Page 1

V

V

Touch Screen Digitizer

FEATURES

4-wire touch screen interface

On-chip temperature sensor: −40°C to +85°C

On-chip 2.5 V reference

Direct battery measurement (0 V to 6 V)

Touch-pressure measurement

Specified throughput rate of 125 kSPS

Single supply, V

Ratiometric conversion

High speed serial interface

Programmable 8-bit or 12-bit resolution

One auxiliary analog input

Shutdown mode: 1 µA max

16-lead QSOP, TSSOP, and LFCSP packages

APPLICATIONS

Personal digital assistants

Smart hand-held devices

Touch screen monitors

Point-of-sale terminals

Pagers

GENERAL DESCRIPTION

of 2.2 V to 5.25 V

CC

AUX

BAT

REF

AD7873

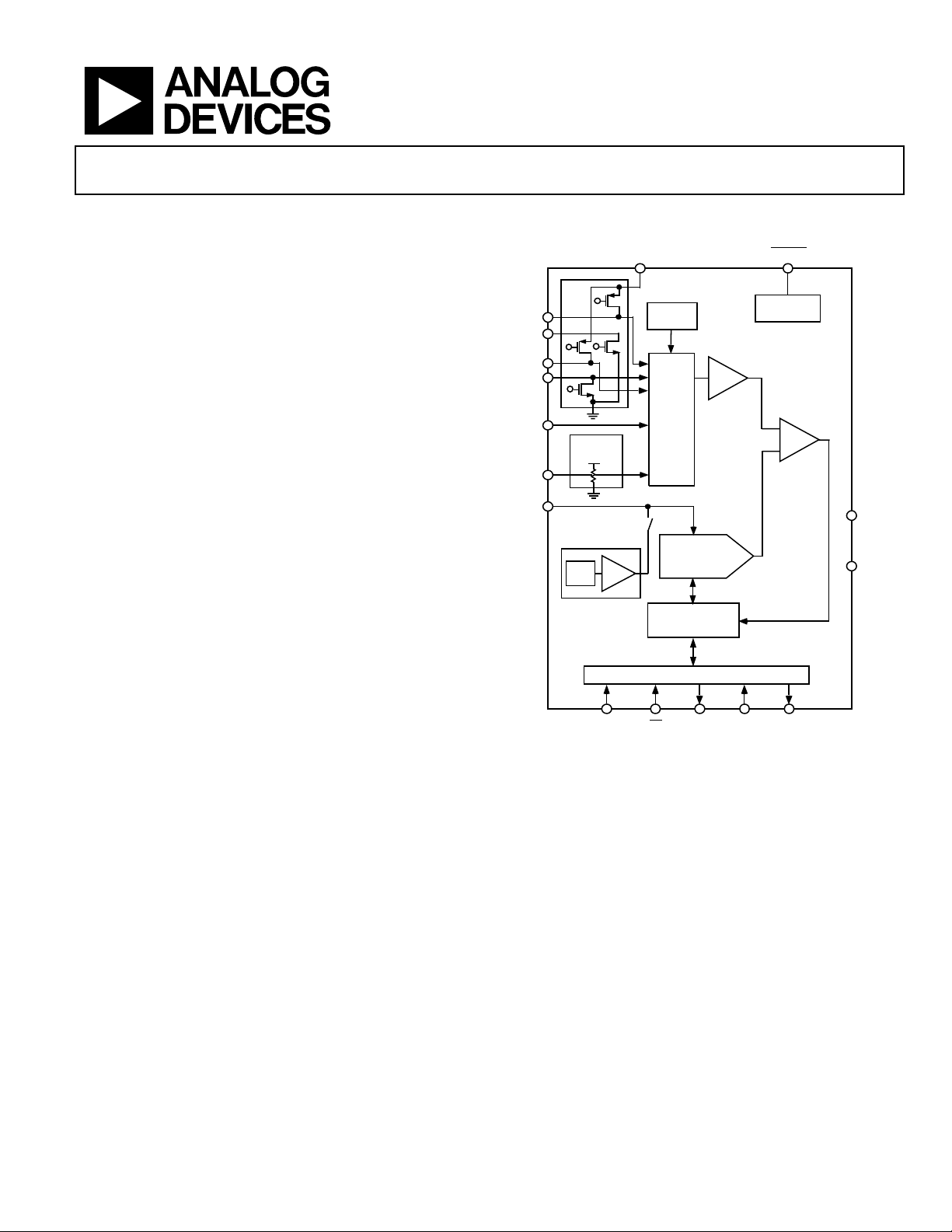

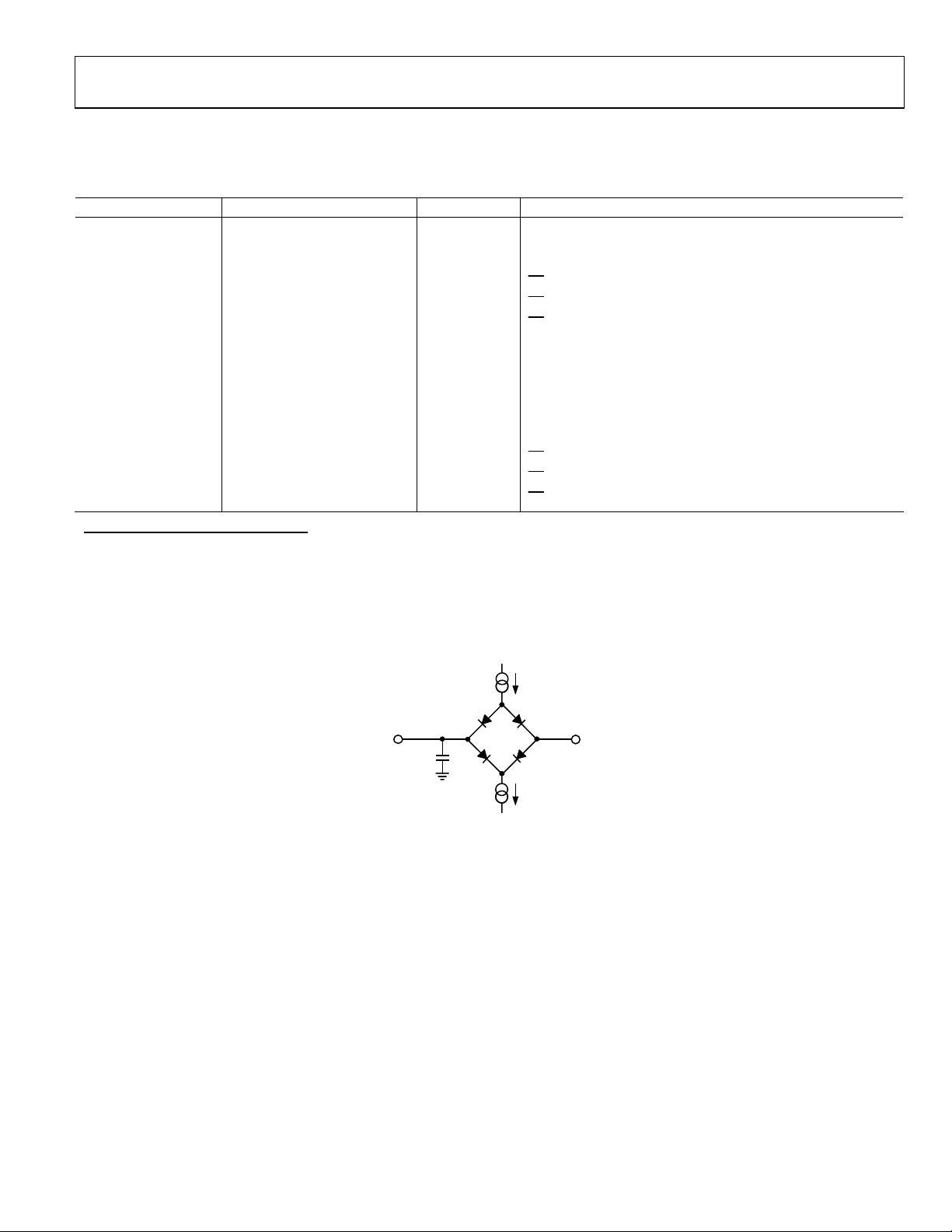

FUNCTIONAL BLOCK DIAGRAM

+V

CC

X+

X–

Y+

Y–

BATTERY

MONITOR

2.5V

BUF

REF

TEMP

SENSOR

6-TO-1

I/P

MUX

REDISTRIBUTION

CONTROL LOGIC

T/H

CHARGE

DAC

SAR + ADC

PENIRQ

PEN

INTERRUPT

AD7873

COMP

GND

+V

CC

The AD7873 is a 12-bit successive approximation ADC with a

synchronous serial interface and low on resistance switches for

driving touch screens. The AD7873 operates from a single 2.2 V

to 5.25 V power supply and features throughput rates greater

than 125 kSPS.

The AD7873 features direct battery measurement, temperature

measurement, and touch-pressure measurement. The AD7873

also has an on-board reference of 2.5 V that can be used for the

auxiliary input, battery monitor, and temperature measurement

modes. When not in use, the internal reference can be shut

down to conserve power. An external reference can also be

applied and can be varied from 1 V to V

input range is from 0 V to V

. The device includes a shutdown

REF

, while the analog

CC

mode that reduces the current consumption to less than 1 µA.

The AD7873 features on-board switches. This, coupled with low

power and high speed operation, makes the device ideal for

battery-powered systems such as personal digital assistants with

resistive touch screens and other portable equipment. The part

is available in a 16-lead 0.15" quarter size outline package

(QSOP), a 16-lead thin shrink small outline package (TSSOP),

and a 16-lead lead frame chip scale package (LFCSP).

Rev. D

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

SPORT

DIN CS DOUT DCLK BUSY

Figure 1.

PRODUCT HIGHLIGHTS

1. Ratiometric conversion mode available, eliminating errors

due to on-board switch resistances.

2. On-board temperature sensor: −40°C to +85°C.

3. Battery monitor input.

4. Touch-pressure measurement capability.

5. Low power consumption of 1.37 mW max with the

reference off, or 2.41 mW typ with the reference on, at

125 kSPS and V

6. Package options include 4 mm × 4 mm LFCSP.

7. Analog input range from 0 V to V

8. Vers ati l e s e ri a l I / O p o rt s .

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

at 3.6 V.

CC

.

