Page 1

270 MHz, 400 A

a

FEATURES

Ultralow Power

400 A Power Supply Current (4 mW on ⴞ5 V

Specified for Single Supply Operation

High Speed

270 MHz, –3 dB Bandwidth (G = +1)

170 MHz, –3 dB Bandwidth (G = +2)

280 V/s Slew Rate (G = +2)

28 ns Settling Time to 0.1%, 2 V Step (G = +2)

Low Distortion/Noise

–63 dBc @ 1 MHz, V

–50 dBc @ 10 MHz, V

= 2 V p-p

O

= 2 V p-p

O

4.0 nV/√Hz Input Voltage Noise @ 10 MHz

Good Video Specifications (RL = 1 k⍀, G = +2)

Gain Flatness 0.1 dB to 30 MHz

0.11% Differential Gain Error

0.4ⴗ Differential Phase Error

APPLICATIONS

Signal Conditioning

A/D Buffer

Power-Sensitive, High-Speed Systems

Battery Powered Equipment

Loop/Remote Power Systems

Communication or Video Test Systems

Portable Medical Instruments

PRODUCT DESCRIPTION

The AD8005 is an ultralow power, high-speed amplifier with a

wide signal bandwidth of 170 MHz and slew rate of 280 V/µs.

This performance is achieved while consuming only 400 µA of

quiescent supply current. These features increase the operating

time of high-speed battery-powered systems without reducing

dynamic performance.

)

S

Current Feedback Amplifier

AD8005

FUNCTIONAL BLOCK DIAGRAM

8-Lead Plastic DIP and SOIC

AD8005

NC

1

2

–IN

+IN

3

–V

4

S

NC = NO CONNECT

5-Lead SOT-23

OUT

–V

2

S

+IN

3

AD8005

The current feedback design results in gain flatness of 0.1 dB

to 30 MHz while offering differential gain and phase errors of

0.11% and 0.4°. Harmonic distortion is low over a wide

bandwidth with THDs of –63 dBc at 1 MHz and –50 dBc at

10 MHz. Ideal features for a signal conditioning amplifier or

buffer to a high-speed A-to-D converter in portable video,

medical or communication systems.

The AD8005 is characterized for +5 V and ±5 V supplies and

will operate over the industrial temperature range of –40°C to

+85°C. The amplifier is supplied in 8-lead plastic DIP, 8-lead

SOIC and 5-lead SOT-23 packages.

