Page 1

3-Channel, Low Noise, Low Power, 16-/24-Bit

FEATURES

RMS noise:

27 nV at 4.17 Hz (AD7799)

65 nV at 16.7 Hz (AD7799)

40 nV at 4.17 Hz (AD7798)

85 nV at 16.7 Hz (AD7798)

Current: 380 µA typ

Power-down: 1 µA max

Low noise programmable gain instrumentation-amp

Update rate: 4.17 Hz to 500 Hz

3 differential inputs

Internal clock oscillator

Simultaneous 50 Hz/60 Hz rejection

Reference Detect

Low-side power switch

Programmable digital outputs

Burnout currents

Power supply: 2.7 V to 5.25 V

–40°C to +105°C temperature range

Independent interface power supply

16-lead TSSOP package

INTERFACE

3-wire serial

SPI®-, QSPI™-, MICROWIRE™-, and DSP-compatible

Schmitt trigger on SCLK

APPLICATIONS

Weigh scales

Pressure measurement

Strain gauge transducers

Gas analysis

Industrial process control

Instrumentation

Portable instrumentation

Blood analysis

Smart transmitters

Liquid/gas chromotography

6-digit DVM

Sigma-Delta ADC with On-Chip In-Amp

AD7798/AD7799

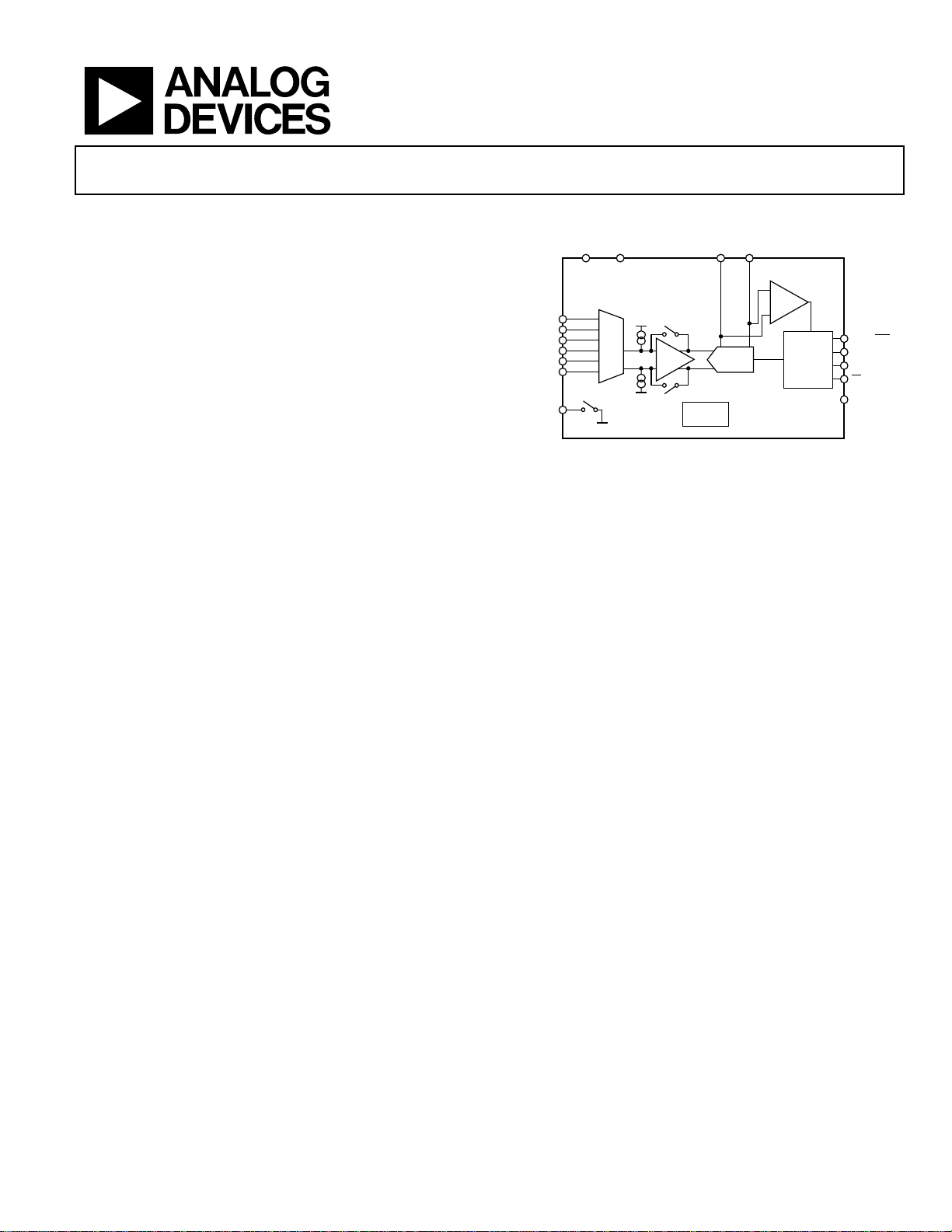

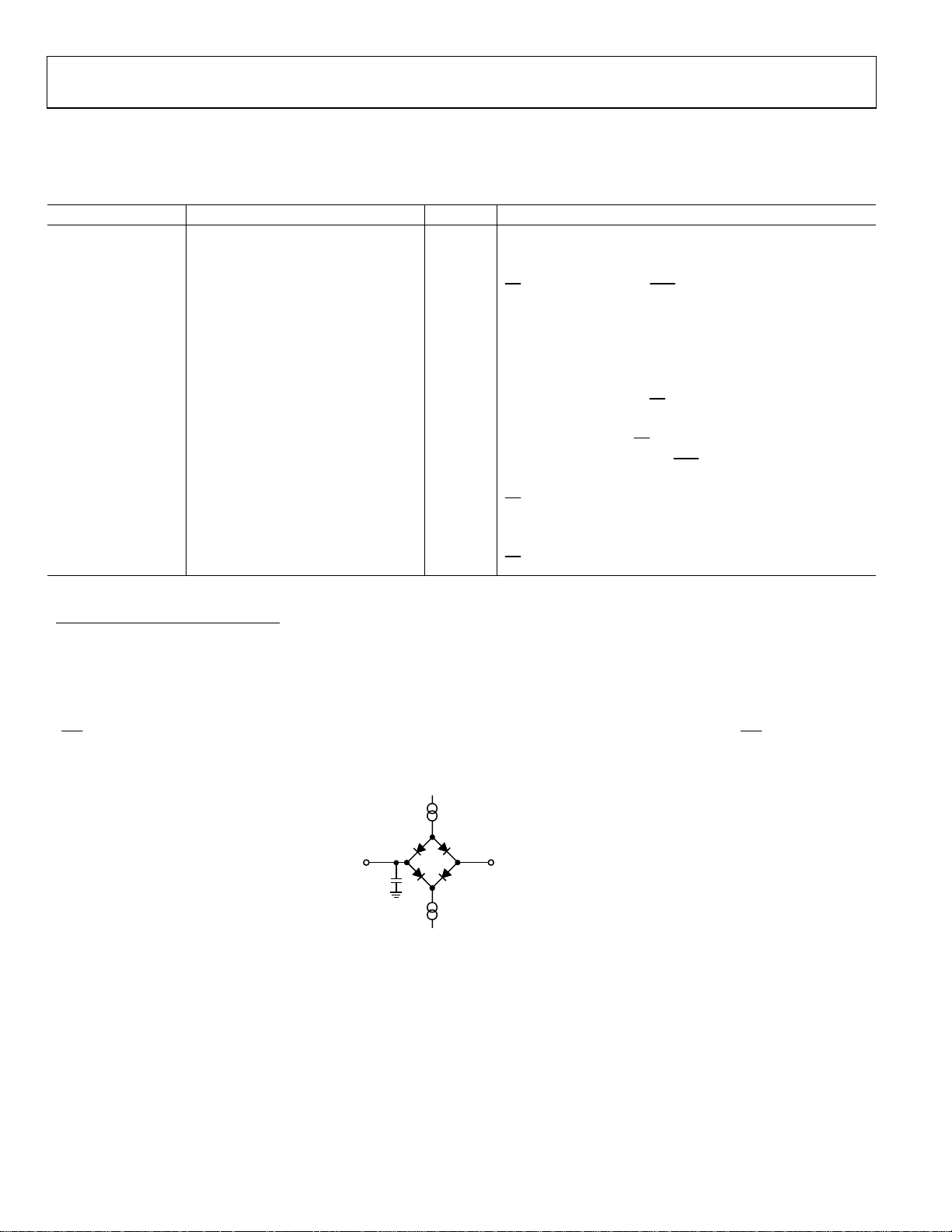

FUNCTIONAL BLOCK DIAGRAM

GND AV

DD

AD7798/AD7799

AIN1(+)

AIN1(–)

AIN2(+)

AIN2(–)

AIN3(+)/P1

AIN3(–)/P2

PSW

GND

MUX

AV

GND

DD

IN-AMP

INTERNAL

CLOCK

Figure 1.

GENERAL DESCRIPTION

The AD7798/AD7799 are low power, low noise, complete

analog front ends for high precision measurement applications.

The AD7798/AD7799 contains a low noise, 16-/24-bit ∑-∆

ADC with three differential analog inputs. The on-chip, low

noise instrumentation amplifier means that signals of small

amplitude can be interfaced directly to the ADC. With a gain

setting of 64, the rms noise is 27 nV for the AD7799 and 40 nV

for the AD7798 when the update rate equals 4.17 Hz.

On-chip features include a low-side power switch, reference

detect, programmable digital output pins, burnout currents,

and an internal clock oscillator. The output data rate from the

part is software-programmable and can be varied from 4.17 Hz

to 500 Hz.

The part operates with a power supply from 2.7 V to 5.25 V.

The AD7798 consumes a current of 300 µA typical, whereas the

AD7799 consumes 380 µA typical. Both devices are housed in a

16-lead TSSOP package.

REFIN(+)

Σ-∆

ADC

REFIN(–)

AD7798: 16-BIT

AD7799: 24-BIT

REFERENCE

DETECT

SERIAL

INTERFACE

AND

CONTROL

LOGIC

DOUT/RDY

DIN

SCLK

CS

DV

DD

04856-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2005 Analog Devices, Inc. All rights reserved.

