eliminating the inductor required for a

switching design. Because of the power-saving nature of

LED lamps as compared to incandescent lamps, a

switching driver is typically not required.

V

O

8

R1

350k

R2

250k

4

GND

Ω

Ω

04824-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

AD8240

TABLE OF CONTENTS

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 4

Product Description ......................................................................... 5

Linear Regulator (Block A)......................................................... 5

High-Side Current-Sense Amplifier with Open LED

Detection (Block B)

Comparator with Latch-off OverCurrent Protection

(Block C)

Intelligent Driver (Block D)........................................................ 5

........................................................................................ 5

REVISION HISTORY

...................................................................... 5

Using/Evaluating the AD8240 LED Driver Monitor....................6

Setup................................................................................................6

Controlling the LED lamp............................................................7

Using/Evaluating the V

Advantages of Driving LED Lamps with Constant Voltage ........8

Background....................................................................................8

Monitoring the LEDs ....................................................................8

Driving Automotive LEDs............................................................8

Outline Dimensions....................................................................... 10

Ordering Guide .......................................................................... 11

Output.............................................7

Sense

4/04—Revision 0: Initial Version

Rev. 0 | Page 2 of 12

Page 3

AD8240

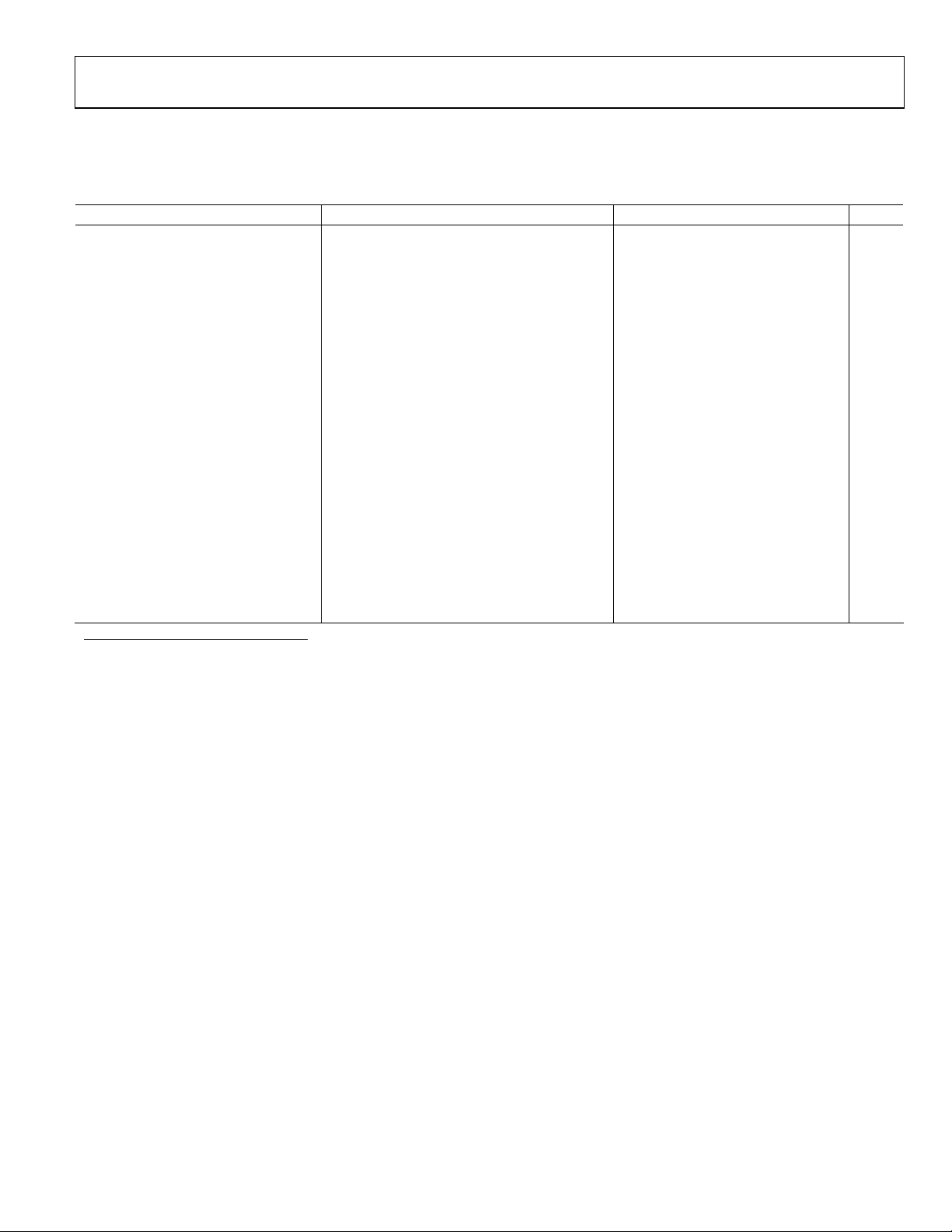

SPECIFICATIONS

TA = operating temperature range, V

Table 1.

Parameter Conditions Min Typ Max Unit

V

O

VO Regulation1 at 25°C V

VO Regulation2 -40°C to 125°C V

3

I

OUT

VO Rise Time I

V

