Page 1

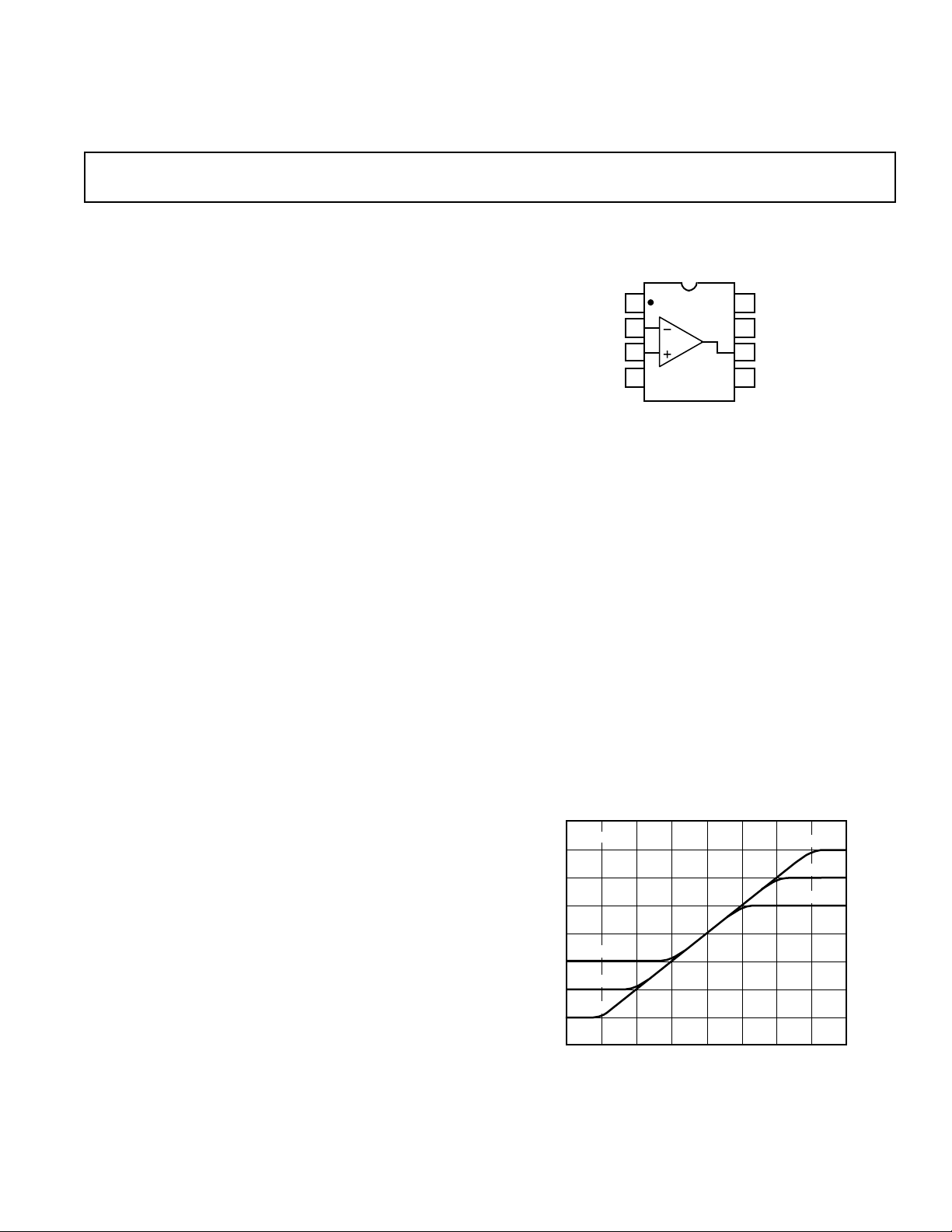

–4 –3 –2 –1 0 1 2 3 4

4

3

2

1

0

–1

–2

–3

–4

INPUT VOLTAGE – Volts

OUTPUT VOLTAGE – Volts

VL = –3V

VL = –2V

VL = –1V

VH = 1V

VH = 2V

VH = 3V

AD8036

1

2

3

4

8

7

6

5

AD8036/

AD8037

NC

–INPUT

+INPUT

–V

S

+V

S

OUTPUT

(Top View)

NC = NO CONNECT

V

L

V

H

Low Distortion, Wide Bandwidth

a

Voltage Feedback Clamp Amps

AD8036/AD8037

FEATURES

Superb Clamping Characteristics

3 mV Clamp Error

1.5 ns Overdrive Recovery

Minimized Nonlinear Clamping Region

240 MHz Clamp Input Bandwidth

ⴞ3.9 V Clamp Input Range

Wide Bandwidth AD8036 AD8037

Small Signal 240 MHz 270 MHz

Large Signal (4 V p-p) 195 MHz 190 MHz

Good DC Characteristics

2 mV Offset

10 V/ⴗC Drift

Ultralow Distortion, Low Noise

–72 dBc typ @ 20 MHz

4.5 nV/√Hz Input Voltage Noise

High Speed

Slew Rate 1500 V/s

Settling 10 ns to 0.1%, 16 ns to 0.01%

ⴞ3 V to ⴞ5 V Supply Operation

APPLICATIONS

ADC Buffer

IF/RF Signal Processing

High Quality Imaging

Broadcast Video Systems

Video Amplifier

Full Wave Rectifier

and large-signal bandwidths and ultralow distortion. The

AD8036 achieves –66 dBc at 20 MHz, and 240 MHz smallsignal and 195 MHz large-signal bandwidths. The AD8036 and

AD8037’s recover from 2× clamp overdrive within 1.5 ns.

These characteristics position the AD8036/AD8037 ideally for

driving as well as buffering flash and high resolution ADCs.

In addition to traditional output clamp amplifier applications,

the input clamp architecture supports the clamp levels as additional inputs to the amplifier. As such, in addition to static dc

clamp levels, signals with speeds up to 240 MHz can be applied

to the clamp pins. The clamp values can also be set to any

value within the output voltage range provided that V

that V

AD8037 can be used in nontraditional applications such as a

full-wave rectifier, a pulse generator, or an amplitude modula-

PRODUCT DESCRIPTION

The AD8036 and AD8037 are wide bandwidth, low distortion

clamping amplifiers. The AD8036 is unity gain stable. The

AD8037 is stable at a gain of two or greater. These devices allow the designer to specify a high (V

) and low (VCL) output

CH

clamp voltage. The output signal will clamp at these specified

tor. These novel applications are only examples of some of the

diverse applications which can be designed with input clamps.

The AD8036 is offered in chips, industrial (–40°C to +85°C)

and military (–55°C to +125°C) package temperature ranges

and the AD8037 in industrial. Industrial versions are available

in plastic DIP and SOIC; MIL versions are packaged in cerdip.

levels. Utilizing a unique patent pending CLAMPIN™ input

clamp architecture, the AD8036 and AD8037 offer a 10× im-

provement in clamp performance compared to traditional output clamping devices. In particular, clamp error is typically

3 mV or less and distortion in the clamp region is minimized.

This product can be used as a classical op amp or a clamp amplifier where a high and low output voltage are specified.

The AD8036 and AD8037, which utilize a voltage feedback architecture, meet the requirements of many applications which

previously depended on current feedback amplifiers. The

AD8036 and AD8037 exhibit an exceptionally fast and accurate

pulse response (16 ns to 0.01%), extremely wide small-signal

CLAMPIN is a trademark of Analog Devices, Inc.

FUNCTIONAL BLOCK DIAGRAM

8-Lead Plastic DIP (N), Cerdip (Q),

and SO Packages

is greater

. Due to these clamp characteristics, the AD8036 and

L

H

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Figure 1. Clamp DC Accuracy vs. Input Voltage

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD8036/AD8037–SPECIFICATIONS

(±VS = ±5 V; R

ELECTRICAL CHARACTERISTICS

Parameter Conditions Min Typ Max Min Typ Max Units

DYNAMIC PERFORMANCE

Bandwidth (–3 dB)

Small Signal V

Large Signal

1

Bandwidth for 0.1 dB Flatness V

Slew Rate, Average +/– V

Rise/Fall Time V

Settling Time

To 0.1% V

To 0.01% V

HARMONIC/NOISE PERFORMANCE

2nd Harmonic Distortion 2 V p-p; 20 MHz, R

3rd Harmonic Distortion 2 V p-p; 20 MHz, R

3rd Order Intercept 25 MHz +46 +41 dBm

Noise Figure R

Input Voltage Noise 1 MHz to 200 MHz 6.7 4.5 nV√Hz

Input Current Noise 1 MHz to 200 MHz 2.2 2.1 pA√Hz

Average Equivalent Integrated

Input Noise Voltage 0.1 MHz to 200 MHz 95 60 µV rms

Differential Gain Error (3.58 MHz) R

Differential Phase Error (3.58 MHz) R

Phase Nonlinearity DC to 100 MHz 1.1 1.1 Degree

CLAMP PERFORMANCE

Clamp Voltage Range

2

Clamp Accuracy 2× Overdrive, V

Clamp Nonlinearity Range

Clamp Input Bias Current (V

3

or VL) 8036, V

H

Clamp Input Bandwidth (–3 dB) V

Clamp Overshoot 2× Overdrive, V

Overdrive Recovery 2× Overdrive 1.5 1.3 ns

4,

R

DC PERFORMANCE

Input Offset Voltage

5

= 150 Ω

L

Offset Voltage Drift ±10 ± 10 µV/°C

Input Bias Current 410 39µA

Input Offset Current 0.3 3 0.1 3 µA

Common-Mode Rejection Ratio V

Open-Loop Gain V

INPUT CHARACTERISTICS

Input Resistance 500 500 kΩ

Input Capacitance 1.2 1.2 pF

Input Common-Mode Voltage Range ±2.5 ± 2.5 V

OUTPUT CHARACTERISTICS

Output Voltage Range, R

= 150 Ω±3.2 ±3.9 ± 3.2 ±3.9 V

L

Output Current 70 70 mA

Output Resistance 0.3 0.3 Ω

Short Circuit Current 240 240 mA

POWER SUPPLY

Operating Range ±3.0 ±5.0 ±6.0 ±3.0 ±5.0 ±6.0 V

Quiescent Current 20.5 21.5 18.5 19.5 mA

Power Supply Rejection Ratio T

NOTES

1

See Max Ratings and Theory of Operation sections of data sheet.

2

See Max Ratings.