REF

www.analog.com

02164-D-001

Page 2

AD7873

TABLE OF CONTENTS

Specifications..................................................................................... 3

Analog Input............................................................................... 14

Timing Specifications .................................................................. 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configurations and Function Descriptions ........................... 7

Te r m in o l o g y ...................................................................................... 8

Typical Performance Characteristics ............................................. 9

Circuit Information........................................................................ 13

ADC Transfer Function............................................................. 13

Typical C o n necti on D i a g ram ................................................... 13

REVISION HISTORY

6/04—Changed from Rev. C to Rev. D

Updated Format..................................................................Universal

Changes to Absolute Maximum Ratings ....................................... 6

Additions to PD0 and PD1 Description...................................... 21

PBC Guidelines for Chip Scale Package Added ......................... 23

Additions to Ordering Guide........................................................ 25

4/03—Changed from Rev. B to Rev. C

Changes to Formatting ......................................................Universal

Updated Outline Dimensions....................................................... 19

Measurements............................................................................. 16

Pen Interrupt Request ................................................................ 18

Control Register ......................................................................... 19

Power vs. Throughput Rate ....................................................... 20

Serial Interface............................................................................ 21

Grounding and Layout .................................................................. 23

PCB Design Guidelines for Chip Scale Package .................... 23

Outline Dimensions....................................................................... 24

Ordering Guide .......................................................................... 25

1/02—Changed from Rev. A to Rev. B

Addition of 16-Lead Lead Frame Chip Scale Package ..Universal

Edits to Features.................................................................................1

Edits to General Description ...........................................................1

Addition of LFCSP Pin Configuration...........................................4

Edit to Absolute Maximum Ratings................................................4

Addition to Ordering Guide ............................................................4

Addition of CP-16 Outline Dimensions ..................................... 19

2/01—Changed from Rev. 0 to Rev A

Edits to Notes in the Ordering Guide

Rev. D | Page 2 of 28

Page 3

AD7873

SPECIFICATIONS

VCC = 2.7 V to 3.6 V, V

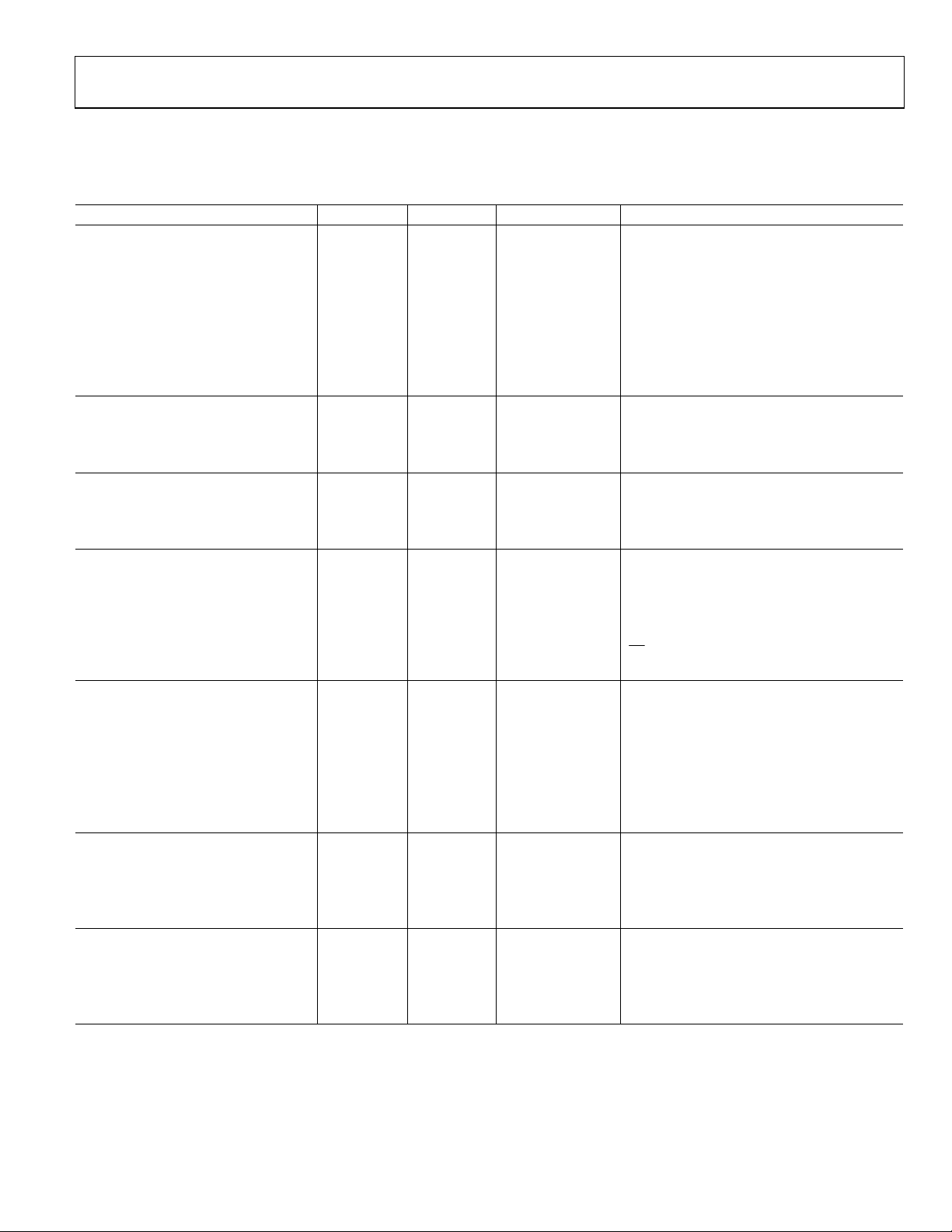

Table 1.

Parameter AD7873A1AD7873B1 Unit Test Conditions/Comments

DC ACCURACY

Resolution 12 12 Bits

No Missing Codes 11 12 Bits min

Integral Nonlinearity

Differential Nonlinearity

Offset Error

Gain Error

2

2

Noise 70 70 µV rms typ

Power Supply Rejection 70 70 dB typ

SWITCH DRIVERS

On Resistance

2

Y+, X+ 5 5 Ω typ

Y–, X– 6 6 Ω typ

ANALOG INPUT

Input Voltage Ranges 0 to V

DC Leakage Current ±0.1 ±0.1 µA typ

Input Capacitance 37 37 pF typ

REFERENCE INPUT/OUTPUT

Internal Reference Voltage 2.45/2.55 2.45/2.55 V min/max

Internal Reference Tempco ± 15 ± 15 ppm/°C typ

V

Input Voltage Range 1/VCC 1/VCC V min/max

REF

DC Leakage Current ±1 ± 1 µA max

V

Input Impedance 1 1 GΩ typ

REF

TEMPERATURE MEASUREMENT

Temperature Range –40/+85 –40/+85 °C min/max

Resolution

Differential Method

Single Conversion Method

Accuracy

Differential Method

Single Conversion Method

BATTERY MONITOR

Input Voltage Range 0/6 0/6 V min/max

Input Impedance 10 10 kΩ typ Sampling; 1 GΩ when battery monitor off

Accuracy ± 2.5 ± 2 % max External reference

± 3 ± 3 % max Internal reference

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, IIN ±1 ±1 µA max Typically 10 nA, VIN = 0 V or +V

Input Capacitance, C

Footnotes on next page.

= 2.5 V internal or external, f

REF

2

2

±2 ± 1 LSB max

–0.9/+1.5 LSB max

= 2 MHz; TA = −40°C to +85°C, unless otherwise noted.