Gain 24

SENSE

V

Accuracy −7 ±3 +7 %

SENSE

V

Output Impedance 8 10 12 kΩ

SENSE

Base Drive 15 mA

PWM Turn-On Threshold 3.5 V

PWM Turn-Off Threshold 1.4 V

V

Latch-Off Threshold4 0 0.1 0.3 V

SENSE

Latch-Off Delay

5

PWM Frequency Range DC 500 Hz

C

M

C

Range CL = 47 nF −30 +30 %

LOAD

Operating Current

V

Operating Range 9 27 V

PLUS

6

Shutdown Current PWM low 10 µA

5 V Reference Current 160 200 240 µA

Operating Temperature Range −40 +125 °C

1

VO = 12/5 of the applied reference voltage ±1% typical. Minimum V

2

VO = 12/5 of the applied reference voltage ±2% typical. Minimum V

3

The maximum output current level is set by the selection of the current shunt and power transistor.

4

(V

– 5 V Reference) The latch-off level is determined by the output level of the sense amplifier. When the amplifier output approaches 5 V, the output is latched off.

SENSE

This allows the maximum current output level to be determined by the shunt resistor value. Latch-off can be restored to on by cycling the PWM input off and back on.

5

Internal delay only. The external delay depends on the external capacitor values, LED string impedance, and wiring inductance.

6

This specifies V

only—ground current includes external transistor base drive.

PLUS

= 13.5 V, unless otherwise noted.

PLUS

5 V Reference = 5 V 12 V

= 13 V to 27 V −3 ±1 +3 %

PLUS

= 13 V to 27 V −6 ±2 +6 %

PLUS

R

= 0.4 Ω 500 mA

SHUNT

= 250 mA, CM = 22 nF, CL = 47 nF 12 µs

OUT

2 µs

22 nF

V

> 13 V 360 µA

PLUS

voltage for regulation depends on the external transistor Vbe and the shunt voltage.

PLUS

voltage for regulation depends on the external transistor Vbe and the shunt voltage.

PLUS

Rev. 0 | Page 3 of 12

Page 4

AD8240

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameters Rating

Supply Voltage, Continuous 27 V

Supply Voltage, Transient 30 V

Reverse Supply Protection −0.3 V

Operating Temperature 125°C

Storage Temperature −65°C to +150°C

Output Short-Circuit Duration1Indefinite

1

Output short circuits result in a latch-off condition.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Rev. 0 | Page 4 of 12

