Page 1

16-Bit 900 kSPS - ADC with a

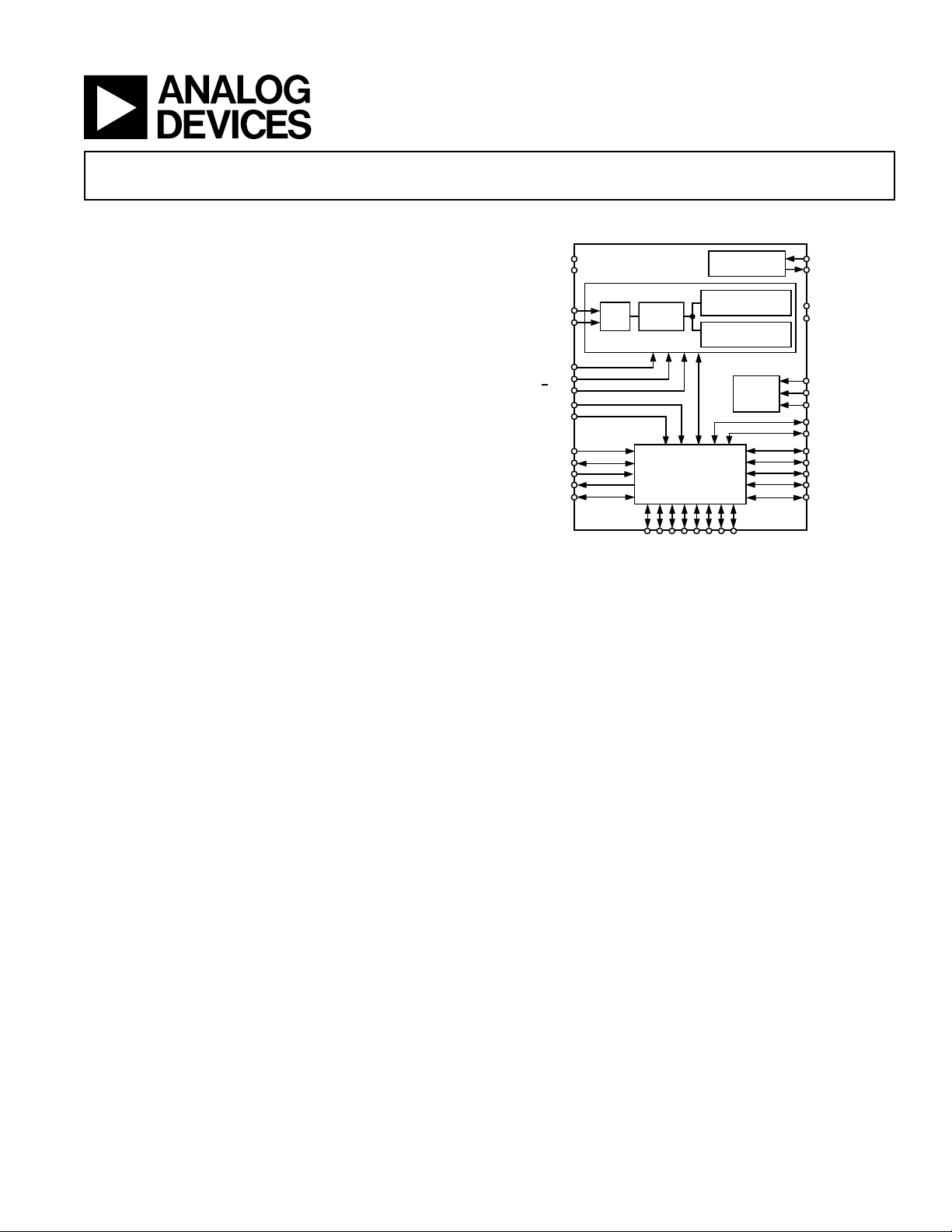

2.5V

REFERENCE

POST-

PROCESSOR

DEFAULT FILTER

(ROM )

XTAL

CLOCK

PRESET

FILTER

MOD

CONTROL

LOGIC

UNI

HALF

PWR

STBY

SYNC

S/P

V

IN

(+)

V

IN

(–)

RD/ WR

SOE/ CS

CFMT/RS

DVAL/ INT

SDI/DB0

ERR/ DB1

DB2

DB3

RESETCFG/DB4

INT/DB5

FSI/ DB6

SCO/ DB7

SDO/ DB8

SCR/ DB13

CFGEND/DB12

DB11

DB10

FSO/DB9

SMODE1/ DB15

SMODE0/ DB14

XTAL_OFF

XTAL

CLKIN

DV

DD

DGND

REF2

REF1

AV

DD

AGND

AD7725

Programmable Postprocessor

AD7725

FEATURES

Programmable Filtering:

Any Characteristic up to 108 Tap FIR and/or IIR

Polynomial Signal Conditioning up to 8

th

Order

Programmable Decimation and Output Word Rate

Flexible Programming Modes:

Boot from DSP or External EPROM

Parallel/Serial Interface

Internal Default Filter for Evaluation

14.4 MHz Max Master Clock Frequency

0 V to +4 V (Single-Ended) or 2 V (Differential) Input

Range

Power Supplies: AVDD, DVDD: 5 V 5%

On-Chip 2.5 V Voltage Reference

44-Lead MQFP Package

TYPICAL APPLICATIONS

Radar

Sonar

Auxiliary Car Functions

Medical Communications

GENERAL DESCRIPTION

The AD7725 is a complete 16-bit, - analog-to-digital converter with on-chip, user-programmable signal conditioning. The

output of the modulator is processed by three cascaded finite

impulse response (FIR) filters, followed by a fully user-programmable postprocessor. The postprocessor provides processing

power of up to 130 million accumulates (MAC) per second. The

user has complete control over the filter response, the filter coefficients, and the decimation ratio.

The postprocessor permits the signal conditioning characteristics

to be programmed through a parallel or serial interface.

is programmed by loading a user-defined filter in the form of a

configuration file. This filter can be loaded from a DSP or an

external serial EPROM. It is generated using a digital filter

design package called Filter Wizard, which is available from the

AD7725 section on the Analog

Devices

website.

FUNCTIONAL BLOCK DIAGRAM

t

Filter Wizard allows the user

and generates the appropriate

loaded to the postprocessor. The

o design different filter types

configuration file to be down-

AD7725 also has an internal

default filter for evaluation purposes.

It provides 16-bit performance for input bandwidths up to

350 kHz with an output word rate of 900 kHz maximum. The

input sample rate is set either by the crystal oscillator or an

external clock.

This part has an accurate on-chip 2.5 V reference for the modu-

It

lator. A reference input/output function allows either the

internal reference or an external system reference to be used as

the reference source for the modulator.

The device is available in a 44-lead MQFP package and is specified over a –40°C to +85°C temperature range.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

(AVDD = 5 V 5%, AGND = AGND1 = AGND2 = DGND = 0 V,

1

AD7725–SPECIFICATIONS

2

f

= 9.6 MHz, REF2 = 2.5 V, TA = T

CLKIN

MIN

to T

, unless otherwise noted.)

MAX

B Version

Parameter Test Conditions/Comments Min Typ Max Unit

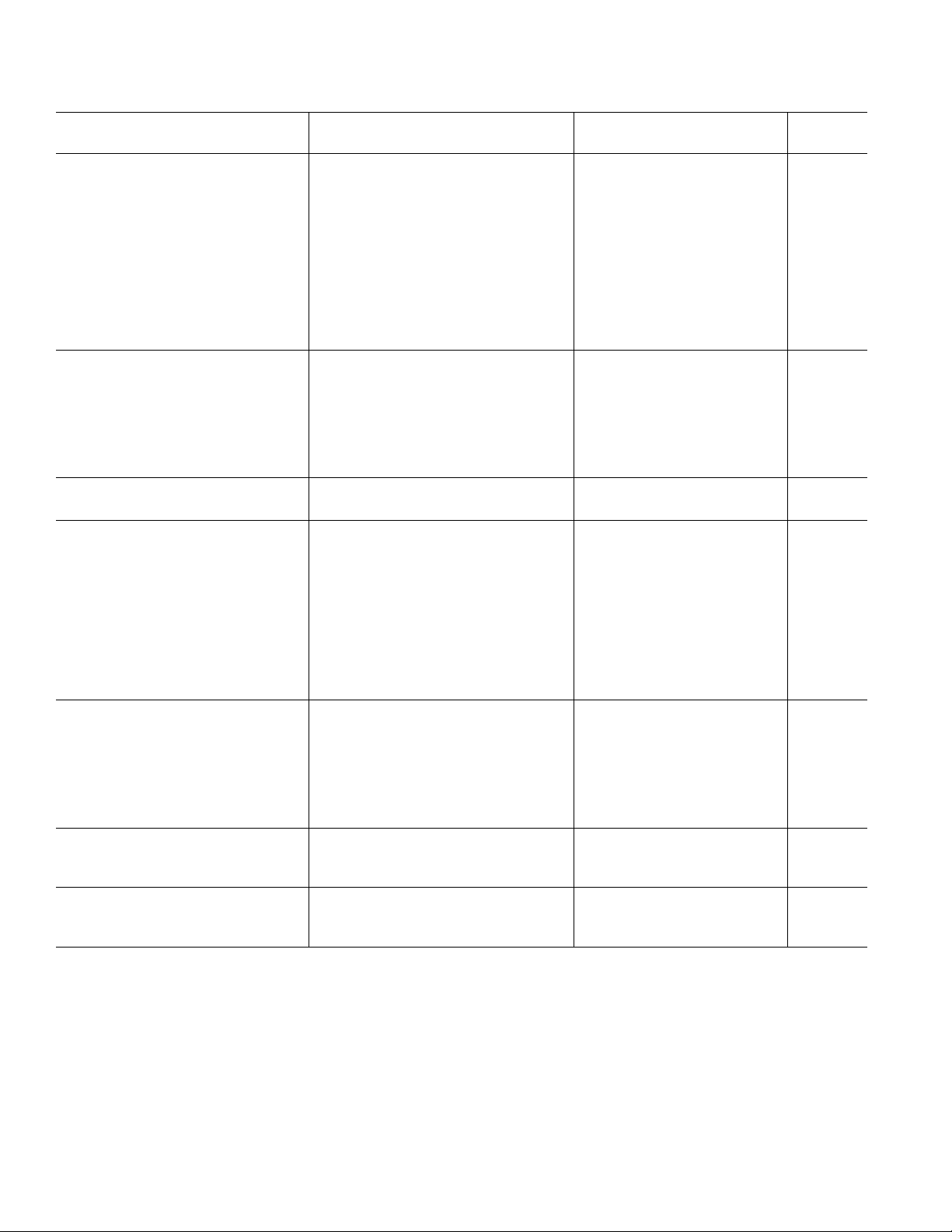

DYNAMIC SPECIFICATIONS When tested with the FIR filter in

Figure 1, HALF_PWR = Logic High

Bipolar Mode

Signal-to-Noise

3

Measurement Bandwidth = 0.5 f

4

O

2.5 V Reference 77 83 dB

3 V Reference 79 85 dB

3, 5

Measurement Bandwidth = 0.5 f

4

O

–94 –86 dB

–98 –89 dB

83 dB

–94 dB

Total Harmonic Distortion

Spurious Free Dynamic Range

Unipolar Mode

Signal-to-Noise

3

Total Harmonic Distortion

3, 5

3, 5

ANALOG INPUTS

Full-Scale Input Span V

Bipolar Mode Differential or Single-Ended Input ±4/5 V

Unipolar Mode Single-Ended Input 0 8/5 V

Absolute Input Voltage V

Input Sampling Capacitance 2 pF

Input Sampling Rate, f

CLKIN

(+) – VIN(–)