3

Nonlinearity is defined as the voltage delta between the set input clamp voltage (VH or VL) and the voltage at which V

4

Measured at AV = 50.

5

Measured with respect to the inverting input.

ations subject to change without notice.

Specific

OUT

8036, V

OUT

8036, R

OUT

OUT

V

OUT

OUT

OUT

R

L

R

L

S

L

L

VCH or V

T

MIN–TMAX

T

MIN–TMAX

CH

T

MIN–TMAX

T

MIN–TMAX

T

MIN–TMAX

CM

OUT

T

MIN–TMAX

T

MIN–TMAX

MIN–TMAX

otherwise noted)

≤ 0.4 V p-p 150 240 200 270 MHz

= 2.5 V p-p; 8037, V

OUT

≤ 0.4 V p-p

= 140 Ω; 8037, RF = 274 Ω 130 130 MHz

F

= 4 V Step, 10–90% 900 1200 1100 1500 V/µs

= 0.5 V Step, 10–90% 1.4 1.2 ns

= 4 V Step, 10–90% 2.6 2.2 ns

= 2 V Step 10 10 ns

= 2 V Step 16 16 ns

= 100 Ω –59 –52 –52 –45 dBc

= 500 Ω –66 –59 –72 –65 dBc

= 500 Ω –72 –65 –80 –73 dBc

= 50 Ω 18 14 dB

= 150 Ω 0.05 0.09 0.02 0.04 %

= 150 Ω 0.02 0.04 0.02 0.04 Degree

CL

H, L

or V

CL

= ±2 V 66 90 70 90 dB

= ±2.5 V 48 55 54 60 dB

L

= 100 Ω –68 –61 –70 –63 dBc

L

= +2 V, V

CH

= ±1 V; 8037, V

= 2 V p-p 150 240 180 270 MHz

or VCL = 2 V p-p 1 5 1 5 %

CH

= 100 Ω; A

LOAD

= +1 (AD8036); AV = +2 (AD8037), VH, VL open, unless

V

AD8036A AD8037A

= 3.5 V p-p 160 195 160 190 MHz

OUT

±3.3 ±3.9 ±3.3 ± 3.9 V

= –2 V ±3 ± 10 ±3 ±10 mV

CL

±20 ±20 mV

100 100 mV

= ±0.5 V ±40 ±60 ±50 ± 70 µA

H, L

±80 ±90 µA

27 27mV

11 10 mV

15 15 µA

55µA

40 46 dB

25 24 mA

50 60 56 66

starts deviating from VIN (see Figure 73).

OUT

d

B

REV. A–2–

Page 3

AD8036/AD8037

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.6 V

Voltage Swing × Bandwidth Product . . . . . . . . . . . 350 V-MHz

|V

|V

Internal Power Dissipation

| . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 6.3 V

H–VIN

| . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .≤ 6.3 V

L–VIN

2

Plastic DIP Package (N) . . . . . . . . . . . . . . . . . . . . 1.3 Watts

Small Outline Package (SO) . . . . . . . . . . . . . . . . . . 0.9 Watts

Input Voltage (Common Mode) . . . . . . . . . . . . . . . . . . . . ±V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ±1.2 V

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range N, R . . . . . . . . . –65°C to +125°C

Operating Temperature Range (A Grade) . . . –40°C to +85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

8-Lead Plastic DIP: θJA = 90°C/W

8-Lead SOIC: θJA = 155°C/W

8-Lead Cerdip: θJA = 110°C/W.

METALIZATION PHOTO

Dimensions shown in inches and (mm).

Connect Substrate to –V

–IN

2

V

.

S

+V

H

8

S

7

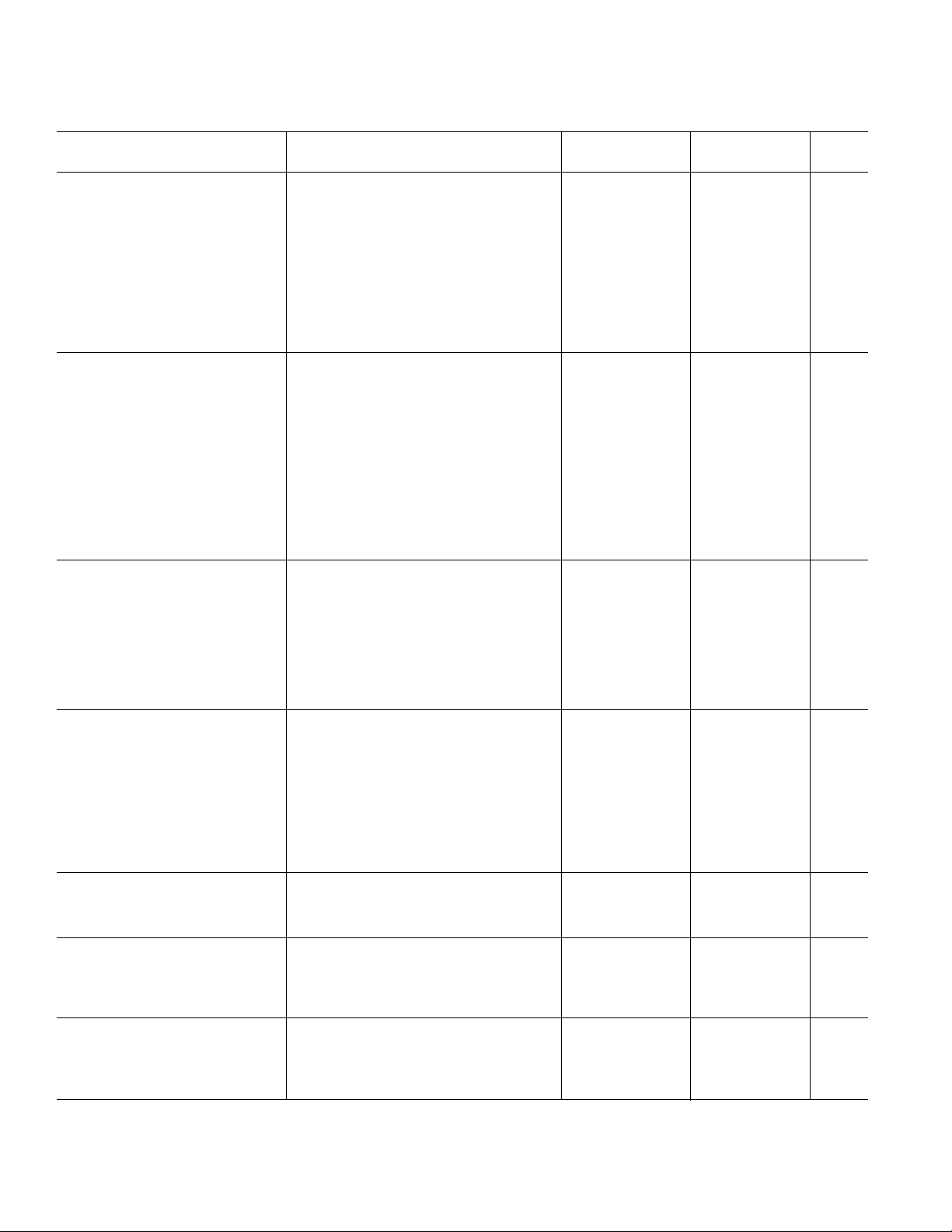

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by these devices is limited by the associated rise in junction temperature.

The maximum safe junction temperature for plastic encapsulated devices is determined by the glass transition temperature

of the plastic, approximately +150°C. Exceeding this limit tem-

porarily may cause a shift in parametric performance due to a

change in the stresses exerted on the die by the package. Exceed-

ing a junction temperature of +175°C for an extended period can

result in device failure.

While the AD8036 and AD8037 are internally short circuit protected, this may not be sufficient to guarantee that the maxi-

mum junction temperature (+150°C) is not exceeded under all

conditions. To ensure proper operation, it is necessary to observe the maximum power derating curves.

2.0

1.5

1.0

0.5

MAXIMUM POWER DISSIPATION – Watts

0

–50 80

–40

8-LEAD PLASTIC DIP

PACKAGE

8-LEAD SOIC

PACKAGE

010–10–20–30 20 30 40 50 60 70 90

AMBIENT TEMPERATURE – 8C

TJ = +1508C

0.046

(1.17)

OUT

6

Figure 2. Plot of Maximum Power Dissipation vs.

Temperature

ORDERING GUIDE

45

3

+IN –V

S

0.050 (1.27)

–IN

2

8036

AD8036

V

L

V

H

87

+V

S

Model Range Description Option

AD8036AN –40°C to +85°C Plastic DIP N-8

AD8036AR –40°C to +85°C SOIC SO-8

AD8036AR-REEL –40°C to +85°C 13" Tape and Reel SO-8

AD8036AR-REEL7 –40°C to +85°C 7" Tape and Reel SO-8

AD8036ACHIPS –40°C to +85°CDie

Temperature Package Package

AD8036-EB Evaluation Board

5962-9559701MPA –55°C to +125°C Cerdip Q-8

0.046

(1.17)

OUT

6

AD8037AN –40°C to +85°C Plastic DIP N-8

AD8037AR –40°C to +85°C SOIC SO-8

AD8037AR-REEL –40°C to +85°C 13" Tape and Reel SO-8

AD8037AR-REEL7 –40°C to +85°C 7" Tape and Reel SO-8

AD8037ACHIPS –40°C to +85°CDie

AD8037-EB Evaluation Board

3

45

+IN –V

S

0.050 (1.27)

8037

AD8037

V

L

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although these devices feature proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. A –3–

