Datasheet AD743SQ-883B, AD743KR-16-REEL, AD743KR-16, AD743KN, AD743JR-16-REEL Datasheet (Analog Devices)

...Page 1

Ultralow Noise

a

FEATURES

ULTRALOW NOISE PERFORMANCE

2.9 nV/√Hz at 10 kHz

0.38 V p-p, 0.1 Hz to 10 Hz

6.9 fA/√Hz Current Noise at 1 kHz

EXCELLENT DC PERFORMANCE

0.5 mV Max Offset Voltage

250 pA Max Input Bias Current

1000 V/mV min Open-Loop Gain

AC PERFORMANCE

2.8 V/s Slew Rate

4.5 MHz Unity-Gain Bandwidth

THD = 0.0003% @ 1 kHz

Available in Tape and Reel in Accordance with

EIA-481A Standard

APPLICATIONS

Sonar Preamplifiers

High Dynamic Range Filters (>140 dB)

Photodiode and IR Detector Amplifiers

Accelerometers

PRODUCT DESCRIPTION

The AD743 is an ultralow noise precision, FET input, monolithic

operational amplifier. It offers a combination of the ultralow

voltage noise generally associated with bipolar input op amps

and the very low input current of a FET-input device. Furthermore, the AD743 does not exhibit an output phase reversal

when the negative common-mode voltage limit is exceeded.

The AD743’s guaranteed, maximum input voltage noise of

4.0nV/√Hz at 10 KHz is unsurpassed for a FET-input monolithic

op amp, as is the maximum 1.0 µV p-p, 0.1 Hz to 10 Hz noise.

The AD743 also has excellent dc performance with 250 pA

maximum input bias current and 0.5 mV maximum offset voltage.

The AD743 is specifically designed for use as a preamp in

capacitive sensors, such as ceramic hydrophones. It is available

in five performance grades. The AD743J is rated over the

commercial temperature range of 0°C to 70°C.

The AD743 is available in 8-Lead plastic mini-DIP, and

16-pin SOIC.

PRODUCT HIGHLIGHTS

1. The low offset voltage and low input offset voltage drift of

the AD743 coupled with its ultralow noise performance

mean that the AD743 can be used for upgrading many

applications now using bipolar amplifiers.

BiFET Op Amp

AD743

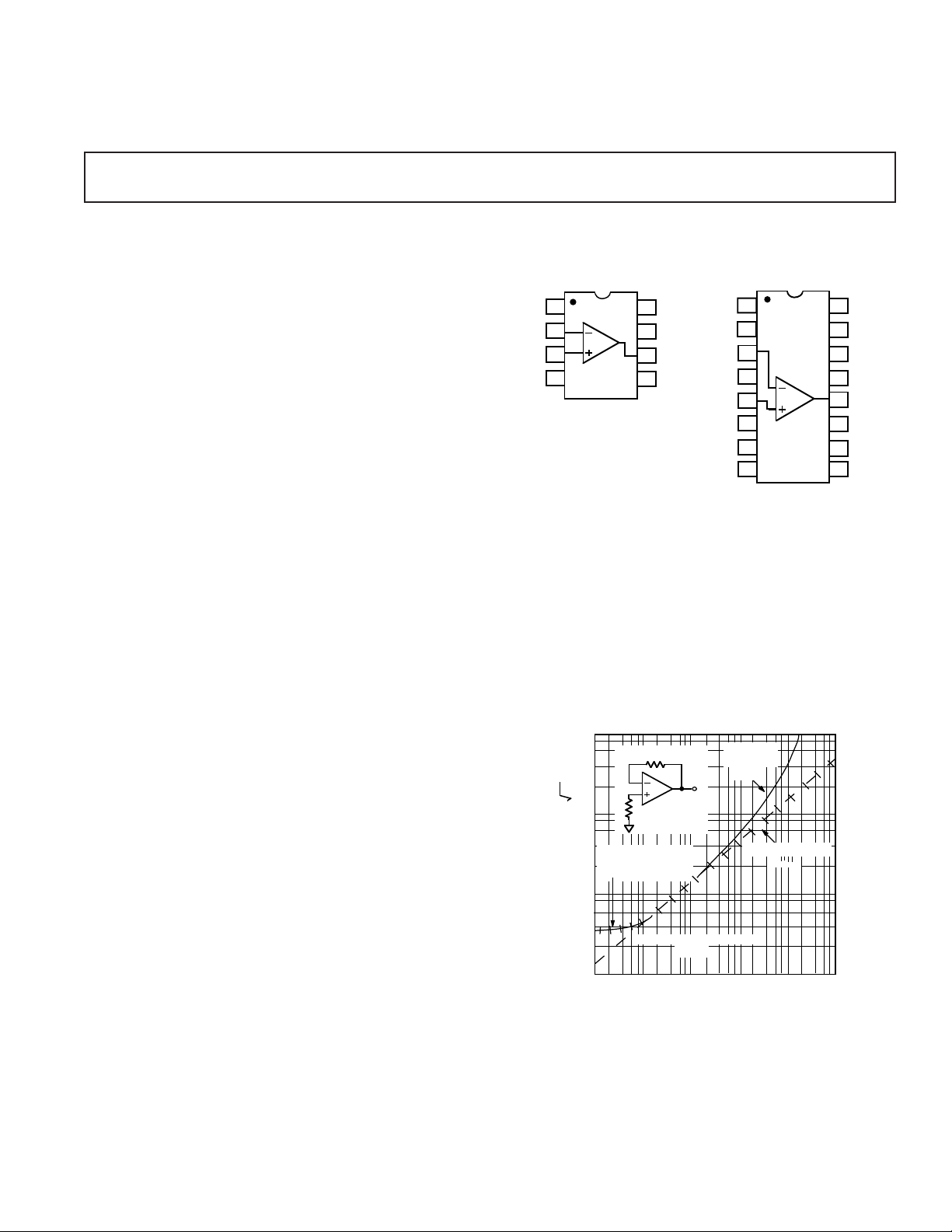

CONNECTION DIAGRAMS

8-Lead Plastic Mini-DIP (N)

