Page 1

325 MHz, 8 8 Buffered Video

a

FEATURES

8 8 High-Speed Nonblocking Switch Arrays

AD8108: G = +1

AD8109: G = +2

Serial or Parallel Programming of Switch Array

Serial Data Out Allows “Daisy Chaining” of Multiple

8 8s to Create Larger Switch Arrays

Output Disable Allows Connection of Multiple Devices

Pin-Compatible with AD8110/AD8111 16 8 Switch

Arrays

For 16 16 Arrays See AD8116

Complete Solution

Buffered Inputs

Eight Output Amplifiers,

AD8108 (G = +1),

AD8109 (G = +2)

Drives 150 Loads

Excellent Video Performance

60 MHz 0.1 dB Gain Flatness

0.02%/0.02 Differential Gain/Differential Phase Error

= 150 )

(R

L

Excellent AC Performance

AD8108 AD8109

–3 dB Bandwidth 325 MHz 250 MHz

Slew Rate 400 V/s 480 V/s

Low Power of 45 mA

Low All Hostile Crosstalk of –83 dB @ 5 MHz

Reset Pin Allows Disabling of All Outputs (Connected

Through a Capacitor to Ground Provides “PowerOn” Reset Capability)

Excellent ESD Rating: Exceeds 4000 V Human Body

Model

80-Lead LQFP Package (12 mm 12 mm)

APPLICATIONS

Routing of High-Speed Signals Including:

Composite Video (NTSC, PAL, S, SECAM.)

Component Video (YUV, RGB)

Compressed Video (MPEG, Wavelet)

3-Level Digital Video (HDB3)

PRODUCT DESCRIPTION

The AD8108 and AD8109 are high-speed 8 × 8 video crosspoint switch matrices. They offer a –3 dB signal bandwidth

greater than 250 MHz and channel switch times of less than

25 ns with 1% settling. With –83 dB of crosstalk and –98 dB

isolation (@ 5 MHz), the AD8108/AD8109 are useful in many

high-speed applications. The differential gain and differential

Crosspoint Switches

AD8108/AD8109

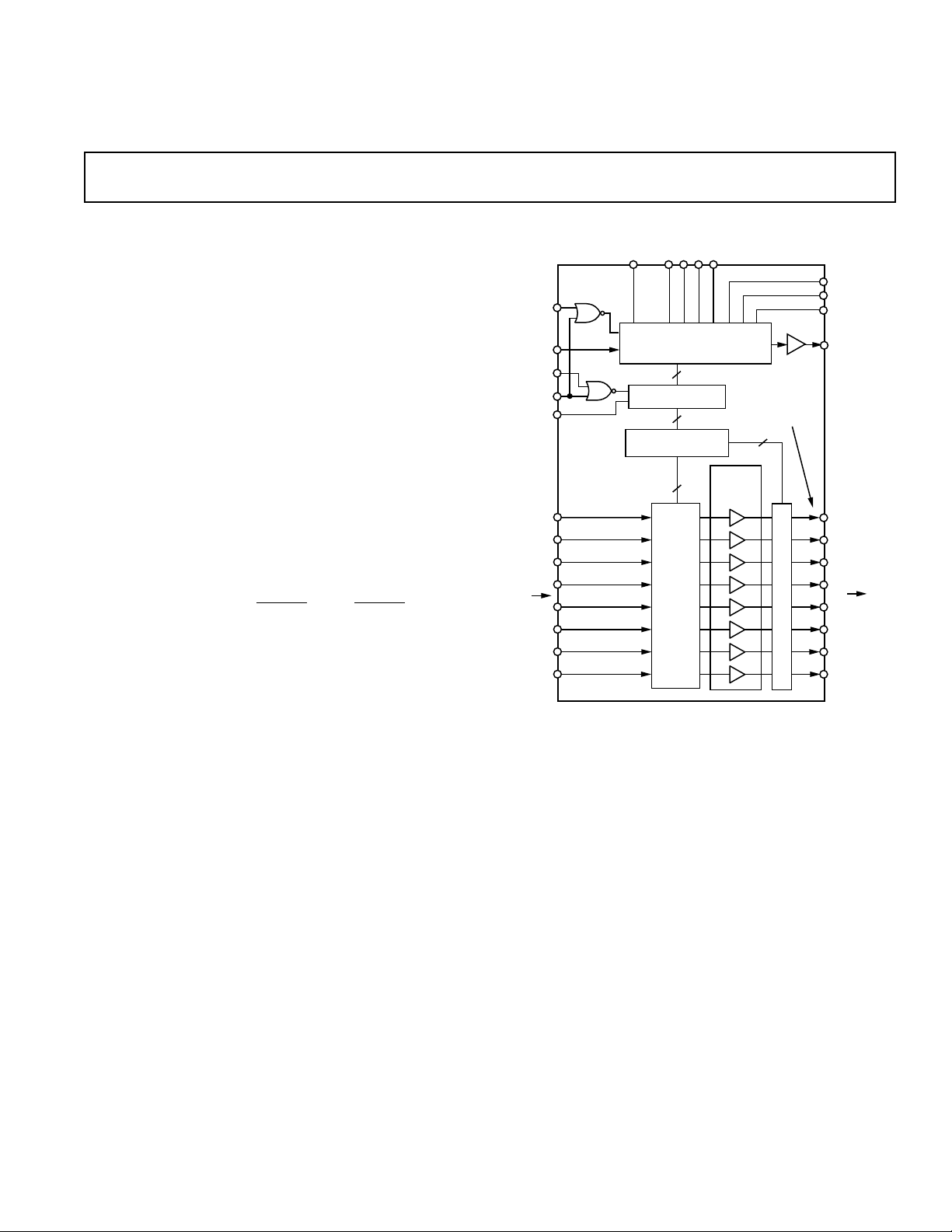

FUNCTIONAL BLOCK DIAGRAM

SER/PAR

CLK

DATA IN

UPDATE

CE

RESET

AD8108/AD8109

8 INPUTS

phase of better than 0.02% and 0.02° respectively along with

0.1 dB flatness out to 60 MHz make the AD8108/AD8109 ideal

for video signal switching.

The AD8108 and AD8109 include eight independent output buffers that can be placed into a high impedance state for paralleling

crosspoint outputs so that off channels do not load the output bus.

The AD8108 has a gain of +1, while the AD8109 offers a gain

of +2. They operate on voltage supplies of ±5 V while consuming

only 45 mA of idle current. The channel switching is performed via

a serial digital control (which can accommodate “daisy chaining”

of several devices) or via a parallel control allowing updating of

an individual output without re-programing the entire array.

The AD8108/AD8109 is packaged in an 80-lead LQFP package

and is available over the extended industrial temperature range

of –40°C to +85°C.

D0 D1 D2 D3

32-BIT SHIFT REGISTER

WITH 4-BIT

PARALLEL LOADING

32

PARALLEL LATCH

32

DECODE

8 4:8 DECODERS

OUTPUT

BUFFER

64

G = +1,

SWITCH

MATRIX

SET INDIVIDUAL

OR RESET ALL

OUTPUTS

TO "OFF"

8

G = +2

ENABLE/DISABLE

*

A0

A1

A2

DATA

OUT

8 OUTPUTS

*Patent Pending.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

AD8108/AD8109–SPECIFICATIONS

(VS = 5 V, TA = +25C, RL = 1 k unless otherwise noted)

AD8108/AD8109 Reference

Parameter Conditions Min Typ Max Unit Figure No.

DYNAMIC PERFORMANCE

–3 dB Bandwidth 200 mV p-p, R

2 V p-p, R

Propagation Delay 2 V p-p, R

Slew Rate 2 V Step, R

Settling Time 0.1%, 2 V Step, R

Gain Flatness 0.05 dB, 200 mV p-p, R

0.05 dB, 2 V p-p, R

0.1 dB, 200 mV p-p, R

0.1 dB, 2 V p-p, RL = 150 Ω 80/50 MHz TPC 1, 7

NOISE/DISTORTION PERFORMANCE

Differential Gain Error NTSC or PAL, R

NTSC or PAL, R

Differential Phase Error NTSC or PAL, R

NTSC or PAL, R

Crosstalk, All Hostile f = 5 MHz 83/85 dB TPC 2, 8

f = 10 MHz 76/83 dB TPC 2, 8

Off Isolation, Input-Output f = 10 MHz, R

Input Voltage Noise 0.01 MHz to 50 MHz 15 nV/√Hz TPC 14, 20

DC PERFORMANCE

Gain Error R

= 1 kΩ 0.04/0.1 0.07/0.5 %

L

R

= 150 Ω 0.15/0.25 %

L

Gain Matching No Load, Channel-Channel 0.02/1.0 %

= 1 kΩ, Channel-Channel 0.09/1.0 %

R

L

Gain Temperature Coefficient 0.5/8 ppm/°C

OUTPUT CHARACTERISTICS

Output Impedance DC, Enabled 0.2 Ω TPC 18, 24

Disabled 10/0.001 MΩ TPC 15, 21

Output Disable Capacitance Disabled 2 pF

Output Leakage Current Disabled, AD8108 Only 1/NA µA

Output Voltage Range No Load ±2.5 ± 3V

Output Current 20 40 mA

Short Circuit Current 65 mA

INPUT CHARACTERISTICS

Input Offset Voltage Worst Case (All Configurations) 5 20 mV TPC 29, 35

Temperature Coefficient 12 µV/°C TPC 30, 36

Input Voltage Range ±2.5/±1.25 ±3/±1.5 V

Input Capacitance Any Switch Configuration 2.5 pF

Input Resistance 1 10 MΩ

Input Bias Current Per Output Selected 2 5 µA

SWITCHING CHARACTERISTICS

Enable On Time 60 ns

Switching Time, 2 V Step 50% UPDATE to 1% Settling 25 ns

Switching Transient (Glitch) Measured at Output 20/30 mV p-p TPC 16, 22

POWER SUPPLIES

Supply Current AVCC, Outputs Enabled, No Load 33 mA

AVCC, Outputs Disabled 10 mA

AVEE, Outputs Enabled, No Load 33 mA

AVEE, Outputs Disabled 10 mA

DVCC 10 mA

Supply Voltage Range ±4.5 to ±5.5 V

PSRR f = 100 kHz 73/78 dB TPC 13, 19

f = 1 MHz 55/58 dB

OPERATING TEMPERATURE RANGE

Temperature Range Operating (Still Air) –40 to +85 °C

θ

JA

Specifications subject to change without notice.

