Page 1

a

A

781/461-3113

2010

1 MSPS, Serial 14-Bit SAR ADC

AD7485

FEATURES

Fast Throughput Rate: 1 MSPS

Wide Input Bandwidth: 40 MHz

Excellent DC Accuracy Performance

Flexible Serial Interface

Low Power:

80 mW (Full Power) and 3 mW (NAP Mode)

STANDBY Mode: 2 A Max

Single 5 V Supply Operation

Internal 2.5 V Reference

Full-Scale Overrange Indication

GENERAL DESCRIPTION

The AD7485 is a 14-bit, high speed, low power, successiveapproximation ADC. The part features a serial interface with

throughput rates up to 1 MSPS. The part contains a low noise,

wide bandwidth track-and-hold that can handle input frequencies

in excess of 40 MHz.

The conversion process is a proprietary algorithmic successiveapproximation technique. The input signal is sampled and a

conversion is initiated on the falling edge of the CONVST signal.

The conversion process is controlled by an external master

clock. Interfacing is via standard serial signal lines, making the

part directly compatible with microcontrollers and DSPs.

The AD7485 provides excellent ac and dc performance specifications. Factory trimming ensures high dc accuracy resulting in

very low INL, DNL, offset, and gain errors.

The part uses advanced design techniques to achieve very low

power dissipation at high throughput rates. Power consumption

in the normal mode of operation is 80 mW. There are two powersaving modes: a NAP mode keeps reference circuitry alive for

quick power-up and consumes 3 mW, while a STANDBY mode

reduces power consumption to a mere 10 µW.

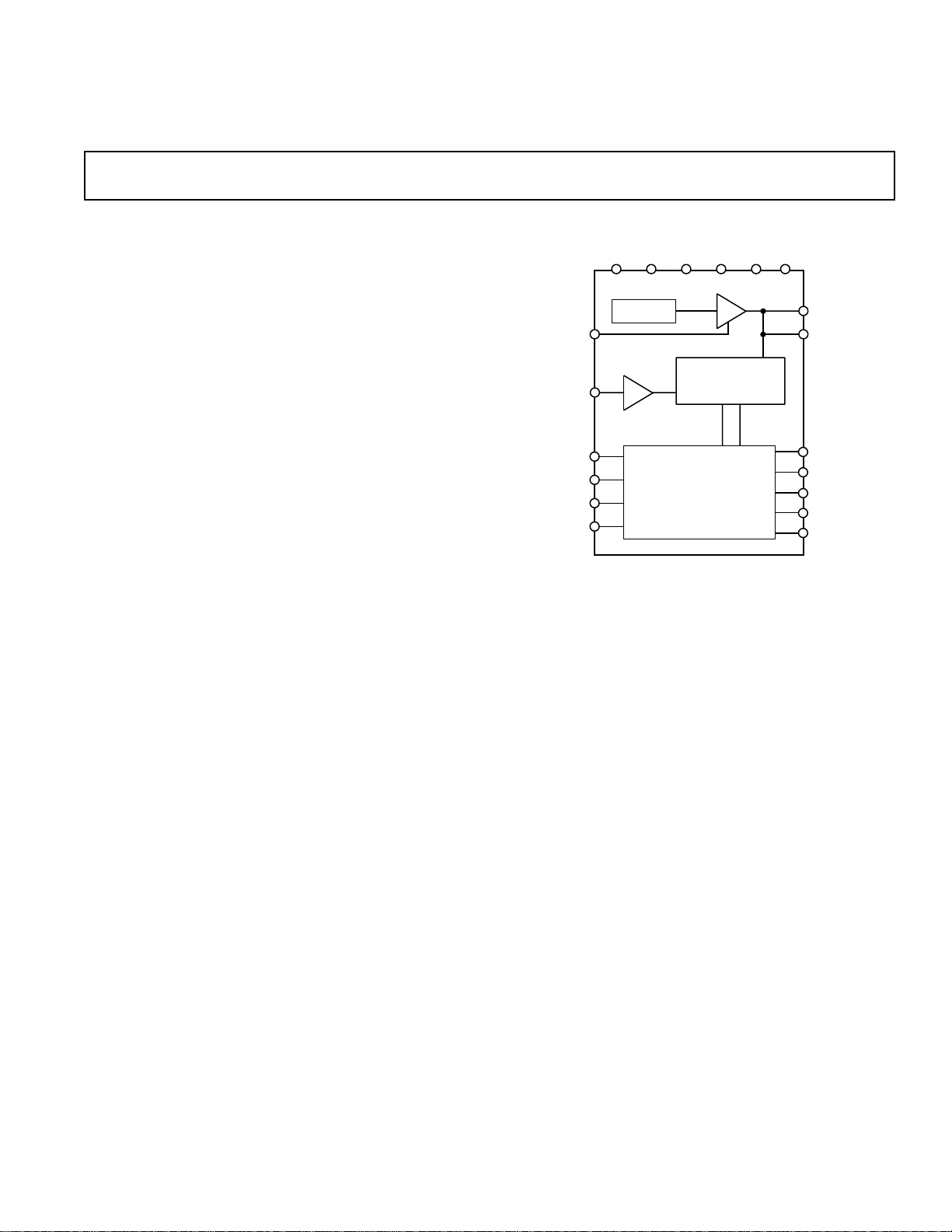

FUNCTIONAL BLOCK DIAGRAM

REFSEL

VIN

NAP

STBY

RESET

CONVST

AVDDAGND C

2.5 V

REFERENCE

T/H

AD7485

LOGIC AND I/O

BIASDVDD

ALGORITHMIC

CONTROL

REGISTERS

BUF

14-BIT

SAR

V

DRIVE

DGND

REFOUT

REFIN

MCLK

TFS

SCO

SDO

SMODE

The AD7485 features an on-board 2.5 V reference, but the part can

also accommodate an externally provided 2.5 V reference source.

