Page 1

Six-Input Channel

a

FEATURES

Six 16-Bit A/D Converters

Programmable Input Sample Rate

Simultaneous Sampling

76 dB SNR

64 kS/s Maximum Sample Rate

–95 dB Crosstalk

Low Group Delay (25 s Typ per ADC Channel)

Programmable Input Gain

Flexible Serial Port Which Allows Multiple Devices to

Be Connected in Cascade

Single (2.7 V to 3.6 V) Supply Operation

80 mW Max Power Consumption at 2.7 V

On-Chip Reference

28-Lead SOIC Package

APPLICATIONS

General-Purpose Analog Input

Industrial Power Metering

Motor Control

Simultaneous Sampling Applications

GENERAL DESCRIPTION

The AD73360L is a six-input channel analog front-end processor for general-purpose applications, including industrial power

Analog Front End

AD73360L

metering or multichannel analog inputs. It features six 16-bit

A/D conversion channels, each of which provides 76 dB signalto-noise ratio over a dc-to-4 kHz signal bandwidth. Each

channel also features a programmable input gain amplifier (PGA)

with gain settings in eight stages from 0 dB to 38 dB.

The AD73360L is particularly suitable for industrial power

metering as each channel samples synchronously, ensuring that

there is no (phase) delay between the conversions. The AD73360L

also features low group delay conversions on all channels.

An on-chip reference voltage is included with a nominal value

of 1.2 V.

The sampling rate of the device is programmable, with four

separate settings offering 64 kHz, 32 kHz, 16 kHz, and 8 kHz

sampling rates (from a master clock of 16.384 MHz).

A serial port (SPORT) allows easy interfacing of single or cascaded devices to industry-standard DSP engines. The SPORT

transfer rate is programmable to allow interfacing to both fast

and slow DSP engines.

The AD73360L is available in 28-lead SOIC package.

VINP1

VINN1

VINP2

VINN2

VINP3

VINN3

REFCAP

REFOUT

VINP4

VINN4

VINP5

VINN5

VINP6

VINN6

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

SIGNAL

CONDITIONING

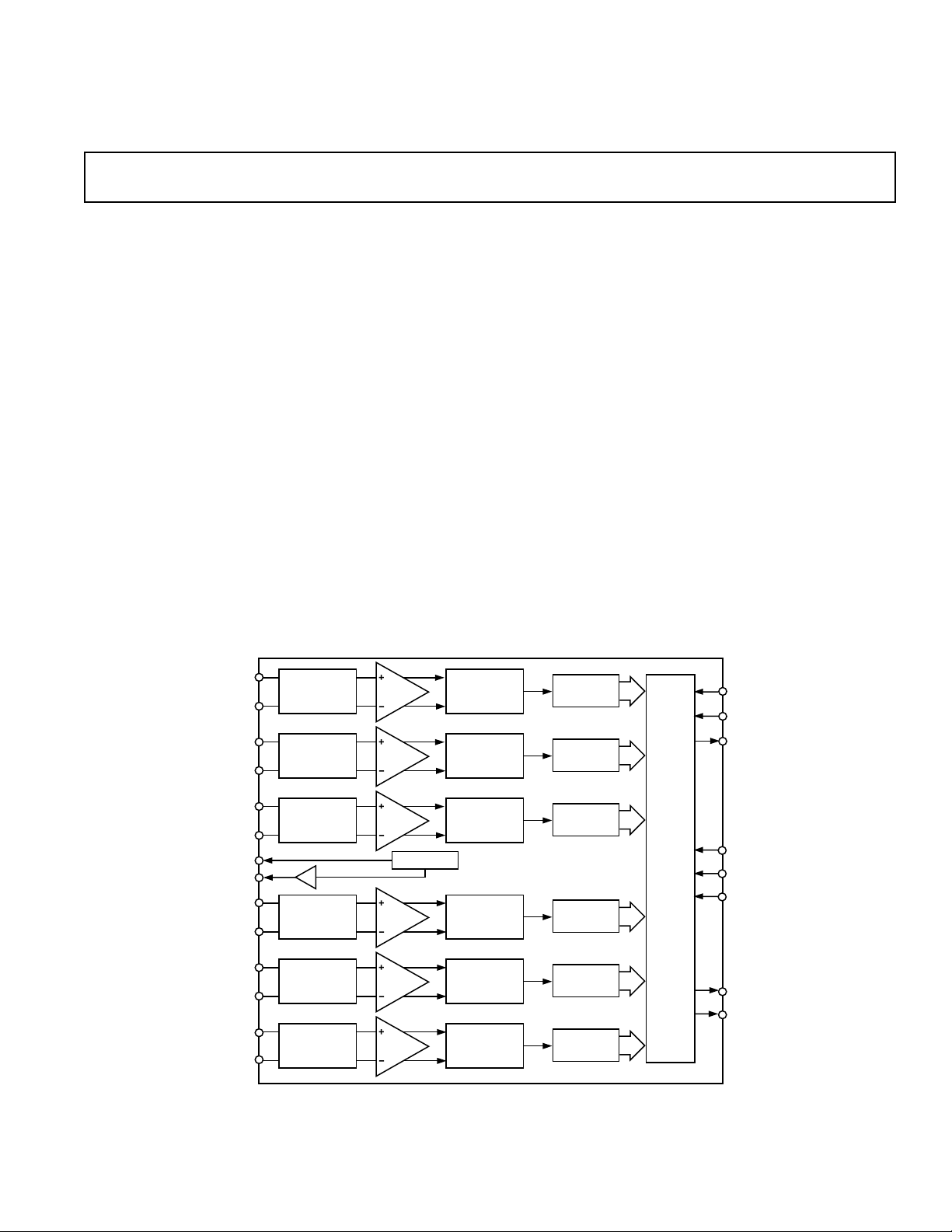

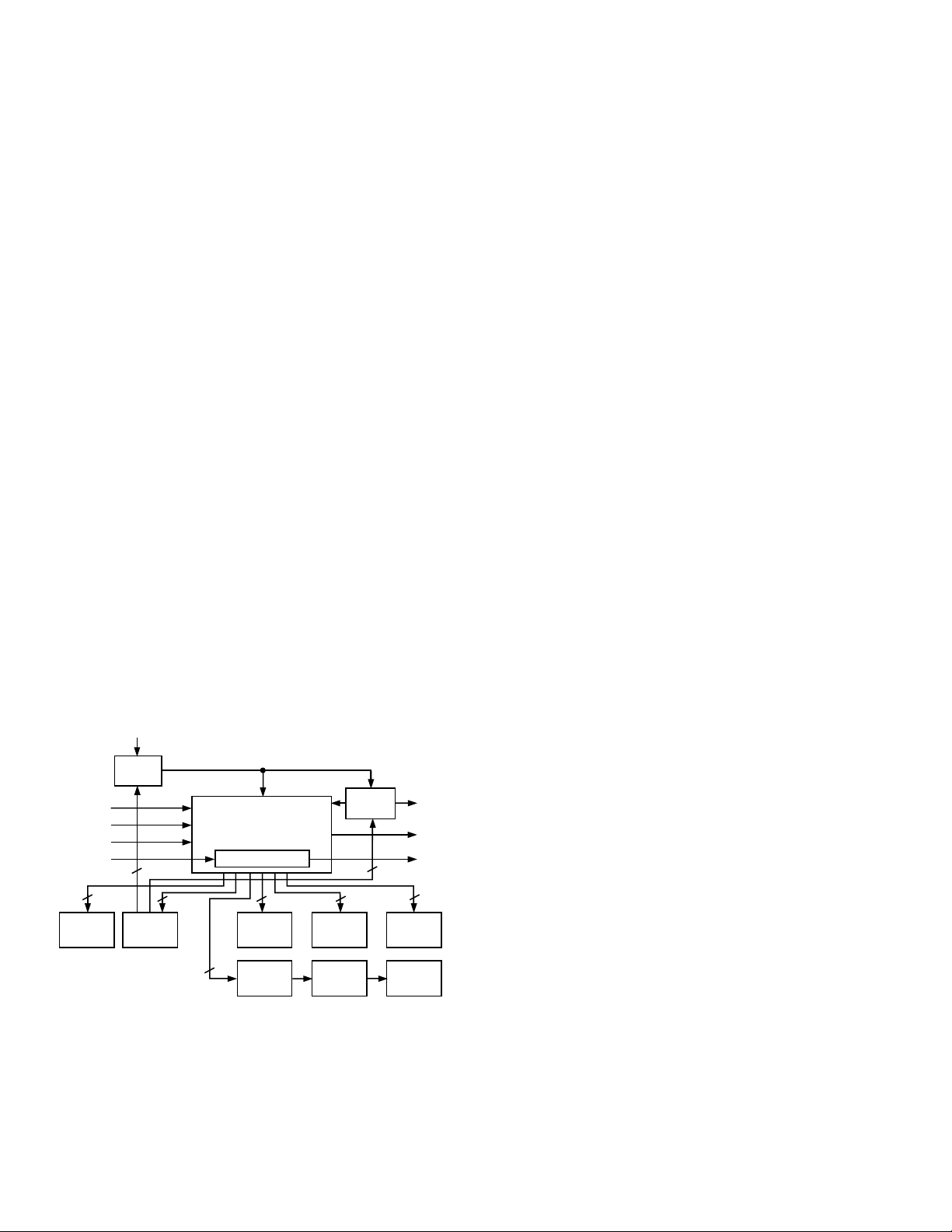

FUNCTIONAL BLOCK DIAGRAM

0/38dB

PGA

0/38dB

PGA

0/38dB

PGA

REFERENCE

0/38dB

PGA

0/38dB

PGA

0/38dB

PGA

ANALOG

⌺-⌬

MODULATOR

ANALOG

⌺-⌬

MODULATOR

ANALOG

⌺-⌬

MODULATOR

ANALOG

⌺-⌬

MODULATOR

ANALOG

⌺-⌬

MODULATOR

ANALOG

⌺-⌬

MODULATOR

DECIMATOR

DECIMATOR

DECIMATOR

AD73360L

DECIMATOR

DECIMATOR

DECIMATOR

SERIAL

I/O

PORT

SDI

SDIFS

SCLK

RESET

MCLK

SE

SDO

SDOFS

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

AD73360L–SPECIFICATIONS

(AVDD = 2.7 V to 3.6 V; DVDD = 2.7 V to 3.6 V; DGND = AGND = 0 V, f

1

f

= 8.192 MHz, fS = 8 kHz; TA = T

SCLK

MIN

to T

, unless otherwise noted.)

