Page 1

8-Bit 20 MSPS, 60 mW

1

2

7

8

3

4

5

6

9

10

151614

13

12

11

19

20

17

18

21

24

23

22

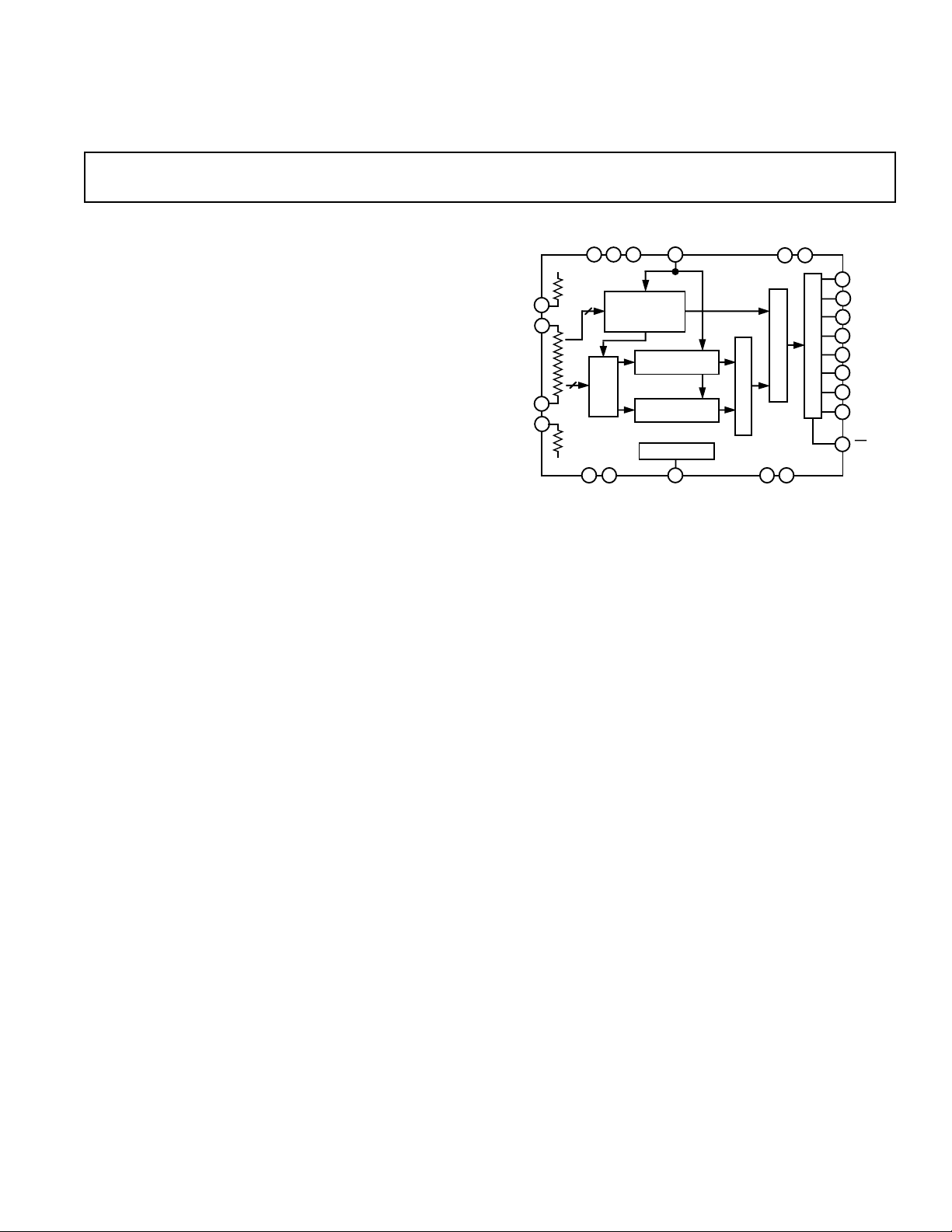

CLOCK LOGIC

FINE COMPARATORS

BANK B

FINE COMPARATORS

BANK A

COARSE

COMPARATORS

CORRECTION LOGIC

AV

DD

AV

SS

3-STATE OUTPUT LATCHES

D7 (MSB)

D0 (LSB)

RREF

15

SWITCH

MATRIX

V

RTS

V

RT

V

RB

V

RBS

OE

AV

SS

CLK DV

SS

AV

DD

V

IN

DV

DD

AD775

4

8

5

255

LSB MULTIPLEXOR

a

FEATURES

CMOS 8-Bit 20 MSPS Sampling A/D Converter

Low Power Dissipation: 60 mW

+5 V Single Supply Operation

Differential Nonlinearity: 0.3 LSB

Differential Gain: 1%

Differential Phase: 0.5 Degrees

Three-State Outputs

On-Chip Reference Bias Resistors

Adjustable Reference Input

Video Industry Standard Pinout

Small Packages:

24-Pin 300 Mil SOIC Surface Mount

24-Pin 400 Mil Plastic DIP

PRODUCT DESCRIPTION

The AD775 is a CMOS, low power, 8-bit, 20 MSPS sampling

analog-to-digital converter (ADC). The AD775 features a builtin sampling function and on-chip reference bias resistors to provide a complete 8-bit ADC solution. The AD775 utilizes a

pipelined/ping pong two-step flash architecture to provide high

sampling rates (up to 35 MHz) while maintaining very low

power consumption (60 mW).

Its combination of excellent DNL, fast sampling rate, low differential gain and phase errors, extremely low power dissipation,

and single +5 V supply operation make it ideally suited for a

variety of video and image acquisition applications, including

portable equipment. The AD775’s reference ladder may be connected in a variety of configurations to accommodate different

input ranges. The low input capacitance (11 pF typical) provides

an easy-to-drive input load compared to conventional flash

converters.

