Page 1

High Current Output,

a

FEATURES

Drives 13 V Output

Drives Unlimited Capacitive Load

High Current Output Drive: 70 mA

Excellent Video Specifications (R

Gain Flatness 0.1 dB to 10 MHz

0.06% Differential Gain Error

0.02 Differential Phase Error

Power

Operates on 2.5 V to 7.5 V Supply

10.0 mA/Amplifier Max Power Supply Current

High Speed

250 MHz Unity Gain Bandwidth (3 dB)

1200 V/s Slew Rate

Fast Settling Time of 35 ns (0.1%)

High Speed Disable Function

Turn-Off Time 30 ns

Easy to Use

200 mA Short Circuit Current

Output Swing to 1 V of Rails

APPLICATIONS

LCD Displays

Video Line Driver

Broadcast and Professional Video

Computer Video Plug-In Boards

Consumer Video

RGB Amplifier in Component Systems

PRODUCT DESCRIPTION

The AD8023 is a high current output drive, high voltage output

drive, triple video amplifier. Each amplifier has 70 mA of output

current and is optimized for driving large capacitive loads. The

amplifiers are current feedback amplifiers and feature gain

flatness of 0.1 dB to 10 MHz while offering differential gain and

phase error of 0.06% and 0.02°.

= 150 )

L

Triple Video Amplifier

AD8023

PIN CONFIGURATION

14-Lead SOIC

14

OUT 2

–IN 2

13

+IN 2

12

–V

11

S

+IN 3

10

9

–IN 3

OUT 3

8

+V

+IN 1

–IN 1

OUT 1

1

2

3

AD8023

4

S

5

6

7

DISABLE 1

DISABLE 2

DISABLE 3

The AD8023 uses maximum supply current of 10.0 mA per

amplifier and runs on ±2.5 V to ±7.5 V power supply. The

outputs of each amplifier swing to within one volt of either

supply rail to easily accommodate video signals. The AD8023

is unique among current feedback op amps by virtue of its large

capacitive load drive with a small series resistor, while still

achieving rapid settling time. For instance, it can settle to 0.1% in

35 ns while driving 300 pF capacitance.

The bandwidth of 250 MHz along with a 1200 V/µs slew rate

make the AD8023 useful in high speed applications requiring

a single +5 V or dual power supplies up to ±7.5 V. Furthermore, the AD8023 contains a high speed disable function for

each amplifier in order to power down the amplifier or high

impedance the output. This can then be used in video multiplexing applications. The AD8023 is available in the industrial temperature range of –40°C to +85°C.