MAX

= 16.384 MHz,

MCLK

AD73360LA

Parameter Min Typ Max Unit Test Conditions/Comments

REFERENCE

REFCAP

Absolute Voltage, V

REFCAP

1.08 1.2 1.32 V

REFCAP TC 50 ppm/°C 0.1 µF Capacitor Required from REFCAP

to AGND2

REFOUT

Typical Output Impedance 130 Ω

Absolute Voltage, V

REFOUT

1.08 1.2 1.32 V Unloaded

Minimum Load Resistance 1 kΩ

Maximum Load Capacitance 100 pF

ADC SPECIFICATIONS

Maximum Input Range at VIN

2, 3

1.578 V p-p Measured Differentially

–2.85 dBm

Nominal Reference Level at VIN 1.0954 V p-p Measured Differentially

(0 dBm0) –6.02 dBm

Absolute Gain

PGA = 0 dB –1.3 +0.6 dB 1.0 kHz

PGA = 38 dB 0.6 dB 1.0 kHz

Signal to (Noise + Distortion)

PGA = 0 dB 76 dB 0 Hz to 4 kHz; f

PGA = 0 dB 71 76 dB 0 Hz to 2 kHz; f

PGA = 38 dB 58 dB 0 Hz to 4 kHz; f

= 8 kHz

S

= 8 kHz; f

S

= 64 kHz

S

= 60 Hz

IN

Total Harmonic Distortion

PGA = 0 dB –80 –71 dB 0 Hz to 2 kHz; f

PGA = 38 dB –64 dB 0 Hz to 2 kHz; f

= 8 kHz; f

S

= 64 kHz; f

S

= 60 Hz

IN

= 60 Hz

IN

Intermodulation Distortion –78 dB PGA = 0 dB

Idle Channel Noise –68 dB PGA = 0 dB, f

= 64 kHz; S

S

= 16 MHz

CLK

Crosstalk ADC-to-ADC –95 dB ADC1 at Idle

ADC2 to ADC6 Input Signal: 60 Hz

DC Offset –30 +30 mV PGA = 0 dB

Power Supply Rejection –55 dB Input Signal Level at AVDD and DVDD

Pins 1.0 kHz, 100 mV p-p Sine Wave

Group Delay

4, 5

25 µs 64 kHz Output Sample Rate

50 µs 32 kHz Output Sample Rate

95 µs 16 kHz Output Sample Rate

Input Resistance at VIN

2, 4

Phase Mismatch 0.15 Degrees f

190 µs 8 kHz Output Sample Rate

25 kΩ

6

DMCLK = 16.384 MHz

= 1 kHz

IN

0.01 Degrees fIN = 60 Hz

FREQUENCY RESPONSE

(ADC)7 Typical Output

Frequency (Normalized to f

)

S

00dB

0.03125 –0.1 dB

0.0625 –0.25 dB

0.125 –0.6 dB

0.1875 –1.4 dB

0.25 –2.8 dB

0.3125 –4.5 dB

0.375 –7.0 dB

0.4375 –9.5 dB

> 0.5 < –12.5 dB

LOGIC INPUTS

V

, Input High Voltage VDD – 0.8 V

INH

, Input Low Voltage 0 0.8 V

V

INL

I

, Input Current 10 µA

IH

DD

V

CIN, Input Capacitance 10 pF

–2–

REV. 0

Page 3

AD73360L

AD73360LA

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC OUTPUT

VOH, Output High Voltage VDD – 0.4 V

V

, Output Low Voltage 0 0.4 V |IOUT| ≤ 100 µA

OL

DD

Three-State Leakage Current –10 +10 µA

POWER SUPPLIES

AVDD1, AVDD2 2.7 3.6 V

DVDD 2.7 3.6 V

8

I

DD

NOTES

1

Operating temperature range is as follows: –40°C to +85°C. Therefore, T

2

Test conditions: Input PGA set for 0 dB gain (unless otherwise noted).

3

At input to sigma-delta modulator of ADC.

4

Guaranteed by design.

5

Overall group delay will be affected by the sample rate and the external digital filtering.

6

The ADC’s input impedance is inversely proportional to DMCLK and is approximated by: (4 × 1011)/DMCLK.

7

Frequency response of ADC measured with input at audio reference level (the input level that produces an output level of –10 dBm0), with 38 dB preamplifier

bypassed and input gain of 0 dB.

8

Test Conditions: no load on digital inputs, analog inputs ac-coupled to ground.

Specifications subject to change without notice.

= –40°C and T

MIN

Table I. Current Summary (AVDD = DVDD = 3.3 V)

Total

Current MCLK

Conditions (Max) SE ON Comments

ADCs Only On 25 1 Yes REFOUT Disabled

REFCAP Only On 1.0 0 No REFOUT Disabled

REFCAP and REFOUT Only On 3.5 0 No

All Sections On 26.5 1 Yes REFOUT Enabled

All Sections Off 1.0 0 Yes MCLK Active Levels Equal to 0 V and DVDD

All Sections Off 0.05 0 No Digital Inputs Static and Equal to 0 V or DVDD

The above values are in mA and are typical values unless otherwise noted. MCLK = 16.384 MHz; SCLK = 16.384 MHz.

V |IOUT| ≤ 100 µA

See Table I

= +85°C.

MAX

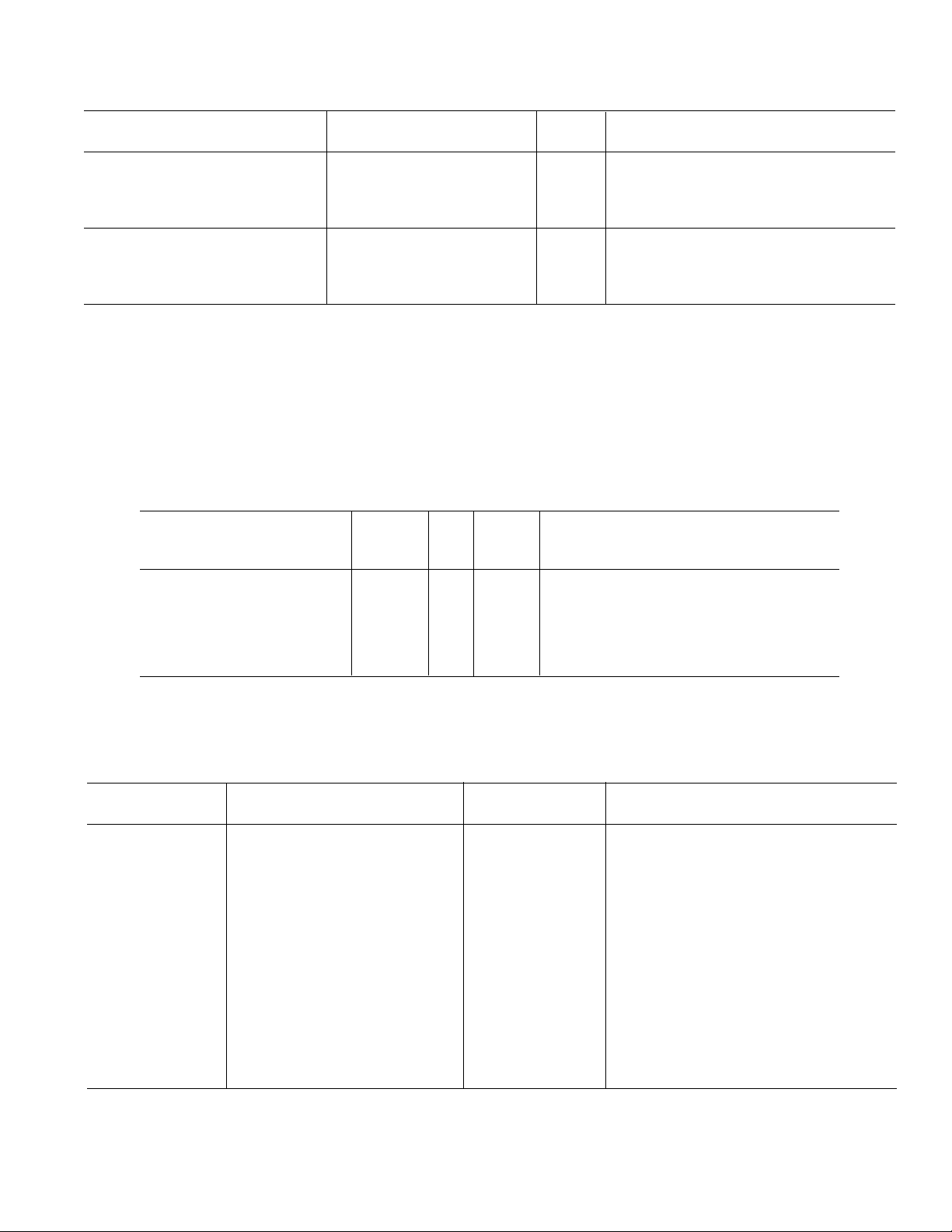

TIMING CHARACTERISTICS

(AVDD = 2.7 V to 3.6 V; DVDD = 2.7 V to 3.6 V; AGND = DGND = 0 V; TA = T

wise noted.)

MlN

Limit at

Parameter TA = –40ⴗC to +85ⴗC Unit Description

Clock Signals See Figure 1.

t

1

t

2

t

3

61 ns min MCLK Period

24.4 ns min MCLK Width High

24.4 ns min MCLK Width Low

Serial Port See Figures 3 and 4.

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

REV. 0

t

1

0.4 × t

1

0.4 × t

1

20 ns min SDI/SDIFS Setup before SCLK Low

0 ns min SDI/SDIFS Hold after SCLK Low

10 ns max SDOFS Delay from SCLK High

10 ns max SDOFS Hold after SCLK High

10 ns max SDO Hold after SCLK High

10 ns max SDO Delay from SCLK High

30 ns max SCLK Delay from MCLK

ns min SCLK Period

ns min SCLK Width High

ns min SCLK Width Low

–3–

to T

MAX

, unless other-

Page 4

AD73360L

t

t

2

Figure 1. MCLK Timing

TO OUTPUT

PIN

C

15pF

Figure 2. Load Circuit for Timing Specifications

1

t

3

100A

L

100A

I

OL

I

OH

2.1V

80

70

60

50

40

30

S/(N+D) – dB

20

10

0

–10

–85 5–75 –65 –55 –45 –35 –25 –15 –5

VIN – dBm0

3.17

Figure 5. S/(N+D) vs. VIN (ADC @ 3 V) Over Voiceband

Bandwidth (300 Hz–3.4 kHz)

MCLK

SCLK*

SE (I)

SCLK (O)

SDIFS (I)

SDI (I)

SDOFS (O)

SDO (O)

t

1

t

13

* SCLK IS INDIVIDUALLY PROGRAMMABLE

IN FREQUENCY (MCLK/4 SHOWN HERE).

t

2

t

5

t

4

Figure 3. SCLK Timing

THREESTATE

t

THREESTATE

THREESTATE

9

t

3

t

6

t

7

t

8

t

10

t

t

12

11

D15 D2 D1 D0 D14

t

8

t

7

D0

D15D1D14D15

D15

Figure 4. Serial Port (SPORT)

–4–

REV. 0

Page 5

AD73360L

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C unless otherwise noted)

AVDD, DVDD to GND . . . . . . . . . . . . . . . . –0.3 V to +4.6 V

AGND to DGND . . . . . . . . . . . . . . . . . . . . . –0.3 V to +0.3 V

Digital I/O Voltage to DGND . . . . . –0.3 V to DVDD + 0.3 V

Analog I/O Voltage to AGND . . . . . . . . . . . . –0.3 V to AVDD

Operating Temperature Range

Industrial (A Version) . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 150°C

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD73360LAR –40°C to +85°C Small Outline IC (SOIC) R-28

PIN CONFIGURATION

1

VINP2

2

VINN2

3

VINP1

4

VINN1

5

REOUT

AVDD2

AGND2

DGND

DVDD

RESET

SCLK

MCLK

SDO

6

AD73360L

7

TOP VIEW

(Not to Scale)

8

9

10

11

12

13

14

REFCAP

SOIC, θJA Thermal Impedance . . . . . . . . . . . . . . . . . . 75°C/W

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

R-28

28

VINN3

27

VINP3

VINN4

26

25

VINP4

24

VINN5

VINP5

23

VINN6

22

VINP6

21

AVDD1

20

AGND1

19

18

SE

17

SDI

16

SDIFS

15

SDOFS

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD73360L features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. 0

–5–

Page 6

AD73360L

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1 VINP2 Analog Input to the Positive Terminal of Input Channel 2.