DCLK

±6 ±6 LSB max +VCC = 2.7 V

±4 ±4 LSB max External reference

0 to V

REF

3

4

3

4

2.4 2.4 V min

INH

0.4 0.4 V max

INL

5

IN

1.6 1.6 °C typ

0.3 0.3 °C typ

±2 ±2 °C typ

±2 ±2 °C typ

10 10 pF max

Volts

REF

CS = GND or +VCC; typically 260 Ω when onboard reference enabled

CC

Rev. D | Page 3 of 28

Page 4

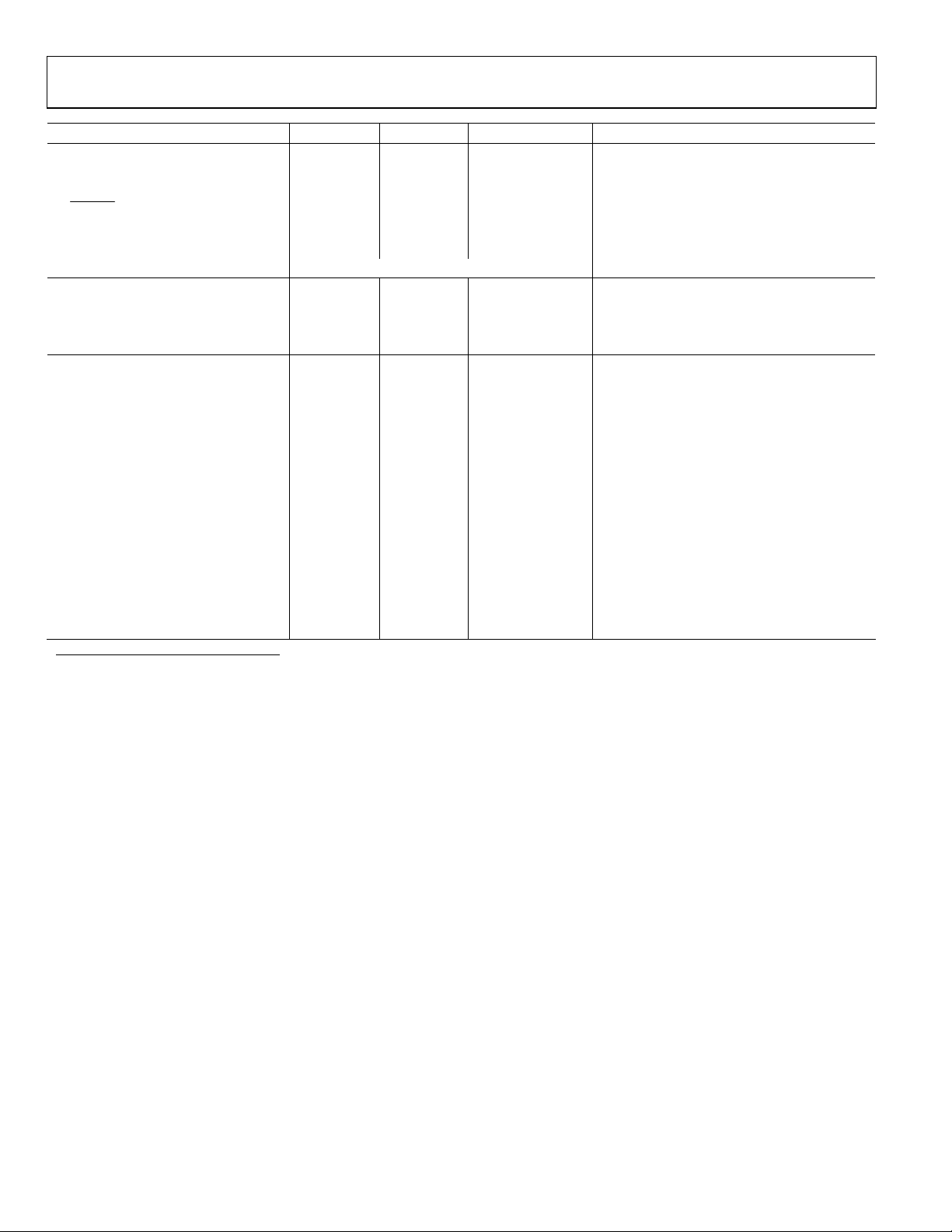

AD7873

Parameter AD7873A1AD7873B1 Unit Test Conditions/Comments

LOGIC OUTPUTS

Output High Voltage, VOH VCC – 0.2 VCC – 0.2 V min I

Output Low Voltage, V

OL

PENIRQ Output Low Voltage, VOL

0.4 0.4 V max I

0.4 0.4 V max 100 kΩ pull-up; I

Floating-State Leakage Current ±10 ±10 µA max

Floating-State Output Capacitance510 10 pF max

Output Coding Straight (Natural) Binary

CONVERSION RATE

Conversion Time 12 12 DCLK cycles max

Track-and-Hold Acquisition Time 3 3 DCLK cycles min

Throughput Rate 125 125 kSPS max

POWER REQUIREMENTS

+VCC (Specified Performance) 2.7/3.6 2.7/3.6 V min/max Functional from 2.2 V to 5.25 V

6

I

CC

Normal Mode (f

= 125 kSPS) 380 380 µA max Internal reference off. VCC = 3.6 V,

SAMPLE

Digital I/Ps = 0 V or VCC

240 µA typ

670 670 µA typ Internal reference on. VCC = 3.6 V

Normal Mode (f

= 12.5 kSPS) 170 170 µA typ Internal reference off. VCC = 2.7 V,

SAMPLE

f

Normal Mode (Static) 150 150 µA typ Internal reference off. VCC = 3.6 V

580 580 µA typ Internal reference on. VCC = 3.6 V

Shutdown Mode (Static) 1 1 µA max 200 nA typ

Power Dissipation

Normal Mode (f

6

= 125 kSPS) 1.368 1.368 mW max VCC = 3.6 V. Internal reference disabled

SAMPLE

2.412 2.412 mW typ VCC = 3.6 V. Internal reference enabled

Shutdown 3.6 3.6 µW max VCC = 3.6 V

1

Temperature range as follows: A, B Versions: –40°C to +85°C.

2

See the section. Terminology

3

Difference between Temp0 and Temp1 measurement. No calibration necessary.

4

Temperature Drift is –2.1 mV/°C.

5

Sample tested @ 25°C to ensure compliance.

6

See the Power vs. Throughput Rate section.

= 250 µA; V

SOURCE

= 250 µA

SINK

= 200 kHz

DCLK

= 2.2 V to 5.25 V

CC

= 250 µA

SINK

Rev. D | Page 4 of 28

Page 5

AD7873

TIMING SPECIFICATIONS

TA = T

Table 2. Timing Specifications

Parameter Limit at T

f

DCLK

2 MHz max

t

ACQ

t1 10 ns min

t2 60 ns max

3

t

3

t4 200 ns min DCLK high pulse width

t5 200 ns min DCLK low pulse width

t6 60 ns max DCLK falling edge to BUSY rising edge

t7 10 ns min Data setup time prior to DCLK rising edge

t8 10 ns min Data valid to DCLK hold time

3

t

200 ns max Data access time after DCLK falling edge

9

t10 0 ns min

t11 100 ns max

t

12

1

Sample tested at 25°C to ensure compliance. All input signals are specified with tr = tf = 5 ns (10% to 90% of VCC) and timed from a voltage level of 1.6 V.

2

Mark/Space ratio for the DCLK input is 40/60 to 60/40.

3

Measured with the load circuit of and defined as the time required for the output to cross 0.4 V or 2.0 V. Figure 2

4

t12 is derived from the measured time taken by the data outputs to change 0.5 V when loaded with the circuit of . The measured number is then extrapolated

back to remove the effects of charging or discharging the 50 pF capacitor. This means that the time, t

time of the part and is independent of the bus loading.

to T

MIN

2

, unless other wise noted; VCC = 2.7 V to 5.25 V, V

MAX

1

, T

MIN

Unit Description

MAX

10 kHz min

= 2.5 V.

REF

1.5 µs min Acquisition time

CS falling edge to first DCLK rising edge

CS falling edge to busy three-state disabled

60 ns max

CS falling edge to DOUT three-state disabled

CS rising edge to DCLK ignored

CS rising edge to BUSY high impedance

4

100 ns max

CS rising edge to DOUT high impedance

, quoted in the timing characteristics is the true bus relinquish

12

Figure 2

I

OL

1.6V

I

OH

02164-D-002

TO

OUTPUT

PIN

50pF

200µA

C

L

200µA

Figure 2. Load Circuit for Digital Output Timing Specifications

Rev. D | Page 5 of 28

Page 6

AD7873

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

+VCC to GND –0.3 V to +7 V

Analog Input Voltage to GND –0.3 V to VCC + 0.3 V

Digital Input Voltage to GND –0.3 V to VCC + 0.3 V

Digital Output Voltage to GND –0.3 V to VCC + 0.3 V

V

to GND –0.3 V to VCC + 0.3 V

REF

Input Current to Any Pin Except Supplies1 ±10 mA

Operating Temperature Range

Commercial (A, B Versions) –40°C to +85°C

Storage Temperature Range –65°C to +150°C

Junction Temperature 150°C

QSOP, TSSOP, LFCSP Packages, Power

Dissipation

θJA Thermal Impedance 149.97°C/W (QSOP)

150.4°C/W (TSSOP)

135.7°C/W (LFCSP)

θJC Thermal Impedance 38.8°C/W (QSOP)

27.6°C/W (TSSOP)

IR Reflow Soldering

Peak Temperature

Time-to-Peak Temperature

Ramp-Down Rate

Pb-free Parts Only:

Peak Temperture 250°C

Time-to-Peak Temperature

Ramp-Up Rate

Ramp-Down Rate

450 mW

220°C (±5°C)

10 sec to 30 sec

6°C/sec max

20 sec to 40 sec

3°C/sec max

6°C/sec max

___________________________

1

Transient currents of up to 100 mA do not cause SCR latch-up.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. D | Page 6 of 28

Page 7

AD7873

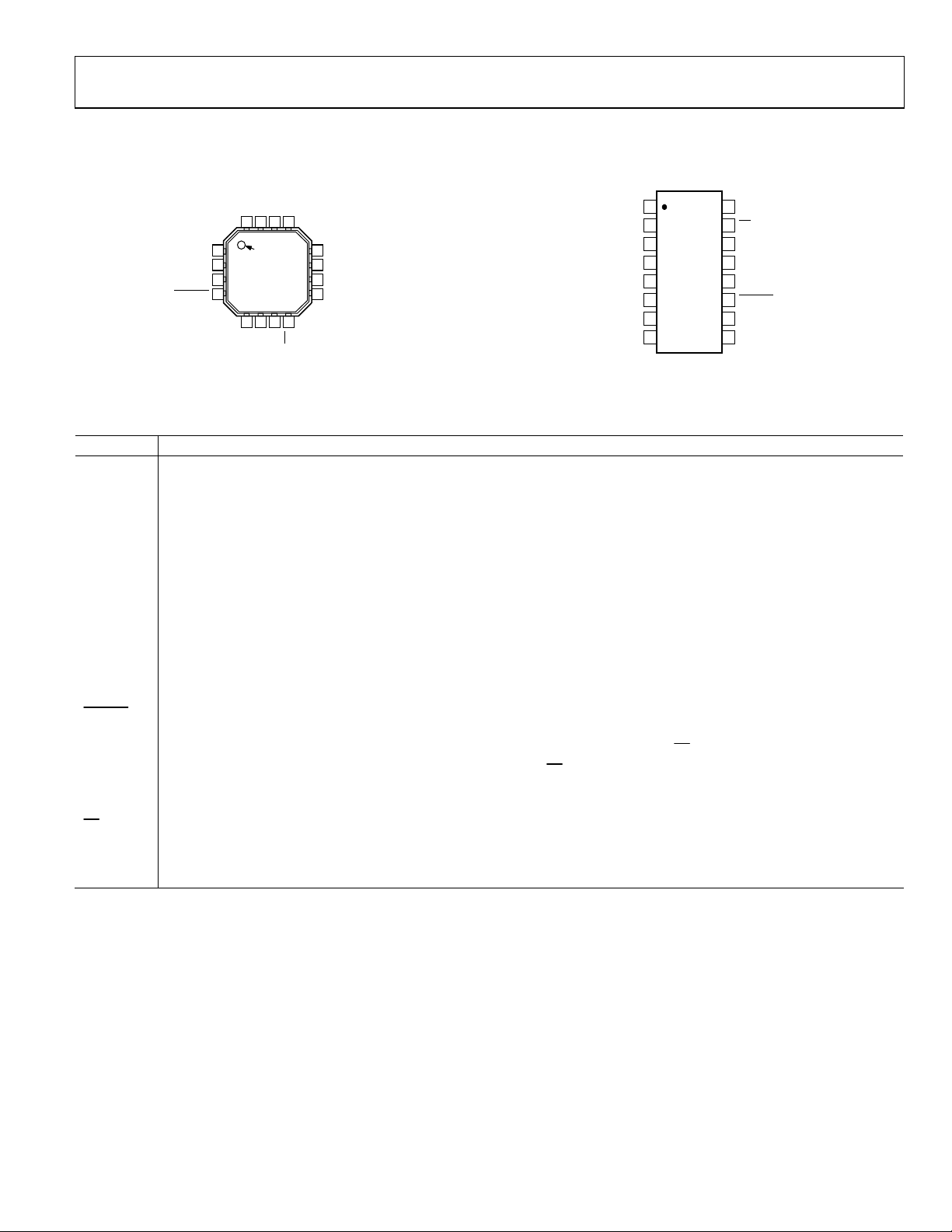

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

BAT

V

GNDY–X–

16 15 14 13

1

2

3

4

(Not to Scale)

PIN 1

INDICATOR

AD7873

TOP VIEW

5678

DIN

BUSY

DOUT

CS

AUX

V

REF

+V

PENIRQ

CC

Figure 3. LFCSP Pin Configuration

1

+V

CC

2

X+

3

GND

V

AUX

Y+

X–

Y–

BAT

AD7873

4

TOP VIEW

5

(Not to Scale)

6

7

8

12

Y+

11

X+

+V

10

CC

9

DCLK

02164-D-003

Figure 4.QSOP/TSSOP Pin Configuration

16

15

14

13

12

11

10

9

DCLK

CS

DIN

BUSY

DOUT

PENIRQ

+V

CC

V

REF

02164-D-004

Table 4. Pin Function Descriptions

Mnemonic Function

+VCC

Power Supply Input. The +V

range for the AD7873 is from 2.2 V to 5.25 V. Both +VCC pins should be connected directly

CC

together.