The nominal analog input range is 0 V to 2.5 V.

The AD7485 also provides the user with overrange indication via a

fifteenth bit. If the analog input range strays outside the 0 V to

2.5 V input range, the fifteenth data bit is set to a logic high.

The AD7485 is powered from a 4.75 V to 5.25 V supply. The

part also provides a V

pin that allows the user to set the

DRIVE

voltage levels for the digital interface lines. The range for this

V

pin is from 2.7 V to 5.25 V. The part is housed in a

DRIVE

48-lead LQFP package and is specified over a –40°C to +85°C

temperature range.

REV.

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: © Analog Devices, Inc.,

Page 2

AD7485–SPECIFICATIONS

A

(VDD = 5 V 5%, AGND = DGND = 0 V, V

1

tions T

MIN

to T

MAX

and valid for V

DRIVE

= External, f

REF

= 1 MSPS; all specifica-

SAMPLE

= 2.7 V to 5.25 V, unless otherwise noted.)

Parameter Specification Unit Test Conditions/Comments

DYNAMIC PERFORMANCE

2, 3

Signal to Noise + Distortion (SINAD)

4

76.5 dB min

fIN = 500 kHz Sine Wave

78 dB typ

Total Harmonic Distortion (THD)

4

77 dB typ Internal Reference

–90 dB max

–95 dB typ

–92 dB typ Internal Reference

Peak Harmonic or Spurious Noise (SFDR)

Intermodulation Distortion (IMD)

4

Second-Order Terms –96 dB typ f

4

–88 dB max

= 95.053 kHz, f

IN1

= 105.329 kHz

IN2

Third-Order Terms –94 dB typ

Aperture Delay 10 ns typ

Full Power Bandwidth 40 MHz typ @ 3 dB

3.5 MHz typ @ 0.1 dB

DC ACCURACY

Resolution 14 Bits

Integral Nonlinearity

Differential Nonlinearity

Offset Error

Gain Error

4

4

4

4

± 1LSB max

± 0.5 LSB typ

± 0.75 LSB max Guaranteed No Missed Codes to 14 Bits

± 0.25 LSB typ

± 6LSB max

0.036 %FSR max

± 6LSB max

0.036 %FSR max

ANALOG INPUT

Input Voltage 0 V min

2.5 V max

DC Leakage Current ± 1 µA max

Input Capacitance

5

35 pF typ

REFERENCE INPUT/OUTPUT

V

Input Voltage 2.5 V ± 1% for Specified Performance

REFIN

V

Input DC Leakage Current ± 1 µA max

REFIN

V

Input Capacitance

REFIN

V

Input Current

REFIN

V

V

V

V

Output Voltage 2.5 V typ

REFOUT

Error @ 25°C ± 50 mV typ

REFOUT

Error T

REFOUT

Output Impedance 1 Ω typ

REFOUT

MIN

6

to T

5

MAX

25 pF typ

220 A typ External Reference

± 100 mV max

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, I

Input Capacitance, C

LOGIC OUTPUTS

Output High Voltage, V

Output Low Voltage, V

Floating-State Leakage Current ± 10 µA max

Floating-State Output Capacitance

INH

INL

IN

5

IN

7

OH

7

OL

5

V

–1V min

DRIVE

0.4 V max

± 1 µA max

10 pF typ

0.7 × V

0.3 × V

DRIVE

DRIVE

V min

V max

10 pF max

Output Coding Straight (Natural) Binary

CONVERSION RATE

Conversion Time 24 MCLKs

Track/Hold Acquisition Time 100 ns max Sine Wave Input

70 ns max Full-Scale Step Input

Throughput Rate 1 MSPS max

REV. –2–

Page 3

Parameter Specification Unit Test Conditions/Comments

131785

A

POWER REQUIREMENTS

V

DD

V

DRIVE

5V± 5%

2.7 V min

5.25 V max

I

DD

Normal Mode (Static) mA max

Normal Mode (Operational) mA max

NAP Mode 0.6 mA max

STANDBY Mode

8

2 µA max

0.5 µA typ

Power Dissipation

Normal Mode (Operational) mW max

NAP Mode 3 mW max

STANDBY Mode

NOTES

1

Temperature ranges as follows: –40°C to +85°C.

2

SINAD figures quoted include external analog input circuit noise contribution of approximately 1 dB.

3

See Typical Performance Characteristics section for analog input circuits used.

4

See Terminology.

5

Sample tested @ 25°C to ensure compliance.

6

Current drawn from external reference during conversion.

7

I

= 200 µA.

LOAD

8

Digital input levels at GND or V

Specifications subject to change without notice.

8

.

DRIVE

10 µW max

AD7485

TIMING CHARACTERISTICS

(VDD = 5 V 5%, AGND = DGND = 0 V, V

1

valid for V

= 2.7 V to 5.25 V, unless otherwise noted.)

DRIVE

= External; all specifications T

REF

MIN

to T

MAX

and

Parameter Symbol Min Typ Max Unit

Master Clock Frequency f

MCLK Period t

Conversion Time t

CONVST Low Period (Mode 1)

CONVST High Period (Mode 1)

2

2

MCLK High Period t

MCLK Low Period t

CONVST Falling Edge to MCLK Rising Edge t

MCLK Rising Edge to MSB Valid t

Data Valid before SCO Falling Edge t

Data Valid after SCO Falling Edge t

CONVST Rising Edge to SDO Three-State t

CONVST Low Period (Mode 2)

CONVST High Period (Mode 2)

2

3

CONVST Falling Edge to TFS Falling Edge t

TFS Falling Edge to MSB Valid t

TFS Rising Edge to SDO Three-State t

TFS Low Period

TFS High Period

4

4

MCLK Fall Time t

MCLK Rise Time t

MCLK – SCO Delay t

NOTES

1

All timing specifications given above are with a 25 pF load capacitance. With a load capacitance greater than this value, a digital buffer or latch must be used.

