Page 1

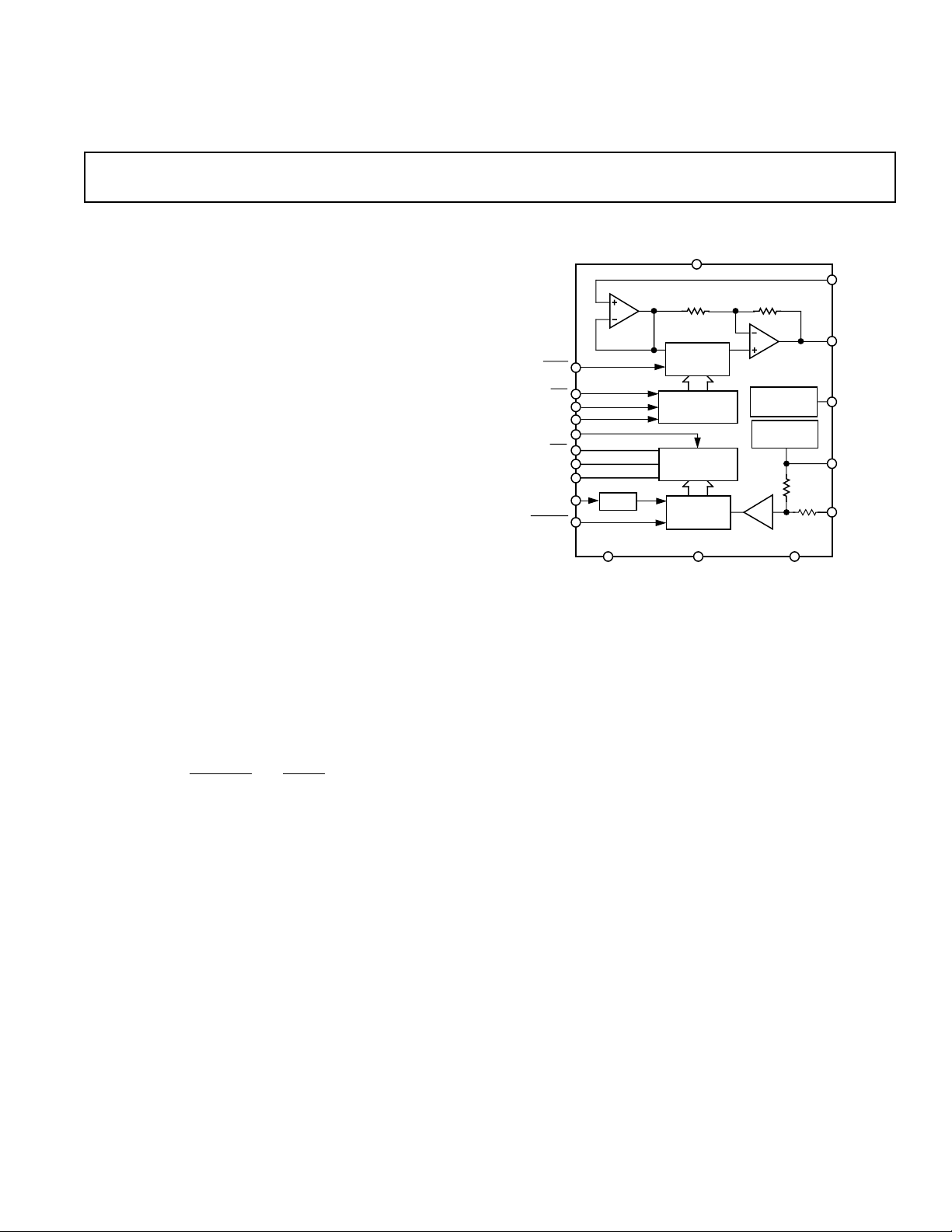

LC2MOS

RO DAC

RI DAC

DGND

AD7868

R

R

RO ADC

AGND

CLOCK

R

R

12-BIT

DAC

DAC SERIAL

INTERFACE

ADC SERIAL

INTERFACE

12-BIT

ADC

DAC 3V

REFERENCE

ADC 3V

REFERENCE

TRACK/HOLD

V

IN

V

OUT

LDAC

TFS

TCLK

DT

CONTROL

RFS

RCLK

DR

CLK

CONVST

V

DD

V

SS

a

Complete, 12-Bit Analog I/O System

FEATURES

Complete 12-Bit I/O System, Comprising:

12-Bit ADC with Track/Hold Amplifier

83 kHz Throughout Rate

72 dB SNR

12-Bit DAC with Output Amplifier

3 ms Settling Time

72 dB SNR

On-Chip Voltage Reference

Operates from 65 V Supplies

Low Power – 130 mW typ

Small 0.3" Wide DIP

APPLICATIONS

Digital Signal Processing

Speech Recognition and Synthesis

Spectrum Analysis

High Speed Modems

DSP Servo Control

GENERAL DESCRIPTION

The AD7868 is a complete 12-bit I/O system containing a DAC

and an ADC . The ADC is a successive approximation type

with a track-and-hold amplifier having a combined throughput

rate of 83 kHz. The DAC has an output buffer amplifier with a

settling time of 3 µs to 12 bits. Temperature compensated 3 V

buried Zener references provide precision references for the

DAC and ADC.

Interfacing to both the DAC and ADC is serial, minimizing pin

count and giving a small 24-pin package size. Standard control

signals allow serial interfacing to most DSP machines. Asynchronous ADC conversion control and DAC updating is made

possible with the

CONVST and LDAC logic inputs.

The AD7868 operates from ±5 V power supplies, the analog input/output range of the ADC/DAC is ±3 V. The part is fully

specified for dynamic parameters such as signal-to-noise ratio

and harmonic distortion as well as traditional dc specifications.

The part is available in a 24-pin, 0.3" wide, plastic or hermetic

dual-in-line package (DIP) and in a 28-pin, plastic SOIC

package.

AD7868

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Complete 12-Bit I/O System.

The AD7868 contains a 12-bit ADC with a track-and-hold

amplifier and a 12-bit DAC with output amplifier. Also

included are separate on-chip voltage references for the DAC

and the ADC.

2. Dynamic Specifications for DSP Users.

In addition to traditional dc specifications, the AD7868 is

specified for ac parameters including signal-to-noise ratio

and harmonic distortion. These parameters along with important timing parameters are tested on every device.

