Page 1

24-Bit Capacitance-to-Digital Converter

V

FEATURES

Capacitance-to-digital converter

New standard in single chip solutions

Interfaces to single or differential grounded sensors

Resolution down to 20 aF (that is, up to 19.5-bit ENOB)

Accuracy: 10 fF

Linearity: 0.01%

Common-mode (not changing) capacitance up to 17 pF

Full-scale (changing) capacitance range ±8 pF

Update rate: 5 Hz to 45 Hz

Simultaneous 50 Hz and 60 Hz rejection at 8.1 Hz update

Active shield for shielding sensor connection

Temperature sensor on-chip

Resolution: 0.1°C, accuracy: ±2°C

Voltage input channel

Internal clock oscillator

2-wire serial interface (I

Power

2.7 V to 5.25 V single-supply operation

0.7 mA current consumption

Operating temperature: −40°C to +125°C

16-lead TSSOP package

APPLICATIONS

Automotive, industrial, and medical systems for

Pressure measurement

Position sensing

Proximity sensing

Level sensing

Flow metering

Impurity detection

2

C® compatible)

with Temperature Sensor

AD7747

GENERAL DESCRIPTION

The AD7747 is a high-resolution, Σ- capacitance-to-digital

converter (CDC). The capacitance to be measured is connected

directly to the device inputs. The architecture features inherent

high resolution (24-bit no missing codes, up to 19.5-bit effective

resolution), high linearity (±0.01%), and high accuracy (±10 fF

factory calibrated). The AD7747 capacitance input range is

±8 pF (changing), and it can accept up to 17 pF common-mode

capacitance (not changing), which can be balanced by a programmable on-chip digital-to-capacitance converter (CAPDAC).

The AD7747 is designed for single-ended or differential

capacitive sensors with one plate connected to ground. For

floating (not grounded) capacitive sensors, the AD7745 or

AD7746 are recommended.

The part has an on-chip temperature sensor with a resolution of

0.1°C and accuracy of ±2°C. The on-chip voltage reference and

the on-chip clock generator eliminate the need for any external

components in capacitive sensor applications. The part has a

standard voltage input that, together with the differential reference

input, allows easy interface to an external temperature sensor,

such as an RTD, thermistor, or diode.

2

The AD7747 has a 2-wire, I

part can operate with a single power supply of 2.7 V to 5.25 V.

It is specified over the automotive temperature range of

−40°C to +125°C and is housed in a 16-lead TSSOP package.

C-compatible serial interface. The

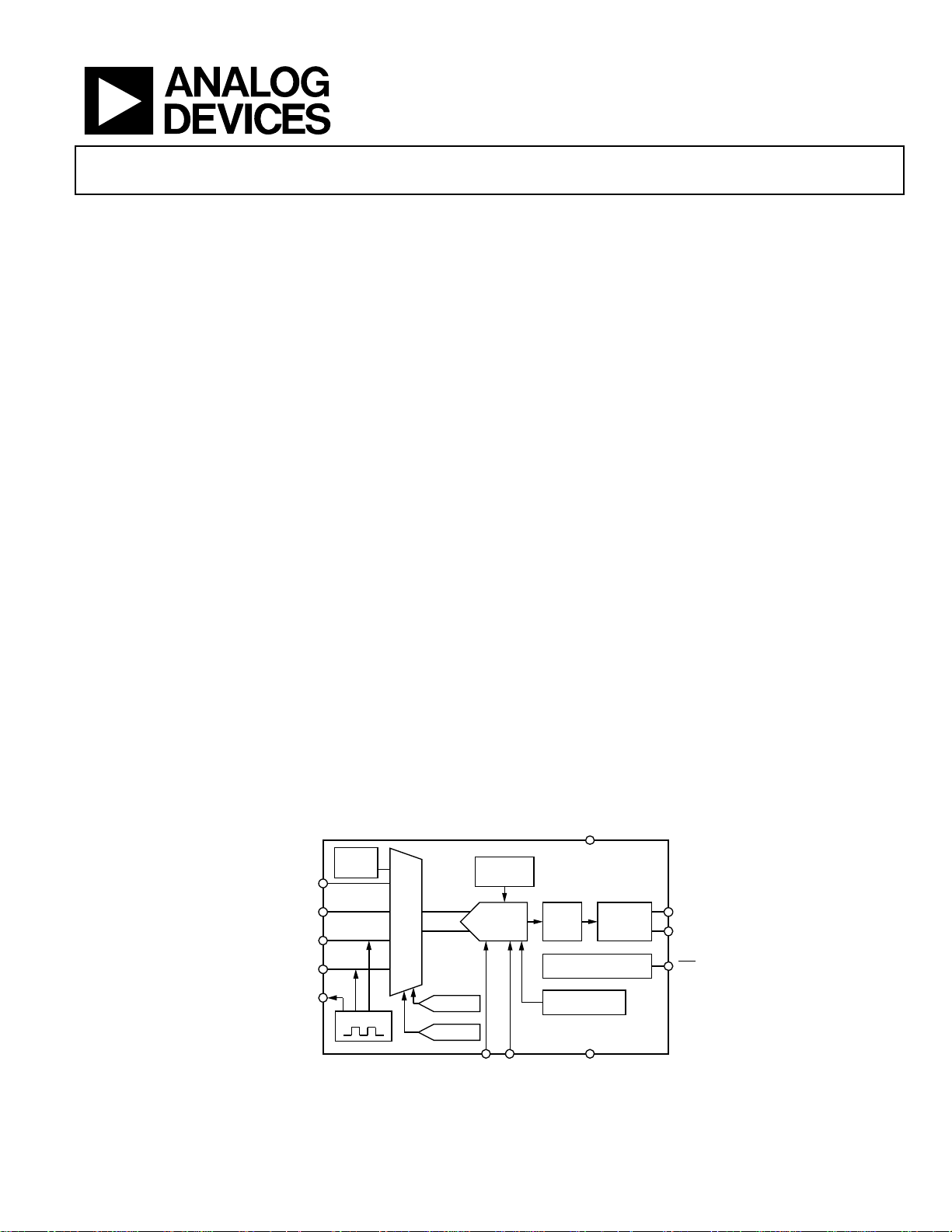

FUNCTIONAL BLOCK DIAGRAM

DD

TEMP

SENSOR

VIN(+)

VIN(–)

CIN1(+)

CIN1(–)

SHLD

EXCITATION

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

MUX

CAP DAC 1

CAP DAC 2

CLOCK

GENERATOR

24-BIT Σ-Δ

GENERATOR

REFIN( +) REFIN( –)

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

AD7747

DIGITAL

FILTER

CONTROL LOG IC

CALIBRATION

VOLTAGE

REFERENCE

GND

I2C

SERIAL

INTERFACE

SDA

SCL

RDY

05469-001

Page 2

AD7747

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Specifications .................................................................. 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Output Noise and Resolution Specifications ..............................11

Serial Interface ................................................................................ 12

Read Operation........................................................................... 12

Write Operation.......................................................................... 12

AD7747 Reset.............................................................................. 13

General Call................................................................................. 13

Register Descriptions ..................................................................... 14

Status Register............................................................................. 15

Cap Data Register....................................................................... 15

VT Data Register ........................................................................15

Cap Setup Register ..................................................................... 16

VT Setup Register....................................................................... 16

EXC Setup Register ....................................................................17

Configuration Register .............................................................. 18

Cap DAC A Register .................................................................. 19

Cap DAC B Register................................................................... 19

Cap Offset Calibration Register ............................................... 20

Cap Gain Calibration Register.................................................. 20

Volt Gain Calibration Register ................................................. 20

Circuit Description......................................................................... 21

Overview ..................................................................................... 21

Capacitance-to-Digital Converter............................................ 21

Active AC Shield Concept......................................................... 21

CAPDAC..................................................................................... 21

Single-Ended Capacitive Configuration ................................. 22

Differential Capacitive Configuration..................................... 22

Parasitic Capacitance................................................................. 23

Parasitic Resistance.................................................................... 23

Parasitic Serial Resistance ......................................................... 23

Capacitive Gain Calibration ..................................................... 23

Capacitive System Offset Calibration...................................... 24

Internal Temperature Sensor .................................................... 24

External Temperature Sensor ................................................... 24

Voltage Input............................................................................... 25

V

Monitor................................................................................ 25

DD

Typical Application Diagram.................................................... 26

Outline Dimensions....................................................................... 27

Ordering Guide .......................................................................... 27

