Page 1

200 mA Output Current

16

15

14

13

1

2

3

4

NC = NO CONNECT

NC

–IN

+IN

NC

+V

S

OUT

NC

–V

S

12

11

10

9

5

6

7

8

NC

NC

NC

NC

NC

NC

NC

NC

AD8010

V

IN

+5V

–5V

75V

V

OUT1

V

OUT2

V

OUT3

V

OUT4

V

OUT5

V

OUT6

V

OUT7

V

OUT8

75V

AD8010

R

T

R

G

R

F

R

S

a

FEATURES

200 mA of Output Current

9 ⍀ Load

SFDR –54 dBc @ 1 MHz

Differential Gain Error 0.04%, f = 4.43 MHz

Differential Phase Error 0.06ⴗ, f = 4.43 MHz

Maintains Video Specifications Driving Eight Parallel

75 ⍀ Loads

0.02% Differential Gain

0.03ⴗ Differential Phase

0.1 dB Gain Flatness to 60 MHz

THD –72 dBc @ 1 MHz, R

IP3 42 dBm @ 5 MHz, R

1 dB Gain Compression 21 dBm @ 5 MHz, R

230 MHz –3 dB Bandwidth, G = +1, R

800 V/s Slew Rate, R

25 ns Settling Time to 0.1%

Available in 8-Lead DIP, 16-Lead Wide Body SOIC and

Thermally Enhanced 8-Lead SOIC

APPLICATIONS

Video Distribution Amplifier

VDSL, xDSL Line Driver

Communications

ATE

Instrumentation

= 18.75 ⍀

L

= 18.75 ⍀

L

= 18.75 ⍀

L

L

= 18.75 ⍀

L

= 100 ⍀

High Speed Amplifier

AD8010

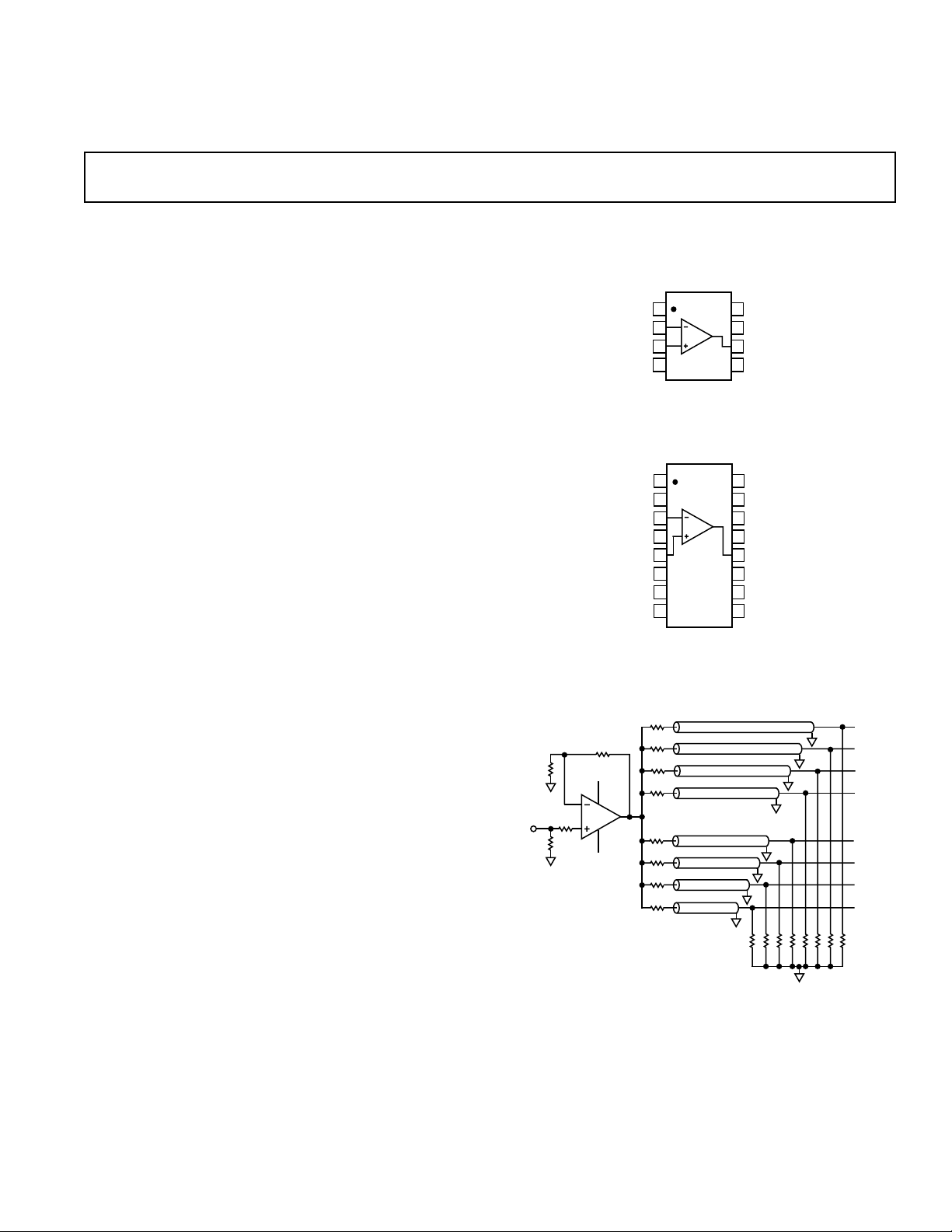

CONNECTION DIAGRAMS

8-Lead DIP and SOIC

AD8010

1

NC

2

–IN

3

+IN

4

S

NC = NO CONNECT

16-Lead Wide Body SOIC

8

NC

7

+V

S

6

OUT

5

NC–V

PRODUCT DESCRIPTION

The AD8010 is a low power, high current amplifier capable of

delivering a minimum load drive of 175 mA. Signal performance

such as 0.02% and 0.03° differential gain and phase error is

maintained while driving eight 75 Ω back terminated video lines.

