Datasheet AD8012ARM-REEL7, AD8012ARM-REEL, AD8012ARM, AD8012AR-REEL7, AD8012AR-REEL Datasheet (Analog Devices)

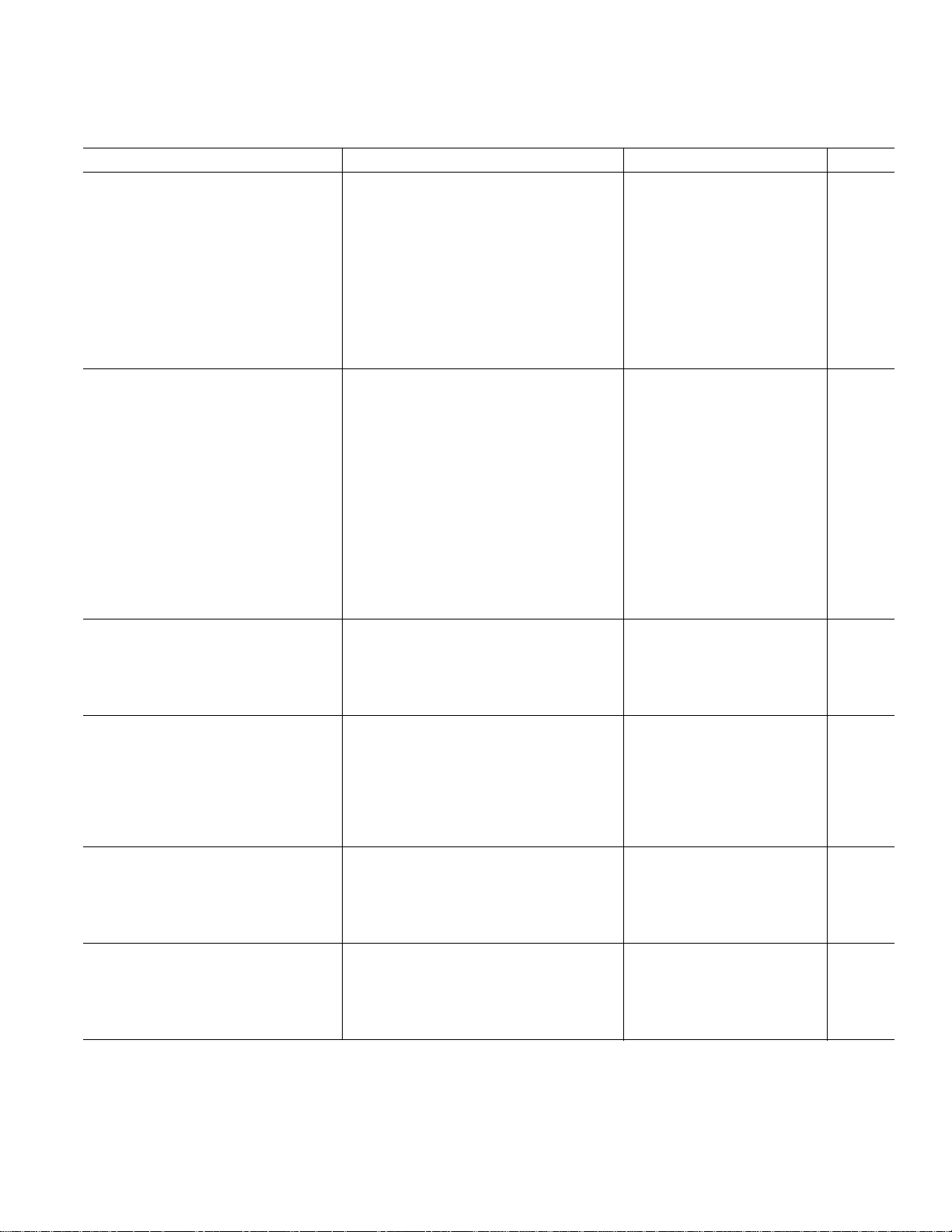

...Page 1

Dual 350 MHz

AMP 1

V

IN

V

REF

R2

R1

RL = 100V

OR

135V

V

OUT

Np:Ns

TRANSFORMER

LINE

POWER

IN dB

+V

S

+

–

–V

S

+

–

a

FEATURES

Low Power

1.7 mA/Amplifier Supply Current

Fully Specified for ⴞ5 V and +5 V Supplies

High Output Current, 125 mA

High Speed

350 MHz, –3 dB Bandwidth (G = +1)

150 MHz, –3 dB Bandwidth (G = +2)

2,250 V/s Slew Rate

20 ns Settling Time to 0.1%

Low Distortion

–72 dBc Worst Harmonic @ 500 kHz, R

–66 dBc Worst Harmonic @ 5 MHz, R

Good Video Specifications (R

= 1 k⍀, G = +2)

L

0.02% Differential Gain Error

0.06ⴗ Differential Phase Error

Gain Flatness 0.1 dB to 40 MHz

60 ns Overdrive Recovery

Low Offset Voltage, 1.5 mV

Low Voltage Noise, 2.5 nV/√Hz

Available in 8-Lead SOIC and 8-Lead microSOIC

APPLICATIONS

XDSL, HDSL Line Driver

ADC Buffer

Professional Cameras

CCD Imaging System

Ultrasound Equipment

Digital Camera

PRODUCT DESCRIPTION

The AD8012 is a dual low power current feedback amplifier

capable of providing 350 MHz bandwidth while using only

1.7 mA per amplifier. It is intended for use in high frequency,

wide dynamic range systems where low distortion, high speed

are essential and low power is critical.

With only 1.7 mA of supply current, the AD8012 also offers

exceptional ac specs such as 20 ns settling time and 2,250 V/µs

slew rate. The video specifications are 0.02% differential gain

and 0.06 degree differential phase, excellent for such a low power

amplifier. In addition, the AD8012 has a low offset of 1.5 mV.

The AD8012 is well suited for any application that requires high

performance with minimal power.

The product is available in standard 8-lead SOIC or microSOIC packages and operates over the industrial temperature

range –40°C to +85°C.