V

IN

V

O

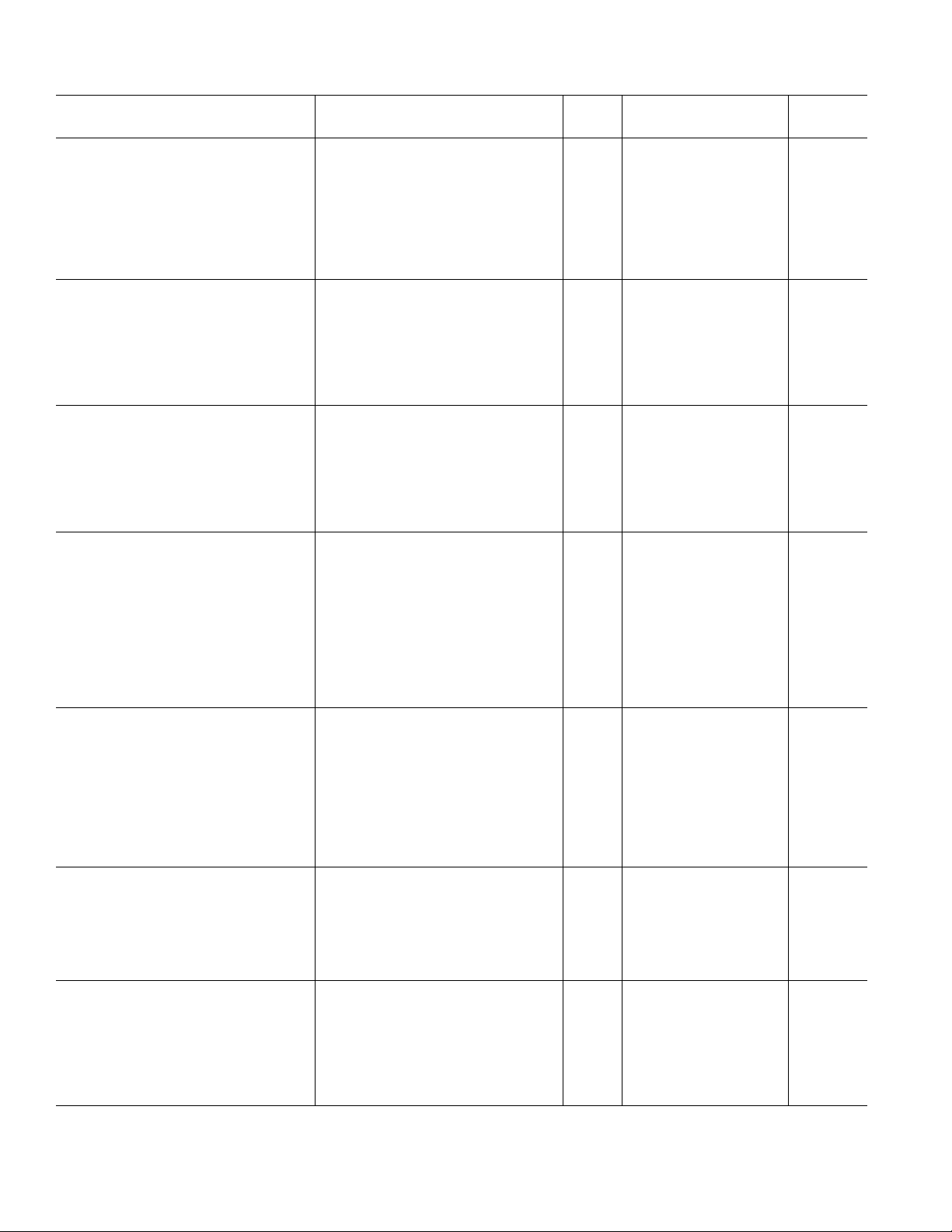

Figure 1. Pulse Response Driving a Large Load Capacitor,

= 300 pF, G = +3, RF = 750 Ω, RS = 16.9 Ω, RL = 10 k

C

L

Ω

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

V

IN

V

O

Figure 2. Output Swing Voltage,

= 150Ω; VS = ±7.5 V, G = +10

R

L

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

AD8023–SPECIFICATIONS

(@ TA = +25C, VS = 7.5, C

= 10 pF, R

LOAD

= 150 , unless otherwise noted)

LOAD

Model AD8023A

Conditions V

Min Typ Max Units

S

DYNAMIC PERFORMANCE

Bandwidth (3 dB) R

= 750 Ω No Peaking, G = +3 125 MHz

FB

Bandwidth (0.1 dB) No Peaking, G = +3 7 MHz

Slew Rate 5 V Step 1200 V/µs

Settling Time to 0.1% 0 V to ±6 V (6 V Step)

