Page 1

LC2MOS

a

12-Bit, 750 kHz/1 MHz, Sampling ADC

FEATURES

750 kHz/1 MHz Throughput Rate

1 ms/750 ns Conversion Time

12-Bit No Missed Codes Over Temperature

67 dB SNR at 100 kHz Input Frequency

Low Power—250 mW typ

Fast Bus Access Time—57 ns max

APPLICATIONS

Digital Signal Processing

Speech Recognition and Synthesis

Spectrum Analysis

DSP Servo Control

GENERAL DESCRIPTION

The AD7886 is a 12-bit ADC with a sample-and-hold amplifier

offering high speed performance combined with low power dissipation. The AD7886 is a triple pass flash ADC that uses 15

comparators in a 4-bit flash technique to achieve 12-bit accuracy

in 1 µs/750 ns conversion time. An on-chip clock oscillator pro-

vides the appropriate timing for each of the three conversion

stages, eliminating the need for any external clocks. Acquisition

time of the sample-and-hold amplifier gives a resulting throughput rate of 750 kHz/1 MHz.*

The AD7886 operates from ±5 V power supplies. Pin-strappable

inputs offer a choice of three analog input ranges: 0 V to 5 V,

0 V to 10 V or ±5 V.

In addition to the traditional dc accuracy specifications such as

linearity, offset and full-scale errors, the AD7886 is also specified for dynamic performance parameters, including harmonic

distortion and signal-to-noise ratio.

The AD7886 has a high speed digital interface with three-state

data outputs. Conversion control is provided by a

put. Data access is controlled by

CS and RD inputs, standard

CONVST in-

microprocessor signals. The data access time of less than 57 ns

means that the AD7886 can interface directly to most modern

microprocessors, including DSP processors.

*Contact your local salesperson for further information on the 1 MHz

version.

AD7886

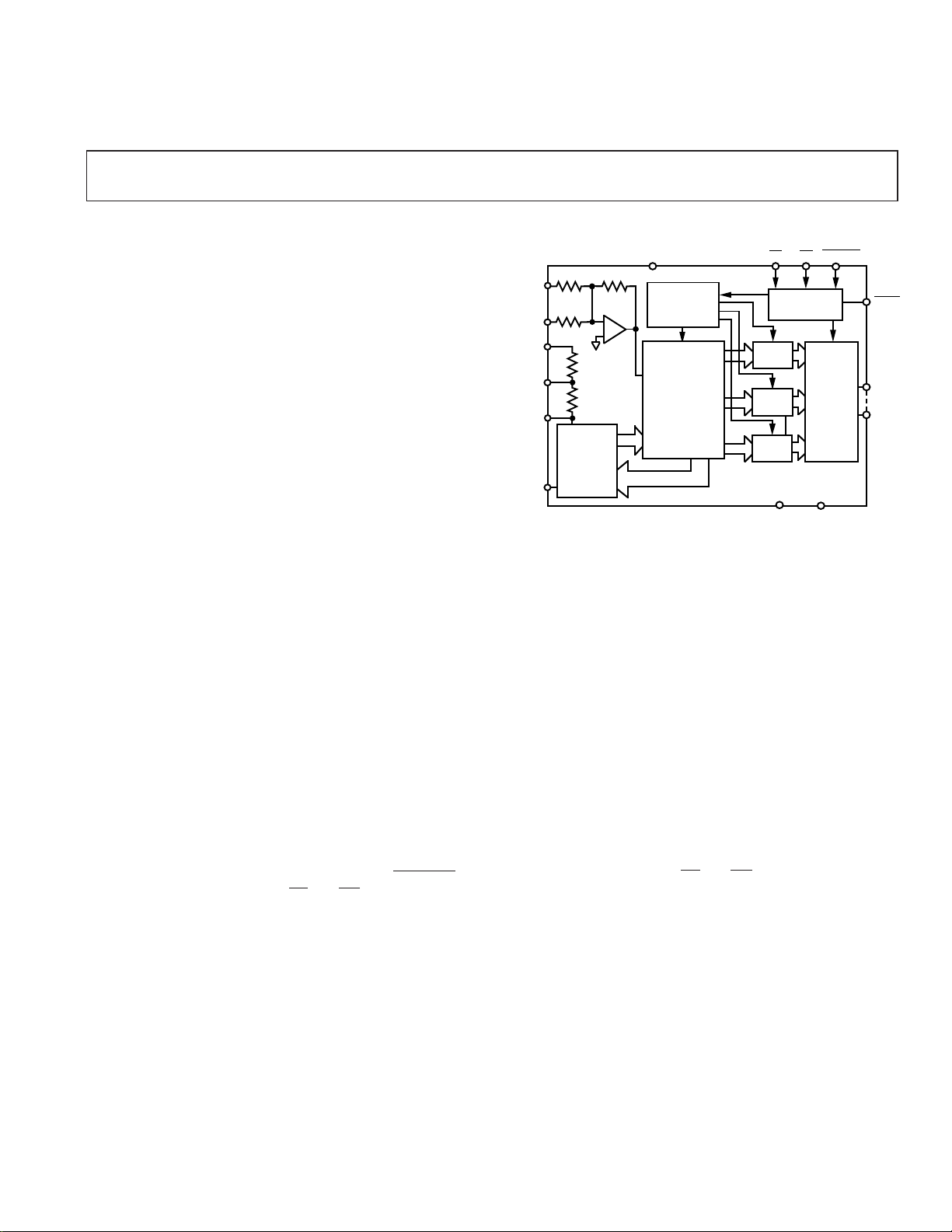

FUNCTIONAL BLOCK DIAGRAM

V

DD

R3

R4

R1

9k

R2

6.3k

4096

RESISTOR

DAC

R5

OSCILLATOR

–

+

AND TIMER

T/H

COMPARATORS

4-BIT FLASH

SEGMENT SELECT

CLOCK

15

AND

LOGIC

VIN1

VIN2

+5REF

SUM

V

REF

AGND

10k 3.5k

10k

The AD7886 is fabricated in Analog Devices’ Linear Compatible CMOS process, a mixed technology process that

combines precision bipolar circuits with low power CMOS

logic.

The AD7886 is available in both a 28-pin DIP and a 28-pin

leaded chip carrier.

PRODUCT HIGHLIGHTS

1. Fast 1.33 µs/1 µs Throughput Time.

Fast throughput time makes the AD7886 suitable for a

wide range of data acquisition applications.

2. Dynamic Specifications for DSP Users.

The AD7886 is specified for ac parameters, including

signal-to-noise ratio, harmonic distortion and intermodulation distortion. Key digital timing parameters are

also tested and guaranteed over the full operating temperature range.

3. Fast Microprocessor Interface.

Standard control signals,

CS and RD, and fast bus access times make the AD7886 easy to interface to microprocessors.

4. Low Power.

2

LC

MOS fabrication process gives low power dissipa-

tion of 250 mW.