8

NC

7

+V

S

OUT

6

NC

5

+V

51

S

–IN

4

3

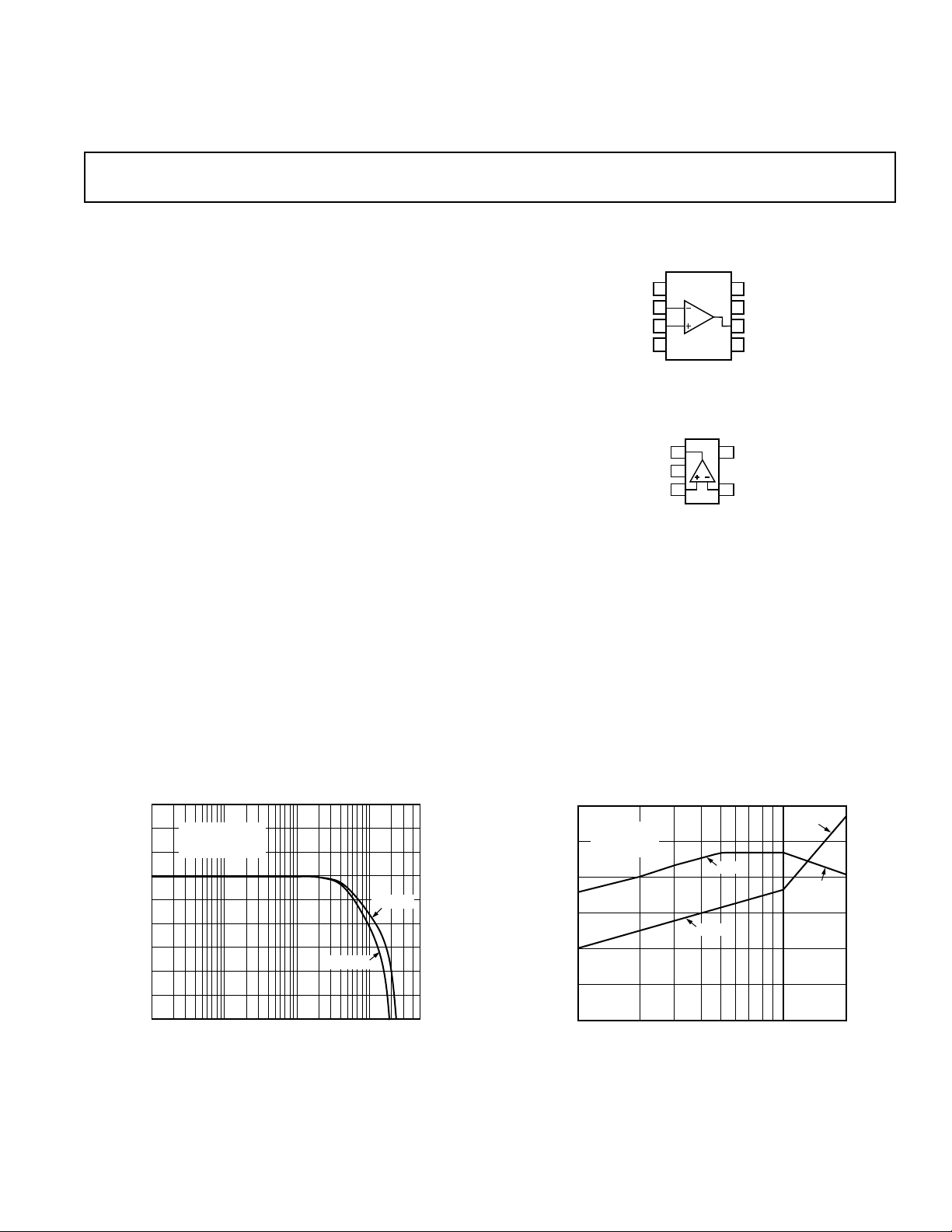

G = +2

2

1

0

–1

–2

–3

NORMALIZED GAIN – dB

–4

–5

–6

0.1 50010 100

V

R

OUT

= 1kV

L

= 200mV p-p

1

FREQUENCY – MHz

VS = ±5V

VS = +5V

Figure 1. Frequency Response; G = +2, VS = +5 V or ±5V

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

–40

G = +2

V

= 2V p-p

OUT

–50

RL = 1kV

–60

–70

–80

DISTORTION – dBc

–90

–100

1

3RD

2ND

FREQUENCY – MHz

2ND

3RD

2010

Figure 2. Distortion vs. Frequency; VS = ±5V

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD8005–SPECIFICATIONS

ⴞ5 V SUPPLIES

(@ TA = +25ⴗC, VS = ⴞ5 V, RL = 1 k⍀ unless otherwise noted)

