Page 1

LC2MOS

a

FEATURES

2 ms ADC with Track/Hold

1 ms DAC with Output Amplifier

AD7569, Single DAC Output

AD7669, Dual DAC Output

On-Chip Bandgap Reference

Fast Bus Interface

Single or Dual 5 V Supplies

GENERAL DESCRIPTION

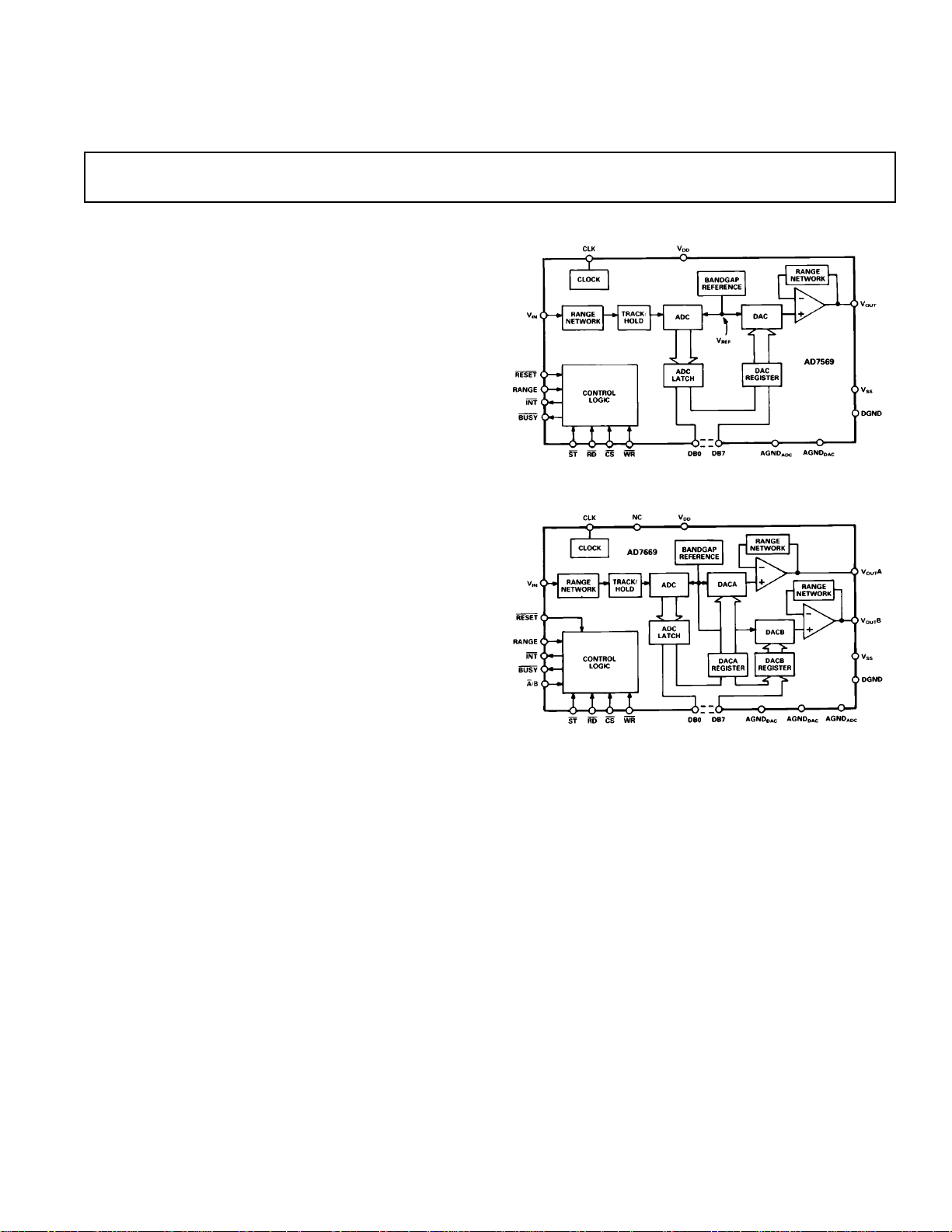

The AD7569/AD7669 is a complete, 8-bit, analog I/O system

on a single monolithic chip. The AD7569 contains a high speed

successive approximation ADC with 2 µs conversion time, a track/

hold with 200 kHz bandwidth, a DAC and an output buffer amplifier with 1 µs settling time. A temperature-compensated 1.25 V

bandgap reference provides a precision reference voltage for the

ADC and the DAC. The AD7669 is similar, but contains two

DACs with output buffer amplifiers.

A choice of analog input/output ranges is available. Using a supply voltage of +5 V, input and output ranges of zero to 1.25 V

and zero to 2.5 volts may be programmed using the RANGE input pin. Using a ±5 V supply, bipolar ranges of ±1.25 V or

±2.5 V may be programmed.

Digital interfacing is via an 8-bit I/O port and standard microprocessor control lines. Bus interface timing is extremely fast, allowing easy connection to all popular 8-bit microprocessors. A

separate start convert line controls the track/hold and ADC to

give precise control of the sampling period.

The AD7569/AD7669 is fabricated in Linear-Compatible

CMOS (LC

combining precision bipolar circuits with low power CMOS

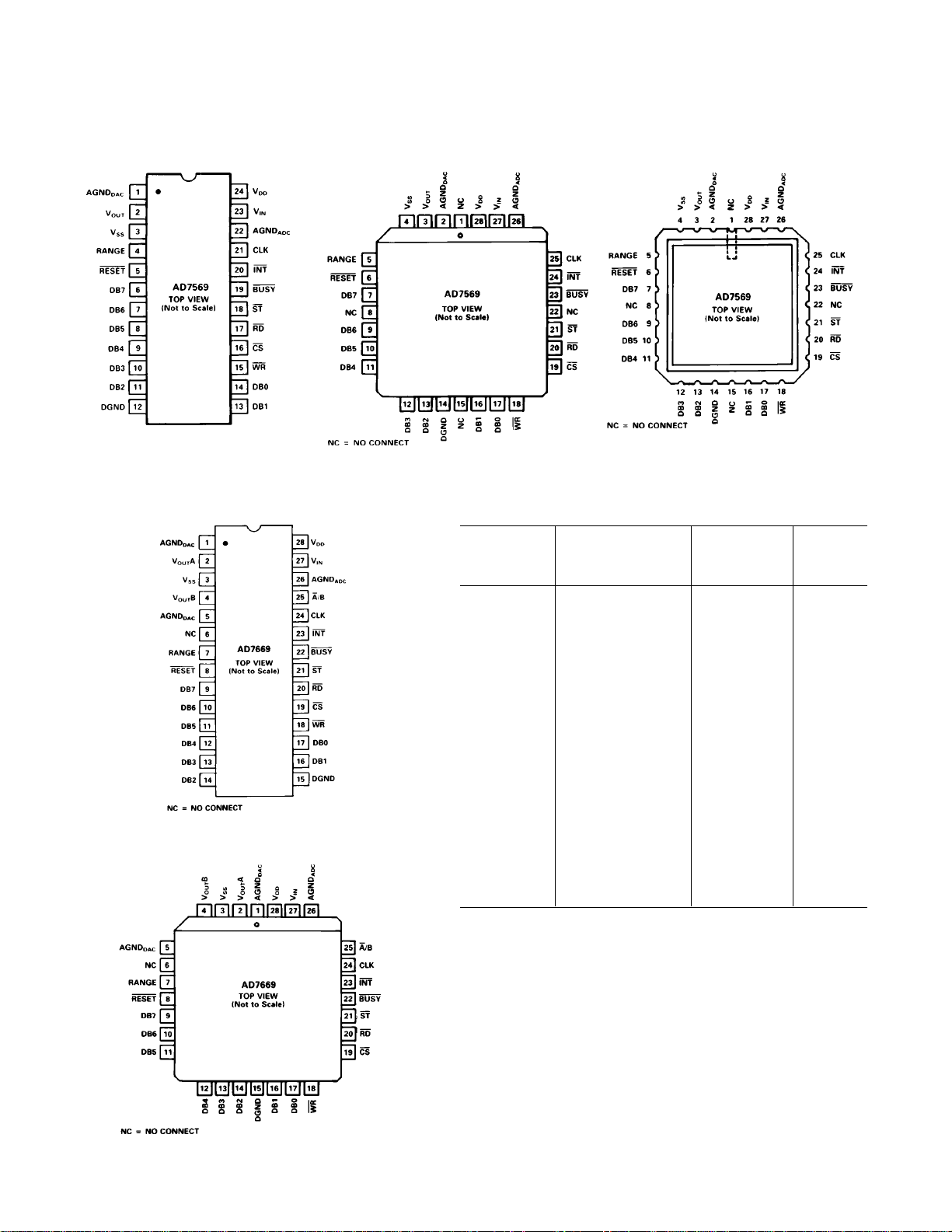

logic. The AD7569 is packaged in a 24-pin, 0.3" wide “skinny”

DIP, a 24-terminal SOIC and 28-terminal PLCC and LCCC

packages. The AD7669 is available in a 28-pin, 0.6" plastic

DIP, 28-terminal SOIC and 28-terminal PLCC package.

2

MOS), an advanced, mixed technology process

Complete, 8-Bit Analog I/0 Systems

AD7569/AD7669

AD7569 FUNCTIONAL BLOCK DIAGRAM

AD7669 FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Complete Analog I/O on a Single Chip.

The AD7569/AD7669 provides everything necessary to

interface a microprocessor to the analog world. No external

components or user trims are required and the overall accuracy of the system is tightly specified, eliminating the need

to calculate error budgets from individual component

specifications.

2. Dynamic Specifications for DSP Users.

In addition to the traditional ADC and DAC specifications,

the AD7569/AD7669 is specified for ac parameters, including signal-to-noise ratio, distortion and input bandwidth.

