Page 1

Quad High Speed

R

F

R

G

R

G

R

F

V

EE

V

CC

AD8026

R

F

R

P

R

P

OUT A

–IN A

+IN A

+IN B

–IN B

OUT B

OUT D

–IN D

+IN D

+IN C

–IN C

OUT C

R

F

R

G

R

P

R

P

R

G

a

FEATURES

Voltage Feedback, Rail-to-Rail Output

Rated Settling Time to Within 0.5 V of Supply Rail

Quad High Speed Amplifier

Settling Time to 0.1% of 55 ns (4 V Swing, C

Slew Rate 135 V/ms (4 V Swing)

–3 dB Bandwidth 60 MHz

Fixed Gain Resistors for High DC Accuracy

Low Voltage Offset 0.5 mV RTO Typical

Gain Error Less than 0.05%

Low Supply Current 3.4 mA

Nominal +12 V Supply

14-Lead SOIC Package

APPLICATIONS

LCD Source Drivers

CD DVD

CDR

PRODUCT DESCRIPTION

The AD8026 is a complete low cost, closed loop, voltage feedback, quad amplifier. Precision trimmed resistors set a fixed R

ratio of 5/3 to a typical gain accuracy of 0.02%. Manufac-

R

G

tured on ADI’s proprietary XFCB high speed bipolar process,

which enables the output drivers to settle to within 0.1% within

55 ns into a 100 pF load (4 V swing) and drive output voltages

to rated settling time to within 0.5 V from the rail. The typical

3 dB bandwidth is 60 MHz, at G = +2.67. The AD8026 is

laser trimmed to produce both exceptional offset and gain

performance.

The low settling time, high slew rate, low offset and rail-to-rail

output voltage drive capability makes the AD8026 ideal for

driving LCD displays.

The AD8026 is available in a 14-lead SOIC package.

= 100 pF)

