Page 1

Ultralow Power, 1.8 V, 3 mm × 3 mm,

V

www.BDTIC.com/ADI

FEATURES

Ultralow power

Power supply voltage: 1.8 V to 3.6 V

Operation power supply current: 70 μA typical

Power-down current: 2 μA typical

Fast response time

Conversion time: 10 ms per channel

Wake-up time from serial interface: 300 μs

Adaptive environmental compensation

2 capacitance input channels

Sensor capacitance (C

Sensitivity up to 3 fF

2 modes of operation

Standalone with fixed settings

Interfaced to a microcontroller for user-defined settings

2 detection output flags

2-wire serial interface (I

Operating temperature: −40°C to +85°C

10-lead LFCSP package (3 mm × 3 mm × 0.8 mm)

APPLICATIONS

Buttons and switches

Proximity sensing

Contactless switching

Position detection

Level detection

Portable products

): 0 pF up to 13 pF

SENS

2

C-compatible)

2-Channel Capacitance Converter

AD7156

GENERAL DESCRIPTION

The AD7156 delivers a complete signal processing solution for

capacitive sensors, featuring an ultralow power converter with

fast response time.

The AD7156 uses an Analog Devices, Inc., capacitance-todigital converter (CDC) technology, which combines features

important for interfacing to real sensors, such as high input

sensitivity and high tolerance of both input parasitic ground

capacitance and leakage current.

The integrated adaptive threshold algorithm compensates for

any variations in the sensor capacitance due to environmental

factors like humidity and temperature or due to changes in the

dielectric material over time.

By default, the AD7156 operates in standalone mode using the

fixed power-up settings and indicates detection on two digital

outputs. Alternatively, the AD7156 can be interfaced to a microcontroller via the serial interface, the internal registers can be

programmed with user-defined settings, and the data and status

can be read from the part.

The AD7156 operates with a 1.8 V to 3.6 V power supply. It is

specified over the temperature range of −40°C to +85°C.

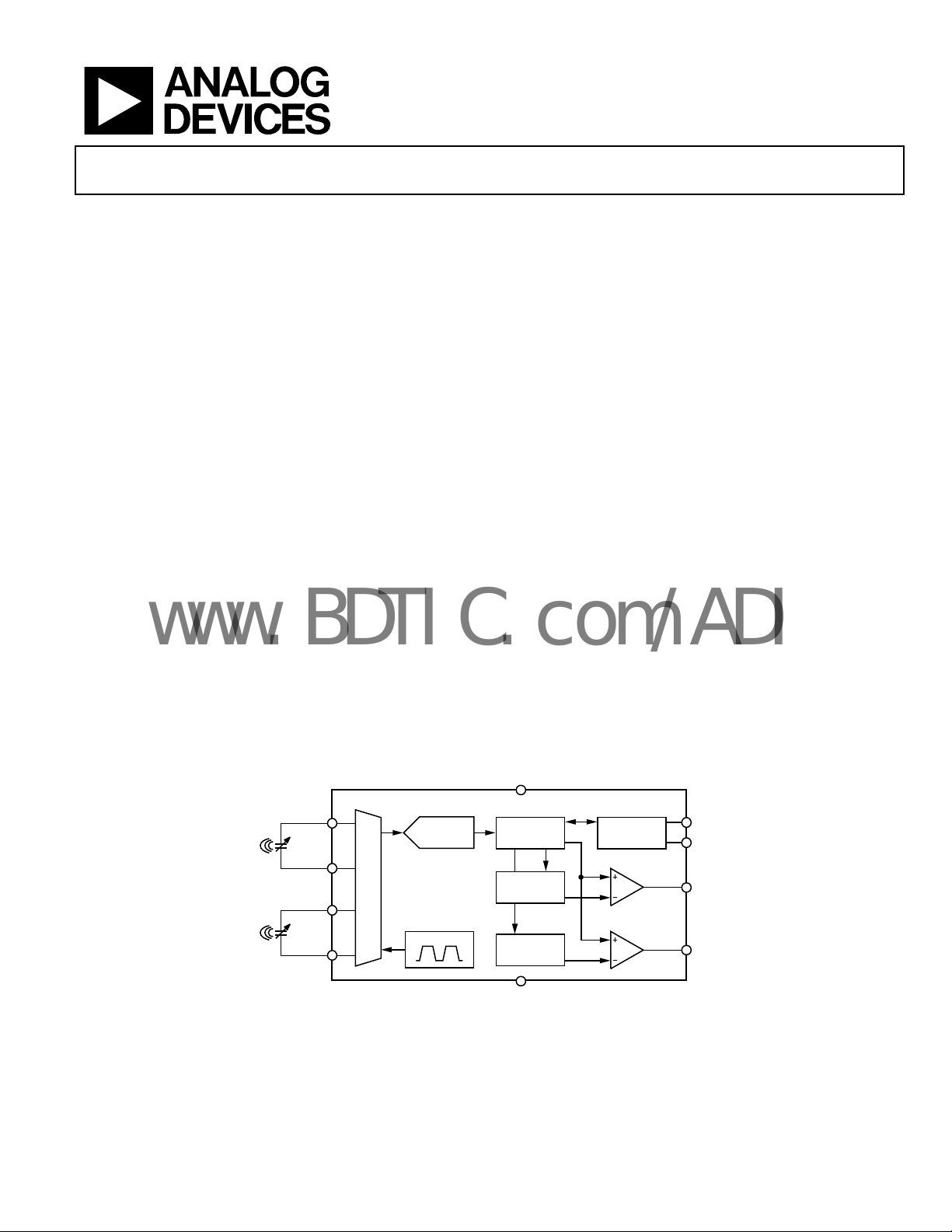

FUNCTIONAL BLOCK DIAGRAM

C

SENS1

C

SENS2

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of p atents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

CIN1

EXC1

CIN2

EXC2

MUX

- CDC

AD7156

EXCITATION

DD

DIGITAL

FILTER

THRESHOLD

THRESHOLD

GND

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

SERIAL

INTERFACE

SCL

SDA

OUT1

OUT2

7726-001

Page 2

AD7156

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 5

Absolute Maximum Ratings ............................................................ 6

ESD Caution .................................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 11

Capacitance-to-Digital Converter ............................................ 11

CAPDAC ..................................................................................... 11

Comparator and Threshold Modes .......................................... 12

Adaptive Threshold .................................................................... 12

Sensitivity..................................................................................... 12

Data Average ............................................................................... 13

Hysteresis ..................................................................................... 13

Timeout ........................................................................................ 13

Auto-DAC Adjustment .............................................................. 14

Power-Down Timer ................................................................... 14

Register Descriptions ..................................................................... 15

Status Register ............................................................................. 16

Data Registers ............................................................................. 17

Average Registers ........................................................................ 18

Fixed Threshold Registers ......................................................... 18

Sensitivity Registers ................................................................... 18

Timeout Registers ....................................................................... 18

Setup Registers ............................................................................ 19

Configuration Register .............................................................. 20

Power-Down Timer Register .................................................... 21

CAPDAC Registers .................................................................... 21

Serial Number Register .............................................................. 21

Chip ID Register ......................................................................... 21

Serial Interface ................................................................................ 22

Read Operation........................................................................... 22

Write Operation.......................................................................... 22

AD7156 Reset ............................................................................. 23

General Call ................................................................................ 23

Hardware Design Considerations ................................................ 24

Overview ..................................................................................... 24

Parasitic Capacitance to Ground .............................................. 24

Parasitic Resistance to Ground ................................................. 24

Parasitic Parallel Resistance ...................................................... 24

Parasitic Serial Resistance ......................................................... 25

Input Overvoltage Protection ................................................... 25

Input EMC Protection ............................................................... 25

Power Supply Decoupling and Filtering .................................. 25

Application Examples ................................................................ 26

Outline Dimensions ....................................................................... 27

Ordering Guide .......................................................................... 27

REVISION HISTORY

10/08—Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

AD7156

www.BDTIC.com/ADI

SPECIFICATIONS

VDD = 1.8 V to 3.6 V, GND = 0 V, temperature range = −40°C to +85°C, unless otherwise noted.

Table 1.

Parameter Min Typ Max Unit

CAPACITIVE INPUT

2, 3

Conversion Input Range, CIN to EXC

3.2 4 pF 4 pF input range

1.6 2 pF 2 pF input range

0.8 1 pF 1 pF input range

0.4 0.5 pF 0.5 pF input range

Resolution

4, 5

2.0 fF 4 pF input range

1.6 fF 2 pF input range

1.4 fF 1 pF input range

1.0 fF 0.5 pF input range

4, 6

Maximum Allowed Capacitance, CIN to GND

Minimum Allowed Resistance, CIN to GND

Maximum Allowed Serial Resistance

4, 6

50 kΩ See Figure 14

4, 6

50 pF

10 MΩ See Figure 10 and Figure 11

Gain Error −20 +20 %

Gain Deviation over Temperature

Gain Matching Between Ranges

Offset Error

4

50 fF CIN and EXC pins disconnected

Offset Deviation over Temperature

Integral Nonlinearity (INL)

Channel-to-Channel Isolation

Power Supply Rejection

4

4 fF/V

4

0.5 %FSR See Figure 17

4

−2 +2 %

4

4

0.05 %

4

60 dB

5 fF

CAPDAC

Full Range 10 12.5 pF

Resolution (LSB)

Differential Nonlinearity (DNL)

Auto-DAC Increment/Decrement

4

200 fF

4

0.25 LSB

4, 7

25 75 % of C

EXCITATION

4, 7

Voltage

±VDD/2 V

Frequency 16 kHz See Figure 18

4, 6

Maximum Allowed Capacitance EXC to GND

Minimum Allowed Resistance EXC to GND

4, 6

1 MΩ See Figure 12 and Figure 13

1000 pF

LOGIC OUTPUTS (OUT1, OUT2)

Output Low Voltage (VOL) 0.4 V I

Output High Voltage (VOH) VDD – 0.6 V I

SERIAL INTERFACE INPUTS (SCL, SDA)

Input High Voltage (VIH) 70 % of VDD

Input Low Voltage (VIL) 25 % of VDD

Input Leakage Current ±0.1 ±5 µA

Input Pin Capacitance 6 pF

OPEN-DRAIN OUTPUT (SDA)

Output Low Voltage (VOL) 0.4 V

Output High Leakage Current (IOH) 0.1 5 µA V

1

range

IN

Test Conditions/Comments

See Figure 4, Figure 5, and

Figure 6

CIN and EXC pins disconnected

See Figure 16

See Figure 7, Figure 8, and

= −3 mA

SINK

= +3 mA

SOURCE

= −6.0 mA

SINK

= VDD

OUT

Figure 9

I

Rev. 0 | Page 3 of 28

Page 4

AD7156

www.BDTIC.com/ADI

Parameter Min Typ Max Unit

1

Test Conditions/Comments

POWER REQUIREMENTS

VDD-to-GND Voltage 1.8 3.6 V

IDD Current

4, 8

65 75 µA V

≤ 2.7 V, see Figure 20

DD

70 85 µA VDD = 3.6 V, see Figure 20

IDD Current Power-Down Mode

4, 8

2 10 µA V

≤ 2.7 V, see Figure 21

DD

2 17 µA VDD = 3.6 V, see Figure 21

1

Capacitance units: 1 pF = 1 × 10

2

The CAPDAC can be used to shift (offset) the input range. The total capacitance of the sensor can therefore be up to the sum of the CAPDAC value and the conversion

input range. With the auto-DAC feature, the CAPDAC is adjusted automatically when the CDC input value is lower than 25% or higher than 75% of the CDC nominal

input range.