3. Fast Microprocessor Interface.

The AD7569/AD7669 has bus interface timing compatible

with all modern microprocessors, with bus access and relinquish times less than 75 ns and write pulse width less than

80 ns.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.com

Fax: 617/326-8703 © Analog Devices, Inc., 1996

Page 2

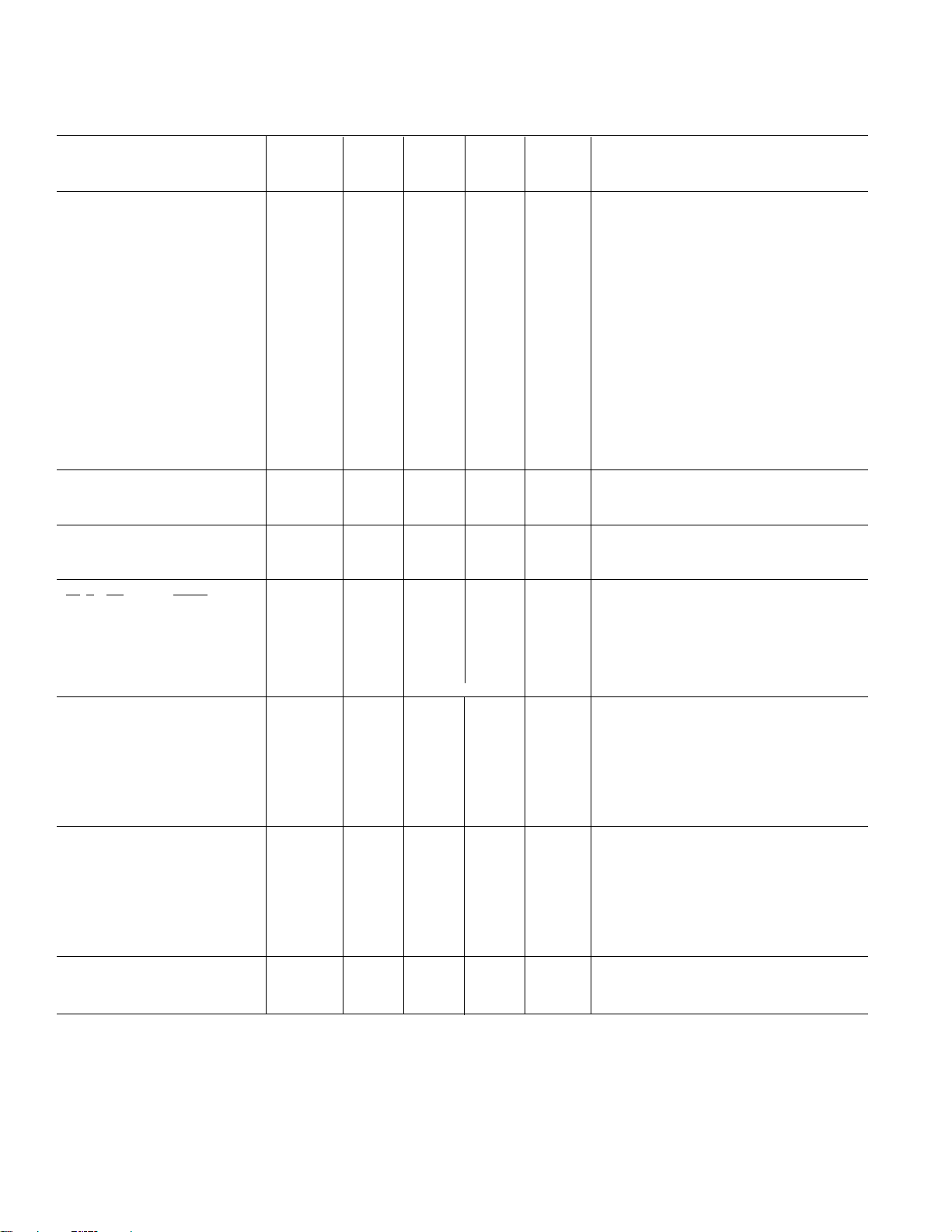

AD7569/AD7669–SPECIFICATIONS

(VDD = +5 V 6 5%; V

DAC SPECIFICATIONS

Parameter J Version Versions S Version T Version Units Conditions/Comments

STATIC PERFORMANCE

Resolution

Total Unadjusted Error

Relative Accuracy

Differential Nonlinearity

Unipolar Offset Error DAC data is all 0s; V

Bipolar Zero Offset Error DAC data is all 0s; V

Full-Scale Error

4

5

5

5

@ +25°C ± 2 ±1.5 ±2 ±1.5 LSB max Typical tempco is 10 µV/°C for +1.25 V range

T

to T

MIN

MAX

@ +25°C ± 2 ±1 5 ±2 ±1.5 LSB max Typical tempco is 20 µV/°C for ±1.25 V range

T

to T

MIN

MAX

6

(AD7569 Only) VDD = 5 V

1

unless otherwise noted. All specifications T

AD7569

J, A Versions

AD7669 K, B AD7569 AD7569

8 8 8 8 Bits

± 2 ± 2 ± 3 ± 3 LSB typ

± 1 ± 1/2 ±1 ±1/2 LSB max

± 1 ± 3/4 ±1 ±3/4 LSB max Guaranteed Monotonic

±2.5 ±2 ±2.5 ±2 LSB max

±2.5 ±2 ±2.5 ±2 LSB max

3

AD7569

2

= RANGE = AGND

SS

= AGND

DAC

MIN

= DGND = 0 V; RL = 2 kV, CL = 100 pF to AGND

ADC

to T

unless otherwise noted.)

MAX

= 0 V

SS

= –5 V

SS

DAC

@ +25°C ± 2 ±1 ±2 ±1 LSB max

T

to T

MIN

Full-Scale Error

MAX

6

(AD7669 Only) VDD = 5 V

±3 ±2 ±4 ±3 LSB max

@ +25°C ± 3 LSB max

T

to T

MIN

DACA/DACB Full-Scale Error Match

MAX

±4.5 LSB max

6

(AD7669 Only) ± 2.5 LSB max VDD = 5 V

∆Full Scale/∆V

∆Full Scale/∆V

Load Regulation at Full Scale 0.2 0.2 0.2 0.2 LSB max RL = 2 kΩ to °/C

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio

Total Harmonic Distortion

Intermodulation Distortion5 (IMD) 55 55 55 55 dB typ fa = 18.4 kHz, fb = 14.5 kHz with f

, TA = +25°C 0.5 0.5 0.5 0.5 LSB max V

DD

, TA = +25°C 0.5 0.5 0.5 0.5 LSB max V

SS

5

(SNR) 44 46 44 46 dB min V

5

(THD) 48 48 48 48 dB max V

= 2.5 V; ∆VDD = ±5%

OUT

= –2.5 V; ∆VSS = ±5%

OUT

= 20 kHz full-scale sine wave with f

OUT

= 20 kHz full-scale sine wave with f

OUT

SAMPLING

SAMPLING

SAMPLING

= 400 kHz

= 400 kHz

= 400 kHz

ANALOG OUTPUT

Output Voltage Ranges

Unipolar 0 to +1.25/2.5 Volts V

Bipolar ±1.25/±2.5 Volts VDD = +5 V, VSS = –5 V

LOGIC INPUTS

CS, X/B,WR, RANGE, RESET, DB0–DB7

Input Low Voltage, V

Input High Voltage, V

Input Leakage Current 10 10 10 10 µA max V

Input Capacitance

DB0–DB7

Input Coding (Single Supply) Binary

INL

INH

7

0.8 0.8 0.8 0.8 V max

2.4 2.4 2.4 2.4 V min

10 10 10 10 pF max

= +5 V, VSS = 0 V

DD

= 0 to V

IN

DD

Input Coding (Dual Supply) 2s Complement

AC CHARACTERlSTICS

Voltage Output Settling Time Settling time to within ±1/2 LSB of final value

7

Positive Full-Scale Change 2 2 2 2 µs max Typically 1 µs

Negative Full-Scale Change (Single Supply) 4 4 4 4 µs max Typically 2 µs

Negative Full-Scale Change (Dual Supply) 2 2 2 2 µs max Typically 1 µs

Digital-to-Analog Glitch Impulse

Digital Feedthrough

to V

V

IN

OUT

DAC to DAC Crosstalk

5

Isolation 60 60 60 60 dB typ VIN = ±2.5 V, 50 kHz Sine Wave

5

15 15 15 15 nV secs typ

1 1 1 1 nV secs typ

5

(AD7669 Only) 1 nV secs typ

DACA to DACB Isolation5 (AD7669 Only) –70 dB max

POWER REQUIREMENTS

V

Range 4.75/5.25 4.75/5.25 4.75/5.25 4.75/5.25 V min/V max For Specified Performance

DD

Range (Dual Supplies) –4.75/–5.25 –4.75/–5.25 –4.75/–5.25 –4.75/–5.25 V min/V max Specified Performance also applies to VSS = 0 V

V

SS

I

DD

(AD7569) 13 13 13 13 mA max Output unloaded

for unipolar ranges.

V

= VIN = 2.5 V; Logic Inputs = 2.4 V; CLK = 0.8 V

OUT

(AD7669) 18 mA max Outputs unloaded

I

(Dual Supplies) V

SS

(AD7569) 4 4 4 4 mA max Output unloaded

= VIN = –2.5 V; Logic Inputs = 2.4 V; CLK = 0.8 V

OUT

(AD7669) 6 mA max Outputs unloaded

DAC/ADC MATCHING

Gain Matching

@ +25°C 1 111% typ20 kHz sine wave

T

MIN

NOTES

1

Specifications apply to both DACs in the AD7669. V

2

Except where noted, specifications apply for all output ranges including bipolar ranges with dual supply operation.

3

Temperature ranges as follows: J, K versions; 0°C to +70°C

4

1 LSB = 4.88 mV for 0 V to +1.25 V output range, 9.76 mV for 0 V to +2.5 V and ±1.25 V ranges and 19.5 mV for ±2.5 V range.

5

See Terminology.

6

Includes internal voltage reference error and is calculated after offset error has been adjusted out. Ideal unipolar full-scale voltage is (FS – 1 LSB); ideal bipolar positive full-scale voltage is (FS/2 – 1 LSB)

and ideal bipolar negative full-scale voltage is –FS/2.

7

Sample tested at +25°C to ensure compliance.

Specifications subject to change without notice.

to T

MAX

6

VIN to V

match with VIN = ±2.5 V,

OUT

1 111% typ

applies to both V

OUT

A, B versions; –40°C to +85°C

S, T versions; –55°C to +125°C

OUT

A and V

B of the AD7669.