L

/

F

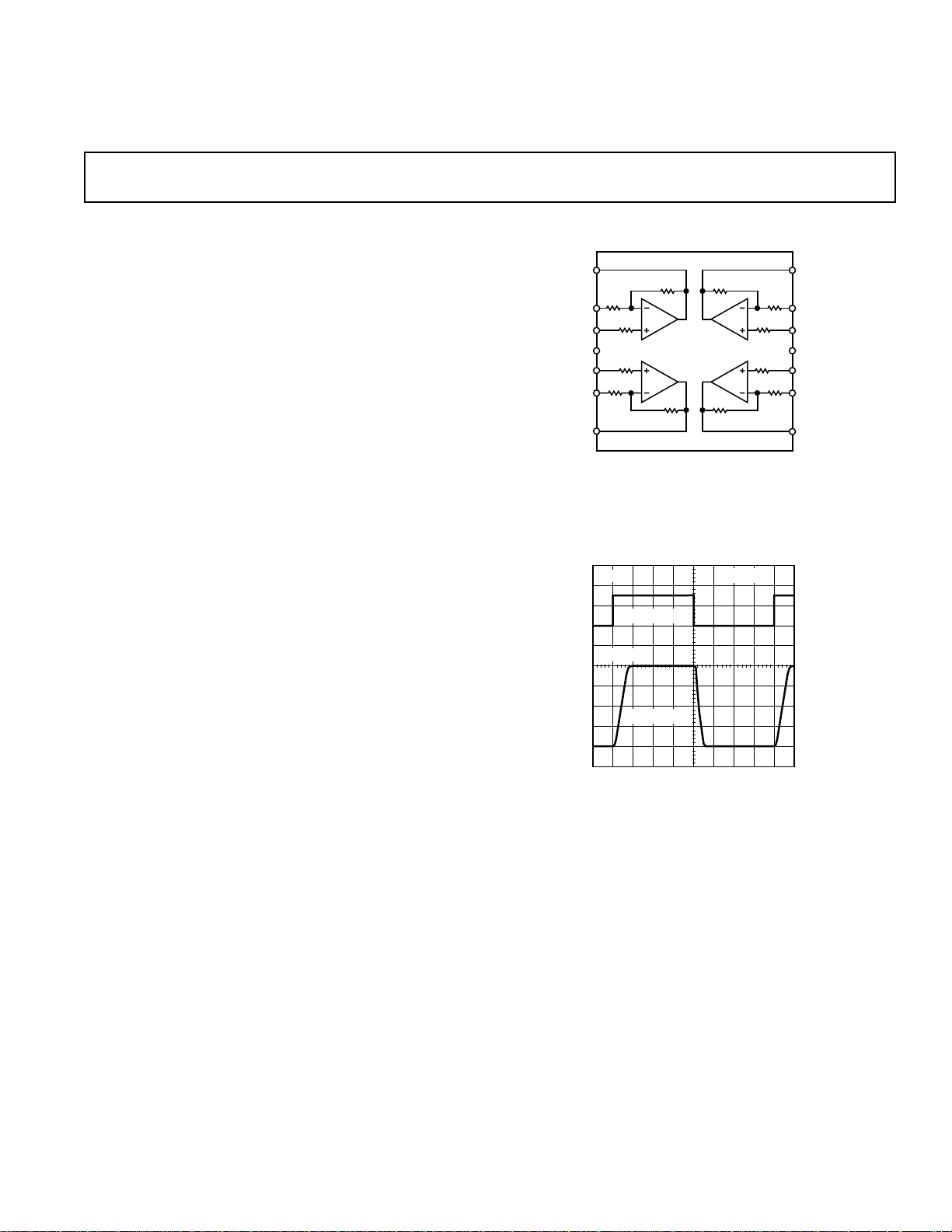

FUNCTIONAL BLOCK DIAGRAM

RL = 10kV

50ns/DIV

1V/DIV

1V/DIV

INPUT

OUTPUT

VIN = 1.5V

V

= 4V

OUT

Figure 1. 4 V Step Response

Amplifier

AD8026

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

(@ +258C, VS = 66 V, RI = 500 V, RL = 10 kV, RF = 5K, RG = 3K Noninverting

AD8026–SPECIFICATIONS

Configuration, T

= 08C, T

MIN

= +708C, unless otherwise noted.)

MAX

Parameter Conditions Min Typ Max Units

DYNAMIC PERFORMANCE

–3 dB Small Signal Bandwidth V

Bandwidth for 0.1 dB Flatness V

Slew Rate V

Full Power Response V

Settling Time to 0.1% V

= 50 mV rms

IN

= 1 kΩ 20 60 MHz

R

L

= 50 mV rms

IN

= 1 kΩ 12 MHz

R

L

= 4 V Step 135 V/µs

O

= 2 V p-p 10 MHz

O

= 4 V Step, CL = 100 pF,

O

R

= 50 Ω 55 ns

S

NOISE/DISTORTION PERFORMANCE

Total Harmonic Distortion f

Voltage Noise (RTO)

1

Crosstalk, Output to Output f = 5 MHz, V

Differential Gain Error NTSC R

Differential Phase Error NTSC R