C

= 300 pF

LOAD

R

> 1 kΩ, RFB = 750 Ω

LOAD

TA = +25°C to +70°C, RS = 16.9 Ω 30 ns

NOISE/HARMONIC PERFORMANCE

Total Harmonic Distortion

fC = 5 MHz, RL = 150 Ω, VO = 2 p-p –72 dBc

Input Voltage Noise f = 10 kHz 2.0 nV/√Hz

Input Current Noise f = 10 kHz (–I

Differential Gain (R

= 150 Ω) f = 3.58 MHz, G = +2, RFB = 750 Ω 0.06 %

L

) 14 pA/√Hz

IN

Differential Phase (RL = 150 Ω) f = 3.58 MHz, G = +2, RFB = 750 Ω 0.02 Degrees

DC PERFORMANCE

Input Offset Voltage T

MIN

to T

MAX

–5 2 5 mV

Offset Drift 2 µV/°C

Input Bias Current (–) T

Input Bias Current (+) T

MIN

MIN

to T

to T

MAX

MAX

–45 15 45 µA

–25 5 25 µA

Open-Loop Transresistance 67 111 kΩ

T

MIN

to T

MAX

50 111 kΩ

INPUT CHARACTERISTICS

Input Resistance

+Input T

–Input T

MIN

MIN

to T

to T

MAX

MAX

100 kΩ

75 Ω

Input Capacitance 2pF

Input Common-Mode Voltage Range ±6.0 V

Common-Mode Rejection Ratio

Input Offset Voltage 50 56 dB

–Input Current 0.2 µA/V

+Input Current 5 µA/V

OUTPUT CHARACTERISTICS

Output Voltage Swing

RL = 1 kΩ VOL–V

V

= 150 Ω VOL–V

R

L

CC–VOH

V

CC–VOH

EE

EE

0.8 1.0 V

0.8 1.0 V

1.0 1.3 V

1.0 1.3 V

Output Current 50 70 mA

Short-Circuit Current 300 mA

Capacitive Load Drive 1000 pF

MATCHING CHARACTERISTICS

Dynamic

Crosstalk G = +2, f = 5 MHz 70 dB

DC

Input Offset Voltage –5 0.3 5 mV

–Input Bias Current –10 3 10 µA

POWER SUPPLY

Operating Range Single Supply +4.2 +15 V

Dual Supply ±2.1 ±7.5 V

Quiescent Current/Amplifier 6.2 mA

7.0 10.0 mA

T

MIN to TMAX

Power-Down 1.3 4.0 mA

–2–

REV. A

Page 3

Model AD8023A

Conditions V

Min Typ Max Units

S

POWER SUPPLY (Continued)

Power Supply Rejection Ratio V

= ±2.5 V to ±7.5 V dB

S

Input Offset Voltage 54 76 dB

–Input Current 0.03 µA/V

+Input Current 0.07 µA/V

DISABLE CHARACTERISTICS

Off Isolation f = 6 MHz –70 dB

Off Output Capacitance G = +1 12 pF

Turn-On Time 50 ns

Turn-Off Time R

Switching Threshold V

Specifications subject to change without notice.

= 150 Ω 30 ns

L

TH

– V

EE

1.6 V

AD8023

ABSOLUTE MAXIMUM RATINGS

*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 15.5 V Total

Internal Power Dissipation

Small Outline (R) . . . . 1.0 Watts (Observe Derating Curves)

Input Voltage (Common Mode) . . . . . . . . . . . . . . . . . . . .±V

S

Differential Input Voltage . . . . . . . . . . . . . . . .±3 V (Clamped)

Output Voltage Limit

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+V

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –V

S

S

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range

R Package . . . . . . . . . . . . . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range

AD8023A . . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . +300°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD8023AR –40°C to +85°C 14-Lead Plastic SOIC R-14