Page 5

AD8240

PRODUCT DESCRIPTION

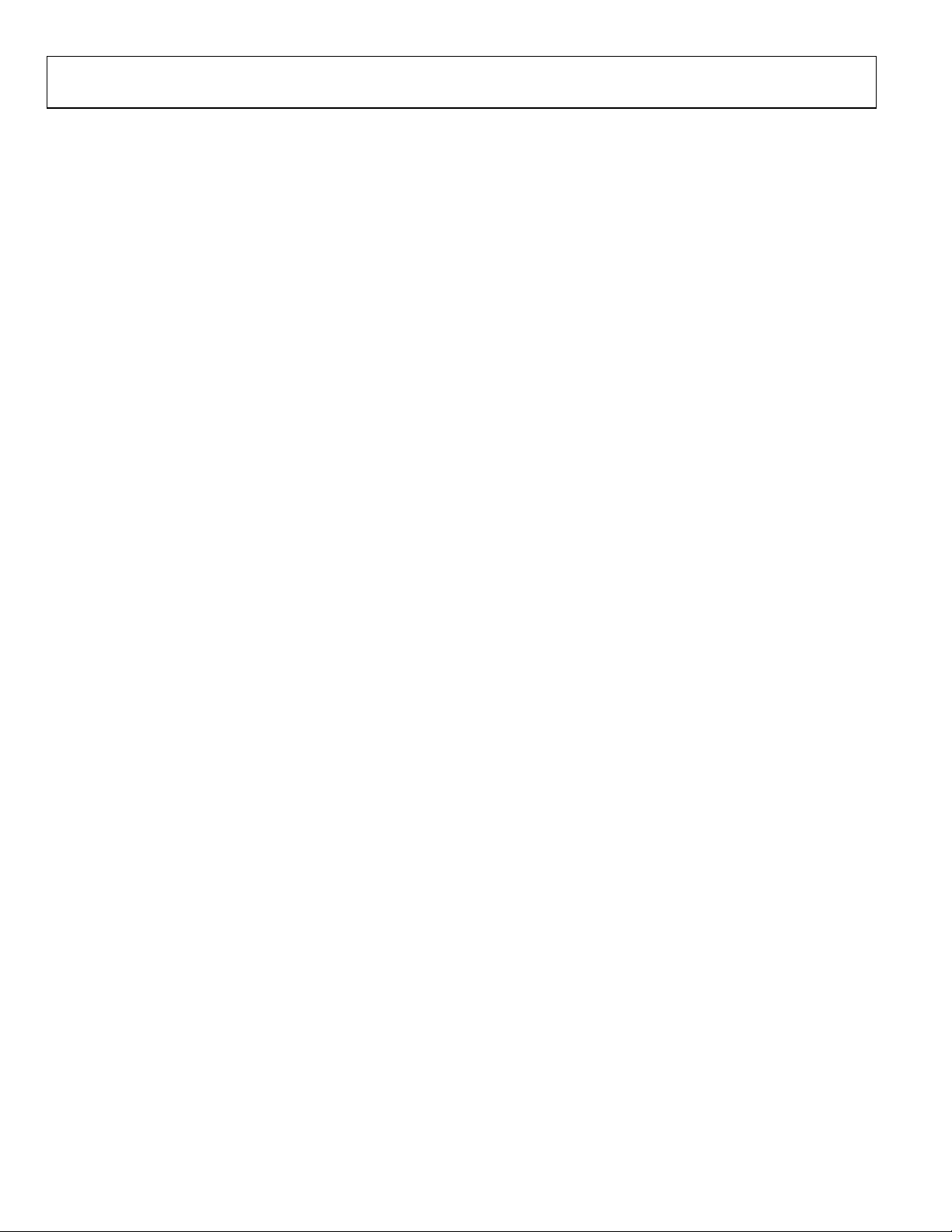

The AD8240 consists of four functional blocks labeled A

through D, as shown in Figure 2.

V

SENSE

REFERENCE

PWM

V

PLUS

B

C

5V

BASESHUNT

D

V

A

O

HIGH-SIDE CURRENT-SENSE AMPLIFIER WITH

OPEN LED DETECTION (BLOCK B)

This amplifier is used to measure the LED current by amplifying the voltage across a user-selected shunt resistor. It has a

gain of 24 and an overall accuracy of 5%. The output of the

amplifier is typically connected to a microcontroller A/D

converter input so that the condition of the LED lamp can be

determined. This output can also be tied to other devices such

as a latching comparator or output buffer. It is important to note

that the output of this amplifier has a relatively high impedance

of approximately 10 kΩ. As a result, a buffer amplifier should be

used if the load is less than 100 kΩ.

