Page 1

5 V, Rail-to-Rail, High-Output Current,

ⴙV

S

–IN2

ⴙIN2

6

5

7

8

OUT2

OUT1

–IN1

ⴙIN1

–V

S

1

2

3

4

AD8018AR

a

FEATURES

Ideal xDSL Line Drive Amplifier for USB, PCMCIA, or

PCI-Based Customer Premise Equipment (CPE). The

AD8018 provides maximum reach on 5 V supply,

driving 16 dBm of power into a back-terminated,

transformer-coupled 100 ⍀ while maintaining –82 dBc

of out-of-band SFDR.

Rail-to-Rail Output Voltage and High Output Current

Drive

400 mA Output Current into Differential Load of 10 ⍀

@ 8 V p-p

Low Single-Tone Distortion

–86 dBc Worst Harmonic, 6 V p-p into Differential 10 ⍀

@ 100 kHz

Low Noise

4.5 nV/√Hz Voltage Noise Density, 100 kHz

Out-of-Band SFDR = –82 dBc, 144 kHz to 500 kHz,

= 12.5 ⍀, P

R

LOAD

Low-Power Operation

3.3 V to 8 V Power Supply Range

Two Logic Bits for Standby and Shutdown

Low Supply Current of 9 mA/Amplifier (Typ)

Current Feedback Amplifiers

High Speed

130 MHz Bandwidth (–3 dB)

300 V/s Slew Rate

APPLICATIONS

xDSL USB, PCI, PCMCIA Cards

Consumer DSL Modems

Twisted Pair Line Driver

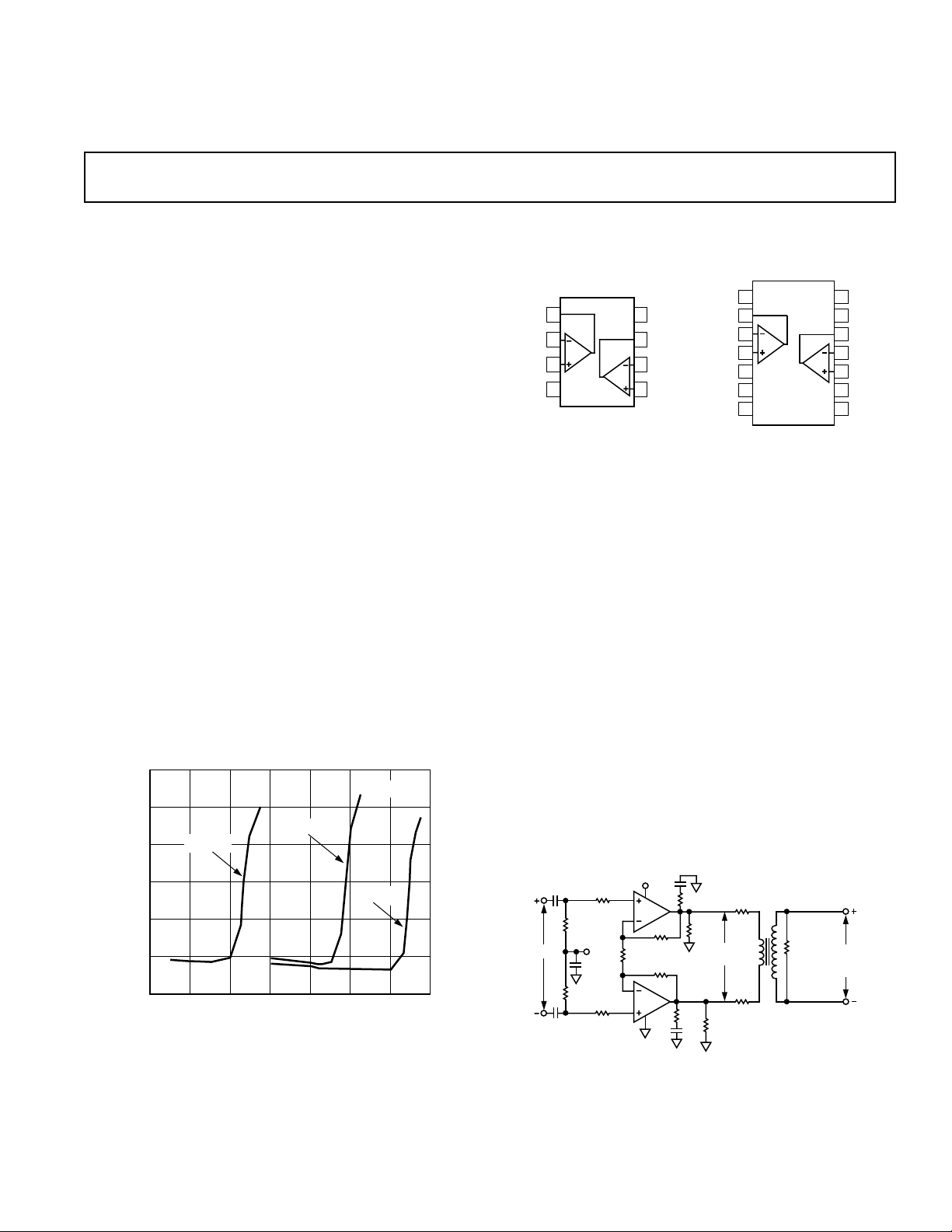

–30

–40

–50

VS = 3.3V

= 13 dBm

LINE

N = 4.0

VS = 5V

xDSL Line Drive Amplifier

AD8018

PIN CONFIGURATIONS

8-Lead SOIC

(Thermal Coastline)

PRODUCT DESCRIPTION

The AD8018 is intended for use in single-supply (5 V) xDSL

modems where high-output current and low distortion are

essential to achieve maximum reach. The dual high-speed

amplifiers are capable of driving low distortion signals to within

0.5 V of the power supply rail. Each amplifier can drive 400 mA

of current into 10 Ω (differential) while maintaining –82 dBc

out-of-band SFDR. The AD8018 is available with flexible standby

and shutdown modes. Two digital logic bits (PWDN1 and

PWDN0) may be used to put the AD8018 into one of three

modes: full power, standby (outputs low impedance), and

shutdown (outputs high impedance).

Fabricated with ADI’s high-speed XFCB (eXtra Fast Complementary Bipolar) process, the high bandwidth and fast slew rate

of the AD8018 keep distortion to a minimum, while dissipating a minimum of power. The quiescent current of the AD8018

is a low 9 mA/amplifier. The AD8018 drive capability comes in

compact 8-lead Thermal Coastline SOIC and 14-lead TSSOP

packages. Low-distortion, rail-to-rail output voltage, and highcurrent drive in small packages make the AD8018 ideal for use

in low-cost USB, PCMCIA, and PCI Customer Premise Equipment for ADSL, SDSL, VDSL, and proprietary xDSL systems.

Both models will operate over the temperature range –40°C to

+85°C.

14-Lead TSSOP

NC

2

OUT1

3

–IN1

ⴙIN1

4

5

–V

S

6

PWDN1

7

NC

NC = NO CONNECT

AD8018ARU

81

9

10

11

12

13

14

NC

ⴙV

S

OUT2

–IN2

ⴙIN2

PWDN0

DGND

–60

SFDR – dBc

–70

–80

–90

4186 8 10 12 14 16

P

– dBm

LINE

VS = 8V

Figure 1. Out-of-Band SFDR vs. ADSL Upstream Line Power;

= 5 V, N = 4 Turns, 144 kHz to 500 kHz. See Evaluation

V

S

Board Schematics in Figure 11.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

5V

750⍀

1nF

750⍀

750⍀

10⍀

10⍀

1nF

10k⍀

R1

3.1⍀

P

OUT

16dBm

R2

3.1⍀

TRANSFORMER

10k⍀

1:4

RL = 100⍀

LINEPOWER

13dBm

0.01F

V

IN

0.01F

10k⍀

10k⍀

100⍀

V

REF

0.01F

100⍀

Figure 2. Single-Supply Voltage Differential Drive Circuit

for xDSL Applications

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

AD8018–SPECIFICATIONS

(@ 25ⴗC, VS = 5 V, RL = 100 ⍀, RF = RG = 750 ⍀ unless otherwise noted.)