X+ X+ Position Input. ADC Input Channel 1.

Y+ Y+ Position Input. ADC Input Channel 2.

X– X– Position Input.

Y– Y– Position Input. ADC Input Channel 3.

GND

Analog Ground. Ground reference point for all circuitry on the AD7873. All analog input signals and any external reference

signals should be referred to this GND voltage.

V

BAT

Battery Monitor Input. ADC Input Channel 4.

AUX Auxiliary Input. ADC Input Channel 5.

V

REF

Reference Output for the AD7873. Alternatively an external reference can be applied to this input. The voltage range for the

external reference is 1.0 V to +V

. For specified performance, it is 2.5 V on the AD7873. The internal 2.5 V reference is

CC

available on this pin for use external to the device. The reference output must be buffered before it is applied elsewhere in a

system. A 0.1 µF capacitor is recommended between this pin and GND to reduce system noise effects.

PENIRQ

DOUT

BUSY

DIN

Pen Interrupt. CMOS logic open drain output (requires 10 kΩ to 100 kΩ pull-up resistor externally).

Data Out. Logic Output. The conversion result from the AD7873 is provided on this output as a serial data stream. The bits are

clocked out on the falling edge of the DCLK input. This output is high impedance when

BUSY Output. Logic Output. This output is high impedance when

CS is high.

CS is high.

Data In. Logic Input. Data to be written to the AD7873 control register is provided on this input and is clocked into the

register on the rising edge of DCLK (see the Control Register section).

CS Chip Select Input. Active Low Logic Input. This input provides the dual function of initiating conversions on the AD7873 and

enabling the serial input/output register.

DCLK

External Clock Input. Logic Input. DCLK provides the serial clock for accessing data from the part. This clock input is also used

as the clock source for the AD7873 conversion process.

Rev. D | Page 7 of 28

Page 8

AD7873

TERMINOLOGY

Integral Nonlinearity

This is the maximum deviation from a straight line passing

through the endpoints of the ADC transfer function. The

endpoints of the transfer function are zero scale, a point 1 LSB

below the first code transition, and full scale, a point 1 LSB

above the last code transition.

Differential Nonlinearity

This is the difference between the measured and the ideal 1 LSB

change between any two adjacent codes in the ADC.

Offset Error

This is the deviation of the first code transition (00 . . . 000) to

(00 . . . 001) f rom the ideal, that is, AGND + 1 LSB.

Gain Error

This is the deviation of the last code transition (111 . . . 110) to

(111 . . . 111) from the ideal (that is, V

error is adjusted out.

Track-and-Hold Acquisition Time

The track-and-hold amplifier enters the acquisition phase on

the fifth falling edge of DCLK after the START bit has been

detected. Three DCLK cycles are allowed for the track-and-hold

acquisition time. The input signal is fully acquired to the 12-bit

level within this time even with the maximum specified DCLK

frequency. See the Analog Input section for more details.

On-Resistance

This is a measure of the ohmic resistance between the drain and

source of the switch drivers.

– 1 LSB) after the offset

REF

Rev. D | Page 8 of 28

Page 9

AD7873

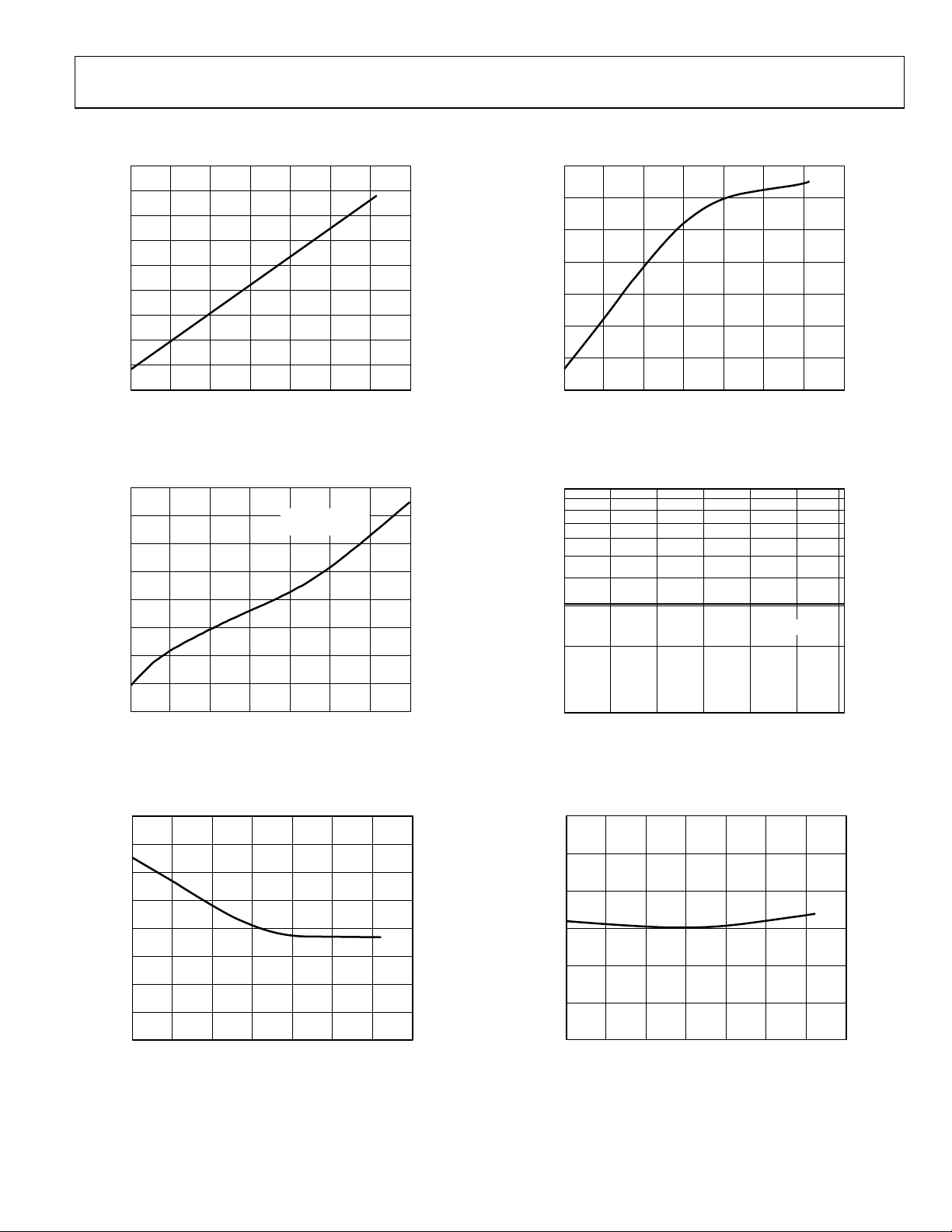

TYPICAL PERFORMANCE CHARACTERISTICS

207

206

205

204

203

202

201

SUPPLY CURRENT (µA)

200

199

198

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

Figure 5. Supply Current vs. Temperature

230

f

220

210

SAMPLE

V

REF

= 12.5kHz

= +V

CC

02164-D-005

141

140

139

138

137

136

SUPPLY CURRENT (nA)

135

134

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

Figure 8. Power-Down Supply Current vs. Temperature

1000

02164-D-008

200

190

180

SUPPLY CURRENT (µA)

170

160

150

2.2 2.6 3.0 3.4 3.8 4.2 4.6 5.0

+V

(V)

CC

Figure 6. Supply Current vs. +V

CC

0.20

0.15

0.10

0.05

0

–0.05

DELTA FROM 25°C (LSB)

–0.10

–0.15

02164-D-006

SAMPLE RATE (kSPS)

100

0.6

0.4

0.2

0

–0.2

DELTA FROM 25°C (LSB)

–0.4

V

REF

3.2 3.72.2 2.7 4.2 4.7 5.2

+V

(V)

CC

Figure 9. Maximum Sample Rate vs. +V

= +V

CC

CC

02164-D-009

–0.20

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

Figure 7. Change in Gain vs. Temperature

02164-D-007

Rev. D | Page 9 of 28

–0.6

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

Figure 10. Change in Offset vs. Temperature

02164-D-010

Page 10

AD7873

7.5

6.5

5.5

4.5

3.5

2.5

REFERENCE CURRENT (µA)

1.5

0.5

10

705525 4010 85 100 115 130

SAMPLE RATE (kHz)

Figure 11. Reference Current vs. Sample Rate

02164-D-011

14

13

12

11

10

9

8

7

6

5

REFERENCE CURRENT (µA)

4

3

2

020–40 –20 40 60 80

TEMPERATURE (°C)

02164-D-014

Figure 14. Reference Current vs. Temperature

9

9

Y+

X+

8

(Ω)

7

ON

R

6

5

4

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

X–

Y–

+V

(V)

CC

Figure 12. Switch On Resistance vs. +V

(X+, Y+: +V

to Pin; X-, Y-: Pin to GND)

CC

2.0

1.8

1.6

1.4

1.2

1.0

0.8

ERROR (LSB)

0.6

0.4

0.2

0

15 35 55 75 95 115 135 155 175 195

INL: R = 500Ω

DNL: R = 2kΩ

DNL: R = 500Ω

SAMPLING RATE (kSPS)

INL: R = 2kΩ

8

7

(Ω)

6

ON

R

5

4

3

–40 –20 0 20 40 60 80 100

02164-D-012

CC

Figure 15. Switch On Resistance vs. Temperature

Y–

Y+

TEMPERATURE (°C)