The AD775 is offered in both 300 mil SOIC and 400 mil DIP

plastic packages, and is designed to operate over an extended

commercial temperature range (–20°C to +75°C).

Sampling A/D Converter

AD775

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

Low Power: The AD775 has a typical supply current of 12 mA,

for a power consumption of 60 mW. Reference ladder current

is also low: 6.6 mA typical, minimizing the reference power

consumption.

Complete Solution: The AD775’s switched capacitor design

features an inherent sample/hold function: no external SHA is

required. On-chip reference bias resistors are included to allow

a supply-based reference to be generated without any external

resistors.

Excellent Differential Nonlinearity: The AD775 features a

typical DNL of 0.3 LSBs, with a maximum limit of 0.5 LSBs.

No missing codes is guaranteed.

Single +5 V Supply Operation: The AD775 is designed to operate on a single +5 V supply, and the reference ladder may be

configured to accommodate analog inputs inclusive of ground.

Low Input Capacitance: The 11 pF input capacitance of the

AD775 can significantly decrease the cost and complexity of

input driving circuitry, compared with conventional 8-bit flash

ADCs.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

(TA = +258C with AVDD, DVDD = +5 V, AVSS, DVSS = 0 V, VRT = 2.6 V, VRB = +0.6 V,

AD775–SPECIFICA TIONS

CLOCK = 20 MHz unless otherwise noted)

AD775J

Parameter Min Typ Max Units

RESOLUTION 8 Bits

DC ACCURACY

Integral Nonlinearity (INL) +0.5 1.3 LSB

Differential Nonlinearity (DNL) ±0.3 ± 0.5 LSB

No Missing Codes GUARANTEED

Offset

To Top of Ladder V

To Bottom of Ladder V

VIDEO ACCURACY

RT

RB

1

–10 –35 –60 mV

0 +15 +45 mV

Differential Gain Error 1.0 %

Differential Phase Error 0.5 Degrees

ANALOG INPUT

Input Range (V

) 2.0 V p-p

RT–VRB

Input Capacitance 11 pF

AC SPECIFICATIONS

2

Signal-to-Noise and Distortion (S/(N + D))

f

= 1 MHz 47 dB

IN

f

= 5 MHz 41 dB

IN

Total Harmonic Distortion (THD)

f

= 1 MHz –51 dB

IN

fIN = 5 MHz –42 dB

REFERENCE INPUT

Reference Input Resistance (R

Case 1: V

RT

= V

, VRB = V

RTS

) 230 300 450 Ω

REF

RBS

Reference Bottom Voltage (VRB) 0.60 0.64 0.68 V

Reference Span (V

Reference Ladder Current (I

Case 2: V

RT

= V

RTS

) 1.96 2.09 2.21 V

RT–VRB

, VRB = AV

) 4.4 7.0 9.6 mA

REF

SS

Reference Span (VRT–VRB) 2.25 2.39 2.53 V

Reference Ladder Current (I

) 5811 mA

REF

POWER SUPPLIES

Operating Voltages

AV

DV

DD

DD

+4.75 +5.25 Volts

+4.75 +5.25 Volts

Operating Current

IAV

DD

IDV

DD

IAVDD + IDV

DD

9.5 mA

2.5 mA

12 17 mA

POWER CONSUMPTION 60 85 mW

TEMPERATURE RANGE

Operating –20 +75 °C

NOTES

1

NSTC 40 IRE modulation ramp, CLOCK = 14.3 MSPS.

2

fIN amplitude = 0.3 dB full scale.

Specifications subject to change without notice. See Definition of Specifications for additional information.

–2–

REV. 0

Page 3

(TA = +258C with AVDD, DVDD = +5 V, AVSS, DVSS = 0 V, VRT = 2.6 V, VRB = +0.6 V,

DIGITAL SPECIFICATIONS

CLOCK = 20 MHz unless otherwise noted)