Parameter Conditions Min Typ Max Unit

DYNAMIC PERFORMANCE

–3 dB Bandwidth G = 1, V

G = 1, V

G = 2, V

G = 2, V

0.1 dB Bandwidth V

Large Signal Bandwidth V

OUT

OUT

Slew Rate Noninverting, V

Rise and Fall Time Noninverting, V

Settling Time 0.1%, V

< 0.4 V p-p, RL = 5 Ω 40 50 MHz

OUT

< 0.4 V p-p, RL = 100 Ω 100 130 MHz

OUT

< 0.4 V p-p, RL = 5 Ω 35 40 MHz

OUT

< 0.4 V p-p, RL = 100 Ω 80 100 MHz

OUT

< 0.4 V p-p, RL = 100 Ω 10 MHz

= 4 V p-p, G = +2 80 MHz

= 4 V p-p 300 V/s

OUT

= 2 V p-p 5.5 ns

OUT

= 2 V p-p, RL = 100 Ω 25 ns

OUT

NOISE/HARMONIC

PERFORMANCE

Distortion, V

Second Harmonic 100 kHz, R

= 6 V p-p (Differential)

OUT

= 10 Ω –89 –94 dBc

L

500 kHz, RL = 10 Ω –61 –63 dBc

Third Harmonic 100 kHz, R

= 10 Ω –86 –89 dBc

L

500 kHz, RL = 10 Ω –74 –77 dBc

MTPR (In-Band) 25 kHz to 138 kHz, R

SFDR (Out-of-Band) 144 kHz to 500 kHz, RL = 12.5 Ω, P

= 12.5 Ω, P

L

= +13 dBm –70 dBc

LINE

= +13 dBm –82 dBc

LINE

Input Noise Voltage f = 100 kHz 4.5 5 nV√Hz

Input Noise Current f = 100 kHz (+Inputs) 1 pA√Hz

f = 100 kHz (–Inputs) 10 pA√Hz

Crosstalk f = 1 MHz, G = +2 –74 dB

DC PERFORMANCE

Input Offset Voltage 115mV

T

MIN

to T

MAX

17 mV

Input Offset Voltage Match 0.1 2.6 mV

Transimpedance V

= 2 V p-p, RL = 5 Ω 830 2000 kΩ

OUT

T

MIN

to T

MAX

700 kΩ

INPUT CHARACTERISTICS

Input Resistance +Input 10 M⍀

–Input 125 Ω

Input Capacitance +Input 1 pF

Input Bias Current (–) 0.3 8 A

T

MIN

to T

MAX

14 A

Input Bias Current (–) Match 0.1 5.5 A

T

MIN

to T

MAX

8 A

Input Bias Current (+) 1 1.5 A

T

MIN

to T

MAX

2.5 A

Input Bias Current (+) Match 0.1 0.5 A

T

CMRR V

to T

MIN

IN

MAX

2 V to 4 V 51 54 dB

1 A

Input CM Voltage Range 1.2 3.8 V

OUTPUT CHARACTERISTICS

Cap Load 30% Overshoot 1000 pF

Output Resistance Frequency = 100 kHz, PWDN1, PWDN0 = 1 0.2 Ω

Output Voltage Swing R

= 100 Ω 0.16 to 4.87 V

L

RL = 5 Ω 0.5 to 4.5 V

Linear Output Current SFDR < –85 dBc, f = 100 kHz, R

= 10 Ω 350 400 mA

L

Short-Circuit Current 1000 mA

POWER SUPPLY

Supply Current/Amp PWDN1 = 1, PWDN0 = 1 9 10 mA

T

MIN

to T

MAX

11.4 mA

STBY Supply Current/Amp PWDN1 = 0, PWDN0 = 1 or 4.5 5.1 mA

PWDN1 = 1, PWDN0 = 0 4.5 5.1 mA

SHUTDOWN Supply Current/Amp PWDN1 = 0, PWDN0 = 0 0.3 0.55 mA

Operating Range Single Supply 3.3 8 V

+Power Supply Rejection Ratio ⌬V

–Power Supply Rejection Ratio ⌬V

= ⫾1 V 60 66 dB

S

T

to T

MIN

T

MIN

MAX

= ⫾1 V 52 55 dB

S

to T

MAX

56 dB

50 dB

–2–

REV. 0

Page 3

AD8018

WARNING!

ESD SENSITIVE DEVICE

Parameter Conditions Min Typ Max Unit

LOGIC INPUTS (PWDN1, 0)

Logic “1” Voltage 2.0 V

Logic “0” Voltage 0.8 V

Logic Input Bias Current 240 A

Standby Recovery Time RL = 10 Ω, G = +2, IS = 90% of Typical 500 ns

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 V

Internal Power Dissipation

2

1

Small Outline Package (R) . . . . . . . . . . . . . . . . . . . 650 mW

TSSOP Package (RU) . . . . . . . . . . . . . . . . . . . . . . 565 mW

Input Voltage (Common-Mode) . . . . . . . . . . . . . . . . . . . . ±V

Logic Voltage, PWDN0, 1 . . . . . . . . . . . . . . . . . . . . . . . . . ±V

S

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ± 1.6 V

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range RU, R . . . . . . . –65°C to +125°C

Operating Temperature Range . . . . . . . . . . . –40°C to +85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for the device in free air:

8-Lead SOIC Package: θJA = 100°C/W.

8-Lead TSSOP Package: θJA = 115°C/W.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD8018AR –40°C to +85°C 8-Lead Plastic SO-8

SOIC

AD8018AR–REEL –40°C to +85°C 8-Lead SOIC SO-8

AD8018ARU –40°C to +85°C 14-Lead Plastic RU-14

TSSOP

AD8018ARU–REEL –40°C to +85°C 14-Lead Plastic RU-14

TSSOP

AD8018ARU–EVAL Evaluation Board RU-14

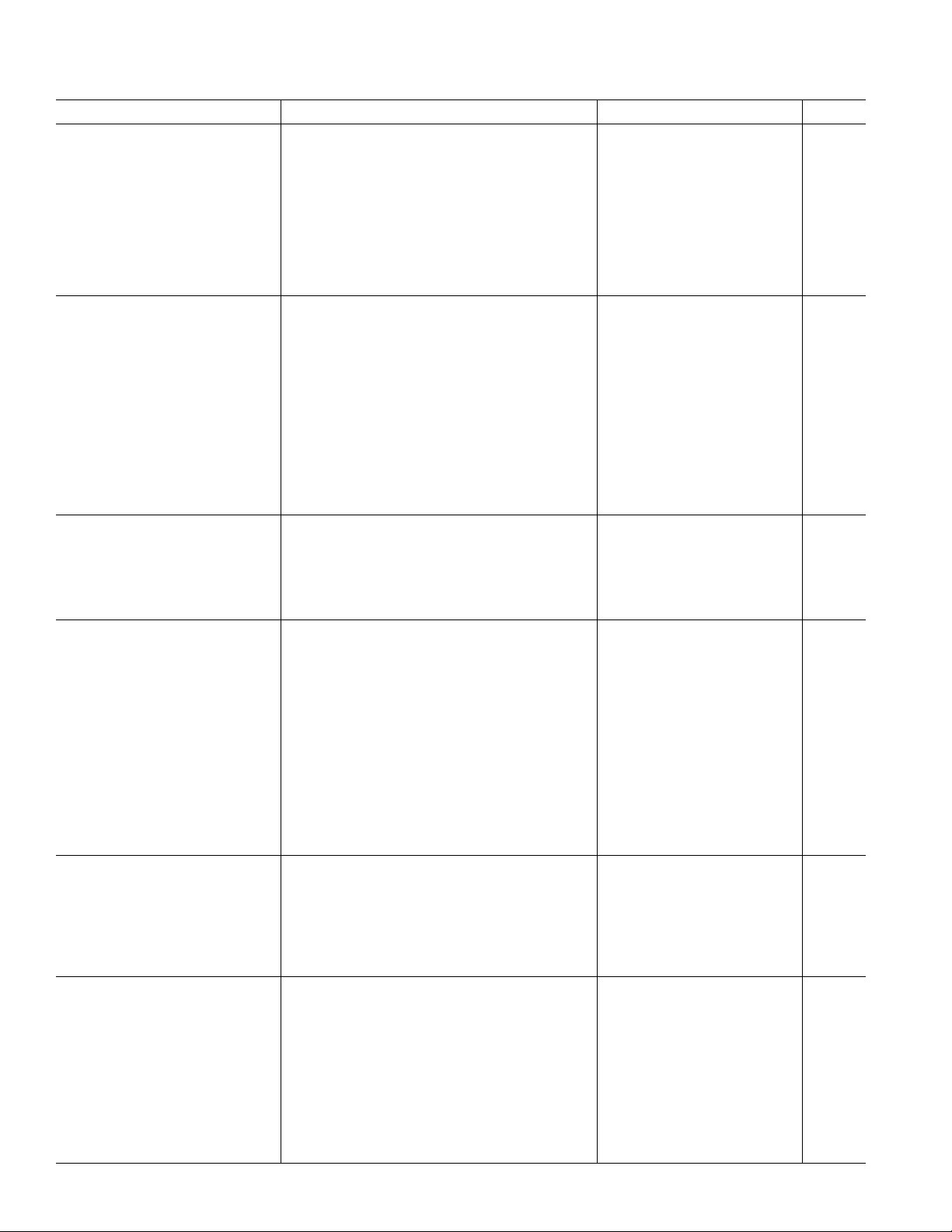

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the AD8018

is limited by the associated rise in junction temperature. The

maximum safe junction temperature for plastic encapsulated

devices is determined by the glass transition temperature of the

plastic, approximately 150°C. Temporarily exceeding this limit

may cause a shift in parametric performance due to a change

in the stresses exerted on the die by the package. Exceeding a

junction temperature of 175°C for an extended period can result

in device failure.