3. Small Package.

The AD7868 is available in a 24-pin DIP and a 28-pin SOIC

package.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

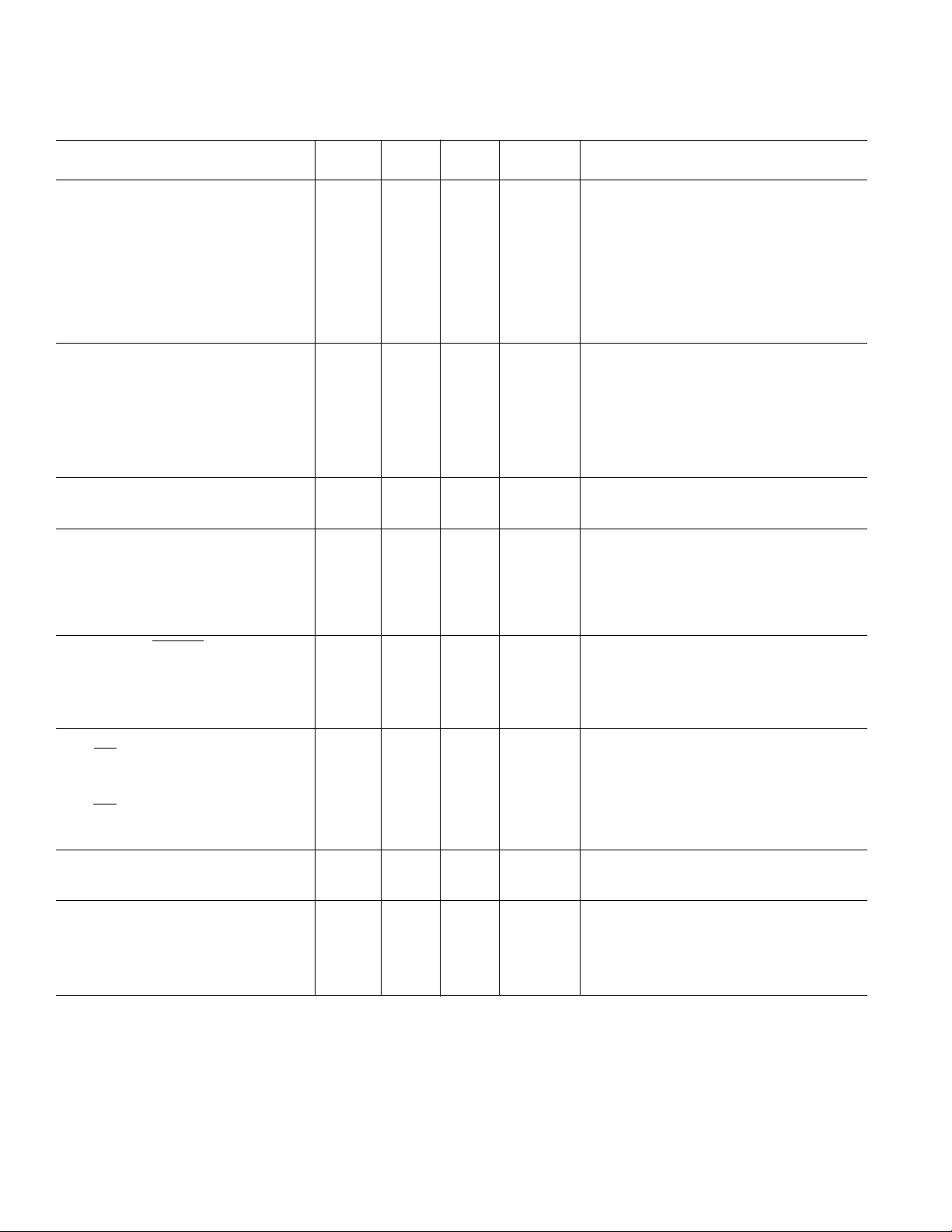

Page 2

AD7868–SPECIFICA TIONS

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, AGND = DGND = 0 V, f

ADC SECTION

unless otherwise noted.)

= 2.0 MHz external. All specifications T

CLK

MIN

to T

MAX-

Parameter Version1Version1Version1Units Test Conditions/Comments

ABT

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio

T

to T

MIN

Total Harmonic Distortion (THD) –78 –78 –76 dB max VIN = 10 kHz Sine Wave, f

MAX

Peak Harmonic or Spurious Noise –78 –78 –76 dB max VIN = 10 kHz Sine Wave, f

2

3, 4

(SNR) @ +25°C 70 72 70 dB min VIN = 10 kHz Sine Wave, f

70 71 70 dB min Typically 71.5 dB for 0 < VIN < 41.5 kHz

Typically 71.5 dB for 0 < VIN < 41.5 kHz

Typically 71.5 dB for 0 < VIN < 41.5 kHz

SAMPLE

SAMPLE

SAMPLE

= 83 kHz

= 83 kHz

= 83 kHz

Intermodulation Distortion (IMD)

Second Order Terms –78 –78 –76 dB max fa = 9 kHz, fb = 9.5 kHz, f

Third Order Terms –80 –80 –78 dB max fa = 9 kHz, fb = 9.5 kHz, f

Track/Hold Acquisition Time 2 2 2 µs max

SAMPLE

SAMPLE

= 50 kHz

= 50 kHz

DC ACCURACY

Resolution 12 12 12 Bits

Minimum Resolution 12 12 12 Bits No Missing Codes Are Guaranteed

Integral Nonlinearity ± 12 ± 12 ±12 LSB typ

Integral Nonlinearity ± 1 ±1 LSB max

Differential Nonlinearity ± 0.9 ± 0.9 ± 0.9 LSB max

Bipolar Zero Error ±5 ±5 ±5 LSB max

Positive Gain Error

Negative Gain Error

5

5

±5 ±5 ±5 LSB max

±5 ±5 ±5 LSB max

ANALOG INPUT

Input Voltage Range ±3 ±3 ±3 Volts

Input Current ± 1 ±1 ±1 mA max

REFERENCE OUTPUT

6

RO ADC @ +25°C 2.99/3.01 2.99/3.01 2.99/3.01 V min/V max

RO ADC TC ±25 ±25 ±25 ppm/°C typ

RO ADC TC ±40 ±50 ppm/°C max

Reference Load Sensitivity (∆RO ADC vs. ∆I) –1.5 –1.5 –1.5 mV max Reference Load Current Change (0 µA–500 µA),

Reference Load Should Not Be Changed

During Conversion

LOGIC INPUTS (CONVST, CLK, CONTROL)

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Current7 (CONTROL Input Only) ±10 ±10 ±10 µA max VIN = VSS to DGND

Input Capacitance, C

INH

INL

IN

8

IN

2.4 2.4 2.4 V min VDD = 5 V ± 5%

0.8 0.8 0.8 V max VDD = 5 V ± 5%

±10 ±10 ±10 µA max VIN = 0 V to V

10 10 10 pF max

DD

LOGIC OUTPUTS

DR, RFS Outputs

Output Low Voltage, V

RCLK Output

Output Low Voltage, V

DR, RFS, RCLK Outputs

Floating-State Leakage Current ± 10 ±10 ±10 µA max

Floating-State Output Capacitance

OL

OL

8

0.4 0.4 0.4 V max I

0.4 0.4 0.4 V max I

15 15 15 pF max

= 1.6 mA, Pull-Up Resistor = 4.7 kΩ

SINK

= 2.6 mA, Pull-Up Resistor = 2 kΩ

SINK

CONVERSION TIME

External Clock 10 10 10 µs max

Internal Clock 10 10 10 µs max The Internal Clock Has a Nominal Value of 2.0 MHz

POWER REQUIREMENTS For Both DAC and ADC

V

DD

V

SS

I

DD

I

SS

+5 +5 +5 V nom ± 5% for Specified Performance

–5 –5 –5 V nom ±5% for Specified Performance

22 22 25 mA max Cumulative Current from the Two VDD Pins

12 12 13 mA max Cumulative Current from the Two VSS Pins

Total Power Dissipation 170 170 190 mW max Typically 130 mW

NOTES

1

Temperature ranges are as follows: A/B Versions, –40°C to +85 °C; T Version, –55 °C to +125°C.

2

VIN = ±3 V

3

SNR calculation includes distortion and noise components.

4

SNR degradation due to asynchronous DAC updating during conversion is 0.1 dB typ.

5

Measured with respect to internal reference.

6

For capacitive loads greater than 50 pF a series resistor is required (see INTERNAL REFERENCE section).

7

Tying the CONTROL input to VDD places the device in a factory test mode where normal operation is not exhibited.

8

Sample tested @ +25°C to ensure compliance.

Specifications subject to change without notice.

