Page 1

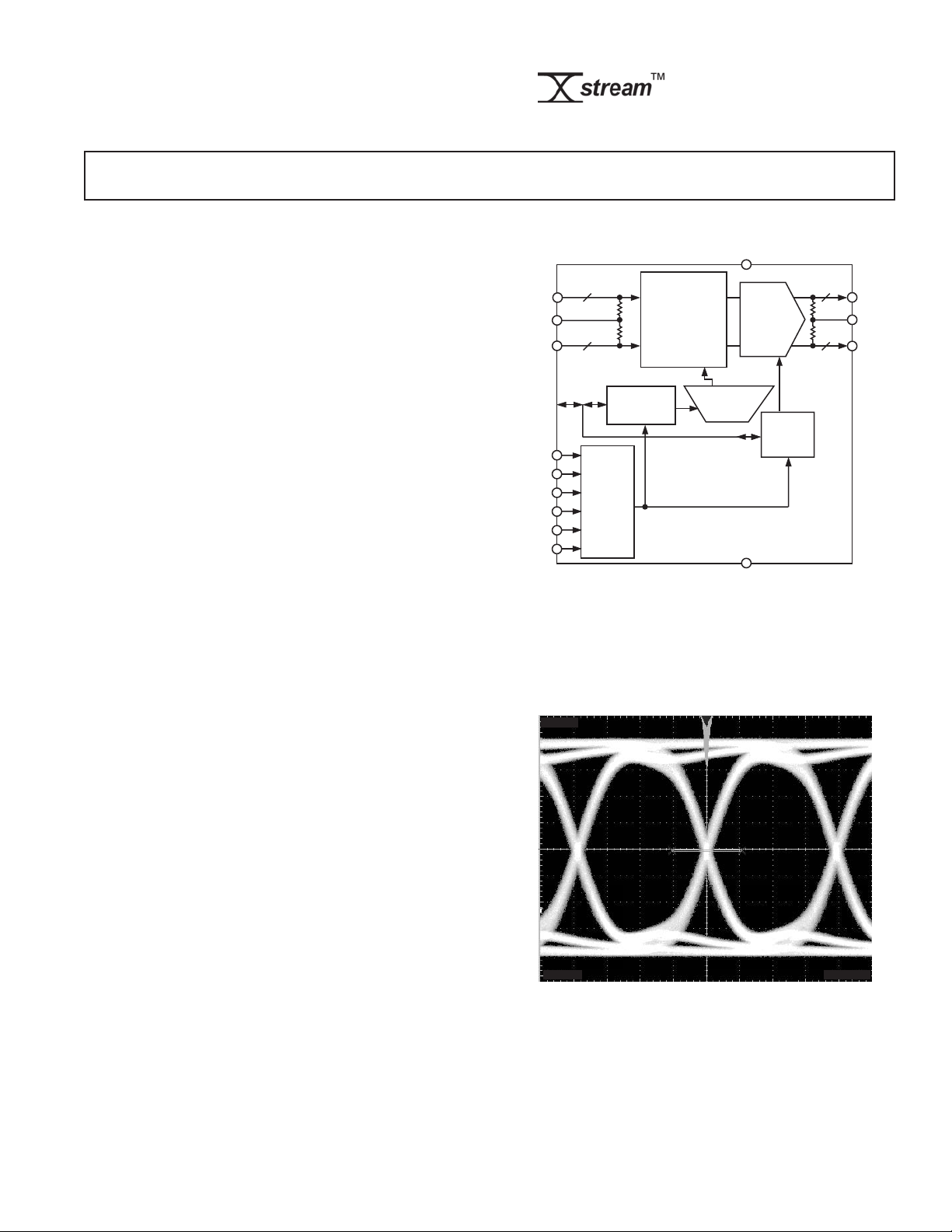

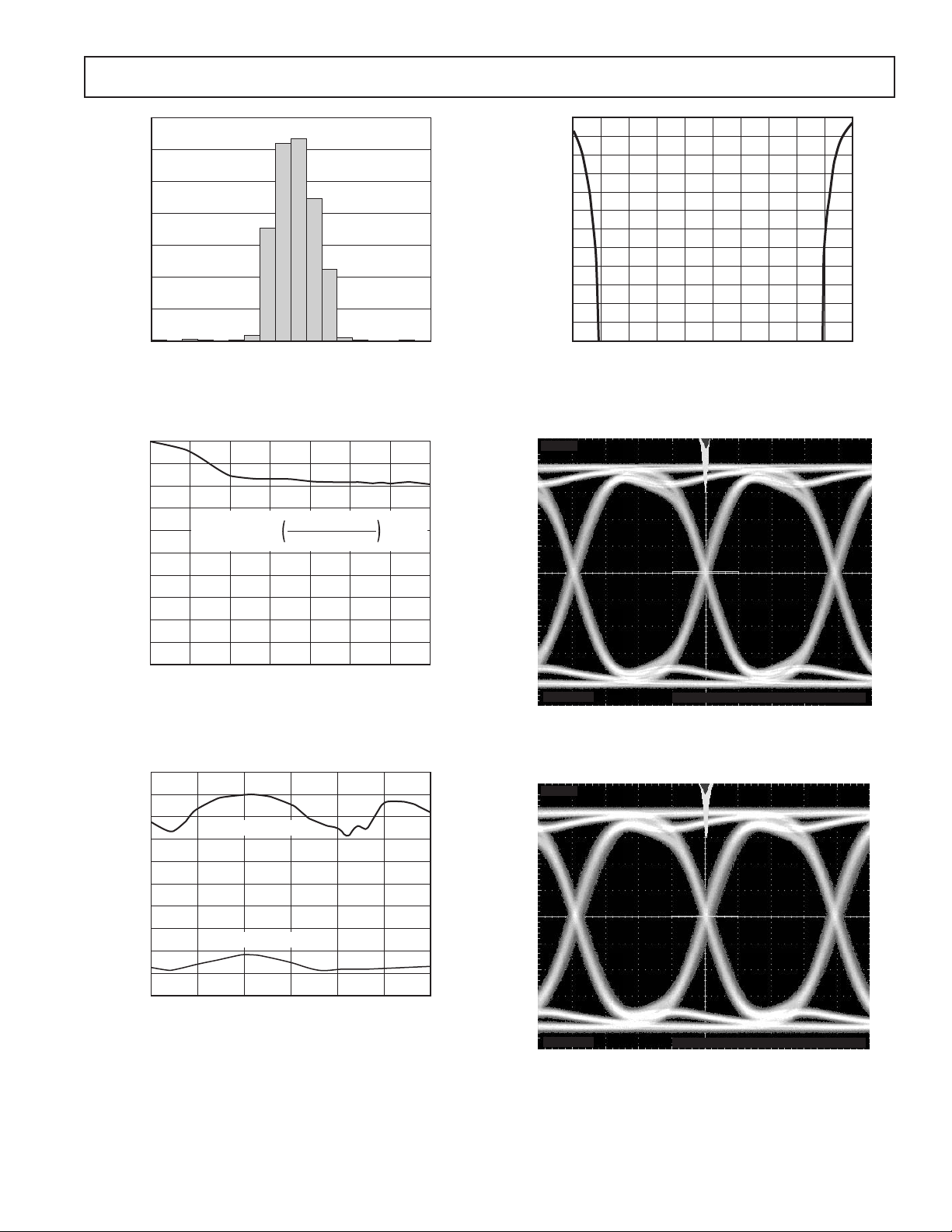

34 ⴛ 34, 3.2 Gbps

OUTPUT

LEVEL

DACs

OUTN

OUTP

VTTO

34 ⴛ 34

DIFFERENTIAL

SWITCH MATRIX

34

34

MATRIX

CONNECTION

LATCHES

CONNECTION

DECODE

OUTPUT

LEVEL

LATCHES

CONTROL

LOGIC

INN

VTTI

INP

D[5:0]

A[6:0]

RE

WE

RESET

CS

UPDATE

VEE

VCC

AD8152

34

34

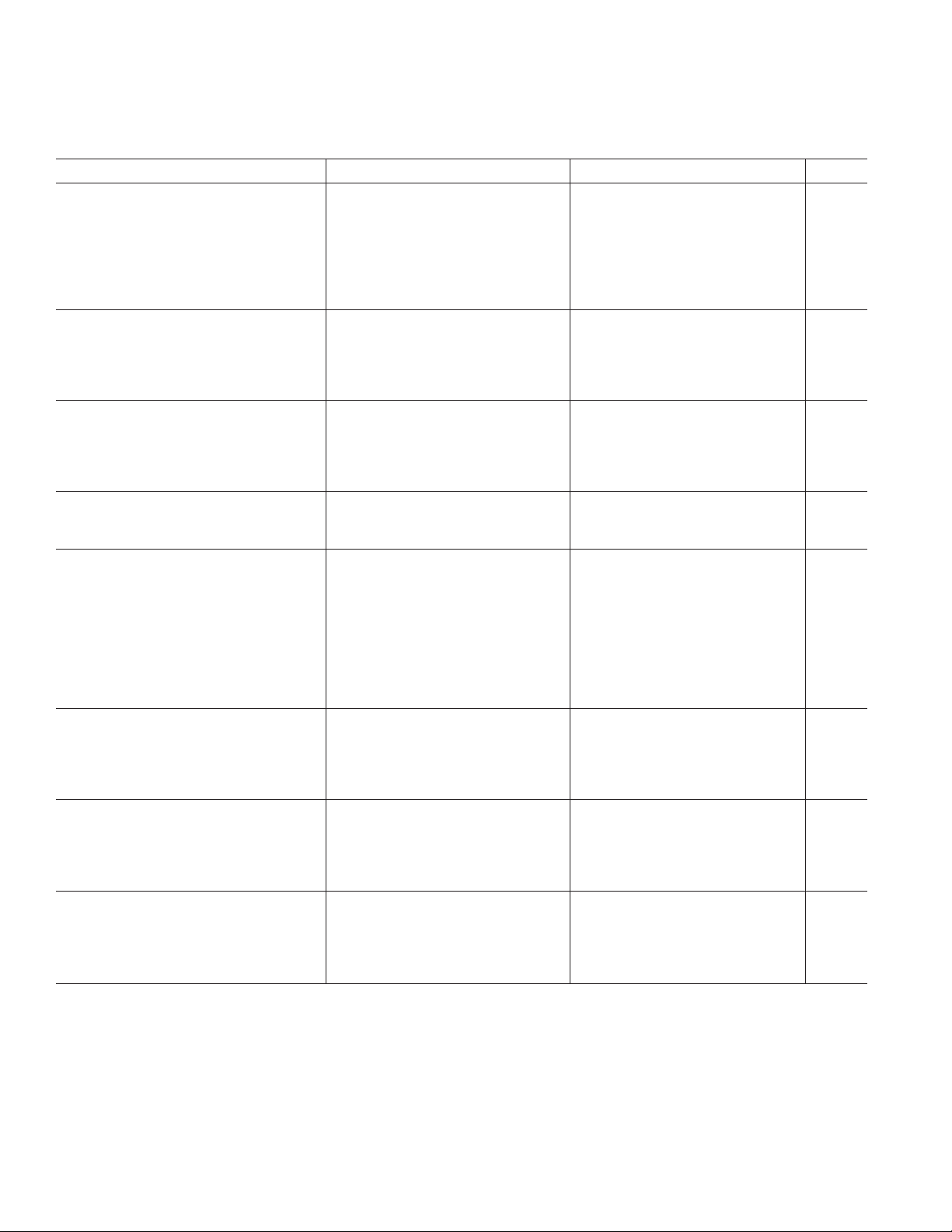

80ps/DIV

100mV/DIV

a

Asynchronous Digital Crosspoint Switch

FEATURES

Low Cost

Low Power

2.0 W @ 2.5 V (Outputs Enabled)

<100 mW @ 2.5 V (Outputs Disabled)

34 ⴛ 34, Fully Differential, Nonblocking Array

3.2 Gbps per Port NRZ Data Rate

Wide Power Supply Range: 2.5 V to 3.3 V

LVTTL or LVCMOS Level Control Inputs:

@ 2.5 V to 3.3 V

Low Jitter: 45 ps

Drives a Backplane Directly

Programmable Output Swing

100 mV to 1.6 V Differential

50 ⍀ On-Chip I/O Termination

User Controlled Voltage at the Load

Minimizes Power Dissipation

Dual Rank Latches

Available in 256-Ball Grid Array

APPLICATIONS

Fiber Optic Network Switching

High Speed Serial Backplane Routing to OC-48 with FEC

Gigabit Ethernet

Digital Video (HDTV)

Data Storage Networks

AD8152

FUNCTIONAL BLOCK DIAGRAM

*

GENERAL DESCRIPTION

AD8152 is a member of the Xstream line of products and is a

breakthrough in digital switching, offering a large switch array

(34 × 34) on very little power, typically 2.0 W. Additionally, it

operates at data rates up to 3.2 Gbps per port, making it suitable

for Sonet/SDH OC-48 with Forward Error Correction (FEC).