CS RD CONVST

CONTROL

TIMER

4-BIT

LATCH

4-BIT

LATCH

4-BIT

LATCH

THREE

STATE

OUTPUTS

AD7886

V

DGND

SS

BUSY

DB11

DB0

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1997

Page 2

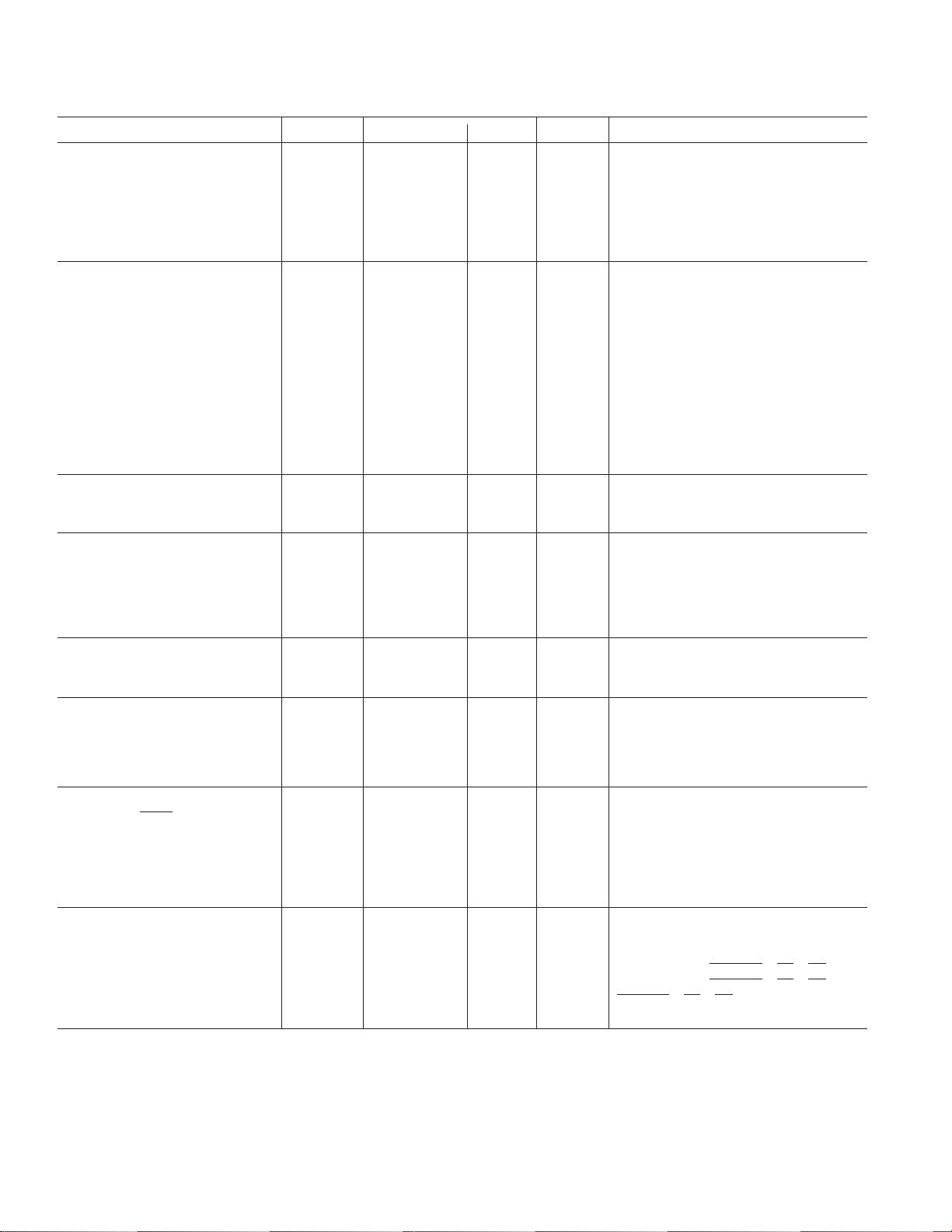

AD7886–SPECIFICATIONS

as shown in Figure 2. All Specifications T

MIN

to T

unless otherwise noted. Specifications apply for 750 kHz version.)

MAX

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, A6ND = DGND = O V, V

= –3.5 V, connected

REF

Parameter J Version1K, B Versions1T Version1Units Test Conditions/Comments

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio3 (SNR) 65 67 65 dB min VIN = 100 kHz Sine Wave, f

Total Harmonic Distortion (THD) –75 –75 –75 dB typ VIN = 100 kHz Sine Wave, f

Peak Harmonic or Spurious Noise –77 –77 –77 dB typ VIN = 100 kHz Sine Wave, f

2

SAMPLE

SAMPLE

SAMPLE

Intermodulation Distortion (IMD)

Second Order Terms –80 –80 –80 dB typ fa = 96 kHz, fb = 103 kHz, f

SAMPLE

= 750 kHz

Third Order Terms –80 –80 –80 dB typ

ACCURACY

Resolution 12 12 12 Bits

Integral Linearity T

MIN

to T

MAX

±2 ±2 LSB max

Minimum Resolution for Which

No Missing Codes Are Guaranteed 12 12 12 Bits

Unipolar Offset Error @ +25°C ±5 ±5 ±5 LSB max Input Range: 0 V to 5 V or 0 V to 10 V

T

MIN

to T

MAX

±5 ±5 ±5 LSB max

Bipolar Offset Error @ +25°C ±5 ±5 ±5 LSB max Input Range: ± 5 V

T

MIN

to T

MAX

±5 ±5 ±5 LSB max

Unipolar Gain Error @ +25°C ±5 ±5 ±5 LSB max Input Range: 0 V to 5 V or 0 V to 10 V

T

MIN

to T

MAX

±5 ±5 ±5 LSB max

Bipolar Gain Error @ +25°C ±5 ±5 ±5 LSB max Input Range: ± 5 V

T

MIN

to T

MAX

±5+5 ±5 LSB max

ANALOG INPUT

Unipolar Input Current 1.5 1.5 1.5 mA max Input Ranges: 0 V to 5 V or 0 V to 10 V

Bipolar Input Current ±0.75 ±0.75 ±0.75 mA max Input Range: ±5 V

= 750 kHz

= 750 kHz

= 750 kHz

REFERENCE INPUT

V

REF

–3.5 –3.5 –3.5 Volts ± 2% For Specified Performance

Input Reference Current –10 –10 –10 mA max

R1, Resistance 9 9 9 kΩ nom ±25%

R2, Resistance 6.3 6.3 6.3 kΩ nom ±25%

R2/R1 Ratio 0.7 0.7 0.7 nom ±0.1%

POWER SUPPLY REJECTION

VDD Only, (FS Change) 0.5 0.5 0.5 LSB typ VSS = –5 V, VDD = +4.75 V to +5.25 V

VSS Only, (FS Change) 0.5 0.5 0.5 LSB typ VDD = +5 V, VSS = –4.75 V to –5.25 V

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

INH

INL

IN

4

IN

LOGIC OUTPUTS

DB11–DB0, BUSY

Output High Voltage, V

Output Low Voltage, V

OH

OL

DB11–DB0

Floating-State Leakage Current ±10 ±10 ±10 pA max

Floating-State Output Capacitance415 15 15 pF max

POWER REQUIREMENTS

V

DD

V

SS

I

DD

I

SS

Power Dissipation 250 250 250 mW typ CONVST = CS = RD = V

NOTES

I

Temperature ranges are as follows: J, K Versions: 0°C to +70°C; B Version: –40°C to +85°C; T Version: –55°C to + 125°C.

2

Applies to all three input ranges, VIN = 0 to FS, pk-to-pk V.

3

SNR calculation includes distortion and noise components.

4

Sample tested @ +25°C to ensure compliance.

Specifications subject to change without notice.

2.4 2.4 2.4 V min VDD = 5 V ± 5%

0.8 0.8 0.8 V max VDD = 5 V ± 5%

±10 ±10 ±10 µA max VIN = 0 V to V

DD

10 10 10 pF max

4 4 4 V min I

0.4 0.4 0.4 V max I

SOURCE

= 1.6 mA

SINK

= 200 µA

+5 +5 +5 V nom ±5% for Specified Performance

–5 –5 –5 V nom ±5% for Specified Performance

35 35 35 mA max Typically 25 mA, CONVST = CS = RD = V

–35 –35 –35 mA max Typically 25 mA, CONVST = CS = RD = V

350 350 350 mW max

DD

DD

DD

–2–

REV. B

Page 3

1

WARNING!

ESD SENSITIVE DEVICE

TIMING CHARACTERISTICS

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, AGND = DGND = 0 V)

Limit at Limit at Limit at

T

MIN

, T

MAX

T

MIN

, T

MAX

T

, T

MIN

MAX

Parameter (J, K Versions) (B Version) (T Version) Units Conditions/Comments

AD7886

t

1

50 50 50 ns min CONVST Pulse Width

1 1 1 Fs max

t

2

t

3

t

4

t

5

t

6

3

t

7

0 0 0 ns min CS to RD Setup Time

0 0 0 ns min CS to RD Hold Time

60 60 75 ns min RD Pulse Width

100 100 100 ns max CONVST to BUSY Propagation Delay, (CL = 10 pF)

57 57 70 ns max Data Access Time After RD

10 10 10 ns min Bus Relinquish Time After RD

50 50 60 ns max

t

8

3

t

9

20 20 14 ns min Data Setup Time Prior to BUSY, (CL = 20 pF)

10 10 0 ns min Data Setup Time Prior to

BUSY, (CL = 100 pF)

10 10 10 ns min Bus Relinquish Time After CONVST

100 100 100 ns max

t

10

t

11

t

12

t

13

t

CONV

0 0 0 ns min CS High to CONVST Low

0 0 0 ns min BUSY High to RD Low

250 250 250 ns typ BUSY High to CONVST Low, SHA Acquisition Time

1.333 1.333 1.333 µs min Sampling Interval

950 950 950 ns typ Conversion Time

1000 1000 1000 ns max

NOTES

1

Timing specifications in bold print are 100% production tested. All other times are sample tested at +25°C to ensure compliance. All input signals are specified with tr =

tf = 5 ns (10% to 90% of 5 V) and timed from a voltage level of 1.6 V.