–2–

REV. B

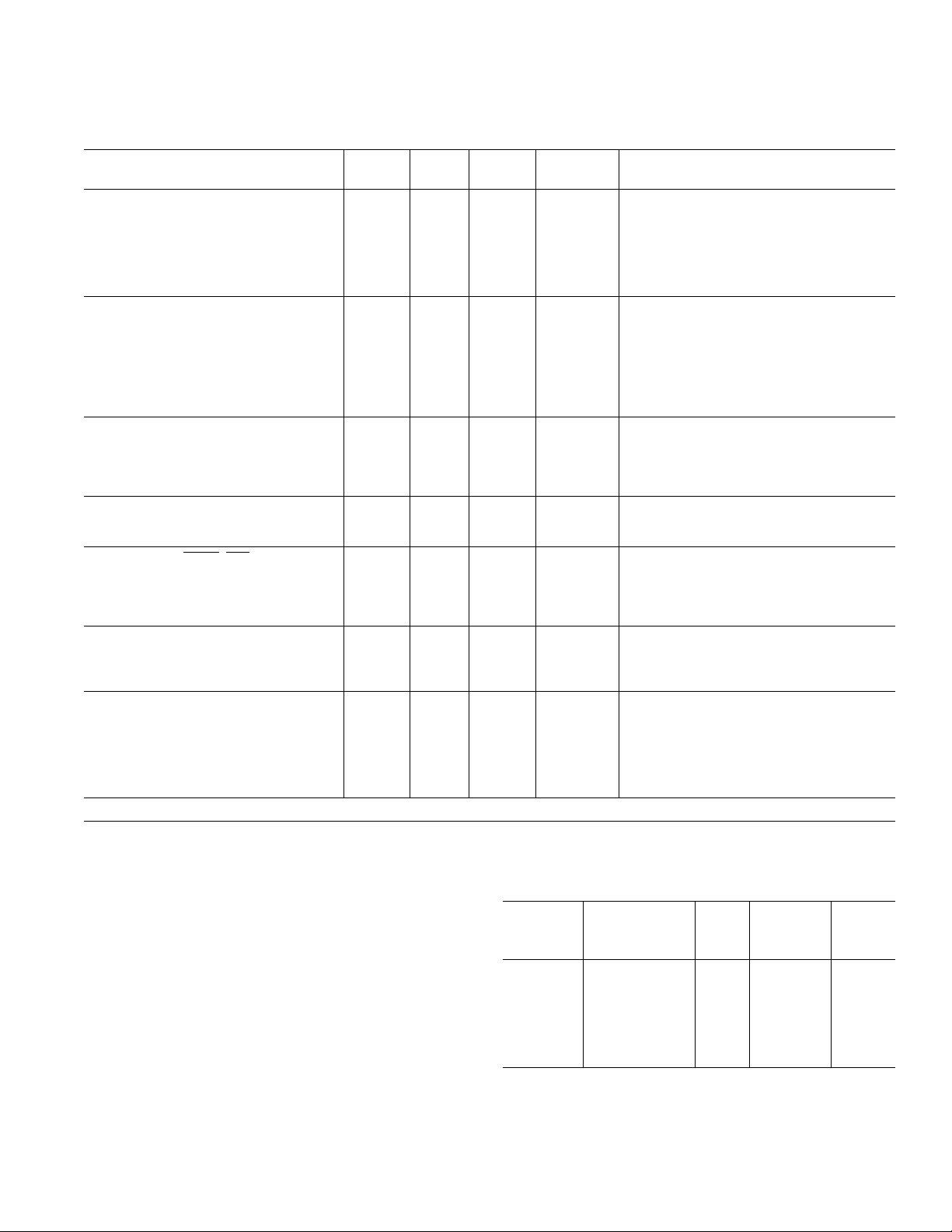

Page 3

DAC SECTION

AD7868

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, AGND = DGND = 0 V, RI DAC = +3 V and decoupled as shown in Figure 2, V

Load to AGND; RL = 2 kΩ, CL = 100 pF. All specifications T

MIN

to T

unless otherwise noted.)

MAX

OUT

Parameter Version1Version1Version1Units Test Conditions/Comments

ABT

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio3 (SNR) @ +25°C 70 72 70 dB min V

T

to T

MIN

Total Harmonic Distortion (THD) –78 –78 –76 dB max V

MAX

Peak Harmonic or Spurious Noise –78 –78 –76 dB max V

2

= 1 kHz Sine Wave, f

70 71 70 dB min Typically 71.5 dB at +25°C for 0 < V

OUT

= 1 kHz Sine Wave, f

OUT

Typically –84 dB at +25°C for 0 < V

= 1 kHz Sine Wave, f

OUT

Typically –84 dB at +25°C for 0 < V

SAMPLE

SAMPLE

SAMPLE

= 83 kHz

< 20 kHz

OUT

= 83 kHz

< 20 kHz

OUT

= 83 kHz

< 20 kHz

OUT

DC ACCURACY

Resolution 12 12 12 Bits

Integral Nonlinearity ±1/2 ±1/2 ±1/2 LSB typ

Integral Nonlinearity ± 1 ±1 LSB max

Differential Nonlinearity ± 0.9 ± 0.9 ± 0.9 LSB max Guaranteed Monotonic

Bipolar Zero Error ±5 ±5 ±5 LSB max

Positive Full-Scale Error

Negative Full-Scale Error

REFERENCE OUTPUT

5

5

6

± 5 ±5 ±5 LSB max

±5 ±5 ±5 LSB max

RO ADC @ +25°C 2.99/3.01 2.99/3.01 2.99/3.01 V min/V max

RO ADC TC ±25 ±25 ±25 ppm/°C typ

RO ADC TC ±40 ±50 ppm/°C max

Reference Load Change (∆RO DAC vs. ∆I) –1.5 –1.5 –1.5 mV max Reference Load Current Change (0–500 µA)

REFERENCE INPUT

RI DAC Input Range 2.85/3.15 2.85/3.15 2.85/3.15 V min/V max 3 V ± 5%

Input Current 1 1 1 µA max

LOGIC INPUTS (LDAC, TFS, TCLK, DT)

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

IN

INL

IN

INH

7

2.4 2.4 2.4 V min VDD = 5 V ± 5%

0.8 0.8 0.8 V max VDD = 5 V ± 5%

±10 ±10 ±10 µA max VIN = 0 V to V

10 10 10 pF max

DD

ANALOG INPUT

Output Voltage Range ±3 ±3 ±3 V nom

dc Output Impedance 0.3 0.3 0.3 Ω typ

Short-Circuit Current 20 20 20 mA typ

AC CHARACTERISTICS

7

Voltage Output Settling-Time Settling Time to Within ± 1/2 LSB of Final Value

Positive Full-Scale Change 3 3 3 µs max Typically 2 µs

Negative Full-Scale Change 3 3 3 µs max Typically 2.5 µs

Digital-to-Analog Glitch Impulse 10 10 10 nV secs typ DAC Code Change All 1s to All 0s

Digital Feedthrough 2 2 2 nV secs typ

VIN to V

Isolation 100 100 100 dB typ VIN = ±3 V, 41.5 kHz Sine Wave

OUT

POWER REQUIREMENTS As per ADC Section

NOTES

1

Temperature ranges are as follows: A/B Versions, –40°C to +85 °C; T Version, –55 °C to +125°C.

2

V

(pk–pk) = ±3 V.

OUT

3

SNR calculation includes distortion and noise components.

4

Using external sample and hold.

5

Measured with respect to RI DAC and includes bipolar offset error.

6

For capacitive loads greater than 50 pF a series resistor is required

(see INTERNAL REFERENCE section).

7

Sample tested @ +25°C to ensure compliance.

Specifications subject to change without notice.

Model Range SNR (LSB) Option*

AD7868AN –40°C to +85°C 70 dB ±1/2 typ N-24

ORDERING GUIDE

Relative

Temperature Accuracy Package

AD7868AQ –40°C to +85°C 70 dB ± 1/2 typ Q-24

AD7868BN –40°C to +85°C 72 dB ± 1 max N-24

AD7868BQ –40°C to +85°C 72 dB ±1 max Q-24

AD7868AR –40°C to +85°C 70 dB ±1/2 typ R-28

AD7868BR –40°C to +85°C 72 dB ± 1 max R-28

*N = Plastic DIP; Q = Cerdip; R = SOIC (Small Outline IC).