Operating (Still Air) 48 °C/W

= 150 Ω 240/150 325/250 MHz TPC 1, 7

L

= 150 Ω 140/160 MHz TPC 1, 7

L

= 150 Ω 5ns

L

= 150 Ω 400/480 V/µs

L

= 150 Ω 40 ns TPC 6, 12

L

= 150 Ω 60/50 MHz TPC 1, 7

L

= 150 Ω 60/50 MHz TPC 1, 7

L

= 150 Ω 70/65 MHz TPC 1, 7

L

= 1 kΩ 0.01 %

L

= 150 Ω 0.02 %

L

= 1 kΩ 0.01 Degrees

L

= 150 Ω 0.02 Degrees

L

=150 Ω, One Channel 93/98 dB TPC 17, 23

L

–2–

REV. A

Page 3

AD8108/AD8109

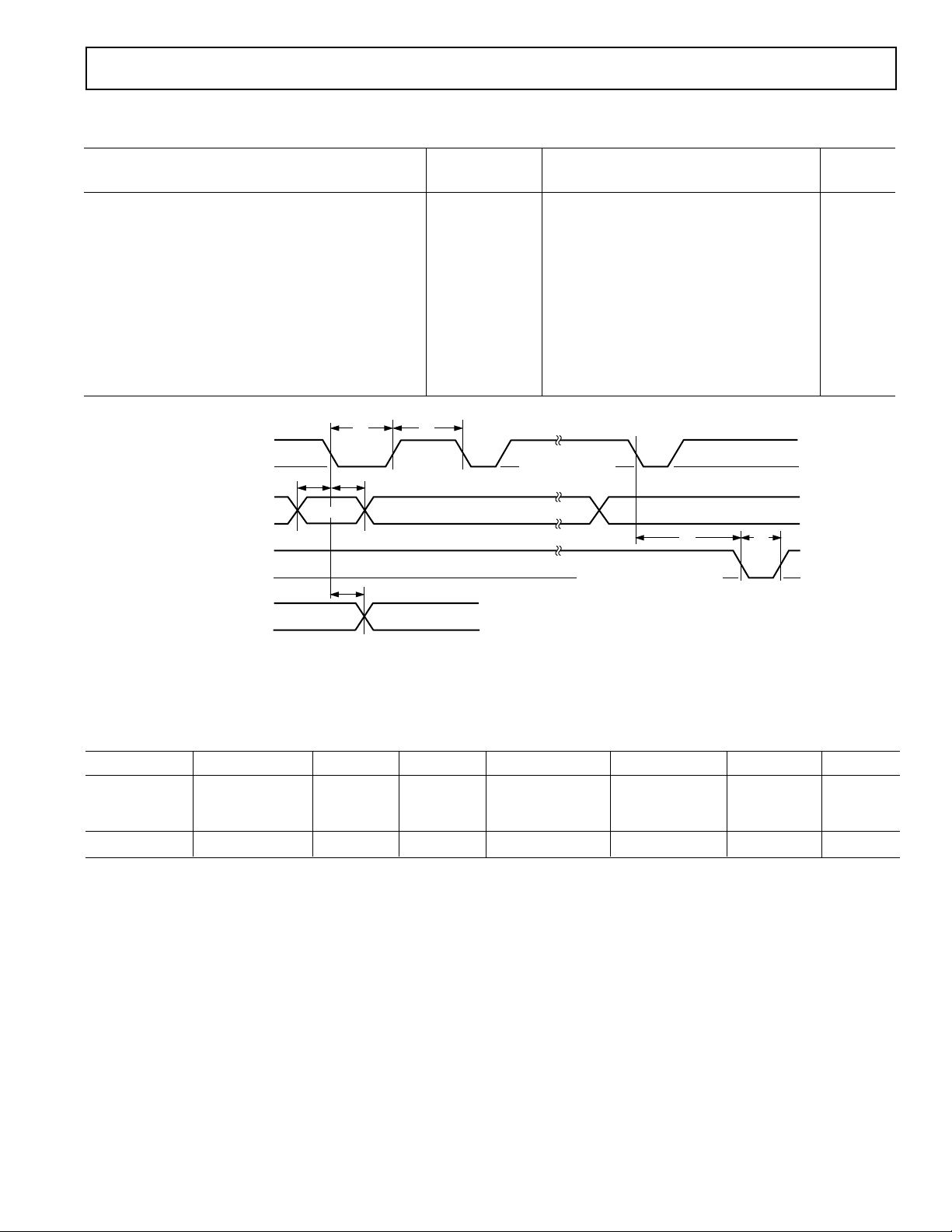

TIMING CHARACTERISTICS (Serial)

Limit

Parameter Symbol Min Typ Max Unit

Serial Data Setup Time t

CLK Pulsewidth t

Serial Data Hold Time t

CLK Pulse Separation, Serial Mode t

CLK to UPDATE Delay t

UPDATE Pulsewidth t

CLK to DATA OUT Valid, Serial Mode t

1

2

3

4

5

6

7

20 ns

100 ns

20 ns

100 ns

0ns

50 ns

180 ns

Propagation Delay, UPDATE to Switch On or Off – 8 ns

Data Load Time, CLK = 5 MHz, Serial Mode – 6.4 µs

CLK, UPDATE Rise and Fall Times – 100 ns

RESET Time – 200 ns

CLK

DATA IN

1 = LATCHED

UPDATE

0 = TRANSPARENT

DATA OUT

t

1

0

t

1

1

OUT7 (D3)

0

2

t

3

t

7

t

4

LOAD DATA INTO

SERIAL REGISTER

ON FALLING EDGE

OUT7 (D2) OUT00 (D0)

TRANSFER DATA FROM SERIAL

REGISTER TO PARALLEL

LATCHES DURING LOW LEVEL

t

5

t

6

Figure 1. Timing Diagram, Serial Mode

Table I. Logic Levels

V

IH

RESET, SER/PAR RESET, SER/PAR RESET, SER/PAR RESET, SER/PAR

CLK, DATA IN, CLK, DATA IN, CLK, DATA IN, CLK, DATA IN,

CE, UPDATE CE, UPDATE DATA OUT DATA OUT CE, UPDATE CE, UPDATE DATA OUT DATA OUT

2.0 V min 0.8 V max 2.7 V min 0.5 V max 20 µA max –400 µA min –400 µA max 3.0 mA min

V

IL

V

OH

V

OL

I

IH

I

IL

I

OH

I

OL

–3–REV. A

Page 4

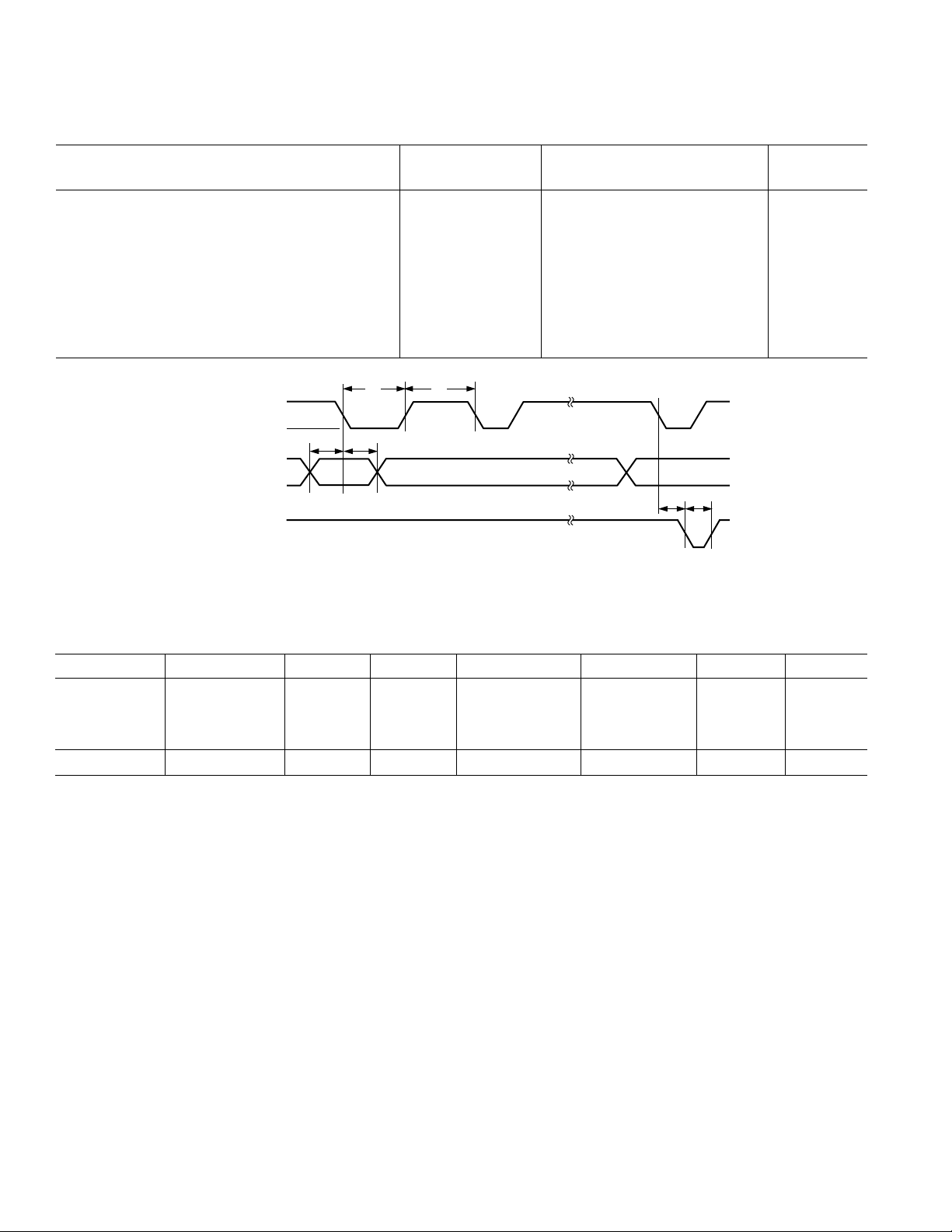

AD8108/AD8109

TIMING CHARACTERISTICS (Parallel)