3

The maximum capacitance of the sensor connected between the EXCx and CINx pins is equal to the sum of the minimum guaranteed value of the CAPDAC and the

minimum guaranteed input range.

4

The maximum specification is not production tested but is supported by characterization data at initial product release.

5

The resolution of the converter is not limited by the output data format or output data LSB (least significant bit) size, but by the converter and system noise level. The

noise-free resolution is defined as level of peak-to-peak noise coming from the converter itself, with no connection to the CIN and EXC pins.

6

These specifications are understood separately. Any combination of the capacitance to ground and serial resistance may result in additional errors, for example gain

error, gain drift, offset error, offset drift, and power supply rejection.

7

Specification is not production tested but is guaranteed by design.

8

Digital inputs equal to VDD or GND.

−12

F; 1 fF = 10

−15

F.

Rev. 0 | Page 4 of 28

Page 5

AD7156

www.BDTIC.com/ADI

TIMING SPECIFICATIONS

VDD = 1.8 V to 3.6 V, GND = 0 V, Input Logic 0 = 0 V, Input Logic 1 = VDD, temperature range = −40°C to +85°C, unless otherwise noted.

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

CONVERTER

Conversion Time

Wake-Up Time from Power-Down Mode

Power-Up Time

Reset Time

SERIAL INTERFACE

SCL Frequency 0 400 kHz

SCL High Pulse Width, t

SCL Low Pulse Width, t

SCL, SDA Rise Time, tR 0.3 µs

SCL, SDA Fall Time, t

Hold Time (Start Condition), t

Setup Time (Start Condition), t

Data Setup Time, t

Setup Time (Stop Condition), t

Data Hold Time (Master), t

Bus-Free Time (Between Stop and Start Conditions), t

1

Conversion time is 304 internal clock cycles for both channels (nominal clock 16 kHz); the internal clock frequency is equal to the specified excitation frequency.

2

Specification is not production tested but is supported by characterization data at initial product release.

3

Wake-up time is the maximum delay between the last SCL edge writing the configuration register and the start of conversion.

4

Power-up time is the maximum delay between the VDD crossing the minimum level (1.8 V) and either the start of conversion or when ready to receive a serial

interface command.

5

Reset time is the maximum delay between the last SCL edge writing the reset command and either the start of conversion or when ready to receive a serial

interface command.

6

Sample tested during initial release to ensure compliance.

7

All input signals are specified with input rise/fall times = 3 ns, measured between the 10% and 90% points. Timing reference points at 50% for inputs and outputs.

Output load = 10 pF.

1

2, 3

2, 4

2 ms

2, 5

6, 7

0.6 µs

HIGH

1.3 µs

LOW

F

0.6 µs After this period, the first clock is generated.

HD;STA

SU;STA

0.1 µs

SU;DAT

SU;STO

10 ns

HD;DAT

t

LOW

0.3 ms

0.6 µs Relevant for repeated start condition.

0.6 µs

t

R

20 ms Both channels, 10 ms per channel.

2 ms

See Figure 2.

0.3 µs

1.3 µs

BUF

t

F

t

HD;STA

SCL

SDA

t

t

BUF

PS

HD;STA

t

HD;DAT

t

HIGH

t

SU;DAT

t

SU;STA

S

Figure 2. Serial Interface Timing Diagram

Rev. 0 | Page 5 of 28

t

SU;STO

P

07726-002

Page 6

AD7156

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

Positive Supply Voltage VDD to GND

Voltage on Any Input or Output to GND –0.3 V to VDD + 0.3 V

ESD Rating

ESD Association Human Body Model, S5.1

Field-Inducted Charged Device Model

Operating Temperature Range −40°C to +85°C

Storage Temperature Range –65°C to +150°C

Maximum Junction Temperature 150°C

LFCSP Package

θJA, Thermal Impedance to Air

θJC, Thermal Impedance to Case

Reflow Soldering (Pb-Free)

Peak Temperature 260(0/−5)°C

Time at Peak Temperature 10 sec to 40 sec

−0.3 V to +3.9 V

4 kV

500 V

49°C/W

3°C/W

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 6 of 28

Page 7

AD7156

www.BDTIC.com/ADI

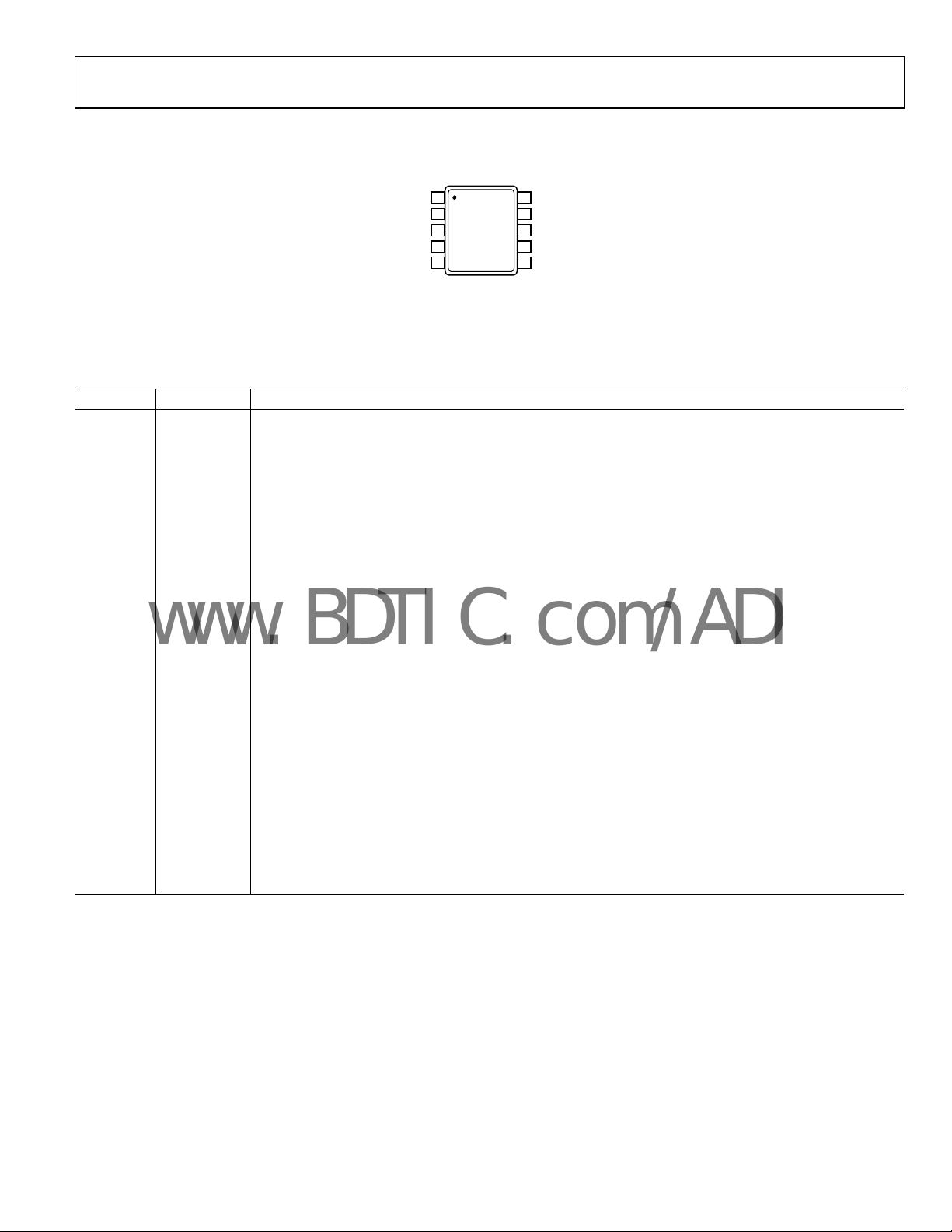

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

GND

VDD

2

CIN2

CIN1

EXC2

NOTES

1. THE EXPOSED PAD MUST BE CONNECTED TO

GND OR IT MUST BE ISOLATED (FLOATING).

AD7156

3

TOP VIEW

(Not to Scale)

4

5

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 GND Ground Pin.

2 VDD

Power Supply Voltage. This pin should be decoupled to GND using a low impedance capacitor, such as a

0.1 F X7R multilayer ceramic capacitor.

3 CIN2

CDC Capacitive Input Channel 2. The measured capacitance (sensor) is connected between the EXC2 pin and

the CIN2 pin. If not used, this pin can be left open circuit or be connected to GND. When a conversion is

performed on Channel 2, the CIN2 pin is internally connected to a high impedance input of the Σ-∆

modulator. When a conversion is performed on the other channel or in idle mode or power-down mode,

the CIN2 pin is internally disconnected and left floating by the part.