REVISION HISTORY

1/07—Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

AD7747

SPECIFICATIONS

VDD = 2.7 V to 3.6 V or 4.75 V to 5.25 V; GND = 0 V; EXC = ±V

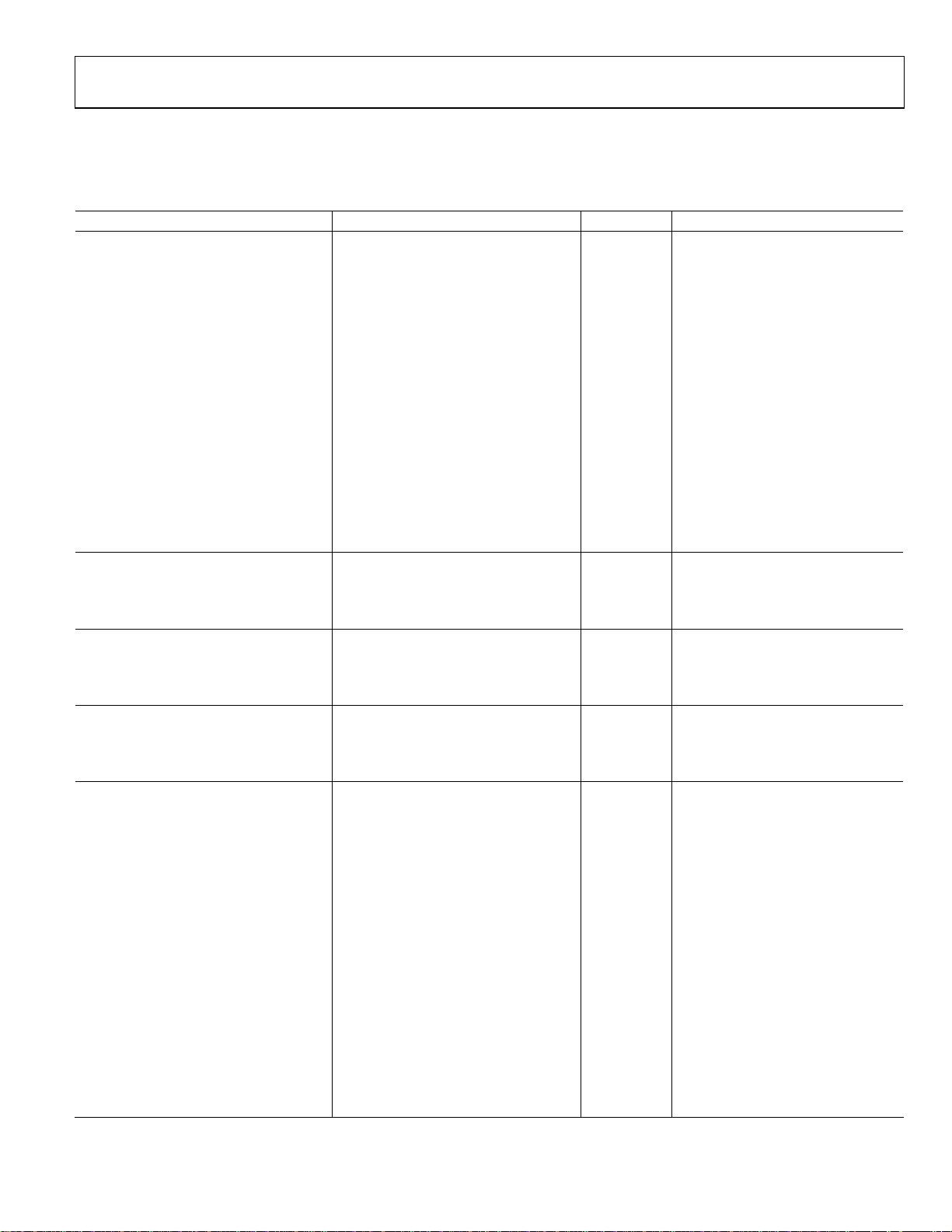

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

CAPACITIVE INPUT

Conversion Input Range ±8.192 pF1 Factory calibrated

Integral Nonlinearity (INL)2 ±0.01 % of FSR1

No Missing Codes2 24 Bit Conversion time ≥ 124 ms

Resolution, p-p 16.5 Bit Conversion time 124 ms, see Table 5

Resolution Effective 19.1 Bit Conversion time 124 ms, see Table 5

Output Noise, rms 11.0

Absolute Error3 ±10 fF1 25°C, VDD = 5 V, after offset calibration

Offset Error

4, 5

32 aF1

System Offset Calibration Range5 ±1 pF

Offset Deviation over Temperature2 0.4 fF See Figure 6

Gain Error6 0.02 0.11 % of FS1 25°C, VDD = 5 V

Gain Drift vs. Temperature2 −23 −26 −29 ppm of FS/°C

Power Supply Rejection2 0.5 4 fF/V

Normal Mode Rejection5 72 dB 50 Hz ± 1%, conversion time 124 ms

60 dB 60 Hz ± 1%, conversion time 124 ms

CAPDAC

Full Range 17 21 pF 6-bit CAPDAC

Differential Nonlinearity (DNL) 0.3 LSB See Figure 16

Drift vs. Temperature2 26 ppm of FS/°C

EXCITATION

Frequency 16 kHz

AC Voltage Across Capacitance ±VDD × 3/8 V To be configured via digital interface

Average DC Voltage Across Capacitance VDD/2 V

TEMPERATURE SENSOR7 V

Resolution 0.1 °C

Error2 ±0.5 ±2 °C Internal temperature sensor

±2 °C External sensing diode8

VOLTAGE INPUT7 V

Differential VIN Voltage Range ±V

Absolute VIN Voltage2 GND − 0.03 VDD + 0.03 V

Integral Nonlinearity (INL) ±3 ±15 ppm of FS

No Missing Codes2 24 Bit Conversion time = 122.1 ms

Resolution, p-p 16 Bits

Output Noise 3 μV rms

Offset Error ±3 μV

Offset Drift vs. Temperature 15 nV/°C

Full-Scale Error

2, 9

0.025 0.1 % of FS

Full-Scale Drift vs. Temperature 5 ppm of FS/°C Internal reference

0.5 ppm of FS/°C External reference

Average VIN Input Current 300 nA/V

Analog VIN Input Current Drift ±50 pA/V/°C

Power Supply Rejection 80 dB Internal reference, VIN = V

90 dB External reference, VIN = V

× 3/8; −40°C to +125°C, unless otherwise noted.

DD

aF/√Hz

Conversion time 124 ms, see Table 5

After system offset calibration,

excluding effect of noise

REF

REF

V

REF

Conversion time = 62 ms,

see Table 6 and Table 7

Conversion time = 62 ms,

see Table 6 and Table 7

internal

internal or V

= 2.5 V

REF

4

/2

REF

/2

REF

Rev. 0 | Page 3 of 28

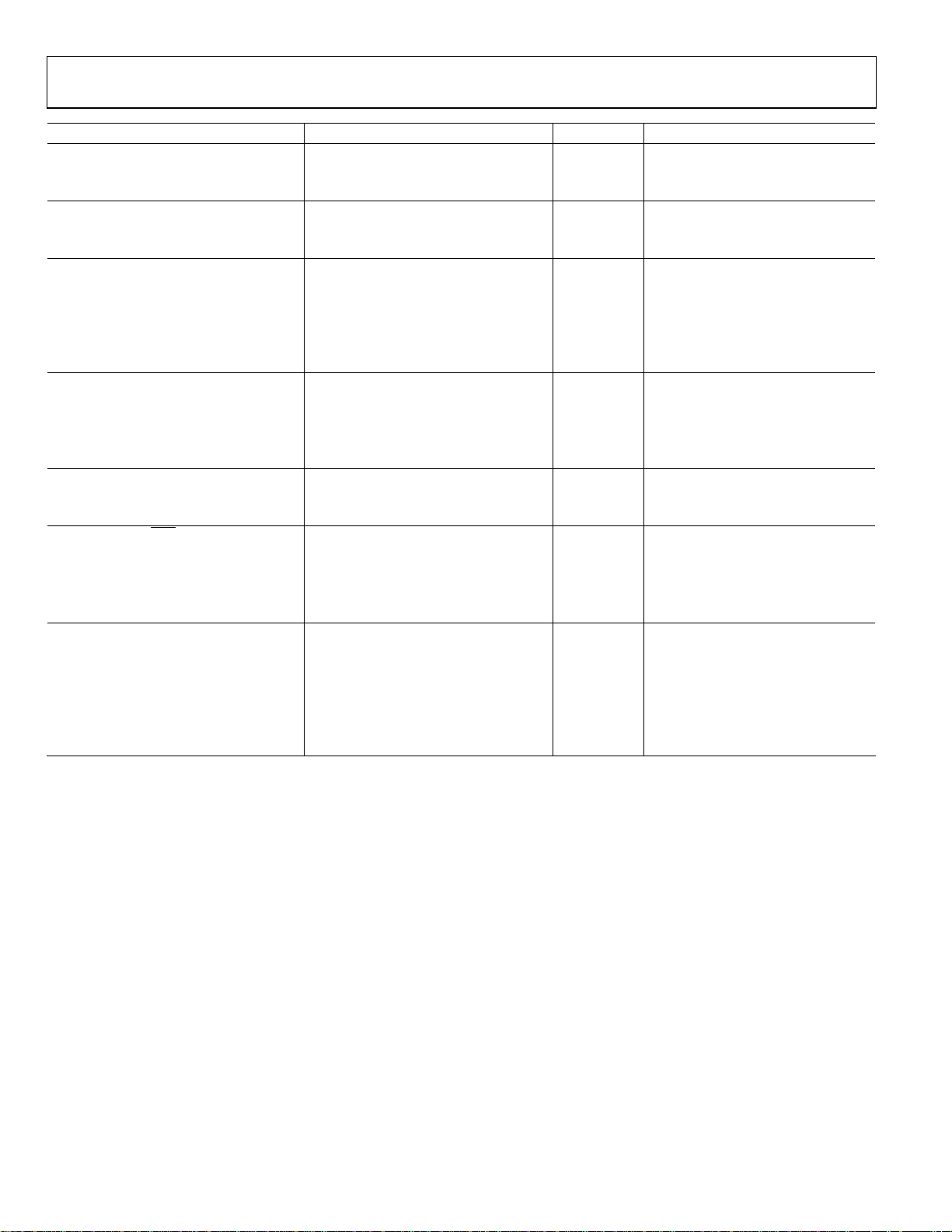

Page 4

AD7747

Parameter Min Typ Max Unit Test Conditions/Comments

Normal Mode Rejection5 75 dB 50 Hz ± 1%, conversion time = 122.1 ms

50 dB 60 Hz ± 1%, conversion time = 122.1 ms

Common-Mode Rejection2 95 dB VIN = 1 V

INTERNAL VOLTAGE REFERENCE

Voltage 1.169 1.17 1.171 V TA = 25°C

Drift vs. Temperature 5 ppm/°C

EXTERNAL VOLTAGE REFERENCE INPUT

Differential REFIN Voltage2 0.1 2.5 VDD V

Absolute REFIN Voltage2 GND − 0.03 VDD + 0.03 V

Average REFIN Input Current 400 nA/V

Average REFIN Input Current Drift ±50 pA/V/°C

Common-Mode Rejection 80 dB

SERIAL INTERFACE LOGIC INPUTS (SCL, SDA)

VIH Input High Voltage 2.1 V

VIL Input Low Voltage 0.8 V

Hysteresis 150 mV

Input Leakage Current (SCL) ±0.1 ±1 μA

OPEN-DRAIN OUTPUT (SDA)

VOL Output Low Voltage 0.4 V I

IOH Output High Leakage Current 0.1 1 μA V

LOGIC OUTPUT (

RDY

)

VOL Output Low Voltage 0.4 V I

VOH Output High Voltage 4.0 V I

VOL Output Low Voltage 0.4 V I

VOH Output High Voltage VDD − 0.6 V I

POWER REQUIREMENTS

VDD-to-GND Voltage 4.75 5.25 V VDD = 5 V, nominal

2.7 3.6 V VDD = 3.3 V, nominal

IDD Current 850 μA Digital inputs equal to VDD or GND

750 μA VDD = 5 V

700 μA VDD = 3.3 V

IDD Current Power-Down Mode 0.5 2 μA Digital inputs equal to VDD or GND

1

Capacitance units: 1 pF = 10

2

Specification is not production tested, but is supported by characterization data at initial product release.

3

Factory calibrated. The absolute error includes factory gain calibration error, integral nonlinearity error, and offset error after system offset calibration, all at 25°C.

At different temperatures, compensation for gain drift over temperature is required.

4

The capacitive input offset can be eliminated using a system offset calibration. The accuracy of the system offset calibration is limited by the offset calibration register

LSB size (32 aF) or by converter + system p-p noise during the system capacitive offset calibration, whichever is greater. To minimize the effect of the converter +

system noise, longer conversion times should be used for system capacitive offset calibration. The system capacitance offset calibration range is ±1 pF; the larger

offset can be removed using CAPDACs.

5

Specification is not production tested, but guaranteed by design.

6

The gain error is factory calibrated at 25°C. At different temperatures, compensation for gain drift over temperature is required.

7

The VTCHOP bit in the VT SETUP register must be set to 1 for the specified temperature sensor and voltage input performance.

8

Using an external temperature sensing diode 2N3906, with nonideality factor nf = 1.008, connected as in Figure 37, with total serial resistance <100 Ω.

9

Full-scale error applies to both positive and negative full scale.