The AD8152’s useful supply voltage range allows the user to

operate at LVPECL/CML data levels down to 2.5 V. The control

interface is LVTTL or LVCMOS compatible on 2.5 V to 3.3 V.

The AD8152’s fully differential signal path reduces jitter and

crosstalk while allowing the use of smaller single-ended voltage

swings. It is offered in a 256-ball SBGA package that operates

over the industrial temperature range of 0°C to 85°C.

*Patent Pending

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

Figure 1. Eye Pattern, 3.2 Gbps, PRBS 23

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

Page 2

AD8152

(@ 25ⴗC, VCC = 2.5 V to 3.3 V, VEE = 0 V, RL = 50 ⍀, Differential Output Swing = 800 mV p-p,

ELECTRICAL CHARACTERISTICS

Parameter Condition Min Typ Max Unit

DYNAMIC PERFORMANCE

Max Data Rate/Channel (NRZ) 3.2 Gbps

Channel Jitter Data Rate £ 3.2 Gbps; PRBS 2

RMS Channel Jitter <10 ps

Propagation Delay Input to Output 660 800 ps

Propagation Delay Match ± 50 ± 120 ps

Output Rise/Fall Time 20% to 80% 100 ps

INPUT CHARACTERISTICS

Input Voltage Swing Single-Ended (See TPC 14) 50 1000 mV p-p

Input Voltage Range Common-Mode (See TPC 15) VEE + 0.8 VCC + 0.2 V

Input Bias Current 2 mA

Input Capacitance 2pF

OUTPUT CHARACTERISTICS

Output Voltage Swing Differential (See TPC 18) 100 800 1600 mV p-p

Output Voltage Range VCC – 1.2 VCC + 0.2 V

Output Current 2 32 mA

Output Capacitance 2pF

TERMINATION CHARACTERISTICS

Resistance 43 50 57 W

Temperature Coefficient 0.05 W/∞C

POWER SUPPLY

Operating Range

VCC VEE = 0 V 2.25 3.63 V

Quiescent Current

VCC All Outputs Disabled 32 45 mA

VEE All Outputs Disabled 32 45 mA

LOGIC INPUT CHARACTERISTICS

Input High (VIH) VCC = 3.3 V 2 V

Input Low (VIL) VCC = 3.3 V 0.8 V

Input High (VIH) VCC = 2.5 V 1.7 V

Input Low (VIL) VCC = 2.5 V 0.7 V

LOGIC OUTPUT CHARACTERISTICS

Output High (VOH) VCC = 3.3 V, IOH = –2 mA 2.4 V

Output Low (VOL) VCC = 3.3 V, IOL = +2 mA 0.4 V

Output High (VOH) VCC = 2.5 V, IOH = –100 uA 2.1 V

Output Low (VOL) VCC = 2.5 V, IOL = +100 uA 0.2 V

THERMAL CHARACTERISTICS

Operating Temperature Range 0 85 ∞C

JA

Specifications subject to change without notice.

unless otherwise noted.)

23

– 1 45 ps p-p

All Outputs Enabled 190 mA

All Outputs Enabled 770 mA

to T

T

MIN

Still Air 15 ∞C/W

200 lfpm 12 ∞C/W

400 lfpm 11 ∞C/W

All Outputs Enabled 800 mA

MAX,

REV. A–2–

Page 3

AD8152

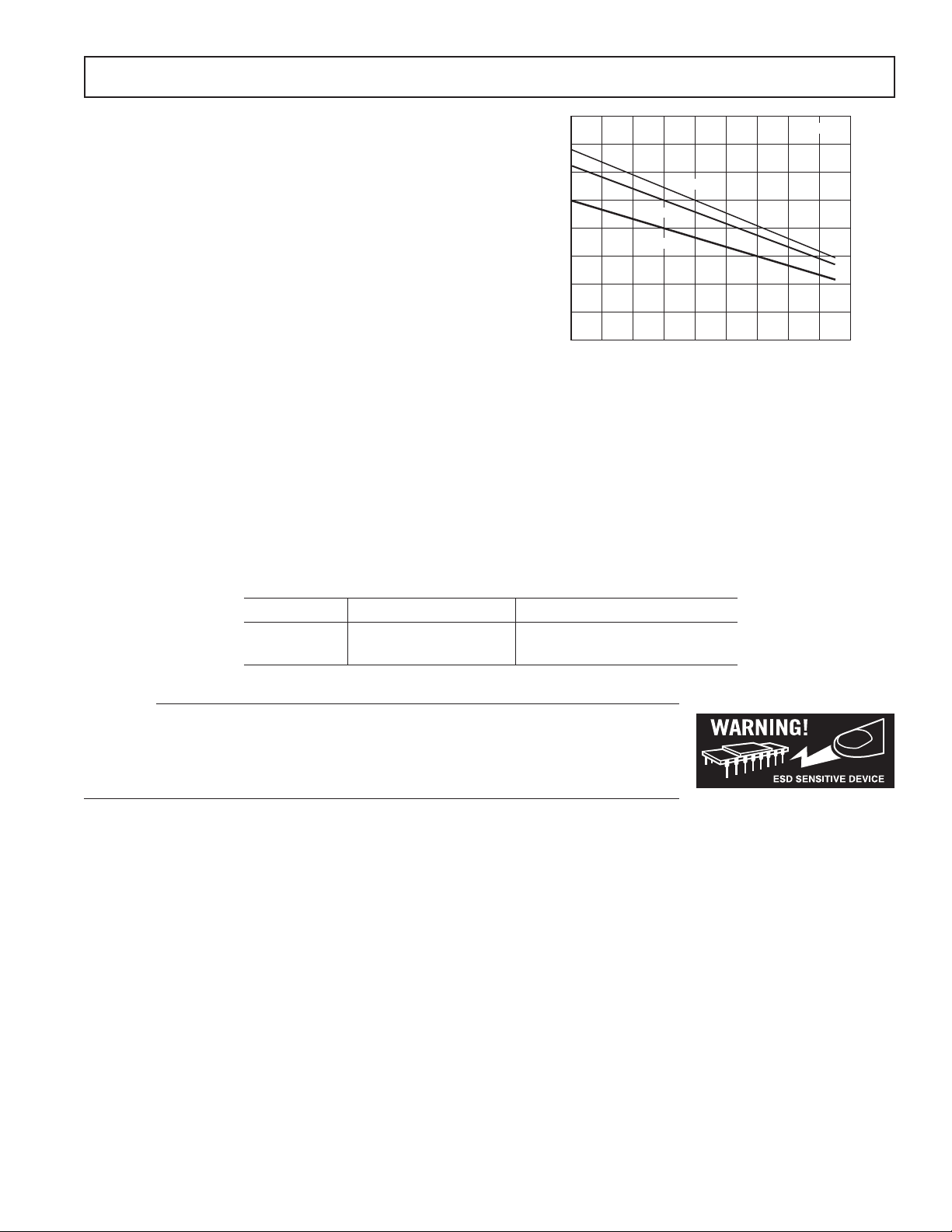

16

0

09010 20 30 40 50 60 70 80

14

8

6

4

2

12

10

AMBIENT TEMPERATURE – ⴗC

MAXIMUM POWER DISSIPATION – W

Tj = 150ⴗC

400 lfpm

200 lfpm

STIL L AIR

ABSOLUTE MAXIMUM RATINGS

1

VCC to VEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7 V

VTTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC + 0.6 V

VTTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC + 0.6 V

Internal Power Dissipation

2

AD8152 256-Ball SBGA (BP) . . . . . . . . . . . . . . . . . .8.33 W

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . VCC + 0.6 V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . 1.7 V

Logic Input Voltage . . . . . . VEE – 0.3 V < V

< VCC + 0.6 V

IN

Storage Temperature Range . . . . . . . . . . . . . –65°C to +125°C

Lead Temperature Range . . . . . . . . . . . . . . . . . . . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for the device in free air (TA = 25°C): JA = 15°C/W @ still air.

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the AD8152 is

limited by the associated rise in junction temperature. The maximum safe junction temperature for plastic encapsulated devices

is determined by the glass transition temperature of the plastic,

approximately 150°C. Temporarily exceeding this limit may cause

Figure 2. Maximum Power Dissipation vs. Temperature

a shift in parametric performance due to a change in the stresses

exerted on the die by the package. Exceeding a junction temperature of 175°C for an extended period can result in device

failure. To ensure proper operation, it is necessary to observe the

maximum power derating curves shown in Figure 2.

ORDERING GUIDE

Model Temperature Range Package Description

AD8152JBP 0°C to 85°C 256-Ball SBGA (27 mm × 27 mm)

AD8152-EVAL Evaluation Board

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD8152 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. A