AD8005A

Parameter Conditions Min Typ Max Units

DYNAMIC PERFORMANCE R

–3 dB Small Signal Bandwidth G = +1, V

Bandwidth for 0.1 dB Flatness G = +2, V

Large Signal Bandwidth G = +10, V

Slew Rate (Rising Edge) G = +2, V

= 3.01 kΩfor “N” Package or

F

R

= 2.49 kΩ for “R” Package or

F

R

= 2.10 kΩ for “RT” Package

F

G = +2, V

G = –1, V

= 0.2 V p-p 225 270 MHz

O

= 0.2 V p-p 140 170 MHz

O

= 0.2 V p-p 10 30 MHz

O

= 4 V p-p, R

O

= 4 V Step 280 V/µs

O

= 4 V Step, R

O

= 499 Ω 40 MHz

F

= 1.5 kΩ 1500 V/µs

F

Settling Time to 0.1% G = +2, VO = 2 V Step 28 ns

DISTORTION/NOISE PERFORMANCE R

Total Harmonic Distortion f

= 3.01 kΩ for “N” Package or

F

= 2.49 kΩ for “R” Package or

R

F

R

= 2.10 kΩ for “RT” Package

F

= 1 MHz, VO = 2 V p-p, G = +2 –63 dBc

C

= 10 MHz, VO = 2 V p-p, G = +2 –50 dBc

f

C

Differential Gain NTSC, G = +2 0.11 %

Differential Phase NTSC, G = +2 0.4 Degrees

Input Voltage Noise f = 10 MHz 4.0 nV/√Hz

Input Current Noise f = 10 MHz, +I

–I

IN

IN

1.1 pA/√Hz

9.1 pA/√Hz

DC PERFORMANCE

Input Offset Voltage 530±mV

to T

T

MIN

MAX

50 ±mV

Offset Drift 40 µV/°C

+Input Bias Current 0.5 1 ±µA

to T

T

MIN

MAX

2 ±µA

–Input Bias Current 510±µA

to T

T

MIN

MAX

12 ±µA

Input Bias Current Drift (±) 6nA/°C

Open-Loop Transimpedance 400 1000 kΩ

INPUT CHARACTERISTICS

Input Resistance +Input 90 MΩ

–Input 260 Ω

Input Capacitance +Input 1.6 pF

Input Common-Mode Voltage Range 3.8 ±V

Common-Mode Rejection Ratio V

= ±2.5 V 46 54 dB

CM

OUTPUT CHARACTERISTICS

Output Voltage Swing Positive +3.7 +3.90 V

Negative –3.90 –3.7 V

Output Current R

= 50 Ω 10 mA

L

Short Circuit Current 60 mA

POWER SUPPLY

Quiescent Current 400 475 µA

Power Supply Rejection Ratio V

to T

T

MIN

S

MAX

= ±4 V to ±6 V 56 66 dB

560 µA

OPERATING TEMPERATURE RANGE –40 +85 °C

Specifications subject to change without notice.

–2–

REV. A

Page 3

AD8005

+5 V SUPPLY

(@ TA = +25ⴗC, VS = +5 V, RL = 1 k⍀ to 2.5 V unless otherwise noted)

AD8005A

Parameter Conditions Min Typ Max Units

DYNAMIC PERFORMANCE R

–3 dB Small Signal Bandwidth G = +1, V

Bandwidth for 0.1 dB Flatness G = +2, V

Large Signal Bandwidth G = +10, V

Slew Rate (Rising Edge) G = +2, V

= 3.01 kΩ for “N” Package or

F

R

= 2.49 kΩ for “R” Package or

F

R

= 2.10 kΩ for “RT” Package

F

G = +2, V

G = –1, V

= 0.2 V p-p 190 225 MHz

O

= 0.2 V p-p 110 130 MHz

O

= 0.2 V p-p 10 30 MHz

O

= 2 V p-p, R

O

= 2 V Step 260 V/µs

O

= 2 V Step, R

O

= 499 Ω 45 MHz

F

= 1.5 kΩ 775 V/µs

F

Settling Time to 0.1% G = +2, VO = 2 V Step 30 ns

DISTORTION/NOISE PERFORMANCE R

Total Harmonic Distortion f

Differential Gain NTSC, G = +2, R

Differential Phase NTSC, G = +2, R

= 3.01 kΩ for “N” Package or

F

= 2.49 kΩ for “R” Package or

R

F

R

= 2.10 kΩ for “RT” Package

F

= 1 MHz, VO = 2 V p-p, G = +2 –60 dBc

C

= 10 MHz, VO = 2 V p-p, G = +2 –50 dBc

f

C

to 1.5 V 0.14 %

L

to 1.5 V 0.70 Degrees

L

Input Voltage Noise f = 10 MHz 4.0 nV/√Hz

Input Current Noise f = 10 MHz, +I

–I

IN

IN

1.1 pA/√Hz

9.1 pA/√Hz

DC PERFORMANCE

Input Offset Voltage 535±mV

to T

T

MIN

MAX

50 ±mV

Offset Drift 40 µV/°C

+Input Bias Current 0.5 1 ±µA

to T

T

MIN

MAX

2 ±µA

–Input Bias Current 510±µA

to T

T

MIN

MAX

11 ±µA

Input Bias Current Drift (±)8nA/°C

Open-Loop Transimpedance 50 500 kΩ

INPUT CHARACTERISTICS

Input Resistance +Input 120 MΩ

–Input 300 Ω

Input Capacitance +Input 1.6 pF

Input Common-Mode Voltage Range 1.5 to 3.5 V

Common-Mode Rejection Ratio VCM = 1.5 V to 3.5 V 48 54 dB

OUTPUT CHARACTERISTICS

Output Voltage Swing 1.1 to 3.9 0.95 to 4.05 V

Output Current R

= 50 Ω 10 mA

L

Short Circuit Current 30 mA

POWER SUPPLY

Quiescent Current 350 425 µA

to T

T

MIN

MAX

475 µA

Power Supply Rejection Ratio VS = +4 V to +6 V 56 66 dB

OPERATING TEMPERATURE RANGE –40 +85 °C

Specifications subject to change without notice.