Parameter Symbol DV

LOGIC INPUT

High Level Input Voltage V

Low Level Input Voltage V

IH

IL

5.0 4.0 V

5.0 1.0 V

High Level Input Current

(V

= DVDD)I

IH

IH

5.25 5 µA

Low Level Input Current

(V

= 0 V) I

IL

Logic Input Capacitance C

IL

IN

5.25 –5 µA

LOGIC OUTPUTS

High Level Output Current

OE = DVSS, VOH = DVDD–0.5 V I

OE = DVDD, VOH = DV

DD

OH

I

OZ

4.75 –1.1 mA

5.25 16 µA

Low Level Output Current

OE = DVSS, VOL = 0.4 V I

OE = DVDD, VOL = 0 V I

OL

OZ

4.75 3.7 mA

5.25 16 µA

TIMING SPECIFICATIONS

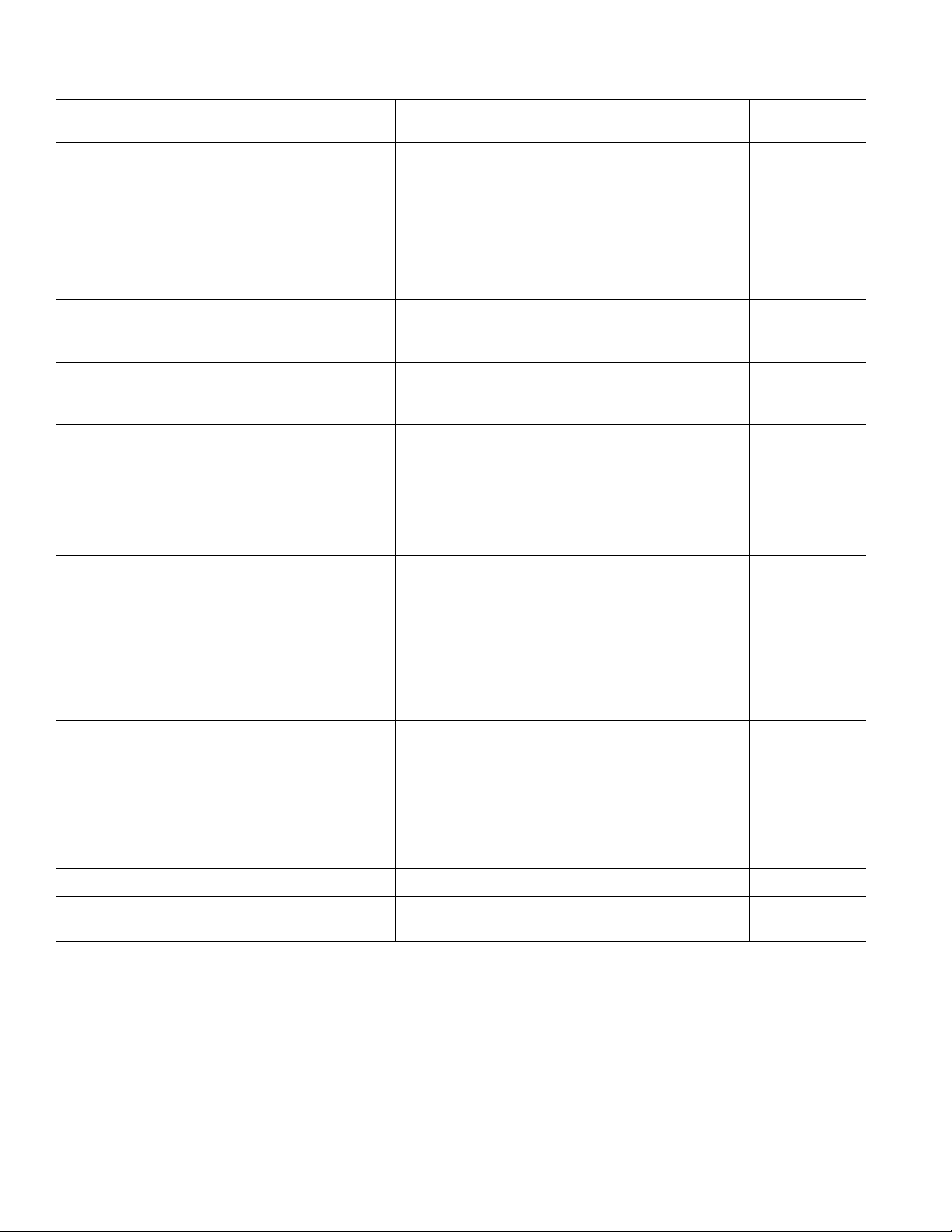

Symbol Min Typ Max Units

DD

AD775

AD775J

Min Typ Max Units

5pF

Maximum Conversion Rate 20 35 MHz

Clock Period t

Clock High t

Clock Low t

Output Delay t

C

CH

CL

OD

50 ns

25 ns

25 ns

18 30 ns

Pipeline Delay (Latency) 2.5 Clock Cycles

Sampling Delay t

DS

4ns

Aperture Jitter 30 ps

Specifications subject to change without notice.