Page 4

AD8036/AD8037

+V

S

RL = 100V

–V

S

49.9V

V

IN

R

F

130V

V

OUT

0.1mF

10mF

AD8036

0.1mF

10mF

PULSE

GENERATOR

TR/T

F

= 350ps

+V

H

V

L

0.1mF

0.1mF

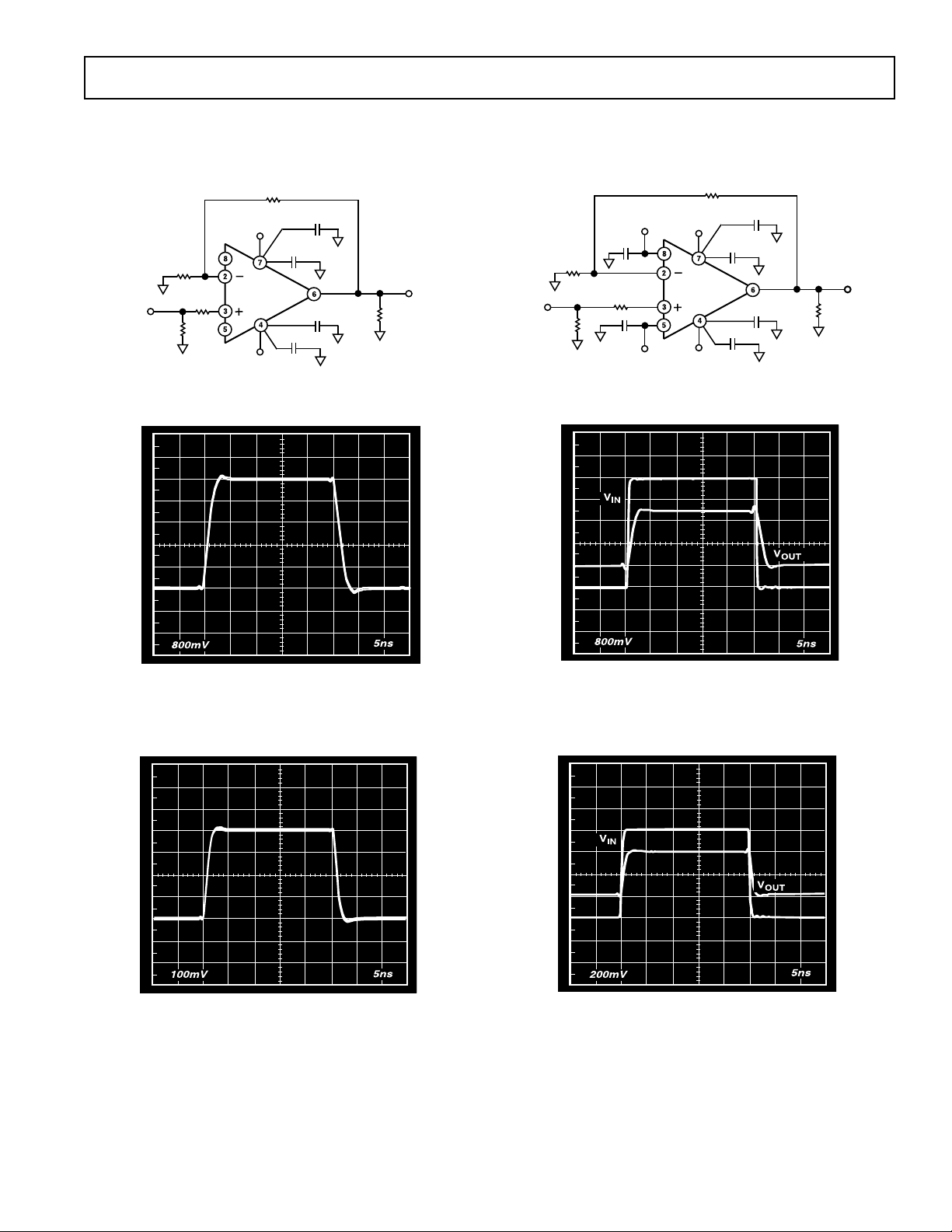

AD8036–Typical Characteristics

R

F

10mF

S

0.1mF

0.1mF

10mF

S

PULSE

GENERATOR

TR/T

= 350ps

F

V

IN

49.9V

130V

+V

AD8036

–V

V

RL = 100V

OUT

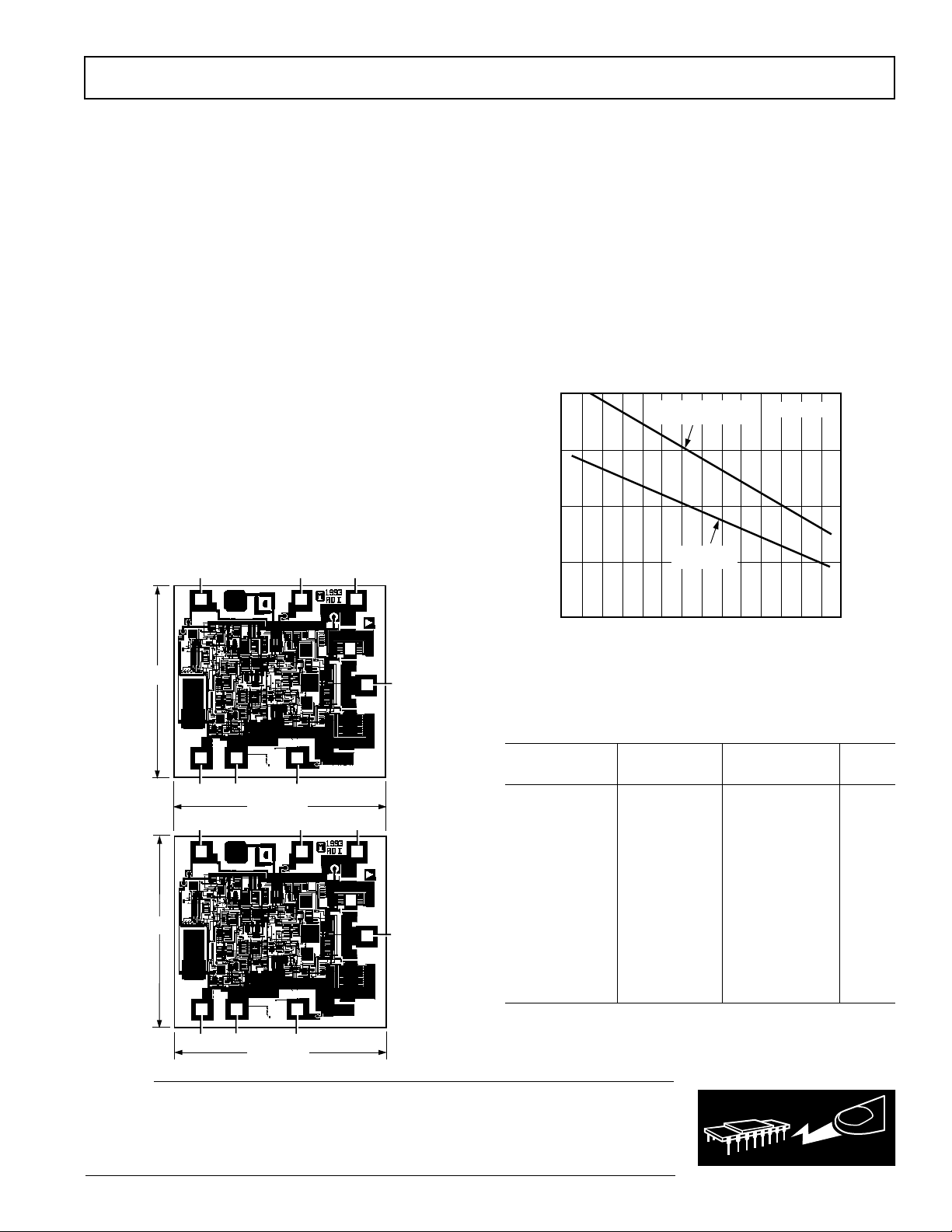

Figure 3. Noninverting Configuration, G = +1

Figure 4. Large Signal Transient Response; VO = 4 V p-p,

G = +1, R

= 140

F

Ω

Figure 6. Noninverting Clamp Configuration, G = +1

Figure 7. Clamped Large Signal Transient Response (2

Overdrive); VO = 2 V p-p, G = +1, RF = 140 Ω, VH = +1 V,

V

= –1 V

L

×

Figure 5. Small Signal Transient Response; VO = 400 mV

p-p, G = +1, R

F

= 140

Ω

Figure 8. Clamped Small Signal Transient Response

(2

×

Overdrive); VO = 400 mV p-p, G = +1, RF = 140 Ω,

V

= +0.2 V, VL = –0.2 V

H

REV. A–4–

Page 5

AD8037–Typical Characteristics

R

IN

+V

S

RL = 100V

–V

S

49.9V

V

IN

R

F

100V

V

OUT

0.1mF

10mF

AD8037

0.1mF

10mF

PULSE

GENERATOR

TR/T

F

= 350ps

+V

H

V

L

0.1mF

0.1mF

R

F

PULSE

GENERATOR

TR/T

= 350ps

F

+V

R

IN

10mF

S

0.1mF

AD8036/AD8037

V

IN

100V

49.9V

AD8037

–V

S

0.1mF

10mF

V

RL = 100V

OUT

Figure 9. Noninverting Configuration, G = +2

Figure 10. Large Signal Transient Response; VO = 4 V p-p,

G = +2, R

= RIN = 274

F

Ω

Figure 12. Noninverting Clamp Configuration, G = +2

Figure 13. Clamped Large Signal Transient Response

(2

×

Overdrive); VO = 2 V p-p, G = +2, RF = RIN = 274 Ω,

V

= +0.5 V, VL = –0.5 V

H

Figure 11. Small Signal Transient Response;