4

4

4

REV. B

–3–

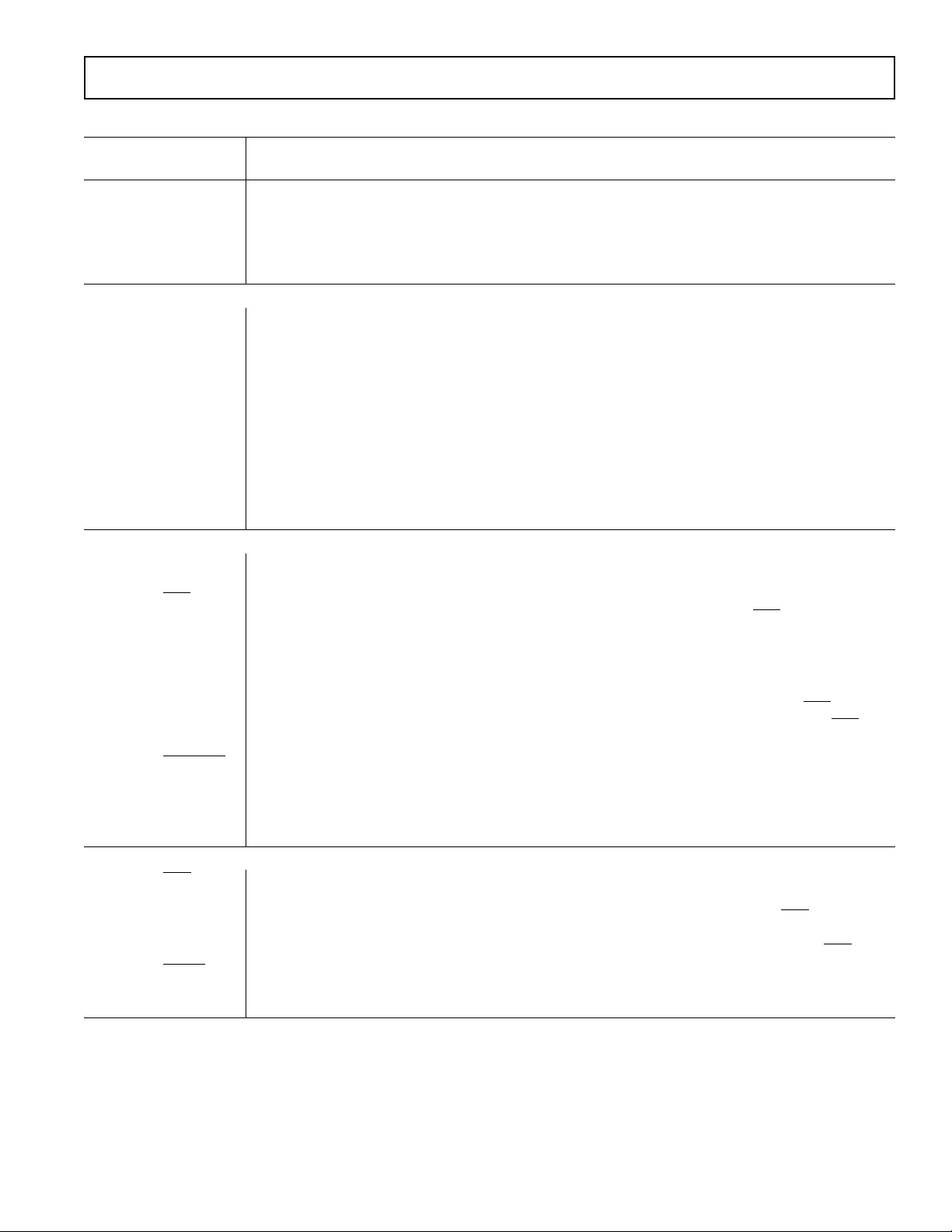

Page 4

AD7868

WARNING!

ESD SENSITIVE DEVICE

RO ADC

DGND

TCLK

DT

RI DAC

AGND

CONTROL

CLK

RCLK

DR

DGND

AGND

RO DAC

NC

V

DD

NC = NO CONNECT

1

7

8

9

24

23

22

21

20

19

18

17

16

15

14

12

13

AD7868

TOP VIEW

(Not to Scale)

CONVST

RFS

V

SS

V

OUT

V

IN

TFS

LDAC

10

11

3

4

5

6

2

28

27

26

25

NC

NC

NC

NC

V

DD

V

SS

TIMING CHARACTERISTICS

1, 2

(VDD = +5 V 6 5%, VSS = –5 V 6 5%, AGND = DGND = 0 V)

Limit at T

MIN

, T

MAX

Limit at T

MIN

, T

MAX

Parameter (A, B Versions) (T Version) Units Conditions/Comments

ADC TIMING

t

1

3

t

2

t

3

t

4

4

t

5

t

6

5

t

13

50 50 ns min CONVST Pulse Width

440 440 ns min RCLK Cycle Time, Internal Clock

100 100 ns min RFS to RCLK Falling Edge Setup Time

20 20 ns min RCLK Rising Edge to RFS

100 100 ns max

155 155 ns max RCLK to Valid Data Delay, CL = 35 pF

4 4 ns min Bus Relinquish Time after RCLK

100 100 ns max

2 RCLK +200 to 2 RCLK +200 to ns typ CONVST to RFS Delay

3 RCLK + 200 3 RCLK + 200

DAC TIMING

t

7

t

8

6

t

9

t

10

t

11

t

12

NOTES

1

Timing specifications are sample tested at +25°C to ensure compliance. All input signals are specified with tr = tf = 5 ns (10% to 90% of 5 V) and timed from a

voltage level of 1.6 V.

2

Serial timing is measured with a 4.7 kΩ pull-up resistor on DR and RFS and a 2 k Ω pull-up resistor on RCLK . The capacitance on all three output is 35 pF.

3

When using internal clock, RCLK mark/space ratio (measured from a voltage level of 1.6 V) range is 40/60 to 60/40. For external clock, RCLK mark/space ratio =

external clock mark/space ratio.

4

DR will drive higher capacitance loads but this will add to t5 since it increases the external RC time constant (4.7 kΩ/CL) and hence the time to reach 2.4 V.

5

Time 2 RCLK to 3 RCLK depends on conversion start to ADC clock synchronization.

6

TCLK mark/space ratio is 40/60 to 60/40.

50 50 ns min TFS to TCLK Falling Edge

75 100 ns min TCLK Falling Edge to TFS

150 200 ns min TCLK Cycle Time

30 40 ns min Data Valid to TCLK Setup Time

75 100 ns min Data Valid to TCLK Hold Time

40 40 ns min LDAC Pulse Width

ABSOLUTE MAXIMUM RATINGS*

(TA = +25°C unless otherwise noted)

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

V

SS

AGND to DGND . . . . . . . . . . . . . . . . . –0.3 V to V

V

OUT

VIN to AGND . . . . . . . . . . . . . . . . VSS –0.3 V to VDD + 0.3 V

RO ADC to AGND . . . . . . . . . . . . . . . –0.3 V to V

RO DAC to AGND . . . . . . . . . . . . . . . –0.3 V to V

RI DAC to AGND . . . . . . . . . . . . . . . –0.3 V to V

Digital Inputs to AGND . . . . . . . . . . . –0.3 V to V

Digital Outputs to AGND . . . . . . . . . . –0.3 V to V

Operating Temperature Range

A, B Versions . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

T Version . . . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . +300°C

Power Dissipation (Any Package) to +75°C . . . . . . . . 450 mW

Derates above +75°C by . . . . . . . . . . . . . . . . . . . . 10 mW/°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those listed in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7868 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V to –7 V

+0.3 V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . VSS to V

DD

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

DD

–4–

CONVST

CLK

RFS

RCLK

DGND

V

AGND

V

OUT

V

RO DAC

RI DAC

1

2

3

4

5

DR

6

7

DD

8

9

SS

10

11

12

PIN CONFIGURATIONS

DIP

AD7868

TOP VIEW

(Not to Scale)

NC = NO CONNECT

24

23

22

21

20

19

18

17

16

15

14

13

CONTROL

V

DD

V

SS

V

IN

RO ADC

AGND

NC

DGND

TCLK

DT

TFS

LDAC

SOIC

REV. B

Page 5

AD7868

PIN FUNCTION DESCRIPTION

DIP Pin

Number Mnemonic Function

POWER SUPPLY

7 & 23 V

10 & 22 V

DD

SS

8 & 19 AGND Analog Ground. Both AGND pins must be tied together.

6 &17 DGND Digital Ground. Both DGND pins must be tied together.

ANALOG SIGNAL AND REFERENCE

21 V

9V

IN

OUT

20 RO ADC Voltage Reference Output. The internal ADC 3 V reference is provided at this pin. This output may be

11 RO DAC DAC Voltage Reference Output. This is one of two internal voltage references. To operate the DAC

12 RI DAC DAC Voltage Reference Input. The voltage reference for the DAC must be applied to this pin. It is

Positive Power Supply, 5 V ± 5%. Both VDD pins must be tied together.

Negative Power Supply, –5 V ± 5%. Both VSS pins must be tied together.

ADC Analog Input. The ADC input range is ± 3 V.

Analog Output Voltage from DAC. This output comes from a buffer amplifier. The range is

bipolar, ±3 V with RI DAC = +3 V.

used as a reference for the DAC by connecting it to the RI DAC input. The external load capability of

this reference is 500 µA.

with this internal reference, RO DAC should be connected to RI DAC. The external load capability of

the reference is 500 µA.

internally buffered before being applied to the DAC. The nominal reference voltage for correct

operation of the AD7868 is 3 V.

ADC INTERFACE AND CONTROL

2 CLK Clock Input. An external TTL-compatible clock may be applied to this input. Alternatively, tying pin to

V

enables the internal laser-trimmed oscillator.

SS

3

RFS Receive Frame Synchronization, Logic Output. This is an active low open-drain output which provides

a framing pulse for serial data. An external 4.7 kΩ pull-up resistor is required on

RFS.

4 RCLK Receive Clock, Logic Output. RCLK is the gated serial clock output which is derived from the internal

or external ADC clock. If the CONTROL input is at V

the clock runs continuously. With the

SS

CONTROL input at DGND the RCLK output is gated off (three-stated) after serial transmission is

complete. RCLK is an open-drain output and requires an external 2 kΩ pull-up resistor.

5 DR Receive Data, Logic Output. This is an open-drain data output used in conjunction with

RCLK to transmit data from the ADC. Serial data is valid on the falling edge of RCLK when

RFS and

RFS is

low. An external 4.7 kΩ resistor is required on the DR output.

1

CONVST Convert Start, Logic Input. A low to high transition on this input puts the track-and-hold amplifier into

the hold mode and starts an ADC conversion. This input in asynchronous to the CLK input.