X+

X–

02164-D-015

(X+, Y+: +VCC to Pin; X-, Y-: Pin to GND)

2.5006

2.5004

2.5002

2.5000

(V)

REF

2.4998

2.4996

2.4994

INTERNAL V

2.4992

2.4990

2.4988

–40 –30 –20 –10 0 10 20 30 40 50 60 70 80

02164-D-013

TEMPERATURE (°C)

02164-D-016

Figure 13. Maximum Sampling Rate vs. R

IN

Figure 16. Internal V

vs. Temperature

REF

Rev. D | Page 10 of 28

Page 11

AD7873

2.504

2.502

2.500

2.498

2.496

(V)

2.494

REF

V

2.492

2.490

2.488

2.486

2.484

2.9 3.12.5 2.7 3.3 3.5 3.7

+V

(V)

CC

Figure 17. Internal V

REF

vs. +V

CC

850

800

95.95mV

750

700

650

600

550

TEMP DIODE VOLTAGE (mV)

500

450

–40 –30 –20 –10 0 10 20 30 40 50 60 70 80

TEMP1

TEMP0

TEMPERATURE (°C)

Figure 18. Temp Diode Voltage vs. Temperature (2.7 V Supply)

730

729

728

727

726

725

724

723

TEMP1 DIODE VOLTAGE (mV)

722

721

720

2.7 3.33.0 3.6

V

(V)

SUPPLY

142.15mV

02164-D-017

02164-D-018

02164-D-019

5

4

(V)

3

REF

NO CAP (7µS)

2

SETTLING TIME

INTERNAL V

1

0

0 200 400 600 800 1000 1200 1400 1600 1800

Figure 20. Internal V

1µF CAP (1800µS)

SETTLING TIME

TURN-ON TIME (µS)

vs. Turn-on Time

REF

610

609

608

607

606

605

604

603

TEMP0 DIODE VOLTAGE (mV)

602

601

600

2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 3.6

V

(V)

SUPPLY

Figure 21. Temp0 Diode Voltage vs. V

SUPPLY

0

f

= 125kHz

SAMPLE

f

= 15kHz

20

40

60

SNR (dB)

80

100

120

30.022.57.5 15.00 37.5 45.0 52.5 60.0

FREQUENCY (kHz)

IN

SNR = 68.34dB

02164-D-020

02164-D-021

(25°C)

02164-D-022

Figure 19. Temp 1 Diode Voltage vs. V

SUPPLY

(25°C)

Rev. D | Page 11 of 28

Figure 22. Auxiliary Channel Dynamic Performance

( f

SAMPLE

=125 kHz, f

= 15 kHz)

INPUT

Page 12

AD7873

0

VCC = 3V

100mV p-p SINEWAVE ON +V

–20

V

REF

f

SAMPLE

–40

= 2.5V EXT REFERENCE

= 125kHz,

f

= 20kHz

IN

Figure 23 shows the power supply rejection ratio versus V

CC

supply frequency for the AD7873. The power supply rejection

DD

ratio is defined as the ratio of the power in the ADC output at

full-scale frequency, f, to the power of a 100 mV sine wave

applied to the ADC V

supply of frequency fS:

CC

–60

PSRR (dB)

–80

–100

–120

0 102030405060708090100

RIPPLE FREQUENCY (kHz)

V

CC

Figure 23. AC PSRR vs. Supply Ripple Frequency

02164-D-023

PSSR (dB) = 10 log (Pf/Pfs)

where:

Pf is power at frequency, f, in ADC output.

Pfs is power at frequency, f

Here a 100 mV p-p sine wave is coupled onto the V

, coupled onto t he ADC VCC supply.

S

supply.

CC

Decoupling capacitors of 10 µF and 0.1 µF were used on the

supply.

Rev. D | Page 12 of 28

Page 13

AD7873

CIRCUIT INFORMATION

The AD7873 is a fast, low-power, 12-bit, single-supply A/D

converter. The AD7873 can be operated from a 2.2 V to 5.25 V

supply. When operated from either a 5 V supply or a 3 V supply,

the AD7873 is capable of throughput rates of 125 kSPS when

provided with a 2 MHz clock.

The AD7873 provides the user with an on-chip track-and-hold,

multiplexer, A/D converter, reference, temperature sensor, and

serial interface housed in a tiny 16-lead QSOP, TSSOP, or

LFCSP package, which offers the user considerable space-saving

advantages over alternative solutions. The serial clock input

(DCLK) accesses data from the part and also provides the clock

source for the successive approximation ADC. The analog input

range is 0 V to V

REF

between 1 V and +V

(where the externally applied V

). The AD7873 has a 2.5 V reference on

CC

can be

REF

board with this reference voltage available for use externally if

buffered.

The analog input to the ADC is provided via an on-chip

multiplexer. This analog input can be any one of the X, Y, and Z

panel coordinates, battery voltage, or chip temperature. The

multiplexer is configured with low-resistance switches that

allow an unselected ADC input channel to provide power and

an accompanying pin to provide ground for an external device.

For some measurements, the on-resistance of the switches could

present a source of error. However, with a differential input to

the converter and a differential reference architecture, this error

can be negated.

ADC TRANSFER FUNCTION

The output coding of the AD7873 is straight binary. The

designed code transitions occur at successive integer LSB values

(that is, 1 LSB, 2 LSBs, and so on). The LSB size is V

REF

/4096.

The ideal transfer characteristic for the AD7873 is shown in

Figure 24.

111...111

111...110

111...000

011...111

ADC CODE

000...010

000...001

000...000

1LSB

0V

ANALOG INPUT

Figure 24. Transfer Characteristic

1LSB = V

/4096

REF

+V

–1LSB

REF

02164-D-024

TYPICAL CONNECTION DIAGRAM

Figure 25 shows a typical connection diagram for the AD7873

in a touch screen control application. The AD7873 features an

internal reference, but this can be overdriven with an external

low impedance source between 1 V and +V

reference voltage sets the input range of the converter. The

conversion result is output MSB first, followed by the remaining

11 bits and three trailing zeroes, depending on the number of

clocks used per conversion. (See the Serial Interface section.)

For applications where power consumption is a concern, the

power management option should be used to improve power

performance. See Table 7 for available power management

options.

. The value of the

CC

2.2V TO 5V

TOUCH

SCREEN

1µF TO 10µF

(OPTIONAL)

TO BATTERY

VOLTAGE

REGULATOR

AUXILIARY

INPUT

0.1µF

1

2

3

4

5

6

7

8

+V

CC

X+

AD7873

Y+

X–

Y–

GND

V

BAT

AUX

DCLK

CS

DIN

BUSY

DOUT

PENIRQ

+V

V

REF

16

15

14

13

12

11

10

CC

9

0.1µF

SERIAL/CONVERSION CLOCK

CHIP SELECT

SERIAL DATA IN

CONVERTER STATUS

SERIAL DATA OUT

PEN INTERRUPT

50kΩ

02164-D-025

Figure 25. Typical Application Circuit

Rev. D | Page 13 of 28

Page 14

AD7873

ANALOG INPUT

Figure 26 shows an equivalent circuit of the analog input

structure of the AD7873, which contains a block diagram of the

input multiplexer, the differential input of the ADC, and the

differential reference.

Table 5 shows the multiplexer address corresponding to each

analog input, both for the SER/

set high and low. The control bits are provided serially to the

device via the DIN pin. For more information on the control

register, see the Control Register section.

When the converter enters hold mode, the voltage difference

between the +IN and –IN inputs (see Figure 26) is captured on

the internal capacitor array. The input current on the analog

inputs depends on the conversion rate of the device. During the

sample period, the source must charge the internal sampling

capacitor (typically 37 pF). Once the capacitor is fully charged,

there is no further input current. The rate of charge transfer

from the analog source to the converter is a function of

conversion rate.

bit in the control register

DFR

V

BAT

AUX

TEMP

X+

Y+

Y–

V

CC

X+

X–

Y+

Y–

ON-CHIP SWITCHES

IN+

6-TO-1

MUX

IN+

Figure 26. Equivalent Analog Input Circuit

REF

INT/

X+ Y+

EXT

3-TO-1

MUX

REF+

ADC CORE DATA OUT

IN– REF–

3-TO-1

MUX

X– Y– GND

02164-D-026

Table 5. Analog Input, Reference, and Touch Screen Control

A2 A1 A0

SER/

DFR

Analog Input X Switches Y Switches +REF

0 0 0 1 TEMP0 OFF OFF V

0 0 1 1 X+ OFF ON V

0 1 0 1 VBAT OFF OFF V

0 1 1 1 X+ (Z1) X+ OFF Y+ ON V

1

–REF1

GND

REF

GND

REF

REF

REF

GND

GND

X– ON Y– OFF

1 0 0 1 Y– (Z2) X+ OFF Y+ ON V

GND

REF

X– ON Y– OFF

1 0 1 1 Y+ ON OFF V

1 1 0 1 AUX OFF OFF V

1 1 1 1 TEMP1 OFF OFF V

0 0 0 0

Invalid Address. Test Mode: Switches out the Temp0 diode to the

GND

REF

REF

GND

REF

PENIRQ

pin.

GND

0 0 1 0 X+ OFF ON Y+ Y–

0 1 0 0

Invalid Address

0 1 1 0 X+ (Z1) X+ OFF Y+ ON Y+ X–

X– ON Y– OFF

1 0 0 0 Y– (Z2) X+ OFF Y+ ON Y+ X–

X– ON Y– OFF

1 0 1 0 Y+ ON OFF X+ X–

1 1 0 0

1 1 1 0

Outputs Identity Code, 1000 0000 0000.

Invalid address. Test mode: Switches out the Temp1 diode to the

PENIRQ

pin.

1

Internal node, not directly accessible by the user.

Rev. D | Page 14 of 28

Page 15

AD7873

Acquisition Time

The track-and-hold amplifier enters tracking mode on the

falling edge of the fifth DCLK after the START bit is detected

(see Figure 35). The time required for the track-and-hold

amplifier to acquire an input signal depends on how quickly the

37 pF input capacitance is charged. With zero source impedance

on the analog input, three DCLK cycles are always sufficient to

acquire the signal to the 12-bit level. With a source impedance

on the analog input, the actual acquisition time required is

R

IN

calculated using the formula:

where R

()

Rt

INACQ

is the source impedance of the input signal, and 100 Ω,

IN

pF371004.8 ×Ω+×=

37 pF is the input RC. Depending on the frequency of DCLK

used, three DCLK cycles may or may not be sufficient to acquire

the analog input signal with various source impedance values.