−12

F; 1 fF = 10

−15

F; 1 aF = 10

−18

F. Full scale (FS) = 8.192 pF; full-scale range (FSR) = ±8.192 pF.

= −6.0 mA

SINK

= VDD

OUT

= 1.6 mA, VDD = 5 V

SINK

= 200 μA, VDD = 5 V

SOURCE

= 100 μA, VDD = 3 V

SINK

= 100 μA, VDD = 3 V

SOURCE

Rev. 0 | Page 4 of 28

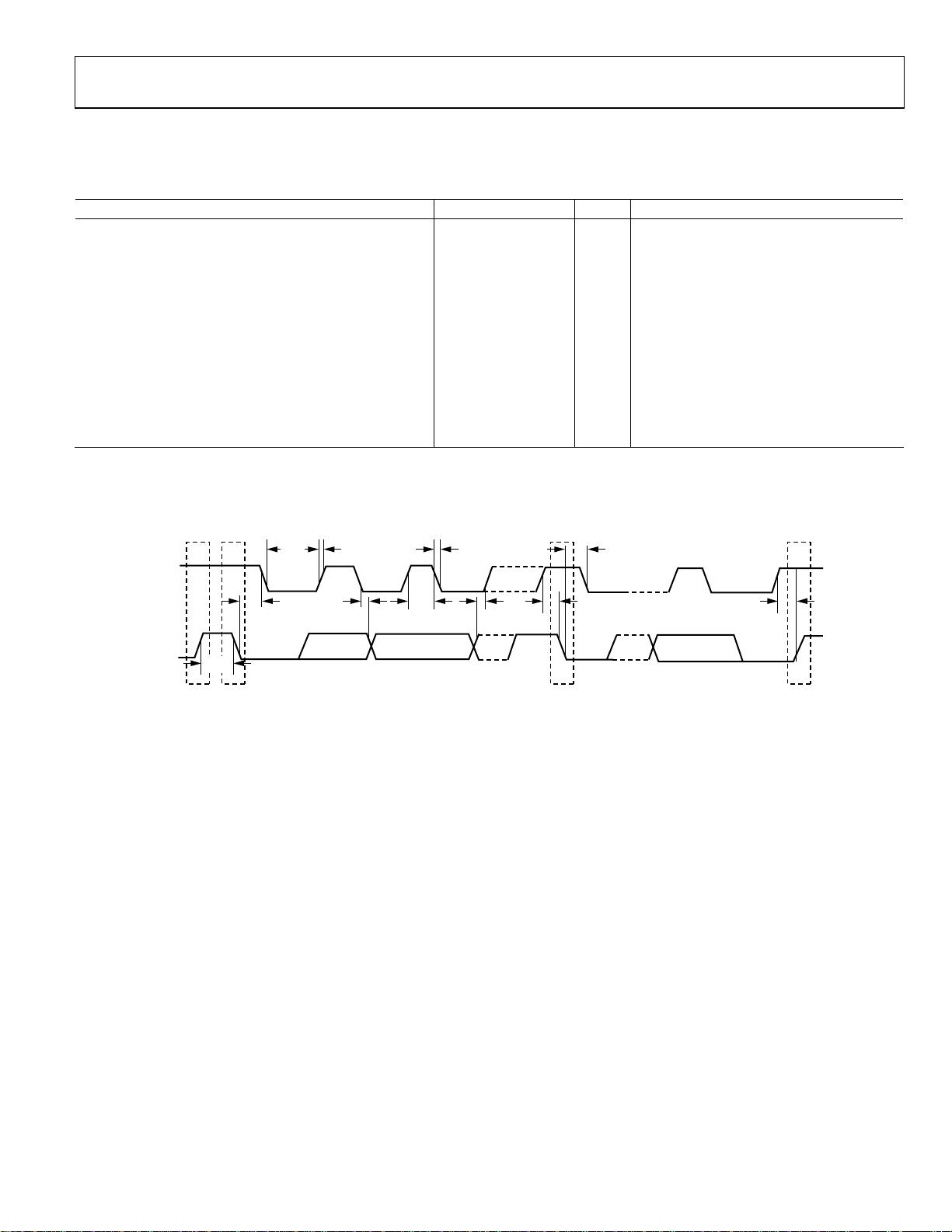

Page 5

AD7747

TIMING SPECIFICATIONS

VDD = 2.7 V to 3.6 V, or 4.75 V to 5.25 V; GND = 0 V; Input Logic 0 = 0 V; Input Logic 1 = VDD; −40°C to +125°C, unless otherwise noted.

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

SERIAL INTERFACE

SCL Frequency 0 400 kHz

SCL High Pulse Width, t

SCL Low Pulse Width, t

SCL, SDA Rise Time, tR 0.3 μs

SCL, SDA Fall Time, t

Hold Time (Start Condition), t

Setup Time (Start Condition), t

Data Setup Time, t

Setup Time (Stop Condition), t

Data Hold Time, t

Bus-Free Time (Between Stop and Start Condition, t

1

Sample tested during initial release to ensure compliance.

2

All input signals are specified with input rise/fall times = 3 ns, measured between the 10% and 90% points. Timing reference points at 50% for inputs and outputs.

Output load = 10 pF.

1, 2

See Figure 2

0.6 μs

HIGH

1.3 μs

LOW

F

0.6 μs After this period, the first clock is generated

HD;STA

0.6 μs Relevant for repeated start condition

SU;STA

0.1 μs

SU;DAT

0.6 μs

SU;STO

(Master) 0 μs

HD;DAT

t

R

t

LOW

0.3 μs

) 1.3 μs

BUF

t

F

t

HD;STA

SCL

t

SDA

t

t

BUF

PS

HD;STA

t

HD;DAT

HIGH

t

SU;DAT

t

SU;STA

S

t

SU;STO

P

05469-002

Figure 2. Serial Interface Timing Diagram

Rev. 0 | Page 5 of 28

Page 6

AD7747

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

Positive Supply Voltage VDD to GND −0.3 V to +6.5 V

Voltage on any Input or Output Pin to

GND

ESD Rating (ESD Association Human Body

Model, S5.1)

Operating Temperature Range −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Junction Temperature 150°C

TSSOP Package θ

(Thermal Impedance-to-Air)

TSSOP Package θJC

(Thermal Impedance-to-Case)

Peak Reflow Soldering Temperature

Pb Free (20 sec to 40 sec) 260°C

JA

−0.3 V to V

2000 V

128°C/W

14°C/W

+ 0.3 V

DD

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 6 of 28

Page 7

AD7747

V

V

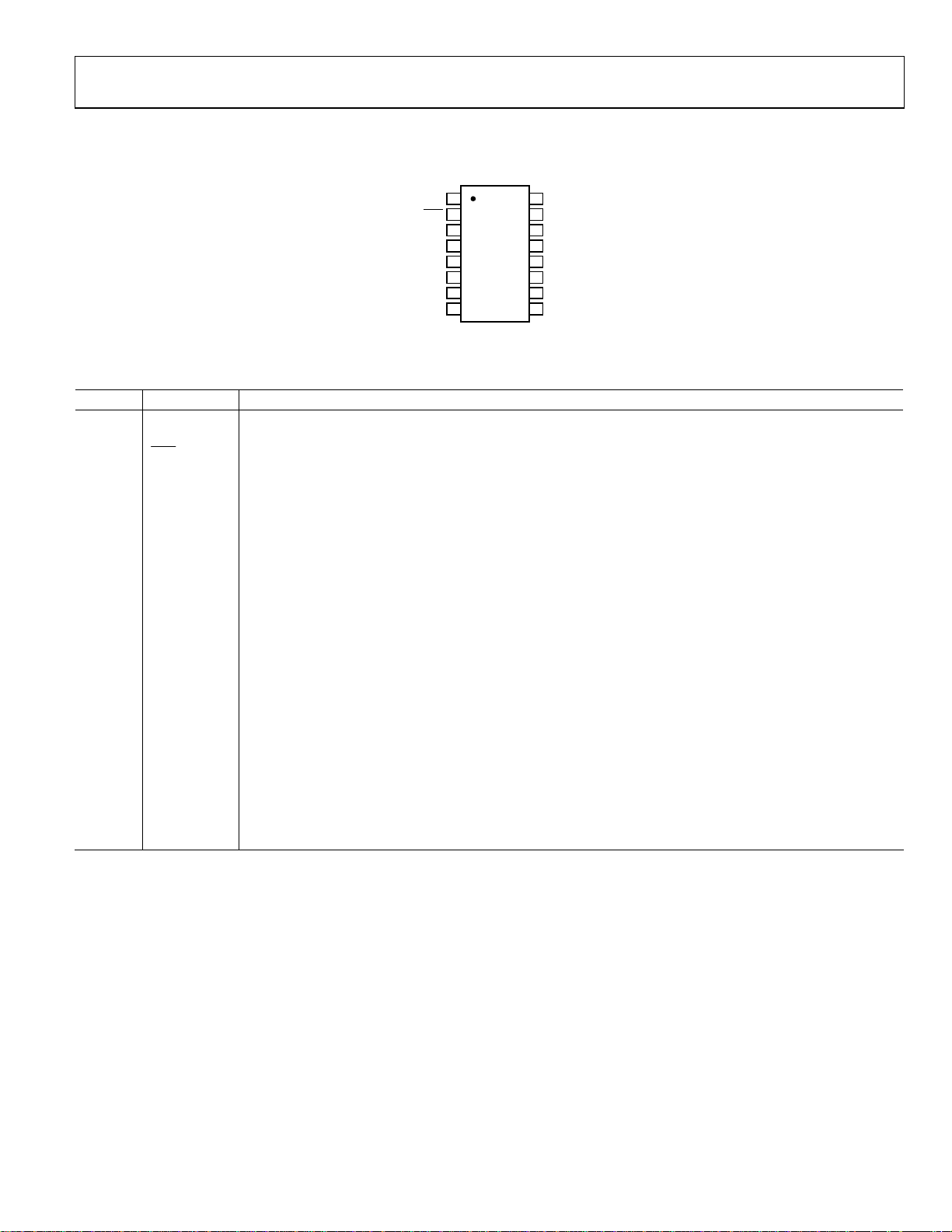

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

SCL

1

2

RDY

3

SHLD

TST

REFIN(+)

REFIN(–)

CIN1(–)

CIN1(+)

AD7747

4

TOP VIEW

5

(Not to Scale)

6

7

8

NC = NO CONNECT

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 SCL

Serial Interface Clock Input. Connects to the master clock line. Requires pull-up resistor if not already provided

in the system.

2

Logic Output. A falling edge on this output indicates that a conversion on enabled channel(s) has been finished

RDY

and the new data is available. Alternatively, the status register can be read via the 2-wire serial interface and the

relevant bit(s) decoded to query the finished conversion. If not used, this pin should be left as an open circuit.

3 SHLD

Capacitive Input Active AC Shielding. To eliminate the CIN parasitic capacitance to ground, the SHLD signal

can be used for shielding the connection between the sensor and CIN. If not used, this pin should be left as an

open circuit.

4 TST This pin must be left as an open circuit for proper operation.

5, 6

REFIN(+),

REFIN(−)

Differential Voltage Reference Input for the Voltage Channel (ADC). Alternatively, the on-chip internal reference

can be used for the voltage channel. These reference input pins are not used for conversion on capacitive

channel(s) (CDC). If not used, these pins can be left as an open circuit or connected to GND.

7 CIN1(−)

CDC Negative Capacitive Input. The measured capacitance is connected between the CIN1(−) pin and GND. If

not used, this pin should be left as an open circuit.