2 VINN2 Analog Input to the Negative Terminal of Input Channel 2.

3 VINP1 Analog Input to the Positive Terminal of Input Channel 1.

4 VINN1 Analog Input to the Negative Terminal of Input Channel 1.

5 REFOUT Buffered Output of the Internal Reference, which has a nominal value of 1.2 V.

6 REFCAP Reference Voltage for ADCs. A Bypass Capacitor to AGND2 of 0.1 µF is required for the on-chip

reference. The capacitor should be fixed to this pin. The internal reference can be overdriven by an

external reference connected to this pin if required.

7 AVDD2 Analog Power Supply Connection.

8 AGND2 Analog Ground/Substrate Connection.

9 DGND Digital Ground/Substrate Connection.

10 DVDD Digital Power Supply Connection.

11 RESET Active Low-Reset Signal. This input resets the entire chip, resetting the control registers and clearing

the digital circuitry.

12 SCLK Output Serial Clock, whose rate determines the serial transfer rate to/from the AD73360L. It is used

to clock data or control information to and from the serial port (SPORT). The frequency of SCLK is

equal to the frequency of the master clock (MCLK) divided by an integer number—this integer num-

ber being the product of the external master clock rate divider and the serial clock rate divider.

13 MCLK Master Clock Input. MCLK is driven from an external clock signal.

14 SDO Serial Data Output of the AD73360L. Both data and control information may be output on this

pin and are clocked on the positive edge of SCLK. SDO is in three-state when no information is being

transmitted and when SE is low.

15 SDOFS Framing Signal Output for SDO Serial Transfers. The frame sync is one bit wide and it is active one

SCLK period before the first bit (MSB) of each output word. SDOFS is referenced to the positive

edge of SCLK. SDOFS is in three-state when SE is low.

16 SDIFS Framing Signal Input for SDI Serial Transfers. The frame sync is one-bit wide and it is valid one

SCLK period before the first bit (MSB) of each input word. SDIFS is sampled on the negative edge of

SCLK and is ignored when SE is low.

17 SDI Serial Data Input of the AD73360L. Both data and control information may be input on this pin and

are clocked on the negative edge of SCLK. SDI is ignored when SE is low.

18 SE SPORT Enable. Asynchronous input enable pin for the SPORT. When SE is set low by the DSP, the

output pins of the SPORT are three-stated and the input pins are ignored. SCLK is also disabled inter-

nally in order to decrease power dissipation. When SE is brought high, the control and data registers of

the SPORT are at their original values (before SE was brought low); however, the timing counters and

other internal registers are at their reset values.

19 AGND1 Analog Ground Connection.

20 AVDD1 Analog Power Supply Connection.

21 VINP6 Analog Input to the Positive Terminal of Input Channel 6.

22 VINN6 Analog Input to the Negative Terminal of Input Channel 6.

23 VINP5 Analog Input to the Positive Terminal of Input Channel 5.

24 VINN5 Analog Input to the Negative Terminal of Input Channel 5.

25 VINP4 Analog Input to the Positive Terminal of Input Channel 4.

26 VINN4 Analog Input to the Negative Terminal of Input Channel 4.

27 VINP3 Analog Input to the Positive Terminal of Input Channel 3.

28 VINN3 Analog Input to the Negative Terminal of Input Channel 3.

–6–

REV. 0

Page 7

AD73360L

TERMINOLOGY

Absolute Gain

Absolute gain is a measure of converter gain for a known signal.

Absolute gain is measured (differentially) with a 1 kHz sine

wave at 0 dBm0 for each ADC. The absolute gain specification

is used for gain tracking error specification.

Crosstalk

Crosstalk is due to coupling of signals from a given channel to

an adjacent channel. It is defined as the ratio of the amplitude of

the coupled signal to the amplitude of the input signal. Crosstalk

is expressed in dB.

Gain Tracking Error

Gain tracking error measures changes in converter output for

different signal levels relative to an absolute signal level. The

absolute signal level is 0 dBm0 (equal to absolute gain) at 1 kHz

for each ADC. Gain tracking error at 0 dBm0 (ADC) is 0 dB by

definition.

Group Delay

Group delay is defined as the derivative of radian phase with

respect to radian frequency, dø(f)/df. Group delay is a measure

of average delay of a system as a function of frequency. A linear

system with a constant group delay has a linear phase response.

The deviation of group delay from a constant indicates the

degree of nonlinear phase response of the system.

Idle Channel Noise

Idle channel noise is defined as the total signal energy measured

at the output of the device when the input is grounded (measured in the frequency range 0 Hz–4 kHz).

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb, any active device with nonlinearities will create distortion

products at sum and difference frequencies of mfa ± nfb where

m, n = 0, 1, 2, 3, etc. Intermodulation terms are those for which

neither m nor n are equal to zero. For final testing, the second

order terms include (fa + fb) and (fa – fb), while the third order

terms include (2fa + fb), (2fa – fb), (fa + 2fb) and (fa – 2fb).

Power Supply Rejection

Power supply rejection measures the susceptibility of a device to

noise on the power supply. Power supply rejection is measured

by modulating the power supply with a sine wave and measuring

the noise at the output (relative to 0 dB).

Sample Rate

The sample rate is the rate at which each ADC updates its output

register. It is set relative to the DMCLK and the programmable

sample rate setting.

SNR + THD

Signal-to-noise ratio plus harmonic distortion is defined to be

the ratio of the rms value of the measured input signal to the

rms sum of all other spectral components in a given frequency

range, including harmonics but excluding dc.

ABBREVIATIONS

ADC Analog-to-Digital Converter.

BW Bandwidth.

CRx A Control Register where x is a placeholder for

an alphabetic character (A–E). There are eight

read/write control registers on the AD73360L—

designated CRA through CRE.

CRx:n A bit position, where n is a placeholder for a

numeric character (0–7), within a control register; where x is a placeholder for an alphabetic

character (A–E). Position 7 represents the MSB

and Position 0 represents the LSB.

DMCLK Device (Internal) Master Clock. This is the

internal master clock resulting from the external

master clock (MCLK) being divided by the onchip master clock divider.

FSLB Frame Sync Loop-Back—where the SDOFS of

the final device in a cascade is connected to the

RFS and TFS of the DSP and the SDIFS of first

device in the cascade. Data input and output

occur simultaneously. In the case of non-FSLB,

SDOFS and SDO are connected to the Rx Port

of the DSP while SDIFS and SDI are connected

to the Tx Port.

PGA Programmable Gain Amplifier.

SC Switched Capacitor.

SNR Signal-to-Noise Ratio.

SPORT Serial Port.

THD Total Harmonic Distortion.

VBW Voice Bandwidth.

REV. 0

–7–

Page 8

AD73360L

FUNCTIONAL DESCRIPTION

General Description

The AD73360L is a six-input channel, 16-bit, analog front end.

It comprises six independent encoder channels each featuring

signal conditioning, programmable gain amplifier, sigma-delta

A/D converter and decimator sections. Each of these sections is

described in further detail below.

Encoder Channel

Each encoder channel consists of a signal conditioner, a switched

capacitor PGA, and a sigma-delta analog-to-digital converter

(ADC). An on-board digital filter, which forms part of the

sigma-delta ADC, also performs critical system-level filtering.

Due to the high-level of oversampling, the input antialias requirements are reduced such that a simple single pole RC stage is

sufficient to give adequate attenuation in the band of interest.

Signal Conditioner

Each analog channel has an independent signal conditioning

block. This allows the analog input to be configured by the user

depending on whether differential or single-ended mode is used.

Programmable Gain Amplifier

Each encoder section’s analog front end comprises a switched

capacitor PGA that also forms part of the sigma-delta modulator. The SC sampling frequency is DMCLK/8. The PGA,

whose programmable gain settings are shown in Table II, may

be used to increase the signal level applied to the ADC from

low-output sources such as microphones, and can be used to

avoid placing external amplifiers in the circuit. The input signal

level to the sigma-delta modulator should not exceed the maximum input voltage permitted.

The PGA gain is set by bits IGS0, IGS1, and IGS2 in control

Registers D, E, and F.

Table II. PGA Settings for the Encoder Channel

IxGS2 IxGS1 IxGS0 Gain (dB)

000 0

001 6

010 12

011 18

100 20

101 26

110 32

111 38

ADC

Each channel has its own ADC consisting of an analog sigmadelta modulator and a digital antialiasing decimation filter. The

sigma-delta modulator noise-shapes the signal and produces

1-bit samples at a DMCLK/8 rate. This bitstream, representing

the analog input signal, is input to the antialiasing decimation

filter. The decimation filter reduces the sample rate and increases

the resolution.

Analog Sigma-Delta Modulator

The AD73360L input channels employ a sigma-delta conversion technique, which provides a high resolution 16-bit output

with system filtering being implemented on-chip.

Sigma-delta converters employ a technique known as oversampling, where the sampling rate is many times the highest

frequency of interest. In the case of the AD73360L, the initial

sampling rate of the sigma-delta modulator is DMCLK/8. The

main effect of oversampling is that the quantization noise is

spread over a very wide bandwidth, up to f

/2 = DMCLK/16

S

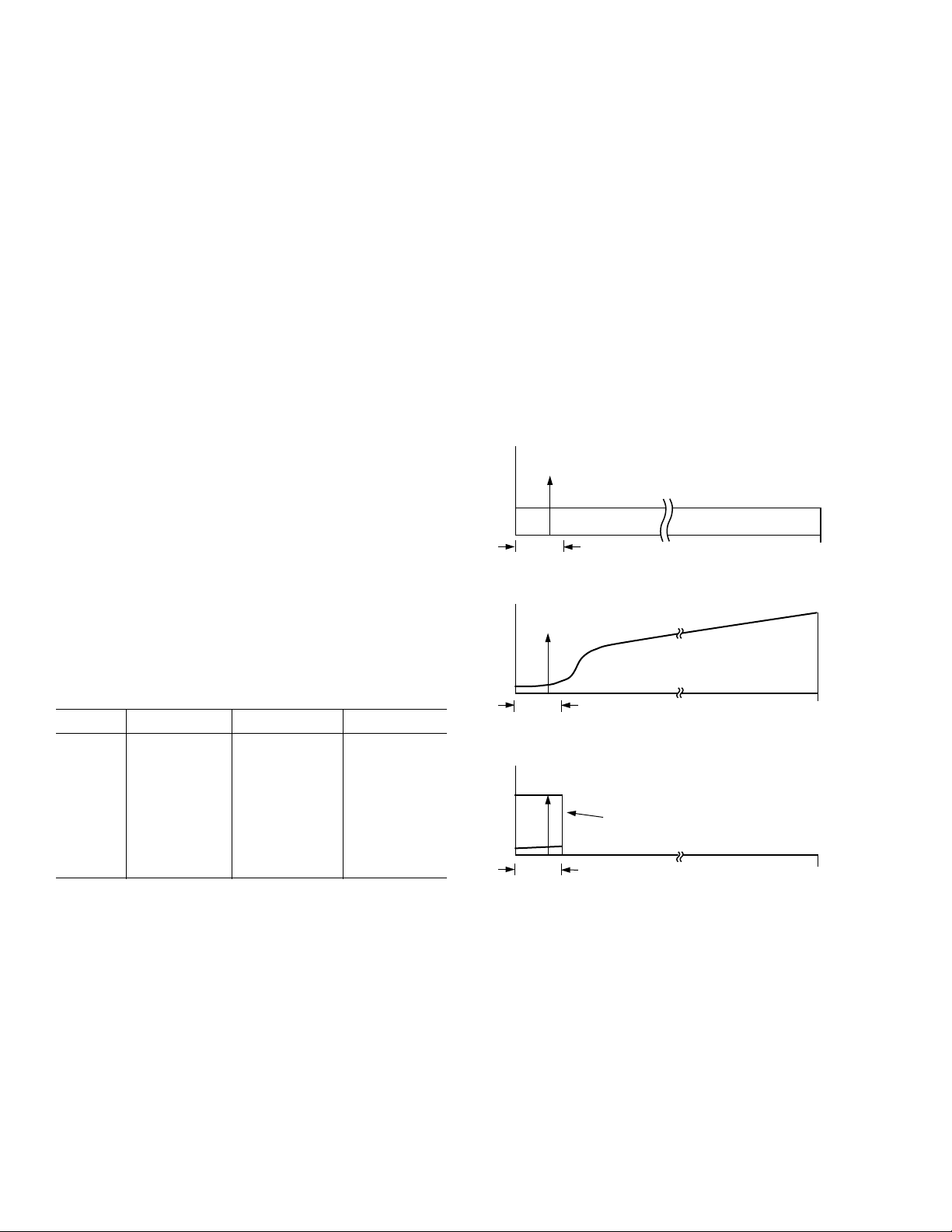

(Figure 6a). This means that the noise in the band of interest is

much reduced. Another complementary feature of sigma-delta

converters is the use of a technique called noise-shaping. This

technique has the effect of pushing the noise from the band of

interest to an out-of-band position (Figure 6b). The combination of these techniques, followed by the application of a digital