The current feedback amplifier features gain flatness to 60 MHz

and –3 dB (G = +1) signal bandwidth of 230 MHz and only

requires a typical of 15.5 mA supply current from ±5 V supplies.

These features make the AD8010 an ideal component for Video

Distribution Amplifiers or as the drive amplifier within high data

rate Digital Subscriber Line (VDSL and xDSL) systems.

The AD8010 is an ideal component choice for any application

that needs a driver that will maintain signal quality when driving

low impedance loads.

The AD8010 is offered in three package options: an 8-lead DIP,

16-lead wide body SOIC and a low thermal resistance 8-lead

SOIC, and operates over the industrial temperature range of

–40°C to +85°C.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

Figure 1. Video Distribution Amplifier

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

AD8010–SPECIFICATIONS

RF = RG = 562 ⍀ (N-8), RF = RG = 499 ⍀ (R-8). T

M

odel Conditions Min Typ Max Units

(@ +25ⴗC, VS = ⴞ5 V, G = +2, RL = 18.75 ⍀, RS+ = 150 ⍀, RF = RG = 604 ⍀ (R-16),

= –40ⴗC, T

MIN

= +85ⴗC unless otherwise noted)

MAX

DYNAMIC PERFORMANCE

–3 dB Bandwidth G = +1, V

G = +2, V

0.1 dB Bandwidth V

Large Signal Bandwidth V

Peaking V

Slew V

Rise and Fall Time V

= 0.2 V p-p 30 60 MHz

OUT

= 4 V p-p 90 MHz

OUT

= 0.2 V p-p, < 5 MHz 0.02 dB

OUT

= 2 V p-p 800 V/µs

OUT

= 2 V p-p 2.0 ns

OUT

Settling Time 0.1%, V

= 0.2 V p-p 180 230 MHz

OUT

= 0.2 V p-p 130 190 MHz

OUT

= 2 V p-p 25 ns

OUT

NOISE/HARMONIC PERFORMANCE

Distortion V

= 2 V p-p

OUT

2nd Harmonic 1 MHz –73 dBc

5 MHz –58 dBc

10 MHz –53 dBc

10 MHz, R

= 39 Ω –67 dBc

L

20 MHz –44 dBc

3rd Harmonic 1 MHz –77 dBc

5 MHz –63 dBc

10 MHz –57 dBc

10 MHz, R

= 39 Ω –63 dBc

L

20 MHz –50 dBc

IMD 5 MHz ∆f = 10 kHz –73 dBc

IP3 5 MHz 42 dBm

1 dB Gain Compression 5 MHz 21 dBm

Input Noise Voltage f = 10 kHz 2 nV√Hz

Input Noise Current f = 10 kHz, +In 3 pA√Hz

f = 20 kHz, –In 20 pA√Hz

Differential Gain f = 4.43 MHz, R

f = 4.43 MHz, R

Differential Phase f = 4.43 MHz, R

f = 4.43 MHz, R

= 150 Ω 0.02 %

L

= 18.75 Ω 0.02 %

L

= 150 Ω 0.02 Degrees

L

=18.75 Ω 0.03 Degrees

L

DC PERFORMANCE

Input Offset Voltage 512mV

T

MIN–TMAX

15 mV

Offset Drift 10 µV/°C

Input Bias Current (–) 10 135 µA

T

MIN–TMAX

200 µA

Input Bias Current (+) 612µA

T

MIN–TMAX

20 µA

INPUT CHARACTERISTICS

Input Resistance +Input 125 kΩ

–Input 12.5 Ω

Input Capacitance 2.75 pF

Common-Mode Rejection Ratio V

= ±2.5 V 50 54 dB

CM

Input Common-Mode Voltage Range ±2.5 V

Open Loop Transresistance V

= ±2.5 V 300 500 kΩ

OUT

T

MIN–TMAX

250 kΩ

OUTPUT CHARACTERISTICS

Output Voltage Swing

= 18.75 Ω ±2.1 ±2.5 V

R

L

= 150 Ω ±2.7 ±3.0 V

R

L

Output Current R

= 9 Ω 175 200 mA

L

Short-Circuit Current 240 mA

Capacitive Load Drive 40 pF

POWER SUPPLY

Operating Range ±4.5 ±6.0 V

Quiescent Current 15.5 17 mA

T

Power Supply Rejection Ratio +V

to T

MIN

MAX

= +4 V to +6 V, –VS = +5 V 60 66 dB

S

20 mA

+VS = +5 V, –VS = –4 V to –6 V 50 56 dB

Specifications subject to change without notice.