24 CONTROL Control, Logic Input. With this pin at 0 V, the RCLK is noncontinuous. With this pin at –5 V, the

RCLK is continuous. Note, tying this pin to V

places the part in a factory test mode where normal

DD

operation is not exhibited.

DAC INTERFACE AND CONTROL

14

TFS Transmit Frame Synchronization, Logic Input. This is a frame or synchronization signal for the DAC

with serial data expected after the falling edge of this signal.

15 DT Transmit Data, Logic Input. This is the data input which is used in conjunction with

TFS and TCLK

to transfer serial data to the input latch.

16 TCLK Transmit Clock, Logic Input. Serial data bits are latched on the falling edge of TCLK when

13

LDAC Load DAC, Logic Input. A new word is transferred into the DAC latch from the input latch on the

TFS is low.

falling edge of this signal.

18 NC No Connect.

REV. B

–5–

Page 6

AD7868

CONVERTER DETAILS

The AD7868 is a complete 12-bit I/O port, the only external

components required for normal operation are pull-up resistors

for the ADC data outputs and power supply decoupling capacitors. It is comprised of a 12-bit successive approximation ADC

with a track/hold amplifier, a 12-bit DAC with a buffered output

and two 3 V buried Zener references, a clock oscillator and control logic.

ADC CLOCK

The AD7868 has an internal clock oscillator which can be used

for the ADC conversion procedure. The oscillator is enabled by

tying the CLK input to V

. The oscillator in laser trimmed at

SS

the factory to give a conversion time of between 8.5 and 10 µs.

The mark/space ratio can vary from 40/60 to 60/40. Alternatively, an external TTL compatible clock may be applied to this

input. The allowable mark/space ratio of an external clock is

40/60 to 60/40. RCLK is a clock output, used for the serial interface. This output is derived directly from the ADC clock

source and can be switched off at the end of conversion with the

CONTROL input.

ADC CONVERSION TIMING

The conversion time for both external clock and continuous internal clock can vary from 19 to 20 rising clock edges depending

on the conversion start to ADC clock synchronization. If a conversion is initiated within 30 ns prior to a rising edge of the ADC

clock, the conversion time will consist of 20 rising clock edges,

i.e., 9.5 µs conversion time. For noncontinuous internal clock,

the conversion time is always 19 rising clock edges.

ADC TRACK-AND-HOLD AMPLIFIER

The track-and-hold amplifier on the analog input of the AD7868

allows the ADC to accurately convert an input sine wave of 6 V

peak–peak amplitude to 12-bit accuracy. The input impedance is

typically 9 kΩ, an equivalent circuit is shown in Figure 1. The

input bandwidth of the track/hold amplifier is much greater than

the Nyquist rate of the ADC, even when the ADC is operated at

its maximum throughput rate. The 0.1 dB cutoff frequency occurs typically at 500 kHz. The track/hold amplifier acquires an

input signal to 12-bit accuracy in less than 2 µs.

The operation of the track/hold amplifier is essentially transparent to the user. The track/hold amplifier goes from its track

mode to its hold mode at the start of conversion on the rising

edge of

CONVST.

INTERNAL REFERENCES

The AD7868 has two on-chip temperature compensated buried

Zener references which are factory trimmed to 3 V ± 10 mV.

One reference provides the appropriate biasing for the ADC,

while the other is available as a reference of the DAC. Both reference outputs are available (labeled RO DAC and RO ADC)

and are capable of providing up to 500 µA to an external load.

The DAC input reference (RI DAC) can be stored externally or

connected to any of the two on-chip references. Applications

requiring good full-scale error matching between the DAC and

the ADC should use the ADC reference as shown in Figure 4.

The maximum recommended capacitance on either of the reference output pins for normal operation is 50 pF. If either of the

reference outputs is required to drive a capacitive load greater

than 50 pF, then a 200 Ω resistor must be placed in series with

the capacitive load. The addition of decoupling capacitors,

10 µF in parallel with 0.1 µF, as shown in Figure 2, improves

noise performance. The improvement in noise performance can

be seen from the graph in Figure 3. Note, this applies for the

DAC output only; reference decoupling components do not affect ADC performance. So, a typical application will have just

the DAC reference source decoupled with the other one open

circuited.

RO DAC

or

RO ADC*

RI DAC

*RO DAC/RO ADC CAN BE LEFT

OPEN CIRCUIT IF NOT USED

200Ω

10µF

EXT LOAD

GREATER THAN 50pF

0.1µF

Figure 2. Reference Decoupling Circuitry

TRACK/HOLD

V

IN

4.5kΩ

4.5kΩ

*ADDITIONAL PINS OMITTED FOR CLARITY

AMPLIFIER

AD7868*

TO INTERNAL

3V REFERENCE

TO INTERNAL

COMPARATOR

Figure 1. ADC Analog Input

The overall throughput rate is equal to the conversion time plus

the track/hold amplifier acquisition time. For a 2.0 MHz input

clock the throughput time is 12 µs max.

–6–

DAC OUTPUT AMPLIFIER

The output from the voltage-mode DAC is buffered by a noninverting amplifier. The buffer amplifier is capable of developing

±3 V across 2 kΩ and 100 pF load to ground and can produce

6 V peak-to-peak sine wave signals to a frequency of 20 kHz.

The output is updated on the falling edge of the

LDAC input.

The output voltage settling time, to within 1/2 LSB of its final

value, is typically less than 2 µs.

The small signal (200 mV p-p) bandwidth of the output buffer

amplifier is typically 1 MHz. The output noise from the amplifier is low with a figure of 30 nV/√

Hz at a frequency of 1 kHz.

The broadband noise from the amplifier exhibits a typical peakto-peak figure of 150 µV for a 1 MHz output bandwidth. Fig-

ure 3 shows a typical plot of noise spectral density versus frequency for the output buffer amplifier and for either of the

on-chip references.

REV. B

Page 7

AD7868

500

TA = +25°C

V

= +5V

200

100

nV – √Hz

50

20

10

50 100 200

REF OUT

DAC OUTPUT

WITH ALL 0s

LOADED

REF OUT DECOUPLED

AS SHOWN IN

FIGURE 2

1k 2k

FREQUENCY – Hz

DD

V

= –5V

SS

10k

20k

100k

Figure 3. Noise Spectral Density vs. Frequency

INPUT/OUTPUT TRANSFER FUNCTIONS

A bipolar circuit for the AD7868 is shown in Figure 4. The analog input/output voltage range of the AD7868 is ± 3 V. The designed code transitions for the ADC occur midway between

successive integer LSB values (i.e., 1/2 LSB, 3/2 LSB, 5/2 LSB

. . . FS – 3/2 LSBs). The input/output code is 2s complement

binary with 1 LSB = FS/4096 = 1.46 mV. The ideal transfer

function is shown in Figure 5.

ANALOG INPUT

RANGE = ±3V

10µF

AD7868*

V

IN

RI DAC

R1

200

C1

*ADDITIONAL PINS OMITTED FOR CLARITY

C2

0.1µF

RO ADC

AGND

ANALOG OUTPUT

RANGE = ±3V

V

OUT

Figure 4. AD7868 Basic Bipolar Operation Using RO ADC

as a Reference Input for the DAC

OUTPUT

CODE

011...111

011...110

000...010

000...001

000...000

111...111

111...110

100...001

100...000

-FS

2

0V

INPUT VOLTAGE

+

FS

FS = 6V

1LSB =

-1LSB

2

FS

4096

Figure 5. AD7868 Input/Output Transfer Function

OFFSET AND FULL-SCALE ADJUSTMENT

In most digital signal processing (DSP) applications, offset and

full-scale errors have little or no effect on system performance.

Offset error can always be eliminated in the analog domain by

ac coupling. Full-scale errors do not cause problems as long as

REV. B

–7–

the input signal is within the full dynamic range of the ADC. For

applications which require that the input signal range match the

full analog input dynamic range of the ADC, offset and full-scale

errors have to be adjusted to zero.

ADC ADJUSTMENT

Figure 6 has signal conditioning at the input and output of the

AD7868 for trimming the end points of the transfer functions of

both the ADC and the DAC. Offset error must be adjusted before full-scale error. For the ADC, this is achieved by trimming

the offset of A1 while the input voltage, V1, is 1/2 LSB below

ground. The trim procedure is as follows: apply a voltage of

–0.73 mV (–1/2 LSB) at V1 in Figure 6 and adjust the offset

voltage of A1 until the ADC output code flickers between 1111

1111 1111 (FFF HEX) and 0000 0000 0000 (000 HEX).

