Page 1

14-Bit 128 kSPS

a

FEATURES

AC and DC Characterized and Specified

(K, B, T Grades)

128k Conversions per Second

1 MHz Full Power Bandwidth

500 kHz Full Linear Bandwidth

80 dB S/N+D (K, B, T Grades)

Twos Complement Data Format (Bipolar Mode)

Straight Binary Data Format (Unipolar Mode)

10 MV Input Impedance

8-Bit Bus Interface (See AD779 for 16-Bit Interface)

On-Board Reference and Clock

10 V Unipolar or Bipolar Input Range

Pin Compatible with AD678 12-Bit, 200 kSPS ADC

MIL-STD-883 Compliant Versions Available

GENERAL DESCRIPTION

The AD679 is a complete, multipurpose 14-bit monolithic

analog-to-digital converter, consisting of a sample-hold amplifier (SHA), a microprocessor compatible bus interface, a voltage

reference and clock generation circuitry.

The AD679 is specified for ac (or “dynamic”) parameters such

as S/N+D ratio, THD and IMD which are important in signal

processing applications. In addition, the AD679K, B and T

grades are fully specified for dc parameters which are important

in measurement applications.

The 14 data bits are accessed in two read operations (8+6), with

left justification. Data format is straight binary for unipolar

mode and twos complement binary for bipolar mode. The input

has a full-scale range of 10 V with a full power bandwidth of

1 MHz and a full linear bandwidth of 500 kHz. High input impedance (10 MΩ) allows direct connection to unbuffered

sources without signal degradation. Conversions can be initiated

either under microprocessor control or by an external clock

asynchronous to the system clock.

This product is fabricated on Analog Devices’ BiMOS process,

combining low power CMOS logic with high precision, low

noise bipolar circuits; laser-trimmed thin-film resistors provide

high accuracy. The converter utilizes a recursive subranging algorithm which includes error correction and flash converter circuitry to achieve high speed and resolution.

The AD679 operates from +5 V and ±12 V supplies and dissipates 560 mW (typ). 28-pin plastic DIP, ceramic DIP and 44

J-leaded ceramic surface mount packages are available.

*Protected by U.S. Patent Nos. 4,804,960; 4,814,767; 4,833,345; 4,250,445;

4,808,908; RE 30,586

Complete Sampling ADC

AD679*

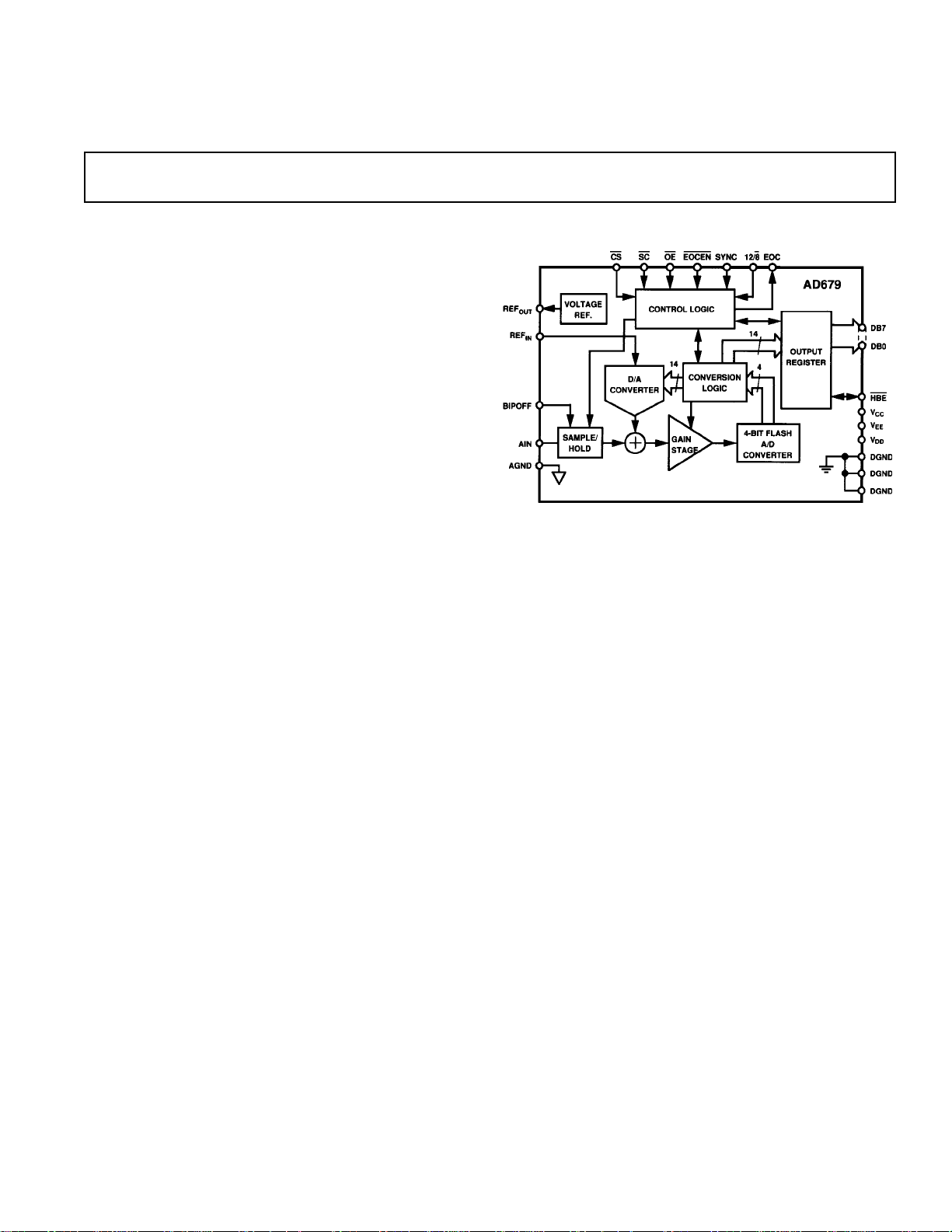

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. COMPLETE INTEGRATION: The AD679 minimizes

external component requirements by combining a high

speed sample-hold amplifier (SHA), ADC, 5 V reference,

clock and digital interface on a single chip. This provides a

fully specified sampling A/D function unattainable with

discrete designs.

