Page 1

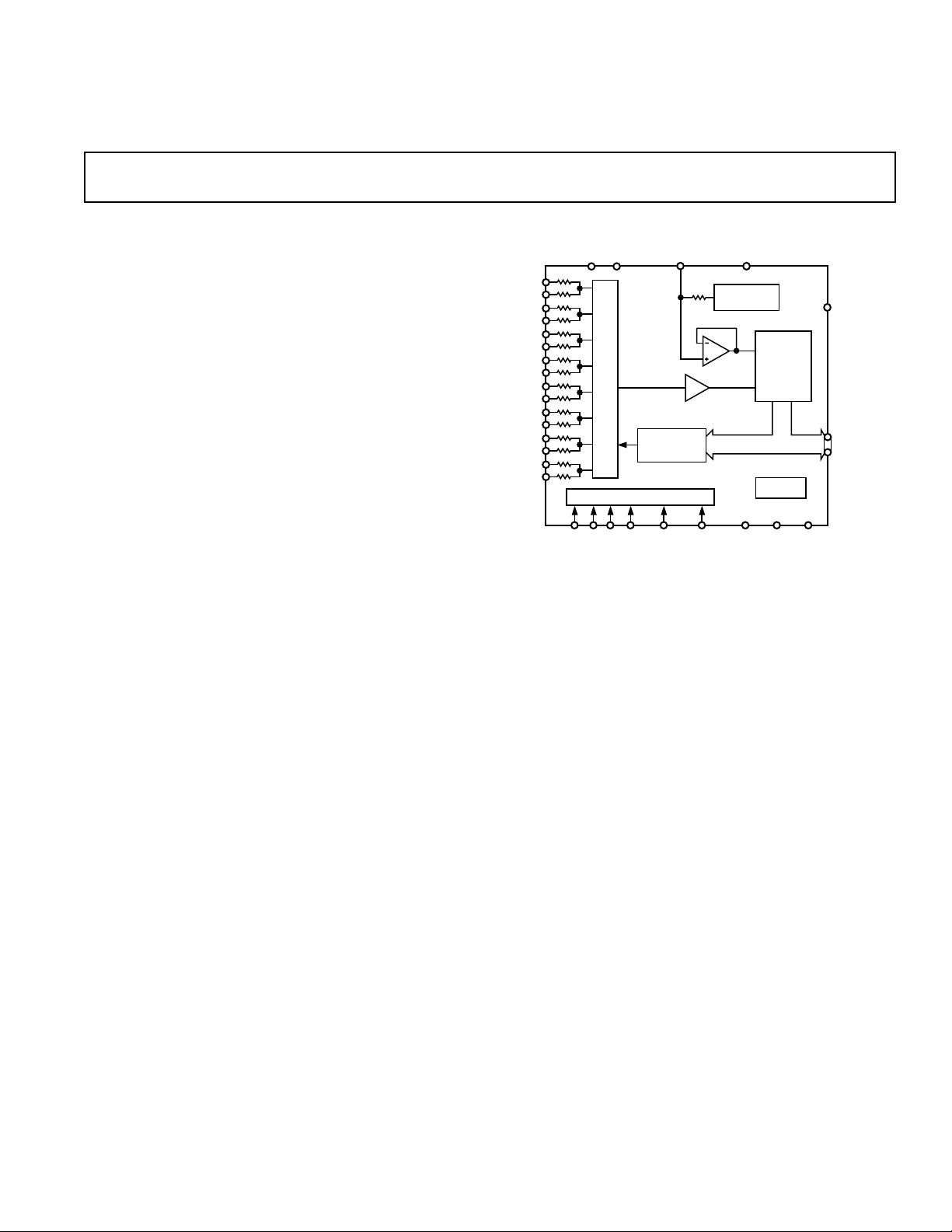

LC2MOS 8-Channel, 12-Bit

+2.5V

REFERENCE

TRACK/HOLD

V

IN1A

V

IN1B

V

IN2A

V

IN2B

V

IN3A

V

IN3B

V

IN4A

V

IN4B

V

IN5A

V

IN5B

V

IN6A

V

IN6B

V

IN7A

V

IN7B

V

IN8A

V

IN8B

CONTROL LOGIC

WR CS RD EOC CONVST

MODE AGND

AGND DGND

CLOCK

VDDV

DD

AD7891

12-BIT

ADC

ADDRESS

DECODE

REF OUT/

REF IN

REF GND

STANDBY

M

U

X

DATA/

CONTROL

LINES

a

High Speed Data Acquisition System

AD7891

FEATURES

Fast 12-Bit ADC with 1.6 s Conversion Time

Eight Single-Ended Analog Input Channels

Overvoltage Protection on Each Channel

Selection of Input Ranges:

ⴞ5 V, ⴞ10 V for AD7891-1

0 to +2.5 V, 0 to +5 V, ⴞ2.5 V for AD7891-2

Parallel and Serial Interface

On-Chip Track/Hold Amplifier

On-Chip Reference

Single Supply, Low Power Operation (85 mW max)

Power-Down Mode (75 W typ)

APPLICATIONS

Data Acquisition Systems

Motor Control

Mobile Communication Base Stations

Instrumentation

GENERAL DESCRIPTION

The AD7891 is an eight-channel 12-bit data acquisition system

with a choice of either parallel or serial interface structure. The

part contains an input multiplexer, an on-chip track/hold amplifier, a high speed 12-bit ADC, a +2.5␣ V reference and a high

speed interface. The part operates from a single +5 V supply

and accepts a variety of analog input ranges across two models,

the AD7891-1 (±5␣ V and ±10␣ V) and the AD7891-2 (0 V to

+2.5 V, 0 V to +5␣ V and ±2.5␣ V).

The AD7891 provides the option of either a parallel interface or

serial interface structure determined by the MODE pin. The

part has standard control inputs and fast data access times for

both the serial and parallel interfaces which ensures easy interfacing to modern microprocessors, microcontrollers and digital

signal processors.

In addition to the traditional dc accuracy specifications such as

linearity, full-scale and offset errors, the part is also specified for

dynamic performance parameters including harmonic distortion

PRODUCT HIGHLIGHTS

1. The AD7891 is a complete monolithic 12-bit data acquisition

system combining an eight-channel multiplexer, 12-bit ADC,

+2.5␣ V reference and track/hold amplifier on a single chip.

2. The AD7891-2 features a conversion time of 1.6 µs and an

acquisition time of 0.4␣ µs. This allows a sample rate of

500␣ kSPS when sampling one channel and 62.5 kSPS when

channel hopping. These sample rates can be achieved using

either a software or hardware convert start. The AD7891-1

has an acquisition time of 0.6 µs when using a hardware

convert start and an acquisition time of 0.7 µs when using a

software convert start. These acquisition times allow sample

rates of 454.5 kSPS and 435 kSPS respectively for hardware

and software convert start.

3. Each channel on the AD7891 has overvoltage protection.

This means that an overvoltage on an unselected channel

does not affect the conversion on a selected channel. The

AD7891-1 can withstand overvoltages of ±17 V.

and signal-to-noise ratio.

Power dissipation in normal mode is 90 mW typical while in

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

the standby mode this is reduced to 75 µW typ. The part is

available in a 44-terminal plastic quad flatpack (PQFP) and a

44-lead plastic leaded chip carrier (PLCC).

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

FUNCTIONAL BLOCK DIAGRAM

Page 2

AD7891–SPECIFICATIONS

(VDD = +5 V ⴞ 5%, AGND = DGND = 0 V, REF IN = +2.5 V. All Specifications T

T

unless otherwise noted.)

MAX

MIN

to

ABY

Parameter Version1Version Version Units Test Conditions/Comments

DYNAMIC PERFORMANCE

2

Signal to (Noise + Distortion) Ratio

4

Sample Rate = 454.5 kSPS3 (AD7891-1),

500 kSPS

3

(AD7891-2). Any Channel

@ +25°C 707070dB min

T

to T

MIN

Total Harmonic Distortion

Peak Harmonic or Spurious Noise

Intermodulation Distortion

MAX

4

4

70 70 70 dB min

–78 –78 –78 dB max

4

–80 –80 –80 dB max

fa = 9 kHz, fb = 9.5 kHz

2nd Order Terms –80 –80 –80 dB typ

3rd Order Terms –80 –80 –80 dB typ

Channel-to-Channel Isolation

4

–80 –80 –80 dB max

DC ACCURACY Any Channel

Resolution 12 12 12 Bits

Minimum Resolution for Which

No Missing Codes are Guaranteed 12 12 12 Bits

Relative Accuracy

Differential Nonlinearity

Positive Full-Scale Error

Positive Full-Scale Error Match

4

4

4

±1 ±0.75 ±1 LSB max

±1 ±1 ±1 LSB max

±3 ±3 ±3 LSB max

4, 5

0.6 0.6 0.6 LSB typ 1.5 LSB max

Unipolar Offset Error ±3 ±3 ±3 LSB max Input Ranges of 0 V to +2.5␣ V, 0 V to +5␣ V

Unipolar Offset Error Match

Negative Full-Scale Error

Negative Full-Scale Error Match

5

4

0.1 0.1 0.1 LSB typ 1 LSB max

±3 ±3 ±3 LSB max Input Ranges of ±2.5␣ V, ±5␣ V, ±10␣ V

4, 5

0.6 0.6 0.6 LSB typ 1.5 LSB max

Bipolar Zero Error ±4 ±4 ±4 LSB max Input Ranges of ±2.5␣ V, ±5␣ V, ±10␣ V

Bipolar Zero Error Match

5

0.2 0.2 0.2 LSB typ 1.5 LSB max

ANALOG INPUTS

AD7891-1 Input Voltage Range

AD7891-1 V

AD7891-1 V

±5␣ ±5␣ ±5␣ Volts Input Applied to Both V

±10␣ ±10␣ ±10 Volts Input Applied to V

Input Resistance 7.5 7.5 7.5 kΩ min Input Range of ±5␣ V

INXA

Input Resistance 15 15 15 kΩ min Input Range of ±10␣ V

INXA

INXA

INXA

, V

and V

= AGND

INXB

INXB

AD7891-2 Input Voltage Range

AD7891-2 V

AD7891-2 V

0 to +2.5␣ 0 to +2.5␣ 0 to +2.5␣ ␣ Volts Input Applied to Both V

0 to +5␣ 0 to +5␣ 0 to +5␣ Volts Input Applied to V

±2.5␣ ± 2.5␣ ±2.5␣ Volts Input Applied to V

Input Resistance 1.5 1.5 1.5 kΩ min Input Ranges of ±2.5␣ V and 0 to +5␣ V

INXA

Input Current ±50 ±50 ±50 nA max Input Range of 0 V to +2.5␣ V

INXA

INXA

INXA

INXA

, V

, V

and V

= AGND

INXB

= REF IN

INXB

INXB

6

REFERENCE INPUT/OUTPUT

REF IN Input Voltage Range 2.375/2.625 2.375/2.625 2.375/2.625 V min/V max 2.5 V ± 5%