2

t6 is measured with the load circuit of Figure 1 and defined as the time required for an output to cross 0.8 V or 2.4 V.

3

t7 and t9 are derived from the measured time taken by the data outputs to change by 0.5 V when loaded with the circuit of Figure 1. The measured number is then extrapolated back to remove the effects of charging or discharging the load capacitor, C

relinquish times of the part and as such are independent of external bus loading capacitances.

Specifications subject to change without notice.

. This means that the times, t7 and t9, quoted in the timing characteristics are the true bus

L

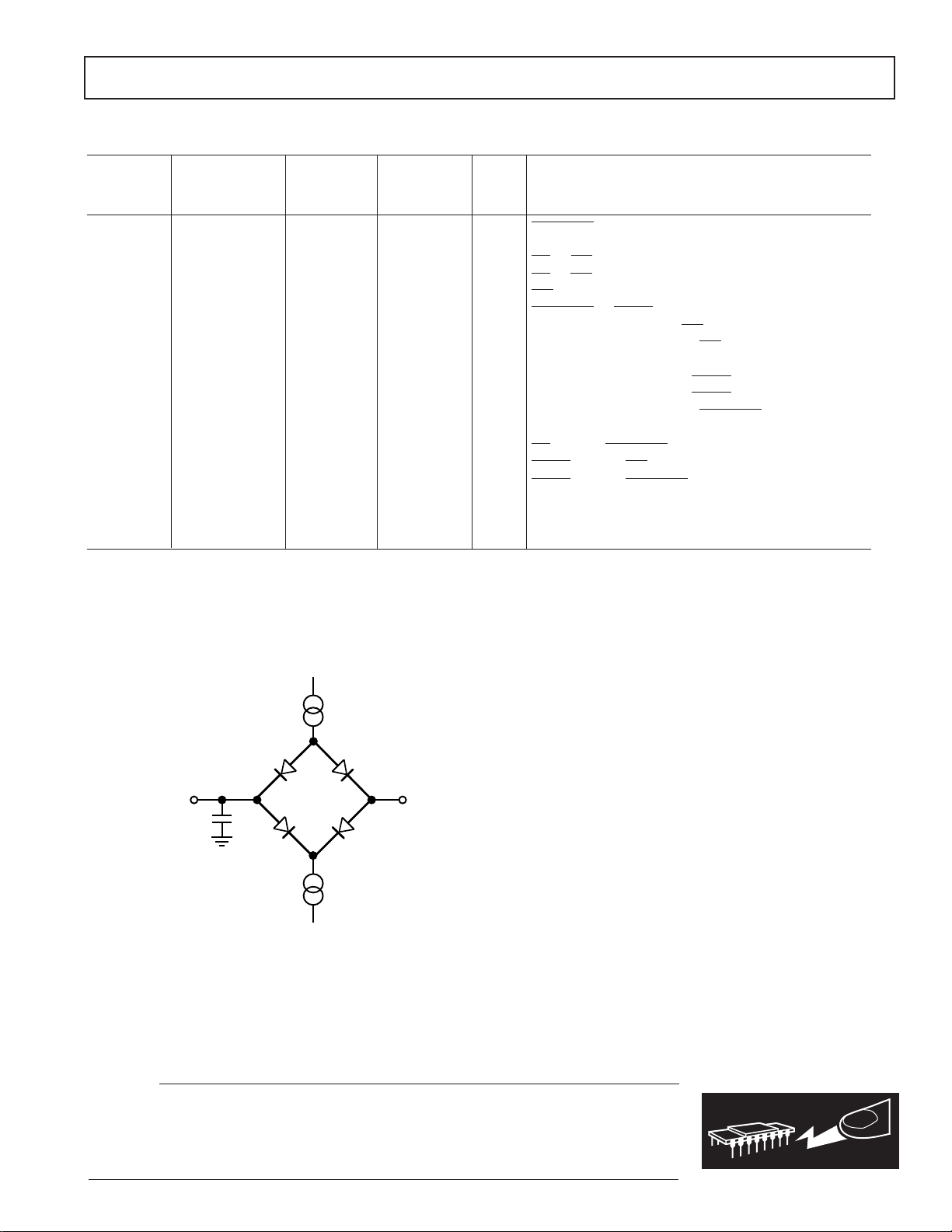

Figure 1. Load Circuit for Bus Access and Relinquish Time

ABSOLUTE MAXIMUM RATINGS

(T

V

DD

V

SS

AGND to DGND . . . . . . . . . . . . . . . . . –0.3 V to V

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7886 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. B

I

OL

TO OUTPUT

PIN

= +25°C unless otherwise noted)

A

C

L

1, 2

I

OH

+2.1V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V to –7 V

+0.3 V

DD

VIN1, VIN2, SUM, +5REF to AGND . . . . . . –15 V to +15 V

V

to AGND . . . . . . . . . . . . . . . . VSS –0.3 V to V

REF

DD

+0.3 V

Digital Inputs to DGND

CS, RD, CONVST . . . . . . . . . . . . . . –0.3 V to V

+0.3 V

DD

Digital Outputs to DGND

DB0 to DB11, BUSY . . . . . . . . . . . . . –0.3 V to V

+0.3 V

DD

Operating Temperature Range

Commercial (J, K Versions) . . . . . . . . . . . . . . 0°C to +70°C

Industrial (B Version) . . . . . . . . . . . . . . . . –40°C to +85°C

Extended (T Version) . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . .–65°C to + 150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . .+300°C