2

CONVST idling high. See Serial Interface section for further details.

3

CONVST idling low. See Serial Interface section for further details.

4

TFS can also be tied low in this mode.

Specifications subject to change without notice.

MCLK

1

2

t

3

t

4

5

6

7

8

9

10

11

t

12

t

13

14

15

16

t

17

t

18

19

20

21

0.01 25 MHz

40 100000 ns

t1 24 ns

t1 22 ns

10 ns

0.4 t

0.4 t

1

1

0.6 t

0.6 t

1

1

ns

ns

7ns

15 ns

10 ns

20 ns

6ns

10 t1 2ns

10 ns

10 ns

30 ns

8ns

t1 22 ns

10 ns

525ns

525ns

625ns

REV.

–3–

Page 4

AD7485

A

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C, unless otherwise noted.)

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

V

to GND . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

DRIVE

Analog Input Voltage to GND . . . . . . –0.3 V to AV

Digital Input Voltage to GND . . . . . –0.3 V to V

REFIN to GND . . . . . . . . . . . . . . . . –0.3 V to AV

DD

DRIVE

DD

+ 0.3 V

+ 0.3 V

+ 0.3 V

Input Current to Any Pin except Supplies . . . . . . . . . ±10 mA

Operating Temperature Range

Commercial . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

JA Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . . 50°C/W

Thermal Impedance . . . . . . . . . . . . . . . . . . . . . . . 10°C/W

JC

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 kV

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate

on the human body and test equipment and can discharge without detection. Although the AD7485

features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to

high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid

performance degradation or loss of functionality.

PIN CONFIGURATION

AGND

AGND

AVDDDVDDDGND

DGND

RESET

CONVST

SCO

DGND

DGND

SDO

DGND

DGND

DGND

36

35

34

33

32

31

30

29

28

27

26

25

DGND

SMODE

TFS

DGND

DGND

V

DRIVE

DGND

DGND

DV

DD

DGND

DGND

DGND

DGND

AV

C

BIAS

AGND

AGND

AV

AGND

VIN

REFOUT

REFIN

REFSEL

AGND

AGND

48 47 46 45 44 39 38 3743 42 41 40

1

DD

PIN 1

2

IDENTIFIER

3

4

5

DD

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

DD

AV

AGND

AGND

AD7485

TOP VIEW

(Not to Scale)

NAP

STBY

MCLK

DGND

DGND

WARNING!

ESD SENSITIVE DEVICE

REV. –4–

Page 5

AD7485

A

PIN FUNCTION DESCRIPTIONS

Pin

No. Mnemonic Description

1, 5, 13, 46 AV

2C

DD

BIAS

3, 4, 6, 11, 12, AGND Power Supply Ground for Analog Circuitry

14, 15, 47, 48

7VIN Analog Input. Single-ended analog input channel.

8 REFOUT Reference Output. REFOUT connects to the output of the internal 2.5 V reference buffer. A 470 nF

9 REFIN Reference Input. A 470 nF capacitor must be placed between this pin and AGND. When using

10 REFSEL Reference Decoupling Pin. When using the internal reference, a 1 nF capacitor must be connected

16 STBY Standby Logic Input. When this pin is logic high, the device will be placed in STANDBY mode.

17 NAP Nap Logic Input. When this pin is logic high, the device will be placed in a very low power mode.

18 MCLK

19, 20, 22–28 DGND Ground Reference for Digital Circuitry

30, 31, 33, 34

37–39, 43, 44

21 SDO Serial Data Output. The conversion data is latched out on this pin on the rising edge of SCO. It

29, 45 DV

32 V

DD

DRIVE

35 TFS Transmit Frame Sync Input. In Serial Mode 2, this pin acts as a framing signal for the serial data

36 SMODE Serial Mode Input. A logic low on this pin selects Serial Mode 1 and a logic high selects Serial

40 SCO Serial Clock Output. This clock is derived from MCLK and is used to latch conversion data from

41 CONVST

42 RESET Reset Logic Input. A falling edge on this pin resets the internal state machine and terminates a

Positive Power Supply for Analog Circuitry

Decoupling Pin for Internal Bias Voltage. A 1 nF capacitor should be placed between this pin

and AGND.

capacitor must be placed between this pin and AGND.

an external voltage reference source, the reference voltage should be applied to this pin.

from this pin to AGND. When using an external reference source, this pin should be connected

directly to AGND.

See the Power Saving section for further details.

See the Power Saving section for further details.

Master Clock Input. This is the input for the master clock, which controls the conversion cycle. The fre-

quency of this clock may be up to 25 MHz. Twenty-four clock cycles are required for each conversion.

should be latched into the receiving serial port of the DSP on the falling edge of SCO. The overrange bit is latched out first, then 14 bits of data (MSB first) followed by a trailing zero.

Positive Power Supply for Digital Circuitry

Logic Power Supply Input. The voltage supplied at this pin determines at what voltage the interface

logic of the AD7485 will operate.

being clocked out on SDO. A falling edge on TFS brings SDO out of three-state and the data starts

to get clocked out on the next rising edge of SCO.

Mode 2. See the Serial Interface section for further details.

the device. See the Serial Interface section for further details.

Convert Start Logic Input. A conversion is initiated on the falling edge of the CONVST signal. The

input track/hold amplifier goes from track mode to hold mode and the conversion process commences.

conversion that may be in progress. Holding this pin low keeps the part in a reset state.

REV.

–5–

Page 6

AD7485

A

TERMINOLOGY

Integral Nonlinearity

This is the maximum deviation from a straight line passing

through the endpoints of the ADC transfer function. The endpoints of the transfer function are zero scale, a point 1/2 LSB

below the first code transition, and full scale, a point 1/2 LSB

above the last code transition.