Page 2

AD7798/AD7799

TABLE OF CONTENTS

Specifications..................................................................................... 3

Timing Characteristics..................................................................... 6

Absolute Maximum Ratings............................................................ 8

ESD Caution.................................................................................. 8

Pin Configuration and Function Descriptions............................. 9

Output Noise and Resolution Specifications .............................. 10

AD7798........................................................................................ 10

AD7799........................................................................................ 11

Typical Performance Characteristics ...........................................12

On-Chip Registers.......................................................................... 13

Communication Register ..........................................................13

Status Register............................................................................. 14

Mode Register ............................................................................. 14

Configuration Register ..............................................................16

Data Register............................................................................... 17

ADC Circuit Information.............................................................. 19

Overview ..................................................................................... 19

Digital Interface.......................................................................... 20

Circuit Description......................................................................... 23

Analog Input Channel............................................................... 23

Instrumentation Amplifier........................................................ 23

Bipolar/Unipolar Configuration .............................................. 23

Data Output Coding .................................................................. 24

Burnout Currents....................................................................... 24

Reference ..................................................................................... 24

Reference Detect......................................................................... 24

Reset ............................................................................................. 25

AV

Monitor ............................................................................. 25

DD

Calibration................................................................................... 25

Grounding and Layout.............................................................. 26

ID Register................................................................................... 17

IO Register................................................................................... 17

Offset Register............................................................................. 18

Full-Scale Register ...................................................................... 18

REVISION HISTORY

1/05—Revision 0: Initial Version

Applications..................................................................................... 27

Weigh Scales................................................................................ 27

Outline Dimensions....................................................................... 28

Ordering Guide .......................................................................... 28

Rev. 0 | Page 2 of 28

Page 3

AD7798/AD7799

SPECIFICATIONS

AVDD = 2.7 V to 5.25 V; DVDD = 2.7 V to 5.25 V; GND = 0 V; REFIN(+) = AVDD; REFIN(−) = 0 V. All specifications T

otherwise noted.

Table 1.

Parameter AD7798B/AD7799B1 Unit Test Conditions/Comments

ADC CHANNEL

Output Update Rate 4.17 − 500 Hz nom

No Missing Codes2 24 Bits min AD7799: f

< 250 Hz

ADC

16 Bits min AD7798

Resolution See Table 5 to Table 8

Output Noise and Update Rates See Table 5 to Table 8

Integral Nonlinearity ±15 ppm of FSR max

Offset Error3 ±1 µV typ

Offset Error Drift vs. Temperature4 ±10 nV/°C typ

Full-Scale Error

3, 5

±10 µV typ

Gain Drift vs. Temperature4 ±1 ppm/°C typ

Power Supply Rejection 100 dB min AIN = 1 V/gain, gain ≥ 4

ANALOG INPUTS

Differential Input Voltage Ranges ±V

/gain V nom V

REF

= REFIN(+) – REFIN(–), gain = 1 to 128

REF

Absolute AIN Voltage Limits2

MIN

to T

MAX

, unless

Unbuffered Mode GND − 30 mV V min Gain = 1 or 2

AVDD + 30 mV V max

Buffered Mode GND + 100 mV V min Gain = 1 or 2

AVDD – 100 mV V max

In-Amp Active GND + 300 mV V min Gain = 4 to 128

AVDD − 1.1 V max

Common-Mode Voltage, VCM 0.5 V min VCM = (AIN(+) + AIN(−))/2, gain = 4 to 128

Analog Input Current

Buffered Mode or In-Amp Active

Average Input Current2 ±1 nA max Gain = 1 or 2, update rate < 100 Hz

±250 pA max Gain = 4 to 128, update rate < 100 Hz

±1 nA max AIN3(+)/AIN3(−), update rate < 100 Hz

Average Input Current Drift ±2 pA/°C typ

Unbuffered Mode Gain = 1 or 2

Average Input Current ±400 nA/V typ Input current varies with input voltage

Average Input Current Drift ±50 pA/V/°C typ

Normal-Mode Rejection2

@ 50 Hz, 60 Hz 65 dB min 80 dB typ, 50 ± 1 Hz, 60 ± 1 Hz (FS[3:0] = 1010)6

@ 50 Hz 80 dB min 90 dB typ, 50 ± 1 Hz (FS[3:0] = 1001)6

@ 60 Hz 90 dB min 100 dB typ, 60 ± 1 Hz (FS[3:0] = 1000)6

Common-Mode Rejection

@ DC 100 dB min AIN = 1 V/gain, gain ≥4

@ 50 Hz, 60 Hz2 100 dB min 50 ± 1 Hz, 60 ± 1 Hz (FS[3:0] = 1010)6

@ 50 Hz, 60 Hz2 100 dB min

50 ± 1 Hz (FS[3:0] = 1001

(FS[3:0] = 1000

6

)

6

), 60 ± 1 Hz

Rev. 0 | Page 3 of 28

Page 4

AD7798/AD7799

Parameter AD7798B/AD7799B1 Unit Test Conditions/Comments

REFERENCE

External REFIN Voltage 2.5 V nom REFIN = REFIN(+) − REFIN(−)

Reference Voltage Range2 0.1 V min

AVDD V max

When V

limited to (0.9 x V

Absolute REFIN Voltage Limits2 GND − 30 mV V min

AV

+ 30 mV V max

DD

Average Reference Input Current 400 nA/V typ

Average Reference Input Current Drift ±0.03 nA/V/°C typ

Normal-Mode Rejection

Same as for analog

inputs

Common-Mode Rejection 100 dB typ

Reference Detect Levels 0.3 V min

0.65 V max NOXREF bit active if V

LOW-SIDE POWER SWITCH

RON 7 Ω max AVDD = 5 V

9 Ω max AVDD = 3 V

Allowable Current2 30 mA max Continuous current

DIGITAL OUTPUTS (P1 and P2)

Output High Voltage, V

Output Low Voltage, V

Output High Voltage, V

Output Low Voltage, V

2

AVDD − 0.6 V min AVDD = 3 V, I

OH

2

0.4 V max AVDD = 3 V, I

OL

2

4 V min AVDD = 5 V, I

OH

2

0.4 V max AVDD = 5 V, I

OL

INTERNAL CLOCK

Frequency2 64 ± 3% kHz min/max

LOGIC INPUTS

CS2

Input Low Voltage, V

Input High Voltage, V

SCLK and DIN

(Schmitt-Triggered Input)

0.8 V max DVDD = 5 V

INL

INH

2

0.4

2.0

V max

V min

DV

DV

VT(+) 1.4/2 V min/max DVDD = 5 V

VT(–) 0.8/1.7 V min/max DVDD = 5 V

VT(+) – VT(–) 0.1/0.17 V min/max DVDD = 5 V

VT(+) 0.9/2 V min/max DVDD = 3 V

VT(–) 0.4/1.35 V min/max DVDD = 3 V

VT(+) − VT(–) 0.06/0.13 V min/max DVDD = 3 V

Input Currents ±10 µA max VIN = DVDD or GND

Input Capacitance 10 pF typ All digital inputs

LOGIC OUTPUTS

Output High Voltage, V

Output Low Voltage, V

Output High Voltage, V

Output Low Voltage, V

2

DVDD − 0.6 V min DVDD = 3 V, I

OH

2

0.4 V max DVDD = 3 V, I

OL

2

4 V min DVDD = 5 V, I

OH

2

0.4 V max DVDD = 5 V, I

OL

Floating-State Leakage Current ±10 µA max

Floating-State Output Capacitance 10 pF typ

Data Output Coding Offset binary

= AVDD, the differential input must be

REF

= 3 V

DD

= 3 V or 5 V

DD

/gain) if the in-amp is active.

REF

< 0.3 V

REF

= 100 µA

SOURCE

= 100 µA

SINK

= 200 µA

SOURCE

= 800 µA

SINK

= 100 µA

SOURCE

= 100 µA

SINK

= 200 µA

SOURCE

= 1.6 mA

SINK

Rev. 0 | Page 4 of 28

Page 5

AD7798/AD7799

Parameter AD7798B/AD7799B1 Unit Test Conditions/Comments

SYSTEM CALIBRATION2

Full-Scale Calibration Limit 1.05 × FS V max

FS = Full scale analog input. When V

differential input must be limited to (0.9 x V

if the in-amp is active.

Zero-Scale Calibration Limit −1.05 × FS V min

Input Span 0.8 × FS V min

2.1 × FS V max

POWER REQUIREMENTS7

Power Supply Voltage

AVDD – GND 2.7/5.25 V min/max

DVDD – GND 2.7/5.25 V min/max

Power Supply Currents

IDD Current 140 µA max

180 µA max

400 µA max

500 µA max

Unbuffered mode, 110 µA typ @ AV

125 µA typ @ AV

= 5 V

DD

Buffered mode, Gain = 1 or 2, 130 µA typ @ AV

165 µA typ @ AV

= 5 V

DD

AD7798: Gain = 4 to 128, 300 µA typ @ AV

350 µA typ @ AV

= 5 V

DD

AD7799: Gain = 4 to 128, 380 µA typ @ AV

440 µA typ @ AV

= 5 V

DD

IDD (Power-Down Mode) 1 µA max

1

Temperature range is –40°C to +105°C.

2

Specification is not production tested, but is supported by characterization data at initial product release.

3

Following a calibration, this error is in the order of the noise for the programmed gain and update rate selected.

4

Recalibration at any temperature removes these errors.

5

Full-scale error applies to both positive and negative full scale and applies at the factory calibration conditions (AVDD = 4 V, gain = 1, TA = 25°C).

6

FS[3:0] are the four bits used in the mode register to select the output word rate.

7

Digital inputs equal to DVDD or GND.

= AVDD, the

REF

= 3 V,

DD

DD

DD

/gain)

REF

= 3 V,

DD

= 3 V,

= 3 V,

Rev. 0 | Page 5 of 28

Page 6

AD7798/AD7799

TIMING CHARACTERISTICS

AVDD = 2.7 V to 5.25 V, DVDD = 2.7 V to 5.25 V, GND = 0 V, Input Logic 0 = 0 V, Input Logic 1 = DVDD, unless otherwise noted.

Table 2.