–3–

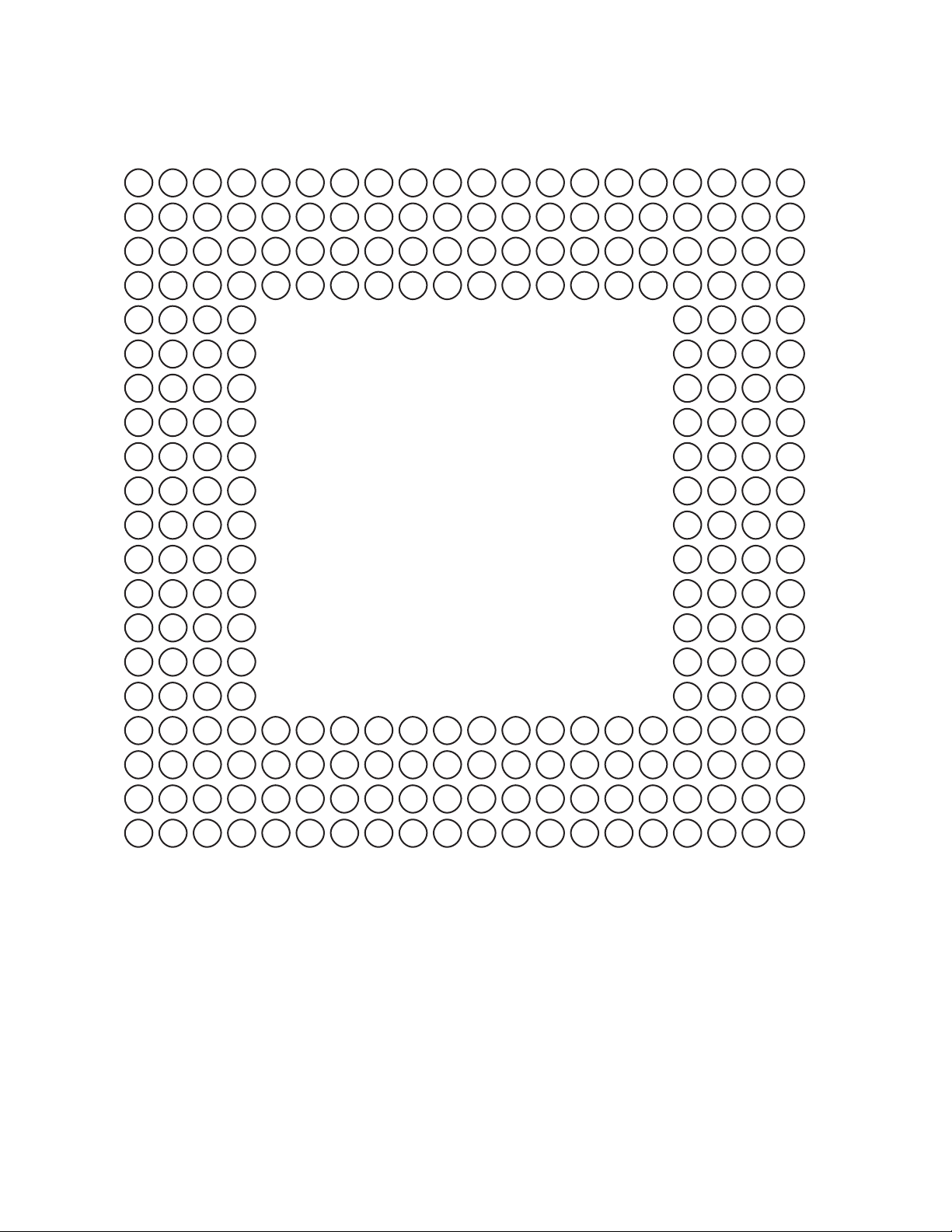

Page 4

AD8152

A

BALL GRID ARRAY

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

VEE

VEE

VEE

VEE

VEE

O14P

O11P

VCCVCC

O08P

VTTOVTTO

O05P

VTTOVTTO

O02P

VTTO

VCC

VEE

VEE

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

VEE

VEE

VEEVEE

D1

RESET

CS

RE

VCC

I19P

I19N

VTTI

VTTI

I22N

I22P

VTTI VTTI

I25N

I25P

VCC

VCC

I28N

I28P

VTTI VTTI

I31N

VEE

VEE

D5D4

D2 D3D0

N/C N/C

I17P

I17N

I18PI18N

I20N

I20P

I21N I21P

I23N

I23P

I24P

I24N

I26P I26N

I27P

I27N

I29P I29N

I30N

I30PI31P

VCC

VTTO

O16N

O15P

O16P O15N

VTTO

O14N

O12P

O13P O12N

O11N

O10N

O10P

O09P

O09N

VTTO VTTO

O08N

O07N

O06P O04NO13N

O07P O06N

O05N

O03P O01N

O04P O03N

VTTO

O02N

O00P

O01P O00N

VEE

VCCVCC

A5A6

A4 A3

N/C

N/C

I00N

I00P

I01P I02PI02N

I01N

I03N I03P

I04P

I04N I05N I05P

I06N I06P

I07P

I07N I08N I08P

I09N

I09P

I10P I10N

I12P

I12N

I13NI13P

VEE

VEE

UPDATE

WE

VTTI

VTTI

I11N I11P

VTTI

I14N I14P

VEE

VEE

A1A2

A0

VCC

VTTI

VTTI

VCCVCC

VTTI

B

C

D

E

F

G

H

J

K

L

M

N

P

R

VTTI

VTTI

T

VCC

U

VEE

V

VEE

W

VEE

Y

VCC

VEE

VEE

VEE

I32P I32N

I33N

VEE

VEE

VEE

VEE

VEE

O21P

O29NO30P

VTTO

VTTO

O27P O26N

O27N

O26PO32P

VCC

O28N

VCC

O28P

O32N

O33P

I33P

O33N

VCC VCC

VTTO

O31N

VCC

O31P

O23NO24P

O24N O23P

O25N

VTTOVTTO

O25P

O21NO30N O29P

O22N

O22P

O20N

O20P

VTTO

VTTO

O18N O17P

O19N

O19P

O17NO18P

VTTOVTTO

VTTO

I15N

VEEVEE

VCC

I15P

I16NI16P

VEE VEE VEE

VEE VEE VEE

VEE VEE VEE

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

Ball Diagram, View from the Bottom

VTTI

VTTI

VCC VCC

T

U

V

W

Y

REV. A–4–

Page 5

BALL GRID DESCRIPTIONS

AD8152

Ball Mnemonic Type Description

A1 VEE Power Negative Supply

A2 VEE Power Negative Supply

A3 VEE Power Negative Supply

A4 VCC Power Positive Supply

A5 VTTO Power Output Termination Supply

A6 OUT02P I/O High Speed Output

A7 VTTO Power Output Termination Supply

A8 OUT05P I/O High Speed Output

A9 VTTO Power Output Termination Supply

A10 OUT08P I/O High Speed Output

A11 VCC Power Positive Supply

A12 OUT11P I/O High Speed Output

A13 VTTO Power Output Termination Supply

A14 OUT14P I/O High Speed Output

A15 VTTO Power Output Termination Supply

A16 VCC Power Positive Supply

A17 VEE Power Negative Supply

A18 VEE Power Negative Supply

A19 VEE Power Negative Supply

A20 VEE Power Negative Supply

B1 VEE Power Negative Supply

B2 VEE Power Negative Supply

B3 VEE Power Negative Supply

B4 VCC Power Positive Supply

B5 VTTO Power Output Termination Supply

B6 OUT02N I/O High Speed Output Complement

B7 VTTO Power Output Termination Supply

B8 OUT05N I/O High Speed Output Complement

B9 VTTO Power Output Termination Supply

B10 OUT08N I/O High Speed Output Complement

B11 VCC Power Positive Supply

B12 OUT11N I/O High Speed Output Complement

B13 VTTO Power Output Termination Supply

B14 OUT14N I/O High Speed Output Complement

B15 VTTO Power Output Termination Supply

B16 VCC Power Positive Supply

B17 VEE Power Negative Supply

B18 VEE Power Negative Supply

B19 VEE Power Negative Supply

B20 VEE Power Negative Supply

C1 VEE Power Negative Supply

C2 VEE Power Negative Supply

C3 A5 Control Output Address Pin (MSB)

C4 A6 Control Output Address Pin (Bank Des.)

C5 OUT00P I/O High Speed Output

C6 OUT01N I/O High Speed Output Complement

C7 OUT03P I/O High Speed Output

C8 OUT04N I/O High Speed Output Complement

C9 OUT06P I/O High Speed Output

C10 OUT07N I/O High Speed Output Complement

C11 OUT09P I/O High Speed Output

Ball Mnemonic Type Description

C12 OUT10N I/O High Speed Output Complement

C13 OUT12P I/O High Speed Output

C14 OUT13N I/O High Speed Output Complement

C15 OUT15P I/O High Speed Output

C16 OUT16N I/O High Speed Output Complement

C17 D5 Control Input Address Pin (MSB)

C18 D4 Control Input Address Pin

C19 VEE Power Negative Supply

C20 VEE Power Negative Supply

D1 A1 Control Output Address Pin

D2 A2 Control Output Address Pin

D3 A3 Control Output Address Pin

D4 A4 Control Output Address Pin

D5 OUT00N I/O High Speed Output Complement

D6 OUT01P I/O High Speed Output

D7 OUT03N I/O High Speed Output Complement

D8 OUT04P I/O High Speed Output

D9 OUT06N I/O High Speed Output Complement

D10 OUT07P I/O High Speed Output

D11 OUT09N I/O High Speed Output Complement

D12 OUT10P I/O High Speed Output

D13 OUT12N I/O High Speed Output Complement

D14 OUT13P I/O High Speed Output

D15 OUT15N I/O High Speed Output Complement

D16 OUT16P I/O High Speed Output

D17 D3 Control Input Address Pin

D18 D2 Control Input Address Pin

D19 D1 Control Input Address Pin

D20 D0 Control Input Address Pin (LSB)

E1 A0 Control Output Address Pin (LSB)

E2 UPDATE Control Second Rank Write Enable

E3 N/C Reserved Do Not Connect

E4 N/C Reserved Do Not Connect

E17 N/C Reserved Do Not Connect

E18 N/C Reserved Do Not Connect

E19 RESET Control Reset/Disable Outputs

E20 CS Control Chip Select Enable

F1 VCC Power Positive Supply

F2 WE Control First Rank Write Enable

F3 IN00P I/O High Speed Input

F4 IN00N I/O High Speed Input Complement

F17 IN17N I/O High Speed Input Complement

F18 IN17P I/O High Speed Input

F19 RE Control Readback Enable

F20 VCC Power Positive Supply

G1 IN02P I/O High Speed Input

G2 IN02N I/O High Speed Input Complement

G3 IN01N I/O High Speed Input Complement

G4 IN01P I/O High Speed Input

G17 IN18P I/O High Speed Input

G18 IN18N I/O High Speed Input Complement

REV. A

–5–

Page 6

AD8152

BALL GRID DESCRIPTIONS (continued)

Ball Mnemonic Type Description

G19 IN19N I/O High Speed Input Complement

G20 IN19P I/O High Speed Input

H1 VTTI Power Input Termination Supply

H2 VTTI Power Input Termination Supply

H3 IN03P I/O High Speed Input

H4 IN03N I/O High Speed Input Complement

H17 IN20N I/O High Speed Input Complement

H18 IN20P I/O High Speed Input

H19 VTTI Power Input Termination Supply

H20 VTTI Power Input Termination Supply

J1 IN05P I/O High Speed Input

J2 IN05N I/O High Speed Input Complement

J3 IN04N I/O High Speed Input Complement

J4 IN04P I/O High Speed Input

J17 IN21P I/O High Speed Input

J18 IN21N I/O High Speed Input Complement

J19 IN22N I/O High Speed Input Complement

J20 IN22P I/O High Speed Input

K1 VTTI Power Input Termination Supply

K2 VTTI Power Input Termination Supply

K3 IN06P I/O High Speed Input Complement

K4 IN06N I/O High Speed Input

K17 IN23N I/O High Speed Input Complement

K18 IN23P I/O High Speed Input

K19 VTTI Power Input Termination Supply

K20 VTTI Power Input Termination Supply

L1 IN08P I/O High Speed Input

L2 IN08N I/O High Speed Input Complement

L3 IN07N I/O High Speed Input Complement

L4 IN07P I/O High Speed Input

L17 IN24P I/O High Speed Input

L18 IN24N I/O High Speed Input Complement

L19 IN25N I/O High Speed Input Complement

L20 IN25P I/O High Speed Input

M1 VCC Power Positive Supply

M2 VCC Power Positive Supply

M3 IN09P I/O High Speed Input

M4 IN09N I/O High Speed Input Complement

M17 IN26N I/O High Speed Input Complement

M18 IN26P I/O High Speed Input

M19 VCC Power Positive Supply

M20 VCC Power Positive Supply

N1 IN11P I/O High Speed Input

N2 IN11N I/O High Speed Input Complement

N3 IN10N I/O High Speed Input Complement

N4 IN10P I/O High Speed Input

N17 IN27P I/O High Speed Input

N18 IN27N I/O High Speed Input Complement

N19 IN28N I/O High Speed Input Complement

N20 IN28P I/O High Speed Input

P1 VTTI Power Input Termination Supply

Ball Mnemonic Type Description

P2 VTTI Power Input Termination Supply

P3 IN12P I/O High Speed Input

P4 IN12N I/O High Speed Input Complement

P17 IN29N I/O High Speed Input Complement

P18 IN29P I/O High Speed Input

P19 VTTI Power Input Termination Supply

P20 VTTI Power Input Termination Supply

R1 IN14P I/O High Speed Input

R2 IN14N I/O High Speed Input Complement

R3 IN13N I/O High Speed Input Complement

R4 IN13P I/O High Speed Input

R17 IN30P I/O High Speed Input

R18 IN30N I/O High Speed Input Complement

R19 IN31N I/O High Speed Input Complement

R20 IN31P I/O High Speed Input

T1 VTTI Power Input Termination Supply

T2 VTTI Power Input Termination Supply

T3 IN15P I/O High Speed Input

T4 IN15N I/O High Speed Input Complement

T17 IN32N I/O High Speed Input Complement

T18 IN32P I/O High Speed Input

T19 VTTI Power Input Termination Supply

T20 VTTI Power Input Termination Supply

U1 VCC Power Positive Supply

U2 VCC Power Positive Supply

U3 IN16N I/O High Speed Input Complement

U4 IN16P I/O High Speed Input

U5 OUT17N I/O High Speed Output Complement

U6 OUT18P I/O High Speed Output

U7 OUT20N I/O High Speed Output Complement

U8 OUT21P I/O High Speed Output

U9 OUT23N I/O High Speed Output Complement

U10 OUT24P I/O High Speed Output

U11 OUT26N I/O High Speed Output Complement

U12 OUT27P I/O High Speed Output

U13 OUT29N I/O High Speed Output

U14 OUT30P I/O High Speed Output

U15 OUT32N I/O High Speed Output Complement

U16 OUT33P I/O High Speed Output

U17 IN33P I/O High Speed Input

U18 IN33N I/O High Speed Input Complement

U19 VCC Power Positive Supply

U20 VCC Power Positive Supply

V1 VEE Power Negative Supply

V2 VEE Power Negative Supply

V3 VEE Power Negative Supply

V4 VEE Power Negative Supply

V5 OUT17P I/O High Speed Output

V6 OUT18N I/O High Speed Output Complement

V7 OUT20P I/O High Speed Output

V8 OUT21N I/O High Speed Output Complement

REV. A–6–

Page 7

BALL GRID DESCRIPTIONS (continued)