Differential Nonlinearity

This is the difference between the measured and the ideal

1 LSB change between any two adjacent codes in the ADC.

Offset Error

This is the deviation of the first code transition (00 . . . 000) to

(00 . . . 001) from the ideal, i.e., AGND + 0.5 LSB.

Gain Error

This is the deviation of the last code transition (111 . . . 110) to

(111 . . . 111) from the ideal (i.e., V

– 1.5 LSB) after the

REF

offset error has been adjusted out.

Track/Hold Acquisition Time

Track/hold acquisition time is the time required for the output

of the track/hold amplifier to reach its final value, within ±1/2 LSB,

after the end of conversion (the point at which the track/hold

returns to track mode).

Signal to (Noise + Distortion) Ratio

This is the measured ratio of signal to (noise + distortion) at

the output of the A/D converter. The signal is the rms amplitude

of the fundamental. Noise is the sum of all nonfundamental

signals up to half the sampling frequency (f

/2), excluding dc.

S

The ratio is dependent on the number of quantization levels in

the digitization process; the more levels, the smaller the quantization noise. The theoretical signal to (noise + distortion) ratio

for an ideal N-bit converter with a sine wave input is given by:

Signal to Noise Distortion N dB()..+=+

602 176

()

Thus, for a 14-bit converter this is 86.04 dB.

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the rms sum

of the harmonics to the fundamental. For the AD7485, it is

defined as:

VVVVV

++++

THD dB log

where V1 is the rms amplitude of the fundamental and V2, V3,

V

, V5, and V6 are the rms amplitudes of the second through

4

=

20

()

223242526

V

1

2

sixth harmonics.

Peak Harmonic or Spurious Noise

Peak harmonic or spurious noise is defined as the ratio of the

rms value of the next largest component in the ADC output

spectrum (up to f

/2 and excluding dc) to the rms value of the

S

fundamental. Normally, the value of this specification is determined by the largest harmonic in the spectrum, but for ADCs

where the harmonics are buried in the noise floor, it will be a

noise peak.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and fb,

any active device with nonlinearities will create distortion products

at sum and difference frequencies of mfa ± nfb where m, n = 0, 1, 2,

3, and so on. Intermodulation distortion terms are those for which

neither m nor n is equal to zero. For example, the second-order

terms include (fa + fb) and (fa – fb), while the third-order terms

include (2fa + fb), (2fa – fb), (fa + 2fb), and (fa – 2fb).

The AD7485 is tested using the CCIF standard where two

input frequencies near the top end of the input bandwidth are

used. In this case, the second-order terms are usually distanced

in frequency from the original sine waves while the third-order

terms are usually at a frequency close to the input frequencies.

As a result, the second- and third-order terms are specified

separately. The calculation of the intermodulation distortion

is as per the THD specification where it is the ratio of the rms

sum of the individual distortion products to the rms amplitude

of the sum of the fundamentals expressed in dBs.