SAMPLE N+2

t

OD

VIN

CLK

OUT

t

DS

SAMPLE N+1

SAMPLE N

t

CH

t

CL

t

C

DATA N-3 DATA N-2 DATA N-1 DATA N

Figure 1. AD775 Timing Diagram

REV. 0

–3–

Page 4

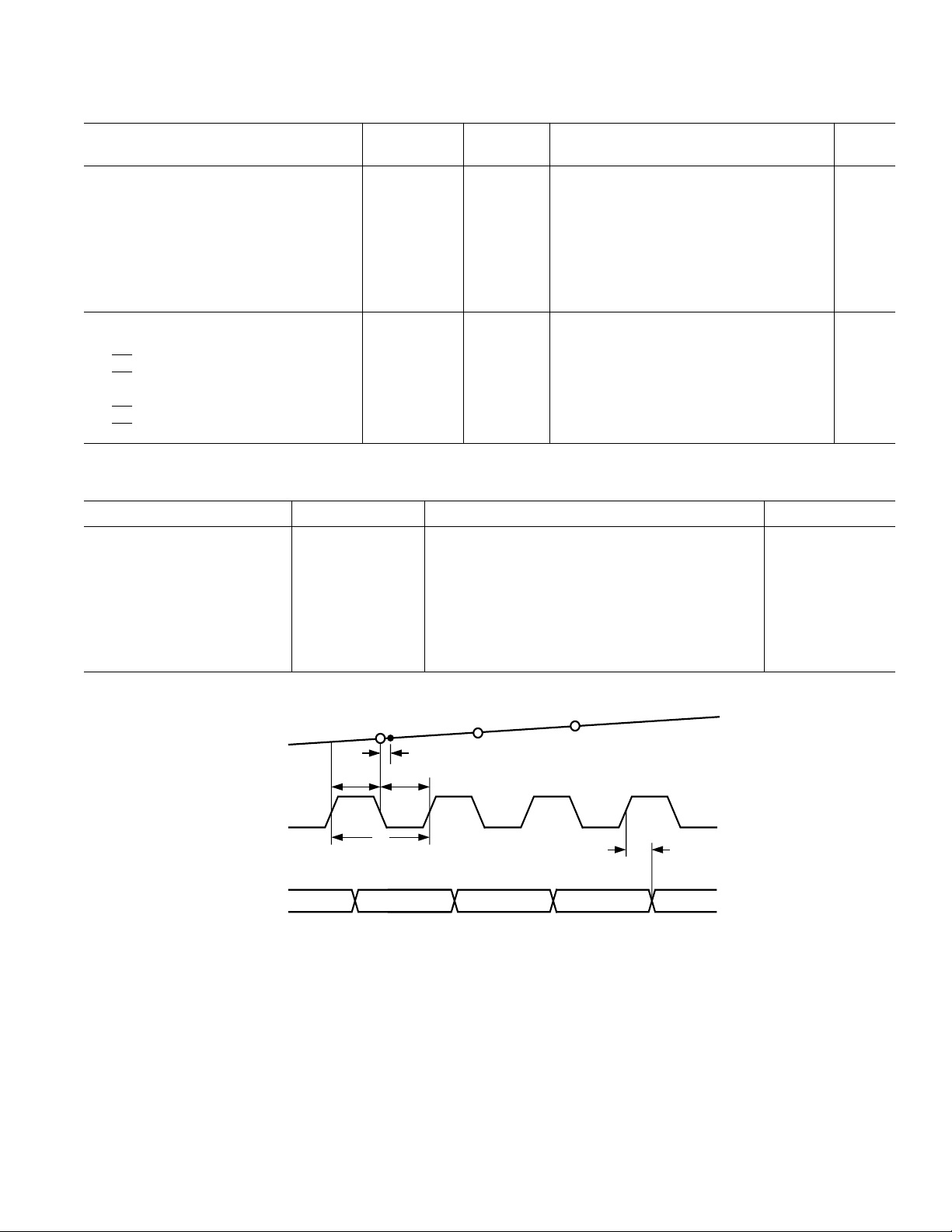

AD775

WARNING!

ESD SENSITIVE DEVICE

Pin No. Symbol Type Name and Function

PIN DESCRIPTION

1

OE DI OE = Low OE = High

Normal Operating Mode. High Impedance Outputs.

2, 24 DV

SS

P Digital Ground. Note: DVSS and AVSS pins should share a common ground plane on the circuit board.

3 D0 (LSB) DO Least Significant Bit, Data Bit 0.

4–9 D1–D6 DO Data Bits 1 Through 6.

10 D7 (MSB) DO Most Significant Bit, Data Bit 7.

11, 13 DV

DD

P +5 V Digital Supply. Note: DVDD and AVDD pins should share a common supply on the circuit board.

12 CLK DI Clock Input.

16 V

17 V

23 V

22 V

14, 15, 18 AV

RTS

RT

RB

RBS

DD

AI Reference Top Bias. Short to VRT for Self-Bias.

AI Reference Ladder Top.

AI Reference Ladder Bottom.

AI Reference Bottom Bias. Short to VRB for Self-Bias.

P +5 V Analog Supply. Note: DVDD and AVDD pins should share a common supply within 0.5 inches

of the AD775.

19 V

20, 21 AV

IN

SS

AI Analog Input. Input Span = VRT–VRB.

P Analog Ground. Note: DVSS and AVSS pins should share a common ground within 0.5 inches of the

AD775.

NOTE

Type: AI = Analog Input; DI = Digital Input; DO = Digital Output; P = Power.

PIN CONFIGURATION

(DIP and SOIC)

MAXIMUM RATINGS*

Supply Voltage (AVDD, DVDD) . . . . . . . . . . . . . . . . . . . . 7 V

Supply Difference (AV

Ground Difference (AV

Reference Voltage (V

Analog Input Voltage (VIN) . . . . . . . . . . . . . . . . . . VDD to V

Digital Input Voltage (CLK) . . . . . . . . . . . . . . . . . VDD to V

Digital Output Voltage (VOH, VOL) . . . . . . . . . . . . VDD to V

–DVDD) . . . . . . . . . . . . . . . . . . 0 V

DD

–DVSS) . . . . . . . . . . . . . . . . . . . 0 V

SS

, VRB) . . . . . . . . . . . . . . . . VDD to V

RT

SS

SS

SS

SS

Storage Temperature . . . . . . . . . . . . . . . . . . –55°C to +150°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Temperature Package Package

Model Range Description Option

AD775JN –20°C to +75°C 24-Pin 400 Mil Plastic DIP N-24B

AD775JR –20°C to +75°C 24-Pin 300 Mil SOIC R-24A

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD775 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–4–

ORDERING GUIDE

REV. 0

Page 5

–30

–54

0.1 1 10

–36

–42

–48

f

IN

– MHz

THD – dB

+1

–1

+FULLSCALE–FULLSCALE

0

INL – LSB

54

48

42

36

30

24

S/(N + D) – dB

18

12

6

0

0.1 1 10

fIN – MHz

Figure 2. S/(N + D) vs. Input Frequency at 20 MSPS Clock

Rate (V

= –0.3 dB)

IN

AD775

Figure 5. THD vs. Input Frequency at 20 MSPS Clock Rate

= –0.3 dB)

(V

IN

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

1.0

0

FREQUENCY – MHz

10.0

9.08.07.06.05.04.03.02.0

Figure 3. Typical FFT at 1 MHz Input, 20 MSPS Clock Rate

= –0.5 dB)

(V

IN

+0.4

+0.3

+0.2

+0.1

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

1.0

0

FREQUENCY – MHz

10.0

9.08.07.06.05.04.03.02.0

Figure 6. Typical FFT at 5 MHz Input, 20 MSPS Clock Rate

(V

= –0.5 dB)

IN

0

DNL – LSB

–0.1

–0.2

–0.3

–0.4

–FULLSCALE

Figure 4. Typical Differential Nonlinearity (DNL)

REV. 0

+FULLSCALE

Figure 7. Typical Integral Nonlinearity (INL)

–5–

Page 6

AD775

16

23

17

22

AV

DD

AV

SS

325Ω

90Ω

300Ω

AD775

*VALUES FOR

RESISTANCE

ARE TYPICAL

0.1µF

0.1µF

DEFINITIONS OF SPECIFICATIONS

Integral Nonlinearity (INL)

Integral nonlinearity refers to the deviation of each individual

code from a line drawn from “zero” through “full scale.” The

point used as “zero” occurs 1/2 LSB before the first code transition. “Full scale” is defined as a level 1 1/2 LSB beyond the

last code transition. The deviation is measured from the center

of each particular code to the true straight line.