2. SPECIFICATIONS: The AD679K, B and T grades provide

fully specified and tested ac and dc parameters. The AD679J,

A and S grades are specified and tested for ac parameters; dc

accuracy specifications are shown as typicals. DC specifications (such as INL, gain and offset) are important in control

and measurement applications. AC specifications (such as

S/N+D ratio, THD and IMD) are of value in signal processing applications.

3. EASE OF USE: The pinout is designed for easy board layout, and the two read output provides compatibility with 8bit buses. Factory trimming eliminates the need for calibration

modes or external trimming to achieve rated performance.

4. RELIABILITY: The AD679 utilizes Analog Devices’ monolithic BiMOS technology. This ensures long term reliability

compared to multichip and hybrid designs.

5. UPGRADE PATH: The AD679 provides the same pinout as

the 12-bit, 200 kSPS AD678 ADC.

6. The AD679 is available in versions compliant with MILSTD-883. Refer to the Analog Devices Military Products

Databook or current AD679/883B data sheet for detailed

specifications.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

AD679–SPECIFICATIONS

(T

to T

, VCC = +12 V 6 5%, VEE = –12 V 6 5%, VDD = +5 V 6 10%, f

MAX

1

AC SPECIFICATIONS

MIN

unless otherwise noted)

AD679J/A/S AD679K/B/T

Parameter Min Typ Max Min Typ Max Units

SIGNAL-TO-NOISE AND DISTORTION (S/N+D) RATIO

2

–0.5 dB Input (Referred to –0 dB Input) 78 79 80 81 dB

–20 dB Input (Referred to –20 dB Input) 58 59 60 61 dB

–60 dB Input (Referred to –60 dB Input) 18 19 20 21 dB

TOTAL HARMONIC DISTORTION (THD)

3

@ +25°C –90 –84 –90 –84 dB

0.003 0.006 0.003 0.006 %

T

MIN

to T

MAX

–88 –82 –88 –82 dB

0.004 0.008 0.004 0.008 %

PEAK SPURIOUS OR PEAK HARMONIC COMPONENT –90 –84 –90 –84 dB

FULL POWER BANDWIDTH 1 1 MHz

FULL LINEAR BANDWIDTH 500 500 kHz

INTERMODULATION DISTORTION (IMD)

4

2nd Order Products –90 –84 –90 –84 dB

3rd Order Products –90 –84 –90 –84 dB

= 128 kSPS, fIN = 10.009 kHz

SAMPLE

DIGITAL SPECIFICATIONS

(All device types T

MIN

to T

, VCC = +12 V 6 5%, VEE = –12 V 6 5%, VDD = +5 V 6 10%)

MAX

Parameter Test Conditions Min Max Units

LOGIC INPUTS

V

IH

V

IL

I

IH

I

IL

C

IN

High Level Input Voltage 2.0 V

DD

V

Low Level Input Voltage 0 0.8 V

High Level Input Current V

Low Level Input Current V

= 5 V –10 +10 µA

IN

= 0 V –10 +10 µA

IN

Input Capacitance 10 pF

LOGIC OUTPUTS

V

OH

V

OL

I

OZ

C

OZ

NOTES

1

flN amplitude = –0.5 dB (9.44 V p-p) bipolar mode full scale unless otherwise indicated. All measurements referred to a –0 dB (9.997 V p-p) input signal

unless otherwise noted.

2

See Figure 15 for higher frequencies and other input amplitudes.

3

See Figures 13 and 14 for higher frequencies and other input amplitudes.

4

fA = 9.08 kHz, fB = 9.58 kHz, with f

Specifications subject to change without notice.

High Level Output Voltage IOH = 0.1 mA 4.0 V

I

= 0.5 mA 2.4 V

OH

Low Level Output Voltage IOL = 1.6 mA 0.4 V

High Z Leakage Current V

= 0 or 5 V –10 +10 µA

IN

High Z Output Capacitance 10 pF

100 kSPS. See Definition of Specifications section.

SAMPLE

REV. C–2–

Page 3

AD679

(T

to T

DC SPECIFICATIONS

MIN

Parameter Min Typ Max Min Typ Max Units

TEMPERATURE RANGE

J, K Grades 0 +70 0 +70 ° C

A, B Grades –40 +85 –40 +85 °C

S, T Grades –55 +125 –55 +125 °C

ACCURACY

Resolution 14 14 Bits

Integral Nonlinearity (INL) ±2 ±1 62 LSB

Differential Nonlinearity (DNL) 14 14 Bits

Unipolar Zero Error

Bipolar Zero Error

Gain Error

1, 2

Temperature Drift

Unipolar Zero

1

(@ +25°C) 0.08 0.05 0.07 % FSR*

1

(@ +25°C) 0.08 0.05 0.07 % FSR

(@ +25°C) 0.12 0.09 0.11 % FSR

3

J, K Grades 0.04 0.04 0.05 % FSR

A, B Grades 0.05 0.05 0.07 % FSR

S, T Grades 0.09 0.09 0.10 % FSR

Bipolar Zero

3

J, K Grades 0.02 0.02 0.04 % FSR

A, B Grades 0.04 0.04 0.05 % FSR

S, T Grades 0.08 0.08 0.09 % FSR

3

Gain

J, K Grades 0.09 0.09 0.11 % FSR

A, B Grades 0.10 0.10 0.16 % FSR

S, T Grades 0.20 0.20 0.25 % FSR

4

Gain

J, K Grades 0.04 0.04 0.05 % FSR

A, B Grades 0.05 0.05 0.07 % FSR

S, T Grades 0.09 0.09 0.10 % FSR

ANALOG INPUT

Input Ranges

Unipolar Mode 0 +10 0 +10 V

Bipolar Mode –5 +5 –5 +5 V

Input Resistance 10 10 MΩ

Input Capacitance 10 10 pF

Input Settling Time 1.5 1.5 µs

Aperture Delay 10 10 ns

Aperture Jitter 150 150 ps

INTERNAL VOLTAGE REFERENCE

Output Voltage

5

External Load

Unipolar Mode +1.5 +1.5 mA

Bipolar Mode +0.5 +0.5 mA

POWER SUPPLIES

Power Supply Rejection

= +12 V ± 5% ±6 66 LSB

V

CC

= –12 V ± 5% ±6 66 LSB

V

EE

= +5 V ± 10% ±6 66 LSB

V

DD

Operating Current

I

CC

I

EE

I

DD

Power Consumption 560 745 560 745 m

NOTES

1

Adjustable to zero. See Figures 5 and 6.