= 100 ⍀

L

= 1 k⍀

L

Low Power Amplifier

AD8012

FUNCTIONAL BLOCK DIAGRAM

+V

2nd

3rd

8

S

OUT2

7

6

–IN2

+IN2–V

5

G = +2

= 2V p-p

V

OUT

R

= 750V

F

OUT1

1

2

–IN1

3

+IN1

4

S

AD8012

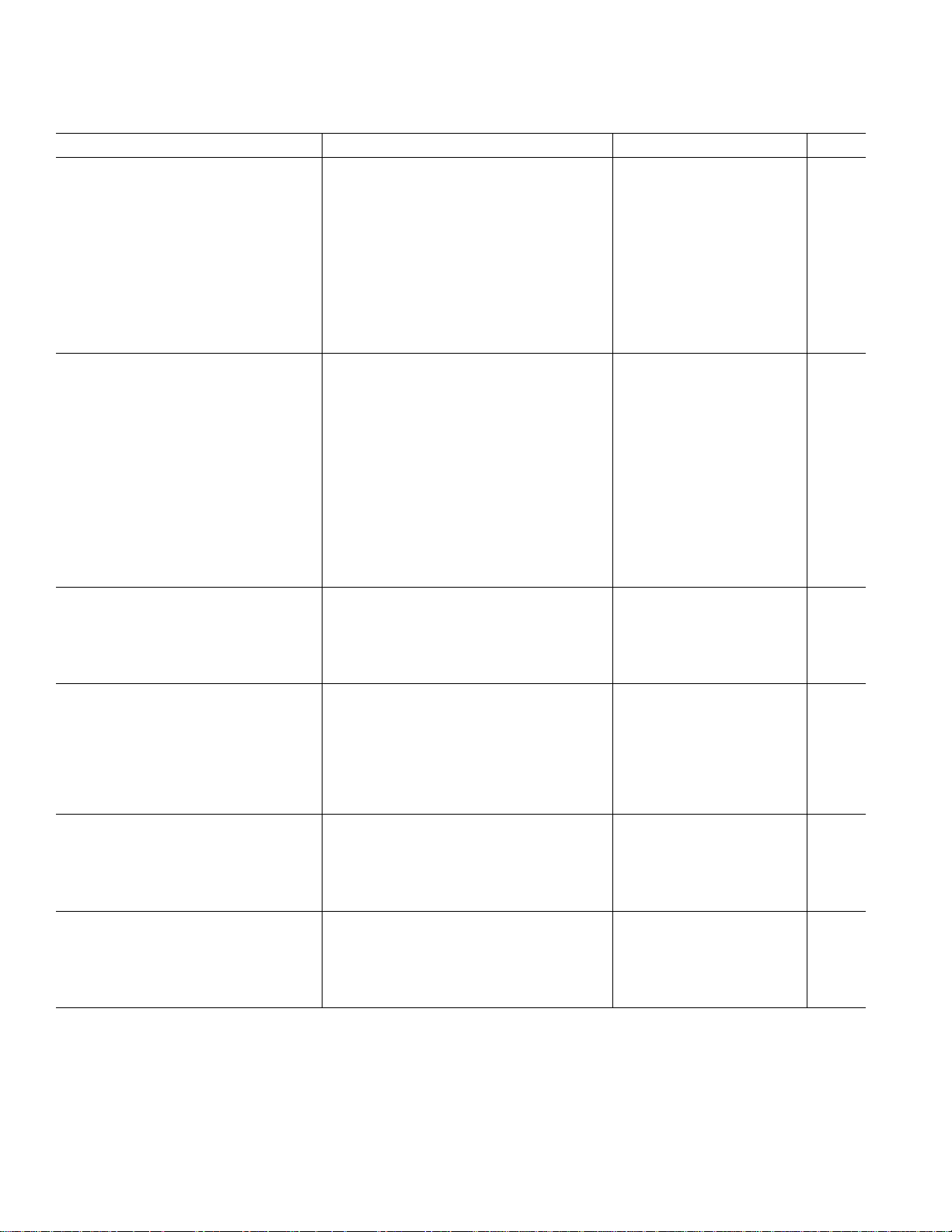

–40

–50

–60

–70

DISTORTION – dBc

–80

–90

10 1k100

RL – V

Figure 1. Distortion vs. Load Resistance, VS = ±5 V,

Frequency = 500 kHz

Figure 2. Differential Drive Circuit for XDSL Applications

*

*Protected under U.S. Patent Number 5,537,079.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD8012–SPECIFICATIONS

DUAL SUPPLY

(@ TA = +25ⴗC, VS = ⴞ5 V, G = +2, RL = 100 ⍀, RF = RG = 750 ⍀, unless otherwise noted)