–2– REV. A

Page 3

AD8010

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply␣ Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.6␣ V

Internal␣ Power␣ Dissipation

2

1

Plastic␣ Package (N) . . . . . . . Observe Power Derating Curves

Small␣ Outline␣ Package (R) . . Observe Power Derating Curves

Wide Body SOIC (R-16) . . . . Observe Power Derating Curves

Input Voltage (Common-Mode) . . . . . . . . . . . . . . . . . . . .±V

S

Differential␣ Input␣ Voltage . . . . . . . . . . . . . . . . . . . . . . ±1.2␣ V

Output Short Circuit Duration

.␣ . . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range N, R . . . . . . . . –65°C to +125°C

Operating Temperature Range (A Grade) . . . –40°C to +85°C

Lead Temperature Range (Soldering␣ 10␣ sec) . . . . . . . .+300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

8-Lead Plastic Package: θJA = 90°C/Watt

8-Lead SOIC Package: θJA = 122°C/Watt

16-Lead SOIC Package: θJA = 73°C/Watt

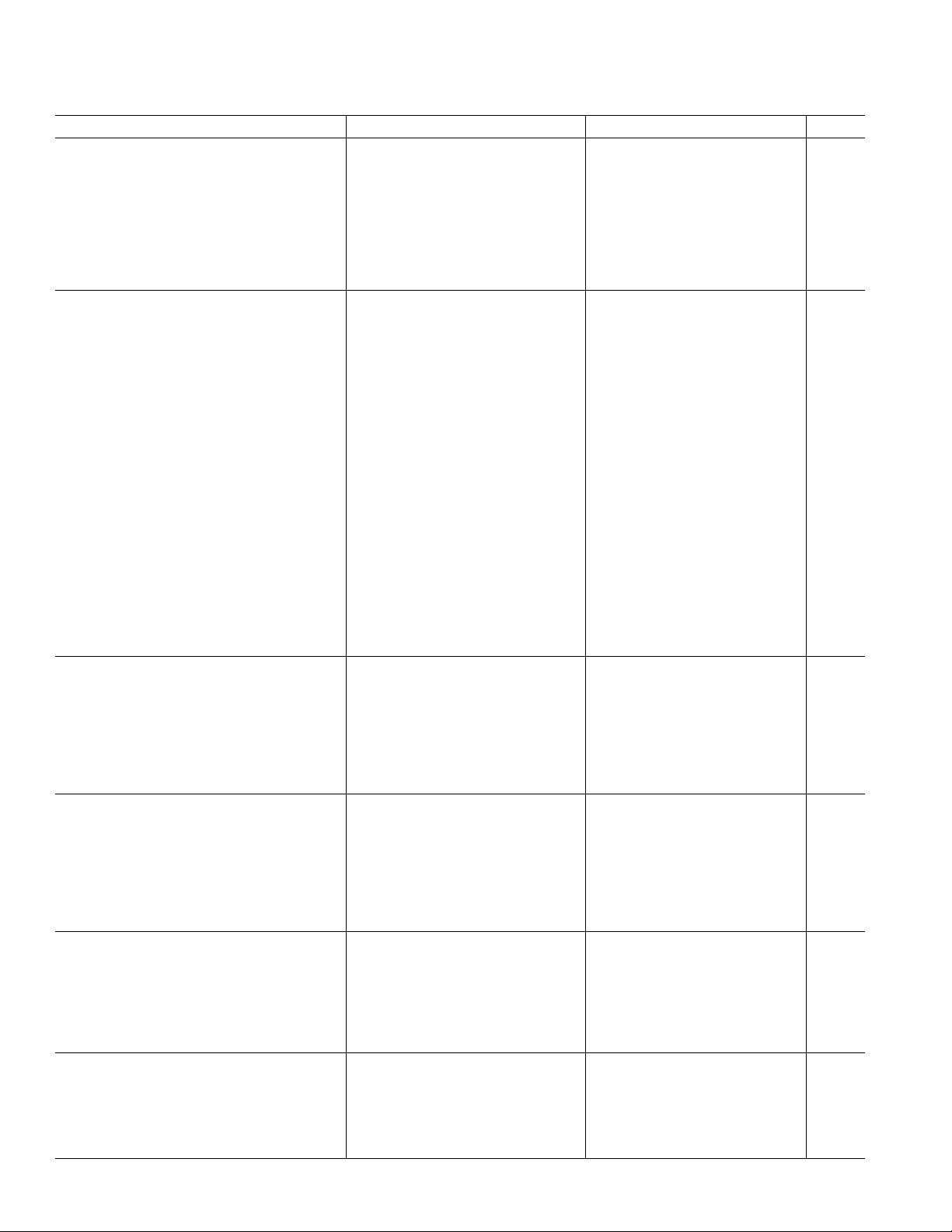

3.0

2.5

8-LEAD MINI-DIP PACKAGE

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8010 is limited by the associated rise in junction temperature. The maximum safe junction temperature for plastic

encapsulated devices is determined by the glass transition tem-

perature of the plastic, approximately +150°C. Temporarily

exceeding this limit may cause a shift in parametric performance due to a change in the stresses exerted on the die by the

package. Exceeding a junction temperature of +175°C for an

extended period can result in device failure.

While the AD8010 is internally short circuit protected, this

may not be sufficient to guarantee that the maximum junction

temperature (+150°C) is not exceeded under all conditions. To

ensure proper operation, it is necessary to observe the maximum

power derating curves.

TJ = +1508C

2.0

1.5

1.0

8-LEAD SOIC PACKAGE

0.5

MAXIMUM POWER DISSIPATION – Watts

0

–40 –30 –20 –10 0 10 20 30 40 50 60 70 80 90

–50

AMBIENT TEMPERATURE – 8C

16-LEAD SOIC

PACKAGE (WIDEBODY)

Figure 2. Plot of Maximum Power Dissipation vs. Temperature

ORDERING GUIDE

Model Temperature Range Package Description Package Options

AD8010AN –40°C to +85°C 8-Lead Plastic DIP N-8

AD8010AR –40°C to +85°C 8-Lead Plastic SOIC SO-8

AD8010AR-16 –40°C to +85°C 16-Lead Wide Body SOIC R-16

AD8010AR-REEL REEL SOIC 13" REEL

AD8010AR-REEL7 REEL SOIC 7" REEL

AD8010AR-16-REEL REEL SOIC 13" REEL

AD8010AR-16-REEL7 REEL SOIC 7" REEL

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8010 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. A