Limit

Parameter Symbol Min Max Unit

Data Setup Time t

CLK Pulsewidth t

Data Hold Time t

CLK Pulse Separation t

CLK to UPDATE Delay t

UPDATE Pulsewidth t

1

2

3

4

5

6

20 ns

100 ns

20 ns

100 ns

0ns

50 ns

Propagation Delay, UPDATE to Switch On or Off – 8 ns

CLK, UPDATE Rise and Fall Times – 100 ns

RESET Time – 200 ns

CLK

D0–D3

A0–A2

1 = LATCHED

UPDATE

0 = TRANSPARENT

t

1

0

t

1

1

0

2

t

3

t

4

t6t

5

Figure 2. Timing Diagram, Parallel Mode

Table II. Logic Levels

V

IH

V

IL

V

OH

V

OL

I

IH

I

IL

I

OH

I

OL

RESET, SER/PAR RESET, SER/PAR RESET, SER/PAR RESET, SER/PAR

CLK, D0, D1, D2, CLK, D0, D1, D2, CLK, D0, D1, D2, CLK, D0, D1, D2,

D3, A0, A1, A2 D3, A0, A1, A2 D3, A0, A1, A2 D3, A0, A1, A2

CE, UPDATE CE, UPDATE DATA OUT DATA OUT CE, UPDATE CE, UPDATE DATA OUT DATA OUT

2.0 V min 0.8 V max 2.7 V min 0.5 V max 20 µA max –400 µA min –400 µA max 3.0 mA min

–4–

REV. A

Page 5

AD8108/AD8109

AMBIENT TEMPERATURE – C

5.0

MAXIMUM POWER DISSIPATION – W

4.0

0

–50 80–40 –30 –20 –100 10203040506070

3.0

2.0

1.0

TJ = 150C

90

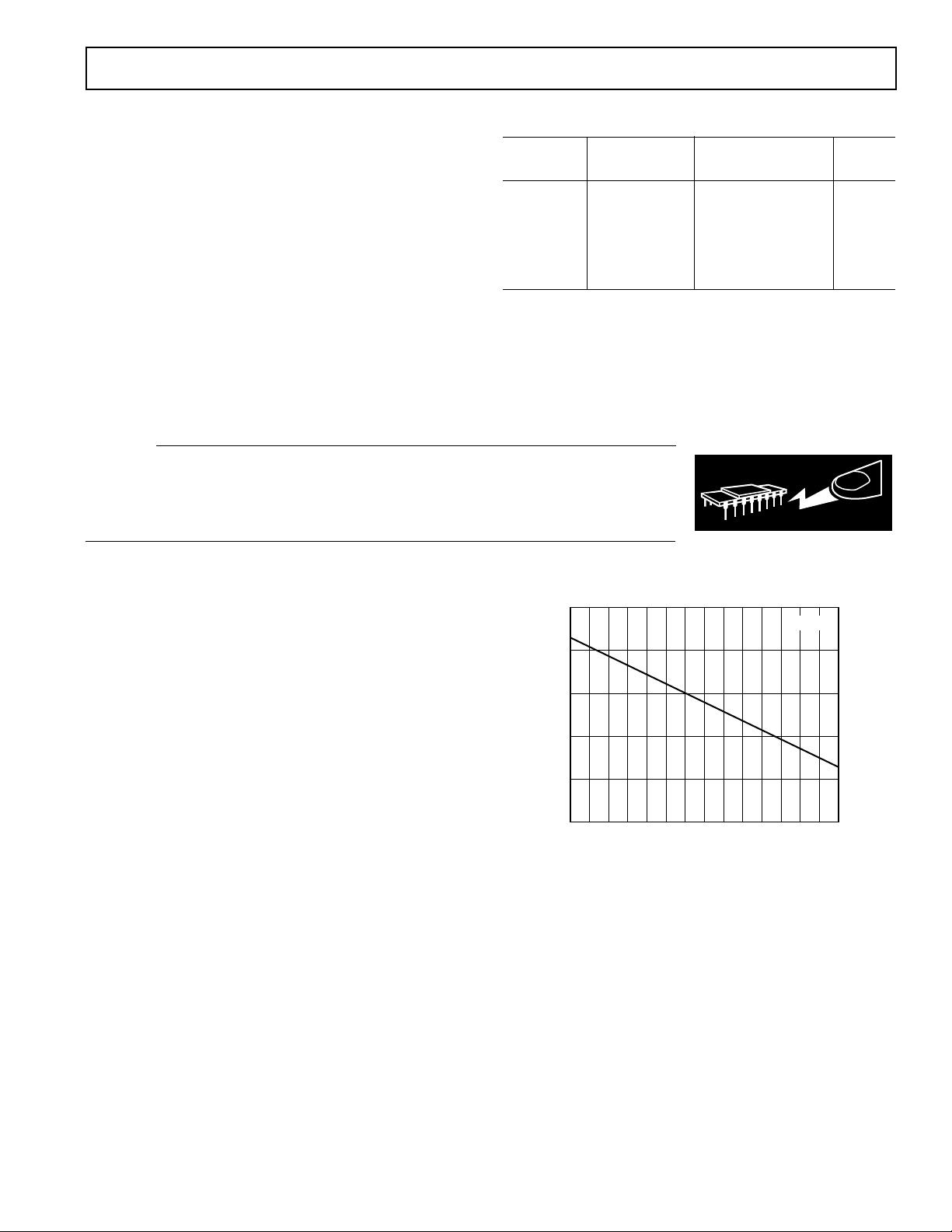

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.0 V

Internal Power Dissipation

2

1

AD8108/AD8109 80-Lead Plastic LQFP (ST) . . . . . 2.6 W

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±V

S

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range . . . . . . . . . . . . –65°C to +125°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air (TA = 25°C):

80-lead plastic LQFP (ST): θJA = 48°C/W.

Model Range Description Option

AD8108AST –40°C to +85°C 80-Lead Plastic LQFP ST-80A

AD8109AST –40°C to +85°C 80-Lead Plastic LQFP ST-80A

AD8108-EB Evaluation Board

AD8109-EB Evaluation Board

ORDERING GUIDE

Temperature Package Package

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8108/AD8109 features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high-energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

(12 mm × 12 mm)

(12 mm × 12 mm)

WARNING!

ESD SENSITIVE DEVICE

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8108/AD8109 is limited by the associated rise in junction

temperature. The maximum safe junction temperature for plastic

encapsulated devices is determined by the glass transition temperature of the plastic, approximately 150°C. Temporarily

exceeding this limit may cause a shift in parametric performance

due to a change in the stresses exerted on the die by the package.

Exceeding a junction temperature of 175°C for an extended

period can result in device failure.

While the AD8108/AD8109 is internally short circuit protected,

this may not be sufficient to guarantee that the maximum junction

temperature (150°C) is not exceeded under all conditions. To

ensure proper operation, it is necessary to observe the maximum

power derating curves shown in Figure 3.

Figure 3. Maximum Power Dissipation vs. Temperature

–5–REV. A

Page 6

AD8108/AD8109

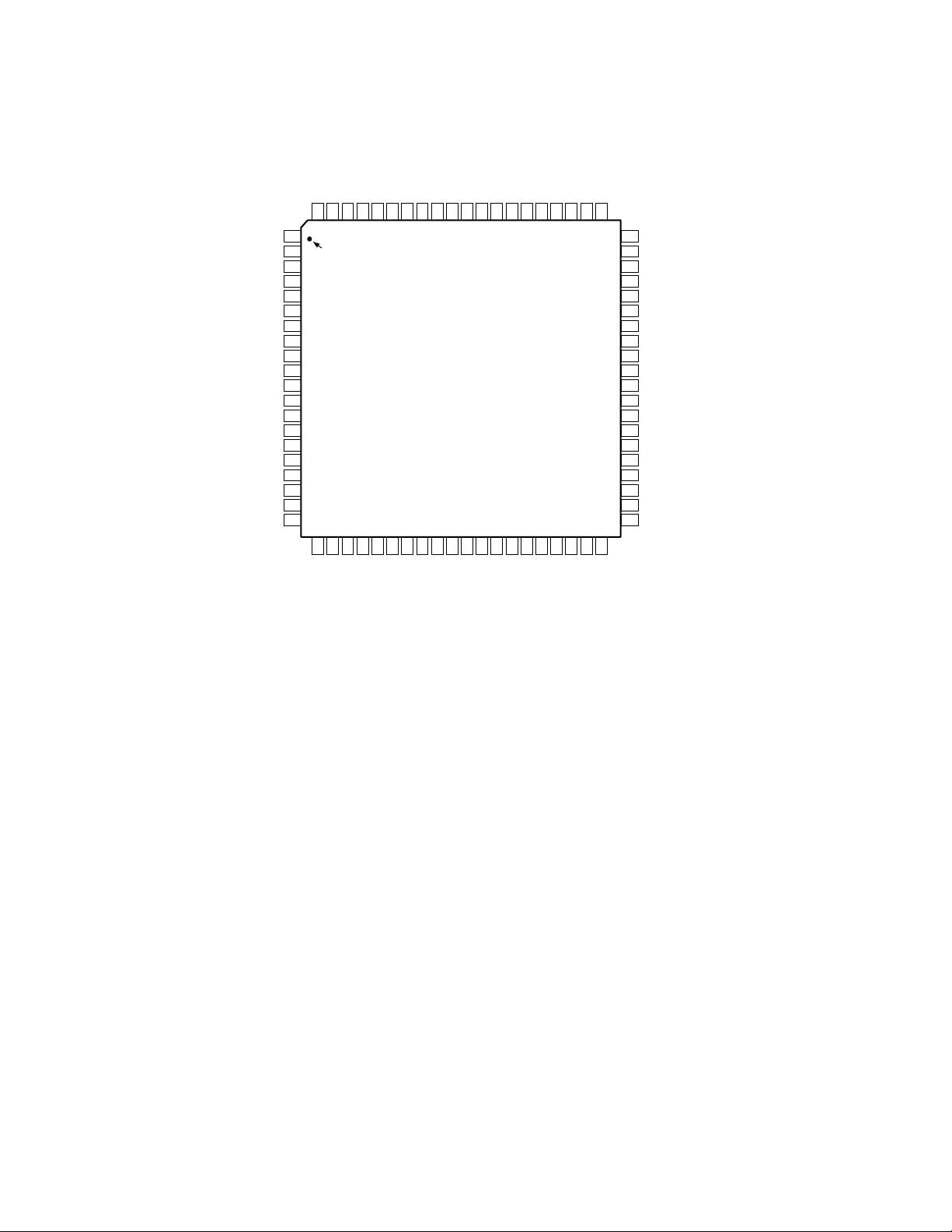

PIN CONFIGURATION

1

IN00

2

AGND

3

IN01

4

AGND

5

IN02

6

AGND

7

IN03

8

AGND

9

IN04

10

AGND

11

IN05

12

AGND

13

IN06

14

AGND

15

IN07

16

AGND

17

AVEE

18

AVCC

19

AVCC07

20

OUT07

NC = NO CONNECT

NC

NC

NC

NC

NC

DVCC

DGND

80

79787776757473727170696867

PIN 1

IDENTIFIER

NC

NC

NC

NC

AD8108/AD8109

TOP VIEW

(Not to Scale)

22

23

21

AGND07

AVEE06/07

24

OUT06

AGND06

25

26

OUT05

AVCC05/06

27

28

AGND05

AVEE04/05

30

29

OUT04

AGND04

31

AVCC03/04

NC

NC

33

32

OUT03

AGND03

NC

NC

NC

66

656463

35

36

34

OUT02

AGND02

AVEE02/03

DGND

DVCC

NC

62

37

38

39

OUT01

AGND01

AVCC01/02

RESET

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

AVEE00/01

CE

DATA OUT

CLK

DATA IN

UPDATE

SER/PAR

A0

A1

A2

D0

D1

D2

D3

NC

AGND

AVEE

AVCC

AVCC00

AGND00

OUT00

–6–

REV. A

Page 7

AD8108/AD8109

PIN FUNCTION DESCRIPTIONS

Pin Name Pin Numbers Pin Description

INxx 1, 3, 5, 7, 9, 11, 13, 15 Analog Inputs; xx = Channel Numbers 00 Through 07.

DATA IN 57 Serial Data Input, TTL Compatible.

CLK 58 Clock, TTL Compatible. Falling Edge Triggered.

DATA OUT 59 Serial Data Output, TTL Compatible.

UPDATE 56 Enable (Transparent) “Low.” Allows serial register to connect directly to switch

matrix. Data latched when “High.”

RESET 61 Disable Outputs, Active “Low.”

CE 60 Chip Enable, Enable “Low.” Must be “low” to clock in and latch data.

SER/PAR 55 Selects Serial Data Mode, “Low” or Parallel Data Mode, “High.” Must be connected.

OUTyy 41, 38, 35, 32, 29, 26, 23, 20 Analog Outputs yy = Channel Numbers 00 Through 07.

AGND 2, 4, 6, 8, 10, 12, 14, 16, 46 Analog Ground for Inputs and Switch Matrix.

DVCC 63, 79 5 V for Digital Circuitry

DGND 62, 80 Ground for Digital Circuitry

AVEE 17, 45 –5 V for Inputs and Switch Matrix.

AVCC 18, 44 +5 V for Inputs and Switch Matrix.

AGNDxx 42, 39, 36, 33, 30, 27, 24, 21 Ground for Output Amp, xx = Output Channel Numbers 00 Through 07. Must be connected.

AVCCxx/yy 43, 37, 31, 25, 22, 19 +5 V for Output Amplifier that is shared by Channel Numbers xx and yy. Must be connected.

AVEExx/yy 40, 34, 28, 22 –5 V for Output Amplifier that is shared by Channel Numbers xx and yy. Must be connected.

A0 54 Parallel Data Input, TTL Compatible (Output Select LSB).

A1 53 Parallel Data Input, TTL Compatible (Output Select).

A2 52 Parallel Data Input, TTL Compatible (Output Select MSB).

D0 51 Parallel Data Input, TTL Compatible (Input Select LSB).

D1 50 Parallel Data Input, TTL Compatible (Input Select).

D2 49 Parallel Data Input, TTL Compatible (Input Select MSB).

