Page 1

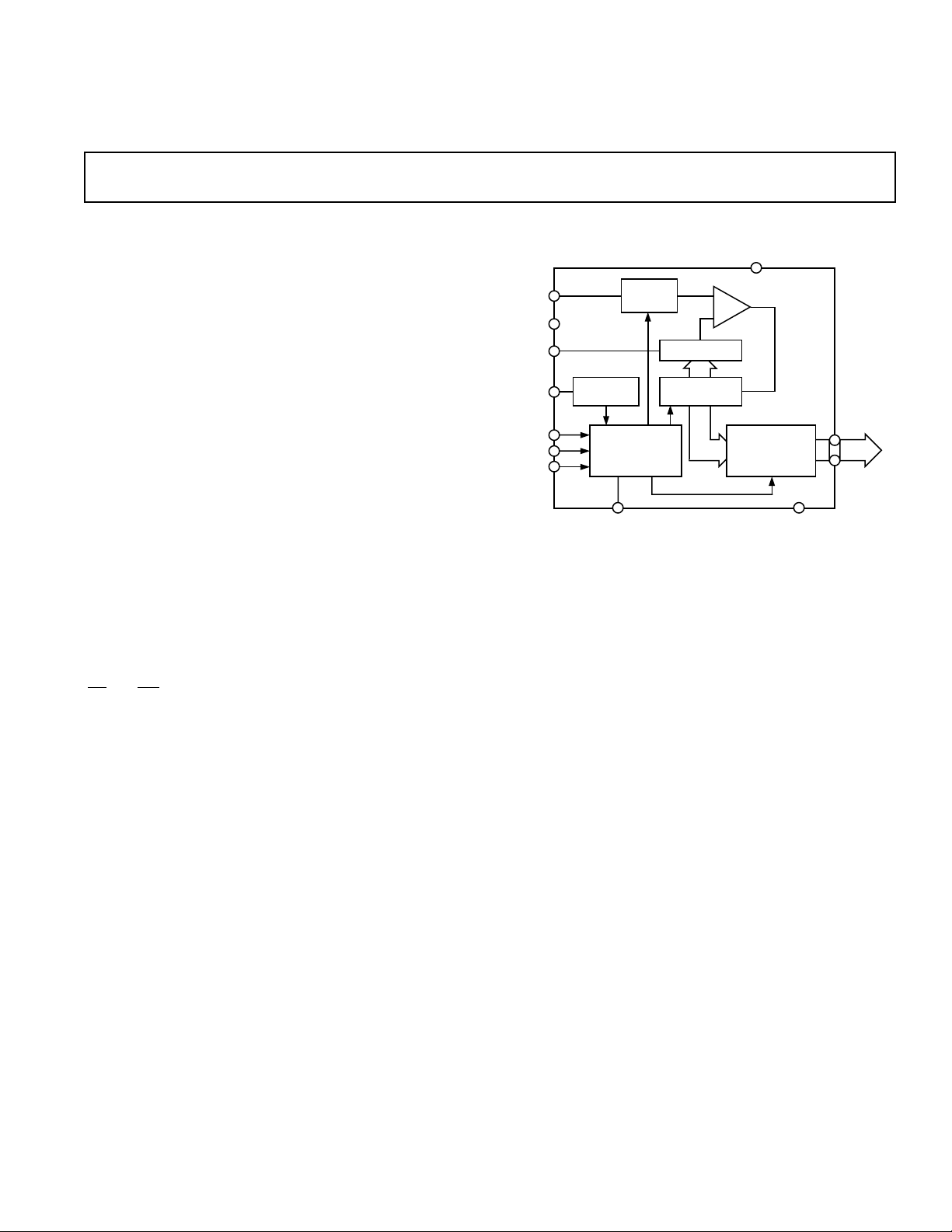

LC2MOS

TRACK

AND

HOLD

CLOCK

OSCILLATOR

DAC

SAR

COMP

CONTROL

LOGIC

LATCH AND

THREE STATE

OUTPUT DRIVERS

AD7575

V

DD

AIN

AGND

V

REF

CLK

CS

RD

TP

BUSY

DGND

DB7

DB0

a

FEATURES

Fast Conversion Time: 5 s

On-Chip Track/Hold

Low Total Unadjusted Error: 1 LSB

Full Power Signal Bandwidth: 50 kHz

Single +5 V Supply

100 ns Data Access Time

Low Power (15 mW typ)

Low Cost

Standard 18-Lead DlPs or 20-Terminal

Surface Mount Packages

GENERAL DESCRIPTION

The AD7575 is a high speed 8-bit ADC with a built-in track/

hold function. The successive approximation conversion tech-

nique is used to achieve a fast conversion time of 5 µs, while the

built-in track/hold allows full-scale signals up to 50 kHz (386 mV/µs

slew rate) to be digitized. The AD7575 requires only a single +5 V

supply and a low cost, 1.23 V bandgap reference in order to convert

an input signal range of 0 to 2 V

The AD7575 is designed for easy interfacing to all popular 8-bit

microprocessors using standard microprocessor control signals

(

CS and RD) to control starting of the conversion and reading of

the data. The interface logic allows the AD7575 to be easily

configured as a memory mapped device, and the part can be

interfaced as SLOW-MEMORY or ROM. All data outputs of

the AD7575 are latched and three-state buffered to allow direct

connection to a microprocessor data bus or I/O port.

The AD7575 is fabricated in an advanced, all ion-implanted high

speed Linear Compatible CMOS (LC

available in a small, 0.3" wide, 18-lead DIP, 18-lead SOIC or in

other 20-terminal surface mount packages.

REF

.

2

MOS) process and is

5 s 8-Bit ADC with Track/Hold

AD7575

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Fast Conversion Time/Low Power

The fast, 5 µs, conversion time of the AD7575 makes it

suitable for digitizing wideband signals at audio and ultrasonic frequencies while retaining the advantage of low

CMOS power consumption.

2. On-Chip Track/Hold

The on-chip track/hold function is completely self-contained

and requires no external hold capacitor. Signals with slew

rates up to 386 mV/µs (e.g., 2.46 V peak-to-peak 50 kHz sine

waves) can be digitized with full accuracy.

3. Low Total Unadjusted Error

The zero, full-scale and linearity errors of the AD7575 are so

low that the total unadjusted error at any point on the transfer function is less than 1 LSB, and offset and gain adjustments are not required.

4. Single Supply Operation

Operation from a single +5 V supply with a low cost +1.23 V

bandgap reference allows the AD7575 to be used in 5 V

microprocessor systems without any additional power

supplies.