Page 4

AD8010

NUMBER OF VIDEO LOADS

0.05

0.04

DIFFERENTIAL PHASE

0

162 4 6 8 10 12 14

0.03

0.02

0.01

DIFFERENTIAL GAIN – %

1

0.10

0.08

0

0.06

0.04

0.02

DIFFERENTIAL PHASE – Degrees

DIFFERENTIAL GAIN

FREQUENCY – MHz

45

40

5

1 10010

INTERCEPT POINT – dBm

35

30

10

25

20

15

G = +2

RL = 18.75V

6.5

6.4

6.3

6.2

6.1

6.0

5.9

5.8

5.7

5.6

5.5

1

FREQUENCY – MHz

G = +2

V

O

= 0.2V p-p

NUMBER OF VIDEO

LOADS AS SHOWN

4

6

8

10

14

12

1

10 100

1000

2

GAIN FLATNESS – dB

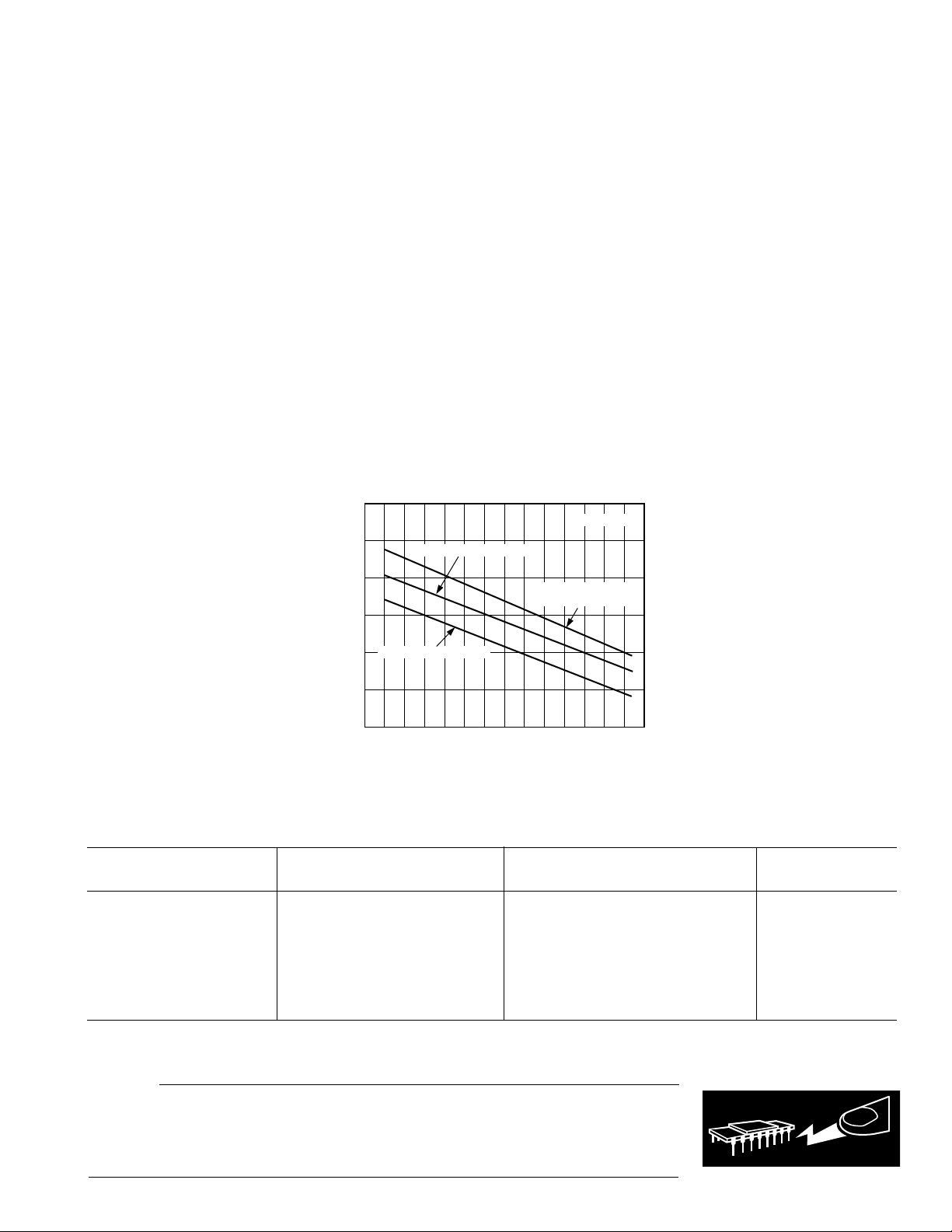

–Typical Performance Characteristics

60

50

40

30

20

PERCENTAGE OF UNITS

10

dG

df

dG

df

dG

0

0

dG

0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12

DIFFERENTIAL GAIN dG IN %

DIFFERENTIAL PHASE df IN Degrees

df

df

df

dG (%)/df – Degrees

SAMPLE SIZE = 300

G = +2

f = 4.43MHz (PAL)

RL = 18.75V

df

df df df df df

Figure 3. Distribution of Differential Gain (dG) and

Differential Phase (d

–45

G = +2

–50

VO = 2V p-p

RL AS SHOWN

–55

–60

RL = 18.75V

–65

–70

–75

–80

HARMONIC DISTORTION – dBc

RL = 100V

–85

–90

–95

12 56789102034

φ

); RL = 18.75

2ND

3RD

3RD

2ND

FREQUENCY – MHz

Ω

Figure 4. Harmonic Distortion vs. Frequency; G = +2

0.130.01

Figure 6. Differential Gain and Phase vs. Number of Video

Loads Over Temperature (–40

°

C to +85°C); f = 4.43 MHz

Figure 7. Two-Tone, 3rd Order IMD Intercept vs.