Input Impedance 1.6 1.6 1.6 kΩ min Resistor Connected to Internal Reference Node

Input Capacitance

5

10 10 10 pF max

REF OUT Output Voltage 2.5 2.5 2.5 V␣ nom

REF OUT Error @ +25°C ±10 ±10 ±10 mV max

T

MIN

to T

MAX

±20 ±20 ±20 mV max

REF OUT Temperature Coefficient 25 25 25 ppm/°C typ

REF OUT Output Impedance 5 5 5 kΩ nom See REF IN Input Impedance

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

INL

INH

Input Capacitance,5 C

INH

IN

2.4 2.4 2.4 V min V

0.8 0.8 0.8 V max V

±10 ±10 ±10 µA max

10 10 10 pF max

= 5 V ± 5%

DD

= 5 V ± 5%

DD

–2– REV. A

Page 3

AD7891

WARNING!

ESD SENSITIVE DEVICE

ABY

Parameter Version1Version Version Units Test Conditions/Comments

LOGIC OUTPUTS

Output High Voltage, V

Output Low Voltage, V

OH

OL

4.0 4.0 4.0 V min I

0.4 0.4 0.4 V max I

DB11–DB0

Floating-State Leakage Current ±10 ±10 ±10 µA max

Floating-State Capacitance

5

15 15 15 pF max

Output Coding

Straight (Natural) Binary Data Format Bit of Control Register = 0

2s Complement Data Format Bit of Control Register = 1

CONVERSION RATE

Conversion Time 1.6 1.6 1.6 µs max

Track/Hold Acquisition Time 0.6 0.6 0.6 µs max AD7891-1 Hardware Conversion

0.7 0.7 0.7 µs max AD7891-1 Software Conversion

0.4 0.4 0.4 µs max AD7891-2

POWER REQUIREMENTS

V

DD

I

DD

+5 +5 +5 V nom ±5% for Specified Performance

Normal Mode 17 17 18 mA max

Standby Mode 80 80 80 µA max Logic Inputs = 0 V or V

Power Dissipation VDD = 5 V

Normal Mode 85 85 90 mW max Typically 70␣ mW

Standby Mode 400 400 400 µW max Typically 75 µW

NOTES

1

Temperature Ranges for the A and B Versions: –40°C to +85°C. Temperature Range for the Y Version: –55°C to +105°C.

2

The AD7891-1’s dynamic performance (THD and SNR) and the AD7891-2’s THD are measured with an input frequency of 10␣ kHz. The AD7891-2’s SNR is

evaluated with an input frequency of 100␣ kHz.

3

This throughput rate can only be achieved when the part is operated in the parallel interface mode. Maximum achievable throughput rate in the serial interface mode

is 357␣ kSPS.

4

See Terminology.

5

Sample tested during initial release and after any redesign or process change that may affect this parameter.

6

REF IN must be buffered before being applied to V

Specifications subject to change without notice.

INXB

.

SOURCE

= 1.6 mA

SINK

= 200 µA

DD

ABSOLUTE MAXIMUM RATINGS*

(T

= +25°C unless otherwise noted)

A

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7␣ V

V

DD

Analog Input Voltage to AGND

AD7891-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±17␣ V

AD7891-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5 V, +10␣ V

Reference Input Voltage to AGND . . . . –0.3 V to V

Digital Input Voltage to DGND . . . . . . –0.3 V to V

Digital Output Voltage to DGND . . . . . –0.3 V to V

+ 0.3␣ V

DD

+ 0.3 V

DD

+ 0.3 V

DD

Operating Temperature Range

Commercial (A, B Version) . . . . . . . . . . . . – 40°C to +85°C

Automotive (Y Version) . . . . . . . . . . . . . . –55°C to +105°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . +150°C

PQFP Package, Power Dissipation . . . . . . . . . . . . . . 450 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . 95°C/W

θ

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

PLCC Package, Power Dissipation . . . . . . . . . . . . . . 500 mW

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . 55°C/W

θ

JA

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . +215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . +220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7891 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. A

Page 4

AD7891

TIMING CHARACTERISTICS

1, 2

Parameter A, B, Y Versions Units Test Conditions/Comments

t

CONV

1.6 µs max Conversion Time

Parallel Interface

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

3

t

9

4

t

10

0 ns min CS to RD/WR Setup Time

35 ns min Write Pulsewidth

25 ns min Data Valid to Write Setup Time

5 ns min Data Valid to Write Hold Time

0 ns min CS to RD/WR Hold Time

35 ns min CONVST Pulsewidth

55 ns min EOC Pulsewidth

35 ns min Read Pulsewidth

25 ns min Data Access Time after Falling Edge of RD

5 ns min Bus Relinquish Time after Rising Edge of RD

30 ns max

Serial Interface

t

t

t

t

t

t

t

t

t

11

12

13

14

15

16

17

18

18A

3

3

3

4

4

30 ns min RFS Low to SCLK Falling Edge Setup Time

20 ns max RFS Low to Data Valid Delay

25 ns min SCLK High Pulsewidth

25 ns min SCLK Low Pulsewidth

5 ns min SCLK Rising Edge to Data Valid Hold Time

15 ns max SCLK Rising Edge to Data Valid Delay

20 ns min RFS to SCLK Falling Edge Hold Time

0 ns min Bus Relinquish Time after Rising Edge of RFS

30 ns max

0 ns min Bus Relinquish Time after Rising Edge of SCLK

30 ns max

t

19

t

20

t

21

t

22

NOTES

1

Sample tested during initial release and after any redesign or process change that may affect this parameter. All input signals are measured with tr = tf = 1 ns (10% to

90% of +5 V) and timed from a voltage level of +1.6 V.

2

See Figures 2, 3 and 4.

3

Measured with the load circuit of Figure 1 and defined as the time required for an output to cross 0.8␣ V or 2.4␣ V.

4

These times are derived from the measured time taken by the data outputs to change 0.5␣ V when loaded with the circuit of Figure 1. The measured number is then

extrapolated back to remove the effects of charging or discharging the 50 pF capacitor. This means that the times quoted in the timing characteristics are the true bus

relinquish times of the part and as such are independent of external bus loading capacitances.

Specifications subject to change without notice.