1

NULL

2

–IN

3

+IN

–V

4

S

NC = NO CONNECT

AD743

TOP VIEW

8

8

NC

+V

7

6

OUT

NULL

5

2. The combination of low voltage and low current noise make

the AD743 ideal for charge sensitive applications such as

accelerometers and hydrophones.

3. The low input offset voltage and low noise level of the

AD743 provide >140 dB dynamic range.

4. The typical 10 kHz noise level of 2.9 nV/√Hz permits a three

op amp instrumentation amplifier, using three AD743s, to be

built which exhibits less than 4.2 nV/√Hz noise at 10 KHz

and which has low input bias currents.

1000

R

SOURCE

100

10

INPUT NOISE VOLTAGE – nV/ Hz

1

R

SOURCE

AD743 & RESISTOR

OR

OP27 & RESISTOR

RESISTOR NOISE ONLY

100

1k

SOURCE RESISTANCE – Ω

Input Noise Voltage vs. Source Resistance

16-Lead SOIC (R) Package

1

NC

OFFSET

S

E

O

(– – –)

10k 100k

2

NULL

3

–IN

4

NC

+IN

5

–V

6

S

7

NC

8

NC

NC = NO CONNECT

OP27 &

RESISTOR

( — )

AD743 + RESISTOR

AD743

)

(

1M

16 NC

15

14

13

12

11

10

10M

8

9

NC

NC

+V

S

OUTPUT

OFFSET

NULL

NC

NC

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

AD743–SPECIFICATIONS

(@ 25ⴗC and ⴞ15 V dc, unless otherwise noted)

Model Conditions Min Typ Max Min Typ Max Unit

AD743J AD743K

INPUT OFFSET VOLTAGE

1

Initial Offset 0.25 1.0/0.8 0.1 0.5/0.25 mV

Initial Offset T

vs. Temp. T

vs. Supply (PSRR) 12 V to 18 V

vs. Supply (PSRR) T

INPUT BIAS CURRENT

3

MIN

MIN

MIN

to T

to T

to T

MAX

MAX

MAX

2

90 96 100 106 dB

21µV/°C

88 98 100 dB

1.5 1.0/0.50 mV

Either Input VCM = 0 V 150 400 150 250 pA

Either Input

@ T

MAX

Either Input V

VCM = 0 V 8.8/25.6 5.5/16 nA

= 10 V 250 600 250 400 pA

CM

Either Input, VS = ±5 V VCM = 0 V 30 200 30 125 pA

INPUT OFFSET CURRENT VCM = 0 V 40 150 30 75 pA

Offset Curren

@ T

MAX

VCM = 0 V 2.2/6.4 1.1/3.2 nA

FREQUENCY RESPONSE

Gain BW, Small Signal G = –1 4.5 4.5 MHz

Full Power Response VO = 20 V p-p 25 25 kHz

Slew Rate, Unity Gain G = –1 2.8 2.8 V/µs

Settling Time to 0.01% 6 6 µs

Total Harmonic f = 1 kHz

Distortion4 (Figure 16) G = –1 0.0003 0.0003 %

INPUT IMPEDANCE

Differential 1 ⫻ 1010||20 1 ⫻ 1010||20 Ω||pF

Common Mode 3 ⫻ 1011||18 3 ⫻ 1011||18 Ω||pF

INPUT VOLTAGE RANGE

Differential

Common-Mode Voltage +13.3, –10.7 +13.3, –10.7 V

Over Max Operating Range

5

6

–10 +12 –10 +12 V

±20 ±20 V

Common-Mode

Rejection Ratio VCM = ±10 V 80 95 90 102 dB

T

MIN

to T

MAX

78 88 dB

INPUT VOLTAGE NOISE 0.1 Hz to 10 Hz 0.38 0.38 1.0 µV p-p

f = 10 Hz 5.5 5.5 10.0 nV/√Hz

f = 100 Hz 3.6 3.6 6.0 nV/√Hz

f = 1 kHz 3.2 5.0 3.2 5.0 nV/√Hz

f = 10 kHz 2.9 4.0 2.9 4.0 nV/√Hz

INPUT CURRENT NOISE f = 1 kHz 6.9 6.9 fA/√Hz

OPEN LOOP GAIN VO = ±10 V

R

≥ 2 kΩ 1000 4000 2000 4000 V/mV

LOAD

T

to T

MIN

R

MAX

= 600 Ω 1200 1200 V/mV

LOAD

800 1800 V/mV

OUTPUT CHARACTERISTICS

Voltage R

≥ 600 Ω +13, –12 +13, –12 V

LOAD

R

≥ 600 Ω +13.6, –12.6 +13.6, –12.6 V

LOAD

T

to T

MIN

R

MAX

≥ 2 kΩ±12 +13.8, –13.1 ±12 +13.8, –13.1 V

LOAD

+12, –10 +12, –10 V

Current Short Circuit 20 40 20 40 mA

POWER SUPPLY

Rated Performance ±15 ±15 V

Operating Range ±4.8 ±18 ±4.8 ±18 V

Quiescent Current 8.1 10.0 8.1 10.0 mA

TRANSISTOR COUNT # of Transistors 50 50

NOTES

1

Input offset voltage specifications are guaranteed after 5 minutes of operation at TA = 25°C.