Frequency; G = +2, R

= 18.75

L

Ω

6.20

6.15

6.10

6.05

6.0

5.95

5.90

GAIN FLATNESS – dB

5.85

5.80

Figure 5. Gain Flatness vs. Frequency Over Temperature

(–40

°

C to +85°C)

G = +2

RL = 18.75V

= 0.2V p-p

V

O

0.1 1

+858C

+258C

FREQUENCY – MHz

10 100

–408C

500

Figure 8. Gain Flatness vs. Frequency vs. Number of

Video Loads

–4– REV. A

Page 5

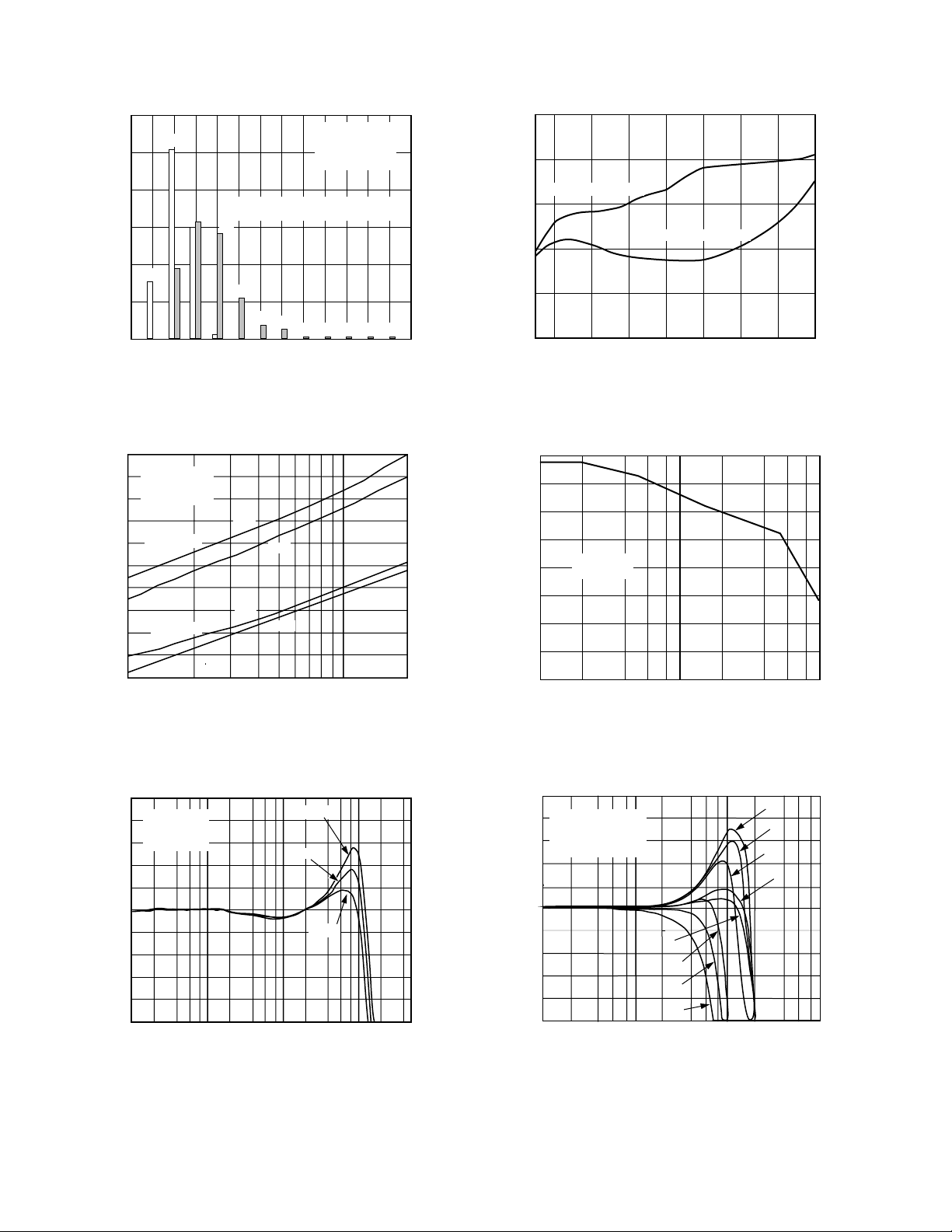

AD8010

G = +2

VO = 2V p-p

f = 5MHz

LOAD – V

–55

–60

–65

–70

–75

–80

–85

–90

15 100 200 300 400 500

2

ND

3

RD

HARMONIC DISTORTION – dBc

5

–5

–15

–25

–35

–45

–55

–65

–75

INTERMODULATION DISTORTION – dBm

–85

P

4dBm

OUT

G = +2

RL = 18.75V

fO = 5MHz

Df = 10kHz

–69dBm –69dBm

FREQUENCY – MHz

4dBm

Figure 9. Intermodulation Distortion

–35

FREQUENCY = 5MHz

G = +2

–45

RL = AS SHOWN (SEE SCHEMATIC)