Parameter

t3 100 ns min SCLK high pulse width

t4 100 ns min SCLK low pulse width

Read Operation

t1 0 ns min

60 ns max DVDD = 4.75 V to 5.25 V

80 ns max DVDD = 2.7 V to 3.6 V

t

60 ns max DVDD = 4.75 V to 5.25 V

80 ns max DVDD = 2.7 V to 3.6 V

t

80 ns max

t6 0 ns min

t7 10 ns min

Write Operation

t8 0 ns min

t9 30 ns min Data valid to SCLK edge setup time

t10 25 ns min Data valid to SCLK edge hold time

t11 0 ns min

1, 2

Limit at T

3

0 ns min SCLK active edge to data valid delay4

2

5, 6

10 ns min

5

MIN

, T

(B Version) Unit Conditions/Comments

MAX

falling edge to DOUT/RDY active time

CS

Bus relinquish time after CS

SCLK inactive edge to CS

inactive edge

inactive edge

SCLK inactive edge to DOUT/RDY

falling edge to SCLK active edge setup time4

CS

rising edge to SCLK edge hold time

CS

high

1

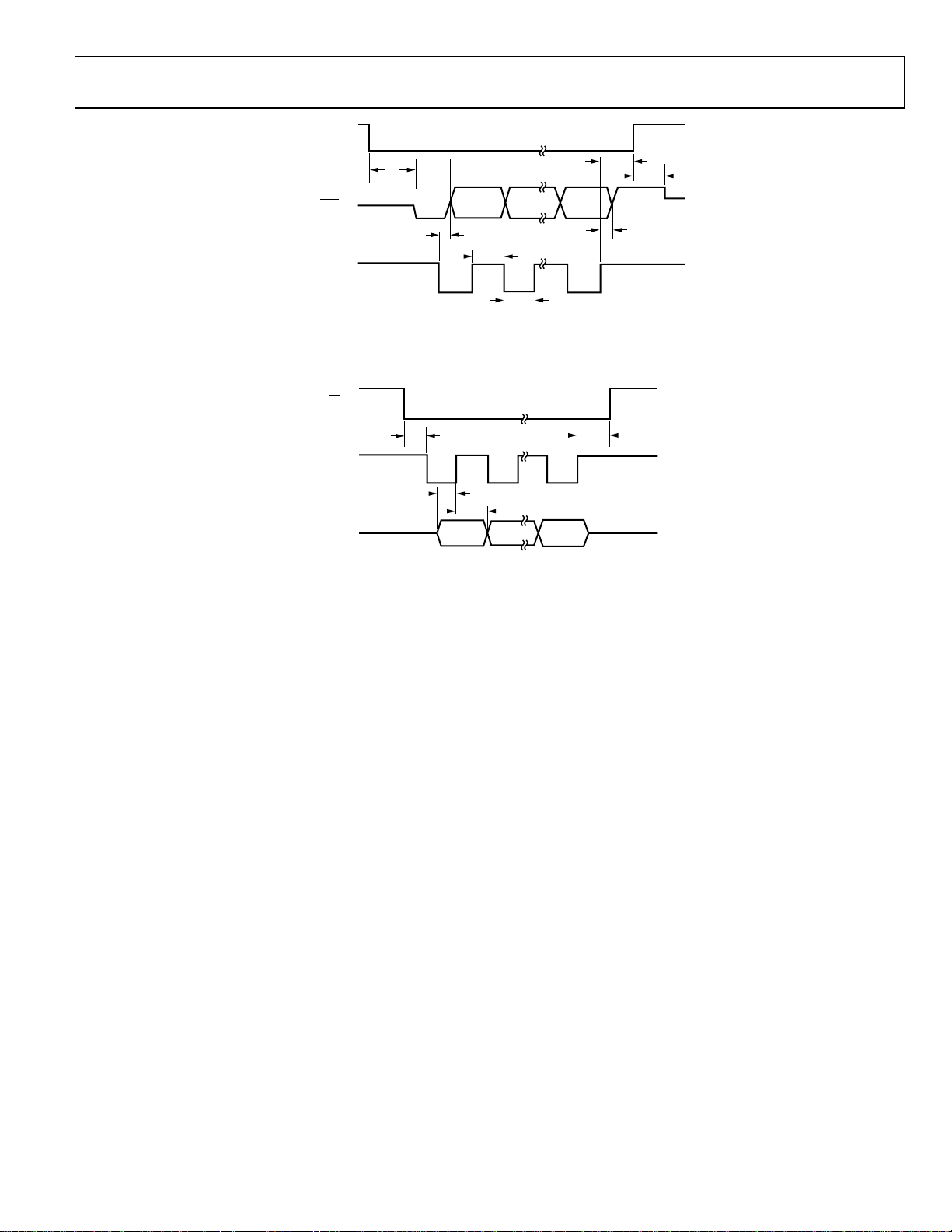

Sample tested during initial release to ensure compliance. All input signals are specified with tR = tF = 5 ns (10% to 90% of DVDD) and timed from a voltage level of 1.6 V.

2

See Figure 3 and Figure 4.

3

These times are measured with the load circuit of Figure 2 and defined as the time required for the output to cross the VOL or VOH limits.

4

SCLK active edge is the falling edge of SCLK.

5

These times are derived from the measured time taken by the data output to change 0.5 V when loaded with the circuit of Figure 2. The measured time is then

extrapolated back to remove the effects of charging or discharging the 50 pF capacitor. This means that the times quoted in the timing characteristics are the true bus

relinquish times of the part and, as such, are independent of external bus loading capacitances.

6

RDY

returns high after a read of the ADC. In single-conversion mode and continuous-conversion mode, data can be reread, if required, while

should be taken to ensure that subsequent reads do not occur close to the next output update. In continuous read mode, the digital word can be read only once.

RDY

is high, but care

I

(1.6mA WITH DVDD = 5V,

SINK

TO

OUTPUT

PIN

50pF

100µA WITH DV

I

SOURCE

100µA WITH DV

= 3V)

DD

1.6V

(200µA WITH DVDD = 5V,

= 3V)

DD

04856-002

Figure 2. Load Circuit for Timing Characterization

Rev. 0 | Page 6 of 28

Page 7

AD7798/AD7799

S

CS (I)

t

t

1

DOUT/RDY (O)

SCLK (I)

t

2

I = INPUT, O = OUTPUT

MSB LSB

t

3

t

4

Figure 3. Read Cycle Timing Diagram

CS (I)

6

t

5

t

7

04856-003

t

11

04856-004

CLK (I)

DIN (I)