Parameter Conditions Min Typ Max Units

DYNAMIC PERFORMANCE

–3 dB Small Signal Bandwidth G = +1, V

G␣ =␣ +2, V

G␣ =␣ +2, V

0.1 dB Bandwidth V

Large Signal Bandwidth V

Slew Rate V

Rise and Fall Time V

< 0.4 V p-p, R

OUT

= 4 V p-p 75 MHz

OUT

= 4 V p-p 2,250 V/µs

OUT

= 2 V p-p 3 ns

OUT

Settling Time 0.1%, V

0.02%, V

< 0.4 V p-p, R

OUT

< 0.4 V p-p, R

OUT

< 0.4 V p-p, R

OUT

= 2 V p-p 20 ns

OUT

= 2 V p-p 35 ns

OUT

= 1 kΩ/100 Ω 40/23 MHz

L

= 1 kΩ 270 350 MHz

L

= 1 kΩ 95 150 MHz

L

= 100 Ω 90 MHz

L

Overdrive Recovery 2× Overdrive 60 ns

NOISE/HARMONIC PERFORMANCE

Distortion V

2nd Harmonic 500 kHz, R

3rd Harmonic 500 kHz, R

Output IP3 500 kHz, ∆f = 10 kHz, R

IMD 500 kHz, ∆f = 10 kHz, R

Crosstalk 5 MHz, R

= 2 V p-p, G = +2

OUT

5 MHz, R

5 MHz, R

= 1 kΩ/100 Ω –89/–73 dBc

L

= 1 kΩ/100 Ω –78/–62 dBc

L

= 1 kΩ/100 Ω –84/–72 dBc

L

= 1 kΩ/100 Ω –66/–52 dBc

L

= 100 Ω –70 dB

L

= 1 kΩ/100 Ω 30/40 dBm

L

= 1 kΩ/100 Ω –79/–77 dBc

L

Input Voltage Noise f = 10 kHz 2.5 nV/√Hz

Input Current Noise f = 10 kHz,␣ +Input, –Input 15 pA/√Hz

Differential Gain f = 3.58 MHz, R

Differential Phase f = 3.58 MHz, R

= 150 Ω/1 kΩ, G = +2 0.02/0.02 %

L

= 150 Ω/1 kΩ, G = +2 0.3/0.06 Degrees

L

DC PERFORMANCE

Input Offset Voltage ±1.5 ±4mV

Open-Loop Transimpedance V

T

MIN–TMAX

= ±2 V, RL = 100 Ω 240 500 kΩ

OUT

T

MIN–TMAX

200 kΩ

±5mV

INPUT CHARACTERISTICS

Input Resistance +Input 450 kΩ

Input Capacitance +Input 2.3 pF

Input Bias Current +Input, –Input ±3 ±12 µA

Common-Mode Rejection Ratio V

+Input, –Input, T

= ±2.5 V –56 –60 dB

CM

MIN–TMAX

±15 µA

Input Common-Mode Voltage Range ±3.8 ±4.1 V

OUTPUT CHARACTERISTICS

Output Resistance G = +2 0.1 Ω

Output Voltage Swing ±3.85 ±4V

Output Current T

MIN–TMAX

70 125 mA

Short Circuit Current 500 mA

POWER SUPPLY

Supply Current/Amp 1.7 1.8 mA

T

MIN–TMAX

1.9 mA

Operating Range Dual Supply ±1.5 ±6.0 V

Power Supply Rejection Ratio –58 –60 dB

Specifications subject to change without notice.

–2– REV. A

Page 3

AD8012

SINGLE SUPPLY

(@ TA +25ⴗC, VS = +5 V, G = +2, RL = 100 ⍀, RF = RG = 750 ⍀, unless otherwise noted)

Parameter Conditions Min Typ Max Units

DYNAMIC PERFORMANCE

–3 dB Small Signal Bandwidth G = +1, V

G␣ =␣ +2, V

G␣ =␣ +2, V

0.1 dB Bandwidth V

Large Signal Bandwidth V

Slew Rate V

Rise and Fall Time V

< 0.4 V p-p, R

OUT

= 2 V p-p 60 MHz

OUT

= 3 V p-p 1,200 V/µs

OUT

= 2 V p-p 2 ns

OUT

Settling Time 0.1%, V

0.02%, V

< 0.4 V p-p, R

OUT

< 0.4 V p-p, R

OUT

< 0.4 V p-p, R

OUT

= 2 V p-p 25 ns

OUT

= 2 V p-p 40 ns

OUT

= 1 kΩ/100 Ω 43/24 MHz

L

= 1 kΩ 220 300 MHz

L

= 1 kΩ 90 140 MHz

L

= 100 Ω 85 MHz

L

Overdrive Recovery 2× Overdrive 60 ns

NOISE/HARMONIC PERFORMANCE

Distortion V

2nd Harmonic 500 kHz, R

3rd Harmonic 500 kHz, R

Output IP3 500 kHz, R

IMD 500 kHz, R

Crosstalk 5 MHz, R

= 2 V p-p, G = +2

OUT

5 MHz, R

5 MHz, R

= 1 kΩ/100 Ω –87/–71 dBc

L

= 1 kΩ/100 Ω –77/–61 dBc

L

= 1 kΩ/100 Ω –89/–72 dBc

L

= 1 kΩ/100 Ω –78/–52 dBc

L

= 1 kΩ/100 Ω 30/40 dBm

L

= 1 kΩ/100 Ω –77/–80 dBc

L

= 100 Ω –70 dB

L

Input Voltage Noise f = 10 kHz 2.5 nV/√Hz

Input Current Noise f = 10 kHz,␣ +Input, –Input 15 pA/√Hz

Black Level Clamped to +2 V, f = 3.58 MHz

Differential Gain R

Differential Phase R

= 150 Ω/1 kΩ 0.03/0.03 %

L

= 150 Ω/1 kΩ 0.4/0.08 Degrees

L

DC PERFORMANCE

Input Offset Voltage ±1 ±3mV

±4mV

Open-Loop Transimpedance V

T

MIN–TMAX

= 2 V p-p, R

OUT

T

MIN–TMAX

= 100 Ω 200 400 kΩ

L

150 kΩ

INPUT CHARACTERISTICS

Input Resistance +Input 450 kΩ

Input Capacitance +Input 2.3 pF

Input Bias Current +Input, –Input ±3 ±12 µA

Common-Mode Rejection Ratio V

+Input, –Input, T

= 1.5 V to 3.5 V –56 –60 dB

CM

MIN–TMAX

±15 µA

Input Common-Mode Voltage Range 1.5 to 3.5 1.2 to 3.8 V

OUTPUT CHARACTERISTICS

Output Resistance G = +2 0.1 Ω

Output Voltage Swing 1 to 4 0.9 to 4.2 V

Output Current T

MIN–TMAX

50 100 mA

Short Circuit Current 500 mA

POWER SUPPLY

Supply Current/Amp 1.55 1.75 mA

T

MIN–TMAX

1.85 mA

Operating Range Single Supply 3 12 V

Power Supply Rejection Ratio –58 –60 dB

Specifications subject to change without notice.

–3–REV. A

Page 4

AD8012

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply␣ Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.6␣ V

Internal␣ Power␣ Dissipation

2

1

Small␣ Outline␣ Package (R) . . . . . . . . . . . . . . . . . . . . . 0.8␣ W

microSOIC Package (RM) . . . . . . . . . . . . . . . . . . . . . 0.6 W

Input Voltage (Common Mode) . . . . . . . . . . . . . . . . . . . ±V

S

Differential␣ Input␣ Voltage . . . . . . . . . . . . . . . . . . . . . . ±2.5␣ V

Output Short Circuit Duration

␣ ␣ . . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range RM, R . . . . . . –65°C to +125°C

Operating Temperature Range (A Grade) . . –40°C to +85°C

Lead Temperature Range (Soldering␣ 10␣ sec) . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air at +25°C