4 CIN1

CDC Capacitive Input Channel 1. The measured capacitance (sensor) is connected between the EXC1 pin and

the CIN1 pin. If not used, this pin can be left open circuit or be connected to GND. When a conversion is

performed on Channel 1, the CIN1 pin is internally connected to a high impedance input of the Σ-∆

modulator. When a conversion is performed on the other channel or in idle mode or power-down mode,

the CIN1 pin is internally disconnected and left floating by the part.

5 EXC2

CDC Excitation Output Channel 2. The measured capacitance is connected between the EXC2 pin and the

CIN2 pin. If not used, this pin should be left as an open circuit. When a conversion is performed on Channel 2,

the EXC2 pin is internally connected to the output of the excitation signal driver. When a conversion is performed on the other channel or in idle mode or power-

to GND.

6 EXC1

CDC Excitation Output Channel 1. The measured capacitance is connected between the EXC1 pin and the

CIN1 pin. If not used, this pin should be left as an open circuit. When a conversion is performed on Channel 1,

the EXC1 pin is internally connected to the output of the excitation signal driver. When a conversion is performed on the other channel or in idle mode or power-

to GND.

7 OUT1 Logic Output Channel 1. A high level on this output indicates proximity detected on CIN1.

8 OUT2 Logic Output Channel 2. A high level on this output indicates proximity detected on CIN2.

9 SCL

Serial Interface Clock Input. This pin connects to the master clock line and requires a pull-up resistor if not

provided elsewhere in the system.

10 SDA

Serial Interface Bidirectional Data. This pin connects to the master data line and requires a pull-up resistor if

not provided elsewhere in the system.

10

SDA

SCL

9

OUT2

8

7

OUT1

EXC1

6

07726-003

down mode, the EXC2 pin is internally connected

down mode, the EXC1 pin is internally connected

Rev. 0 | Page 7 of 28

Page 8

AD7156

www.BDTIC.com/ADI

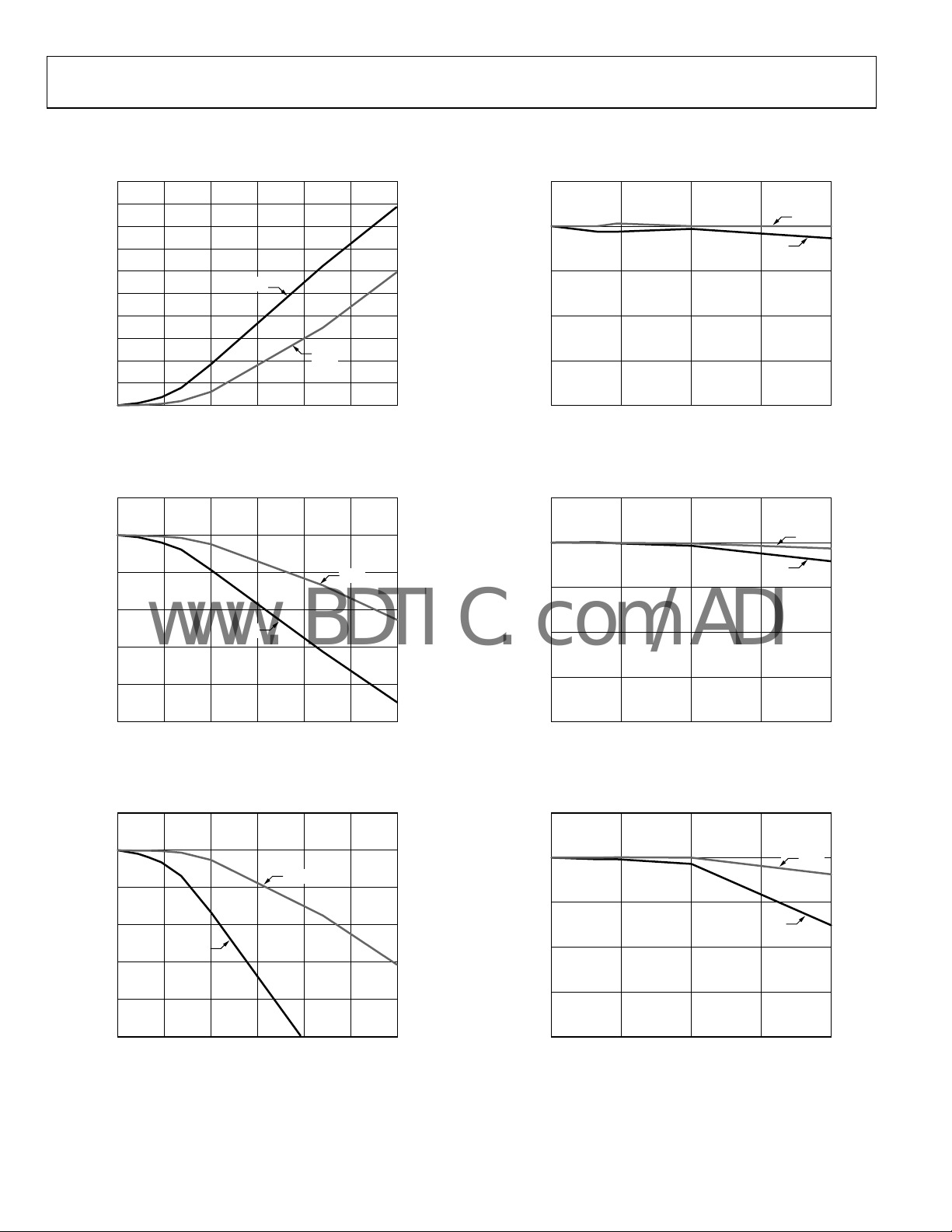

TYPICAL PERFORMANCE CHARACTERISTICS

2.0

1.8

1.6

1.4

1.2

1.0

0.8

OFFSET ERROR (pF)

0.6

0.4

0.2

0

0 50 100 150 200 250 300

CAPACITANCE CIN T O GROUND (pF )

1.8V

3.3V

Figure 4. Capacitance Input Offset Error vs. Capacitance CIN to GND,

= 1.8 V and 3.3 V, EXC Pin Open Circuit

V

DD

5

0

–5

–10

1.8V

–15

GAIN ERROR (%F SR)

–20

3.3V

1

0

–1

–2

OFFSET ERROR (fF)

–3

07726-004

–4

0 500 1000 1500 2000

CAPACITANCE EXC TO GROUND (pF )

3.3V

1.8V

07726-007

Figure 7. Capacitance Input Offset Error vs. Capacitance EXC to GND,

VDD = 1.8 V and 3.3 V, CIN Pin Open Circuit

1

0

–1

–2

GAIN ERROR (%F SR)

–3

3.3V

1.8V

–25

0 50 100 150 200 250 300

CAPACITANCE CIN T O GROUND (pF )

Figure 5. Capacitance Input Gain Error vs. Capacitance CIN to GND,

= 1.8 V and 3.3 V, CIN to EXC = 3 pF

V

DD

5

0

–5

–10

–15

GAIN ERROR (%F SR)

–20

–25

0 50 100 150 200 250 300

1.8V

CAPACITANCE CIN T O GROUND (pF )

3.3V

Figure 6. Capacitance Input Gain Error vs. Capacitance CIN to GND,

= 1.8 V and 3.3 V, CIN to EXC = 9 pF

V

DD

07726-005

07726-006

Rev. 0 | Page 8 of 2

–4

0 500 1000 1500 2000

CAPACITANCE EXC TO GROUND (pF )

Figure 8. Capacitance Input Gain Error vs. Capacitance EXC to GND,

VDD = 1.8 V and 3.3 V, CIN to EXC = 3 pF

1

0

–1

–2

GAIN ERROR (%F SR)

–3

–4

0 500 1000 1500 2000

CAPACITANCE EXC TO GROUND (pF )