–55

RL = 18.75V

–65

–75

–85

–95

TOTAL HARMONIC DISTORTION – dBc

–105

–10 12–8

R

= FOR RL = 100V

L1

R

= 23.1 FOR RL = 18.75V

L1

–6 –4 –2 0 2 4 6 8 10

RL = 100V

R

G

150V

P

IN

50V

P

– dBm

OUT

Figure 10. Total Harmonic Distortion vs. P

0

P

= 10dBm

–10

–20

–30

–40

– dBm

–50

MEASURE

P

–60

–70

–80

5.0355.0155.04.9854.965

–90

010123456789

FREQUENCY – MHz

Figure 12. Multitone Distortion; RL = 100

R

F

50V

P

L1

; G = +2

OUT

OUT

50V

Figure 13. Harmonic Distortion vs. Load

R

MEASURE

(FULL SCALE)

GAIN = 6.6

R

F

R

G

150V

50V

500kHz TONE SPACING FROM

500kHz TO 5.5MHz WITH

4 MISSING TONES

50V

50V

Ω

2

1

0

–1

–2

–3

GAIN AS SHOWN

–4

Figure 11. Small Signal Closed-Loop Frequency

Response; R

VO = 0.2V p-p

NORMALIZED GAIN – dB

= 18.75V

R

L

–5

–6

–7

0.1 10001

= 18.75

L

FREQUENCY – MHz

Ω

G = +3

10 100

G = +1

G = +2

G = +2

8.0

VO = 0.2V p-p

NUMBER OF VIDEO LOADS AS SHOWN

7.0

6.0

5.0

4.0

GAIN – dB

3.0

2.0

1.0

0.0

1 100010

FREQUENCY – MHz

12

4

1

8

100

Figure 14. Closed-Loop Frequency Response vs.

Number of Video Loads

–5–REV. A

Page 6

AD8010

FREQUENCY – Hz

316

0.316

10k 1G100k

TRANSRESISTANCE – kV

1M 10M 100M

100

31.6

10

3.16

1

90

135

180

PHASE – Degrees

225

45

0

TRANSRESISTANCE

1000

PHASE

–10

–20

–30

–40

–50

PSRR – dB

–60

–70

–80

0.03

310

100

31

10

3.1

1

0.31

0.1

0.031

CLOSED-LOOP OUTPUT RESISTANCE – V

–PSRR

+PSRR

0.1

1 10 100

FREQUENCY – MHz

Figure 15. PSRR vs. Frequency

G = +2

500

0

–10

–20

–30

–40

–50

–60

CMRR – dB

–70

–80

–90

–100

0.1 5001

10 100

FREQUENCY – MHz

Figure 18. CMRR vs. Frequency

0.1

1

FREQUENCY – MHz

10 100

500

Figure 16. Closed-Loop Output Resistance vs. Frequency

2

1

0

–1

GAIN AS SHOWN

VO = 2V p-p

–2

= 18.75V

R

L

–3

–4

NORMALIZED GAIN – dB

–5

–6

–7

0.1 10001

Figure 17. Large Signal Frequency Response; VO = 2 V p-p

FREQUENCY – MHz

G = +2

G = +10

10 100

G = +1

Figure 19. Transresistance and Phase vs. Frequency;

R

= 18.75

L

Ω

3.0

2.0

1.0

0.0

–1.0

GAIN AS SHOWN

–2.0

VO = 4V p-p

= 18.75V

R

–3.0

L

–4.0

NORMALIZED GAIN – dB

–5.0

–6.0

–7.0

0.1

0

G = +10

10

FREQUENCY – MHz

100

G = +2

1000

Figure 20. Large Signal Frequency Response; VO = 4 V p-p

–6– REV. A

Page 7

0.2

1V

20ns

G = +2, –1

R

L

= 18.75V

VO = 4V p-p

4

3

2

1

0

–1

–2

–3

–4

VOLTS

0.15

0.1

0.05

VOLTS

–0.05

–0.1

–0.15

–0.2

0

50mV 20ns

G = +1

R

= 18.75V

L

VO = 0.2V p-p

5

4

3

2

1

0

VOLTS

–1

–2

–3

–4

–5

AD8010

G = +1

R

= 18.75V

L

VO = 4V p-p

1V

20ns

Figure 21. Small-Signal Pulse Response; G = +1

0.2

0.15

0.1

0.05

VOLTS

–0.05

–0.1

–0.15

–0.2

0

50mV

G = +2, –1

R

= 18.75V

L

VO = 0.2V p-p

20ns

Figure 22. Small-Signal Pulse Response; G = +2, –1

100

Figure 24. Large-Signal Pulse Response; G = +1

Figure 25. Large-Signal Pulse Response; G = +2, –1

1000

100

10

INPUT VOLTAGE NOISE – nV/ Hz

1

10 100

10k

1k

FREQUENCY – Hz

100k

1M

10M

Figure 23. Input Voltage Noise vs. Frequency

10

INPUT CURRENT NOISE – PA/ Hz

1

10 100 1k 10k 100k 1M

Figure 26. Input Current Noise vs. Frequency

INVERTING CURRENT

NONINVERTING CURRENT

10M

FREQUENCY – Hz

–7–REV. A

Page 8

AD8010

AD8010

V

IN

150V

R

F

R

G

R

T

+V

S

–V

S

FB

C1

+

R

BT

Z

O

R

L

C2

+

Driving Capacitance Loads

The AD8010 was designed primarily to drive nonreactive loads.

If driving loads with a capacitive component is desired, best

frequency response is obtained by the addition of a small series

resistance as shown in Figure 28. The inset figure shows the

optimum value for R

vs. capacitive load. It is worth noting

SERIES

that the frequency response of the circuit when driving large

0

VOLTS

INPUT

OUTPUT

G = +6

R

= 604V

F

= 18.75V

R

L

capacitive loads will be dominated by the passive roll-off of

and CL.