While the AD8018 is internally short circuit protected, this may

not be sufficient to guarantee that the maximum junction temperature (150°C) is not exceeded under all conditions. To ensure

proper operation, it is necessary to observe the maximum power

derating curves.

2.0

1.5

8-LEAD SOIC PACKAGE

1.0

14-LEAD TSSOP PACKAGE

0.5

MAXIMUM POWER DISSIPATION – Watts

0

–40 –30 –20 –100 10 2030 4050 6070 8090

–50

AMBIENT TEMPERATURE – ⴗC

TJ = 150ⴗC

Figure 3. Plot of Maximum Power Dissipation vs.

Temperature

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD8018 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. 0

–3–

Page 4

AD8018

1

FREQUENCY – Hz

10

10

1

100

1000

100 1k 10k 100k 1M

0.1

10

100

VS = ⴞ2.5V

R

L

= 100⍀

V

NOISE

ⴙI

NOISE

ⴚI

NOISE

V

NOISE

– nV/ Hz (RTI)

I

NOISE

– pA/ Hz

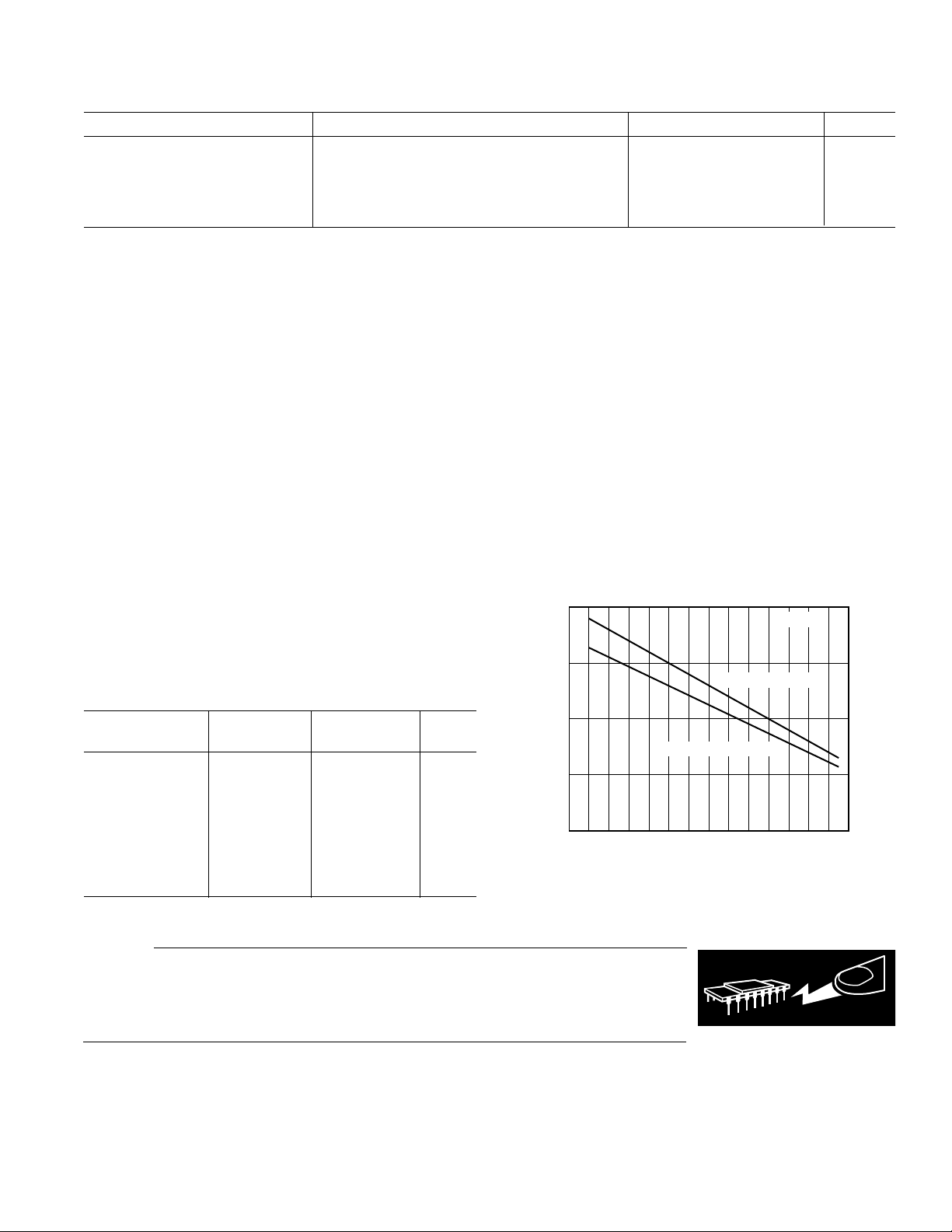

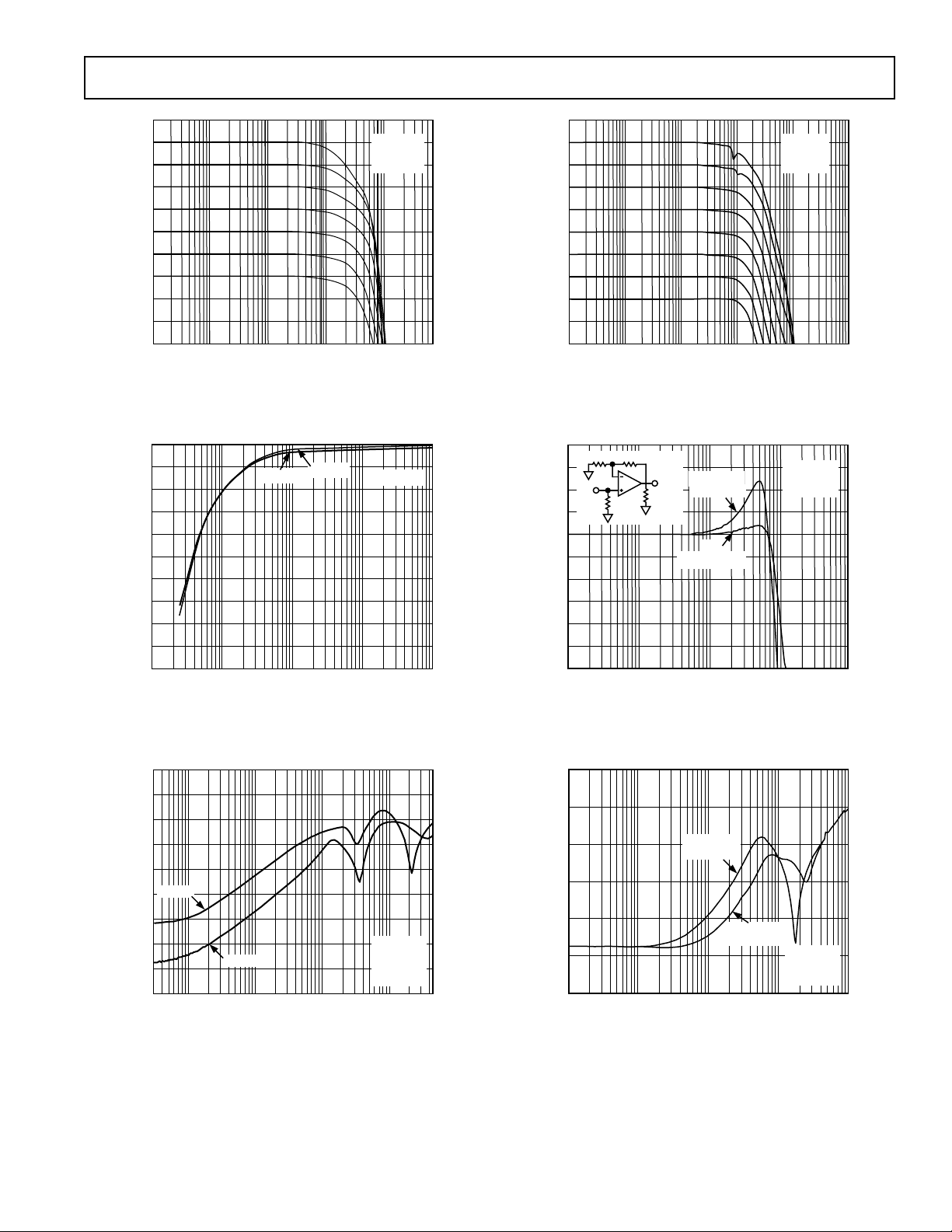

–Typical Performance Characteristics

ⴙV

750⍀

S

750⍀

AD8018

V

SIGNAL

50⍀

–V

S

TPC 1. Single-Ended Test Circuit

150

100

50

0

–50

OUTPUT VOLTAGE – mV

–100

10F

10F

TANT

0.1F

0.1F

TANT

G = 2

V

= ⴞ2.5V

S

R

= 5⍀

L

R

LOAD

V

OUT

TPC 4. I

3k

2.5k

2k

1.5k

1k

OUTPUT IMPEDANCE – ⍀

500

NOISE

and V

vs. Frequency

NOISE

(0,0)