OUT

–2–

REV. B

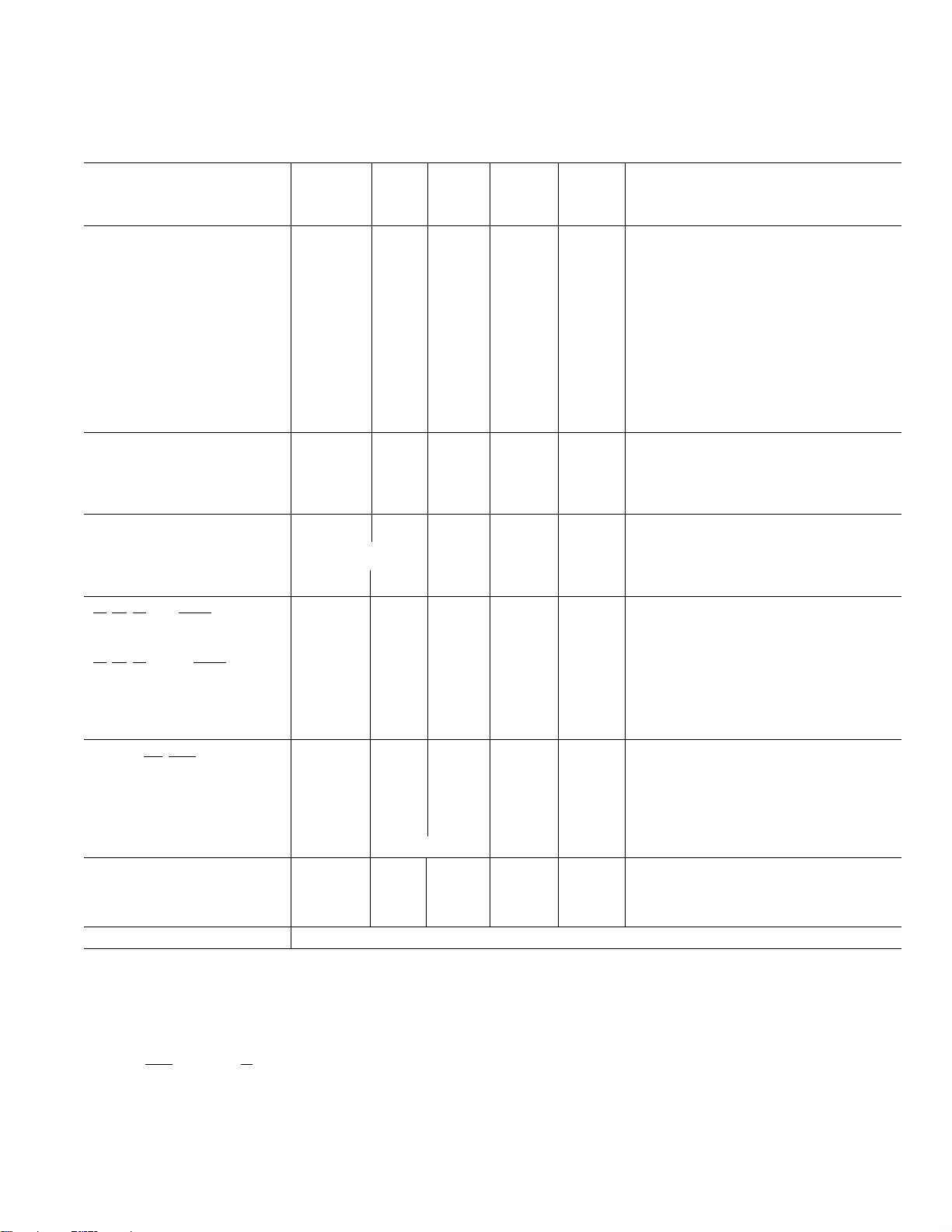

Page 3

AD7569/AD7669

AD7569

1

= RANGE = AGND

SS

= AGND

DAC

= DGND = 0 V; f

DAC

VDD = 5 V

= ±2.5 V, dc to 200 kHz sine wave

IN

= +5 V; VSS = 0 V

DD

= +5 V; VSS = –5 V

DD

= 0 to V

IN

= 1.6 mA

SINK

SOURCE

= 5 MHz

CLK

DD

DD

= 200 µA

= 5 MHz external unless other-

CLK

SAMPLING

SAMPLING

= 400 kHz

SAMPLING

ADC SPECIFICATIONS

wise noted. All specifications T

Parameter J Version Versions S Version T Version Units Conditions/Comments

DC ACCURACY

DYNAMIC PERFORMANCE

ANALOG INPUT

LOGIC INPUTS

LOGIC OUTPUTS

CONVERSION TIME

3

Resolution

Total Unadjusted Error

Relative Accuracy

Differential Nonlinearity

Unipolar Offset Error Typical tempco is 10 µV/°C for +1.25 V range; V

@ +25°C ±2 ±1.5 ±2 ± 1.5 LSB max

T

to T

MIN

Bipolar Zero Offset Error Typical tempco is 20 µV/°C for + 1.25 V range; V

Full-Scale Error

∆Full Scale/∆V

∆Full Scale/∆VSS, TA = +25°C 0.5 0.5 0.5 0.5 LSB max VIN = –2.5 V; ∆VSS = ± 5%

Signal-to-Noise Ratio

Total Harmonic Distortion4 (THD) 48 48 48 48 dB max VIN = 100 kHz full-scale sine wave with f

Intermodulation Distortion4 (IMD) 60 60 60 60 dB typ fa = 99 kHz, fb = 96.7 kHz with f

Frequency Response 0.1 0.1 0.1 0.1 dB typ V

Track/Hold Acquisition Time

Input Voltage Ranges

Input Current ±300 ± 300 ±300 ±300 µA max See equivalent circuit Figure 5

Input Capacitance 10 10 10 10 pF typ

CS, RD, ST, CLK, RESET, RANGE

CS, RD, ST, RANGE, RESET

CLK

DB0–DB7,

DB0–DB7

Output Coding (Single Supply) Binary

Output Coding (Dual Supply) 2s Complement

With External Clock 2 2 2 2 µs max f

With Internal Clock, T

MAX

@ +25°C ±3 ±2.5 ±3 ± 2.5 LSB max

T

to T

MIN

@ +25°C –4, +0 –4, +0 –4, +0 –4, +0 LSB max

T

to T

MIN

MAX

Unipolar 0 to +1.25/ +2.5 Volts V

Bipolar ± 1.25/±2.5 Volts V

Input Low Voltage, V

Input High Voltage, V

Input Capacitance

Input Leakage Current 10 10 10 10 µA max V

Input Current

I

INL

I

INH

INT, BUSY

VOL, Output Low Voltage 0.4 0.4 0.4 0.4 V max I

V

, Output High Voltage 4.0 4.0 4.0 4.0 V min I

OH

Floating State Leakage Current 10 10 10 10 µA max

Floating State Output Capacitance

4

4

4

MAX

5

, TA = +25°C 0.5 0.5 0.5 0.5 LSB max VIN = +2.5 V; ∆VDD = ±5%

DD

4

(SNR) 44 46 44 45 dB min VIN = 100 kHz full-scale sine wave with f

7

INL

INH

8

8

= +25°C 1.6 1.6 1.6 1.6 µs min Using recommended clock components shown in Figure 21.

A

(VDD = +5 V 6 5%; V

to T

MIN

unless otherwise noted.) Specifications apply to Mode 1 interface.

MAX

AD7569

J, A Versions

AD7669 K, B AD7569 AD7569

8 8 8 8 Bits

± 3 ± 3 ±4 ±4 LSB typ

± 1 ± 1/2 ± 1 ± 1/2 LSB max

± 1 ± 3/4 ± 1 ± 3/4 LSB max No Missing Codes

3

± 3 ±2.5 ± 3 ±2.5 LSB max

±3.5 ±3 ±4 ± 3.5 LSB max

–5.5, +1.5 –5.5, +1.5 –7.5, +2 –7.5, +2 LSB max

200 200 300 300 ns typ

0.8 0.8 0.8 0.8 V max

2.4 2.4 2.4 2.4 V min

10 10 10 10 pF max

–1.6 –1.6 –1.6 –1.6 mA max VIN = 0 V

40 40 40 40 µA max VIN = V

10 10 10 10 pF max

2.6 2.6 2.6 2.6 µs max Clock frequency can be adjusted by varying R

= 0 V

SS

SS

= 400 kHz

= 400 kHz

.

CLK

= –5 V

6

6

POWER REQUIREMENTS As per DAC Specifications

NOTES

1

Except where noted, specifications apply for all ranges including bipolar ranges with dual supply operation.

2

Temperature ranges are as follows: J, K versions; 0°C to +70°C

3

1 LSB = 4.88 mV for 0 V to +1.25 V range, 9.76 mV for 0 V to +2.5 V and ±1.25 V ranges and 19.5 mV for +2.5 V range.

4

See Terminology.

5

Includes internal voltage reference error and is calculated after offset error has been adjusted out. Ideal unipolar last code transition occurs at (FS – 3/2 LSB). Ideal bipolar last code transition occurs at

(FS/2 – 3/2 LSB).

6

Exact frequencies are 101 kHz and 384 kHz to avoid harmonics coinciding with sampling frequency.

7

Rising edge of BUSY to falling edge of ST. The time given refers to the acquisition time, which gives a 3 dB degradation in SNR from the tested figure.

8

Sample tested at +25°C to ensure compliance.

Specifications subject to change without notice.

REV. B

A, B versions; –40°C to +85°C

S, T versions; –55°C to +125°C

–3–

Page 4

1

WARNING!