R

SERIES

INPUT (500mV/DIV)

OUTPUT (1V/DIV)

100ns

Figure 27. Overdrive Recovery; G = +6

OVERDRIVE RECOVERY

Overdrive of an amplifier occurs when the output and/or input

range are exceeded. The amplifier must recover from this overdrive condition. As shown in Figure 27, the AD8010 recovers

within 35 ns from negative overdrive and within 75 ns from

LAYOUT CONSIDERATIONS

The specified high speed performance of the AD8010 requires

careful attention to board layout and component selection.

Proper R

design techniques and low-pass parasitic component

F

selection are necessary.

The PCB should have a ground plane covering all unused portions of the component side of the board to provide low impedance path. The ground plane should be removed from the area

near the input pins to reduce the parasitic capacitance.

positive overdrive.

THEORY OF OPERATION

The AD8010 is a current feedback amplifier optimized for high

current output while maintaining excellent performance with

respect to flatness, distortion and differential gain/phase. As a

video distribution amplifier, the AD8010 will drive up to 12

parallel video loads (12.5 Ω) from a single output with 0.04%

differential gain and 0.04° differential phase errors. This means

that, unlike designs with one driver per output, any output is a

true reflection of the signal on all other outputs.

The high output current capability of the AD8010 also make it

useful in xDSL applications. The AD8010 can drive a 12.5 Ω

single-ended or 25 Ω differential load with low harmonic distor-

tion. This makes it useful in designs that utilize a step-up transformer to drive a twisted-pair transmission line.

To achieve these levels of performance special precautions with

respect to supply bypassing are recommended (Figure 29). This

configuration minimizes the contribution from high frequency

supply rejection to differential gain and phase errors as well as

reducing distortion due to harmonic energy in the power

supplies.

200

100

G = +5

R

R

V

10

IN

F

G

150V

50V

GAIN AS SHOWN

= 0.2V p-p

V

O

w/# 30% OVERSHOOT

R

S

V

OUT

C

L

Figure 29. Standard Noninverting Closed-Loop Configuration with Recommended Bypassing Technique

The standard noninverting closed-loop configuration with the

recommended power supply bypassing technique is shown in

Figure 29. Ferrite beads (Amidon Associates, Torrance CA,

Part Number 43101) are used to suppress high frequency power

supply energy on the DUT supply lines at the DUT. C1 and C2

each represent the parallel combination of a 47 µF (16 V) tanta-

lum electrolytic capacitor, a 10 µF (10 V) tantalum electrolytic

capacitor and a 0.1 µF ceramic chip capacitor. Connect C1

from the +V

pin to the –VS pin. Connect C2 from the –VS pin

S

to signal ground.

The feedback resistor should be located close to the inverting

input pin in order to keep the parasitic capacitance at this node

CAPACITIVE LOAD – pF

Figure 28. Capacitive Load Drive vs. Series Resistor for

G = +2

1

0205

G = +1

10 15

RS – V

to a minimum. Parasitic capacitances of less than 1 pF at the

inverting input can significantly affect high speed performance.

Stripline design techniques should be used for long traces

(greater than about 3 cm). These should be designed with a

characteristic impedance (Z

) of 50 Ω or 75 Ω and be properly

O

terminated at each end.

Various Gains

–8– REV. A

Page 9

AD8010

APPLICATIONS

Video Distribution Amplifier

The AD8010 is optimized for the specific function of providing

excellent video performance when driving multiple video loads

in parallel. Significant power is saved and heat sinking is greatly

simplified because of the ability of the AD8010 to obtain this

performance when running on a ±5 V supply. However, due to

the high currents that flow when driving many parallel video

loads, special layout and bypassing techniques are required to

assure optimal performance.

When designing a video distribution amplifier with the AD8010, it

is very important to keep in mind where the high (ac) currents

will flow. These paths include the power supply pins of the chip

along with the bypass capacitors and the return path for these

capacitors, the output circuits and the return path of the output

current from the loads.

In general, any loops that are formed by any of the above paths

should be made as small as possible. Large loops are both generators and receivers of magnetic fields and can cause undesired

coupling of signals that lowers the performance of the amplifier.

Effects that have not been seen before in other op amp circuits

might arise because of the high currents. Most op amp circuits

output, at most, tens of milliamps and do not require extremely

tight video specifications, while a video distribution amplifier

can output hundreds of milliamps and require extremely low

differential gain and phase errors.

The bypassing scheme that is used for the AD8010 requires

special attention. It was found that the conventional technique

of bypassing each power pin individually to ground can have an

adverse effect on the differential phase error of the circuit. The

cause of this is attributed to the fact that there is an internal

compensation capacitor in the AD8010 that is referenced to the

negative supply.

The recommended technique is to connect parallel bypass

capacitors from the positive supply to the negative supply and

then to bypass the negative supply to ground. For high fre-

quency bypassing, 0.1 µF ceramic capacitors are recommended.

These should be placed within a few millimeters of the power

pins and should preferably be chip type capacitors.

The high currents that can potentially flow through the power

supply pins require large bypassing capacitors. These should be

low inductance tantalum types and at least 47 µF. The ground

side of the capacitor that bypasses the negative supply should be

brought to a single point ground that is the common for the

returns of the outputs.

Figure 30 shows a circuit for making an N-channel video distribution amplifier. As a practical matter, the AD8010 can readily

drive eight standard 150 Ω video loads. When driving up to 12

video loads, there is minimal degradation in video performance.

Another important consideration when driving multiple cables

is the high frequency isolation between the outputs of the

cables. Due to its low output impedance, the AD8010 achieves

better than 46 dB of output-to-output isolation at 5 MHz driv-

ing back terminated 75 Ω cables.

+5V

FB

499V499V

V

IN

75V

150V

AD8010

C1

C2

FB

–5V

75V

75V

75V

75V

75V R

75V R

R

L1

L2

LN

Figure 30. An N-Channel Video Distribution Amplifier Using An AD8010.