3.3V

1.8V

Figure 9. Capacitance Input Gain Error vs. Capacitance EXC to GND,

= 1.8 V and 3.3 V, CIN to EXC = 9 pF

V

DD

8

07726-008

07726-009

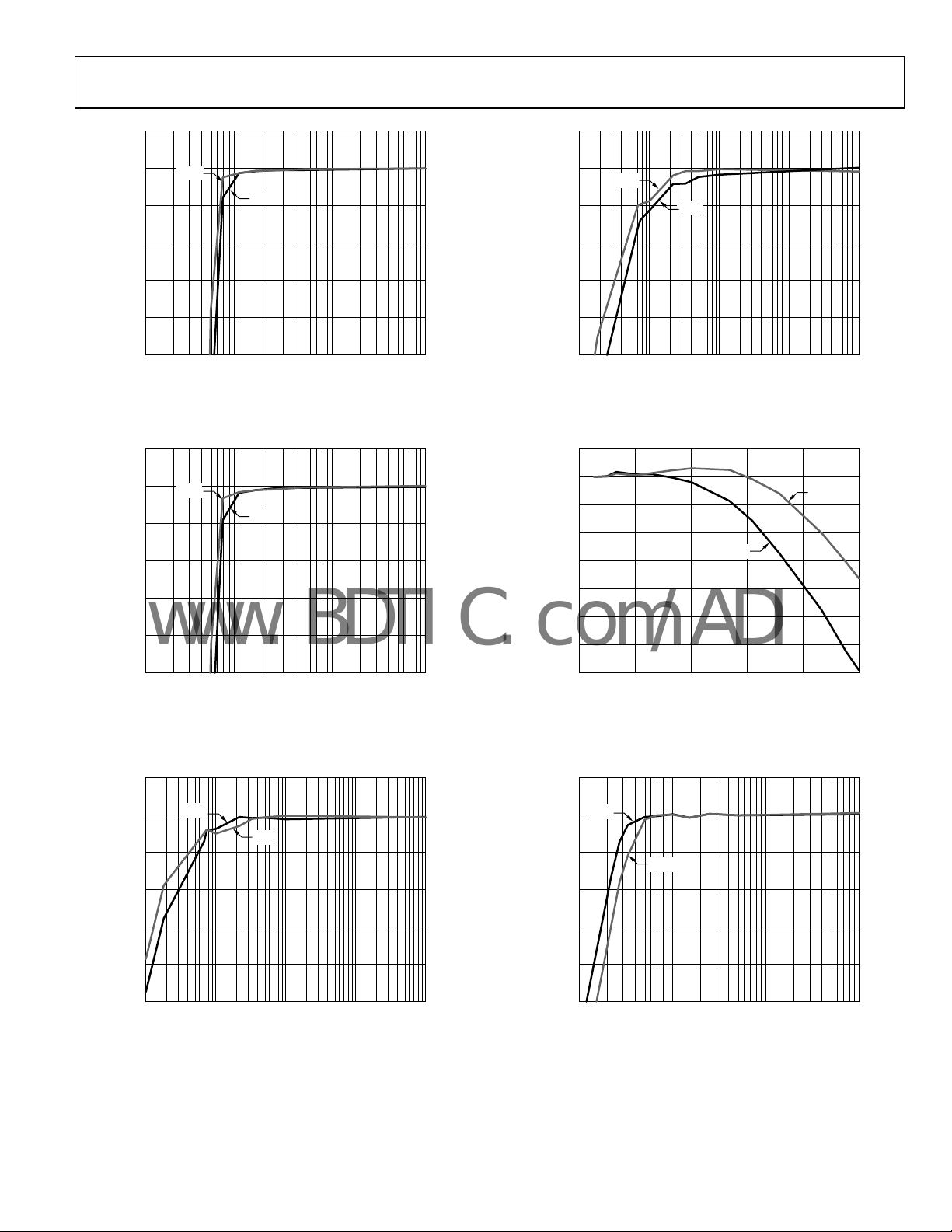

Page 9

AD7156

www.BDTIC.com/ADI

2

0.2

0

3.3V

–2

–4

–6

GAIN ERROR (%F SR)

–8

–10

1 10 100 1k

1.8V

RESISTANCE CIN T O GND (M)

Figure 10. Capacitance Input Gain Error vs. Resistance CIN to GND,

= 1.8 V and 3.3 V, CIN to EXC = 3 pF

V

DD

2

0

3.3V

–2

–4

–6

GAIN ERROR (%F SR)

–8

–10

1 10 100 1k

1.8V

RESISTANCE CI N TO GND (M)

Figure 11. Capacitance Input Gain Error vs. Resistance CIN to GND,

= 1.8 V and 3.3 V, CIN to EXC = 9 pF

V

DD

0

–0.2

–0.4

–0.6

GAIN ERROR (%F SR)

–0.8

07726-010

–1.0

3.3V

1.8V

07726-013

0.1 1 10 100 1k

RESISTANCE EXC TO GROUND (M )

Figure 13. Capacitance Input Gain Error vs. Resistance EXC to GND,

= 1.8 V and 3.3 V, CIN to EXC = 9 pF

V

DD

1

0

–1

–2

–3

–4

GAIN ERROR (%F SR)

–5

1

07726-01

–6

–7

0 20406080100

SERIAL RESI STANCE (k)

1.8V

3.3V

07726-014

Figure 14. Capacitance Input Gain Error vs. Serial Resistance,

= 1.8 V and 3.3 V, CIN to EXC = 3 pF

V

DD

0.2

0

–0.2

–0.4

–0.6

GAIN ERROR (%F SR)

–0.8

–1.0

1.8V

3.3V

0.1 1 10 100 1k

RESISTANCE EXC TO GROUND (M )

Figure 12. Capacitance Input Gain Error vs. Resistance EXC to GND,

= 1.8 V and 3.3 V, CIN to EXC = 3 pF

V

DD

2

07726-01

10

1.8V

0

–10

–20

–30

GAIN ERROR (%F SR)

–40

–50

1 10 100 1k

Figure 15. Capacitance Input Gain Error vs. Parallel Resistance,

= 1.8 V and 3.3 V, CIN to EXC = 3 pF

V

DD

Rev. 0 | Page 9 of 28

3.3V

07726-015

PARELLEL RE SISTANCE (M)

Page 10

AD7156

www.BDTIC.com/ADI

5

4

3

2

1

0

–1

OFFSET ERROR (fF)

–2

–3

–4

–5

–50 –25 500 25 75 100

TEMPERATURE (°C)

3.3V

Figure 16. Capacitance Input Offset Error vs. Temperature,

= 1.8 V and 3.3 V, CIN and EXC Pins Open Circuit

V

DD

1.8V

07726-016

20

10

0

DNL (fF)

–10

–20

010 205152530

Figure 19. CAPDAC Differential Nonlinearity (DNL), V

CAPDAC CODE

= 1.8 V

DD

07726-019

0.35

0.25

0.15

0.05

–0.05

GAIN ERROR (%F SR)

–0.15

–0.25

–0.35

–50 0 50 100

TEMPERATURE (°C)

Figure 17. Capacitance Input Gain Error vs. Temperature,

= 2.7 V, CIN to EXC = 4 pF

V

DD

16.50

16.25

16.00

15.75

15.50

15.25

FREQUENCY (kHz)

15.00

14.75

14.50

–50 0 50–25 25 75 100

1.8V

2.7V

2V

3.6V

TEMPERATURE ( °C)

Figure 18. EXC Frequency Error vs. Temperature,

= 1.8 V, 2 V, 2.7 V, and 3.6 V

V

DD

7

07726-01

8

07726-01

80

3.6V

70

2.7V

60

MAX (µA)

DD

I

1.8V

50

40

–50 0 50–25 25 75

2V

TEMPERATURE (° C)

Figure 20. Current vs. Temperature,

VDD = 1.8 V, 2 V, 2.7 V, and 3.6 V

4.0

3.5

3.0

2.5

2.0

MAX (µA)

DD

I

1.5

1.0

0.5

0

–50 0 50–25 25 75

3.6V

2.7V

2V

TEMPERATURE (°C)

Figure 21. Power-Down Current vs. Temperature,

VDD = 1.8 V, 2 V, 2.7 V, and 3.6 V

07726-020

1.8V

07726-021

Rev. 0 | Page 10 of

28

Page 11

AD7156

V

www.BDTIC.com/ADI

THEORY OF OPERATION

3.3

VDD

AD7156

CIN1

C

X1

EXC1

MUX

CIN2

C

X2

EXC2

CLOCK

GENERATOR

- CDC

CAPDAC

EXCITATION

POWER-DOWN

THRESHOLD

THRESHOLD

Figure 22. AD7156 Block Diagram

The AD7156 core is a high performance capacitance-to-digital

converter (CDC) that allows the part to be interfaced directly

to a capacitive sensor.

The comparators compare the CDC results with thresholds, either

fixed or dynamically adjusted by the on-chip adaptive threshold

algorithm engine. Thus, the outputs indicate a defined change in

the input sensor capacitance.

The AD7156 also integrates an excitation source, CAPDAC

for the capacitive inputs, an input multiplexer, a complete clock

generator, a power-down timer, a power supply monitor, control

logic, and an I

2

C®-compatible serial interface for configuring the

part and accessing the internal CDC data and status, if required

in the system (see Figure 22).

CAPACITANCE-TO-DIGITAL CONVERTER

Figure 23 shows the CDC simplified functional diagram. The

converter consists of a second-order Σ-Δ charge balancing

modulator and a third-order digital filter. The measured

capacitance C

and the Σ-Δ modulator input. The excitation signal is applied

on the C

continuously samples the charge going through the C

digital filter processes the modulator output, which is a stream

of 0s and 1s containing the information in 0 and 1 density. The

data is processed by the adaptive threshold engine and output

comparators; the data can also be read through the serial interface.

The AD7156 is designed for floating capacitive sensors.

Therefore, both C

or any other fixed potential node in the system.

The AD7156 features slew rate limiting on the excitation voltage

output, which decreases the energy of higher harmonics on the

excitation signal and dramatically improves the system electromagnetic compatibility (EMC).

is connected between an excitation source

X

capacitor during the conversion, and the modulator

X

. The

X

plates have to be isolated from ground

X

TIMER

DIGITAL

FILTER

GND

SCL

SERIAL

INTERFACE

CIN

C

X

0pF TO 4pF

EXC

PROGRAMMING

SDA

INTERFACE

OUT1

DIGITAL

OUTPUTS

OUT2

7726-030

CAPACITANCE-TO -DIGIT AL CONVERTE R

CLOCK

GENERATOR

-

MODULATOR

EXCITATION

(CDC)

0x0000 TO 0xFFF0

DIGITAL

FILTER

DATA

07726-031

Figure 23. CDC Simplified Block Diagram

CAPDAC

The AD7156 CDC core maximum full-scale input range is 0 pF

to 4 pF. However, the part can accept a higher input capacitance,

caused, for example, by a nonchanging offset capacitance of up to

10 pF. This offset capacitance can be compensated for by using

the programmable on-chip CAPDAC.

CAPDAC

10pF

CIN

C

X

10pF TO 14pF

EXC

Figure 24. Using a CAPDAC

The CAPDAC can be understood as a negative capacitance

connected internally to a CIN pin. The CAPDAC has a 6-bit

resolution and a monotonic transfer function. Figure 24 shows

how to use the CAPDAC to shift the CDC 0 pF to 4 pF input

range to measure capacitance between 10 pF and 14 pF.

0x0000 TO 0xFFF0

0pF TO 4pF

DATA

07726-032

Rev. 0 | Page 11 of 28

Page 12

AD7156

CA

A

A

www.BDTIC.com/ADI

COMPARATOR AND THRESHOLD MODES

The AD7156 comparators and their thresholds can be

programmed to operate in two modes: fixed and adaptive

threshold modes. In an adaptive mode, the threshold

is dynamically adjusted and the comparator output indicates

fast changes and ignores slow changes in the input (sensor)

capacitance. Alternatively, the threshold can be programmed

as a constant (fixed) value, and the output then indicates any

change in the input capacitance that crosses the defined fixed

threshold.

The AD7156 logic output (active high) indicates either a positive or

a negative change in the input capacitance, in both adaptive and

fixed threshold modes (see Figure 25 and Figure 26).

POSITI VE CHANGE

POSITIVE

THRESHOLD

INPUT

CAPACITANCE

OUTPUT

Figure 25. Positive Threshold Mode

Indicates Positive Change in Input Capacitance

INPUT

PACITANCE

NEGATIVE

THRESHOLD

OUTPUT

Figure 26. Negative Threshold Mode

Indicates Negative Change in Input Capacitance

Additionally, for the adaptive mode only, the comparators can

work as window comparators, indicating input either inside or

outside a selected sensitivity band (see Figure 27 and Figure 28).