AD8152

Ball Mnemonic Type Description

V9 OUT23P I/O High Speed Output

V10 OUT24N I/O High Speed Output Complement

V11 OUT26P I/O High Speed Output

V12 OUT27N I/O High Speed Output Complement

V13 OUT29P I/O High Speed Output

V14 OUT30N I/O High Speed Output Complement

V15 OUT32P I/O High Speed Output

V16 OUT33N I/O High Speed Output Complement

V17 VEE Power Negative Supply

V18 VEE Power Negative Supply

V19 VEE Power Negative Supply

V20 VEE Power Negative Supply

W1 VEE Power Negative Supply

W2 VEE Power Negative Supply

W3 VEE Power Negative Supply

W4 VCC Power Positive Supply

W5 VTTO Power Output Termination Supply

W6 OUT19N I/O High Speed Output Complement

W7 VTTO Power Output Termination Supply

W8 OUT22N I/O High Speed Output Complement

W9 VTTO Power Output Termination Supply

W10 OUT25N I/O High Speed Output Complement

W11 VCC Power Positive Supply

W12 OUT28N I/O High Speed Output Complement

W13 VTTO Power Output Termination Supply

W14 OUT31N I/O High Speed Output Complement

Ball Mnemonic Type Description

W15 VTTO Power Output Termination Supply

W16 VCC Power Positive Supply

W17 VEE Power Negative Supply

W18 VEE Power Negative Supply

W19 VEE Power Negative Supply

W20 VEE Power Negative Supply

Y1 VEE Power Negative Supply

Y2 VEE Power Negative Supply

Y3 VEE Power Negative Supply

Y4 VCC Power Positive Supply

Y5 VTTO Power Output Termination Supply

Y6 OUT19P I/O High Speed Output

Y7 VTTO Power Output Termination Supply

Y8 OUT22P I/O High Speed Output

Y9 VTTO Power Output Termination Supply

Y10 OUT25P I/O High Speed Output

Y11 VCC Power Positive Supply

Y12 OUT28P I/O High Speed Output

Y13 VTTO Power Output Termination Supply

Y14 OUT31P I/O High Speed Output

Y15 VTTO Power Output Termination Supply

Y16 VCC Power Positive Supply

Y17 VEE Power Negative Supply

Y18 VEE Power Negative Supply

Y19 VEE Power Negative Supply

Y20 VEE Power Negative Supply

REV. A

–7–

Page 8

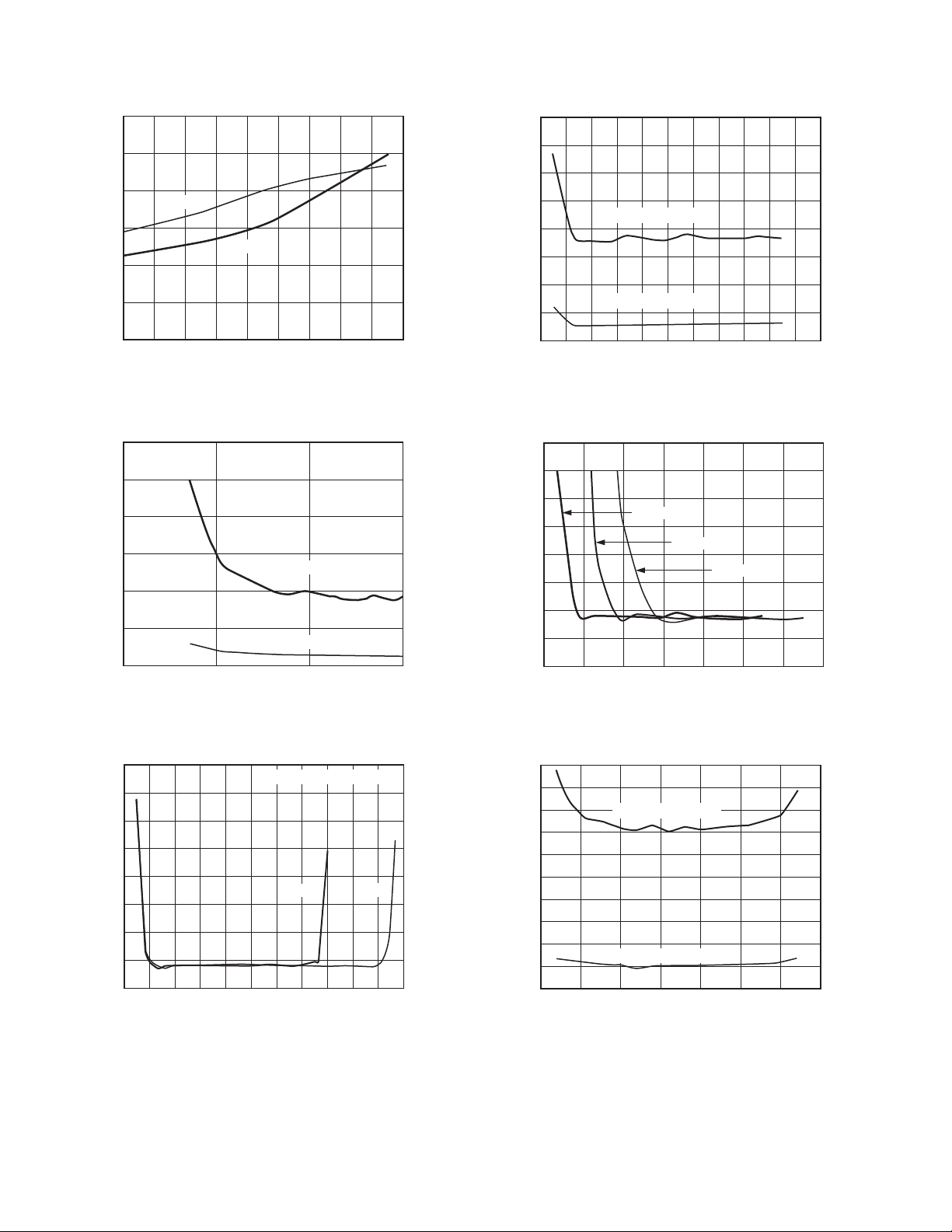

AD8152–Typical Performance Characteristics

(2.5 V Supply, VCC = VTTI = VTTO, Data Rate = 3.2 Gbps;

PRBS 223–1; Differential Output Swing = 800 mV p-p; RL = 50 ⍀; Input Amplitude = 0.4 V p-p Single-Ended; unless otherwise noted.)

100mV/DIV

100mV/DIV

80ps/DIV

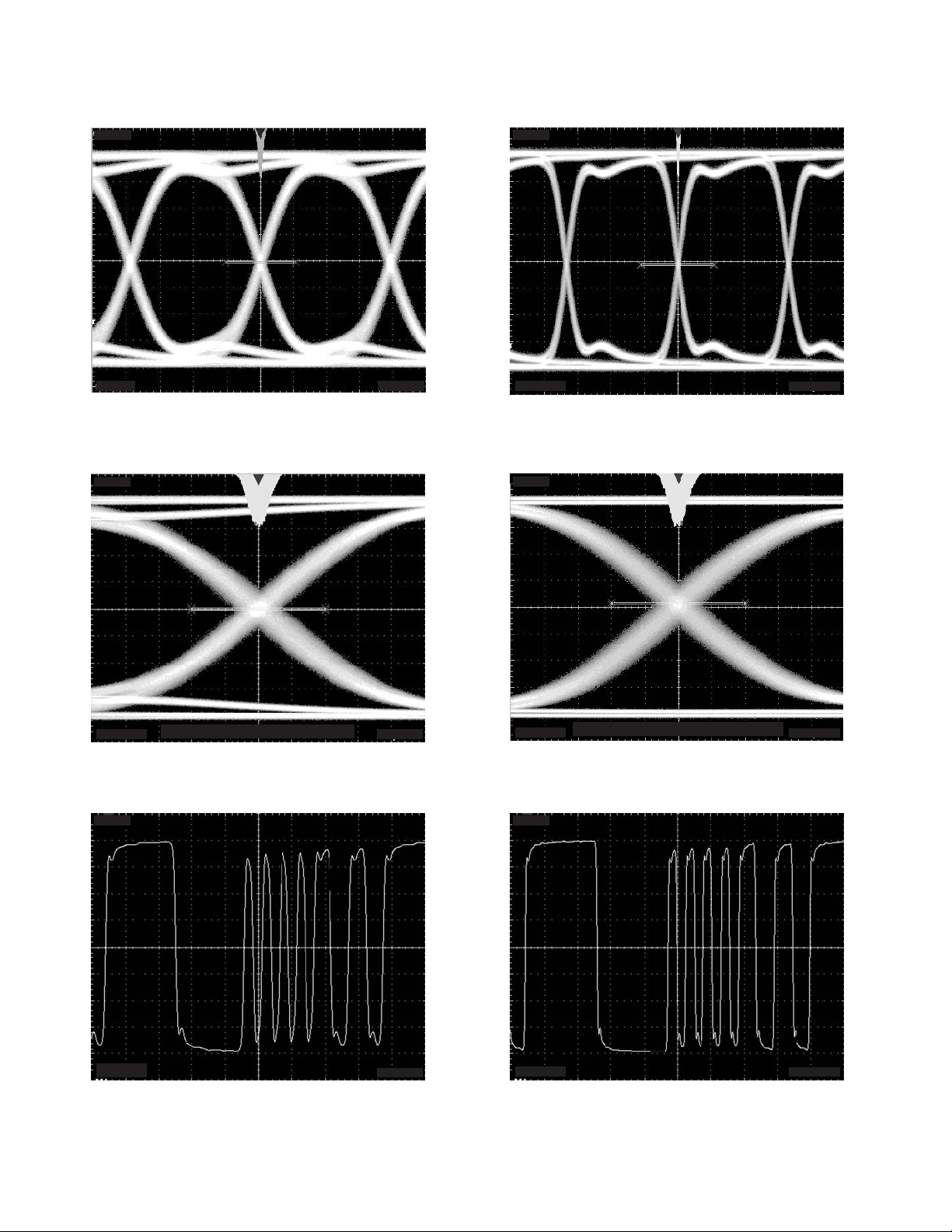

TPC 1. Eye Pattern 3.2 Gbps

PEAK-PEAK JITTER = 35ps STD DEV = 5.1ps

20ps/DIV

TPC 2. Jitter @ 3.2 Gbps

100mV/DIV

200ps/DIV

TPC 4. Eye Pattern 1.5 Gbps

100mV/DIV

PEAK-PEAK JITTER = 35ps STD DEV = 5.2ps

20ps/DIV

TPC 5. Jitter @ 1.5 Gbps

100mV/DIV

1.2ns/DIV

TPC 3. Response, 3.2 Gbps, 32-Bit Pattern

1111 1111 0000 0000 1010 1010 1100 1100

100mV/DIV

2.5ns/DIV

TPC 6. Response, 1.5 Gbps, 32-Bit Pattern

1111 1111 0000 0000 1010 1010 1100 1100

REV. A–8–

Page 9

AD8152

UNIT INTERVAL

1.E+00

0.1

–0.5

BIT ERROR RATE

–0.4

–0.3 –0.2 –0.1 0 0.2 0.3 0.4 0.5

1.E–01

1.E–02

1.E–03

1.E–04

1.E–05

1.E–06

1.E–07

1.E–08

1.E–09

1.E–10

1.E–11

1.E–12

100mV/DIV

80ps/DIV

PEAK-PEAK JITTER = 35ps STD DEV = 5.6ps

100mV/DIV

80ps/DIV

PEAK-PEAK JITTER = 46ps STD DEV = 6.5ps

1400

1200

1000

800

600

FREQUENCY

400

200

0

–40 –20–30 –10 10

–50 30

DUTY CYCLE DISTORTION – ps

020

BIN WIDTH = 5ps

TPC 7. Duty Cycle Distortion Distribution

100

90

80

70

60

50

40

EYE HEIGHT – %

30

20

10

0

1.0

0.5

%EYE HEIGHT =

1.5

V

@ DATA RATE

OUT

V

@ 0.5Gbps

OUT

2.0 2.5 3.0 3.5

DATA RATE – Gbps

40 50

TPC 10. Bit Error Rate vs. Unit Interval

ⴛ100

4.0

TPC 8. Eye Height vs. Data Rate

50

45

40

35

30

25

20

JITTER – ps

15

10

5

0

1.0

PEAK-PEAK JITTER

STANDARD DEVIATION

2.0 2.5 3.0 3.5

1.5

DATA RATE – Gbps

TPC 9. Jitter vs. Data Rate

REV. A

TPC 11. Crosstalk, 3.2 Gbps, Attack Signal OFF

(See TPC 25)

4.0

TPC 12. Crosstalk, 3.2 Gbps, Attack Signal ON

(See TPC 25)