VS=ⴞ2.5V

(1,0)

(1,1)

–150

50

0

150 200 250 300 350 400 450 500

100

TIME – ns

TPC 2. Small Signal Step Response

TPC 5. Output Impedance vs. Frequency, for Full Power,

0

0.01

0.1 1 10 100

FREQUENCY – MHz

1k

Standby, and Shutdown Modes

(+0.1%)

(–0.1%)

3

2

1

0

mV

V

– (VINⴛ2)

–1

–2

–3

10 20 30 40 50 60 70 80 10090

0

OUT

TIME – ns

TPC 6. 0.1% Settling Time

G = 2

V

= ⴞ2.5

S

V

IN

R

L

= 100⍀

= 2V p-p

3

G = 2

V

= ⴞ2.5V

S

= 5⍀

R

L

2

1

0

–1

OUTPUT VOLTAGE – V

–2

–3

0

100

50

150 200 250 300 350 400 450 500

TIME – ns

TPC 3. Large Signal Step Response

–4–

REV. 0

Page 5

5

FREQUENCY – Hz

10k

OUTPUT VOLTAGE – dBv

–25

1M

5

10M 100M 1G100k

–22

–19

–16

–13

–10

–7

–4

–1

2

G = 2

V

S

= ⴞ2.5

R

L

= 5⍀

FREQUENCY – Hz

100k

CMRR – dB

–70

1M 10M 100M

–60

–50

–40

–30

–20

–10

1G

G = 2

V

S

= ⴞ2.5V

R

L

= 100⍀

STANDBY

(1,0) or (0,1)

(1,1)

FULL POWER

2

–1

–4

–7

–10

–13

–16

OUTPUT VOLTAGE – dBv

–19

–22

–25

10k

100k

1M

FREQUENCY – Hz

10M 100M

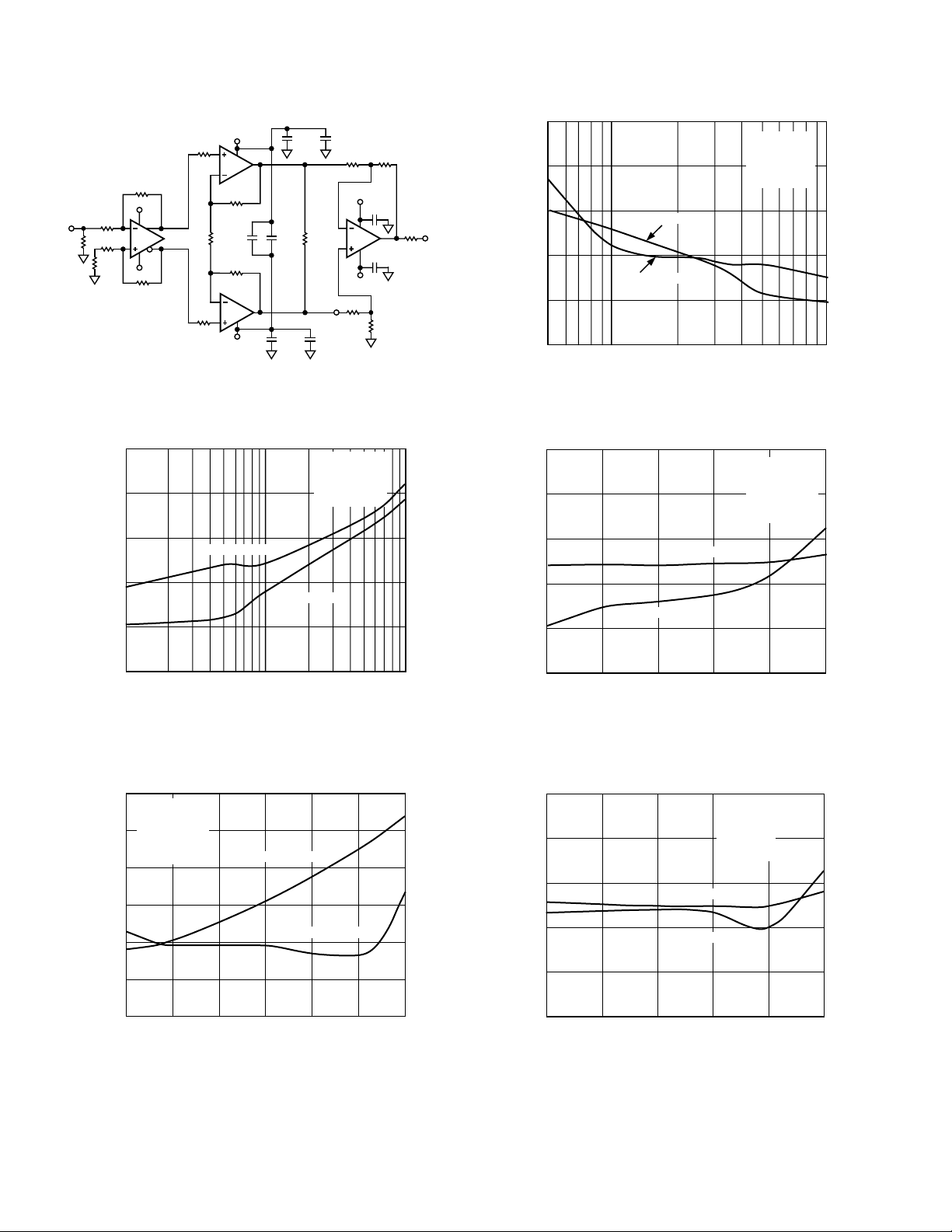

TPC 7. Output Voltage vs. Frequency

G = 2

V

= ⴞ2.5V

S

R

= 100⍀

L

AD8018

1G

TPC 10. Output Voltage vs. Frequency

2.5

2.4

2.3

2.2

2.1

2.0

1.9

1.8

OUTPUT SWING – Volts

1.7

1.6

1.5

1

10

TPC 8. Output Swing vs. R

0

–10

–20

–30

–40

ⴚPSRR

–50

PSRR – dB

–60

–70

–80

–90

100k

TPC 9. PSRR vs. Frequency

REV. 0

ⴙSWING

LOAD RESISTANCE – ⍀

ⴙPSRR

100 1000 10k

1M 10M

FREQUENCY – Hz

–SWING

VS = ⴞ2.5V

LOAD

G = 2

V

⌬V

R

= ⴞ2.5V

S

= ⴞ1V

S

= 100⍀

L

100M

12

750⍀ 750⍀

NORMALIZED GAIN – dB

–12

–15

–18

–3

–6

–9

9

6

3

0

100k

STANDBY

V

1M

R

L

OUT

(1,0) or (0,1)

(1,1)