REV. A

–3–

Page 4

AD8005

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.6 V

Internal Power Dissipation

2

1

Plastic DIP Package (N) . . . . . . . . . . . . . . . . . . . . 1.3 Watts

Small Outline Package (R) . . . . . . . . . . . . . . . . . . 0.75 Watts

SOT-23-5 Package (RT) . . . . . . . . . . . . . . . . . . . 0.5 Watts

Input Voltage (Common Mode) . . . . . . . . . . . . . . . ±V

± 1V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ±3.5 V

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . Observe Power Derating Curves

Storage Temperature Range

N, R & RT Package . . . . . . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range (A Grade) . . . –40°C to +85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

8-Lead Plastic DIP Package: θJA = 90°C/W

8-Lead SOIC Package: θJA = 155°C/W

5-Lead SOT-23 Package: θJA = 240°C/W

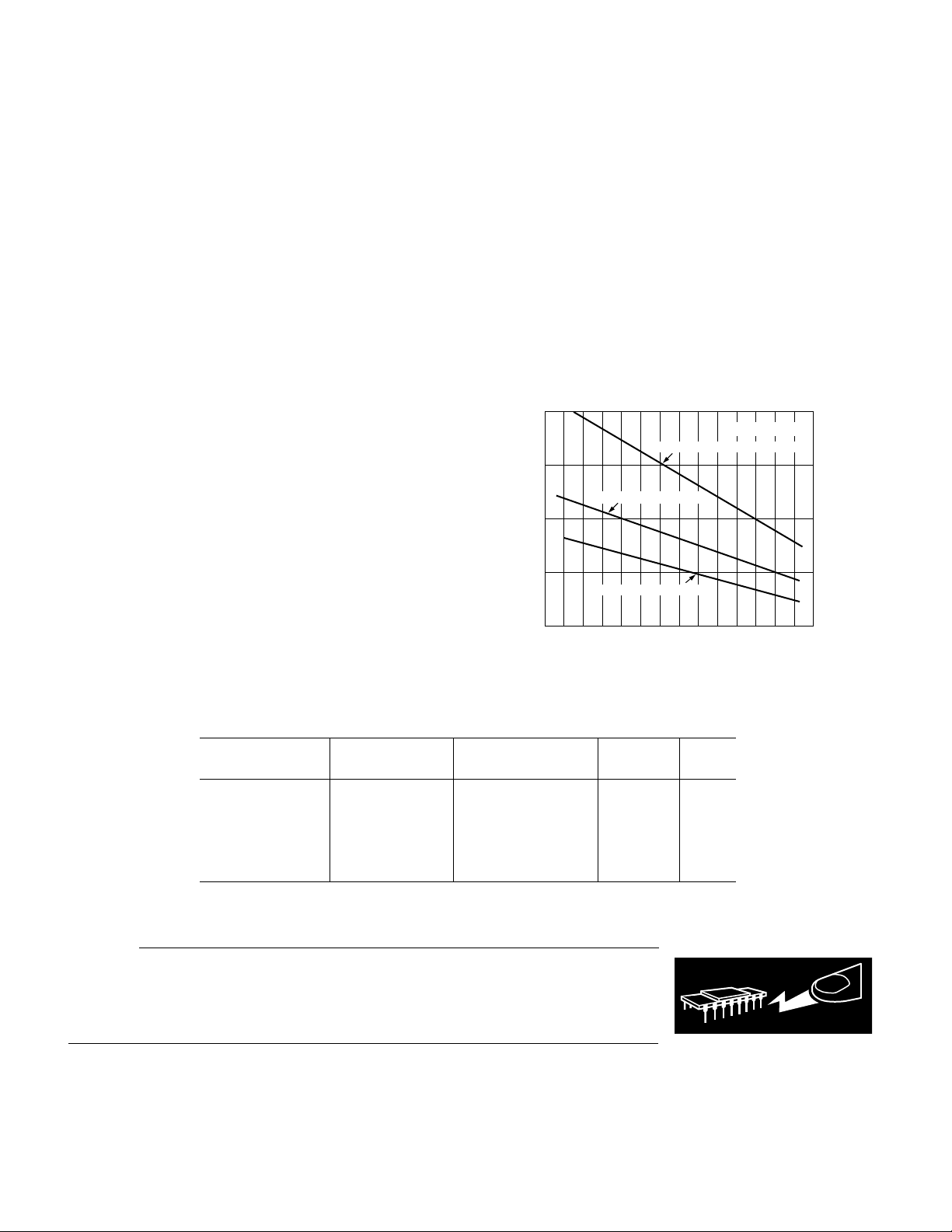

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8005 is limited by the associated rise in junction temperature. The maximum safe junction temperature for plastic

encapsulated devices is determined by the glass transition tem-

perature of the plastic, approximately +150°C. Exceeding this

limit temporarily may cause a shift in parametric performance

due to a change in the stresses exerted on the die by the package.

Exceeding a junction temperature of +175°C for an extended

period can result in device failure.

While the AD8005 is internally short circuit protected, this may

not be sufficient to guarantee that the maximum junction tem-

perature (+150°C) is not exceeded under all conditions. To

ensure proper operation, it is necessary to observe the maximum

power derating curves shown in Figure 3.