V

REV. A –5–

= 400 mV p-p, G = +2, RF = RIN = 274

O

Ω

Figure 14. Clamped Small Signal Transient Response

(2

×

Overdrive); VO = 400 mV p-p, G = +2, RF = R

V

= +0.1 V, VL = –0.1 V

H

= 274 Ω,

IN

Page 6

AD8036/AD8037

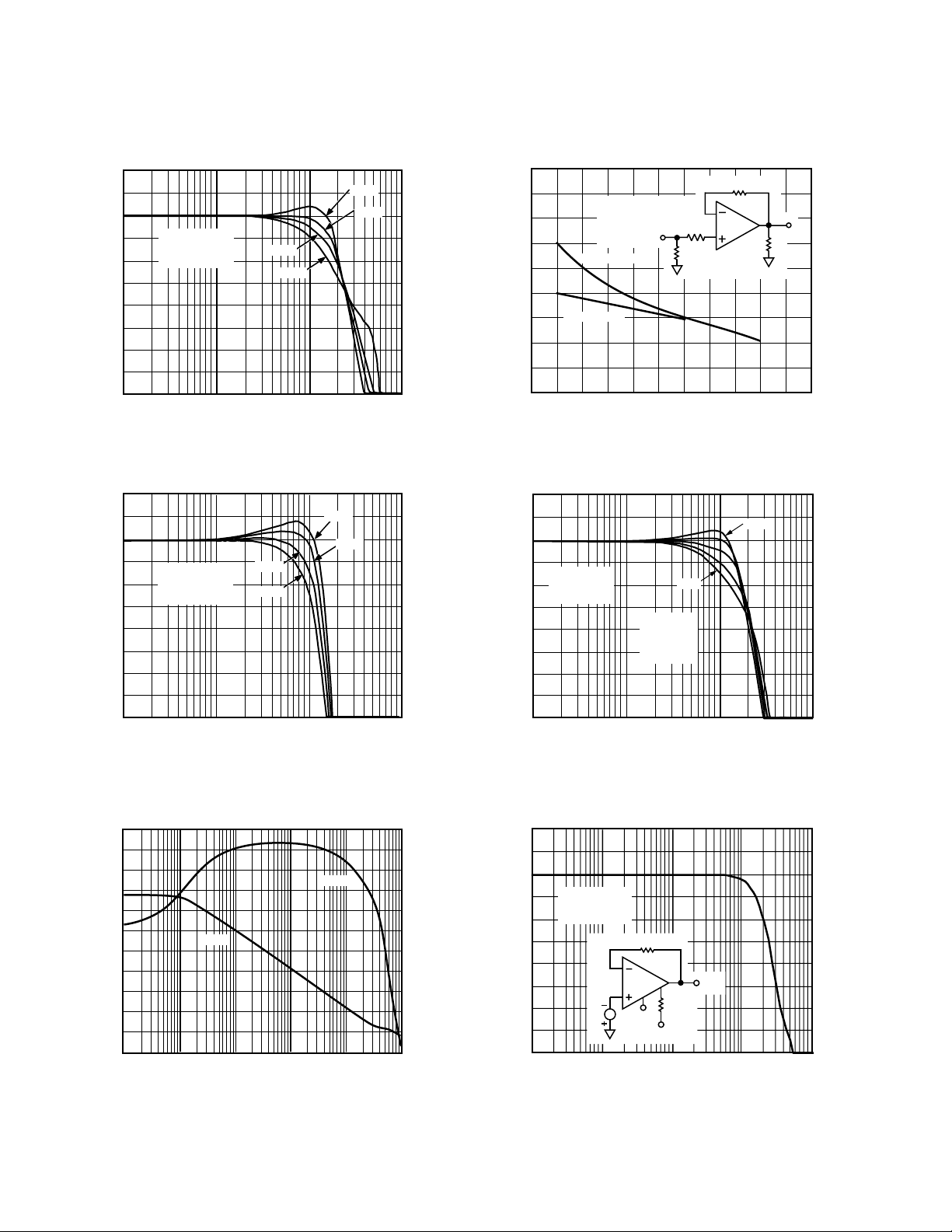

VALUE OF FEEDBACK RESISTOR (RF) – V

–3dB BANDWIDTH – MHz

20 24040 200 2201801601401201008060

R PACKAGE

R

F

130V

AD8036

VS = 65V

R

L

= 100V

GAIN = +1

R

L

49.9V

N PACKAGE

400

350

300

250

200

OUTPUT – dB

1M

FREQUENCY – Hz

10M

100M 1G

250V

RF = 50V

TO

250V

BY

50V

50V

VS = 65V

V

O

= 2.5V

p-p

R

L

= 100V

–8

–7

–6

–5

–4

–3

–2

–1

0

1

2

FREQUENCY – Hz

GAIN – dB

1M 10M

100M 1G

100k

VS = 65V

V

O

= 300mV

p-p

RL = 100V

–8

–7

–6

–5

–4

–3

–2

–1

0

1

2

140V

V

H

100V

VL (VIN)

(VO)

1V

AD8036

AD8036–Typical Characteristics

2

1

0

–1

–2

–3

GAIN – dB

–4

–5

–6

–7

–8

1M

VO = 300mV p-p

V

= 65V

S

= 100V

R

L

10M

102V

49.9V

FREQUENCY – Hz

100M 1G

200V

140V

Figure 15. AD8036 Small Signal Frequency Response,

G = +1

0.2

0.1

–0.1

–0.2

–0.3

GAIN – dB

–0.4

–0.5

–0.6

–0.7

–0.8

Figure 16. AD8036 0.1 dB Flatness, N Package (for R

Package Add 20

90

80

70

60

50

40

30

Figure 17. AD8036 Open-Loop Gain and Phase Margin vs.

Frequency, R

20

OPEN -LOOP GAIN – dB

10

–10

–20

0

VO = 300mV p-p

V

= 65V

S

= 100V

R

L

1M

0

10k 100k 10M1M

= 100

L

10M

Ω

to RF)

GAIN

Ω

140V

130V

FREQUENCY – Hz

FREQUENCY – Hz

158V

150V

100M 1G

PHASE

100M 1G

100

80

60

40

20

0

–20

–40

–60

PHASE MARGIN – Degrees

–80

–100

–120

Figure 18. AD8036 Small Signal –3 dB Bandwidth vs. R

Figure 19. AD8036 Large Signal Frequency Response,

G = +1

Figure 20. AD8036 Clamp Input Bandwidth, VH, V

L

REV. A–6–

F

Page 7

–30

DIFF GAIN – %

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th

DIFF PHASE – Degrees

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th

0.04

0.02

0.00

–0.02

–0.04

0.04

0.02

0.00

–0.02

–0.04

0.06

–0.06

SETTLING TIME – ns

0 5 10 15 20 25 30 35 40 45

ERROR – %

–0.05

–0.04

–0.03

–0.02

–0.01

0

0.01

0.02

0.03

0.04

0.05

SETTLING TIME - ms

0 2 4 6 8 10 12 14 16 18

ERROR – %

–0.6

–0.5

–0.4

–0.3

–0.2

–0.1

0

0.1

0.2

0.3

0.4

–50

–70

VO = 2V p-p

= 65V

V

S

= 500V

R

L

G = +1

AD8036/AD8037

–90

–110

HARMONIC DISTORTION – dBc

–130

100k 100M10M1M10k

2ND HARMONIC

3RD HARMONIC

FREQUENCY – Hz

Figure 21. AD8036 Harmonic Distortion vs. Frequency,

R

= 500

L

Ω

–30

VO = 2V p-p

V

= 65V

S

RL = 100V

–50

G = +1

–70

–90

HARMONIC DISTORTION – dBc

–110

–130

100k 100M10M1M10k

FREQUENCY – Hz

2ND HARMONIC

3RD HARMONIC

Figure 24. AD8036 Differential Gain and Phase Error,

G = +1, R

= 150 Ω, F = 3.58 MHz

L

Figure 22. AD8036 Harmonic Distortion vs. Frequency,

R

= 100

L

Figure 23. AD8036 Third Order Intercept vs. Frequency

REV. A –7–

Ω

60

50

40

INTERCEPT – +dBm

30

20

10

20 40 8060

FREQUENCY – MHz

100

Figure 25. AD8036 Short-Term Settling Time to 0.01%, 2 V

Step, G = +1, R

= 100

L

Ω

Figure 26. AD8036 Long-Term Settling Time, 2 V Step,

G = +1, R

= 100

L

Ω

Page 8

AD8036/AD8037

RF = 475V

RF = 75V

TO

475V

BY

100V

VO = 3.5 V p-p

V

S

= 65V

R

L

= 100V

RF = 75V

1M

FREQUENCY – Hz

10M 100M 1G

GAIN – dB

–2

–1

0

1

2

3

4

5

6

7

8

FREQUENCY – Hz

GAIN – dB

VS = 65V

V

O

= 300mV p-p

R

L

= 100V

274V

V

H

100V

AD8037

VL (VIN)

(VO)

1V

274V

100k 1M 10M 100M 1G

–2

–1

0

1

2

3

4

5

6

7

8

AD8037–Typical Characteristics

8

7

6

5

4

3

GAIN – dB

2

1

0

–1

–2

1M

VO = 300mV p-p

V

= 65V

S

= 100V

R

L

10M 100M 1G

FREQUENCY – Hz

475

374

274

174

350

300

250

200

–3dB BANDWIDTH – MHz

150

VS = 65V

= 100V

R

L

GAIN = +2

R PACKAGE

100 550500450400350300250200150

R

IN

100V

49.9V

N PACKAGE

VALUE OF RF,RIN – V

AD8037

R

F

R

L

Figure 27. AD8037 Small Signal Frequency Response,

G = +2

0.2

0.1

0

1M

VO = 3.00mV p-p

V

= 65V

S

= 100V

R

L

10M

249

224

FREQUENCY – Hz

100M 1G

–0.1

–0.2

–0.3

GAIN – dB

–0.4

–0.5

–0.6

–0.7

–0.8

Figure 28. AD8037 0.1 dB Flatness, N Package

(for R Package Add 20

65

60

55

50

45

40

35

30

25

20

15

10

OPEN -LOOP GAIN – dB

5

0

–5

–10

Figure 29. AD8037 Open-Loop Gain and Phase Margin

vs. Frequency, R

–15

10k 100k 1G100M10M1M

= 100

L

Ω

FREQUENCY – Hz

Ω

to RF)