AD8023AR- –40°C to +85°C 13" Tape and Reel R-14

REEL

AD8023AR- –40°C to +85°C 7" Tape and Reel R-14

REEL7

AD8023ACHIPS –40°C to +85°CDie

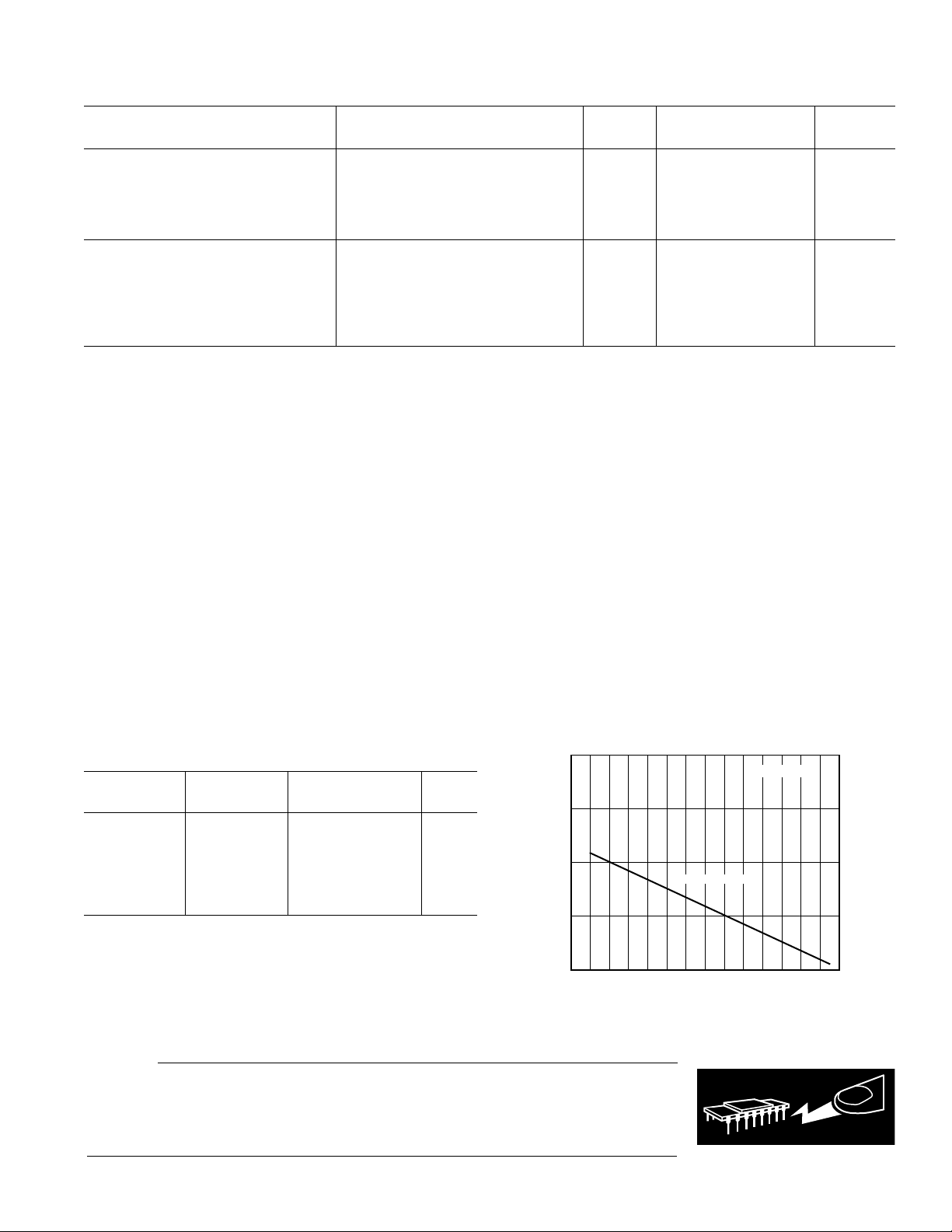

Maximum Power Dissipation

The maximum power that can be safely dissipated by the AD8023

is limited by the associated rise in junction temperature. The

maximum safe junction temperature for the plastic encapsulated

parts is determined by the glass transition temperature of the

plastic, about 150°C. Temporarily exceeding this limit may

cause a shift in parametric performance due to a change in the

stresses exerted on the die by the package. Exceeding a junction

temperature of 175°C for an extended period can result in

device failure.

While the AD8023 is internally short circuit protected, this may

not be enough to guarantee that the maximum junction temperature is not exceeded under all conditions. To ensure proper

operation, it is important to observe the derating curves.

It must also be noted that in (noninverting) gain configurations

(with low values of gain resistor), a high level of input overdrive

can result in a large input error current, which may result in a

significant power dissipation in the input stage. This power

must be included when computing the junction temperature rise

due to total internal power.

2.5

TJ = +150C

2.0

1.5

14-LEAD SOIC

1.0

MAXIMUM POWER DISSIPATION – Watts

0.5

–50 90–40 –30 –20 0 1020 30 4050 6070 80

–10

AMBIENT TEMPERATURE – C

Figure 3. Maximum Power Dissipation vs. Ambient

Temperature

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD8023 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality.

REV. A

–3–

WARNING!