REV. –6–

Page 7

1.0

INPUT FREQUENCY – kHz

100

THD – dB

–60

–100

1000 10000

–40

–80

–90

–70

–50

100

51

10

0

FREQUENCY – kHz

10

PSRR – dB

–20

–60

100 1000

0

–40

–50

–30

–10

–80

–70

100mV p-p SINE WAVE ON SUPPLY PINS

TEMPERATURE – C

–55

REFOUT – V

–0.0004

35 125

0.0004

–0.0008

–0.0012

0

–0.0020

–0.0016

–25 5 65 95

A

0.8

0.6

0.4

0.2

0

DNL – LSB

–0.2

–0.4

–0.6

–0.8

–1.0

0

1.0

0.8

0.6

0.4

0.2

0

INL – LSB

–0.2

–0.4

–0.6

–0.8

–1.0

0

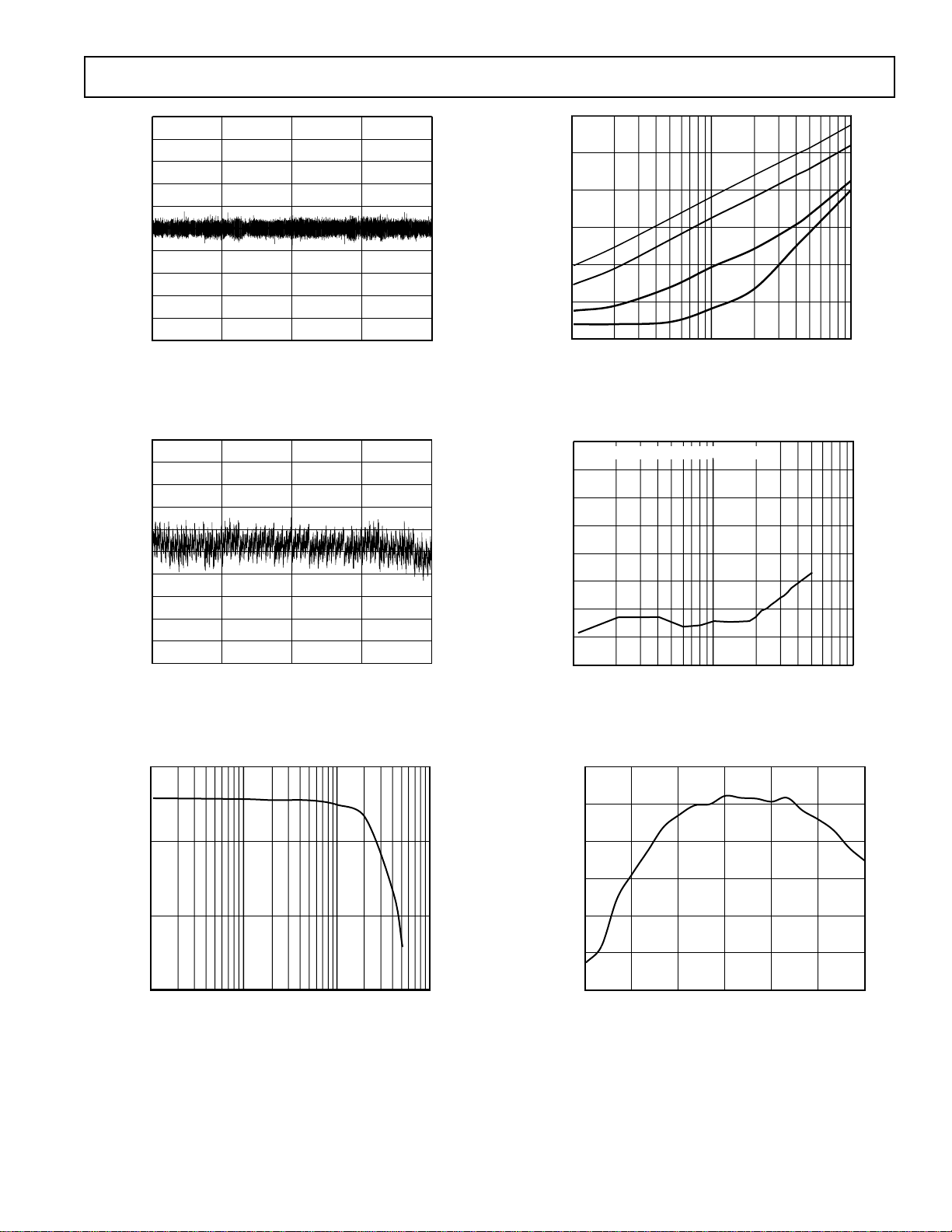

Typical Performance Characteristics–AD7485

4096 8192 12288 16384

ADC CODE

TPC 1. Typical DNL

4096 8192 12288 16384

ADC CODE

TPC 4. THD vs. Input Tone for Different Input Resistances

SINAD – dB

TPC 3. SINAD vs. Input Tone (AD8021 Input Circuit)

REV.

TPC 2. Typical INL

80

75

70

65

10

100 1000 10000

INPUT FREQUENCY – kHz

TPC 5. PSRR without Decoupling

TPC 6. Reference Error

–7–

Page 8

AD7485

A

0

–20

–40

–60

dB

–80

–100

–120

–140

0 300100 200 400 500

FREQUENCY – kHz

f

= 10.7kHz

IN

SNR = 78.76dB

SNR + D = 78.70dB

THD = –97.10dB

TPC 7. 64k FFT Plot with 10 kHz Input Tone

+V

S

SIGNAL

BIAS

VOLTA G E

1k

AC

100

1k

3

2

150

8

+

AD829

–

1

5

7

220pF

V

6

4

–V

S

IN

Figure 1. Analog Input Circuit Used for 10 kHz Input Tone

+V

S

SIGNAL

BIAS

VOLTA G E

50

AC

220

2

3

8

+

AD8021

–

1

220

10pF

5

7

10pF

V

6

4

–V

S

IN

Figure 2. Analog Input Circuit Used for 500 kHz Input Tone

0

f

= 507.3kHz

IN

SNR = 78.35dB

–20

SNR + D = 78.33dB

THD = –100.33dB

–40

–60

dB

–80

–100

–120

–140

0 300100 200 400 500

FREQUENCY – kHz

TPC 8. 64k FFT Plot with 500 kHz Input Tone

Figure 1 shows the analog input circuit used to obtain the data

for the FFT plot shown in TPC 7. The circuit uses an Analog

Devices AD829 op amp as the input buffer. A bipolar analog

signal is applied as shown and biased up with a stable, low noise

dc voltage connected to the labeled terminal shown. A 220 pF

compensation capacitor is connected between Pin 5 of the AD829

and the analog ground plane. The AD829 is supplied with +12 V

and –12 V supplies. The supply pins are decoupled as close to

the device as possible, with both a 0.1 µF and 10 µF capacitor

connected to each pin. In each case, the 0.1 µF capacitor should be

the closer of the two capacitors to the device. More information

on the AD829 is available on the Analog Devices website.

For higher input bandwidth applications, Analog Devices’ AD8021

op amp (also available as a dual AD8022) is the recommended

choice to drive the AD7485. Figure 2 shows the analog input

circuit used to obtain the data for the FFT plot shown in TPC 8.

A bipolar analog signal is applied to the terminal shown and

biased with a stable, low noise dc voltage connected as shown. A

10 pF compensation capacitor is connected between Pin 5 of the

AD8021 and the negative supply. As with the previous circuit,

the AD8021 is supplied with +12 V and –12 V supplies. The

supply pins are decoupled as close to the device as possible with

both a 0.1 µF and 10 µF capacitor connected to each pin. In each

case, the 0.1 µF capacitor should be the closer of the two capaci-

tors to the device. The AD8021 Logic Reference pin is tied to

analog ground and the DISABLE pin is tied to the positive supply as shown. Detailed information on the AD8021 is available

on the Analog Devices website.

REV. –8–

Page 9

AD7485

A

CIRCUIT DESCRIPTION

CONVERTER OPERATION

The AD7485 is a 14-bit algorithmic successive-approximation

analog-to-digital converter based around a capacitive DAC. It provides the user with track-and-hold, reference, an A/D converter,

and versatile interface logic functions on a single chip. The analog

input signal range that the AD7485 can convert is 0 V to 2.5 V.

The part requires a 2.5 V reference that can be provided from

the part’s own internal reference or an external reference source.

Figure 3 shows a very simplified schematic of the ADC. The

Control Logic, SAR, and Capacitive DAC are used to add and

subtract fixed amounts of charge from the sampling capacitor to

bring the comparator back to a balanced condition.