IN

(+) and/or VIN(–) AGND AV

IN

14.4

DD

V

REF2

REF2

V

V

6

MHz

CLOCK

CLKIN Duty Ratio 45 55 %

REFERENCE

REF1 Output Resistance 3.5 kΩ

Reference Buffer

Offset Voltage Offset between REF1 and REF2 ±3mV

Using Internal Reference

REF2 Output Voltage 2.39 2.54 2.69 V

REF2 Output Voltage Drift 60 ppm/°C

Using External Reference

REF2 Input Impedance REF1 = AGND 8 kΩ

REF2 External Voltage Input

7

2.5 V

STATIC PERFORMANCE

Resolution 16 Bits

Differential Nonlinearity (DNL)

Integral Nonlinearity (INL)

3

3

Guaranteed Monotonic ±0.5 ±1

±2 LSB

8

LSB

DC CMRR 80 dB

Offset Error ±20 mV

Gain Error

3, 9

±0.5 %FSR

LOGIC INPUTS (Excluding CLKIN)

V

, Input High Voltage 2.0 V

INH

V

, Input Low Voltage 0.8 V

INL

CLOCK INPUT (CLKIN)

V

, Input High Voltage 0.7 DV

INH

V

, Input Low Voltage 0.3 DV

INL

DD

DD

V

V

REV. A–2–

Page 3

AD7725

B Version

Parameter Test Conditions/Comments Min Typ Max Unit

ALL LOGIC INPUTS

IIN, Input Current VIN = 0 V to DV

DD

CIN, Input Capacitance 10 pF

LOGIC OUTPUTS

, Output High Voltage |I

V

OH

VOL, Output Low Voltage |I

POWER SUPPLIES

AV

DD

11

AI

DD

DV

DD

13

DI

DD

Power Consumption

NOTES

1

Operating temperature range is as follows: B Version: –40°C to +85°C.

2

f

is the CLKIN frequency.

CLKIN

3

See Terminology section.

4

FO = output data rate.

5

When using the internal reference, THD and SFDR specifications apply only to input signals above 10 kHz with a 10 µF decoupling capacitor between REF2 and

AGND2. At frequencies below 10 kHz, THD degrades to –80 dB and SFDR degrades to –83 dB.

6

See Figures 23 and 24 for information regarding the number of filter taps allowed and the current consumption as the CLKIN frequency is varied.

7

The AD7725 can operate with an external reference input in the range of 1.2 V to 3.15 V.

8

Guaranteed by the design.

9

Gain Error excludes reference error.

10

All IDD tests are done with the digital inputs equal to 0 V or DVDD.

11

Analog current does not vary as the CLKIN frequency and the number of filter taps used in the postprocessor is varied.

12

If HALF_PWR is logic low, AIDD will typically double.

13

Digital current varies as the CLKIN frequency and the number of filter taps used in the postprocessor is varied. See Figures 23 and 24.

14

Digital inputs static and equal to 0 V or DVDD.

Specifications subject to change without notice.

10

14

| = 200 µA 4.0 V

OUT

| = 1.6 mA 0.4 V

OUT

HALF_PWR = Logic High

12

4.75 5.25 V

28 33 mA

4.75 5.25 V

With the Filter in Figure 1 84 90 mA

Standby Mode 30 mW

±10 µA

0

–20

–40

–60

–80

ATTENUATION – dB

–100

–120

–140

0 30050

CUTOFF FREQUENCY = 50kHz

STOP-BAND FREQUENCY = 116kHz

NUMBER OF FILTER TAPS USED IN

THE POSTPROCESSOR = 108

OUPUT DATA RATE = CLKIN/16

100 150 200 250

116

FREQUENCY – kHz

Figure 1. Digital Filter Characteristics Used for Specifications

REV. A

–3–

Page 4

AD7725

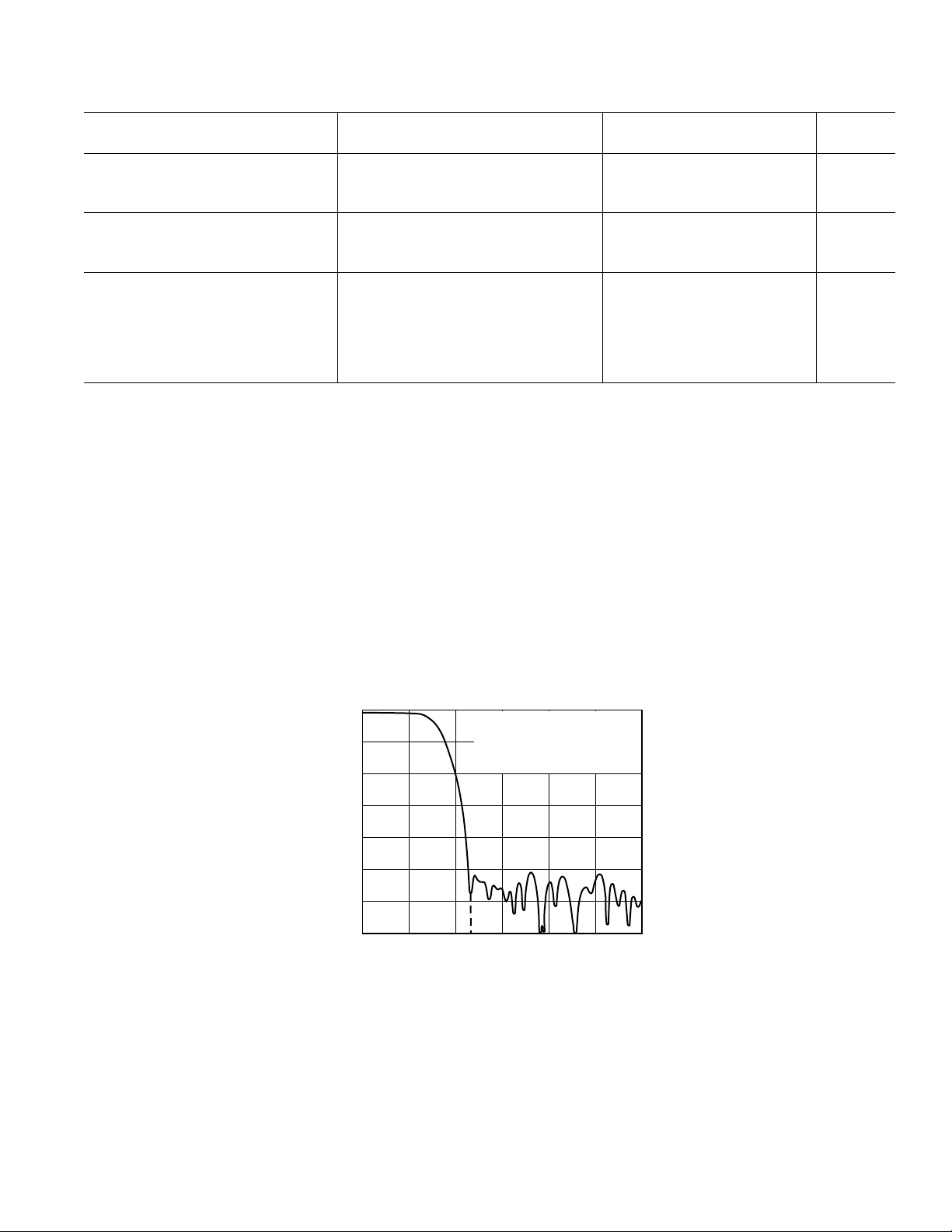

Preset Filter, Default Filter, and Postprocessor Characteristics

1, 2

Parameter Test Conditions/Comments Min Typ Max Unit

DIGITAL FILTER RESPONSE

PRESET FIR

Data Output Rate f

/8 Hz

CLKIN

Stop-Band Attenuation 70 dB

Low-Pass Corner Frequency f

Group Delay

Settling Time

3

3

/16 Hz

CLKIN

133/(2 f

133/f

CLKIN

)s

CLKIN

s

DEFAULT FILTER Internal FIR Filter Stored in ROM

Number of Taps 106

Frequency Response

0 kHz to f

/195.04 –3 dB

f

CLKIN

f

/184.08 –6 dB

CLKIN

/133.2 to f

f

CLKIN

Group Delay

Settling Time

Output Data Rate, f

/546.08 ± 0.001 dB

CLKIN

/2 –120 dB

CLKIN

3

3

O

2141/(2 f

2141/f

CLKIN

f

/32 Hz

CLKIN

)s

CLKIN

s

POSTPROCESSOR CHARACTERISTICS

Input Data Rate f

Coefficient Precision

4

24 Bits

/8 Hz

CLKIN

Arithmetic Precision 30 Bits

Number of Taps Permitted 108

Decimation Factor 2 256

Number of Decimation Stages 1 5

Output Data Rate f

NOTES

1

These characteristics are fixed by the design.

2

f

is the CLKIN frequency.

CLKIN

3

See Terminology section.

4

See the Configuration File Format section for more information.