POSITIVE

THRESHOLD

INPUT CAPACIT ANCE

NEGATIVE

THRESHOLD

OUTPUT

Figure 27. In-Window (Adaptive) Threshold Mode

INPUT INSI DE THRESHOL D WINDOW

OUTPUT ACTIVE

OUTPUT ACTIVE

TIME

NEGATIVE CHANGE

OUTPUT ACTIVE

TIME

TIME

07726-033

07726-034

INPUT OUTSIDE THRESHOLD WINDOW

POSITIVE

THRESHOLD

INPUT CAPACIT ANCE

NEGATIVE

THRESHOLD

OUTPUT

OUTPUT ACTI VE

TIME

07726-036

Figure 28. Out-Window (Adaptive) Threshold Mode

ADAPTIVE THRESHOLD

In an adaptive mode, the thresholds are dynamically adjusted,

ensuring indication of fast changes (for example, an object

moving close to a capacitive proximity sensor) and eliminating

slow changes in the input (sensor) capacitance, usually caused

by environment changes such as humidity or temperature or

changes in the sensor dielectric material over time (see Figure 29).

FAST CHANGE

INPUT C

PACITANCE

THRESHOLD

OUTPUT ACTIVE

OUTPUT

Figure 29. Adaptive Threshold Indicates Fast Changes and Eliminates Slow

Changes in Input Capacitance

SLOW CHANGE

TIME

07726-037

SENSITIVITY

In adaptive threshold mode, the output comparator threshold

is set as a defined distance (sensitivity) above the data average,

below the data average, or both, depending on the selected

threshold mode of operation (see Figure 30). The sensitivity

value is programmable in the range of 0 LSB to 255 LSB of the

12-bit CDC converter (see the Register Descriptions section).

DAT

POSITIVE

THRESHOLD

DATA AVERAGE

NEGATIVE

THRESHOLD

OUTPUT ACTIVE

TIME

Figure 30. Threshold Sensitivity

07726-035

SENSITIVITY

SENSITIVITY

7726-039

Rev. 0 | Page 12 of 28

Page 13

AD7156

−

A

AAV

A

www.BDTIC.com/ADI

DATA AVERAGE

The adaptive threshold algorithm is based on an average calculated

from the previous CDC output data, using the following equation:

)1()(

+−=

NAverageNAverage

−

+

gThrSettlin

2

where:

Av erag e (N) is the new average value.

Av erag e (N − 1) is the average value from the previous cycle.

Data(N) is the latest complete CDC conversion result.

ThrSettling is a parameter, programmable in the setup registers.

A more specific case of the input capacitance waveform is a step

change. The response of the average to an input capacitance step

change (more exactly, response to a step change in the CDC output

data) is an exponential settling curve, which can be characterized

by the following equation:

/TimeConstN

eChangeAverageNAverage −+=

where:

Av erag e (N) is the value of average N complete CDC conversion

cycles after a step change on the input.

Av erag e (0) is the value before the step change.

TimeConst = 2

(ThrSettling + 1)

ThrSettling is a parameter, programmable in the setup registers.

See Figure 31 and the Register Descriptions section for further

information.

INPUT CAPACITANCE

(CDC DATA) CHANGE

)1()(

NAverageNData

1

)1()0()(

TIMEOUT

In the case of a large, long change in the capacitive input, when

the data average adapting to a new condition takes too long, a

timeout can be set.

The timeout becomes active (counting) when the CDC data

goes outside the band of data average ± sensitivity. When the

timeout elapses (a defined number of CDC conversions is

counted), the data average (and thus the thresholds), is forced

to follow the new CDC data value immediately (see Figure 33).

The timeout can be set independently for approaching (for change

in data toward the threshold) and for receding (for change in data

away from the threshold). See Figure 34, Figure 35, and the Register

Descriptions section for further information.

DAT

ERAGE

+ SENSITIVITY

DATA AVERAGE

DATA AVERAGE

– SENSITIVITY

Figure 33. Threshold Timeout After a Large Change in CDC Data

INPUT

CAPACITANCE

THRESHOLD

DATA AVERAGE

TIMEO UT APPROACHING

LARGE CHANGE IN DATA

TIMEOUT

TIME

07726-041

DATA AVERAGE RESPONSE

TIME

Figure 31. Data Average Response to Data Step Change

07726-038

HYSTERESIS

In adaptive threshold mode, the comparator features hysteresis.

The hysteresis is fixed to ¼ of the threshold sensitivity and can

be programmed on or off. The comparator does not have hysteresis in the fixed threshold mode.

DAT

POSITIVE

THRESHOLD

DATAAVERAGE

OUTPUT ACTIV E

OUTPUT

Figure 32. Threshold Hysteresis

TIME

HYSTERSIS

07726-040

OUTPUT ACT IVE

OUTPUT

Figure 34. Approaching Timeout in Negative Threshold Mode

Shortens False Output Trigger

TIME

07726-042

TIMEOUT RECEDING

LARGE CHANGE

INPUT

C

PACITANCE

THRESHOLD

OUTPUT ACTIVE

OUTPUT

TIME

Figure 35. Positive Timeout in Negative Threshold Mode

Shortens Period of Missing Output Trigger

7726-043

Rev. 0 | Page 13 of 28

Page 14

AD7156

www.BDTIC.com/ADI

AUTO-DAC ADJUSTMENT

In adaptive threshold mode, the part can dynamically adjust the

CAPDAC to keep the CDC in an optimal operating capacitive

range. When the auto-DAC function is enabled, the CAPDAC

value is automatically incremented when the data average

exceeds ¾ of the CDC full range (average > 0xA800), and

the CAPDAC value is decremented when the data average

goes below ¼ of the CDC full range (average < 0x5800).

The auto-DAC increment or decrement step depends on

the selected CDC capacitive input range (see the Setup Registers

section).

When the CAPDAC value reaches 0, the ¼ threshold for further

decrementing is ignored. Similarly, when the CAPDAC value

reaches its full range, the ¾ threshold is ignored. The CDC and

the rest of the algorithm are continuously working, and they are

functional down to a capacitance input of 0 pF or as high as the

capacitance input of (CAPDAC full range + CDC full range),

respectively.

POWER-DOWN TIMER

In power sensitive applications, the AD7156 can be set to

automatically enter power-down mode after a programmed

period of time in which the outputs have not been activated.

The AD7156 can then be returned to a normal operational

mode either via the serial interface or by the power supply

off/on sequence.

Rev. 0 | Page 14 of 28

Page 15

AD7156

www.BDTIC.com/ADI

REGISTER DESCRIPTIONS

Table 5. Register Summary1

Addr Pointer

Register

Status 0 0x00 R PwrDown

Ch 1 Data High 1 0x01 R 0x00

Ch 1 Data Low 2 0x02 R 0x00

Ch 2 Data High 3 0x03 R 0x00

Ch 2 Data Low 4 0x04 R 0x00

Ch 1 Average High 5 0x05 R 0x00

Ch 1 Average Low 6 0x06 R 0x00

Ch 2 Average High 7 0x07 R 0x00

Ch 2 Average Low 8 0x08 R 0x00

R/W Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Dec Hex

DacStep2

OUT2

DacStep1

OUT1 C1/C2

RDY2

(0) (1) (0) (1) (0) (0) (1) (1)

RDY1

Ch 1 Sensitivity/

Ch 1 Threshold High

Ch 1 Timeout/

Ch 1 Threshold Low

Ch 1 Setup 11 0x0B R/W RngH1 RngL1

Ch 2 Sensitivity/

Ch 2 Threshold High

Ch 2 Timeout/

Ch 2 Threshold Low

Ch 2 Setup 14 0x0E R/W RngH2 RngL2

Configuration 15 0x0F R/W ThrFixed ThrMD1 ThrMD0 EnCh1 EnCh2 MD2 MD1 MD0

Power-Down Timer 16 0x10 R/W Power-down timeout (6-bit value)

Ch 1 CAPDAC 17 0x11 R/W DacEn1 DacAuto1 DacValue1 (6-bit value)

Ch 2 CAPDAC 18 0x12 R/W DacEn2 DacAuto2 DacValue2 (6-bit value)

Serial Number 3 19 0x13 R Serial number—Byte 3 (MSB)

Serial Number 2 20 0x14 R Serial number—Byte 2

9 0x09 R/W Ch 1 sensitivity (in adaptive threshold mode)/Ch 1 threshold high byte (in fixed threshold mode)

0x08

10 0x0A R/W Ch 1 timeout (in adaptive threshold mode)/CH 1threshold low byte (in fixed threshold mode)

0x86

Hyst1

(0) (0) (0) (0) (0x0B)

12 0x0C R/W Ch 2 sensitivity (in adaptive threshold mode)/Ch 2 threshold high byte (in fixed threshold mode)

0x08

13 0x0D R/W Ch 2 timeout (in adaptive threshold mode)/Ch 2 threshold low byte (in fixed threshold mode)

0x86

Hyst2

(0) (0) (0) (0) (0x0B)

(0) (0) (0) (1) (1) (0) (0) (1)

(0) (1) (0x00)

(1) (1) (0x00)

(1) (1) (0x00)

ThrSettling1 (4-bit value)

ThrSettling2 (4-bit value)

Serial Number 1 21 0x15 R Serial number—Byte 1

Serial Number 0 22 0x16 R Serial number—Byte 0 (LSB)

Chip ID 23 0x17 R Chip identification code

1

The default values are given in parentheses.

Rev. 0 | Page 15 of 28

Page 16

AD7156

www.BDTIC.com/ADI

STATUS REGISTER

Address Pointer 0x00 8 Bits, Read Only Default Value 0x53 Before Conversion, 0x54 After Conversion

The status register indicates the status of the part. The register can be read via the 2-wire serial interface to query the status of the outputs,

check the CDC finished conversion, and check whether the CAPDAC has been changed by the auto-DAC function.

Table 6. Status Register Bit Map1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PwrDown

DacStep2

(0) (1) (0) (1) (0) (0) (1) (1)

1

The default values are given in parentheses.