20 ns min TFS Low to SCLK Falling Edge Setup Time

15 ns min Data Valid to SCLK Falling Edge Setup Time

10 ns min Data Valid to SCLK Falling Edge Hold Time

30 ns min TFS Low to SCLK Falling Edge Hold Time

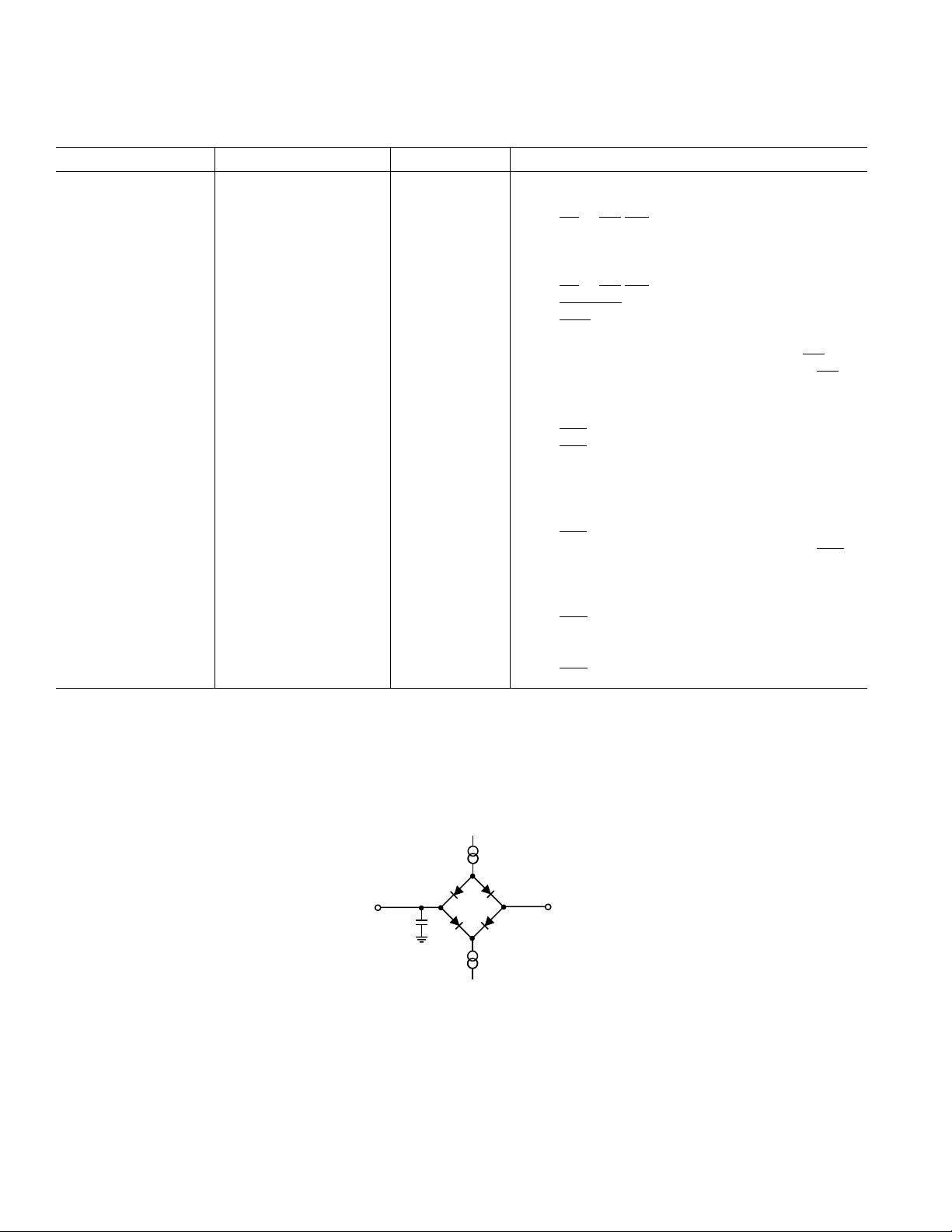

1.6mA

TO

OUTPUT

PIN

50pF

200mA

+1.6V

Figure 1. Load Circuit for Access Time and Bus Relinquish Time

–4– REV. A

Page 5

AD7891

V

IN6A

AGND

EOC

NC

CONVST

CS

REF GND

NC

REF OUT/REF IN

V

DD

AGND

MODE

DB11/TEST

DB10/TEST

DB9/TFS

DB8/RFS

DB7/DATA IN

STANDBY

V

IN1A

DB6/SCLK

V

DD

DGND

DB5/A2/DATA OUT

DB3/A0

DB2/SWCON

DB1/SWSTBY

DB0/FORMAT

WR

RD

DB4/A1

V

IN1BVIN2AVIN2BVIN3AVIN3BVIN4AVIN4BVIN5AVIN5B

V

IN6B

V

IN7A

V

IN7B

V

IN8A

V

IN8B

NC = NO CONNECT

44 43 42 41 40 39 38 37 36 35 34

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18 19 20 21 22

33

32

31

30

29

28

27

26

25

24

23

PIN 1

IDENTIFIER

TOP VIEW

(Not to Scale)

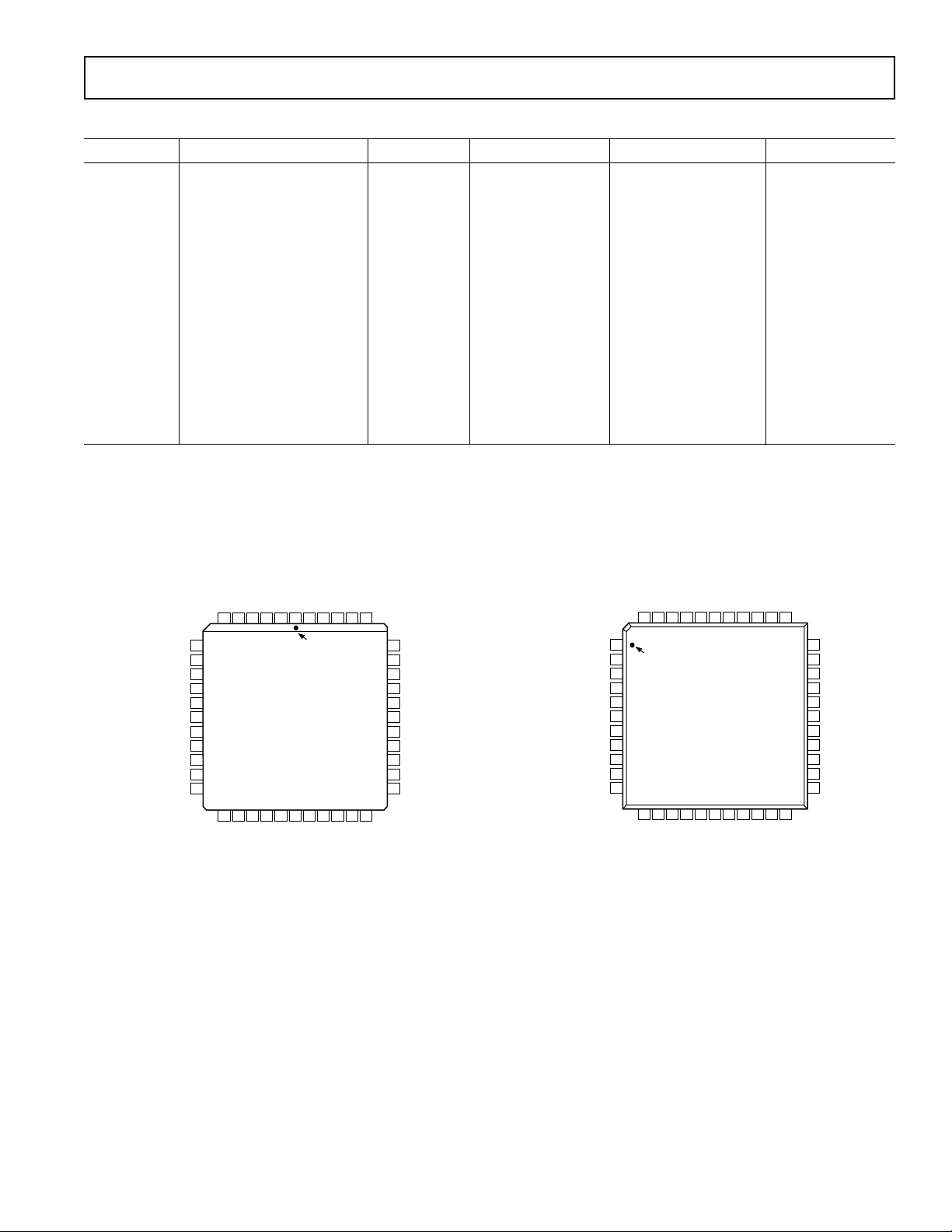

AD7891 PQFP

ORDERING GUIDE

Model Input Ranges Sample Rate Relative Accuracy Temperature Range Package Options*

AD7891AS-1 ±5 V or ±10 V 454 kSPS ±1 LSB –40°C to +85°CS-44

AD7891AP-1 ±5 V or ±10 V 454 kSPS ±1 LSB –40°C to +85°C P-44A

AD7891BS-1 ±5 V or ±10 V 454 kSPS ±0.75 LSB –40°C to +85°CS-44

AD7891BP-1 ±5 V or ±10 V 454 kSPS ±0.75 LSB –40°C to +85°C P-44A

AD7891YS-1 ±5 V or ±10 V 454 kSPS ±1 LSB –55°C to +105°CS-44

AD7891YP-1 ±5 V or ±10 V 454 kSPS ±1 LSB –55°C to +105°C P-44A

AD7891AS-2 0 V to +5 V, 0 V to +2.5 V 500 kSPS ±1 LSB –40°C to +85°CS-44

or ±2.5 V

AD7891AP-2 0 V to +5 V, 0 V to +2.5 V 500 kSPS ±1 LSB –40°C to +85°C P-44A

or ±2.5 V

AD7891BS-2 0 V to +5 V, 0 V to +2.5 V 500 kSPS ±0.75 LSB –40°C to +85°CS-44

or ±2.5 V

AD7891BP-2 0 V to +5 V, 0 V to +2.5 V 500 kSPS ±0.75 LSB –40°C to +85°C P-44A

or ±2.5 V

AD7891YS-2 0 V to +5 V, 0 V to +2.5 V 500 kSPS ±1 LSB –55°C to +105°CS-44

or ±2.5 V

*S = Plastic Quad Flatpack (PQFP); P = Plastic Leaded Chip Carrier (PLCC).

PIN CONFIGURATIONS

REF GND

REF OUT/REF IN

DB11/TEST

DB10/TEST

DB9/TFS

DB8/RFS

DB7/DATA IN

NC = NO CONNECT

6 5 4 3 2 1 44 43 42 41 40

7

8

NC

9

10

V

DD

11

AGND

12

MODE

13

14

15

16

17

18 19 20 21 22 23 24 25 26 27 28

DB6/SCLK

PLCC

IN1A

IN1BVIN2AVIN2BVIN3AVIN3BVIN4AVIN4BVIN5AVIN5B

STANDBY

V

V

PIN 1

IDENTIFIER

AD7891 PLCC

TOP VIEW

(Not to Scale)

DD

V

DGND

DB3/A0

DB4/A1

DB2/SWCON

DB5/A2/DATA OUT

RD

WR

DB0/FORMAT

DB1/SWSTBY

39

38

37

36

35

34

33

32

31

30

29

V

IN6A

V

IN6B

V

IN7A

V

IN7B

V

IN8A

V

IN8B

AGND

EOC

NC

CONVST

CS

PQFP

–5–REV. A

Page 6

AD7891

TERMINOLOGY

Signal to (Noise + Distortion) Ratio

This is the measured ratio of signal to (noise + distortion) at the

output of the A/D converter. The signal is the rms amplitude of

the fundamental. Noise is the rms sum of all nonfundamental

signals up to half the sampling frequency (f

/2), excluding dc.

S

The ratio is dependent upon the number of quantization levels

in the digitization process; the more levels, the smaller the quantization noise. The theoretical signal to (noise +distortion) ratio

for an ideal N-bit converter with a sine wave input is given by:

Signal to (Noise + Distortion) = (6.02N + 1.76) dB

Thus for a 12-bit converter, this is 74␣ dB.

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the rms sum of

harmonics to the fundamental. For the AD7891 it is defined as:

2

THD dB

()

VVVVV

++++

=

20

223242526

log

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

, V5 and V6 are the rms amplitudes of the second through the

V

4

sixth harmonics.