FULL POWER

10M 100M

FREQUENCY – Hz

V

IN

50⍀

G = 2

= ⴞ2.5V

V

S

= 100⍀

R

L

TPC 11. Small Signal Frequency Response

TPC 12. CMRR vs. Frequency, Full Power, and Standby

Mode

–5–

1G

Page 6

AD8018

VSIG

50⍀

ⴙV

S

100⍀

1/2

500⍀

500⍀

500⍀

25⍀

ⴙ6V

AD8138

ⴚ6V

500⍀

IN

100⍀

AD8018

750⍀

0.1F

500⍀

750⍀

AD8018

1/2

ⴚV

S

10F0.1F

220F

AD9632

R

L

10F0.1F

7.96k⍀ 402⍀

0.1F

ⴙ6V

0.1F

0.1F

ⴚ6V

7.96k⍀

50⍀

OUT

402⍀

TPC 13. Differential Test Circuit

–60

–70

–80

3RD HARMONIC

V

= 6V p–p

OUT

R

= 10⍀

L

V

= ⴞ 2.5V

S

PWDN 1,0 = 1,1

–60

–70

–80

–90

–100

DIFFERENTIAL DISTORTION – dBc

–110

510

2ND HARMONIC

3RD HARMONIC

LOAD RESISTANCE – ⍀

TPC 16. Differential Distortion vs. R

–60

–70

–80

2ND HARMONIC

VS = ⴞ2.5V

G = 4

f

= 100kHz

O

V

= 6V p–p

OUT

LOAD

VS = ⴞ2.5V

R

= 10⍀

L

G = 4

f

= 100kHz

O

PWDN 1,0 = 1,1

100

–90

–100

DIFFERENTIAL DISTORTION – dBc

–110

0.01 0.1

FREQUENCY – MHz

2ND HARMONIC

1.0

TPC 14. Differential Distortion vs. Frequency

–50

VS = ⴞ2.5V

R

= 3

⍀

L

G

= 4

–60

f

= 100kHz

DIFFERENTIAL DISTORTION – dBc

–100

–110

–70

–80

–90

O

PWDN 1,0 = 1,1

200

300

PEAK OUTPUT CURRENT – mA

3RD HARMONIC

2ND HARMONIC

400 500 600 700 800

TPC 15. Differential Distortion vs. Peak Output Current

–90

3RD HARMONIC

–100

DIFFERENTIAL DISTORTION – dBc

–110

3

45 678

OUTPUT VOLTAGE – Volts

TPC 17. Differential Distortion vs. Peak-to-Peak Output

Voltage

DIFFERENTIAL DISTORTION – dBc

–60

–70

–80

–90

–100

–110

2ND HARMONIC

3

45678

OUTPUT VOLTAGE – Volts

VS = ⴞ2.5V

R

= 10⍀

L

G = 4

f

= 100kHz

O

PWDN 1,0 = 1,0 or 0,1

3RD HARMONIC

TPC 18. Differential Distortion vs. Peak-to-Peak Output

Voltage

–6–

REV. 0

Page 7

AD8018

TRANSFORMER TURNS RATIO

P

LINE

– dBm

3.0

16

6

8

10

14

3.2 4.0 4.2 4.4 4.63.4 3.6 3.8

18

12

VS = 4.75

VS = 8.00

VS = 5.00

VS = 3.33

VS = 4.50

4.8

g

16

15

14

13

– dBm

LINE

P

12

11

10

3.0

VS = 5.25

3.2 4.0 4.2 4.4 4.6 4.83.4

3.6

TRANSFORMER TURNS RATIO

VS = 4.75

3.8

VS = 5.00

TPC 19. Line Power vs. Turns Ratio; MTPR = –65 dBc,

f = 43 kHz

–20

–30

–40

–50

MTPR – dBc

–60

–70

–80

3 4

TRANSFORMER TURNS RATIO – N

VS = 5V

R

LINE

f = 93kHz

P = 13dBm

P = 13.5dBm

P = 14dBm

P = 12.5dBm

P = 12dBm

= 100⍀

5

TPC 20. MTPR vs. Turns Ratio

TPC 22. Line Power vs. Turns Ratio; –75 dBc Out-of-Band

SFDR, f = 361 kHz

10M

1M

100k

10k

1k

100

10

TRANSIMPEDANCE – ⍀

1

0.1

0.01

1k 10k 100k 1M 10M 100M 1G

TRANSIMPEDANCE

FREQUENCY – Hz

PHASE

200

150

100

50

0

–50

–100

–150

–200

TPC 23. Open Loop Transimpedance and Phase

rees

PHASE – De

–30

–40

–50

–60

SFDR – dBc

–70

–80

P = 12dBm

–90

3

TRANSFORMER TURNS RATIO – N

4

TPC 21. Out-of-Band SFDR vs. Turns Ratio for Various

VS = 5V

R

LINE

f = 361kHz

P = 12.5dBm

P = 13dBm

P = 13.5dBm

P = 14dBm

= 100⍀

Line Power

REV. 0

20

18

DECREASING

16

14

12

10

TOTAL SUPPLY CURRENT – mA

8

5

6

0.86

0.88 0.90 0.92 0.94 0.96 0.98 1.00 1.02

LOGIC 0 TO 1

POWER-DOWN VOLTAGE – Volts

LOGIC 1 TO 0

INCREASING

TPC 24. Power-Up/-Down Threshold Voltage

–7–

Page 8

AD8018

–10

VIN = 2V p-p

G = 2

–20

V

= ⴞ2.5

S

–30

–40

–50

–60

–70

CROSSTALK – dB

–80

–90

–100

–110

RL = 5

SIDE B DRIVEN

100k

TPC 25. Crosstalk vs. Frequency

THEORY OF OPERATION

The AD8018 is composed of two current feedback amplifiers

capable of delivering 400 mA of output current while swinging

to within 0.5 V of either power supply, and maintaining low

distortion. A differential line driver using the AD8018 can provide

CPE performance on a single 5 V supply. This performance is

enabled by Analog Device’s XFCB process and a novel, twostage current feedback architecture featuring a patent-pending

rail-to-rail output stage.

A simplified schematic is shown in Figure 4. Emitter followers

buffer the positive input, V

, to provide low input current and

P

current noise. The low impedance current feedback summing

junction is at the negative input, V

. The output stage is another

N

high-gain amplifier used as an integrator to provide frequency

compensation. The complementary common-emitter output

provides the extended output swing.

A current feedback amplifier’s dynamic and distortion performance

is relatively insensitive to its closed-loop signal gain, which is

a distinct advantage over a voltage-feedback architecture. Figure

5 shows a simplified model of a current feedback amplifier. The

feedback signal is a current into the inverting node. R

is inversely

IN

proportional to the transconductance of the amplifier’s input stage,

g

. Circuit analysis of the pictured follower with gain yields:

mi

T

ZS

VV G

/

OUT IN

=×

TRGR

ZS F IN

()

()

++×

where:

GRR

=+

1

/

FG

R

/

1

S

CR

+

T

()

TT

Ω

T

=

ZS

()

Rg

=≅

1 125

IN mi

Recognizing that G ⫻ RIN < RF, and that the –3 dB point is set

when T

= RF, one can see that the amplifier’s bandwidth

Z(S)

depends primarily on the feedback resistor. There is a value of

R

below which the amplifier will be unstable, as an actual ampli-

F

fier will have additional poles that will contribute excess phase

shift. The optimum value for R

depends on the gain and the

F

amount of peaking tolerable in the application.

⍀

RL = 5

⍀

SIDE A DRIVEN

RL = 100

SIDE A DRIVEN

1M 10M

FREQUENCY – Hz

RL = 100

⍀

SIDE B DRIVEN

⍀

100M

V

P

V

N

1G

V

O

BIAS

Figure 4. Simplified Schematic

+

V

IN

–

G = 1

V

I

IN

IT = IINCTR

R

F

R

IN

R

G

O

T

+

V

OUT

–

Figure 5. Model of Current Feedback Amplifier

FEEDBACK RESISTOR SELECTION

In current feedback amplifiers, selection of the feedback and gain

resistors will impact on the MTPR performance, bandwidth,

noise, and gain flatness. Care should be exercised in the selection

of these resistors so that the optimum performance is achieved.

Table I shows the recommended resistor values for use in a variety

of gain settings for the test circuit in TPC 1. These values are

intended to be a starting point when designing for any application.

–8–

REV. 0

Page 9

AD8018

Table I. Resistor Selection Guide

Gain RF (⍀)R

(⍀)

G

–1 681 681

+1 1 k ∞

+2 750 750

+3 511 256

+4 340 113

+5 230 59

POWER-DOWN FEATURES

Two digitally programmable logic pins, PWDN1 and PWDN0,

are available on the TSSOP-14 package to select among three

different modes of operation, full power, standby and shutdown.

The DGND pin is the logic ground reference. The logic threshold voltage is established 1 V above DGND. In a typical 5 V

single-supply application, the DGND pin is connected to analog

ground. If PWDN1, PWDN0, and DGND are left unconnected,

the AD8018 will operate at full power.

Table II. Power-Down Features and Truth Table

Supply Output

PWDN0 PWDN1 State Current Impedance

High High Full Power 18 mA Low

Low High Standby 9 mA Low

High Low Standby 9 mA Low

Low Low Disabled 300 µA High

V

IN

0.47F

ERR

ADP3331

C1

IN

SD GND

OUT

FB

ON

OFF

330k⍀

953k⍀

301k⍀

R3

R1

R2

C2

0.47F

E

OUT

V

OUT

Figure 6. ADP3331 LDO

METHOD FOR GENERATING A MIDSUPPLY VOLTAGE

To operate an amplifier on a single voltage supply, a voltage

midway between the supply and ground must be generated to

properly bias the inputs and the outputs.

A voltage divider can be created with two equal value resistors

(Figure 7). There is a trade-off between the power consumed by

the divider and the voltage drop across these resistors due to the

positive input bias currents. Selecting 2.5 kΩ for R1 and R2 will

create a voltage divider that draws only 1 mA from a 5 V supply.

The voltage generated with this topology can vary due to the

temperature coefficient (TC) of resistance. Resistors that are

closely matched and have a low TC will minimize variations in

the voltage reference due to temperature. One should also be

sure to use a decoupling capacitor (0.1 µF) at the node where

is generated.

V

REF

5V

POWER SUPPLY AND DECOUPLING

The AD8018 can be powered with a good quality (i.e., low-noise)

supply anywhere in the range from 3.3 V to 8 V. However, in

order to optimize the ADSL upstream drive capability to +13 dBm

and maintain the best Spurious Free Dynamic Range (SFDR),

the AD8018 circuit should be supplied with a well regulated 5 V

supply. The 5 V supplied at the USB port may be poorly regulated. Improving the quality of the 5 V supply will optimize the

performance of the AD8018 in a USB-supplied CPE ADSL

modem. This can be accomplished through the use of a step-up

dc-to-dc converter or switching power supply followed by a low

dropout (LDO) regulator such as the ADP3331 (see Figure 6).