8 CIN1(+)

CDC Positive Capacitive Input. The measured capacitance is connected between the CIN1(+) pin and GND. If not

used, this pin should be left as an open circuit.

9, 10 NC Not Connected. These pins should be left as an open circuit.

11, 12 VIN(+), VIN(−)

Differential Voltage Input for the Voltage Channel (ADC). These pins are also used to connect an external

temperature sensing diode. If not used, these pins can be left as an open circuit or connected to GND.

13 GND Ground Pin.

14 VDD

Power Supply Voltage. This pin should be decoupled to GND, using a low impedance capacitor, for example in

combination with a 10 μF tantalum and a 0.1 μF multilayer ceramic.

15 NC Not Connected. This pin should be left as an open circuit.

16 SDA

Serial Interface Bidirectional Data. Connects to the master data line. Requires a pull-up resistor if not provided

elsewhere in the system.

SDA

16

15

NC

14

VDD

13

GND

12

IN(–)

11

IN(+)

10

NC

9

NC

05469-003

Rev. 0 | Page 7 of 28

Page 8

AD7747

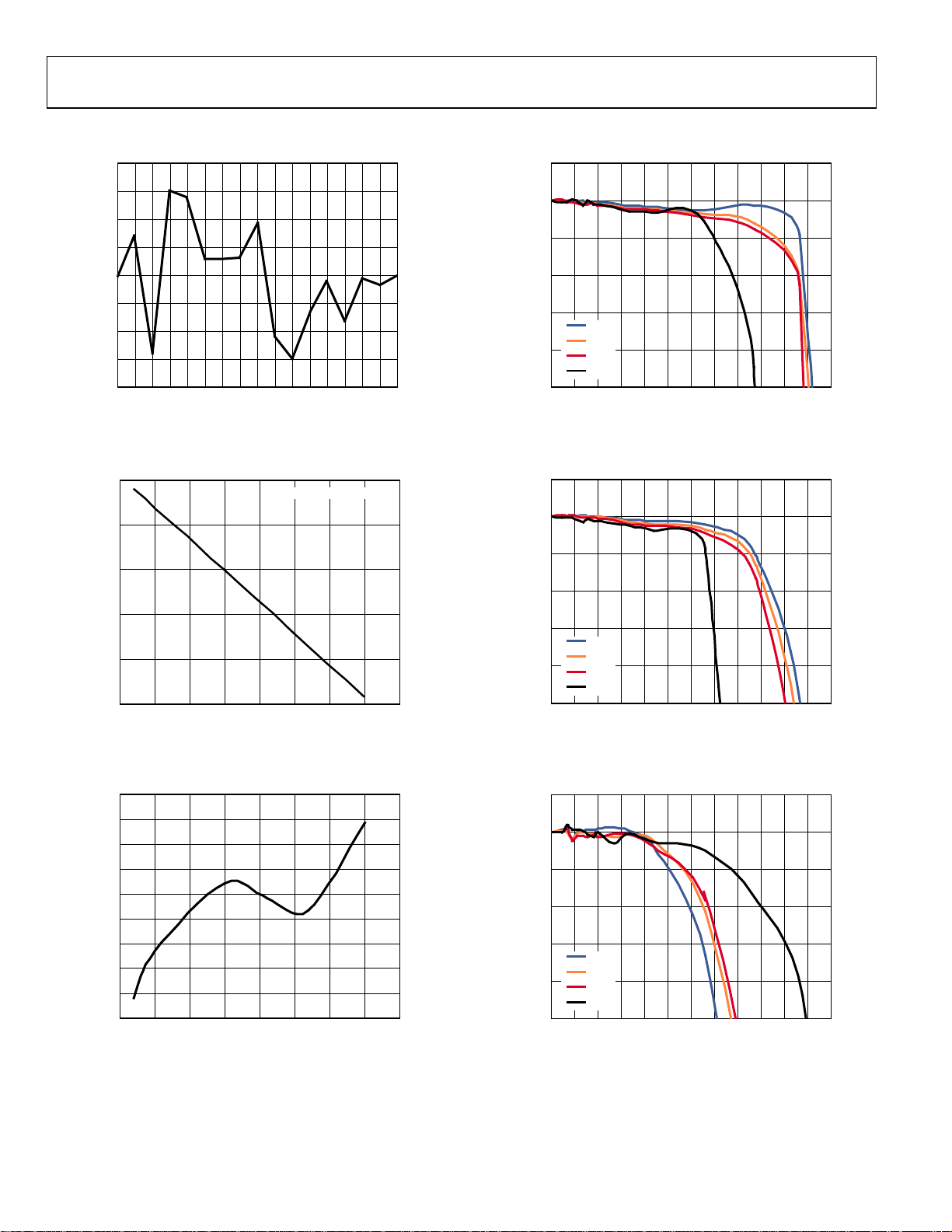

TYPICAL PERFORMANCE CHARACTERISTICS

80

10

60

40

20

0

INL (ppm)

–20

–40

–60

–80

–8 –7 –6 –5 –4 –3 –1–2 8

INPUT CAPACIT ANCE (pF)

01234567

Figure 4. Capacitance Input Integral Nonlinearity;

= 5 V, CAPDAC = 0x3F

V

DD

2000

1000

0

–1000

GAIN ERROR (ppm)

–2000

–3000

–50 150

–25 0 25 50 75 100 125

TEMPERATURE (ºC)

GAIN TC ≈ –28ppm/ºC

Figure 5. Capacitance Input Gain Drift vs. Temperature;

V

= 5 V, CIN(+) to GND = 8 pF

DD

.20

.15

.10

.050

–0.05

–0.10

–0.15

OFFSET ERROR (fF)

–0.20

–0.25

–0.30

–50 150

–25 0 25 50 75 100 125

TEMPERATURE (ºC)

0

–10

–20

CAP ERROR (fF)

–30

–40

05469-004

–50

2.7V

3.0V

3.3V

5.0V

0 600500

50 100 150 200 250 300 350 400 450 550

CAPACITANCE SHLD T O GND (pF )

05469-007

Figure 7. Capacitance Input Error vs. Capacitance Between SHLD and GND;

CIN(+) to GND = 8 pF, V

10

0

–10

–20

CAP ERROR (fF)

–30

–40

05469-005

–50

2.7V

3.0V

3.3V

5.0V

0 600500

50 100 150 200 250 300 350 400 450 550

CAPACITANCE SHLD T O GND (pF )

= 2.7 V, 3 V, 3.3 V, and 5 V

DD

05469-008

Figure 8. Capacitance Input Error vs. Capacitance Between SHLD and GND;

CIN(+) to GND = 25 pF, V

10

0

–10

–20

CAP ERROR (fF)

–30

–40

05469-006

–50

2.7V

3.0V

3.3V

5.0V

0 600500

50 100 150 200 250 300 350 400 450 550

CAPACITANCE CIN TO SHLD (pF )

= 2.7 V, 3 V, 3.3 V, and 5 V

DD

05469-009

Figure 6. Capacitance Input Offset Drift vs. Temperature;

= 5 V, CIN(+) Open

V

DD

Rev. 0 | Page 8 of 28

Figure 9. Capacitance Input Error vs. Capacitance Between CIN(+) and SHLD;

CIN(+) to GND = 8 pF, V

= 2.7 V, 3 V, 3.3 V, and 5V

DD

Page 9

AD7747

150

100

50

0

CAP ERROR (fF)

–50

–100

–150

01k

10 100

PARALLEL RESISTANCE (MΩ)

05469-010

Figure 10. Capacitance Input Error vs. Parallel Resistance;

CIN(+) to GND = 8 pF, V

0

–100

–200

–300

–400

–500

–600

CAP ERROR (fF)

–700

–800

–900

–1000

0 200

25 50 75 1 00 125 150 175

CIN TO SHLD RE SISTANCE (kΩ)

= 5 V

DD

05469-058

Figure 11. Capacitance Input Error vs. Resistance Between CIN1(+) and SHLD;

DD

= 5 V

05469-059

100

–100

–200

–300

–400

–500

–600

CAP ERROR (fF)

–700

–800

–900

–1000

CIN(+) to GND = 8 pF, V

0

0.091

0.27 0. 48 0. 96 5 25 100

CIN TO SHLD RE SISTANCE (MΩ)

Figure 12. Capacitance Input Error vs. Resistance Between CIN(+) and SHLD;

CIN(+) to GND = 25 pF, V

DD

= 5 V

1.0

0.8

0.6

0.4

0.2

0

–0.2

CAP ERROR (pF)

–0.4

–0.6

–0.8

–1.0

0.01

0.1 1.0 10.0

SHLD TO GND RESI STANCE (MΩ)

100

05469-066

Figure 13. Capacitance Input Error vs. Resistance Between SHLD and GND;

= 5 V

DD

8 pF

25 pF

05469-067

10

100

CAP ERROR (fF)

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CIN(+) to GND = 8 pF; V

10

0

1

SERIAL RESISTANCE (kΩ)

Figure 14. Capacitance Input Error vs. Serial Resistance;

CIN(+) to GND = 8 pF and 25pF, V

0.2

0

–0.2

CAP ERROR (fF)

–0.4

–0.6

3.0 3.5 4. 0 4.5 5.0

2.5 5.5

VDD (V)

DD

= 5 V

05469-062

Figure 15. Capacitance Input Power Supply Rejection (PSR);

CIN(+) to GND = 8 pF

Rev. 0 | Page 9 of 28

Page 10

AD7747

200

0

150

100

50

0

–50

CAPDAC DNL (fF)