ESD SENSITIVE DEVICE

Page 4

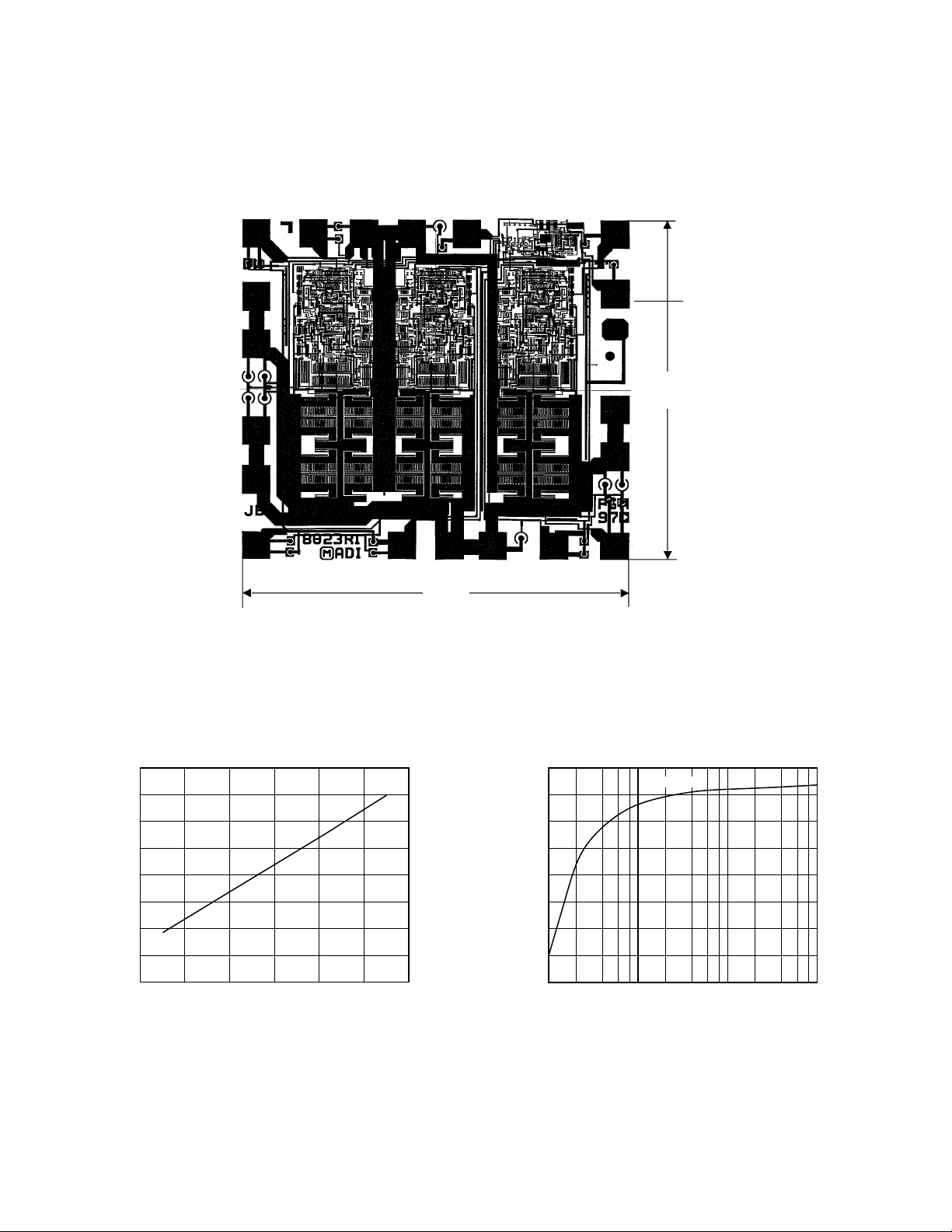

AD8023

METALIZATION PHOTO

Contact factory for latest dimensions.

Dimensions shown in inches and (mm).

7

OUT 1

8

OUT 3

–IN1

6

–IN3

+IN

5

9

+IN 3

DISABLE 3

+V

S

4

10

0.0713

(1.81)

3

–V

S

11

+IN 2

DISABLE 2

2

DISABLE 1

1

0.0634

(1.61)

14

OUT 2

–IN 2

13

12

Typical Performance Characteristics

8

7

6

5

4

3

2

1

COMMON-MODE VOLTAGE RANGE – Volts

0

2834567

Figure 4. Input Common-Mode Voltage Range vs.