D3 48 Parallel Data Input, TTL Compatible (Output Enable).

NC 47, 64–78 No Connect.

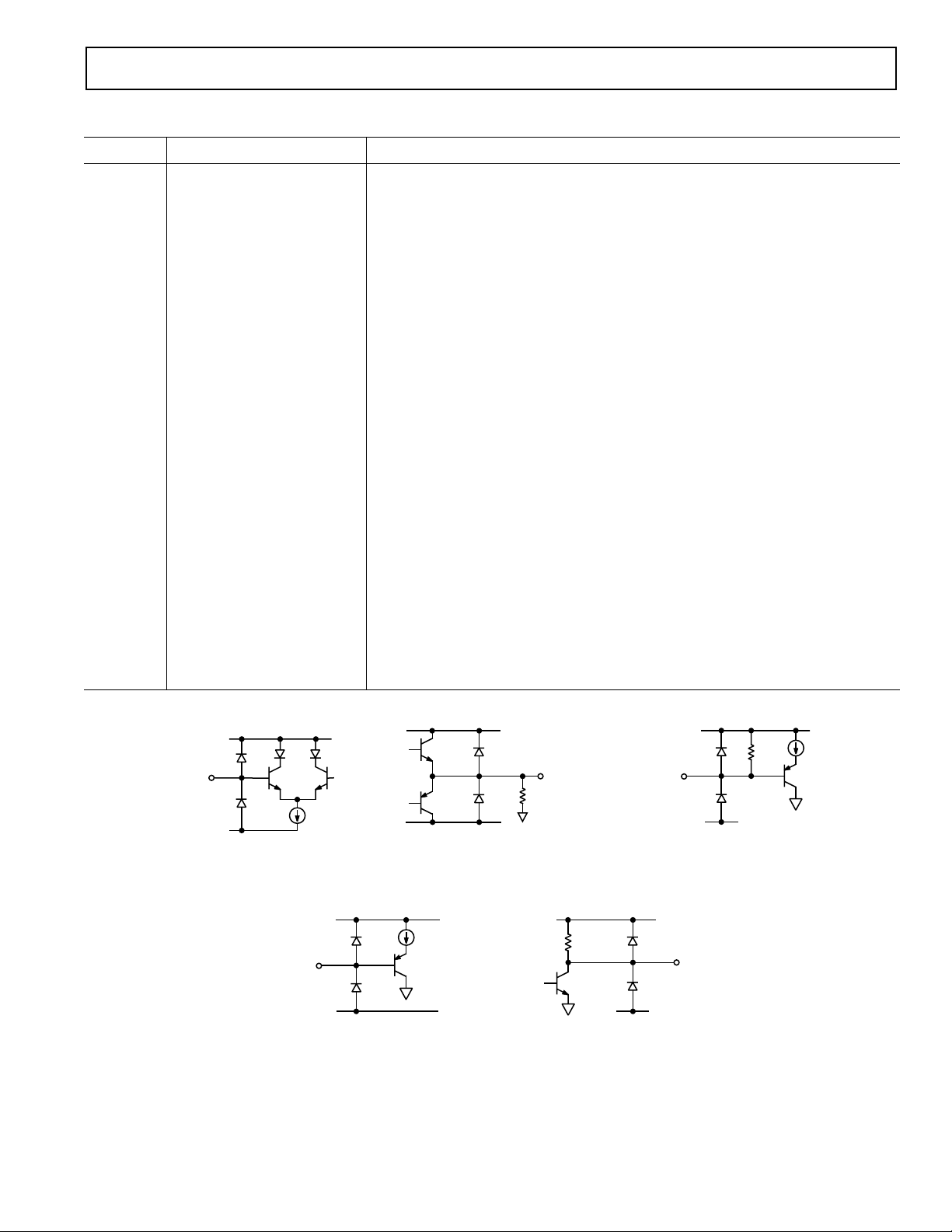

V

CC

AVEE

INPUT

ESD

ESD

V

CC

AVEE

a. Analog Input c. Reset Inputb. Analog Output

V

CC

ESD

INPUT

ESD

DGND

d. Logic Input e. Logic Output

Figure 5. I/O Schematics

ESD

ESD

OUTPUT

1k

(AD8109 ONLY)

2k

V

CC

DGND

RESET

ESD

ESD

V

CC

ESD

ESD

OUTPUT

20k

DGND

–7–REV. A

Page 8

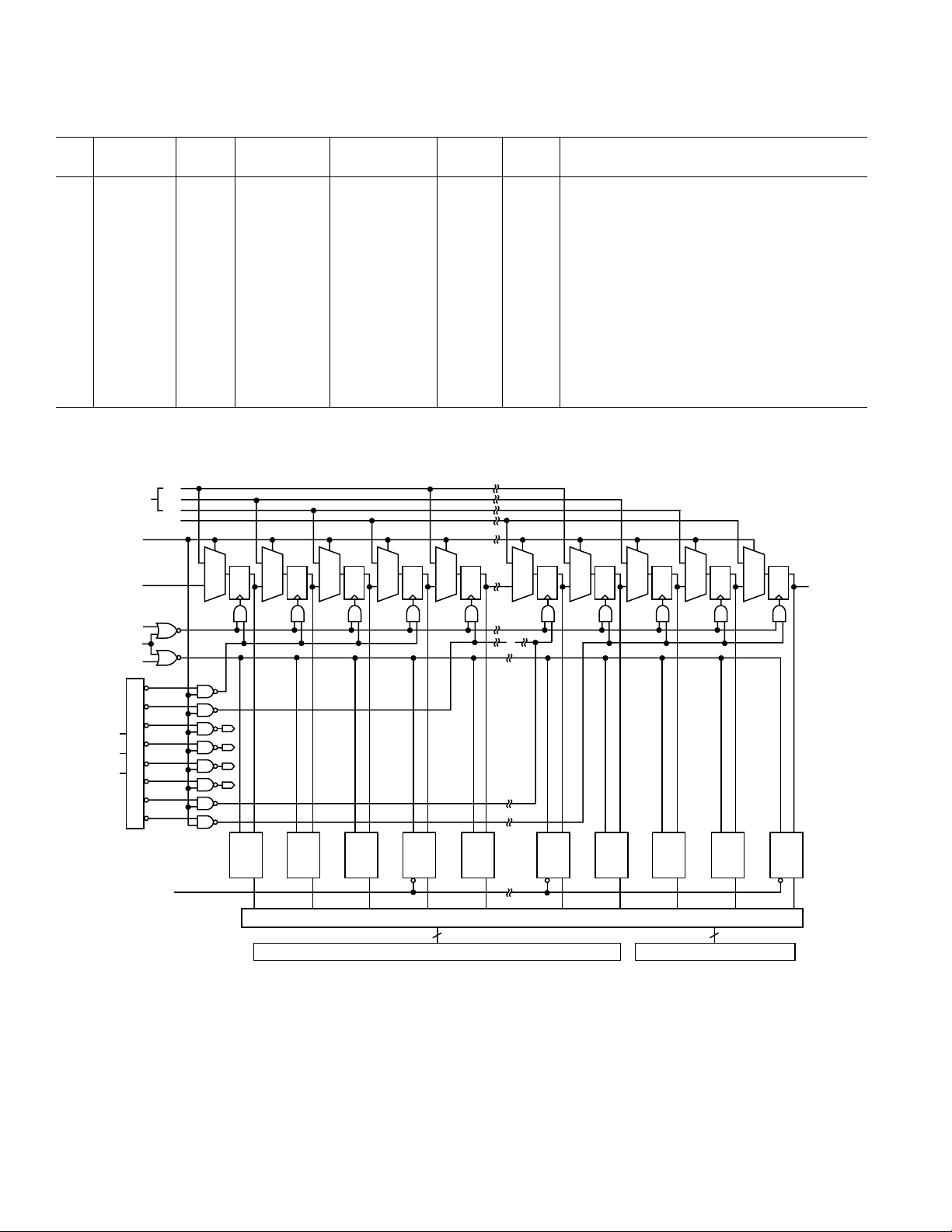

AD8108/AD8109

Table III. Operation Truth Table

SER/

CE UPDATE CLK DATA IN DATA OUT RESET PAR Operation/Comment

1 X X X X X X No change in logic.

01 f Data

i

01 f D0 . . . D3, NA in Parallel 1 1 The data on the parallel data lines, D0–D3, are

A0...A2 Mode loaded into the 32-bit serial shift register loca-

0 0 X X X 1 X Data in the 32-bit shift register transfers into the

X X X X X 0 X Asynchronous operation. All outputs are disabled.

D0

PARALLEL DATA

(OUTPUT ENABLE)

SER/PAR

DATA IN

(SERIAL)

D1

D2

D3

S

D1

Q

D0

D

CLK

S

D1

Q

DQ

Q

D0

CLK

D1

D0

S

Q

Data

DQ

CLK

i-32

1 0 The data on the serial DATA IN line is loaded

into serial register. The first bit clocked into

the serial register appears at DATA OUT 32

clocks later.

tion addressed by A0–A2.

parallel latches that control the switch array.

Latches are transparent.

Remainder of logic is unchanged.

S

D1

Q

D0

DQ

CLK

S

D1

DQ

Q

D0

CLK

S

D1

Q

D0

DQ

CLK

S

D1

Q

D0

DQ

CLK

S

D1

Q

D0

DQ

CLK

S

D1

Q

D0

DQ

CLK

S

D1

Q

Q

D

CLK

DATA

OUT

D0

CLK

CE

UPDATE

OUT0 EN

OUT1 EN

OUT2 EN

A0

OUT3 EN

A1

OUT4 EN

A2

OUT5 EN

3 TO 8 DECODER

OUT6 EN

OUT7 EN

(OUTPUT ENABLE)