2

Includes internal voltage reference error.

3

Includes internal voltage reference drift.

4

Excludes internal voltage reference drift.

5

With maximum external load applied.

*% FSR = percent of full-scale range.

Specifications shown in boldface are tested on all devices at final electrical test with worst case supply voltages at T

calculate outgoing quality levels. All min and max specifications are guaranteed, although only those shown in boldface are tested.

Specifications subject to change without notice.

, VCC = +12 V 6 5%, VEE = –12 V 6 5%, VDD = +5 V 6 10% unless otherwise noted)

MAX

AD679J/A/S AD679K/B/T

4.98 5.02 4.98 5.02 V

18 20 18 20 mA

25 34 25 34 mA

8 12 8 12 mA

25°C and T

MIN,

. Results from those tests are used to

MAX

W

REV. C

–3–

Page 4

AD679

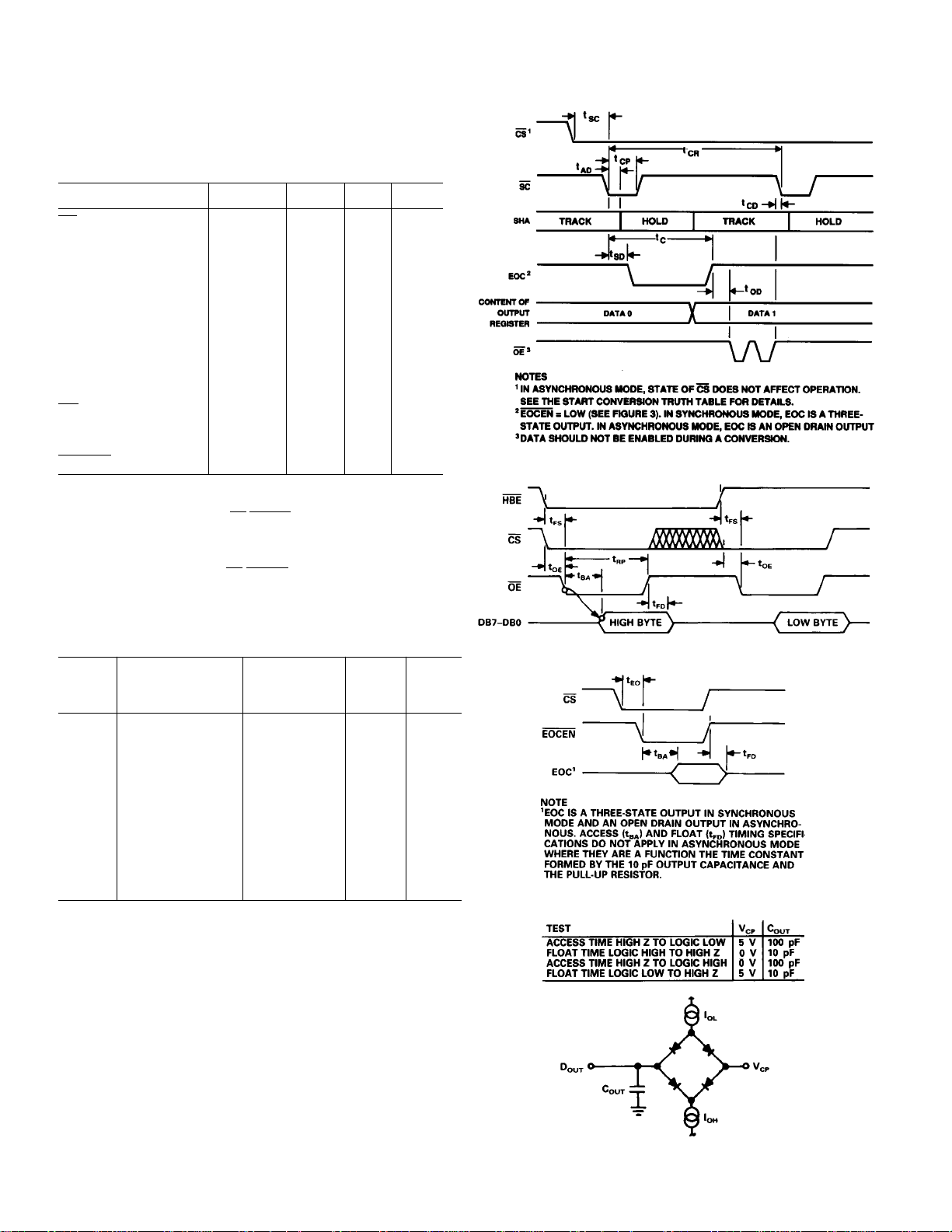

TIMING SPECIFICATIONS

(All device types T

VDD = +5 V 6 10%)

Parameter Symbol Min Max Units

MIN

to T

, VCC = +12 V 6 5%, VEE = –12 V 6 5%,

MAX

SC Delay t

Conversion Time t

Conversion Rate

1

Convert Pulse Width t

Aperture Delay t

Status Delay t

Access Time

Float Delay

2, 3

5

Output Delay t

Format Setup t

OE Delay t

Read Pulse Width t

Conversion Delay t

EOCEN Delay t

NOTES

1

Includes Acquisition Time.