Power Dissipation (Any Package) to +75°C . . . . . . 1000 mW

Derates above +75°C by . . . . . . . . . . . . . . . . . . . . 10 mW/°C

NOTES

1

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only; functional operation

of the device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

If VSS is open circuited with VDD and AGND applied, the VSS pin will be pulled

positive, exceeding the Absolute Maximum Ratings. If this possibility exists, a

Schottky diode from VSS to DGND (cathode end to GND) ensures that the

–3–

Page 4

AD7886

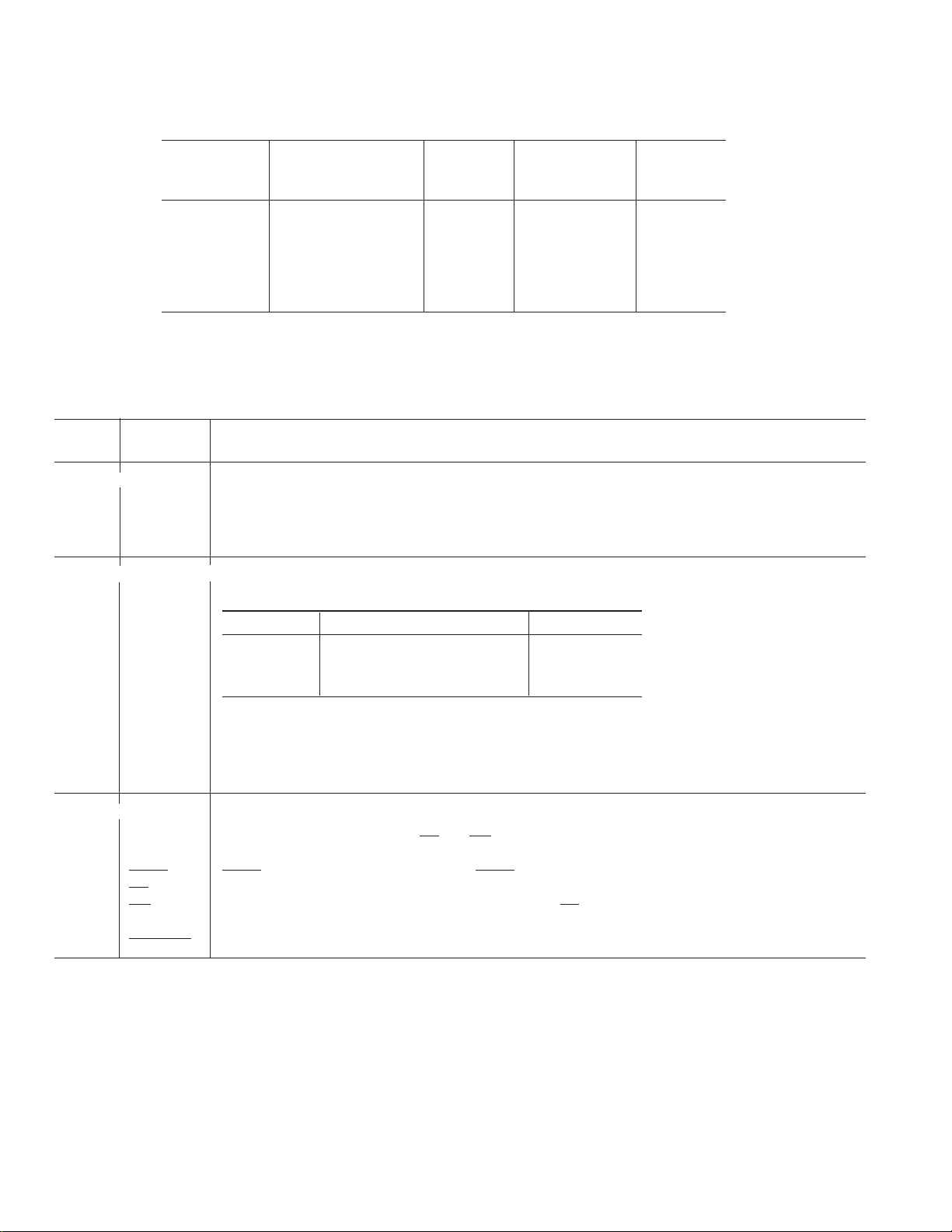

ORDERING GUIDE

Integral

1, 2

Model

AD7886JD 0°C to +70°C 65 D-28

AD7886KD 0°C to +70°C67±2.0 D-28

AD7886JP 0°C to +70°C 65 P-28A

AD7886KP 0°C to +70°C67±2.0 P-28A

AD7886BD –40°C to +85°C67 ±2.0 D-28

AD7886TD –55°C to +125°C65 ±2.0 D-28

NOTES

1Contact your sales office for availability of AD7886BD, AD7886TD and 1 MHz version.

2

Analog Devices reserves the right to ship J-Leaded Ceramic Chip Carrier (JLCCC) in lieu of PLCC packages.

3

D = Ceramic DIP; P = Plastic Leaded Chip Carrier.

DIP Pin

Number Mnemonic Description

Power Supply

10 & 19 V

15 & 24 V

DD

SS

Positive Power Supply, +5 V ± 5%. Both V

Negative Power Supply, –5 V ± 5%. Both V

16 & 23 AGND Analog Ground. Both AGND pins must be tied together.

5 DGND Digital Ground.

Temperature SNR Nonlinearity Package

Range (dBs) (LSBs) Option

PIN FUNCTION DESCRIPTION

pins must be tied together.

DD

pins must be tied together.

SS

3

2

2

Analog and Reference Inputs

17 & 18 VIN Analog Inputs, VIN1 and VIN2. The part can be pin strapped for any one of three analog input ranges;

Range Pin Strap Signal Input

0 V to 5 V Connect VIN2 to VIN1 VIN1 & VIN2

0 V to 10 V Connect VIN2 to GND VIN1

±5 V Connect VIN2 to +5 V VIN1

20 +5REF +5 V Reference input. This input is used in conjunction with SUM and V

inputs to scale an external

REF

+5 V reference to –3.5 V, the required reference for the part (see Figure 2).

21 SUM Summing Point. This input is used in conjunction with +5REF and V

inputs to scale an external

REF

+5 V reference to –3.5 V, the required reference for the part (see Figure 2).

22 V

REF

Voltage Reference Input. The AD7886 is specified with V

REF

= –3.5 V.

Interface and Control

1–4, DB7–DB4 Three-state data outputs.

6–9, DB3–DB0 These outputs are controlled by

CS and RD. DB11 is the Most Significant Bit (MSB).

25–28 DB11–DB8

11

12

13

BUSY BUSY Output indicates converter status. BUSY is low during conversion.

CS Chip Select Input. The device is selected when this input is low.

RD Read Input. This active low signal, in conjunction with CS, is used to enable the output data three-state

drivers.

14 CONVST Conversion Start Input. This input is used to start conversion.

–4–

REV. B

Page 5

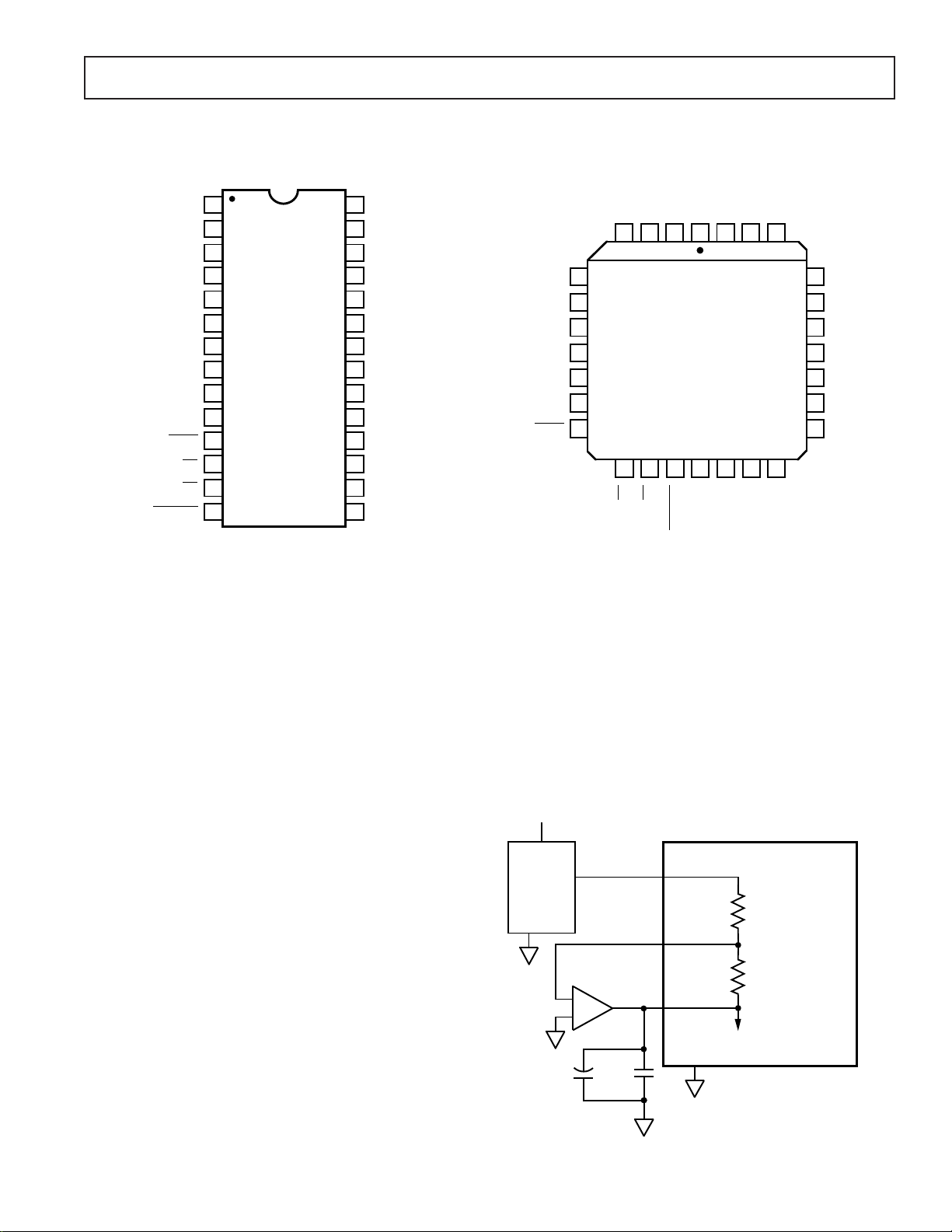

PIN CONFIGURATIONS

AGND

VIN1

VIN2

DB4

DB5

DB6

DB11

DB10

DB9

DB8

DB7

AGND

SUM

+5REF

DB2

DB1

DB0

DGND

DB3

V

SS

V

REF

V

DD

CS

RD

CONVST

V

SS

V

DD

BUSY

AD7886

TOP VIEW

(Not to Scale)

5

6

7

8

9

10

11

28 27 2612

3

4

25

24

23

22

21

20

19

12

13 14 15 16 17 18

AD7886

DIP

DB7

DB6

DB5

DB4

DGND

DB3

DB2

DB1

DB0

V

DD

BUSY

CS

RD

CONVST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

AD7886

TOP VIEW

(Not to Scale)

28

27

26

25

24

23

22

21

20

19

18

17

16

15

DB8

DB9

DB10

DB11

V

SS

AGND

V

REF

SUM

+5REF

V

DD

VIN2

VIN1

AGND

V

SS

TERMINOLOGY

Unipolar Offset Error

The ideal first code transition should occur when the analog

input is 1 LSB above AGND. The deviation of the actual transition from that point is termed the offset error.