Setting R1 to be 953 kΩ and R2 to be 301 kΩ will result in a

of 5 V.

V

OUT

Careful attention must be paid to decoupling the power supply

pins at the output of the dc-to-dc converter, the output of the

LDO regulator and the supply pins of the AD8018. High-quality

capacitors with low equivalent series resistance (ESR) such as

multilayer ceramic capacitors (MLCCs) should be used to minimize supply voltage ripple and power dissipation. A large, usually

tantalum, 10 µF to 47 µF capacitor located in proximity to the

AD8018 is required to provide good decoupling for lower frequency signals. In addition, 0.1 µF MLCC decoupling capacitors

should be located as close to each of the power supply pins as is

physically possible, no more than 1/8 inch away. An additional

large (4.7 µF to 10 µF) tantalum capacitor should be placed on the

board near the supply terminals to supply current for fast, largesignal changes at the AD8018 outputs.

R1

2.5k⍀

2.5k⍀

R2

0.1F

V

REF

Figure 7. Midsupply Reference

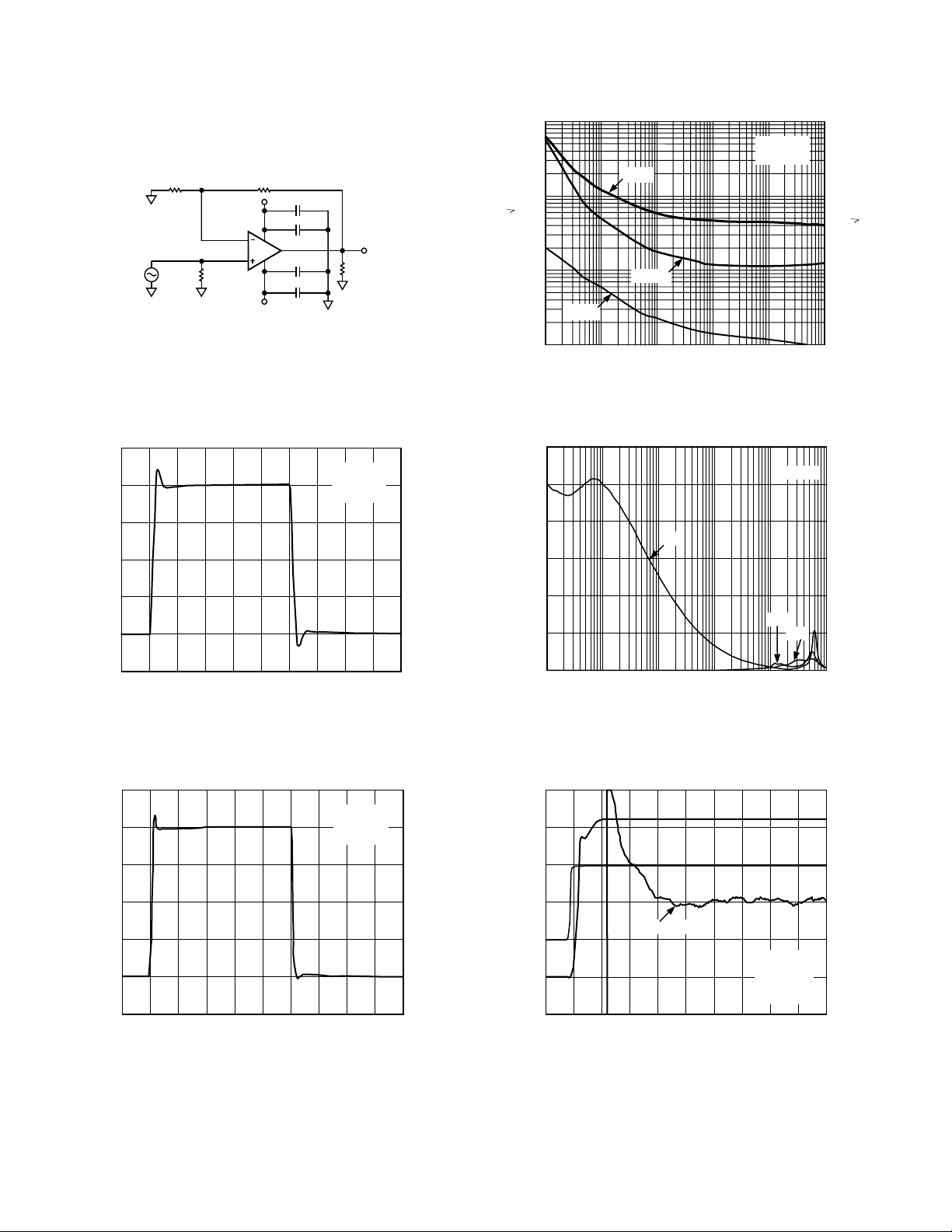

DIFFERENTIAL TESTING

The test circuit shown in TPC 13 is used for measuring the differential distortion of the AD8018. A single-ended test signal is

applied to the inverting input of the AD8138 differential driver

with the noninverting input grounded. Applying the differential

output of the AD8138 through 100 Ω resistors serves to isolate

the inputs of the AD8018 differential driver and provide a wellbalanced low-distortion input signal. The differential load (R

)

L

of the AD8018 can be set to the equivalent of the line impedance reflected through a transformer. The AD9632 converts

the differential output voltage back to a single-ended signal.

The differential-to- single-ended converter using the AD9632

has an attenuation of –26 dB and is wired with precision resistors to optimize the balance of differential input signal. The

resulting smaller output signal can be easily measured using a

50 Ω spectrum analyzer.

REV. 0

–9–

Page 10

AD8018

This circuit requires significant power supply bypassing. The

AD8018 operates on a split supply in this circuit. The bypassing

technique shown in TPC 13 utilizes a 220 µF tantalum capacitor

and a 0.1 µF ceramic chip capacitor in parallel, connected from

the positive to negative supply, and a 10 µF tantalum and 0.1 µF

ceramic chip capacitor in parallel, connected from each supply to

ground. The capacitors connected between the power supplies

serve to minimize any voltage ripples that might appear at the

supplies while sourcing or sinking any large differential current.

The large capacitor has a pool of charge instantly available for

the AD8018 to draw from, thus preventing any erroneous distortion results.

POWER DISSIPATION

It is important to consider the total power dissipation of the

AD8018 in order to properly size the heat sink area of an

application. Figure 8 is a simple representation of a differential

driver. With some simplifying assumptions we can estimate the

total power dissipated in this circuit. If the output current is

large compared to the quiescent current, computing the dissipation in the output devices and adding it to the quiescent power

dissipation will give a close approximation of the total power

dissipation in the package. A factor α (~0.6-1) corrects for the

slight error due to the Class A/B operation of the output stage.

It can be estimated by subtracting the quiescent current in the

output stage from the total quiescent current and ratioing that

to the total quiescent current. For the AD8018, α = 0.833.

1

P V rms V V rms

=×++408

TOT O S O

(. – ) α

2

R

L

IV P

2

Q S OUT

For the AD8018, operating on a single 5 V supply and delivering a total of 16 dBm (13 dBm to the line and 3 dBm to the

matching network) into 12.5 Ω (100 Ω reflected back through

a 1:4.0 transformer plus back termination), the power is:

= 261 mW + 40 mW

= 301 mW

Using these calculations, and a θ

of 115°C/W for the TSSOP

JA

package and 100°C/W for the SOIC, Tables III and IV show

junction temperature versus power delivered to the line for several supply voltages.

Table III. Junction Temperature vs. Line Power and

V

SUPPLY

AMB

= 85ⴗC

Operating Voltage for TSSOP, T

P

LINE

56 7 8

13 115 122 129 136

14 117 125 132 140

15 119 127 136 144

16 121 130 139 148

17 123 133 143 153

18 125 136 147 158

+V

S

+V

O

R

L

–V

S

–V

+V

S

O

–V

S

Figure 8. Simplified Differential Driver

Remembering that each output device dissipates for only half

the time gives a simple integral that computes the power for

each device:

1

2

( – )VV

SO

∫

V

2

O

×

R

L

The total supply power can then be computed as:

2

PVVV

TOT S O O

=

−

|| α

∫

∫

1

×+ +4

2

IV P

R

L

Q S OUT

In this differential driver, VO is the voltage at the output of one

amplifier, so 2 V

is the voltage across RL, which is the total

O

impedance seen by the differential driver, including back termination. Now, with two observations, the integrals are easily

evaluated. First, the integral of V

rms value of V

. Second, the integral of |VO| is equal to the

O

average rectified value of V

2

is simply the square of the

O

, sometimes called the Mean Aver-

O

age Deviation, or MAD. It can be shown that for a DMT signal,

the MAD value is equal to 0.8 times the rms value.