Table 7. Status Register Bit Descriptions

Bit Mnemonic Description

7 PwrDown PwrDown = 1 indicates that the part is in a power-down.

6

DacStep2

DacStep2 = 0 indicates that the Channel 2 CAPDAC value was changed after the last CDC conversion as part of

the auto-DAC function. The bit value is updated after each finished CDC conversion on this channel.

5 OUT2

OUT2 = 1 indicates that the Channel 2 data (CIN2 capacitance) crossed the threshold, according to the selected

comparator mode of operation. The bit value is updated after each finished CDC conversion on this channel.

4

DacStep1

DacStep1 = 0 indicates that the Channel 1 CAPDAC value was changed during the last conversion as part of the

auto-DAC function. The bit value is updated after each finished CDC conversion on this channel.

3 OUT1

OUT1 = 1 indicates that the Channel 1 data (CIN1 capacitance) crossed the threshold, according to the selected

comparator mode of operation. The bit value is updated after each finished CDC conversion on this channel.

2 C1/C2

C1/C2 = 0 indicates that the last finished CDC conversion was on Channel 1.

C1/C2 = 1 indicates that the last finished CDC conversion was on Channel 2.

1

RDY2 = 0 indicates a finished CDC conversion on Channel 2. The bit is reset back to 1 when the Channel 2 data

RDY2

register is read via the serial interface or after a part reset or power-up.

0

RDY1 = 0 indicates a finished CDC conversion on Channel 1. The bit is reset back to 1 when the Channel 1 data

RDY1

register is read via serial interface or after a part reset or power-up.

OUT2

DacStep1

OUT1 C1/C2

RDY2

RDY1

Rev. 0 | Page 16 of 28

Page 17

AD7156

−

−

−

x

−

W

www.BDTIC.com/ADI

DATA REGISTERS

Ch 1 Address Pointer 0x01, Address Pointer 0x02 Ch 2 Address Pointer 0x03, Address Pointer 0x04 16 Bits, Read Only Default Value 0x0000

Data from the last complete capacitance-to-digital conversion

reflects the capacitance on the input. Only the 12 MSBs of the

data registers are used for the CDC result. The 4 LSBs are

always 0, as shown in Figure 36.

The data register is updated after a finished conversion on the

capacitive channel, with one exception: when the serial interface

read operation from the data register is in progress, the data

register is not updated and the new capacitance conversion

result is lost.

The stop condition on the serial interface is considered to be

the end of the read operation. Therefore, to prevent incorrect

data reading through the serial interface, the two bytes of a

data register should be read sequentially using the register

address pointer autoincrement feature of the serial interface.

The nominal AD7156 CDC transfer function (an ideal transfer

function excluding offset and/or gain error) maps the input

capacitance between zero scale and full scale to output data

codes between 0x3000 and 0xD000 only (see Tabl e 8 ).

DATA HIGHMSB DATA LO

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2

BIT 1 BIT 0 BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2

For an ideal part, linear, with no offset error and no gain error,

the input capacitance can be calculated from the output data

using the following equation:

Data

pF)( RangeInput

C ×

=

288,12

960,40

(pF)_

where Input_Range = 4 pF, 2 pF, 1 pF, or 0.5 pF.

The following is the same equation written with hexadecimal

numbers:

Data

pF)( RangeInput

C ×

=

3000x0

000xA0

(pF)_

With offset error and gain error included, the equation is:

Data

pF)(

=

C

⎛

1

+

⎜

⎝

288,12

960,40

(%)_

ErrorGain

⎞

+

⎟

%100

⎠

(pF)_

RangeInput

××

ErrorOffset

)pF(_

Or the same equation with hexadecimal numbers:

Data

0

C

pF)(

=

⎛

+

1

⎜

⎝

3000

000xA0

ErrorGain

(%)_

⎞

+

⎟

%100

⎠

RangeInput

ErrorOffset

××

(pF)_

)pF(_

LSB

BIT 1 BIT 0

12-BIT CDC RESULT

Figure 36. CDC Data Register

Table 8. AD7156 Capacitance-to-Data Mapping1

Data Input Capacitance

0x0000 Under range (below 0 pF)

0x3000 Zero scale (0 pF)

0x5800 Quarter scale (+0.5 pF)—auto-DAC step down

0x8000 Midscale (+1 pF)

0xA800 Three-quarter scale (+1.5 pF)—auto-DAC step up

0xD000 Full scale (+2 pF)

0xFFF0 Over range (above +2 pF)

1

An ideal part with no offset and gain error, values shown in picofarad for 2 pF capacitance input range.

0

07726-044

Rev. 0 | Page 17 of 28

Page 18

AD7156

A

_

g

www.BDTIC.com/ADI

AVERAGE REGISTERS

Ch 1 Address Pointer 0x05, Address Pointer 0x06 Ch 2 Address Pointer 0x07, Address Pointer 0x08 16 Bits, Read Only Default Value 0x0000

These registers show the average calculated from the previous

CDC data. The 12-bit CDC result corresponds to the 12 MSBs

of the average register.

The settling time of the average can be set by programming

the ThrSettling bits in the setup registers. The average register

is overwritten directly with the CDC output data, that is, the

history is erased if the timeout is enabled and elapses.

FIXED THRESHOLD REGISTERS

Ch 1 Address Pointer 0x09, Address Pointer 0x0A Ch 2 Address Pointer 0x0C, Address Pointer 0x0D 16 Bits, Read/Write, Factory Preset 0x0886

A constant threshold for the output comparator in the fixed

threshold mode can be set using these registers. The 12-bit

CDC result corresponds to the 12 MSBs of the threshold register. The fixed threshold registers share the address pointer and

location on chip with the sensitivity and timeout registers. The

fixed threshold registers are not accessible in the adaptive threshold mode.

SENSITIVITY REGISTERS

Ch 1 Address Pointer 0x09 Ch 2 Address Pointer 0x0C 8 Bits, Read/Write, Factory Preset 0x08

Sensitivity registers set the distance of the positive threshold above

the data average, and the distance of the negative threshold below

the data average, in the adaptive threshold mode.

DAT

POSITIVE

THRESHOLD

DATA AVERAGE

NEGATIVE

THRESHOLD

OUTPUT ACTIVE

TIME

Figure 37. Threshold Sensitivity

The sensitivity is an 8-bit value and is mapped to the lower eight

bits of the 12-bit CDC data, that is, it corresponds to the 16-bit

data register as shown in Figure 38.

SENSITIVIT Y

BIT 7 BIT 6 BIT 5 BIT 4 BI T 3

DATA HIGH DATA LOW

BIT 7 BIT 6 BIT 5 BIT 4 BI T 3 BIT 2

Figure 38. Relation Between Sensitivity Register and CDC Data Register

BIT 1 BIT 0 BI T 7 BIT 6 BI T 5 BIT 4 BIT 3 BI T 2

12-BI T CDC RESULT

BIT 2 BIT 1 BIT 0

SENSITIVITY

SENSITIVITY

7726-045

BIT 1 BIT 0

07726-046

For an ideal part with no gain error, the sensitivity can be

calculated using the following equation:

)pF( RangeInput

ySensitivit ×=

2560

RegSens

)(pF_

_

Or the same equation with hexadecimal numbers

)pF( RangeInput

ySensitivit ×=

RegSens

00xA0

)(pF_

_

With gain error included, the sensitivity can be calculated using

the following equation:

_

)pF(

ySensitivit

⎛

⎜

+

1

⎜

⎝

ErrorGain

%100

RegSense

2560

(%)_

⎞

⎟

⎟

⎠

RangeInput

××=

)pF(_

Or the same equation with hexadecimal numbers

Sense

ySensitivit

)pF(

ErrorGain

⎛

⎜

+

1

⎜

⎝

(%)_

%100

Re

00xA0

⎞

⎟

⎟

⎠

RangeInput

××=

)pF(_

TIMEOUT REGISTERS

Ch 1 Address Pointer 0x0A Ch 2 Address Pointer 0x0D 8 Bits, Read/Write, Factory Preset 0x86

Table 9. Timeout Register Bit Map

Bit Mnemonic Default

[7:4]

[3:0]

These registers set timeouts for the adaptive threshold mode.

The approaching timeout starts when the CDC data crosses the

data average ± sensitivity band toward the threshold, according

to the selected positive, negative, or window threshold mode.

The approaching timeout elapses after the number of conversion

cycles equals 2

four most significant bits of the timeout register.

The receding timeout starts when the CDC data crosses

the data average ± sensitivity band away from the threshold,

according to the selected positive or negative threshold mode.

The receding timeout is not used in the window threshold

mode. The receding timeout elapses after the number of

conversion cycles equals 2

value of the four least significant bits of the timeout register.

When either the approaching or receding timeout elapses (that

is, after the defined number of CDC conversions is counted),

the data average (and thus the thresholds) is forced to follow

the new CDC data value immediately.

When the timeout register equals 0, timeouts are disabled.

TimeOutApr 0x08

TimeOutRec 0x06

TimeOutApr

, where TimeOutApr is the value of the

TimeOutRec

, where TimeOutRec is the

Rev. 0 | Page 18 of 28

Page 19

AD7156

www.BDTIC.com/ADI

SETUP REGISTERS

Ch 1 Address Pointer 0x0B Ch 2 Address Pointer 0x0E 8 Bits, Read/Write, Factory Preset 0x0B

Table 10. Setup Registers Bit Map1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

RngH RngL

(0) (0) (0) (0) (0x0B)

1

The default values are given in parentheses.

Hyst

Table 11. Setup Registers Bit Descriptions

Bit Mnemonic Description

7

6

5 This bit should be 0 for the specified operation.

4

[3:0] ThrSettling

RngH

RngL

Hyst

Range bits set the CDC input range and determine the step for the auto-DAC function.

RngH RngL Capacitive Input Range (pF) Auto-DAC Step (CAPDAC LSB)

0 0 2 4

0 1 0.5 1

1 0 1 2

1 1 4

Hyst = 1 disables hysteresis in adaptive threshold mode. This bit has no effect in fixed threshold mode;

hysteresis is always disabled in the fixed threshold mode.

Determines dynamic behavior of the data average and thus the settling time of the adaptive thresholds. Data

average is calculated from the previous CDC output data, using equation:

−−

NAverageNData

+−=

NAverageNAverage

)1()(

where:

Averag e(N) is the new average value.