/4096 f

CLKIN

/16 Hz

CLKIN

REV. A–4–

Page 5

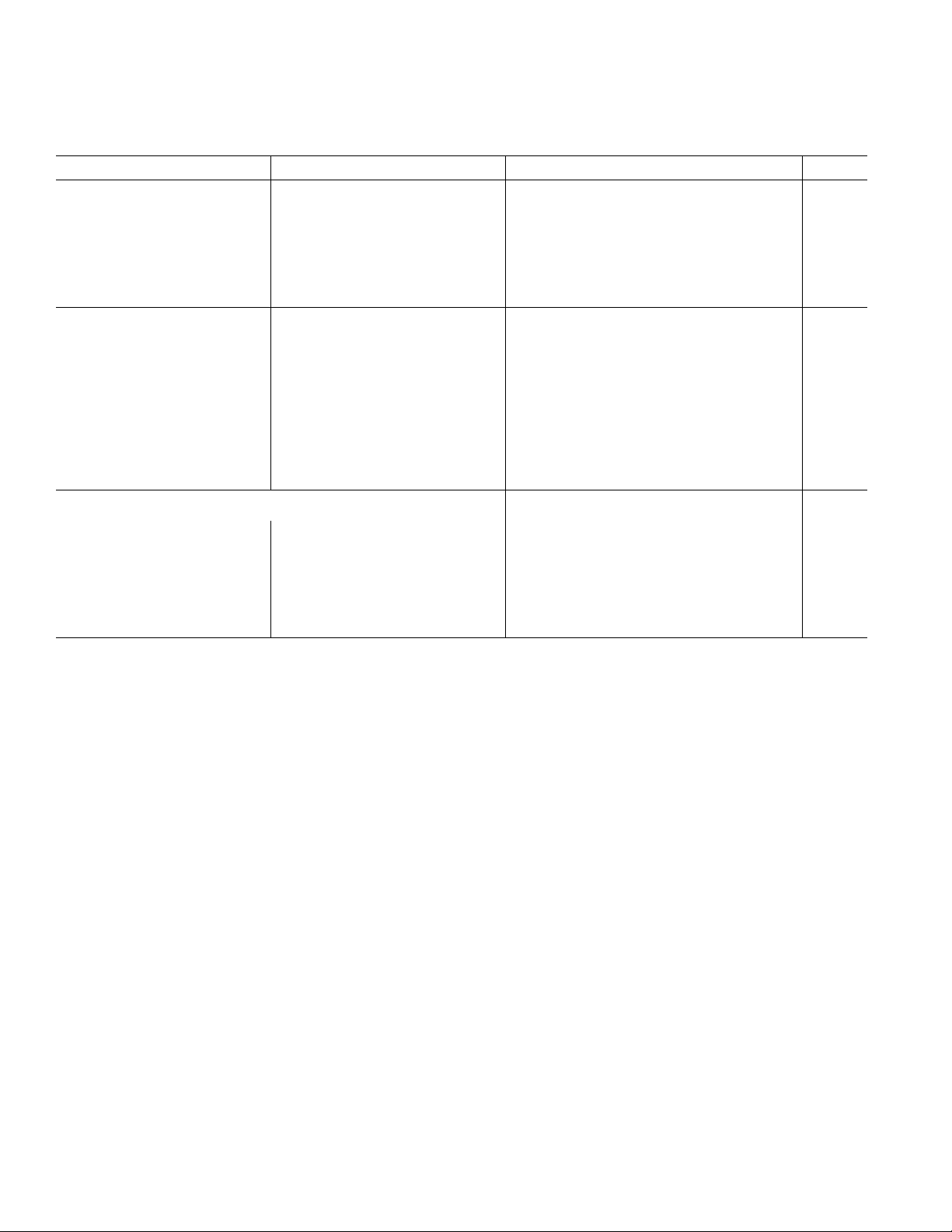

TIMING SPECIFICATIONS

(AVDD = 5 V 5%; DVDD = 5 V 5%; AGND = DGND = 0 V, REF2 = 2.5 V,

unless otherwise noted.)

AD7725

1, 2

Parameter Symbol Min Typ Max Unit

CLKIN Frequency f

CLKIN Period (t

CLK

= 1/f

)t

CLKIN

CLKIN Low Pulse Width t

CLKIN High Pulse Width t

CLKIN Rise Time t

CLKIN Fall Time t

CLKIN to SCO Delay t

SCO Period: SCR = 0 t

SCR = 1 t

CLKIN

1

2

3

4

5

6

7

7

114.4MHz

0.07 1 µs

0.45 t

0.45 t

1

1

0.55 t

0.55 t

1

1

5ns

5ns

35 50 ns

1t

2t

SERIAL INTERFACE (DSP MODE ONLY)

FSI Setup Time before SCO Transition t

FSI Hold Time after SCO Transition t

SDI Setup Time t

SDI Hold Time t

8

9

10

11

30 ns

0ns

30 ns

0ns

SERIAL INTERFACE (DSP AND BFR MODES)

SCO Transition to FSO High Delay t

SCO Transition to FSO Low Delay t

SDO Setup before SCO Transition t

SDO Hold after SCO Transition t

12

13

14

15

0ns

20 ns

20 ns

10 ns

SERIAL INTERFACE (EPROM MODE)

SCO High Time t

SCO Low Time t

SOE Low to First SCO Rising Edge t

Data Setup before SCO Rising Edge t

16

17

18

19

22 ns

8t

8t

20 t

PARALLEL INTERFACE

DATA WRITE

RS Low to CS Low t

WR Setup before CS Low t

RS Hold after CS Rising Edge t

CS Pulse Width t

WR Hold after CS Rising Edge t

Data Setup Time t

Data Hold Time t

20

21

22

23

24

25

26

15 ns

15 ns

0ns

50 ns

0ns

10 ns

5ns

DATA READ

RS Low to CS Low t

RD Setup before CS Low t

RS Hold after CS Rising Edge t

RD Hold after CS Rising Edge t

Data Valid after CS Falling Edge

3

Data Hold after CS Rising Edge t

27

28

29

30

t

31

32

15 ns

15 ns

0ns

0ns

30 ns

10 ns

STATUS READ/INSTRUCTION WRITE

CS Duty Cycle t

Interrupt Clear after CS Low t

RD Setup to CS Low t

RD Hold after CS Rising Edge t

Read Data Access Time

3

Read Data Hold after CS Rising Edge t

Write Data Setup before CS Rising Edge t

Write Data Hold after CS Rising Edge t

NOTES

1

Guaranteed by design.

2

Guaranteed by characterization. All input signals are specified with tr tf 5 ns (10% to 90% of DVDD) and timed from a voltage level of 1.6 V.

3

Measured with the load circuit in Figure 2 and defined as the time required for the output to cross 0.8 V and 2.4 V.

33

34

35

36

t

37

38

39

40

1t

15 ns

15 ns

0ns

30 ns

10 ns

10 ns

5ns

CLK

CLK

CLK

CLK

CLK

CLK

REV. A

–5–

Page 6

AD7725

I

OL

1.6mA

TO

OUTPUT

PIN

25pF

C

L

I

OH

200A

1.6V

Figure 2. Load Circuit for Digital Output Timing Specifications

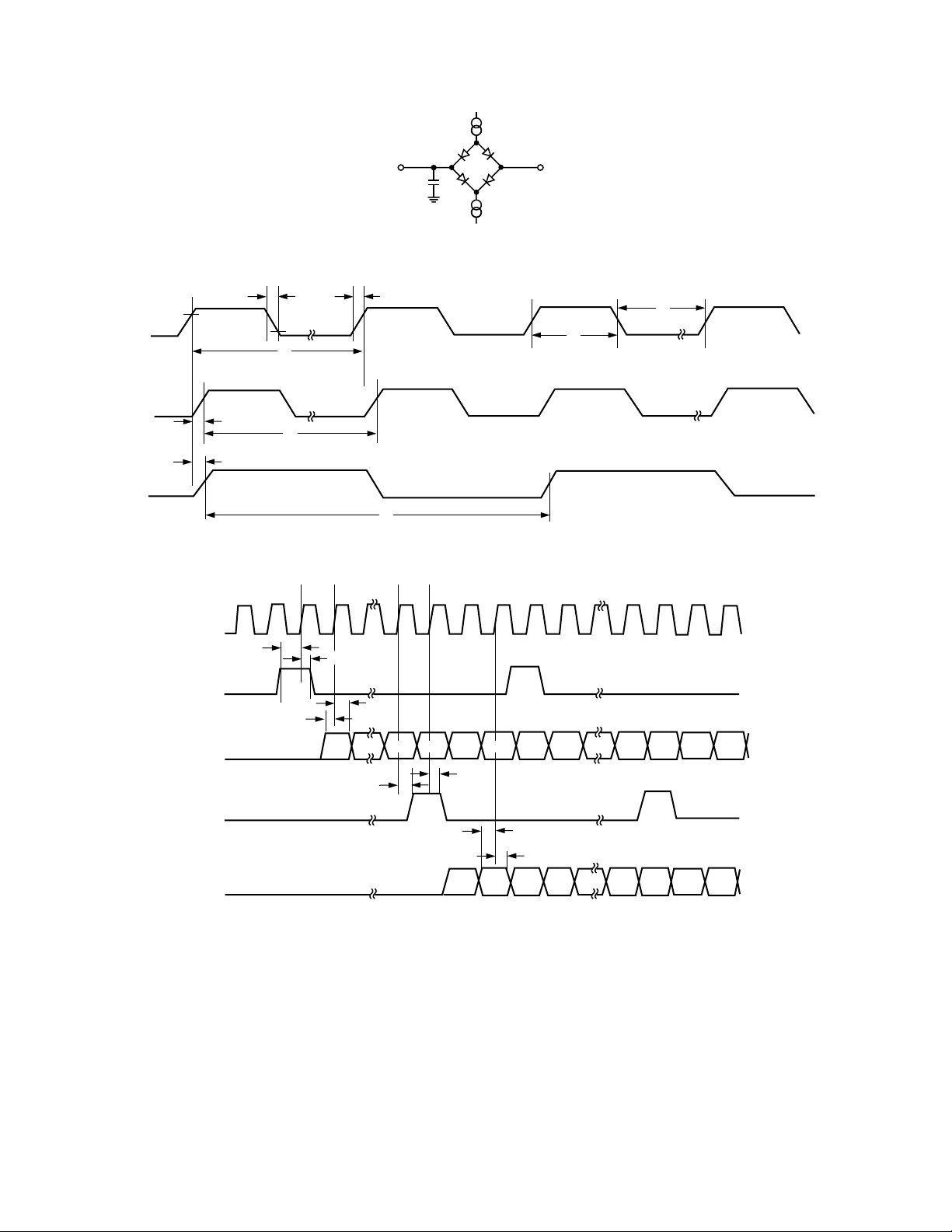

CLKIN

SCO

SCR = 0

SCO

SCR = 1

2.3V

CFMT = 0

SCO

FSI

SDI

t

5

0.8V

t

1

t

6

t

6

t

7

t

4

t

3

t

7

t

2

Figure 3. CLKIN to SCO Relationship

t

8

t

9

t

t

10

11

D15 D0 D15 D4 D3 D2 D1

D4 D2D3 D1

t

13

t

14

t

15

D15 D14 D13 D12 D1 D0 D15 D14

FSO

SDO

t

12

Figure 4. Serial Mode (DSP Mode and Boot from ROM (BFR) Mode). In BFR Mode, FSI and SDI are not used.