ESD SENSITIVE DEVICE

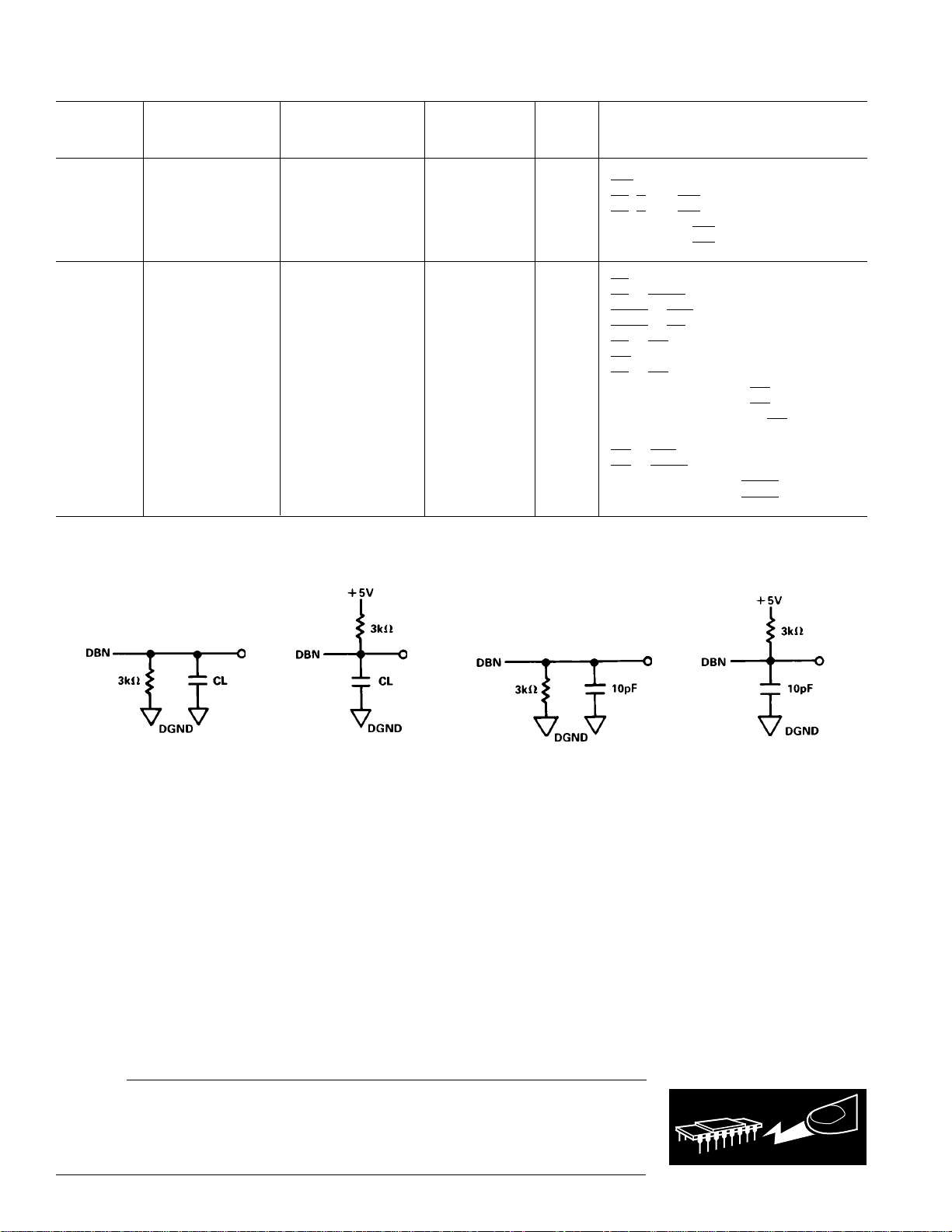

AD7569/AD7669–TIMING CHARACTERISTICS

(See Figures 8, 10, 12; VDD = 5 V 6 5%; VSS = 0 V or –5 V 6 5%)

Limit at Limit at

Limit at T

MIN

, T

MAX

T

, T

MIN

MAX

Parameter 258C (All Grades) (J, K, A, B Grades) (S, T Grades) Units Test Conditions/Comments

DAC Timing

t

1

t

2

t

3

t

4

t

5

80 80 90 ns min WR Pulse Width

0 0 0 ns min CS, A/B to WR Setup Time

0 0 0 ns min CS, A/B to WR Hold Time

60 70 80 ns min Data Valid to WR Setup Time

10 10 10 ns min Data Valid to WR Hold Time

ADC Timing

t

6

t

7

t

8

t

9

t

10

t

11

t

12

2

t

13

3

t

14

50 50 50 ns min ST Pulse Width

110 130 150 ns max ST to BUSY Delay

20 30 30 ns max BUSY to INT Delay

0 0 0 ns min BUSY to CS Delay

0 0 0 ns min CS to RD Setup Time

60 75 90 ns min RD Pulse Width Determined by t13.

0 0 0 ns min CS to RD Hold Time

60 75 90 ns max Data Access Time after RD; CL = 20 pF

95 120 135 ns max Data Access Time after

RD; CL = 100 pF

10 10 10 ns min Bus Relinquish Time after RD

60 75 85 ns max

t

15

t

16

2

t

17

65 75 85 ns max RD to INT Delay

120 140 160 ns max RD to BUSY Delay

60 75 90 ns max Data Valid Time after BUSY; CL = 20 pF

90 115 135 ns max Data Valid Time after BUSY; CL = 100 pF

NOTES

1

Sample tested at +25°C to ensure compliance. All input control signals are specified with tR = tF = 5 ns (10% to 90% of +5 V) and timed from a voltage level of 1.6 V.

2

t13 and t17 are measured with the load circuits of Figure 1 and defined as the time required for an output to cross either 0.8 V or 2.4 V.

3

tl4 is defined as the time required for the data line to change 0.5 V when loaded with the circuit of Figure 2.

Specifications subject to change without notice.

a. High-Z to V

OH

Figure 1. Load Circuits for Data Access Time Test

ABSOLUTE MAXIMUM RATINGS

VDD to AGND

V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . .–0.3 V, +7 V

DD

V

to VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +14 V

DD

AGND

AGND

or AGND

DAC

to AGND

DAC

or AGND

DAC

ADC

to DGND . . . . –0.3 V, VDD + 0.3 V

ADC

. . . . . . . . . . . . . . . . . . . . . . . . . ±5 V

ADC

Logic Voltage to DGND . . . . . . . . . . . . . –0.3 V, V

CLK Input Voltage to DGND . . . . . . . . . –0.3 V, V

V

(V

OUT

1

A, V

DAC

OUT

AGND

V

to AGND

IN

NOTE

1

Output may be shorted to any voltage in the range VSS to VDD provided that the

power dissipation of the package is not exceeded. Typical short circuit current for

a short to AGND or VSS is 50 mA.

B) to

OUT

. . . . . . . . . . . . . . . . . VSS – 0.3 V, VDD + 0.3 V

. . . . . . . . . . . . . . . VSS – 0.3 V, VDD + 0.3 V

ADC

b. High-Z to V

OL

. . . . . . . . . . . . . –0.3 V, +7 V

+ 0.3 V

DD

+ 0.3 V

DD

a. VOH to High-Z b. VOL to High-Z

Figure 2. Load Circuits for Bus Relinquish Time Test

Power Dissipation (Any Package) to +75°C . . . . . . . . 450 mW

Derates above 75°C by . . . . . . . . . . . . . . . . . . . . . 6 mW/°C

Operating Temperature Range

Commercial (J, K) . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

Industrial (A, B) . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Extended (S, T) . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 secs) . . . . . . . . . . . +300°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only; functional operation

of the device at these or any other condition above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7569/AD7669 features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper

ESD precautions are recommended to avoid performance degradation or loss of functionality.

–4–

REV. B

Page 5

AD7569/AD7669

NOTE:

The term DAC (Digital-to-Analog Converter) throughout the

data sheet applies equally to the dual DACs in the AD7669 as

well as to the single DAC of the AD7569 unless otherwise

stated. It follows that the term V

V

B of the AD7669 also.

OUT

TERMINOLOGY

Total Unadjusted Error

applies to both V

OUT

OUT

A and

Total unadjusted error is a comprehensive specification that includes internal voltage reference error, relative accuracy, gain

and offset errors.

Relative Accuracy (DAC)

Relative Accuracy or endpoint nonlinearity is a measure of the

maximum deviation from a straight line passing through the

endpoints of the DAC transfer function. It is measured after allowing for offset and gain errors. For the bipolar output ranges,

the endpoints of the DAC transfer function are defined as those

voltages that correspond to negative full-scale and positive fullscale codes. For the unipolar output ranges, the endpoints are

code 1 and code 255. Code 1 is chosen because the amplifier is

now working in single supply and, in cases where the true offset

of the amplifier is negative, it cannot be seen at code 0. If the

relative accuracy were calculated between code 0 and code 255,

the “negative offset” would appear as a linearity error. If the offset is negative and less than 1 LSB, it will appear at code 1, and

hence the true linearity of the converter is seen between code 1

and code 255.

Relative Accuracy (ADC)

Relative Accuracy is the deviation of the ADC’s actual code

transition points from a straight line drawn between the endpoints of the ADC transfer function. For the bipolar input

ranges, these points are the measured, negative, full-scale transition point and the measured, positive, full-scale transition point.

For the unipolar ranges, the straight line is drawn between the

measured first LSB transition point and the measured full-scale

transition point.

Differential Nonlinearity

Differential Nonlinearity is the difference between the measured

change and an ideal 1 LSB change between any two adjacent

codes. A specified differential nonlinearity of ± 1 LSB max ensures monotonicity (DAC) or no missed codes (ADC). A differential nonlinearity of ±3/4 LSB max ensures that the minimum

step size (DAC) or code width (ADC) is 1/4 LSB, and the maximum step size or code width is 3/4 LSB.

Digital-to-Analog Glitch Impulse

Digital-to-Analog Glitch Impulse is the impulse injected into the

analog output when the digital inputs change state with the

DAC selected. It is normally specified as the area of the glitch in

nV secs and is measured when the digital input code is changed

by 1 LSB at the major carry transition.

Digital Feedthrough

Digital Feedthrough is also a measure of the impulse injected to

the analog output from the digital inputs, but is measured when

the DAC is not selected. It is essentially feedthrough across the

die and package. It is also a measure of the glitch impulse transferred to the analog output when data is read from the internal

ADC. It is specified in nV secs and is measured with

WR high

and a digital code change from all 0s to all 1s.

DAC-to-DAC Crosstalk (AD7669 Only)

The glitch energy transferred to the output of one DAC due to

an update at the output of the second DAC. The figure given is

the worst case and is expressed in nV secs. It is measured with

an update voltage of full scale.

DAC-to-DAC Isolation (AD7669 Only)

DAC-to-DAC Isolation is the proportion of a digitized sine

wave from the output of one DAC, which appears at the output

of the second DAC (loaded with all 1s). The figure given is the

worst case for the second DAC output and is expressed as a ratio in dBs. It is measured with a digitized sine wave (f

SAMPLING

=

100 kHz) of 20 kHz at 2.5 V pk-pk.

Signal-to-Noise Ratio

Signal-to-Noise Ratio (SNR) is the measured signal to noise at

the output of the converter. The signal is the rms magnitude of

the fundamental. Noise is the rms sum of all the nonfundamental signals (excluding dc) up to half the sampling frequency.

SNR is dependent on the number of quantization levels used in

the digitization process; the more levels, the smaller the quantization noise. The theoretical SNR for a sine wave is given by

SNR = (6.02N + 1.76) dB

where N is the number of bits. Thus for an ideal 8-bit converter,

SNR = 50 dB.

Harmonic Distortion

Harmonic Distortion is the ratio of the rms sum of harmonics to

the fundamental. For the AD7569/AD7669, Total Harmonic

Distortion (THD) is defined as

2

2

2

2

2

+V

5

6

20 log

+V

+V

V

2

3

+V

4

V

1

where V1 is the rms amplitude of the fundamental and V2, V3,

V

, V5 and V6 are the rms amplitudes of the individual

4

harmonics.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products, of order (m + n), at sum and difference frequencies of

mfa ± nfb where m, n = 0, l, 2, 3,… . Intermodulation terms

are those for which m or n is not equal to zero. For example,

the second order terms include (fa + fb) and (fa – fb) and the

third order terms include (2fa + fb), (2fa – fb), (fa + 2fb) and

(fa – 2fb).