5. Fast Digital Interface

Fast interface timing allows the AD7575 to interface easily to

the fast versions of most popular microprocessors such as the

Z80H, 8085A-2, 6502B, 68B09 and the DSP processor, the

TMS32010.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

AD7575–SPECIFICATIONS

(VDD = +5 V, V

all specifications T

= +1.23 V, AGND = DGND = 0 V; f

REF

to T

MIN

unless otherwise noted)

MAX

= 4 MHz external;

CLK

Parameter J, A Versions1K, B Versions S Version T Version Units Conditions/Comments

ACCURACY

Resolution 8 8 8 8 Bits

Total Unadjusted Error ±2 ±1 ±2 ±1 LSB max

Relative Accuracy ±1 ±1/2 ±1 ±1/2 LSB max

Minimum Resolution for Which

No Missing Codes Is Guaranteed 8 8 8 8 Bits max

Full-Scale Error

+25°C ±1 ±1 ±1 ±1 LSB max Full-Scale TC Is Typically 5 ppm/°C

T

to T

MIN

Offset Error

MAX

2

±1 ±1 ±1 ±1 LSB max

+25°C ±1/2 ±1/2 ±1/2 ±1/2 LSB max Offset TC Is Typically 5 ppm/°C

T

MIN

to T

MAX

±1/2 ±1/2 ±1/2 ±1/2 LSB max

ANALOG INPUT

Voltage Range 0 to 2 V

REF

0 to 2 V

REF

0 to 2 V

REF

0 to 2 V

Volts 1 LSB = 2 V

REF

/256; See Figure 16

REF

DC Input Impedance 10 10 10 10 MΩ min

Slew Rate, Tracking 0.386 0.386 0.386 0.386 V/µs max

3

SNR

45 45 45 45 dB min VIN = 2.46 V p-p @ 10 kHz; See Figure 11

REFERENCE INPUT

V

(For Specified Performance) 1.23 1.23 1.23 1.23 Volts ±5%

REF

I

REF

500 500 500 500 µA max

LOGIC INPUTS

CS, RD

V

, Input Low Voltage 0.8 0.8 0.8 0.8 V max

INL

V

, Input High Voltage 2.4 2.4 2.4 2.4 V min

INH

IIN, Input Current

+25°C ±1 ±1 ±1 ±1 µA max V

T

to T

MIN

MAX

CIN, Input Capacitance

3

±10 ±10 ±10 ±10 µA max V

10 10 10 10 pF max

= 0 or V

IN

= 0 or V

IN

DD

DD

CLK

V

, Input Low Voltage 0.8 0.8 0.8 0.8 V max

lNL

V

, Input High Voltage 2.4 2.4 2.4 2.4 V min

INH

I

, Input Low Current 700 700 800 800 µA max V

INL

I

, Input High Current 700 700 800 800 µA max V

INH

INL

INH

= 0 V

= V

DD

LOGIC OUTPUTS

BUSY, DB0 to DB7

VOL, Output Low Voltage 0.4 0.4 0.4 0.4 V max I

VOH, Output High Voltage 4.0 4.0 4.0 4.0 V min I

= 1.6 mA

SINK

SOURCE

= 40 µA

DB0 to DB7

Floating State Leakage Current ±1 ±1 ±10 ±10 µA max V

OUT

= 0 to V

DD

Floating State Output Capacitance310 10 10 10 pF max

CONVERSION TIME

With External Clock 5 5 5 5 µsf

With Internal Clock, T

4

= 4 MHz

= +25°C5 5 5 5 µs min Using Recommended Clock

A

CLK

15 15 15 15 µs max Components Shown in Figure 15

POWER REQUIREMENTS

V

DD

I

DD

5

+5 +5 +5 +5 Volts ±5% for Specified Performance

6 6 7 7 mA max Typically 3 mA with VDD = +5 V

Power Dissipation 15 15 15 15 mW typ

Power Supply Rejection ±1/4 ±1/4 ±1/4 ±1/4 LSB max 4.75 V ≤ VDD ≤ 5.25 V

NOTES

1

Temperature ranges are as follows:

J, K Versions; 0°C to +70°C

A, B Versions; –25°C to +85°C

S, T Versions; –55°C to +125°C

2

Offset error is measured with respect to an ideal first code transition that occurs at 1/2 LSB.

3

Sample tested at +25°C to ensure compliance.

4

Accuracy may degrade at conversion times other than those specified.

5

Power supply current is measured when AD7575 is inactive i.e., when CS = RD = BUSY = logic HIGH.

Specifications subject to change without notice.

–2–

REV. B

Page 3

AD7575

WARNING!

ESD SENSITIVE DEVICE

DGND

3kV 10pF

DBN

TIMING SPECIFICATIONS

Limit at +25ⴗC Limit at T

1

(VDD = +5 V, V

MIN

= +1.23 V, AGND = DGND = 0 V)

REF

, T

MAX

Limit at T

MIN

, T

MAX

Parameter (All Versions) (J, K, A, B Versions) (S, T Versions) Units Conditions/Comments

t

1

t

2

2

t

3

t

4

t

5

2

t

6

3

t

7

0 0 0 ns min CS to RD Setup Time

100 100 120 ns max RD to BUSY Propagation Delay

100 100 120 ns max Data Access Time after RD

100 100 120 ns min RD Pulse Width

0 0 0 ns min CS to RD Hold Time

80 80 100 ns max Data Access Time after BUSY

10 10 10 ns min Data Hold Time

80 80 100 ns max

t

8

NOTES

1

Timing specifications are sample tested at +25°C to ensure compliance. All input control signals are specified with tr = tf = 20 ns (10% to 90% of +5 V)

and timed from a voltage level of 1.6 V.

2

t3 and t6 are measured with the load circuits of Figure 1 and defined as the time required for an output to cross 0.8 V or 2.4 V.

3

t7 is defined as the time required for the data lines to change 0.5 V when loaded with the circuits of Figure 2.

Specifications subject to change without notice.