REV. A–6–

Page 7

S

INT

RD/WR

RS

CS

t

16

SCO

t

17

t

19

CO

SDI

t

18

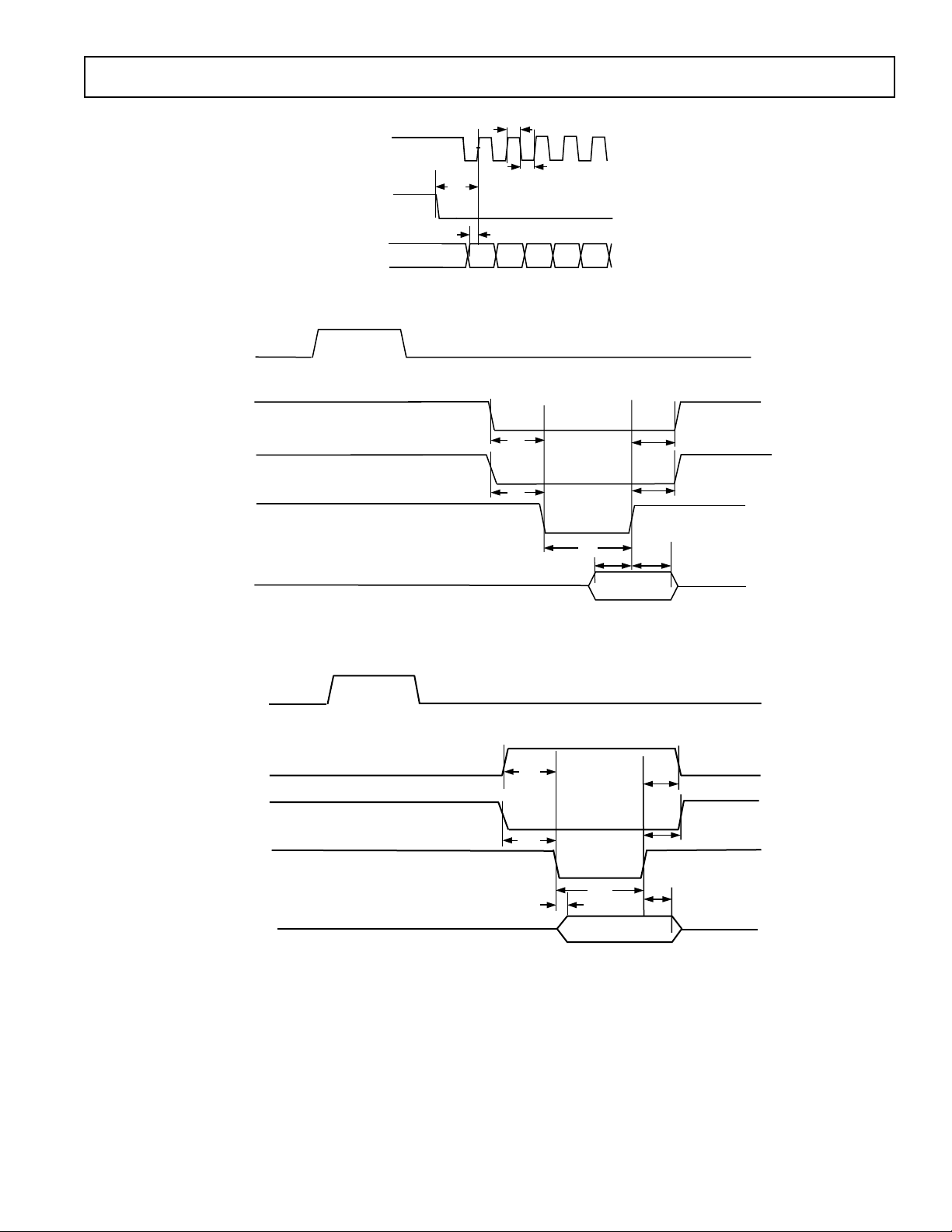

Figure 5. Serial Mode (EPROM Mode)

t

21

t

20

AD7725

t

24

t

22

DB0 DB15

–

RD/WR

DB0 DB15

–

INT

RS

CS

t

23

THREE-STATE

t

t

26

25

VALID DATA

Figure 6. Parallel Mode (Writing Data to the AD7725)

t

THREE-STATE

28

t

27

t

t

31

23

VA LID DATA

t

30

t

29

t

32

Figure 7. Parallel Mode (Reading Data from the AD7725)

THREE-STATE

THREE-STATE

REV. A

–7–

Page 8

AD7725

INT

t

34

RD/WR

RS

CS

DB0 DB15

–

t

35

t

37

STATU

THREE-STATE THREE-STATE THREE-STATE

S

t

36

t

23

t

33

t

38

t

39

INSTRUCTI

ON

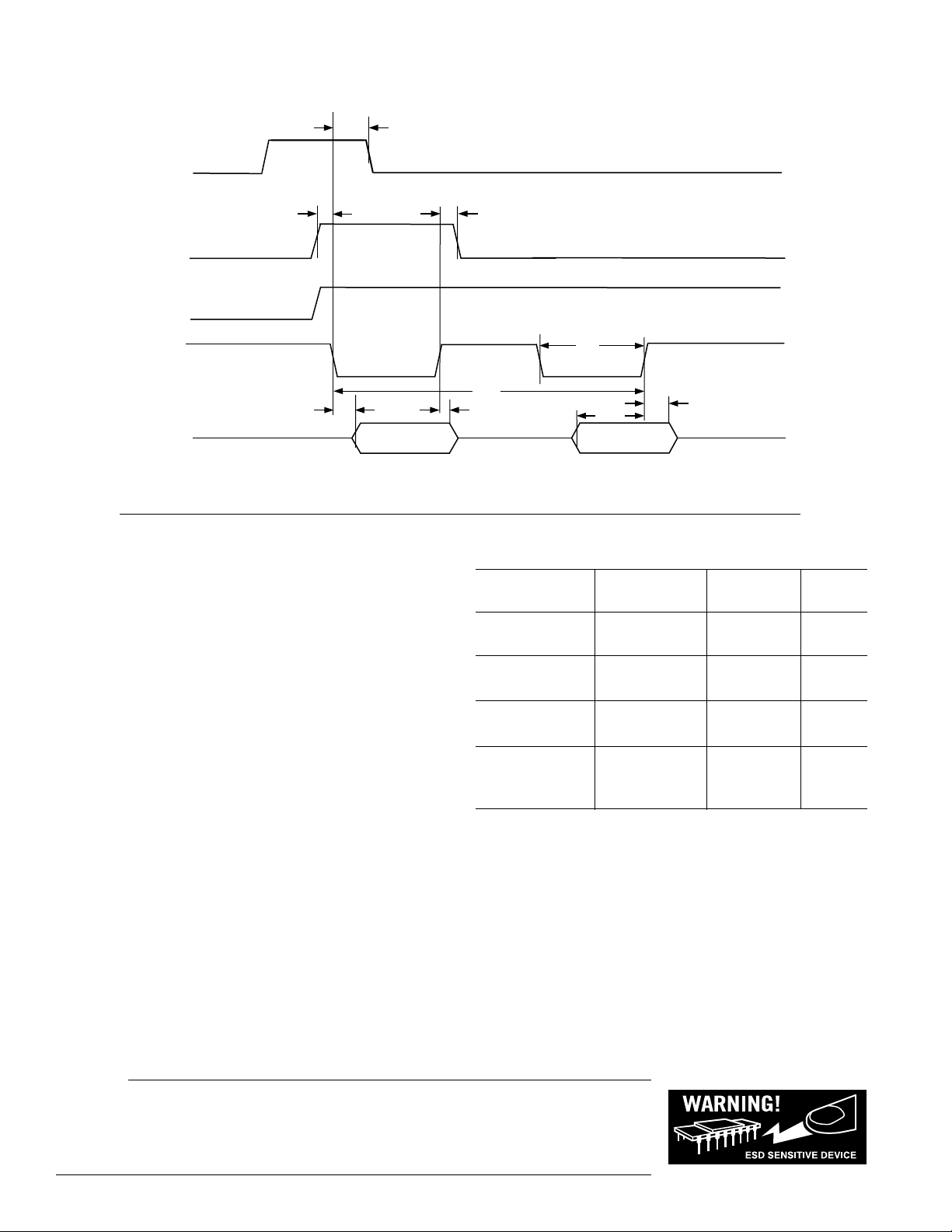

Figure 8. Parallel Mode (Reading the Status Register and Writing Instructions)

ABSOLUTE MAXIMUM RATINGS

(TA = 25°C, unless otherwise noted.)

to DGND . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

DV

DD

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

AV

DD

AV

DD

, AV

to DVDD . . . . . . . . . . . . . . . . . . . . –1 V to +1 V

DD1

1

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD7725BS –40°C to +85°CMetric Quad S-44-2

AGND, AGND1 to DGND . . . . . . . . . . . . . –0.3 V to +0.3 V

Digital Inputs to DGND . . . . . . . . . . –0.3 V to DV

Digital Outputs to DGND . . . . . . . . . –0.3 V to DV

V

(+), VIN(–) to AGND . . . . . . . . . . . –0.3 V to AVDD + 0.3 V

IN

REF1 to AGND . . . . . . . . . . . . . . . . . –0.3 V to AV

REF2 to AGND . . . . . . . . . . . . . . . . . –0.3 V to AV

REFIN to AGND . . . . . . . . . . . . . . . . –0.3 V to AV

DGND, AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 0.3 V

Input Current to Any Pin except Supplies

I

(AI

DD

+ DIDD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 mA

DD

2

. . . . . . . . . ± 10 mA

Operating Temperature Range . . . . . . . . . . . .–40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . . . 58°C/W

JA

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . . . 20°C/W

JC

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 kV

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Transient currents of up to 100 mA will not cause SCR latch-up.

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

+ 0.3 V

DD

AD7725BS-REEL –40°C to +85°CMetric Quad S-44-2

EVAL- Evaluation

AD7725CB

2

EVAL- Controller

CONTROL Board

3

BRD2

NOTES

1

S = Metric Quad Flat Package (MQFP).

2

This board can be used as a standalone evaluation board or in conjunction with the

Evaluation Board Controller for evaluation/demonstration purposes. It is accompanied by software and technical documentation.

3

Evaluation Board Controller. This board is a complete unit allowing a PC to

control and communicate with all Analog Devices boards ending in the CB

designator. To obtain the complete evaluation kit, the following needs to be

ordered: EVAL-AD7725CB, EVAL-CONTROL BRD2, and a 12 V ac transformer.

The Filter Wizard software can be downloaded from the Analog Devices website.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD7725 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

t

40

1

Flatpack

Flatpack

Board

REV. A–8–

Page 9

EFMT/DB2

ERR/DB1

SDI/DB0

CFMT/RS

DVAL/INT

DGND

RD/WR

S/P

AGND1

AGND1

AV

DD1

PIN CONFIGURATION

DD

RESETCFG/DB4

DGND/DB3

1

PIN 1

IDENTIFIER

2

3

4

5

6

7

8

9

10

11

12 13 14 15 1 6 17 18 19 20 21 2 2

CLKIN

FSI/DB6

INIT/DB5

(Not to Scale)

XTAL

XTALOFF

HALF_PWR

SDO/DB8

DV

SCO/DB7

40 39 3841424344 36 35 3437

AD7725

TOP VIEW

DD

AGND

AV

AGND

DGND/DB10

FSO/DB9

)

)

–

+

(

(

IN

IN

V

V

CFGEND/DB12

DGND/DB11

33

32

31

30

29

28

27

26

25

24

23

REF1

AGND2

SCR/DB13

SMODE0/DB14

SMODE1/DB15

SOE/CS

SYNC

DGND

STBY

AV

DD

AGND

UNI

REF2

AD7725

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic S/P Description

1 EFMT/DB2 Serial Mode. EFMT–Serial Clock Format, Logic Input. This clock format pin selects

the clock edge to be used during configuration. When EFMT is low, Serial Data In is

valid on the rising edge of SCO; when EFMT is high, Serial Data In is valid

on the falling edge of SCO. During normal operation, this pin is ignored.

Parallel Mode. DB2–Data Input/Output Bit.

2 ERR/DB1 Serial Mode. ERR–Configuration Error Flag, Logic Output. If an error occurs during

configuration, this output goes low and is reset high by a pulse on the RESETCFG pin.

Parallel Mode. DB1–Data Input/Output Bit.

3 SDI/DB0 Serial Mode. SDI–Serial Data Input. Serial data is shifted in to the AD7725 MSB first, in

twos complement format, synchronous with SCO.

Parallel Mode. DB0–Data Input/Output Bit (LSB).

4 CFMT/RS Serial Mode. CFMT–Serial Clock Format, Logic Input. This clock format pin selects the

clock edge to be used during normal operation. When CFMT is low, Serial Data Out is

valid on the rising edge of SCO; when CFMT is high, Serial Data Out is valid on the

falling edge of SCO. During configuration, this pin is ignored.

Parallel Mode. RS–Register Select. RS selects between the data register, used to read

conversion data or write configuration data, and the instruction register. When RS is high,

the status register can be read or an instruction can be written to the AD7725. When RS

is low, data such as the configuration file can be written to the ADC while data such as the

device ID or a conversion result can be read from the AD7725 (see Table I).

REV. A

–9–

Page 10

AD7725

Pin No. Mnemonic S/P Description

5 DVAL/INT Serial Mode. DVAL–Data Valid Logic Output. This output is low when there are no

overflows in the postprocessor and goes high when an overflow occurs in the postprocessor.