filter, reduces the noise in band sufficiently to ensure good

dynamic performance from the part (Figure 6c).

BAND

OF

INTEREST

BAND

OF

INTEREST

a.

NOISE-SHAPING

f

/2

S

DMCLK/16

fS/2

DMCLK/16

b.

DIGITAL FILTER

BAND

OF

INTEREST

c.

/2

f

S

DMCLK/16

Figure 6. Sigma-Delta Noise Reduction

–8–

REV. 0

Page 9

AD73360L

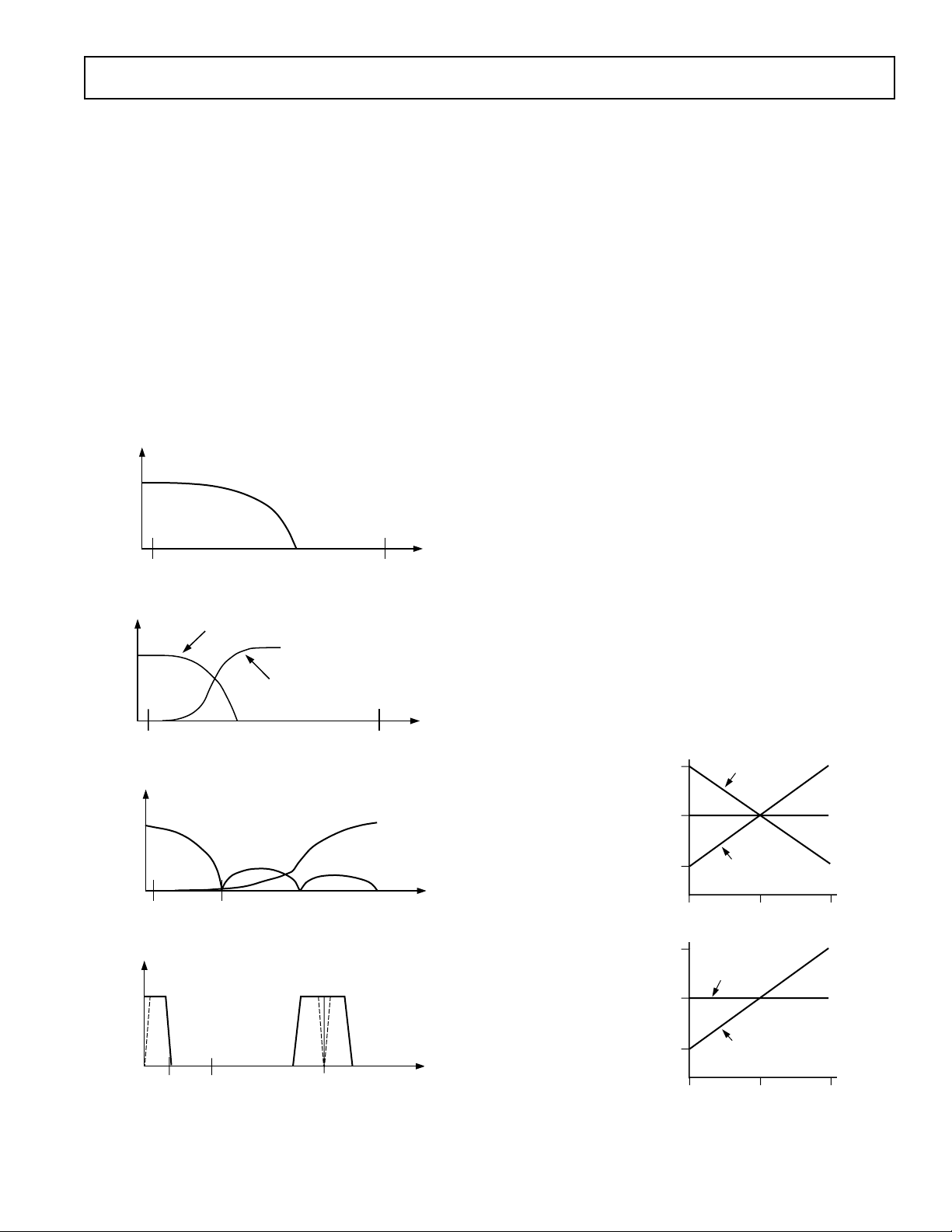

Figure 7 shows the various stages of filtering that are employed

in a typical AD73360L application. In Figure 7a we see the transfer function of the external analog antialias filter. Even though it

is a single RC pole, its cutoff frequency is sufficiently far away

from the initial sampling frequency (DMCLK/8) that it takes care

of any signals that could be aliased by the sampling frequency.

This also shows the major difference between the initial oversampling rate and the bandwidth of interest. In Figure 7b, the signal

and noise-shaping responses of the sigma-delta modulator are

shown. The signal response provides further rejection of any

high-frequency signals while the noise-shaping will push the

inherent quantization noise to an out-of-band position. The detail

of Figure 7c shows the response of the digital decimation filter

(sinc-cubed response) with nulls every multiple of DMCLK/

256, which is the decimation filter update rate. The final detail

in Figure 7d shows the application of a final antialias filter in the

DSP engine. This has the advantage of being implemented according to the user’s requirements and available MIPS. The filtering in

Figures 7a through 7c is implemented in the AD73360L.

= DMCLK/8

FB = 4kHz

F

SINIT

a. Analog Antialias Filter Transfer Function

SIGNAL TRANSFER FUNCTION

NOISE TRANSFER FUNCTION

FB = 4kHz

F

SINIT

= DMCLK/8

b. Analog Sigma-Delta Modulator Transfer Function

Decimation Filter

The digital filter used in the AD73360L carries out two important functions. Firstly, it removes the out-of-band quantization

noise, which is shaped by the analog modulator and secondly, it

decimates the high-frequency bitstream to a lower rate 15-bit word.

The antialiasing decimation filter is a sinc-cubed digital filter

that reduces the sampling rate from DMCLK/8 to DMCLK/

256, and increases the resolution from a single bit to 15 bits. Its

Z transform is given as: [(1–Z

–32

)/(1–Z–1)]3. This ensures a mini-

mal group delay of 25 µs.

Word growth in the decimator is determined by the sampling

rate. At 64 kHz sampling, where the oversampling ratio between

the sigma-delta modulator and decimator output equals 32,

there are five bits per stage of the three-stage Sinc

3

filter. Due to

symmetry within the sigma-delta modulator, the LSB will always

be a zero; therefore, the 16-bit ADC output word will have

2 LSBs equal to zero, one due to the sigma-delta symmetry and

the other being a padded zero to make up a 16-bit word. At

lower sampling rates, decimator word growth will be greater

than the 16-bit sample word, therefore truncation occurs in transferring the decimator output as the ADC word. For example

at 8 kHz sampling, word growth reaches 24 bits due to the OSR

of 256 between sigma-delta modulator and decimator. This yields

eight bits per stage of the three stage Sinc

3

filter.

ADC Coding

The ADC coding scheme is in two’s complement format (see

Figure 8). The output words are formed by the decimation

filter, which grows the word length from the single-bit output of

the sigma-delta modulator to a 15-bit word, which is the final

output of the ADC block. In 16-bit Data Mode this value is left

shifted with the LSB being set to 0. For input values equal to or

greater than positive full scale, however, the output word is set

at 0x7FFF, which has the LSB set to 1. In mixed Control/Data

Mode, the resolution is fixed at 15 bits, with the MSB of the

16-bit transfer being used as a flag bit to indicate either control

or data in the frame.

V

+ (V

REF

ⴛ 0.32875)

REF

V

INN

REV. 0

F

F

= 4kHz

SINTER

= DMCLK/256

c. Digital Decimator Transfer Function

FB = 4kHz F

SFINAL

= 8kHz

SINTER

= DMCLK/256F

d. Final Filter LPF (HPF) Transfer Function

Figure 7. DC Frequency Responses

–9–

ANALOG

INPUT

ANALOG

INPUT

V

– (V

REF

V

+ (V

REF

V

– (V

REF

ⴛ 0.32875)

REF

ⴛ 0.6575)

REF

ⴛ 0.6575)

REF

V

REF

10...00

ADC CODE DIFFERENTIAL

V

10...00 00...00

ADC CODE SINGLE-ENDED

Figure 8. ADC Transfer Function

V

INP

00...00

INN

V

INP

01...11

01...11

Page 10

AD73360L

Voltage Reference

The AD73360L reference, REFCAP, is a bandgap reference

that provides a low noise, temperature-compensated reference

to the ADC. A buffered version of the reference is also made

available on the REFOUT pin and can be used to bias other

external analog circuitry. The reference has a default nominal

value of 1.2 V.

The reference output (REFOUT) can be enabled for biasing

external circuitry by setting the RU bit (CRC:6) of CRC.

Serial Port (SPORT)

The AD73360Ls communicate with a host processor via the

bidirectional synchronous serial port (SPORT) which is compatible with most modern DSPs. The SPORT is used to transmit

and receive digital data and control information. Two AD73360Ls

can be cascaded together to provide additional input channels.

In both transmit and receive modes, data is transferred at the

serial clock (SCLK) rate with the MSB being transferred first.

Due to the fact that the SPORT of each AD73360L block uses

a common serial register for serial input and output, communications between an AD73360L and a host processor (DSP

engine) must always be initiated by the AD73360Ls themselves.

In this configuration the AD73360Ls are described as being in

Master mode. This ensures that there is no collision between

input data and output samples.

SPORT Overview

The AD73360L SPORT is a flexible, full-duplex, synchronous

serial port whose protocol has been designed to allow up to

eight AD73360L devices to be connected in cascade, to a single

DSP via a six-wire interface. It has a very flexible architecture

that can be configured by programming two of the internal

control registers in each device. The AD73360L SPORT has

three distinct modes of operation: Control Mode, Data Mode

and Mixed Control/Data Mode.