Bipolar Zero Error

The ideal midscale transition (i.e., 0111 1111 1111 to 1000

0000 0000) for the +5 V range should occur when the analog

input is at zero volts. Bipolar zero error is the deviation of the

actual transition from that point.

Gain Error

In the unipolar mode, gain error is measured with respect to the

first and last code transition points. The ideal difference between these points is FS–2 LSBs. For bipolar applications, the

gain error is measured from the midscale transition to both the

first and last code transitions. The ideal difference in this case is

FS/2–1 LSB. The gain error is defined as the deviation between

the ideal difference, given above, and the measured difference.

For the bipolar case, there are two gain errors; the figure in the

specification page represents the worst case. Ideal FS depends

on the +5REF input; for the 0 V to 5 V input, ideal FS = +5REF

and for the 0 V to 10 V and +5 V ranges, ideal FS = 2 × + 5REF.

CONVERTER DETAILS

The AD7886 is a triple-pass flash ADC that uses 15 comparators in a 4-bit flash technique to perform the 12-bit conversion

procedure. Each of the 4096 quantization levels is realized internally with a precision resistor DAC.

The fifteen comparators first compare the analog input voltage

to the V

four most significant bits and selects 1 out of 16 voltage segments. The comparators are then switched to 15 subvoltages on

that segment to determine the next four bits and select 1 out of

/16 voltages of the resistor array. This determines the

REF

256 voltage segments. A further switching of the comparators to

another 15 subvoltages produces the complete 12-bit conversion

REV. B

PLCC

result. The 12 bits of data are then stored internally in a threestate output latch.

REFERENCE INPUT

The AD7886 operates from a 3.5 V reference, which must be

provided at the V

input. Two on-chip resistors for use with

REF

an external amplifier can be used for deriving 3.5 V from standard 5 V references. Figure 2 shows an example with the AD586

which a is a high performance voltage reference exhibiting

excellent stability performance, 5 ppm/°C max. The external

amplifier serves a second function of force/sensing the V

REF

input. Force/sensing minimizes error contributions from

+V

+V

AD586

GND

IN

+5V

V

OUT

AD707

–

–3.5V

+5REF

SUM

V

REF

R1

9k

R2

6.3k

AD7886*

+

TO DAC

C1

10µF

C2

0.1µF

AGND

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 2. Typical Reference Circuitry

–5–

Page 6

AD7886

this amplifier typically by 20 MHz which is much greater than

the Nyquist limit of the ADC; as a result, it can be used for

undersampling applications. The track-and-hold amplifier acquires the input signal to 12-bit accuracy in less than 333 ns.

The overall throughput time is equal to the conversion time

plus the track/ hold amplifier acquisition time, which is 1.333 µs

for the AD7886.

The operation of the track/hold amplifier is essentially transparent to the user. The track-to-hold transition occurs at the start

of conversion on the falling edge of

procedure does not start until the rising edge of

width of the

CONVST pulse low time determines the track-to

hold settling time. The track/hold reverts back to the track

mode at the end of conversion when

0 TO 5V ANALOG INPUT RANGE

CONVST. The conversion

CONVST. The

BUSY has returned high.

3.5k

+V

+V

IN

V

AD586

GND

OUT

+

5V

AIN

0 TO 5V

OR

0 TO 10V

AD707

–

+

+

5V

V

VIN1

VIN2**

AGND

DD

AD7886*

+

5REF

SUM

–

3.5V

V

REF

10k

0 TO 5V

0 TO 10V

±5V

+5V

VIN1

10k

VIN2

0 TO 10V ANALOG INPUT RANGE

10k

VIN1

10k

VIN2

±5V ANALOG INPUT RANGE

10k

VIN1

10k

VIN2

–

+

3.5k

TO

COMPARATORS

–

+

3.5k

TO

COMPARATORS

–

+

TO

COMPARATORS

Figure 3. Analog Input Range Configurations

ANALOG INPUT RANGES

The AD7886 has three user selectable analog input ranges: 0 V

to 5 V, 0 V to 10 V and ±5 V. Figure 3 shows how to configure

the two analog inputs (VIN1 and VIN2) for these ranges.

UNIPOLAR OPERATION

Figure 4 shows a typical unipolar circuit for the AD7886. The

ideal input/output characteristic is shown in Figure 5. The

designed code transitions occur on integer multiples of 1 LSB.

The output code is natural binary with 1 LSB = FS/4096. FS is

either +5 V or +10 V, depending on how the analog inputs are

configured.

V

C1

10µF

*ADDITIONAL PINS OMITTED FOR CLARITY

**0 TO 5V RANGE: CONNECT VIN2 TO VIN1

0 TO 10V RANGE: CONNECT VIN2 TO AGND

C2

0.1µF

SS

–

5V

Figure 4. Unipolar Operation

OUTPUT

CODE

11...111

11...110

11...101

11...100

FS

4096

00...011

1LSB =

00...010

00...001

00...000

123

FS

VIN, INPUT VOLTAGE (LSBS)

FS – 1LSB

Figure 5. Ideal Input/Output Transfer Characteristic for

Unipolar Operation

–6–

REV. B

Page 7

AD7886

OFFSET AND GAIN ADJUSTMENT

In most digital signal processing (DSP) applications, offset and

full-scale errors have little or no effect on system performance.

Offset error can usually be eliminated in the analog domain by

ac coupling. Full-scale errors do not cause problems as long as

the input signal is within the full dynamic range of the ADC.

For applications requiring that the input signal range match the

full analog input dynamic range of the ADC, offset and fullscale errors must be adjusted to zero.

UNIPOLAR OFFSET AND GAIN ERROR ADJUSTMENT

If absolute accuracy is an application requirement, offset and

gain can be adjusted to zero. Offset error must be adjusted before gain error. Zero offset is achieved by adjusting the offset of

the op amp driving the analog input (i.e., A1 in Figure 6). For

zero offset error, apply a voltage of 1 LSB to AIN and adjust

the op amp offset until the ADC output code flickers between

0000 0000 0000 and 0000 0000 0001.

0 V to 5 V Range: 1 LSB = 1.22 mV

0 V to 10 V Range: 1 LSB = 2.44 mV

For zero gain, error apply an analog input voltage equal to

FS–1 LSB (last code transition) at AIN and adjust R3 until the

ADC output code flickers between 1111 1111 1110 and 1111

1111 1111.

0 V to 5 V Range: FS–1 LSB = 4.99878 V

0 V to 10 V Range: FS–1 LSB = 9.99756 V

+

5REF

5V

V

DD

AIN

0 TO 5V

OR

0 TO 10V

+V

+V

IN

V

AD586

GND

OUT

AD845

+

A1

VIN1

–

VIN2**

AGND

5V+

R1

82k

+

SUM

AD707

R3

5k

–

–

+

3.5V

V

REF

AD7886*

R2

56k

*ADDITIONAL PINS OMITTED FOR CLARITY

**0 TO 5V RANGE: CONNECT VIN2 TO VIN1

0 TO 10V RANGE: CONNECT VIN2 TO AGND

C1

10µF

C2

0.1µF

V

SS

–

5V

Figure 6. Unipolar Operation with Gain Error Adjust

BIPOLAR OPERATION

Bipolar operation is achieved by providing a +10 V span on

the VIN1 input while offsetting the VIN2 input by +5 V. A

typical circuit is shown in Figure 7. The output code is offset binary. The ideal input/output transfer characteristic is

shown in Figure 8. The LSB size is (10/4096) V = 2.44 mV.