2

Test conditions: +VS = 15 V, –VS = 12 V to 18 V and +VS = 12 V to 18 V, –VS = 15 V.

3

Bias current specifications are guaranteed maximum at either input after 5 minutes of operation at TA = 25°C. For higher temperature, the current doubles every 10°C.

4

Gain = –1, RL = 2 kΩ, CL = 10 pF.

5

Defined as voltage between inputs, such that neither exceeds ±10 V from common.

6

Thc AD743 does not exhibit an output phase reversal when the negative common-mode limit is exceeded.

All min and max specifications are guaranteed.

Specifications subject to change without notice.

–2–

REV. D

Page 3

AD743

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation

2

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± V

1

S

Output Short Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

and –V

S

S

Storage Temperature Range (N, R) . . . . . . . –65°C to +125°C

Operating Temperature Range

AD743J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

Lead Temperature Range (Soldering 60 seconds) . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; and functional operation of

the device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

8-pin plastic package: θJA = 100°C/Watt, θJC = 50°C/Watt

16-pin plastic SOIC package: θJA = 100°C/Watt, θJC = 30°C/Watt

ESD SUSCEPTIBILITY

An ESD classification per method 3015.6 of MIL-STD-883C

has been performed on the AD743. The AD743 is a class 1

device, passing at 1000 V and failing at 1500 V on null pins 1

and 5, when tested, using an IMCS 5000 automated ESD

tester. Pins other than null pins fail at greater than 2500 V.

ORDERING GUIDE

Package

Model Temperature Range Option

AD743JN 0°C to +70°C N-8

AD743KN

AD743JR-16 0°C to +70°C R-16

AD743KR-16

AD743SQ/883B

2

2

2

0°C to +70°C N-8

0°C to +70°C R-16

–55°C to +125°C Q-8

1

AD743JR-16-REEL 0°C to +70°C Tape & Reel

AD743KR-16-REEL20°C to +70°C Tape & Reel

1

N = Plastic DIP; R = Small Outline IC; Q = Cerdip.