MCLK

DMCLK

(INTERNAL)

SERIAL PORT

(SPORT)

3

88

B

SERIAL REGISTER

CONTROL

REGISTER

CONTROL

8

REGISTER

C

F

DIVIDER

8

CONTROL

REGISTER

D

CONTROL

REGISTER

G

SCLK

SCLK

SDOFS

SDO

2

CONTROL

REGISTER

CONTROL

REGISTER

8

E

H

SE

RESET

SDIFS

SDI

8

CONTROL

REGISTER

A

MCLK

DIVIDER

CONTROL

REGISTER

Figure 9. SPORT Block Diagram

Note: As each AD73360L has its own SPORT section, the

register settings in all SPORTs must be programmed. The registers that control SPORT and sample rate operation (CRA and

CRB) must be programmed with the same values, otherwise

incorrect operation may occur.

In Program Mode (CRA:0 = 0), the device’s internal configuration can be programmed by writing to the eight internal control

registers. In this mode, control information can be written to or

read from the AD73360L. In Data Mode (CRA:0 = 1), any information that is sent to the device is ignored, while the encoder

section (ADC) data is read from the device. In this mode, only

ADC data is read from the device. Mixed mode (CRA:0 = 1 and

CRA:1 = 1) allows the user to send control information and

receive either control information or ADC data. This is achieved

by using the MSB of the 16-bit frame as a flag bit. Mixed mode

reduces the resolution to 15 bits with the MSB being used to

indicate whether the information in the 16-bit frame is control

information or ADC data.

The SPORT features a single 16-bit serial register that is used for

both input and output data transfers. As the input and output

data must share the same register, some precautions must be

observed. The primary precaution is that no information must be

written to the SPORT without reference to an output sample

event, which is when the serial register will be overwritten with

the latest ADC sample word. Once the SPORT starts to output

the latest ADC word, it is safe for the DSP to write new control

words to the AD73360L. In certain configurations, data can be

written to the device to coincide with the output sample being

shifted out of the serial register—see section on interfacing

devices. The serial clock rate (CRB:2–3) defines how many 16-bit

words can be written to a device before the next output sample

event will happen.

The SPORT block diagram, shown in Figure 9, details the blocks

associated with AD73360L including the eight control registers

(A–H), external MCLK to internal DMCLK divider and serial

clock divider. The divider rates are controlled by the setting of

Control Register B. The AD73360L features a master clock

divider that allows users the flexibility of dividing externally

available high-frequency DSP or CPU clocks to generate a lower

frequency master clock internally in the AD73360L which may be

more suitable for either serial transfer or sampling rate requirements. The master clock divider has five divider options (÷1

default condition, ÷ 2, ÷ 3, ÷4, ÷ 5) that are set by loading the

master clock divider field in Register B with the appropriate

code (see Table XIII). Once the internal device master clock

(DMCLK) has been set using the master clock divider, the sample

rate and serial clock settings are derived from DMCLK.

The SPORT can work at four different serial clock (SCLK) rates:

chosen from DMCLK, DMCLK/2, DMCLK/4 or DMCLK/8,

where DMCLK is the internal or device master clock resulting

from the external or pin master clock being divided by the master

clock divider. Care should be taken when selecting Master Clock,

Serial Clock, and Sample Rate divider settings to ensure that

there is sufficient time to read all the data from the AD73360L

before the next sample interval.

–10–

REV. 0

Page 11

AD73360L

Table III. Control Register Map

Address (Binary) Name Description Type Width Reset Setting (Hex)

000 CRA Control Register A R/W 8 0x00

001 CRB Control Register B R/W 8 0x00

010 CRC Control Register C R/W 8 0x00

011 CRD Control Register D R/W 8 0x00

100 CRE Control Register E R/W 8 0x00

101 CRF Control Register F R/W 8 0x00

110 CRG Control Register G R/W 8 0x00

111 CRH Control Register H R/W 8 0x00

Table IV. Control Word Description

1514131211109876543210

C/D R/W

Control Frame Description

Bit 15 Control/Data When set high, it signifies a control word in Program or Mixed Program/Data Modes. When set

Bit 14 Read/Write When set low, it tells the device that the data field is to be written to the register selected by the

Bits 13–11 Device Address This 3-bit field holds the address information. Only when this field is zero is a device selected. If

Bits 10–8 Register Address This 3-bit field is used to select one of the eight control registers on the AD73360L.

Bits 7–0 Register Data This 8-bit field holds the data that is to be written to the selected register provided the device

DEVICE ADDRESSS REGISTER ADDRESS REGISTER DATA

low, it signifies an invalid control word in Program Mode.

register field setting provided the address field is zero. When set high, it tells the device that the

selected register is to be written to the data field in the serial register and that the new control

word is to be output from the device via the serial output.

the address is not zero, it is decremented and the control word is passed out of the device via the

serial output.

address field is zero.

CONTROL REGISTER A

REV. 0

Table V. Control Register A Description

7 654321 0

RESET DC2 DC1 DC0 SLB RES MM

DATA/PGM

Bit Name Description

0 DATA/PGM Operating Mode (0 = Program; 1 = Data Mode)

1 MM Mixed Mode (0 = OFF; 1 = Enabled)

2 Reserved Must Be Programmed to Zero (0)

3 SLB SPORT Loop-Back Mode (0 = OFF; 1 = Enabled)

4 DC0 Device Count (Bit 0)

5 DC1 Device Count (Bit 1)

6 DC2 Device Count (Bit 2)

7 RESET Software Reset (0 = OFF; 1 = Initiates Reset)

–11–

Page 12

AD73360L

Table VI. Control Register B Description

CONTROL REGISTER B

CONTROL REGISTER C

76543210

C E E MCD2 MCD1 MCD0 SCD1 SCD0 DR1 DR0

Bit Name Description

0 DR0 Decimation Rate (Bit 0)

1 DR1 Decimation Rate (Bit 1)

2 SCD0 Serial Clock Divider (Bit 0)

3 SCD1 Serial Clock Divider (Bit 1)

4 MCD0 Master Clock Divider (Bit 0)

5 MCD1 Master Clock Divider (Bit 1)

6 MCD2 Master Clock Divider (Bit 2)

7 CEE Control Echo Enable (0 = OFF; 1 = Enabled)

Table VII. Control Register C Description

76543210

RES RU PUREF RES RES RES RES GPU

Bit Name Description

0 GPU Global Power-Up Device (0 = Power Down; 1 = Power Up)

1 Reserved Must Be Programmed to Zero (0)

2 Reserved Must Be Programmed to Zero (0)

3 Reserved Must Be Programmed to Zero (0)

4 Reserved Must Be Programmed to Zero (0)

5 PUREF REF Power (0 = Power Down; 1 = Power Up)

6 RU REFOUT Use (0 = Disable REFOUT; 1 = Enable REFOUT)

7 Reserved Must Be Programmed to Zero (0)

CONTROL REGISTER D

Table VIII. Control Register D Description

76543210

PUI2 I2GS2 I2GS1 I2GS0 PUI1 I1GS2 I1GS1 I1GS0

Bit Name Description

0 I1GS0 ADC1:Input Gain Select (Bit 0)

1 I1GS1 ADC1:Input Gain Select (Bit 1)

2 I1GS2 ADC1:Input Gain Select (Bit 2)

3 PUI1 Power Control (ADC1); 1 = ON, 0 = OFF

4 I2GS0 ADC2:Input Gain Select (Bit 0)

5 I2GS1 ADC2:Input Gain Select (Bit 1)

6 I2GS2 ADC2:Input Gain Select (Bit 2)

7 PUI2 Power Control (ADC2); 1 = ON, 0 = OFF

–12–

REV. 0

Page 13

Table IX. Control Register E Description

AD73360L

CONTROL REGISTER E

CONTROL REGISTER F

76543210

PUI4 I4GS2 I4GS1 I4GS0 PUI3 I3GS2 I3GS1 I3GS0

Bit Name Description

0 I3GS0 ADC3:Input Gain Select (Bit 0)

1 I3GS1 ADC3:Input Gain Select (Bit 1)

2 I3GS2 ADC3:Input Gain Select (Bit 2)

3 PUI3 Power Control (ADC3); 1 = ON, 0 = OFF

4 I4GS0 ADC4:Input Gain Select (Bit 0)

5 I4GS1 ADC4:Input Gain Select (Bit 1)

6 I4GS2 ADC4:Input Gain Select (Bit 2)

7 PUI4 Power Control (ADC4); 1 = ON, 0 = OFF

Table X. Control Register F Description

76543210

PUI6 I6GS2 I6GS1 I6GS0 PUI5 I5GS2 I5GS1 I5GS0

Bit Name Description

0 I5GS0 ADC5:Input Gain Select (Bit 0)

1 I5GS1 ADC5:Input Gain Select (Bit 1)

2 I5GS2 ADC5:Input Gain Select (Bit 2)

3 PUI5 Power Control (ADC5); 1 = ON, 0 = OFF

4 I6GS0 ADC6:Input Gain Select (Bit 0)

5 I6GS1 ADC6:Input Gain Select (Bit 1)

6 I6GS2 ADC6:Input Gain Select (Bit 2)

7 PUI6 Power Control (ADC6); 1 = ON, 0 = OFF

CONTROL REGISTER G

Table XI. Control Register G Description

76543210

SEEN RMOD CH6 CH5 CH4 CH3 CH2 CH1

Bit Name Description

0 CH1 Channel 1 Select

1 CH2 Channel 2 Select

2 CH3 Channel 3 Select

3 CH4 Channel 4 Select

4 CH5 Channel 5 Select

5 CH6 Channel 6 Select

6 RMOD Reset Analog Modulator

7 SEEN Enable Single-Ended Input Mode

REV. 0

–13–

Page 14

AD73360L

Table XII. Control Register H Description

CONTROL REGISTER H

REGISTER BIT DESCRIPTIONS

Control Register A

CRA:0 Data/Program Mode. This bit controls the operating mode of the AD73360L. If CRA:1 is 0, a 0 in this bit places the

part in Program Mode. If CRA:1 is 0, a 1 in this bit places the part in Data Mode.

CRA:1 Mixed Mode. If this bit is a 0, the operating mode is determined by CRA:0. If this bit is a 1, the part operates in

Mixed Mode.

CRA:2 Reserved. This bit is reserved and should be programmed to 0 to ensure correct operation.

CRA:3 SPORT Loop Back. This is a diagnostic mode. This bit should be set to 0 to ensure correct operation.

CRA:4–6 Device Count Bits. These bits tell the AD73360L how many devices are used in a cascade. Both devices in the

cascade should be programmed to the same value ensure correct operation. See Table XVI.

CRA:7 Reset. Writing a 1 to this bit will initiate a software reset of the AD73360L.

Control Register B

CRB:0–1 Decimation Rate. These bits are used to set the decimation of the AD73360L. See Table XV.

CRB:2–3 Serial Clock Divider. These bits are used to set the serial clock frequency. See Table XIV.

CRB:4–6 Master Clock Divider. These bits are used to set the Master Clock Divider ratio. See Table XIII.

CRB:7 Control Echo Enable. Setting this bit to a 1 will cause the AD73360L to write out any control words it receives.

This is used as a diagnostic mode. This bit should be set to 0 for correct operation in Mixed Mode or Data Mode.

Control Register C

CRC:0 Global Power-Up. Writing a 1 to this bit will cause all six channels of the AD73360L to power up, regardless of

the status of the Power Control Bits in CRD-CRF. If fewer than six channels are required, this bit should be set to

0 and the Power Control Bits of the relevant channels should be set to 1.