I = INPUT, O = OUTPUT

t

8

t

9

t

10

MSB LSB

Figure 4. Write Cycle Timing Diagram

Rev. 0 | Page 7 of 28

Page 8

AD7798/AD7799

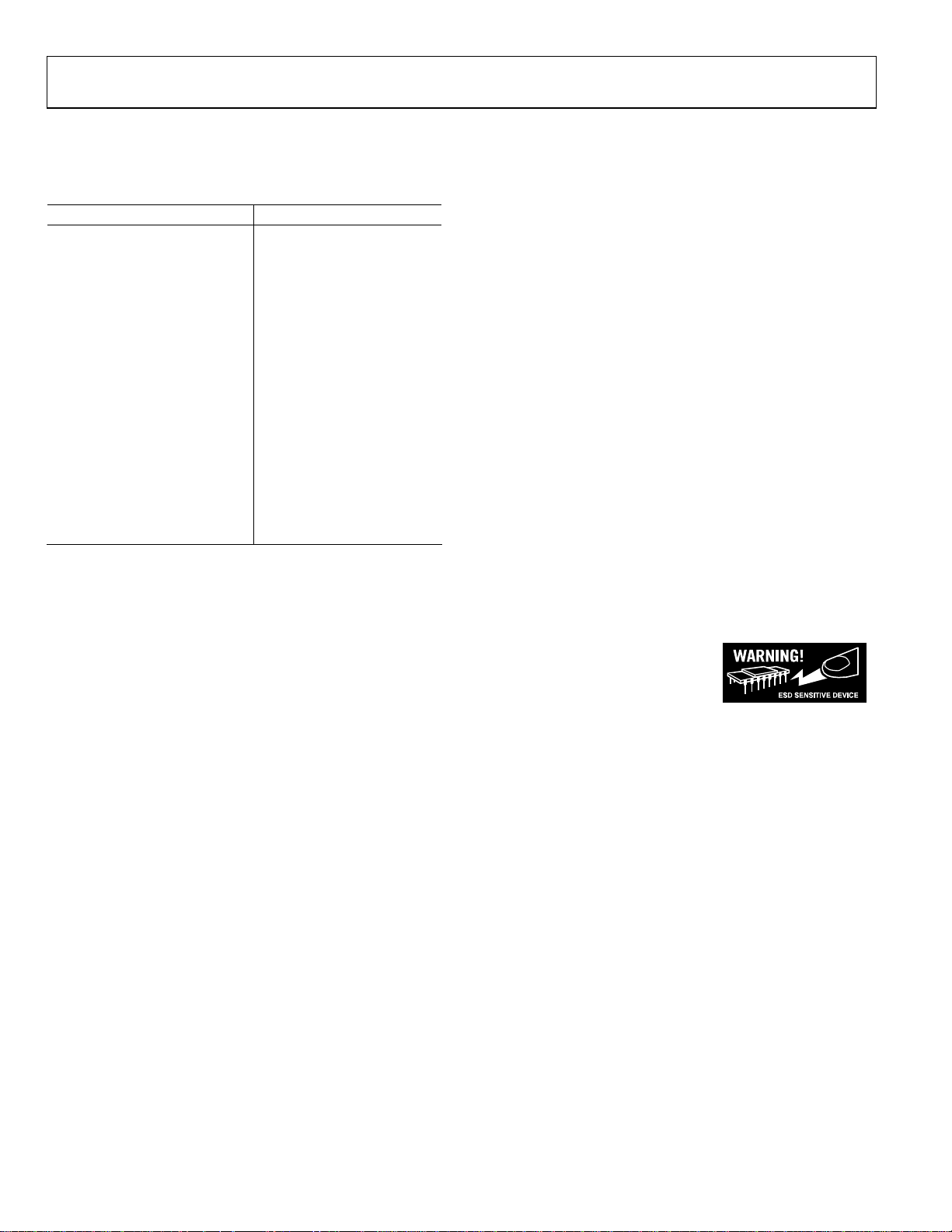

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

AVDD to GND −0.3 V to +7 V

DVDD to GND −0.3 V to +7 V

Analog Input Voltage to GND −0.3 V to AVDD + 0.3 V

Reference Input Voltage to GND −0.3 V to AVDD + 0.3 V

Digital Input Voltage to GND −0.3 V to DVDD + 0.3 V

Digital Output Voltage to GND −0.3 V to DVDD + 0.3 V

AIN/Digital Input Current 10 mA

Operating Temperature Range −40°C to +85°C

Storage Temperature Range −65°C to +150°C

Maximum Junction

Temperature

TSSOP

θJA Thermal Impedance 128°C/W

θJC Thermal Impedance 14°C/W

Lead Temperature, Soldering

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 8 of 28

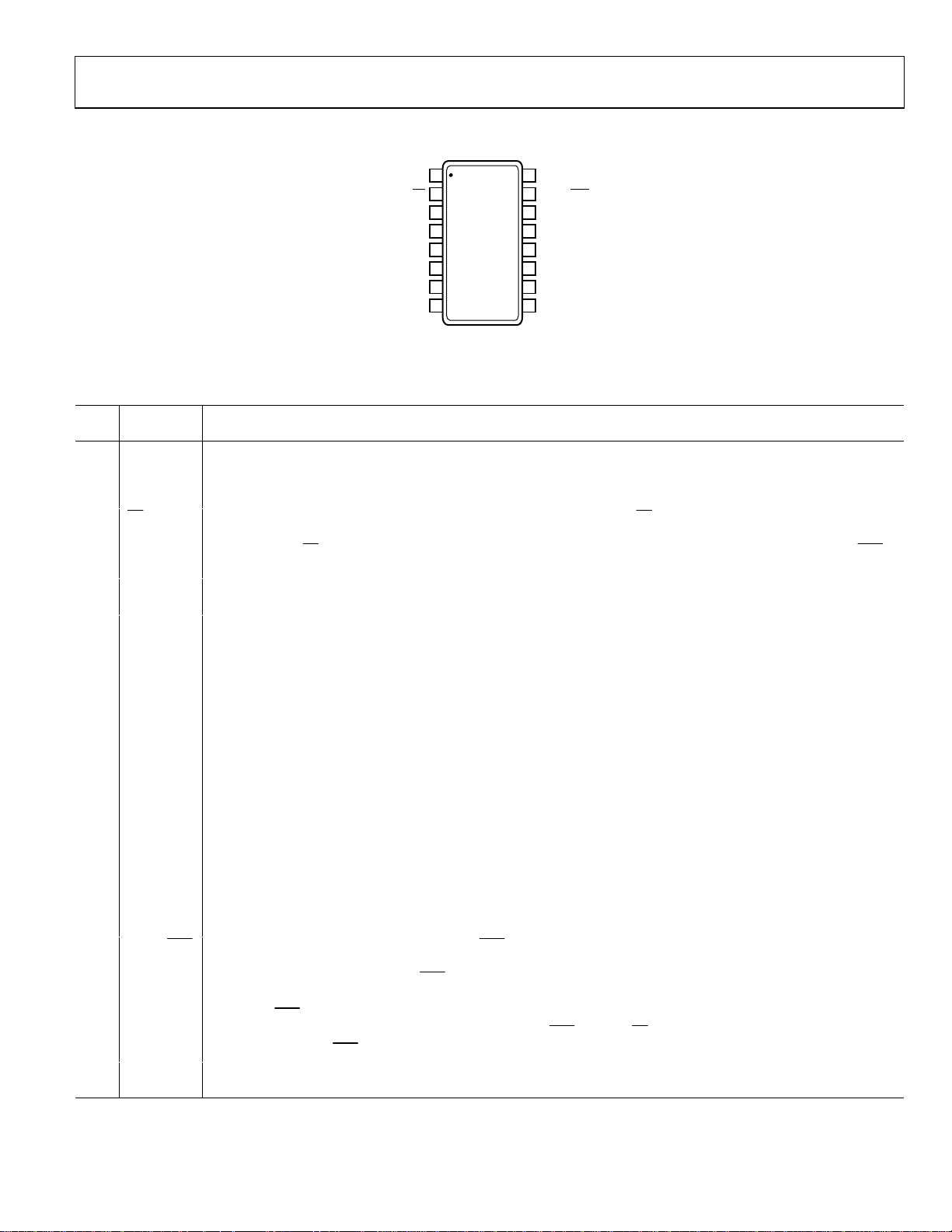

Page 9

AD7798/AD7799

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

SCLK

2

CS

AIN3(+)/P1

AIN3(–)/P2

3

AD7798/

4

AD7799

TOP VIEW

5

AIN1(+)

AIN1(–)

AIN2(+)

AIN2(–) REFIN(+)

(Not to Scale)

6

7

8

16

DIN

15

DOUT/RDY

14

DV

13

AV

12

GND

11

PSW

10

REFIN(–)

9

DD

DD

04856-005

Figure 5. Pin Configuration

Table 4. Pin Function Descriptions

Pin

No. Mnemonic Description

1 SCLK

Serial Clock Input for Data Transfers to and from the ADC. The SCLK has a Schmitt-triggered input, making the

interface suitable for opto-isolated applications. The serial clock can be continuous, with all data transmitted in a

continuous train of pulses. Alternatively, it can be noncontinuous, with the information transmitted to or from the

ADC in smaller batches of data.

2

Chip Select Input. This is an active low logic input used to select the ADC. CS can be used to select the ADC in systems

CS

with more than one device on the serial bus, or it can be used as a frame synchronization signal when communicating

with the device. CS

can be hardwired low, allowing the ADC to operate in 3-wire mode, with SCLK, DIN, and DOUT/RDY

used to interface with the device.

3 AIN3(+)/P1

4 AIN3(−)/P2

Analog Input/Digital Output Pin. AIN3(+) is the positive terminal of the differential analog input pair AIN3(+)/AIN3(−).

Alternatively, this pin can function as a general-purpose output bit referenced between AV

and GND

DD

Analog Input/Digital Output Pin. AIN3(−) is the negative terminal of the differential analog input pair AIN3(+)/AIN3(−).

Alternatively, this pin can function as a general-purpose output bit referenced between AV

and GND

DD

5 AIN1(+) Analog Input. AIN1(+) is the positive terminal of the differential analog input pair AIN1(+)/AIN1(−).

6 AIN1(−) Analog Input. AIN1(−) is the negative terminal of the differential analog input pair AIN1(+)/AIN1(−).

7 AIN2(+) Analog Input. AIN2(+) is the positive terminal of the differential analog input pair AIN2(+)/AIN2(−).

8 AIN2(−) Analog Input. AIN2(−) is the negative terminal of the differential analog input pair AIN2(+)/AIN2(−).

9 REFIN(+)

10 REFIN(−)

Positive Reference Input. An external reference can be applied between REFIN(+) and REFIN(−). REFIN(+) can lie

anywhere between AV

can function with a reference from 0.1 V to AV

and GND + 0.1 V. The nominal reference voltage (REFIN(+) – REFIN(−)) is 2.5 V, but the part

DD

.

DD

Negative Reference Input. REFIN(−) is the negative reference input for REFIN. This reference input can lie anywhere

between GND and AV

− 0.1 V.

DD

11 PSW Low-Side Power Switch to GND.

12 GND Ground Reference Point.

13 AVDD Supply Voltage. 2.7 V to 5.25 V.

14 DVDD

15

DOUT/RDY

Digital Interface Supply Voltage. The logic levels for the serial interface pins are related to this supply, which is

between 2.7 V and 5.25 V. The DV

DV

at 3 V, or vice versa.

DD

voltage is independent of the voltage on AVDD; therefore, AVDD can equal 5 V with

DD

Serial Data Output/Data Ready Output. DOUT/RDY serves a dual purpose. It functions as a serial data output pin to

access the output shift register of the ADC. The output shift register can contain data from any of the on-chip data or

control registers. In addition, DOUT/RDY

operates as a data ready pin, going low to indicate the completion of a

conversion. If the data is not read after the conversion, the pin goes high before the next update occurs.

16 DIN

The DOUT/RDY

external serial clock, the data can be read using the DOUT/RDY

placed on the DOUT/RDY

Serial Data Input to the Input Shift Register on the ADC. Data in this shift register is transferred to the control registers

falling edge can be used as an interrupt to a processor, indicating that valid data is available. With an

pin. With CS low, the data/control word information is

pin on the SCLK falling edge and is valid upon the SCLK rising edge.

within the ADC, with the register selection bits of the communication register identifying the appropriate register.

Rev. 0 | Page 9 of 28

Page 10

AD7798/AD7799

OUTPUT NOISE AND RESOLUTION SPECIFICATIONS

AD7798

Table 5 shows the AD7798’s output rms noise for some update

rates and gain settings. The numbers given are for the bipolar

input range with a 2.5 V reference. These numbers are typical

and are generated with a differential input voltage of 0 V. Table 6

shows the effective resolution, and the output peak-to-peak

resolution is shown in parentheses. It is important to note that

Table 5. Output RMS Noise (µV) vs. Gain and Output Update Rate for the AD7798 Using a 2.5 V Reference

Update Rate Gain of 1 Gain of 2 Gain of 4 Gain of 8 Gain of 16 Gain of 32 Gain of 64 Gain of 128

4.17 Hz 0.64 0.6 0.29 0.22 0.1 0.065 0.039 0.041

8.33 Hz 1.04 0.96 0.38 0.26 0.13 0.078 0.057 0.055

16.7 Hz 1.55 1.45 0.54 0.36 0.18 0.11 0.087 0.086

33.3 Hz 2.3 2.13 0.74 0.5 0.23 0.17 0.124 0.118

62.5 Hz 2.95 2.85 0.92 0.58 0.29 0.2 0.153 0.144

125 Hz 4.89 4.74 1.49 1 0.48 0.32 0.265 0.283

250 Hz 11.76 9.5 4.02 1.96 0.88 0.45 0.379 0.397

500 Hz 11.33 9.44 3.07 1.79 0.99 0.63 0.568 0.593

Table 6. Typical Resolution (Bits) vs. Gain and Output Update Rate for the AD7798 Using a 2.5 V Reference

Update Rate Gain of 1 Gain of 2 Gain of 4 Gain of 8 Gain of 16 Gain of 32 Gain of 64 Gain of 128

4.17 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16)

8.33 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16)

16.7 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16)

33.3 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16)

62.5 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (15.5)

125 Hz 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (16) 16 (15.5) 16 (14.5)

250 Hz 16 (16) 16 (15.5) 16 (15.5) 16 (15.5) 16 (16) 16 (16) 16 (15) 16 (14)

500 Hz 16 (16) 16 (15.5) 16 (16) 16 (16) 16 (15.5) 16 (15.5) 16 (14.5) 15.5 (13.5)

the effective resolution is calculated using the rms noise, whereas

the peak-to-peak resolution is based on the peak-to-peak noise.

The peak-to-peak resolution represents the resolution for which

there is no code flicker. These numbers are typical and are

rounded to the nearest LSB.

Rev. 0 | Page 10 of 28

Page 11

AD7798/AD7799

AD7799

Table 7 shows the AD7799 output rms noise for some update

rates and gain settings. The numbers given are for the bipolar

input range with a 2.5 V reference. These numbers are typical

and are generated with a differential input voltage of 0 V. Table 8

shows the effective resolution, and the output peak-to-peak

resolution is given in parentheses. Note that the effective

Table 7. Output RMS Noise (µV) vs. Gain and Output Update Rate for the AD7799 Using a 2.5 V Reference

Update Rate Gain of 1 Gain of 2 Gain of 4 Gain of 8 Gain of 16 Gain of 32 Gain of 64 Gain of 128

4.17 Hz 0.64 0.6 0.185 0.097 0.075 0.035 0.027 0.027

8.33 Hz 1.04 0.96 0.269 0.165 0.108 0.048 0.037 0.040

16.7 Hz 1.55 1.45 0.433 0.258 0.176 0.085 0.065 0.065

33.3 Hz 2.3 2.13 0.647 0.364 0.24 0.118 0.097 0.094

62.5 Hz 2.95 2.85 0.952 0.586 0.361 0.178 0.133 0.134

125 Hz 4.89 4.74 1.356 0.785 0.521 0.265 0.192 0.192

250 Hz 11.76 9.5 3.797 2.054 1.027 0.476 0.326 0.308

500 Hz 11.33 9.44 3.132 1.773 1.107 0.5 0.413 0.374

Table 8. Typical Resolution (Bits) vs. Gain and Output Update Rate for the AD7799 Using a 2.5 V Reference

Update Rate Gain of 1 Gain of 2 Gain of 4 Gain of 8 Gain of 16 Gain of 32 Gain of 64 Gain of 128

4.17 Hz 23 (20.5) 22 (19.5) 22.5 (20) 22.5 (20) 22 (19.5) 22 (19.5) 21.5 (19) 20.5 (18)

8.33 Hz 22 (19.5) 21.5 (19) 22 (19.5) 22 (19.5) 21.5 (19) 21.5 (19) 21 (18.5) 20 (17.5)

16.7 Hz 21.5 (19) 20.5 (18) 21.5 (19) 21 (18.5) 21 (18.5) 21 (18.5) 20 (17.5) 19 (16.5)

33.3 Hz 21 (18.5) 20 (17.5) 21 (18.5) 20.5 (18) 20.5 (18) 20.5 (18) 19.5 (17) 18.5 (16)

62.5 Hz 20.5 (18) 19.5 (17) 20.5 (18) 20 (17.5) 19.5 (17) 19.5 (17) 19 (16.5) 18 (15.5)

125 Hz 20 (17.5) 19 (16.5) 20 (17.5) 19.5 (17) 19 (16.5) 19 (16.5) 18.5 (16) 17.5 (15)

250 Hz 18.5 (16) 18 (15.5) 18.5 (16) 18 (15.5) 18 (15.5) 18.5 (16) 18 (15.5) 17 (14.5)

500 Hz 18.5 (16) 18 (15.5) 18.5 (16) 18.5 (16) 18 (15.5) 18.5 (16) 17.5 (15) 16.5 (14)

resolution is calculated using the rms noise, whereas the

peak-to-peak resolution is based on peak-to-peak noise. The

peak-to-peak resolution represents the resolution for which

there is no code flicker. These numbers are typical and are

rounded to the nearest LSB.