AD8240

GND

Figure 2. Simplified Functional Block Diagram

Table 3 briefly describes the blocks, while the sections that

follow provide more detailed information.

Table 3.

Block Description

A Linear regulator

B High-side current-sense amplifier

C Comparator

D Driver

LINEAR REGULATOR (BLOCK A)

The simplified architecture of the linear regulator block is an

amplifier and resistor divider. One input to the amplifier is

tied to the 5 V reference. The other input is tied to a resistor

divider that sets the ratio of the 5 V reference to V

result, the accuracy of the voltage output is proportional to

the accuracy of the 5 V reference. For example, if the 5 V

reference is 5% high (5.25 V), the output is 5% high (12.6 V).

. As a

O

04824-0-002

COMPARATOR WITH LATCH-OFF OVERCURRENT PROTECTION (BLOCK C)

This block is used to shut down the output in the case of a

short circuit or an overcurrent condition. When the output

of the high-side current-sense amplifier approaches 5 V, the

comparator output switches, causing the driver to latch off the

output voltage.

INTELLIGENT DRIVER (BLOCK D)

The intelligent driver provides multiple functions:

• Level shifts and conditions the output of the regulator

amplifier to drive an external user-selected power

transistor.

• Accepts PWM input so that LED brightness can be

controlled by a user-supplied PWM signal.

• The PWM input can also be used as a simple on/off

control for applications that do not require variable

brightness.

• Latch-off input that latches the output off when the

comparator trips during an overcurrent event. The latch

is reset by cycling the PWM input.

Rev. 0 | Page 5 of 12

Page 6

AD8240

≤

USING/EVALUATING THE AD8240 LED DRIVER MONITOR

Figure 3 shows a connection diagram for a typical application.

SETUP

In order to set up and evaluate the AD8240, the following

components and equipment are needed:

• A shunt resistor (typically 0.1 Ω to 0.5 Ω depending on the

load). See the Shunt Resistor Selection section.

• A transistor (the type depends on the load)

• Two capacitors

• LED load

• 5 V reference voltage

• 9 V to 27 V supply

• Oscilloscope

• Digital voltmeter (DVM)

Shunt Resistor Selection

The shunt resistor is chosen by the equation

SHUNT

For example if the load is expected to be 500 mA, the shunt

value should be equal to or less than 0.4 Ω. This keeps the

output of the current sense amplifier from being greater than

4.8 V in normal operation to prevent noise from causing the

output to latch off.

Circuit Configuration

Connect the pass transistor, capacitors, and LED load(s) as

shown in Figure 3. It is important to note that the value of CM

should be at least 22 nF to ensure circuit stability.

The LED lamp should be configured to expect 12 V. This is

the result of selecting the series/parallel combinations of LEDs

and series resistors. The series resistors can be used to adjust

for LED supplier brightness variations from lot to lot.

IR V2.0

LOAD

V

BATT

V

SENSE

REFERENCE

PWM

Connect 5 V to Pin 2 (5 V reference) and at least 9 V to Pin 5

(V

). It may be necessary to raise the V

PLUS

voltage to more

PLUS

than 13 V, depending on the drop across the pass transistor, for

the output to be regulated at 12 V. This varies according to the

application and the pass transistor type.

.

R

SHUNT

C

M

V

PLUS

SHUNT

5

R

SENSE

1

10k

Ω

5V

2

3

6

LATCH-OFF

DRIVER

7

BASE

22nF

V

O

8

R1

Ω

350k

R2

Ω

250k

CL

47nF

4

GND

04824-0-003

Figure 3. Connections for Typical Applications

Rev. 0 | Page 6 of 12

Page 7

AD8240

CONTROLLING THE LED LAMP

The LEDs are turned on and off depending on the CMOS

compatible digital voltage level present at the PWM pin (Pin 3).

This voltage can be continuous for a simple on/off function, or

PWM for dimming control. The PWM frequency should be less

than 500 Hz with a range from 5% to 100%. Typical values are

5% for running and 95% for braking.