RESET

LE

OUT0

LE

OUT0

B1

D

Q

D

B0

Q

LE

OUT0

B2

D

Q

LE

OUT0

EN

D

QCLR

LE

OUT1

B0

D

Q

LE

OUT6

EN

D

QCLR

LE

OUT7

B0

D

Q

LE

OUT7

D

B1

Q

LE

OUT7

D

B2

Q

LE

OUT7

EN

D

QCLR

DECODE

64

8

OUTPUT ENABLESWITCH MATRIX

Figure 4. Logic Diagram

–8–

REV. A

Page 9

+1.0V

+0.5V

0

–0.5V

–1.0V

500mV/DIV

10ns/DIV

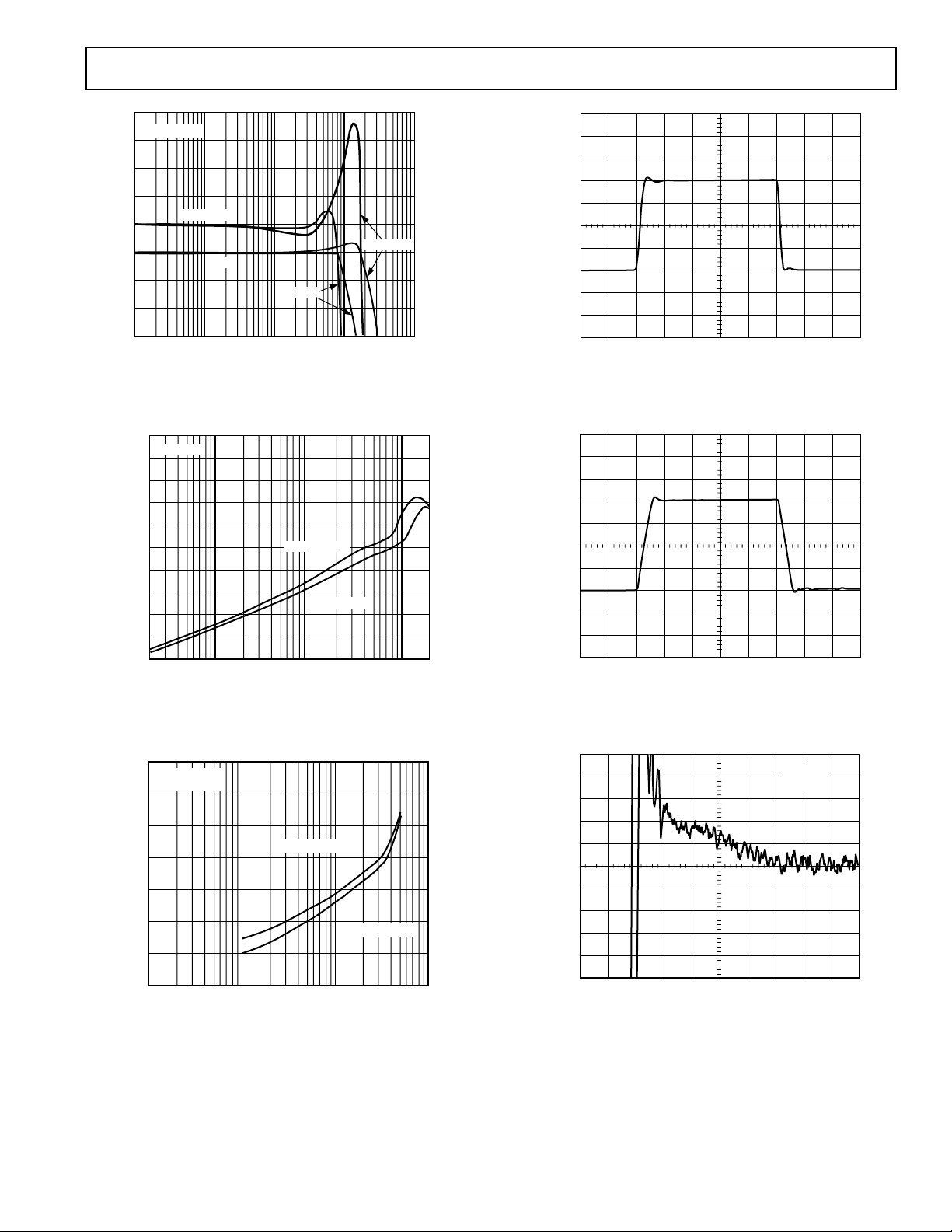

Typical Performance Characteristics—

AD8108/AD8109

5

RL = 150

4

3

2

1

GAIN – dB

0

–1

–2

–3

100k 1M 1G

FLATNESS

GAIN

2V p-p

10M 100M

FREQUENCY – Hz

200mV p-p

TPC 1. AD8108 Frequency Response

–10

RL = 1k

–20

–30

–40

–50

–60

–70

CROSSTALK – dB

–80

–90

–100

–110

0.2 1 20010 100

ALL HOSTILE

ADJACENT

FREQUENCY – MHz

TPC 2. AD8108 Crosstalk vs. Frequency

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

FLATNESS – dB

+50mV

+25mV

0

25mV/DIV

–25mV

–50mV

10ns/DIV

TPC 4. AD8108 Step Response, 100 mV Step

TPC 5. AD8108 Step Response, 2 V Step

–30

RL = 150

V

= 2V p-p

OUT

–40

–50

–60

–70

DISTORTION – dB

–80

–90

–100

100k 1M 10M 100M

2ND HARMONIC

3RD HARMONIC

FREQUENCY – Hz

TPC 3. AD8108 Distortion vs. Frequency

2V STEP

= 150

R

L

0.2

0.1

0

0.1%/DIV

–0.1

–0.2

0 10203040 50607080

10ns/DIV

TPC 6. AD8108 Settling Time

–9–REV. A

Page 10

AD8108/AD8109

5

4

3

2

1

GAIN – dB

0

–1

–2

–3

100k 1M 1G10M 100M

FLATNESS

GAIN

2V p-p

2V p-p

FREQUENCY – Hz

TPC 7. AD8109 Frequency Response

–20

RL = 1k

–30

–40

–50

–60

–70

–80

CROSSTALK – dB

–90

–100

–110

300k 1M 10M 100M

ADJACENT

ALL HOSTILE

FREQUENCY – Hz

TPC 8. AD8109 Crosstalk vs. Frequency

200mV p-p

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

200M

FLATNESS – dB

+50mV

+25mV

0

25mV/DIV

–25mV

–50mV

10ns/DIV

TPC 10. AD8109 Step Response, 100 mV Step

+1.0V

+0.5V

0

0.5V/DIV

–0.5V

–1.0V

10ns/DIV

TPC 11. AD8109 Step Response, 2 V Step

–30

RL = 150

–40

V

= 2V p-p

OUT

–50

–60

–70

DISTORTION – dB

–80

–90

–100

100k 1M 10M 100M

2ND HARMONIC

3RD HARMONIC

FREQUENCY – Hz

TPC 9. AD8109 Distortion vs. Frequency

–10–

0.2

0.1

0

0.1%/DIV

–0.1

–0.2

2V STEP

= 150

R

L

0 1020 3040 50 60 7080

10ns/DIV

TPC 12. AD8109 Settling Time

REV. A

Page 11

–30

OFF ISOLATION – dB

FREQUENCY – Hz

100k 10M 100M 500M

1M

VIN = 2V p-p

R

L

= 150

–50

–60

–70

–80

–90

–100

–110

–120

–130

–40

–140

OUTPUT IMPEDANCE –

1k

100

10

1

FREQUENCY – Hz

100k 10M 100M 500M

0.1

1M

RL = 150

–40

–50

–60

–70

–80

POWER SUPPLY REJECTION – dB

–90

10k 100k 1M 10M

FREQUENCY – Hz

TPC 13. AD8108 PSRR vs. Frequency

100

56.3

31.6

AD8108/AD8109

5

4

3

1V/DIV10mV/DIV

2

1

0

10

0

–10

TPC 16. AD8108 Switching Transient (Glitch)

SWITCHING BETWEEN

TWO INPUTS

UPDATE INPUT

TYPICAL VIDEO OUT (RTO)

50ns/DIV

17.8

nV/ Hz

10

5.63

3.16

FREQUENCY – Hz

TPC 14. AD8108 Voltage Noise vs. Frequency

1M

100k

10k

OUTPUT IMPEDANCE –

1k

100

0.1 10 100 500

1

FREQUENCY – MHz

TPC 15. AD8108 Output Impedance, Disabled

10k1k100

100k 1M 10M10

TPC 17. AD8108 Off Isolation, Input-Output

TPC 18. AD8108 Output Impedance, Enabled

–11–REV. A

Page 12

AD8108/AD8109

–30

RL = 150

–40

–50

–60

–70

–80

POWER SUPPLY REJECTION – dB RTI

–90

10k 100k 1M 10M

TPC 19. AD8109 PSRR vs. Frequency

FREQUENCY – Hz

5

4

3

1V/DIV10mV/DIV

2

1

0

10

0

–10

SWITCHING BETWEEN

TWO INPUTS

UPDATE INPUT

TYPICAL VIDEO OUT (RTO)

50ns/DIV

TPC 22. AD8109 Switching Transient (Glitch)

100.0

56.3

31.6

17.8

nV/ Hz

10.0

5.63

3.16

FREQUENCY – Hz

100k 1M 10M10

10k1k100

TPC 20. AD8109 Voltage Noise vs. Frequency

100k

10k

1k

–40

V

= 2V p-p

OUT

–50

R

= 150

L

–60

–70

–80

–90

–100

–110

OFF ISOLATION – dB

–120

–130

–140

100k 10M 100M 500M

1M

FREQUENCY – Hz

TPC 23. AD8109 Off Isolation, Input-Output

1k

100

10

OUTPUT IMPEDANCE –

100

1

100k 10M 100M 500M

1M

FREQUENCY – Hz

TPC 21. AD8109 Output Impedance, Disabled

–12–

OUTPUT IMPEDANCE –

1

0.1

100k 10M 100M 500M

1M

FREQUENCY – Hz

TPC 24. AD8109 Output Impedance, Enabled

REV. A

Page 13

100k

TEMPERATURE – C

V

OS

– mV

–60

2.0

1.5

0.0

–1.0

–2.0

1.0

0.5

–0.5

–1.5

–40 –20 0 20 40 60 80 100

INPUT IMPEDANCE –

1M

10k

AD8108/AD8109

V

1

0

1V/DIV2V/DIV

–1

5

1k

0

INPUT 1 AT +1V

INPUT 0 AT –1V

OUT

UPDATE

100

30k

1M 500M10M 100M100k

FREQUENCY – Hz

TPC 25. AD8108 Input Impedance vs. Frequency

VIN = 200mV

8

R

= 150

GAIN – dB

L

6

4

2

0

–2

–4

–6

–8

FREQUENCY – Hz

CL = 18pF

CL = 12pF

100M1M 10M30k 3G1G100k

TPC 26. AD8108 Frequency Response vs. Capacitive Load

0.5

VIN = 200mV

0.4

R

= 150

FLATNESS – dB

L

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

CL = 18pF

CL = 12pF

FREQUENCY – Hz

100M1M 10M30k 3G1G100k

TPC 27. AD8108 Flatness vs. Capacitive Load

50ns/DIV

TPC 28. AD8108 Switching Time

900

800

700

600

500

400

FREQUENCY

300

200

100

0

–0.020

–0.010 0.000 0.010 0.020

OFFSET VOLTAGE – Volts

TPC 29. AD8108 Offset Voltage Distribution

TPC 30. AD8108 Offset Voltage Drift vs. Temperature

°

(Normalized at 25

C)

–13–REV. A

Page 14

AD8108/AD8109

1M

100k

10k

INPUT IMPEDANCE –

1k

1

0

1V/DIV2V/DIV

–1

5

0

INPUT 1 AT +1V

INPUT 0 AT –1V

V

OUT

UPDATE

100

30k

1M 500M10M 100M100k

FREQUENCY – Hz

TPC 31. AD8109 Input Impedance vs. Frequency

VIN = 100mV

8

R

= 150

L

GAIN – dB

6

4

2

0

–2

–4

–6

–8

FREQUENCY – Hz

CL = 18pF

CL = 12pF

100M1M 10M30k 3G1G100k

TPC 32. AD8109 Frequency Response vs. Capacitive

Load

VIN = 100mV

0.4

R

= 150

L

GAIN – dB

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

CL = 18pF

CL = 12pF

FREQUENCY – Hz

100M1M 10M30k 3G1G100k

TPC 33. AD8109 Flatness vs. Capacitive Load

50ns/DIV

TPC 34. AD8109 Switching Time

320

300

280

260

240

220

200

180

160

140

FREQUENCY

120

100

80

60

40

0

–0.020

–0.010 0.000 0.010 0.020

OFFSET VOLTAGE – V

TPC 35. AD8109 Offset Voltage Distribution (RTI)

2.0

1.5

1.0

0.5

– mV

0.0

OS

V

–0.5

–1.0

–1.5

–2.0

–60

–40 –200 20406080100

TEMPERATURE – C

TPC 36. AD8109 Offset Voltage Drift vs. Temperature

°

(Normalized at 25

C)

–14–

REV. A

Page 15

AD8108/AD8109

THEORY OF OPERATION

The AD8108 (G = +1) and AD8109 (G = +2) share a common

core architecture consisting of an array of 64 transconductance

(gm) input stages organized as eight 8:1 multiplexers with a

common, 8-line analog input bus. Each multiplexer is basically a

folded-cascode high-impedance voltage feedback amplifier with

eight input stages. The input stages are NPN differential pairs

whose differential current outputs are combined at the output

stage, which contains the high impedance node, compensation

and a complementary emitter follower output buffer. In the

AD8108, the output of each multiplexer is fed back directly to the

inverting inputs of its eight gm stages. In the AD8109, the

feedback network is a voltage divider consisting of two equal

resistors.