REV. B

–5–

Page 6

AD7569/AD7669

AD7569 PIN CONFIGURATIONS

DIP, SOIC

AD7669 PIN CONFIGURATIONS

DIP, SOIC

PLCC

PLCC

LCCC

ORDERING GUIDE

Relative

Temperature Accuracy Package

Model Range T

MIN –TMAX

Option

AD7569JN 0°C to +70°C ±1 LSB N-24

AD7569JR 0°C to +70°C ±1 LSB R-24

AD7569AQ –40°C to +85°C ±1 LSB Q-24

AD7569SQ

2

–55°C to +125°C ±1 LSB Q-24

AD7569BN –40°C to +85°C ±0.5 LSB N-24

AD7569KN 0°C to +70°C ±0.5 LSB N-24

AD7569BR –40°C to +85°C ±0.5 LSB R-24

AD7569BQ –40°C to +85°C ±0.5 LSB Q-24

AD7569TQ

AD7569JP 0°C to +70°C ±1 LSB P-28A

AD7569SE

AD7569KP 0°C to +70°C ±1/2 LSB P-28A

AD7569TE

2

–55°C to +125°C ±1/2 LSB Q-24

2

–55°C to +125°C ±1 LSB E-28A

2

–55°C to +125°C ±1/2 LSB E-28A

AD7669AN –40°C to +85°C ±1 LSB N-28

AD7669JN 0°C to +70°C ±1 LSB N-28

AD7669JP 0°C to +70°C ±1 LSB P-28A

AD7669AR –40°C to +85°C ±1 LSB R-28

AD7669JR 0°C to +70°C ±1 LSB R-28

NOTES

1

E = Leadless Ceramic Chip Carrier; N = Plastic DIP; P = Plastic Leaded Chip

Carrier; Q = Cerdip; R = Small Outline SOIC.

2

To order MIL-STD-883, Class B processed parts, add /883B to part number.

Contact your local sales office for military data sheet.

1

–6–

REV. B

Page 7

PIN FUNCTION DESCRIPTION

(Applies to the AD7569 and AD7669 unless otherwise stated.)

AD7569/AD7669

Pin

Mnemonic Description

AGND

DAC

Analog Ground for the DAC(s). Separate

ground return paths are provided for the

DAC(s) and ADC to minimize crosstalk.

V

(V

OUT

OUT

A, V

OUT

Output Voltage. V

B) voltage from the AD7569 DAC. V

V

B are the buffered DAC output voltages

OUT

is the buffered output

OUT

OUT

A and

from the AD7669. Four different output voltage ranges can be achieved (see Table I).

V

SS

Negative Supply Voltage (–5 V for dual supply or 0 V for single supply). This pin is also

used with the RANGE pin to select the different input/output ranges and changes the data

format from binary (V

ment (V

= –5 V) (see Table I).

SS

= 0 V) to 2s comple-

SS

RANGE Range Selection Input. This is used with the

V

input to select the different ranges as per

SS

Table I. The range selected applies to both

the analog input voltage of the ADC and the

output voltage from the DAC(s).

RESET Reset Input (Active Low). This is an asyn-

chronous system reset that clears the DAC

register(s) to all 0s and clears the

INT line of

the ADC (i.e., makes the ADC ready for new

conversion). In unipolar operation, this input

sets the output voltage to 0 V; in bipolar

operation, it sets the output to negative full

scale.

DB7 Data Bit 7. Most Significant Bit (MSB).

DB6–DB2 Data Bit 6 to Data Bit 2.

DGND Digital Ground.

DB1 Data Bit 1.

DB0 Data Bit 0. Least Significant Bit (LSB).

WR Write Input (Edge triggered). This is used in

conjunction with

CS to write data into the

AD7569 DAC register. It is used in conjunction with

CS and A/B to write data into the

selected DAC register of the AD7669. Data is

transferred on the rising edge of WR.

Pin

Mnemonic Description

CS Chip Select Input (Active Low). The device is

selected when this input is active.

RD READ Input (Active Low). This input must

be active to access data from the part. In the

Mode 2 interface,

version. It is used in conjunction with the

RD going low starts con-

CS

input (see Digital Interface Section).

ST Start Conversion (Edge triggered). This is

used when precise sampling is required. The

falling edge of

ST starts conversion and drives

BUSY low. The ST signal is not gated with

CS.

BUSY BUSY Status Output (Active Low). When

this pin is active, the ADC is performing a

conversion. The input signal is held prior to

the falling edge of

BUSY (see Digital Inter-

face Section).

INT INTERRUPT Output (Active Low). INT go-

ing low indicates that the conversion is complete.

INT goes high on the rising edge of CS

or

RD and is also set high by a low pulse on

RESET (see Digital Interface Section).

A/B (AD7669 DAC Select Input. This input selects which

Only) DAC register data is written to under control

of

CS and WR. With this input low, data is

written to the DACA register; with this input

high, data is written to the DACB register.

CLK A TTL compatible clock signal may be used

to determine the ADC conversion time. Internal clock operation is achieved by connecting

a resistor and capacitor to ground.

AGND

V

IN

ADC

Analog Ground for the ADC.

Analog Input. Various input ranges can be se-

lected (see Table I).

V

DD

Positive Supply Voltage (+5 V).

REV. B

Table I. Input/Output Ranges

Input/Output DB0–DB7

Range V

SS

Voltage Range Data Format

0 0 V 0 V to +1.25 V Binary

1 0 V 0 V to +2.5 V Binary

0 –5 V ±1.25 V 2s Complement

1 –5 V ±2.5 V 2s Complement

–7–

Page 8

AD7569/AD7669—Typical Performance Graphs

Noise Spectral Density vs. Frequency

Positive-Going Settling Time (±2.5 V Range)

Power Supply Rejection Ratio vs. Frequency

Negative-Going Settling Time (±2.5 V Range)

DAC/ADC Full-Scale Temperature Coefficient

–8–

IMD Plot for ADC

REV. B

Page 9

AD7569/AD7669

CIRCUIT DESCRIPTION

D/A SECTION

The AD7569 contains an 8-bit, voltage-mode, D/A converter

that uses eight equally weighted current sources switched into

an R-2R ladder network to give a direct but unbuffered 0 V to

+1.25 V output range. The AD7669 is similar, but contains two

D/A converters. The current sources are fabricated using PNP

transistors. These transistors allow current sources that are

driven from positive voltage logic and give a zero-based output

range. The output voltage from the voltage switching R-2R ladder network has the same positive polarity as the reference;

therefore, the D/A converter can be operated from a single

power supply rail.

The PNP current sources are generated using the on-chip

bandgap reference and a control amplifier. The current sources

are switched to either the ladder or AGND

by high speed

DAC

p-channel switches. These high-speed switches ensure a fast settling time for the output voltage of the DAC. The R-2R ladder

network of the DAC consists of highly stable, thin-film resistors.

A simplified circuit diagram for the D/A converter section is

shown in Figure 3. An identical D/A converter is used as part of

the A/D converter, which is discussed later.

Figure 3. DAC Simplified Circuit Diagram

OP AMP SECTION

The output from the D/A converter is buffered by a high speed,

noninverting op amp. This op amp is capable of developing

±2.5 V across a 2 kΩ and 100 pF load to AGND

. The am-

DAC

plifier can be operated from a single +5 V supply to give two

unipolar output ranges, or from dual supplies (± 5 V) to allow

two bipolar output ranges.

The feedback path of the amplifier contains a gain/offset network that provides four voltage ranges at the output of the op

amp. The output voltage range is determined by the RANGE

and V

inputs. (See Table I in the Pin Function Description

SS

section.) The four possible output ranges are: 0 V to +1.25 V,

0 V to +2.5 V, ±1.25 V and ±2.5 V. It should be noted that

whichever range is selected for the output amplifier also applies

to the input voltage range of the A/D converter.

The output amplifier settles to within 1/2 LSB of its final value

in typically less than 500 ns. Operating the part from single or

dual supplies has no effect on the positive-going settling time.

However, the negative-going output settling time to voltages

near 0 V in single supply will be slightly longer than the settling

time to negative full scale for dual supply operation. Additionally, to ensure that the output voltage can go to 0 V in single

supply, a transistor on the output acts as a passive pull-down

with output voltages near 0 V with V

= 0 V. This means that

SS

the sink capability of the amplifier is reduced as the output voltage nears 0 V in single supply. In dual supply operation the full

sink capability of 1.25 mA is maintained over the entire output

voltage range.

For all other parameters, the single and dual supply performances of the amplifier are essentially identical. The output

noise from the amplifier, with full scale on the DAC, is 200 µV

peak-to-peak. The spot noise at 1 kHz is 35 nV/√

Hz with all 0s

on the DAC. A noise spectral density versus frequency plot for

the amplifier is shown in the typical performance graphs.

VOLTAGE REFERENCE

The AD7569/AD7669 contains an on-chip bandgap reference

that provides a low noise, temperature compensated reference

voltage for both the DAC and the ADC. The reference is

trimmed for absolute accuracy and temperature coefficient. The

bandgap reference is generated with respect to V

. It is buff-

DD

ered by a separate control amplifier for both the DAC and the

ADC reference. This can be seen in the DAC ladder network

configuration in Figure 3.

DIGITAL SECTION

The data pins on the AD7569/AD7669 provide a connection

between the external bus and DAC data inputs and ADC data

outputs. The threshold levels of all digital inputs and outputs

are compatible with either TTL or 5 V CMOS levels. Internal

input protection of all digital pins is achieved by on-chip distributed diodes.

The data format is straight binary when the part is used in single

supply (V

= 0 V). However, when a VSS of –5 V is applied, the

SS

data format becomes twos complement. This data format applies to the digital inputs of the DAC and the digital outputs of

the ADC.

ADC SECTION

The analog-to-digital converter on the AD7569/AD7669 uses

the successive approximation technique to achieve a fast conversion time of 2 µs and provides an 8-bit parallel digital output.

The reference for the ADC is provided by the on-chip bandgap

reference.

Conversion start is controlled by

ST or by CS and RD. Once a

conversion has been started, another conversion start should not

be attempted until the conversion in progress is completed.

Exercising the

RESET input does not affect conversion; the

RESET input resets the INT line high, which is useful in inter-

rupt driven systems where a READ has not been performed at

the end of the previous conversion. The

INT line does not have

to be cleared at the end of conversion. The ADC will continue

to convert correctly, but the function of the

INT line will be

affected.

Figure 4 shows the operating waveforms for a conversion cycle.

The analog input voltage, V

ing edge of

ST or (CS & RD). The MSB decision is made ap-

, is held 50 ns typical after the fall-

IN

proximately 50 ns after the second falling edge of the input

CLK following a conversion start. If t

in Figure 4 is greater

1

than 50 ns, then the falling edge of the input CLK will be seen

as the first falling clock edge. If t

is less than 50 ns, the first fall-

1

ing clock edge of the conversion will not occur until one clock

cycle later. The succeeding bit decisions are made approximately 50 ns after a CLK edge until conversion is complete.

REV. B

–9–

Page 10

AD7569/AD7669

At the end of conversion, the SAR contents are transferred to

the output latch, and the SAR is reset in readiness for a new

conversion. A single conversion lasts for 8 input clock cycles.