Peak Harmonic or Spurious Noise

Peak harmonic or spurious noise is defined as the ratio of the

rms value of the next largest component in the ADC output

spectrum (up to f

/2 and excluding dc) to the rms value of the

S

fundamental. Normally, the value of this specification is determined by the largest harmonic in the spectrum, but for parts

where the harmonics are buried in the noise floor, it will be a

noise peak.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products at sum and difference frequencies of mfa ± nfb where

m, n = 0, 1, 2, 3, etc. Intermodulation terms are those for which

neither m nor n are equal to zero. For example, the second

order terms include (fa + fb) and (fa – fb), while the third order

terms include (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb).

The AD7891 is tested using the CCIF standard where two

input frequencies near the top end of the input bandwidth are

used. In this case, the second and third order terms are of different significance. The second order terms are usually distanced

in frequency from the original sine waves while the third order

terms are usually at a frequency close to the input frequencies.

As a result, the second and third order terms are specified separately. The calculation of the intermodulation distortion is as

per the THD specification where it is the ratio of the rms sum of

the individual distortion products to the rms amplitude of the

fundamental expressed in dBs.

Channel-to-Channel Isolation

Channel-to-channel isolation is a measure of the level of

crosstalk between channels. It is measured by applying a fullscale 20 kHz (AD7891-1) or 100 kHz (AD7891-2) sine wave

signal to one input channel and determining how much that

signal is attenuated in each of the other channels. The figure

given is the worst case across all eight channels.

Relative Accuracy

Relative accuracy or endpoint nonlinearity is the maximum

deviation from a straight line passing through the endpoints of

the ADC transfer function.

Differential Nonlinearity

This is the difference between the measured and the ideal 1 LSB

change between any two adjacent codes in the ADC.

Positive Full-Scale Error (AD7891-1, ±10 V and ±5 V,

AD7891-2, ±2.5 V)

This is the deviation of the last code transition (01. . .110 to

01. . .111) from the ideal 4 × REF IN – 3/2 LSB (AD7891-1

±10 V range), 2 × REF IN – 3/2 LSB (AD7891-1 ± 5 V range)

or REF IN – 3/2 LSB (AD7891-2, ±2.5 V range), after the

Bipolar Zero Error has been adjusted out.

Positive Full-Scale Error (AD7891-2, 0 V to 5 V and 0 V to

2.5 V)

This is the deviation of the last code transition (11. . .110 to

11. . .111) from the ideal 2 × REF IN – 3/2 LSB (0 V to 5 V

range) or REF IN – 3/2 LSB (0 V to 2.5 V range), after the

unipolar offset error has been adjusted out.

Bipolar Zero Error (AD7891-1, ±10 V and ± 5 V, AD7891-2 ,

±2.5 V)

This is the deviation of the midscale transition (all 0s to all 1s)

from the ideal AGND – 1/2 LSB.

Unipolar Offset Error (AD7891-2, 0 V to 5 V and 0 V to 2.5 V)

This is the deviation of the first code transition (00. . .000 to

00. . .001) from the ideal AGND + 1/2 LSB.

Negative Full-Scale Error (AD7891-1, ±10 V and ±5 V,

AD7891-2, ±2.5 V)

This is the deviation of the first code transition (10. . .000 to

10. . .001) from the ideal –4 × REF IN + 1/2 LSB (AD7891-1

±10 V range), –2 × REF IN + 1/2 LSB (AD7891-1 ± 5 V range)

or –REF IN + 1/2 LSB (AD7891-2, ±2.5 V range), after Bipolar

Zero Error has been adjusted out.

Track/Hold Acquisition Time

Track/hold acquisition time is the time required for the output

of the track/hold amplifier to reach its final value, within

±1/2 LSB, after the end of conversion (the point at which the

track/hold returns to track mode). It also applies to situations

where a change in the selected input channel takes place or

where there is a step input change on the input voltage applied

to the selected V

input of the AD7891. It means that the user

IN

must wait for the duration of the track/hold acquisition time

after the end of conversion or after a channel change/step input

change to V

before starting another conversion, to ensure that

IN

the part operates to specification.

–6– REV. A

Page 7

Mnemonic Description

AD7891

PIN FUNCTION DESCRIPTIONS

V

INXA

, V

INXB

Analog Input Channels. The AD7891 contains eight pairs of analog input channels. Each channel contains two input pins to allow a number of different input ranges to be used with the AD7891. There are

two possible input voltage ranges on the AD7891-1. The ±5␣ V input range is selected by connecting the

input voltage to both V

voltage to V

and connecting V

INXA

INXA

and V

0 V to +2.5␣ V input range is selected by connecting the analog input voltage to both V

0 V to +5␣ V input range is selected by applying the input voltage to V

while the ±2.5␣ V input range is selected by connecting the analog input voltage to V

to REF␣ IN (provided this REF IN voltage comes from a low impedance source). The channel to be

V

INXB

, while the ±10␣ V input range is selected by applying the input

INXB

to AGND. The AD7891-2 has three possible input ranges. The

INXB

and connecting V

INXA

and V

INXA

INXB

and connecting

INXA

to AGND

INXB

; the

converted is selected by the A2, A1 and A0 bits of the control register. In the parallel interface mode,

these bits are available as three data input lines (DB3 to DB5) in a parallel write operation while in the

serial interface mode, these three bits are accessed via the DATA IN line in a serial write operation. The

multiplexer has guaranteed break-before-make operation.

V

DD

Positive supply voltage, +5 V ± 5%.

AGND Analog Ground. Ground reference for track/hold, comparator and DAC.

DGND Digital Ground. Ground reference for digital circuitry.

STANDBY Standby Mode Input. TTL-compatible input which is used to put the device into the power save or

standby mode. The

STANDBY input is high for normal operation and low for standby operation.

REF OUT/REF␣ IN Voltage Reference Output/Input. The part can either be used with its own internal reference or with an

external reference source. The on-chip +2.5␣ V reference voltage is provided at this pin. When using this

internal reference as the reference source for the part, REF␣ OUT should be decoupled to REF␣ GND with

a 0.1␣ µF disc ceramic capacitor. The output impedance of the reference source is typically 2␣ kΩ. When

using an external reference source as the reference voltage for the part, the reference source should be

connected to this pin. This overdrives the internal reference and provides the reference source for the

part. The reference pin is buffered on-chip but must be able to sink or source current through this 2␣ kΩ

resistor to the output of the on-chip reference. The nominal reference voltage for correct operation of the

AD7891 is +2.5 V.

REF GND Reference Ground. Ground reference for the part’s on-chip reference buffer. The REF OUT pin of the

part should be decoupled with a 0.1␣ µF capacitor to this REF GND pin. If the AD7891 is used with an

external reference, the external reference should also be decoupled to this pin. The REF␣ GND pin should

be connected to the AGND pin or the system’s AGND plane.

CONVST Convert Start. Edge-triggered logic input. A low to high transition on this input puts the track/hold into

hold and initiates conversion. When changing channels on the part, sufficient time should be given for

multiplexer settling and track/hold acquisition between the channel change and the rising edge of

CONVST.

EOC End-of-Conversion. Active low logic output indicating converter status. The end of conversion is signified

by a low-going pulse on this line. The duration of this

EOC pulse is nominally 80␣ ns.

MODE Interface Mode. Control input which determines the interface mode for the part. With this pin at a logic

low, the AD7891 is in its serial interface mode; with this pin at a logic high, the device is in its parallel

interface mode.

NC No Connect. The two NC pins on the device can be left unconnected. If they are to be connected to a

voltage it should be to ground potential. To ensure correct operation of the AD7891, neither of the NC

pins should be connected to a logic high potential.

–7–REV. A

Page 8

AD7891

PARALLEL INTERFACE MODE FUNCTIONS

Mnemonic Description

CS Chip Select Input. Active low logic input which is used in conjunction with RD to enable the data

outputs and with

RD Read Input. Active low logic input which is used in conjunction with CS low to enable the data outputs.

WR Write Input. Active low, logic input used in conjunction with CS to latch the multiplexer address and

software control information. The rising edge of this input also initiates an internal pulse. When using

the software start facility, this pulse delays the point at which the track/hold goes into hold and conversion is initiated. This allows the multiplexer to settle and acquisition time of the track/hold to

elapse when a channel address is changed. If the SWCON bit of the control register is set to 1, when

this pulse times out, the track/hold then goes into hold and conversion is initiated. If the SWCON bit

of the control register is set to 0 the track/hold and conversion sequence are unaffected by the

operation.

Data I/O Lines

There are 12 data input/output lines on the AD7891. When the part is configured for parallel mode (MODE = 1), the output data

from the part is provided at these 12 pins during a read operation. For a write operation in parallel mode, these lines provide access

to the part’s Control Register.

Parallel Read Operation

During a parallel read operation the 12 lines become the 12 data bits containing the conversion result from the AD7891. These data

bits are labelled Data Bit 0 (LSB) to Data Bit 11 (MSB). They are three-state TTL-compatible outputs. Output data coding is twos

complement when the data FORMAT Bit of the control register is 1 and straight binary when the data FORMAT Bit of the control

register is 0.

WR to allow input data to be written to the part.

WR

Mnemonic Description

DB0–DB11 Data Bit 0 (LSB) to Data Bit 11 (MSB). Three-state TTL-compatible outputs which are controlled

by the CS and RD inputs.

Parallel Write Operation

During a parallel write operation the following functions can be written to the control register via the 12 data input/output pins.

Mnemonic Description

A0 Address Input. The status of this input during a parallel write operation is latched to the A0 bit of the

control register (see Control Register section).

A1 Address Input. The status of this input during a parallel write operation is latched to the A1 bit of the

control register (see Control Register section).

A2 Address Input. The status of this input during a parallel write operation is latched to the A2 bit of the

control register (see Control Register section).

SWCON Software Conversion Start. The status of this input during a parallel write operation is latched to the

SWCONV bit of the control register (see Control Register section).

SWSTBY Software Standby Control. The status of this input during a parallel write operation is latched to the

SWSTBY bit of the control register (see Control Register section).

FORMAT Data Format Selection. The status of this input during a parallel write operation is latched to the

FORMAT bit of the control register (see Control Register section).

–8– REV. A

Page 9

AD7891

SERIAL INTERFACE MODE FUNCTIONS

When the part is configured for serial mode (MODE = 0), five of the 12 data input/output lines provide serial interface functions.