2.0

TJ = +150°C

8-LEAD PLASTIC-DIP PACKAGE

1.5

8-LEAD SOIC PACKAGE

1.0

0.5

MAXIMUM POWER DISSIPATION – Watts

0

–50

5-LEAD SOT-23 PACKAGE

AMBIENT TEMPERATURE – °C

Figure 3. Maximum Power Dissipation vs. Temperature

ORDERING GUIDE

Temperature Package Package Brand

Model Range Description Option Code

AD8005AN –40°C to +85°C 8-Lead Plastic DIP N-8

AD8005AR –40°C to +85°C 8-Lead Plastic SOIC SO-8

AD8005AR-REEL –40°C to +85°C 13" Tape and Reel SO-8

AD8005ART-REEL –40°C to +85°C 13" Tape and Reel RT-5 H1A

AD8005AR-REEL7 –40°C to +85°C 7" Tape and Reel SO-8

AD8005ART-REEL7 –40°C to +85°C 7" Tape and Reel RT-5 H1A

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8005 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

9080

706050403020100–40 –30 –20 –10

–4–

REV. A

Page 5

Typical Characteristics–AD8005

5

4

VS = 65V

3

V

= 200mV p-p

OUT

R

= 1kV

L

2

1

0

–1

–2

NORMALIZED GAIN – dB

–3

–4

–5

1 50010 100

G = +10

R

= 499V

F

FREQUENCY – MHz

G = +1

G = +2

Figure 4. Frequency Response; G = +1, +2, +10; VS = ±5 V

6.2

6.1

6.0

5.9

5.8

G = +2

5.7

V

= 200mV p-p

OUT

R

= 1kV

GAIN – dB

5.6

5.5

5.4

5.3

5.2

L

0.1

FREQUENCY – MHz

50010 1001

5

VS = 65V

4

V

= 200mV p-p

OUT

R

= 1kV

3

L

2

1

0

–1

–2

NORMALIZED GAIN – dB

–3

–4

–5

1 50010 100

G = –10

R

= 1kV

F

FREQUENCY – MHz

G = –1

R

= 1.5kV

F

Figure 7. Frequency Response; G = –1, –10; VS = ±5 V

140

120

100

80

60

GAIN – dB

40

20

0

1k 100M10k 100k 1M 10M 1G

FREQUENCY – Hz

PHASE

GAIN

0

–40

–80

–120

–160

PHASE – Degrees

–200

–240

–280

Figure 5. Gain Flatness; G = +2; VS = ±5 V or +5 V

7

6

5

4

3

2

GAIN – dB

1

0

–1

–2

1 50010 100

VS = 65V

V

= 4V p-p

OUT

FREQUENCY – MHz

VS = 65V

V

= 2V p-p

OUT

Figure 6. Large Signal Frequency Response;