Differential Nonlinearity (DNL, No Missing Codes)

An ideal ADC exhibits code transitions that are exactly 1 LSB

apart. DNL is the deviation from this ideal value. It is often

specified in terms of the resolution for which no missing codes

(NMC) is guaranteed.

Offset Error

The first code transition should occur at a level 1/2 LSB above

nominal negative full scale. Offset referred to the Bottom of

Ladder V

is defined as the deviation from this ideal. The last

RB

code transition should occur 1 1/2 LSB below the nominal

positive full scale. Offset referred to the Top of Ladder V

RT

is

defined as the deviation from this ideal.

Differential Gain

The percentage difference between the output amplitudes of a

small high frequency sine wave at two stated levels of a low frequency signal on which it is superimposed.

Differential Phase

The difference in the output phase of a small high frequency

sine wave at two stated levels of a low frequency signal on which

it is superimposed.

Pipeline Delay (Latency)

The number of clock cycles between conversion initiation and

the associated output data being made available. New output

data is provided every clock cycle.

Signal-to-Noise Plus Distortion Ratio (S/N+D)

S/N+D is the ratio of the rms value of the measured input signal

to the rms sum of all other spectral components including harmonics but excluding dc. The value for S/N+D is expressed in

decibels.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of the measured input signal and is expressed as a percentage or in decibels.

THEORY OF OPERATION

The AD775 uses a pipelined two-step (subranging) flash architecture to achieve significantly lower power and lower input

capacitance than conventional full flash converters while still

maintaining high throughput. The analog input is sampled by

the switched capacitor comparators on the falling edge of the

input clock: no external sample and hold is required. The coarse

comparators determine the top four bits (MSBs), and select the

appropriate reference ladder taps for the fine comparators. With

the next falling edge of the clock, the fine comparators determine

the bottom four bits (LSBs). Since the LSB comparators require

a full clock cycle between their sampling instant and their decision, the converter alternates between two sets of fine comparators in a “ping-pong” fashion. This multiplexing allows a new

input sample to be taken on every falling clock edge, thereby

providing 20 MSPS operation. The data is accumulated in the

correction logic and output through a three-state output latch

on the rising edge of the clock. The latency between input sampling and the corresponding converted output is 2.5 clock cycles.

All three comparator banks utilize the same resistive ladder for

their reference input. The analog input range is determined by

the voltages applied to the bottom and top of the ladder, and

the AD775 can digitize inputs down to 0 V using a single supply. On-chip application resistors are provided to allow the

ladder to be conveniently biased by the supply voltage.

The AD775 uses switched capacitor autozeroing techniques to

cancel the comparators’ offsets and achieve excellent differential

nonlinearity performance: typically ± 0.3 LSB. The integral

nonlinearity is determined by the linearity of the reference ladder and is typically +0.5 LSB.

APPLYING THE AD775

REFERENCE INPUT

The AD775 features a resistive reference ladder similar to that

found in most conventional flash converters. The analog input

range of the converter falls between the top (V

(V

) voltages of this ladder. The nominal resistance of the lad-

RB

) and bottom

RT

der is 300 ohms, though this may vary from 230 ohms to 450

ohms. The minimum recommended voltage for V

is 0 V; the

RB

linearity performance of the converter may deteriorate for input

spans (V

maximum ladder top voltage (V

as high as the positive supply voltage (AV

) below 1.8 V. While 2.8 V is the recommended

RB–VRB

), the top of the ladder may be

RT

) with minimal lin-

DD

earity degradation.

Figure 8. Reference Configuration: 0.64 V to 2.73 V

To simplify biasing of the AD775, on-chip reference bias resistors are provided on Pins 16 and 22. The two recommended

configurations for these resistors are shown in Figures 8 and 9.

–6–

REV. 0

Page 7

In the topology shown in Figure 8, the top of the ladder (VRT)

16

22

17

23

AD775

NC

NC

NC = NO CONNECT

0.1µF

V

RTS

V

RT

V

RBS

V

RB

1

3

2

AD822

500pF

10kΩ

20Ω

10kΩ

0.1µF

7

5

6

AD822

500pF

10kΩ

20Ω

10kΩ

0.1µF

422Ω

140Ω

422Ω

1

3

2V

OUT

GND

V

IN

AD680

0.1µF

+5V

is shorted to the top bias resistor (V

16), while the bottom of the ladder (V

tom bias resistor (V

) (Pin 23 shorted to Pin 22). This creates

RBS

a resistive path (nominally 725 ohms) between AV

) (Pin 17 shorted to Pin

RTS

) is shorted to the bot-

RB

and AVSS.

DD

For nominal supply voltages (5 V and 0 V respectively), this

creates an input range of 0.64 V to 2.73 V.

Both top and bottom of the reference ladder should be decoupled, preferably with a chip capacitor to ground to minimize

reference noise.

The topology shown in Figure 9 provides a ground-inclusive

input range. The bottom of the ladder (V

(0 V), while the top of the ladder (V

board bias resistor (V

of 0 V to +2.4 V for AV

floating, or shorted to AV

). This provides a nominal input range

RTS

of 5 V. The V

DD

.

SS

) is shorted to AVSS.

RB

) is connected to the on-

RT

pin may be left

RBS

AD775

Figure 11. Reference Configuration: 0.7 V to 3.2 V

ANALOG INPUT

The impedance looking into the analog input is essentially

capacitive, as shown in the equivalent circuit of Figure 12, typically totalling around 11 pF. A portion of this capacitance is

parasitic; the remainder is part of the switched capacitor struc-

0.1µF

AV

DD

325Ω

16

17

AD775

ture of the comparator arrays. The switches close on the rising

300Ω

90Ω

AV

SS

*VALUES FOR

RESISTANCE

ARE TYPICAL

AV

SS

23

22

Figure 9. Reference Configuration: 0 V to +2.4 V

edge of the clock, acquire the input voltage, and open on the

clock’s falling edge (the sampling instant). The charge that must

be moved onto the capacitors during acquisition will be a function of the converter’s previous two samples, but there should be

no sample-to-sample crosstalk so long as ample driving impedance and acquisition time are provided.