2

Not for new design, obsolete april 2002

REV. D

–3–

Page 4

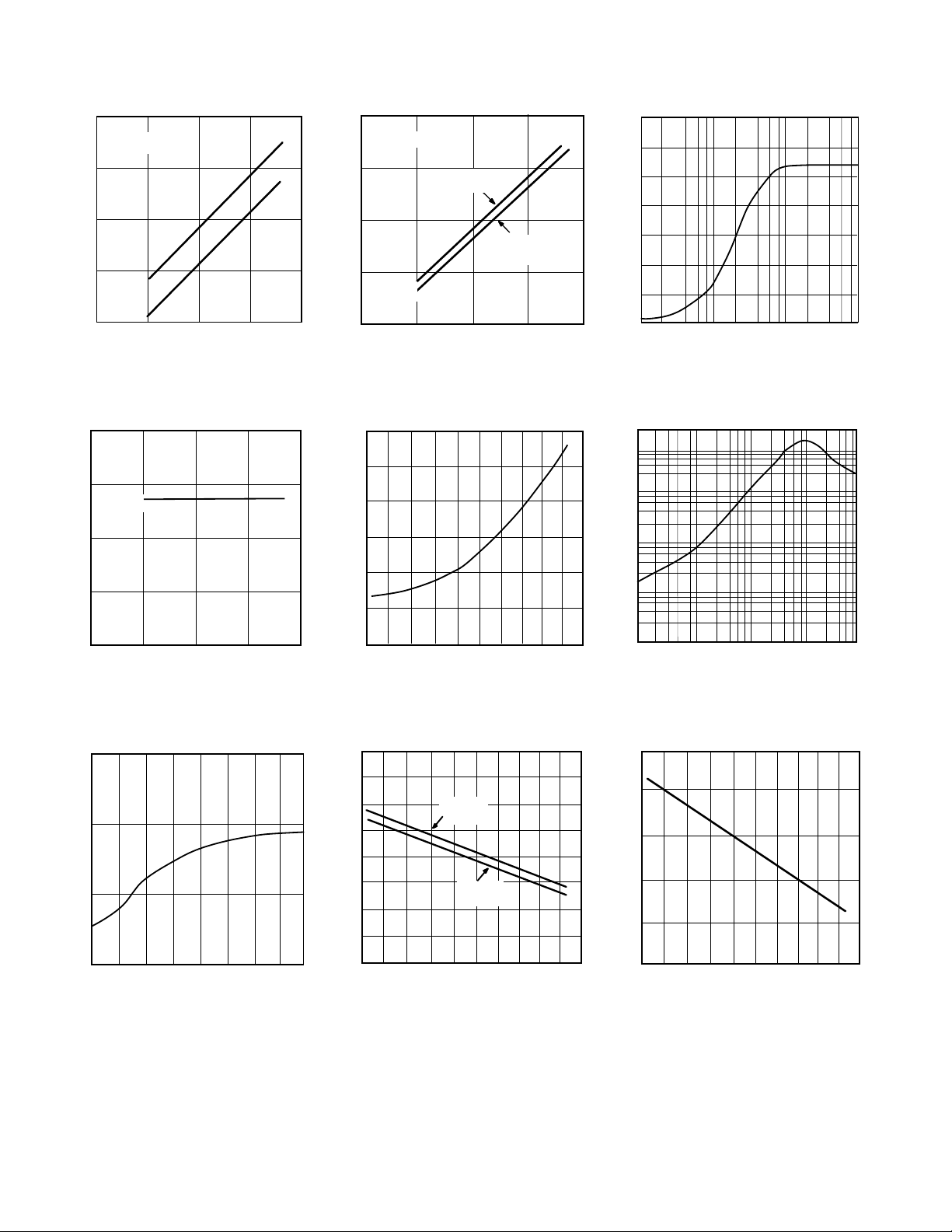

AD743

–60 –40 –20 0 20 40 60 80 100 120 140

3.0

4.0

5.0

6.0

7.0

2.0

TEMPERATURE – °C

GAIN BANDWIDTH PRODUCT

– MHz

–Typical Performance Characteristics

(@ 25ⴗC, VS = 15 V)

20

R = 10kΩ

LOAD

15

– Volts

10

5

INPUT VOLTAGE SWING

0

0

51015

SUPPLY VOLTAGE ± VOLTS

+V

IN

–V

IN

TPC 1. Input Voltage Swing

vs. Supply Voltage

12

9

– mA

6

QUIESCENT CURRENT

3

0

0510

SUPPLY VOLTAGE ± VOLTS

15 20

20

R = 10kΩ

LOAD

15

10

5

OUTPUT VOLTAGE SWING – Volts

0

20

0510

POSITIVE

SUPPLY

NEGATIVE

SUPPLY

SUPPLY VOLTAGE ± VOLTS

15

20

TPC 2. Output Voltage Swing vs.

Supply Voltage

–6

10

–7

10

–8

10

– Amps

–9

10

–10

10

INPUT BIAS CURRENT

–11

10

–12

10

–60 –40 –20

0

20 40 60 80 100

TEMPERATURE – °C

120

140

35

30

25

20

15

10

OUTPUT VOLTAGE SWING – Volts p-p

5

0

10

100

LOAD RESISTANCE – Ω

1k

TPC 3. Output Voltage Swing vs.

Load Resistance

200

100

10

1

OUTPUT IMPEDANCE – Ω

0.1

0.01

10k

100k 1M

FREQUENCY – Hz

10M

10k

100M

TPC 4. Quiescent Current vs.

Supply Voltage

300

200

100

INPUT BIAS CURRENT – pA

0

–9 –6 –3

COMMON MODE VOLTAGE – Volts

TPC 7. Input Bias Current vs.

Common-Mode Voltage

3

0–12 12

9

6

TPC 5. Input Bias Current vs.

Temperature

80

70

60

50

40

30

CURRENT LIMIT – mA

20

10

0

–40 –20 0 20 40 60 80 100 120 140

–60

+ OUTPUT

CURRENT

– OUTPUT

CURRENT

TEMPERATURE – °C

TPC 8. Short Circuit Current

Limit vs. Temperature

TPC 6. Output Impedance vs.

Frequency (Closed Loop Gain = –1)

TPC 9. Gain Bandwidth Product

vs. Temperature

REV. D–4–

Page 5

AD743

100

80

60

40

20

OPEN-LOOP GAIN – dB

0

–20

100 1k 10k 100k

FREQUENCY – Hz

PHASE

GAIN

1M 10M 100M

TPC 10. Open-Loop Gain and

Phase vs. Frequency

120

100

V = ±10V

80

60

40

COMMON-MODE REJECTION – dB

20

0

100 1k 10k 100k 1M

CM

FREQUENCY – Hz

TPC 13. Common-Mode Rejection

vs. Frequency

100

60

80

40

20

0

–20

3.5

3.0

2.5

SLEW RATE – Volts/µs

PHASE MARGIN – Degrees

2.0

–60 –40 –20 0

20

TEMPERATURE – °C

40

TPC 11. Slew Rate vs.

Temperature (Gain = –1)

120

100

+ SUPPLY

FREQUENCY – Hz

POWER SUPPLY REJECTION – dB

80

60

40

20

0

100

– SUPPLY

1k 10k 100k

TPC 14. Power Supply Rejection

vs. Frequency

60 80 100 120 140

1M 10M 100M

150

140

– dB

130

120

OPEN-LOOP GAIN

100

80

05

SUPPLY VOLTAGE ± VOLTS

10 15 20

TPC 12. Open-Loop Gain vs.