Rev. 0 | Page 11 of 28

Page 12

AD7798/AD7799

TYPICAL PERFORMANCE CHARACTERISTICS

8388640

8388630

8388620

8388610

CODE

8388600

OCCURRENCE

30

25

20

15

10

5

8388590

8388580

0 200 400 600 800 999

Figure 6. AD7799 Noise (V

50

40

30

20

OCCURRENCE

10

0

8388581

8388590

SAMPLES

= AVDD/2, Gain = 64, Update Rate = 4.17 Hz)

REF

8388600

CODE

8388610

Figure 7. AD7799 Noise Distribution Histogram (V

Update Rate = 4.17 Hz)

8388680

8388620

= AVDD/2, Gain = 64,

REF

8388630

04856-006

04856-007

8388635

0

8388549

8388560

8388580

Figure 9. AD7799 Noise Distribution Histogram (V

8388600

CODE

8388620

8388640

= AVDD/2, Gain = 64,

REF

04856-009

8388669

Update Rate = 16.7 Hz)

3.0

VDD = 5V

UPDATE RATE = 16.6Hz

= 25°C

T

A

2.5

2.0

1.5

RMS NOISE (µV)

1.0

0.5

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

REFERENCE VOLTAGE (V)

04856-010

Figure 10. RMS Noise vs. Reference Voltage (Gain = 1)

8388660

8388640

8388620

CODE

8388600

8388580

8388560

8388540

0 200 400 600 800 999

Figure 8. AD7799 Noise (V

SAMPLES

= AVDD/2, Gain = 64, Update Rate = 16.7 Hz)

REF

04856-008

Rev. 0 | Page 12 of 28

Page 13

AD7798/AD7799

ON-CHIP REGISTERS

The ADC is controlled and configured via a number of on-chip registers, which are described on the following pages. In the following

descriptions, set implies a Logic 1 state and cleared implies a Logic 0 state, unless otherwise stated.

COMMUNICATION REGISTER

RS2, RS1, RS0 = 0, 0, 0

The communication register is an 8-bit, write-only register. All communication to the part must start with a write operation to the

communication register. The data written to the communication register determines whether the next operation is a read or write

operation, and to which register this operation takes place. After the read or write operation is complete, the interface returns to its

default state, where it expects a write operation to the communication register. In situations where the interface sequence is lost, a write

operation of at least 32 serial clock cycles with DIN high returns the ADC to this default state by resetting the entire part. Tabl e 9 o u t li n es

the bit designations for the communication register. CR0 through CR7 indicate the bit location, with CR denoting that the bits are in the

communication register. CR7 denotes the first bit of the data stream. The number in parentheses indicates the power-on/reset default

status of that bit.

CR7 CR6 CR5 CR4 CR3 CR2 CR1 CR0

WEN(0) R/W(0)

Table 9. Communication Register Bit Designations

Bit Location Bit Name Description

CR7

CR6

CR5 to CR3 RS2 to RS0

CR2 CREAD

CR1 to CR0 0 These bits must be programmed to Logic 0 for correct operation.

Write Enable Bit. A 0 must be written to this bit so that the write to the communication register occurs. If

WEN

Read/Write Bit. A 0 in this bit location indicates that the next operation is a write to a specified register. A

R/W

Table 10. Register Selection

RS2 RS1 RS0 Register Register Size

0 0 0 Communication register during a write operation 8 bits

0 0 0 Status register during a read operation 8 bits

0 0 1 Mode register 16 bits

0 1 0 Configuration register 16 bits

0 1 1 Data register 16 bits (AD7798)/24 bits (AD7799)

1 0 0 ID register 8 bits

1 0 1 IO register 8 bits

1 1 0 Offset register 16 bits (AD7798)/24 bits (AD7799)

1 1 1 Full-scale register 16 bits (AD7798)/24 bits (AD7799)

RS2(0) RS1(0) RS0(0) CREAD(0) 0(0) 0(0)

a 1 is the first bit written, the part does not clock subsequent bits into the register. It stays at this bit

location until a 0 is written to this bit. Once a 0 is written to the WEN

to the communication register.

1 in this position indicates that the next operation is a read from the designated register.

Register Address Bits. These bits are used to select the register during the serial interface

communication. See Table 10.

Continuous Read of the Data Register Bit. When this bit is set to 1 and the data register is selected, the

serial interface is configured so that the data register can be continuously read, that is, the contents of

the data register are placed on the DOUT pin automatically when the SCLK pulses are applied after the

RDY

pin goes low to indicate that a conversion is complete. The communication register does not have

to be written to for data reads. To enable continuous read mode, the instruction 01011100 must be

written to the communication register. To exit the continuous read mode, the instruction 01011000

must be written to the communication register while the RDY

the ADC monitors activity on the DIN line for the instruction to exit continuous read mode. Additionally,

a reset occurs if 32 consecutive 1s are seen on DIN. Therefore, DIN should be held low in continuous read

mode until an instruction is to be written to the device.

bit, the next seven bits are loaded

pin is low. While in continuous read mode,

Rev. 0 | Page 13 of 28

Page 14

AD7798/AD7799

STATUS REGISTER

RS2, RS1, RS0 = 0, 0, 0; Power-On/Reset = 0x80 (AD7798)/0x88 (AD7799)

The status register is an 8-bit, read-only register. To access the status register, the user must write to the communication register, select the

next operation to be a read, and load bits RS2, RS1, and RS0 with 0. Table 11 outlines the bit designations for the status register. SR0

through SR7 indicate the bit locations, with SR denoting that the bits are in the status register. SR7 denotes the first bit of the data stream.

The number in parentheses indicates the power-on/reset default status of the bit.

SR7 SR6 SR5 SR4 SR3 SR2 SR1 SR0

RDY(1)

Table 11. Status Register Bit Designations

Bit Location Bit Name Description

SR7

SR6 ERR

SR5 NOREF

SR4 0 This bit is automatically cleared.

SR3 0/1 This bit is automatically cleared on the AD7798 and automatically set on the AD7799.

SR2 to SR0 CH2 to CH0 These bits indicate which channel is being converted by the ADC.

ERR(0) NOREF(0) 0(0) 0/1 CH2(0) CH1(0) CH0(0)

Ready Bit. Cleared when data is written to the data register. Set after the data register is read or after a period

RDY

of time before the data register is updated with a new conversion result to indicate to the user not to read

the conversion data. It is also set when the part is placed in power-down mode. The end of a conversion is

indicated by the DOUT/RDY

the ADC for conversion data.

Error Bit. This bit is written to at the same time as the RDY

data register is clamped to all 0s or all 1s. Error sources include overrange and underrange. Cleared by a write

operation to start a conversion.

No Reference Bit. Set to indicate that the reference (REFIN) is at a voltage below a specified threshold. When

NOREF is set, conversion results are clamped to all 1s. Cleared to indicate that a valid reference is applied to

the reference pins. The NOREF bit is enabled by setting the REF_DET bit in the configuration register to 1.

pin. This pin can be used as an alternative to the status register for monitoring

bit. Set to indicate that the result written to the

MODE REGISTER

RS2, RS1, RS0 = 0, 0, 1; Power-On/Reset = 0x000A

The mode register is a 16-bit register from which data can be read or to which data can be written. This register is used to select the

operating mode, update rate, and low-side power switch. Table 12 outlines the bit designations for the mode register. MR0 through MR15

indicate the bit locations, with MR denoting that the bits are in the mode register. MR15 denotes the first bit of the data stream. The

number in parentheses indicates the power-on/reset default status of that bit. A write to the mode register resets the modulator and filter

RDY

and sets the

MR15 MR14 MR13 MR12 MR11 MR10 MR9 MR8

MD2(0) MD1(0) MD0(0) PSW(0) 0(0) 0(0) 0(0) 0(0)

MR7 MR6 MR5 MR4 MR3 MR2 MR1 MR0

0(0) 0(0) 0(0) 0(0) FS3(1) FS2(0) FS1(1) FS0(0)

Table 12. Mode Register Bit Designations

Bit Location Bit Name Description

MR15 to MR13 MD2 to MD0 Mode Select Bits. These bits select the operational mode of the AD7798/AD7799 (see Table 13).

MR12 PSW

MR11 to MR4 0 These bits must be programmed with a Logic 0 for correct operation.

MR3 to MR0 FS3 to FS0 Filter Update Rate Select Bits (see Table 14).

bit.

Power Switch Control Bit. Set by user to close the power switch PSW to GND. The power switch can

sink up to 30 mA. Cleared by user to open the power switch. When the ADC is placed in power-down

mode, the power switch is opened.

Rev. 0 | Page 14 of 28

Page 15

AD7798/AD7799

Table 13. Operating Modes

MD2 MD1 MD0 Mode

0 0 0

Continuous-Conversion Mode (default). In continuous-conversion mode, the ADC continuously performs conversions

and places the result in the data register. RDY

change, or a write to the mode, configuration, or IO registers, the first conversion is available after a period 2/f

and subsequent conversions are available at a frequency of f

goes low when a conversion is complete. After power-on, a channel

ADC

ADC

.

,

0 0 1

Single-Conversion Mode. When single-conversion mode is selected, the ADC powers up and performs a single

conversion. The oscillator requires 1 ms to power up and settle. The ADC then performs the conversion, which takes

a time of 2/f

down mode. The conversion remains in the data register and RDY

. The conversion result in placed in the data register, RDY goes low, and the ADC returns to power-

ADC

remains active (low) until the data is read or

another conversion is performed.

0 1 0

Idle Mode. In idle mode, the ADC filter and modulator are held in a reset state, although the modulator clocks are

still provided.