2

Measured from the falling edge of OE/EOCEN (0.8 V) to the time at which the

data lines/EOC cross 2.0 V or 0.8 V. See Figure 4.

3

C

= 100 pF.

OUT

4

C

= 50 pF.

OUT

5

Measured from the rising edge of OE/EOCEN (2.0 V) to the time at which the

output voltage changes by 0.5. See Figure 4; C

Specifications subject to change without notice.

SC

C

t

CR

CP

AD

SD

t

BA

t

FD

OD

FS

OE

RP

CD

EO

ORDERING GUIDE

Model2Package Range Specified Option

Temperature and Package

50 ns

6.3 µs

7.8 µs

0.097 3.0 µs

520ns

0 400 ns

10 100 ns

10 57

4

ns

10 80 ns

0ns

100 ns

20 ns

195 ns

400 ns

50 ns

= 10 pF.

OUT

1

Tested

Figure 1. Conversion Timing

Figure 2. Output Timing

3

AD679JN 28-Pin Plastic DIP 0°C to +70°C AC N-28

AD679KN 28-Pin Plastic DIP 0°C to +70°C AC + DC N-28

AD679JD 28-Pin Ceramic DIP 0°C to +70°C AC D-28

AD679KD 28-Pin Ceramic DIP 0°C to +70°C AC + DC D-28

AD679AD 28-Pin Ceramic DIP –40°C to +85°C AC D-28

AD679BD 28-Pin Ceramic DIP –40°C to +85°C AC + DC D-28

AD679SD 28-Pin Ceramic DIP –55°C to +125°C AC D-28

AD679TD 28-Pin Ceramic DIP –55°C to +125°C AC + DC D-28

AD679AJ 44-Lead Ceramic JLCC –40°C to +85°C AC J-44

AD679BJ 44-Lead Ceramic JLCC –40°C to +85°C AC + DC J-44

AD679SJ 44-Lead Ceramic JLCC –55°C to +125°C AC J-44

AD679TJ 44-Lead Ceramic JLCC –55°C to +125°C AC + DC J-44

NOTES

1

For parallel read (14-bits) interface to 16-bit buses, see AD779.

2

For details grade and package offerings screened in accordance with MIL-STD883, refer to the Analog Devices Miliary Products Databook or current AD679/

883B data sheet.

3

N = Plastic DIP; D = Ceramic DIP; J = J-Leaded Ceramic Chip Carrier.

Figure 3. EOC Timing

Figure 4. Load Circuit for Bus Timing Specifications

REV. C–4–

Page 5

ABSOLUTE MAXIMUM RATINGS*

With

Respect

Specification To Min Max Units

AD679

With

Respect

Specification To Min Max Units

V

CC

V

EE

V

(Note 1) V

CC

V

DD

AGND DGND –1 +1 V

AIN, REF

IN

Digital Inputs DGND –0.5 +7 V

Digital Outputs DGND –0.5 V

Max Junction

Temperature 175 °C

AGND –0.3 +18 V

AGND –18 +0.3 V

EE

–0.3 +26.4 V

DGND 0 +7 V

AGND V

EE

V

CC

DD

+ 0.3 V

Operating

Temperature

J and K Grades 0 +70 °C

A and B Grades –40 +85 °C

S and T Grades –55 +125 °C

V

Storage Temperature –65 +150 °C

Lead Temperature

(10 sec max) +300 °C

NOTES

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in

the operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

1

The AD679 is not designed to operate from ±15 V supplies.

CAUTION

The AD679 features input protection circuitry consisting of large “distributed” diodes and

polysilicon series resistors to dissipate both high energy discharges (Human Body Model) and fast,

low energy pulses (Charged Device Model). Per Method 3015.2 of MIL-STD-883C, the AD679 has

been classified as a Category 1 device.

Proper ESD precautions are strongly recommended to avoid functional damage or performance

degradation. Charges as high as 4000 volts readily accumulate on the human body and test equipment and discharge without detection. Unused devices must be stored in conductive foam or shunts,

and the foam should be discharged to the destination socket before devices are removed. For further

information on ESD precautions, refer to Analog Devices’ ESD Prevention Manual.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

44-Lead J-Leaded Chip Carrier (J-44)28-Pin Ceramic DIP Package (D-28)

WARNING!

ESD SENSITIVE DEVICE

REV. C

28-Lead Plastic DIP Package (N-28)

–5–

Page 6

AD679

PIN DESCRIPTION

28-Pin 44-Lead

DIP JLCC

Symbol Pin No. Pin No. Type Name and Function

AGND 7 11 P Analog Ground. This is the ground return for AIN only.

AIN 6 10 AI Analog Signal Input.

BIPOFF 10 15 AI Bipolar Offset. Connect to AGND for +10 V input unipolar mode and straight

binary output coding. Connect to REF

twos complement binary output coding.

CS 4 6 DI Chip Select. Active LOW.

DGND 12, 14 23 P Digital Ground.

DB7–DB0 26–19 40, 39, 37, 36, DO Data Bits. These pins provide all 14 bits in two bytes (8+6 bits). Active HIGH.

35, 34, 33, 31

EOC 27 42 DO End-of-Convert. EOC goes LOW when a conversion starts and goes HIGH

when the conversion finishes. In asynchronous mode, EOC is an open drain

output and requires an external 3 kΩ pull-up resistor. See

pins for information on EOC gating.

EOCEN 1 1 DI End-of-Convert Enable. Enables EOC pin. Active LOW.

HBE 15 25 DI High Byte Enable. If LOW, output contains high byte. If HIGH, output

contains low byte (corresponding to the most recently read high byte).

OE 2 3 DI Output Enable. A down-going transition on OE enables DB7–DB0. Gated with

CS. Active LOW.

REF

REF

IN

OUT

9 14 AI Reference Input. +5 V input gives 10 V full-scale range.

8 12 AO +5 V Reference Output. Tied to REFIN for normal operation.