USING/EVALUATING THE V

Important: The output impedance of V

OUTPUT

SENSE

SENSE

is approximately

10 kΩ. Because of this, it may be necessary to buffer the output

in order to drive a load of less than 100 kΩ. An oscilloscope,

micro-controller A/D converter, or DVM may be used to

accurately measure the voltage at the V

The V

output is used to detect a partial LED failure, or an

SENSE

overcurrent condition. The voltage present at V

SENSE

pin.

is propor-

SENSE

tional to the current through the load with the equation

I

LOAD

= (V

SENSE

/24)/R

SHUNT

Selection of the shunt resistor can be found by manipulating this

equation.

For example

V

= I

SENSE

LOAD

× R

SHUNT

To determine if the load is correct, the voltage at V

be as follows during full power operation:

500 mA × 0.4 Ω × 24 V/V = 4.8 V

If there is a partial LED failure, V

drops in proportion to the

SENSE

quantity of the failure. For example, if 25% of the LEDs fail, the

voltage drops by 25%.

If there is a short to ground, V

is near 0 V because the

SENSE

output is latched off and no current is flowing.

Using/Evaluating the Short-Circuit Protection Feature

If there is a short or an overload condition, the voltage at

V

falls close to zero, and the output shuts down

SENSE

(the transistor driver shuts off). This resets when the PWM

voltage is brought low and then high again. If the condition

persists, the AD8240 attempts to drive the output to 12 V and

then immediately shuts down. If a PWM voltage is used, the

AD8240 attempts to start after each PWM cycle.

This can be simulated by increasing the load so the voltage at

V

slightly exceeds 5 V. When this happens, the output shuts

SENSE

down, and the V

voltage is close to 0 V.

SENSE

SENSE

should

Expected Load = 500 mA

R

= 0.4 Ω

SHUNT

Rev. 0 | Page 7 of 12

Page 8

AD8240

ADVANTAGES OF DRIVING LED LAMPS WITH CONSTANT VOLTAGE

The advantages of driving LED lamps with constant voltage are

Low system cost

•

Accurate monitoring

•

Proven strategy

•

BACKGROUND

A great variety of LED lamps are being used in automotive

applications. The most popular application is center brake

lamps. Currently, many manufacturers are developing

technology to use LEDs for left/right brake lamps, running

lamps, and turn signals. There are also plans to use high power

LEDs for forward lighting fog lamps and low beams.

There are two fundamental types of LEDs used in these applications. The first is the low power bright LED. The second type is

the high power, extremely bright LED in the 1 W to 10 W range.

While the following information can be applied to applications

using the high power LED, or incandescent lamps, the constant

voltage method is designed for applications typically using the

low power bright LEDs. This type of LED is used in arrays that

form LED lamps.

MONITORING THE LEDS

In addition to driving the LED lamp, the electronics in the

control module must include a method for monitoring partial

LED failure in the lamp. Certain factors, such as overdriving

and mechanical stress, can cause LED failures.

Auto manufacturers are using LED lamps as a way to differentiate themselves and give a car a unique appearance. Several

failed LEDs in the lamp would ruin the aesthetics of the lamp.

As a result, manufacturers are demanding the ability to monitor

the LED lamps for partial failure.

In addition to monitoring the LEDs for aesthetic reasons,

monitoring must also be included as a result of automotive

regulations. These regulations specify the minimum light

output of external lamps. For example, if half of the LEDs in

a particular lamp failed, the lamp would still operate, but the

light output would be insufficient to meet automotive

regulations for brightness. This concern is not an issue for

incandescent bulbs, because they are either completely on or

completely off. The ability of the LED lamp to provide some

light output in the case of partial outage, however, allows for an

extra degree of safety over incandescent lamps. Additionally,

there are automotive regulations requiring the monitoring of

the turn signals regardless of the type of light source.

DRIVING AUTOMOTIVE LEDS

There are two different architectures for driving LEDs in

left/right/center brake lamps, running lamps, and turn signals.