Supply Voltage, R

35

30

25

20

– Volts p-p

15

R = 2kΩ

L

10

OUTPUT VOLTAGE

5

0

1k 10k

FREQUENCY – Hz

LOAD

= 2K

100k

TPC 15. Large Signal Frequency

Response

1M

–70

–80

–90

–100

–110

THD – dB

–120

–130

–140

GAIN = +10

GAIN = –1

10

100

1k 10k

FREQUENCY – Hz

TPC 16. Total Harmonic Distortion

vs. Frequency

REV. D

100k

100

– nV Hz

10

1.0

0.1

NOISE VOLTAGE (REFERRED TO INPUT)

1

10

CLOSED-LOOP GAIN = 1

CLOSED-LOOP GAIN = 10

100

1k 10k 100k

FREQUENCY – Hz

TPC 17. Input Noise Voltage

Spectral Density

–5–

1k

– fA/ Hz

100

10

CURRENT NOISE SPECTRAL DENSITY

1.0

1

1M

10M

10

FREQUENCY – Hz

100

1k

10k 100k

TPC 18. Input Noise Current

Spectral Density

Page 6

AD743

NUMBER OF UNITS

69

63

57

51

45

39

33

27

21

15

9

3

2.5

2.7 2.9 3.1

INPUT VOLTAGE NOISE – nV

3.3

TPC 19. Typical Noise Distribution

@ 10 kHz (602 Units)