Parallel Mode. INT–Interrupt Logic Output. INT idles low. A logic high on this output pin

indicates that user intervention is required. There are several cases when this may occur:

•

An instruction is completed. Writing an instruction or reading the status register clears

the interrupt.

•

Write data is requested. Writing data clears the interrupt.

•

Read data is ready. Reading data clears the interrupt.

•

An error occurs – ID or CRC error in the configuration file format, or an overflow in

the postprocessor. Reading the status register clears the interrupt.

•

The device completes power-on reset. Reading the status register clears the interrupt.

6 DGND Ground Reference for Digital Circuitry.

7 RD/WR Serial Mode. This input is not used in serial mode and should be tied to DGND.

Parallel Mode. Read/Write Logic Input. This input is used in conjunction with the CS

input to read data from or write data to the device. A read cycle is initiated when RD/WR

is high. A write cycle is initiated when RD/WR is low. To read or write data, CS should be low.

8S/P Serial/Parallel Interface Select. When S/P is tied low, parallel mode is selected. Serial

mode is selected when S/P is tied high. To change the mode, a full power cycle needs

to be performed.

9, 10 AGND1 Digital Logic Power Supply Ground for the Analog Modulator.

11 AV

12 CLKIN Clock Input. An external clock source can be applied directly to this pin with XTALOFF

13 XTAL Input to Crystal Oscillator Amplifier. If an external clock is used, XTAL should be tied

14 XTALOFF Oscillator Enable Input. A logic high disables the crystal oscillator amplifier to allow the use

15 HALF_PWR Logic Input. When this input is low, the typical analog current is 50 mA and a maximum

16, 18 AGND Power Supply Ground for the Analog Modulator.

17 AV

19 V

20 V

21 REF1 Reference Output. REF1 is connected to the output of the internal 2.5 V reference through a

22 AGND2 Power Supply Ground for the Reference Circuitry, REF2, of the Analog Modulator.

23 REF2 Reference Input. REF2 connects to the output of an external buffer amplifier used to drive

24 UNI Analog Input Range Select Input. The UNI pin selects the analog input range for either

25 AGND Power Supply Ground for the Analog Modulator.

26 AV

DD1

DD

(–) Negative Terminal of the Differential Analog Input.

IN

(+) Positive Terminal of the Differential Analog Input.

IN

DD

Digital Logic Power Supply for the Analog Modulator.

tied high. Alternatively, a parallel resonant fundamental frequency crystal, in parallel with a

1 M resistor, can be connected between the XTAL pin and the CLKIN pin with

XTALOFF tied low. External capacitors are then required from the CLKIN and XTAL

pins to ground. Consult the crystal manufacturer’s recommendation for the load capacitors.

In both cases, once power is applied to the AD7725, the clock input has to be continual.

to AGND1.

of an external clock source. Set low to enable the crystal oscillator amplifier when using an

external crystal between the CLKIN and XTAL pins.

CLKIN frequency of 14.4 MHz applies. When this input is high, the analog current typically

halves and a maximum CLKIN frequency of 9.6 MHz applies.

Power Supply Voltage for the Analog Modulator.

3 k resistor and to a reference buffer amplifier that drives the - modulator. When the

internal reference is used, a 1 µF capacitor is required between REF1 and AGND to decouple

the band gap noise and REF2 should be decoupled to AGND with a 220 nF and a 10 nF

capacitor in parallel.

the - modulator. When REF2 is used as an input, REF1 must be connected to AGND

to disable the internal buffer amplifier.

bipolar (differential or single-ended input) or unipolar (single-ended input) operation. A

logic high input selects unipolar operation and a logic low input selects bipolar operation.

Power Supply Voltage for the Analog Modulator.

REV. A–10–

Page 11

AD7725

Pin No. Mnemonic S/P Description

27 STBY

28 DGND Ground Reference for Digital Circuitry.

29 SYNC Synchronization Logic Input. When using more than one AD7725 operated from a

30 SOE/CS Serial Mode. SOE–Serial Output Enable. In EPROM mode, SOE going low enables the

31 SMODE1/DB15 Serial Mode. SMODE1–Serial Mode Select, Logic Input. This pin selects the serial mode to

32 SMODE0/DB14 Serial Mode. SMODE0–Serial Mode Select, Logic Input. This pin selects the serial mode to

33 SCR/DB13 Serial Mode. SCR–Serial Clock Rate Select, Logic Input. With SCR set to logic low,

34 CFGEND/DB12 Serial Mode. CFGEND–Configuration End, Logic Output. A logic high on CFGEND

35 DGND/DB11 Serial Mode. DGND–Digital Ground.

36 DGND/DB10 Serial Mode. DGND–Digital Ground.

37 FSO/DB9 Serial Mode. FSO–Frame Synchronization Output. FSO indicates the beginning of a

Standby, Logic Input. When STBY is taken high, the device will enter a low power mode.

If the device was fully configured before entering this mode, it will not lose its configuration data.

When STBY is brought low, the device exits the low power mode. If the device

was partially configured before entering the low power mode, it will restart the configuration

process in the case of boot from ROM (BFR) mode, DSP mode, and EPROM mode or, in

parallel mode, a new configure instruction must be issued to configure the device. If the device

was fully configured before entering the low power mode, it will continue to output conversion

results in all serial modes; in parallel mode, the device will wait for an instruction to begin

converting. In STBY mode, the clock input must be continual.

common master clock, SYNC allows each ADC to simultaneously sample its analog input

and update its output register. When SYNC is high, the digital filter sequencer counter is

reset to zero and the postprocessor core is reset. Because the digital filter and sequencer

are completely reset during this action, SYNC pulses cannot be applied continuously.

When SYNC is taken low, normal conversions continue, with valid data resulting after the

filter setting time.

external EPROM and is used to reset the EPROM’s address counter. In DSP mode, SOE is an

active high interrupt. It goes high after a power-on reset and after a pulse on the RESETCFG

pin, indicating the device is ready to be configured. It also goes high following a successful

configuration, indicating that the device was configured correctly. SOE is reset low when FSI

mode,

is detected high by CLKIN. In BFR

of a successful configuration.

Parallel Mode. CS–Chip Select Logic Input. This is an active low logic input used in

conjunction with the RD/WR input to read data from or write data to the device. For a

read operation, the falling edge of CS takes the bus out of three-state and either the

conversion data or the status register data (depending on the state of the RS input), is

placed onto the data bus, after the time t

is used to latch either the configuration data or the instruction (depending on the state of

the RS input) into the AD7725. In this case, the data should be set up for a time t

the CS rising edge.

be used (see Table IV) and thus informs the device where to download configuration data from

automatically on power up. To change the value on this pin, a full power cycle

needs to be performed.

Parallel Mode. DB15–Data Input/Output Bit (MSB).

be used (see Table IV) and thus informs the device where to download configuration data

from automatically on power-up. To change the value on this pin, a full power cycle needs to

be performed.

Parallel Mode. DB14–Data Input/Output Bit.

the serial clock output frequency, SCO, is equal to the CLKIN frequency. A logic high

sets the frequency of SCO to one half the CLKIN frequency.

Parallel Mode. DB13–Data Input/Output Bit.

indicates that device programming is complete and no programming errors occurred.

Parallel Mode. DB12–Data Input/Output Bit.

Parallel Mode. DB11–Data Input/Output Bit.

Parallel Mode. DB10–Data Input/Output Bit.

word transmission on the SDO pin. The FSO signal is a positive pulse approximately

one SCO period wide.

Parallel Mode. DB9–Data Input/Output Bit.

SOE pulses high for eight CLKIN cycles at the end

. For a write operation, the rising edge of CS

31

before

25

REV. A

–11–

Page 12

AD7725

Pin No. Mnemonic S/P Description

38 SDO/DB8 Serial Mode. SDO–Serial Data Output. The serial data is shifted out of the AD7725 MSB

first, in twos complement format, synchronous with SCO.

Parallel Mode. DB8–Data Input/Output Bit.

39 DV

40 SCO/DB7 Serial Mode. SCO–Serial Clock Output. The frequency of SCO is a function of the CLKIN

41 FSI/DB6 Serial Mode. FSI–Frame Synchronization Input. FSI indicates the beginning of a word

42 INIT/DB5 Serial Mode. INIT–Logic Input. When the device is correctly configured, a logic low on this

43 RESETCFG/DB4 Serial Mode. RESETCFG–Logic Input. RESETCFG is used to reset the part when a

44 DGND/DB3 Serial Mode. DGND–Digital Ground.

DD

Digital Power Supply Voltage.

frequency and is set by the SCR pin. When configuration data is being loaded into the

AD7725, SCO = f

Parallel Mode. DB7–Data Input/Output Bit.

transmission on the SDI pin.

Parallel Mode. DB6–Data Input/Output Bit.

pin will prevent the device from converting. When this pin is taken high, the device will start

converting. When daisy-chaining multiple devices, this pin ensures that all devices sample their

analog inputs simultaneously without needing to activate the SYNC pin.

Parallel Mode. DB5–Data Input/Output Bit.

configuration error occurs. A low pulse on this pin will reset the part, and the configuration

file will be downloaded again. The SOE pin will go high following a pulse on the RESETCFG

pin and then again following a successful configuration.

Parallel Mode. DB4–Data Input/Output Bit.

Parallel Mode. DB3–Data Input/Output Bit.

CLKIN

/16.

REV. A–12–

Page 13

AD7725

TERMINOLOGY

Integral Nonlinearity (INL)

This is the maximum deviation of any code from a straight line

passing through the endpoints of the transfer function. The

endpoints of the transfer function are zero scale (not to be

confused with bipolar zero), a point 0.5 LSB below the first

code transition (100 . . . 00 to 100 . . . 01 in bipolar mode,

000 . . . 00 to 000 . . . 01 in unipolar mode) and full scale, a

point 0.5 LSB above the last code transition (011 ...10 to

011 . . . 11 in bipolar mode, 111 . . . 10 to 111 ...11 in

unipolar mode). The error is expressed in LSBs.

Differential Nonlinearity (DNL)

This is the difference between the measured and the ideal

1LSB change between two adjacent codes in the ADC.

Unipolar Offset Error

Unipolar offset error is the deviation of the first code transition

from the ideal V

(+) voltage, which is (VIN(–) + 0.5 LSB) when

IN

operating in the unipolar mode.

Bipolar Offset Error

This is the deviation of the midscale transition code

(111 . . . 11 to 000 . . . 00) from the ideal V

which is (V

Gain Error

(–) – 0.5 LSB) when operating in the bipolar mode.

IN

(+) voltage,

IN

The first code transition should occur at an analog value

0.5 LSB above negative full scale. The last code transition

should occur for an analog value 1.5 LSB below the nominal

full scale. Gain error is the deviation of the actual difference

between first and last code transitions and the ideal difference

between first and last code transitions.

Signal-to-Noise Ratio (SNR)

SNR is the measured signal-to-noise ratio at the output of the

ADC. The signal is the rms magnitude of the fundamental.

Noise is the rms sum of all of the nonfundamental signals up

half the output data rate (f

/2), excluding dc. The ADC is

O

to

evaluated by applying a low noise, low distortion sine wave

signal to the input pins. By generating a Fast Fourier Transform (FFT) plot, the SNR data can then be obtained from the

output spectrum.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of the harmonics to the rms

value of the fundamental. THD is defined as

2

THD =

20 log

+ +++

VVVVV

223242526

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

V4, V5, and V6 are the rms amplitudes of the second through

sixth harmonics.