These functions are outlined below.

Mnemonic Description

SCLK Serial Clock Input. This is an externally applied serial clock which is used to load serial data to the control

register and to access data from the output register.

TFS Transmit Frame Synchronization Pulse. Active low logic input with serial data expected after the falling

edge of this signal.

RFS Receive Frame Synchronization Pulse. This is an active low logic input with RFS provided externally as a

strobe or framing pulse to access serial data from the output register. For applications that require that

data be transmitted and received at the same time,

DATA OUT Serial Data Output. Sixteen bits of serial data are provided with the data FORMAT bit and the three

address bits of the control register preceding the 12 bits of conversion data. Serial data is valid on the

falling edge of SCLK for sixteen edges after

ment when the FORMAT Bit of the control register is 1 and straight binary when the FORMAT Bit of the

control register is 0.

DATA IN Serial Data Input. Serial data to be loaded to the control register is provided at this input. The first six bits

of serial data are loaded to the control register on the first six falling edges of SCLK after

Serial data on subsequent SCLK edges is ignored while

TEST Test Pin. When the device is configured for serial mode of operation, two of the pins which had been data

inputs become test inputs. To ensure correct operation of the device, both TEST inputs should be tied to

a logic low potential.

RFS and TFS should be connected together.

RFS goes low. Output conversion data coding is twos comple-

TFS goes low.

TFS remains low.

CONTROL REGISTER

The control register for the AD7891 contains 6 bits of information as described below. These 6 bits can be written to the control

register either in a parallel mode write operation or via a serial mode write operation. The default (power-on) condition of all bits in

the control register is 0. Six serial clock pulses must be provided to the part in order to write data to the control register. If

turns high before six serial clock cycles then no data transfer takes place to the control register and the write cycle will have to be

restarted to write data to the control register. However, if the SWCONV bit of the register was previously set to a logic 1 and

brought high before six serial clock cycles, then another conversion will be initiated.

BSM

2A1A0AVNOCWSYBTSWSTAMROF

A2 Address Input. This input is the most significant address input for multiplexer channel selection.

A1 Address Input. This is the second most significant address input for multiplexer channel selection.

A0 Address Input. Least significant address input for multiplexer channel selection. When the address is written to

the control register, an internal pulse is initiated to allow for the multiplexer settling time and track/hold acquisition time before the track/hold goes into hold and conversion is initiated. When the internal pulse times out, the

track/hold goes into hold and conversion is initiated. The selected channel is given by the formula:

A2 × 4 + A1 × 2 + A0 + 1

SWCONV Conversion Start. Writing a 1 to this bit initiates a conversion in a similar manner to the

tinuous conversion starts do not take place when there is a 1 in this location. The internal pulse and the conversion process are initiated when a 1 is written to this bit. With a 1 in this bit, the hardware conversion start, i.e.,

CONVST input, is disabled. Writing a 0 to this bit enables the hardware CONVST input.

the

SWSTBY Standby Mode Input. Writing a 1 to this bit places the device in its standby or power-down mode. Writing a 0 to

this bit places the device in its normal operating mode.

FORMAT Data Format. Writing a 0 to this bit sets the conversion data output format to straight (natural) binary. This

data format is generally be used for unipolar input ranges. Writing a 1 to this bit sets the conversion data output

format to twos complement. This output data format is generally used for bipolar input ranges.

CONVST input. Con-

TFS re-

TFS is

–9–REV. A

Page 10

AD7891

t

6

t

7

t

CONV

t

1

t

5

t

8

t

1

t

5

t

2

VALID DAT A

OUTPUT

VALID DAT A

OUTPUT

t

9

t

10

t

3

t

4

CONVST (I)

EOC (O)

CS (O)

WR (I)

RD (I)

DB0 - DB11

(I/O)

NOTE

I - INPUT

O = OUTPUT

CONVERTER DETAILS

The AD7891 is an eight-channel, high speed, 12-bit data acquisition system. It provides the user with signal scaling, multiplexer, track/hold, reference, A/D converter and high speed

parallel and serial interface logic functions on a single chip. The

signal conditioning on the AD7891-1 allows the part to accept

analog input ranges of ±5␣ V or ±10␣ V when operating from a

single supply. The input circuitry on the AD7891-2 allows the

part to handle input signal ranges of 0 V to +2.5␣ V, 0 V to +5␣ V

and ±2.5␣ V again while operating from a single +5␣ V supply.

The part requires a +2.5 V reference which can be provided

from the part’s own internal reference or from an external reference source.

Conversion is initiated on the AD7891 either by pulsing the

CONVST input or by writing a logic 1 to the SWCONV bit of

the control register. When using the hardware

CONVST input,

the on-chip track/hold goes from track to hold mode and the

conversion sequence is started on the rising edge of the

CONVST

signal. When a software conversion start is initiated, an internal

pulse is generated which delays the track/hold acquisition point

and the conversion start sequence until the pulse is timed out.

This internal pulse is initiated (goes from low to high) whenever

a write to the AD7891 control register takes place with a 1 in

the SWCONV bit. It then starts to discharge and the track/hold

cannot go into hold and conversion cannot be initiated until the

pulse signal goes low.

The conversion clock for the part is internally generated and

conversion time for the AD7891 is 1.6␣ µs from the rising edge of

the hardware

CONVST signal. The track/hold acquisition time

for the AD7891-1 is 600␣ ns while the track/hold acquisition time

for the AD7891-2 is 400 ns. To obtain optimum performance

from the part, the data read operation should not occur during

the conversion or during 100␣ ns prior to the next conversion.

This allows the AD7891-1 to operate at throughput rates up to

454.5 kSPS and the AD7891-2 at throughput rates up to

500␣ kSPS in the parallel mode and achieve data sheet specifications. In the serial mode, the maximum achievable throughput rate for both the AD7891-1 and the AD7891-2 is 357␣ kSPS

(assuming a 20␣ MHz serial clock).

All unused analog inputs should be tied to a voltage within the

nominal analog input range to avoid noise pickup. For minimum power consumption, the unused analog inputs should be

tied to AGND.

INTERFACE INFORMATION

The AD7891 provides two interface options, a 12-bit parallel

interface and a high speed serial interface. The required interface mode is selected via the MODE pin. The two interface

modes are discussed in the following sections.

Parallel Interface Mode

The parallel interface mode is selected by tying the MODE

input to a logic high. Figure 2 shows a timing diagram illustrating

the operational sequence of the AD7891 in parallel mode for a

hardware conversion start. The multiplexer address is written to

the AD7891 on the rising edge of the

track/hold goes into hold mode on the rising edge of

WR input. The on-chip

CONVST

and conversion is also initiated at this point. When the conversion

is complete, the end of conversion line (

EOC) pulses low to

indicate that new data is available in the AD7891’s output register. This

rupt of a microprocessor.

EOC line can be used to drive an edge-triggered inter-

CS and RD going low accesses the

12-bit conversion result. In systems where the part is interfaced

to a gate array or ASIC, this

EOC pulse can be applied to the

CS and RD inputs to latch data out of the AD7891 and into the

gate array or ASIC. This means that the gate array or ASIC does

not need any conversion status recognition logic and it also eliminates the logic required in the gate array or ASIC to generate

the read signal for the AD7891.

Figure 2. Parallel Mode Timing Diagram

–10– REV. A

Page 11

AD7891

Serial Interface Mode

The serial interface mode is selected by tying the MODE input

to a logic low. In this case, five of the data/control inputs of the

parallel mode assume serial interface functions.

The serial interface on the AD7891 is a five-wire interface with

read and write capabilities, with data being read from the output

register via the DATA OUT line and data being written to the

control register via the DATA IN line. The part operates in a

slave or external clocking mode and requires an externally applied serial clock to the SCLK input to access data from the

data register or write data to the control register. There are

separate framing signals for the read (RFS) and write (TFS)

operations. The serial interface on the AD7891 is designed to

allow the part to be interfaced to systems that provide a serial

clock that is synchronized to the serial data, such as the 80C51,

87C51, 68HC11 and 68HC05 and most digital signal processors.

When using the AD7891 in serial mode, the data lines DB11–

DB10 should be tied to logic low, and the

CS, WR and RD

inputs should be tied to logic high. Pins DB4–DB0 can be tied

to either logic high or logic low, but must not be left floating as

this condition could cause the AD7891 to draw large amounts

of current.

Read Operation

Figure 3 shows the timing diagram for reading from the AD7891

in serial mode.

RFS goes low to access data from the AD7891.

The serial clock input does not have to be continuous. The serial

data can be accessed in a number of bytes. However,

RFS must

remain low for the duration of the data transfer operation. Sixteen bits of data are transmitted in serial mode with the data

FORMAT bit first, followed by the three address bits in the

control register, followed by the 12-bit conversion result starting

with the MSB. Serial data is clocked out of the device on the

rising edge of SCLK and is valid on the falling edge of SCLK.

At the end of the read operation, the DATA OUT line is threestated by a rising edge on either the SCLK or

RFS inputs, which-

ever occurs first.

Write Operation

Figure 4 shows a write operation to the control register of the

AD7891. The

TFS input goes low to indicate to the part that a

serial write is about to occur. The AD7891 Control Register

requires only six bits of data. These are loaded on the first six

clock cycles of the serial clock with data on all subsequent clock

cycles being ignored. Serial data to be written to the AD7891

must be valid on the falling edge of SCLK.

Simplifying the Serial Interface

To minimize the number of interconnect lines to the AD7891 in

serial mode, the user can connect the

RFS and TFS lines of the

AD7891 together and read and write from the part simultaneously. In this case, new control register data line selecting the

input channel and providing a conversion start command should

be provided on the DATA IN line, while the part provides the

result from the conversion just completed on the DATA OUT

line.