SC 3 5 DI Start Convert. Active LOW. See SYNC pin for gating.

SYNC 13 21 DI SYNC Control. If tied to V

by

CS. If tied to DGND (asynchronous mode), SC and EOCEN are indepen-

dent of

CS, and EOC is an open drain output. EOC requires an external 3 kΩ

(synchronous mode), SC and EOCEN are gated

DD

pull-up resistor in asynchronous mode.

V

CC

V

EE

V

DD

11 17 P +12 V Analog Power.

5 8 P –12 V Analog Power.

28 43 P +5 V Digital Power.

— 16 U Tie to DGND.

— 17–18 2, 4, 7, 9, 13, U These pins are unused and should be connected to DGND or V

16, 18, 19, 20,

22, 24, 26, 27,

28, 29, 30, 32,

38, 41, 44

Type: AI = Analog Input. AO = Analog Output. DI = Digital Input (TTL and 5 V CMOS compatible). DO = Digital Output (TTL and 5 V CMOS compatible).

All DO pins are three-state drivers. P = Power. U = Unused.

for ±5 V input bipolar mode and

OUT

EOCEN and SYNC

.

DD

DIP Package

PIN CONFIGURATION

JLCC Package

REV. C–6–

Page 7

AD679

NYQUIST FREQUENCY

An implication of the Nyquist sampling theorem, the “Nyquist

Frequency” of a converter is that input frequency which is onehalf the sampling frequency of the converter.

SIGNAL-TO-NOISE AND DISTORTION (S/N+D) RATIO

S/N+D is the ratio of the rms value of the measured input signal

to the rms sum of all other spectral components below the

Nyquist frequency, including harmonics but excluding dc.

TOTAL HARMONIC DISTORTION (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of a full-scale input signal and is expressed as a percentage or in decibels. For input signals or

harmonics that are above the Nyquist frequency, the aliased

component is used.

PEAK SPURIOUS OR PEAK HARMONIC COMPONENT

The peak spurious or peak harmonic component is the largest

spectral component excluding the input signal and dc. This

value is expressed in decibels relative to the rms value of a fullscale input signal.

INTERMODULATION DISTORTION (IMD)

With inputs consisting of sine waves at two frequencies, fa and

fb, any device with nonlinearities will create distortion products,

of order (m + n), at sum and difference frequencies of mfa ±

nfb, where m, n = 0, 1, 2, 3. . . . Intermodulation terms are

those for which m or n is not equal to zero. For example, the

second order terms are (fa + fb) and (fa – fb) and the third order terms are (2 fa + fb), (2 fa – fb), (fa + 2 fb) and (fa – 2 fb).

The IMD products are expressed as the decibel ratio of the rms

sum of the measured input signals to the rms sum of the distortion terms. The two signals applied to the converter are of equal

amplitude and the peak value of their sum is –0.5 dB from fullscale (9.44 V p-p). The IMD products are normalized to a 0-dB

input signal.

BANDWIDTH

The full-power bandwidth is that input frequency at which the

amplitude of the reconstructed fundamental is reduced by 3 dB

for a full-scale input.

The full-linear bandwidth is the input frequency at which the

slew rate limit of the sample-hold-amplifier (SHA) is reached.

At this point, the amplitude of the reconstructed fundamental

has degraded by less than –0.1 dB. Beyond this frequency, distortion of the sampled input signal increases significantly.

The AD679 has been designed to optimize input bandwidth, allowing it to undersample input signals with frequencies significantly above the converter’s Nyquist frequency.

APERTURE JITTER

Aperture jitter is the variation in aperture delay for successive

samples and is manifested as noise on the input to the A/D.

INPUT SETTLING TIME

Settling time is a function of the SHA’s ability to track fast slewing signals. This is specified as the maximum time required in

track mode after a full-scale step input to guarantee rated conversion accuracy.

DIFFERENTIAL NONLINEARITY (DNL)

In an ideal ADC, code transitions are 1 LSB apart. Differential

linearity is the deviation from this ideal value. It is often specified in terms of resolution for which no missing codes (NMC)

are guaranteed.

INTEGRAL NONLINEARITY (INL)

The ideal transfer function for a linear ADC is a straight line

drawn between “zero” and “full scale.” The point used as

“zero” occurs 1/2 LSB before the first code transition. “Full

scale” is defined as a level 1 1/2 LSB beyond the last code transition. Integral linearity error is the worst case deviation of a

code from the straight line. The deviation of each code is measured from the middle of that code.

Note that the linearity error is not user adjustable.

POWER SUPPLY REJECTION

Variations in power supply will affect the full-scale transition,

but not the converter’s linearity. Power Supply Rejection is the

maximum change in the full-scale transition point due to a

change in power supply voltage from the nominal value.

TEMPERATURE DRIFT

This is the maximum change in the parameter from the initial

value (@ +25°C) to the value at T

UNIPOLAR ZERO ERROR

MIN

or T

MAX

.

In unipolar mode, the first transition should occur at a level

1/2 LSB above analog ground. Unipolar zero error is the deviation of the actual transition from that point. This error can be

adjusted as discussed in the Input Connections and Calibration

section.

BIPOLAR ZERO ERROR

In the bipolar mode, the major carry transition (11 1111 1111

1111 to 00 0000 0000 0000 ) should occur at an analog value

1/2 LSB below analog ground. Bipolar zero error is the deviation of the actual transition from that point. This error can be

adjusted as discussed in the Input Connections and Calibration

section.

APERTURE DELAY

Aperture delay is a measure of the SHA’s performance and is

measured from the falling edge of Start Convert (

SC) to when

the input signal is held for conversion. In synchronous mode,

Chip Select (

CS) should be LOW before SC to minimize aper-

ture delay.

REV. C

GAIN ERROR

The last transition should occur at an analog value 1 1/2 LSB

below the nominal full scale (9.9991 volts for a 0 V–10 V range,

4.9991 volts for a ±5 V range). The gain error is the deviation of

the actual level at the last transition from the ideal level with the

zero error trimmed out. This error can be adjusted as shown in

the Input Connections and Calibration section.