3.8

3.5

Hz

TPC 22b. Unity-Gain Follower

Small Signal Pulse Response

100pF

2kΩ

+V

V

IN

SQUARE WAVE

INPUT

2kΩ

2

3

S

7

AD743

4

–V

S

1µF

1µF

6

0.1µF

0.1µF

V

C

L

100pF

OUT

TPC 20. Offset Null Configuration

TPC 21. Unity-Gain Follower

TPC 23a. Unity-Gain Inverter

TPC 23b. Unity-Gain Inverter

Large Signal Pulse Response

TPC 22a. Unity-Gain Follower

Large Signal Pulse Response

TPC 23c. Unity-Gain Inverter

Small Signal Pulse Response

REV. D–6–

Page 7

AD743

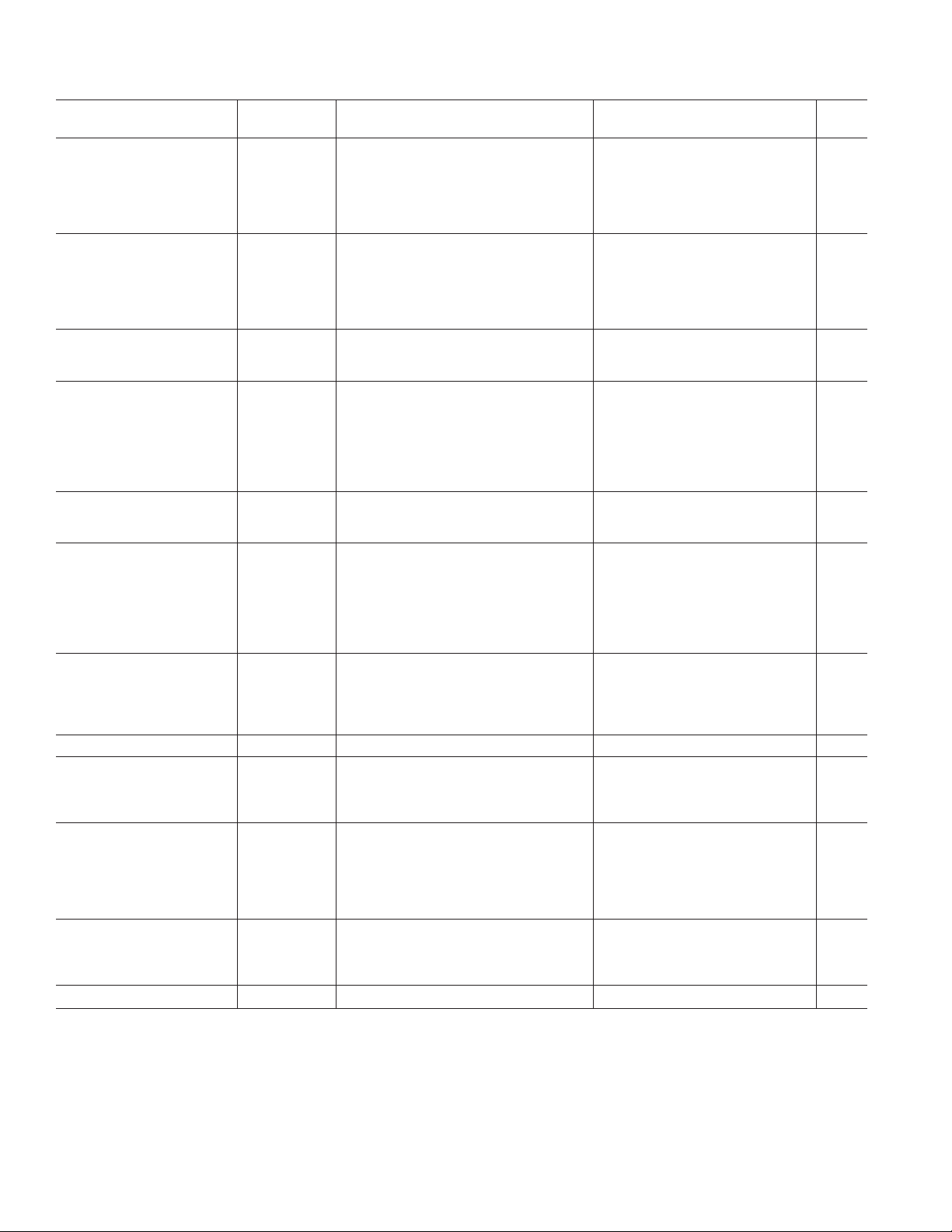

OP AMP PERFORMANCE: JFET VS. BIPOLAR

The AD743 is the first monolithic JFET op amp to offer the low

input voltage noise of an industry standard bipolar op amp

without its inherent input current errors. This is demonstrated

in Figure 1, which compares input voltage noise vs. input source

resistance of the OP27 and the AD743 op amps. From this

figure, it is clear that at high source impedance the low current

noise of the AD743 also provides lower total noise. It is also

important to note that with the AD743 this noise reduction

extends all the way down to low source impedances. The lower

dc current errors of the AD743 also reduce errors due to offset

and drift at high source impedances (Figure 2).

1000

R

SOURCE

100

– nV/ Hz

10

INPUT NOISE VOLTAGE

1

R

SOURCE

AD743 & RESISTOR

OR

OP27 & RESISTOR

RESISTOR NOISE ONLY

100

1k

SOURCE RESISTANCE – Ω

10k 100k

E

(– – –)

O

OP27 &

RESISTOR

( — )

AD743 + RESISTOR

)

(

1M

10M

Figure 1. Total Input Noise Spectral Density @ 1 kHz vs.

Source Resistance

100

ADOP27G

10

1.0

INPUT OFFSET VOLTAGE – mV

AD743 KN

0.1

100

1k 10k 100k

SOURCE RESISTANCE – Ω

1M 10M

Figure 2. Input Offset Voltage vs. Source Resistance

DESIGNING CIRCUITS FOR LOW NOISE

An op amp’s input voltage noise performance is typicaly divided

into two regions: flatband and low frequency noise. The AD743

offers excellent performance with respect to both. The figure of

2.9 nV/√Hz @ 10 kHz is excellent for JFET input amplifier.

The 0.1 Hz to 10 Hz noise is typically 0.38 µV p-p. The user

should pay careful attention to several design details in order to

optimize low frequency noise performance. Random air currents

can generate varying thermocouple voltages that appear as low

frequency noise: therefore sensitive circuitry should be well

shielded from air flow. Keeping absolute chip temperature low

also reduces low frequency noise in two ways: first, the low

frequency noise is strongly dependent on the ambient

temperature and increases above +25°C. Second, since the

gradient of temperature from the IC package to ambient is

greater, the noise generated by random air currents, as

previously mentioned, will be larger in magnitude. Chip

temperature can be reduced both by operation at reduced

supply voltages and by the use of a suitable clip-on heat sink, if

possible.

Low frequency current noise can be computed from the

magnitude of the dc bias current (~I

below approximately 100 Hz with a 1/f power spectral density.

n

=

2qIB∆f

) and increases

For the AD743 the typical value of current noise is 6.9 fA/√Hz

at 1 kHz. Using the formula, ~I

Johnson noise of a resistor, expressed as a current, one can see

that the current noise of the AD743 is equivalent to that of a

3.45 ⫻ 10

8

Ω source resistance.

n

=

4kT /R∆f ,

to compute the

At high frequencies, the current noise of a FET increases

proportionately to frequency. This noise is due to the “real” part

of the gate input impedance, which decreases with frequency.

This noise component usually is not important, since the voltage

noise of the amplifier impressed upon its input capacitance is an

apparent current noise of approximately the same magnitude.

In any FET input amplifier, the current noise of the internal

bias circuitry can be coupled externally via the gate-to-source

capacitances and appears as input current noise. This noise is

totally correlated at the inputs, so source impedance matching

will tend to cancel out its effect. Both input resistance and input

capacitance should be balanced whenever dealing with source

capacitances of less than 300 pF in value.

LOW NOISE CHARGE AMPLIFIERS

As stated, the AD743 provides both low voltage and low current

noise. This combination makes this device particularly suitable

in applications requiring very high charge sensitivity, such as

capacitive accelerometers and hydrophones. When dealing with

a high source capacitance, it is useful to consider the total input

charge uncertainty as a measure of system noise.

Charge (Q) is related to voltage and current by the simply stated

fundamental relationships:

Q = CV and I =

dQ

dt

As shown, voltage, current and charge noise can all be directly

related. The change in open circuit voltage (∆V) on a capacitor

will equal the combination of the change in charge (∆Q/C) and

the change in capacitance with a built in charge (Q/∆C).

REV. D

–7–

Page 8

AD743

Figures 3 and 4 show two ways to buffer and amplify the output

of a charge output transducer. Both require using an amplifier

which has a very high input impedance, such as the AD743.

Figure 3 shows a model of a charge amplifier circuit. Here,

amplification depends on the principle of conservation of charge

at the input of amplifier A1, which requires that the charge on

capacitor C

output voltage of ∆Q/C

appear at the output amplified by the noise gain (1 + (C

be transferred to capacitor CF, thus yielding an

S

. The amplifiers input voltage noise will

F

S/CF

))

of the circuit.

Figure 3. A Charge Amplifier Circuit

Figure 5 shows that these two circuits have an identical

frequency response and the same noise performance (provided

that C

“T” network is used to increase the effective resistance of R

= R1/ R2). One feature of the first circuit is that a

S/CF

B

and improve the low frequency cutoff point by the same factor.