RFS (I)

SCLK (I)

DATA OUT (O)

TFS (I)

SCLK (I)

DATA IN (I)

NOTE

I = INPUT

O = OUTPUT

NOTE

I = INPUT

t

11

t

12

FORMAT A2 A1 A0 DB11 DB10 DB0

t

13

t

14

t

15

t

16

Figure 3. Serial Mode Read Operation

t

19

t

t

20

21

CONV STBY

FORMATA0A1A0

DONT

CARE

t

22

Figure 4. Serial Mode Write Operation

t

17

DONT

CARE

t

18

t

18A

3-STATE

–11–REV. A

Page 12

AD7891

1.8kV

V

INXA

V

INXB

AGND

TO

MULTIPLEXER

AD7891-2

2kV

REF OUT/REF IN

TO ADC

REFERENCE

CIRCUITRY

1.8kV

2.5V

REFERENCE

CIRCUIT DESCRIPTION

Reference

The AD7891 contains a single reference pin labelled REF OUT/

REF IN, which either provides access to the part’s own +2.5 V

internal reference or to which an external +2.5 V reference can

be connected to provide the reference source for the part. The

part is specified with a +2.5 V reference voltage. Errors in the

reference source will result in gain errors in the transfer function

of the AD7891 and will add to the specified full scale errors on

the part. They will also result in an offset error injected into the

attenuator stage.

The AD7891 contains an on-chip +2.5 V reference. To use this

reference as a reference source for the AD7891, simply connect

a 0.1 µF disc ceramic capacitor from the REF OUT/REF IN pin

to REFGND. REFGND should be connected to AGND or the

analog ground plane. The voltage that appears at the REF OUT/

REF IN pin is internally buffered before being applied to the

ADC. If this reference is required for use external to the AD7891,

it should be buffered as the part has a FET switch in series with

the reference, resulting in a source impedance for this output of

2 kΩ nominal. The tolerance of the internal reference is ±10 mV

at +25°C with a typical temperature coefficient of 25 ppm/°C

and a maximum error over temperature of ±20 mV.

If the application requires a reference with a tighter tolerance or

if the AD7891 needs to be used with a system reference, then an

external reference can be connected to the REF OUT/REF IN

pin. The external reference will overdrive the internal reference

and thus provide the reference source for the ADC. The reference input is buffered before being applied to the ADC and the

maximum input current is ±100 µA. Suitable reference for the

AD7891 include the AD580, the AD680, the AD780 and the

REF43 precision +2.5 V references.

Analog Input Section

The AD7891 is offered as two part types, the AD7891-1 where

each input can be configured to have a ±10 V or a ±5 V input

range and the AD7891-2 where each input can be configured to

have a 0 V to 2.5 V, 0 V to 5 V and ±2.5 V input range.

AD7891-1

Figure 5 shows the analog input section of the AD7891-1. Each

input can be configured for ±5 V or ±10 V operation. For +5 V

operation, the V

INXA

and V

inputs are tied together and the

INXB

input voltage is applied to both. For ±10 V operation, the V

input is tied to AGND and the input voltage is applied to the

input. The V

V

INXA

INXA

and V

inputs are symmetrical and

INXB

fully interchangeable. Thus for ease of PCB layout on the ±10 V

range, the input voltage may be applied to the V

the V

input is tied to AGND.

INXA

TO ADC

REFERENCE CIRCUITRY

30kV

V

INXA

30kV

V

INXB

Figure 5. AD7891-1 Analog Input Structure

7.5kV

TO

MULTIPLEXER

15kV

AD7891-1

AGND

REF OUT/REF IN

INXB

2kV

2.5V

REFERENCE

INXB

input while

The input resistance for the ±5 V range is typically 20 kΩ. For

the ±10 V input range the input resistance is typically 34.3 kΩ.

The resistor input stage is followed by the multiplexer and this

is followed by the high input impedance stage of the track/hold

amplifier.

The designed code transitions take place midway between successive integer LSB values (i.e., 1/2 LSB, 3/2 LSBs, 5/2 LSBs,

etc.). LSB size is given by the formula, 1 LSB = FS/4096. Thus

for the ±5 V range, 1 LSB = 10 V/4096 = 2.44 mV. For the

±10 V range, 1 LSB = 20 V/4096 = 4.88 mV. Output coding is

determined by the FORMAT bit of the control register. The

ideal input/output code transitions are shown in Table I.

AD7891-2

Figure 6 shows the analog input section of the AD7891-2. Each

input can be configured for input ranges of 0 V to +5 V, 0 V to

+2.5 V or ±2.5 V. For the 0 V to +5 V input range, the V

INXB

input is tied to AGND and the input voltage is applied to the

input. For the 0 V to +2.5 V input range, the V

V

INXA

inputs are tied together and the input voltage is applied to

V

INXB

both. For the ±2.5 V input range, the V

+2.5 V and the input voltage is applied to the V

input is tied to

INXB

INXA

and

INXA

input. The

+2.5 V source must have a low output impedance. If the internal reference on the AD7891 is used, then it must be buffered

before being applied to V

INXB

. The V

INXA

and V

inputs are

INXB

symmetrical and fully interchangeable. Thus for ease of PCB

layout on the 0 V to +5 V range or the ±2.5 V range, the input

voltage may be applied to the V

INXB

input while the V

INXA

input

is tied to AGND or +2.5 V.

Figure 6. AD7891-2 Analog Input Structure

The input resistance for both the 0 V to +5 V and ±2.5 V ranges

is typically 3.6 kΩ. When an input is configured for 0 V to 2.5 V

operation, the input is fed into the high impedance stage of the

track/hold amplifier via the multiplexer and the two 1.8 kΩ

resistors in parallel.

The designed code transitions occur midway between successive

integer LSB values (i.e., 1/2 LSB, 3/2 LSBs, 5/2 LSBs etc.).

LSB size is given by the formula 1 LSB = FS/4096. Thus for the

0 V to +5 V range, 1 LSB = 5 V/4096 = 1.22 mV, for the 0 V

to +2.5 V range, 1 LSB = 2.5 V/4096 = 0.61 mV and for the

±2.5 V range, 1 LSB = 5 V/4096 = 1.22 mV. Output coding is

determined by the FORMAT bit in the control register. The

ideal input/output code transitions for the ±2.5 V range are

shown in Table I. The ideal input/output code transitions for

the 0 V to +5 V range and the 0 V to +2.5 V range are shown in

Table II.

–12– REV. A

Page 13

AD7891

Table I. Ideal Code Transition Table for the AD7891-1, ⴞ10 V and ⴞ5 V Ranges and the AD7891-2, ⴞ2.5 V Range

Digital Output Code Transition

Analog Input Input Voltage Twos Complement Straight Binary

+FSR

2

/2 – 3/2 LSBs

3

(9.99268 V, 4.99634 V or 2.49817 V)

4

011...110 to 011...111 111...110 to 111...111

+FSR/2 – 5/2 LSBs (9.98779 V, 4.99390 V or 2.49695 V) 011...101 to 011...110 111...101 to 111...110

+FSR/2 – 7/2 LSBs (9.99145 V, 4.99146 V or 2.49573 V) 011...100 to 011...101 111...100 to 111...101

AGND + 3/2 LSBs (7.3242 mV, 3.6621 mV or 1.8310 mV) 000...001 to 000...010 100...001 to 100...010

AGND + 1/2 LSB (2.4414 mV, 1.2207 mV or 0.6103 mV) 000...000 to 000...001 100...000 to 100...001

AGND – 1/2 LSB (–2.4414 mV, –1.2207 mV or –0.6103 mV) 111...111 to 000...000 011...111 to 100...000

AGND – 3/2 LSBs (–7.3242 mV, –3.6621 mV or –1.8310 mV) 111...110 to 111...111 011...110 to 011...111

–FSR/2 + 5/2 LSBs (–9.98779 V, –4.99390 V or –2.49695 V) 100...010 to 100...011 000...010 to 000...011

–FSR/2 + 3/2 LSBs (–9.99268 V, –4.99634 V or –2.49817 V) 100...001 to 100...010 000...001 to 000...010

–FSR/2 + 1/2 LSB (–9.99756 V, –4.99878 V or –2.49939 V) 100...000 to 100...001 000...000 to 000...001

NOTES

1

Output Code format is determined by the FORMAT bit in the control register

2

FSR is full-scale range and is 20 V for the ±10 V range, 10 V for the ±5 V range and 5 V for the ±2.5 V range, with REFIN = +2.5 V .

3

1 LSB = FSR/4096 = 4.88 mV (±10 V range), 2.44 mV (±5 V range) and 1.22 mV (±2.5 V range), with REF IN = +2.5 V.

4

±10 V range, ±5 V range or ± 2.5 V range.

Table II. Ideal Code Transition Table for the AD7891-2, 0 V to +5 V and 0 V to +2.5 V Ranges

Digital Output Code Transition

Analog Input Input Voltage Twos Complement Straight Binary

+FSR

2

– 3/2 LSBs

3

(4.99817 V or 2.49908 V)

4

011...110 to 011...111 111...110 to 111...111

+FSR – 5/2 LSBs (4.99695 V or 2.49847 V) 011...101 to 011...110 111...101 to 111...110

+FSR – 7/2 LSBs (4.99573 V or 2.49786 V) 011...100 to 011...101 111...100 to 111...101

1

1

AGND + 5/2 LSBs (3.0518 mV or 1.52588 mV) 100...010 to 000...011 000...010 to 000...011

AGND + 3/2 LSBs (1.83105 mV or 0.9155 mV) 100...001 to 000...010 000...001 to 000...010

AGND + 1/2 LSB (0.6103 mV or 0.3052 mV) 100...000 to 000...001 000...000 to 000...001

NOTES

1

Output Code format is determined by the FORMAT bit in the control register

2

FSR is full-scale range and is 5 V for the 0 to 5 V range and 2.5 V for the 0 to 2.5 V range with REF IN = +2.5 V.