–100

–150

–200

8 162432404856

064

CAPDAC CODE

05469-050

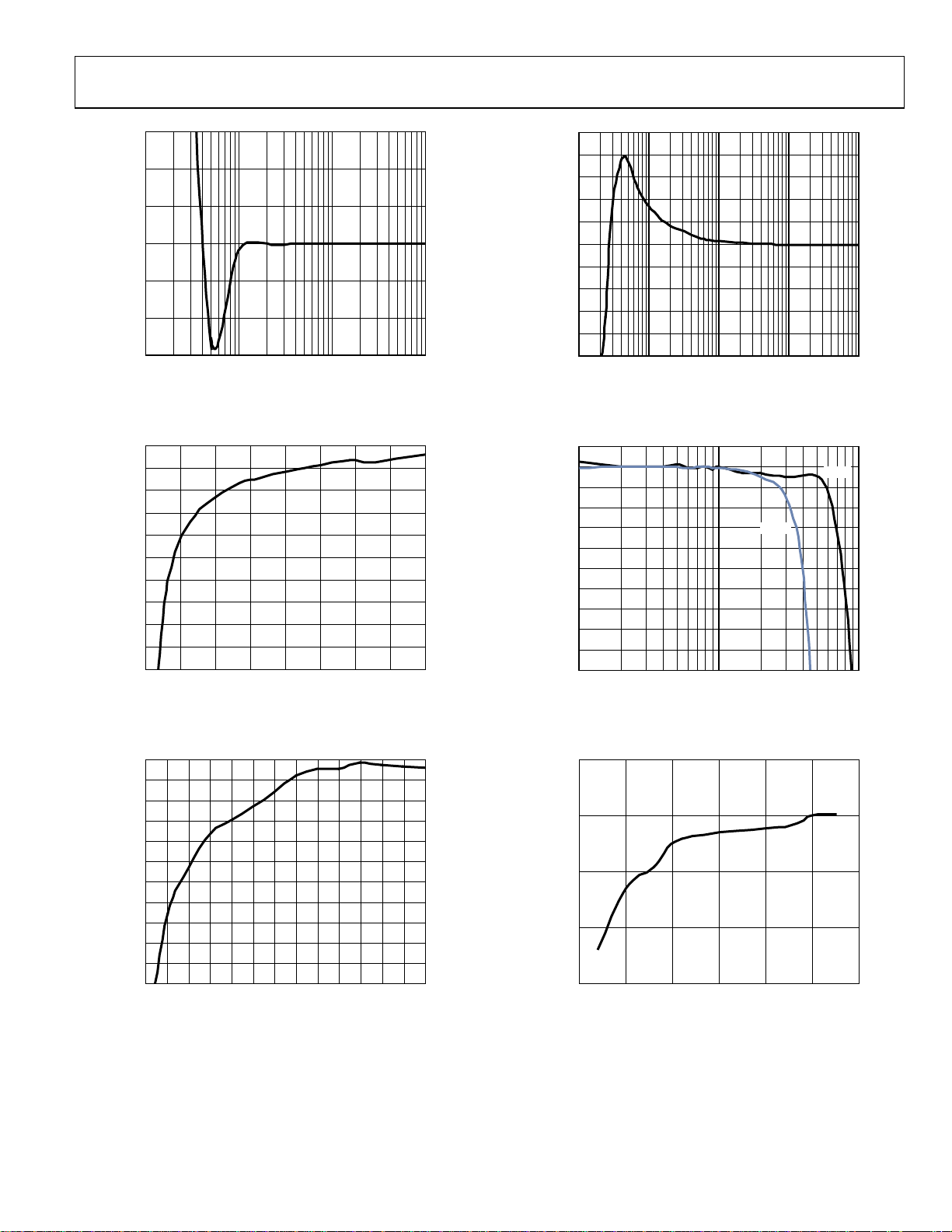

Figure 16. CAPDAC Differential Nonlinearity (DNL)

2.0

1.5

1.0

0.5

0

ERROR (°C)

–0.5

–1.0

–1.5

–2.0

–50

–25 0 25 50 75 100 125

TEMPERATURE (°C)

150

05469-034

Figure 17. Internal Temperature Sensor Error vs. Temperature

–20

–40

–60

GAIN (dB)

–80

–100

–120

100 200 300 400 500 600 700 800 900

01k

Figure 19. Capacitive Channel Frequency Response;

0

–20

–40

–60

GAIN (dB)

–80

–100

–120

25 50 75 1 00 125 150 175

0 200

Figure 20. Capacitive Channel Frequency Response;

INPUT SIGNAL FREQUENCY ( Hz)

Conversion Time = 22 ms

INPUT SIGNAL FREQUENCY ( Hz)

Conversion Time = 124 ms

05469-051

05469-052

1.0

0.5

0

–0.5

–1.0

ERROR (°C)

–1.5

–2.0

–2.5

–3.0

–50

–25 0 25 50 75 100 125

TEMPERATURE (°C)

Figure 18. External Temperature Sensor Error vs. Temperature

05469-035

150

Rev. 0 | Page 10 of 28

0

–20

–40

–60

GAIN (dB)

–80

–100

–120

0

50 100 150 200 250 300 350

INPUT SIGNAL FREQUENCY (Hz)

Figure 21. Voltage Channel Frequency Response;

Conversion Time = 122.1 ms

400

05469-039

Page 11

AD7747

OUTPUT NOISE AND RESOLUTION SPECIFICATIONS

The AD7747 resolution is limited by noise. The noise

performance varies with the selected conversion time.

Table 5 shows typical noise performance and resolution for the

capacitive channel. These numbers were generated from 1000

data samples acquired in continuous conversion mode, at an

excitation of 16 kHz, ±V

× 3/8, and with all CIN and SHLD

DD

pins connected only to the evaluation board (no external

capacitors).

Table 5. Typical Capacitive Input Noise and Resolution vs. Conversion Time (Bold line represents default setting)

Conversion

Time (ms)

22.0 45.5 43.6 28.8 190 821 16.4 14.3

23.9 41.9 39.5 23.2 146 725 16.8 14.5

40.0 25.0 21.8 11.1 52 411 18.3 15.3

76.0 13.2 10.9 11.2 37 262 18.7 15.9

124.0 8.1 6.9 11.0 29 174 19.1 16.5

154.0 6.5 5.3 10.4 24 173 19.3 16.5

184.0 5.4 4.4 10.0 21 141 19.6 16.8

219.3 4.6 4.0 9.0 18 126 19.9 17.0

Output Data

Rate (Hz)

−3 dB Frequency

(Hz)

RMS Noise

(aF/√Hz)

Table 6 and Table 7 show typical noise performance and

resolution for the voltage channel. These numbers were

generated from 1000 data samples acquired in continuous

conversion mode with VIN pins shorted to ground.

RMS noise represents the standard deviation and p-p noise

represents the difference between minimum and maximum

results in the data. Effective resolution is calculated from rms

noise, and p-p resolution is calculated from p-p noise.

RMS

Noise (aF)

P-P

Noise (aF)

Effective Resolution

(Bits)

P-P Resolution

(Bits)

Table 6. Typical Voltage Input Noise and Resolution vs. Conversion Time, Internal Voltage Reference

Conversion

Time (ms)

20.1 49.8 26.4 11.4 62 17.6 15.2

32.1 31.2 15.9 7.1 42 18.3 15.7

62.1 16.1 8.0 4.0 28 19.1 16.3

122.1 8.2 4.0 3.0 20 19.5 16.8

Output Data

Rate (Hz)

−3 dB Frequency

(Hz)

RMS Noise

(μV)

P-P Noise

(μV)

Effective Resolution

(Bits)

P-P Resolution

(Bits)

Table 7. Typical Voltage Input Noise and Resolution vs. Conversion Time, External 2.5 V Voltage Reference

Conversion

Time (ms)

20.1 49.8 26.4 14.9 95 18.3 15.6

32.1 31.2 15.9 6.3 42 19.6 16.8

62.1 16.1 8.0 3.3 22 20.5 17.7

122.1 8.2 4.0 2.1 15 21.1 18.3

Output Data

Rate (Hz)

−3 dB Frequency

(Hz)

RMS Noise

(μV)

P-P Noise

(μV)

Effective Resolution

(Bits)

P-P Resolution

(Bits)

Rev. 0 | Page 11 of 28

Page 12

AD7747

SERIAL INTERFACE

The AD7747 supports an I2C-compatible 2-wire serial interface.

The two wires on the I

(data). These two wires carry all addressing, control, and data

information one bit at a time over the bus to all connected

peripheral devices. The SDA wire carries the data, while the

SCL wire synchronizes the sender and receiver during the data

transfer. I

A device that initiates a data transfer message is called a master,

while a device that responds to this message is called a slave.

To control the AD7747 device on the bus, the following

protocol must be followed. First, the master initiates a data

transfer by establishing a start condition, defined by a high-tolow transition on SDA while SCL remains high. This indicates

that the start byte follows. This 8-bit start byte is made up of a

7-bit address plus an R/W bit indicator.

All peripherals connected to the bus respond to the start

condition and shift in the next 8 bits (7-bit address + R/W bit).

The bits arrive MSB first. The peripheral that recognizes the

transmitted address responds by pulling the data line low

during the ninth clock pulse. This is known as the acknowledge

bit. All other devices withdraw from the bus at this point and

maintain an idle condition. An exception to this is the general

call address, which is described later in this document. The idle

condition is where the device monitors the SDA and SCL lines

waiting for the start condition and the correct address byte. The

R/W bit determines the direction of the data transfer. A Logic 0

LSB in the start byte means that the master writes information

to the addressed peripheral. In this case, the AD7747 becomes a

slave receiver. A Logic 1 LSB in the start byte means that the

master reads information from the addressed peripheral. In this

case, the AD7747 becomes a slave transmitter. In all instances, the

AD7747 acts as a standard slave device on the I

The start byte address for the AD7747 is 0x90 for a write and

0x91 for a read.

2

C devices are classified as either master or slave devices.

2

C bus are called SCL (clock) and SDA

2

C bus.

READ OPERATION

When a read is selected in the start byte, the register that is

currently addressed by the address pointer is transmitted on to

the SDA line by the AD7747. This is then clocked out by the

master device and the AD7747 awaits an acknowledge from the

master.

If an acknowledge is received from the master, the address autoincrementer automatically increments the address pointer

register and outputs the next addressed register content on to

the SDA line for transmission to the master. If no acknowledge

is received, the AD7747 returns to the idle state and the address

pointer is not incremented.

The address pointer’s auto-incrementer allows block data to be

written or read from the starting address and subsequent

incremental addresses.

In continuous conversion mode, the address pointer’s autoincrementer should be used for reading a conversion result.

That means the three data bytes should be read using one

multibyte read transaction rather than three separate single byte

transactions. The single byte data read transaction may result in

the data bytes from two different results being mixed. The same

applies for six data bytes if both the capacitive and the

voltage/temperature channel are enabled.

The user can also access any unique register (address) on a oneto-one basis without having to update all the registers. The

address pointer register’s contents cannot be read.

If an incorrect address pointer location is accessed, or if the user

allows the auto-incrementer to exceed the required register

address, the following applies:

• In read mode, the AD7747 continues to output various

internal register contents until the master device issues a

no acknowledge, start, or stop condition. The address

pointer auto-incrementer’s contents are reset to point to

the status register at Address 0x00 when a stop condition is

received at the end of a read operation. This allows the

status register to be read (polled) continually without

having to constantly write to the address pointer.

• In write mode, the data for the invalid address is not

loaded into the AD7747 registers, but an acknowledge is

issued by the AD7747.

WRITE OPERATION

When a write is selected, the byte following the start byte is

always the register address pointer (subaddress) byte, which

points to one of the internal registers on the AD7747. The

address pointer byte is automatically loaded into the address

pointer register and acknowledged by the AD7747. After the

address pointer byte acknowledge, a stop condition, a repeated

start condition, or another data byte can follow from the master.

A stop condition is defined by a low-to-high transition on SDA

while SCL remains high. If a stop condition is ever encountered

by the AD7747, it returns to its idle condition and the address

pointer is reset to Address 0x00.

If a data byte is transmitted after the register address pointer

byte, the AD7747 loads this byte into the register that is

currently addressed by the address pointer register, sends an

acknowledge, and the address pointer auto-incrementer

automatically increments the address pointer register to the

next internal register address. Thus, subsequent transmitted

data bytes are loaded into sequentially incremented addresses.

If a repeated start condition is encountered after the address

pointer byte, all peripherals connected to the bus respond

exactly as outlined above for a start condition, that is, a repeated

start condition is treated the same as a start condition. When a

master device issues a stop condition, it relinquishes control of

Rev. 0 | Page 12 of 28

Page 13

AD7747

the bus, allowing another master device to take control of the

bus. Therefore, a master wanting to retain control of the bus

issues successive start conditions known as repeated start

conditions.