SWITCHES EACH

AV

DD

CLOCK CYCLE

More elaborate topologies can be used for those wishing to

provide an input span based on an external reference voltage.

C2

The circuit in Figure 10 uses the AD780 2.5 V reference to

drive the top of the ladder (V

ladder grounded to provide an input span of 0 V to +2.5 V. This is

modified in Figure 11 to shift the 2.5 V span up 700 mV.

+5V

AD780

1

NC

2

3

NC

0.1µF

4

), with the bottom (VRB) of the

RT

8

NC

16

7

NC

6

NC

5

NC

0.1µF

17

AD775

V

IN

AV

C1

SS

C1 + C2 + C3 ≈ 11pF

SWITCHES ON ALTERNATE

CLOCK CYCLES

C3

AD775

Figure 12. Equivalent Analog Input Circuit (VIN)

For example, to ensure accurate acquisition (to 1/4 bit accuracy)

of a full-scale input step in less than 20 ns, a source impedance

22

NC

23

NC = NO CONNECT

Figure 10. Reference Configuration: 0 V to 2.5 V

The AD775 can accommodate dynamic changes in the reference

voltage for gain or offset adjustment. However, conversions that

are in progress, including those in the converter pipeline, while

the reference voltages are changing will be invalid.

REV. 0

of less than 100 ohms is recommended. Figure 13 shows one

option of input buffer circuitry using the AD817. The AD817

acts as both an inverting buffer and level shifting circuit. In

order to level shift the ground-based input signal to the dc level

required by the input of the AD775, the supply voltage is resistively divided to produce the appropriate voltage at the noninverting input of the AD817. For most applications, the AD817

provides a low cost, high performance level shifter. The AD811

is recommended for systems which require faster settling times.

–7–

Page 8

AD775

0V

+5V

1kΩ

100

1kΩ

DC

5.6kΩ

AD817

1.5V

AD775

DC

A

19

IN

90

80

10µF

1kΩ

Figure 13. Level Shifting Input Buffer

The analog input range is set by the voltage at the top and bottom of the reference ladder. In general, the larger the span

(V

), the better the differential nonlinearity (DNL) of the

RT–VRB

converter; a 1.8 V span is suggested as a minimum to realize

good linearity performance. AS the input voltage exceeds 2.8 V

(for AV

= 4.75 V), the input circuitry may start to slightly

DD

degrade the acquisition performance.

CLOCK INPUT

The AD775’s internal control circuitry makes use of both clock

edges to generate on-chip timing signals. To ensure proper

settling and linearity performance, both t

and tCL times

CH

should be 25 ns or greater. For sampling frequencies at or near

20 MSPS, a 50% duty cycle clock is recommended. For slower

sampling applications, the AD775 can accommodate a wider

range of duty cycles, provided each clock phase is as least 25 ns.

Under certain conditions, the AD775 can be operated at sampling rates above 20 MSPS. Figure 14 shows the signal-to-noise

plus distortion (S/(N+D)) performance of a typical AD775

versus clock frequency. It is extremely important to note that the

maximum clock rate will be a strong function of both temperature and

supply voltage. In general, the part slows down with increasing

temperature and decreasing supply voltage.

50

40

30

20

S(N + D) – dB

70

60

50

POWER DISSIPATION – mW

40

30

0

10

CLOCK FREQUENCY – MHz

20

30

40

Figure 15. Power Dissipation vs. Clock Frequency

In applications sensitive to aperture jitter, the clock signal

should have a fall time of less than 3 ns. High speed CMOS

logic families (HC/HCT) are recommended for their symmetrical swing and fast rise/fall times. Care should be taken to minimize the fanout and capacitive loading of the clock input line.

DIGITAL INPUTS AND OUTPUTS

The AD775’s digital interface uses standard CMOS, with logic

thresholds roughly midway between the supplies (DV

, DVDD).

SS

The digital output is presented in straight binary format, with

full scale (1111 1111) corresponding to V

(0000 0000) corresponding to V

= VRB. Excessive capacitive

IN

= VRT, and zero

IN

loading of the digital output lines will increase the dynamic

power dissipation as well as the on-chip digital noise. Logic

fanout and parasitic capacitance on these lines should be minimized for optimum noise performance.

The data output lines may be placed in a high output impedance

state by bringing

typical timing for access and float delay times (t

OE (Pin 1) to a logic high. Figure 16 indicates

and t

HL

DD

respectively). Note that even when the outputs are in a high

impedance state, activity on the digital bus can couple back to

the sensitive analog portions of the AD775 and corrupt conversions in progress.

OE

t

DD

t

HL

10

0

0.1 1 10010

CLOCK FREQUENCY – MHz

Figure 14. S(N + D) vs. Clock Frequency (Temperature

°

C)

= +25

A significant portion of the AD775’s power dissipation is proportional to the clock frequency: Figure 15 illustrates this

tradeoff for a typical part.