COMPARATOR

CAPACITIVE

DAC

V

IN

REF

SWITCHES

SAR

CONTROL

LOGIC

OUTPUT DATA

14-BIT SERIAL

V

CONTROL

INPUTS

Figure 3. Simplified Block Diagram

Conversion is initiated on the AD7485 by pulsing the CONVST

input. On the falling edge of CONVST, the track/hold goes from

track to hold mode and the conversion sequence is started.

Conversion time for the part is 24 MCLK periods. Figure 4 shows

the ADC during conversion. When conversion starts, SW2 will

open and SW1 will move to position B causing the comparator to

become unbalanced. The ADC then runs through its successive

approximation routine and brings the comparator back into a

balanced condition. When the comparator is rebalanced, the

conversion result is available in the SAR register.

CAPACITIVE

DAC

A

V

AGND

IN

SW1

B

SW2

+

–

COMPARATOR

CONTROL LOGIC

Figure 4. ADC Conversion Phase

At the end of conversion, track-and-hold returns to tracking

mode and the acquisition time begins. The track/hold acquisition

time is 70 ns. Figure 5 shows the ADC during its acquisition

phase. SW2 is closed and SW1 is in position A. The comparator

is held in a balanced condition and the sampling capacitor acquires

the signal on V

.

IN

CAPACITIVE

DAC

V

AGND

A

IN

SW1

B

SW2

+

–

COMPARATOR

CONTROL LOGIC

Figure 5. ADC Acquisition Phase

ADC TRANSFER FUNCTION

The output coding of the AD7485 is straight binary. The designed

code transitions occur midway between successive integer LSB

values (i.e., 1/2 LSB, 3/2 LSB, and so on). The LSB size is

V

/16384. The nominal transfer characteristic for the

REF

AD7485 is shown in Figure 6.

111...111

111...110

111...000

011...111

ADC CODE

000...010

000...001

000...000

0V

0.5LSB

1LSB = V

ANALOG INPUT

+V

REF

/16384

REF

–1.5LSB

Figure 6. Transfer Characteristic

POWER SAVING

The AD7485 uses advanced design techniques to achieve very

low power dissipation at high throughput rates. In addition to

this, the AD7485 features two power saving modes, NAP mode

and STANDBY mode. These modes are selected by bringing

either the NAP or STBY pin to a logic high.

When operating the AD7485 with a 25 MHz MCLK in normal,

fully powered mode, the current consumption is 16 mA during

conversion and the quiescent current is 12 mA. Operating at a

throughput rate of 500 kSPS, the conversion time of 960 ns

contributes 38.4 mW to the overall power dissipation.

960 2 5 16 38 4ns s V mA mW/.

()

××

()

=

For the remaining 1.04 µs of the cycle, the AD7485 dissipates

31.2 mW of power.

104 2 5 12 312./ .ss V mA mW

()

××

()

=

Thus the power dissipated during each cycle is:

38 4 31 2 69 6...mW mW mW+=

REV.

–9–

Page 10

AD7485

C

C

A

Figure 7 shows the AD7485 conversion sequence operating in

normal mode.

2s

ONVST

TFS

READ DATA CONVERSION

960ns 1.04s

FINISHED

Figure 7. Normal Mode Power Dissipation

In NAP mode, all the internal circuitry except for the internal

reference is powered down. In this mode, the power dissipation

of the AD7485 is reduced to 3 mW. When exiting NAP mode,

a minimum of 300 ns when using an external reference must be

waited before initiating a conversion. This is necessary to allow

the internal circuitry to settle after power-up and for the track/hold

to properly acquire the analog input signal.

If the AD7485 is put into NAP mode after each conversion, the

average power dissipation will be reduced but the throughput

rate will be limited by the power-up time. Using the AD7485 with

a throughput rate of 100 kSPS while placing the part in NAP

mode after each conversion would result in average power dissipation as follows:

The power-up phase contributes:

300 10 5 12 1 8ns s V mA mW/.

()

××

()

=

The conversion phase contributes:

960 10 5 16 7 68ns s V mA mW/.

()

××

()

=

While in NAP mode for the rest of the cycle, the AD7485 dissipates

only 2.185 mW of power.

874 10 5 06 2622./ . .ssV mA mW

()

××

()

=

Thus the power dissipated during each cycle is:

18 768 2622 12 1.. . .mW mW mW mW++ +

Figure 8 shows the AD7485 conversion sequence if putting the

part into NAP mode after each conversion.

1.26s

NAP

300ns

ONVST

TFS

8.74s

Figures 9 and 10 show a typical graphical representation of

power versus throughput for the AD7485 when in normal and

NAP modes, respectively.

80

78

76

74

72

70

68

POWER – mW

66

64

62

60

0 100

200 400300 500 600 700 800 900 1000

THROUGHPUT – kSPS

Figure 9. Normal Mode, Power vs. Throughput

50

45

40

35

30

25

20

POWER – mW

15

10

5

0

050

100 200150 250 300 350 400 450 500

THROUGHPUT – kSPS

Figure 10. NAP Mode, Power vs. Throughput

In STANDBY mode, all the internal circuitry is powered down

and the power consumption of the AD7485 is reduced to 10 µW.

Because the internal reference has been powered down, the

power-up time necessary before a conversion can be initiated is

longer. If using the internal reference of the AD7485, the ADC

must be brought out of STANDBY mode 500 ms before a conversion is initiated. Initiating a conversion before the required

power-up time has elapsed will result in incorrect conversion

data. If an external reference source is used and kept powered up

while the AD7485 is in STANDBY mode, the power-up time

required will be reduced to 80 µs.