AD7747 RESET

To reset the AD7747 without having to reset the entire I2C bus,

an explicit reset command is provided. This uses a particular

address pointer word as a command word to reset the part and

upload all default settings. The AD7747 does not respond to the

2

C bus commands (do not acknowledge) during the default

I

values upload for approximately 150 µs (max 200 µs).

The reset command address word is 0xBF.

SDATA

GENERAL CALL

When a master issues a slave address consisting of seven 0s with

the eighth bit (R/W bit) set to 0, this is known as the general call

address. The general call address is for addressing every device

connected to the I

address and read in the following data byte.

If the second byte is 0x06, the AD7747 is reset, completely

uploading all default values. The AD7747 does not respond to

2

the I

C bus commands (do not acknowledge) during the default

values upload for approximately 150 µs (200 µs maximum).

The AD7747 does not acknowledge any other general call

commands.

2

C bus. The AD7747 acknowledges this

SCLOCK

1–7

START ADDR ACK ACK DATA ACK STOPSUBADDRESS

R/W

P981–7981–798S

05469-011

Figure 22. Bus Data Transfer

WRITE

SEQUENCE

READ

SEQUENCE

LSB = 0

S SLAVE ADDR A(S) SUB ADDR A(S) S SLAVE ADDR A(S) DATA

S = START BIT

P = STOP BIT

A(S) = ACKNOWLEDGE BY SLAVE

A(M) = ACKNOWLEDGE BY MASTER

Figure 23. Write and Read Sequences

DATA A(S)S SLAVE ADDR A(S) SUB ADDR A(S)

LSB = 1

A(S) = NO ACKNOWLEDGE BY SLAVE

A(M) = NO ACKNOWLEDGE BY MASTER

DATA P

A(M)

A(S)

DATA P

A(M)

05469-012

Rev. 0 | Page 13 of 28

Page 14

AD7747

REGISTER DESCRIPTIONS

The master can write to or read from all of the AD7747 registers

except the address pointer register, which is a write-only

register. The address pointer register determines which register

the next read or write operation accesses. All communications

with the part through the bus start with an access to the address

pointer register. After the part has been accessed over the bus

Table 8. Register Summary

Address

Pointer

Register (Dec) (Hex) Dir Default Value

Cap Data H 1 0x01 R Capacitive channel data—high byte, 0x00

Cap Data M 2 0x02 R Capacitive channel data—middle byte, 0x00

Cap Data L 3 0x03 R Capacitive channel data—low byte, 0x00

VT Data H 4 0x04 R Voltage/temperature channel data—high byte, 0x00

VT Data M 5 0x05 R Voltage/temperature channel data—middle byte, 0x00

VT Data L 6 0x06 R Voltage/temperature channel data—low byte, 0x00

Cap Offset H 13 0x0D R/W Capacitive offset calibration—high byte, 0x80

Cap Offset L 14 0x0E R/W Capacitive offset calibration—low byte, 0x00

Cap Gain H 15 0x0F R/W Capacitive gain calibration—high byte, factory calibrated

Cap Gain L 16 0x10 R/W Capacitive gain calibration—low byte, factory calibrated

Volt Gain H 17 0x11 R/W Voltage gain calibration—high byte, factory calibrated

Volt Gain L 18 0x12 R/W Voltage gain calibration—low byte, factory calibrated

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

– – – – – RDY RDYVT RDYCAP Status 0 0x00 R

0 0 0 0 0 1 1 1

CAPEN – CAPDIFF – – – – – Cap Setup 7 0x07 R/W

0 0 0 0 0 0 0 0

VTEN VTMD1 VTMD0 EXTREF – – VTSHORT VTCHOP VT Setup 8 0x08 R/W

0 0 0 0 0 0 0 0

– – – – EXCDAC EXCEN EXCLVL1 EXCLVL0 EXC Setup 9 0x09 R/W

0 0 0 0 0 0 1 1

VTFS1 VTFS0 CAPFS2 CAPFS1 CAPFS0 MD2 MD1 MD0 Configuration 10 0x0A R/W

1 0 1 0 0 0 0 0

DACAENA – DACA—6-Bit Value Cap DAC A 11 0x0B R/W

0 0 0x00

DACBENB – DACB—6-Bit Value Cap DAC B 12 0x0C R/W

0 0 0x00

and a read/write operation is selected, the address pointer

register is set up. The address pointer register determines from

or to which register the operation takes place. A read/write

operation is performed from/to the target address, which then

increments to the next address until a stop command on the bus

is performed.

Rev. 0 | Page 14 of 28

Page 15

AD7747

STATUS REGISTER

Address Pointer 0x00, Read Only, Default Value 0x07

This register indicates the status of the converter. The status register can be read via the 2-wire serial interface to query a finished

conversion.

RDY

The

pin reflects the status of the RDY bit. Therefore, the

the finished conversion.

Table 9. Status Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic – – – – – RDY RDYVT RDYCAP

Default 0 0 0 0 0 1 1 1

Table 10.

Bit Mnemonic Description

7 to 3 – Not used, always read 0.

2 RDY

1 RDYVT

0 RDYCAP RDYCAP = 0 indicates that a conversion on the capacitive channel is complete and new unread data is available.

RDY = 0 indicates that conversion on the enabled channel(s) is complete and new unread data is available.

If both capacitive and voltage/temperature channels are enabled, the RDY bit is changed to 0 after conversion

on both channels is complete. The RDY bit returns to 1 either when data is read or prior to finishing the next

conversion. If, for example, only the capacitive channel is enabled, then the RDY bit reflects the RDYCAP bit.

RDYVT = 0 indicates that a conversion on the voltage/temperature channel is complete and new unread data

is available.

RDY

pin high-to-low transition can be used as an alternative indication of

CAP DATA REGISTER

24 Bits, Address Pointer 0x01, 0x02, 0x03, Read-Only, Default Value 0x000000

This register contains the capacitive channel output data. The

register is updated after finished conversion on the capacitive

channel, with one exception: When the serial interface read

operation from the Cap Data register is in progress, the data

register is not updated and the new capacitance conversion

result is lost.

The stop condition on the serial interface is considered to be the

end of the read operation. Therefore, to prevent data corruption,

all three bytes of the data register should be read sequentially

using the register address pointer auto-increment feature of the

serial interface.

To prevent losing some of the results, the Cap Data register

should be read before the next conversion on the capacitive

channel is finished.

The 0x000000 code represents negative full scale (−8.192 pF),

the 0x800000 code represents zero scale (0 pF), and the

0xFFFFFF code represents positive full scale (+8.192 pF).

VT DATA REGISTER

24 Bits, Address Pointer 0x04, 0x05, 0x06, Read-Only, Default Value 0x000000

This register contains the voltage/temperature channel output

data. The register is updated after finished conversion on the

voltage channel or temperature channel, with one exception:

When the serial interface read operation from the VT Data

register is in progress, the data register is not updated and the

new voltage/temperature conversion result is lost.

The stop condition on the serial interface is considered to be the

end of the read operation. Therefore, to prevent data corruption,

all three bytes of the data register should be read sequentially

using the register address pointer auto-increment feature of the

serial interface.

For voltage input, Code 0 represents negative full scale (−V

the 0x800000 code represents zero scale (0 V), and the

0xFFFFFF code represents positive full scale (+V

REF

).

To prevent losing some of the results, the VT Data register

should be read before the next conversion on the voltage/

temperature channel is complete.

For the temperature sensor, the temperature can be calculated

from code using the following equation:

Temperature (°C) = (Code/2048) − 4096

REF

),

Rev. 0 | Page 15 of 28

Page 16

AD7747

CAP SETUP REGISTER

Address Pointer 0x07, Default Value 0x00

Capacitive channel setup.

Table 11. Cap Setup Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic CAPEN – CAPDIFF – – – – –

Default 0 0 0 0 0 0 0 0

Table 12.

Bit Mnemonic Description

7 CAPEN CAPEN = 1 enables capacitive channel for single conversion, continuous conversion, or calibration.

6 – This bit must be 0 for proper operation.

5 CAPDIFF This bit must be set to 1 for proper operation.

4 to 0 – These bits must be 0 for proper operation.

VT SETUP REGISTER

Address Pointer 0x08, Default Value 0x00

Voltage/Temperature channel setup.

Table 13. VT Setup Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic VTEN VTMD1 VTMD0 EXTREF – – VTSHORT VTCHOP

Default 0 0 0 0 0 0 0 0

Table 14.

Bit Mnemonic Description

7 VTEN VTEN = 1 enables voltage/temperature channel for single conversion, continuous conversion, or calibration.

6

5

4 EXTREF

3 to 2 – These bits must be 0 for proper operation.

1 VTSHORT VTSHORT = 1 internally shorts the voltage/temperature channel input for test purposes.

0 VTCHOP = 1

VTMD1

VTMD0

Voltage/temperature channel input configuration.

VTMD1 VTMD0 Channel Input

0 0 Internal temperature sensor

0 1 External temperature sensor diode

1 0 VDD monitor

1 1 External voltage input (VIN)

EXTREF = 1 selects an external reference voltage connected to REFIN(+), REFIN(−) for the voltage input or the

monitor.

V

DD

EXTREF = 0 selects the on-chip internal reference. The internal reference must be used with the internal

temperature sensor for proper operation.

VTCHOP = 1 sets internal chopping on the voltage/temperature channel.

The VTCHOP bit must be set to 1 for the specified voltage/temperature channel performance.

Rev. 0 | Page 16 of 28

Page 17

AD7747

EXC SETUP REGISTER

Address Pointer 0x09, Default Value 0x03

Capacitive channel excitation setup.

Table 15. EXC Setup Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic – – – – EXCDAC EXCEN EXCLVL1 EXCLVL0

Default 0 0 0 0 0 0 1 1

Table 16.

Bit Mnemonic Description

7 to 4 – These bits must be 0 for proper operation.

3 EXCDAC CAPDAC excitation. This bit must be set to 1 for the proper capacitive channel operation.

2 EXCEN CIN and AC SHLD excitation. This bit must be set to 1 for the proper capacitive channel operation.

1

0

EXCLVL1,

EXCLVL0

Excitation Voltage Level. Must be set to ±VDD × 3/8 to allow operation for specified performance.

EXCLVL1 EXCLVL0 Voltage on Cap EXC Low Level EXC High Level

0 0 ±VDD/8 V

0 1 ±VDD/4 V

1 0 ±V

1 1 ±V

× 3/8 V

DD

/2 0 VDD

DD

× 3/8 V

DD

× 1/4 V

DD

× 1/8 V

DD

DD

DD

DD

× 5/8

× 3/4

× 7/8

Rev. 0 | Page 17 of 28

Page 18

AD7747

CONFIGURATION REGISTER

Address Pointer 0x0A, Default Value 0xA0

Converter update rate and mode of operation setup.

Table 17. Configuration Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic VTFS1 VTFS0 CAPFS2 CAPFS1 CAPFS0 MD2 MD1 MD0

Default 0 0 0 0 0 0 0 0

Table 18.

Bit Mnemonic Description

7

6

5

4

3

2

1

0

VTFS1

VTFS0

CAPFS2

CAPFS1

CAPFS0

MD2

MD1

MD0

Voltage/temperature channel digital filter setup—conversion time/update rate setup.