This switched-gm architecture results in a low power crosspoint

switch that is able to directly drive a back terminated video load

(150 Ω) with low distortion (differential gain and differential

phase errors are better than 0.02% and 0.02°, respectively).

This design also achieves high input resistance and low input

capacitance without the signal degradation and power dissipation

of additional input buffers. However, the small input bias current

at any input will increase almost linearly with the number of

outputs programmed to that input.

The output disable feature of these crosspoints allows larger

switch matrices to be built by simply busing together the outputs

of multiple 8 × 8 ICs. However, while the disabled output impedance of the AD8108 is very high (10 MΩ), that of the AD8109

is limited by the resistive feedback network (which has a nominal

total resistance of 1 kΩ that appears in parallel with the disabled

output. If the outputs of multiple AD8109s are connected through

separate back termination resistors, the loading due to these finite

output impedances will lower the effective back termination

impedance of the overall matrix. This problem is eliminated if the

outputs of multiple AD8109s are connected directly and share a

single back termination resistor for each output of the overall

matrix. This configuration increases the capacitive loading of the

disabled AD8109s on the output of the enabled AD8109.

APPLICATIONS

The AD8108/AD8109 have two options for changing the programming of the crosspoint matrix. In the first, a serial word of 32

bits can be provided that will update the entire matrix each time.

The second option allows for changing a single output’s programming via a parallel interface. The serial option requires fewer

signals, but requires more time (clock cycles) for changing the

programming, while the parallel programming technique requires

more signals, but can change a single output at a time and requires

fewer clock cycles to complete programming.

Serial Programming

The serial programming mode uses the device pins CE, CLK,

DATA IN, UPDATE, and SER/PAR. The first step is to assert

a LOW on SER/PAR in order to enable the serial programming

mode. CE for the chip must be LOW to allow data to be clocked

into the device. The CE signal can be used to address an individual

device when devices are connected in parallel.

The UPDATE signal should be HIGH during the time that data

is shifted into the device’s serial port. Although the data will still

shift in when UPDATE is LOW, the transparent, asynchronous

latches will allow the shifting data to reach the matrix. This will

cause the matrix to try to update to every intermediate state as

defined by the shifting data.

The data at DATA IN is clocked in at every down edge of CLK.

A total of 32 data bits must be shifted in to complete the programming. For each of the eight outputs, there are three bits (D0–D2)

that determine the source of its input followed by one bit (D3)

that determines the enabled state of the output. If D3 is LOW

(output disabled), the three associated bits (D0–D2) do not

matter because no input will be switched to that output.

The most significant output address data is shifted in first, then

following in sequence until the least significant output address

data is shifted in. At this point UPDATE can be taken LOW,

which will cause the programming of the device according to the

data that was just shifted in. The UPDATE registers are asynchronous and when UPDATE is LOW, they are transparent.

If more than one AD8108/AD8109 device is to be serially programmed in a system, the DATA OUT signal from one device

can be connected to the DATA IN of the next device to form a

serial chain. All of the CLK, CE, UPDATE, and SER/PAR pins

should be connected in parallel and operated as described

above. The serial data is input to the DATA IN pin of the first

device of the chain, and it will ripple on through to the last.

Therefore, the data for the last device in the chain should come

at the beginning of the programming sequence. The length of the

programming sequence will be 32 times the number of devices

in the chain.

PARALLEL PROGRAMMING

When using the parallel programming mode, it is not necessary

to reprogram the entire device when making changes to the

matrix. In fact, parallel programming allows the modification of

a single output at a time. Since this takes only one CLK/UPDATE

cycle, significant time savings can be realized by using parallel

programming.

One important consideration in using parallel programming is that

the RESET signal does not reset all registers in the AD8108/AD8109.

When taken low, the RESET signal will only set each output to the

disabled state. This is helpful during power-up to ensure that two

parallel outputs will not be active at the same time.

After initial power-up, the internal registers in the device will

generally have random data, even though the RESET signal was

asserted. If parallel programming is used to program one output,

that output will be properly programmed but the rest of the device

will have a random program state depending on the internal

register content at power-up. Therefore, when using parallel

programming, it is essential that all outputs be programmed to a

desired state after power-up. This will ensure that the programming

matrix is always in a known state. From then on, parallel programming can be used to modify a single, or more, output at a time.

–15–REV. A

Page 16

AD8108/AD8109

In a similar fashion, if both CE and UPDATE are taken LOW after

initial power-up, the random power-up data in the shift register will

be programmed into the matrix. Therefore, in order to prevent the

crosspoint from being programmed into an unknown state do

not apply low logic levels to both CE and

initially applied. Programming the full shift register one time to a

desired state by either serial or parallel programming after initial

power-up will eliminate the possibility of programming the

matrix to an unknown state.

To change an output’s programming via parallel programming,

SER/PAR and UPDATE should be taken HIGH and CE should

be taken LOW. The CLK signal should be in the HIGH state.

The address of the output that is to be programmed should be

put on A0–A2. The first three data bits (D0–D2) should contain

the information that identifies the input that is programmed to the

output that is addressed. The fourth data bit (D3) will determine

the enabled state of the output. If D3 is LOW (output disabled)

the data on D0–D2 does not matter.

After the desired address and data signals have been established,

they can be latched into the shift register by a HIGH to LOW

transition of the CLK signal. The matrix will not be programmed,

however, until the UPDATE signal is taken low. Thus, it is possible to latch in new data for several or all of the outputs first via

successive negative transitions of CLK while UPDATE is held

high, and then have all the new data take effect when UPDATE

goes LOW. This is the technique that should be used when programming the device for the first time after power-up when

using parallel programming.

POWER-ON RESET

When powering up the AD8108/AD8109 it is usually desirable

to have the outputs come up in the disabled state. The RESET

pin, when taken LOW will cause all outputs to be in the disabled state. However, the RESET signal does not reset all registers

in the AD8108/AD8109. This is important when operating in

the parallel programming mode. Please refer to that section for

information about programming internal registers after powerup. Serial programming will program the entire matrix each

time, so no special considerations apply.

Since the data in the shift register is random after power-up,

they should not be used to program the matrix or else the matrix

can enter unknown states. To prevent this, do not apply logic low

CE

and

signals to both

register should first be loaded with the desired data, and then

UPDATE can be taken LOW to program the device.

The RESET pin has a 20 kΩ pull-up resistor to DVDD that can

be used to create a simple power-up reset circuit. A capacitor

from RESET to ground will hold RESET LOW for some time

while the rest of the device stabilizes. The LOW condition will

cause all the outputs to be disabled. The capacitor will then

charge through the pull-up resistor to the HIGH state, thus

allowing full programming capability of the device.

UPDATE

UPDATE

initially after power-up. The shift

after power is

Gain Selection

The 8 × 8 crosspoints come in two versions depending on the

desired gain of the analog circuit paths. The AD8108 device is

unity gain and can be used for analog logic switching and other

applications where unity gain is desired. The AD8108 can also

be used for the input and interior sections of larger crosspoint

arrays where termination of output signals is not usually used.

The AD8108 outputs have a very high impedance when their

outputs are disabled.

For devices that will be used to drive a terminated cable with its

outputs, the AD8109 can be used. This device has a built-in gain

of two that eliminates the need for a gain-of-two buffer to drive

a video line. Because of the presence of the feedback network in

these devices, the disabled output impedance is about 1 kΩ.

If external amplifiers will be used to provide a G = +2, Analog

Devices’ AD8079 is a fixed gain of +2 buffer.

Creating Larger Crosspoint Arrays

The AD8108/AD8109 are high density building blocks for creating crosspoint arrays of dimensions larger than 8 × 8. Various

features such as output disable, chip enable, and gain-of-one

and-two options are useful for creating larger arrays. For very

large arrays, they can be used along with the AD8116, a 16 × 16

video crosspoint device. In addition, systems that require more

inputs than outputs can use the AD8110 and/or the AD8111,

which are (gain-of-one and gain-of-two) 16 × 8 crosspoint

switches.

The first consideration in constructing a larger crosspoint is to

determine the minimum number of devices required. The 8 × 8

architecture of the AD8108/AD8109 contains 64 “points,” which

is a factor of 16 greater than a 4 × 1 crosspoint. The PC board

area and power consumption savings are readily apparent when

compared to using these smaller devices.

For a nonblocking crosspoint, the number of points required is

the product of the number of inputs multiplied by the number

of outputs. Nonblocking requires that the programming of a given

input to one or more outputs does not restrict the availability of

that input to be a source for any other outputs.

Some nonblocking crosspoint architectures will require more than

this minimum as calculated above. Also, there are blocking

architectures that can be constructed with fewer devices than this

minimum. These systems have connectivity available on a statistical basis that is determined when designing the overall system.

The basic concept in constructing larger crosspoint arrays is to

connect inputs in parallel in a horizontal direction and to “wire-OR”

the outputs together in the vertical direction. The meaning of

horizontal and vertical can best be understood by looking at a diagram.

An 8 input by 16 output crosspoint array can be constructed as

shown in Figure 6. This configuration parallels two inputs per

channel and does not require paralleling of any outputs. Inputs are

easier to parallel than outputs, because there are lower parasitics

involved. For a 16 × 8 crosspoint, the AD8110 (gain of one) or

AD8111 (gain of two) device can be used. These devices are already

configured into a 16 × 8 crosspoint in a single device.

–16–

REV. A

Page 17

AD8108/AD8109

AD8108

8

ONE

PER INPUT

8

8

OR

AD8109

AD8108

OR

AD8109

8

16 OUTPUTS

OUT 00–15

8

8 INPUTS

IN 00–07

TERMINATION

Figure 6. 8 × 16 Crosspoint Array Using Two AD8108s

(Unity Gain) or Two AD8109s (Gain-of-Two)

Figure 7 illustrates a 16 × 16 crosspoint array, while a 24 × 24

crosspoint is illustrated in Figure 8. The 16 × 16 crosspoint

requires that each input driver drive two inputs in parallel and

each output be wire-ORed with one other output. The 24 × 24

crosspoint requires driving three inputs in parallel and having

the outputs wire-ORed in groups of three. It is required of the

system programming that only one output of a wired-OR node

be active at a time.

IN 00–07

8

8 8 8 8

8

00–07

8

R

TERM

8

At some point, the number of outputs that are wire-ORed becomes

too great to maintain system performance. This will vary according

to which system specifications are most important. For example,

a 64 × 8 crosspoint can be created with eight AD8108/AD8109s.

This design will have 64 separate inputs and have the corresponding outputs of each device wire-ORed together in groups of eight.

Using additional crosspoint devices in the design can lower the

number of outputs that must be wire-ORed together. Figure 9

shows a block diagram of a system using eight AD8108s and

two AD8109s to create a nonblocking, gain-of-two, 64 × 8 crosspoint that restricts the wire-ORing at the output to only four

outputs. The rank 1 wire-ORed devices are the AD8108,

which has a higher disabled output impedance than the AD8109.