–10–

Table IV. Junction Temperature vs. Line Power and

Operating Voltage for SOIC, T

P

dBm 5 6 7 8

LINE,

AMB

V

SUPPLY

= 85ⴗC

13 111 117 123 129

14 113 119 126 133

15 115 122 129 136

16 116 124 132 140

17 118 127 136 144

18 120 130 139 149

Running the AD8018 at voltages near 8 V can produce junction

temperatures that exceed the thermal rating of the TSSOP packages and should be avoided. The shaded areas indicate junction

temperatures greater than 150°C.

LAYOUT CONSIDERATIONS

As is the case with all high-speed applications, careful attention

to printed circuit board layout details will prevent associated

board parasitics from becoming problematic. Proper RF design

technique is mandatory. The PCB should have a ground plane

covering all unused portions of the component side of the board

to provide a low-impedance return path. Removing the ground

plane on all layers from the area near the input and output pins

will reduce stray capacitance, particularly in the area of the

inverting inputs. Signal lines connecting the feedback and gain

resistors should be as short as possible to minimize the inductance

and stray capacitance associated with these traces. Termination

resistors and loads should be located as close as possible to their

respective inputs and outputs. Input and output traces should

be kept as far apart as possible to minimize coupling (crosstalk)

though the board. Adherence to stripline design techniques for

long signal traces (greater than about 1 inch) is recommended.

REV. 0

Page 11

AD8018

Following these generic guidelines will improve the performance

of the AD8018 in all applications.

To optimize the AD8018’s performance as an ADSL differential

line driver, locate the transformer hybrid near the AD8018 drivers

and as close to the RJ11 jack as possible. Maintain differential

circuit symmetry into the differential driver and from the output

of the drivers through the transformer-coupled output of the bridge

circuit as much as possible.

CPE ADSL Application

The low-cost, high-output current dual AD8018 xDSL driver

amplifiers have been specifically designed to drive high fidelity

xDSL signals to within 0.5 V of the power rails, the performance

needed to provide CPE ADSL on a single 5 V supply. The

AD8018 may be used in transformer-coupled bridge hybrid circuits to drive modulated signals including Discrete MultiTone

(DMT) upstream to the central office.

Evaluation Board

The AD8018ARU-EVAL evaluation board circuit in Figure 12

offers the ability to evaluate the AD8018 in a typical xDSL bridge

hybrid circuit.

The receiver circuit on these boards is typically unpopulated.

Requesting samples of the AD8022AR with the AD8018ARUEVAL board will provide the capability to evaluate the

AD8018ARU along with other Analog Devices products in a typical transceiver circuit. The evaluation circuits have been designed

to replicate the CPE side analog transceiver hybrid circuits.

The circuit mentioned above is designed using a one-transformer

transceiver topology including a line receiver, line driver, line

matching network, an RJ11 jack for interfacing to line simulators,

and transformer-coupled inputs for single-ended-to-differential

input conversion.

AC-coupling capacitors of 0.01 µF, C8, and C10, in combina-

tion with 10 kΩ resistors R24 and R25, will form a zero frequency

at 1.6 kHz.

Transformer Selection

Customer premise ADSL requires the transmission of a +13 dBm

(20 mW) DMT signal. The DMT signal can have a crest factor

as high as 5.3, requiring the line driver to provide peak line power

of 27.5 dBm (560 mW). 27.5 dBm peak line power translates

into a 7.5 V peak voltage on the 100 Ω telephone line. Assuming

that the maximum low-distortion output swing available from

the AD8018 line driver on a 5 V supply is 4 V and, taking into

account the power lost due to the termination resistance, a step-up

transformer with turns ratio of 4.0 or greater is needed.

In the simplified differential drive circuit shown in Figure 2, the

AD8018 is coupled to the phone line through a step-up transformer with a 1:4 turns ratio. R1 and R2 are back-termination

or line-matching resistors, each 3.1 Ω (100 Ω/(2 × 4

100 Ω is the approximate phone line impedance. The total differential load for the AD8018, including the termination resistors,

is 12.5 Ω. Even under these conditions the AD8018 provides low

distortion signals to within 0.5 V of the power rails.

2

)), where

Stability Enhancements

The CPE bridge hybrid circuit presents a complex impedance to

the drive amplifiers, particularly when transformer parasitics are

factored in. To ensure stable operation under the full range of

load conditions, a series R-C network (Zoebel Network) should

be connected between each amplifier’s output and ground. The

recommended values are 10 Ω for the resistor and 1 nF for the

capacitor to create a low impedance path to ground at frequencies above 16 MHz (see Figure 2). R33 and R34 are added to

improve common-mode stability.

Receive Channel Considerations

A transformer used at the output of the differential line driver to

step up the differential output voltage to the line has the inverse

effect on signals received from the line. A voltage reduction

or attenuation equal to the inverse of the turns ratio is realized

in the receive channel of a typical bridge hybrid. The turns ratio

of the transformer may also be dictated by the ability of the receive

circuitry to resolve low-level signals in the noisy twisted pair telephone plant. Higher turns ratio transformers effectively reduce the

received signal-to-noise ratio due to the reduction in the received

signal strength.

The AD8022, a dual amplifier with typical RTI voltage noise of

only 2.5 nV/√Hz and a low supply current of 4 mA/amplifier, is

recommended for the receive channel.

DMT Modulation, MultiTone Power Ratio (MTPR), and

Out-of-Band SFDR

ADSL systems rely on DMT modulation to carry digital data

over phone lines. DMT modulation appears in the frequency

domain as power contained in several individual frequency

subbands, sometimes referred to as tones or bins, each of which

is uniformly separated in frequency. A uniquely encoded, Quadrature Amplitude Modulation (QAM)-like signal occurs at the center

frequency of each subband or tone. See Figure 9 for an example

of a DMT waveform in the frequency domain, and Figure 10 for

a time domain waveform. Difficulties will exist when decoding

these subbands if a QAM signal from one subband is corrupted

by the QAM signal(s) from other subbands, regardless of whether

the corruption comes from an adjacent subband or harmonics of

other subbands.

Conventional methods of expressing the output signal integrity

of line drivers, such as single-tone harmonic distortion or THD,

two-tone InterModulation Distortion (IMD), and third order

intercept (IP3), become significantly less meaningful when

amplifiers are required to process DMT and other heavily

modulated waveforms. A typical ADSL upstream DMT signal

can contain as many as 27 carriers (subbands or tones) of

QAM signals. MultiTone Power Ratio (MTPR) is the relative

difference between the measured power in a typical subband (at

one tone or carrier) versus the power at another subband specifically selected to contain no QAM data. In other words, a

selected subband (or tone) remains open or void of intentional

power (without a QAM signal), yielding an empty frequency bin.

MTPR, sometimes referred to as the “empty bin test,” is

typically expressed in dBc, similar to expressing the relative

difference between single-tone fundamentals and second or

third harmonic distortion components. Measurements of MTPR

are typically made on the line side or secondary side of the

transformer.

REV. 0

–11–

Page 12

AD8018

20

0

–20

–40

POWER – dBm

–60

–80

0 150

50

FREQUENCY – kHz

100

Figure 9. DMT Waveform in the Frequency Domain

MTPR versus transformer turns ratio is depicted in TPC 21 and

covers a variety of line power ranging from +12 dBm to +14 dBm.

As the turns ratio increases, the driver hybrid can deliver more

undistorted power due to higher output current capability.

Significant degradation of MTPR will occur if the output of the

driver swings to the rails, causing clipping at the DMT voltage

peaks. Driving DMT signals to such extremes not only compromises “in-band” MTPR, but will also produce spurs that exist

outside of the frequency spectrum containing the desired DMT

power. “Out-of-band” spurious free dynamic range (SFDR) can

be defined as the relative difference in amplitude between these

spurs and a tone in one of the upstream bins. Compromising

out-of-band SFDR is equivalent to increasing near end crosstalk (NEXT). Regardless of terminology, maintaining out-of-band

SFDR while reducing NEXT will improve the overall performance

of the modems connected at either end of the twisted pair.

TPC 21 shows how SFDR varies versus transformer turns ratio

for line power ranging from +12 dBm to +14 dBm. As line

power increases, or turns ratio decreases, SFDR degrades. The

power contained in the spurs can be measured relative to the

power contained in a typical upstream carrier and is expressed

in dBc as SFDR, similar to MTPR.

The supply voltage of the driver can also affect SFDR. As the

supply voltage is increased, voltage swing is increased as well,

resulting in the ability to deliver more power to the line without sacrificing performance. This can be seen in TPC 22. Less

undistorted power is available when lower turns ratio transformers are used due to voltage clipping of the signal.