VTFS1 VTFS0 Conversion Time (ms) Update Rate (Hz) −3 dB Frequency (Hz)

0 0 20.1 49.8 26.4

0 1 32.1 31.2 15.9

1 0 62.1 16.1 8.0

1 1 122.1 8.2 4.0

Capacitive channel digital filter setup—conversion time/update rate setup.

CAPFS2 CAPFS1 CAPFS0 Conversion Time (ms) Update Rate −3 dB Frequency (Hz)

0 0 0 22.0 45.5 43.6

0 0 1 23.9 41.9 39.5

0 1 0 40.0 25.0 21.8

0 1 1 76.0 13.2 10.9

1 0 0 124.0 8.1 6.9

1 0 1 154.0 6.5 5.3

1 1 0 184.0 5.5 4.4

1 1 1 219.3 4.6 4.0

Converter mode of operation setup.

MD2 MD1 MD0 Mode

0 0 0 Idle

0 0 1 Continuous conversion

0 1 0 Single conversion

0 1 1 Power-down

1 0 0 –

1 0 1 Capacitance system offset calibration

1 1 0 Capacitance or voltage system gain calibration

1 1 1 –

VTCHOP = 1

Rev. 0 | Page 18 of 28

Page 19

AD7747

CAP DAC A REGISTER

Address Pointer 0x0B, Default Value 0x00

Capacitive DAC setup.

Table 19. Cap DAC A Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic DACAENA – DACA—6-Bit Value

Default 0 0 0x00

Table 20.

Bit Mnemonic Description

7 DACAENA DACAENA = 1 connects capacitive DACA to the positive capacitance input.

6 – This bit must be 0 for proper operation.

5 to 1 DACA

CAP DAC B REGISTER

Address Pointer 0x0C, Default Value 0x00

Capacitive DAC setup.

DACA value, Code 0x00 ≈ 0 pF, Code 0x3F ≈ full range.

Table 21. Cap DAC B Register Bit Map

Bit Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Mnemonic DACBENB – DACB—6-Bit Value

Default 0 0 0x00

Table 22.

Bit Mnemonic Description

7 DACBENB DACBENB = 1 connects capacitive DACB to the negative capacitance input.

6 – This bit must be 0 for proper operation.

5 to 1 DACB

DACB value, Code 0x00 ≈ 0 pF, Code 0x3F ≈ full range.

Rev. 0 | Page 19 of 28

Page 20

AD7747

CAP OFFSET CALIBRATION REGISTER

16 Bits, Address Pointer 0x0D, 0x0E, Default Value 0x8000

The capacitive offset calibration register holds the capacitive

channel zero-scale calibration coefficient. The coefficient is

used to digitally remove the capacitive channel offset. The

register value is updated automatically following the execution

of a capacitance offset calibration. The capacitive offset calibration resolution (cap offset register LSB) is less than 32 aF; the

full range is ±1 pF.

CAP GAIN CALIBRATION REGISTER

16 Bits, Address Pointer 0x0F, 0x10, Default Value 0xXXXX

Capacitive gain calibration register. The register holds the

capacitive channel full-scale factory calibration coefficient.

VOLT GAIN CALIBRATION REGISTER

16 Bits, Address Pointer 0x11,0x12, Default Value 0xXXXX

Voltage gain calibration register. The register holds the voltage

channel full-scale factory calibration coefficient.

Rev. 0 | Page 20 of 28

Page 21

AD7747

V

CIRCUIT DESCRIPTION

DD

TEMP

VIN(+)

VIN(–)

CIN1(+)

CIN1(–)

SHLD

SENSOR

EXCITATION

MUX

CAP DAC 1

CAP DAC 2

CLOCK

GENERATOR

24-BIT Σ-Δ

GENERATOR

REFIN(+) REF IN(–)

AD7747

DIGITAL

FILTER

CONTROL LOG IC

CALIBRATION

VOLTAGE

REFERENCE

GND

I2C

SERIAL

INTERFACE

SDA

SCL

RDY

Figure 24. AD7747 Block Diagram

OVERVIEW

The AD7747 core is a high precision converter consisting of a

second-order (Σ- or charge balancing) modulator and a thirdorder digital filter. It works as a CDC for the capacitive inputs

and as a classic ADC for the voltage input or for the voltage

from a temperature sensor.

In addition to the converter, the AD7747 integrates a multiplexer, an excitation source and CAPDACs for the capacitive

inputs, a temperature sensor and a voltage reference for the

voltage and temperature inputs, a complete clock generator,

a control and calibration logic, and an I

2

C-compatible serial

interface.

CAPACITANCE-TO-DIGITAL CONVERTER

Figure 25 shows the CDC simplified functional diagram. The

measured capacitance C

lator input and ground. A square-wave excitation signal is

applied on the C

X

continuously samples the charge going through the C

digital filter processes the modulator output, which is a stream

of 0s and 1s containing the information in 0 and 1 density. The

data from the digital filter is scaled, applying the calibration

coefficients, and the final result can be read through the serial

interface.

CIN

C

X

SHLD

Figure 25. CDC Simplified Block Diagram

is connected between the Σ- modu-

X

during the conversion and the modulator

. The

X

CAPACITANCE TO DIGITAL CONVERTER

CLOCK

GENERATOR

24-BIT Σ-Δ

MODULATOR

EXCITATION

(CDC)

DIGITAL

FILTER

DATA

05469-014

05469-013

ACTIVE AC SHIELD CONCEPT

The AD7747 measures capacitance between CIN and ground.

That means any capacitance to ground on signal path between

the AD7747 CIN pin(s) and sensor is included in the AD7747

conversion result.

The parasitic capacitance of the sensor connections can easily

be in the same, if not even higher, order as the capacitance of

the sensor itself. If that parasitic capacitance is stable, it can be

treated as a nonchanging capacitive offset. However, the parasitic capacitance of sensor connections is often changing as a

result of mechanical movement, changing ambient temperature,

ambient humidity, etc. These changes are seen as drift in the

conversion result and may significantly compromise the system

accuracy.

To eliminate the CIN parasitic capacitance to ground, the

AD7747 SHLD signal can be used for shielding the connection

between the sensor and CIN, as shown in

Figure 25. The SHLD

output is basically the same signal waveform as the excitation of

the CIN pin; the SHLD is driven to the same voltage potential

as the CIN pin. Therefore, there is no ac current between CIN

and SHLD pins, and any capacitance between these pins does

not affect the CIN charge transfer. Ideally, the CIN to SHLD

capacitance does not have any contribution to the AD7747 result.

To get the best result, locate the AD7747 as close as possible to

the capacitive sensor. Keep the connection between the sensor

and AD7747 CIN pin, and also the return path between sensor

ground and the AD7747 GND pin, short. Shield the PCB track

to the CIN pin and connect the shielding to the AD7747 SHLD

pin. In addition, if a shielded cable is used for sensor connection,

the shield should be connected to the AD7747 SHLD pin.

CAPDAC

The AD7747 CDC full-scale input range is ±8.192 pF. For simplicity of calculation, however, the following text and figures use

±8 pF. The part can accept a higher capacitance on the input

and the common-mode or offset (nonchanging component)

capacitance can be balanced by programmable on-chip CAPDACs.

CAPDAC(+)

CIN(+)

CIN(–)

CAPDAC(–)

C

C

Y

X

SHLD

CDC

Figure 26. Using a CAPDAC

DATA

05649-015

Rev. 0 | Page 21 of 28

Page 22

AD7747

The CAPDAC can be understood as a negative capacitance

connected internally to the CIN pin. There are two independent

CAPDACs, one connected to the CIN(+) and the second connected to the CIN(−). The relation between the capacitance

input and output data can be expressed as

()()

YX

)()( −−−+−≈ CAPDACCCAPDACCDATA

The CAPDACs have a 6-bit resolution, monotonic transfer

function, are well matched to each other, and have a defined

temperature coefficient. The CAPDAC full range (absolute

value) is not factory calibrated and can vary up to ±20% with

the manufacturing process. See the

Specifications section and

Figure 16 of the typical performance characteristics.

SINGLE-ENDED CAPACITIVE CONFIGURATION

The AD7747 can be used for interfacing to a single-ended

capacitive sensor. In this configuration the sensor should be

connected to one of the AD7747 CIN pins, for example CIN(+)

and the other pin should be left open circuit. Note that the

CAPDIFF bit in the Cap Setup register must be set to 1 at all

times for the correct operation.

It is recommended to guard the unused CIN input with the

active shield to ensure the best performance in terms of noise,

offset, and offset drift.

The CDC (without using the CAPDACs) measure the positive

(or the negative) input capacitance in the range of 0 pF to 8 pF

Figure 27).

(see

0...8pF

CDC

0x800000

TO

0xFFFFFF

DATA

C

X

0...8pF

CIN(+)

CIN(–)

CAPDAC(+)

OFF

CAPDIFF = 1

CAPDAC(–)

OFF

Figure 29 shows how to shift the input range further, up to

25 pF absolute value of capacitance connected to the CIN(+).

±8pF

CDC

0x000000

TO

0xFFFFFF

DATA

05469-018

CAPDAC(+)

17pF

CAPDIFF = 1

CAPDAC(–)

0pF

C

X

9...25p F

(17pF ± 8pF)

CIN(+)

CIN(–)

SHLD

Figure 29. Using CAPDAC in Single-Ended Configuration

DIFFERENTIAL CAPACITIVE CONFIGURATION

When the AD7747 is used for interfacing to a differential

capacitive sensor, each of the two input capacitances, C

must be less than 8 pF (without using the CAPDACs) or must

be less than 25 pF and balanced by the CAPDACs. Balancing

by the CAPDACs means that both C

C

− CAPDAC(−) are less than 8 pF.

Y

− CAPDAC(+) and

X

If the unbalanced capacitance connected to CIN pins is higher

than 8 pF, the CDC introduces a gain error, an offset error, and

nonlinearity error.

See the examples shown in

C

X

0...8pF

C

Y

0...8pF

Figure 30, Figure 31, and Figure 32.

CAPDAC(+)

CIN(+)

CIN(–)

OFF

CAPDIFF = 1

CAPDAC(–)

OFF

±8pF

CDC

and CY,

X

0x000000

TO

0xFFFFFF

DATA

SHLD

05469-016

Figure 27. CDC Single-Ended Input Configuration

The CAPDAC can be used for programmable shifting of the

input range. The example in

Figure 28 shows how to use the full

±8 pF CDC span to measure capacitance between 0 pF to 16 pF.

±8pF

CDC

0x000000

TO

0xFFFFFF

DATA

05469-017

Rev. 0 | Page 22 of 28

CAPDAC(+)

8pF

CAPDIFF = 1

CAPDAC(–)

0pF

C

X

0...16pF

CIN(+)

CIN(–)

SHLD

Figure 28. Using CAPDAC in Single-Ended Configuration

SHLD

Figure 30. CDC Differential Input Configuration

CAPDAC(+)

17pF

CIN(+)

CAPDIFF = 1

CIN(–)

CAPDAC(–)

C

X

13...21pF

(17pF ± 4pF)

C

Y

13...21pF

(17pF ± 4pF)

17pF

SHLD

Figure 31. Using CAPDAC in Differential Configuration

±8pF

CDC

0x000000

TO

0xFFFFFF

DATA

05469-019

05469-020

Page 23

AD7747

Parasitic resistances, as shown in Figure 34, cause leakage

currents, which affect the CDC result. The AD7747 CDC

measures the charge transfer between the CIN pin and ground.