CRC:1–4 Reserved. These bits are reserved and should be programmed to 0 to ensure correct operation.

CRC:5 Power-Up Reference. This bit controls the state of the on-chip reference. A 1 in this bit will power up the refer-

ence. A 0 in this bit will power down the reference. Note that the reference is automatically powered up if any

channel is enabled.

CRC:6 Reference Output. When this bit is set to 1, the REFOUT pin is enabled.

CRC:7 Reserved. This bit is reserved and should be programmed to 0 to ensure correct operation.

Control Register D

CRD:0–2 Input Gain Selection. These bits select the input gain for ADC1. See Table II.

CRD:3 Power Control for ADC1. A 1 in this bit powers up ADC1.

CRD:4–6 Input Gain Selection. These bits select the input gain for ADC2. See Table II.

CRD:7 Power Control for ADC2. A 1 in this bit powers up ADC2.

Control Register E

CRE:0–2 Input Gain Selection. These bits select the input gain for ADC3. See Table II.

CRE:3 Power Control for ADC3. A 1 in this bit powers up ADC3.

CRE:4–6 Input Gain Selection. These bits select the input gain for ADC4. See Table II.

CRE:7 Power Control for ADC4. A 1 in this bit powers up ADC4.

76543210

INV TME CH6 CH5 CH4 CH3 CH2 CH1

Bit Name Description

0 CH1 Channel 1 Select

1 CH2 Channel 2 Select

2 CH3 Channel 3 Select

3 CH4 Channel 4 Select

4 CH5 Channel 5 Select

5 CH6 Channel 6 Select

6 TME Test Mode Enable

7 INV Enable Invert Channel Mode

–14–

REV. 0

Page 15

AD73360L

Control Register F

CRF:0–2 Input Gain Selection. These bits select the input gain for ADC5. See Table II.

CRF:3 Power Control for ADC5. A 1 in this bit powers up ADC5.

CRF:4–6 Input Gain Selection. These bits select the input gain for ADC6. See Table II.

CRF:7 Power Control for ADC6. A 1 in this bit powers up ADC6.

Control Register G

CRG:0–5 Channel Select. These bits are used in association with CRG:6 and CRG:7. If the Reset Analog Modulator bit

(CRG:6) is 1, a 1 in a Channel Select bit location will reset the Analog Modulator for that channel. If the SingleEnded Enable Mode bit (CRG:7) is 1, a 1 in a Channel Select bit location will put that channel into Single-Ended

Mode. If any channel has its Channel Select bit set to 0, the channel will be set for Differentially-Ended Mode and

will not have its analog modulator reset regardless of the state of CRG:6 and CRG:7.

CRG:6 Reset Analog Modulator. Setting this bit to a 1 will reset the Analog Modulators for any channel whose Channel

Select bit (CRG:0–5) is set to 1. This bit should be set to 0 for normal operation.

CRG:7 Single-Ended Enable Mode. Setting this bit to a 1 will enable Single-Ended Mode on any channel whose Channel

Select bit (CRG:0–5) is set to 1. Setting this bit to 0 will select Differentially-Ended Input Mode for all channels.

Control Register H

CRH:0–5 Invert Select. These bits are used in association with CRH:7. If the Enable Invert Channel Mode bit (CRH:7) is 1,

a 1 in a Channel Select bit location will put that channel into Inverted Mode. If any channel has its Channel Select

bit set to 0, the channel will not be inverted regardless of the state CRH:7.

CRH:6 Test Mode Enable. This bit should be set to 0 to ensure normal operation.

CRH:7 Enable Invert Channel Mode. Setting this bit to a 1 will enable invert any channel whose Channel Select bit

(CRH:0–5) is set to 1. Setting this bit to 0 will select Noninverted (Normal) Mode for all channels.

SPORT Register Maps

There are eight control registers for the AD73360L, each eight

bits wide. Table III shows the control register map for the

AD73360L. The first two control registers, CRA and CRB, are

reserved for controlling the SPORT. They hold settings for

parameters such as bit rate, internal master clock rate, and device

count. If two AD73360Ls are cascaded, Registers CRA and

CRB on each device must be programmed with the same setting

to ensure correct operation (this is shown in the programming

examples). The other six registers; CRC through CRH are

used to hold control settings for the Reference, Power Control,

ADC channel, and PGA sections of the device. It is not necessary

that the contents of CRC through CRH on each AD73360L

are similar. Control registers are written to on the negative

edge of SCLK.

Master Clock Divider

The AD73360L features a programmable master clock divider

that allows the user to reduce an externally available master

clock, at pin MCLK, by one of the ratios 1, 2, 3, 4, or 5 to

produce an internal master clock signal (DMCLK) that is used

to calculate the sampling and serial clock rates. The master

clock divider is programmable by setting CRB:4-6. Table XIII

shows the division ratio corresponding to the various bit settings. The default divider ratio is divide-by-one.

Table XIII. DMCLK (Internal) Rate Divider Settings

MCD2 MCD1 MCD0 DMCLK Rate

0 0 0 MCLK

0 0 1 MCLK/2

0 1 0 MCLK/3

0 1 1 MCLK/4

1 0 0 MCLK/5

1 0 1 MCLK

1 1 0 MCLK

1 1 1 MCLK

Serial Clock Rate Divider

The AD73360L features a programmable serial clock divider

that allows users to match the serial clock (SCLK) rate of the

data to that of the DSP engine or host processor. The maximum

SCLK rate available is DMCLK and the other available rates

are: DMCLK/2, DMCLK/4, and DMCLK/8. The slowest rate

(DMCLK/8) is the default SCLK rate. The serial clock divider

is programmable by setting bits CRB:2–3. Table XIV shows the

serial clock rate corresponding to the various bit settings.

Table XIV. SCLK Rate Divider Settings

SCD1 SCD0 SCLK Rate

0 0 DMCLK/8

0 1 DMCLK/4

1 0 DMCLK/2

1 1 DMCLK

REV. 0

–15–

Page 16

AD73360L

Decimation Rate Divider

The AD73360L features a programmable decimation rate divider

that allows users flexibility in matching the AD73360L’s ADC

sample rates to the needs of the DSP software. The maximum

sample rate available is DMCLK/256 and the other available

rates are: DMCLK/512, DMCLK/1024, and DMCLK/2048. The

slowest rate (DMCLK/2048) is the default sample rate. The

sample rate divider is programmable by setting bits CRB:0-1.

Table XV shows the sample rate corresponding to the various

bit settings.

Table XV. Decimation Rate Divider Settings

DR1 DR0 Sample Rate

0 0 DMCLK/2048

0 1 DMCLK/1024

1 0 DMCLK/512

1 1 DMCLK/256

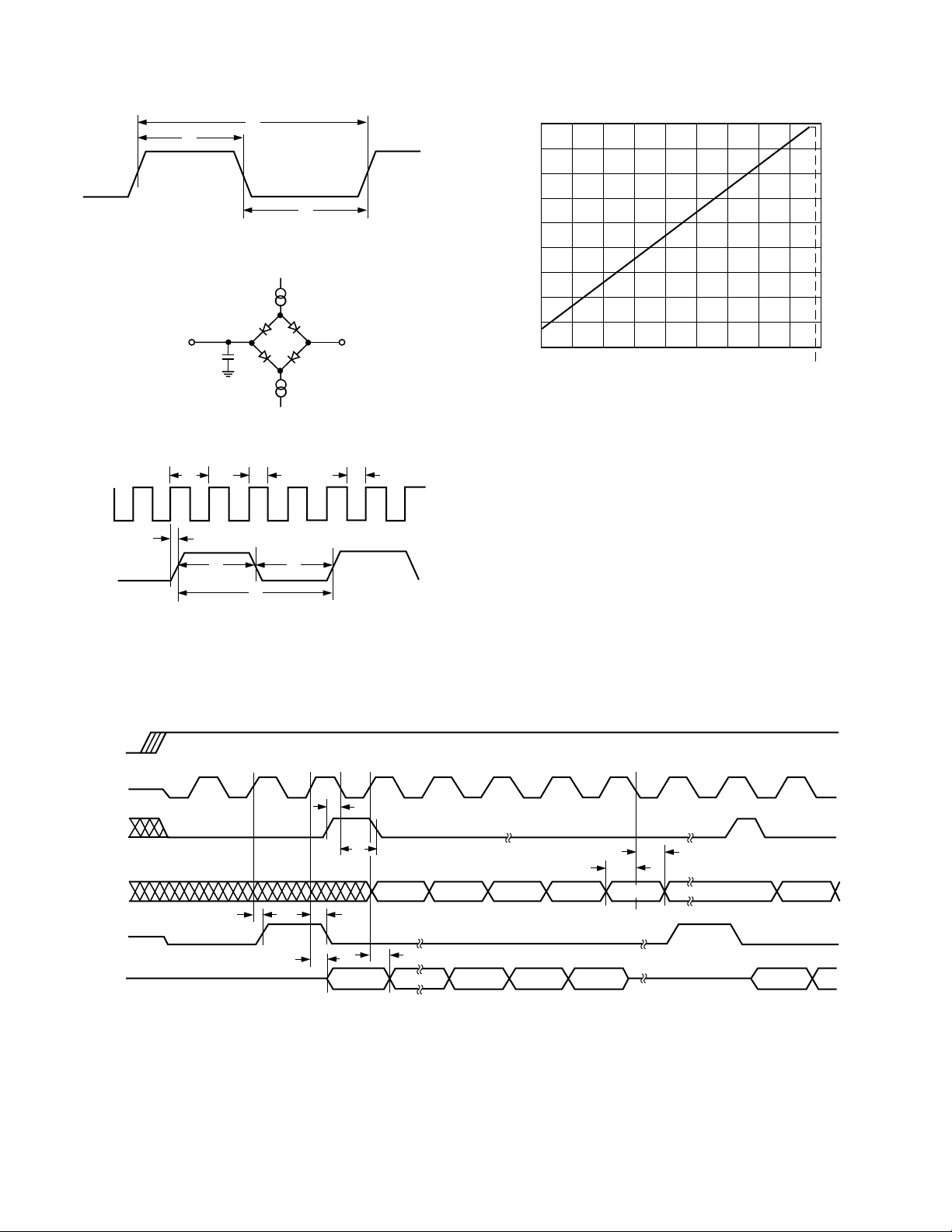

OPERATION

General Description

The AD73360L inputs and outputs data in a Time Division

Multiplexing (TDM) format. When data is being read from the

AD73360L each channel has a fixed time slot in which its data

is transmitted. If a channel is not powered up, no data is transmitted during the allocated time slot and the SDO line will be

three-stated. When the AD73360L is first powered up or reset it

will be set to Program Mode and will output an SDOFS. After a

reset the SDOFS will be asserted once every sample period

(125 µs assuming 16.384 MHz master clock). If the AD73360L

is configured in Frame Sync Loop-Back Mode, one control

word can be transmitted after each SDOFS pulse. Figure 10a

shows the SDO and SDOFS lines after a reset. The serial data

sent by SDO will not contain valid ADC data until the AD73360L

is put into Data Mode or Mixed Mode. Control Registers D

through F allow channels to be powered up individually. This

gives greater flexibility and control over power consumption.

Figure 10b shows the SDOFS and SDO of the AD73360L when

all channels are powered up and Figure 10c shows SDOFS and

SDO with Channels 1, 3, and 5 powered up.