–7–

Page 8

AD679

CONVERSION CONTROL

In synchronous mode (SYNC = HIGH), both Chip Select (CS)

and Start Convert (

version.

CS should be LOW tSC before SC is brought LOW. In

SC) must be brought LOW to start a con-

asynchronous mode (SYNC = LOW), a conversion is started by

bringing

SC low, regardless of the state of CS.

Before a conversion is started, End-of-Convert (EOC) is HIGH

and the sample-hold is in track mode. After a conversion is

started, the sample-hold goes into hold mode and EOC goes

LOW, signifying that a conversion is in progress. During the

conversion, the sample-hold will go back into track mode and

start acquiring the next sample.

In track mode, the sample-hold will settle to ±0.003% (14 bits)

in 1.5 µs maximum. The acquisition time does not affect the

throughput rate as the AD679 goes back into track mode more

than 2 µs before the next conversion. In multichannel systems,

the input channel can be switched as soon as EOC goes LOW.

Bringing

OE LOW tOE after CS goes LOW makes the output

register contents available on the output data bits (DB7–DB0).

A period of time t

is required after OE is brought HIGH be-

CD

fore the next SC instruction is issued.

SC is held LOW, conversion accuracy may deteriorate. For

If

this reason,

SC should not be held low in an attempt to operate

in a continuously converting mode.

START CONVERSION TRUTH TABLE

INPUTS

SYNC CS SC STATUS

1 1 X No Conversion

Synchronous 1 0 f Start Conversion

Mode

1 f 0 Start Conversion

(Not Recommended)

1 0 0 Continuous Conversion

(Not Recommended)

0 X 1 No Conversion

Asynchronous 0 X f Start Conversion

Mode 0 X 0 Continuous Conversion

(Not Recommended)

NOTES

1 = HIGH voltage level.

0 = LOW voltage level.

X = Don’t care.

= HIGH to LOW transition. Must stay low for t = tCP.

14-BIT MODE CODING FORMAT (1 LSB = 0.61 mV)

END-OF-CONVERT

In asynchronous mode, End-of-Convert (EOC) is an open drain

output (requiring a minimum 3 kΩ pull-up resistor) enabled by

End-of-Convert Enable (

is a three-state output which is enabled by

Conversion Status Truth Table. Access (t

EOCEN). In synchronous mode, EOC

EOCEN and CS. See

) and float (tFD)

BA

timing specifications do not apply in asynchronous mode where

they are a function of the time constant formed by the external

load capacitance and the pull-up resistor.

OUTPUT ENABLE OPERATION

The data bits (DB7–DB0) are three-state outputs that are enabled by Chip Select (

be LOW t

before OE is brought LOW.

OE

CS) and Output Enable (OE). CS should

When EOC goes HIGH, the conversion is completed and the

output data may be read. The output is read in two steps as a

16-bit word, with the high byte read first, followed by the low

byte. High Byte Enable (

HBE) controls the output sequence.

The 14-bit result is left justified within the 16-bit field.

In unipolar mode (BIPOFF tied to AGND), the output coding

is straight binary. In bipolar mode (BIPOFF tied to REF

OUT

),

output coding is twos-complement binary.

POWER-UP

The AD679 typically requires 10 µs after power-up to reset in-

ternal logic.

CONVERSION STATUS TRUTH TABLE

INPUTS OUTPUT

SYNC CS EOCEN EOC STATUS

1 0 0 0 Converting

1 0 0 1 Not Converting

Synchronous 1 1 X High Z Either

Mode 1 X 1 High Z Either

0 X 0 0 Converting

Asynchronous

0 X 0 High Z Not Converting

Mode* 0 X 1 High Z Either

NOTES

1 = HIGH voltage level.

0 = LOW voltage level.

X = Don’t care.

*EOC requires a pull-up resistor in asynchronous mode.

OUTPUT ENABLE TRUTH TABLE

INPUTS OUTPUTS

HBE (CS U OE) DB7 . . . DB0

Unipolar Coding Bipolar Coding

(Straight Binary) (Twos Complement)

VIN* Output Code VIN* Output Code

0.00000 V 000 . . . 0 –5.00000 V 100 . . . 0

5.00000 V 100 . . . 0 –0.00061 V 111 . . . 1

9.99939 V 111 . . . 1 0.00000 V 000 . . . 0

+2.50000 V 010 . . . 0

+4.99939 V 011 . . . 1

*Code center.

X1 ←High Z →

Unipolar or 0 0 a b c d e f g h

Bipolar 1 0 i j k l m n 0 0

NOTES

1 = HIGH voltage level. a = MSB.

0 = LOW voltage level. n = LSB.

X = Don’t care.

U = Logical OR.

Data coding is binary for Unipolar Mode and 2s Complement Binary for Bipolar

Mode.

REV. C–8–

Page 9

AD679

INPUT CONNECTIONS AND CALIBRATION

The high (10 MΩ) input impedance of the AD679 eases the

task of interfacing to high source impedances or multiplexer

channel-to-channel mismatches of up to 300 Ω. The 10 V p-p

full-scale input range accepts the majority of signal voltages

without the need for voltage divider networks which could deteriorate the accuracy of the ADC.

The AD679 is factory trimmed to minimize offset, gain and linearity errors. In unipolar mode, the only external component

that is required is a 50 Ω ±1% resistor. Two resistors are required in bipolar mode. If offset and gain are not critical (as in

some ac applications), even these components can be eliminated.

In some applications, offset and gain errors need to be trimmed

out completely. The following sections describe the correct procedure for these various situations.

BIPOLAR RANGE INPUTS

The connections for the bipolar mode are shown in Figure 5. In

this mode, data output coding will be twos complement binary.

This circuit will allow approximately ± 25 mV of offset trim

range (±40 LSB) and ±0.5% of gain trim range (±80 LSB).