10s

Figure 8. NAP Mode Power Dissipation

REV. –10–

Page 11

C/P

RESET

SMODE

NAP

STBY

CONVST

TFS

SCO

SDO

C

BIAS

REFSEL

REFIN

REFOUT

V

IN

AD7485

ADM809

V

DRIVEDVDDAVDD

0.1F

DIGITAL

SUPPLY

4.75V–5.25V

10F 1nF+0.1F 0.1F

+

47F

ANALOG

SUPPLY

4.75V–5.25V

0V TO 2.5V

1nF

0.47F

0.47F

AD780 2.5V

REFERENCE

25MHz

XO

MCLK

A

SERIAL INTERFACE

The AD7485 has two serial interface modes, selected by the state

of the SMODE pin. In both these modes, the MCLK pin must be

supplied with a clock signal of between 10 kHz and 25 MHz. This

MCLK signal controls the internal conversion process and is also

used to derive the SCO signal. As the AD7485 uses an algorithmic

successive-approximation technique, 24 MCLK cycles are

required to complete a conversion. Due to the error-correcting

operation of this ADC, all bit trials must be completed before the

conversion result is calculated. This results in a single sample

delay in the result that is clocked out.

In Serial Mode 1 (Figure 13), the CONVST pin is used to

initiate the conversion and also frame the serial data. When

CONVST is brought low, the SDO line is taken out of threestate, the overrange bit will be clocked out on the next rising

edge of SCO followed by the 14 data bits (MSB first) and a

trailing zero. CONVST must remain low for 22 SCO pulses to

allow all the data to be clocked out and the conversion in

progress to be completed. When CONVST returns to a logic

high, the SDO line returns to three-state. TFS should be tied to

ground in this mode.

In Serial Mode 2 (Figure 14), the CONVST pin is used to

initiate the conversion, but the TFS signal is used to frame the

serial data. The CONVST signal can idle high or low in this

mode. Idling high, the CONVST pulsewidth must be

10 ns and two MCLK periods. Idling low, the

between

CONVST

pulsewidth must be at least 10 ns. TFS must remain low for a

minimum of 22 SCO cycles in this mode but can also be tied

permanently low. If TFS is tied low, the SDO line will always

be driven.

The relationship between the MCLK and SCO signals is shown

in Figure 15.

Figure 11 shows a typical connection diagram for the AD7485.

In this case, the MCLK signal is provided by a 25 MHz crystal

oscillator module. It could also be provided by the second serial

port of a DSP (e.g., ADSP-2189M) if one were available.

In Figure 11 the V

output levels being either 0 V or DV

V

controls the voltage value of the output logic signals. For

DRIVE

example, if DV

DD

pin is tied to DVDD, which results in logic

DRIVE

is supplied by a 5 V supply and V

. The voltage applied to

DD

DRIVE

by a 3 V

supply, the logic output levels would be either 0 V or 3 V. This

feature allows the AD7485 to interface to 3 V devices while still

enabling the A/D to process signals at 5 V supply.

The maximum slew rate at the input of the ADC should be

limited to 500 V/µs while the conversion is taking place. This

will prevent corruption of the current conversion. In any multiplexed application, the channel switching should occur as early

as possible after the first MCLK period.

AD7485

Figure 11. Typical Connection Diagram

Driving the CONVST Pin

To achieve the specified performance from the AD7485, the

CONVST pin must be driven from a low jitter source. Since the

falling edge on the CONVST pin determines the sampling instant,

any jitter that may exist on this edge will appear as noise when

the analog input signal contains high frequency components.

The relationship between the analog input frequency (f

jitter (t

), and resulting SNR is given by the equation below.

j

SNR dB

() log

J

ITTER

=

10

1

ft

()

××

π

2

IN j

As an example, if the desired SNR due to jitter was 100 dB with

a maximum full-scale analog input frequency of 500 kHz, ignoring all other noise sources we get an allowable jitter

on the

CONVST falling edge. For a 14-bit converter (ideal

SNR = 86.04 dB), the allowable jitter will be greater than the

figure given above; but due consideration needs to be given to the

design of the CONVST circuitry to achieve 14-bit performance

with large analog input frequencies.

), timing

IN

2

of 3.18 ps

REV.

–11–

Page 12

AD7485

A

Board Layout and Grounding

To obtain optimum performance from the AD7485, it is recommended that a printed circuit board with a minimum of three

layers is used. One of these layers, preferably the middle layer,

should be as complete a ground plane as possible to give the

best shielding. The board should be designed in such a way that

the analog and digital circuitry are separated and confined to

certain areas of the board. This practice, along with avoiding

running digital and analog lines close together, should help to

avoid coupling digital noise onto analog lines.

The power supply lines to the AD7485 should be approximately

3 mm wide to provide a low impedance path and reduce the

effects of glitches on the power supply lines. It is vital that good

decoupling is also present. A combination of ferrites and

decoupling capacitors should be used as shown in Figure 11.

The decoupling capacitors should be as close to the supply pins

as possible. This is made easier by the use of multilayer boards.

The signal traces from the AD7485 pins can be run on the top

layer while the decoupling capacitors and ferrites mounted on

the bottom layer where the power traces exist. The ground

plane between the top and bottom planes provides excellent

shielding.

Figures 12a–12e show a sample layout of the board area immediately surrounding the AD7485. Pin 1 is the bottom left corner

of the device. Figure 12a shows the top layer where the AD7485

is mounted with vias to the bottom routing layer highlighted.

Figure 12b shows the bottom layer where the power routing is

with the same vias highlighted. Figure 12c shows the bottom

layer silkscreen where the decoupling components are soldered

directly beneath the device. Figure 12d shows the silkscreen

overlaid on the solder pads for the decoupling components, and

Figure 12e shows the top and bottom routing layers overlaid.

The black area in each figure indicates the ground plane present

on the middle layer.