GAIN

301

274

PHASE

100

50

0

–50

–100

–150

PHASE MARGIN – Degrees

–200

–250

Figure 30. AD8037 Small Signal –3 dB Bandwidth

vs. R

, R

F

IN

Figure 31. AD8037 Large Signal Frequency Response,

G = +2

Figure 32. AD8037 Clamp Input Bandwidth, VH, V

L

REV. A–8–

Page 9

–30

DIFF GAIN – %

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th

DIFF PHASE – Degrees

1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th

0.03

0.02

0.01

0.00

–0.01

–0.02

–0.03

0.03

0.02

0.01

0.00

–0.01

–0.02

–0.03

SETTLING TIME – ns

0 5 10 15 20 25 30 35 40 45

ERROR – %

–0.05

–0.04

–0.03

–0.02

–0.01

0

–0.01

–0.02

–0.03

–0.04

–0.05

SETTLING TIME – ms

0 2 4 6 8 10 12 14 16 18

ERROR – %

–0.6

–0.5

–0.4

–0.3

–0.2

–0.1

0

0.1

0.2

0.3

0.4

–50

–70

–90

AD8036/AD8037

VO = 2V p-p

VS = 65V

RL = 500V

G = +2

2ND HARMONIC

HARMONIC DISTORTION – dBc

–110

–130

100k

FREQUENCY – Hz

3RD HARMONIC

10M1M10k

100M

Figure 33. AD8037 Harmonic Distortion vs. Frequency,

R

= 500

L

Ω

–30

VO = 2V p-p

–50

VS = 65V

RL = 100V

G = +2

–70

–90

HARMONIC DISTORTION – dBc

–110

–130

100k

2ND HARMONIC

3RD HARMONIC

FREQUENCY – Hz

10M1M10k

100M

Figure 36. AD8037 Differential Gain and Phase Error

G = +2, R

= 150 Ω, F = 3.58 MHz

L

Figure 34. AD8037 Harmonic Distortion vs. Frequency,

R

= 100

L

Figure 35. AD8037 Third Order Intercept vs. Frequency

REV. A –9–

Ω

60

50

40

INTERCEPT – +dBm

30

20

10

20 40 8060

FREQUENCY – MHz

100

Figure 37. AD8037 Short-Term Settling Time to 0.01%,

2 V Step, G = +2, R

= 100

L

Ω

Figure 38. AD8037 Long-Term Settling Time 2 V Step,

R

= 100

L

Ω

Page 10

AD8036/AD8037–Typical Characteristics

100 100k10k1k10

FREQUENCY – Hz

VS = 65V

INPUT NOISE VOLTAGE – nV/ Hz

17

15

13

11

9

7

5

3

80

70

60

50

40

30

20

10

0

75

65

55

45

35

25

15

5

10k 100k 1G100M10M1M

FREQUENCY – Hz

PSRR – dB

–PSRR

+PSRR

100

90

80

70

60

50

40

30

20

100k 1G100M10M1M

FREQUENCY – Hz

CMRR – dB

VS = 65V

DVCM = 1V

RL = 100V

32

28

24

20

16

12

INPUT NOISE VOLTAGE – nV/ Hz

8

4

100 10k1k10

FREQUENCY – Hz

Figure 39. AD8036 Noise vs. Frequency

80

75

70

65

+PSRR

60

55

50

45

40

35

PSRR – dB

30

25

20

15

10

5

0

10k 100k 1G100M10M1M

–PSRR

FREQUENCY – Hz

VS = 65V

100k

Figure 42. AD8037 Noise vs. Frequency

100

90

80

70

60

CMRR – dB

50

40

30

20

100k 1G100M10M1M

Figure 40. AD8036 PSRR vs. Frequency

VS = 65V

DVCM = 1V

RL = 100V

FREQUENCY – Hz

Figure 41. AD8036 CMRR vs. Frequency

Figure 43. AD8037 PSRR vs. Frequency

Figure 44. AD8037 CMRR vs. Frequency

REV. A–10–

Page 11

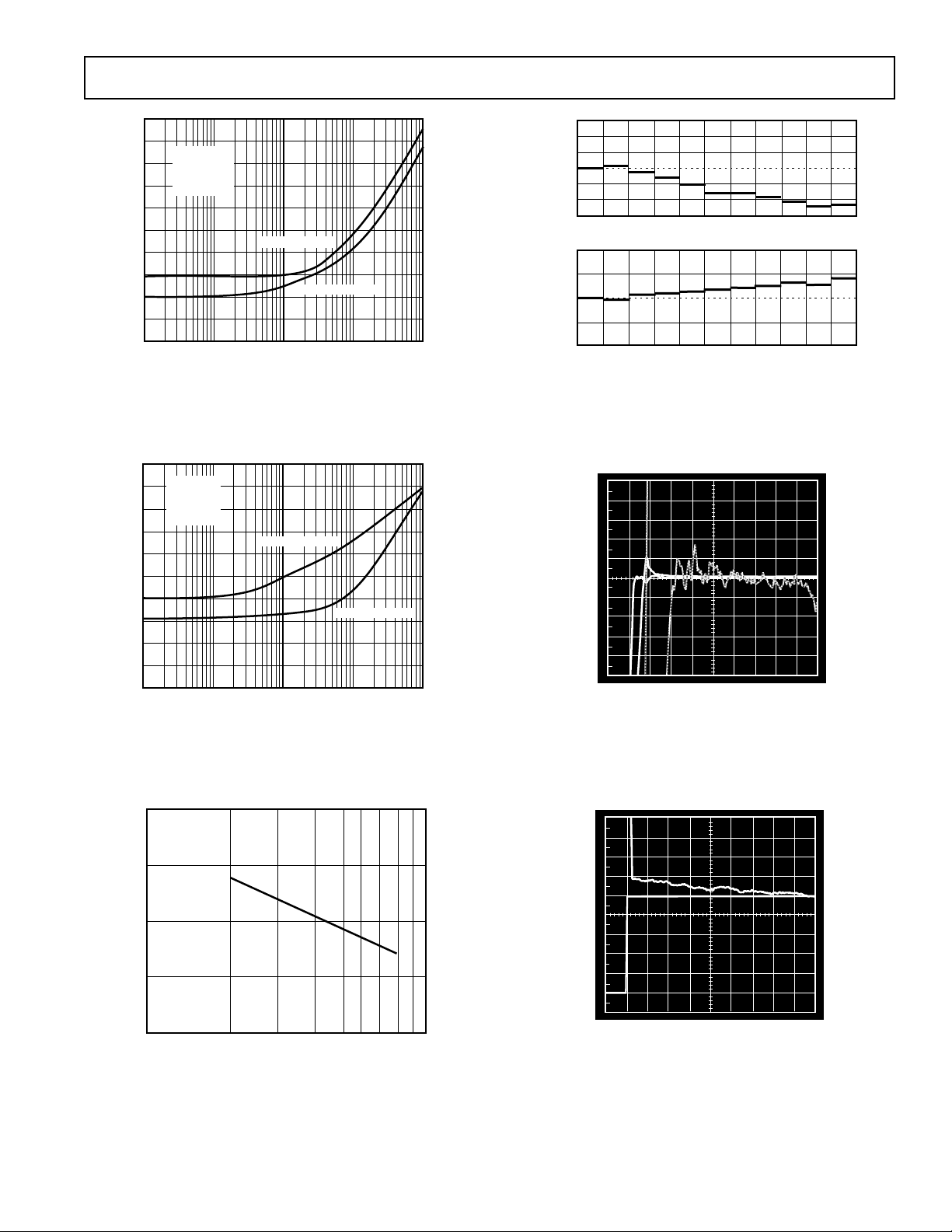

AD8036/AD8037

1400

1300

1200

1100

1000

900

800

700

600

500

400

–60 –40 –20 0 20 40 60 80 100 120 140

–A

OL

+A

OL

–A

OL

+A

OL

AD8036

AD8037

JUNCTION TEMPERATURE – 8C

OPEN -LOOP GAIN – V/ V

–60 –40 –20 0 20 40 60 80 100 120 140

PSRR – dB

JUNCTION TEMPERATURE – 8C

–PSRR

AD8037

AD8036

AD8037

AD8036

+PSRR

+PSRR

–PSRR

74

72

70

68

66

64

62

60

15 25 35 45 55 65 75 85 95

CMRR – dB

JUNCTION TEMPERATURE – 8C

DV

CM

= 2V

96

95

94

93

92

91

90

89

88

1k

VS = 65V

G = +1

300M

– V

R

OUT

0.01

100

0.1

10

1

0.1M

1.0M 100M

FREQUENCY – Hz

10M

Figure 45. AD8036 Output Resistance vs. Frequency

1k

VS = 65V

G = +2

– V

R

OUT

100

10

1

Figure 48. Open-Loop Gain vs. Temperature

0.1

0.01

0.1M

1.0M 100M

FREQUENCY – Hz

10M

Figure 46. AD8037 Output Resistance vs. Frequency

4.2

4.1

4.0

3.9

3.8

3.7

OUTPUT SWING – Volts

3.6

3.5

3.4

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE – 8C

Figure 47. AD8036/AD8037 Output Swing vs. Temperature

REV. A –11–

+V

OUT

–V

OUT

+V

OUT

–V

OUT

300M

Figure 49. PSRR vs. Temperature

RL=150

RL= 50

Figure 50. AD8036/AD8037 CMRR vs. Temperature

Page 12

AD8036/AD8037–Typical Characteristics

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE – 8C

AD8037

AD8036

AD8036

SHORT CIRCUIT CURRENT – mA

AD8037

SINK

SOURCE

270

260

250

240

230

220

210

200

INPUT OFFSET VOLTAGE – mV

COUNT

3 WAFER LOTS

COUNT = 853

FREQ. DIST

48

44

40

36

32

28

24

20

16

12

8

4

0

–4.5 –4.0 –3.5 –3.0 –2.5 –2.0 –1.5 –1.0 –0.5 0 0.5

24

23

22

21

20

19

SUPPLY CURRENT – mA

18

17

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE – 8C

AD8036, VS = 66V

AD8037, VS = 66V

AD8036, VS = 65V

AD8037, VS = 65V

Figure 51. Supply Current vs. Temperature

–2.50

–2.25

–2.00

–1.75

VS = 65V

–1.50

–1.25

–1.00

INPUT OFFSET VOLTAGE – mV

–0.75

AD8037

AD8036

VS = 66V

VS = 66V

VS = 65V

Figure 54. Short Circuit Current vs. Temperature

4.5

4.0

3.5

3.0

2.5

INPUT BIAS CURRENT – mA

2.0

AD8036

AD8037

–IB

+IB

–IB

+IB

–0.50

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE – 8C

Figure 52. Input Offset Voltage vs. Temperature

44

3 WAFER LOTS

40

COUNT = 632

36

32

28

24

20

COUNT

16

12

8

4

0

–6–5–4–3–2–101234

Figure 53. AD8036 Input Offset Voltage Distribution

INPUT OFFSET VOLTAGE – mV

FREQ. DIST

1.5

–60 –40 –20 0 20 40 60 80 100 120 140

JUNCTION TEMPERATURE – 8C

Figure 55. Input Bias Current vs. Temperature

Figure 56. AD8037 Input Offset Voltage Distribution

REV. A–12–

Page 13

0.6 0.65 0.7 0.75 0.8 0.85 0.9 0.95 1.0

–80

–75

–70

–65

–60

–55

–50

–45

–40

–35

–30

ABSOLUTE VALUE OF OUTPUT VOLTAGE – Volts

HARMONIC DISTORTION – dBc

VH +1V +0.5V

V

L

–1V –0.5V

G +1V +2V

AD8036 AD8037

AD8037 3RD

HARMONIC

AD8036 3RD

HARMONIC

AD8036 2ND

HARMONIC

AD8037 2ND

HARMONIC

–5 –4 –3 –2 –1 0 1 2 3 4 5

INPUT CLAMP VOLTAGE (V

H,VL

) – Volts

I

BH

I

BL

POSITIVE IBH, IBL DENOTES

CURRENT FLOW INTO

CLAMP INPUTS VH, V

L

CLAMP INPUT BIAS CURRENT – mA

80

60

40

20

0

–20

–40

–60

–80

REF

+2V

+1V

0V

Clamp Characteristics–AD8036/AD8037

20

15

VCL =

VCL =

–3V

10

5

0

–5

–10

INPUT ERROR VOLTAGE – mV

–15

–20

–3 –2 –1 0 1 2 3

VCL =

–2V

–1V

OUTPUT VOLTAGE – Volts

AD8036, ACL = +1

AD8037, A

AD8036

AD8037

V

=

VCH =

CH

+1V

+2V

= +2

CL

V

=

CH

+3V

Figure 57. Input Error Voltage vs. Clamped Output

Voltage

20

15

10

5

VH = + 1V

V

= – 1V

L

Figure 60. Harmonic Distortion as Output Approaches

Clamp Voltage; V

= 2 V p-p, RL = 100 ⍀, f = 20 MHz

O

0

–5

NONLINEARITY – mV

–10

–15

–20

INPUT VOLTAGE A

Figure 58. AD8036/AD8037 Nonlinearity Near Clamp

Voltage

+2V

+1V

Figure 59. AD8036 Clamp Overdrive (2X) Recovery

REV. A –13–

REF

– Volts

V

1.0–0.8–1.0 0.80.60.40.20.0–0.2–0.4–0.6

Figure 61. AD8036/AD8037 Clamp Input Bias Current vs.