8-Lead SOIC Package: θJA = 155°C/W

8-Lead microSOIC Package: θJA = 200°C/W

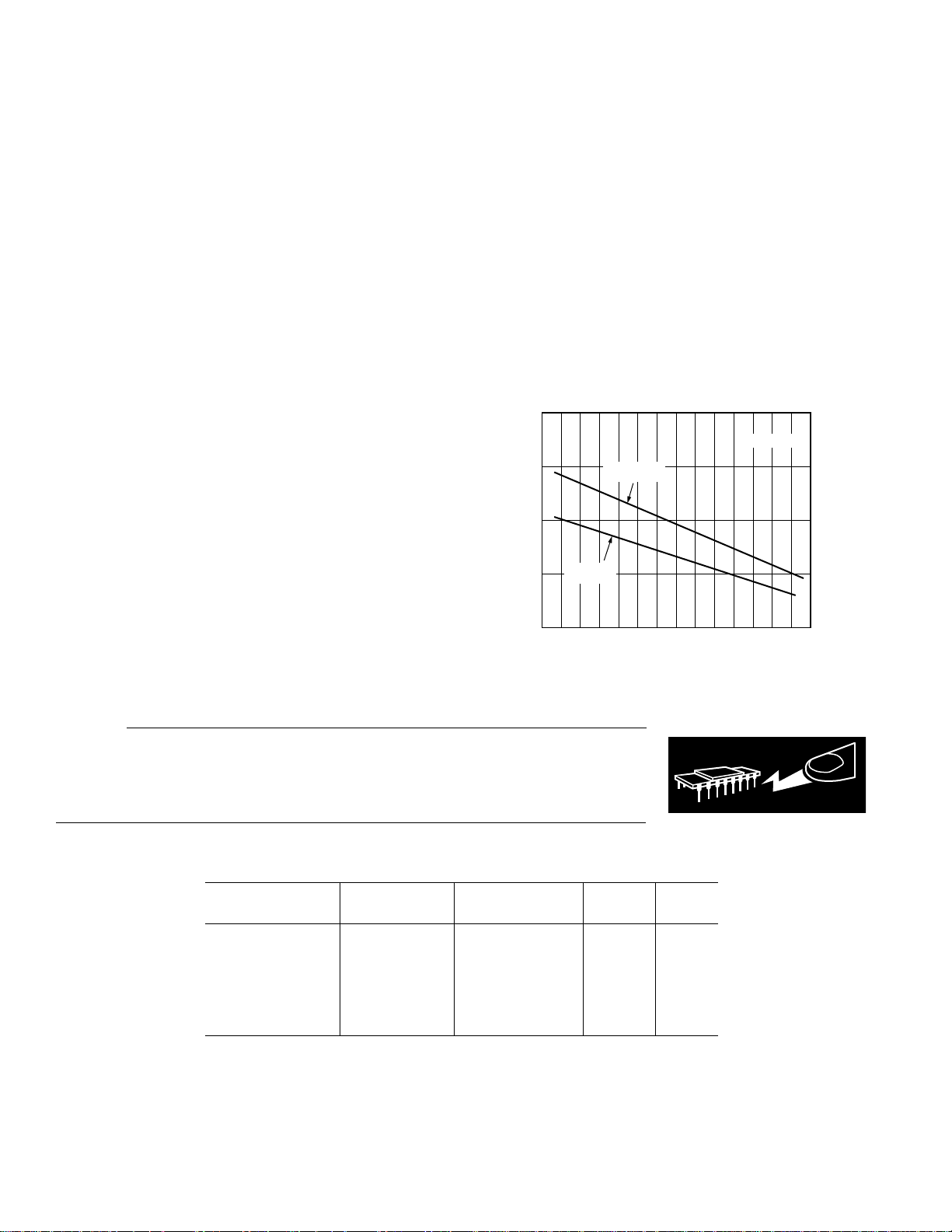

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the AD8012

is limited by the associated rise in junction temperature. The maximum safe junction temperature for plastic encapsulated devices

is determined by the glass transition temperature of the plastic,

approximately +150°C. Temporarily exceeding this limit may

cause a shift in parametric performance due to a change in the

stresses exerted on the die by the package. Exceeding a junction

temperature of +175°C for an extended period can result in device failure.

The output stage of the AD8012 is designed for maximum load

current capability. As a result, shorting the output to common

can cause the AD8012 to source or sink 500 mA. To ensure

proper operation, it is necessary to observe the maximum power

derating curves. Direct connection of the output to either power

supply rail can destroy the device.

2.0

TJ = +1508C

1.5

1.0

8-LEAD SOIC

PACKAGE

0

–50

8-LEAD

microSOIC

–40 –30

0 102030405060708090

–20 –10

AMBIENT TEMPERATURE – 8C

0.5

MAXIMUM POWER DISSIPATION – Watts

Figure 3. Plot of Maximum Power Dissipation vs.

Temperature for AD8012

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8012 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ORDERING GUIDE