DC PERFORMANCE

RTO Offset Voltage

2

= 5 MHz, VO = 2 V p-p,

C

= 1 kΩ –60 dBc

R

L

f = 10 kHz 67 nV/√Hz

= 2 V p-p,

= 1 kΩ –80 dB

R

L

O

= 1 kΩ 0.02 %

L

= 1 kΩ 0.02 Degrees

L

VIN = 0 V 0.5 5.5 mV

to T

T

MIN

MAX

6mV

RTO Offset Drift 10 µV/°C

+Input Bias Current 0.6 1.6 µA

Closed-Loop Gain Error

Gain Matching Channel-to-Channel, R

3

R

= 10 kΩ, –2.67 < V

L

to T

T

MIN

MAX

< +2.67 –0.02 0.05 %

O

0.05 %

= 10 kΩ 0.03 %

L

INPUT CHARACTERISTICS

+Input Resistance 170 kΩ

+Input Capacitance 2.5 pF

OUTPUT CHARACTERISTICS

Output Voltage Swing R

= 10 kΩ, V

L

– VOH, VEE + V

CC

OL

0.2 0.25 V

Short Circuit Output Current 175 mA

POWER SUPPLY

Operating Range

4

13 V

Quiescent Current/Amp 3.2 3.4 mA/Amp

Power Supply Rejection Ratio (RTO) +V

= 5.5 V to 6.5 V, –VS = –6 V 48 60 dB

S

–VS = –5.5 V to –6.5 V, +VS = 6 V 48 65 dB

OPERATING TEMPERATURE RANGE 0 +70 °C

NOTES

1

Includes gain resistor thermal noise.