Input Clamp Voltage

0V

Figure 62. AD8037 Clamp Overdrive (2X) Recovery

Page 14

AD8036/AD8037–Clamp Characteristics

0 5 10 15 20 25 30 35 40

SETTLING TIME – ns

ERROR – %

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0 5 10 15 20 25 30 35 40

SETTLING TIME – ns

ERROR – %

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR – %

–0.2

–0.3

–0.4

–0.5

0 102030405060708090

SETTLING TIME – ns

Figure 63. AD8036 Clamp Settling (0.1%), VH = +1 V,

V

= –1 V, 2× Overdrive

L

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR – %

–0.2

–0.3

–0.4

–0.5

0 5 10 15 20 25 30 35 40

SETTLING TIME – ns

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR – %

–0.2

–0.3

–0.4

–0.5

0 102030405060708090

SETTLING TIME – ns

Figure 66. AD8037 Clamp Settling (0.1%), VH = +0.5 V,

V

= –0.5 V, 2× Overdrive

L

Figure 64. AD8036 Clamp Recovery Settling Time (High),

from +2

×

Overdrive to 0 V

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR – %

–0.2

–0.3

–0.4

–0.5

0 5 10 15 20 25 30 35 40

SETTLING TIME – ns

Figure 65. AD8036 Clamp Recovery Settling Time (Low),

from –2

×

Overdrive to 0 V

Figure 67. AD8037 Clamp Recovery Settling Time (High),

from +2

×

Overdrive to 0 V

Figure 68. AD8037 Clamp Recovery Settling Time (Low),

from –2

×

Overdrive to 0 V

REV. A–14–

Page 15

AD8036/AD8037

R

L

1kV

R

F

R

IN

R

SERIES

C

L

AD8036/

AD8037

R

IN

THEORY OF OPERATION

General

The AD8036 and AD8037 are wide bandwidth, voltage feedback clamp amplifiers. Since their open-loop frequency response follows the conventional 6 dB/octave roll-off, their gain

bandwidth product is basically constant. Increasing their

closed-loop gain results in a corresponding decrease in small signal bandwidth. This can be observed by noting the bandwidth

specification, between the AD8036 (gain of 1) and AD8037

(gain of 2). The AD8036/AD8037 typically maintain 65 degrees of phase margin. This high margin minimizes the effects

of signal and noise peaking.

While the AD8036 and AD8037 can be used in either an inverting or noninverting configuration, the clamp function will only

work in the noninverting mode. As such, this section shows connections only in the noninverting configuration. Applications

that require an inverting configuration will be discussed in the

Applications section. In applications that do not require clamping, Pins 5 and 8 (respectively V

and VH) may be left floating.

L

See Input Clamp Amp Operation and Applications sections

otherwise.

Feedback Resistor Choice

The value of the feedback resistor is critical for optimum performance on the AD8036 (gain +1) and less critical as the gain increases. Therefore, this section is specifically targeted at the

AD8036.

At minimum stable gain (+1), the AD8036 provides optimum

dynamic performance with R

= 140 Ω. This resistor acts only

F

as a parasitic suppressor against damped RF oscillations that

can occur due to lead (input, feedback) inductance and parasitic

capacitance. This value of R

provides the best combination of

F

wide bandwidth, low parasitic peaking, and fast settling time.

In fact, for the same reasons, a 100–130 Ω resistor should be

placed in series with the positive input for other AD8036 noninverting configurations. The correct connection is shown in

Figure 69.

+V

S

R

F

G = 1+

R

G

100 - 130V

V

IN

R

TERM

AD8036/

AD8037

10mF

V

H

V

L

0.1mF

0.1mF

10mF

V

OUT

R

F

This estimation loses accuracy for gains of +2/–1 or lower due

to the amplifier’s damping factor. For these “low gain” cases,

the bandwidth will actually extend beyond the calculated value

(see Closed-Loop BW plots, Figures 15 and 27).

Pulse Response

Unlike a traditional voltage feedback amplifier, where the slew

speed is dictated by its front end dc quiescent current and gain

bandwidth product, the AD8036 and AD8037 provide “on demand” current that increases proportionally to the input “step”

signal amplitude. This results in slew rates (1200 V/µs) compa-

rable to wideband current feedback designs. This, combined

with relatively low input noise current (2.1 pA/√Hz), gives the

AD8036 and AD8037 the best attributes of both voltage and

current feedback amplifiers.

Large Signal Performance

The outstanding large signal operation of the AD8036 and

AD8037 is due to a unique, proprietary design architecture.

In order to maintain this level of performance, the maximum

350 V-MHz product must be observed, (e.g., @ 100 MHz,

≤ 3.5 V p-p).

V

O

Power Supply and Input Clamp Bypassing

Adequate power supply bypassing can be critical when optimizing the performance of a high frequency circuit. Inductance in

the power supply leads can form resonant circuits that produce

peaking in the amplifier’s response. In addition, if large current

transients must be delivered to the load, then bypass capacitors

(typically greater than 1 µF) will be required to provide the best

settling time and lowest distortion. A parallel combination of at

least 4.7 µF, and between 0.1 µF and 0.01 µF, is recommended.

Some brands of electrolytic capacitors will require a small series

damping resistor ≈4.7 Ω for optimum results.

When the AD8036 and AD8037 are used in clamping mode,

and V

and a dc voltage is connected to clamp inputs V

H

, a 0.1 µF

L

bypassing capacitor is required between each input pin and

ground in order to maintain stability.

Driving Capacitive Loads

The AD8036 and AD8037 were designed primarily to drive

nonreactive loads. If driving loads with a capacitive component

is desired, the best frequency response is obtained by the addition of a small series resistance as shown in Figure 70. The accompanying graph shows the optimum value for R

SERIES

vs.

capacitive load. It is worth noting that the frequency response of

the circuit when driving large capacitive loads will be dominated

by the passive roll-off of R

6 pF or less, no R

is necessary.

SERIES

and CL. For capacitive loads of

SERIES

–V

S

R

G

Figure 69. Noninverting Operation

For general voltage gain applications, the amplifier bandwidth

can be closely estimated as:

ω

f

≅

3 dB

REV. A –15–

2π 1+

O

R

F

R

G

Figure 70. Driving Capacitive Loads

Page 16

AD8036/AD8037

A

B

C

S1

R

F

140V

A B C

0 1 0

1 0 0

0 0 1

S1

V

IN

> V

H

VL ≤ VIN ≤ V

H

V

IN

< V

L

–V

IN

+V

IN

V

H

V

L

V

OUT

+1

+1

+1

C

H

C

L

A1

A2

+1

40

30

– V

SERIES

R

20

Operation of the AD8036 for negative input voltages and negative clamp levels on V

ling S1. Since the comparators see the voltage on the +V

as their common reference level, then the voltage V

defined as “High” or “Low” with respect to +V

is set to zero volts, VH is open, and VL is +1 V, compara-

if V

IN

will switch S1 to “C,” so the AD8036 will buffer the

tor C

L

voltage on V

and ignore +VIN.

L

is similar, with comparator CL control-

L

. For example,

IN

pin

IN

and VL are

H

The performance of the AD8036 and AD8037 closely matches

the ideal just described. The comparator’s threshold extends

from 60 mV inside the clamp window defined by the voltages on

V

and VH to 60 mV beyond the window’s edge. Switch S1 is

L

10

0 5 10 15 20 25

Figure 71. Recommended R

CL– pF

vs. Capacitive Load

SERIES

INPUT CLAMPING AMPLIFIER OPERATION

The key to the AD8036 and AD8037’s fast, accurate clamp and

amplifier performance is their unique patent pending CLAMPIN

input clamp architecture. This new design reduces clamp errors

by more than 10× over previous output clamp based circuits, as

well as substantially increasing the bandwidth, precision and

versatility of the clamp inputs.

Figure 72 is an idealized block diagram of the AD8036 connected as a unity gain voltage follower. The primary signal path

comprises A1 (a 1200 V/µs, 240 MHz high voltage gain, differ-

ential to single-ended amplifier) and A2 (a G = +1 high current

gain output buffer). The AD8037 differs from the AD8036 only

in that A1 is optimized for closed-loop gains of two or greater.

The CLAMPIN section is comprised of comparators C

, which drive switch S1 through a decoder. The unity-gain

C

L

buffers in series with +V

, VH, and VL inputs isolate the input

IN

H

and

pins from the comparators and S1 without reducing bandwidth

or precision.

The two comparators have about the same bandwidth as A1

(240 MHz), so they can keep up with signals within the useful

bandwidth of the AD8036. To illustrate the operation of the

CLAMPIN circuit, consider the case where V

+1 V, V

is open, and the AD8036 is set for a gain of +1, by

L

is referenced to

H

implemented with current steering, so that A1’s +input makes a

continuous transition from say, V

to VH as the input voltage

IN

traverses the comparator’s input threshold from 0.9 V to 1.0 V

= 1.0 V.

for V

H

The practical effect of these nonidealities is to soften the

transition from amplification to clamping modes, without compromising the absolute clamp limit set by the CLAMPIN circuit. Figure 73 is a graph of V

vs. VIN for the AD8036 and a

OUT

typical output clamp amplifier. Both amplifiers are set for G =

+1 and V

The worst case error between V

= +1 V.