Temperature Package Package Brand

Model Range Description Options Code

AD8012AR –40°C to +85°C 8-Lead SOIC SO-8

AD8012AR-REEL –40°C to +85°C13” Tape and Reel SO-8

AD8012AR-REEL7 –40°C to +85°C7” Tape and Reel SO-8

AD8012ARM –40°C to +85°C 8-Lead microSOIC RM-08 H6A

AD8012ARM-REEL –40°C to +85°C13” Tape and Reel RM-08 H6A

AD8012ARM-REEL7 –40°C to +85°C7” Tape and Reel RM-08 H6A

␣␣␣␣

–4– REV. A

Page 5

0.1mF

0.1mF

10mF

10mF

R

L

V

IN

V

OUT

750V 750V

53.6V

+V

S

–V

S

+

+

Typical Performance Characteristics–

AD8012

750V 750V

V

IN

49.9V

0.1mF

0.1mF

+

+

10mF

10mF

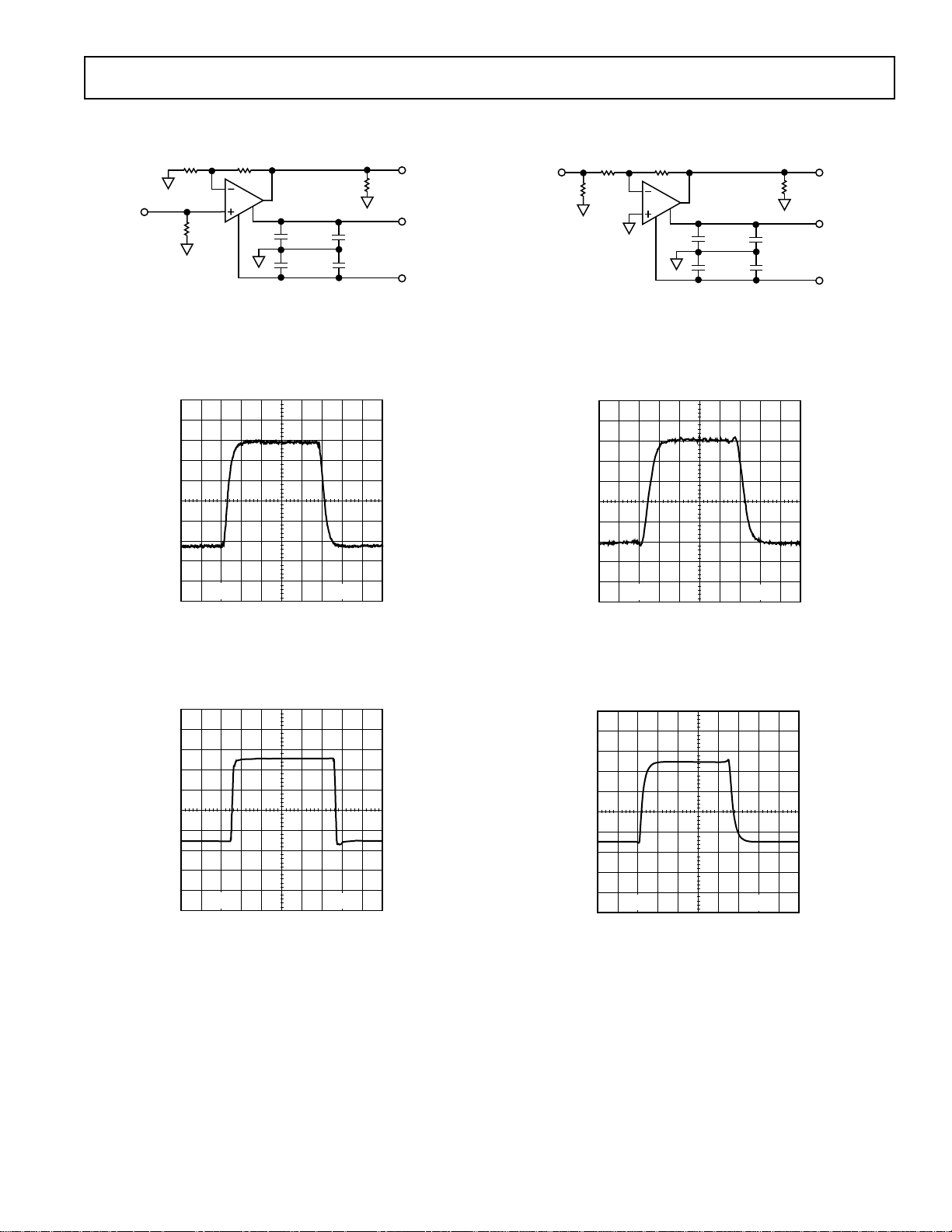

Figure 4. Test Circuit; Gain = +2

20mV

5ns

V

OUT

R

L

+V

S

–V

S

Figure 7. Test Circuit; Gain = –1

20mV

5ns

Figure 5.* 100 mV Step Response; G = +2, VS = ±2.5 V or

±

5 V, RL = 1 k

Ω

1V

10ns

Figure 6. 4 V Step Response; G = +2, VS = ±5 V, RL = 1 k

Figure 8.* 100 mV Step Response; G = –1, VS = ±2.5 V or

±

5 V, RL = 1 k

Ω

Figure 9. 4 V Step Response; G = –1, VS = ±5 V, RL = 1 k

Ω

1V 10ns

Ω

*NOTE:␣ VS = ±2.5 V operation is identical to VS = +5 V single supply operation.

–5–REV. A

Page 6

AD8012

20mV

5ns

Figure 10.* 100 mV Step Response; G = +2, VS = ±2.5 V or

±

5 V, RL = 100

Ω

500mV

10ns

Figure 11. 2 V Step Response; G = +2, VS = ±2.5 V, RL = 100

20mV

5ns

Figure 13.* 100 mV Step Response; G = –1, VS = ±2.5 V or

±

5 V, RL = 100

Figure 14. 2 V Step Response; G = –1, VS = ±2.5 V, RL = 100

Ω

Ω

500mV

10ns

Ω

1V

10ns

Figure 12. 4 V Step Response; G = +2, VS = ±5 V, RL = 100

*NOTE:␣ VS = ±2.5 V operation is identical to VS = +5 V single supply operation.