2

RTO offset includes effects of input voltage offset, input current, and input offset current.

3

Measured in the inverting mode.

4

Observe Absolute Maximum Ratings.

Specifications subject to change without notice.

–2– REV. 0

Page 3

AD8026

AMBIENT TEMPERATURE – 8C

1.5

1.0

0.5

–10 800

MAXIMUM POWER DISSIPATION – Watts

10 20 30 40 50 60 70

TJ = +1508C

WARNING!

ESD SENSITIVE DEVICE

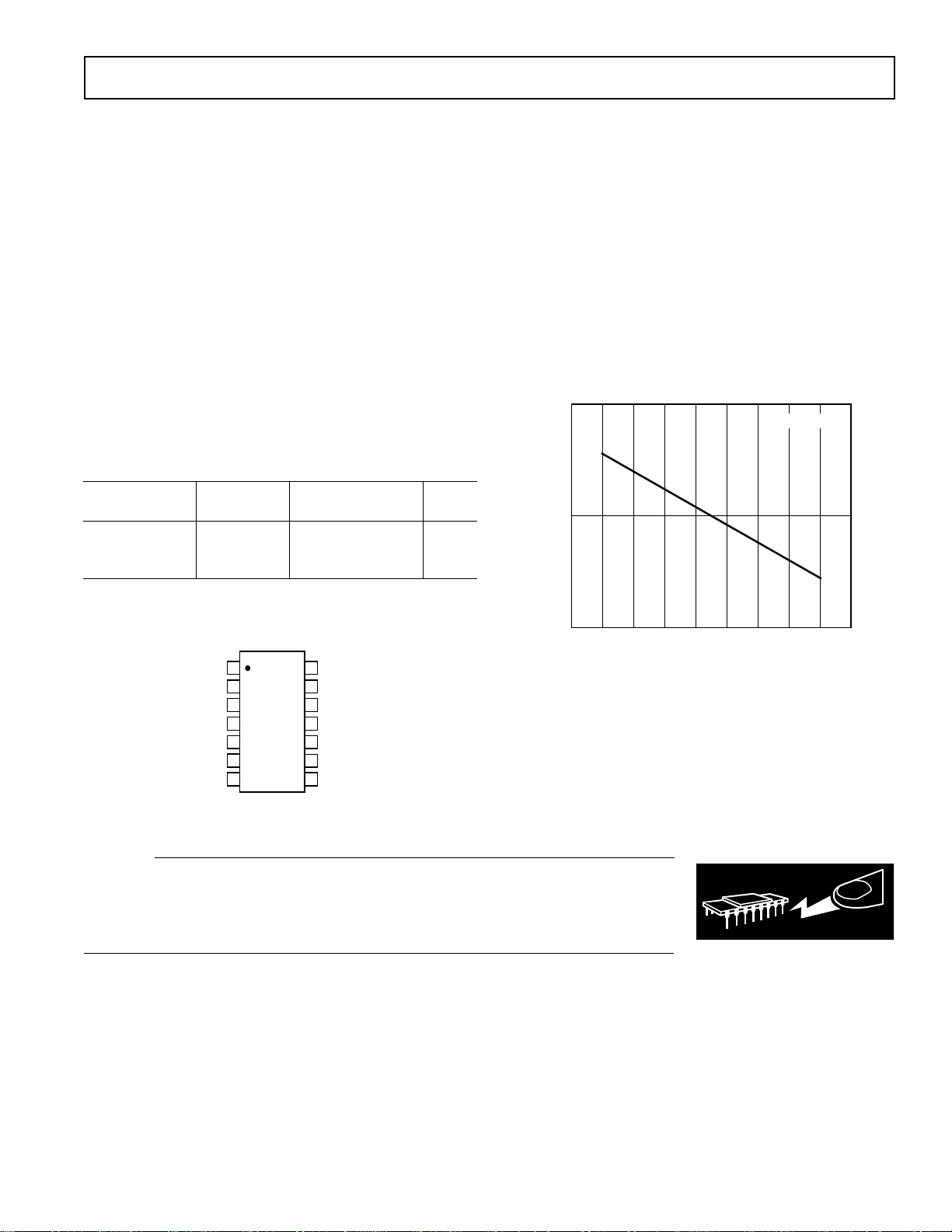

ABSOLUTE MAXIMUM RATINGS

Supply␣ Voltage VCC–VEE . . . . . . . . . . . . . . . . . . . . . . . 14.0␣ V

Internal␣ Power␣ Dissipation

␣␣

Small␣ Outline␣ Package (R) . . . . . . . . . . . . . . . . . . . . 0.9␣ W

+Input Voltage V

CC–VIN

2

+ . . . . . . . . . . . . . . . . . . . . . . < 12 V

–Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . < V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . > V

1

+ 12 V

EE

– 12 V

EE

Output Short Circuit Duration

␣ ␣ . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range (A Grade) . . . . 0°C to +70°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

14-Lead SOIC Package: θJA = 120°C/W, where P

= (TJ – T

D

)/θ

.

A

JA

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD8026AR 0°C to +70°C 14-Lead Plastic SOIC SO-14

AD8026AR-REEL 0°C to +70°C REEL SOIC SO-14

AD8026AR-REEL7 0°C to +70°C REEL 7 SOIC SO-14

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8026 is limited by the associated rise in junction temperature. The maximum safe junction temperature for plastic

encapsulated devices is determined by the glass transition tem-

perature of the plastic, approximately +150°C. Exceeding this

limit temporarily may cause a shift in parametric performance

due to a change in the stresses exerted on the die by the package.

Exceeding a junction temperature of +175°C for an extended

period can result in device failure.

While the AD8026 is internally short circuit protected, this

may not be sufficient to guarantee that the maximum junction

temperature (+150°C) is not exceeded under all conditions. To

ensure proper operation, it is necessary to observe the maximum

power derating curves.

PIN CONFIGURATION

OUT A

–IN A

+IN A

V

+IN B

–IN B

OUT B

CC

1

2

3

AD8026

4

TOP VIEW

(Not to Scale)

5

6

7

14

13

12

11

10

9

8

OUT D

–IN D

+IN D

V

EE

+IN C

–IN C

OUT C

Figure 2. Maximum Power Dissipation vs. Temperature

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8026 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. 0