Spurious Free Dynamic Range (SFDR)

Defined as the difference, in dB, between the peak spurious or

harmonic component in the ADC output spectrum (up to

/2 and excluding dc) and the rms value of the fundamental.

f

O

Normally, the value of this specification will be determined by

the largest harmonic in the output spectrum of the FFT. For

input signals whose second harmonics occur in the stop band

region of the digital filter, the spur in the noise floor limits

the SFDR.

Settling Time and Group Delay

The settling time of a digital filter is dependent on the amount

of decimation employed and the number of filter taps used in

the filter design and is calculated as follows:

settling time

1

data input rate

number of taps=

×

The settling time for each filter stage should be calculated

separately and then added to get the total filter settling time.

Group delay is half the settling time.

REV. A

–13–

Page 14

AD7725–Typical Performance Characteristics

PERFORMANCE PLOTS

The following typical plots are generated using the digital filter shown in Figure 1.

= DVDD, TA = 25C, CLKIN = 9.6 MHz, External Reference = 2.5 V, unless otherwise noted.)

(AV

DD

110

INPUT FREQUENCY = 10kHz

100

90

80

70

dB

60

50

40

30

–50 0

SFDR

–40 –30 –20

ANALOG INPUT LEVEL – dB

THD

SNR

–10

TPC 1. SNR, THD, and SFDR vs. Analog Input

Level Relative to Full Scale

120

INPUT FREQUENCY = 10kHz

110

100

90

dB

80

70

60

2.4 7.2 9.6

0 14.4

SFDR

4.8

CLKIN FREQUENCY – MHz

THD

SNR

12

TPC 2. SNR, THD, and SFDR vs. Sampling Frequency

5000

8192 SAMPLES TAKEN

(+) = VIN(–)

V

IN

MAXIMUM OUTPUT DATA RATE

4000

3000

2000

1000

FREQUENCY OF OCCURRENCE

0

32718 32721 32722

32717 32726

32719 32720 32723 32725

CODE

32724

TPC 4. Histogram of Output Codes for a DC Input

0

–20

–40

–60

–80

–100

–120

–140

POWER LEVEL RELATIVE TO FULL SCALE – dB

–160

50 100 150

0 300

FREQUENCY – kHz

SNR = 84dB

THD = –93.85dB

SFDR = –98.47dB

AIN = 10kHz

MEASURED BW = 300kHz

200

250

TPC 5. 16k Point FFT

110

INPUT FREQUENCY = 10kHz

105

100

95

90

dB

85

80

75

70

–25 0 25

–50 100

TEMPERATURE – C

THD

SFDR

SNR

50

75

TPC 3. SNR, THD, and SFDR vs. Temperature

0

–20

–40

–60

–80

–100

–120

–140

POWER LEVEL RELATIVE TO FULL SCALE – dB

–160

50 100 150

0 300

FREQUENCY – kHz

SNR = 80.48dB

THD = –90.62dB

SFDR = –98dB

AIN = 10kHz

MEASURED BW = 450kHz

250

200 350 400 450

TPC 6. 16k Point FFT for a 108 Tap Low-Pass FIR

Filter Operating with a CLKIN Frequency of 14.4 MHz

REV. A–14–

Page 15

AD7725

CIRCUIT DESCRIPTION

The AD7725 employs a - conversion technique to convert

the analog input into an equivalent digital word. The modulator

samples the input waveform and outputs an equivalent digital

word at the input clock frequency, f

CLKIN

.

Due to the high oversampling rate, which spreads the quantization noise from 0 to f

/2, the noise energy contained in the

CLKIN

band of interest is reduced (Figure 9a). To further reduce the

quantization noise, a high order modulator is employed to shape

the noise spectrum so that most of the noise energy is shifted

out of the band of interest (Figure 9b).

The digital filtering that follows the modulator removes the

large out-of-band quantization noise (Figure 9c) while also

reducing the data rate from f

/16 or less at the output of the filter, depending on the

f

CLKIN

at the input of the filter to

CLKIN

filter type used.

Digital filtering has certain advantages over analog filtering.

Because digital filtering occurs after the A/D conversion, it can

remove noise injected during the conversion process. Analog

filtering cannot do this. The digital filter also has a linear

phase response.

QUANTIZATION NOISE

f

/2

BAND OF INTEREST

BAND OF INTEREST

BAND OF INTEREST

a.

NOISE SHAPING

b.

DIGITAL FILTER CUTOFF FREQUENCY

c.

CLKIN

f

CLKIN

f

CLKIN

/2

/2

Figure 9. - ADC

The AD7725 employs three fixed finite impulse response (FIR)

filters in series. Each individual filter’s output data rate is half

that of its input data rate. The fourth stage is programmable;

the user can select a range of different filter responses at this

stage. Both the filter response and the decimation are user programmable. See the Filtering section for more details.

APPLYING THE AD7725

Analog Input Range

The AD7725 has differential inputs to provide common-mode

noise rejection. In unipolar mode, the analog input is singleended and its range is 0 V to (8/5 V

). In bipolar mode,

REF2

the analog input is single-ended or differential, and its input

range is ±(4/5 V

). The output code is twos complement

REF2

in both modes with 1 LSB = 61 µV.

The ideal input/output transfer characteristics for the two

modes are shown in Figure 10. In both modes, the absolute

voltage on each input must remain within the supply range

AGND to AV

. Bipolar mode allows either single-ended or

DD

differential input signals while unipolar mode allows singleended signals.

011...111

011...110

000...010

000...001

000...000

111...111

OUTPUT CODE

111...110

100...001

100...000

–4/5 V

REF2

(0V)

DIFFERENTIAL INPUT VOLTAGE, VIN(+) – VIN(–)

(4/5 V

0V

REF2

)

4/5 V

(8/5 V

– 1LSB BIPOLAR

REF2

– 1LSB) UNIPOLAR

REF2

Figure 10. Bipolar/(Unipolar) Mode Transfer Function

The AD7725 will accept full-scale inband signals; however,

large scale out-of-band signals can overload the modulator inputs.

A minimal single-pole RC antialias filter set to f

/24 will allow

CLKIN

full-scale input signals over the entire frequency spectrum.

Analog Input

The analog input of the AD7725 uses a switched capacitor

technique to sample the input signal. For the purpose of driving

the AD7725, an equivalent circuit of the analog inputs is shown

in Figure 11. For each half-clock cycle, two highly linear sampling capacitors are switched to both inputs, converting the

input signal into an equivalent sampled charge. A signal source

driving the analog inputs must be able to source this charge,

while also settling to the required accuracy by the end of each

half-clock phase.

REV. A

–15–

Page 16

AD7725

220pF

AD7725

VIN(+)

V

IN

(–)

27

R

IN

390

220

220

10k

10nF220nF

1F

27

R

SOURCE

AIN = 2V

BIASED

ABOUT +2.5V

REF2

REF1

R

FB

220

50

V+

V–

V+

V–

AD7725

2pF

2pF

AC GROUND

VIN(+)

V

IN

500

(–)

500

CLKIN

A

B

A

B

A A BB

Figure 11. Analog Input Equivalent Circuit

Driving the Analog Inputs

To interface the signal source to the AD7725, at least one op

amp will generally be required. The choice of op amp will be

critical to achieving the full performance of the AD7725. The

op amp not only has to recover from the transient loads that the

ADC imposes on it, but it must also have good distortion characteristics and very low input noise. Resistors in the signal path

will also add to the overall thermal noise floor, necessitating the

choice of low value resistors.

Placing an RC filter between the drive source and the ADC

inputs, as shown in Figure 12, has a number of beneficial

effects: transients on the op amp outputs are significantly

reduced since the external capacitor now supplies the instantaneous charge required when the sampling capacitors are switched

to the ADC input pins, and input circuit noise at the sample

images is now significantly attenuated, resulting in improved

overall SNR. The external resistor serves to isolate the external

capacitor from the ADC output, thus improving op amp stability while also isolating the op amp output from any remaining

transients on the capacitor. By experimenting with different

filter values, the optimum performance can be achieved for each

application. As a guideline, the RC time constant (R C) should

be less than a quarter of the clock period to avoid nonlinear

currents from the ADC inputs being stored on the external

capacitor and degrading distortion. This restriction means that

this filter cannot form the main antialias filter for the ADC.

With the unipolar input mode selected, just one op amp is

required to buffer the single-ended input signal to the V

input, and a dc input is applied to the V

(–) pin to provide an

IN

(+)

IN

offset. However, driving the AD7725 with differential signals

(i.e., the bipolar input range is selected) has some distinct

advantages: even-order harmonics in both the drive circuits and

the AD7725 front end are attenuated, and the peak-to-peak

input signal range on both inputs is halved. Halving the input

signal range allows some op amps to be powered from the same

supplies as the AD7725. An example of providing differential

drive to the AD7725 is to use a dual op amp.

Dual Op Amp

Although this differential drive circuit will require two op amps

per ADC, it may avoid the need to generate additional supplies

just for these op amps.

Figures 13 and 14 show two circuits for driving the AD7725.

Figure 13 is intended for use when the input signal is biased

about 2.5 V, while Figure 14 is used when the input signal is

biased about ground. While both circuits convert the input

signal into a differential signal, the circuit in Figure 14 also level

shifts the signal so that both outputs are biased about 2.5 V.

Suitable op amps include the AD8047, the AD8041 and its dual

equivalent the AD8042, or the AD8022. The AD8047 has

lower input noise than the AD8041/AD8042 but has to be

supplied from a +7.5 V/–2.5 V supply. The AD8041/AD8042

will typically degrade the SNR from 83 dB to 81 dB but can be

powered from the same single 5 V supply as the AD7725.

R

C

R

Figure 12. Input RC Network

VIN(+)

V

IN

AD7725

(–)

Figure 13. Single-Ended-to-Differential Input Circuit

for Bipolar Mode Operation (Analog Input Biased

about 2.5 V)

REV. A–16–

Page 17

AD7725

R

FB

220

220

220

27

220pF

27

10nF220nF

1F

VIN(+)

AD7725

V

(–)

IN

REF2

REF1

AIN =

BIASED

ABOUT

GROUND

R

50

R

SOURCE

220

20k

390

IN

2V

10k

Figure 14. Single-Ended-to-Differential Input Circuit for Bipolar

Mode Operation (Analog Input Biased about Ground)

Applying the Reference

The AD7725 can operate with either an external reference or

with its on-chip 2.5 V reference. A block diagram of the internal

reference circuit is shown in Figure 15. The internal reference

circuitry includes an on-chip 2.5 V band gap reference and a

reference buffer circuit. The internal 2.5 V reference voltage is

connected to the REF1 pin through a 3 kΩ resistor. It is buffered

to drive the analog modulator’s switched capacitor DAC (REF2)

as shown in Figure 15. When using the internal reference, a 1 µF

capacitor is required between REF1 and AGND to decouple the

band gap noise. If the internal reference is required to bias

external circuits, an external precision op amp should be used to

buffer REF1.

COMPARATOR

REF1

1F

REF2

220nF 10nF

1V

REFERENCE

BUFFER

2.5

REFERENCE

3k

AD7725

SWITCHED-CAPACITOR

DAC REFERENCE

Where the output common-mode range of the amplifier driving

the inputs is restricted, the full-scale input signal span can be

reduced by applying a lower than 2.5 V reference. For example,

a 1.25 V reference would make the bipolar (differential) input

range ±1 V but would degrade SNR.