+

5V

V

DD

+V

+V

AIN

±

5V

IN

+

5V

V

OUT

VIN1

VIN2

AGND

+

5REF

AD586

GND

AD707

–

+

C1

10µF

*ADDITIONAL PINS OMITTED FOR CLARITY

C2

0.1µF

–

3.5V

SUM

AD7886*

V

REF

V

SS

–

5V

Figure 7. Bipolar Operation

OUTPUT

CODE

11...111

11...110

11...101

10...010

10...001

10...000

01...111

01...110

01...101

00...001

00...000

–

FS

2

+1LSB

1LSB–

+1LSB

FS = 10V

1LSB =

VIN, INPUT VOLTAGE – LSBs

+

FS

2

FS

4096

– 1LSB

Figure 8. Ideal Input/Output Characteristics for

Bipolar Operation

REV. B

–7–

Page 8

AD7886

BIPOLAR OFFSET AND GAIN ADJUSTMENT

In applications where absolute accuracy is important, offset and

gain error can be adjusted to zero. Offset is adjusted by trimming the voltage at the VIN1 or VIN2 input when the analog input is at zero volts. This can be achieved by adjusting the offset

of an external amplifier used to drive either of these inputs (see

A1 in Figure 9). The trim procedure is as follows:

Apply zero volts at AIN and adjust the offset of A1 until the

ADC output code flickers between 0111 1111 1111 and 1000

0000 0000.

Gain error can be adjusted at either the first code transition

(ADC negative full scale) or the last code transition (ADC positive full scale). Adjusting the reference, as in Figure 9, will trim

the positive gain error only. The trim procedure is as follows:

Apply a voltage of 4.99756 V, (FS/2–1 LSB) at AIN and

adjust R3 until the output code flickers between 1111 1111

1110 and 1111 11111111.

If the first code transition needs adjusting, a gain trim must be

included in the analog signal path. The trim procedure will then

consist of applying an analog signal of –4.99756 V (–FS/2+1 LSB)

and adjusting the trim until the output code flickers between

0000 0000 0000 and 0000 0000 0001.

+

VIN1

VIN2

AGND

+

5REF

SUM

V

REF

5V

V

DD

AIN

±

+V

+V

IN

V

OUT

AD586

GND

5V

R3

5k

5V+

R1

82k

+

–

AD845

A1

AD707

–

+

3.5V–

AD7886*

R2

56k

*ADDITIONAL PINS OMITTED FOR CLARITY

C1

10µF

C2

0.1µF

V

SS

5V–

Figure 9. Bipolar Operation with Gain Error Adjust

TIMING AND CONTROL

Conversion start is controlled by the CONVST input (see Figures 10 and 11). A high to low going edge on the

CONVST input puts the track/hold amplifier into the hold mode. The ADC

conversion procedure does not begin until a rising

pulse edge occurs. The width of the

CONVST pulse low time

determines the track-to-hold settling time. The

CONVST

BUSY output,

which indicates the status of the ADC, goes low while conversion is in progress. At the end of conversion

BUSY returns high,

indicating that new data is available on the AD7886’s output

latches. The track/hold amplifier returns to the track mode at

the end of conversion and remains there until the next

CONVST pulse. Conversion starts must not be attempted while

conversion is in progress as this will cause erroneous results.

Data read operations are controlled by the

CS and RD inputs.

These digital inputs, when low, enable the AD7886’s threestate output latches. Note, these latches cannot be enabled during conversion. In applications where

CS and RD are tied permanently low, as in Figure 11, the data bus will go into the

three-state condition at the start of conversion and return to its

active state when conversion is complete. Tying

CS and RD

permanently low is useful when external latches are used to

store the conversion results. The data bus becomes active before

BUSY returns high at the end of conversion, so that BUSY can

be used as a clocking signal for the external latches.

A typical DSP application would have a timer connected to the

CONVST input for precise sampling intervals. BUSY would be

connected to the interrupt of a microprocessor that would be

asserted at the end of every conversion. The microprocessor

would then assert the

CS and RD inputs and read the data from

the ADC. For applications where both data reading and conversion control need to be managed by a microprocessor, a

CONVST

pulse can be decoded from the address bus. One decoding possibility is that a write instruction to the ADC address starts a

conversion, and a read instruction reads the conversion result.

TRACK-TO-HOLD

TRANSITION

t

13

t

CONVST

CS

RD

BUSY

DATA

1

t

5

HIGH IMPEDANCE

CONVERSION

START

HOLD TO

TRACK

TRANSITION

t

CONV

t

11

t

t

12

t

10

t

2

t

4

6

DATA

VALID

t

3

t

7

Figure 10. Conversion Start and Data Read Timing

Diagram

TRACK-TO-HOLD

TRANSITION

t

13

t

1

CONVST

t

BUSY

DATA

CONVERSION

START

5

t

9

HIGH IMPEDANCE

t

CONV

t

12

HOLD TO TRACK

t

8

TRANSITION

DATA

VALID

Figure 11. Conversion Start and Data Read

Timing Diagram, (

CS

= RD = 0 V)

–8–

REV. B

Page 9

AD7886

AD7886 DYNAMIC SPECIFICATIONS

The AD7886 is specified for dynamic performance specifications as well as traditional dc specifications such as integral and

differential nonlinearity. These ac specifications are required for

signal processing applications such as speech recognition, spectrum analysis and high speed modems. These applications require

information on the ADC’s effect on the spectral content of the

input signal. Hence, the parameters for which the AD7886 is

specified include SNR, harmonic distortion, intermodulation

distortion and peak harmonics. These terms are discussed in

more detail in the following sections.

Signal-to-Noise Ratio (SNR)

SNR is the measured signal-to-noise ratio at the output of the

ADC. The signal is the rms magnitude of the fundamental.

Noise is the rms sum of all the nonfundamental signals up to

half the sampling frequency (FS/2), excluding dc. SNR is dependent upon the number of quantization levels used in the

digitization process; the more levels, the smaller the quantization noise. The theoretical signal to noise ratio for a sine wave

input is given by

SNR = (6.02N + 1.76) dB (1)

where N is the number of bits. Thus, for an ideal 12-bit converter, SNR = 74 dB.

The output spectrum from the ADC is evaluated by applying a

sine wave signal of very low distortion to the VIN input, which

is sampled at a 750 kHz sampling rate. A Fast Fourier Transform (FFT) plot is generated from which the SNR data can be

obtained. Figure 12 shows a typical 2048 point FFT plot with

an input signal of 100 kHz and a sampling frequency of 750 kHz.

Figure 12. AD7886 FFT Plot

The SNR obtained from this graph is 68 dB. It should be noted

that the harmonics are taken into account when calculating the

SNR.

Effective Number of Bits

The formula given in Equation 1 relates the SNR to the number

of bits. Rewriting the formula, as in Equation 2, it is possible to

obtain a measure of performance expressed in effective number of bits (N).

SNR –1.76

N =

6.02

(2)

The effective number of bits for a device can be calculated directly from its measured SNR.

Figure 13 shows a typical plot of effective number of bits versus

frequency for a sampling frequency of 750 kHz. Input frequency

range for this particular graph was limited by the test equipment

to FS/4. The effective number of bits typically falls between

10.9 and 11.2, corresponding to SNR figures of 67.38 dB and

69.18 dB.

12

11.5

11

10.5

EFFECTIVE NUMBER OF BITS

10

0

SAMPLING FREQUENCY = 750kHz

T = 25 C

A

INPUT FREQUENCY

FS/4

Figure 13. Effective Number of Bits vs. Frequency

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of harmonics to the fundamental. For the AD7886, THD is defined as

2

2

2

2

+V

+V

V

2

where V

V

, V5 and V6 are the rms amplitudes of the second through the

4

THD =20 log

is the rms amplitude of the fundamental and V2, V3,

1

3

+V

4

V

1

+V

5

2

6

(3)

sixth harmonic. The THD is also derived from the FFT plot of

the ADC output spectrum.

Intermodulation Distortion (IMD)

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products at sum and difference frequencies of mfa ± nfb where

m, n = 0, 1, 2, 3, etc. Intermodulation terms are those for which

neither m nor n are equal to zero. For example, the second order terms include (fa + fb) and (fa – fb) while the third order

terms include (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb).

Using the CCIF standard, where two input frequencies near the

top end of the input bandwidth are used, the second and third

order terms are of different significance. The second order terms

are usually distanced in frequency from the original sine waves,

while the third order terms are usually at a frequency close to

the input frequencies. As a result, the second and third order

terms are specified separately. The calculation of the intermodulation distortion is per the THD specification where it is the

ratio of the rms sum of the individual distortion products to the

rms amplitude of the fundamental, expressed in dBs. In this

case, the input consists of two, equal amplitude, low distortion

sine waves. Figure 14 shows a typical IMD plot for the AD7886.