0 1 1 Power-Down Mode. In this mode, all AD7798/AD7799 circuitry is powered down, including the burnout currents.

1 0 0

Internal Zero-Scale Calibration. An internal short is automatically connected to the enabled channel. A calibration

takes two conversion cycles to complete. RDY

goes high when the calibration is initiated and returns low when the

calibration is complete. The ADC is placed in idle mode following a calibration. The measured offset coefficient is

placed in the offset register of the selected channel.

1 0 1

Internal Full-Scale Calibration. A full-scale input voltage is automatically connected to the selected analog input for

this calibration. When the gain equals 1, a calibration takes two conversion cycles to complete. For higher gains,

four conversion cycles are required to perform the full-scale calibration. RDY

goes high when the calibration is

initiated and returns low when the calibration is complete. The ADC is placed in idle mode following a calibration.

The measured full-scale coefficient is placed in the full-scale register of the selected channel. Internal full-scale

calibrations cannot be performed when the gain equals 128. The ADC is factory-calibrated at a gain of 128 and this

factory-generated value is placed in the full-scale register on power up and when the gain is set to 128. With this

gain setting, a system full-scale calibration can be performed. To minimize the full-scale error, a full-scale calibration

is required each time the gain of a channel is changed.

1 1 0

System Zero-Scale Calibration. Users should connect the system zero-scale input to the channel input pins as

selected by the CH2 to CH0 bits. A system offset calibration takes two conversion cycles to complete. RDY

goes high

when the calibration is initiated and returns low when the calibration is complete. The ADC is placed in idle mode

following a calibration. The measured offset coefficient is placed in the offset register of the selected channel. A

zero-scale calibration is required each time the gain of a channel is changed.

1 1 1

System Full-Scale Calibration. Users should connect the system full-scale input to the channel input pins, as selected

by the CH2 to CH0 bits. A calibration takes two conversion cycles to complete. RDY

goes high when the calibration

is initiated and returns low when the calibration is complete. The ADC is placed in idle mode following a calibration.

The measured full-scale coefficient is placed in the full-scale register of the selected channel. A full-scale calibration

is required each time the gain of a channel is changed.

Table 14. Update Rates Available

FS3 FS2 FS1 FS0 f

(Hz) t

ADC

(ms) Rejection @ 50 Hz/60 Hz

SETTLE

0 0 0 0 Reserved

0 0 0 1 500 4

0 0 1 0 250 8

0 0 1 1 125 16

0 1 0 0 62.5 32

0 1 0 1 50 40

0 1 1 0 39.2 48

0 1 1 1 33.3 60

1 0 0 0 19.6 101 90 dB (60 Hz only)

1 0 0 1 16.7 120 80 dB (50 Hz only)

1 0 1 0 16.7 120 65 dB

Rev. 0 | Page 15 of 28

Page 16

AD7798/AD7799

FS3 FS2 FS1 FS0 f

1 0 1 1 12.5 160 66 dB

1 1 0 0 10 200 69 dB

1 1 0 1 8.33 240 70 dB

1 1 1 0 6.25 320 72 dB

1 1 1 1 4.17 480 74 dB

CONFIGURATION REGISTER

RS2, RS1, RS0 = 0, 1, 0; Power-On/Reset = 0x0710

The configuration register is a 16-bit register from which data can be read or to which data can be written. This register is used to

configure the ADC for unipolar or bipolar mode, to enable or disable the buffer, to enable or disable the burnout currents, to select the

gain, and to select the analog input channel. Table 15 outlines the bit designations for the filter register. CON0 through CON15 indicate

the bit locations, with CON denoting that the bits are in the configuration register. CON15 denotes the first bit of the data stream. The

number in parentheses indicates the power-on/reset default status of the bit.

CON15 CON14 CON13 CON12 CON11 CON10 CON9 CON8

0(0) 0(0) BO(0)

CON7 CON6 CON5 CON4 CON3 CON2 CON1 CON0

0(0) 0(0) REF_DET(0) BUF(1) 0(0) CH2(0) CH1(0) CH0(0)

Table 15. Configuration Register Bit Designations

Bit

Location

CON15 to

CON14

CON13 BO

CON12

CON11 0 This bit must be programmed with a Logic 0 for correct operation.

CON10 to

CON8

0 0 0 1 (in-amp not used) 2.5 V

0 0 1 2 (in-amp not used) 1.25 V

0 1 0 4 625 mV

0 1 1 8 312.5 mV

1 0 0 16 156.2 mV

1 0 1 32 78.125 mV

1 1 0 64 39.06 mV

1 1 1 128 19.53 mV

CON7 to

CON6

CON5 REF_DET

Bit

Name Description

0 These bits must be programmed with a Logic 0 for correct operation.

Burnout Current Enable Bit. When this bit is set to 1 by the user, the 100 nA current sources in the signal path are

enabled. When BO = 0, the burnout currents are disabled. The burnout currents can be enabled only when the

buffer or in-amp is active.

Unipolar/Bipolar Bit. Set by the user to enable unipolar coding, that is, zero differential input results in 0x000000

U/B

output, and a full-scale differential input results in 0xFFFFFF output. Cleared by the user to enable bipolar coding.

Negative full-scale differential input results in an output code of 0x000000, zero differential input results in an

output code of 0x800000, and a positive full-scale differential input results in an output code of 0xFFFFFF.

G2 to G0 Gain Select Bits. Written to by the user to select the ADC input range as follows:

G2 G1 G0 Gain ADC Input Range (2.5 V Reference)

0 These bits must be programmed with a Logic 0 for correct operation.

Enables the reference detect function. When REF_DET is set, the NOREF bit in the status register indicates when

the external reference being used by the ADC is open circuit or less than 0.5 V. When cleared, the reference detect

function is disabled.

(Hz) t

ADC

(ms) Rejection @ 50 Hz/60 Hz

SETTLE

U/B

(0)

0(0) G2(1) G1(1) G0(1)

Rev. 0 | Page 16 of 28

Page 17

AD7798/AD7799

Bit

Location

CON4 BUF

CON3 0 This bit must be programmed with a Logic 0 for correct operation.

CON2 to

CON0

0 0 0 AIN1(+) – AIN1(–) 0

0 0 1 AIN2(+) – AIN2(–) 1

0 1 0 AIN3(+) – AIN3(–) 2

0 1 1 AIN1(–) – AIN1(–) 0

1 0 0 Reserved

1 0 1 Reserved

1 1 0 Reserved

1 1 1 AVDD monitor

Bit

Name Description

Configures the ADC for buffered or unbuffered modes. If BUF is cleared, the ADC operates in unbuffered mode,

lowering the power consumption of the device. If BUF is set, the ADC operates in buffered mode, allowing the

user to place source impedances on the front end without contributing gain errors to the system. The buffer can

be disabled when the gain equals 1 or 2. For higher gains, the buffer is automatically enabled. With the buffer

disabled, the voltage on the analog input pins can range from 30 mV below GND to 30 mV above AV

buffer is enabled, it requires some headroom; therefore, the voltage on any input pin must be limited to 100 mV

within the power supply rails.

CH2 to

CH0

Channel Select Bits. Written to by the user to select the active analog input channel to the ADC as follows:

CH2 CH1 CH0 Channel Calibration Pair

. When the

DD

Automatically selects gain = 1/6 and internal reference

= 1.17 V

DATA REGISTER

RS2, RS1, RS0 = 0, 1, 1; Power-On/Reset = 0x0000(00)

The conversion result from the ADC is stored in the data register. This is a read-only register. Upon completion of a read operation from

this register, the

RDY

bit and DOUT/

RDY

pin are set.

ID REGISTER

RS2, RS1, RS0 = 1, 0, 0; Power-On/Reset = 0xX8 (AD7798)/0xX9 (AD7799)

The identification number for the AD7798/AD7799 is stored in the ID register. This is a read-only register.

IO REGISTER

RS2, RS1, RS0 = 1, 0, 1; Power-On/Reset = 0x00

The IO register is an 8-bit register from which data can be read or to which data can be written. This register is used to select the function

of the AIN3(+)/AIN3(-) pins. Table 18 outlines the bit designations for the IO register. IO0 through IO7 indicate the bit locations, with IO

denoting that the bits are in the IO register. IO7 denotes the first bit of the data stream. The number in parentheses indicates the poweron/reset default status of that bit.

IO7 IO6 IO5 IO4 IO3 IO2 IO1 IO0

0(0) IOEN(0) IO2DAT(0) IO1DAT(0) 0(0) 0(0) 0(0) 0(0)

Rev. 0 | Page 17 of 28

Page 18

AD7798/AD7799

Table 16. IO Register Bit Designations

Bit Location Bit Name Description

IO7 0 This bit must be programmed with a Logic 0 for correct operation.

IO6 IOEN

IO5, IO4 IO2DAT, IO1DAT

IO3 to IO0 0 These bits must be programmed with a Logic 0 for correct operation.

OFFSET REGISTER

RS2, RS1, RS0 = 1, 1, 0; Power-On/Reset = 0x8000(AD7798)/0x800000(AD7799)

Each analog input channel has a dedicated offset register that holds the offset calibration coefficient for the channel. This register is

16 bits wide on the AD7798 and 24 bits wide on the AD7799, and its power-on/reset value is 8000(00) hex. The offset register is used in

conjunction with its associated full-scale register to form a register pair. The power-on/reset value is automatically overwritten if an

internal or system zero-scale calibration is initiated by the user. The offset register is a read/write register. However, the AD7798/AD7799

must be in idle mode or power-down mode when writing to the offset register.

FULL-SCALE REGISTER

RS2, RS1, RS0 = 1, 1, 1; Power-On/Reset = 0x5XXX (AD7798)/0x5XXX00 (AD7799)

The full-scale register is a 16-bit register on the AD7798 and a 24-bit register on the AD7799. The full-scale register holds the full-scale

calibration coefficient for the ADC. The AD7798/AD7799 has three full-scale registers, with each channel having a dedicated full-scale

register. The full-scale registers are read/write registers. However, when writing to the full-scale registers, users must place the ADC in

power-down mode or idle mode. Upon power-on, these registers are configured with factory-calibrated, full-scale calibration coefficients,

with the calibration performed at gain = 128, the default gain setting. The default value is automatically overwritten if an internal or

system full-scale calibration is initiated by the user, or the full-scale register is written to.

Configures the pins AIN3(+)/P1 and AIN3(−)/P2 as analog input pins or digital output pins. When

this bit is set, the pins are configured as Digital Output Pins P1 and P2. When this bit is cleared,

these pins are configured as analog input pins AIN3(+) and AIN3(−).

P1/P2 Data. When IOEN is set, the data for the Digital Output Pins P1 and P2 is written to Bit IO1DAT

and Bit IO2DAT.

Rev. 0 | Page 18 of 28

Page 19

AD7798/AD7799

ADC CIRCUIT INFORMATION

OVERVIEW

The AD7798/AD7799 are low power ADCs that each incorporate

a ∑-∆ modulator, a buffer, an in-amp, and on-chip digital filtering

intended for the measurement of wide dynamic range, low

frequency signals such as those in pressure transducers and

weigh scales.