Supply Voltage

SUPPLY VOLTAGE – Volts

14

13

12

11

10

9

8

OUTPUT VOLTAGE SWING – V p-p

7

6

10 10k100 1k

VS = 7.5V

LOAD RESISTANCE –

Figure 5. Output Voltage Swing vs. Load Resistance

–4–

REV. A

Page 5

AD8023

TEMPERATURE – C

1

–2

–40 90–30

–20

–10 0 1020304050607080

0

–1

VS = 2.5V

VS = 7.5V

INPUT OFFSET VOLTAGE – mV

FREQUENCY – MHz

100

1 300

10

100

31

10

0.1

3.1

1

0.31

G = +2

VS = 2.5V

VS = 7.5V

CLOSED-LOOP OUTPUT RESISTANCE – V

TOTAL SUPPLY CURRENT – mA

25

20

15

10

5

0

192

TA = +25C

4

3

SUPPLY VOLTAGE – Volts

6

5

8

7

Figure 6. Total Supply Current vs. Supply Voltage

16

TA = +25C

14

12

10

8

6

SWING

NO LOAD

SWING

R

L

= 150

35

30

25

20

–I

15

10

INPUT BIAS CURRENT – A

5

0

–50 –40 –30 –20–10 0 10 20

B

+I

B

TEMPERATURE – C

30 40 50 60 70 80 90

100

Figure 9. Input Bias Current vs. Temperature

OUTPUT VOLTAGE SWING – Vp-p

4

2

2834567

SUPPLY VOLTAGE – Volts

Figure 7. Output Voltage Swing vs. Supply Voltage

24

22

20

18

16

14

TOTAL SUPPLY CURRENT – mA

12

10

–40 –30 –20

–50

–10010

TEMPERATURE – C

Figure 8. Total Supply Current vs. Temperature

REV. A

VS = 7.5V

VS = 2.5V

20

40 50 60 70 8090100

30

Figure 10. Input Offset Voltage vs. Temperature

Figure 11. Closed-Loop Output Resistance vs. Frequency

–5–

Page 6

AD8023

200

100

– I NOISE

+I NOISE

10

VOLTAGE NOISE – nVHz

V NOISE

1

0.1 100110

FREQUENCY – kHz

Figure 12. Input Current and Voltage Noise vs. Frequency

200

100

10

CURRENT NOISE – pAHz

0

90

80

70

60

50

40

30

20

COMMON-MODE REJECTION – dB

10

0

1 200

VS = 7.5V

VS = 2.5V

10

FREQUENCY – MHz

R

V

CM

R

R

R

100

Figure 15. Common-Mode Rejection vs. Frequency

450

400

350

300

SHORT CIRCUIT CURRENT – mA

250

SOURCE

SINK

–30 –20 –10 0 10203040506070

–50 80–40

TEMPERATURE – C

VS = 7.5V

90 100

Figure 13. Short Circuit Current vs. Temperature

10k

1k

100

10

OUTPUT RESISTANCE –

1 100

G = +1

VS = 7.5V

10

FREQUENCY – Hz

200

Figure 14. Output Resistance vs. Frequency,

Disabled State

70

60

VS = 7.5V (+PSRR)

VS = 2.5V (+PSRR)

50

40

30

VS = 2.5V (–PSRR)

20

POWER SUPPLY REJECTION – dB

10

0

1

VS = 7.5V (–PSRR)

10 100

FREQUENCY – MHz

Figure 16. Power Supply Rejection Ratio vs. Frequency

0

G = +1

= 7.5V

V

S

–10

= 2V p-p

V

O

–20

–30

–40

–50

–60

–70

HARMONIC DISTORTION – dBc

–80

–90

1 10010

2ND

3RD

FREQUENCY – MHz

Figure 17. Harmonic Distortion vs. Frequency, RL = 150

Ω

–6–

REV. A

Page 7

100k

p

SUPPLY VOLTAGE – V

1600

0

1400

800

600

400

200

1200

1000

2834 5 67

G = –1

G = +2

G = +1

G = +10

SLEW RATE – V/s

AD8023

10k

1k

TRANSIMPEDANCE –

100

10

1k 1G10k

100k 1M 100M

FREQUENCY – Hz

10M

Figure 18. Open-Loop Transimpedance vs. Frequency

SLEW RATE V/s

1600

1400

1200

1000

800

600

400

200

G = +2

G = +1

0

0

OUTPUT VOLTAGE STEP – V p-

345

2

G = –1

G = +10

61

Figure 19. Slew Rate vs. Output Step Size

V

IN

V

O

Figure 21. Small Signal Pulse Response, Gain = +1,

(R

= 2 kΩ, RL = 150 Ω, VS = ±7.5 V)

F

Figure 22. Maximum Slew Rate vs. Supply Voltage

V

IN

V

O

Figure 20. Large Signal Pulse Response,

Gain = +1, (R

= 2 kΩ, RL = 150 Ω, VS = ±7.5 V)

F

REV. A

V

IN

V

O

Figure 23. Large Signal Pulse Response,

Gain = +10, (R

= 274 Ω, RL = 150 Ω, VS = ±7.5 V)

F

–7–

Page 8

AD8023

+2

CLOSED-LOOP GAIN (NORMALIZED) – dB

+1

GAIN

0

–1

–2

PHASE

–3

–4

–5

G = +10

–6

R

L

–7

–8

1

VS = 2.5V

= 150

VS = 7.5V

VS = 7.5V

VS = 2.5V

10 100

FREQUENCY – MHz

500

0

–90

–180

PHASE SHIFT – Degrees

Figure 24. Closed-Loop Gain and Phase vs. Frequency,

= 150

G = +10, R

+1

0

–1

–2

–3

–4

PHASE

–5

–6

–7

CLOSED-LOOP GAIN (NORMALIZED) – dB

–8

–9

1

L

GAIN

Ω

10

FREQUENCY – MHz

VS = 2.5V

100

VS = 7.5V

0

–90

–180

PHASE SHIFT – Degrees

400

Figure 25. Closed-Loop Gain and Phase vs. Frequency,

= 150

G = +1, R

L

Ω

+1

GAIN

0

–1

–2

–3

PHASE

–4

–5

–6

G = +1

–7

= 150

R

L

–8

CLOSED-LOOP GAIN (NORMALIZED) – dB

–9

1 50010

VS = 2.5V

VS = 7.5V

VS = 2.5V

FREQUENCY – MHz

VS = 7.5V

100

0

–90

–180

PHASE SHIFT – Degrees

Figure 27. Closed-Loop Gain and Phase vs. Frequency,

G = –1, R

= 150

L

V

IN

V

O

Ω

Figure 28. Small Signal Pulse Response,

Gain = +10, (R

= 274 Ω, RL = 150 Ω, VS = ±7.5 V)