0 0 0 ns min BUSY to CS Delay

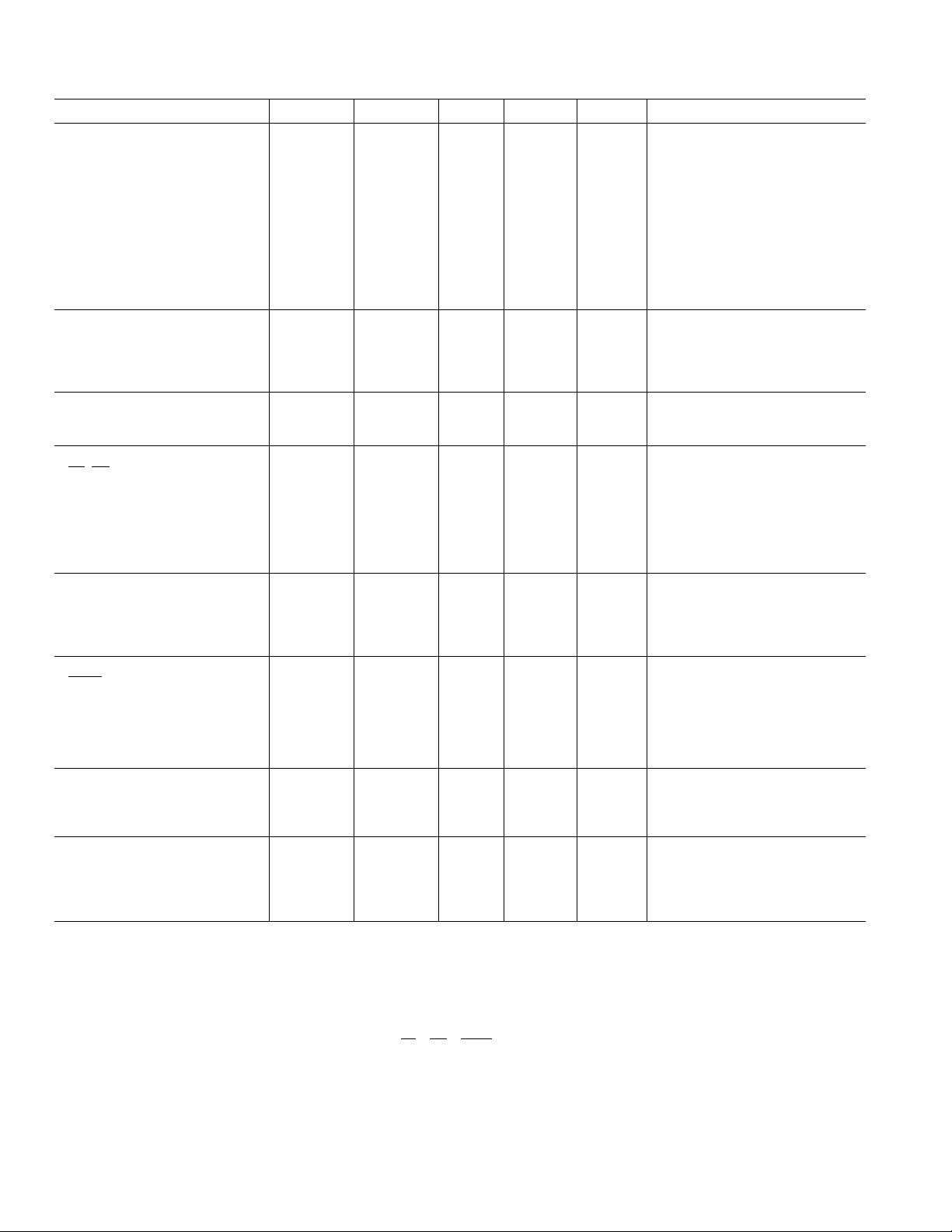

Test Circuits

+5V

3kV

DBN

10pF

DGND

DBN

3kV 100pF

DGND

+5V

3kV

DBN

100pF

DGND

a. High-Z to V

OH

b High-Z to V

OL

a. VOH to High-Z b. VOL to High-Z

Figure 1. Load Circuits for Data Access Time Test Figure 2. Load Circuits for Data Hold Time Test

ABSOLUTE MAXIMUM RATINGS*

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +7 V

V

to DGND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +7 V

DD

AGND to DGND . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

DD

Digital Input Voltage to DGND . . . . . . . –0.3 V, VDD + 0.3 V

Digital Output Voltage to DGND . . . . . . –0.3 V, V

CLK Input Voltage to DGND . . . . . . . . . –0.3 V, V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

V

REF

AIN to AGND . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

+ 0.3 V

DD

+ 0.3 V

DD

DD

DD

Operating Temperature Range

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300°C

Power Dissipation (Any Package) to +75°C . . . . . . . 450 mW

Derates above +75°C by . . . . . . . . . . . . . . . . . . . . . 6 mW/°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

Commercial (J, K Versions) . . . . . . . . . . . . . . 0°C to +70°C

Industrial (A, B Versions) . . . . . . . . . . . . . –25°C to +85°C

Extended (S, T Versions) . . . . . . . . . . . . . –55°C to +125°C

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7575 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. B

–3–

Page 4

AD7575

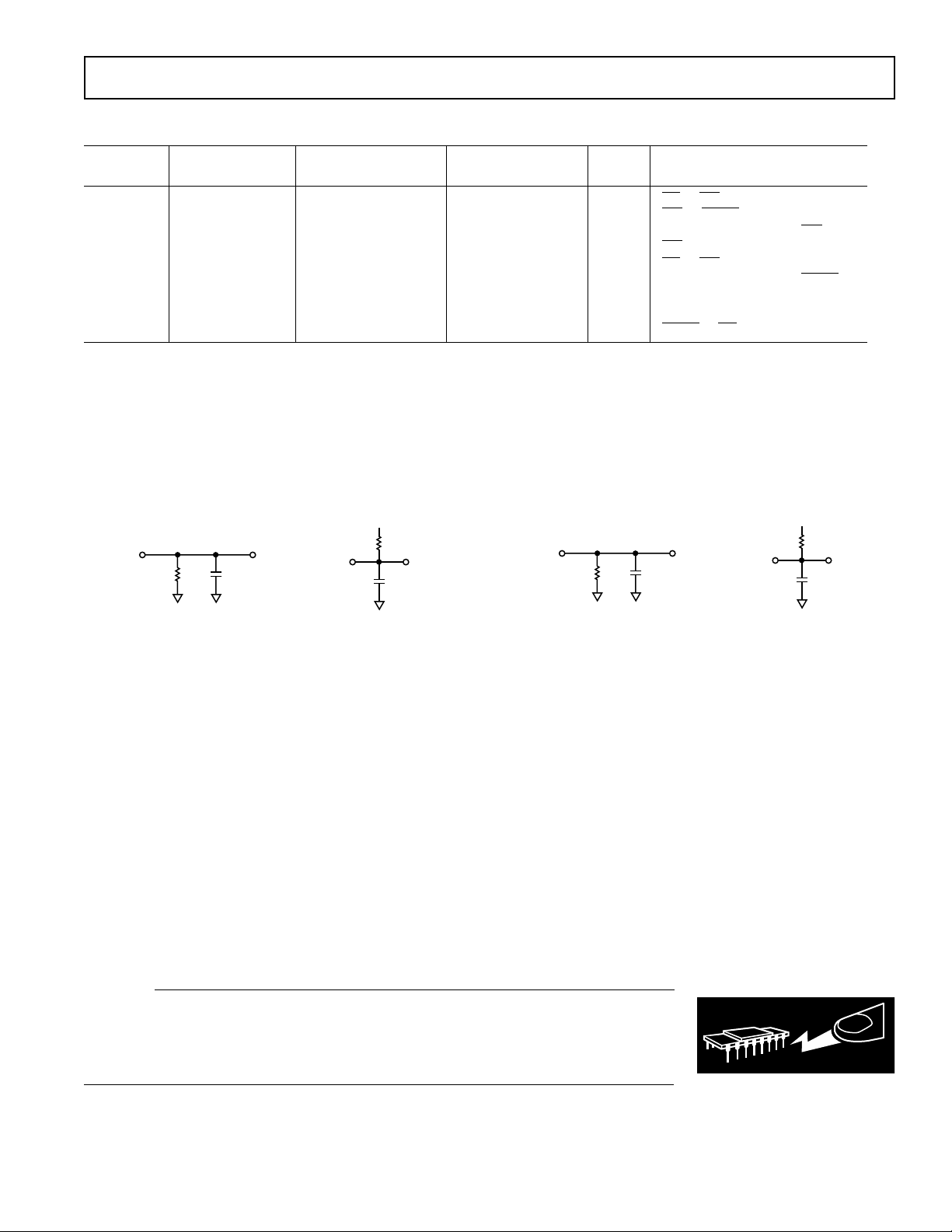

PIN CONFIGURATIONS

LCCC

CS

RD

BUSY

CLK

DB7 (MSB)