Peak Harmonic or Spurious Noise

Peak harmonic or spurious noise is defined as the ratio of the

rms value of the next largest component in the ADC output

spectrum (up to FS/2 and excluding dc) to the rms value of the

fundamental. Normally, the value of this specification will be

REV. B

–9–

Page 10

AD7886

determined by the largest harmonic in the spectrum, but for

parts where the harmonics are buried in the noise floor, the peak

will be a noise peak.

Figure 14. AD7886 IMD Plot

MICROPROCESSOR INTERFACING

The AD7886 is designed to interface to microprocessors as a

memory mapped device. Its

CS and RD control inputs are common to all memory peripheral interfacing. Figures 15 to 21

demonstrate typical interfaces for the AD7886.

AD7886–TMS320C10/TMS32020

Figures 15 and 16 show typical interfaces for the TMS320C10

and the TMS32020 DSP processors. An external timer controls

conversion start to the processor. At the end of each conversion,

the ADC’s

BUSY output interrupts the microprocessor. The

conversion result can then be read from the ADC with the following instruction:

IN D,ADC (ADC = ADC address)

AD788S ADSP-2100/TMS320C25/DSP56000

Some of the faster DSP processors have data access times outside the capabilities of the AD7886. Interfacing to such processors requires the use of either a single WAIT state or external

latches. Examples are shown in Figures 17, 18 and 19.

The use of a single WAIT state for the TMS320C25 and the

ADSP-2100 interfaces extends the read instruction to the ADC

by one processor CLK OUT cycle. In the DSP56000 example,

the ADC’s data is first clocked into 74HC374 latches before being read by the processor. The AD7886’s

tied permanently low, and the rising edge of

CS and RD inputs are

BUSY updates the

latches at the end of conversion. Both methods of overcoming

the very fast data access time required by these processors are

interchangeable, i.e., a WAIT state can be used for the DSP56000,

eliminating the need for latches or vice or versa, for the other

two interfaces.

For all three interfaces, an external timer controls conversion

start; the processor is interrupted at the end of each conversion

by the ADC’s

BUSY output. The following instruction then

reads data from the ADC:

TIMER

PA2

PA0

MEN

ADDRESS BUS

ADDR

ENCODE

EN

TMS320C10

INT

DEN

D15

D0

*ADDITIONAL PINS OMITTED FOR CLARITY

DATA BUS

Figure 15. AD7886-TMS320C10 Interface

TIMER

A15

A0

IS

ADDRESS BUS

ADDR

ENCODE

EN

TMS32020

INTn

STRB

R/W

D15

D0

*ADDITIONAL PINS OMITTED FOR CLARITY

DATA BUS

Figure 16. AD7886-TMS32020 Interface

CONVST

CS

AD7886*

BUSY

RD

DB11

DB0

CONVST

CS

AD7886*

BUSY

RD

DB11

DB0

ADSP-2100 – MR = DM(ADC)

TMS320C25 – IN D,ADC

DSP56000 – MOVEP Y:ADC,XO

Assuming the ADC is memory mapped into the top

64 locations in Y memory space. (ADC = ADC address)

–10–

REV. B

Page 11

AD7886

A0

A15

D11

D0

ADDR

ENCODE

ADDRESS BUS

DATA BUS

CONVST

CS

DB11

DB0

RD

BUSY

AD7886*

MC68000

*ADDITIONAL PINS OMITTED FOR CLARITY

R/W

EN

DTACK

AS

CLK

DMA13

OUT

DMA0

DMACK

ADSP-2100

DMRD

DMD15

DMD0

ADDRESS BUS

ADDR

ENCODE

DMS

IRQn

EN

Q

74HC74

DATA BUS

*ADDITIONAL PINS OMITTED FOR CLARITY

CLR

CLK

Figure 17. AD7886–ADSP-2100 Interface

A15

ADDRESS BUS

A0

TMS320C25

IS

ADDR

ENCODE

EN

TIMER

AD7886–MC68000

Applications requiring conversions to be initiated by the microprocessor rather than an external timer may decode a

CONVST

signal from the address bus. An example is given in Figure 20

CONVST

CS

AD7886*

+

5V

D

with the MC68000 processor. A write instruction starts conversion while a read instruction reads the data when conversion is

complete. A delay at least as long as the ADC conversion time

must be allowed between initiating a conversion and reading the

ADC data into the processor. In Figure 20,

BUSY is used to

drive the processor into a WAIT state if the processor attempts

to read data before conversion is complete.

BUSY

RD

DB11

DB0

Conversion is initiated with a write instruction to the ADC:

Move.W D0,ADC (ADC = ADC address)

Data is transferred to the processor with a read instruction;

BUSY will force the processor to WAIT for the end of conversion if a conversion is in progress.

Move.W ADC,DO (ADC = ADC address)

TIMER

CONVST

CS

READY

MSC

STRB

R/W

INT

D15

D0

G2

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 18. AD7886–TMS320C25 Interface

A15

A0

X/Y

DSP56000

REV. B

DS

IRQ

RD

D23

D0

Figure 19. AD7886–DSP56000 Interface

ADDRESS BUS

ADDR

EN1

ENCODE

EN2

DATA BUS

*ADDITIONAL PINS OMITTED FOR CLARITY

DATA BUS

CLKOE

Q11

D11

D0

Q0

2X

74HC374

AD7886*

RD

BUSY

DB11

DB0

TIMER

CONVST

CS

RD

BUSY

AD7886*

DB11

DB0

Figure 20. AD7886–MC68000 Interface

AD7886–Z-80/8085A

For 8-bit processors, an external latch is required to store four

bits of the conversion result (4 LSBs in Figure 21). The data is

then read in two bytes: one read from the ADC and a second

from the latch.

Figure 21 shows a typical interface suitable for the Z-80 or the

8085A. Not shown in the Figure is the 8-bit latch needed to

demultiplex the 8085A common address/data bus. The following LOAD instruction reads the conversion result into the HL

register pair:

For the 8085A–LHLD (ADC) (ADC = ADC address)

For the Z-80–LDHL (ADC) (ADC = ADC address)

This is a two byte read instruction. The first byte to be read has

to be the high byte (DB11 to DB4). At the end of the first read

operation, the rising edge of

CS and RD clocks the 4 LSBs into

74HC374 latches. The second byte (4 LSBs) is then read from

these latches.

–11–

Page 12

AD7886

MREQ

Z-80

8085A

A15

A0

RD

INT

D7

D0

ADDRESS BUS

ADDR

ENCODE

EN

CLK

OE

Q3

D3

Q0

D0

74HC374

DATA BUS

*ADDITIONAL PINS OMITTED FOR CLARITY

TIMER

CONVST

CS

RD

BUSY

AD7886*

DB3

DB0

DB11

DB4

Figure 21. AD7886–Z-80/8085A Interface

APPLICATION HINTS

Good printed circuit (PC) board layout is as important as the

circuit design itself in achieving high speed A/D performance.

The AD7886’s comparators are required to make bit decisions

on an LSB size of 1.22 mV. To achieve this, the designer has to

be conscious of noise in both the ADC itself and in the preceding analog circuitry. Switching mode power supplies are not recommended as the switching spikes will feed through to the

comparator, causing noisy code transitions. Other causes of concern are ground loops and digital feedthrough from microprocessors. These are factors that influence any ADC, and a proper

PC board layout that minimizes these effects is essential for best

performance.

LAYOUT HINTS

Ensure that the layout for the printed circuit board has the digital and analog signal lines separated as much as possible. Take

care not to run any digital track alongside an analog signal track.

Guard (screen) the analog input with AGND.

Establish a single point analog ground (star ground) separate

from the logic system ground at the AD7886 AGND or as close

as possible to the AD7886. Connect all other grounds and the

AD7886 DGND to this single analog ground point. Do not

connect any other digital grounds to this analog ground point.

Because low impedance analog and digital power supply common returns are essential to low noise operation of the ADC,

make the foil width for these tracks as wide as possible. The use

of ground planes minimizes impedance paths and also guards

the analog circuitry from digital noise. The circuit layout of Figures 25 and 26 have both analog and digital ground planes that are

kept separated and only joined together at the AD7886 AGND.

NOISE

Keep the input signal leads to VIN and signal return leads from

AGND as short as possible to minimize input noise coupling. In

applications where this is not possible, use a shielded cable between the source and the ADC. Reduce the ground circuit impedance as much as possible since any potential difference in

grounds between the signal source and the ADC appears as an

error voltage in series with the input signal.