3

1 LSB = FS/4096 = 1.22 mV (0 to 5 V range) or 610 µV (0 to 2.5 V range), with REF IN = 2.5 V.

4

0 V to +5 V range or 0 V to + 2.5 V range.

Transfer Function of the AD7891-1 and AD7891-2

The transfer function of the AD7891-1 and AD7891-2 can be

expressed as follows:

Input Voltage = (M × REFIN × D/4096) + (N × REFIN)

D is the output data from the AD7891 and is in the range 0 to

4095 for straight binary encoding and from –2048 to 2047 for

twos complement encoding. Values for M depend upon the

input voltage range. Values for N depend upon the input voltage range and the output data format. These values are given in

Table III. REFIN is the reference voltage applied to the AD7891.

Range Output Data Format M N

AD7891-1

±10 V Straight Binary 8 –4

±10 V Twos Complement 8 0

±5 V Straight Binary 4 –2

±5 V Twos Complement 4 0

AD7891-2

0 V to +5 V Straight Binary 2 0

0 V to +5 V Twos Complement 2 1

Table III. Transfer Function M and N Values

0 V to +2.5 V Straight Binary 1 0

0 V to +2.5 V Twos Complement 1 0.5

±2.5 V Straight Binary 2 –1

±2.5 V Twos Complement 2 0

–13–REV. A

Page 14

AD7891

Track/Hold Amplifier section

The track/hold amplifier on the AD7891 allows the ADC to

accurately convert an input sine wave of full-scale amplitude to

12-bit accuracy. The input bandwidth of the track/hold is

greater than the Nyquist rate of the ADC even when the ADC is

operated at its maximum throughput rate of 454 kHz (AD7891-

1) or 500 kHz (AD7891-2). In other words, the track/hold

amplifier can handle input frequencies in excess of 227 kHz

(AD7891-1) or 250 kHz (AD7891-2).

The track/hold amplifier acquires an input signal in 600 ns

(AD7891-1) or 400 ns (AD7891-2). The operation of the track/

hold is essentially transparent to the user. The track/hold amplifier goes from its tracking mode to its hold mode on the rising

edge of

the delay between the external

hold actually going into hold) is typically 15 ns. At the end of

conversion, the part returns to its tracking mode. The track/hold

starts acquiring the next signal at this point.

STANDBY Operation

The AD7891 can be put into power save or standby mode by

use of the

register. Normal operation of the AD7891 takes place when the

STANDBY input is at a logic one and the SWSTBY bit is at a

logic zero. When the

written to the SWSTBY bit, then the part goes into its standby

mode of operation, which reduces its power consumption to

typically 75 µW.

The AD7891 is returned to normal operation when the

STANDBY input is at a logic 1 and the SWSTBY bit is a logic

zero. The wake-up time of the AD7891 is normally determined

by the amount of time required to charge the 0.1 µF capacitor

between the REF OUT/REF IN pin and REFGND. If the internal reference is being used as the reference source, then this

capacitor is charged via a nominal 2 kΩ resistor. Assuming 10

time constants to charge the capacitor to 12-bit accuracy, this

implies a wake-up time of 2 ms.

If an external reference is used, then this will have to be taken

into account when working out how long it will take to charge

the capacitor. If the external reference has remained at 2.5 V

during the time the AD7891 was in standby mode, then the

capacitor will already be charged when the part is taken out of

standby mode. Thus the wake-up time is now the time required

for the internal circuitry of the AD7891 to settle to 12-bit accu-

racy. This typically takes 5 µs. If the external reference was also

put into standby then the wake-up time of the reference, combined with the amount of time taken to recharge the reference

capacitor from the external reference, determines how much

time must elapse before conversions can begin again.

MICROPROCESSOR INTERFACING

AD7891 to 8X51 Serial Interface

A serial interface between the AD7891 and the 8X51 microcontroller is shown in Figure 7. TXD of the 8X51 drives SCLK

of the AD7891 while RXD transmits data to and receives data

from the part. The serial clock speed of the 8X51 is slow compared to the maximum serial clock speed of the AD7891, so

maximum throughput of the AD7891 is not achieved with this

interface.

CONVST. The aperture time for the track/hold (i.e.,

CONVST signal and the track/

STANDBY pin or the SWSTBY bit of the control

STANDBY pin is brought low or a one is

P3.4

8X51*

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 7. AD7891 to 8X51 Interface

P3.3

TXD

RXD

RFS

TFS

AD7891*

SCLK

DATA IN

DATA OUT

The 8X51 provides the LSB of its SBUF register as the first bit

in the serial data stream. The AD7891 expects the MSB of the

6-bit write first. Therefore, the data in the SBUF register must

be arranged correctly so that this is taken into account. When

data is to be transmitted to the part, P3.3 is taken low. The

8XC51 transmits its data in 8-bit bytes with only 8 falling clock

edges occurring in the transmit cycle. One 8-bit transfer is

needed to write data to the control register of the AD7891.

After the data has been transferred, the P3.3 line is taken high

to complete the transmission.

When reading data from the AD7891, P3.4 of the 8X51 is taken

low. Two 8-bit serial reads are performed by the 8X51 and P3.4

is taken high to complete the transfer. Again, the 8X51 expects

the LSB first, while the AD7891 transmits MSB first, so this

must be taken into account in the 8X51 software.

No provision has been made in the given interface to determine

when a conversion has ended. If the conversions are initiated by

software, then the 8X51 can wait a predetermined amount of

time before reading back valid data. Alternately the falling edge

of the

EOC signal can be used to initiate an interrupt service

routine which reads the conversion result from part to part.

AD7891 to 68HC11 Serial Interface

Figure 8 shows a serial interface between the AD7891 and the

68HC11 microcontroller. SCK of the 68HC11 drives SCLK of

the AD7891, the MOSI output drives DATA IN of the AD7891

and the MISO input receives data from DATA OUT of the

AD7891. Ports PC6 and PC7 of the 68HC11 drive the

RFS lines of the AD7891 respectively.

and

TFS

For correct operation of this interface, the 68HC11 should be

configured such that its CPOL bit is a 1 and its CPHA bit is a 0.

When data is to be transferred to the AD7891, PC7 is taken

low. When data is to be received from the AD7891, PC6 is

taken low. The 68HC11 transmits and receives its serial data in

8-bit bytes, MSB first. The AD7891 transmits and receives data

MSB first also. Eight falling clock edges occur in a read or write

cycle from the 68HC11. A single 8-bit write with PC7 low is

required to write to the control register. When data has been

written, PC7 is taken high. When reading from the AD7891,

PC6 is left low after the first eight bits have been read. A second

byte of data is then transmitted serially from the AD7891. When

this transfer is complete, the PC6 line is taken high.

–14– REV. A

Page 15

AD7891

DSP56000/

DSP56002*

DATA OUT

AD7891*

*ADDITIONAL PINS OMITTED FOR CLARITY

SCLK

DATA IN

RFS

TFS

FST (SC2)

SCK

STD

SRD

TMS32020/

TMS320C25/

TMS320C5X/

TMS320C3X*

DATA OUT

AD7891*

*ADDITIONAL PINS OMITTED FOR CLARITY

SCLK

DATA IN

RFS

TFS

FSX

CLKX

DX

DR

CLKR

FSR

TIMING

GENERATION

CIRCUITRY

As in the 8X51 circuit above, the way that the 68HC11 is informed that a conversion is completed is not shown in the diagram. The

EOC line can be used to inform the 68HC11 that a

conversion is complete by using it as an interrupt signal. The

interrupt service routine reads in the result of the conversion. If

a software conversion start is used, the 68HC11 can wait for

2.0 µs (AD7891-2) or 2.2 µs (AD7891-1) before reading from

the AD7891.

PC7

68HC11*

*ADDITIONAL PINS OMITTED FOR CLARITY

PC6

SCK

MOSI

MOSO

RFS

TFS

AD7891*

SCLK

DATA IN

DATA OUT

Figure 8. AD7891 to 68HC11 Interface

AD7891 to ADSP-21xx Serial Interface

An interface between the AD7891 and the ADSP-21xx is shown

in Figure 9. In the interface shown either SPORT0 or SPORT1

can be used to transfer data to the AD7891. When reading from

the part, the SPORT must be set up with a serial word length of

16 bits. When writing to the AD7891, a serial word length of 6

bits or more can be used. Other setups for the serial interface on

the ADSP-21xx internal SCLK, alternate framing mode and

active low framing signal. Normally the

AD7891 would be connected to the

EOC line from the

IRQ2 line of the ADSP-

21xx to interrupt the DSP at the end of a conversion (not shown

in diagram).

AD7891 to DSP5600x Serial Interface

Figure 10 shows a serial interface between the AD7891 and the

DSP5600x series of DSPs. When reading from the AD7891, the

DSP5600x should be set up for 16-bit data transfers, MSB first,

normal mode synchronous operation, internally generated word

frame sync and gated clock. When writing to the AD7891, 8-bit

or 16-bit data transfers can be used. The frame sync signal from

the DSP5600x must be inverted before being applied to the

RFS and TFS inputs of the AD7891 as shown in Figure 10.

To monitor the conversion time of the AD7891, a scheme such

as outlined in previous interfaces with

can be implemented by connecting the

EOC can be used. This

EOC line directly to the

IRQA input of the DSP5600x.

Figure 10. AD7891 to DSP5600x Serial Interface

AD7891 to TMS320xxx Serial Interface

The AD7891 can be interfaced to the serial port of TMS320xxx

DSPs as shown in Figure 11. External timing generation circuitry is necessary to generate the serial clock and syncs necessary for the interface.

ADSP-21xx*

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 9. AD7891 to ADSP-2101 Serial Interface

RFS

TFS

SCLK

DT

DR

RFS

TFS

AD7891*

SCLK

DATA IN

DATA OUT

Figure 11. AD7891 to TMSxxx Serial Interface

–15–REV. A

Page 16

AD7891

EXPANSION DATA BUS

ADDRESS BUS

DB11–DB0

AD7891*

*ADDITIONAL PINS OMITTED FOR CLARITY

CS

WR

INTx

XD23–XD0

EOC

RD

ADDR

DECODE

XA15–XA0

XR/W

IOSTRB

TMS320C30*

PARALLEL INTERFACING

The parallel port on the AD7891 allows the device to be interfaced to microprocessors or DSP processors as a memory

mapped or I/O mapped device. The

CS and RD inputs are

common to all memory peripheral interfacing. Typical interfaces

to different processors are shown in Figures 12 to 15. In all the

interfaces shown, an external timer controls the

of the AD7891 and the

EOC output interrupts the host DSP.