–8–

DATA

OUTPUT

THREE-STATE

(HIGH IMPEDANCE)

t

= 18ns TYPICAL

DD

DATA ACTIVE

t

= 12ns TYPICAL

HL

Figure 16. High Impedance Output Timing

REV. 0

Page 9

AD775

J6

C15

D

C13

A

J3

TP4

V

RT

C12

+5V

D

C18

+5VA

J9

J5

C14

J4

TP3

VRB

3

2

1

AD822

C4

390pF

R10

20

1/2 U2

R9

10k

8

C9

A

+5VA

6

AD822

7

C3

390pF

R5

20

1/2 U2

R6

10k

J2

5

4

A

A

R7

10k

A

A

9

3

4

5

1

2

6

7

8

10

G1

A1

A2

A3

A4

A5

A6

A7

A8

GND

74ALS541

12

18

17

16

20

19

15

14

13

11

D

D

C22

+5V

V

CC

G2

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

TP13

ENABLE

J10

D

D

D

1

40

D

P2-40 PIN IDC

A

R8

10k

D

3

2

U1

VINV

OUT

GND

AD680

1

A

+5VA

A

C2

R3

499

C1

A

R2

500

R1

500

R11

75

R12

4.99k

3

2

6

AD817

U3

7

C6

A

C8

22µF

R13

20

Q1

2N3904

TP2

R4

49.9

A

TP1

J1

ANALOG

INPUT

4

C5

V

EE

V

CC

V

EE

A

V

CC

R14

500

+5VA

R15

499

CR1

1N4148

+5VA

A

C7

10pF

TP5

V

IN

TP10

R16

49.9

D

TP9

J8

CLOCK

( )

56

1/6

U7

98

1/6

U7

13

14

17

18

19

15

16

20

21

22

23

24

2

12

11

8

7

6

10

9

5

4

3

1

DV

SS

D2

D3

D4

D0

D1

D5

D6

D7

DV

DD

CLK

OE

V

RB

AV

SS

V

IN

AV

DD

AV

SS

V

RT

V

RTS

AV

DD

AV

DD

DV

DD

DV

SS

V

RBS

AD775

= 47µF ELECTROLYTIC CAPACITOR

UNLESS OTHERWISE NOTED

= 0.1µF CERAMIC CAPACITOR

UNLESS OTHERWISE NOTED

NOTES

VINV

OUT

GND

U4

78M05

J7

C11

D

C21

TP12

TP6

+5V

+5VA

A

V

CC

C16

C20

C19

TP7

TP8

TP11

V

CC

V

EE

1

2

3

4

5

6

V

U5

U6

POWER SUPPLY CONNECTIONS AND DECOUPLING

The analog and digital supplies of the AD775 have been separate to prevent the typically large transients associated with the

on-chip digital circuitry from coupling into the analog supplies

(AV

, AVSS). However, in order to avoid possible latch-up

DD

conditions, AV

and DVDD must share a common supply

DD

external to the part, preferably a common source somewhere on

the PC board.

Each supply should be decoupled by a 0.1 µF capacitor located

as close to the device pin as possible. Surface-mount capacitors,

by virtue of their low parasitic inductance, are preferable to

through-hole types. A larger capacitor (10 µF electrolytic)

should be located somewhere on the board to help decouple

large, low frequency supply noise. For specific layout information, refer to the AD775 Evaluation Board section of the data

sheet.