1V

Ω

Figure 15. 4 V Step Response; G = –1, VS = ±5 V, RL = 100

10ns

–6– REV. A

Ω

Page 7

–40

RL – V

–40

–90

10 1k100

DISTORTION – dBc

–70

–80

–60

–50

G = +2

V

OUT

= 2V p-p

R

F

= 750V

2nd

3rd

–40

–100

10 20

DISTORTION – dBc

–80

–60

G = +2

V

OUT

= 2V p-p

R

F

= 750V

FREQUENCY – MHz

1

3rd

R

L

= 1kV

2nd

R

L

= 1kV

3rd

R

L

= 100V

2nd

R

L

= 100V

FREQUENCY 2 MHz

0.1

10 100

G = +2

VO = 0.3V p-p

R

F

= 750V

R

L

= 100V

V

S

= +5V

1

0.3

–0.3

0.2

–0.1

0.1

0

–0.2

–0.4

–0.5

0.4

0.5

NORMALIZED GAIN 2 dB

–50

–60

G = +2

V

OUT

R

= 750V

F

AD8012

= 2V p-p

–70

DISTORTION – dBc

–80

–90

10 1k100

3rd

2nd

RL – V

Figure 16. Distortion vs. Load Resistance; VS = ±5 V,

Frequency = 500 kHz

–40

3rd

R

= 100V

L

2nd

R

= 100V

3rd

RL = 1kV

L

G = +2

V

= 2V p-p

OUT

R

= 750V

F

10 20

–60

–80

DISTORTION 2 dBc

–100

2nd

RL = 1kV

1

FREQUENCY 2 MHz

Figure 19. Distortion vs. Load Resistance; VS = +5 V,

Frequency = 500 kHz

NORMALIZED GAIN 2 dB

Figure 17. Distortion vs. Frequency; VS = ±5 V

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

–0.4

–0.5

0.1

Figure 18. Gain Flatness; VS = ±5 V

1

FREQUENCY 2 MHz

G = +2

VO = 0.3V p-p

R

= 750V

F

= 100V

R

L

= 65V

V

S

10 100

Figure 20. Distortion vs. Frequency; VS = +5 V

Figure 21. Gain Flatness; VS = +5 V

–7–REV. A

Page 8

AD8012

0

–10

–20

–30

–40

–60

–70

–80

100k 1M 10M 100M 500M

FREQUENCY – Hz

–50

–90

–100

PSRR – dB

VS = +5V OR 65V

G = +2

R

F

= 750V

–PSRR

+PSRR

NORMALIZED GAIN 2 dB

5

4

3

2

1

0

–1

–2

–3

–4

–5

1

G = +10

10

FREQUENCY 2 MHz

G = +2

100 500

VO = 0.3V p-p

R

= 750V

F

= 100V

R

L

= 65V

V

S

G = +1

Figure 22. Frequency Response; VS = ±5 V

–12

OUTPUT VOLTAGE 2 dBV

–15

–18

–21

9

6

3

1V RMS

0

–3

–6

–9

1

10

FREQUENCY 2 MHz

G = +2

RF = 750V

R

= 100V

L

= 65V

V

S

100 500

Figure 23. Output Voltage vs. Frequency; VS = ±5 V,

G = +2 V, R

= 100

L

Ω

5

4

3

2

1

0

–1

–2

NORMALIZED GAIN 2 dB

–3

–4

–5

1

G = +10

G = +2

10

FREQUENCY – MHz

VO = 0.3V p-p

R

= 750V

F

= 100V

R

L

V

= +5V

S

G = +1

100 500

Figure 25. Frequency Response; VS = +5 V

3

–12

–15

–18

OUTPUT VOLTAGE 2 dBV

–21

–24

–27

1VRMS

0

–3

–6

–9

1

10

FREQUENCY 2 MHz

G = +2

RF = 750V

R

= 100V

L

= +5V

V

S

100 500

Figure 26. Output Voltage vs. Frequency; VS = +5 V,

G = +2 V, R

= 100

L

Ω

0

–10

–20

–30

–40

–50

–60

CMRR 2 dB

–70

–80

–90

–100

Figure 24. CMRR vs. Frequency; VS = ±5 V, +5 V

VIN = 0.2V p-p

V

= 65V, +5V

S

10.03 0.1

FREQUENCY – MHz

10

100 500

Figure 27. PSRR vs. Frequency; VS = ±5 V, +5 V

–8– REV. A

Page 9

AD8012

1k

G = +2

RF = 750V

VS = +5V

10.03 0.1

FREQUENCY – MHz

10

VS = 65V

100 500

OUTPUT RESISTANCE 2 V

0.01

100

10

1

0.1

Figure 28. Output Resistance vs. Frequency

135

115

95

75

2 dB V

Z

55

T

35

15

–5

1E+03 1E+04 1E+05 1E+06 1E+07 1E+08 1E+09

FREQUENCY 2 Hz

TZ(s)

PHASE

0

–40

–80

–120

–160

–200

–240

–280

Figure 29. Open-Loop Transimpedance and Phase vs.

Frequency

PHASE – Degrees

4.0

3.8

3.6

Hz

3.4

3.2

3.0

INPUT VOLTAGE NOISE – nV/

2.8

2.6

2.4

2.2

2.0

100

FREQUENCY – Hz

CURRENT NOISE

+IN/–IN

VOLTAGE NOISE

10k1k

Figure 31. Noise vs. Frequency

9

8

f = 5MHz

G = 12

7

R

= 750V

F

6

5

4

3

2

1

0

PEAK-TO-PEAK OUTPUT AT 5MHz (#1% THD) 2 V

3 4 5 6 7 8 9 10 11

TOTAL SUPPLY VOLTAGE 2 Volts

RL = 1kV

RL = 100V

Figure 32. Output Swing vs. Supply

30

28

26

Hz

24

22

20

18

16

14

INPUT CURRENT NOISE – pA/

12

10

100k

9

8

7

6

5

4

SWING – V p-p

3

2

1

0

10

LOAD – V

Figure 30. Output Swing vs. Load

G = +2

R

65V

+5V

OUTPUT VOLTAGE ERROR – 0.1%/Div

0.1%

1k 10k100

= 750V

F

= 100V

R

L

2V STEP

5ns

t = 0

Figure 33. Settling Time, VS = ±5 V

–9–REV. A

Page 10

AD8012

5

VO = 0.3V p-p

R

F

R

L

G = +2

100 500

NORMALIZED GAIN 2 dB

4

3

2

1

0

–1

–2

–3

–4

–5

1

G = +10

10

FREQUENCY – MHz

Figure 34. Frequency Response; VS = ±5 V

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

NORMALIZED GAIN – dB

–0.3

–0.4

–0.5

0.1

FREQUENCY – MHz

VO = 0.3V p-p

G = +2

R

= 750V

F

= 1kV

R

L

101 100

Figure 35. Gain Flatness; VS = ±5 V

= 750V

= 1kV

G = +1

NORMALIZED GAIN 2 dB

5

4

3

2

1

0

–1

–2

–3

–4

–5

1

G = +10

10

FREQUENCY – MHz

VO = 0.3V p-p

R

F

R

L

G = +1

G = +2

100 500

Figure 37. Frequency Response; VS = +5 V

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

NORMALIZED GAIN – dB

–0.3

–0.4

–0.5

0.1

FREQUENCY – MHz

VO = 0.3V p-p

R

= 750V

F

= 1kV

R

L

101 100

Figure 38. Gain Flatness; VS = +5 V

= 750V

= 1kV

–20

DRIVER

–30

V

= 2V p-p

O

R

= 100V

L

SIDE 1

SIDE 2

10.03 0.1

FREQUENCY – MHz

INPUT REFERRED ERROR – dB

–40

–50

–60

–70

–80

–90

–100

–110

–120

Figure 36. Crosstalk vs. Frequency

+3V

V

OUT

V

0V

0V

–3V

V

, 2V/DIV

OUT

10

100 500

IN

V

IN

V

OUT

0V

0V

20ns

Figure 39. Overdrive Recovery; VS = ±5 V, G = +2,

R

= 750Ω, RL = 100Ω, VIN = 3 V p-p (T = 1µs)

F

–10– REV. A

Page 11

AD8012

THEORY OF OPERATION

The AD8012 is a dual high speed CF amplifier that attains new

levels of bandwidth (BW), power, distortion and signal swing

capability. Its wide dynamic performance (including noise) is

the result of both a new complementary high speed bipolar

process and a new and unique architectural design. The AD8012

basically uses a two gain stage complementary design approach

versus the traditional “single stage” complementary mirror

structure sometimes referred to as the Nelson amplifier. Though

twin stages have been tried before, they typically consumed

high power since they were of a folded cascade design much like

the AD9617. This design allows for the standing or quiescent

current to add to the high signal or slew current-induced stages.