Figure 4. Operating Waveforms Using External Clock

ANALOG INPUT

The analog input of the AD7569/AD7669 feeds into an on-chip

track-and-hold amplifier. To accommodate different full-scale

ranges, the analog input signal is conditioned by a gain/offset

network that conditions all input ranges so the internal ADC always works with a 0 V to +1.25 V signal. As a result, the input

current on the V

input varies with the input range selected as

IN

shown in Figure 5.

INTERNAL CLOCK

Clock pulses are generated by the action of an internal current

source charging the external capacitor (C

capacitor discharging through the external resistor (R

) and this external

CLK

CLK

).

When a conversion is complete, this internal clock stops operating and the CLK pin goes to the DGND potential. Connections

for R

CLK

and C

are shown in the operating diagram of Fig-

CLK

ure 21. The nominal conversion time versus temperature for the

recommended R

CLK

and C

combination is shown in Figure

CLK

6. The internal clock provides a convenient clock source for the

AD7569/AD7669. Due to process variations, the actual operating frequency for this R

CLK/CCLK

combination can vary from

device to device by up to ±25%.

Figure 5. Equivalent VIN Circuit

TRACK-AND-HOLD

The track-and-hold (T/H) amplifier on the analog input of the

AD7569/AD7669 allows the ADC to accurately convert an input sine wave of 2.5 V peak-to-peak amplitude up to a frequency of 200 kHz, the Nyquist frequency of the ADC when

operated at its maximum throughput rate of 400 kHz. This

maximum rate of conversion includes conversion time and time

between conversions. Because the input bandwidth of the T/H

amplifier is much larger than 200 kHz, the input signal should

be band-limited to avoid converting high-frequency noise

components.

The operation of this T/H amplifier is essentially transparent to

the user. The T/H amplifier goes from its tracking mode to its

hold mode at the start of conversion. This occurs when the

ADC receives a conversion start command from either

ST or

CS & RD. At the end of conversion (BUSY going high), the

T/H reverts back to tracking the input signal.

EXTERNAL CLOCK

The AD7569/AD7669 ADC can be used with its on-chip clock

or with an externally applied clock. When using an external

clock, the CLK input of the AD7569/AD7669 may be driven

directly from 74HC, 4000B series buffers (such as 4049) or

from TTL buffers. When conversion is complete, the internal

clock is disabled. The external clock can continue to run between conversions without being disabled. The mark/space ratio

of the external clock can vary from 70/30 to 30/70.

Figure 6. Conversion Time vs. Temperature for Internal

Clock Operation

DIGITAL INTERFACE

DAC Timing and Control—AD7569

Table II shows the truth table for DAC operation for the

AD7569. The part contains an 8-bit DAC register, which is

loaded from the data bus under control of

CS and WR. The

data contained in the DAC register determines the analog output from the DAC. The

WR input is an edge-triggered input,

and data is transferred into the DAC register on the rising edge

of

WR. Holding CS and WR low does not make the DAC regis-

ter transparent.

Table II. AD7569 DAC Truth Table

CS WR RESET DAC Function

H H H DAC Register Unaffected

L L H DAC Register Unaffected

L g H DAC Register Updated

g L H DAC Register Updated

X X L DAC Register Loaded with All Zeros

L = Low State, H = High State, X = Don’t Care

The contents of the DAC register are reset to all 0s by an active

low pulse on the

the output remains at 0 V after

polar output ranges, a low pulse on

go to negative full scale.

RESET line, and for the unipolar output ranges,

RESET returns high. For the bi-

RESET causes the output to

In unipolar applications, the RESET line

can be used to ensure power-up to 0 V on the AD7569 DAC output and is also useful when used as a zero override in system calibration cycles. If the

RESET input is connected to the system

–10–

REV. B

Page 11

AD7569/AD7669

RESET line, the DAC output resets to 0 V when the entire

system is reset. Figure 7 shows the input control logic for the

AD7569 DAC; the write cycle timing diagram is shown in

Figure 8.

Figure 7. AD7569 DAC Input Control Logic

The contents of the DAC registers are reset to all 0s by an active

low pulse on the

ranges, the outputs remain at 0 V after

For the bipolar output ranges, a low pulse on

outputs to go to negative full scale. In unipolar applications, the

RESET line can be used to ensure power-up to 0 V on the

AD7669 DAC outputs and is also useful when used as a zero

override in system calibration cycles. If the

nected to the system

to 0 V when the entire system is reset. Figure 9 shows the DAC

input control logic for the AD7669, and the write cycle timing

diagram is shown in Figure 8.

RESET line, and for the unipolar output

RESET returns high.

RESET causes the

RESET input is con-

RESET line, then the DAC outputs reset

Figure 8. AD7569/AD7669 Write Cycle Timing Diagram

DAC Timing and Control—AD7669

Table III shows the truth table for the dual DAC operation of

the AD7669. The part contains two 8-bit DAC registers that are

loaded from the data bus under the control of

Address line

loaded to. The data contained in the DAC registers determines

the analog output from the respective DACs. The

an edge-triggered input, and data is transferred into the selected

DAC register on the rising edge of

low does not make the selected DAC register transparent. The

A/B input should not be changed while CS and WR are low.

CS WR A/B RESET DAC Function

H H X H DAC Registers Unaffected

L g L H DACA Register Updated

g L L H DACA Register Updated

L g H H DACB Register Updated

g L H H DACB Register Updated

X X X L DAC Registers Loaded with

L = Low State, H = High State, X = Don’t Care

A/B selects which DAC register the data is

WR. Holding CS and WR

Table III. AD7669 DAC Truth Table

All Zeros

CS, A/B and WR.

WR input is

Figure 9. AD7669 DAC Control Logic

ADC Timing and Control

The ADC on the AD7569/AD7669 is capable of two basic operating modes. In the first mode, the

version and drive the track-and-hold into hold mode. At the end

of conversion, the track-and-hold returns to its tracking mode.

The second mode is achieved by hard-wiring the

In this case,

sor is driven into a WAIT state for the duration of conversion by

BUSY.

CS and RD start conversion, and the microproces-

Figure 10. ADC Mode 1 Interface Timing

ST line is used to start con-

ST line high.

REV. B

–11–

Page 12

AD7569/AD7669

MODE 1 INTERFACE

The timing diagram for the first mode is shown in Figure 10. It

can be used in digital signal processing and other applications

where precise sampling in time is required. In these applications, it is important that the signal sampling occurs at exactly

equal intervals to minimize errors due to sampling uncertainty

or jitter. In these cases, the

ST line is driven by a timer or some

precise clock source.

The falling edge of the

ST pulse starts conversion and drives the

AD7569/AD7669 track-and-hold amplifier into its hold mode.

BUSY stays low for the duration of conversion and returns high

at the end of conversion and the track-and hold amplifier reverts

to its tracking mode on this rising edge of

BUSY. The INT line

can be used to interrupt the microprocessor. A READ to the

AD7569/AD7669 address accesses the data, and the

reset on the rising edge of

be used to trigger a pulse that drives the

CS or RD. Alternatively, the INT can

CS and RD and places

INT line is

the data into a FIFO or buffer memory. The microprocessor can

then read a batch of data from the FIFO or buffer memory at

some convenient time. The

ST input should not be high when

RD is brought low; otherwise, the part will not operate correctly

in this mode.

It is important, especially in systems where the conversion start

(

ST pulse) is asynchronous to the microprocessor, that a READ

does not occur during a conversion. Trying to read data from

the device during a conversion can cause errors to the conversion in progress. Also, pulsing the

ST line a second time before

conversion ends should be avoided since it too can cause errors

in the conversion result. In applications where precise sampling

is not critical, the

cessor

WR or RD line gated with a decoded address (different

from AD7569/AD7669

ST pulse can be generated from a micropro-

CS address).

Figure 11. Multichannel Inputs

This interface mode is also useful in applications where a number of input channels are required to be converted by the ADC.

Figure 11 shows the circuit configuration for such an application. The signal that drives the

ST input of the AD7569/

AD7669 is also used to drive the ENABLE input of the multiplexer. The multiplexer is enabled on the rising edge of the

ST

pulse while the input signal is held on the falling edge; therefore,

the signal must have settled to within 8 bits over the duration of

this

ST pulse. The settling time, including t

(ENABLE) of

ON

the multiplexer plus the T/H acquisition time (typically 200 ns),

thus determines the width of the

ST pulse. This is suited to applications where a number of input channels needs to be successively sampled or scanned.

MODE 2 INTERFACE

The second interface mode is intended for use with microprocessors, which can be forced into a WAIT state for at least 2 µs.

The

ST line of the AD7569/AD7669 must be hardwired high to

achieve this mode. The microprocessor starts a conversion and

is halted until the result of the conversion is read from the converter. Conversion is initiated by executing a memory READ to

the AD7569/AD7669 address, bringing

CS and RD low. BUSY

subsequently goes low (forcing the microprocessor READY or

WAIT input low), placing the microprocessor into a WAIT

state. The input signal is held on the falling edge of

ing

CS is already low or is coincident with RD). When the con-

version is complete (

BUSY goes high), the processor completes

RD (assum-

the memory READ and acquires the newly converted data.

While conversion is in progress, the ADC places old data (from

the previous conversion) on the data bus. The timing diagram

for this interface is shown in Figure 12.

Figure 12. ADC Mode 2 Interface Timing

The major advantage of this interface is that it allows the microprocessor to start conversion, WAIT, and then READ data with

a single READ instruction. The user does not have to worry

about servicing interrupts or ensuring that software delays are

long enough to avoid reading during conversion. The fast conversion time of the ADC ensures that for many microprocessors,

the processor is not placed in a WAIT state for an excessive

amount of time.

DIGITAL SIGNAL PROCESSING APPLICATIONS

In Digital Signal Processing (DSP) application areas such as

voice recognition, echo cancellation and adaptive filtering, the

dynamic characteristics (SNR, Harmonic Distortion, Intermodulation Distortion) of both the ADC and DAC are critical. The

AD7569/AD7669 is specified dynamically as well as with standard dc specifications. Because the track/hold amplifier has a

wide bandwidth, an antialiasing filter should be placed on the

V

input to avoid aliasing of high-frequency noise back into the

IN

band of interest.

The dynamic performance of the ADC is evaluated by applying a

sine-wave signal of very low distortion to the V

input, which is

IN

sampled at a 409.6 kHz sampling rate. A Fast Fourier Transform

(FFT) plot or Histogram plot is then generated from which SNR,

harmonic distortion and dynamic differential nonlinearity data

can be obtained. For the DAC, the codes for an ideal sine wave

are stored in PROM and loaded down to the DAC. The output

spectrum is analyzed, using a spectrum analyzer to evaluate SNR

–12–

REV. B

Page 13

and harmonic distortion performance. Similarly, for intermodulation distortion, an input (either to V

or DAC code)

IN

consisting of pure sine waves at two frequencies is applied to the

AD7569/AD7669.