–9–

Page 10

AD8152

55

50

45

40

35

PEAK-PEAK JITTER – ps

30

25

1.5 Gbps

10 20 30 40

0

3.2 Gbps

50

TEMPERATURE – ⴗC

60 70 80 90

TPC 13. Single Point Jitter vs. Temperature

120

100

80

60

JITTER – ps

40

20

0

0

PEAK–PEAK JITTER

STANDARD DEVIATION

10 100 1000

INPUT AMPLITUDE – mV

80

70

60

50

40

JITTER – ps

30

20

10

0

PEAK-PEAK JITTER

STANDARD DEVIATION

TPC 16. Jitter vs. Supply

160

140

120

100

80

60

PEAK-PEAK JITTER – ps

40

20

0

–1.2 –1.0 –0.6 –0.4 –0.2 0

–1.4

SUPPLY VOLTAGE – V

I

= 16mA

OUT

I

= 24mA

OUT

I

OUT

–0.8

VOL – V

4.03.63.43.23.02.82.62.42.22.01.8 3.8

= 32mA

TPC 14. Jitter vs. Single-Ended Input Amplitude

180

160

140

120

100

80

PEAK-PEAK JITTER – ps

60

40

20

INPUT AMPLITUDE = 50mV p-p

@2.5V

INPUT CML – V

@3.3V

3.83.22.92.62.32.01.71.41.10.80.5 3.5

TPC 15. Jitter vs. Input Common-Mode Level

TPC 17. Jitter vs. V

50

45

40

35

30

25

20

JITTER – ps

15

10

5

0

0

STANDARD DEVIATION

5101520253035

PEAK–PEAK JITTER

(Relative to VCC)

OL

I

– mA

OUT

TPC 18. Jitter vs. Programmed I

OUT

REV. A–10–

Page 11

AD8152

SUPPLY VOLTAGE – V

725

PROPAGATION DELAY – ps

700

675

650

625

600

750

2.82.62.42.22.0 3.0 3.2 3.4 3.6 3.8

160

140

120

100

80

FREQUENCY

60

40

20

0

600

625 650 675 700 725 750

PROPAGATION DELAY – ps

BIN WIDTH = 5ps

TPC 19. Variation in Propagation Delay

800

780

760

740

720

700

680

660

PROPAGATION DELAY – ps

640

620

600

4030201005060708090

TEMPERATURE – ⴗC

TPC 20. Propagation Delay vs. Temperature

TPC 21. Propagation Delay vs. Supply

34

32

30

28

26

24

22

20

18

– mA

16

OUT

I

14

12

10

8

6

4

2

0

012345678

MEAS URED

TPC 22. I

OUT

I

OUT

vs. I

IDEA L

10 11 12 13 14 15 16

9

CODE

Code

OUT

REV. A

–11–

Page 12

AD8152

PATTERN

GENERATOR

DATA OUT

DATA OUT

TRIGGER OUT

PATTERN

GENERATOR

DATA OUT

DATA OUT

TRIGGER OUT

–6dB

–6dB

–6dB

–6dB

VTTI

IN##P

VCC

VTTO

OUT##P

AD8152

IN##N

VEE = –2.5V

= 16mA, V

I

OUT

V

AMPLITUDE = 400mV p-p SINGLE-ENDED, VIN HI = –0.2V PRBS 2

IN

OUT

HI = 0V, V

OUT##N

LO = –0.4V

OUT

TPC 23. Negative Supply Test Circuit

2.5V

VTTI

0.1F

IN##P

VCC

VTTO

0.1F

OUT##P

AD8152

VEE

OUT##N

OUT

0.1F

LO = 2.1V

IN##N

0.1F

I

= 16mA, V

OUT

AMPLITUDE = 400mV p-p SINGLE-ENDED, VIN HI = 2.7V

V

IN

23

PRBS 2

HI = 2.5V, V

OUT

– 1, INPUTS AND OUTPUTS ARE AC-COUPLED

TPC 24. Positive Supply Test Circuit

–6dB

–6dB

23

– 1

–6dB

–6dB

HIGH SPEED

SAMPLING

OSCILLOSCOPE

50⍀

50⍀

TRIGGER IN

HIGH SPEED

SAMPLING

OSCILLOSCOPE

50⍀

50⍀

TRIGGER IN

PATTERN

GENERATOR #1

AT TACK SIGNAL

DATA OUT

DATA OUT

PATTERN

GENERATOR #2

DATA OUT

DATA OUT

TRIGGER OUT

VCC

VTTO

OUT00P...OUT26P

OUT28P...OUT33P

OUT00N...OUT26N

OUT28N...OUT33N

50⍀

50⍀

–6dB

–6dB

VTTI

IN25P

IN25N

AD8152

–6dB

–6dB

ATTACK SIGNAL APPLIED TO IN25. IN25 BROADCAST TO ALL OUTPUTS EXCEPT OUT27.

TWO SEPARATE PATTERN GENERATORS USED TO PROVIDE INPUT PATTERN TO AD8152.

OUTPUTS NOT CONNECTED TO OSCILLOSCOPE ARE TERMINATED WITH EXTERNAL 50⍀ TO GND.

IN24P

IN24N

OUT27P

OUT27N

VEE = –2.5V

–6dB

–6dB

TPC 25. Crosstalk Test Circuit

HIGH SPEED

SAMPLING

OSCILLOSCOPE

50⍀

50⍀

TRIGGER IN

REV. A–12–

Page 13

AD8152

Table I. Address and Data Buses

Connection/Current Bit Output Address Pins Data Pins

A6 A5 A4 A3 A2 A1 A0 D5 D4 D3 D2 D1 D0

0 = CONNECTION LATCHES

1 = OUTPUT CURRENT LEVEL MSB LSB MSB LSB

Table II. Connection Data and Address Programming Examples

Connection/ Data Pins

Current Bit Output Address Pins (Used to Select Inputs) Comments

0 = CONNECTION MSB LSB MSB LSB

A6 A5 A4 A3 A2 A1 A0 D5 D4 D3 D2 D1 D0

0 000000 000000 Program IN00 to OUT00

0 000000 100001 Program IN33 to OUT00

0 100001 011111 Program IN31 to OUT33

0 111111 000000 Broadcast IN00 to All Outputs

0 000000 111111 Disable OUT00

0 100001 111111 Disable OUT33

0 111111 111111 Disable All Outputs (Broadcast)

Table III. Output-Current Level Data and Address Programming Examples

Connection/ Data Pins

Current Bit Output Address Pins (Used to Select Inputs) Comments

1 = CURRENT LEVEL MSB LSB MSB LSB

A6 A5 A4 A3 A2 A1 A0 D5 D4 D3 D2 D1 D0

100000 0XX0 000 Program OUT00 to Current—Code 00 (2 mA)

100000 0XX1 111 Program OUT00 to Current—Code 15 (32 mA)

110000 1XX0 111 Program OUT33 to Current—Code 07 (16 mA)

111111 1XX1 000 Broadcast Current—Code 08 to All

Outputs (18 mA)

Table IV. Basic Control Strobe Functions

RESET CS WE RE UPD Function

0XXXXGlobal Reset. Disables all outputs and resets all output current to code 0111 (16 mA).

11XXX Disable All Control Signals. Signal matrix/currents remain the same. D5:D0 are high impedance.

1001XWrite Enable. Write D5:D0 data into first rank register addressed by A6:A0.

10X0X Single-Output Readback. Second rank register data for output A6:A0 appears on D5:D0.

10XX0

10010 Transparent Write and Update. D5:D0 immediately control programming. Use RE as gating signal.

Global Update. Copy all first rank data into second rank registers.

REV. A

–13–

Page 14

AD8152

CS

WE

A[6:0]INPUTS

D[5:0]INPUTS

t

CSW

t

ASW

t

WP

t

DSW

Figure 3a. First Rank Write Cycle

Table V. First Rank Write Cycle

Symbol Parameter Conditions Min Typ Max Unit

t

CSW

t

ASW

t

DSW

t

CHW

t

AHW

t

DHW

t

WP

Setup Time Chip Select to Write Enable TA = 25ⴗC0 ns

Address to Write Enable 0 ns

Data to Write Enable VCC = 3.3 V 1 ns

Hold Time Chip Select from Write Enable 0 ns

Address from Write Enable 0 ns

Data from Write Enable 0 ns

Width of Write Enable Pulse 10 ns

t

AHW

t

DHW

t

t

CHW

AHW

CS

UPDATE

ENABLING

OUT[0:33][N:P]

OUTPUTS

TOGGLE

OUT[0:33][N:P]

OUTPUTS

DISABLING

OUT[0:33][N:P]

OUTPUTS

PREVIOUS RANK 2 DATA

DATA FROM RANK 2

t

CSU

t

UOE

t

UOD

t

UOT

DATA FROM RANK 1

t

UW

DATA FROM RANK 1

t

CHU

Figure 3b. Second Rank Update Cycle

Table VI. Second Rank Update Cycle

Symbol Parameter Conditions Min Typ Max Unit

t

CSU

t

CHU

t

UOE

t

UOT

t

UOD

t

UW

Setup Time Chip Select to Update TA = 25ⴗC0 ns

Hold Time Chip Select from Update 0 ns

Output Enable Times Update to Output Enable VCC = 3.3 V 25 45 ns

Output Toggle Times Update to Output Reprogram 25 45 ns

Output Disable Times Update to Output Disabled 25 45 ns

Width of Update Pulse 10 ns

REV. A–14–

Page 15

AD8152

CS

UPDATE

WE

ENABLING

OUT[0:33][N:P]

OUTPUTS

DISABLING

OUT[0:33][N:P]

OUTPUTS

t

CSU

t

Figure 4a. Transparent Write and Update Cycle

Table VII. Transparent Update Cycle

Symbol Parameter Conditions Min Typ Max Unit

t

CSU

t

CHU

t

UOE

t

WOE

t

UOT

t

WOT

t

UOD

t

WOD

t

WHU

t

UW

*Not shown

Setup Time Chip Select to Update TA = 25ⴗC0 ns

Hold Time Chip Select from Update VCC = 3.3 V 0 ns

Output Enable Times Update to Output Enable 35 50 ns

* Write Enable to Output Enable 35 50 ns

Output Toggle Times Update to Output Reprogram 25 45 ns

Write Enable to Output Reprogram 25 45 ns

* Output Disable Times Update to Output Disabled 25 45 ns

Write Enable to Output Disabled 25 45 ns

Setup Time Write Enable to Update 0 ns

Width of Update Pulse 10 ns

UOT

t

UOE

INPUT {DATA 1}

INPUT {DATA 1}INPUT {DATA 0}

t

UW

t

WOT

t

WOD

INPUT {DATA 2}

t

CHU

t

WHU

CS

RE

D[5:0]

INPUT

A[5:0]

OUTPUTS

ADDR 1 ADDR 2

DATA

{ADDR 1}

t

CSR

t

RDE

t

AA

DATA {ADDR 2}

t

RHA

t

RDD

t

CHR

Figure 4b. Second Rank Readback Cycle

Table VIII. Second Rank Readback Cycle

Symbol Parameter Conditions Min Typ Max Unit

t

CSR

t

CHR

t

RHA

t

RDE

t

AA

Setup Time Chip Select to Read Enable TA = 25ⴗC0 ns

Hold Time Chip Select from Read Enable VCC = 3.3 V 0 ns

Address from Read Enable 5 ns

Enable Time Data from Read Enable 15 ns

Access Time Data from Address 15 30 ns

REV. A

–15–

Page 16

AD8152

RESET

DISABLING

OUT[0:33][N:P]

OUTPUTS

t

TOD

t

TW

Figure 5. Asynchronous Reset

Table IX. Asynchronous Reset

Symbol Parameter Conditions Min Typ Max Unit

t

TOD

t

TW

Disable Time Output Disable from Reset TA = 25ⴗC1025ns

Width of Reset Pulse VCC = 3.3 V 10 ns

CONTROL INTERFACE

The AD8152 control interface receives and stores the desired

connection matrix and output levels for the 34 input and 34 output

signal pairs. The interface consists of 34 rows of double-rank

6-bit latches, one for each output. The 6-bit data-word stored

in these latches indicates to which (if any) of the 34 inputs the

output will be connected, as well as the full-scale output current.

One output at a time can be preprogrammed by addressing the

output and writing the desired connection data or output current into the first rank of latches. This process can be repeated

until each of the desired output changes has been preprogrammed.

All output connections can then be programmed at once by passing

the data from the first rank of latches into the second rank. The

output connections always reflect the data programmed into the

second rank of latches and do not change until the first rank of

data is passed into the second rank.