DB6

DB5

DGND

TP

1

2

3

4

AD7575

5

TOP VIEW

(Not to Scale)

6

7

8

9

18

V

17

V

16

AIN

15

AGND

14

DB0 (LSB)

13

DB1

12

DB2

11

DB3

10

DB4

DD

REF

BUSY

CLK

DB7 (MSB)

DB6

DB5

NC = NO CONNECT

3

4

5

6

(Not to Scale)

7

8

9 10111213

TPRDCS

2

AD7575

TOP VIEW

DGND

ORDERING GUIDE

Relative

Temperature Accuracy Package

Range (LSB) Options

2

Model

1

AD7575JR 0°C to +70°C ±1 max R-18

AD7575JN 0°C to +70°C ±1 max N-18

AD7575KN 0°C to +70°C ±1/2 max N-18

AD7575JP 0°C to +70°C ±1 max P-20A

AD7575KP 0°C to +70°C ±1/2 max P-20A

AD7575AQ –25°C to +85°C ±1 max Q-18

AD7575BQ –25°C to +85°C ±1/2 max Q-18

AD7575SQ –55°C to +125°C ±1 max Q-18

AD7575TQ –55°C to +125°C ±1/2 max Q-18

AD7575SE –55°C to +125°C ±1 max E-20A

AD7575TE –55°C to +125°C ±1/2 max E-20A

NOTES

1

To order MIL-STD-883, Class B process parts, add /883B to part number.

Contact local sales office for military data sheet. For U.S. Standard Military

Drawing (SMD), see DESC drawing #5962-87762.

2

E = Leadless Ceramic Chip Carrier; N = Plastic DIP; P = Plastic Leaded Chip

Carrier; Q = Cerdip, R = SOIC.

PLCCDIP/SOIC

NC

NC

20 191

VDDV

DB4

REF

DB3

18

AIN

AGND

17

16

DB0 (LSB)

15

DB1

14

DB2

4

TP

5

BUSY

6

CLK

DB6

7

8

DB7 (MSB)

NC = NO CONNECT

RDCSNC

3 2 1 20 19

AD7575

TOP VIEW

(Not to Scale)

9 10 11 12 13

DB5

DGND

VDDV

PIN 1

IDENTIFIER

NC

DB4

REF

DB3

18

AIN

17

AGND

16

DB0 (LSB)

15

DB1

14

DB2

TERMINOLOGY

LEAST SIGNIFICANT BIT (LSB)

An ADC with 8-bits resolution can resolve 1 part in 28 (i.e.,

256) of full scale. For the AD7575 with +2.46 V full-scale one

LSB is 9.61 mV.

TOTAL UNADJUSTED ERROR

This is a comprehensive specification that includes full-scale

error, relative accuracy and offset error.

RELATIVE ACCURACY

Relative Accuracy is the deviation of the ADC’s actual code

transition points from a straight line drawn between the devices

measured first LSB transition point and the measured full-scale

transition point.

SNR

Signal-to-Noise Ratio (SNR) is the ratio of the desired signal to

the noise produced in the sampled and digitized analog signal.

SNR is dependent on the number of quantization levels used in

the digitization process; the more levels, the smaller the quantization noise. The theoretical SNR for a sine wave input is given by

SNR = (6.02 N + 1.76) dB

where N is the number of bits in the ADC.

FULL-SCALE ERROR (GAIN ERROR)

The gain of a unipolar ADC is defined as the difference between

the analog input levels required to produce the first and the last

digital output code transitions. Gain error is a measure of the

deviation of the actual span from the ideal span of FS – 2 LSBs.

ANALOG INPUT RANGE

With V

= +1.23 V, the maximum analog input voltage range

REF

is 0 V to +2.46 V. The output data in LSBs is related to the

analog input voltage by the integer value of the following

expression:

Data (LSBs) =

256 AIN

2 V

REF

+ 0.5

SLEW RATE

Slew Rate is the maximum allowable rate of change of input

signal such that the digital sample values are not in error. Slew

Rate limitations may restrict the analog signal bandwidth for

full-scale analog signals below the bandwidth allowed from

sampling theorem considerations.

–4–

REV. B

Page 5

CS

RD

BUSY

DATA

t

1

t

HIGH IMPEDANCE

BUS

2

t

3

t

CONV

OLD DATA

t

6

Figure 3. Slow Memory Interface Timing Diagram

NEW

DATA

t

5

t

7

HIGH IMPEDANCE

AD7575

BUS

TIMING AND CONTROL OF THE AD7575

The two logic inputs on the AD7575, CS and RD, control both

the starting of conversion and the reading of data from the part.

A conversion is initiated by bringing both of these control inputs

LOW. Two interface options then exist for reading the output

data from the AD7575. These are the Slow Memory Interface

and ROM Interface, their operation is outlined below. It should

be noted that the TP pin of the AD7575 must be hard-wired

HIGH to ensure correct operation of the part. This pin is used

in testing the device and should not be used as a feedthrough pin

in double-sided printed circuit boards.

SLOW MEMORY INTERFACE

The first interface option is intended for use with microproces-

sors that can be forced into a WAIT STATE for at least 5 µs.

The microprocessor (such as the 8085A) starts a conversion and

is halted until the result of the conversion is read from the converter. Conversion is initiated by executing a memory READ to

the AD7575 address, bringing

CS and RD LOW. BUSY subsequently goes LOW (forcing the microprocessor READY input

LOW), placing the processor into a WAIT state. The input

signal, which had been tracked by the analog input, is held on

the third falling clock edge of the input clock after

CS and RD

have gone LOW (see Figure 12). The AD7575 then performs a

conversion on this acquired input signal value. When the conversion is complete (

BUSY goes HIGH), the processor completes the memory READ and acquires the newly converted

data. The timing diagram for this interface is shown in Figure 3.

A8–A15

8085A–2

AD0–AD7

READY

ALE

S0

ADDRESS

LATCH

ADDRESS BUS

+5V

ADDRESS

DECODE

DATA BUS

*LINEAR CIRCUITRY OMITTED FOR CLARITY

SO = 0 FOR READ CYCLES

TP

CS

AD7575*

RD

BUSY

DB0–DB7

Figure 4. AD7575 to 8085A-2 Slow Memory Interface

The major advantage of this interface is that it allows the microprocessor to start conversion, WAIT, and then READ data with

a single READ instruction. The fast conversion time of the

AD7575 ensures that the microprocessor is not placed in a

WAIT state for an excessive amount of time.