Figure 13. ADC FFT Plot

Figure 13 shows a 2048 point FFT plot of the ADC with an input signal of 130 kHz. The SNR is 48.4 dB. It can be seen that

most of the harmonics are buried in the noise floor. It should be

noted that the harmonics are taken into account when calculating the SNR. The relationship between SNR and resolution (N)

is expressed by the following equation:

SNR = (6.02N + 1.76) dB

This is for an ideal part with no differential or integral linearity

errors. These errors will cause a degradation in SNR. By working backward from the above equation, it is possible to get a

measure of ADC performance expressed in effective number of

bits (N). This effective number of bits is plotted versus frequency in Figure 14. The effective number of bits typically falls

between 7.7 and 7.8, corresponding to SNR figures of 48.1 dB

and 48.7 dB.

Figure 15 shows a spectrum analyzer plot of the output spectrum from the DAC with an ideal sine-wave table loaded to the

data inputs of the DAC. In this case, the SNR is 46 dB.

AD7569/AD7669

Figure 15. DAC Output Spectrum

HISTOGRAM PLOT

When a sine wave of specified frequency is applied to the VIN input of the AD7569/AD7669 and several thousand samples are

taken, it is possible to plot a histogram showing the frequency of

occurrence of each of the 256 ADC codes. If a particular step is

wider than the ideal 1 LSB width, the code associated with that

step will accumulate more counts than for the code for an ideal

step. Likewise, a step narrower than ideal width will have fewer

counts. Missing codes are easily seen because a missing code

means zero counts for a particular code. The absence of large

spikes in the plot indicates small differential nonlinearity.

Figure 16 shows a histogram plot for the ADC indicating very

small differential nonlinearity and no missing codes for an input

frequency of 204 kHz. For a sine-wave input, a perfect ADC

would produce a cusp probability density function described by

the equation

π(A

1

2−V2)1/ 2

p(V ) =

where A is the peak amplitude of the sine wave and p(V) the

probability of occurrence at a voltage V.

The histogram plot of Figure 16 corresponds very well with this

cusp shape.

Further typical plots of the performance of the AD7569/AD7669

are shown in the Typical Performance Graphs section of the data

sheet.

Figure 14. Effective Number of Bits vs. Frequency

REV. B

Figure 16. ADC Histogram Plot

–13–

Page 14

AD7569/AD7669

INTERFACING THE AD7569/AD7669

AD7569/AD7669—Z80 INTERFACE

Figure 17 shows a typical interface to the Z80 microprocessor.

The ADC is configured for operation in the Mode 1 interface

mode. A precise timer or clock source starts conversion in applications requiring equidistant sampling intervals. The scheme

used, whereby

rupt on the Z80, is limited in that it does not allow the ADC to

be sampled at the maximum rate. This is because the time between samples has to be long enough to allow the Z80 to service

its interrupt and read data from the ADC. To overcome this,

some buffer memory or FIFO could be placed between the

AD7569/AD7669 and the Z80. Writing data to the relevant

AD7569/AD7669 DAC simply consists of a <LD (nn), A> instruction where nn is the decoded address for that DAC. Reading data from the ADC, after an

consists of a < LDA, (nn)> instruction.

AD7569/AD7669—68008 INTERFACE

A typical interface to the 68008 is shown in Figure 18. In this

case, the ADC is configured in the Mode 2 interface mode. This

means that the one read instruction starts conversion and reads

the data. The read cycle is stretched out over the entire conversion period by taking the

of the 68008. The additional gates are required so the 68008

receives a

AD7569/AD7669. In this case, there are no wait states introduced into the write cycle. Writing data to the relevant AD7569/

AD7669 DAC consists of a <MOVE.B Dn, addr> where Dn is

the data register, which contains the data to be loaded to that

DAC, and addr is the decoded address for the DAC. Data is

read from the ADC using a <MOVE.B addr,Dn> with the conversion result placed in register Dn.

INT of the AD7569/AD7669 generates an inter-

INT has been received,

Figure 17. AD7569/AD7669 to Z80 Interface

INT line back into the DTACK input

DTACK when the processor is writing data to the

AD7569/AD7669—ADSP-2100 INTERFACE

Figure 19 shows a typical interface to the DSP processor, the

ADSP-2100. The ADC is in the Mode 2 interface mode, which

means that the ADSP-2100 is halted during conversion. This is

achieved using the decoded address output. This is gated with

DMWR to ensure that it halts the processor for READ instructions only.

processor and allows it to finish off the READ instruction.

Because the instruction cycle of the ADSP-2100 is so fast

(125 ns cycle), the

for write cycles. This is achieved using the 74121, which generates a pulse that is fed back to DMACK. The duration of this

pulse determines how long the ADSP-2100 write cycle is

stretched. The buffers driving the DMACK line must have

open-collector outputs. Writing data to the relevant AD7569/

AD7669 DAC is achieved using a single instruction, <DM

(addr) = MRO>, where addr is the decoded address of that

DAC, and MRO contains the data to be loaded to the DAC register. Data is read from the ADC also, using a single instruction

<MRO = DM (addr)>, where the conversion result is placed in

the MRO data register.

AD7569/AD7669—IBM PC* INTERFACE

The AD7569/AD7669 is ideal for implementing an analog input/output port for the IBM PC. Figure 20 shows an interface

that realizes this function. The ADC is configured in the Mode

1 interface mode, and conversions are initiated using a precise

clock source for equidistant sampling intervals. At the end of

conversion, the

INT going low at the end of conversion releases the

Figure 19. AD7569/AD7669 to ADSP-2100 Interface

DMWR pulse also has to be stretched also

INT line goes low, and the 74121 generates

Figure 18. AD7569/AD7669 to 68008 Interface

Figure 20. AD7569/AD7669 to IBM PC Interface

*IBM PC is a trademark of International Business Machines Corp.

–14–

REV. B

Page 15

AD7569/AD7669

an RD pulse for the AD7569/AD7669. This RD pulse accesses

data from the ADC and places the conversion result into a register on the 74646. The rising edge of this pulse generates an interrupt request to the processor. The conversion result is read

from the 74646 register by performing an I/O read to the

decoded address of the 74646. Writing data to the relevant

AD7569/AD7669 DAC involves an I/O write to the 74646,

which transfers the data to the data inputs of the AD7569/

AD7669. Data is latched into the selected DAC register on the

rising edge of

IOW.

APPLYING THE AD7569/AD7669 DAC

An internal gain/offset network on the AD7569/AD7669 allows

several output voltage ranges. The part can produce unipolar

output ranges of 0 V to +1.25 V or 0 V to +2.5 V and bipolar

output ranges of –1.25 V to +1.25 V or –2.5 V to +2.5 V. Connections for these various output ranges are outlined below.

UNIPOLAR (0 V to +1.25 V) CONFIGURATION

The first of the configurations provides an output voltage range

of 0 V to +1.25 V. This is achieved by tying the V

RANGE inputs to AGND

(= 0 V). Figure 21 shows the con-

DAC

SS

and

figuration of the AD7569 to achieve this output range. A similar

configuration of the AD7669 gives the same output range. The

table for output voltage versus the digital code in the DAC register is shown in Table IV.

UNIPOLAR (0 V to +2.5 V) CONFIGURATION

The 0 V to +2.5 V output voltage range is achieved by tying V

to AGND

(= 0 V) and the RANGE input to VDD. The table

DAC

SS

for output voltage versus digital code is as in Table IV with

2.V

replacing V

REF

. Note that for this range

REF

1 LSB = 2.V

(2−8) =V

REF

REF

1

128

BIPOLAR (–1.25 V to +1.25 V) CONFIGURATION

The first of the bipolar configurations is achieved by tying the

RANGE input to AGND

(= 0 V) and VSS to –5 V. The V

DAC

SS

voltage level at which the AD7569/AD7669 changes to bipolar

operation is approximately –1 V. When the part is configured

for bipolar outputs, the input coding becomes twos complement. The table for output voltage versus the digital code in the

DAC register is shown in Table V. Note as with the unipolar

configuration, a digital input code of all 0s produces an output

of 0 V. It should be noted, however, that a low pulse on the

RESET line for the bipolar ranges sets the output voltage to

negative full scale.

Table V. Bipolar (–1.25 V to +1.25 V) Code Table

DAC Register Contents

MSB LSB Analog Output, V

0111 1111 +V

0000 0001 +V

REF

REF

127

128

1

128

OUT

Figure 21. AD7569 Unipolar (0 V to +1.25 V) Operation

Table IV. Unipolar (0 V to +1.25 V) Code Table

DAC Register Contents

MSB LSB Analog Output, V

1111 1111 +V

1000 0001 +V

1000 0000 +V

0111 1111 +V

0000 0001 +V

REF

REF

REF

REF

REF

255

256

129

256

128

256

127

256

1

256

= +V

OUT

REF

/2

0000 0000 0 V

1111 1111 –V

1000 0001 –V

1000 0000 –V

NOTE: 1 LSB = (V

)(2–7) = V

REF

REF

(1/128)

REF

REF

REF

1

128

127

128

128

128

= –V

REF

BIPOLAR (–2.5 V to +2.5 V) CONFIGURATION

The –2.5 V to +2.5 V bipolar output range is achieved by tying

the RANGE input to V

and the VSS input to –5 V. Once

DD

again, the input coding is 2s complement. The table for output

voltage versus digital code is as in Table V with 2.V

V

. Note that for this range

REF

1 LSB = 4.V

(2−8) =V

REF

REF

1

64

replacing

REF

0000 0000 0 V

NOTE: 1 LSB = (V

) (2–8) = V

REF

(1/256); V

REF

REV. B

= +1.25 V Nominal

REF

–15–

Page 16

AD7569/AD7669

APPLYING THE AD7569/AD7669 ADC

The analog input on the AD7569/AD7669 accepts the same

four input ranges as the output ranges on the DAC. Whatever

output range is selected for the DAC also applies to the input

range of the ADC.

Although separate AGNDs exist for both the DAC and ADC to

minimize crosstalk, writing data to the DAC while the ADC is

performing a conversion may result in an incorrect conversion

from the ADC due to an interaction of currents between the

DAC and ADC. Therefore, to ensure correct operation of the

ADC, the DAC register should not be updated while the ADC

is converting.

UNIPOLAR OPERATION

The circuit of Figure 21 shows the AD7569 configured for both

an input and output range of 0 V to +1.25 V (the AD7669 configuration is similar). The nominal transfer characteristic for this

range is shown in Figure 22. The output code is Natural Binary

with 1 LSB = (1.25/256)V = 4.88 mV.