= 1 k

G = +2, R

Ω

L

Figure 8. Transimpedance Gain and Phase vs. Frequency

10

9

8

7

6

VS = +5V

5

G = +2

V

= 1k

R

L

4

1%THD) – Volts

(

3

2

PEAK-TO-PEAK OUTPUT VOLTAGE

1

0

0.5 100110

FREQUENCY – MHz

Figure 9. Output Swing vs. Frequency; VS = ±5 V

REV. A

–5–

Page 6

AD8005–Typical Characteristics

–40

G = +2

= 2V p-p

V

–50

OUT

= 1kV

R

L

–60

–70

–80

DISTORTION – dBc

–90

–100

1

3RD

2ND

FREQUENCY – MHz

2ND

3RD

2010

Figure 10. Distortion vs. Frequency; VS = ±5 V

0.10

0.05

0.00

–0.05

DIFF GAIN – %

–0.10

0.06

0.04

0.02

0.00

–0.02

–0.04

DIFF PHASE – Degrees

–0.06

MIN = –0.06 MAX = 0.03 p-p/MAX = 0.09

MIN = –0.01 MAX = 0.39 p-p = 0.40

MODULATING RAMP LEVEL – IRE

VS = ±5V

= 1kV

R

L

G = +2

VS = ±5V

R

= 1kV

L

G = +2

11th1st 2nd 3rd 4th 5t h 6th 7th 8th 9th 10th

Figure 11. Differential Gain and Phase, VS = ±5 V

–40

G = +2

= 2V p-p

V

–50

OUT

= 1kV

R

L

–60

–70

–80

DISTORTION – dBc

–90

–100

1

3RD

2ND

FREQUENCY – MHz

2ND

3RD

2010

Figure 13. Distortion vs. Frequency VS = +5 V

0.10

0.05

0.00

–0.05

DIFF GAIN – %

–0.10

1.0

0.5

0.0

–0.5

DIFF PHASE – Degrees

–1.0

MIN = –0.08 MAX = 0.04 p-p/MAX = 0.12

VS = +5V

R

= 1kV TO +1.5V

L

G = +2

MIN = 0.00 MAX = 0.70 p-p = 0.70

VS = +5V

R

= 1kV TO +1.5V

L

G = +2

MODULATING RAMP LEVEL – IRE

11th1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th

Figure 14. Differential Gain and Phase, VS = +5 V

9

8

7

6

5

4

SWING – V p-p

3

2

1

0

10

VS = 65V

VS = +5V

LOAD RESISTANCE – V

1k 10k100

Figure 12. Output Voltage Swing vs. Load

–6–

9

8

f = 5MHz

G = +2

7

R

= 1kV

L

6

5

4

3

PEAK-TO-PEAK OUTPUT

2

AT 5MHz ( 0.5% THD) – Volts

1

0

31145678910

TOTAL SUPPLY VOLTAGE – Volts

Figure 15. Output Swing vs. Supply

REV. A

Page 7

AD8005

–5

VS = +5V OR 65V

–10

G = +2

–15

R

= 1kV

L

–20

–25

–30

CMRR – dB

–35

–40

–45

–50

–55

0.03

0.1 100

110

FREQUENCY – MHz

Figure 16. CMRR vs. Frequency; VS = +5 V or ±5 V

VS = +5V AND 65V

= 1k

R

V

100

OUTPUT RESISTANCE – V

L

G = +2

10

1

0.03 500

VS = +5V

VS = 65V

0.1 100

110

FREQUENCY – MHz

12.5

10.0

7.5

5.0

2.5

INPUT VOLTAGE NOISE – nV/ Hz

0

10 10M100

1k 10k 100k 1M

FREQUENCY – Hz

Figure 19. Noise vs. Frequency; VS = +5 V or ±5 V

62.5

50.0

37.5

25.0

12.5

INPUT CURRENT NOISE – pA/ Hz

0

10 10M100 1k 10k 100k 1M

INVERTING CURRENT

NONINVERTING CURRENT

FREQUENCY – Hz

Figure 17. Output Resistance vs. Frequency;

= ±5 V and +5 V

V

S

10

VS = +5V OR 65V

0

G = +2

–10

R

= 1kV

L

–20

–30

–40

PSRR – dB

–50

–60

–70

–80

0.03 500

0.1 100

110

FREQUENCY – MHz

–PSRR

+PSRR

Figure 18. PSRR vs. Frequency; VS = +5 V or ±5 V

Figure 20. Noise vs. Frequency; VS = +5 V or ±5 V

100

90

10

0%

V

OUT

V

IN

1V 2V

VS = 65V

G = +6

= 1kV

R

L

150ns

Figure 21.±Overdrive Recovery, VS = ±5 V, VIN = 2 V Step

REV. A

–7–

Page 8

AD8005–Typical Characteristics

R

F

= 10pF NOMINAL

LOAD

C

0.01mF

0.01mF

PROBE

10mF

10mF

R

1kV

V

OUT

L

+V

S

–V

S

V

IN

R

G

50V

PROBE : TEK P6137

C

Figure 22. Test Circuit; G = +2; RF = RG = 3.01 kΩ for

N Package; R

= RG = 2.49 kΩ for R and RT Packages

F

100

90

10

0%

50mV

10ns

V

IN

1.5kV

51.1V

PROBE : TEK P6137

C

1.5kV

= 10pF NOMINAL

LOAD

C

0.01mF

0.01mF

PROBE

R

1kV

10mF

10mF

V

OUT

L

+V

S

–V

S

Figure 25. Test Circuit; G = –1, RF = RG = 1.5 kΩ for

N, R and RT Packages

100

90

10

0%

50mV

10ns

Figure 23. 200 mV Step Response; G = +2, VS = ±2.5 V

±

5 V

or

100

90

10

0%

1V

10ns

Figure 24. Step Response; G = +2, VS = ±5 V

Figure 26. 200 mV Step Response; G = –1, VS = ±2.5 V

±

5 V

or

100

90

10

0%

1V

10ns

Figure 27. Step Response; G = –1, VS = ±5 V

–8–

REV. A

Page 9

AD8005

APPLICATIONS

Driving Capacitive Loads

Capacitive loads interact with an op amp’s output impedance

to create an extra delay in the feedback path. This reduces

circuit stability, and can cause unwanted ringing and oscillation. A given value of capacitance causes much less ringing

when the amplifier is used with a higher noise gain.