Faster versions of many processors, including the 8085A-2, test

the condition of the READY input very soon after the start of

an instruction cycle. Therefore,

BUSY of the AD7575 must go

LOW very early in the cycle for the READY input to be effective in forcing the processor into a WAIT state. When using the

8085A-2, the processor S0 status signal provides the earliest

possible indication that a READ operation is about to occur.

Hence, S0 (which is LOW for a READ cycle) provides the

READ signal to the AD7575. The connection diagram for the

AD7575 to 8085A-2 Slow Memory interface is shown in

Figure 4.

ROM INTERFACE

The alternative interface option on the AD7575 avoids placing

the microprocessor into a WAIT state. In this interface, a conversion is started with the first READ instruction, and the second READ instruction accesses the data and starts a second

conversion. The timing diagram for this interface is shown in

Figure 5. It is possible to avoid starting another conversion on

the second READ (see below).

Conversion is initiated by executing a memory READ instruction to the AD7575 address, causing

CS and RD to go LOW.

Data is also obtained from the AD7575 during this instruction.

This is old data and may be disregarded if not required.

BUSY

goes LOW, indicating that conversion is in progress, and returns HIGH when conversion is complete. Once again, the

input signal is held on the third falling edge of the input clock

CS and RD have gone LOW.

after

The

BUSY line may be used to generate an interrupt to the

microprocessor or monitored to indicate that conversion is

complete. The processor then reads the newly-converted data.

Alternatively, the delay between the convert start (first READ

instruction) and the data READ (second READ instruction)

must be at least as great as the AD7575 conversion time. For

the AD7575 to operate correctly in the ROM interface mode,

CS and RD should not go LOW before BUSY returns HIGH.

Normally, the second READ instruction starts another conversion as well as accessing the output data. However, if

CS and

RD are brought LOW within one external clock period of

BUSY going HIGH, a second conversion does not occur.

REV. B

–5–

Page 6

AD7575

CS

t

1

t

5

t

RD

BUSY

DATA

IMPEDANCE BUS

HIGH

t

3

4

t

2

t

7

OLD

DATA

HIGH IMPEDANCE

Figure 5. ROM Interface Timing Diagram

Figures 6 and 7 show connection diagrams for interfacing the

AD7575 in the ROM Interface mode. Figure 6 shows the

AD7575 interface to the 6502/6809 microprocessors while the

connection diagram for interfacing to the Z-80 is shown in

Figure 7.

As a result of its very fast interface timing, the AD7575 can also

be interfaced to the DSP processor, the TMS32010. The

AD7575 will (within specifications) interface to the TMS32010,

running at up to 18 MHz, but will typically work over the full

clock frequency range of the TMS32010. Figure 8 shows the

connection diagram for this interface. The AD7575 is mapped

at a port address. Conversion is initiated using an IN A, PA

instruction where PA is the decoded port address for the

AD7575. The conversion result is obtained from the part using

a second IN A, PA instruction, and the resultant data is placed

in the TMS32010 accumulator.

In many applications it is important that the signal sampling

occurs at exactly equal intervals to minimize errors due to sampling uncertainty or jitter. The interfaces outlined previously

require that for sampling at equidistant intervals, the user must

count clock cycles or match software delays. This is especially

difficult in interrupt-driven systems where uncertainty in interrupt servicing delays would require that the AD7575 have priority interrupt status and even then redundant software delays

may be necessary to equalize loop delays.

This problem can be overcome by using a real time clock to

control the starting of conversion. This can be derived from the

clock source used to drive the AD7575 CLK pin. Since the

sampling instant occurs three clock cycles after

CS and RD go

LOW, the input signal sampling intervals are equidistant. The

resultant data is placed in a FIFO latch that can be accessed by

the microprocessor at its own rate whenever it requires the data.

This ensures that data is not READ from the AD7575 during a

conversion. If a data READ is performed during a conversion,

valid data from the previous conversion will be accessed, but the

conversion in progress may be interfered with and an incorrect

result is likely.

If

CS and RD go LOW within 20 ns of a falling clock edge, the

AD7575 may or may not see that falling edge as the first of the

three falling clock edges to the sampling instant. In this case, the

sampling instant could vary by one clock period. If it is important to know the exact sampling instant,

CS and RD should not

go LOW within 20 ns of a falling clock edge.

t

8

BUS

t

3

A0–A15

6502/6809

f2 OR E

D0–D7

R/W

t

7

NEW

DATA

*LINEAR CIRCUITRY OMITTED FOR CLARITY

HIGH IMPEDANCE

BUS

ADDRESS BUS

ADDRESS

DECODE

EN

DATA BUS

Figure 6. AD7575 to 6502/6809 ROM Interface

ADDRESS BUS

Z–80

MREQ

RD

DB7

DB0

*LINEAR CIRCUITRY OMITTED FOR CLARITY

ADDRESS

DECODE

EN

DATA BUS

Figure 7. AD7575 to Z-80 ROM Interface

PA2

PA0

TMS32010

MEN

DEN

D7

D0

*LINEAR CIRCUITRY OMITTED FOR CLARITY

ADDRESS BUS

ADDRESS

DECODE

EN

DATA BUS

Figure 8. AD7575 to TMS32010 ROM Interface

+5V

+5V

+5V

TP

CS

AD7575*

RD

DB0–DB7

TP

CS

AD7575*

RD

DB7

DB0

TP

CS

AD7575*

RD

DB7

DB0

–6–

REV. B

Page 7

AD7575

A SAMPLED-DATA INPUT

The AD7575 makes use of a sampled-data comparator. The

equivalent input circuit is shown in Figure 9. When a conversion

starts, switch S1 is closed, and the equivalent input capacitance

is charged to V

. With a switch resistance of typically

IN

500 Ω and an input capacitance of typically 2 pF, the input time

constant is 1 ns. Thus C

becomes charged to within ±1/4 LSB

IN

in 6.9 time constants or about 7 ns. Since the AD7575 requires

two input clock cycles (at a clock frequency of 4 MHz) before

going into the compare mode, there is ample time for the input

voltage to settle before the first comparator decision is made.

Increasing the source resistance increases the settling time required. Input bypass capacitors placed directly at the analog

input act to average the input charging currents. The average

current flowing through any source impedance can cause

full-scale errors.

R

ON

V

IN

0.5pF

500V

C

S

S1

2pF

Figure 9. Equivalent Input Circuit

REFERENCE INPUT

The reference input impedance on the AD7575 is code dependent and varies by a ratio of approximately 3-to-1 over the digi-

tal code range. The typical resistance range is from 6 kΩ to 18 kΩ.

As a result of the code dependent input impedance, the V

REF

input must be driven from a low impedance source. Figure 10

shows how an AD589 can be configured to produce a nominal

reference voltage of +1.23 V.