–100

–110

–120

Hz

–130

–140

–150

–160

–170

–180

–190

DECIBELS REFERENCED TO 1V/

–200

–210

–220

10M

100M

1 10 100

FREQUENCY – Hz

1k

10k 100k

TOTAL OUTPUT

NOISE

NOISE DUE TO

R ALONE

B

NOISE DUE TO

I ALONE

B

Figure 5. Noise at the Outputs of the Circuits of Figures

3 and 4. Gain = 10, C

However, this does not change the noise contribution of R

= 3000 pF, RB = 22 M

S

Ω

B

which, in this example, dominates at low frequencies. The graph

of Figure 6 shows how to select an R

large enough to minimize

B

this resistor’s contribution to overall circuit noise. When the

equivalent current noise of R

(

), there is diminishing return in making RB larger.

2qI

B

10

5.2 x 10

((√4kT)/R) equals the noise of I

B

B

Figure 4. Model for a High Z Follower with Gain

The second circuit, Figure 4, is simply a high impedance

follower with gain. Here the noise gain (1 + (R1/R2)) is the

same as the gain from the transducer to the output. Resistor R

,

B

in both circuits, is required as a dc bias current return.

There are three important sources of noise in these circuits.

Amplifiers A1 and A2 contribute both voltage and current noise,

while resistor R

contributes a current noise of:

B

~

N =

T

4k

∆f

R

B

where:

k = Boltzman’s Constant = 1.381 x 10

–23

Joules/Kelvin

T = Absolute Temperature, Kelvin (0°C = 273.2 Kelvin)

∆

f = Bandwidth – in Hz (Assuming an Ideal “Brick Wall”

Filter)

This must be root-sum-squared with the amplifier’s own current

noise.

9

5.2 x 10

Ω

8

5.2 x 10

RESISTANCE IN

7

5.2 x 10

6

5.2 x 10

1pA 10pA

100pA 1nA

INPUT BIAS CURRENT

10nA

Figure 6. Graph of Resistance vs. Input Bias Current

√4kT/R

where the Equivalent Noise

of the Bias Current

2qI

B

, Equals the Noise

To maximize dc performance over temperature, the source

resistances should be balanced on each input of the amplifier.

This is represented by the optional resistor R

in Figures 3 and

B

4. As previously mentioned, for best noise performance care should

be taken to also balance the source capacitance designated by C

The value for C

At values of C

noise; capacitor C

in Figure 3 would be equal to CS, in Figure 4.

B

over 300 pF, there is a diminishing impact on

B

can then be simply a large bypass of 0.01 µF

B

.

B

or greater.

REV. D–8–

Page 9

AD743

HOW CHIP PACKAGE TYPE AND POWER DISSIPATION

AFFECT INPUT BIAS CURRENT

As with all JFET input amplifiers, the input bias current of the

AD743 is a direct function of device junction temperature, I

B

approximately doubling every 10°C. Figure 7 shows the

relationship between bias current and junction temperature for

the AD743. This graph shows that lowering the junction

temperature will dramatically improve I

–6

10

–7

10

10

10

–10

10

INPUT BIAS CURRENT – Amps

–11

10

–12

10

–8

–9

–60

–20 0

–40

JUNCTION TEMPERATURE – °C

V = ±15V

T = 25°C

20 40 60 80 100 120 140

.

B

S

+

A

Figure 7. Input Bias Current vs. Junction Temperature

The dc thermal properties of an IC can be closely approximated

by using the simple model of Figure 8 where current represents

power dissipation, voltage represents temperature, and resistors

represent thermal resistance (θ in °C/Watt).

T

θ

J

JC

θ

P

IN

WHERE:

P

= DEVICE DISSIPATION

IN

T

= AMBIENT TEMPERATURE

A

= JUNCTION TEMPERATURE

T

J

= THERMAL RESISTANCE – JUNCTION TO CASE

θ

JC

= THERMAL RESISTANCE – CASE TO AMBIENT

θ

CA

θ

CA

JA

T

A

Figure 8. A Device Thermal Model

From this model TJ = TA + θJA Pin. Therefore, IB can be

determined in a particular application by using Figure 7

together with the published data for θ

The user can modify θ

by use of an appropriate clip-on heat

JA

sink such as the Aavid #5801. θ

and power dissipation.

JA

is also a variable when using

JA

the AD743 in chip form. Figure 9 shows bias current vs. supply

voltage with θ

predict bias current after θ

as the third variable. This graph can be used to

JA

has been computed. Again bias

JA

current will double for every 10°C. The designer using the

AD743 in chip form (Figure 10) must also be concerned with

both θ

and θCA, since θJC can be affected by the type of die

JC

mount technology used.

Typically, θ

’s will be in the 3°C to 5°C/watt range; therefore,

JC

for normal packages, this small power dissipation level may be

ignored. But, with a large hybrid substrate, θ

proportionately more of the total θ

.