RANK 1

(64:16)

IN 00–07

IN 08–15

IN 16–23

IN 24–31

IN 32–39

IN 40–47

8

8

8

8

8

8

AD8108

AD8108

AD8108

AD8108

AD8108

AD8108

4

4

4

4

4

4

4

4

4

4

4

4

4

1k

4

1k

RANK 2

16 8 NONBLOCKING

16 16 BLOCKING

4

1k

4

1k

AD8109

AD8109

4

4

4

4

OUT 00–07

NONBLOCKING

ADDITIONAL

8 OUTPUTS

(SUBJECT TO

BLOCKING)

IN 08–15

8

8 8 8 8

8

OUT 00–07

08–15

8

R

TERM

8

OUT 08–15

Figure 7. 16 × 16 Crosspoint Array Using Four AD8108s

or AD8109s

IN 00–07

IN 08–15

IN 16–23

8

8 8

8 8

8

8 8 8 8 8 8

8 8

8

8 8 8 8 8 8

8 8 8

OUT 00–07

8 8 8 8

OUT 08–15

8

8

R

8

R

R

TERM

TERM

TERM

8

8

OUT 16–23

Figure 8. 24 × 24 Crosspoint Array Using Nine AD8108s or

AD8109s

IN 48–55

IN 56–63

8

8

AD8108

AD8108

4

4

4

4

Figure 9. Nonblocking 64 × 8 Array with Gain-of-Two

×

16 Blocking)

(64

Additionally, by using the lower four outputs from each of the

two rank 2 AD8109s, a blocking 64 × 16 crosspoint array can be

realized. There are, however, some drawbacks to this technique.

The offset voltages of the various cascaded devices will accumulate and the bandwidth limitations of the devices will compound.

In addition, the extra devices will consume more current and

take up more board space. Once again, the overall system design

specifications will determine how to make the various tradeoffs.

Multichannel Video

The excellent video specifications of the AD8108/AD8109 make

them ideal candidates for creating composite video crosspoint

switches. These can be made quite dense by taking advantage

of the AD8108/AD8109’s high level of integration and the fact

that composite video requires only one crosspoint channel per

system video channel. There are, however, other video formats

that can be routed with the AD8108/AD8109 requiring more

than one crosspoint channel per video channel.

–17–REV. A

Page 18

AD8108/AD8109

Some systems use twisted-pair wiring to carry video signals.

These systems utilize differential signals and can lower costs

because they use lower cost cables, connectors and termination

methods. They also have the ability to lower crosstalk and reject

common-mode signals, which can be important for equipment

that operates in noisy environments or where common-mode voltages are present between transmitting and receiving equipment.

In such systems, the video signals are differential; there is a positive

and negative (or inverted) version of the signals. These complementary signals are transmitted onto each of the two wires of the

twisted pair, yielding a first order zero common- mode signal. At

the receive end, the signals are differentially received and converted

back into a single-ended signal.

When switching these differential signals, two channels are

required in the switching element to handle the two differential

signals that make up the video channel. Thus, one differential video

channel is assigned to a pair of crosspoint channels, both input

and output. For a single AD8108/AD8109, four differential video

channels can be assigned to the eight inputs and eight outputs.

This will effectively form a 4 × 4 differential crosspoint switch.

Programming such a device will require that inputs and outputs

be programmed in pairs. This information can be deduced by

inspection of the programming format of the AD8108/AD8109

and the requirements of the system.

There are other analog video formats requiring more than one

analog circuit per video channel. One two-circuit format that is

commonly being used in systems such as satellite TV, digital cable

boxes and higher quality VCRs, is called S-video or Y/C video.

This format carries the brightness (luminance or Y) portion of the

video signal on one channel and the color (chrominance, chroma

or C) on a second channel.

Since S-video also uses two separate circuits for one video channel, creating a crosspoint system requires assigning one video

channel to two crosspoint channels as in the case of a differential video system. Aside from the nature of the video format,

other aspects of these two systems will be the same.

There are yet other video formats using three channels to carry

the video information. Video cameras produce RGB (red, green,

blue) directly from the image sensors. RGB is also the usual

format used by computers internally for graphics. RGB can also

be converted to Y, R–Y, B–Y format, sometimes called YUV

format. These three-circuit, video standards are referred to as

component analog video.

The component video standards require three crosspoint channels per video channel to handle the switching function. In a

fashion similar to the two-circuit video formats, the inputs and

outputs are assigned in groups of three and the appropriate logic

programming is performed to route the video signals.

CROSSTALK

Many systems, such as broadcast video, that handle numerous

analog signal channels have strict requirements for keeping the

various signals from influencing any of the others in the system.

Crosstalk is the term used to describe the coupling of the signals

of other nearby channels to a given channel.

When there are many signals in proximity in a system, as will

undoubtedly be the case in a system that uses the AD8108/

AD8109, the crosstalk issues can be quite complex. A good

understanding of the nature of crosstalk and some definition of

terms is required in order to specify a system that uses one or

more AD8108/AD8109s.

TYPES OF CROSSTALK

Crosstalk can be propagated by means of any of three methods.

These fall into the categories of electric field, magnetic field and

sharing of common impedances. This section will explain these effects.

Every conductor can be both a radiator of electric fields and a

receiver of electric fields. The electric field crosstalk mechanism

occurs when the electric field created by the transmitter propagates

across a stray capacitance (e.g., free space) and couples with the

receiver and induces a voltage. This voltage is an unwanted crosstalk

signal in any channel that receives it.

Currents flowing in conductors create magnetic fields that circulate

around the currents. These magnetic fields will then generate

voltages in any other conductors whose paths they link. The undesired induced voltages in these other channels are crosstalk signals.

The channels that crosstalk can be said to have a mutual inductance that couples signals from one channel to another.

The power supplies, grounds and other signal return paths of a multichannel system are generally shared by the various channels. When

a current from one channel flows in one of these paths, a voltage

that is developed across the impedance becomes an input crosstalk

signal for other channels that share the common impedance.

All these sources of crosstalk are vector quantities, so the magnitudes cannot simply be added together to obtain the total

crosstalk. In fact, there are conditions where driving additional

circuits in parallel in a given configuration can actually reduce the

crosstalk.

Areas of Crosstalk

For a practical AD8108/AD8109 circuit, it is required that it be

mounted to some sort of circuit board in order to connect it to

power supplies and measurement equipment. Great care has been

taken to create a characterization board (also available as an evaluation board) that adds minimum crosstalk to the intrinsic device.

This, however, raises the issue that a system’s crosstalk is a combination of the intrinsic crosstalk of the devices in addition to the

circuit board to which they are mounted. It is important to try to

separate these two areas of crosstalk when attempting to minimize

its effect.

In addition, crosstalk can occur among the inputs to a crosspoint

and among the outputs. It can also occur from input to output.

Techniques will be discussed for diagnosing which part of a system

is contributing to crosstalk.

Measuring Crosstalk

Crosstalk is measured by applying a signal to one or more channels and measuring the relative strength of that signal on a desired

selected channel. The measurement is usually expressed as dB

down from the magnitude of the test signal. The crosstalk is

expressed by:

|XT| = 20 log

where s = jω is the Laplace transform variable, Asel(s) is the

amplitude of the crosstalk-induced signal in the selected channel

and Atest(s) is the amplitude of the test signal. It can be seen

that crosstalk is a function of frequency, but not a function of

the magnitude of the test signal (to first order). In addition, the

crosstalk signal will have a phase relative to the test signal associated with it.

(Asel(s)/Atest(s))

10

–18–

REV. A

Page 19

AD8108/AD8109

A network analyzer is most commonly used to measure crosstalk

over a frequency range of interest. It can provide both magnitude

and phase information about the crosstalk signal.

As a crosspoint system or device grows larger, the number of theoretical crosstalk combinations and permutations can become

extremely large. For example, in the case of the 8 × 8 matrix of the

AD8108/AD8109, we can examine the number of crosstalk

terms that can be considered for a single channel, say IN00

input. IN00 is programmed to connect to one of the AD8108/

AD8109 outputs where the measurement can be made.

We can first measure the crosstalk terms associated with driving

a test signal into each of the other seven inputs one at a time.

We can then measure the crosstalk terms associated with driving

a parallel test signal into all seven other inputs taken two at a time

in all possible combinations; and then three at a time, etc., until,

finally, there is only one way to drive a test signal into all seven

other inputs.

Each of these cases is legitimately different from the others and

might yield a unique value depending on the resolution of the

measurement system, but it is hardly practical to measure all these

terms and then to specify them. In addition, this describes the

crosstalk matrix for just one input channel. A similar crosstalk

matrix can be proposed for every other input. In addition, if the

possible combinations and permutations for connecting inputs

to the other (not used for measurement) outputs are taken into

consideration, the numbers rather quickly grow to astronomical

proportions. If a larger crosspoint array of multiple AD8108/

AD8109s is constructed, the numbers grow larger still.

Obviously, some subset of all these cases must be selected to be

used as a guide for a practical measure of crosstalk. One common

method is to measure “all hostile” crosstalk. This term means that

the crosstalk to the selected channel is measured, while all other

system channels are driven in parallel. In general, this will yield

the worst crosstalk number, but this is not always the case due

to the vector nature of the crosstalk signal.

Other useful crosstalk measurements are those created by one

nearest neighbor or by the two nearest neighbors on either side.

These crosstalk measurements will generally be higher than those

of more distant channels, so they can serve as a worst-case measure

for any other one-channel or two-channel crosstalk measurements.

Input and Output Crosstalk

The flexible programming capability of the AD8108/AD8109

can be used to diagnose whether crosstalk is occurring more on the

input side or the output side. Some examples are illustrative. A

given input channel (IN03 in the middle for this example) can be

programmed to drive OUT03. The input to IN03 is just terminated

to ground (via 50 Ω or 75 Ω) and no signal is applied.

All the other inputs are driven in parallel with the same test signal

(practically provided by a distribution amplifier), with all other

outputs except OUT03 disabled. Since grounded IN03 is programmed to drive OUT03, there should be no signal present.

Any signal that is present can be attributed to the other seven

hostile input signals, because no other outputs are driven. (They

are all disabled.) Thus, this method measures the all-hostile input

contribution to crosstalk into IN03. Of course, the method can be

used for other input channels and combinations of hostile inputs.

For output crosstalk measurement, a single input channel is

driven (IN00, for example) and all outputs other than a given

output (IN03 in the middle) are programmed to connect to

IN00. OUT03 is programmed to connect to IN07 (far away

from IN00), which is terminated to ground. Thus OUT03

should not have a signal present since it is listening to a quiet

input. Any signal measured at the OUT03 can be attributed to

the output crosstalk of the other seven hostile outputs. Again,

this method can be modified to measure other channels and

other crosspoint matrix combinations.

Effect of Impedances on Crosstalk

The input side crosstalk can be influenced by the output impedance of the sources that drive the inputs. The lower the

impedance of the drive source, the lower the magnitude of the

crosstalk. The dominant crosstalk mechanism on the input side

is capacitive coupling. The high impedance inputs do not have

significant current flow to create magnetically induced crosstalk.

However, significant current can flow through the input termination resistors and the loops that drive them. Thus, the PC

board on the input side can contribute to magnetically coupled

crosstalk.

From a circuit standpoint, the input crosstalk mechanism looks

like a capacitor coupling to a resistive load. For low frequencies

the magnitude of the crosstalk will be given by:

where R

|XT| = 20 log

is the source resistance, CM is the mutual capacitance

S

[(RS CM) × s]

10

between the test signal circuit and the selected circuit, and s is

the Laplace transform variable.

From the equation it can be observed that this crosstalk mechanism

has a high-pass nature; it can also be minimized by reducing the

coupling capacitance of the input circuits and lowering the output

impedance of the drivers. If the input is driven from a 75 Ω

terminated cable, the input crosstalk can be reduced by buffering

this signal with a low output impedance buffer.