Constant Current

The most common method for driving LEDs is with a constant

current. This current can be supplied from a constant current

source or from a constant voltage source in series with a ballast

resistor. Driving LEDs without some form of ballast carries

some risk of premature LED failure due to thermal runaway in

high temperature ambient conditions.

For example, in the simplest application, the center brake lamp

is driven from a relatively constant voltage with brightness

controlled by a series ballast resistor. This simple driving

method has been used in a wide variety of automotive platforms

for some time. With this method, the LEDs and ballast resistors

are preselected for brightness as part of the manufacturing

strategy.

When driving with a constant current source, LED driving

and monitoring cannot be done using two or fewer wires

(shared ground). Since the current is constant, it does not

change with partial LED failure. Instead, the current is divided

among the remaining functional LEDs, causing them to fail

prematurely at an unpredictable rate. Additionally, it is not

possible to detect partial failure by measuring the voltage

change. The voltage does not change by a detectable amount

because of the steep V/I curve exhibited by bright LEDs. When

using a constant current scheme, at least one additional wire

per lamp must be added to the harness to monitor partial or

total LED failure. Additionally, electronic modules must be

added to each lamp.

Constant Voltage

Driving LEDs with a constant voltage allows for easy, low cost

detection of partial failure, an advantage not available with a

constant-current architecture. This is because the current from

the voltage source changes in direct proportion to the number

of LEDs that have failed. This current can be measured with a

low cost shunt and an amplifier back at the body control

module. This detection scheme is implemented in the AD8240

LED driver/monitor through the use of a high-side, currentsensing amplifier. The current is measured on the high side in

order to separate the current from those combined in the

chassis ground return or shared-wire ground return.

Rev. 0 | Page 8 of 12

Page 9

AD8240

As a result, the constant voltage driving/monitoring method is

the lowest cost and least-prone-to-failure method for driving

and monitoring LEDs from a system perspective. This is

primarily because the number of wires and connections can be

minimized. By using a constant voltage driver and measuring

the current, an LED lamp can be driven

only two wires (power and ground). In many cases, this can be

reduced to one wire when the chassis or shared ground return

is used. This is a similar architecture used with incandescent

bulbs, which means no changes to the wiring harness are

necessary with this LED implementation.

Most automotive platforms no longer use a switch on the

dashboard to directly control the incandescent lamps. These

lamps are now controlled and driven by the body control ECU.

By using this constant voltage architecture, the control and drive

function for the LEDs can remain in the ECU with minimal

design modification.

and monitored using

Constant voltage driving/monitoring is a proven method

already in use in a number of automotive platforms to drive

LED tail, running, and turn-indicator lamps.

The AD8240 LED lamp driver/monitor is designed for use in

the body control or related module. When used this way, it is

very similar to the method that has been used to control

external incandescent lamps. By utilizing the existing lamp

driving architecture, additional modules are not required to

drive the external lamps, which further minimizes the cost.

It is possible to retrofit existing lamp driving modules with

the AD8240 with minimal engineering time required.

Rev. 0 | Page 9 of 12

Page 10

AD8240

OUTLINE DIMENSIONS

3.00

BSC

85

3.00

BSC

PIN 1

0.65 BSC

0.15

0.00

0.38

0.22

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187AA

4

SEATING

PLANE

4.90

BSC

1.10 MAX

0.23

0.08

8°

0°

0.80

0.60

0.40

Figure 4. 8-Lead Mini Small Outline Package [MSOP]

(RM-8)

Dimensions shown in millimeters

Rev. 0 | Page 10 of 12

Page 11

AD8240

ORDERING GUIDE

Model Temperature Range Package Description Package Option Package Outline

AD8240YRM −40°C to +125°C 8-Lead MSOP RM-8 JTA

AD8240YRM-REEL −40°C to +125°C MSOP, 13” Tape and Reel RM-8 JTA

AD8240YRM-REEL7 −40°C to +125°C MSOP, 7” Tape and Reel RM-8 JTA

Rev. 0 | Page 11 of 12

Page 12

AD8240

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D04824-0-4/04(0)

Rev. 0 | Page 12 of 12

Loading...

Loading...