40

42

44

46

SNR – dB

48

50

52

54

100 100k

INPUT FREQUENCY – Hz

TA = +258C

10k1k

Figure 11. SNR vs. Input Frequency

The input signal is held on the third falling edge of the input

clock after

CS and RD go LOW. This is indicated in Figure 12

for the Slow Memory Interface. Between conversions, the input

signal is tracked by the AD7575 track-and-hold. Since the

sampled signal is held on a small, on-chip capacitor, it is advisable that the data bus be kept as quiet as possible during a

conversion.

CS

RD

BUSY

+5V

3.3kV

AD589

1.23V

+

–

47mF 0.1mF

Figure 10. Reference Circuit

TRACK-AND-HOLD

The on-chip track-and-hold on the AD7575 means that input

signals with slew rates up to 386 mV/µs can be converted with-

out error. This corresponds to an input signal bandwidth of

50 kHz for a 2.46 V peak-to-peak sine wave. Figure 11 shows

a typical plot of signal-to-noise ratio versus input frequency over

the input bandwidth of the AD7575. The SNR figures are generated using a 200 kHz sampling frequency, and the reconstructed

sine wave passes through a filter with a cutoff frequency

of 50 kHz.

The improvement in the SNR figures seen at the higher frequencies is due to the sharp cutoff of the filter (50 kHz, 8th

order Chebyshev) used in the test circuit.

EXTERNAL

CLOCK

INPUT SIGNAL

HELD HERE

Figure 12a. Track-and-Hold (Slow Memory Interface) with

External Clock

CS

RD

BUSY

INTERNAL

CLOCK

INPUT SIGNAL

HELD HERE

Figure 12b. Track-and-Hold (Slow Memory Interface) with

Internal Clock

REV. B

–7–

Page 8

AD7575

INTERNAL/EXTERNAL CLOCK

The AD7575 can be used with its own internal clock or with an

externally applied clock. In either case, the clock signal appearing at the CLK pin is divided internally by two to provide an

internal clock signal for the AD7575. A single conversion lasts

for 20 input clock cycles (10 internal clock cycles).

INTERNAL CLOCK

Clock pulses are generated by the action of the external capacitor (C

) charging through an external resistor (R

CLK

CLK

) and

discharging through an internal switch. When a conversion is

complete, the internal clock stops operating. In addition to

conversion, the internal clock also controls the automatic internal reset of the SAR. This reset occurs at the start of each conversion cycle during the first internal clock pulse.

Nominal conversion times versus temperature for the recommended R

and C

CLK

14

R

= 100kV

CLK

C

CLK

= 100pF

13

12

11

10

combination are shown in Figure 13.

CLK

EXTERNAL CLOCK

The CLK input of the AD7575 may be driven directly from

74 HC, 4000B series buffers (such as 4049) or from LS TTL

with a 5.6 kΩ pull-up resistor. When conversion is complete, the

internal clock is disabled even if the external clock is still applied. This means that the external clock can continue to run

between conversions without being disabled. The mark/space

ratio of the external clock can vary from 70/30 to 30/70.

The AD7575 is specified for operation at a 5 µs conversion rate;

with a 4 MHz input clock frequency. If the part is operated at

slower clock frequencies, it may result in slightly degraded accuracy performance from the part. This is a result of leakage effects on the hold capacitor. Figure 14 shows a typical plot of

accuracy versus conversion time for the AD7575.

2.5

TA = +258C

2.0

1.5

1.0

RELATIVE ACCURACY – LSB

0.5

AD7575KN

9

CONVERSION TIME – ms

8

7

–55 +125–25

0 +25 +50 +75 +100

AMBIENT TEMPERATURE – 8C

Figure 13. Typical Conversion Times vs. Temperature

Using Internal Clock

The internal clock is useful because it provides a convenient

clock source for the AD7575. Due to process variations, the

actual operating frequency for this R

CLK/CCLK

combination can

vary from device to device by up to ±50%. For this reason it is

recommended that an external clock be used in the following

situations:

1. Applications requiring a conversion time that is within 50% of

5 µs, the minimum conversion time for specified accuracy. A

clock frequency of 4 MHz at the CLK pin gives a conversion

time of 5 µs.

2. Applications where time related software constraints cannot

accommodate time differences that may occur due to unit to

unit clock frequency variations or temperature.

0

5 10000

100 1000 500010

50 500

CONVERSION TIME – ms

Figure 14. Accuracy vs. Conversion Time

–8–

REV. B

Page 9

AD7575

–1/2LSB

+1/2LSB

–FS

+FS –1LSB

AIN

FS = 5V

1LSB =

FS

256

OUTPUT

CODE

111...111

111...110

100...010

100...001

100...000

011...111

011...110

000...001

000...000

UNIPOLAR OPERATION

The basic operation for the AD7575 is in the unipolar single

supply mode. Figure 15 shows the circuit connections to achieve

this, while the nominal transfer characteristic for unipolar operation is given in Figure 16. Since the offset and full-scale errors

on the AD7575 are very small, in many cases it will not be necessary to adjust out these errors. If calibration is required, the

procedure is as follows:

Offset Adjust

Offset error adjustment in single-supply systems is easily achievable by means of the offset null facility of an op amp when used

as a voltage follower for the analog input signal, AIN. The op

amp chosen should be able to operate from a single supply and

allow a common-mode input voltage range that includes 0 V

(e.g., TLC271). To adjust for zero offset, the input signal

source is set to +4.8 mV (i.e., 1/2 LSB) while the op amp offset

is varied until the ADC output code flickers between 000 . . . 00

and 000 . . . 01.

Full-Scale Adjust

The full scale or gain adjustment is made by forcing the analog

input AIN to +2.445 V (i.e., Full-Scale Voltage –3/2 LSB). The

magnitude of the reference voltage is then adjusted until the

ADC output code flickers between 111 . . . 10 and 111. . . 11.

AD589

+5V

+

–

A

+5V

3.3kV

47mF 0.1mF

47mF 0.1mF

+2.46V

MAX

+1.23V

AA

AA

V

DD

AIN

AD7575

V

REF

AGND

A

CLK

BUSY

CS

RD

TP

DGND

D

+5V

D

CONTROL

INPUTS

+5V

DB7–DB0

DATA OUT

R

CLK

100kV, 1%

C

CLK

100pF, 2%

Figure 15. Unipolar Configuration

BIPOLAR OPERATION

The circuit of Figure 17 shows how the AD7575 can be configured for bipolar operation. The output code provided by the

AD7575 is offset binary. The analog input voltage range is

±5 V, although the voltage appearing at the AIN pin of the

AD7575 is in the range 0 V to +2.46 V. Figure 18 shows the

transfer function for bipolar operation. The LSB size is now

39.06 mV. Calibration of the bipolar operation is outlined below. Once again, because the errors are small, it may not be

necessary to adjust them. To maintain specified performance

without the calibration, all resistors should be 0.1% tolerance

with R4 and R5 replaced by one 3.3 kΩ resistor and R2 and R3

replaced by one 2.5 kΩ resistor.