JA

will dominate

JC

300

= +25 C

T

A

200

θ

= 115 C/W

100

INPUT BIAS CURRENT – pA

0

51510

JA

SUPPLY VOLTAGE – Volts

θJA= 165 C/W

θ

JA

= 0 C/W

Figure 9. Input Bias Current vs. Supply Voltage for

Various Values of

θ

JA

Figure 10. A Breakdown of Various Package Thermal

Resistances

REDUCED POWER SUPPLY OPERATION FOR

LOWER I

B

Reduced power supply operation lowers IB in two ways: first, by

lowering both the total power dissipation and second, by

reducing the basic gate-to-junction leakage (Figure 32). Figure

34 shows a 40 dB gain piezoelectric transducer amplifier, which

operates without an ac coupling capacitor, over the –40°C to

+85°C temperature range. If the optional coupling capacitor is

used, this circuit will operate over the entire –55°C to +125°C

military temperature range.

Figure 11. A Piezoelectric Transducer

REV. D

–9–

Page 10

AD743

AN INPUT-IMPEDANCE-COMPENSATED, SALLEN-KEY FILTER

The simple high pass filter of Figure 12 has an important source

of error which is often overlooked. Even 5 pF of input capacitance

in amplifier “A” will contribute an additional 1% of passband

amplitude error, as well as distortion, proportional to the C/V

characteristics of the input junction capacitance. The addition

of the network designated “Z” will balance the source

impedance–as seen by “A”–and thus eliminate these errors.

Figure 12. An Input Impedance Compensated

Sallen-Key Filter

TWO HIGH PERFORMANCE ACCELEROMETER AMPLIFIERS

Two of the most popular charge-out transducers are hydrophones

and accelerometers. Precision accelerometers are typically

calibrated for a charge output (pC/g).* Figures 13a and 13b

show two ways in which to configure the AD743 as a low noise

charge amplifier for use with a wide variety of piezoelectric

accelerometers. The input sensitivity of these circuits will be

determined by the value of capacitor C1 and is equal to:

∆Q

∆V

OUT

The ratio of capacitor C1 to the internal capacitance (CT) of the

transducer determines the noise gain of this circuit (1 + C

The amplifiers voltage noise will appear at its output amplified

by this amount. The low frequency bandwidth of these circuits

will be dependent on the value of resistor R1. If a “T” network

is used, the effective value is: R1 (1 + R2/R3).

OUT

=

C1

/C1).

T

Figure 13b. An Accelerometer Circuit Employing a

DC Servo Amplifier

A dc servo-loop (Figure 13b) can be used to assure a dc output

which is <10 mV, without the need for a large compensating

resistor when dealing with bias currents as large as 100 nA. For

optimal low frequency performance, the time constant of the

servo loop (R4C2 = R5C3) should be:

Time Constant ≥ 10 R11+

A LOW NOISE HYDROPHONE AMPLIFIER

R2

R3

C1

Hydrophones are usually calibrated in the voltage-out mode.

The circuits of Figures 14a and 14b can be used to amplify the

output of a typical hydrophone. Figure 14a shows a typical dc

coupled circuit. The optional resistor and capacitor serve to

counteract the dc offset caused by bias currents flowing through

resistor R1. Figure 14b, a variation of the original circuit, has a

low frequency cutoff determined by an RC time constant equal

to:

Time Constant =

2π×C

1

×100Ω

C

*pC = Picocoulombs

Figure 13a. A Basic Accelerometer Circuit

g = Earth's Gravitational Constant

Figure 14a. A Basic Hydrophone Amplifier

REV. D–10–

Page 11

Figure 14b. An AC-Coupled, Low Noise

Hydrophone Amplifier

AD743

Where the dc gain is 1 and the gain above the low frequency

cutoff (1/(2πC

14a. The circuit of Figure 14c uses a dc servo loop to keep the

dc output at 0 V and to maintain full dynamic range for I

to 100 nA. The time constant of R7 and C2 should be larger

than that of R1 and C

The transducer shown has a source capacitance of 7500 pF. For

smaller transducer capacitances (≤300 pF), lowest noise can be

achieved by adding a parallel RC network (R4 = R1, C1 = C

in series with the inverting input of the AD743.

BALANCING SOURCE IMPEDANCES

As mentioned previously, it is good practice to balance the

source impedances (both resistive and reactive) as seen by the

inputs of the AD743. Balancing the resistive components will

optimize dc performance over temperature because balancing

will mitigate the effects of any bias current errors. Balancing

input capacitance will minimize ac response errors due to the

amplifier’s input capacitance and, as shown in Figure 15, noise

performance will be optimized. Figure 16 shows the required

external components for noninverting (A) and inverting (B)

configurations.

(100 Ω))) is the same as the circuit of Figure

C

’s up

B

for a smooth low frequency response.

T

)

T

Figure 14c. A Hydrophone Amplifier Incorporating a

DC Servo Loop

Figure 16. Optional External Components for Balancing Source Impedances

REV. D

Figure 15. RTI Voltage Noise vs. Input Capacitance

–11–

Page 12

AD743

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Pin Plastic Mini-DIP (N)

C00830-0-2/02(D)

16-Pin SOIC (R) Package

Revision History

Location Page

Data Sheet changed from REV. C to REV. D.

Edits to PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to CONNECTION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Deleted AD7435 column from SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted METALIZATION PHOTOGRAPH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to REDUCE POWER SUPPLY OPERATION FOR LOWER I

Deleted 8-Pin Cerdip (Q) package Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B

REV. D–12–

PRINTED IN U.S.A.

Loading...

Loading...