–12–

DATA ACQUISITION BOARD

Figure 23 shows a typical data acquisition circuit designed for a

microprocessor environment. The corresponding PC board layout and silkscreen are shown in Figures 24 to 26.

The analog input to the AD7886 is buffered with an AD845 op

amp. A component grid is provided near the analog input on the

PC board that may be used for an antialiasing filter or any other

conditioning circuitry. To facilitate this option, a link (labeled

LK4) is required on the analog input.

An AD586 voltage reference and an AD707 op amp provide the

appropriate reference biasing required by the AD7886. The

ADC’s data outputs are buffered with 74HC374 latches. These

provide data bus isolation and improve data access time. Data

access time is reduced to under 30 ns, allowing interfacing to

virtually any microprocessor, including the high speed DSP processors. Data format can be either a complete parallel load for

16-bit processors or a two-byte load for 8-bit processors.

INTERFACE CONNECTIONS

There are two connectors labeled SKT3 and SKT4. SKT3 is a

96-contact (3-row) connector, which is directly compatible with

the ADSP-2100 evaluation board prototype expansion connector. The expansion connector on the ADSP-2100 board has

eight decoded chip enable outputs labeled

ECE1 to ECE8.

ECE6 is used to select the AD7886 data acquisition board. To

avoid selecting on-board RAM sockets at the same time, LK6

on the ADSP-2100 board must be removed. In addition, the

ADSP-2100 expansion connector has four interrupts labeled

EIRQ0 to EIRQ3. The AD7886’s BUSY output connects to

EIRQ0. SKT3 pinout is shown in Figure 23.

Data format to the ADSP-2100 connector is left justified, i.e.,

DB11 of the conversion result is connected to DMD15 of the

connector. DMD3 to DMD0 are always zero.

SKT4 is a 22-way (2 row) pin-header connector. This connector contains all the signal contacts as SKT3 with the exception

of EDMACK and the 4 trailing zeros of the 16-bit data word.

Only the 12-bit conversion results go to SKT4. The pinout is

shown in Figure 22.

DB0

DB2

DB4

DB6

DB8

DB10

BUSY

CS

NC

V

CC

DGND

NC = NO CONNECT

2122

DB1

1920

DB3

1718

DB5

1516

DB7

1314

DB9

1112

DB11

910

OUT1

8

6

4

7

OUT2

5

RD

V

3

CC

12

DGND

Figure 22. SKT4 Pinout

REV. B

Page 13

AD7886

POWER SUPPLY CONNECTIONS

The PC board requires two analog power supplies and one 5 V

digital supply. Connections to the analog supply are made directly to the PC board as shown on the silkscreen in Figure 24.

The connections are labeled V+ and V–, and the range for both

of these supplies is 12 V to 15 V. Connection to the 5 V digital

supply is made through either of the two connectors (SKT3 or

SKT4). The +5 V analog supplies required by the AD7886 are

generated from voltage regulators on the V– and V+ power

supplies.

LINK OPTIONS

There are five link options, labeled LK1 to LK5, which must be

set before using the board.

LK1 Input Range Select

The AD7886 can accommodate three possible analog input

ranges: 0 V to 5 V, 0 to 10 V and +5 V. The link options are as

follows:

0 V to 5 V Use Link C

0 V to 10 V Use Link B

±5 V Use Link A

LK2 and LK3 Control Input Options

The evaluation board includes two latches to increase the data

access time when interfacing to the faster DSP machines. If

V

DD

DB11

DB4

AD7886

DB3

DB0

BUSY

CS

RD

CONVST

OUT

+

5V

C8

0.1µF

V

+

IC1

DGND

AGND

AGND

V

SS

C10/C18

DD

5REF

SUM

V

REF

VIN1

VIN2

V

0.1µF

SS

C7

10µF

0.1µF

–

SKT3

96-WAY

CONNECTOR

A31

B11

B18

C22

B6

C11

B20

B27

A9

C14

C13

C12

A32/B32/

C32

C20

0.1µF

+

5V

DMD15

DMD8

ECE6 (OUT1)

EDMACK

LK5

OUT2

DMD7

DMD0

EIRQ0

CS

RD

CONVST

DIGITAL

GND

CONVST

+

5V

+

5V

Q7

Q0

O/P

74HC374

IC9

O/P

Q7

Q0

GND

LK2 LK3

SKT1

C19

10µF

V

CC

74HC374

IC8

GND

0.1µF

V

CC

CLK

+V

C23

D7

D4

D3

D2

D1

D0

D7

D0

CLK

IN

+

–V

OUT

78L05

IC5

GND

5V

IN

79L05

IC6

GND

these latches are not required, they may be removed and the

data digital paths shorted out, i.e., latch inputs Dx shorted to

outputs Qx using wire links in the latch sockets. When using the

latches, the AD7886 control inputs,

CS and RD, must be tied

low via links 2 and 3. The latches are updated by the rising edge

of the

BUSY signal at the end of every conversion. Data is then

read by asserting the latch output enable signals. The alternative

is to remove the latches and assert the ADC’s control inputs

from either of the connectors, SKT3 or SKT4, as outlined in

the data sheet.

Latches Included Latches Removed

Insert Link 2 Remove Link 2

Insert Link 3 Remove Link 3

LK4 Analog Input Option

LK4 connects the analog input to a component grid or to a

buffer amplifier that drives the ADC input.

LK5

Data format can be 16-bits parallel or two bytes for 8-bit processors. There are two data enable controls for the 74HC374

latches, labeled

(IC8), and

OUT1 and OUT2. OUT1 enables the 8 MSBs

OUT2 enables the 4 LSBs (IC9). Link options are:

for 16-bit format, include LK5, for a two byte read format,

remove LK5.

+V

C10

5V

C14

0.1µF

10µF

C9/C17

10µF

C11

A

C

B

C13

10µF

IC4

AD707

C16

0.1µF

LK1

–

+

C4

0.1µF

–V

C15

10µF

+V

C3

10µF

IC2

AD845

C2

0.1µF

V

OUT

AD586

IC3

GND

–

+

–V

+V

IN

0.1µF

LK4

C1

10µF

C6

SKT2

ANALOG

+V

INPUT

C5

10µF

REV. B

Figure 23. Data Acquisition Circuit Using the AD7886

–13–

Page 14

AD7886

COMPONENT LIST

IC1 AD7886, 12-Bit Sampling ADC

IC2 AD845, Op Amp

IC3 AD586, Precision Voltage Reference

IC4 AD707, Op Amp

IC5 MC78L05, + 5 V Regulator

IC6 MC79L05, –5 V Regulator

IC7 74HC04, Hex Inverter

IC8, IC9 74HC374, Octal Latches with Three-State

Outputs

C1, C3, C5, C7,

C9, C11, C13, C15 10 µF Capacitors

C17, C19, C21

C2, C4, C6, C8,

C10, C12, C14,

C16, C18, C20, 0.1 µF Capacitors

C22, C23

SKT1, SKT2 BNC Sockets

SKT3 96-Contact (3 Row) Eurocard Connector

SKT4 22-Way (2 Row) Pin Header and Socket

Figure 24. PC Board Silkscreen for Figure 23

–14–

REV. B

Page 15

AD7886

Figure 25. PC Board Component Side Layout for Figure 23

REV. B

Figure 26. PC Board Solder Side Layout for Figure 23

–15–

Page 16

AD7886

0.048 (1.21)

0.042 (1.07)

0.020

(0.50)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Pin Ceramic DIP (D-28)

28-Pin PLCC (P-28A)

0.180 (4.57)

0.050

(1.27)

BSC

0.165 (4.19)

0.110 (2.79)

0.085 (2.16)

0.048 (1.21)

0.042 (1.07)

4

5

11

12

0.456 (11.58)

R

0.450 (11.43)

0.495 (12.57)

0.485 (12.32)

PIN 1

IDENTIFIER

TOP VIEW

(PINS DOWN)

0.056 (1.42)

0.042 (1.07)

26

25

19

18

SQ

SQ

0.025 (0.63)

0.015 (0.38)

0.021 (0.53)

0.013 (0.33)

0.032 (0.81)

0.026 (0.66)

0.040 (1.01)

0.025 (0.64)

C1485b–10–4/91

0.430 (10.92)

0.390 (9.91)

–16–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...