Touch Screen Settling

In some applications, external capacitors could be required

across the touch screen to filter noise associated with it, for

example, noise generated by the LCD panel or backlight

circuitry. The value of these capacitors causes a settling time

requirement when the panel is touched. The settling time

typically appears as a gain error. There are several methods for

minimizing or eliminating this issue. The problem may be that

the input signal, reference, or both, have not settled to their final

value before the sampling instant of the ADC. Additionally, the

reference voltage could still be changing during the conversion

cycle. One option is to stop or slow down the DCLK for the

required touch screen settling time. This allows the input and

reference to stabilize for the acquisition time, which resolves the

issue for both single-ended and differential modes.

The other option is to operate the AD7873 in differential mode

only for the touch screen, and program the AD7873 to keep the

touch screen drivers on and not go into power-down (PD0 =

PD1 = 1). Several conversions could be required, depending on

the settling time required and the AD7873 data rate. Once the

required number of conversions have been made, the AD7873

can then be placed in a power-down state on the last measurement. The last method is to use the 15 DCLK cycle mode, which

maintains the touch screen drivers on until it is commanded by

the processor to stop.

Internal Reference

The AD7873 has an internal reference voltage of 2.5 V. The

internal reference is available on the V

pin for external use in

REF

the system; however, it must be buffered before it is applied

elsewhere. The on-chip reference can be turned on or off with

the power-down address, PD1 = 1 (see Table 7 and Figure 27).

Typically the reference voltage is only used in single-ended

mode for battery monitoring, temperature measurement, and

for using the auxiliary input. Optimal touch screen performance

is achieved when using the differential mode. The power-up

time of the 2.5 V reference is typically 10 µs without a load;

however, a 0.1 µF capacitor on the V

pin is recommended for

REF

optimum performance, which affects the power-up time. (See

Figure 20.)

X+

Y+

V

REF

SW1

Figure 27. On-Chip Reference Circuitry

2.5V

REF

260Ω

3-TO-1

MUX

BUF

ADC

02164-D-027

Reference Input

The voltage difference between +REF and −REF (see Figure 26)

sets the analog input range. The AD7873 operates with a reference input in the range of 1 V to +V

. Figure 27 shows the on-

CC

chip reference circuitry on the AD7873. The internal reference

on the AD7873 can be overdriven with an external reference;

for best performance, however, the internal reference should be

disabled when an external reference is applied, because SW1 in

Figure 27 opens on the AD7873 when the internal reference is

disabled. The on-chip reference always is available at the V

REF

pin as long as the reference is enabled. The input impedance

seen at the V

pin is approximately 260 Ω when the internal

REF

reference is enabled. When it is disabled, the input impedance

seen at the V

pin is in the gigaOhm region.

REF

When making touch screen measurements, conversions can be

made in differential (ratiometric) mode or single-ended mode.

If the SER/

bit is set to 1 in the control register, then a

DFR

single-ended conversion is performed. Figure 28 shows the

configuration for a single-ended Y coordinate measurement.

The X+ input is connected to the analog-to-digital converter,

the Y+ and Y− drivers are turned on, and the voltage on X+ is

digitized. The conversion is performed with the ADC referenced

from GND to V

. This V

REF

the voltage applied at the V

is either the on-chip reference or

REF

pin externally, and is determined

REF

by the setting of the power management Bits PD0 and PD1 (see

Table 6). The advantage of this mode is that the switches that

Rev. D | Page 15 of 28

Page 16

AD7873

(

(

)

×=∆

κ

(

(

)

×=∆

κ

supply the external touch screen can be turned off once the

acquisition is complete, resulting in a power savings. However,

the on-resistance of the Y drivers affects the input voltage that

can be acquired. The full touch screen resistance could be in the

order of 200 Ω to 900 Ω, depending on the manufacturer. Thus,

if the on-resistance of the switches is approximately 6 Ω, true

full-scale and zero-scale voltages cannot be acquired, regardless

of where the pen/stylus is on the touch screen. Note that the

minimum touch screen resistance recommended for use with

the AD7873 is approximately 70 Ω. In this mode of operation,

therefore, some voltage is likely to be lost across the internal

switches, and it is unlikely that the internal switch resistance

will track the resistance of the touch screen over temperature

and supply, providing an additional source of error.

+V

CC

Y+

X+ IN+

Y–

IN+

ADC CORE

IN–

V

REF

REF+

REF–

MEASUREMENTS

Temperature Measurement

Two temperature measurement options are available on the

AD7873, the single conversion method and the differential

conversion method. Both methods are based on an on-chip

diode measurement.

In the single conversion method, a diode voltage is digitized and

recorded at a fixed calibration temperature. Any subsequent

polling of the diode provides an estimate of the ambient temperature through extrapolation from the calibration temperature

diode result. This assumes a diode temperature drift of

approximately –2.1 mV/°C. This method provides a resolution

of approximately 0.3°C and a predicted accuracy of ±3°C.

The differential conversion method is a 2-point measurement.

The first measurement is performed with a fixed bias current

into a diode, and the second measurement is performed with a

fixed multiple of the bias current into the same diode. The

voltage difference in the diode readings is proportional to

absolute temperature and is given by the following formula:

)

BE

/

NlnqTV

GND

Figure 28. Single-Ended Reference Mode (SER/

The alternative to this situation is to set the SER/

DFR

DFR

02164-D-028

= 1)

bit low.

Again, making a Y coordinate measurement is considered, but

now the +REF and –REF nodes of the ADC are connected

directly to the Y+ and Y– pins. This means the analog-to-digital

conversion is ratiometric. The result of the conversion is always

a percentage of the external resistance, independent of how it

could change with respect to the on resistance of the internal

switches. Figure 29 shows the configuration for a ratiometric Y

coordinate measurement.

+V

CC

Y+

X+ IN+

Y–

GND

Figure 29. Differential Reference Mode (SER/

IN+

ADC CORE

IN–

REF+

REF–

DFR

02164-D-029

= 0)

where V

represents the diode voltage, N is the bias current

BE

multiple, k is Boltzmann’s constant and q is the electron charge.

This method provides more accurate absolute temperature

measurement of ± 2°C. However, the resolution is reduced to

approximately 1.6°C. Assuming a current multiple of 105

(which is typical for the AD7873) taking Boltzmann’s constant,

k = 1.38054 ×10

charge q = 1.602189 × 10

–23

electrons volts/degrees Kelvin, the electron

–19

, then T, the ambient temperature in

degrees centigrade, would be calculated as follows:

)

BE

()

∆V

is calculated from the difference in readings from the first

BE

/

BE

NlnqTV

()

NlnqVT

/

××∆=

κ

3

BE

ΚVCT

2731049.2

−∆××=°

conversion and second conversion.

Figure 30 shows a block diagram of the temperature

measurement mode.

TEMP0 TEMP1

I

105*I

MUX

ADC

The disadvantage of this mode of operation is that during both

the acquisition phase and conversion process, the external touch

screen must remain powered. This results in additional supply

current for the duration of the conversion.

Rev. D | Page 16 of 28

Figure 30. Block Diagram of Temperature Measurement Circuit

02164-D-030

Page 17

AD7873

(

(

[

−

××=

(

(

[

{

Battery Measurement

The AD7873 can monitor a battery voltage from 0 V to 6 V.

Figure 31 shows a block diagram of a battery voltage monitored

through the V

pin. The voltage to the +VCC of the AD7873 is

BAT

maintained at the desired supply voltage via the dc/dc regulator

while the input to the regulator is monitored. This voltage on

V

is divided by 4 so that a 6 V battery voltage is presented to

BAT

the ADC as 1.5 V. To conserve power, the divider is on only

during the sampling of a voltage on V

. Table 5 shows the

BAT

control bit settings required to perform a battery measurement.

DC/DC

BATTERY

0V TO 6V

+

CONVERTER

V

BAT

7.5kΩ

2.5kΩ

+V

0V TO 1.5V

CC

ADC CORE

Pressure Measurement

The pressure applied to the touch screen via a pen or finger can

also be measured with the AD7873 with some simple calculations. The 8-bit resolution mode would be sufficient for this

measurement, but the following calculations are shown with the

12-bit resolution mode. The contact resistance between the X

and Y plates is measured, which provides a good indication of

the size of the depressed area and the applied pressure. The area

of the spot touched is proportional to the size of the object

touching it. The size of this resistance (R

) can be calculated

TOUCH

using two different methods.

The first method requires the user to know the total resistance

of the X-plate tablet. Three touch screen conversions are

required, a measurement of the X-position, Z

-position, and Z2-

1

position (see Figure 32). The following equation calculates the

touch resistance:

)( )

)

1/4095/

ZZXRR

12POSITIONXPLATETOUCH

]

Figure 31. Block Diagram of Battery Measurement Circuit

+

–

X+

TOUCH TOUCH

-POSITION Z1-POSITION

Z

2

X–

Y+

+

–

Y–

MEASURE Z

Figure 32. Pressure Measurement Block Diagram

02164-D-031

X+

TOUCH

X-POSITION

X–

MEASURE Z

MEASURE X-POSITION

Y+

Y–

-POSITION

1

-POSITION

2

The second method requires that the resistance of both the

X-plate and Y-plate tablets are known. Again three touch screen

conversions are required, a measurement of the X-position,

Y-po s itio n , a n d Z

-position (see Figure 32).

1

The following equation also calculates the touch resistance:

ZXZRR

)( )

(){}

YR

×−

POSITIONYPLATE

4095/

−×=

)

1POSITION1XPLATETOUCH

X+

X–

Y+

+

–

Y–

02164-D-032

]

1/40964095//

}

Rev. D | Page 17 of 28

Page 18

AD7873

PEN INTERRUPT REQUEST

The pen interrupt equivalent circuitry is outlined in Figure 33.

By connecting a pull-up resistor (10 kΩ to 100 kΩ) between +V

and this CMOS logic open drain output, the

remains high normally. If

PENIRQ

is enabled (see Table 7), when

PENIRQ

output

the touch screen connected to the AD7873 is touched by a pen

or finger, the

PENIRQ

output goes low, initiating an interrupt to

a microprocessor, which can then instruct a control word to be

written to the AD7873 to initiate a conversion. This output can

also be enabled between conversions during power-down (see

Table 7) allowing power-up to be initiated only when the screen

is touched. The result of the first touch screen coordinate conversion after power-up is valid, assuming any external reference

is settled to the 12-bit or 8-bit level as required.