ADC gain error can be adjusted at either the first code transition (ADC negative full scale) or the last code transition (ADC

positive full scale). The trim procedures for both cases are as

follows (see Figure 6).

ADC Positive Full-Scale Adjustment

Apply a voltage of 2.9978 V (FS/2 – 3/2 LSBs) at V1. Adjust R2

until the ADC output code flickers between 0111 1111 1110

(7FE HEX) and 0111 1111 1111 (7FF HEX).

ADC Negative Full-Scale Adjustment

Apply a voltage of –2.9993 V (–FS/2 + 1/2 LSB) at V1 and

adjust R2 until the ADC output code flickers between 1000

0000 0000 (800 HEX) and 1000 0000 0001 (801 HEX).

DAC ADJUSTMENT

Op amp A2 is included in Figure 6 for the DAC transfer function adjustment. Again offset must be adjusted before full scale.

To adjust offset: load the DAC with 0000 0000 0000 (000

HEX) and trim the offset of A2 to 0 V. As with the ADC adjustment, gain error can be adjusted at either the first code transition (DAC negative full scale) or the last code transition (DAC

positive full scale). The trim procedures for both cases are as

follows:

DAC Positive Full-Scale Adjustment

Load the DAC with 0111 1111 1111 (7FF HEX) and adjust R7

until the op amp output voltage is equal to 2.9985 V, (FS/2 –

1 LSB).

DAC Negative Full-Scale Adjustment

Load the DAC with 1000 0000 0000 (800 HEX) and adjust R7

until the op amp output voltage is equal to 3.0 V (–FS/2).

V1

INPUT VOLTAGE

RANGE = ±3V

R1

10k

R2

500

R3

10k

*ADDITIONAL PINS

OMITTED FOR CLARITY

10k

A1

R4

R5

10k

V

IN

AD7868*

AGND

V

OUT

R6

10k

500

10k

R7

R8

R10

10k

A2

V0

OUTPUT VOLTAGE

RANGE = ± 3V

R9

10k

Figure 6. AD7868 with Input/Output Adjustment

Page 8

AD7868

TIMING AND CONTROL

Communication with the AD7868 is managed by 6 dedicated

pins. These consist of separate serial clocks, word framing or

strobe pulses and data signals for both receiving and transmitting data. Conversion starts and DAC updating are controlled

by two digital inputs;

CONVST and LDAC. These inputs can

be asserted independently of the microprocessor by an external

timer when precise sampling intervals are required. Alternatively, the

LDAC and CONVST can be driven from a decoded

address bus allowing the microprocessor control over conversion

start and DAC updating as well as data communication to the

AD7868.

ADC Timing

Conversion control is provided by the CONVST input. A low to

high transition on

CONVST input starts conversion and drives

the track/hold amplifier into its hold mode. Serial data then becomes available while conversion is in progress. The corresponding timing diagram is shown in Figure 7. The word length is 16

bits; 4 leading zeros, followed by the 12-bit conversion result

starting with the MSB. The data is synchronized to the serial

clock output (RCLK) and is framed by the serial strobe (

RFS).

Data is clocked out on a low to high transition of the serial clock

and is valid on the falling edge of this clock while the

put is low.

RFS goes low at the start of conversion and the first

RFS out-

serial data bit (which is the first leading zero) is valid on the first

falling edge of RCLK. All the ADC serial lines are open-drain

outputs and require external pull-up resistors.

The serial clock out is derived from the ADC master clock

source which may be internal or external. Normally, RCLK is

required during the serial transmission only. In these cases it can

be shut down (i.e., placed into high impedance) at the end of

conversion to allow multiple ADCs to share a common serial

bus. However, some serial systems (e.g., TMS32020) require a

serial clock which runs continuously. Both options are available

on the AD7868 ADC. With the CONTROL input at 0 V, RCLK

is noncontinuous and when it is at –5 V, RCLK is continuous.

DAC Timing

The AD7868 DAC contains two latches, an input latch and a

DAC latch. Data must be loaded to the input latch under the

control of the TCLK,

TFS and DT serial logic inputs. Data is

then transferred from the input latch to the DAC latch under

the control of the

LDAC signal. Only the data in the DAC latch

determines the analog output of the AD7868.

Data is loaded to the input latch under control of TCLK,

TFS

and DT. The AD7868 DAC expects a 16-bit stream of serial

data on its DT input. Data must be valid on the falling edge of

TCLK. The

TFS input provides the frame synchronization signal which tells the AD7868 DAC that valid serial data will be

available for the next 16 falling edges of TCLK. Figure 8 shows

the timing diagram for the serial data format.

Although 16 bits of data are clocked into the input latch, only

12 bits are transferred into the DAC latch. Therefore, 4 bits in

the stream are don’t cares since their value does not affect the

DAC latch data. The bit positions are 4 don’t cares followed by

the 12-bit DAC data starting with the MSB.

The

LDAC signal controls the transfer of data to the DAC

latch. Normally, data is loaded to the DAC latch on the falling

edge of

LDAC. However, if LDAC is held low, then serial data

is loaded to the DAC latch on the sixteenth falling edge of

TCLK. If

LDAC goes low during the loading of serial data to

the input latch, no DAC latch update takes place on the falling

edge of

LDAC. If LDAC stays low until the serial transfer is

completed, then the update takes place on the sixteenth falling

edge of TCLK. If

LDAC returns high before the serial data

transfer is completed, no DAC latch update takes place.

t

1

CONVST

1

RFS

2, 3

RCLK

1

DR

NOTES

1

EXTERNAL 4.7kΩ PULL-UP RESISTOR

2

EXTERNAL 2kΩ PULL-UP RESISTOR

3

CONTINUOUS RCLK (DASHED LINE) WHEN THE CONTROL INPUT = –5V AND

NONCONTINUOUS WHEN THE CONTROL INPUT = 0V

t

13

t

3

CONVERSION TIME

t

DB11 DB10 DB9 DB1 DB0

Figure 7. ADC Control Timing Diagram

t

TFS

TCLK

DT

7

DON'T

CARE

t

9

DON'T

CARE

DON'T

CARE

DON'T

CARE

Figure 8. DAC Control Timing Diagram

–8–

t

2

5

t

11

t

10

DB11 DB10 DB1 DB0

t

4

t

6

t

8

REV. B

Page 9

AD7868

AD7868 DYNAMIC SPECIFICATIONS

The AD7868 is specified and 100% tested for dynamic performance specifications as well as traditional dc specifications such

as integral and differential nonlinearity. These ac specifications

are required for signal processing applications such as speech

recognition, spectrum analysis, and high-speed modems. These

applications require information on the converter’s effect on the

spectral content of the input signal. Hence, the parameters for

which the AD7868 is specified include SNR, harmonic distortion and peak harmonics. These terms are discussed in more detail in the following sections.

Signal-to-Noise Ratio (SNR)

SNR is the measured signal-to-noise ratio at the output of the

ADC or DAC. The signal is the rms magnitude of the fundamental. Noise is the rms sum of all the nonfundamental signals

up to half the sampling frequency (fs/2) excluding dc. SNR is

dependent upon the number of levels used in the quantization

process; the more levels, the smaller the quantization noise. The

theoretical signal-to-noise ratio for a sine wave input is given by

SNR = (6.02N + 1.76) dB (1)

where N is the number of bits. Thus for an ideal 12-bit converter, SNR = 74 dB.

Effective Number of Bits

The formula given in Equation 1 relates the SNR to the number

of bits. Rewriting the formula, as in Equation 2, it is possible to

get a measure of performance expressed in effective number of

bits (N).

Figure 10 shows a typical plot of effective number of bits versus

frequency for an AD7868BQ with a sampling frequency of

83 kHz. The effective number of bits typically falls between 11.7

and 11.85 corresponding to SNR figures of 72.2 and 73.1 dB.

Figure 9. AD7868, ADC FFT Plot

12

11.5

SNR–1.76

N =

6.02

(2)

The effective number of bits for a device can be calculated directly from its measured SNR.

Harmonic Distortion

Harmonic distortion is the ratio of the rms sum of harmonics to

the fundamental. For the AD7868, total harmonic distortion

(THD) is defined as

2

2

2

2

2

+V

5

6

THD =20 log

+V

+V

V

2

+V

3

4

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

V

, V5 and V6 are the rms amplitudes of the second through to

4

the sixth harmonic. The THD is also derived from the FFT plot

of the ADC or DAC output spectrum.