Each part has three differential inputs that can be buffered or

unbuffered. The reference is provided by an external reference

source. Figure 11 shows the basic connections required to

operate the parts.

AV

DD

GND AV

DD

IN+

OUT– OUT+

IN–

REFIN(+)

AIN1(+)

AIN1(–)

AIN2(+)

AIN2(–)

REFIN(–)

PSW

MUX

AD7798/AD7799

AV

DD

IN-AMP

GND

INTERNAL

ADC

CLOCK

Figure 11. Basic Connection Diagram

The output rate of the AD7798/AD7799 (f

mable. The allowable update rates, along with the corresponding

settling times, are listed in Table 14. Normal-mode rejection is

the major function of the digital filter. Simultaneous 50 Hz and

60 Hz rejection is optimized when the update rate equals 16.7 Hz

or less, because notches are placed at both 50 Hz and 60 Hz with

these update rates (see Figure 13).

The AD7798/AD7799 use slightly different filter types,

depending on the output update rate, so that the rejection of

quantization noise and device noise is optimized. When the

update rate ranges from 4.17 Hz to 12.5 Hz, a sinc

with an aver-aging filter, is used. When the update rate ranges

from 16.7 Hz to 39.2 Hz, a modified sinc

filter gives simultaneous 50 Hz and 60 Hz rejection when the

4

update rate equals 16.7 Hz. A sinc

filter is used when the update

rate ranges from 50 Hz to 250 Hz. Finally, an integrate-only filter

is used when the update rate equals 500 Hz. Figure 12 through

Figure 15 show the frequency responses of the different filter

types for a few of the update rates.

REFERENCE

DETECT

SERIAL

Σ-∆

3

INTERFACE

AND

CONTROL

LOGIC

) is user-program-

ADC

3

filter, along

filter is used. This

DOUT/RDY

DIN

SCLK

CS

DV

DD

04856-012

0

–20

–40

(dB)

–60

–80

–100

0 12010080604020

FREQUENCY (Hz)

Figure 12. Filter Profile with Update Rate = 4.17 Hz

0

–20

–40

(dB)

–60

–80

–100

0 20018016014012010080604020

FREQUENCY (Hz)

Figure 13. Filter Profile with Update Rate = 16.7 Hz

0

–20

–40

(dB)

–60

04856-013

04856-014

Rev. 0 | Page 19 of 28

–80

–100

0 30002500200015001000500

FREQUENCY (Hz)

Figure 14. Filter Profile with Update Rate = 250 Hz

04856-015

Page 20

AD7798/AD7799

0

–10

–20

–30

(dB)

–40

–50

–60

0 10000900080007000600050004000300020001000

Figure 15. Filter Response with Update Rate = 500 Hz

FREQUENCY (Hz)

04856-016

DIGITAL INTERFACE

As previously outlined, the programmable functions of the

AD7798/AD7799 are controlled using a set of on-chip registers.

Data is written to these registers via the serial interface, which

also provides read access to the on-chip registers. All

communication with the part must start with a write to the

communication register. After power-on or reset, the device

expects a write to its communication register. The data written

to this register determines whether the next operation is a read

or write operation and to which register this operation occurs.

Therefore, write access to any register begins with a write

operation to the communication register, followed by a write to

the selected register. A read operation from any other register

(except when continuous-read mode is selected) starts with a

write to the communication register, followed by a read

operation from the selected register.

The serial interface of the AD7798/AD7799 consists of four

CS

signals:

, DIN, SCLK, and DOUT/

to transfer data into the on-chip registers, and DOUT/

used for accessing data from the on-chip registers. SCLK is the

serial clock input for the device and all data transfers (either on

DIN or DOUT/

The DOUT/

RDY

) occur with respect to the SCLK signal.

RDY

pin operates as a data ready signal, with the

line going low when a new data-word is available in the output

register. It is reset high when a read operation from the data

register is complete. It also goes high prior to the updating of

the data register to indicate when not to read from the device to

ensure that a data read is not attempted while the register is

CS

being updated.

is used to select a device. It can be used to

decode the AD7798/AD7799 in systems where several

components are connected to the serial bus.

RDY

. The DIN line is used

RDY

is

Figure 3 and Figure 4 show timing diagrams for interfacing to

CS

the AD7798/AD7799, with

being used to decode the part.

Figure 3 shows the timing for a read operation from the

AD7798/AD7799 output shift register, and Figure 4 shows the

timing for a write operation to the input shift register. It is

possible to read the same word from the data register several

RDY

times, even though the DOUT/

line returns high after the

first read operation. However, care must be taken to ensure that

the read operations are complete before the next output update

occurs. In continuous-read mode, the data register can only be

read once.

CS

The serial interface can operate in 3-wire mode by tying

In this case, the SCLK, DIN, and DOUT/

RDY

lines are used to

low.

communicate with the AD7798/AD7799. The end of the conversion can be monitored using the

RDY

bit in the status regis-

ter. This scheme is suitable for interfacing to microcontrollers.

CS

If

is required as a decoding signal, it can be generated from a

port pin. For microcontroller interfaces, it is recommended that

SCLK idles high between data transfers.

CS

The AD7798/AD7799 can be operated with

being used as a

frame-synchronization signal. This scheme is useful for DSP

interfaces. In this case, the first bit (MSB) is effectively clocked

CS

out by

, because CS normally occurs after the falling edge of

SCLK in DSPs. The SCLK can continue to run between data

transfers, provided that the timing numbers are obeyed.

The serial interface can be reset by writing a series of 1s on the

DIN input. If a Logic 1 is written to the AD7798/AD7799 line

for at least 32 serial clock cycles, the serial interface is reset.

This ensures that the interface can be reset to a known state if

the interface is lost due to a software error or a glitch in the

system. Reset returns the interface to the state in which it is

expecting a write to the communication register. This operation

resets the contents of all registers to their power-on values.

Following a reset, the user should allow a period of 500

microseconds before addressing the serial interface.

The AD7798/AD7799 can be configured to continuously

convert or to perform a single conversion. See Figure 16

through Figure 18.

Rev. 0 | Page 20 of 28

Page 21

AD7798/AD7799

Single-Conversion Mode

In single-conversion mode, the AD7798/AD7799 is placed in

power-down mode after conversions. When a single conversion

is initiated by setting MD2, MD1, and MD0 to 0, 0, and 1 in the

mode register, the AD7798/AD7799 powers up, performs a

single conversion, and then returns to power-down mode. The

on-chip oscillator requires approximately 1 ms to power up. A

conversion requires a time period of 2 × t

. DOUT/

ADC

RDY

goes

low to indicate the completion of a conversion. When the dataword has been read from the data register, DOUT/

high. If

CS

is low, DOUT/

RDY

remains high until another

RDY

goes

conversion is initiated and completed. The data register can be

read several times if required, even when DOUT/

CS

RDY

is high.

Continuous-Conversion Mode

This is the default power-up mode. The AD7798/AD7799

continuously converts, with the

going low each time a conversion is complete. If

RDY

DOUT/

line also goes low when a conversion is complete.

RDY

bit in the status register

CS

is low, the

To read a conversion, the user can write to the communication

register, indicating that the next operation is a read of the data

register. The digital conversion is placed on the DOUT/

RDY

pin as soon as SCLK pulses are applied to the ADC.

RDY

DOUT/

returns high when the conversion is read. The

user can reread this register if required. However, the user must

ensure that the data register is not accessed at the completion of

the next conversion, or the new conversion word will be lost.

DIN

DOUT/RDY

SCLK

DIN

DOUT/RDY

CS

0x08 0x200A

0x58

DATA

Figure 16. Single Conversion

0x58 0x58

DATA DATA

04856-017

SCLK

Figure 17. Continuous Conversion

Rev. 0 | Page 21 of 28

04856-018

Page 22

AD7798/AD7799

Y

Continuous Read

Rather than write to the communication register to access the

data each time a conversion is complete, the AD7798/AD7799

can be configured so that the conversions are placed on the

DOUT/

communication register, the user needs only to apply the

appropriate number of SCLK cycles to the ADC, and the

16-/24-bit word is automatically placed on the DOUT/

when a conversion is complete. The ADC should be configured

for continuous conversion mode.

When DOUT/

sufficient SCLK cycles must be applied to the ADC, and the

data conversion is placed on the DOUT/

conversion is read, DOUT/

conversion is available. In this mode, the data can only be read

once. In addition, the user must ensure that the data-word is

RDY

line automatically. By writing 01011100 to the

RDY

goes low to indicate the end of a conversion,

RDY

RDY

returns high until the next

CS

RDY

line. When the

line

read before the next conversion is complete. If the user does not

read the conversion before the completion of the next conversion,

or if insufficient serial clocks are applied to the AD7798/AD7799

to read the word, the serial output register is reset when the

next conversion is complete, and the new conversion is placed

in the output serial register.

To exit the continuous-read mode, the instruction 01011000

must be written to the communication register while the

RDY

DOUT/

pin is low. While in continuous-read mode, the

ADC monitors activity on the DIN line in case the instruction

to exit the continuous read mode occurs. Additionally, a reset

occurs if 32 consecutive 1s are seen on DIN. Therefore, DIN

should be held low in continuous read mode until an

instruction is to be written to the device.

DOUT/RD

SCLK

DIN

0x5C

DATA

Figure 18. Continuous Read

DATA DATA

04856-019

Rev. 0 | Page 22 of 28

Page 23

AD7798/AD7799

CIRCUIT DESCRIPTION

ANALOG INPUT CHANNEL

The AD7798/AD7799 each have three differential analog input

channels. These are connected to the on-chip buffer amplifier

when the devices are operated in buffered mode, and directly to

the modulator when the devices are operated in unbuffered mode.

In buffered mode (the BUF bit in the mode register is set to 1),

the input channel feeds into a high impedance input stage of the

buffer amplifier. Therefore, the input can tolerate significant

source impedances and is tailored for direct connection to

external resistive-type sensors such as strain gauges or

resistance temperature detectors (RTDs).

When BUF = 0, the parts are operated in unbuffered mode.

This results in a higher analog input current. Note that this

unbuffered input path provides a dynamic load to the driving

source. Therefore, resistor/capacitor combinations on the input

pins can cause gain errors, depending on the output impedance

of the source that is driving the ADC input. Table

allowable external resistance/capacitance values for unbuffered

mode such that no gain error at the 20-bit level is introduced.

17. External Resistance/Capacitance Combination for

Table

Unbuffered Mode (Without 20-Bit Gain Error)

Capacitance (pF) Resistance (Ω)

50 9 k

100 6 k

500 1.5 k

1000 900

5000 200

The AD7798/AD7799 can be operated in unbuffered mode only

when the gain equals 1 or 2. At higher gains, the buffer is automatically enabled. The absolute input voltage range in buffered

mode is restricted to a range between GND + 100 mV and

– 100 mV. When the gain is set to 4 or higher, the in-amp

AV

DD

is enabled. The absolute input voltage range when the in-amp is

active is restricted to a range between GND + 300 mV and

− 1.1 V. Care must be taken in setting up the common-

AV

DD

mode voltage so that these limits are not exceeded; otherwise,

linearity and noise performance degrade.