NOTE: Please see Figure 29 for Recommended Bypassing Technique.

–9–REV. A

Page 10

AD8010

Differential Line Driver

Twisted pair transmission lines are more often being used for

high frequency analog and digital signals. Over long distances,

however, the attenuation characteristics of these lines can

degrade the performance of the transmission system. To compensate for this, larger signals are transmitted, which after the

attenuation, will still have useful signal strength.

The high output current of two AD8010s can be used along

with a transformer to create a high power differential line driver.

The differential configuration effectively doubles the output

swing, while the step-up transformer further increases the output voltage.

499V

499V

AD8010

150V

V

IN

402V

806V

In the circuit in Figure 31 the A device is configured as a gainof-two follower, while the B device is a gain-of-two inverter.

These will produce a differential output signal whose maximum

value is twice the peak-to-peak value of the maximum output of

one device. For this circuit a 12 V peak-to-peak output can be

obtained.

The op amps drive a 1:2 step-up transformer that drives a

100 Ω transmission line. Since the impedance reflected back to

the primary varies as the square of the turns ratio, it will appear

as 25 Ω at the primary. This source terminating resistor is split

as a 12.4 Ω resistor at the output of each device.

The circuit shown is capable of delivering 12 V p-p to the line

and operates with a –3 dB bandwidth of 40 MHz. The peak

current output of either op amp is 100 mA.

12.4V

+6

100V

AD8010

150V

12.4V

1:2

–6

Figure 31. High Output Differential Line Driver Using Two AD8010s.

NOTE: Please see Figure 29 for Recommended Bypassing Technique.

–10– REV. A

Page 11

AD8010

150V

50V

R

F

R

G

V

OUT

18.75V

V

IN

Closed-Loop Gain and Bandwidth

The AD8010 is a current feedback amplifier optimized for use

in high performance video and data acquisition applications.

Since it uses a current feedback architecture, its closed-loop

–3 dB bandwidth is dependent on the magnitude of the feedback resistor. The desired closed-loop bandwidth and gain are

obtained by varying the feedback resistor (R

width, and varying the gain resistor (R

) to set the band-

F

) to set the desired gain.

G

The characteristic curves and specifications for this data sheet

reflect the performance of the AD8010 using the values of R

F

noted at the top of the specifications table. If a greater –3 dB bandwidth and/or slew rate is required (at the expense of video performance), Table I provides the recommended resistor values.

Figure 32 shows the test circuit and conditions used to produce

Table I.

Effect of Feedback Resistor Tolerance on Gain Flatness

Because of the relationship between the 3 dB bandwidth and the

feedback resistor, the fine scale gain flatness will, to some extent, vary with feedback resistor tolerance. It is therefore recommended that resistors with a 1% tolerance be used if it is desired

to maintain flatness over a wide range of production lots. In

addition, resistors of different construction have different associated parasitic capacitance and inductance. Metal-film resistors

were used for the bulk of the characterization for this data sheet.

It is possible that values other than those indicated will be optimal for other resistor types.

Quality of Coaxial Cable

Optimum flatness when driving a coax cable is possible only

when the driven cable is terminated at each end with a resistor

matching its characteristic impedance. If the coax was ideal,

then the resulting flatness would not be affected by the length of

the cable. While outstanding results can be achieved using inexpensive cables, it should be noted that some variation in flatness

due to varying cable lengths may be experienced.

Table I. –3 dB Bandwidth and Slew Rate vs. Closed-Loop

Gain and Resistor Values

Package: N-8

Closed-Loop –3 dB BW Slew Rate

Gain RF (⍀)RG (⍀) (MHz) (V/s)

+1 453

∞

285 900

+2 374 374 255 900

+5 348 86.6 200 800

+10 562 61.9 120 550

Package: R-16

Closed-Loop –3 dB BW Slew Rate

Gain RF (⍀)RG (⍀) (MHz) (V/s)

+1 412

∞

245 900

+2 392 392 220 900

+5 392 97.6 160 800

+10 604 66.5 95 550

Package: SO-8

Closed-Loop –3 dB BW Slew Rate

Gain RF (⍀)RG (⍀) (MHz) (V/s)

+1 392

∞

345 950

+2 374 374 305 1000

+5 348 86.6 220 1000

+10 499 54.9 135 650

Figure 32. Test Circuit for Table I

NOTES

1

VO = 0.2 V p-p for –3 dB Bandwidth.

2

VO = 2 V p-p for Slew Rate.

3

Bypassing per Figure 29.

–11–REV. A

Page 12

AD8010

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic Mini-DIP

(N-8)

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

8-Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

C3208a–0–10/98

0.195 (4.95)

0.115 (2.93)

0.0098 (0.25)

0.0040 (0.10)

SEATING

0.0118 (0.30)

0.0040 (0.10)

PIN 1

0.0500

(1.27)

PLANE

BSC

16-Lead Wide Body SOIC

0.4133 (10.50)

0.3977 (10.00)

16 9

PIN 1

0.0500

0.0192 (0.49)

(1.27)

0.0138 (0.35)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

(R-16)

81

0.1043 (2.65)

0.0926 (2.35)

SEATING

PLANE

0.0098 (0.25)

0.0075 (0.19)

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.0196 (0.50)

0.0099 (0.25)

88

08

0.0500 (1.27)

0.0160 (0.41)

0.0291 (0.74)

0.0098 (0.25)

8°

0°

3 458

0.0500 (1.27)

0.0157 (0.40)

x 45°

PRINTED IN U.S.A.

–12–

REV. A

Loading...

Loading...