ADC Testing

The output spectrum from the ADC is evaluated by applying a

sine-wave signal of very low distortion to the V

input which is

IN

sampled at an 83 kHz sampling rate. A Fast Fourier Transform

(FFT) plot is generated from which the SNR data can be obtained. Figure 9 shows a typical 2048 point FFT plot of the

AD7868BQ ADC with an input signal of 10 kHz and a sampling frequency of 83 kHz. The SNR obtained from this graph

is 73 dB. It should be noted that the harmonics are taken into

account when calculating the SNR.

11

10.5

EFFECTIVE NUMBER OF BITS

10

0 41.5

SAMPLE FREQUENCY = 83 kHz

T

= 25°C

A

INPUT FREQUENCY – kHz

Figure 10. Effective Number of Bits vs. Frequency for the

ADC

DAC Testing

A simplified diagram of the method used to test the dynamic

performance specifications of the DAC is outlined in Figure 11.

Data is loaded to the DAC under control of the microcontroller

and associated logic. The output of the DAC is applied to a 9th

order low-pass filter whose cutoff frequency corresponds to the

Nyquist limit. The output of the filter is in turn applied to a

16-bit accurate digitizer. This digitizes the signal and the microcontroller generates an FFT plot from which the dynamic performance of the DAC can be evaluated.

REV. B

–9–

Page 10

AD7868

TA = +25°C

FREQUENCY – kHz

80

70

0

0

205

SNR – dBs

10 15

40

30

20

10

60

50

MICRO-

CONTROLLER

AD7868

DAC

LOW-PASS

FILTER

16-BIT

DIGITIZER

Figure 11. AD7868 DAC Dynamic Performance Test Circuit

The digitizer sampling is synchronized with the DAC update

rate to ease FFT calculations. The digitizer samples the DAC

output after the output has settled to its new value. Therefore, if

the digitizer were to sample the output directly it would effectively be sampling a dc value each time. As a result, the dynamic

performance of the DAC would not be measured correctly. Using the digitizer directly on the DAC output would give better

results than the actual performance of the DAC. Using a filter

between the DAC and the digitizer means that the digitizer

samples a continuously moving signal and the true dynamic performance of the AD7868 DAC output is measured.

Figure 12 shows a typical 2048 point Fast Fourier Transform

plot for the AD7868 DAC with an update rate of 83 kHz and an

output frequency of 1 kHz. The SNR obtained from the graph is

73 dBs.

quencies at an update rate of 83 kHz. The plot of Figure 14 is

without a sample-and-hold on the DAC output while the plot of

Figure 15 is generated with a sample-and-hold on the output.

R2

2k2

C9

330pF

AD711

IN1

LDAC

AD7868*

LDAC

V

OUT

DELAY

1µs

ONE

SHOT

ADG201HS

R1

2k2

S1 D1

Q

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 13. DAC Sample-and-Hold Circuit

80

70

60

50

40

SNR – dBs

30

Figure 12. AD7868 DAC FFT Plot

Some applications will require improved performance versus frequency from the AD7868 DAC. In these applications, a simple

sample-and-hold circuit such as that outlined in Figure 13 will

extend the very good performance of the DAC to 20 kHz. Other

applications will already have an inherent sample-and-hold

function following the AD7868 DAC output. An example of

this type of application is driving a switched-capacitor filter

where the updating of the DAC is synchronized with the

switched-capacitor filter. This inherent sample-and-hold

function also extends the frequency range performance.

Performance versus Frequency

The typical performance plots of Figures 14 and 15 show the

AD7868’s DAC performance over a wide range of input fre-

20

10

0

051

234

FREQUENCY – kHz

TA = +25°C

Figure 14. DAC Performance vs. Frequency (No Sampleand-Hold)

Figure 15. DAC Performance vs. Frequency (Sample-andHold)

–10–

REV. B

Page 11

AD7868

DSP56000

STD

TFS

*ADDITIONAL PINS OMITTED FOR CLARITY

DT

SCK

SRD

RCLK

DR

CONVST

RFS

TIMER

AD7868*

4.7kΩ 2kΩ 4.7kΩ

LDAC

CONTROL

TCLK

5V+

SC0

MICROPROCESSOR INTERFACING

Microprocessor interfacing to the AD7868 is via a serial bus that

uses standard protocol compatible with DSP machines. The

communication interface consists of separate transmit (DAC)

and receive (ADC) sections whose operations can be either synchronous or asynchronous with respect to each other. Each section has a clock signal, a data signal and a frame or strobe pulse.

Synchronous operation means that data is transmitted from the

ADC and to the DAC at the same time. In this mode only one

interface clock is needed and this has to be the ADC clock out,

so RCLK must be connected to TCLK. For asynchronous operation, DAC and ADC data transfers are independent of each

other, the ADC provides the receive clock (RCLK) while the

transmit clock (TCLK) may be provided by the processor or the

ADC or some other external clock source.

Another option to be considered with serial interfacing is the use

of a gated clock. A gated clock means that the device that is

sending the data switches on the clock when data is ready to be

transmitted and three states the clock output when transmission

is complete. Only 16 clock pulses are transmitted with the first

data bit getting latched into the receiving device on the first falling clock edge. Ideally, there is no need for frame pulses, however, the AD7868 DAC frame input (

TFS) has to be driven

high between data transmissions. The easiest method is to use

RFS to drive TFS and use only synchronous interfacing. This

avoids the use of interconnects between the processor and

AD7868 frame signals. Not all processors have a gated clock

facility, Figure 16 shows an example with the DSP56000.

Table I below shows the number of interconnect lines between

the processor and the AD7868 for the different interfacing options. The AD7868 has the facility to use different clocks for

transmitting and receiving data. This option, however, only exists on some processors and normally just one clock (ADC

clock) is used for all communication with the AD7868. For simplicity, all the interface examples in this data sheet use synchronous interfacing and use the ADC clock (RCLK) as an input for

the DAC clock (TCLK). For a better understanding of each of

these interfaces, consult the relevant processor data sheet.

Table I. Interconnect Lines for Different Interfacing Options

DSP56000 internal serial control registers have to be configured

for a 16-bit data word with valid data on the first falling clock

edge. Conversion starts and DAC updating are controlled by an

external timer. Data transfers, which occur during ADC conversions, are between the processor receive and transmit shift registers and the AD7868’s ADC and DAC. At the end of each

16-bit transfer the DSP56000 receives an internal interrupt indicating the transmit register is empty and the receive register is

full.

Figure 16. AD7868—DSP56000 Interface

AD7868—ADSP-2101/ADSP-2102 Interface

An interface which is suitable for the ADSP-2101 or the ADSP2102 is shown in Figure 17. The interface is configured for synchronous, continuous clock operation. The

the DAC gets updated on the sixteenth falling clock after

goes low. Alternatively

LDAC may be driven from a timer as

LDAC is tied low so

TFS

shown in Figure 16. As with the previous interface the processor

receives an interrupt after reading or writing to the AD7868 and

updates its own internal registers in preparation for the next

data transfer.

Configuration Interconnects Signals

Synchronous 4 RCLK, DR, DT and

Asynchronous* 5 or 6 RCLK, DR,

Synchronous 3 RCLK, DR and DT

Gated Clock (TCLK = RCLK, TFS = RFS)

*5 LINES OF INTERCONNECT WHEN TCLK = RCLK

6 LINES OF INTERCONNECT WHEN TCLK = µP SERIAL CLK

AD7868—DSP56000 Interface

Figure 16 shows a typical interface between the AD7868 and

DSP56000. The interface arrangement is synchronous with a

gated clock requiring only three lines of interconnect. The

REV. B

No. of

(TCLK = RCLK,

TFS = RFS)

RFS, DT, TFS

(TCLK = RCLK or

µP serial CLK)

RFS

TIMER

–

5V

ADSP-2101/

ADSP-2102

*ADDITIONAL PINS OMITTED FOR CLARITY

RFS

SCLK

TFS

+

5V

4.7kΩ 2kΩ 4.7kΩ

DR

DT

Figure 17. AD7868—ADSP-2101/ADSP-2102 Interface

–11–

CONVST

CONTROL

AD7868*

RFS

RCLK

DR

TFS

TCLK

DT

LDAC

Page 12

AD7868

AD7868—TMS32020/TMS320C25 Interface

Figure 18 shows an interface which is suitable for the

TMS32020/TMS320C25 processors. This interface is configured for synchronous, continuous clock operation. Note, the

AD7868 will not interface correctly to these processors if the

AD7868 is configured for a noncontinuous clock. Conversion

starts and DAC updating are controlled by an external timer.