In all cases, since the REF2 voltage connects to the analog

modulator, a 220 nF and 10 nF capacitor must connect directly

from REF2 to AGND. The external capacitors provide the

charge required for the dynamic load presented at the REF2 pin

(see Figure 16).

4pF

4pF

A

AD7725

B

A

B

220nF

REF2

10nF

CLKIN

A

B

SWITCHED-CAPACITOR

DAC REFERENCE

A

B

Figure 16. REF2 Equivalent Input Circuit

The AD780 is ideal to use as an external reference with the

AD7725. Figure 17 shows a suggested connection diagram.

Grounding Pin 8 on the AD780 selects the 3 V output mode.

AD780

1F

5V

22nF

1

2

3

4

NC = NO CONNECT

NC

+V

IN

TEMP

GND

O/P

SELECT

NC

V

OUT

TRIM

8

2.5V

7

6

5

220nF 10nF

22F

REF2

AD7725

REF1

Figure 17. External Reference Circuit Connection

Clock Generation

The AD7725 has an on-chip oscillator circuit to allow a crystal

or an external clock signal to generate the master clock for

the ADC. In both cases, the clock input has to be continual;

once power is applied to the AD7725, it has to be continually

clocked. The connection diagram for use with a crystal is shown

in Figure 18. Consult the manufacturer’s recommendation for

the load capacitors. To enable the oscillator circuit on the

AD7725, XTAL_OFF should be tied low.

Figure 15. Reference Circuit Block Diagram

Where gain error or gain drift requires the use of an external

reference, this can be applied directly to the REF2 pin. In this

case, the reference buffer in Figure 15 can be turned off by

grounding the REF1 pin. The AD7725 will accept an external

reference voltage between 1.2 V and 3.15 V.

REV. A

–17–

Page 18

AD7725

POST -

PROCESSOR

MODULATOR

FIR 1

DEC 2

FIR 2

DEC 2

FIR 3

DEC 2

PRESET

FILTER

INPUT WORD

RATE = CLKIN

OUTPUT WORD

RATE = CLKIN/8

XTAL MCLK

Figure 18. Crystal Oscillator Connection

When an external clock source is being used, the internal

lator circuit can be disabled by tying XTAL_OFF high. A low

phase noise clock should be used to generate the ADC sampling clock because sampling clock jitter effectively modulates

the input signal and raises the noise floor. The sampling

generator should be isolated from noisy digital circuits, grounded,

and heavily decoupled to the analog ground plane.

The sampling clock generator should be referenced to the analog

ground in a split ground system; however, this is not always possible because of system constraints. In many applications, the

sampling clock must be derived from a higher frequency multipurpose system clock that is generated on the digital ground

plane. If the clock signal is passed between its origin on a digital

ground plane to the AD7725 on the analog ground plane, the

ground noise between the two planes adds directly to the clock

and will produce excess jitter. The jitter can cause degradation

in the signal-to-noise ratio and also produce unwanted harmonics. This can be remedied somewhat by transmitting the sampling

signal as a differential one, using either a small RF transformer

or a high speed differential driver and a receiver such as PECL.

In either case, the original master system clock should be generated from a low phase noise crystal oscillator.

SYSTEM SYNCHRONIZATION

The SYNC input provides a synchronization function for use in

parallel or serial mode. SYNC allows the user to begin gathering

samples of the analog input from a known point in time.

allows a system using multiple AD7725s, operated from a

common master clock, to be synchronized so that each ADC

simultaneously updates its output register. In a system using

multiple AD7725s, a common signal to their SYNC inputs

will synchronize their operation. When SYNC is high, the digital filter sequencer is reset to zero. A SYNC pulse, one CLKIN

cycle long, can be applied. This way, SYNC is sensed

the next rising edge of CLKIN. When SYNC is sensed low,

normal conversion continues. Following a SYNC, the

tor and filter need time to settle before data can be read from

the AD7725. Also, when INIT is taken high, it activates SYNC,

which ensures that multiple devices cascaded in serial mode will

sample their analog inputs simultaneously.

1M

oscil-

clock

This

low on

modula-

FILTERING

The Preset Filter

The preset filter is the digital filter directly following the modulator. This is a fixed filter whose main function is to remove the

large out-of-band quantization noise shaped by the modulator.

This filter is made up of three cascaded half-band FIR filters,

and each filter decimates by two. The word rate into the preset

filter is CLKIN, and due to the decimation in the three subsequent filter stages, the output word rate of the preset filter, and

thus the input word rate to the postprocessor, is CLKIN/8. See

Figure 19.

Figure 19. The Preset Filter

The Postprocessor

The AD7725 contains Systolix’s PulseDSPTM user-programmable postprocessor. The postprocessor directly follows the

preset filter. The postprocessor core is a systolic array of simple

high performance processors. These processors are grouped into

36 multiply accumulate (MAC) blocks, with each block consisting of three multipliers and one adder. Each block can process

three filter taps, thus the postprocessor allows up to 36 3 = 108

filter taps. In a systolic array, numerical data is pumped around

processors. Each of these processors is allocated to a dedicated

function and only performs that single function. The data is

passed between processors and, in this manner, complex operations are performed on the input signal. In the AD7725, data

transfers between processors are fully synchronous. As a result,

the user does not have to consider timing issues.

The postprocessor core is optimized for signal conditioning

applications. In this type of application, generally the most

common function is filtering. The core can support any filter

structure, whether FIR, IIR, recursive, or nonrecursive. The

core also supports polynomial functions, commonly used in

linearization algorithms.

Data can be transparently decimated or interpolated when

passed between processors. This simplifies the design of multirate

filtering and gives great flexibility when specifying the final

output word rate. The AD7725 postprocessor supports decimation/interpolation by factors up to 256.

REV. A–18–

Page 19

AD7725

Figure 20 shows an example of a filtering function implemented

on the postprocessor. Figure 20a shows the data path representation of an FIR filter, while Figure 20b shows how this algorithm

would be implemented on the AD7725. Because the postprocessor

can implement three filter taps per MAC block, 1.3 MAC

blocks are required to implement a 4-tap FIR filter. This is a

useful guideline when calculating the design requirements for a

new application.

SIGNAL

SIGNAL

OUT

IN

C

0

–1

Z

C

1

–1

Z

C

2

–1

Z

C

3

–1

Z

a) FIR Data Path Representation

1 MAC BLOCK

SIGNAL

SIGNAL

OUT

–1

IN

C

0

Z

C

1

–1

Z

–1

Z

C

2

C

3

–1

Z

–1

Z

b) FIR Postprocessor Implementation

Figure 20. AD7725 Postprocessor Mapping

PROGRAMMING THE POSTPROCESSOR

The postprocessor is programmed by loading a user-defined

filter in the form of a configuration file into the device.

Generating a Configuration File to Load into the Postprocessor

A user-defined configuration file can be generated to load into

the postprocessor on the AD7725 to program the multipliers

and accumulators to perform user-specific filtering requirements. The configuration file can be generated using a digital

filter design package called Filter Wizard, which is available

from the Analog Devices website.

Filter Wizard

This digital filter design package allows the user to design different filter types and then generates the appropriate configuration

file to be loaded into the postprocessor. This application includes

the ability to specify a range of different filter options including

single or multistage; normalized or user-specified output

frequency; FIR or IIR; low-pass, band-pass; Window type;

pass-band frequency and ripple; stop-band frequency, attenuation and ripple; daisy-chaining and interlacing. It also informs

the user of the power dissipation of the AD7725 associated

with the particular filter designed. This is to avoid filters being

designed that result in the device exceeding its maximum power

specifications. The magnitude, phase, and impulse responses

can be plotted so that the user knows the filter response (cutoff

frequency, transition width, attenuation) before generating the

coefficients. Once the filter characteristics have been decided,

the configuration file is generated and will be ready for loading

into the postprocessor.

Filter Configuration File Format

The configuration file that is generated by the Filter Wizard is

made up of 8272 bits of data. The first word in the file is called

the ID word, and the device will accept the configuration file only

if this is 0x7725. The rest of the configuration data is split into 12

blocks of 672 bits. The AD7725 postprocessor therefore accepts

672 bits at a time (42, 16-bit words). Each block of 672 bits is

followed by a cyclic redundancy check (CRC) word. The ID

word and the CRC words are used by the device to check for

errors in the configuration file and are not actually written to the

postprocessor. The postprocessor therefore holds 8064 bits of

data (672 12). See the Serial Mode and Parallel Mode sections

for further information on how configuration errors are detected

and handled. The filter coefficients in the configuration file that

are loaded into the postprocessor have 24-bit precision and have

a value in the range –8 ≤ coefficient < +8. The coefficients are

made up of 1 sign bit, 3 magnitude bits left of the decimal point,

and 20 right of the decimal point.

Using the Internal Default Filter

The AD7725 has a default filter stored in internal ROM that

can be loaded into the postprocessor. This functionality allows

the user to evaluate the device without having to download a

configuration file.

The default filter is a two-stage, low-pass,

FIR

filter whose specifications are directly related to the CLKIN

frequency. With a CLKIN frequency of 9.6 MHz, the default

filter has a cutoff frequency of 49 kHz and a stop-band frequency

of 72.7 kHz. This filter has a total decimation by 4, which occurs

in the first stage, resulting in the output data being available to the

interface at a frequency of CLKIN/32. For more detailed specifications on this filter see the Preset Filter, Default Filter, and

Postprocessor Characteristics section. When powered up in

boot-from-ROM mode, the AD7725 will automatically load the

default filter characteristic into the postprocessor. Figure 21

shows the default filter response, when operating with a 9.6 MHz

CLKIN frequency.

0

–20

–40

–60

–80

–100

ATTENUATION – dB

–120

–140

–160

0 150

50 100

FREQUENCY – kHz

Figure 21. Default Filter Response for CLKIN = 9.6 MHz

REV. A

–19–

Page 20

AD7725

Filter Design

The bit stream of data from the modulator and preset filter is

available to the postprocessor at a frequency of CLKIN/8. Due

to the nature of the design of the postprocessor, there is an

unavoidable minimum decimate by 2 resulting in the maximum

output data rate of any filter being CLKIN/16.

A filter can be either FIR or IIR in design. FIR filters are inherently

stable and have linear phase. However, they are computationally

inefficient and require more coefficients for a given roll-off compared to IIR filters. IIR filters have the disadvantage of being

potentially unstable and having nonlinear phase. The maximum

number of taps that the postprocessor can hold is 108. Therefore,

a single filter with 108 taps can be generated, or a multistage filter

can be designed whereby the total number of taps adds up to 108.

Design Factors

Stop-Band Attenuation and Transition Width

In filter design, it is desirable to have a large stop-band attenuation and a narrow filter transition width. To achieve both of

and a stop-band frequency of 150 kHz if the data stream is

decimated by 2 prior to the filtering stage. For IIR filters,

decimation has no effect on the transition width.

When decimation is performed, the amount of filter coefficients

required to achieve certain filter specifications is reduced, resulting in a reduction in the power dissipation of the device to

realize the filter. Therefore, if a one-stage filter meets the roll-off

and stop-band attenuation requirements of the application but

is dissipating more power than is acceptable, then decimation

will provide a solution here. Prior to decimating, a suggestion is

to use a half-band filter as these require a low number of taps to

accomplish simple low-pass filtering. A half-band filter has its

midpoint of the transition region centered on half the Nyquist

frequency (or f

subsequent stages is reduced, so is the bandwidth.