In the time domain, the large signal output rise/fall time and

slew rate is typically controlled by the small signal BW of the

amplifier and the input signal step amplitude respectively, not

the dc quiescent current of the gain stages (with the exception

of input level shift diodes Q1/Q2). Using two stages vs. one

also allows for a higher overall gain bandwidth product (GBWP)

for the same power, thus lower signal distortion and the ability

to drive heavier external loads. In addition, the second gain

stage also isolates (divides down) A3’s input reflected load drive

and the nonlinearities created resulting in relatively lower distortion and higher open-loop gain.

Overall, when “high” external load drive and low ac distortion

is a requirement, a twin gain stage integrating amplifier like the

AD8012 will provide excellent results for lower power over the

traditional single stage complementary devices. In addition,

being a CF amplifier, closed-loop BW variations versus external gain variations (varying RN) will be much lower compared

to a VF op amp, where the BW varies inversely with gain. Another key attribute of this amplifier is its ability to run on a

single 5 V supply due in part to its wide common-mode input

and output voltage range capability. For 5 V supply operation,

the device obviously consumes half the quiescent power (vs.

10 V supply) with little degradation in its ac and dc performance characteristics. See data sheet comparisons.

DC GAIN CHARACTERISTICS

Gain stages A1/A1B and A2/A2B combined provide negative

feedforward transresistance gain. See Figure 40. Stage A3 is a

unity gain buffer which provides external load isolation to A2.

Each stage uses a symmetrical complementary design. (A3 is

also complementary though not explicitly shown). This is done

to reduce both second order signal distortion and overall quiescent power as discussed above. In the quasi dc to low frequency

region, the closed loop gain relationship can be approximated

as:

G = 1+R

G = –R

F/RN

F/RN

noninverting operation

inverting operation

These basic relationships above are common to all traditional

operational amplifiers.

A1

IPP

Q1

V

P

+–

Q2

INP

IPN

IQ1

Q3

V

N

Z

IE

Q4

IQ1

IPN

A1

C

CP2

A2

A2

D

ICQ + IO

VO 9

Z2

ICQ – IO

C

D

Z1 = R1 || C1

Z1

–V

I

CP1

IR + IFC

I

IR – IFC

–V

Z1

I

CP1

Figure 40. Simplified Block Diagram

A3

R

R

N

AD8012

V

R

F

L

O

C

L

–11–REV. A

Page 12

6V p-p

12V p-p

1:1

+5V

–5V

R

F

750V

R

F

750V

R

G

1.5kV

1/2

AD8012

1/2

AD8012

0.1mF

0.1mF

66.5V

66.5V

6V p-p

1:1

135V

TO

RECEIVER

CIRCUITRY

TO

RECEIVER

CIRCUITRY

GAIN = +2

UP TO

12,000 FEET

+

–

AD8012

APPLICATIONS

Line Driving for HDSL

High Bitrate Digital Subscriber Line (HDSL) is becoming

popular as a means of providing full duplex data communication

at rates up to 1.544 MBPS or 2.048 MBPS over moderate distances via conventional telephone twisted pair wires. Traditional

T1 (E1 in Europe) requires repeaters every 3,000 feet to 6,000

feet to boost the signal strength and allow transmission over

distances of up to 12,000 feet. In order to achieve repeaterless

transmission over this distance, an HDSL modem requires

transmitted power level of +13.5 dBm (assuming a line impedance of 135 Ω).

HDSL uses the Two Binary/One Quaternary line code (2B1Q).

A sample 2B1Q waveform is shown in Figure 41. The digital bit

stream is broken up into groups of two bits. Four analogue

voltages (called quaternary symbols) are used to represent the

four possible combinations of two bits. These symbols are assigned arbitrary names +3, +1, –1 and –3. The corresponding

voltage levels are produced by a DAC that is usually part of an

Analog Front End Circuit (AFEC). Before being applied to the

line, the DAC output is low-pass filtered and acquires the sinusoidal form shown in Figure 41. Finally, the filtered signal is

applied to the line driver. The line voltages that correspond to

the quaternary symbols +3, +1, –1 and –3 are 2.64 V, 0.88 V,

–0.88 V and –2.64 V. This gives a peak-to-peak line voltage of

5.28 V.

SYMBOL

VOLTAGE

NAME

+3 2.64V

+1 0.88V

–1 –0.88V

–3 –2.64V

–101+310+111–300–300+111+310–300–101–101+111–101–3

Figure 41. Time Domain Representation of a HDSL Signal

Many of the elements of a classic differential line driver are

shown in the HDSL line driver in Figure 42. A 6 V peak-topeak differential signal is applied to the input. The differential

gain of the amplifier (1+2 R

differential output signal is 12 V p-p.

As is normal in telephony applications, a transformer galvanically isolates the differential amplifier from the line. In this case

a 1:1 turns ratio is used. In order to correctly terminate the line,

it is necessary to set the output impedance of the amplifier to be

equal to the impedance of the line being driven (135 Ω in this

case). Because the transformer has a turns ratio of 1:1, the impedance reflected from the line is equal to the line impedance

of 135 Ω (R

resistors correctly terminate the line.

REFL

= R

LINE

DAC

OUTPUT

FILTERED

OUTPUT

TO LINE

DRIVER

) is set to +2, so the resulting

F/RG

/Turns Ratio

2

). As a result, two 66.5 Ω

00

Figure 42. Differential for HDSL Applications

The immediate effect of back-termination is that the signal from

the amplifier is halved before being applied to the line. This

doubles the power the amplifier must deliver. However, the

back-termination resistors also play an important second role.

Full-duplex data transmission systems like HDSL simultaneously transmit data in both directions. As a result, the signal

on the line and across the back termination resistors is the composite of the transmitted and received signal. The termination

resistors are used to tap off this signal and feed it to the receive

circuitry. Because the receive circuitry “knows” what is being

transmitted, the transmitted data can be subtracted from the

digitized composite signal to reveal the received data.

Driving a line with a differential signal offers a number of advantages compared to a single-ended drive. Because the two

outputs are always 180 degrees out of phase relative to one

another, the differential signal output is double the output amplitude of either of the op amps. As a result, the differential

amplifier can have a peak-to-peak swing of 16 V (each op amp

can swing to ±4 V), even though the power supply is ±5 V.