Averag e(N − 1) is the average value from the previous cycle.

Data(N) is the latest complete CDC conversion result.

ThrSettling is the programmable parameter.

The response of the average to an input capacitance step change (that is, response to the change in the CDC

output data) is an exponential settling curve characterized by the following equation:

where:

Average(N) is the value of average N complete CDC conversion cycles after a step change on the input.

Averag e(0) is the value before the step change.

TimeConst can be selected in the range between 2 and 65,536 conversion cycle multiples, in steps of power of

2, by programming the ThrSettling bits. TimeConst = 2

2

+

gThrSettlin

/ TimeConstN

eChangeAverageNAverage −+=

1

)1()(

)1()0()(

(ThrSettling + 1)

INPUT CAPAC ITANCE

(CDC DATA) CHANGE

ThrSettling (4-Bit Value)

8

DATAAVERAGE RES PONSE

TIME

Figure 39. Data Average Response to Data Step Change

Rev. 0 | Page 19 of 28

07726-049

Page 20

AD7156

www.BDTIC.com/ADI

CONFIGURATION REGISTER

Address Pointer 0x0F 8 Bits, Read/Write, Factory Preset 0x19

Table 12. Configuration Register Bit Map1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

ThrFixed ThrMD1 ThrMD0 EnCh1 EnCh2 MD2 MD1 MD0

(0) (0) (0) (1) (1) (0) (0) (1)

1

The default values are given in parentheses.

Table 13.Configuration Register Bit Descriptions

Bit Mnemonic Description

7 ThrFixed

6

5

4 EnCh1 Enables conversion on Channel 1

3 EnCh2 Enables conversion on Channel 2

2

1

0

ThrMD1

ThrMD0

MD2

MD1

MD0

ThrFixed = 1 sets the fixed threshold mode; the outputs reflect the comparison of data and a fixed (constant)

value of the threshold registers.

ThrFixed = 0 sets the adaptive threshold mode; the outputs reflect the comparison of data to the adaptive

thresholds. The adaptive threshold is set dynamically, based on the history of the previous data.

These bits set the output comparators mode

Output Active When

ThrMD1 ThrMD0 Threshold Mode

0 0 Negative Data < average – sensitivity Data < threshold

0 1 Positive Data > average + sensitivity Data > threshold

1 0 In-window Data > average – sensitivity

1 1 Out-window Data < average – sensitivity

Converter mode of operation setup

MD2 MD1 MD0 Mode Description

0 0 0 Idle The part is fully powered up, but performing no conversion.

0 0 1

0 1 0 Single conversion

0 1 1 Power-down

1 X X Reserved Do not use these modes.

Continuous

Conversion

Adaptive Threshold Mode Fixed Threshold Mode

and

Data < average + sensitivity

or

Data > average + sensitivity

The part is repeatedly performing conversions on the

enabled channel(s); if two channels are enabled, the part is

sequentially switching between them.

The part performs a single conversion on the enabled

channel; if two channels are enabled, the part performs two

conversions, one on each channel. After finishing the

conversion(s), the part goes to the idle mode.

The part powers down the on-chip circuits, except the

digital interface.

Rev. 0 | Page 20 of 28

Page 21

AD7156

www.BDTIC.com/ADI

POWER-DOWN TIMER REGISTER

Address Pointer 0x10 8 Bits, Read/Write, Factory Preset 0x40

Table 14. Power-Down Timer Register Bit Map1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Power-down timeout (6-bit value)

(0) (1) (0x00)

1

The default values are given in parentheses.

Table 15.Power-Down Timer Register Bit Descriptions

Bit Mnemonic Description

7 This bit must be 0 for proper operation.

6 This bit must be 1 for proper operation.

[5:0]

Power- down

timeout

This bit defines the period duration of the power-down timeout.

If the comparator outputs have not been activated during the programmed period, the part enters power-down

mode automatically. The part can be then returned to a normal operational mode either via the serial interface

or by the power supply off/on sequence.

The period is programmable in steps of 4 hours. For example, setting the value to 0x06 sets the duration to 24

hours. The maximum value of 0x3F corresponds to approximately 10.5 days.

The value of 0x00 disables the power-down timeout, and the part does not enter power-down mode automatically.

CAPDAC REGISTERS

Ch 1 Address Pointer 0x11 Ch 2 Address Pointer 0x12 8 Bits, Read/Write, Factory Preset 0xC0

Table 16. CAPDAC Registers Bit Map1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

DacEn DacAuto DacValue (6-bit value)

(1) (1) (0x00)

1

The default values are given in parentheses.

Table 17. CAPDAC Registers Bit Descriptions

Bit Mnemonic Description

7 DacEn DacEn = 1 enables capacitive the DAC.

6 DacAuto DacAuto = 1 enables the auto-DAC function in the adaptive threshold mode.

When the auto-DAC function is enabled, the part dynamically adjusts the CAPDAC to keep the CDC in an

optimal operating capacitive range. The CAPDAC value is automatically incremented when the data average

exceeds ¾ of the CDC full range, and the CAPDAC value is decremented when the data average goes below ¼

of the CDC full range. The auto-DAC increment or decrement step depends on the selected CDC capacitive

input range.

This bit has no effect in fixed threshold mode; the auto-DAC function is always disabled in the fixed threshold mode.

[5:0] DacValue CAPDAC value, Code 0x00 ≈ 0 pF, Code 0x3F ≈ CAPDAC full range.

SERIAL NUMBER REGISTER

Address Pointer 0x13, Address Pointer 0x14, Address Pointer 0x15, Address Pointer 0x16 32 Bits, Read Only, Factory Preset 0xXXXX

This register holds a serial number, unique for each individual part.

CHIP ID REGISTER

Address Pointer 0x17 8 Bits, Read Only, Factory Preset 0xXX

This register holds the chip identification code, used in factory

manufacturing and testing.

Rev. 0 | Page 21 of 28

Page 22

AD7156

www.BDTIC.com/ADI

SERIAL INTERFACE

The AD7156 supports an I2C-compatible, 2-wire serial interface. The two wires on the serial bus (interface) are called SCL

(clock) and SDA (data). These two wires carry all addressing,

control, and data information one bit at a time over the bus to

all connected peripheral devices. The SDA wire carries the data,

while the SCL wire synchronizes the sender and receiver during

the data transfer. The devices on the bus are classified as either

master or slave devices. A device that initiates a data transfer

message is called a master, whereas a device that responds to

this message is called a slave.

To control the AD7156 device on the bus, the following

protocol must be utilized. First, the master initiates a data

transfer by establishing a start condition, defined by a highto-low transition on SDA while SCL remains high. This

indicates that the start byte follows. This 8-bit start byte is

made up of a 7-bit address plus an R/W bit indicator.

All peripherals connected to the bus respond to the start

condition and shift in the next eight bits (7-bit address + R/W

bit). The bits arrive MSB first. The peripheral that recognizes

the transmitted address responds by pulling the data line low

during the ninth clock pulse. This is known as the acknowledge

bit. All other devices withdraw from the bus at this point and

maintain an idle condition. An exception to this is the general

call address, which is described in the General Call section. In

the idle condition, the device monitors the SDA and SCL lines

waiting for the start condition and the correct address byte.

The R/W bit determines the direction of the data transfer.

A Logic 0 LSB in the start byte means that the master writes

information to the addressed peripheral. In this case, the

AD7156 becomes a slave receiver. A Logic 1 LSB in the

start byte means that the master reads information from

the addressed peripheral. In this case, the AD7156 becomes

a slave transmitter. In all instances, the AD7156 acts as a

standard slave device on the serial bus.

The start byte address for the AD7156 is 0x90 for a write and

0x91 for a read.

READ OPERATION

When a read is selected in the start byte, the register that is

currently addressed by the address pointer is transmitted to the

SDA line by the AD7156. This is then clocked out by the master

device, and the AD7156 awaits an acknowledge from the master.

If an acknowledge is received from the master, the address

autoincrementer automatically increments the address pointer

register and outputs the next addressed register content to the

SDA line for transmission to the master. If no acknowledge is

received, the AD7156 returns to the idle state and the address

pointer is not incremented. The address pointers’ autoincrementer

allows block data to be written to or read from the starting address

and subsequent incremental addresses.

In continuous conversion mode, the address pointers’ autoincrementer should be used for reading a conversion result.

This means that the two data bytes should be read using one

multibyte read transaction rather than two separate single byte

transactions. The single byte data read transaction may result in

the data bytes from two different results being mixed. The same

applies for four data bytes if both capacitive channels are enabled.

The user can also access any unique register (address) on a

one-to-one basis without having to update all the registers.

The address pointer register contents cannot be read.

If an incorrect address pointer location is accessed or if the

user allows the autoincrementer to exceed the required register

address, the following applies:

• In read mode, the AD7156 continues to output various

internal register contents until the master device issues

a no acknowledge, start, or stop condition. The address

pointers’ autoincrementer contents are reset to point to

the status register at the 0x00 address when a stop condition

is received at the end of a read operation. This allows the

status register to be read (polled) continually without

having to constantly write to the address pointer.

• In write mode, the data for the invalid address is not

loaded into the AD7156 registers, but an acknowledge

is issued by the AD7156.

WRITE OPERATION

When a write is selected, the byte following the start byte is

always the register address pointer (subaddress) byte, which

points to one of the internal registers on the AD7156. The

address pointer byte is automatically loaded into the address

pointer register and acknowledged by the AD7156. After the

address pointer byte acknowledge, a stop condition, a repeated

start condition, or another data byte can follow from the master.

A stop condition is defined by a low-to-high transition on SDA

while SCL remains high. If a stop condition is encountered by

the AD7156, it returns to its idle condition and the address

pointer is reset to 0x00.

If a data byte is transmitted after the register address pointer

byte, the AD7156 loads this byte into the register that is currently addressed by the address pointer register and sends

an acknowledge, and the address pointer autoincrementer

automatically increments the address pointer register to the

next internal register address. Thus, subsequent transmitted

data bytes are loaded into sequentially incremented addresses.