Page 4

AD8026–Typical Performance Characteristics

FREQUENCY – Hz

0

–20

–120

100k 100M1M 10M

–40

–60

–80

–100

V

OUT

= 2V p-p

R

L

= 1kV

CROSSTALK – dB

0.5

0.4

0.3

0.2

0.1

0

–0.1

VIN = 50mV rms

–0.2

NORMALIZED FLATNESS – dB

–0.3

–0.4

–0.5

= 1kV

R

L

= 0V

R

S

= 0pF

C

L

100k 500M

1M 10M

FREQUENCY – Hz

100M

2

1

0

–1

–2

–3

–4

–5

NORMALIZED OUTPUT – dB

–6

–7

–8

Figure 3. Small Signal Bandwidth and 0.1 dB Flatness

RL = 10kV

20mV/DIV

25mV/DIV

VIN = 37.5mV

V

= 100mV

OUT

50ns/DIV

Figure 4. 100 mV Step Response

21.5

18.5

15.5

12.5

9.5

6.5

3.5

OUTPUT – dBm

0.5

–2.5

–5.5

–8.5

100k 500M1M 10M 100M

VIN = 2.0V p-p

VIN = 1.0V p-p

VIN = 0.5V p-p

VIN = 0.25V p-p

FREQUENCY – Hz

RL = 1kV

Figure 6. Large Signal Bandwidth

3

VIN = 50mV rms

2

= 1kV

R

L

1

= 25V

R

S

0

–1

–2

–3

–4

NORMALIZED OUTPUT – dB

–5

–6

–7

100k 500M

CL = 300pF

1M

FREQUENCY – Hz

10M 100M

CL = 100pF

CL = 200pF

Figure 7. Cap Load vs. Frequency

VIN = 4V STEP

R

R

C

0.1%/DIV

0 20 40 60 80 100 120 140 160

Figure 5. Short-Term Settling Time

= 10kV

L

= 50V

S

= 100pF

L

TIME – ns

180

Figure 8. Crosstalk (Output-to-Output) vs. Frequency

–4– REV. 0

Page 5

0.03

10

100

NOISE VOLTAGE, RTO – nV/ Hz

NOISE CURRENT – pA/ Hz

FREQUENCY – Hz

10000

10k

100k

1000

100

10

1k

100

10

1

0.1

e

n

i

n

FREQUENCY – Hz

–30

–90

–130

1M 10M

DISTORTION – dBc

–100

–110

–120

100k

–40

–50

–60

–70

–80

RL = 1kV

V

OUT

= 2V p-p

FREQUENCY – Hz

20

10

–80

30k

100M100k 1M 10M

–20

–50

–60

–70

0

–10

–40

–30

POWER SUPPLY REJECTION RATIO – dB

–PSRR

+PSRR

NTSC

0.02

0.01

0.00

–0.01

–0.02

DIFF GAIN – %

–0.03

12345678 91011

0.03

0.02

NTSC

0.01

0.00

–0.01

–0.02

–0.03

DIFF PHASE – Degrees

12345678 91011

IRE

IRE

AD8026

Figure 9. Differential Gain and Differential Phase

0

–0.2

–0.4

–0.6

–0.8

RTO – mV

–1.0

OS

V

–1.2

–1.4

–1.6

–1.8

–15

15 25 40 55 700

TEMPERATURE – 8C

Figure 10. VOS RTO vs. Temperature

0

–0.0005

Figure 12. Noise (RTO) vs. Frequency

Figure 13. Total Harmonic Distortion

–0.001

–0.0015

GAIN ACCURACY – %

–0.002

–0.0025

0

Figure 11. Gain Accuracy vs. Temperature

15 25 40 55 70

TEMPERATURE – 8C

Figure 14. PSRR vs. Frequency

–5–REV. 0

Page 6

AD8026

100

10

1

0.1

OUTPUT IMPEDANCE – V

0.01

10k 100M100k 1M 10M

FREQUENCY – Hz

Figure 15. Output Impedance vs. Frequency

1M

100k

10k

1k

INPUT IMPEDANCE – V

100

10

10k 100M100k 1M 10M

FREQUENCY – Hz

Figure 16. Input Impedance vs. Frequency

20

VIN = 50mV rms

C

= 100pF

L

10

0

–10

NORMALIZED OUTPUT – dB

–20

1

100k

1875V

3kV

1M

+

–

5kV

R

S

FREQUENCY – Hz

0V

49.9V

100V

C

L

10M 100M 500M

Figure 17. Bandwidth and Flatness vs. Series Resistance

into 100 pF

1G

1G

24.9V

THEORY OF OPERATION

The AD8026, a quad voltage feedback amplifier with rail-to-rail

output swing, is internally configured for a gain of either –5/3 or

+8/3. The gain-setting resistors are laser trimmed for precise

control of their ratio. In addition, the amplifier’s frequency

response has been adjusted to compensate for the parasitic

capacitances associated with the gain resistors and with the

amplifier’s inverting input. The result is an amplifier with very

tight control of closed-loop gain and settling time.

The amplifier’s input stage will operate with voltages from about

–0.2 V below the negative supply voltage to within about 1 V of

the positive supply. Exceeding these values will not cause phase

reversal at the output; however, the input ESD protection devices will begin to conduct if the input voltages exceed the supply rails by greater than 0.5 V. The gain resistors that connect to

Pins 2, 6, 9, and 13 are protected from ESD in such a way that

the voltages applied to these pins may exceed the negative supply by as much as –7 V.