H

(ideally clamped) and V

OUT

OUT

(actual) is typically 18 mV times the amplifier closed-loop gain.

This occurs when V

and/or below this limit, V

equals VH (or VL). As VIN goes above

IN

will settle to within 5 mV of the

OUT

ideal value.

In contrast, the output clamp amplifier’s transfer curve typically

will show some compression starting at an input of 0.8 V, and

can have an output voltage as far as 200 mV over the clamp

limit. In addition, since the output clamp in effect causes the

amplifier to operate open loop in clamp mode, the amplifier’s

output impedance will increase, potentially causing additional

errors.

The AD8036’s and AD8037’s CLAMPIN input clamp architecture works only for noninverting or follower applications and,

since it operates on the input, the clamp voltage levels V

, and input error limits will be multiplied by the amplifier’s

V

L

H

and

connecting its output back to its inverting input through the rec-

ommended 140 Ω feedback resistor. Note that the main signal

path always operates closed loop, since the CLAMPIN circuit

only affects A1’s noninverting input.

If a 0 V to +2 V voltage ramp is applied to the AD8036’s +V

for the connection just described, V

should track +VIN per-

OUT

fectly up to +1 V, then should limit at exactly +1 V as +V

IN

IN

con-

tinues to +2 V.

In practice, the AD8036 comes close to this ideal behavior. As

the +V

high limit comparator C

put of C

practically by about 18 mV), C

from “A” to “B” reference level. Since the + input of A1 is now

connected to V

AD8036’s output voltage. In short, the AD8036 is now operating as a unity-gain buffer for the V

V

input voltage ramps from zero to 1 V, the output of the

IN

. When +VIN just exceeds V

L

, for VH > 1 V, will be faithfully reproduced at V

H

starts in the off state, as does the out-

H

, further increases in +VIN have no effect on the

H

(ideally, by say 1 µV,

IN

changes state, switching S1

H

input, as any variation in

H

OUT

.

Figure 72. AD8036/AD8037 Clamp Amp System

REV. A–16–

Page 17

AD8036/AD8037

+5V

R

F

140V

–5V

130V

V

H

V

L

V

IN

V

OUT

0.1mF

10mF

0.1mF

AD8036

0.1mF10mF

V

H

0.1mF

V

L

+5V

R

F

274V

–5V

100V

V

H

V

L

V

IN

V

OUT

0.1mF

10mF

0.1mF

AD8037

0.1mF10mF

V

H

0.1mF

V

L

R

G

274V

49.9V

closed-loop gain at the output. For instance, to set an output

limit of ±1 V for an AD8037 operating at a gain of 3.0, V

would need to be set to +0.333 V and –0.333 V, respectively.

V

L

and

H

The only restriction on using the AD8036’s and AD8037’s

+V

, VL, VH pins as inputs is that the maximum voltage differ-

IN

ence between +V

and VH or VL should not exceed 6.3 V, and

IN

Clamping with Gain

Figure 75 shows an AD8037 configured for a noninverting gain

of two. The AD8037 is used in this circuit since it is compensated for gains of two or greater and provides greater bandwidth. In this case, the high clamping level at the output will

all three voltages be within the supply voltage range. For example, if V

Figure 73. Output Clamp Error vs. Input Clamp Error

AD8036/AD8037 APPLICATIONS

The AD8036 and AD8037 use a unique input clamping circuit

to perform the clamping function. As a result, they provide the

clamping function better than traditional output clamping devices and provide additional flexibility to perform other unique

is set at –3 V, then VIN should not exceed +3.3 V.

L

1.6

1.4

OUT

1.2

CLAMP ERROR – 25mV

AD8036

1.0

AD8036

OUTPUT VOLTAGE – V

0.8

0.6

0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

OUTPUT CLAMP AMP

INPUT VOLTAGE – +V

CLAMP ERROR – >200mV

OUTPUT CLAMP

IN

Figure 74. Unity Gain Noninverting Clamp

occur at 2 × V

. The equations governing the output clamp levels in cir-

2 × V

L

and the low clamping level at the output will be

H

cuits configured for noninverting gain are:

V

= G × V

where: V

CH

V

= G × V

CL

is the high output clamping level

CH

is the low output clamping level

V

CL

H

L

G is the gain of the amplifier configuration

is the high input clamping level (Pin 8)

V

H

is the low input clamping level (Pin 5)

V

*Amplifier offset is assumed to be zero.

L

applications.

There are, however, some restrictions on circuit configurations;

and some calculations need to be performed in order to figure

the clamping level, as a result of clamping being performed at

the input stage.

The major restriction on the clamping feature of the AD8036/

AD8037 is that clamping occurs only when using the amplifiers

in the noninverting mode. To clamp in an inverting circuit, an

additional inverting gain stage is required. Another restriction is

that V

voltage range of the amplifier (±3.9 V). V

and V

be greater than VL, and that each be within the output

H

can go above ground as long as VH is kept higher than VL.

L

can go below ground

H

Unity Gain Clamping

The simplest circuit for calculating the clamp levels is a unity

gain follower as shown in Figure 74. In this case, the AD8036

Figure 75. Gain of Two Noninverting Clamp

should be used since it is compensated for noninverting unity

gain.

This circuit will clamp at an upper voltage set by V

applied to Pin 8) and a lower voltage set by V

plied to Pin 5).

REV. A –17–

(the voltage

H

(the voltage ap-

L

Page 18

AD8036/AD8037

+5V

806V

V

H

AD8037

V

L

+5V

–5V

0.1mF10mF

–2V to 0V

0.1mF

301V

10mF

R2

1N5712

49.9V

CLAMPING

RANGE

–2.1V to +0.1V

0.1mF

AD9002

V

= –2V TO 0V

IN

SUBSTRATE

DIODE

–5.2V

100V

0.1mF

49.9V

100V

806V

100V

0.1mF

–5V

10µF

0.1mF

+5V

AD780

V

2.5V

0.1mF

–0.5V to +0.5V

IN

750V

R1

499V

R3

Figure 76. Gain of Two, Noninverting with Offset AD8037 Driving an AD9002—8-Bit, 125 MSPS A/D Converter

Clamping with an Offset

Some op amp circuits are required to operate with an offset

voltage. These are generally configured in the inverting mode

where the offset voltage can be summed in as one of the inputs.

Since AD8036/AD8037 clamping does not function in the inverting mode, it is not possible to clamp with this configuration.

Figure 76 shows a noninverting configuration of an AD8037

that provides clamping and also has an offset.␣ The circuit shows

the AD8037 as a driver for an AD9002, an 8-bit, 125 Msps

A/D converter and illustrates some of the considerations for using an AD8037 with offset and clamping.

The analog input range of the AD9002 is from ground to –2 V.

The input should not go more than 0.5 V outside this range in

order to prevent disruptions to the internal workings of the A/D

and to avoid drawing excess current. These requirements make

the AD8037 a prime candidate for signal conditioning.

When an offset is added to a noninverting op amp circuit, it is

fed in through a resistor to the inverting input. The result is that

the op amp must now operate at a closed-loop gain greater than

unity. For this circuit a gain of two was chosen which allows the

use of the AD8037. The feedback resistor, R2, is set at 301 Ω

for optimum performance of the AD8037 at a gain of two.

There is an interaction between the offset and the gain, so some

calculations must be performed to arrive at the proper values for

R1 and R3. For a gain of two the parallel combination of resistors R1 and R3 must be equal to the feedback resistor R2. Thus

R1 × R3/R1 + R3 = R2 = 301 Ω

The reference used to provide the offset is the AD780 whose

output is 2.5 V. This must be divided down to provide the 1 V

offset desired. Thus

2.5 V × R1/(R1 + R3) = 1 V

When the two equations are solved simultaneously we get R1 =

499 Ω and R3 = 750 Ω (using closest 1% resistor values in all

cases). This positive 1 V offset at the input translates to a –1 V

offset at the output.

The usable input signal swing of the AD9002 is 2 V p-p. This is

centered about the –1 V offset making the usable signal range

from 0 V to –2 V. It is desirable to clamp the input signal so

that it goes no more than 100 mV outside of this range in either

direction. Thus, the high clamping level should be set at +0.1 V

and the low clamping level should be set at –2.1 V as seen at the

input of the AD9002 (output of AD8037).

Because the clamping is done at the input stage of the AD8037,

the clamping level as seen at the output is affected by not only

the gain of the circuit as previously described, but also by the

offset. Thus, in order to obtain the desired clamp levels, V

H

must be biased at +0.55 V while VL must be biased at –0.55 V.

The clamping levels as seen at the output can be calculated by

the following:

V

= V

CH

VCL = V

Where V

is the offset voltage that appears at the output.

OFF

The resistors used to generate the voltages for V

+ G × V

OFF

+ G × V

OFF

H

L

and VL should

H

be kept to a minimum in order to reduce errors due to clamp

bias current. This current is dependent on V

and VL (see Fig-

H

ure 61) and will create a voltage drop across whatever resistance

is in series with each clamp input. This extra error voltage is

multiplied by the closed-loop gain of the amplifier and can be

substantial, especially in high closed-loop gain configurations. A

0.1 µF bypass capacitor should be placed between input clamp

and VL and ground to ensure stable operation.

pins V

H

The 1N5712 Schottky diode is used for protection from forward

biasing the substrate diode in the AD9002 during power-up

transients.

Programmable Pulse Generator

The AD8036/AD8037’s clamp output can be set accurately and

has a well controlled flat level. This along with wide bandwidth

and high slew rate make them very well suited for programmable

level pulse generators.

Figure 77 is a schematic for a pulse generator that can directly

accept TTL generated timing signals for its input and generate

pulses at the output up to 24 V p-p with 2500 V/µs slew rate.

The output levels can be programmed to anywhere in the range

–12 V to +12 V.

REV. A–18–

Page 19

TTL

INPUT

FULL WAVE

RECTIFIED

OUTPUT

LOWER

CLAMPING

LEVEL WITH

NO NEG INPUT

OUTPUT

LOWER

CLAMPING

LEVEL

–1 3 INPUT

AD8036/AD8037

V

H

0.1mF

200V

IN

100V

1.3kV

–15V

0.1mF

274V

+5V

+15V

AD811

–15V

V

H

AD8037

V

L

V

L

–5V

0.1mF

0.1mF10mF

10mF

274V

100V

150V

Figure 77. Programmable Pulse Generator

0.1mF

0.1mF10mF

604V

10mF

PULSE

OUT

VH 3 10

V

3 10

L

The circuit uses an AD8037 operating at a gain of two with an

AD811 to boost the output to the ±12 V range. The AD811 was

chosen for its ability to operate with ±15 V supplies and its high

slew rate.