Any resistance connected in parallel to the measured

capacitance, C

, such as the parasitic resistance, RP1, also

X

transfers charge. Therefore, the parallel resistor is seen as an

additional capacitance in the output data. A resistance in the

range of R

≥ 10 M causes an offset error in the CDC result.

P1

An offset calibration can be used to compensate for the effect of

small leakage currents. A higher leakage current to ground,

≤ 10 M, results in a gain error, an offset error, and a

R

P1

nonlinearity error. See

Figure 10 in the Ty p i cal Performanc e

Characteristics section.

A parasitic resistance, R

as R

between the CIN pin and the active shield, as shown in

P3

, between SHLD and ground, as well

P2

Figure 34, cause a leakage current, which affects the CDC result

and is seen as an offset in the data. An offset calibration can be

used to compensate for effect of the small leakage current

caused by a resistance R

and RP3 ≥ 200 k. See Figure 11,

P2

Figure 12, and Figure 13 in the Typic a l Pe r fo r mance

Characteristics section.

PARASITIC SERIAL RESISTANCE

±8pF

CDC

0x000000

TO

0xFFFFFF

DATA

C

X

9 TO 25pF

(17pF ± 8pF)

C

Y

17pF

CIN(+)

CIN(–)

SHLD

CAPDAC(+)

17pF

CAPDIFF = 1

CAPDAC(–)

17pF

Figure 32. Using CAPDAC in Differential Configuration

PARASITIC CAPACITANCE

The CDC architecture used in the AD7747 measures the

capacitance C

Most applications use the active shield to avoid external influences during the CDC. However, any parasitic capacitance, C

as shown in

C

P1

connected between the CIN pin and ground.

X

Figure 33, can affect the CDC result.

CIN

C

C

X

P2

C

P3

CDC

DATA

05469-021

,

P

SHLD

Figure 33. Parasitic Capacitance

A parasitic capacitance, CP1, coupled in between CIN and

ground adds directly to the value of the capacitance C

therefore, the CDC result is: DATA ≈ C

+ CP1. An offset cali-

X

and,

X

bration might be sufficient to compensate for a small parasitic

capacitance (C

≤ 1pF). For a larger parasitic capacitance, the

P1

CAPDAC can be used to compensate, followed by an offset

calibration to ensure the full range of ±8pF is available for

the system.

Other parasitic capacitances, such as C

and ground as well as C

between the CIN pin and SHLD,

P3

between active shield

P2

could influence the conversion result. However, the graphs in

the

Typical Performance Characteristics section show that the

effect of parasitic capacitance of type C

insignificant to the CDC result.

gain error caused by C

by C

.

P3

P2

Figure 7 and Figure 8 show the

. Figure 9 shows the gain error caused

below 250 pF is

P2/CP3

PARASITIC RESISTANCE

CIN

R

C

R

P1

X

P2

R

P3

SHLD

CDC

Figure 34. Parasitic Resistance on CIN

DATA

R

05469-041

S

C

X

CIN

SHLD

CDC

DATA

5469-043

Figure 35. Parasitic Serial Resistance

The AD7747 CDC result is affected by a resistance in series

with the measured capacitance. The serial resistance should be

less than 10 kΩ for the specified performance. See

the

Typical Performance Characteristics section.

Figure 14 in

CAPACITIVE GAIN CALIBRATION

The AD7747 gain is factory calibrated for the full scale of

±8.192 pF in the production for each part individually. The

factory gain coefficient is stored in a one-time programmable

(OTP) memory and is copied to the capacitive gain register at

power-up or after reset.

The gain can be changed by executing a capacitance gain calibration mode, for which an external full-scale capacitance needs

to be connected to the capacitance input, or by writing a user

value to the capacitive gain register. This change would be only

temporary, and the factory gain coefficient would be reloaded

back after power-up or reset. The part is tested and specified for

use only with the default factory calibration coefficient.

05649-042

Rev. 0 | Page 23 of 28

Page 24

AD7747

CAPACITIVE SYSTEM OFFSET CALIBRATION

The capacitive offset is dominated by the parasitic offset in the

application, such as the initial capacitance of the sensor, any

parasitic capacitance of tracks on the board, and the capacitance

of any other connections between the sensor and the CDC.

Therefore, the AD7747 is not factory calibrated for capacitive

offset. It is the user’s responsibility to calibrate the system

capacitance offset in the application.

Any offset in the capacitance input larger than ±1 pF should

first be removed using the on-chip CAPDACs. The small offset

within ±1 pF can then be removed by using the capacitance

offset calibration register.

One method of adjusting the offset is to connect a zero-scale

capacitance to the input and execute the capacitance offset

calibration mode. The calibration sets the midpoint of the

±8.192 pF range (that is, Output Code 0x800000) to that

zero-scale input.

Another method is to calculate and write the offset calibration

17

register value; the LSB value is 31.25 aF (8.192 pF/2

).

The offset calibration register is reloaded by the default value at

power-on or after reset. Therefore, if the offset calibration is not

repeated after each system power-up, the calibration coefficient

value should be stored by the host controller and reloaded as

part of the AD7747 setup.

INTERNAL TEMPERATURE SENSOR

INTERNAL TEMPERATURE SENSOR

IN × I

CLOCK

GENERATOR

BE

24-BIT Σ-Δ

MODULATOR

VOLTAGE

REFERENCE

ΔV

Figure 36. Internal Temperature Sensor

The temperature sensing method used in the AD7747 is to

measure a difference in ∆V

two different currents (see

BE

Figure 36). The ∆VBE change with

temperature is linear and can be expressed as

KT

nV

BE

×=Δ

f

q

VDD

FILTER

AND

DATA

05469-026

DIGITAL

SCALING

voltage of a transistor operated at

)ln()( N

where:

K is Boltzmann’s constant (1.38 × 10

−23

).

T is the absolute temperature in Kelvin.

−19

q is the charge on the electron (1.6 × 10

coulombs).

N is the ratio of the two currents.

is the ideality factor of the thermal diode.

n

f

The AD7747 uses an on-chip transistor to measure the

temperature of the silicon chip inside the package. The Σ-

ADC converts the ∆V

to digital; the data are scaled using

BE

factory calibration coefficients. Thus, the output code is

proportional to temperature.

Code

()

CeTemperatur

2048

−=°

4096

The AD7747 has a low power consumption resulting in only a

small effect due to the part self-heating (less than 0.5°C at

= 5 V).

V

DD

If the capacitive sensor can be considered to be at the same

temperature as the AD7747 chip, the internal temperature

sensor can be used as a system temperature sensor. That means

the complete system temperature drift compensation can be

based on the AD7747 internal temperature sensor without need

for any additional external components. See Figure 17 in the

Typical Performance Characteristics section.

EXTERNAL TEMPERATURE SENSOR

× I

N

GENERATOR

24-BIT Σ-Δ

MODULATOR

VOLTAGE

REFERENCE

VDD

CLOCK

DIGITAL

SCALING

DATA

FILTER

AND

method, which

BE

+ RS2 in

S1

EXTERNAL

TEMPERATURE

SENSOR

R

2N3906

ΔV

BE

VIN(+)

S1

R

S2

VIN(–)

Figure 37. Transistor as an External Temperature Sensor

I ...

The AD7747 provides the option of using an external transistor

as a temperature sensor in the system. The ∆V

is similar to the internal temperature sensor method, is used.

However, it is modified to compensate for the serial resistance

of connections to the sensor. Total serial resistance (R

Figure 37) up to 100 Ω is compensated. The VIN(−) pin must

be grounded for proper external temperature sensor operation.

The AD7747 is factory calibrated for Transistor 2N3906 with

the ideality factor n

Figure 18 in the Typical Performance Characteristics section.

See

= 1.008.

f

05469-027

Rev. 0 | Page 24 of 28

Page 25

AD7747

VOLTAGE INPUT

VIN(+)

R

T

RTD

VIN(–)

REFIN(+)

R

REF

REFIN(–)

VDD

ANALOG TO DIGITAL CONVERTER

MODULATOR

(ADC)

CLOCK

GENERATOR

24-BIT Σ-Δ

DIGITAL

FILTER

VOLTAGE

REFERENCE

DATA

The AD7747 Σ- core can work as a high resolution (up to

21 ENOB) classic ADC with a fully differential voltage input.

The ADC can be used either with the on-chip high precision,

low drift, 1.17 V voltage reference, or with an external reference

connected to the fully differential reference input pins.

The voltage and reference inputs are continuously sampled by

a Σ- modulator during the conversion. Therefore, the input

source impedance should be kept low. See the application

example in

Figure 38.

VDD MONITOR

Along with converting external voltages, the AD7747 Σ- ADC

can be used for monitoring the V

the VDD pin is internally attenuated by 6.

voltage. The voltage from

DD

GND

Figure 38. Resistive Temperature Sensor Connected to the Voltage Input

05469-028

Rev. 0 | Page 25 of 28

Page 26

AD7747

V

/5V

TYPICAL APPLICATION DIAGRAM

3

POWER SUPPLY

10kΩ

VDD

+

0.1µF 10µF

10kΩ

VIN (+)

VIN (–)

CIN1( +)

CIN1(–)

SHLD

TEMP

SENSOR

EXCITATION

MUX

GENERATOR

24-BIT Σ-Δ

GENERATOR

CAP DAC 1

CAP DAC 2

REFIN(+) REFIN(–)

CLOCK

AD7747

DIGITAL

FILTER

CONTROL LOGIC

CALIBR ATION

VOLTAGE

REFERENCE

I2C

SERIAL

INTERFACE

GND

SDA

SCL

RDY

HOST

SYSTEM

5469-029

Figure 39. Basic Application Diagram for a Differential Capacitive Sensor

Rev. 0 | Page 26 of 28

Page 27

AD7747

OUTLINE DIMENSIONS

5.10

5.00

4.90

0.15

0.05

4.50

4.40

4.30

PIN 1

16

0.65

BSC

COPLANARITY

COMPLIANT TO JEDEC STANDARDS MO-153-AB

0.10

0.30

0.19

9

81

1.20

MAX

SEATING

PLANE

6.40

BSC

0.20

0.09

8°

0°

0.75

0.60

0.45

Figure 40. 16-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-16)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD7747ARUZ1 −40°C to +125°C 16-Lead TSSOP RU-16

AD7747ARUZ-REEL1 −40°C to +125°C 16-Lead TSSOP RU-16

AD7747ARUZ-REEL71 −40°C to +125°C 16-Lead TSSOP RU-16

EVAL-AD7747EBZ1 Evaluation Board

1

Z = Pb-free part.

Rev. 0 | Page 27 of 28

Page 28

AD7747

NOTES

Purchase of licensed I2C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips I2C Patent

Rights to use these components in an I

2

C system, provided that the system conforms to the I2C Standard Specification as defined by Philips.

©2007 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05469-0-1/07(0)

Rev. 0 | Page 28 of 28

Loading...

Loading...