Rev. 0 | Page 22 of 28

Page 23

AD7156

www.BDTIC.com/ADI

If a repeated start condition is encountered after the address

pointer byte, all peripherals connected to the bus respond exactly

as outlined previously for a start condition; that is, a repeated

start condition is treated the same as a start condition. When a

master device issues a stop condition, it relinquishes control of

the bus, allowing another master device to take control of the

bus. Therefore, a master wanting to retain control of the bus

issues successive start conditions known as repeated start

conditions.

AD7156 RESET

To reset the AD7156 without having to reset the entire serial

bus, an explicit reset command is provided. This uses a particular

address pointer word as a command word to reset the part and

upload all default settings. The AD7156 does not respond to the

serial bus commands (do not acknowledge) during the default

values upload for approximately 2 ms.

The reset command address word is 0xBF.

SDA

GENERAL CALL

When a master issues a slave address consisting of seven 0s

with the eighth bit (R/W) set to 0, this is known as the general

call address. The general call address is for addressing every

device connected to the serial bus. The AD7156 acknowledges

this address and reads in the following data byte.

If the second byte is 0x06, the AD7156 is reset, completely

uploading all default values. The AD7156 does not respond

to the serial bus commands (do not acknowledge) during the

default values upload for approximately 2 ms.

The AD7156 does not acknowledge any other general call

commands.

SCL

START ADDR

89 8 9 89 PS

1 – 7 1 – 7 1 – 7

ACK SUBADDRESS ACK DATA ACK S TOP

R/W

Figure 40. Bus Data Transfer

7726-050

WRITE

SEQUENCE

READ

SEQUENCE

LSB = 0

S SLAVE ADDR A(S ) SUB ADDR A(S) S SLAVE ADDR A(S) DATA

S = START BIT

P = STOP BIT

A(S) = ACKNOWLEDGE BY SLAVE

A(M) = ACKNOWLEDGE BY MASTER

Figure 41. Write and Read Sequences

DATA A(S)S SLAVE ADDR A(S) SUB ADDR A(S)

LSB = 1

A(S) = NO ACKNOWLEDGE BY SLAVE

A(M) = NO ACKNOWLEDG E BY MASTER

DATA P

A(M)

A(S)

DATA P

A(M)

07726-051

Rev. 0 | Page 23 of 28

Page 24

AD7156

www.BDTIC.com/ADI

HARDWARE DESIGN CONSIDERATIONS

OVERVIEW

The AD7156 is an interface to capacitive sensors.

On the input side, Sensor C

can be connected directly between

X

the AD7156 EXC and CIN pins. The way it is connected and the

electrical parameters of the sensor connection, such as parasitic

resistance or capacitance, can affect the system performance.

Therefore, any circuit with additional components in the capacitive

front end, such as overvoltage protection, has to be carefully

designed, considering the AD7156 specified limits and information provided in this section.

On the output side, the AD7156 can work as a standalone device,

using the power-up default register settings and flagging the

result on the digital outputs. Alternatively, the AD7156 can be

interfaced to a microcontroller via the 2-wire serial interface,

offering flexibility by overwriting the AD7156 register values

from the host with a user-specific setup.

PARASITIC CAPACITANCE TO GROUND

PARASITIC RESISTANCE TO GROUND

R

R

GND1

GND2

CIN

C

X

EXC

Figure 43. Parasitic Resistance to Ground

CDC

DATA

The AD7156 CDC result is affected by a leakage current from

to ground; therefore, CX should be isolated from the ground.

C

X

The equivalent resistance between C

and ground should be

X

maximized (see Figure 43). For more information, see Figure 10

to Figure 13.

PARASITIC PARALLEL RESISTANCE

07726-053

C

C

GND1

GND2

CIN

C

X

EXC

Figure 42. Parasitic Capacitance to Ground

CDC

DATA

The CDC architecture used in the AD7156 measures the

capacitance, C

CIN pins. In theory, any capacitance, C

, connected between the EXC pins and the

X

, to ground should

GND

not affect the CDC result (see Figure 42).

The practical implementation of the circuitry in the chip implies

certain limits, and the result is gradually affected by capacitance

to ground (for information about the allowed capacitance to

GND for CIN and information about excitation see Tabl e 1

and Figure 4 to Figure 9).

CIN

R

C

P

X

07726-052

EXC

Figure 44. Parasitic Parallel Resistance

CDC

DATA

07726-054

The AD7156 CDC measures the charge transfer between the

EXC and CIN pins. Any resistance connected in parallel to the

measured capacitance, C

(see Figure 44), such as the parasitic

X

resistance of the sensor, also transfers charge. Therefore, the

parallel resistor is seen as an additional capacitance in the

output data. The equivalent parallel capacitance (or error

caused by the parallel resistance) can be approximately

calculated as

=

C

P

P

41××

fR

EXC

where:

is the parallel resistance.

R

P

is the excitation frequency.

f

EXC

For additional information, see Figure 15.

Rev. 0 | Page 24 of 28

Page 25

AD7156

V

www.BDTIC.com/ADI

PARASITIC SERIAL RESISTANCE

R

S1

C

X

R

S2

CIN

EXC

Figure 45. Parasitic Serial Resistance

CDC

DATA

The AD7156 CDC result is affected by a resistance in series

with the measured capacitance.

The total serial resistance (R

+ RS2 in Figure 45) should be in

S1

the order of hundreds of Ω (see Figure 14).

INPUT OVERVOLTAGE PROTECTION

CDC

R

S1

CIN

C

X

R

S2

EXC

07726-055

INPUT EMC PROTECTION

82k39k

CIN

C

X

Figure 47. AD7156 CIN EMC Protection

10k

22pF68pF

EXC

47pF

GND

CDC

07726-057

Some applications may require an additional input filter for

improving EMC. Any input filter must be carefully designed,

considering the balance between the system capacitance

performance and system electromagnetic immunity.

Figure 47 shows one of the possible input circuit configurations

for significantly improving the system immunity against high

frequency noise while only slightly affecting the AD7156

performance in terms of additional gain and offset error.

POWER SUPPLY DECOUPLING AND FILTERING

CDC

1k

0.1µF 10µF

SDA

SCL

DD

1k 1k

GND

07726-056

Figure 46. AD7156 CIN Overvoltage Protection

The AD7156 capacitive input has an internal ESD protection.

However, some applications may require an additional overvoltage protection, depending on the application-specific

requirements. Any additional circuit in the capacitive front

end must be carefully designed, especially with respect to the

limits recommended for maximum capacitance to ground,

maximum serial resistance, maximum leakage, and so on.

GND

Figure 48. AD7156 V

Decoupling and Filtering

DD

7726-058

The AD7156 has good dc and low frequency power supply

rejection but may be sensitive to higher frequency ripple and

noise, specifically around the excitation frequency and its

harmonics. Figure 48 shows a possible circuit configuration

for improving the system immunity against ripple and noise

coupled to the AD7156 via the power supply.

If the serial interface is connected to the other circuits in the

system, it is better to connect the pull-up resistors on the other

side of the V

filter than to connect to the AD7156. If the

DD

AD7156 is used in standalone mode and the serial interface

is not used, it is better to connect the pull-up resistors directly

to the AD7156 V

DD

.

Rev. 0 | Page 25 of 28

Page 26

AD7156

V

V

www.BDTIC.com/ADI

APPLICATION EXAMPLES

1k0.1µF 1k

1k 1k

LED1 LED2

3V

BATTERY

07726-059

C

SENS1

C

SENS2

CIN1

EXC1

CIN2

EXC2

VDD

AD7156

SDA

SCL

OUT1

OUT2

GND

Figure 49. AD7156 Standalone Operation Application Diagram

3.3

1k0.1µF 1k

SDA

SCL

HOST

MICROCONTRO LLER

C

SENS1

CIN1

EXC1

VDD

AD7156

SDA

SCL

CIN2

C

SENS2

EXC2

OUT1

OUT2

GND

IRQ1

IRQ2

07726-060

Figure 50. AD7156 Interfaced to a Host Microcontroller

C

SENS1

C

SENS2

39k

39k

68pF

68pF

82k

10k

82k

10k

1k

0.1µF 10µF 1µF 1µF

CIN1

22pF

EXC1

47pF

CIN2

22pF

EXC2

47pF

VDD

AD7156

SDA

SCL

OUT1

OUT2

GND

Figure 51. AD7156 Standalone Operation with EMC Protection

3.3V

ADP1720-3.3

1k1k

Q1

SUPPLY

R1

R2

OUT1

OUT2

Q2

7726-061

Rev. 0 | Page 26 of 28

Page 27

AD7156

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.50

0.40

0.30

0.05 MAX

0.02 NOM

0.20 REF

0.30

0.23

0.18

6

*

EXPOSED

PAD

(BOTTOM VIEW)

5

2.48

2.38

2.23

10

1

0.50 BSC

I

P

N

I

R

(

1.74

1.64

1.49

N

D

0

1

A

R

O

T

C

I

)

0

2

.

031208-B

PIN 1 INDEX

AREA

0.80

0.75

0.70

SEATING

PLANE

3.00

BSC SQ

TOP VIEW

0.80 MAX

0.55 NOM

*

FOR PROPER CONNECTION OF THE EXPOSED PAD PLEASE REFER TO

THE PIN CONF IGURATION AND FUNCTIO N DESCRIPTIONS SECTIO N

OF THIS DATA SHEET.

Figure 52. 10-Lead Lead Frame Chip Scale Package [LFCSP_WD]

3 mm × 3 mm Body, Very Thin, Dual Lead

(CP-10-9)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option Branding

AD7156BCPZ-REEL

AD7156BCPZ-REEL71 −40°C to +85°C 10-Lead Lead Frame Chip Scale Package [LFCSP_WD] CP-10-9 C6L

EVAL-AD7156EBZ

1

Z = RoHS Compliant Part.

1

−40°C to +85°C 10-Lead Lead Frame Chip Scale Package [LFCSP_WD] CP-10-9 C6L

1

Evaluation Board

Rev. 0 | Page 27 of 28

Page 28

AD7156

www.BDTIC.com/ADI

NOTES

Purchase of licensed I2C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips I2C Patent

Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard Specification as defined by Philips.

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07726-0-10/08(0)

Rev. 0 | Page 28 of 28

Loading...

Loading...