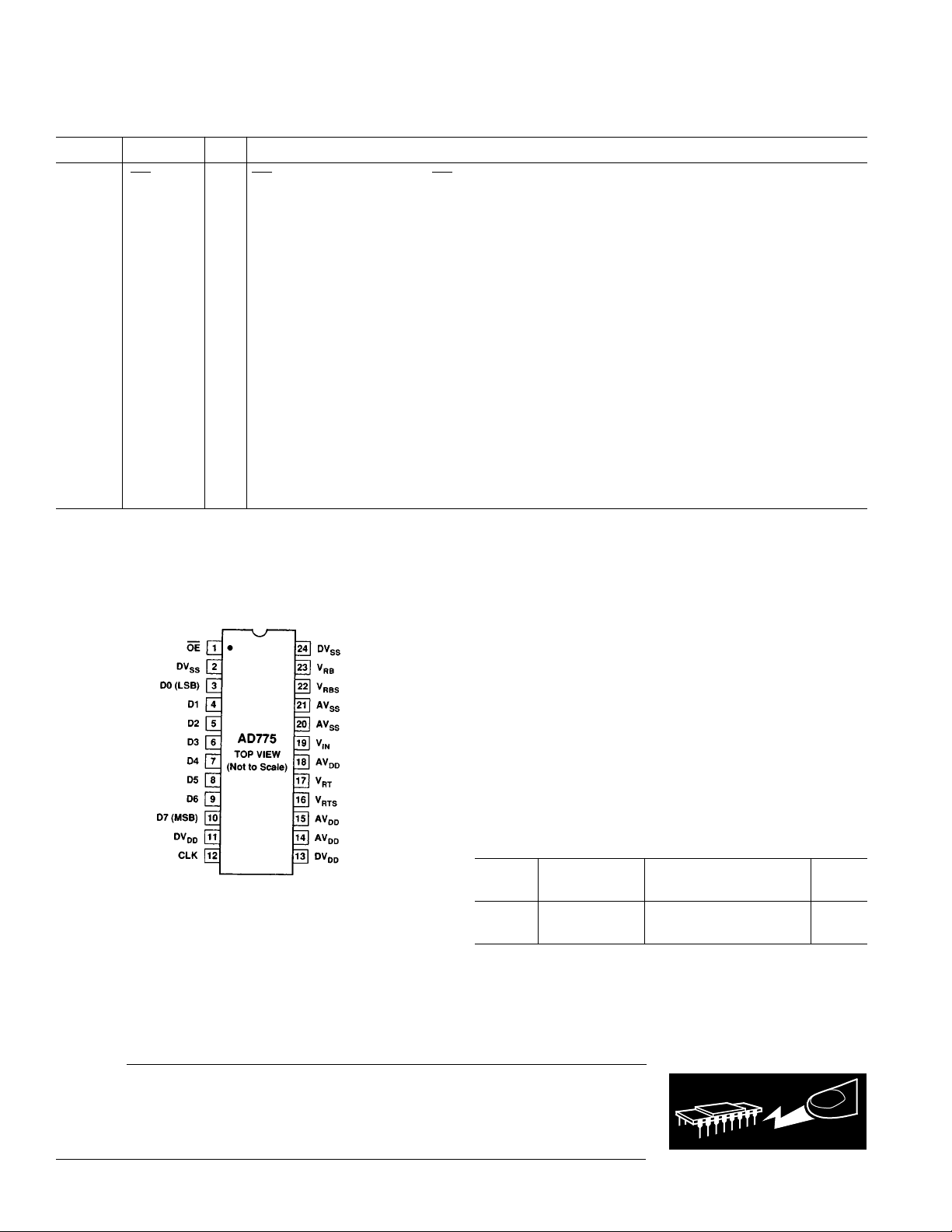

Figure 17. AD775 Evaluation Board Schematic

REV. 0

APPLICATIONS

AD775 EVALUATION BOARD

Figures 17 through 22 show the schematic and printed circuit

board (PCB) layout for the AD775 evaluation board. Referring

to Figure 17, the input signal is buffered by U3, an AD817 op

amp configured as a unity-gain follower. The signal is then accoupled and dc-biased by adjusting potentiometer R14. Video

and imaging applications would typically use a dc-restoration

circuit instead of the manual potentiometer adjustment. Q1, an

emitter-follower, buffers the input signal and provides ample

current to drive a simple low-pass filter. The filtering is included

to limit wideband noise and highlight the fact that the AD775

can be driven from a nonzero source impedance.

The reference circuit is similar to the one shown in Figure 11

with the exception that R1 and R2 allow precise adjustment of

–9–

Page 10

AD775

VRT and VRB. Note that the VRT and VRB traces (see Figures 19

and 20) are run in parallel and in the same proximity. Any noise

coupling is likely to be common mode to both signals and would

result in an offset error but not a gain error. The entire reference

circuit is powered by a single +5 V supply. The minimum voltage for V

is determined by the impedance of the AD822 out-

RB

put stage and the amount of current flowing through the

internal resistor ladder of the AD775.

The sampling clock is buffered by U7, a 74HC04 inverter. It is

recommended that the output loading of the inverter is minimized in order to maintain fast transition times on the clock. An

additional inverter is used to provide a buffered clock signal

whose rising edges indicate that data is valid. A 74ALS541

buffers the eight digital data outputs of the AD775 to improve

the load driving capability.

The multilayer PCB board layout shows some of the important

design guidelines recommended for the AD775. The most im-

Table I. Components List

Reference Designator Description Quantity

R1, R2, R14 Potentiometer 3

R3, R15 Resistor, 1%, 499 Ω 2

R4, R13, R16 Resistor, 1%, 49.9 Ω 3

R5, R10 Resistor, 1%, 20 Ω 2

R6–R9 Resistor, 1%, 10 kΩ 4

R11 Resistor, 1%, 75 Ω 1

R12 Resistor, 1%, 4.99 kΩ 1

CR1 Diode, 1N4148 1

C1, C2, C5, C6, C9, C12–C15, C18

C20, C22, C23 Ceramic Cap, Z5U, 0.1 µF13

C3, C4 Capacitor, Mica, 390 pF 2

C7 Capacitor, Mica, 10 pF 1

C8 Capacitor, Tantalum, 22 µF, 16 V 1

C11, C16, C19, C21 Capacitor, Alum. Electrolytic, 47 µF, 16 V 4

Q1 Transistor, 2N3904 1

U1 AD680JT 1

U2 AD822AN 1

U3 AD817AN 1

U4 78M05 1

U5 AD775 1

U6 74ALS541N 1

U7 74HC04N 1

J1, J8 BNC Jack 2

portant aspect is the power and ground distribution. While the

AD775 has separate analog and digital power and ground pins,

the AD775 should be treated as an entirely analog component.

The ground plane is joined close to the ADC in order to maintain a low potential difference across the analog and digital

ground pins. Because the power and grounds are derived from a

common point, a slit in the ground plane is used to minimize

any interaction between the analog and digital return currents.

The power for the AD775, AV

the same supply. Separate traces are run to AV

and DVDD, are derived from

DD

and DV

DD

DD

and joined together at the source. While not used on the evaluation board, a ferrite bead or inductor can effectively isolate noise

generated by digital circuitry such as the output buffers. In cases

where only a single supply is available, the inductor should not

be placed between AV

and DVDD. Instead, both supplies of

DD

the AD775 should be connected together and isolated from

entirely digital components.

–10–

REV. 0

Page 11

AD775

Figure 18. Silkscreen Layer (Not to Scale)

Figure 20. Solder Side PCB Layout (Not to Scale)

Figure 19. Component Side PCB Layout (Not to Scale)

REV. 0

Figure 21. Ground Plane PCB Layout (Not to Scale)

–11–

Page 12

AD775

PIN 1

13

24

12

1

0.221 (5.6)

0.205 (5.2)

0.327 (8.3)

0.295 (7.5)

0.022 (0.55)

0.014 (0.35)

0.050 (1.27)

BSC

0.606 (15.4)

0.586 (14.9)

0.089 (2.25)

0.067 (1.70)

0.012 (0.12)

0.002 (0.05)

0.012 (0.30)

0.006 (0.15)

0.028 (0.7)

0.012 (0.3)

0.272 (6.9)

C1830–18–8/93

PIN 1

0.200 (5.05)

0.125 (3.18)

0.118 (3.00)

24

MIN

0.024 (0.60)

0.016 (0.40)

Figure 22. Power Plane PCB Layout (Not to Scale)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Plastic DIP (N-24B)

13

0.346 (8.80)

0.330 (8.40)

0.053 (1.35)

0.041 (1.05)

12

0.020

(0.50)

MIN

SEATING

PLANE

0.400 (10.16)

15

°

0.014 (0.35)

0

°

0.008 (0.20)

0.195 (4.95)

0.125 (3.18)

1

1.205 (30.60)

1.185 (30.10)

0.100

(2.54)

BSC

SOIC (R-24A)

PRINTED IN U.S.A.

–12–

REV. 0

Loading...

Loading...