Figure 22 shows that for a given transition width, as the

decimation factor prior to the filter is increased the current

consumption is reduced, resulting in reduced power dissipation.

these, a large number of filter taps is required. Therefore some

compromises have to be made during the design to be able to

optimize the amount of taps used. There is usually a trade-off of

stop-band attenuation for transition width, or vice versa. For

example, a filter with a cutoff frequency of 100 kHz that rolls off

between 100 kHz and 200 kHz uses fewer taps than a filter with a

cutoff frequency of 100 kHz that rolls off between 100 kHz and

150 kHz. To reduce the number of taps used to achieve a

certain specification, a multistage filter can be designed that

performs

decimation between stages. The first filter stage can be

used to perform decimation and as a prefilter to remove out-ofband noise, then the subsequent stages can have more stringent

specifications.

Decimation

Decimation reduces the output data rate of the filter, resulting in

lower input data rates for subsequent filter stages.

is used in a multistage filter, the noise is wrapped around f

When decimation

/2 each

S

time the bit stream is decimated by 2. It is therefore important to

appropriately filter out the quantization noise that will wrap into

the band of interest when decimation occurs, prior to decimation.

With appropriate filtering, the noise floor will increase by 3 dB each

time the data stream is decimated by 2; however the noise floor is

down at 120 dB prior to decimation. Therefore, with suitable decimation, the SNR will be 83 dB typically at the AD7725 output.

Decimating the data rate allows an improvement in the filter

transition width equal to the inverse of the decimation factor.

For FIR filters, if a filter is designed for an input data rate of

half the maximum data rate, i.e., the previous filter stage had

decimation by 2, the filter can obtain half the transition width of

a filter designed for the maximum input data rate for a given

number of taps. For example, the number of taps required to

generate a filter with a cutoff frequency of 100 kHz and a

stop-band frequency of 200 kHz will equal the number of taps

required to generate a filter with a cutoff frequency of 100 kHz

Power Consumption vs. Filter Taps vs. CLKIN Frequency

When designing filters for the AD7725, an important factor to

take into account is the power consumption. There is a direct

relationship between DI

the postprocessor, and the CLKIN frequency. The maximum

I

DD

age is 150 mA. The more filter taps used, the higher the DI

Also, the higher the CLKIN frequency, the higher the DI

Therefore, a trade-off sometimes needs to be made between

CLKIN frequency and filter taps to stay within the power

budget of the part.

These power constraints are built into the filter design package,

Filter Wizard. As the filter is being designed, the power consumption is shown and is highlighted once the power budget

has been exceeded.

/4). By decimating though, because the input to

S

120

100

80

– mA

DD

I

60

40

082

46

DECIMATION FACTOR

Figure 22. IDD vs. Decimation for a Filter with a

Transition Width of 66 kHz as Shown in Figure 1

, the number of filter taps used in

DD

(combined AIDD and DIDD) allowed by the AD7725 pack-

.

DD

.

DD

REV. A–20–

Page 21

AD7725

AD7725

S/P

SYNC

RS

CS

RD/WR

DATA[ 15:0]

DVAL/INT

DSP/P

ADDR

RD

DATA[ 15:0]

INTERRUPT

ADDR

DECODER

WR

Figures 23 and 24 show plots of filter taps and CLKIN

frequency versus I

180

160

140

120

100

– mA

80

DD

I

60

40

20

0

0 14.4

.

DD

MAXIMUM I

2.4 4.8 7.2 9.6 12.0

DD

54 TAPS

CLKIN – MHz

108 TAPS

90 TAPS

72 TAPS

HALF_PWR DISABLEDHALF_PWR ENABLED

36 TAPS

Figure 23. Typical IDD vs. CLKIN for Various

Numbers of Filter Taps

To get a more accurate number of taps for a given CLKIN

frequency, see Figure 24.

180

160

140

120

100

– mA

80

DD

I

60

40

20

0

0 10010

MAXIMUM I

DD

2.4MHz

20 30 40 50 60 70 80 90

FILTER TAPS

14.4MHz

12MHz

9.6MHz

7.2MHz

4.8MHz

1MHz

110

Figure 24. Typical IDD vs. Filter Taps for Various

CLKIN Frequencies

Figures 23 and 24 were created for a one-stage low-pass FIR

filter, which will give the worst case I

The I

will decrease as the amount of decimation employed in

DD

figures.

DD

the filter is increased.

MODES OF OPERATION

The AD7725 can operate with either a serial or a parallel interface.

These modes are chosen by setting the logic state of the S/P pin.

REV. A

PARALLEL MODE

The parallel mode is selected by tying S/P to DGND. Programming the postprocessor and operation of the AD7725 in

parallel mode requires the use of an instruction set. The user

also has access to an on-chip status register that provides information about the operation of the device. The parallel interface

is a standard interface that interfaces to digital signal processors

and microprocessors. Figure 25 shows the interface between the

AD7725 and a DSP/microprocessor, and Figures 6, 7, and 8

show the timing of the parallel interface.

Figure 25. AD7725 Parallel Interface to Microprocessor

Operating the AD7725 in Parallel Mode

The AD7725 uses an instruction set, its interrupt pin output

(the INT pin), and an on-chip status register to communicate

with the DSP/microprocessor. An interrupt is issued by the

AD7725 whenever user intervention is required. The interrupt

can be cleared by either writing an instruction or reading the

status register. At the completion of power-on reset, the

AD7725 will issue an interrupt to indicate that user intervention

is required for it to begin communicating with the DSP/microprocessor. An instruction should then be issued to load the

configuration data to program the postprocessor. Once the

configuration file has been loaded, another interrupt is issued by

the device. The status register can then be read to check if any

errors occurred during configuration. If no errors occur during

the configuration process, an instruction can be issued to inform

the device to begin converting.

Pins RD/WR, CS, and RS are used along with the data pins D0

to D15 to write instructions/configuration data and read the

status register/conversion data.

During a read cycle, the RS pin informs the AD7725 whether

the status register or a conversion result is being read. When RS

is high, the status register is read while the data register, such as

the device ID or a conversion result, is read when RS is low.

Similarly, during a WR cycle, an instruction is written when RS

is high and data (such as configuration data) is written when RS

is low (see Table I).

Table I. Reading and Writing

RD/WR (Pin 7) RS (Pin 4) Operation

00Write Data

01Write Instruction

10Read Data

11Read Status Register

–21–

Page 22

AD7725

Status Register

The status register is a 16-bit register that provides the user with

information about the status of the device. The information available to the user includes whether a configuration file was loaded

successfully, what errors if any, occurred the last instruction

written, and other information that may be useful to the user

when operating the device. To read the status register, RS is

taken high and RD/WR is taken high. When CS is taken low, the

contents of the status register will be output. The status register is

shown in Table II and the instruction set in Table III.

Table II. Status Register

Bit Name Function

15 InstrBUSY This bit is set to 1 when an

instruction is performed.

14 Data Ready This bit is set to 1 when data is

ready to be read from the device

(a read data cycle is required).

13 Data Request This bit is set to 1 when the device.

requires data to be written to it (a write

data cycle is required).

12 ID Error This bit is set to 1 if the programming

data has an incorrect ID value.

11 CRC Error This bit is set to 1 if corrupt

data is loaded into the device.

10 Data Error This bit is set to 1 if an overflow occurs

to indicate that the conversion result is

invalid.

9 InstrReg[15] Instruction Register Bit 15

8 InstrReg[13] Instruction Register Bit 13

7 InstrReg[12] Instruction Register Bit 12

6 InstrReg[11] Instruction Register Bit 11

5 InstrReg[6] Instruction Register Bit 6

4 InstrReg[5] Instruction Register Bit 5

3 InstrReg[4] Instruction Register Bit 4

2 InstrReg[1] Instruction Register Bit 1

1 InstrReg[0] Instruction Register Bit 0

0 CFGEND Configuration End Flag. This is set to 1

when the device has been configured

correctly and is ready to start converting.

Table III. Instruction Set for Parallel Mode

Instruction Hex Code Description

RdID 0x8802 Read Device ID

RdCONV 0x8D21 Read Converter Data. When

this instruction is issued to the

AD7725, the device continues to

output conversion data until the

ABORT instruction is issued.

WrConfig 0x1800 Write Configuration Data

WrConfigEM 0x1A00 Write Configuration Data,

Mask Errors

ABORT 0x0000 Abort. This instruction is a

soft reset, that is, it breaks the

conversion process and leaves

the device in a clean state,

still configured, ready for the

next instruction.

BFR 0x2000 Boot from Internal ROM

Configuring the Device

Following power-up, the AD7725 is configured by loading a userdefined filter from an external source via the parallel interface.

Three in

Table III).

•

•

For evaluation purposes, the user can load the default filter

stored in internal ROM into the postprocessor. In this case the

following instruction should be issued:

structions are provided for configuring the AD7725 (see

WrConfig (Write Configuration)

When this instruction is issued, the device generates an

interrupt every time a new word of the configuration data is

required. The interrupt is cleared on the falling edge of CS

during the data write cycle. This continues until the complete file is written. Immediately after the last word of the

configuration data is written, a final interrupt is asserted to

indicate “Instruction Done.”

However, if an error occurred during the configuration

process, for example, if the configuration data is corrupt or

in the wrong format, an interrupt will be asserted.

It is advised that when using this instruction, the status register be read after each interrupt to ensure no errors occurred

and that the correct response is made. If configuration data is

corrupt, it will not be internally written to the postprocessor.

WrConfigEM (Write Configuration with Error Mask)

When this instruction is issued, no interrupts to signal

will ever be asserted during the download of the configuration file. This saves reading the status register in response

to every interrupt as with the previous instruction. The

configuration process will always run through the 504

(42 writes 12 blocks) data write cycles in the configuration file and once this is complete, the “Instruction Done”

interrupt is issued. In this case, the status register should be

checked at the end of the configuration to verify whether

any errors occurred. If configuration data is corrupt, it will

not be internally written to the postprocessor.

errors

•

BFR (Boot from ROM)

This instruction informs the device to load the configuration

data for the default filter stored in internal ROM.

REV. A–22–

Page 23

AD7725

Converting

To begin conversions, the RdCONV (Read Converter Data)

instruction is issued (see Table III). INT is asserted as soon as

the conversion data is ready to be read (Bit 14 of the status

register will be set). INT remains high until the digital word is

read from the device. It will then go low and return high when

the next conversion is complete. The device continues to convert until the ABORT instruction is issued.

SERIAL MODE

The serial mode is selected by tying S/P to DVDD. Figure 4

shows the serial interface of the AD7725. The AD7725 operates

solely as a master providing two serial data input pins for the

transfer of configuration data into the device (FSI and SDI),

two serial data output pins for transfer of conversion data out of

the device (FSO and SDO), and a serial clock output (SCO).

Data is shifted in or out of the device synchronous with SCO.

The FSI and FSO signals are used to indicate to either the

device or the processor, the beginning of a word transmission

into or out of the device. The AD7725 provides the clock for

conversion and data transfers. The CFMT pin selects the active

edge of SCO during conversions and the EFMT pin selects the

active edge of SCO during configuration.

Programming the postprocessor and operating the AD7725 in