As before, to achieve the unipolar 0 V to +2.5 V input range,

V

is connected to 0 V, and the RANGE input is tied to a logic

SS

high. The nominal transfer characteristic is as in Figure 22 but,

in this case, 1 LSB = (2.5/256)V = 9.76 mV.

Figure 22. Nominal Transfer Characteristic for Unipolar

(0 V to +1.25 V) Operation

BIPOLAR OPERATION

The analog input of the AD7569/AD7669 ADC is configured

for bipolar inputs when V

by the part is twos complement. Figure 23 shows the transfer

function for bipolar (–1.25 V to +1.25 V) operation. The LSB

size for this range is (2.5/256)V = 9.76 mV.

The transfer function for the –2.5 V to +2.5 V range is identical

to that of Figure 23, but now FS = 5 V and the LSB size is

(5/256)V = 19.5 mV.

= –5 V. The output code provided

SS

Figure 23. Nominal Transfer Characteristic for Bipolar

(–1.25 V to +1.25 V) Operation

typical example is a digital filter where an ac analog signal is

quantized by the ADC, digitally processed and recreated using

the DAC. In these types of applications, the offset error can be

eliminated by ac coupling the recreated signal. Full-scale error

effect is linear and does not cause problems as long as the input

signal is within the full dynamic range of the ADC. An important parameter in DSP applications is Differential Nonlinearity,

and this is not affected by either offset or full-scale error.

In applications where absolute accuracy is important ADC offset and full-scale error can be adjusted to zero. Figure 24 shows

the additional components required for offset and full-scale error adjustment. Offset error must be adjusted before full-scale

error. Zero offset is achieved by adjusting the offset of the op

amp driving V

(i.e., A1 in Figure 23). In unipolar applica-

IN

tions, for zero offset error, apply 1/2 LSB at the analog input

and adjust the op amp offset voltage until the ADC output code

flickers between 0000 0000 and 0000 0001. For zero full-scale

error, apply an analog input of FS – 3/2 LSBs and adjust R1 until the ADC output code flickers between 1111 1110 and 1111

1111.

In bipolar applications, to adjust for bipolar zero offset, apply

–1/2 LSB at the analog input and adjust the op amp offset voltage until the output code flickers between 1111 1111 and 0000

0000. For zero full-scale error, apply +FS/2 – 3/2 LSB at the

analog input and adjust R1 until the ADC output code flickers

between 0111 1110 and 0111 1111.

ADC OFFSET AND FULL-SCALE ERROR ADJUSTMENT

In most Digital Signal Processing (DSP) applications, offset and

full-scale error have little or no effect on system performance. A

–16–

Figure 24. ADC Error Adjust Circuit

REV. B

Page 17

Figure 25. Peak-Reading A/D Converter

AD7569/AD7669

PEAK DETECTION—AD7569

The circuit of Figure 25 shows a peak-reading A/D converter,

which is useful in such applications as monitoring flow rates,

temperature, pressure, etc. The circuit ensures that a peak will

not be missed while at the same time does not require the microprocessor to frequently monitor the data. The peak value is

stored in the A/D converter and can be read at any time.

The gain on the AD524 is adjusted to yield a 0 V to +2.5 V output. When the input signal exceeds the current stored value, the

output of the TL311 goes low, triggering the

Q output of the

74121. This low-going pulse starts a conversion on the AD7569

ADC, and at the end of conversion latches the result into the

DAC. This pulse must be at least 120 ns greater than the conversion time of the ADC. The Q output is used to drive the

strobe input of the TL311, resetting the TL311 output high in

readiness for another conversion.

The additional gates on the

RD and WR inputs are to allow the

data to be read by the microprocessor while at the same time

ensuring that the DAC is not updated when the microprocessor

reads the data. It may be necessary to monitor the AD7569

BUSY line to ensure that a processor READ is not attempted

while the AD7569 is in the middle of a conversion. The READ

pulse width from the processor must be less than 1 µs to ensure

correct data is read from the ADC. A low-going pulse on the

RESET line resets the DAC output to 0 V and starts a new “peakdetection” period. This

DISK DRIVE APPLICATION—AD7669

Closed-Loop Microstepping

RESET pulse must also be less than 1 µs.

Microstepping is a popular technique in low density disk drives

(both floppy and hard disk) that allows higher positional resolution of the disk drive head over that obtainable from a full- step

driven stepper motor. Typically, a two-phase stepper motor has

its phase currents driven with a sine-cosine relationship. These

cosinusoidal signals are generated by two DACs driven with the

appropriate data. The resolution of the DACs determines the

number of microsteps into which each full step can be divided.

For example, with a 1.8° full-step motor and a 4-bit DAC, a

microstep size of 0.11° (1.8°/(2

n

)) is obtainable.

The microstepping technique improves the positioning resolution possible in any control application; however, the positional

accuracy can be significantly worse than that offered by the

original full-step accuracy specification due to load torque effects.

To ensure that the increased resolution is usable, it is necessary

to use a closed-loop system where the position of the disk drive

head (or motor) is monitored. The closed-loop system allows an

error between the desired position and the actual position to be

monitored and corrected. The correction is achieved by adjusting the ratio of the phase currents in the motor windings until

the required head position is reached.

The AD7669 is ideally suited for the closed-loop microstepping

technique with its on-chip dual DACs for positioning the disk

drive head, and onboard ADC for monitoring the position of the

head. A generalized circuit for a closed-loop microstepping system is shown in Figure 26. The DAC waveforms are shown in

Figure 27, along with the direction information for clockwise rotation supplied by the controller.

Figure 26. Typical Closed-Loop Microstepping Circuit with

the AD7669

The AD7669 is used in the unipolar 0 V to +2.5 V configuration. This allows the circuit of Figure 26 to be completely unipolar (+5 V, +12 V supplies); no negative power supplies are

required. The power output stage is a dual H-Bridge device

such as the UDN-2998W from Sprague Electric. The phase

currents in both windings are detected by means of the small

value sense resistors, R

A and RSB, in series with the windings.

S

The voltage developed across these resistors is amplified and

compared with the respective DAC output voltage. The comparators in turn chop the phase winding current. The ADC

completes the feedback path by converting information from a

suitable transducer for analysis by the controller.

REV. B

–17–

Page 18

AD7569/AD7669

Figure 27. Typical DAC Output Voltages for Microstepping

and Direction Signals for Clockwise Rotation with the

UDN-2998W

ANALOG DELAY LINE—AD7569

In many applications, especially in audio systems, it is necessary

to provide a delay on the input signal. The circuit of Figure 28

shows how a simple analog delay line can be implemented,

based on the AD7569. The input signal is sampled using the

AD7569 ADC, and converted data is loaded into the 6116 (2K

3 8 static ram). The inverted input clock drives a counter that

selects the address for the 6116. The delay is selected by choosing one of the output lines of the HCT4040 counter to reset the

coun-ter. This can be done using a simple switch in a manual

system or by a multiplexer in a programmable delay application.

Data is written to the DAC using the inverted input clock signal.

On initial start-up, the output voltage, VO, will be invalid until

the length of the delay is reached (i.e., until the counter is reset). From this point forward, the delayed data is read from the

6116 and loaded to the DAC before the newly converted data is

written into the same memory location. The input clock to the

system can be a square wave of maximum input frequency 200

kHz

(assuming 2 µs conversion time for the ADC). The mark/space

ratio of the input clock can be varied to maximize the sampling

frequency if required. The clock low time has to be equal to the

conversion time and access time of the ADC plus the setup time

required for the 6116. The clock high time has only to be equal

to the setup time for the DAC plus the delay time through the

counter and the access time of the 6116.

The amount of memory used, as well as the sampling frequency,

determines the maximum possible delay. Using the HCT4040,

and the 6116 with an input clock frequency of 200 kHz, the

maximum delay is 5 ms on a maximum input frequency of

100 kHz. Using 64K memory, with an 8 kHz input clock frequency, the maximum delay is 8 seconds on a maximum input

frequency of 4 kHz.

TRANSIENT RECORDER—AD7569

The scheme just outlined can also form the basis for a transient

recorder. In this case, transients on the input signal are converted and stored in memory. The transient can then be recalled

from memory at a later time, and the transient waveform can be

recreated using the AD7569 DAC.

INFINITE SAMPLE-AND-HOLD—AD7569

The AD7569 is ideal for implementing a single-chip infinite

sample-and-hold function. Basically, the ADC samples and converts the input signal into an 8-bit digital word. The 8 bits of

data are then loaded to the DAC and the sampled value is restored to analog form. The sampled value is held until the DAC

register is updated. The full-scale matching between the ADC

and the DAC on the AD7569 ensures a typical error of less than

1% between the analog input voltage and the “held” output

voltage. Figure 29 shows the connections required on the

AD7569 to achieve this infinite sample-and-hold function.

Figure 28. Analog Delay Line

–18–

Figure 29. Infinite Sample-and-Hold

REV. B

Page 19

AD7569/AD7669

TARE FUNCTION FOR WEIGH SCALE—AD7569

The infinite sample-and-hold just outlined can also form the basis of a circuit to provide a tare function for a weigh scale system. Figure 30 shows a circuit for a weigh scale system. It

incorporates a tare function using a simple circuit based on the

AD7569.

The AD587, along with the 2N6285, provides a buffered +10 V

reference to supply the low impedance load cell transducer. The

load cell output is amplified by the AD624 precision instrumentation amplifier with gain adjustment provided by R1. The output of the AD624 is applied to the noninverting input of a unity

gain differential summing amplifier that uses the AD707, a high

precision op amp with low drift. The AD707 feeds a 3 1/2 digit

panel meter module that converts the signal for digital readout.

The input signal to the panel meter is also applied to the analog

input of the AD7569 for the tare function. When the tare switch

(S1) is closed, a tare cycle commences and V

held infinitely at V

until the next tare cycle. V

OUT

is sampled and

IN

drives the

OUT

inverting input of the differential amplifier and forces its output

to zero. Thus, the tare function is used to give a readout of zero

for any undesired weight, such as a box, when only the item

placed in it is to be weighed. The tare function can also be used

in calibrating the system, to cancel out offset errors due to the

load cell, AD624 and differential amplifier.

The AD7569 offers many advantages in the system outlined,

such as: simple, low cost circuit—no need for microprocessor,

software, etc.—and low power consumption.

REV. B

Figure 30. Weigh Scale System with Tare Function

–19–

Page 20

AD7569/AD7669

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

24-Pin Plastic (N-24)

28-Terminal Leadless Ceramic Chip Carrier

(E-28A)

24-Pin Cerdip (Q-24)

C1214–10–8/88

28-Terminal Plastic Leaded Chip Carrier

(P-28A)

28-Pin Plastic DIP (N-28) 28-Lead Small Outline (SO)

(R-28)

–20–

PRINTED IN U.S.A.

REV. B

Loading...

Loading...