F

V

IN

V

O

Figure 26. Large Signal Pulse Response,

Gain = –1, (R

= 750 Ω, RL = 150 Ω, VS = ±7.5 V)

F

V

IN

V

O

Figure 29. Small Signal Pulse Response,

Gain = –1, (R

= 750 Ω, RL = 150 Ω, VS = ±7.5 V)

F

–8–

REV. A

Page 9

AD8023

+1

GAIN

0

–1

–2

–3

PHASE

–4

–5

–6

G = –10

–7

= 150

R

L

CLOSED-LOOP GAIN (NORMALIZED) – dB

–8

–9

1 50010

VS = 2.5V

VS = 2.5V

FREQUENCY – MHz

VS = 7.5V

0

–90

–180

PHASE SHIFT – Degrees

100

Figure 30. Closed-Loop Gain and Phase vs. Frequency,

G = –10, R

= 150

L

Ω

General

The AD8023 is a wide bandwidth, triple video amplifier that

offers a high level of performance on less than 9.0 mA per

amplifier of quiescent supply current. The AD8023 achieves

bandwidth in excess of 200 MHz, with low differential gain and

phase errors and high output current making it an efficient video

amplifier.

The AD8023’s wide phase margin coupled with a high output

short circuit current make it an excellent choice when driving

any capacitive load up to 300 pF.

It is designed to offer outstanding functionality and performance

at closed-loop inverting or noninverting gains of one or greater.

Choice of Feedback and Gain Resistors

Because it is a current feedback amplifier, the closed-loop bandwidth of the AD8023 may be customized using different values

of the feedback resistor. Table I shows typical bandwidths at

different supply voltages for some useful closed-loop gains when

driving a load of 150 Ω.

The choice of feedback resistor is not critical unless it is desired

to maintain the widest, flattest frequency response. The resistors

recommended in the table (chip resistors) are those that will

result in the widest 0.1 dB bandwidth without peaking. In

applications requiring the best control of bandwidth, 1%

resistors are adequate. Resistor values and widest bandwidth

figures are shown. Wider bandwidths than those in the table can

be attained by reducing the magnitude of the feedback resistor

(at the expense of increased peaking), while peaking can be

reduced by increasing the magnitude of the feedback resistor.

Increasing the feedback resistor is especially useful when driving

large capacitive loads as it will increase the phase margin of the

closed-loop circuit. (Refer to the Driving Capacitive Loads

section for more information.)

To estimate the –3 dB bandwidth for closed-loop gains of 2 or

greater, for feedback resistors not listed in the following table,

the following single pole model for the AD8023 may be used:

ACL

1+ SC

T(RF

G

+ Gn rin )

where: CT = transcapacitance 1 pF

R

= feedback resistor

F

G = ideal closed loop gain

Gn =

rin = inverting input resistance 150 Ω

1 +

R

F

= noise gain

R

G

ACL = closed loop gain

The –3 dB bandwidth is determined from this model as:

f

3

2 π C

T(RF

1

+ Gn rin)

This model will predict –3 dB bandwidth to within about

10% to 15% of the correct value when the load is 150 Ω and

= ±7.5 V. For lower supply voltages there will be a slight

V

S

decrease in bandwidth. The model is not accurate enough to

predict either the phase behavior or the frequency response

peaking of the AD8023.

It should be noted that the bandwidth is affected by attenuation

due to the finite input resistance. Also, the open-loop output

resistance of about 6 Ω reduces the bandwidth somewhat when

driving load resistors less than about 150 Ω. (Bandwidths will

be about 10% greater for load resistances above a couple

hundred ohms.)

Table I. –3 dB Bandwidth vs. Closed-Loop Gain and Feedback

Resistor, R

= 150 (SOIC)

L

VS – Volts Gain RF – Ohms BW – MHz

±7.5 +1 2000 460

+2 750 240

+10 300 50

–1 750 150

–10 250 60

±2.5 +1 2000 250

+2 1000 90

+10 300 30

–1 750 95

–10 250 50

Driving Capacitive Loads

When used in combination with the appropriate feedback

resistor, the AD8023 will drive any load capacitance without

oscillation. The general rule for current feedback amplifiers is

that the higher the load capacitance, the higher the feedback

resistor required for stable operation. Due to the high open-loop

transresistance and low inverting input current of the AD8023,

the use of a large feedback resistor does not result in large closedloop gain errors. Additionally, its high output short circuit current

makes possible rapid voltage slewing on large load capacitors.