The capacitive load drive of the AD8005 can be increased by

adding a low valued resistor in series with the capacitive load.

Introducing a series resistor tends to isolate the capacitive load

from the feedback loop thereby diminishing its influence. Figure 29 shows the effects of a series resistor on capacitive drive

for varying voltage gains. As the closed-loop gain is increased,

the larger phase margin allows for larger capacitive loads with

less overshoot. Adding a series resistor at lower closed-loop

gains accomplishes the same effect. For large capacitive loads,

the frequency response of the amplifier will be dominated by

the roll-off of the series resistor and capacitive load.

R

F

R

R

G

AD8005

S

R

L

V

1k

C

L

Figure 28. Driving Capacitive Loads

80

VS = 65V

2V OUTPUT STEP

70

WITH 30% OVERSHOOT

60

50

40

30

CAPACITIVE LOAD – pF

20

10

0

1 345

RS = 10V

RS = 5V

RS = 0V

2

CLOSED-LOOP GAIN – V/V

Figure 29. Capacitive Load Drive vs. Closed-Loop Gain

Single-Supply Level Shifter

In addition to providing buffering, many systems require that an

op amp provide level shifting. A common example is the level

shifting that is required to move a bipolar signal into the unipolar range of many modern analog-to-digital converters (ADCs). In

general, single supply ADCs have input ranges that are referenced neither to ground nor supply. Instead the reference level

is some point in between, usually halfway between ground and

supply (+2.5 V for a single supply 5 V ADC). Because highspeed ADCs typically have input voltage ranges of 1 V to 2 V,

the op amp driving it must be single supply but not necessarily

rail-to-rail.

R2

1.5kV

+5V

R1

1.5kV

V

IN

V

REF

+5V

R3

30.1kV

AD8005

R4

10kV

0.1mF

0.01mF 10mF

V

OUT

Figure 30. Bipolar to Unipolar Level Shifter

Figure 30 shows a level shifter circuit that can move a bipolar

signal into a unipolar range. A positive reference voltage, derived

from the +5 V supply, sets a bias level of +1.25 V at the noninverting terminal of the op amp. In ac applications, the accuracy of

this voltage level is not important. Noise is however a serious

consideration. A 0.1 µF capacitor provides useful decoupling of

this noise.

The bias level on the noninverting terminal sets the input commonmode voltage to +1.25 V. Because the output will always be

positive, the op amp may therefore be powered with a single

+5 V power supply.

The overall gain function is given by the equation:

= –

R2

R1

V

OUT

V

+

IN

R3 +R 4

R4

R2

1+

V

R1

REF

In the above example, the equation simplifies to

V

= –VIN+2.5 V

OUT

REV. A

–9–

Page 10

AD8005

Single-Ended-to-Differential Conversion

Many single supply ADCs have differential inputs. In such cases,

the ideal common-mode operating point is usually halfway

between supply and ground. Figure 31 shows how to convert a

single-ended bipolar signal into a differential signal with a

common-mode level of 2.5 V.

BIPOLAR

SIGNAL

60.5V

2.49kV

0.1mF

2.49kV

2.49kV

2.49kV

+5V

+5V

R

IN

1kV

0.1mF

AD8005

R

G

619V

AD8005

+5V

+5V

0.1mF

R

2.49kV

R

3.09kV

0.1mF

F1

F2

V

OUT

Figure 31. Single-Ended-to-Differential Converter

Amp 1 has its +input driven with the ac-coupled input signal

while the +input of Amp 2 is connected to a bias level of +2.5 V.

Thus the –input of Amp 2 is driven to virtual +2.5 V by its

output. Therefore, Amp 1 is configured for a noninverting gain

of five, (1 + R

), because RG is connected to the virtual

F1/RG

+2.5 V of Amp 2’s –input.

When the +input of Amp 1 is driven with a signal, the same

signal appears at the –input of Amp 1. This signal serves as an

input to Amp 2 configured for a gain of –5, (–R

F2/RG

). Thus the

two outputs move in opposite directions with the same gain and

create a balanced differential signal.

This circuit can be simplified to create a bipolar in/bipolar out

single-ended to differential converter. Obviously, a single supply

is no longer adequate and the –V

pins must now be powered

S

with –5 V. The +input to Amp 2 is tied to ground. The ac

coupling on the +input of Amp 1 is removed and the signal can

be fed directly into Amp 1.

Layout Considerations

In order to achieve the specified high-speed performance of the

AD8005 you must be attentive to board layout and component

selection. Proper R

design techniques and selection of compo-

F

nents with low parasitics are necessary.