If necessary for system verification, the data in the second rank

of latches can be read back from the control interface.

At any time, a reset pulse can be applied to the control interface to

globally reset the appropriate second rank data bits, disabling all 34

signal output pairs and resetting the output currents. To facilitate

multiple chip address decoding, there is a chip select pin. All logic

signals except the reset pulse are ignored unless the chip select

pin is active. The chip select pin disables only the control logic

interface and does not change the operation of the signal matrix.

The chip select pin does not power down any of the latches, so any

data programmed in the latches is preserved.

All control pins are level-sensitive, not edge-triggered.

CONTROL PIN DESCRIPTION

A[6:0] Inputs

Output address pins. The binary encoded address applied to the

lower A[5:0] input pins determines which of the 34 outputs is

being programmed (or being read back). The most significant bit,

A6, determines whether the data pins contain information for

the connection register bank or the output level register bank.

Using the broadcast address, A[5:0] = “111111” will simultaneously program data into all outputs at once.

D[5:0] Inputs/Outputs

Input configuration or output level data pins. In write mode,

when the bank selection bit A6 is LOW, the binary encoded data

applied to pins D[5:0] determine which of the 34 inputs is to be

connected to the output specified with the A[5:0] pins. The most

significant bit is D5, and the least significant bit is D0. To disable

an output completely, the input address D[5:0] = “111111”

should be written into the input configuration bank at the desired

output address.

In write mode, when the bank selection bit A6 is HIGH, the

binary encoded data applied to pins D[3:0] indicate the output

current level to be used for the output specified with the A[5:0]

pins. The reset default is “0111” for 16 mA. Each LSB is 2 mA.

In readback mode, pins D[5:0] are low impedance outputs

indicating the data-word stored in the second rank for the output specified with the A[5:0] pins and the bank specified with

the A6 bit. The readback drivers were designed to drive high

impedances only, so external drivers connected to the D[5:0]

should be disabled during readback mode.

WE Input

First rank write enable. Forcing this pin to logic low allows the

data on pins D[5:0] to be stored in the first rank latch for the

output specified by pins A[6:0]. The WE pin must be returned to a

logic high state after a write cycle to avoid overwriting the first

rank data.

UPDATE Input

Second rank write enable. Forcing this pin to logic low allows the

data stored in all 34 first rank latches (in both banks) to be transferred to the second rank latches. The signal connection matrix

will be reprogrammed when the second rank data and levels are

changed. This is a global pin, transferring all 34 rows of data at

once. It is not necessary to program the address pins. It should

be noted that after initial power-up of the device, the first rank

data is undefined. It is desirable to preprogram all 17 outputs

before performing the first update cycle.

RE Input

Second rank read enable. Forcing this pin to logic low enables the

output drivers on the bidirectional D[5:0] pins, entering the readback mode of operation. By selecting an output address with the

A[6:0] pins and forcing RE to logic low, the 6-bit data stored in

the second rank latch for that output address will be written to

D[5:0] pins. Data should not be written to the D[5:0] pins

externally while in readback mode. The RE is a higher priority

pin than the WE pin, so first rank programming is not possible

while in readback mode.

REV. A–16–

Page 17

AD8152

CS Input

Chip select. This pin must be forced to logic low to program or

receive data from the logic interface, with the exception of the

RESET pin, described below. This pin has no effect on the signal

pairs and does not alter any of the stored control data.

RESET Input

Global output disable pin. Forcing the RESET pin to logic low

will disable all outputs, setting both ranks of all 34 input connection latches, regardless of the state of any other pins. This has the

effect of immediately disabling the 34 output signal pairs in the

matrix. The output level information is also changed. It is necessary

to momentarily hold RESET at a logic low state when powering

up the AD8152 in order to avoid random internal contention

where multiple inputs may be connected to one output. The

RESET pin is not gated by the state of the chip select pin, CS.

Control Interface Levels

The AD8152 control interface shares the data path supply pins,

VCC and VEE. The potential between the positive logic supply

VCC and the negative supply VEE

must be at least 2.25 V and no

more than 3.63 V. Regardless of supply, the logic threshold is

approximately one-half the supply range, allowing the interface

to be used with most LVCMOS and LVTTL logic drivers.

Output Addressing

The AD8152 is programmed using a memory interface module,

with parallel address and data buses. Six bits (A5:A0) are used to

address the outputs. By setting the decimal value of these address

bits to a value from 0 to 33 inclusive, then one of the 34 outputs

is uniquely addressed.

One additional code, 63 (all 1s), is used for the broadcast mode.

If this address is selected, then all outputs will receive the same

programming. The remaining addresses in the space are not

valid and are reserved, Codes 34 to 66 inclusive. (See Table I.)

Connection and Output Current Programming

A seventh address bit (A6) determines which of two types of

programming is selected. If A6 = 0, connection matrix programming is selected. If A6 = 1, output current programming is selected.

Using the Data Bus

Once it is determined which output is to be programmed (or broadcast to all outputs) and which type of programming (connection/

output-current), then the data bits (D5:D0) further define the

programming action.

If the selection is connection programming (A6 = 0), then the data

bits select the input that is to be connected to the addressed

output. If the broadcast address is selected, then the data bits select

the input that will be connected to all 34 outputs. (See Table II.)

A disable code (D5:D0 = 63, or all 1s) is used to disable (and

power down) the particular output that is addressed. A broadcast

disable can be effected by setting Code 63 on both the address

bus and the data bus along with A6 = 0.

Output-Current Programming

A current source in each output can be digitally programmed to

any one of 16 different current levels. Changing these current

levels will change the amplitude of the output swing that is

developed across the internal 50 W termination resistors.

To program the current for a particular output, its address is set on

A5:A0 (00–33), while A6 is set to 1. The four LSBs of the data

address (D3:D0) are then used to select one of the 16 output

current levels. D4 and D5 are “don’t cares” for output current

programming. (See Table III.)

REV. A

–17–

If it is desired to program all outputs to the same current level,

then the broadcast Code 63 can be placed on the address bus

(A5:A0), along with A6 = 1. (D3:D0) will then program all output

currents to the same level.

When the current code is set to 0000, a minimum current level

of 2 mA is obtained. For any other code, the current can be

calculated by (current code) ¥ 2 mA + 2 mA. Refer to Table III.

For example, 16 mA can be programmed by Code 0111. This is

7 ¥ 2 mA + 2 mA = 16 mA.

Register-Control Signals

Several single-ended logic input pins control the register loading

associated with the address and data buses described in the previous section. The control functions are tabulated in Table IV.

There are dual ranks of registers for the data that programs the

AD8152. The first rank registers accumulate the data for the

various outputs as they are being programmed one by one. The

second rank registers actually control the functions of the device.

The RESET signal is used to reset the connection matrix, disable

all outputs, and set all of the output currents to a default condition

at Code 0111. This action sets the output current to a nominal

value of 16 mA. The data in the first rank latches is also reset by

the assertion of RESET.

The CS signal is used to enable the control interface. If several

devices are used in a system with the other control signals

bussed, the CS signal can be used to select an individual device

to change its programming.

The WE signal is used to enable writing data to the first rank

registers. This data will not immediately affect the features of

the AD8152.

The UPDATE signal transfers the data from the first rank registers

to the second rank registers. After assertion of UPDATE, the

data actively controls the AD8152 functions.

The second rank registers can be read back through the data bus.

The output is addressed on A5:A0 and the connection/current is

selected via A6. Asserting RE will cause the second rank data to

appear on the data bus. The RE function will dominate over

WE if both are asserted at the same time. Broadcast readback is

not permitted.

Some typical programming waveforms for the control signals are

provided in Figure 6.

A[6:0

]

D[5:0

WE

UPDATE

VALID ADDRESS INPUT

]

VAL ID DATA INPUT

VALID ADDRESS INPUT

VAL ID DATA INPUT

Figure 6. Programming Waveforms

Input/Output Coupling

The AD8152 has internal 50 W termination resistors for each

single-ended input and output. This can also provide a 100 W

termination for a 100 W differential transmission line. All of the

input termination resistors connect to one common point called

VTTI. Similarly, each of the output termination resistors connects

to one common point called VTTO. The voltage can be set

independently at VTTI and VTTO to accommodate various

interface architectures.

Page 18

AD8152

Input Coupling

One way to simplify the input circuit and make it compatible with

a wide variety of driving devices is to use ac coupling. This has

the effect of isolating the dc common-mode levels of the driver

and the AD8152 input circuitry. For example, the XAUI interconnect specification for 10 Gbps Ethernet requires ac coupling

in order to ensure that there are no interactions of dc levels

between the transmitting and receiving devices.

AC coupling requires that the signal patterns have no long-term

dc component, which may occur in any random data stream.

Codes such as 8b/10b, called for in the XAUI specification, are

used in many data communications systems to ensure that the

data pattern is benign in an ac-coupled link. This is accomplished

by run-length limiting (RLL), which sets a maximum for the

number of 1s or 0s that can occur consecutively. In addition,

residual dc components are monitored and modified by keeping

track of the running disparity, excess of 1s versus 0s or vice versa.

For the AD8152 inputs, ac coupling requires a capacitor in series

with each single-ended input signal, as shown in Figure 7. This

should be done in a manner that does not interfere with the high

speed signal integrity of the PC board. The details of this are

covered in the section on board layout guidelines. The two critical

variables are setting the proper voltage for VTTI and selecting

the correct value of coupling capacitors.

VTTI VCC

50⍀

C

INP

INXXP

INXXN

C

INN

50⍀

VEE

Figure 7. AC-Coupling Input Signal from AD8152

On the AD8152 side of the input coupling capacitor, the average

value of the single-ended input voltage will be at the voltage set at

VTTI. The range of allowable voltages is a function of the acceptable input voltages of the active circuitry of the AD8152 inputs

and the amplitude of the input signal. The operating input range

of the AD8152 extends from VCC + 0.2 V to 0.8 V above VEE.

The total range that will be occupied by the input signal will be

its average value (as established by the voltage applied to VTTI)

plus or minus one half the single-ended swing of the signal. For a

standard 800 mV p-p differential signal, the single-ended swing is

400 mV p-p. Thus, the signal will swing ±200 mV about the

average value equal to VTTI.

If VTTI is set equal to VCC, then the single-ended signal will

just meet the specifications where its highest excursion will be

0.2 V higher than VCC. The lowest level to set VTTI is 0.8 V

above VEE. This will cause the negative signal excursions to stay

within the operating range.

With ac-coupled inputs, there is no power consumption advantage associated with varying VTTI. As a practical matter, it

might be desirable to set VTTI at the same voltage as VTTO so

that only one supply is necessary. Refer to the VTTO section for

more information.

Output Coupling

Each single-ended output of the AD8152 has a termination

resistor that ties to a common point called VTTO. When VTTO

is varied, it will change the common-mode levels of the outputs

and the power dissipation of the output stages when they are

enabled.

The individual output currents are programmable. Varying this

current will change the lower level of the output voltage (and thus

the peak-to-peak swing) and also change the power dissipation in

the output stages. To obtain a standard 800 mV p-p differential

output (single-ended = 400 mV p-p), the output current should

be programmed to 16 mA. With an effective termination resistance of 25 W, this will generate the proper differential voltage.

If the AD8152 drives another device that is ac-coupled, there is no

interaction of the dc levels on each side of the coupling capacitors

(see Figure 8). The dc levels for the AD8152 can be calculated

independent of the levels of the device that is driven.

The upper allowable setting for VTTO is 0.2 V higher than VCC.

The signals will be pulled up to this level at their highest excursion.

However at this setting, the power dissipation will be a maximum.

To save power, VTTO can be lowered. The lowest level for

VTTO will be determined by the lowest output level allowable

(V

) by the AD8152 output when it is logically low. The output

OL

at any time should not go lower than 1.0 V below VCC. If the

single-ended swing of an output is 400 mV p-p, then the lowest

that VTTO can go is 0.6 V below VCC. For more information

, see TPC 17.

on V

OL

VCC VTT VCC

AD8152

VEE

VTTO

50⍀ 50⍀

I = 2mA ⴛ (CODE) + 2mA

VEE

OUTXXP

OUTXXN

DRIVEN DEVICE

VEE

Figure 8. AC-Coupling Output Signal from AD8152

REV. A–18–

Page 19

AD8152

AD8152 POWER CONSUMPTION

There are several sections of the AD8152 that draw varying

power depending on the supply voltages, the type of I/O coupling

used, and the status of the AD8152 operation. Figure 9 shows a

block diagram of these sections. These are described briefly below

and then in detail later in the data sheet. Table X summarizes the

power consumption of each section and is a useful guide as the

following sections are reviewed.