CONVST input

AD7891 to ADSP-21xx

Figure 12 shows the AD7891 interfaced to the ADSP-21xx

series of DSPs as a memory mapped device. A single wait state

may be necessary to interface the AD7891 to the ADSP-21xx

depending on the clock speed of the DSP. This wait state can be

programmed via the Data Memory Waitstate Control Register

of the ADSP-21xx (please see ADSP-2100 family Users manual

for details). The following instruction reads data from the

AD7891:

MR = DM(ADC)

where ADC is the address of the AD7891.

RD

ADDRESS BUS

ADDR

DECODE

EN

DATA BUS

CS

WR

AD7891*

RD

EOC

DB11–DB0

A13–A0

ADSP-21xx*

DMS

WR

IRQ2

D23–D8

The parallel interface on the AD7891 is fast enough to interface

to the TMS32020 with no extra wait states. If high speed glue

logic such as 74AS devices are used to drive the

WR and RD

lines when interfacing to the TMS320C25, then again no wait

states are necessary. However, if slower logic is used, data accesses may be slowed sufficiently when reading from and writing

to the part to require the insertion of one wait state. In such a

case, this wait state can be generated using the single OR gate to

combine the

CS and MSC signals to drive the READY line of

the TMS320C25, as shown in Figure 13. Extra wait states will

be necessary when using the TMS320C5x at their fastest clock

speeds. Wait states can be programmed via the IOWSR and

CWSR registers (please see TMS320C5x User Guide for details).

Data is read from the ADC using the following instruction:

IN D,ADC

where D is the memory location where the data is to be stored

and ADC is the I/O address of the AD7891.

AD7891 to TMS320C30

Figure 14 shows a parallel interface between the AD7891 and

the TMS320C3x family of DSPs. The AD7891 is interfaced to

the Expansion Bus of the TMS320C3x. A single wait state is

required in this interface. This can be programmed using the

WTCNT bits of the Expansion Bus Control register (see

TMS320C3x Users guide for details). Data from the AD7891

can be read using the following instruction:

LDI *ARn,Rx

where ARn is an auxiliary register containing the lower 16 bits

of the address of the AD7891 in the TMS320C3x memory

space and Rx is the register into which the ADC data is loaded.

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 12. AD7891 to ADSP-21xx Parallel Interface

AD7891 to TMS32020, TMS320C25 and TMS320C5x

Parallel interfaces between the AD7891 and the TMS32020,

TMS320C25 and TMS320C5x family of DSPs are shown in

Figure 13. The memory mapped address chosen for the

AD7891 should be chosen to fall in the I/O memory space of

the DSPs.

IS

ADDRESS BUS

ADDR

EN

DECODE

DATA BUS

TMS320C25

ONLY

CS

AD7891*

WR

RD

EOC

DB11–DB0

A15–A0

TMS32020/

TMS320C25/

TMS320C50*

READY

MSC

STRB

R/W

INTx

D23–D0

Figure 13. AD7891 to TMS32020/C25/C5x Parallel Interface

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 14. AD7891 to TMS320C30 Parallel Interface

–16– REV. A

Page 17

AD7891

VDD (PIN 10, PQFP

PIN 4, PLCC)

DGND

AD7891

AGND

AGND

V

DD

(PIN 19, PQFP

PIN 13, PLCC)

10mF

0.1mF

0.1mF

AD7891 to DSP5600x

Figure 15 shows a parallel interface between the AD7891 and

the DSP5600x series of DSPs. The AD7891 should be mapped

into the top 64 locations of Y data memory. If extra wait states

are needed in this interface, they can be programmed using

the Port A Bus Control Register (please see DSP5600x users

manual for details). Data can be read from the AD7891 using

the following instruction:

MOVEO Y:ADC,X0

where ADC is the address in the DSP5600x address space to

which the AD7891 has been mapped.

DS

WR

RD

ADDRESS BUS

ADDR

DECODE

DATA BUS

CS

WR

AD7891*

RD

EOC

DB11–DB0

A15–A0

DSP56000/

DSP56002*

*ADDITIONAL PINS OMITTED FOR CLARITY

X/Y

IRQ

D23–D0

Figure 15. AD7891 to DSP5600x Parallel Interface

Power Supply Bypassing and Grounding

In any circuit where accuracy is important, careful consideration

of the power supply and ground return layout helps to ensure

the specified performance. The printed circuit board on which

the AD7891 is mounted should be designed such that the analog and digital sections are separated and confined to certain

areas of the board. This facilitates the use of ground planes that

can be separated easily. A minimum etch technique is generally

best for ground planes as it gives the best shielding. Digital and

analog ground planes should be joined at only one place. If the

AD7891 is the only device requiring an AGND to DGND connection then the ground planes should be connected at the

AGND and DGND pins of the AD7891. If the AD7891 is in a

system where multiple devices require an AGND to DGND

connection, the connection should still be made at one point

only, a star ground point which should be established as close as

possible to the AD7891.

Digital lines running under the device should be avoided as

these will couple noise onto the die. The analog ground plane

should be allowed to run under the AD7891 to avoid noise

coupling. The power supply lines of the AD7891 should use as

large a trace as possible to provide low impedance paths and

reduce the effects of glitches on the power supply line. Fast

switching signals like clocks should be shielded with digital

ground to avoid radiating noise to other parts of the board and

should never be run near the analog inputs. Avoid crossover of

digital and analog signals. Traces on opposite sides of the board

should run at right angles to each other. This reduces the effects

of feedthrough through the board. A microstrip technique is by

far the best but not always possible with a double sided board.

In this technique, the component side of the board is dedicated

to ground plane while signal traces are placed on the solder side.

The AD7891 should have ample supply bypassing located as

close to the package as possible, ideally right up against the

device. One of the V

pins (Pin 10 of the PQFP package, Pin 4

DD

on the PLCC package) drives mainly the analog circuitry on the

chip. This pin should be decoupled to the analog ground plane

with a 10 µF tantalum bead capacitor in parallel with a 0.1 µF

capacitor. The other V

pin (Pin 19 on the PQFP package,

DD

Pin 13 on the PLCC package) drives mainly digital circuitry on

the chip. This pin should be decoupled to the digital ground

plane with a 0.1 µF capacitor. The 0.1 µF capacitors should

have low Effective Series Resistance (ESR) and Effective Series

Inductance (ESI), such as the common ceramic types or surface

mount types, which provide a low impedance path to ground at

high frequencies to handle transient currents due to internal

logic switching. Figure 16 shows the recommended decoupling

scheme.

Figure 16. Recommended Decoupling Scheme for the

AD7891

–17–REV. A

Page 18

AD7891

0

–30

–150

dB

–60

–90

–120

FS/2

2048 POINT FFT

SNR = 72.2dB

0

–30

–150

dB

–60

–90

–120

F

S

/2

2048 POINT FFT

SNR = 71.17dB

AD7891 PERFORMANCE

Linearity

The Linearity of the AD7891 is primarily determined by the onchip 12-bit D/A converter. This is a segmented DAC which is

laser trimmed for 12-bit integral linearity and differential linear-

ity. Typical INL for the AD7891 is ±0.25 LSB while typical

DNL is ±0.5 LSB.

Noise

In an A/D converter, noise exhibits itself as code uncertainty in

dc applications and as the noise floor (in an FFT for example)

in ac applications. In a sampling A/D such as the AD7891, all

information about the analog input appears in the baseband

from dc to half the sampling frequency. The input bandwidth of

the track/hold amplifier exceeds the Nyquist bandwidth and,

therefore, an antialiasing filter should be used to remove unwanted signals above f

/2 in the input signal in applications

S

where such signals exist.

Figure 17 shows a histogram plot for 16384 conversions of a dc

input signal using the AD7891-1. The analog input was set at

the center of a code transition in the following way. An initial dc

input level was selected and a number of conversions were

made. The resulting histogram was noted and the applied level

was adjusted so that only two codes were generated with an

equal number of occurrences. This indicated that the transition

point between the two codes had been found. The voltage level

at which this occurred was recorded. The other edge of one of

these two codes was then found in a similar manner. The dc

level for the center of code could then be calculated as the average of the two transition levels. The AD7891-1 inputs were

configured for ±5 V input range and the data was read from the

part in parallel mode, after conversion. Similar results have been

found with the AD7891-1 on the ±10 V range and on all input

ranges of the AD7891-2. The same performance is achieved in

serial mode, again with the data read from the AD7891-1 after

conversion. All the codes, except for 3, appear in one output

bin, indicating excellent noise performance from the ADC.

Dynamic Performance

The AD7891 contains an on-chip track/hold amplifier, allowing

the part to sample input signals of up to 250 kHz on any of its

input channels. Many of the AD7891’s applications will simply

require it to sequence through low frequency input signals

across its eight channels. There may be some applications, however, for which the dynamic performance of the converter on

signals of up to 250 kHz input frequency is of interest. It is

recommended for these wider bandwidth signals that hardware

conversion start method of sampling is used.

These applications require information on the spectral content

of the input signal. Signal to (noise + distortion), total harmonic

distortion, peak harmonic or spurious tone and intermodulation

distortion are all specified. Figure 18 shows a typical FFT plot

of a 10 kHz, ±10 V input after being digitized by the AD7891-1

operating at 500 kHz, with the input connected for ±10 V opera-

tion. The signal to (noise + distortion) ratio is 72.2 dB and the

total harmonic distortion is –87 dB. Figure 19 shows a typical

FFT plot of a 100 kHz, 0 V to +5 V input after being digitized

by the AD7891-2 operating at 500 kHz, with the input connected

for 0 V to +5 V operation. The signal to (noise + distortion)

ratio is 71.17 dB and the total harmonic distortion is –82.3 dB.

It should be noted that reading from the part during conversion