Resetting the AD73360L

The RESET pin resets all the control registers. All registers are

reset to zero, indicating that the default SCLK rate (DMCLK/8)

and sample rate (DMCLK/2048) are at a minimum to ensure

that slow speed DSP engines can communicate effectively. As

well as resetting the control registers using the RESET pin, the

device can be reset using the RESET bit (CRA:7) in Control

Register A. Both hardware and software resets require four

DMCLK cycles. On reset, DATA/PGM (CRA:0) is set to 0

(default condition) thus enabling Program Mode. The reset

conditions ensure that the device must be programmed to the

correct settings after power-up or reset. Following a reset, the

SDOFS will be asserted approximately 2070 master (MCLK)

cycles after RESET goes high. The data that is output following

the reset and during Program Mode is random and contains no

valid information until either data or mixed mode is set.

Power Management

The individual functional blocks of the AD73360L can be enabled

separately by programming the power control register CRC. It

allows certain sections to be powered down if not required, which

adds to the device’s flexibility in that the user need not incur the

penalty of having to provide power for a certain section if it is

not necessary to their design. The power control registers provide

individual control settings for the major functional blocks on

each analog front-end unit and also a global override that allows

all sections to be powered up/down by setting/clearing the bit.

Using this method the user could, for example, individually

enable a certain section, such as the reference (CRC:5), and

disable all others. The global power-up (CRC:0) can be used to

enable all sections but if power-down is required using the global

1/F

SE

SDOFS

SDO

SAMPLE

Figure 10a. Output Timing After Reset (Program Mode)

SE

SDOFS

SDO

CHANNEL 1 CHANNEL 2 CHANNEL 3 CHANNEL 4 CHANNEL 5 CHANNEL 6

Figure 10b. Output Timing: All Channels Powered Up (Data/Mixed Mode)

SE

SDOFS

SDO

CHANNEL 3

CHANNEL 5CHANNEL 1

Figure 10c. Output Timing: Channels 1, 3, and 5 Powered Up (Data/Mixed Mode)

–16–

REV. 0

Page 17

AD73360L

control, the reference will still be enabled; in this case, because

its individual bit is set. Refer to Table VII for details of the settings

of CRC. CRD–CRF can be used to control the power status of

individual channels allowing multiple channels to be powered

down if required.

Operating Modes

Three operating modes are available on the AD73360L. They are

Program, Data, and Mixed Program/Data. The device configuration—register settings—can be changed only in Program and

Mixed Program/Data Modes. In all modes, transfers of information to or from the device occur in 16-bit packets, therefore

the DSP engine’s SPORT will be programmed for 16-bit transfers.

Program (Control) Mode

In Program Mode, CRA:0 = 0, the user writes to the control

registers to set up the device for desired operation—SPORT

operation, cascade length, power management, input gain, etc. In

this mode, the 16-bit information packet sent to the device by

the DSP engine is interpreted as a control word whose format is

shown in Table IV. In this mode, the user must address the device

to be programmed using the address field of the control word. This

field is read by the device and if it is zero (000 bin), the device

recognizes the word as being addressed to it. If the address field

is not zero, it is then decremented and the control word is passed

out of the device—either to the next device in a cascade or back

to the DSP engine. This 3-bit address format allows the user to

uniquely address any one of up to eight devices in a cascade. If

the AD73360L is used in a stand-alone configuration connected

to a DSP, the device address corresponds to 0. If, on the other

hand, the AD73360L is configured in a cascade of two devices,

its device address corresponds with its hardwired position in

the cascade.

Following reset, when the SE pin is enabled, the AD73360L

responds by raising the SDOFS pin to indicate that an output

sample event has occurred. Control words can be written to the

device to coincide with the data being sent out of the SPORT,

as shown in Figure 12 (Directly Coupled), or they can lag the

output words by a time interval that should not exceed the sample

interval (Indirectly Coupled). Refer to the Digital Interface section

for more information. After reset, output frame sync pulses

will occur at a slower default sample rate, which is DMCLK/

2048, until Control Register B is programmed, after which the

SDOFS will be pulsed at the selected rate. This is to allow

slow controller devices to establish communication with the

AD73360L. During Program Mode, the data output by the

device is random and should not be interpreted as ADC data.

Data Mode

Once the device has been configured by programming the correct settings to the various control registers, the device may exit

Program Mode and enter Data Mode. This is done by programming the DATA/PGM (CRA:0) bit to a 1 and MM (CRA:1) to

0. Once the device is in Data Mode, the input data is ignored.

When the device is in normal Data Mode (i.e., Mixed Mode

disabled), it must receive a hardware reset to reprogram any of

the control register settings.

Appendix C details the initialization and operation of an analog

front-end cascade in normal Data Mode.

Mixed Program/Data Mode

This mode allows the user to send control words to the device

while receiving ADC words. This permits adaptive control of

the device whereby control of the input gains can be affected by

reprogramming the control registers. The standard data frame

remains 16 bits, but now the MSB is used as a flag bit to indicate

that the remaining 15 bits of the frame represent control information. Mixed Mode is enabled by setting the MM bit (CRA:1)

to 1 and the DATA/PGM bit (CRA:0) to 1. In the case where

control setting changes will be required during normal operation, this mode allows the ability to load control information

with the slight inconvenience of formatting the data. Note that

the output samples from the ADC will also have the MSB set to

zero to indicate it is a data word.

A description of a single device operating in mixed mode is

detailed in Appendix B, while Appendix D details the initialization and operation of an analog front-end cascade operating in

mixed mode. Note that it is not essential to load the control

registers in Program Mode before setting mixed mode active.

Mixed Mode may be selected with the first write by programming

CRA and then transmitting other control words.

Channel Selection

The ADC channels of the AD73360L can be powered up or

down individually by programming the PUIx bit of registers CRD

to CRF. If the AD73360L is being used in Mixed Data/Control

Mode individual channels may be powered up or down as the

program requires. In Data Mode, the number of channels selected

while the AD73360L was in Program Mode is fixed and cannot

be altered without resetting and reprogramming the AD73360L.

In all cases, ADC Channel 1 must be powered up as the frame

sync pulse generated by this channel defines the start of a new

sample interval.

INTERFACING

The AD73360L can be interfaced to most modern DSP engines

using conventional serial port connections and an extra enable

control line. Both serial input and output data use an accompanying frame synchronization signal that is active high one clock

cycle before the start of the 16-bit word or during the last bit of

the previous word if transmission is continuous. The serial clock

(SCLK) is an output from the AD73360L and is used to define

the serial transfer rate to the DSP’s Tx and Rx ports. Two primary

configurations can be used: the first is shown in Figure 11 where

the DSP’s Tx data, Tx frame sync, Rx data, and Rx frame sync are

connected to the AD73360L’s SDI, SDIFS, SDO, and SDOFS

respectively. This configuration, referred to as indirectly coupled

or nonframe sync loop-back, has the effect of decoupling the

transmission of input data from the receipt of output data. When

programming the DSP serial port for this configuration, it is

necessary to set the Rx frame sync as an input to the DSP and

the Tx frame sync as an output generated by the DSP. This

configuration is most useful when operating in mixed mode, as

the DSP has the ability to decide how many words can be sent

to the AD73360L(s). This means that full control can be implemented over the device configuration in a given sample interval.

REV. 0

–17–

Page 18

AD73360L

SDIFS

SDI

SCLK

SDO

SDOFS

AD73360L

ADSP-21xx

DSP

TFS

DT

SCLK

DR

RFS

Figure 11. Indirectly Coupled or Nonframe Sync LoopBack Configuration

SDIFS

SDI

SCLK

SDO

SDOFS

AD73360L

ADSP-21xx

DSP

TFS

DT

SCLK

DR

RFS

Figure 12. Directly Coupled or Frame Sync LoopBack Configuration

SDIFS

SDI

SCLK

SDO

SDOFS

RESET

SE

AD73360L

ANALOG

FRONT-END

ADSP-21xx

DSP

TFS

DT

SCLK

DR

RFS

FL0

FL1

Figure 13. AD73360L Connected to ADSP-21xx

SDIFS

SDI

SCLK

SDO

SDOFS

RESET

SE

AD73360L

ANALOG

FRONT-END

TMS320C5x

DSP

FSX

DX

CLKX

CLKR

DR

FSR

XF

Figure 14. AD73360L Connected to TMS320C5x

The second configuration (shown in Figure 12) has the DSP’s

Tx data and Rx data connected to the AD73360L’s SDI and

SDO, respectively, while the DSP’s Tx and Rx frame syncs are

connected to the AD73360L’s SDIFS and SDOFS. In this configuration, referred to as directly coupled or frame sync loop-back,

the frame sync signals are connected together and the input data

to the AD73360L is forced to be synchronous with the output data

from the AD73360L. The DSP must be programmed so that

both the Tx and Rx frame syncs are inputs as the AD73360L’s

SDOFS will be input to both. This configuration guarantees

that input and output events occur simultaneously and is the

simplest configuration for operation in normal Data Mode. Note

that when programming the DSP in this configuration it is

advisable to preload the Tx register with the first control word to

be sent before the AD73360L is taken out of reset. This ensures

that this word will be transmitted to coincide with the first output word from the device(s).

Digital Interfacing

The AD73360L is designed to easily interface to most common

DSPs. The SCLK, SDO, SDOFS, SDI, and SDIFS must be

connected to the SCLK, DR, RFS, DT, and TFS pins of the

DSP respectively. The SE pin may be controlled from a parallel

output pin or flag pin such as FL0–2 on the ADSP-21xx (or XF

on the TMS320C5x) or, where SPORT power-down is not

required, it can be permanently strapped high using a suitable

pull-up resistor. For consistent performance the SE should be

synchronized to the rising edge of MCLK using a circuit similar to

that of Figure 19. The RESET pin may be connected to the system

hardware reset structure or it may also be controlled using a

dedicated control line. In the event of tying it to the global system

reset, it is necessary to operate the device in mixed mode, which

allows a software reset, otherwise there is no convenient way of

resetting the device. Figures 11 and 12 show typical connections

to an ADSP-2181 while Figures 13 and 14 show typical connections to an ADSP-21xx and a TMS320C5x, respectively.

–18–

REV. 0

Page 19

SE

SE

SDOFS

SCLK

SDIFS

SDI

CONTROL WORD

CONTROL WORD

CHANNEL 1 ADC SAMPLE WORDSDO

CHANNEL 6 ADC SAMPLE WORD

SE

SDOFS

SCLK

SDIFS

SDI DON'T CARE

DON'T CARE

CHANNEL 1 ADC SAMPLE WORDSDO CHANNEL 6 ADC SAMPLE WORD

SCLK

SDOFS

AD73360L

SDO

SDIFS

SDI

SE

SCLK

SDOFS

SDO

SDIFS

SDI

UNDEFINED DATA

CONTROL WORD

UNDEFINED DATA

CONTROL WORD

Figure 15a. Interface Signal Timing for Program Mode Operation (Writing to a Register)

UNDEFINED DATA

REGISTER READ INSTRUCTION

READ RESULT

0x7FFF OR CONTROL WORD

Figure 15b. Interface Signal Timing for Program Mode Operation (Reading a Register)

REV. 0

Figure 16a. Interface Signal Timing for Mixed Mode Operation

Figure 16b. Interface Signal Timing for Data Mode Operation

–19–

Page 20

AD73360L

Cascade Operation

The AD73360L has been designed to support two devices in a

cascade connected to a single serial port (see Figure 17). The

SPORT interface protocol has been designed so that device

addressing is built into the packet of information sent to the

device. This allows the cascade to be formed with no extra hardware overhead for control signals or addressing. A cascade can

be formed in either of the two modes previously discussed.