The first section is the input termination resistors. The power

dissipated in the termination resistors is the result of their being

driven by the respective driving stage. Also, there might be dc power

dissipated in the input termination resistors if the inputs are

dc-coupled and the driving source reference is a dc voltage that is

not equal to VTTI.

In the next section, the active part of the input stages, each input

is powered only when it is selected. If an input is not selected, it

VCC

SWITCH

MATRIX

I = 32mA

OUTPUT

PREDRIVER

I = .25 I

OUT

INP

INN

INPU T

TERMINATIONS

P =

50⍀

VTTI

(V

indiffrms

100⍀

50⍀

INPU TS

I = 2mA

PER

2

)

ACT IVE

INPUT

is powered down. Thus, the total number of active inputs will

affect the total power consumption.

The core of the device performs the crosspoint switching function.

It draws a fixed quiescent current whenever the AD8152 is

powered from VCC to VEE.

An output predriver section draws a current that is proportional

to the programmed output current, I

. This current always

OUT

flows from VCC to VEE. It is treated separately from the output

current, which flows from VTTO, and might not be the same

voltage as VCC.

The final section is the outputs. For an individual output, the

programmed output current will flow through two separate paths.

One is the on-chip termination resistor, and the other is the

transmission line and the destination termination resistor. The

nominal parallel impedance of these two paths is 25 W. The sum

VTTO

OUTPUT TERMINATIONS

50⍀

50⍀

OUT-

PUTS

I

OUT

P =

OUTP

OUTN

P =

V

OL

I

OUT

(V

= V

50⍀

2

) (I

OL

OUT

– (I

TTO

VTT

50⍀

OPTIONAL COUPLING CAPACITORS

)

ⴛ 25⍀)

OUT

50⍀

DRIVEN DEVICE

TERMINATIONS

VEE

Figure 9. Power Consumption Block Diagram

Table X. Power Consumption

Output

Input Output Switch +

Termination Input Output Termination Current Total

Resistors Stage Core Predriver Resistors Source Power

Quiescent Current 32 mA

Current per Active Channel VIN/

Current per Active

Channel

(R

TERMINATION

)

2 mA 0.25 ¥ I

OUT

0.5 ¥ I

OUT

I

OUT

for Differential

VIN = 800 mV p-p Sine 566 mV rms/100

V

= 800 mV p-p = 5.66 mA 2 mA 4 mA 4 mA 8 mA 16 mA

OUT

2.5 V Operation (VCC – VEE = 2.5 V, VTTO = 2.5 V, I

= 16 mA)

OUT

Per Channel Power 3.2 mW 5 mW 10 mW 8 mW 33.6 mW

Power for All Channels Active 108.8 mW 170 mW 80 mW 340 mW 272 mW 1.03 W 2.0 W

Percentage of Total Power 5% 8% 4% 17% 13.6% 51%

3.3 V Operation (VCC – VEE = 3.3 V, VTTO = 3.3 V, I

= 16 mA)

OUT

Per Channel Power 3.2 mW 6.6 mW 13.2 mW 8 mW 46.4 mW

Power for All Channels Active 108.8 mW 224 mW 106 mW 449 mW 272 mW 1.47 W 2.63 W

Percentage of Total Power 4% 9% 4% 17% 10% 56%

REV. A

–19–

Page 20

AD8152

of these two currents will flow through the switches and the current

source of the AD8152 output circuit and out through VEE.

The power dissipated in the transmission line and the destination

resistor will not be dissipated in the AD8152, but will have to be

supplied from the power supply, and is a factor in the overall system

power. The current in the on-chip termination resistors and the

output current source will dissipate power in the AD8152 itself.

Input Termination Resistors

The power dissipated in the input termination resistors is

delivered by the driving source. First, assume the driving waveform for an individual input is a differential square wave with an

amplitude of Vinpp. Then the power dissipated in this input is

(Vinpp)

2

/2Rterm.

However, this result is quite pessimistic, because at high frequencies, the wave shape is usually more sinusoidal than square.

If instead, a differential sine wave of amplitude Vinpp is assumed,

then its rms amplitude is 0.7 times that of a square wave. This will

yield a power that is one half of the square wave case. The assumed

wave shape is not too critical because the fraction of the power

dissipated in the input termination resistors is not very large.

A further effect is that the input signal might travel over a path

that attenuates the signal. This will usually be a function of

frequency. Thus, for such a case, some of the signal power will

be dissipated in the signal path. This will reduce the amount of

power dissipated in the AD8152 input terminations.

If dc coupling is used, a dc current will flow from VTTI

through

the termination resistors if the dc voltage of the drive circuit is not

equal to VTTI. The additional power in each input termination

resistor will be the current that flows multiplied by the 50 W

value of the input terminations.

For a point of reference, assume a channel has a sinusoidal input

800 mV p-p differential. The power dissipated for a single input

will be 3.2 mW. If all 34 input channels are driven the same, then

the power in the input terminations will be 109 mW.

Input Stage

The input stages are powered down when not in use. There is

about 2 mA that flows through an enabled input from VCC to VEE.

Thus, the power dissipated by an enabled input is 5 mW for a

supply of 2.5 V and 6.6 mW for a 3.3 V supply. For all 34 inputs

enabled, the respective figures are 170 mW for a 2.5 V supply

and 224 mW for a 3.3 V supply.

Switch Matrix

The switch matrix draws a fixed 32 mA when the AD8152 is

powered. This current flows from VCC to VEE. The power dissipation from this current is 80 mW at 2.5 V and 106 mW at 3.3 V.

Output Predrivers

The output predrivers draw additional current when each of the

outputs is enabled. This extra current is proportional to the

programmed output current. The extra predriver current for a

channel will be 25 percent of the programmed output current

for that channel. This current will also flow from VCC to VEE.

When an output is enabled and programmed to 16 mA, an additional 4 mA will flow in the predriver section. This will dissipate

10 mW at 2.5 V or 13.2 mW at 3.3 V for an individual output.

For all 34 outputs enabled and programmed to 16 mA, the

predriver power will be 340 mW at 2.5 V or 449 mW at 3.3 V.

OUTPUTS

The output current is forced by a current source that is programmed to a variable amount of current from 2 mA to 32 mA

in 2 mA steps. For the two logic switch states, this current flows

through an on-chip termination resistor and a parallel path to the

destination device and its termination resistor. The power in this

parallel path is not dissipated by the AD8152.

The nominal programmed output current is 16 mA. With the two

parallel 50 W resistors at each collector (25 W equivalent), this

current will create a 400 mV p-p swing in each half of the circuit.

The differential output voltage will be 800 mV p-p.

Under steady state conditions and with a data pattern that is

run-length limited so that its low frequency content is significantly

higher than the RC pole formed by the coupling capacitor and the

termination resistors, the common-mode level at the AD8152

outputs will be 400 mV lower than VTTO. Each output will then

swing ± 200 mV from this level, which is a 400 mV p-p singleended output swing.

At the high level, there will be 200 mV across the termination

resistor. This will dissipate a power of 0.8 mW. At the low level, the

600 mV across the termination resistor will dissipate a power of

7.2 mW. Since the output signal is basically 50% duty cycle, the

average power dissipated will be the average of these two values

or 4 mW. By symmetry, the other differential output will dissipate

the same power. This yields an on-chip termination-resistor

power dissipation of 8 mW per channel for each output, or 272 mW

for all 34 outputs.

The full output current (from both on- and off-chip termination

resistors) will flow in the lower part of each output. This current

flows only in the side that is “on,” or in its low state (V

voltage is 600 mV below the dc level at VTTO.

of

Thus, for VTTO = 2.5 V, V

tion for I

power is 1.03 W.

If VTTO = 3.3 V, then V

and the power for all 34 channels is 1.47 W.

If VTTO = 2.5 V, then the additional power is given by 16 mA

¥ [(2.5 V – (16 mA ¥ 25 W)] = 33.6 mW. Thus, the total AD8152

power dissipation for this output is 37.6 mW.

If all 34 outputs are enabled with the same I

dissipation is 1.28 W. Thus it can be seen that the outputs are

the major contributor to the power dissipation.

Power Saving Considerations

While the AD8152 power consumption is very low compared to

similar devices, careful control of its operating conditions can yield

further power savings. Significant power reduction can be realized

by operating the part at a lower voltage. Compared to 3.3 V

operation, a supply voltage of 2.5 V can result in power savings of

about 25 percent. There is virtually no performance penalty when

operating at lower voltage.

A second measure is to disable outputs when they are not being

used. This can be done on a static basis if the output is not used,

or on a dynamic basis if the output does not have a constant

stream of traffic.

Since the majority of the power dissipated is in the output stage,

some of its flexibility can be used to lower the power consumption.

= 1.9 V, and the power dissipa-

= 16 mA is 30.4 mA. For all 34 channels, the

OUT

OL

= 2.7 V. The single power is 43.2 mW

OL

, the total power

OUT

). This

OL

REV. A–20–

Page 21

First, the output current can be programmed to the smallest amount

ALL TOP-MOUNT SMAs SIT ON PCB TOP LEVEL

TOP VIEW OF TOP LEVEL TRACE

MICROSTRIP

SMA CENTER PIN

PLANE RELIEF

DRILL HOLES

(7 EACH)

BOTTOM VIEW OF BOTTOM LEVEL TRACE

required to maintain BER performance. If an output circuit

always has a short length and the receiver has good sensitivity,

then a lower output current can be used.

It is also possible to lower the voltage on VTTO to lower the

power dissipation. The amount that VTTO can be lowered is

dependent on the lowest of all the output’s V

. This will be

OL

determined by the output that is operating at the highest programmed output current since V

OL

= VTTO – (I

¥ 25 W).

OUT

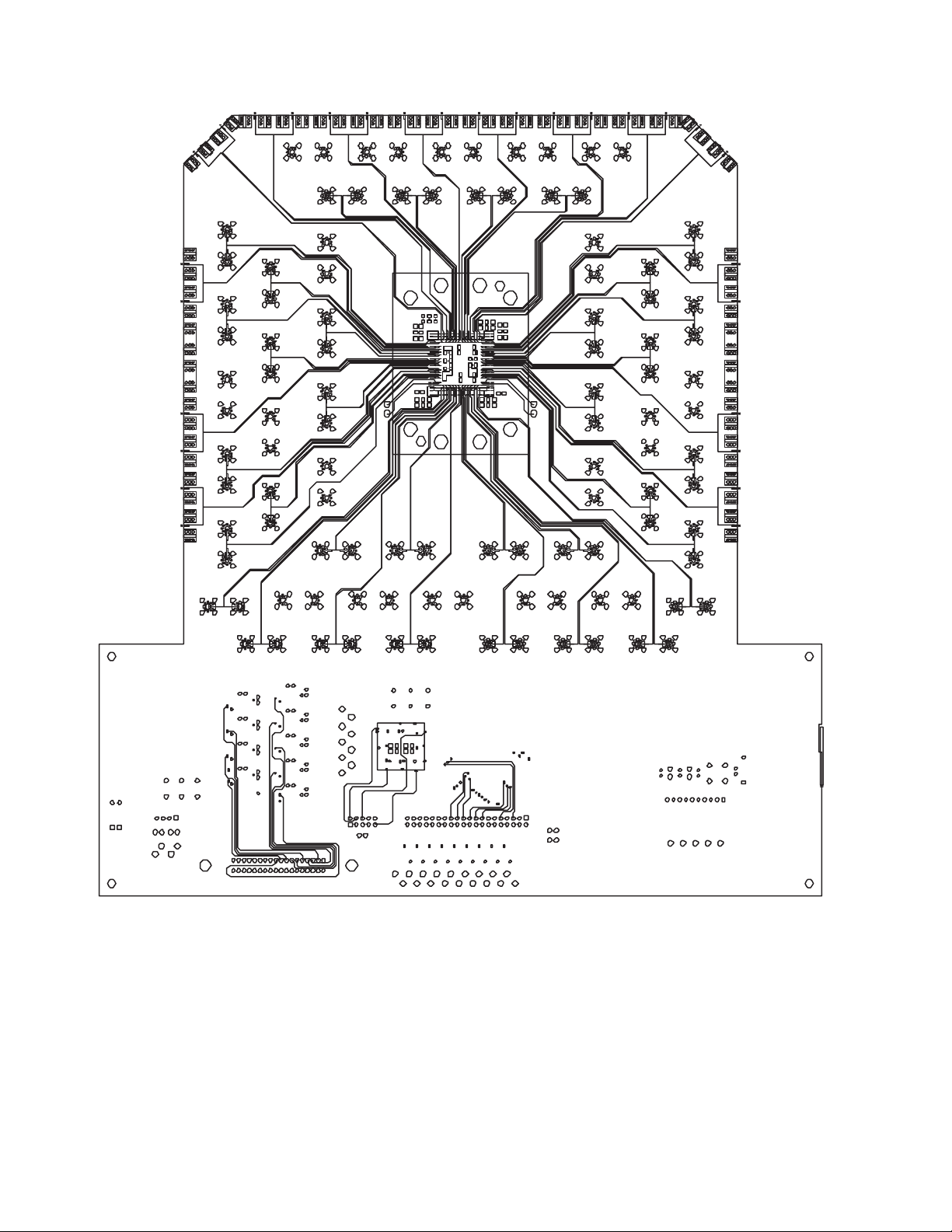

EVALUATION BOARD AND PCB LAYOUT HINTS

The AD8152 evaluation board was designed to allow the user to

analyze signal integrity in many configurations, as controlled by

a standard PC.