Offset Adjust

Offset error adjustment is achieved by applying an analog input

voltage of –4.9805 V (–FS +1/2 LSB). Resistor R3 is then

adjusted until the output code flickers between 000 . . . 00 and

000 . . . 01.

Full-Scale Adjust

Full-scale or gain adjustment is made by applying an analog

input voltage of +4.9414 V (+FS –3/2 LSB). Resistor R4 is then

adjusted until the output code flickers between 111 . . . 10 and

111. . . 11.

+5V

+

47mF 0.1mF

47mF 0.1mF

+5V

TLC271

A

R6

2.5kV

2.5kV

A

CLK

CS

RD

TP

D

+5V

R

CLK

100kV, 1%

C

CLK

100pF, 2%

D

+5V

DB7–DB0

DATA OUT

AA

V

DD

V

REF

AA

AIN

AGND

R7

BUSY

AD7575

DGND

A

AD589

INPUT

VOLTAGE

+5V

10kV

R8

3.3kV

+

–

A

R1

R2

2.2kV

R3

500V

R4

500V

R5

3kV

A

Figure 17. Bipolar Configuration

OUTPUT

CODE

11111111

11111110

11111101

00000011

00000010

00000001

00000000

Figure 16. Nominal Transfer Characteristic for

Unipolar Operation

1LSB 3LSBs

2LSBs

AIN, INPUT VOLTAGE (IN TERMS OF LSBs)

FULL SCALE

TRANSITION

FS = 2V

1LSB =

FS –1LSB

REV. B

REF

FS

256

FS

Figure 18. Nominal Transfer Characteristic for

Bipolar Operation

–9–

Page 10

AD7575

APPLICATION HINTS

1. NOISE: Both the input signal lead to AIN and the signal

return lead from AGND should be kept as short as possible to

minimize input-noise coupling. In applications where this is

not possible, either a shielded cable or a twisted pair transmission line between source and ADC is recommended. Also,

since any potential difference in grounds between the signal

source and ADC appears as an error voltage in series with the

input signal, attention should be paid to reducing the ground

circuit impedance as much as possible. In general, the source

resistance should be kept below 2 kΩ. Larger values of source

resistance can cause undesired system noise pickup.

2. PROPER LAYOUT: Layout for a printed circuit board

should ensure that digital and analog lines are kept separated

as much as possible. In particular, care should be taken not to

run any digital track alongside an analog signal track. Both the

analog input and the reference input should be screened by

AGND. A single point analog ground separate from the logic

system ground, should be established at or near the AD7575.

This single point analog ground subsystem should be connected to the digital system ground by a single-track connection only. Any reference bypass capacitors, analog input filter

capacitors or input signal shielding should be returned to the

analog ground point.

AD7575 WITH AD589 REFERENCE

The AD7575 8-bit A/D converter features a total unadjusted

error specification over its entire operating temperature range.

This total unadjusted error includes all errors in the A/D converter—offset, full scale and linearity. The one feature not provided on the AD7575 is a voltage reference. This section

discusses the use of the AD589 bandgap reference with the

AD7575, and gives the combined reference and ADC error

budget over the full operating temperature range. This allows

the user to compare the combined AD589/AD7575 errors to

ADCs whose specifications include on-chip references.

Two distinct application areas exist. The first is where the reference voltage and the analog input voltage are derived from the

same source. In other words, if the reference voltage varies, the

analog input voltage range varies by a ratioed amount. In this

case, the user is not worried about the absolute value of the

reference voltage. The second case is where changes in the reference voltage are not matched by changes in the analog input

voltage range. Here, the absolute value of the reference voltage,

and its drift over temperature, are of prime importance. Both

applications are discussed below.

If the analog input range varies with the reference voltage, the

part is said to be operating ratiometrically. This is representative

of many applications. If the reference is on-chip, and the user

does not have access to it, it is not possible to get ratiometric

operation. Since the AD7575 uses an external reference, it can

be used in ratiometric applications. However, because the part is

specified with a reference of +1.23 V ± 5%, then the voltage

range for ratiometric operation is limited.

The error analysis over temperature of ratiometric applications

is different from nonratiometric ones. Since the reference and

analog input voltage range are ratioed to each other, temperature variations in the reference are matched by variations in the

analog input range. Therefore, the AD589 contributes no additional errors over temperature to the system errors, and the

combined total unadjusted error specification for the AD589

and AD7575 is as per the total unadjusted error specification in

this data sheet.

With nonratiometric applications, however, the analog input

range stays the same if the reference varies and a full-scale error

is introduced. The amount by which the reference varies determines the amount of error introduced. The AD589 is graded on

temperature coefficient; therefore, selection of different grades

allows the user to tailor the amount of error introduced to suit

the system requirements. The reference voltage from the AD589

can lie between 1.2 V and 1.25 V. This reference voltage can be

adjusted for the desired full-scale voltage range using the circuit

outlined in Figure 19. For example, if an analog input voltage

range of 0 V to +2.46 V is required, the reference should be

adjusted to +1.23 V. Once the reference is adjusted to the de-

sired value at 25°C, the total error is as per the total unadjusted

error specification on the AD7575 specification pages. (To

reduce this still further, offset and full-scale errors of the

AD7575 can be adjusted out using the calibration procedure

outlined in this data sheet.)

+5V

6.8kV

AD589

*ONLY REQUIRED IF IT IS NECESSARY TO ADJUST

THE ABSOLUTE VALUE OF REFERENCE VOLTAGE.

10kV*1kV*

+

10kV*

–

+5V

TLC271*

Figure 19. Reference Adjust Circuit

However, it is as the temperature varies from 25°C that the

AD589 starts to introduce errors. The typical temperature characteristics of the AD589 are shown in Figure 20. The temperature coefficients (TCs) represent the slopes of the diagonals of

the error band from +25°C to T

and +25°C to T

MIN

MAX

. The

AD589 TC is specified in ppm/°C max and is offered in four

different grades.

–10–

REV. B

Page 11

AD7575

1.2370

1.2365

1.2360

1.2355

OUTPUT VOLTAGE – V

1.2350

1.2345

–50 125–25

0255075100

TEMPERATURE – 8C

Figure 20. Typical AD589 Temperature Characteristics

The effect the TC has on the system error is that it introduces a

full-scale error in the ADC. This, in turn, affects the total unadjusted error specification. For example, using the AD589KH

with a 50 ppm/°C max TC the change in reference voltage from

25°C to 70°C will be from 1.23 V to 1.22724 V, a change of –

2.76 mV. This results in a change in the full-scale range of the

ADC of –5.52 mV, since the full-scale range on the AD7575 is

. Because the LSB size for the AD7575 is 9.61 mV, the

2 V

REF

AD589 introduces an additional full-scale error of –0.57 LSBs

on top of the existing full-scale error specification for the ADC.