On the output side, the crosstalk can be reduced by driving a

lighter load. Although the AD8108/AD8109 is specified with

excellent differential gain and phase when driving a standard

150 Ω video load, the crosstalk will be higher than the minimum

obtainable due to the high output currents. These currents will

induce crosstalk via the mutual inductance of the output pins

and bond wires of the AD8108/AD8109.

From a circuit standpoint, this output crosstalk mechanism

looks like a transformer, with a mutual inductance between the

windings, that drives a load resistor. For low frequencies, the

magnitude of the crosstalk is given by:

|XT| = 20 log

(Mxy × s/RL)

10

where Mxy is the mutual inductance of output x to output y and

R

is the load resistance on the measured output. This crosstalk

L

mechanism can be minimized by keeping the mutual inductance

low and increasing R

. The mutual inductance can be kept low

L

by increasing the spacing of the conductors and minimizing

their parallel length.

–19–REV. A

Page 20

AD8108/AD8109

PCB Layout

Extreme care must be exercised to minimize additional crosstalk

generated by the system circuit board(s). The areas that must be

carefully detailed are grounding, shielding, signal routing, and

supply bypassing.

The packaging of the AD8108/AD8109 is designed to help keep

the crosstalk to a minimum. Each input is separated from each

other input by an analog ground pin. All of these AGNDs

should be directly connected to the ground plane of the circuit

board. These ground pins provide shielding, low impedance return

paths and physical separation for the inputs. All of these help to

reduce crosstalk.

Each output is separated from its two neighboring outputs by an

analog ground pin in addition to an analog supply pin of one

polarity or the other. Each of these analog supply pins provides

power to the output stages of only the two nearest outputs. These

supply pins and analog grounds provide shielding, physical separation and a low impedance supply for the outputs. Individual

bypassing of each of these supply pins, with a 0.01 µF chip capaci-

tor directly to the ground plane, minimizes high frequency output

crosstalk via the mechanism of sharing common impedances.

Each output also has an on-chip compensation capacitor that

is individually tied the nearby analog ground pins AGND00

through AGND07. This technique reduces crosstalk by preventing the currents that flow in these paths from sharing a common

impedance on the IC and in the package pins. These AGNDxx

signals should all be directly connected to the ground plane.

The input and output signals will have minimum crosstalk if they

are located between ground planes on layers above and below, and

separated by ground in between. Vias should be located as close

to the IC as possible to carry the inputs and outputs to the inner

layer. The only place the input and output signals surface is at the

input termination resistors and the output series back termination

resistors. These signals should also be separated, to the extent

possible, as soon as they emerge from the IC package.

Evaluation Board

A four-layer evaluation board for the AD8108/AD8109 is available. The exact same board and external components are used

for each device. The only difference is the device itself, which

offers a selection of a gain of unity or gain of two through the

analog channels. This board has been carefully laid out and tested

to demonstrate the specified high-speed performance of the device.

Figure 10 shows the schematic of the evaluation board. Figure

11 shows the component side silk-screen. The layouts of the

board’s four layers are given in Figures 12, 13, 14, and 15.

The evaluation board package includes the following:

•

Fully populated board with BNC-type connectors.

•

Windows® based software for controlling the board from a PC

via the printer port.

•

Custom cable to connect evaluation board to PC.

•

Disk containing Gerber files of board layout.

Windows is a registered trademark of Microsoft Corporation

–20–

REV. A

Page 21

DVCC DGND NCAVEE AGND AVCCNC

P1-1

P1-2

+

0.1F10F

P1-3

CR1

CR2

P1-4

1N4148

0.1F10F

INPUT 00 INPUT 00

INPUT 01 INPUT 01

INPUT 02 INPUT 02

INPUT 03 INPUT 03

INPUT 04 INPUT 04

INPUT 05 INPUT 05

INPUT 06 INPUT 06

INPUT 07 INPUT 07

P2-5

P2-4

P2-2

P2-3

P2-1

P2-6

NC = NO CONNECT

P1-5

+

P1-6

0.1F10F

75

75

75

75

75

75

75

75

P1-7

+

80 46

79

1

2

AGND

3

4

AGND

5

6

AGND

7

8

AGND

9

10

AGND

11

12

AGND

13

14

AGND

15

16

AGND

59

DATA OUT

57

DATA IN

DGNDCECLK

62 61 60 58 56 55 54 53 52 51 50 49 48

P3-1

0.01F

RESET

P3-2

P3-3

DVCCDVCC

63

DVCCDVCCDGND

P3-4

AVCC

0.01F

0.01F

43

AVCC

AD8108/AD8109

UPDATE

SER/PARA0A1A2D0D1D2

P3-5

P3-6

P3-7

P3-8

P3-9

AVCC

0.01F

44

AVCC

P3-10

P3-11

AVEE

45

AVEE

P3-12

0.01F

OUTPUT 00

OUTPUT 01

OUTPUT 02

OUTPUT 03

OUTPUT 04

OUTPUT 05

OUTPUT 06

OUTPUT 07

D3

NC

P3-13

P3-14

AD8108/AD8109

AGND

42

AGND

AVEE

AGND

AVCC

AGND

AVEE

AGND

AVCC

AGND

AVEE

AGND

AVCC

AGND

AVEE

AGND

AVCC

AVCC

AVEE

75

41

40

39

75

38

37

36

75

35

34

33

75

32

31

30

75

29

28

27

75

26

25

24

75

23

22

21

75

20

19

18

17

R25

20k

SERIAL MODE

JUMP

0.01F

0.01F

0.01F

0.01F

0.01F

0.01F

0.01F

0.01F

0.01F

0.01F

DVCC

AVEE

AVCC

AVEE

AVCC

AVEE

AVCC

AVEE

AVCC

AVCC

AVEE

Figure 10. Evaluation Board Schematic

–21–REV. A

Page 22

AD8108/AD8109

Figure 11. Component Side Silkscreen

Figure 12. Board Layout (Component Side)

–22–

REV. A

Page 23

AD8108/AD8109

Figure 13. Board Layout (Signal Layer)

Figure 14. Board Layout (Power Plane)

–23–REV. A

Page 24

AD8108/AD8109

Figure 15. Board Layout (Bottom Layer)

–24–

REV. A

Page 25

AD8108/AD8109

Optimized for video applications, all signal inputs and outputs

are terminated with 75 Ω resistors. Stripline techniques are used

to achieve a characteristic impedance on the signal input and

output lines also of 75 Ω. Figure 16 shows a cross-section of one

of the input or output tracks along with the arrangement of the

PCB layers. It should be noted that unused regions of the four

layers are filled up with ground planes. As a result, the input

and output traces, in addition to having controlled impedances,

are well shielded.

w = 0.008"

(0.2mm)

b = 0.024"

(0.6mm)

a = 0.008"

(0.2mm)

t = 0.00135" (0.0343mm)

h = 0.011325"

(0.288mm)

TOP LAYER

SIGNAL LAYER

POWER LAYER

BOTTOM LAYER

Figure 16. Cross-Section of Input and Output Traces

The board has 16 BNC type connectors: eight inputs and eight

outputs. The connectors are arranged in two crescents around

the device. As can be seen from Figure 11, this results in all

eight input signal traces and all eight signal output traces having

the same length. This is useful in tests such as All-Hostile

Crosstalk where the phase relationship and delay between signals needs to be maintained from input to output.

The three power supply pins AVCC, DVCC, and AVEE should

be connected to good quality, low noise, ±5 V supplies. Where

the same ±5 V power supplies are used for analog and digital,

separate cables should be run for the power supply to the evaluation board’s analog and digital power supply pins.

As a general rule, each power supply pin (or group of adjacent

power supply pins) should be locally decoupled with a 0.01 µF

capacitor. If there is a space constraint, it is more important to

decouple analog power supply pins before digital power supply

pins. A 0.1 µF capacitor, located reasonably close to the pins,

can be used to decouple a number of power supply pins. Finally

a 10 µF capacitor should be used to decouple power supplies as

they come on to the board.

Controlling the Evaluation Board from a PC

The evaluation board include Windows-based control software

and a custom cable that connects the board’s digital interface to

the printer port of the PC. The wiring of this cable is shown in

Figure 17. The software requires Windows 3.1 or later to operate. To install the software, insert the disk labeled “Disk #1 of

2” in the PC and run the file called SETUP.EXE. Additional

installation instructions will be given on-screen. Before beginning installation, it is important to terminate any other Windows

applications that are running.

MOLEX 0.100" CENTER

CRIMP TERMINAL HOUSING

RESET

CLK

CE

UPDATE

DATA IN

DGND

D-SUB-25

2

3

4

5

6

25

1

6

MOLEX

TERMINAL HOUSING

3

1

4

5

2

6

SIGNAL

CE

RESET

UPDATE

DATA IN

CLK

DGND

D-SUB 25 PIN (MALE)

1

14

25

13

EVALUATION BOARD PC

Figure 17. Evaluation Board-PC Connection Cable

–25–REV. A

Page 26

AD8108/AD8109

When you launch the crosspoint control software, you will be

asked to select the printer port you are using. Most modern PCs

have only one printer port, usually called LPT1. However, some

laptop computers use the PRN port.

Figure 18 shows the main screen of the control software in its

initial reset state (all outputs off). Using the mouse, any input

can be connected with one or more outputs by simply clicking

on the appropriate radio buttons in the 8 × 8 on-screen array.

Each time a button is clicked on, the software automatically

sends and latches the required 32-bit data stream to the evaluation

board. An output can be turned off by clicking the appropriate

button in the Off column. To turn off all outputs, click on RESET.

The software offers volatile and nonvolatile storage of configurations. For volatile storage, up to two configurations can be

stored and recalled using the Memory 1 and Memory 2 Buffers.

These function in an identical fashion to the memory on a

pocket calculator. For nonvolatile storage of a configuration, the

Save Setup and Load Setup functions can be used. This stores

the configuration as a data file on disk.

Overshoot on PC Printer Ports’ Data Lines

The data lines on some printer ports have excessive overshoot.

Overshoot on the pin that is used as the serial clock (Pin 6 on

the D-Sub-25 connector) can cause communication problems.

This overshoot can be eliminated by connecting a capacitor

from the CLK line on the evaluation board to ground. A pad

has been provided on the solder-side of the evaluation board to

allow this capacitor to be soldered into place. Depending upon

the overshoot from the printer port, this capacitor may need to

be as large as 0.01 µF.

Figure 18. Evaluation Board Control Panel

–26–

REV. A

Page 27

0.030 (0.75)

0.020 (0.50)

SEATING

PLANE

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

80-Lead Plastic LQFP

(ST-80A)

0.559 (14.20)

0.063 (1.60)

MAX

1

0.543 (13.80)

0.476 (12.10)

0.469 (11.90)

TOP VIEW

(PINS DOWN)

6180

60

0.476 (12.10)

0.469 (11.90)

0.559 (14.20)

0.543 (13.80)

AD8108/AD8109

0.003 (0.08)

MAX

0.006 (0.15)

0.002 (0.05)

0.057 (1.45)

0.053 (1.35)

CONTROLLING DIMENSIONS ARE IN MILLIMETERS (mm)

ENGLISH DIMENSIONS (INCHES) ARE APPROXIMATE CONVERSIONS

20

21

0.020 (0.50)

BSC

0.011 (0.27)

0.007 (0.17)

41

40

–27–REV. A

Page 28

AD8108/AD8109

Revision History

Location Page

Data Sheet changed from REV. 0 to REV. A.

Universal change in nomenclature from MQFP to LQFP

Comment added to OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

C01068–0–1/02(A)

–28–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...