Figure 34 assumes that the

PENIRQ

the last write or that the part was just powered up so

enabled by default. Once the screen is touched, the

output goes low a time t

later. This delay is approximately

PEN

function was enabled in

PENIRQ

PENIRQ

5 µs, assuming a 10 nF touch screen capacitance, and varies with

the touch screen resistance actually used. Once the START bit is

detected, the pen interrupt function is disabled and the

cannot respond to screen touches. The

PENIRQ

PENIRQ

output remains

low until the fourth falling edge of DCLK after the START bit is

clocked in, at which point it returns high as soon as possible,

irrespective of the touch screen capacitance. This does not mean

that the pen interrupt function is now enabled again because

the power-down bits have not yet been loaded to the control

register. Regardless of whether

the

PENIRQ

PENIRQ

conversion is complete, the

screen touch. The fact that

output normally always idles high . Assuming the

is enabled again as shown in Figure 34, then once the

PENIRQ

PENIRQ

PENIRQ

is to be enabled again,

output again responds to a

returns high almost

immediately after the fourth falling edge of DCLK means the

CC

is

user avoids any spurious interrupts on the microprocessor or

DSP, which could occur if the interrupt request line on the

micro/DSP were unmasked during or toward the end of

conversion and the

PENIRQ

START bit is detected by the AD7843, the

pin was still low. Once the next

PENIRQ

function is

again disabled.

If the control register write operation overlaps with the data

read, a START bit is always detected prior to the end of

conversion, meaning that even if the

PENIRQ

function is

enabled in the control register, it is disabled by the START bit

again before the end of the conversion is reached, so the

PENIRQ

function effectively cannot be used in this mode.

However, as conversions are occurring continuously, the

PENIRQ

function is not necessary and is therefore redundant.

+V

CC

100kΩ

Y+

+V

CC

PENIRQ

EXTERNAL

PULL-UP

TOUCH

SCREEN

X+

Y–

Figure 33.

PENIRQ

ENABLE

ON

PENIRQ

Functional Block Diagram

02164-D-033

SCREEN

TOUCHED

PENIRQ

CS

DCLK

DIN

HERE

t

PEN

INTERRUPT

PROCESSOR

NO RESPONSE TO TOUCH

SER/

SA2A1A0 1 0

(START)

Figure 34.

MODE

DFR

PENIRQ

Timing Diagram

Rev. D | Page 18 of 28

PD1 = 1, PD0 = 0, PENIRQ

ENABLED AGAIN

81 1 13 16

02164-D-034

Page 19

AD7873

CONTROL REGISTER

The control word provided to the ADC via the DIN pin is

shown in Table 6. This provides the conversion start, channel

addressing, ADC conversion resolution, configuration, and

power-down of the AD7873.

provides detailed information on the order and

Tabl e 6

description of these control bits within the control word.

Initiate START

The first bit, the S bit, must always be set to 1 to initiate the start

of the control word. The AD7873 ignores any inputs on the DIN

line until the start bit is detected.

Channel Addressing

The next three bits in the control register, A2, A1, and A0, select

the active input channel(s) of the input multiplexer (see Table 5

and Figure 26), touch screen drivers, and the reference inputs.

Mode

The MODE bit sets the resolution of the analog-to-digital

converter. With a 0 in this bit, the following conversion has

12 bits of resolution. With a 1 in this bit, the following

conversion has 8 bits of resolution.

SER/

The SER/

DFR

bit controls the reference mode, which can be

DFR

either single-ended or differential if a 1 or a 0 is written to this

bit respectively. The differential mode is also referred to as the

ratiometric conversion mode. This mode is optimum for

X-position, Y-position, and pressure-touch measurements. The

reference is derived from the voltage at the switch drivers,

which is almost the same as the voltage to the touch screen. In

this case, a separate reference voltage is not needed because the

reference voltage to the ADC is the voltage across the touch

screen. In single-ended mode, the reference voltage to the

converter is always the difference between the V

pins. See Table 5 and Figure 26 through Figure 29 for further

information.

If X-position, Y-position, and pressure touch are measured in

single-ended mode, an external reference voltage or +V

required for maximum dynamic range. The internal reference

can be used for these single-ended measurements; however, a

loss in dynamic range is incurred. If an external reference is

used, the AD7873 should also be powered from the external

reference. Because the supply current required by the device is

so low, a precision reference can be used as the supply source to

the AD7873. It might also be necessary to power the touch

screen from the reference, which could require 5 mA to 10 mA.

A REF19x voltage reference can source up to 30 mA, and, as

such, could supply both the ADC and the touch screen. Care

must be taken however, to ensure that the input voltage applied

to the ADC does not exceed the reference voltage and therefore

the supply voltage. See the Absolute Maximum Ratings section.

Note that the differential mode can only be used for X-position,

Y-position, and pressure touch measurements. All other

measurements require single-ended mode.

PD0 and PD1

The power management options are selected by programming

the power management bits, PD0 and PD1, in the control

register. Table 7 summarizes the options available and the

internal reference voltage configurations. The internal reference

can be turned on or off independent of the analog-to-digital

converter, allowing power saving between conversions using the

power management options. On power-up, PD0 defaults to 0,

while PD1 defaults to 1.

and GND

REF

is

CC

Table 6. Control Register Bit Function Description

MSB

S A2 A1 A0 MODE SER/DFR PD1 PD0

LSB

Bit No. Mnemonic Comment

7 S

6–4 A2–A0

3 MODE

2

1, 0 PD1, PD0 Power Management Bits. These two bits decode the power-down mode of the AD7873 as shown in Table 7.

DFR Single-Ended/Differential Reference Select Bit. Along with Bits A2–A0, this bit controls the setting of the

SER/

Start Bit. The control word starts with the first high bit on DIN. A new control word can start every 15th DCLK cycle

when in the 12-bit conversion mode or every 11th DCLK cycle when in 8-bit conversion mode.

Channel Select Bits. These three address bits along with the SER/DFR bit control the setting of the multiplexer

input, switches, and reference inputs, as detailed in Table 5.

12-Bit/8-Bit Conversion Select Bit. This bit controls the resolution of the following conversion. With a 0 in this bit,

the conversion has 12-bit resolution or, with a 1 in this bit, 8-bit resolution.

multiplexer input, switches, and reference inputs as described in Table 5.

Rev. D | Page 19 of 28

Page 20

AD7873

Table 7. Power Management Options

PD1 PD0

PENIRQ

0 0 Enabled

0 1 Enabled

1 0 Enabled

1 1 Disabled This configuration results in always keeping the device powered up. The reference and the ADC are on.

POWER VS. THROUGHPUT RATE

By using the power-down options on the AD7873 when not

converting, the average power consumption of the device

decreases at lower throughput rates. Figure 35 shows how, as the

throughput rate is reduced while maintaining the DCLK

frequency at 2 MHz, the device remains in its power-down state

longer and the average current consumption over time drops

accordingly.

1000

f

DCLK

100

f

10

SUPPLY CURRENT (µA)

1

DCLK

0 120

Figure 35. Supply Current vs. Throughput (µA)

Description

This configuration results in immediate power-down of the on chip reference as soon as PD1 is set to 0. The ADC

powers down only between conversions. When PD0 is set to 0, the conversion is performed first and the ADC

powers down upon completion of that conversion (or upon the rising edge of

the next conversion, the ADC instantly powers up to full power. This means if the device is being used in the

differential mode, or an external reference is used, there is no need for additional delays to ensure full operation

and the very first conversion is valid. The Y– switch is on while in power-down. When the device is performing

differential table conversions, the reference and reference buffer do not attempt to power up with Bits PD1 and

PD0 programmed in this way.

This configuration results in switching the reference off immediately and the ADC on permanently. When the

device is performing differential tablet conversions, the reference and reference buffer do not attempt to power

up with bits PD1 and PD0 programmed in this way.

This configuration results in switching the reference on and powering the ADC down between conversions. The

ADC powers down only between conversions. When PD0 is set to 0, the conversion is performed first, and the

ADC powers down upon completion of the conversion (or upon the rising edge of CS if it occurs first). At the start

of the next conversion, the ADC instantly powers up to full power. There is no need for additional delays to

ensure full operation as the reference remains permanently powered up.

= 16×f

SAMPLE

= 2MHz

V

T

40 600 20 80 100

THROUGHPUT (kSPS)

= 2.7V

CC

= –40°C TO +85°C

A

02164-D-035

CS if it occurs first). At the start of

For example, if the AD7873 is operated in a 24 DCLK continuous

sampling mode, with a throughput rate of 10 kSPS and a DCLK

of 2 MHz, and the device is placed in the power-down mode

between conversions, (PD0, PD1 = 0, 0), that is, the ADC shuts

down between conversions but the reference remains powered

down permanently, then the current consumption is calculated

as follows. The current consumption during normal operation

with a 2 MHz DCLK is 210 µA (V

= 2.7 V). Assuming an

CC

external reference is used, the power-up time of the ADC is

instantaneous, so when the part is converting, it consumes

210 µA. In this mode of operation, the part powers up on the

fourth falling edge of DCLK after the start bit is recognized. It

goes back into power-down at the end of conversion on the

20th falling edge of DCLK, which means that the part consumes

210 µA for 16 DCLK cycles only, 8 µs during each conversion

cycle. If the throughput rate is 10 kSPS, the cycle time is 100 µs

and the average power dissipated during each cycle is (8/100) ×

(210 µA) = 16.8 µA.

Rev. D | Page 20 of 28

Page 21

AD7873

SERIAL INTERFACE

Figure 36 shows the typical operation of the serial interface of

the AD7873. The serial clock provides the conversion clock and

also controls the transfer of information to and from the

AD7873. One complete conversion can be achieved with 24

DCLK cycles.

signal initiates the data transfer and conversion process.

The

CS

The falling edge of

takes the BUSY output and the serial bus

CS

out of three-state. The first eight DCLK cycles are used to write

to the control register via the DIN pin. The control register is

updated in stages as each bit is clocked in. Once the converter

has enough information about the following conversion to set

the input multiplexer and switches appropriately, the converter

enters the acquisition mode and, if required, the internal switches

are turned on. During acquisition mode, the reference input

data is updated. After the three DCLK cycles of acquisition, the

control word is complete (the power management bits are now

updated) and the converter enters conversion mode. At this

point, track-and-hold goes into hold mode, the input signal is

sampled, and the BUSY output goes high (BUSY returns low on

the next falling edge of DCLK). The internal switches can also

turn off at this point if in single-ended mode, battery-monitor

mode, or temperature measurement mode.