4

3

2

1

VOLTS

0

–1

–2

–3

–0.25

–0.2 –1.5 –1.0

–0.05

TIME – ms

0

0.05 1.0

1.5

0.2

Figure 10. DMT Signal in the Time Domain

Generating DMT Signals

At this time, DMT-modulated waveforms are not typically

menu-selectable items contained within AWGs. Even using

AWG software to generate DMT signals, AWGs that are available

today may not deliver DMT signals sufficient in performance

with regard to MTPR due to limitations in the D/A converters

and output drivers used by AWG manufacturers. Similar to

evaluating single-tone distortion performance of an amplifier,

MTPR evaluation requires a DMT signal generator capable of

delivering MTPR performance better than that of the driver

under evaluation. Generating DMT signals can be accomplished using a Tektronics AWG 2021 equipped with Option

4, (12-/24-bit, TTL Digital Data Out), digitally coupled to

Analog Devices’ AD9754, a 14-bit TxDAC

®

, buffered by an

AD8002 amplifier configured as a differential driver. Note that

the DMT waveforms (available on the Analog Devices website,

http://www.analog.com), or similar .WFM files are needed to

produce the digital data required to drive the TxDAC from the

optional TTL Digital Data output of the TEK AWG2021.

TxDAC is a trademark of Analog Devices, Inc.

–12–

REV. 0

Page 13

AD8018

55

P4 1

P4 2

P4 3

56

R17

2.49k⍀

R16

2.49k⍀

R30

0⍀

V

B

A

B

A

V

R31

0⍀

C20

0.1F

TP10

C8

0.1F

R11

CC

50⍀

C10

0.1F

53

P3 3

P3 2

P3 1

54

R24

10k⍀

R29

10k⍀

3

2

JP4

1

C28

DNI

3

2

JP3

1

R15

50⍀

CC

TP11

V

CC

V

CC

2

0.1F

C5

R8

100⍀

V

CC

2

R14

100⍀

TP17

TP18

R2

750⍀

VCC-R

AGND;4

V

AGND;4

VCC-T

U1

AD8018

R18

750⍀

R19

750⍀

U1

AD8018

VCC-T

VCC-R

;8

CC

+V

10k⍀

10k⍀

+V

U2

AD8022

DNI

R6

DNI

R7

DNI

U2

AD8022

DNI

R33

R34

DNI

TP6

R20

DNI

R3

10⍀

1

R1

10⍀

1WATT

2

R4

10⍀

R21

DNI

TP8

R12

DNI

C1

DNI

R9

DNI

V

CC

2

R5

R10

DNI

C16

DNI

C11

DNI

C22

1000pF

C27

1000pF

C12

DNI

C2

DNI

C18

DNI

C3

DNI

TP7

TP9

TP4

TP5

PR1

PR2

TB1 1

CAPPOLY

CAPPOLY

2TB1

C4

DNI

NC = 5,6

4

2

3

1

C7

DNI

TP23 TP24 TP25 TP26

L5

BEAD

C14

10F

T1

C9

DNI

7

CAPPOLY

9

8

10

C26

0.1F

U2 DECOUPLING

CAPPOLY

C6

DNI

TP1

TP2

C15

0.01F

C23

DNI

R32

DNI

1

2

3

4

5

6

TP19

C17

10F

25V

C19

DNI

25V

78

VCC-T

V

CC

-R

DNI: DO NOT INSTALL

R27

DNI

JP1

R13

DNI

Figure 11. EVAL Board Schematic

V

CC

R28

DNI

100⍀

JP2

R26

100⍀

R25

0.1F

C24

0.1F

C25

PDN0

PDN1

DGND

Figure 12. Input Control Circuit

U1

AD8018

NC1 NC2 NC3

REV. 0

–13–

Page 14

AD8018

Figure 13. Assembly—Primary Side

Figure 14. Silk Screen—Primary Side

–14–

REV. 0

Page 15

Figure 15. Layer 1—Primary Side

AD8018

REV. 0

Figure 16. Layer 2—Ground Plane

–15–

Page 16

AD8018

Figure 17. Layer 3—Power Plane

Figure 18. Layer 4—Secondary Side

–16–

REV. 0

Page 17

AD8018

Figure 19. Assembly—Secondary Side

REV. 0

–17–

Page 18

AD8018

EVALUATION BOARD—BILL OF MATERIALS

Qty. Description Vendor Ref Desc.

2 1,000 pF 50 V. 1206 ceramic chip capacitor ADS # 4-5-20 C22, 27

2 0.01 µF 50 V. 1206 ceramic chip capacitor ADS # 4-5-19 C15, 23

5 0.1 µF 50 V. 1206 size ceramic chip capacitor ADS # 4-5-18 C5, 20, 24 -26

2 1.0 µF 16 V. 1206 size ceramic chip capacitor Newark # 83F6841 C8, 10

4 # 26 red (solid) wire jumper ADS # 10-14-3 C4, 6, 7, 9

3 10 µF 16 V. ‘C’ size Tantalum chip capacitor ADS # 4-7-6 C14, 17, 19

1 Ferrite bead (with # 22 wire) ADS # 48-1-1 L5

1 10 Ω 5% 3.0 W. metal oxide power resistor D-K # P10W-3BK-ND R1

60 Ω 5% 1/8 W. 1206 size chip resistor ADS # 3-18-88 C11, 12, R20, 21, 30, 31

2 10.0 Ω 1% 1/8 W. 1206 size chip resistor ADS # 3-18-120 R3, 4

2 49.9 Ω 1% 1/8 W. 1206 size chip resistor ADS # 3-14-26 R11, 15

5 100 Ω 1% 1/8 W. 1206 size chip resistor ADS # 3-18-40 R 8, 14, 25, 26, 32

2 2.49 kΩ 1% 1/8 W. 1206 size chip resistor ADS # 3-18-71 R16, 17

3 750 Ω 1% 1/8 W. 1206 size chip resistor ADS # 3-18-8 R2, 18, 19

2 10.0 kΩ 0.1% 0805 size chip resistor ADS # 3-36-5 R33, 34

2 10.0 kΩ 1% 1/8 W. 1206 size chip resistor ADS # 3-18-119 R24 and 29

4 Test Point (Black) [GND] ADS # 12-18-44 TP23–26 (GND.)

2 Test Point (Brown) ADS # 12-18-59 TP4, 5

3 Test Point (Red) ADS # 12-18-43 TP17–19

4 Test Point (Orange) ADS # 12-18-60 TP1, 2, 10, 11

1 Test Point (Yellow) ADS # 12-18-32 TP3

2 Test Point (Blue) ADS # 12-18-62 TP6, 8

2 Test Point (Green) ADS # 12-18-61 TP7, 9

12 × 5-pin strips (1/4 of a 20-pin Samtek ‘SIP’ strip socket) ADS # 11-2-14 (T1)

1 2 Pos. GRAY term. blk. # 25.161.0253 (Newark # 51F4106) ADS# 12-19-10 TB1, 2

4 0.1 inch ctr. shunt Berg # 65474 -001 ADS # 11-2-38 JP1–4

2 2 pin gold male header 0.1 inch ctr. Berg # 69157 -102 ADS # 11-2-37 JP1, 2

4 50 Ω BNC pc mount Telegartner # J01001A1944 ADS # 12-6-22 S3–6

1 AMP# 555154 -1 MOD. JACK (SHIELDED) 6 –6 ADS # 12-20-5 P1

2 3-pin gold male header Waldom D-K # WM 2723 -ND ADS # 12-3-80 JP3, 4

2 3-pin gold male locking header Waldom # WM 2701 -ND ADS # 12-3-79 P3, 4

1 AD8018ARU ADSL Driver hybrid ADS # AD8018ARU U1 (D.U.T.)

1 AD8018 TSSOP1T Non-Inverting REV. A Evaluation PC board D C S Eval. PC Board

4# 4 –40 × 1/4" panhead ss machine screw ADS # 30-1-1

4# 4 –40 × 1/2" threaded alum. standoffs ADS # 30-16-2

–18–

REV. 0

Page 19

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

AD8018

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

8 Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

85

1

0.0500 (1.27)

PLANE

CONTROLLING DIMENSIONS ARE IN MILLIMETERS

ALL DIMENSIONS PER JEDEC STANDARDS MS-012 AA

BSC

0.020 (0.51)

0.013 (0.33)

0.2440 (6.20)

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8ⴗ

0.050 (1.27)

0ⴗ

0.016 (0.40)

ⴛ 45ⴗ

0.177 (4.50)

0.173 (4.40)

0.169 (4.30)

0.059 (1.50)

0.093 (1.00)

0.031 (0.80)

14 Lead TSSOP

(RU-14)

0.201 (5.10)

0.197 (5.00)

0.193 (4.90)

14

PIN 1

0.0256 (0.65)

BSC

0.006 (0.15)

0.002 (0.05)

CONTROLLING DIMENSIONS ARE IN MILLIMETERS

0.047 (1.2)

0.0118 (0.30)

0.0075 (0.19)

8

71

MAX

SEATING

PLANE

0.252

(6.40)

BSC

0.008 (0.20)

0.004 (0.09)

C01519–4.5–7/00 (rev. 0)

8ⴗ

0ⴗ

0.030 (0.75)

0.024 (0.60)

0.018 (0.45)

REV. 0

PRINTED IN U.S.A.

–19–

Loading...

Loading...