For the best combination of wide bandwidth and clean pulse

response, a small output series resistor is also recommended.

Table II contains values of feedback and series resistors which

result in the best pulse responses. Figure 28 shows the AD8023

driving a 300 pF capacitor through a large voltage step with

virtually no overshoot. (In this case, the large and small signal

pulse responses are quite similar in appearance.)

REV. A

–9–

Page 10

AD8023

R

F

1.0F

+V

S

R

G

V

IN

R

T

Figure 31. Circuit for Driving a Capacitive Load

Table II. Recommended Feedback and Series Resistors vs.

Capacitive Load and Gain

CL – pF RF – Ohms G = 2 G ≥ 3

20 2k 0 0

50 2k 10 10

100 2k 15 15

200 3k 10 10

300 3k 10 10

≥500 3k 10 10

V

IN

V

O

Figure 32. Pulse Response Driving a Large Load Capacitor.

= 300 pF, G = +3, RF = 750 Ω, RS = 16.9 Ω, RL = 10 k

C

L

Overload Recovery

The three important overload conditions are: input commonmode voltage overdrive, output voltage overdrive, and input

current overdrive. When configured for a low closed-loop gain,

this amplifier will quickly recover from an input common-mode

voltage overdrive; typically in under 25 ns. When configured for

a higher gain, and overloaded at the output, the recovery time

will also be short. For example, in a gain of +10, with 50%

overdrive, the recovery time of the AD8023 is about 20 ns (see

Figure 31). For higher overdrive, the response is somewhat

slower. For 100% overdrive, (in a gain of +10), the recovery

time is about 80 ns.

4

AD8023

11

–V

0.1F

15

1.0F

0.1F

S

R

S

V

O

C

L

RS – Ohms

Ω

V

IN

V

O

Figure 33. 50% Overload Recovery, Gain = +10,

(R

= 300 Ω, RL = 1 kΩ, VS = ±7.5 V)

F

As noted in the warning under Maximum Power Dissipation, a

high level of input overdrive in a high noninverting gain circuit

can result in a large current flow in the input stage. Though this

current is internally limited to about 30 mA, its effect on the

total power dissipation may be significant.

Disable Mode Operation

Pulling the voltage on any one of the Disable pins about 1.6 V up

from the negative supply will put the corresponding amplifier

into a disabled, powered down, state. In this condition, the

amplifier’s quiescent current drops to about 1.3 mA, its output

becomes a high impedance, and there is a high level of isolation

from input to output. In the case of a gain of two line driver for

example, the impedance at the output node will be about the

same as for a 1.5 kΩ resistor (the feedback plus gain resistors)

in parallel with a 12 pF capacitor.

Leaving the Disable pin disconnected (floating) will leave the

corresponding amplifier operational, in the enabled state. The

input impedance of the disable pin is about 25 kΩ in parallel

with a few picofarads. When driven to 0 V, with the negative

supply at –7.5 V, about 100 µA flows into the disable pin.

When the disable pins are driven by complementary output

CMOS logic, on a single 5 V supply, the disable and enable

times are about 50 ns. When operated on dual supplies, level

shifting will be required from standard logic outputs to the

Disable pins. Figure 33 shows one possible method, which

results in a negligible increase in switching time.

+5

V

I

15k

4k

VI HIGH => AMPLIFIER ENABLED

V

LOW => AMPLIFIER DISABLED

I

+7.5V

TO DISABLE PIN

10k

–7.5V

Figure 34. Level Shifting to Drive Disable Pins on Dual

Supplies

The AD8023’s input stages include protection from the large

differential input voltages that may be applied when disabled.

Internal clamps limit this voltage to about ±3 V. The high input to

output isolation will be maintained for voltages below this limit.

–10–

REV. A

Page 11

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

14-Lead Plastic SOIC

(R-14)

0.3444 (8.75)

0.3367 (8.55)

AD8023

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

14 8

PIN 1

0.0500

0.0192 (0.49)

(1.27)

0.0138 (0.35)

BSC

0.2440 (6.20)

71

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0099 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

C3137–0–3/00 (rev. A)

REV. A

PRINTED IN U.S.A.

–11–

Loading...

Loading...