R1 and R2 act as a level shifter to make the TTL signal levels be

approximately symmetrical above and below ground. This ensures that both the high and low logic levels will be clamped by

the AD8037. For well controlled signal levels in the output

pulse, the high and low output levels should result from the

clamping action of the AD8037 and not be controlled by either

the high or low logic levels passing through a linear amplifier.

For good rise and fall times at the output pulse, a logic family

with high speed edges should be used.

The high logic levels are clamped at two times the voltage at V

,

H

while the low logic levels are clamped at two times the voltage

. The output of the AD8037 is amplified by the AD811

at V

L

operating at a gain of 5. The overall gain of 10 will cause the

high output level to be 10 times the voltage at V

output level to be 10 times the voltage at V

H

.

L

, and the low

High Speed, Full-Wave Rectifier

The clamping inputs are additional inputs to the input stage of

the op amp. As such they have an input bandwidth comparable

to the amplifier inputs and lend themselves to some unique

functions when they are driven dynamically.

Figure 78 is a schematic for a full-wave rectifier, sometimes

called an absolute value generator. It works well up to 20 MHz

and can operate at significantly higher frequencies with some

degradation in performance. The distortion performance is significantly better than diode based full-wave rectifiers, especially

at high frequencies.

+5V

100V

V

H

AD8037

V

L

R

V

274V

IN

R

274V

F

G

0.1mF10mF

0.1mF

–5V

10mF

V

OUT = VIN

Figure 78. Full-Wave Rectifier

The circuit is configured as an inverting amplifier with a gain

of one. The input drives the inverting amplifier and also directly

drives V

ing input, V

, the lower level clamping input. The high level clamp-

L

, is left floating and plays no role in this circuit.

H

When the input is negative, the amplifier acts as a regular unitygain inverting amplifier and outputs a positive signal at the same

amplitude as the input with opposite polarity. V

is driven nega-

L

tive by the input, so it performs no clamping action, because the

positive output signal is always higher than the negative level

driving V

.

L

When the input is positive, the output result is the sum of two

separate effects. First, the inverting amplifier multiplies the input by –1 because of its unity-gain inverting configuration. This

effectively produces an offset as explained above, but with a dynamic level that is equal to –1 times the input.

Second, although the positive input is grounded (through 100 Ω),

the output is clamped at two times the voltage applied to V

(a

L

positive, dynamic voltage in this case). The factor of two is because the noise gain of the amplifier is two.

The sum of these two actions results in an output that is equal

to unity times the input signal for positive input signals, see Figure 79. For a input/output scope photo with an input signal of

20 MHz and amplitude ±1 V, see Figure 80.

Figure 79.

REV. A –19–

Page 20

AD8036/AD8037

Figure 80. Full-Wave Rectifier Scope

Thus for either positive or negative input signals, the output is

unity times the absolute value of the input signal. The circuit

can be easily configured to produce the negative absolute value

of the input by applying the input to V

The circuit can get to within about 40 mV of ground during the

time when the input crosses zero. This voltage is fixed over a

wide frequency range and is a result of the switching between

the conventional op amp input and the clamp input. But because there are no diodes to rapidly switch from forward to reverse bias, the performance far exceeds that of diode based full

wave rectifiers.

The 40 mV offset mentioned can be removed by adding an off-

set to the circuit. A 27.4 kΩ input resistor to the inverting input

will have a gain of 0.01, while changing the gain of the circuit by

only 1%. A plus or minus 4 V dc level (depending on the polarity of the rectifier) into this resistor will compensate for the

offset.

Full wave rectifiers are useful in many applications including

AM signal detection, high frequency ac voltmeters and various

arithmetic operations.

Amplitude Modulator

In addition to being able to be configured as an amplitude demodulator (AM detector), the AD8037 can also be configured

as an amplitude modulator as shown in Figure 81.

instead of VL.

H

The modulation signal is applied to both the input of a unity

gain inverting amplifier and to V

is biased at +0.5 V dc.

V

H

, the lower clamping input.

L

To understand the circuit operation, it is helpful to first consider a simpler circuit. If both V

and VH were dc biased at

L

–0.5 V and the carrier and modulation inputs driven as above,

the output would be a 2 V p-p square wave at the carrier frequency riding on a waveform at the modulating frequency. The

inverting input (modulation signal) is creating a varying offset to

the 2 V p-p square wave at the output. Both the high and low

levels clamp at twice the input levels on the clamps because the

noise gain of the circuit is two.

When V

is driven by the modulation signal instead of being

L

held at a dc level, a more complicated situation results. The resulting waveform is composed of an upper envelope and a lower

envelope with the carrier square wave in between. The upper

and lower envelope waveforms are 180° out of phase as in a

typical AM waveform.

The upper envelope is produced by the upper clamp level being

offset by the waveform applied to the inverting input. This offset

is the opposite polarity of the input waveform because of the

inverting configuration.

The lower envelope is produced by the sum of two effects. First,

it is offset by the waveform applied to the inverting input as in

the case of the simplified circuit above. The polarity of this offset is in the same direction as the upper envelope. Second, the

output is driven in the opposite direction of the offset at twice

the offset voltage by the modulation signal being applied to V

.

L

This results from the noise gain being equal to two, and since

there is no inversion in this connection, it is opposite polarity

from the offset.

The result at the output for the lower envelope is the sum of

these two effects, which produces the lower envelope of an amplitude modulated waveform. See Figure 82.

V

+5V

H

–5V

0.1mF10mF

0.1mF

10mF

AM OUT

CARRIER IN

MODULATION IN

100V

R

274V

V

H

AD8037

V

L

R

F

G

274V

Figure 81. Amplitude Modulator

The positive input of the AD8037 is driven with a square wave

of sufficient amplitude to produce clamping action at both the

high and low levels. This is the higher frequency carrier signal.

Figure 82. AM Waveform

The depth of modulation can be modified in this circuit by

changing the amplitude of the modulation signal. This changes

the amplitude of the upper and lower envelope waveforms.

The modulation depth can also be changed by changing the dc

bias applied to V

. In this case the amplitudes of the upper and

H

lower envelope waveforms stay constant, but the spacing between them changes. This alters the ratio of the envelope amplitude to the amplitude of the overall waveform.

REV. A–20–

Page 21

Layout Considerations

IN

R

O

1kV

V

OUT

0.1mF

AD8036/

AD8037

V

H

0.1mF

V

L

R

S

–V

S

+V

S

–V

S

+V

S

R

G

R

F

1kV

–V

S

+V

S

R

T

NONINVERTING CONFIGURATION

C5

10mF

+V

S

–V

S

C3

0.1mF

C1

0.01mF

C6

10mF

C4

0.1mF

C2

0.01mF

OPTIONAL

SUPPLY BYPASSING

The specified high speed performance of the AD8036 and

AD8037 requires careful attention to board layout and component selection. Proper RF design techniques and low pass parasitic component selection are mandatory.

The PCB should have a ground plane covering all unused portions of the component side of the board to provide a low impedance path. The ground plane should be removed from the

area near the input pins to reduce stray capacitance.

Chip capacitors should be used for supply and input clamp bypassing (see Figure 83). One end should be connected to the

ground plane and the other within 1/8 inch of each power and

clamp pin. An additional large (0.47 µF–10 µF) tantalum elec-

trolytic capacitor should be connected in parallel, though not

necessarily so close, to supply current for fast, large signal

changes at the output.

The feedback resistor should be located close to the inverting

input pin in order to keep the stray capacitance at this node to a

minimum. Capacitance variations of less than 1 pF at the inverting input will significantly affect high speed performance.

Stripline design techniques should be used for long signal traces

(greater than about 1 inch). These should be designed with a

characteristic impedance of 50 Ω or 75 Ω and be properly termi-

nated at each end.

Evaluation Board

An evaluation board for both the AD8036 and AD8037 is available that has been carefully laid out and tested to demonstrate

that the specified high speed performance of the device can be

realized. For ordering information, please refer to the Ordering

Guide.

The layout of the evaluation board can be used as shown or

serve as a guide for a board layout.

AD8036/AD8037

Figure 83. Noninverting Configurations for Evaluation

Boards

Component +1 +2 +10 +100 +2 +10 +100

R

F

R

G

(Nominal) 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω

R

O

R

REV. A –21–

S

(Nominal) 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω 49.9 Ω

R

T

Small Signal BW (MHz) 240 90 10 1.3 275 21 3

Table I.

AD8036A AD8037A

Gain Gain

140 Ω 274 Ω 2 kΩ 2 kΩ 274 Ω 2 kΩ 2 kΩ

274 Ω 221 Ω 20.5 Ω 274 Ω 221 Ω 20.5 Ω

130 Ω 100 Ω 100 Ω 100 Ω 100 Ω 100 Ω 100 Ω

Page 22

AD8036/AD8037

Figure 84. Evaluation Board Silkscreen (Top)

Figure 85. Evaluation Board Silkscreen (Bottom)

Figure 86. Board Layout (Solder Side)

Figure 87. Board Layout (Component Side)

REV. A–22–

Page 23

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic DIP

(N Package)

0.430 (10.92)

0.348 (8.84)

8

0.100 (2.54)

5

0.280 (7.11)

14

BSC

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

8-Lead Plastic SOIC

(SO Package)

0.1 968 (5.00)

0.1 890 (4.80)

85

0.2440 (6.20)

0.2284 (5.80)

41

0.195 ( 4.95)

0.115 (2.93)

AD8036/AD8037

C1980a–0–9/99

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

PIN 1

0.200.(5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.0500 (1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

PLANE

0.005 (0.13)

MIN

85

1

0.100 (2.54) BSC

0.405 (10.29) MAX

0.023 (0.58)

0.014 (0.36)

0.070 (1.78)

0.030 (0.76)

0.0688 (1.75)

0.0532 (1.35)

8-Lead Cerdip

(Q Package)

0.055 (1.4)

MAX

0.310 (7.87)

0.220 (5.59)

4

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

0.0098 (0.25)

0.0075 (0.19)

0.320 (8.13)

0.290 (7.37)

15°

0°

0.0196 (0.50)

0.0099 (0.25)

88

0.0500 (1.27)

08

0.0160 (0.41)

0.015 (0.38)

0.008 (0.20)

3 458

PRINTED IN U.S.A.

REV. A –23–

Loading...

Loading...