Since the total unadjusted error specification for the ADC

includes the full-scale error, there is also a corresponding increase in the total unadjusted error of –0.57 LSBs. The change

in reference voltage at 0°C is –1.5 mV, resulting in a full-scale

change of –3 mV or –0.31 LSBs worth of full-scale error. Table I

shows the amount of additional total unadjusted error, which is

introduced by the temperature variation of the AD589, for

different grades and for different temperature ranges. This table

applies only to nonratiometric applications, because the temperature variation of the reference does not affect the system

error in ratiometric applications as outlined earlier. It shows the

amount of error introduced over T

MIN

to T

for a system in

MAX

which the reference has been adjusted to the desired value at

25°C. The final or right-most column of the table gives the total

combined error for the AD589 and the top grade AD7575.

Taking the 25°C measurement as the starting point, the

full-scale error introduced is always in the negative direction

whether the temperature goes to T

MIN

or T

. This can be

MAX

seen from the AD589 temperature characteristic shown in Fig-

ure 20. If the reference voltage is adjusted for 1.23 V at 45°C

(for the 0°C to +70°C range) and 75°C (for the –55°C to

+125°C range) the magnitude of the error introduced is reduced

since it is distributed in both the positive and negative directions. Alternatively, this can be achieved not by adjusting at

these temperatures, which would be impractical, but by adjusting the reference to 1.231 V instead of 1.23 V (for the extended

temperature range) at 25°C. This has the required effect of

distributing the plot of Figure 20 more evenly about the desired

value.

An additional error source is the mismatch between the tem-

perature coefficients (TCs) of the 10 kΩ and 1 kΩ resistors in

the feedback loop of the TLC271. If these resistors have

±50 ppm/°C absolute TCs, the worst case difference in drift between both resistors is 100 ppm/°C. From +25°C to +125°C, this

introduces a worst case shift of 1.22 mV, which results in an addi-

tional full-scale error of 0.25 LSB. If ±25 ppm/°C

resistors are

used, then the worst case error is 0.13 LSB. Over the 0°C to

+70°C range, the ±50 ppm/°C resistors introduce an additional

full-scale error of 0.11 LSB. All these errors are worst case and

assume that the resistance values drift in opposite directions. In

practice, resistors of the same type, and from the same manufacturer, would drift in the same direction and hence the above

error would be considerably reduced. An additional error source

is the offset drift of the TLC271. This is significant only over

the –55°C to +125°C range and, even in this case, it contrib-

utes <0.1 LSB worth of full-scale error.

The error outlined in the right-hand column of Table I is a total

unadjusted error specification, excluding resistor and offset drift

(the effect of these can be controlled by the user). It consists of

errors from two error sources: a ±l LSB contribution from the

AD7575 (including full-scale, offset and relative accuracy errors), and the remainder is a full-scale error introduced by the

AD589. It is important to note that the variation of the AD589

voltage only introduces a full-scale error; the relative accuracy

(or endpoint nonlinearity) of the system, with a top grade

AD7575, is still ±1/2 LSB (i.e., 8-bits accurate).

REV. B

Table I. AD589/AD7575 Error over Temperature (Nonratiometric Applications)

Full-Scale Error Introduced Combined Worst Case

AD589 Temperature by AD589 @ T

MAX

AD589/AD7575

Grade Range (Worst Case) T.U.E. @ T

AD589JH 0°C to +70°C –1.15 LSB –2.15 LSB

AD589KH 0°C to +70°C –0.57 LSB –1.57 LSB

AD589LH 0°C to +70°C –0.29 LSB –1.29 LSB

AD589MH 0°C to +70°C –0.115 LSB –1.115 LSB

AD589SH –55°C to +125°C –2.56 LSB –3.56 LSB

AD589TH –55°C to +125°C –1.28 LSB –2.28 LSB

AD589UH –55°C to +125°C –0.64 LSB –1.64 LSB

*Excluding resistor and offset drift.

–11–

MAX

Page 12

AD7575

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

0.18

(4.58)

MAX

0.065 (1.66)

0.045 (1.15)

0.180 (4.572)

0.140 (3.556)

0.200 (5.080)

0.125 (3.175)

0.023 (0.584)

0.015 (0.381)

18-Lead Plastic DIP

(N-18)

0.91 (23.12)

0.89 (22.61)

18

19

PIN 1

0.02 (0.508)

0.015 (0.381)

10

0.105 (2.67)

0.095 (2.42)

0.26 (6.61)

0.24 (6.10)

0.175 (4.45)

0.12 (3.05)

SEATING

PLANE

0.306 (7.78)

0.294 (7.47)

0.12 (0.305)

0.008 (0.203)

18-Lead Cerdip

(Q-18)

18

1

PIN 1

0.950 (24.13) MAX

0.110 (2.794)

0.090 (2.286)

10

9

0.070 (1.778)

0.030 (0.762)

0.310 (7.874)

0.260 (6.604)

0.060 (1.524)

0.015 (0.381)

SEATING

PLANE

0.015 (0.381)

0.008 (0.203)

0.14 (3.56)

0.12 (3.05)

158

0

0.320 (8.128)

0.290 (7.366)

0.400 (10.160)

0.330 (8.382)

0.045 60.003

(1.143 60.076)

0.020

(0.51)

MAX

0.082 6 0.018

(2.085 6 0.455)

20-Lead PLCC

(P-20A)

0.353 60.003

(8.966 60.076)

3

4

IDENTIFIER

TOP VIEW

(PINS DOWN)

8

9

0.390 60.005

(9.905 60.125)

PIN 1

SQ

19

18

14

13

SQ

20-Terminal LCCC

(E-20A)

0.350 6 0.008

(8.89 6 0.20)

19

20

18

1

BOTTOM

VIEW

14

13

0.050

(1.27)

0.050

(1.27)

4

8

0.173 60.008

(4.388 60.185)

0.105 60.015

(2.665 60.375)

SQ

0.020 3 458

(0.51 3 458)

3

0.025 6 0.003

(0.635 6 0.075)

9

0.040 3 458

(1.02 3 458)

REF 3 PLCS

(0.51)

(0.737 60.076)

0.017 60.004

(0.432 60.101)

0.025

(0.64)

REF

0.020

MIN

0.035 60.01

R

(0.89 60.25)

0.029 60.003

MIN

C945b–0–7/98

18 10

PIN 1

0.0118 (0.30)

0.0040 (0.10)

0.4625 (11.75)

0.4469 (11.35)

0.0500

0.0192 (0.49)

(1.27)

0.0138 (0.35)

BSC

18-Lead SOIC

(R-18)

0.2992 (7.60)

0.2914 (7.40)

91

0.1043 (2.65)

0.0926 (2.35)

0.4193 (10.65)

SEATING

PLANE

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.0291 (0.74)

0.0098 (0.25)

0.0500 (1.27)

88

08

0.0157 (0.40)

3 458

PRINTED IN U.S.A.

–12–

REV. B

Loading...

Loading...