The rail-to-rail output range of the AD8026 is provided by a

complementary common-emitter output stage. The chosen

circuit topology allows the outputs to source and sink 50 mA of

output current and, with the use of an external series resistor, to

achieve rapid settling time while driving capacitive loads within

0.5 V of the supply rails.

Output Referred Offset Voltage

The output referred offset voltage for a voltage feedback amplifier can be estimated with the following equation:

V

OOS=VIOS

× 1 +

R

()

F/RG

+I

× R

OS

()

FiRG

+I

×RP−R

B

()

iR

F

G

()

where:

= output referred offset voltage,

V

OOS

= input referred offset voltage,

V

IOS

= difference of the two input currents,

I

OS

= average of the two input currents,

I

B

= total resistance in series with positive input,

R

P

= 5 kΩ, RG = 3 kΩ for this part.

R

F

This equation leads to the well known conclusion that, for a

voltage feedback amplifier to maintain minimum output offset

voltage, the value of R

combination of R

should be selected to match the parallel

P

and RG. It should be noted that the AD8026

F

was designed for an assumed source impedance, of 500 Ω driv-

ing the +Input. Therefore, the value of R

included on the chip

P

is 500 Ω less than the ideal value for minimum output offset.

Additional resistance may be added externally, in series with the

+Input, if the part is to be driven by a lower impedance source.

APPLICATIONS

The AD8026 is designed with on-chip resistors for each op amp

to provide accurate fixed gain and low output-referenced offset

voltages. This can result in significant cost and board-space savings

for systems that can take advantage of the AD8026 specifications.

The part is actually trimmed in three steps. First, the supply

current of the part is trimmed. Then the gain is accurately

trimmed to specification. This trim adjusts the values of either

the gain or feedback resistor for a ratio of 5 to 3. The final trim

is for the offset voltage. For this trim, the –Input is connected to

ground and the +Input is connected to ground via 500 Ω, while

internal offset resistors are trimmed.

–6– REV. 0

Page 7

AD8026

In a system application, the part is designed assuming that each

–Input will be driven from a low impedance source, while each

+Input will be driven by a current-output DAC with a 500 Ω

termination resistor. Thus, to first order, each on-chip series

input resistor to each +Input is 500 Ω less than the parallel

combination of the gain-setting resistors. The offset-inducing

effect of the bias currents is minimized by this scheme.

Figure 18 shows how to drive the AD8026 with a fixed positive

gain of 8/3 from a current output DAC. The gain and offset

errors are minimized by using a 500 Ω resistor (R

the DAC output current into a voltage. The gain resistor (R

) to convert

I

)

G

should be directly connected to ground, or driven from a low

output impedance source to ensure minimum offset and maximum gain accuracy.

If the +Input of any of the op amps is driven from a voltage

source, the low offset voltage of the AD8026 can be maintained

by adding a series resistance of 500 Ω between the source and

the +Input to the AD8026. This is illustrated in Figure 19. If

the –Input is to be driven, such as when creating an offset voltage, then a low source impedance should be provided in order

to maintain both gain and offset accuracy.

+V

S

10mF

0.1mF

QUAD AMPLIFIER CHARACTERIZATION BOARD

Figure 20. Component Side

1/4 AD8026

R

CURRENT-

OUTPUT

DAC

V

R

500V

P

IN

I

+I

B

R

R

–I

G

F

B

0.1mF

10mF

–V

S

R

V

OUT

S

C

L

Figure 18. Low Offset and High Gain Accuracy Circuit for

Driving the AD8026 from a Current Output DAC

+V

S

10mF

VOLTAGE-

OUTPUT

DRIVER

R

I

500V

V

IN

R

P

+I

B

0.1mF

1/4 AD8026

–I

B

R

G

0.1mF

10mF

R

V

R

F

OUT

S

C

L

Figure 21. Solder Side

–V

S

Figure 19. Low Offset and High Gain Accuracy Circuit for

Driving the AD8026 from a Voltage Source

Figure 22. Silkscreen

–7–REV. 0

Page 8

AD8026

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

14-Lead SOIC

(SO-14)

0.3444 (8.75)

0.3367 (8.55)

14

1

8

0.2440 (6.20)

7

0.2284 (5.80)

C3327–8–4/98

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0099 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

88

08

0.0500 (1.27)

0.0160 (0.41)

3 458

–8–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...