CONVST

LDAC

5V

CONTROL

AD7868*

RFS

RCLK

DR

TFS

TCLK

DT

TMS32020

TMS320C25

CLKR

CLKX

*ADDITIONAL PINS OMITTED FOR CLARITY

FSR

FSX

+

5V

4.7kΩ 2kΩ 4.7kΩ

DR

DX

TIMER

–

Figure 18. AD7868—TMS32020/TMS320C25 Interface

APPLICATION HINTS

Good printed circuit board (PCB) layout is as important as the

circuit design itself in achieving high speed A/D performance.

The AD7868’s comparator is required to make bit decisions on

an LSB size of 1.465 mV. To achieve this, the designer has to

be conscious of noise both in the ADC itself and in the preceding analog circuitry. Switching mode power supplies are not recommended as the switching spikes will feed through to the

comparator causing noisy code transitions. Other causes of concern are ground loops and digital feedthrough from microprocessors. These are factors which influence any ADC, and a

proper PCB layout which minimizes these effects is essential for

best performance.

LAYOUT HINTS

Ensure that the layout for the printed circuit board has the digital and analog signal lines separated as much as possible. Take

care not to run any digital track alongside an analog signal track.

Guard (screen) the analog input with AGND.

Establish a single point analog ground (star ground) separate

from the logic system ground as close as possible to the AD7868

AGND pins. Connect all other grounds and the AD7868

DGND to this single analog ground point. Do not connect any

other digital grounds to this analog ground point.

Low impedance analog and digital power supply common returns are essential to low noise operation of the ADC, so make

the foil width for these tracks as wide as possible. The use of

ground planes minimizes impedance paths and also guards the

analog circuitry from digital noise. The circuit layout of Figures

22 and 23 have both analog and digital ground planes which are

kept separated and only joined together at the AD7868 AGND

pins.

NOISE

Keep the input signal leads to VIN and signal return leads from

AGND as short as possible to minimize input noise coupling. In

applications where this is not possible, use a shielded cable between the source and the ADC. Reduce the ground circuit impedance as much as possible since any potential difference in

grounds between the signal source and the ADC appears as an

error voltage in series with the input signal.

INPUT/OUTPUT BOARD

Figure 19 shows an analog I/O board based on the AD7868.

The corresponding printed circuit board (PCB) layout and

silkscreen are shown in Figures 21 to 23.

The analog input to the AD7868 is buffered with an AD711 op

amp. There is a component grid provided near the analog input

on the PCB which may be used for an antialiasing filter for the

ADC or a reconstruction filter for the DAC or any other conditioning circuitry. To facilitate this option, there are two wire

links (labeled LK1 and LK2) required on the analog input and

output tracks.

The board contains a SHA circuit which can be used on the

output of the AD7868 DAC to extend the very good performance of the part over a wider frequency range. The increased

performance from the SHA can be seen in Figures 14 and 15 of

this data sheet. A wire link (labeled LK3) connects the board

output to either the SHA output or directly to the AD7868

DAC output.

There are three

driven from an external source independent of

LDAC link options on the board; LDAC can be

CONVST,

LDAC can be tied to CONVST or LDAC can be tied to GND.

Choosing the latter option of tying

LDAC to GND disables the

SHA operation, and places the SHA permanently in the track

mode.

Microprocessor connections to the board are made by a 9-way

D-type connector. The pinout is shown in Figure 20. The

ADC’s digital outputs are buffered with 74HC4050s. These

buffers provide a higher current output capability for high

capacitance loads or cables. Normally, these buffers are not

required as the AD7868 will be sitting on the same board as the

processor.

POWER SUPPLY CONNECTIONS

The PCB requires two analog power supplies and one 5 V digital supply. Connections to the analog supply are made directly

to the PCB as shown on the silkscreen in Figure 21. The connections are labeled V+ and V– and the range for both of these

supplies is 12 V to 15 V. Connections to the 5 V digital supply

are made through the D-type connector SKT6. The ± 5 V analog supply required by the AD7868 are generated from two voltage regulators on the V+ and V– supplies.

–12–

REV. B

Page 13

AD7868

ANALOG INPUT

±3V RANGE

SKT1

SKT2

ANALOG OUTPUT

±3V RANGE

AD711

R6

15k

C22

68pF

A

COMPONENT

GRID

IC3

V–

C12

0.1µF

C21

330pF

5V

V

CC

R

EXT/CEXT

C

EXT

IC8 1/2

74HC221

GND

LK1

B

C

COMPONENT

GRID

LK2

A

C10

0.1µFC910µF

+

R2

2kΩ

Q

A

B

CLR

10µF

V

C11

10µF

C5

C

+

B

ADG201HS

5V

V+

0.1µF

C7

10µF

V+

IN OUT

IC5

78L05

C6

+

IC2

0.1µF

B

A

C

LK3

GND

AD711

V–

C8

IC4

R1

2kΩ

C

AB

LK6

5V

V

V

DD

V

RO ADC

IN

RI DAC

RO DAC

IC1

AD7868

CONTROL

AGND

AGND

DGND

DGND

V

OUT

LDAC

CONVST

V

V

SS

SS

C4

0.1µFC310µF

DD

RCLK

TFS

TCLK

RFS

CLK

200

5V

4.7kΩ

OUT

C1

10µF

R7

C24

0.1µF

A

B

LK4

C

–5V

A

B

LK5

C

R3

R4

4.7kΩ

2kΩ

V–

IN

IC6

R5

C23

10µF

IC7 1/2

74HC4050

A

–5V

LK7

SKT6

9-WAY D-TYPE

CONNECTOR

5V

DR

RCLK

RFS

LK8

B

C

LK9

TFS

TCLK

DT

DGND

C2

0.1µF

DR

DT

–5V

79L05

GND

REV. B

SKT3

LDAC

SKT4

CONVST

Figure 19. Input/Output Circuit Based on the AD7868

TCLK

RFS

DT

DR

RCLK

24315

6789

5V

NC

TFS

DGND

NC = NO CONNECT

Figure 20. SKT6, D-Type Connector Pinout

SKT5

EXT CLK

WIRE LINK OPTIONS

LK1, Analog Input Link

LK1 connects the analog input to a component grid or to a

buffer amplifier which drives the ADC input.

LK2, Analog Output Link

LK2 connects the analog output to the component grid or to

either the SHA or DAC output (see LK3).

LK3, SHA or DAC Select

The analog output may be taken directly from the DAC or from

a SHA at the output of the DAC.

–13–

Page 14

AD7868

LK4, DAC Reference Selection

The DAC reference may be connected to either the ADC reference output (RO ADC) or to the DAC reference (RO DAC).

LK5, ADC Internal Clock Selection

This link configures the ADC for continuous or noncontinuous

internal clock operation.

LK6, DAC Updating

The DAC, LDAC input may asserted independently of the

ADC

CONVST signal or it may be tied to CONVST or it may

tied to GND.

LK7, ADC Clock Source

This link provides the option for the ADC to use its own internal clock oscillator or an external TTL compatible clock.

LK8 Frame Synchronous Option

LK8 provides the option of tying the ADC RFS output to the

DAC

TFS input.

LK9 Transmit/Receive Clock Option

LK9 provides the option to connect the ADC RCLK to the

DAC TCLK.

COMPONENT LIST

IC1 AD7868

IC2, IC3 2X AD711

IC4, ADG201HS

IC5, MC78L05

IC6, MC79L05

IC7, 74HC4050

IC8, 74HC221

C1, C3, C5, C7

C9, C11, C13, C15 10 µF Capacitor

C17, C19, C23

C2, C4, C6, C8

C10, C12, C14, C16 0.1 µF Capacitor

C18, C20, C24

C21 330 pF Capacitor

C22 68 pF Capacitor

R1, R2, R4 2 kΩ Resistor

R3, R5 4.7 kΩ Resistor

R6 15 kΩ Resistor

R7 200 Ω Resistor

LK1, LK2, LK3,

LK4, LK5, LK6,

LK7, LK8 Shorting Plugs

LK9

SKT1, SKT2, SKT3,

SKT4, SKT5 BNC Sockets

SKT6 9-Contact D-Type Connector

Figure 21. Silkscreen for the Circuit Diagram of Figure 19

–14–

REV. B

Page 15

AD7868

Figure 22. Component Side Layout for the Circuit Diagram of Figure 19

REV. B

Figure 23. Solder Side Layout for the Circuit Diagram of Figure 19

–15–

Page 16

AD7868

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

24-Pin Plastic (N-24)

24-Pin Cerdip (Q-24)

C1410–10–7/90

28-Pin Plastic SOIC (R-28)

–16–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...