The FR4 board comes equipped with a full complement of

136 SMA connectors to support the complete 34 ⫻ 34 matrix of

points. Each differential pair of microstrip is connected to either

top mount or side-launch SMA connectors. The mounting area of

the short center pin top-mount SMA connectors are drilled (seven

holes) and stubbed for greatly improved performance. In the

area surrounding SMA top-mount center pin and drill holes, all

internal planes are relieved or cleared out (see Figure 10 for layout).

AD8152

Figure 10. Top-Mount SMA PCB Layout, Two Views

The FR4 PC board is eight layers with a thickness of 62 mils

(1.57 mm). The two outer most metal layers hold the high speed

microstrip routing lines. The two outer most dielectric layers are

5 mils thick and must be controlled impedance (50 W) layers. These

are the only two layers that require controlled impedance. The

next two inner metal layers are ground (reference) planes for the

microstrip and are the shell for the SMA connectors. The remaining four inner metal layers are for the four AD8152 supply and

digital control signal routing. From top to bottom the four supply

layers are VTTO, VCC, VEE, and VTTI. Because all four supply

PCB metal layers float, positive, negative, and even dual-supply

configurations are possible. The variety of supply configurations

ease the connection of test equipment. The four inner supply

layers also provide an interlayer capacitance, which has better

impedance versus frequency than standard chip capacitors.

DIELECTRIC

THICKNESS

0.5mils

5.0mils

4.0mils

16.0mils

4.0mils

16.0mils

4.0mils

5.0mils

0.5mils

SILKSCREEN

SILKSCREEN

COPPER

LAYER

NUMBER

1. 1.50/ TOP MICROSTRIP WIDTH = 8.0mils

2. 0.50/GND

3. 0.50/VTTO

4. 0.50/VCC

5. 0.50/VEE

6. 0.50/VTTI

7. 0.50/GND

8. 1.50/BOTTOM MICROSTRIP WIDTH = 8.0mils

THICKNESS/DESIGNATION

(IN OUNCES)

Figure 11. Evaluation Board Stack-Up

REV. A

–21–

Page 22

AD8152

Figure 12. Cross-Sectional Layout and Dimensioning (To Scale) of Differential

The variety of supply configurations cause the need for a supply

agile digital control circuitry. This is done by a programmable

logic device (PLD), which provides instructions to the AD8152.

The PLD supply is typically tied with jumpers across the AD8152’s

VCC and VEE supplies (Jumpers J3 and J4). The PLD is addressed

from the PC by way of digital isolators. These couplers isolate

PC levels from the PLD and allow for any level shifting. If

desired, the user can drive the PLD supply separately as long as

the VEE of the AD8152 and the PLD are tied together (remove

Jumper J3 and leave J4 installed). This allows one to measure

the AD8152 only supply current, for example.

Board Construction or Stack-Up

Figure 11 is a picture of AD8152 evaluation board stack-up from

top to bottom. The layer stack-up has been made symmetrical

to avoid board warpage during manufacture. The microstrip

layout and dimensions are shown in Figure 12. The microstrip

trace width was chosen to be 8 mils. This allows relative ease in

routing through the BGA rows that are 50 mils (1.27 mm) apart.

The outer two out of four rows of high speed signals are routed on

top of the PCB, while the inner two rows are via holed to the

board’s opposite side and then routed outward. Wider microstrip

is desirable for reducing eye height loss versus long traces; however, the routing will be more difficult as the AD8152 is approached.

The wide microstrip would have to be necked down in width in

order to be routed into the BGA. The necking will increase trace

impedance and therefore induce more signal reflection problems.

BGA CORNER OUTLINE

VIA HOLE

(GRAY)

CHIP CAPACITOR

(805) SIZE

MICROSTRIP TRACES

Figure 13. BGA Corner Capacitor Layout

During the layout of the differential microstrip, a software tool

snaps the distance between the two traces to be a constant. If

the distance is not kept constant, impedance variations will

result. These fluctuations can be measured by time domain

reflectometry (TDR).

EXTRA ADDED INDUCTANCE

Figure 14. Poor Capacitor Layout

Bypass Capacitor Layout

The AD8152 8-layer PCB takes advantage of buried interlayer

capacitance. The VEE to VCC planes are placed in the very middle

of the board to make the highest value capacitor. The 4 mil

(0.102 mm) dielectric spacing between VCC/VEE yields 26 nF

of capacitance. Each AD8152 supply pin is directly connected to

its supply plane through a via hole beneath the BGA ball. The

via hole size for a BGA supply pin is slightly bigger than a signal

via. This is to reduce the inductance of the connection, and it

also happens to be a compact layout.

For the chip capacitors, the via holes are placed directly in the

middle of the mounting area and made as large as possible, i.e.,

greater than or equal to 35 mils (0.89 mm). This is to minimize

inductance as much as possible. By minimizing inductance, the

performance of the capacitor or impedance versus frequency

response is not greatly diminished. Note that chip capacitors

will work up to only about 300 MHz.

Figure 14 is an example of a bypass capacitor layout that should

be avoided in any high speed printed circuit board. This layout

connects the chip capacitor mounting pads to small via holes

through a skinny PCB trace. This amounts to four extra inductors

added to the capacitor, two largely from the skinny surface traces

and two from small via holes. Inductance is also variable with

copper thickness and attachment method to power plane. Thermal

relief for soldering purposes also adds unwanted inductance and

should be avoided.

REV. A–22–

Page 23

AD8152

VCC

VTTO

AD8152

ECL

DRIVER

VTTI

PP

IN OUT

NN

= –2V

VEE

TO 50⍀

SCOPE

INPUTS

= –2.5V

Figure 15. Evaluation Board ECL Driver Test Setup

Connections for Testing

The AD8152 evaluation board can be used under a variety of positive or negative supply configurations. Negative supply configurations,

as shown in Figure 15, allow the easiest hookup to test equipment because inputs and outputs can be direct coupled. In a real

world application however, the negative supply configuration would

be difficult because control logic levels must be shifted negative.

Figure 16 is an example of a loop-through test setup using a positive supply. In this case, the test signal goes through the AD8152

twice. It is possible to loop through multiple times if desired, but

jitter will increase with number of loop-throughs. The first

input from the generator and the last output to a scope must be

ac-coupled. However, an AD8152 output driving its own input can

be direct-coupled. Direct coupling to the first AD8152 input is not

effective since generators usually want to see 50 W to ground.

This would require VTTI to be attached to ground, causing

excessive power to be dissipated in the internal 50 W input

termination resistors. Secondly, when the AD8152 output tries

to drive its own input with VTTI = 0 V and VTTO = 2.5 V, the

input will pull the output stage levels down enough to shut off

any signal toggling.

All ac coupling shown is actually done with a set of bias tees. If

desired, the bias tee can be used to monitor average dc voltage

levels at an input or output (depending on direction installed),

and it can also serve to change input dc levels. Make sure the

bias tees used in the setup have enough low frequency bandwidth

to pass long patterns and keep edge rates intact. The longer the

pattern, the more low frequency bandwidth is needed.

If ac coupling is desired on a user board, 0402 or 0603 sized

capacitors can be installed on microstrip lines. The biggest 0402

size, XR7 type usable is 0.01 mF, which will work fine for short

patterns (PRBS 2

7

–1) and data rates down to 1.0 Gbps. For

long patterns a 0603 sized, XR7 type, 0.1 mF should be used. To

decrease capacitive loading from the mounting area, clear out

planes underneath the coupling capacitor.

In Figure 16, 6 dB attenuators are placed before the AD8152

input ac-coupling or bias tees. This is because many generators

won’t go below 500 mV single-ended. The output pair of 6 dB

attenuators is present to protect the scope inputs and allow for

higher scale voltages per division. The eye diagram is usually

viewed differentially by using a simple P – N math function.

Cabling used in this setup must be matched. Mismatched cables

cause either a P or N signal to be falsely delayed. This delay can

show up as a change in the crossing point, from 50 percent in the

eye diagram. To accurately check cable matches, a TDR setup

is recommended.

PATTERN

GENERATOR

DATA OUT

DATA OUT

TRIGGER OUT

2.5V

VTTI

VCC

VTTO

AD8152

–6dB

–6dB

VCC = VTTI = VTTO = 2.5V, VEE = 0V, I

RTI (REFERRED TO INPUT) A MPLITUDE = 400mV SINGLE–ENDED,

HI = 2.7V (IN01), PRBS 2

V

IN

= 2.1V,

V

OL

AC-COUPLED IS FROM BIAS TEES,

PROGRAMMING: IN01 TO OUT02, IN02 TO OUT01.

P

IN01

N

P

IN02

N

VEE

23

–1, V

OUT01

OUT02

OH

P

N

P

N

SET = 16mA

OUT

= 2.5V,

Figure 16. Positive Supply Loop-Through Test Setup

–6dB

–6dB

HIGH SPEED

SAMPLING

OSCILLOSCOPE

50⍀

50⍀

TRIGGER IN

REV. A

–23–

Page 24

AD8152

EVALUATION BOARD CONTROL SOFTWARE

The AD8152 evaluation board can be controlled by using a PC

and a custom software program. The hardware interface uses a

PC parallel (or printer) port. A standard printer cable is used to

connect from the PC DB-25 connector to the Centronics-type

connector on the evaluation board. Figure 17 shows an evaluation

board control panel from a PC display.

A single screen allows control of all the programmable functions

of the AD8152. The programming modes are listed in the Mode

box. Select either I/O Programming or Current Programming by

selecting the appropriate radio button. These will allow either

programming the switch matrix or the output currents one at a time.

An alternative is to use the Broadcast mode. This will either

simultaneously program all of the outputs to one selected input

or program all outputs to the same current.

Figure 17. Evaluation Board Control Panel

In the I/O Programming mode (nonbroadcast), the desired input

is selected from the Input Select box by double-clicking on the

appropriate input channel number. This will cause the same

channel to appear in the Active Input Selection indicator window.

Next, select the desired output from the Output Select box by doubleclicking

Finally, the Program button is clicked and the data is immediately

sent to the evaluation board for programming the part to the

selected I/O combination.

If an additional output(s) is desired to be programmed to the same

input, double-click the desired output channel number and click

the Program button.

The Programmed Output table indicates which outputs are

programmed to the input that is indicated in the Active Input

Selection window. If it is desired to disable an individual output,

its radio button in the Programmed Output table can be clicked,

and it will change from black to white to indicate that it is not

enabled. Note: It is not possible to program outputs by selecting

their radio buttons.

To observe the set of outputs that are connected to any input,

double-click the desired input channel number from the Input

Select box. The selected channel number will show up in the Active

Input Selection window and the programmed outputs will have a

black dot in their radio button in the Programmed Output table.

To program an output current, select the Current Programming

button in the Mode box. Then double-click the desired output

channel number from the Output Select table. Next double-click

the desired entry for the Output Current. Finally, click the

Program button.

If the Broadcast button is selected from the Mode box, all outputs

will be treated the same. If I/O Programming is selected, doubleclick the input channel number from the Input Select table

and click the Program button. This will cause all outputs to be

programmed to the selected output, and all of the buttons will

have a black dot in the Programmed Output table.

For broadcast current programming, double-click the desired

Output Current. Then click the Program button. All of the outputs

will be programmed to the selected output current.

The Reset button will disable all outputs. In addition, all output

currents will be programmed to the nominal value of 16 mA.

the appropriate output channel number.