Either or both of the trim pots can be replaced with 50 Ω ±1%

fixed resistors if the AD679 accuracy limits are sufficient for application. If the pins are shorted together, the additional offset

and gain errors will be approximately 80 LSB.

To trim bipolar zero to its nominal value, apply a signal 1/2 LSB

below midrange (–0.305 mV for a ± 5 V range) and adjust R1

until the major carry transition is located (11 1111 1111 1111 to

00 0000 0000 0000). To trim the gain, apply a signal 1 1/2 LSB

below full scale (+4.9991 V for a ±5 V range) and adjust R2 to

give the last positive transition (01 1111 1111 1110 to 01 1111

1111 1111). These trims are interactive so several iterations may

be necessary for convergence.

A single pass calibration can be done by substituting a bipolar

offset trim (error at minus full scale) for the bipolar zero trim

(error at midscale), using the same circuit. First, apply a signal

1/2 LSB above minus full scale (–4.9997 V for a ± 5 V range)

and adjust R1 until the minus full-scale transition is located

(10 0000 0000 0000 to 10 000 000 0001). Then perform the

gain error trim as outlined above.

UNIPOLAR RANGE INPUTS

Offset and gain errors can be trimmed out by using the configuration shown in Figure 6. This circuit allows approximately

±25 mV of offset trim range (±40 LSB) and ±0.5% of gain trim

range (±80 LSB).

The nominal offset is 1/2 LSB so that the analog range that corresponds to each code will be centered in the middle of that

code (halfway between the transitions to the codes above and

below it). Thus the first transition (from 00 0000 0000 0000 to

00 0000 0000 0001) should nominally occur for an input level

of +1/2 LSB (0.305 mV above ground for a 10 V range). To

trim unipolar zero to this nominal value, apply a 0.305 mV signal to AIN and adjust R1 until the first transition is located.

The gain trim is done by adjusting R2. If the nominal value is

required, apply a signal 1 1/2 LSB below full scale (9.9997 V for

a 10 V range) and adjust R2 until the last transition is located

(11 1111 1111 1110 to 11 1111 1111 1111).

If offset adjustment is not required, BIPOFF should be connected directly to AGND. If gain adjustment is not required, R2

should be replaced with a fixed 50 Ω ±1% metal film resistor. If

REF

is connected directly to REFIN, the additional gain

OUT

error will be approximately 1%.

Figure 6. Unipolar Input Connections with Gain and

Offset Trims

REFERENCE DECOUPLING

It is recommended that a 10 µF tantalum capacitor be con-

nected between REF

(Pin 9) and ground. This has the effect

IN

of improving the S/N+D ratio through filtering possible broadband noise contributions from the voltage reference.

Figure 5. Bipolar Input Connections with Gain and

Offset Trims

REV. C

BOARD LAYOUT

Designing with high resolution data converters requires careful

attention to board layout. Trace impedance is a significant issue.

A 1.22 mA current through a 0.5 Ω trace will develop a voltage

drop of 0.6 mV, which is 1 LSB at the 14 bit level for a 10 V

full-scale span. In addition to ground drops, inductive and capacitive coupling need to be considered, especially when high

accuracy analog signals share the same board with digital signals. Finally, power supplies need to be decoupled in order to

filter out ac noise.

Analog and digital signals should not share a common path.

Each signal should have an appropriate analog or digital return

routed close to it. Using this approach, signal loops enclose a

small area, minimizing the inductive coupling of noise. Wide PC

tracks, large gauge wire, and ground planes are highly recommended to provide low impedance signal paths. Separate analog

–9–

Page 10

AD679

and digital ground planes are also desirable, with a single interconnection point to minimize ground loops. Analog signals

should be routed as far as possible from digital signals and

should cross them at right angles.

The AD679 incorporates several features to help the user’s layout. Analog pins (V

V

) are adjacent to help isolate analog from digital signals. In

CC

, AIN, AGND, REF

EE

, REFIN, BIPOFF,

OUT

addition, the 10 MΩ input impedance of AIN minimizes input

trace impedance errors. Finally, ground currents have been

minimized by careful circuit architecture. Current through

AGND is 200 µA, with no code dependent variation. The cur-

rent through DGND is dominated by the return current for

DB7–DB0 and EOC.

SUPPLY DECOUPLING

The AD679 power supplies should be well filtered, well regulated, and free from high frequency noise. Switching power supplies are not recommended due to their tendency to generate

spikes which can induce noise in the analog system.

Decoupling capacitors should be used in very close layout proximity between all power supply pins and analog ground. A 10 µF

tantalum capacitor in parallel with a 0.1 µF ceramic capacitor

provides adequate decoupling.

An effort should be made to minimize the trace length between

the capacitor leads and the respective converter power supply

and common pins. The circuit layout should attempt to locate

the AD679, associated analog input circuitry and interconnections as far as possible from logic circuitry. A solid analog

ground plane around the AD679 will isolate large switching

ground currents. For these reasons, the use of wire wrap circuit

construction is not recommended; careful printed circuit construction is preferred.

GROUNDING

If a single AD679 is used with separate analog and digital

ground planes, connect the analog ground plane to AGND and

the digital ground plane to DGND keeping lead lengths as short

as possible. Then connect AGND and DGND together at the

AD679. If multiple AD679s are used or the AD679 shares analog supplies with other components, connect the analog and

digital returns together once at the power supplies rather than at

each chip. This prevents large ground loops which inductively

couple noise and allow digital currents to flow through the analog system.

tial value at 25°C. REF

(Pin 9) scales its input by a factor of

IN

two; thus, this change becomes effectively 4.5 mV. When applied to the AD679, this results in a total gain drift of 0.09%

FSR, which is an improvement over the on-chip reference performance of 0.11% FSR. A noise-reduction capacitor, C

, has

N

been shown.

This capacitor reduces the broadband noise of the AD586 out-

put, thereby optimizing the overall ac and dc performance of the

AD679.