Figure 12a

Figure 12c

Figure 12b

Figure 12d

Figure 12e

C1-6 : 100 nF, C7–8: 470 nF, C9: 1 nF

L1-4: Meggit-Sigma Chip Ferrite Beads (BMB2A0600RS2)

REV. –12–

Page 13

C

ONVST

C

A

MCLK

SCO

SDO

ONVST

MCLK

SCO

SDO

TFS

AD7485

t

2

t

3

t

7

t

8

t

1

t

5

t

6

t

9

t

10

D0D1D2D3D4D5D6D7D8D9D10D11D12D13D14

t

Figure 13. Serial Mode 1 (SMODE = 0) Read Cycle

t

2

t

12

t

7

t

14

t

15

t

1

t

5

t

6

t

9

t

10

D0D1D2D3D4D5D6D7D8D9D10D11D12D13D14

t

16

t

4

11

t

13

t

17

t

18

Figure 14. Serial Mode 2 (SMODE = 1) Read Cycle

t

MCLK

SCO

1

t

19

t

21

t

20

t

5

t

6

Figure 15. Serial Clock Timing

REV.

–13–

Page 14

AD7485

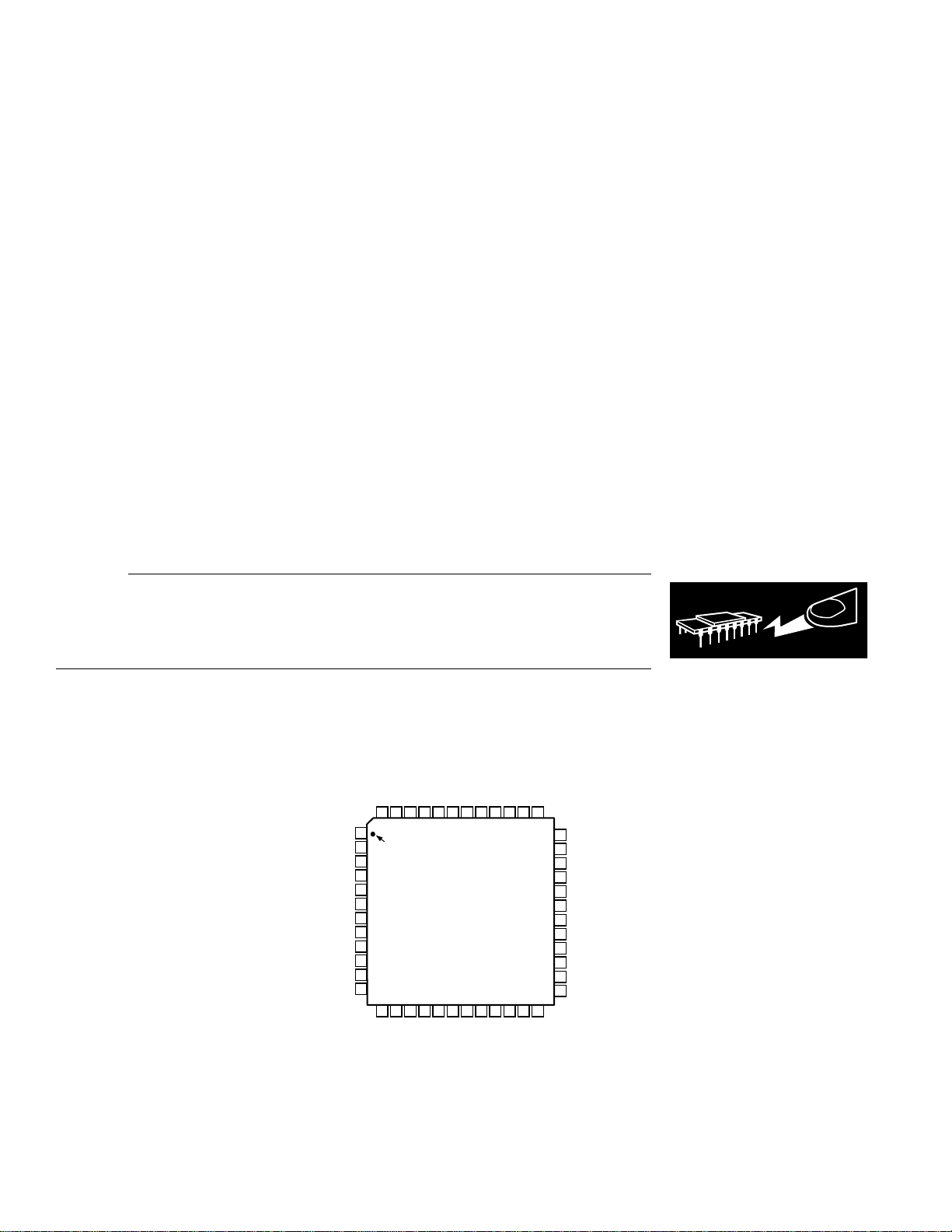

OUTLINE DIMENSIONS

9.20

1

12

0.50

BSC

48

13

9.00 SQ

8.80

PIN 1

TOP VIEW

(PINS DOWN)

37

36

7.20

7.00 SQ

6.80

25

24

0.27

0.22

0.17

051706-A

1.45

1.40

1.35

0.15

SEATING

0.05

PLANE

VIEW A

ROTATED 90° CCW

0.75

0.60

0.45

0.20

0.09

7°

3.5°

0°

0.08

COPLANARITY

COMPLIANT TO JEDE C S TANDARDS MS-026-BBC

1.60

MAX

VIEW A

LEAD PITCH

Figure 1. 48-Lead Low Profile Quad Flatpack [LQFP]

7 mm × 7 mm, Very Thin Quad

(ST-48)

Dimensions shown in millimeters

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

AD7485BSTZ −40°C to +85°C 48-Lead Low Profile Quad Flatpack [LQFP] ST-48

1

Z = RoHS Compliant Part.

REVISION HISTORY

4/10—Rev. 0 to Rev. A

Changes to Specifications Table ............................................................. 3

©2002-2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D02758-0-4/10(A)

Rev. A | Page 14

Loading...

Loading...