In addition to this, even-order harmonics (2nd, 4th, 6th, etc.) of

the two single-ended outputs tend to cancel out one another, so

the Total Harmonic Distortion (quadratic sum of all harmonics)

decreases compared to the single-ended case, even as the signal

amplitude is doubled. This is particularly advantageous for the

case of the second harmonic. As it is very close to the fundamental, filtering becomes difficult. In this application, the THD

is dominated by the third harmonic which is 65 dB below the

carrier (i.e., Spurious Free Dynamic Range = –65 dBc).

Differential line driving also helps to preserve the integrity of

the transmitted signal in the presence of Electro-Magnetic Interference (EMI). EMI tends to induce itself equally on to both

the positive and negative signal line. As a result, a receiver with

good common-mode rejection, will amplify the original signal

while rejecting induced (common-mode) EMI.

–12– REV. A

Page 13

AD8012

0.1mF

INVERTING CONFIGURATION

V

OUT

R

F

RO*

10mF

NONINVERTING CONFIGURATION

V

OUT

R

G

R

F

RO*

R

T

0.1mF

10mF

R

T

V

IN

R

G

V

IN

*RO CHOSEN FOR CHARACTERISTIC IMPEDANCE.

*R

O

CHOSEN FOR CHARACTERISTIC IMPEDANCE.

+V

S

+

+

–V

S

Choosing the Appropriate Turns Ratio for the Transformer

Increasing the peak-to-peak output signal from the amplifier in

the previous example, combined with a variation in the turns

ratio of the transformer, can yield further enhancements to the

circuit. The output signal swing of the AD8012 can be increased

to about ±3.9 V before clipping occurs. This increases the peakto-peak output of the differential amplifier to 15.6 V. Because

the signal applied to the primary winding is now bigger, the

transformer turns ratio of 1:1 can be replaced with a (stepdown) turns ratio of about 1.3:1 (from amplifier to line). This

steps the 7.8 V peak-to-peak primary voltage down to 6 V. This

is the same secondary voltage as before so the resulting power

delivered to the line is the same.

The received signal, which is small relative to the transmitted

signal, will, however be stepped up by a factor of 1.3. Amplifying

the received signal in this manner enhances its signal-to-noise

ratio and is useful when the received signal is small compared to

the to-be-transmitted signal.

The impedance reflected from the 135 Ω line now becomes

228 Ω (1.3

2

times 135 Ω). With a correctly terminated line, the

amplifier must now drive a total load of 456 Ω (114 Ω + 114 Ω

+ 228 Ω), considerably less than the original 270 Ω load. This

reduces the drive current from the op amps by about 40%.

More significant however is the reduction in dynamic power

consumption; that is, the power the amplifier must consume in

order to deliver the load power. Increasing the output signal so

that it is as close as possible to the power rails, minimizes the

power consumed in the amplifier.

There is, however, a price to pay in terms of increased signal

distortion. Increasing the output signal of each op amp from the

original ±3 V to ±3.9 V reduces the Spurious Free Dynamic

Range (SFDR) from –65 dB to –50 dB (measured at 500 kHz),

even though the overall load impedance has increased from

270 Ω to 456 Ω.

The PCB should have a ground plane covering all unused portions of the component side of the board to provide a low impedance ground path. The ground plane should be removed

from the area near the input pins to reduce stray capacitance.

Chip capacitors should be used for supply bypassing (see Figure 43). One end should be connected to the ground plane

and the other within 1/8 in. of each power pin. An additional

(4.7 µF–10 µF) tantalum electrolytic capacitor should be con-

nected in parallel.

The feedback resistor should be located close to the inverting

input pin in order to keep the stray capacitance at this node to a

minimum. Capacitance greater than 1.5 pF at the inverting

input will significantly affect high speed performance when

operating at low noninverting gains.

Stripline design techniques should be used for long signal traces

(greater than about 1 in.). These should be designed with the

proper system characteristic impedance and be properly terminated at each end.

LAYOUT CONSIDERATIONS

The specified high speed performance of the AD8012 requires

careful attention to board layout and component selection.

Table I shows recommended component values for the AD8012

and Figures 44–49 show recommended layouts for the 8-lead

SOIC and microSOIC packages for a positive gain. Proper RF

design techniques and low parasitic component selections are

mandatory.

Figure 43. Inverting and Noninverting Configurations

Table I. Typical Bandwidth vs. Gain Setting Resistors

Small Signal –3 dB BW (MHz),

Gain R

F

R

G

R

T

VS = ⴞ5 V, RL = 1 k⍀

–1 750 Ω 750 Ω 53.6 Ω 110

+1 750 Ω – 49.9 Ω 350

+2 750 Ω 750 Ω 49.9 Ω 150

+10 750 Ω 82.5 Ω 49.9 Ω 40

RT chosen for 50 Ω characteristic input impedance.

–13–REV. A

Page 14

AD8012

Figure 44. Universal SOIC Noninverter Top Silkscreen

Figure 45. Universal SOIC Noninverter Top

Figure 47. Universal microSOIC Noninverter Top Silkscreen

Figure 48. Universal microSOIC Noninverter Top

Figure 46. Universal SOIC Noninverter Bottom

Figure 49. Universal microSOIC Noninverter Bottom

–14– REV. A

Page 15

0.1574 (4.00)

0.1497 (3.80)

0.0098 (0.25)

0.0040 (0.10)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

PIN 1

0.0688 (1.75)

0.0532 (1.35)

0.0196 (0.50)

0.0099 (0.25)

AD8012

C3207a–0–12/99

x 45°

SEATING

PLANE

0.122 (3.10)

0.114 (2.90)

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

0.0500

(1.27)

BSC

0.122 (3.10)

0.114 (2.90)

8

1

PIN 1

0.0256 (0.65) BSC

0.120 (3.05)

0.112 (2.84)

0.018 (0.46)

0.008 (0.20)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

8-Lead microSOIC

(RM-08)

5

0.199 (5.05)

0.187 (4.75)

4

0.043 (1.09)

0.037 (0.94)

0.011 (0.28)

0.003 (0.08)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

0.120 (3.05)

0.112 (2.84)

33°

27°

0.028 (0.71)

0.016 (0.41)

PRINTED IN U.S.A.

–15–REV. A

Loading...

Loading...