The next 12 DCLK cycles are used to perform the conversion

and to clock out the conversion result. If the conversion is

ratiometric (SER/

low), the internal switches are on during

DFR

the conversion. A 13th DCLK cycle is needed to allow the

DSP/micro to clock in the LSB. Three more DCLK cycles clock

out the three trailing zeroes and complete the 24 DCLK transfer.

The 24 DCLK cycles can be provided from a DSP or via three

bursts of eight clock cycles from a microcontroller.

DCLK

BUSY

DOUT

X/Y SWITCHES

(SER/DFR HIGH)

X/Y SWITCHES

(SER/DFR LOW)

CS

1888

DIN

THREE-STATE

THREE-STATE

1

1,2

NOTES

1

Y DRIVERS ARE ON WHEN X+ IS SELECTED INPUT CHANNEL (A2–A0 = 001), X DRIVERS ARE ON WHEN Y+ IS SELECTED INPUT CHANNEL (A2–A0 = 101).

1

WHEN PD1, PD0 = 00, 01 OR 10, Y– WILL TURN ON AT END OF CONVERSION.

2

DRIVERS WILL REMAIN ON IF POWER-DOWN MODE IS 11 (NO POWER-DOWN) UNTIL SELECTED INPUT CHANNEL, REFERENCE MODE,

1

OR POWER-DOWN MODE IS CHANGED, OR CS IS HIGH.

S A2 PD1 PD0A1 A0

(START)

OFF

OFF

MODE

IDLE

t

ACQ

SER/

DFR

ACQUIRE CONVERSION

11 10 9 8 7 6 5 4 3 2 1 0

(MSB) (LSB)

ON

ON

OFF

11

IDLE

THREE-STATE

THREE-STATE

ZERO FILLED

OFF

Figure 36. Conversion Timing, 24 DCLKS per Conversion Cycle, 8-Bit Bus Interface. No DCLK delay required with dedicated serial por t.

CS

t

t

9

6

DB11

DB10

t

10

t

11

t

12

02164-D-037

DCLK

DIN

BUSY

DOUT

t

t

1

t

2

t

3

4

t

5

t

8

t

7

PD0

t

6

Figure 37. Detail Timing Diagram

02164-D-036

Rev. D | Page 21 of 28

Page 22

AD7873

16 Clocks per Cycle

The control bits for the next conversion can be overlapped with

the current conversion to allow for a conversion every 16 DCLK

cycles, as shown in Figure 38. This timing diagram also allows

the possibility of communication with other serial peripherals

between each byte (eight DCLK) transfer between the processor

and the converter. However, the conversion must complete

within a short enough time frame to avoid capacitive droop

effects that could distort the conversion result. It should also be

noted that the AD7873 is fully powered while other serial

communications are taking place between byte transfers.

15 Clocks per Cycle

Figure 39 shows the fastest way to clock the AD7873. This

scheme does not work with most microcontrollers or DSPs

because they are not capable of generating a 15 clock cycle per

serial transfer. However, some DSPs allow the number of clocks

per cycle to be programmed. This method could also be used

with FPGAs (field programmable gate arrays) or ASICs (application specific integrated circuits). As in the 16 clocks per cycle

case, the control bits for the next conversion are overlapped

with the current conversion to allow a conversion every 15

DCLK cycles using 12 DCLKs to perform the conversion and 3

DCLKs to acquire the analog input. This effectively increases

the throughput rate of the AD7873 beyond that used for the

specifications that are tested using 16 DCLKs per cycle, and

DCLK = 2 MHz.

8-Bit Conversion

The AD7873 can be set up to operate in an 8-bit mode rather

than a 12-bit mode by setting the MODE bit in the control

register to 1. This mode allows a faster throughput rate to be

achieved, assuming 8-bit resolution is sufficient. When using 8bit mode, a conversion is complete four clock cycles earlier than

in 12-bit mode. This could be used with serial interfaces that

provide 12 clock transfers, or two conversions could be completed

with three eight-clock transfers. The throughput rate increases

by 25% as a result of the shorter conversion cycle, but the

conversion itself can occur at a faster clock rate because the

internal settling time of the AD7873 is not as critical, because

settling to eight bits is all that is required. The clock rate can be

as much as 50% faster. The faster clock rate and fewer clock

cycles combine to provide double the conversion rate.

DCLK

BUSY

DOUT

DCLK

DIN

BUSY

DOUT

CS

DIN

CS

1

S S

CONTROL BITS CONTROL BITS

Figure 38. Conversion Timing, 16 DCLKS per Cycle, 8-Bit Bus Interface. No DCLK delay required with dedicated serial port.

1

SER/

S A2 PD1 PD0A1 A0

MODE

DFR

Figure 39. Conversion Timing, 15 DCLKS per Cycle, Maximum Throughput Rate

111888

11 10 9 8 7 6 5 4 3 2 1 0 11 10 9

15 1 15 1

SA2 SA2A1 PD1 PD0A0

11 10 9 8 7 6 5 4 3 2 1 0 11 10 9 8 7 6 5 4

MODE

SER/

DFR

02164-D-038

02164-D-039

Rev. D | Page 22 of 28

Page 23

AD7873

GROUNDING AND LAYOUT

For information on grounding and layout considerations for the

AD7873, refer to Application Note AN-577, Layout and

Grounding Recommendations for Touch Screen Digitizers.

PCB DESIGN GUIDELINES FOR CHIP SCALE PACKAGE

The lands on the chip scale package (CP-32), are rectangular.

The printed circuit board pad for these should be 0.1 mm

longer than the package land length and 0.05 mm wider than

the package land width. The land should be centered on the pad.

This will ensure that the solder joint size is maximized.

The bottom of the chip scale package has a central thermal pad.

The thermal pad on the printed circuit board should be at least

as large as this exposed pad. On the printed circuit board, there

should be a clearance of at least 0.25 mm between the thermal

pad and the inner edges of the pad pattern. This ensures that

shorting is avoided.

Thermal vias may be used on the printed circuit board thermal

pad to improve thermal performance of the package. If vias are

used, they should be incorporated in the thermal pad at 1.2mm

pitch grid. The via diameter should be between 0.3 mm and

0.33 mm and the via barrel should be plated with 1 oz. copper

to plug the via.

The user should connect the printed circuit board thermal pad

to GND.

Rev. D | Page 23 of 28

Page 24

AD7873

OUTLINE DIMENSIONS

0.193

BSC

9

0.154

BSC

8

0.069

0.053

0.012

SEATING

0.008

PLANE

(RQ-16)

Dimensions shown in inches

0.065

0.049

0.010

0.004

COPLANARITY

0.004

Figure 40. 16-Lead Shrink Small Outline Package [QSOP]

16

1

PIN 1

0.025

BSC

COMPLIANT TO JEDEC STANDARDS MO-137AB

0.236

BSC

0.010

0.006

5.10

5.00

4.90

16

4.50

4.40

4.30

PIN 1

0.15

0.05

8°

0°

0.050

0.016

0.65

BSC

COPLANARITY

COMPLIANT TO JEDEC STANDARDS MO-153AB

0.10

0.30

0.19

9

81

1.20

MAX

SEATING

PLANE

6.40

BSC

0.20

0.09

8°

0°

0.75

0.60

0.45

Figure 41. 16-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-16)

Dimensions shown in millimeters

PIN 1

INDICATOR

1.00

0.85

0.80

4.0

12° MAX

SEATING

PLANE

BSC SQ

TOP

VIEW

0.80 MAX

0.65 TYP

COMPLIANT TO JEDEC STANDARDS MO-220-VGGC

0.35

0.28

0.25

3.75

BSC SQ

0.20 REF

0.60 MAX

0.65 BSC

0.05 MAX

0.02 NOM

COPLANARITY

0.75

0.60

0.50

0.08

Figure 42. 16-Lead Lead Frame Chip Scale Package [LFCSP]

(CP-16)

Dimensions shown in millimeters

13

12

9

8

0.60 MAX

BOTT OM

VIEW

16

1

4

5

1.95 BSC

PIN 1

INDICATOR

2.25

2.10 SQ

1.95

0.25 MIN

Rev. D | Page 24 of 28

Page 25

AD7873

ORDERING GUIDE

Model Temperature Range Linearity Error (LSB)1 Package Option

AD7873ARQ –40°C to +85°C ± 2 RQ-16

AD7873ARQ-REEL –40°C to +85°C ± 2 RQ-16

AD7873ARQ-REEL7 –40°C to +85°C ± 2 RQ-16

AD7873BRQ –40°C to +85°C ± 1 RQ-16

AD7873BRQ-REEL –40°C to +85°C ± 1 RQ-16

AD7873BRQ-REEL7 –40°C to +85°C ± 1 RQ-16

AD7873ARU –40°C to +85°C ± 2 RU-16

AD7873ARU-REEL –40°C to +85°C ± 2 RU-16

AD7873ARU-REEL7 –40°C to +85°C ± 2 RU-16

AD7873ARUZ-REEL

3

–40°C to +85°C ± 2 RU-16

AD7873ARUZ-REEL73 –40°C to +85°C ± 2 RU-16

AD7873ACP –40°C to +85°C ± 2 CP-16

AD7873ACP-REEL –40°C to +85°C ± 2 CP-16

AD7873ACP-REEL7 –40°C to +85°C ± 2 CP-16

AD7873ACPZ3 –40°C to +85°C ± 2 CP-16

AD7873ACPZ-REEL

AD7873ACPZ-REEL7

3

3

–40°C to +85°C ± 2 CP-16

–40°C to +85°C ± 2 CP-16

AD7873BCP –40°C to +85°C ± 1 CP-16

AD7873BCP-REEL –40°C to +85°C ± 1 CP-16

AD7873BCP-REEL7 –40°C to +85°C ± 1 CP-16

EVAL-AD7873CB

4

Evaluation Board

EVAL-CONTROL BRD25 Controller Board

1

Linearity Error here refers to integral linearity error.

2

RQ = QSOP = 0.15” Quarter Size Outline Package; RU = TSSOP.

3

Z = Pb-free part.

4

This can be used as a standalone evaluation board or in conjunction with the Evaluation Board Controller for evaluation/demonstration purposes.

5

This Evaluation Board Controller is a complete unit allowing a PC to control and communicate with all Analog Devices evaluation boards ending in CB designators.

2

Rev. D | Page 25 of 28

Page 26

AD7873

NOTES

Rev. D | Page 26 of 28

Page 27

AD7873

NOTES

Rev. D | Page 27 of 28

Page 28

AD7873

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

C02164–0–6/04(D)

Rev. D | Page 28 of 28

Loading...

Loading...