The PCB should have a ground plane that covers all unused

portions of the component side of the board. This will provide a

low impedance path for signals flowing to ground. The ground

plane should be removed from the area under and around the

chip (leave about 2 mm between the pin contacts and the

ground plane). This helps to reduce stray capacitance. If both

signal tracks and the ground plane are on the same side of the

PCB, also leave a 2 mm gap between ground plane and track.

R

V

IN

V

IN

G

R

T

R

G

R

NONINVERTING CONFIGURATION

R

F

INVERTING CONFIGURATION

R

F

T

C1

0.01mF

C2

0.01mF

C1

0.01mF

C2

0.01mF

R

O

C3

10mF

C4

10mF

R

O

C3

10mF

C4

10mF

V

OUT

+V

S

–V

S

V

OUT

+V

S

–V

S

Figure 32. Inverting and Noninverting Configurations

Chip capacitors have low parasitic resistance and inductance

and are suitable for supply bypassing (see Figure 32). Make sure

that one end of the capacitor is within 1/8 inch of each power

pin with the other end connected to the ground plane. An

additional large (0.47 µF–10 µF) tantalum electrolytic capacitor

should also be connected in parallel. This capacitor supplies

current for fast, large signal changes at the output. It must not

necessarily be as close to the power pin as the smaller capacitor.

Locate the feedback resistor close to the inverting input pin in

order to keep the stray capacitance at this node to a minimum.

Capacitance variations of less than 1.5 pF at the inverting input

will significantly affect high-speed performance.

Use stripline design techniques for long signal traces (i.e., greater

than about 1 inch). Striplines should have a characteristic

impedance of either 50 Ω or 75 Ω. For the Stripline to be

effective, correct termination at both ends of the line is necessary.

Table I. Typical Bandwidth vs. Gain Setting Resistors

Small Signal –3 dB

BW (MHz),

Gain R

F

R

G

R

T

VS = ⴞ5 V

–1 1.49 kΩ 1.49 kΩ 52.3 120 MHz

–10 1 kΩ 100 Ω 100 Ω 60 MHz

+1 2.49 kΩ ⴥ 49.9 Ω 270 MHz

+2 2.49 kΩ 2.49 kΩ 49.9 Ω 170 MHz

+10 499 Ω 56.2 Ω 49.9 Ω 40 MHz

–10–

REV. A

Page 11

AD8005

Increasing Feedback Resistors

Unlike conventional voltage feedback op amps, the choice of feedback resistor has a direct impact on the closed-loop bandwidth

and stability of a current feedback op amp circuit. Reducing the

resistance below the recommended value makes the amplifier

more unstable. Increasing the size of the feedback resistor

reduces the closed-loop bandwidth.

360mA (rms)

4.99kV

+5V

AD8005

QUIESCENT CURRENT

475mA (MAX)

–5V

V

OUT

2V (rms)

V

0.2V (rms)

562V

IN

Figure 33. Saving Power by Increasing Feedback Resistor

Network

In power-critical applications where some bandwidth can be

sacrificed, increasing the size of the feedback resistor will yield

significant power savings. A good example of this is the gain of

+10 case. Operating from a bipolar supply (±5 V), the quiescent

current is 475 µA (excluding the feedback network). The recom-

mended feedback and gain resistors are 499 Ω and 56.2 Ω

respectively. In order to drive an rms output voltage of 2 V, the

output must deliver a current of 3.6 mA to the feedback network. Increasing the size of the resistor network by a factor of

10 as shown in Figure 33 will reduce this current to 360 µA.

The closed loop bandwidth will however decrease to 20 MHz.

REV. A

–11–

Page 12

AD8005

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead Plastic DIP

(N-8)

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

8-Lead Plastic SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

C2186a–0–8/99

0.195 (4.95)

0.115 (2.93)

0.0098 (0.25)

0.0040 (0.10)

0.0669 (1.70)

0.0590 (1.50)

0.0512 (1.30)

0.0354 (0.90)

PIN 1

SEATING

PLANE

0.0059 (0.15)

0.0019 (0.05)

0.0688 (1.75)

0.0532 (1.35)

0.0500

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

5-Lead Plastic SOT-23

(RT-5)

0.1181 (3.00)

0.1102 (2.80)

1 2 3

0.1181 (3.00)

4

0.0748 (1.90)

BSC

0.0197 (0.50)

0.0138 (0.35)

0.1024 (2.60)

5

0.0374 (0.95) BSC

0.0571 (1.45)

0.0374 (0.95)

SEATING

PLANE

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

10°

0°

x 45°

0.0079 (0.20)

0.0031 (0.08)

0.0217 (0.55)

0.0138 (0.35)

PRINTED IN U.S.A.

–12–

REV. A

Loading...

Loading...