17 shows the

INSTRUMENTATION AMPLIFIER

When the gain equals 4 or higher, the output from the buffer is

applied to the input of the on-chip instrumentation amplifier.

This low noise in-amp means that signals of small amplitude

can be gained within the AD7798/AD7799 while still maintaining

excellent noise performance. For example, when the gain is set

to 64 and the update rate equals 4.17 Hz, the rms noise is 27 nV

typically for the AD7799, which is equivalent to 25.5 bits effective

resolution, or 20 bits peak-to-peak resolution when V

= 5 V.

REF

The AD7798/AD7799 can be programmed to have a gain of 1, 2,

4, 8, 16, 32, 64, or 128 using Bit G2 to Bit G0 in the configuration

register. Therefore, with a 2.5 V reference, the unipolar ranges are

from (0 mV to 19.53 mV) to (0 V to 2.5 V), and the bipolar

ranges are from ±19.53 mV to ±2.5 V. When the in-amp is active

(gain ≥ 4), the common-mode voltage (AIN(+) + AIN(−))/2 must

be greater than or equal to 0.5 V.

If the AD7798/AD7799 operate with a reference that has a value

equal to AV

/gain when the in-amp is active for correct operation.

V

REF

, the analog input signal must be limited to 90% of

DD

BIPOLAR/UNIPOLAR CONFIGURATION

The analog input to the AD7798/AD7799 can accept either

unipolar or bipolar input voltage ranges. A bipolar input range

does not imply that the parts can tolerate negative voltages with

respect to system GND. Unipolar and bipolar signals on the

AIN(+) input are referenced to the voltage on the AIN(–) input.

For example, if AIN(−) is 2.5 V and the ADC is configured for

unipolar mode and a gain of 1, the input voltage range on the

AIN(+) pin is 2.5 V to 5 V.

If the ADC is configured for bipolar mode, the analog input range

on the AIN(+) input is 0 V to 5 V. The bipolar/unipolar option is

B

chosen by programming the U/

bit in the configuration register.

The absolute input voltage in unbuffered mode includes the

range between GND − 30 mV and AV

+ 30 mV as a result of

DD

being unbuffered. The negative absolute input voltage limit

allows the possibility of monitoring small true bipolar signals

with respect to GND.

Rev. 0 | Page 23 of 28

Page 24

AD7798/AD7799

DATA OUTPUT CODING

When the ADC is configured for unipolar operation, the output

code is natural (straight) binary with a zero differential input

voltage resulting in a code of 00...00, a midscale voltage resulting

in a code of 100...000, and a full-scale input voltage resulting in

a code of 111...111. The output code for any analog input voltage

can be represented as

N

Code = (2

When the ADC is configured for bipolar operation, the output

code is offset binary, with a negative full-scale voltage resulting

in a code of 000...000, a zero differential input voltage resulting

in a code of 100...000, and a positive full-scale input voltage

resulting in a code of 111...111. The output code for any analog

input voltage can be represented as

Code = 2

where:

AIN is the analog input voltage.

N = 16 for the AD7798, and N = 24 for the AD7799.

BURNOUT CURRENTS

The AD7798/AD7799 each contain two 100 nA constant

current generators—one sourcing current from AV

AIN(+), and one sinking current from AIN(−) to GND. The

currents are switched to the selected analog input pair. Both

currents are either on or off, depending on the burnout current

enable (BO) bit in the configuration register. These currents can

be used to verify that an external transducer is still operational

before attempting to take measurements on that channel. Once

the burnout currents are turned on, they flow into the external

transducer circuit, and a measurement of the input voltage on

the analog input channel can be taken. If the resultant voltage

measured is full scale, the user must determine why this is the

case. A full-scale reading could mean that the front end sensor

is open circuit, that the front end sensor is overloaded and is

justified in outputting full scale, or that the reference is absent

and, thus, clamping the data to all 1s.

When reading all 1s from the output, the user should check

these three cases before making a judgment. If the voltage

measured is 0 V, it might indicate that the transducer has short

circuited. For normal operation, these burnout currents are

turned off by writing a 0 to the BO bit in the configuration

register. The current sources work over the normal absolute

input voltage range specifications with buffers on.

× AIN × GAIN)/V

N – 1

× [(AIN × GAIN/V

REF

REF

) + 1]

DD

to

REFERENCE

The common-mode range for these differential inputs is from

GND to AV

. The reference input is unbuffered; therefore,

DD

excessive resistance/capacitance source impedances introduce

gain errors. The reference voltage REFIN (REFIN(+) − REFIN(−))

is 2.5 V nominal, but the AD7798/AD7799 are functional with

reference voltages from 0.1 V to AV

. In applications where the

DD

excitation (voltage or current) for the transducer on the analog

input also drives the reference voltage for the part, the effect of

the low frequency noise in the excitation source is removed

because the application is ratiometric. If the AD7798/AD7799

are used in a nonratiometric application, a low noise reference

should be used.

Recommended 2.5 V reference voltage sources for the AD7798/

AD7799 include the ADR381 and ADR391, which are low noise,

low power references. Also note that the reference inputs provide

a high impedance, dynamic load. Because the input impedance

of each reference input is dynamic, resistor/capacitor combinations on these inputs can cause dc gain errors, depending on the

output impedance of the source driving the reference inputs.

Reference voltage sources such as those recommended above

(for example, ADR391) typically have low output impedances

and are, therefore, tolerant to having decoupling capacitors on

REFIN(+) without introducing gain errors in the system.

Deriving the reference input voltage across an external resistor

means that the reference input sees a significant external source

impedance. External decoupling on the REFIN pins is not

recommended in this type of circuit configuration.

REFERENCE DETECT

The AD7798/AD7799 include on-chip circuitry to detect if

there is a valid reference for conversions or calibrations. This

feature is enabled when the REF_DET bit in the configuration

register is set to 1. If the voltage between the REFIN(+) and

REFIN(–) pins goes below 0.3 V, or either the REFIN(+) or

REFIN(–) inputs are open circuit, the AD7798/AD7799 detect

that there is no longer a valid reference. In this case, the NOREF

bit of the status register is set to 1. If the AD7798/AD7799 are

performing normal conversions and the NOREF bit becomes

active, the conversion results revert to all 1s. Therefore, it is not

necessary to continuously monitor the status of the NOREF bit

when performing conversions. It is only necessary to verify its

status if the conversion result read from the ADC data register

is all 1s. If the AD7798/AD7799 are performing an offset of fullscale calibration and the NOREF bit becomes active, the updating

of the respective calibration registers is inhibited to avoid loading

incorrect coefficients to these registers, and the ERR bit in the

status register is set. If the user is concerned about verifying that

a valid reference is in place every time a calibration is performed,

the status of the ERR bit should be checked at the end of the

calibration cycle.

Rev. 0 | Page 24 of 28

Page 25

AD7798/AD7799

RESET

The circuitry and serial interface of the AD7798/AD7799 can

be reset by writing 32 consecutive 1s to the device. This resets

the logic, the digital filter, and the analog modulator, and all

on-chip registers are reset to their default values. A reset is

automatically performed upon power-up. When a reset is

initiated, the user must allow a period of 500 µs before

accessing an on-chip register. A reset is useful if the serial

interface becomes asynchronous due to noise on the SCLK line.

AVDD MONITOR

Along with converting external voltages, the ADC can be used

to monitor the voltage on the AV

equal 1, the voltage on the AV

and the resulting voltage is applied to the ∑-∆ modulator using

an internal 1.17 V reference for analog-to-digital conversion.

This is useful because variations in the power supply voltage

can be monitored.

pin. When Bits CH2 to CH0

DD

pin is internally attenuated by 6,

DD

CALIBRATION

The AD7798/AD7799 provide four calibration modes that can

be programmed via the mode bits in the mode register. These

are internal zero-scale calibration, internal full-scale calibration,

system zero-scale calibration, and system full-scale calibration,

which effectively reduce the offset error and full-scale error to

the order of the noise. After each conversion, the ADC conversion result is scaled using the ADC calibration registers

before being written to the data register. The offset calibration

coefficient is subtracted from the result prior to multiplication

by the full-scale coefficient.

To start a calibration, write the relevant value to the MD2 to

MD0 bits in the mode register. After the calibration is complete,

the contents of the corresponding calibration registers are

RDY

updated, the

RDY

pin goes low (if CS is low), and the AD7798/AD7799

revert to idle mode.

During an internal zero-scale or full-scale calibration, the

respective zero-scale and full-scale input are automatically

connected internally to the ADC input pins. A system calibration,

however, expects the system zero-scale and system full-scale

voltages to be applied to the ADC pins before the calibration

mode is initiated. In this way, external ADC errors are removed.

bit in the status register is set, the DOUT/

From an operational point of view, a calibration should be

treated like an ADC conversion. A zero-scale calibration (if

required) should always be performed before a full-scale

RDY

calibration. System software should monitor the

RDY

status register or the DOUT/

calibration via a polling sequence or an interrupt-driven routine.

Both an internal offset calibration and system offset calibration

take two conversion cycles. An internal offset calibration is not

needed because the ADC itself removes the offset continuously.

To perform an internal full-scale calibration, a full-scale input

voltage is automatically connected to the selected analog input

for this calibration. When the gain equals 1, a calibration takes

two conversion cycles to complete. For higher gains, four

conversion cycles are required to perform the full-scale

RDY

calibration. DOUT/

initiated and returns low when the calibration is complete. The

ADC is placed in idle mode following a calibration. The measured

full-scale coefficient is placed in the full-scale register of the

selected channel. Internal full-scale calibrations cannot be

performed when the gain equals 128. A factory calibration

is performed at this gain setting, and the factory value is

automatically loaded into the full-scale register when the gain is

set to 128. With this gain setting, a system full-scale calibration

can be performed. A full-scale calibration is required each time

the gain of a channel is changed to minimize the full-scale error.

An internal full-scale calibration can only be performed at

specified update rates. For gains of 1, 2, and 4, an internal fullscale calibration can be performed at any update rate. However,

for higher gains, internal full-scale calibrations must be performed

when the update rate is less than or equal to 16.7 Hz, 33.3 Hz,

or 50 Hz. Because the full-scale error does not vary with the

update rate, a calibration at one update rate is valid for all update

rates (assuming the gain or reference source is not changed).

A system full-scale calibration takes two conversion cycles to

complete, irrespective of the gain setting. A system full-scale

calibration can be performed at all gains and update rates. If

system offset calibrations are performed along with system fullscale calibrations, the offset calibration should be performed

before the system full-scale calibration is initiated.

goes high when the calibration is

pin to determine the end of

bit in the

Rev. 0 | Page 25 of 28

Page 26

AD7798/AD7799

GROUNDING AND LAYOUT