Figure 7. Bipolar Input with Gain and Offset Trims

Figure 8 shows the AD679 in unipolar input mode with the

AD588 reference. The AD588 output is accurate to 0.65 mV

from its value at 25°C over the 0°C to 70°C range. This results

in a 0.06% FSR total gain drift for the AD679, which is a substantial improvement over the on-chip reference performance of

0.11% FSR. A noise-reduction network on Pins 4, 6 and 7 has

been shown. The 1 µF capacitors form low pass filters with the

internal resistance of the AD588 Zener and amplifier cells and

external resistance. This reduces the high frequency (to 1 MHz)

noise of the AD588, providing optimum ac and dc performance

of the AD679.

USE OF EXTERNAL VOLTAGE REFERENCE

The AD679 features an on-chip voltage reference. For improved

gain accuracy over temperature, a high performance external

voltage reference may be used in place of the on-chip reference.

The AD586 and AD588 are popular references appropriate for

use with high resolution converters. The AD586 is a low cost

reference which utilizes a buried Zener architecture to provide

low noise and drift. The AD588 is a higher performance reference which uses a proprietary implanted buried Zener diode in

conjunction with laser-trimmed thin-film resistors for low offset

and low drift.

Figure 7 shows the use of the AD586 with the AD679 in a bipolar input mode. Over the 0°C to +70°C range, the AD586

L-grade exhibits less than a 2.25 mV output change from its ini-

Figure 8. Unipolar Input with Gain and Offset Trims

INTERFACING THE AD679 TO MICROPROCESSORS

The I/O capabilities of the AD679 allow direct interfacing to

general purpose and DSP microprocessor buses. The asynchronous conversion control feature allows complete flexibility and

control with minimal external hardware.

REV. C–10–

Page 11

AD679

The following examples illustrate typical AD679 interface

configurations.

AD679 to TMS320C25

In Figure 9 the AD679 is mapped into the TMS320C25 I/O

space. AD679 conversions are initiated by issuing an OUT instruction to Port 1. EOC status and the conversion result are

read in with an IN instruction to Port 1. A single wait state is inserted by generating the processor READY input from

1 and

MSC. Address line A0 provides HBE decoding to select

between the high and low bytes of data. This configuration supports processor clock speeds of 20 MHz and is capable of supporting processor clock speeds of 40 MHz if a NOP instruction

follows each AD679 read instruction.

Figure 9. AD679 to TMS320C25 Interface

AD679 to 80186

Figure 10 shows the AD679 interfaced to the 80186 microprocessor. This interface allows the 80186’s built-in DMA controller to transfer the AD679 output into a RAM based FIFO buffer

of any length, with no microprocessor intervention.

In this application the AD679 is configured in the asynchronous

mode, which allows conversions to be initiated by an external

trigger source independent of the microprocessor clock. After

each conversion, the AD679 EOC signal generates a DMA request to Channel 1 (DRQ1). The subsequent DMA READ sequences the high and low byte AD679 data and resets the

interrupt latch. The system designer must assign a sufficient priority to the DMA channel to ensure that the DMA request will

be serviced before the completion of the next conversion. This

configuration can be used with 6 MHz and 8 MHz 80186

processors.

IS, Port

one 80 ns cycle, the digital signal processor supports the AD679

interface with one wait state.

The converter is configured to run asynchronously using a sampling clock. The EOC output of the AD679 gets asserted at the

end of each conversion and causes an interrupt. Upon interrupt,

the ADSP-2101 immediately asserts its FO pin LOW. In the

following cycle, the processor starts a data memory read by providing an address on the DMA bus. The decoded address gener-

OE for the converter, and the high byte of the conversion

ates

result is read over the data bus. The read operation is extended

with one wait state and thus started and completed within two

processor cycles (160 ns). Next, the ADSP-2101 asserts its FO

HIGH. This allows the processor to start reading the lower byte

of data. This read operation executes in a similar manner to the

first and is completed during the next 160 ns.

Figure 11. AD679 to ADSP-2101 Interface

AD679 to Analog Devices ADSP-2100A

Figure 12 demonstrates the AD679 interfaced to an ADSP-2100A.

With a clock frequency of 12.5 MHz, and instruction execution in

one 80 ns cycle, the digital signal processor will support the AD679

data memory interface with three hardware wait states.

The converter is configured to run asynchronously using a sampling clock. The EOC output of the AD679 gets asserted at the

end of each conversion and causes an interrupt. Upon interrupt,

the ADSP-2100A immediately executes a data memory write instruction which asserts

sor starts a data memory read (high byte read) by providing an

address on the DMA bus. The decoded address generates

for the converter.

force the ADSP-2100A into a one cycle wait state by generating

DMACK. The read operation is thus started and completed

within two processor cycles (160 ns).

“high byte read.” This allows the processor to read the lower

byte of data as soon as “high byte read” is complete. The low

byte read operation executes in a similar manner to the first and

is completed during the next 160 ns.

HBE. In the following cycle, the proces-

OE

OE, together with logic and latch, is used to

HBE is released during

Figure 10. AD679 to 80186 DMA Interface

AD679 to Analog Devices ADSP-2101

Figure 11 demonstrates the AD679 interfaced to an ADSP-2101.

With a clock frequency of 12.5 MHz, and instruction execution in

REV. C

–11–

Figure 12. AD679 to ADSP-2100A Interface

Page 12

AD679

C1419a–5–3/92

Figure 13. Harmonic Distortion vs. Input Frequency

(–0.5 dB Input)

Figure 14. Total Harmonic Distortion vs. Input

Frequency and Amplitude

Figure 16. 5-Plot Averaged 2048 Point FFT at 128

kSPS, f

= 10.009 kHz

IN

Figure 17. Nonaveraged IMD Plot for fIN = 9.08 kHz

(fa), 9.58 kHz (fb) at 128 kSPS

Figure 15. S/(N+D) vs. Input Frequency and Amplitude

Figure 18. Power Supply Rejection (fIN = 10 kHz,

f

SAMPLE

= 128 kSPS, V

= 0.1 V p-p)

RIPPLE

PRINTED IN U.S.A.

REV. C–12–

Loading...

Loading...