Q0

Q1D1

SDIFS

SDI

SCLK

SDO

SDOFS

SDIFS

SDI

SCLK

SDO

SDOFS

AD73360L

DEVICE 1

AD73360L

DEVICE 2

MCLK

SE

RESET

MCLK

SE

RESET

ADSP-21xx

DSP

FL0 FL1

TFS

DT

SCLK

DR

RFS

D0

74HC74

CLK

Figure 17. Connection of Two AD73360Ls Cascaded to

ADSP-21xx

There may be some restrictions in cascade operation due to the

sample clock and the serial clock rate chosen. The formula below

gives an indication of whether the combination of sample rate and

serial clock can be successfully cascaded. This assumes a directly

coupled frame sync arrangement as shown in Figure 12 and does

not take any interrupt latency into account.

×−×+[(( ) ) ]

6 1 16 17

1

≥

f

S

Device Count

SCLK

When using the indirectly coupled frame sync configuration in

cascaded operation it is necessary to be aware of the restrictions

in sending control word data to all devices in the cascade. The

user should ensure that there is sufficient time for all the control

words to be sent between reading the last ADC sample and the

start of the next sample period.

In Cascade Mode, both devices must know the number of devices

in the cascade to be able to output data at the correct time.

Control Register A contains a 3-bit field (DC0–2) that is programmed by the DSP during the programming phase. The default

condition is that the field contains 000b, which is equivalent to a

single device in cascade (see Table XVI). However, for cascade

operation this field must contain a binary value that is one less

than the number of devices in the cascade. With a cascade, each

device takes a turn to send an ADC result to the DSP. For

example, the data will be output as Device 2-Channel 1, Device

1-Channel 1, Device 2-Channel 2, Device 1-Channel 2 etc. When

the first device in the cascade has transmitted its channel data

there is an additional SCLK period during which the last device

asserts its SDOFS as it begins its transmission of the next channel. This will not cause a problem for most DSPs as they count

clock edges after a frame sync and hence the extra bit will be

ignored.

When two devices are connected in cascade there are also restrictions concerning which ADC channels can be powered up. In all

cases the cascaded devices must all have the same channels

powered up (i.e., for a cascade requiring Channels 1 and 2 on

Device 1 and Channel 5 on Device 2, Channels 1, 2, and 5

must be powered up on both devices to ensure correct operation). Figure 18 shows the timing sequence for two devices in

cascade. In all cases Channel 1 of all devices must be powered up.

Table XVI. Device Count Settings

DC2 DC1 DC0 Cascade Length

00 01

00 12

Connection of a cascade of devices to a DSP, as shown in Figure

17, is no more complicated than connecting a single device.

Instead of connecting the SDO and SDOFS to the DSP’s Rx

port, these are now daisy-chained to the SDI and SDIFS of the

next device in the cascade. The SDO and SDOFS of the second

device in the cascade are connected to the DSP’s Rx port to

complete the cascade. SE and RESET on both devices are fed

from the signals that were synchronized with the MCLK using

the circuit of Figure 19. The SCLK from only one device need

be connected to the DSP’s SCLK input(s) as both devices

will be running at the same SCLK frequency and phase.

12345678910111213141516123456 7891011121314151617

DEVICE 2 – CHANNEL 1 DEVICE 1 – CHANNEL 1

Figure 18. Cascade Timing for a Two-Device Cascade

–20–

1234567 8

DEVICE 2 – CHANNEL 2

REV. 0

Page 21

AD73360L

FREQUENCY – kHz

0

0

dB

–20

24

–100

–140

–120

–40

–60

–80

SNR = 78dB (DC TO 4kHz)

DSP CONTROL

TO SE

MCLK

DSP CONTROL

TO RESET

MCLK

Figure 19. SE and

SE SIGNAL SYNCHRONIZED

DQ

1/2

74HC74

CLK

DQ

1/2

74HC74

CLK

RESET

TO MCLK

RESET SIGNAL SYNCHRONIZED

TO MCLK

Sync Circuit for Cascaded

The sampling rate can be varied by programming the Decimation

Rate Divider settings in CRB. For a DMCLK of 16.384 MHz

sample rates of 64 kHz, 32 kHz, 16 kHz and 8 kHz are available.

Figure 21 shows the final spectral response of a signal sampled

at 8 kHz using the maximum oversampling rate.

Operation

PERFORMANCE

As the AD73360L is designed to provide high-performance,

low-cost conversion, it is important to understand the means by

which this high performance can be achieved in a typical application. This section will, by means of spectral graphs, outline

the typical performance of the device and highlight some of the

options available to users in achieving their desired sample rate,

either directly in the device or by doing some post-processing in

the DSP, while also showing the advantages and disadvantages

of the different approaches.

Encoder Section

The encoder section samples at DMCLK/256, which gives a

64 kHz output rate for DMCLK equal to 16.384 MHz. The

noise-shaping of the sigma-delta modulator also depends on the

frequency at which it is clocked, which means that the best

dynamic performance in a particular bandwidth is achieved by

oversampling at the highest possible rate. If we assume that the

signals of interest are in the bandwidth of dc–4 kHz, then sampling at 64 kHz gives a spectral response which ensures good

SNR performance in that bandwidth, as shown in Figure 20.

0

–20

–40

–60

dB

–80

–100

–120

–140

0

8162432

FREQUENCY – kHz

SNR = 59.0dB (DC TO fS/2)

SNR = 78.2dB (DC TO 4kHz)

Figure 21. FFT (ADC 8 kHz Internally Decimated from

64 kHz)

It is possible to generate lower sample rates through reducing

the oversampling ratio by programming the DMCLK Rate

Divider Settings in CRB (MCD2-MCD1). This will have the

effect of spreading the quantization noise over a lesser bandwidth resulting in a degradation of dynamic performance.

Figure 22 shows a FFT plot of a signal sampled at 8 kHz rate

produced by reducing the DMCLK Rate.

–20

–40

–60

dB

–80

–100

–120

–140

0

0

FREQUENCY – kHz

SNR = 72.2dB (DC TO f

24

/2)

S

Figure 22. FFT (ADC 8 kHz Sampling with Reduced

DMCLK Rate)

Figure 20. FFT (ADC 64 kHz Sampling)

REV. 0

–21–

Page 22

AD73360L

Figure 23 shows a comparison of SNR results achieved by varying either the Decimation Rate Setting or the DMCLK Rate

Settings.

81

DMCLK = MCLK

REDUCED

DMCLK

SNR – dB

80

79

78

77

76

75

74

73

72

71

8

16 24 32 40 48 56 64

SAMPLING FREQUENCY – kHz

Figure 23. Comparison of DMCLK and Decimation Rate

Settings

Encoder Group Delay

The AD73360L implementation offers a very low level of group

delay, which is given by the following relationship:

Group Delay (Decimator) = Order × ((M – 1)/2) × Tdec

where:

Order is the order of the decimator (= 3),

M is the decimation factor (= 32), and

Tdec is the decimation sample interval (= 1/2.048e6).

=> Group Delay (Decimator) = 3 × (32 – 1)/2 × (1/2.048e6)

= 22.7 µs

If final filtering is implemented in the DSP, the final filter’s

group delay must be taken into account when calculating overall

group delay.

VIN

TO INPUT BIAS

CIRCUITRY

100⍀

100⍀

0.047F

0.047F

REFOUT

0.1F

VINPx

VINNx

REFCAP

VOLTAGE

REFERENCE

Figure 24. Example Circuit for Differential Input

(DC Coupling)

The AD73360L’s on-chip 38 dB preamplifier can be enabled

when there is not enough gain in the input circuit; the preamplifier is configured by bits IGS0–2 of CRD. The total gain must be

configured to ensure that a full-scale input signal produces a

signal level at the input to the sigma-delta modulator of the

ADC that does not exceed the maximum input range.

The dc biasing of the analog input signal is accomplished with

an on-chip voltage reference. If the input signal is not biased at

the internal reference level (via REFOUT), then it must be

ac-coupled with external coupling capacitors. CIN should be

0.1 µF or larger. The dc biasing of the input can then be accomplished using resistors to REFOUT as in Figure 25.

CIN

VIN

CIN

0.047F

TO INPUT BIAS

CIRCUITRY

100⍀

100⍀

10k⍀

10k⍀

0.047F

REFOUT

0.1F

VINPx

VINNx

REFCAP

VOLTAGE

REFERENCE

Figure 25. Example Circuit for Differential Input

(AC Coupling)

Figures 26 and 27 detail ac- and dc-coupled input circuits for

single-ended operation respectively.

DESIGN CONSIDERATIONS

Analog Inputs

The AD73360L features six signal conditioning inputs. Each

signal conditioning block allows the AD73360L to be used with

either a single-ended or differential signal. The applied signal

can also be inverted internally by the AD73360L if required.

The analog input signal to the AD73360L can be dc-coupled,

provided that the dc bias level of the input signal is the same as

the internal reference level (REFOUT). Figure 24 shows the

recommended differential input circuit for the AD73360L. The

circuit of Figure 24 implements first-order low-pass filters

with a 3 dB point at 34 kHz; these are the only filters that must

be implemented external to the AD73360L to prevent aliasing

of the sampled signal. Since the ADC uses a highly oversampled

approach that transfers the bulk of the antialiasing filtering into

the digital domain, the off-chip antialiasing filter need only be of

a low order. It is recommended that for optimum performance the

capacitors used for the antialiasing filter be of high-quality

dielectric (NPO).

–22–

CIN

VIN

100⍀

0.047F

10k⍀

REFOUT

0.1F

VINPx

VINNx

REFCAP

VOLTAGE

REFERENCE

Figure 26. Example Circuit for Single-Ended Input

(AC Coupling)

VIN

100⍀

0.047F

REFOUT

0.1F

VINPx

VINNx

REFCAP

VOLTAGE

REFERENCE

Figure 27. Example Circuit for Differential Input

(DC Coupling)

REV. 0

Page 23

DIGITAL GROUND

ANALOG GROUND

Digital Interface

As there are a number of variations of sample rate and clock

speeds that can be used with the AD73360L in a particular application, it is important to select the best combination to achieve the

desired performance. High-speed serial clocks will read the data

from the AD73360L in a shorter time, giving more time for

processing at the expense of injecting some digital noise into

the circuit. Digital noise can also be reduced by connecting

resistors (typ <50 Ω) in series with the digital input and output lines. The noise can be minimized by good grounding and

layout. Typically, the best performance is achieved by selecting

the slowest sample rate and SCLK frequency for the required

application as this will produce the least amount of digital noise.

Figure 28 shows combinations of sample rate and SCLK frequency

which will allow data to be read from all six channels in one sample

period. These figures correspond to setting DMCLK = MCLK.

SAMPLE RATE

8kSPS 16kSPS 32kSPS 64kSPS

2MHz YES YES NO NO

4MHz YES YES YES NO

SCLK

8MHz YES YES YES YES

16MHz YES YES YES YES

NOTE: SOME COMBINATIONS OF SCLK AND SAMPLE RATE WILL NOT

BE SUFFICIENT TO READ DATA FROM ALL SIX CHANNELS IN THE

ALLOTTED TIME. THESE ARE DEPICTED AS NO.

Figure 28. SCLK and Sample Rates

Grounding and Layout

Since the analog inputs to the AD73360L are differential, most

of the voltages in the analog modulator are common-mode

voltages. The excellent common-mode rejection of the part will

remove common-mode noise on these inputs. The analog and

digital supplies of the AD73360L are independent and separately

pinned out to minimize coupling between analog and digital