Page 1

Complete 12-Bit

a

FEATURES

Complete Monolithic 12-Bit A/D Converters with

Reference, Clock, and Three-State Output Buffers

Industry Standard Pinout

High Speed Upgrades for AD574A

8- and 16-Bit Microprocessor Interface

8 s (Max) Conversion Time (AD774B)

15 s (Max) Conversion Time (AD674B)

5 V, 10 V, 0 V–10 V, 0 V–20 V Input Ranges

Commercial, Industrial, and Military Temperature

Range Grades

MIL-STD-883-Compliant Versions Available

5V SUPPLY

V

DATA MODE SELECT

SHORT CYCLE A

READ/CONVERT R/C

ANALOG COMMON

REFERENCE INPUT

–12V/–15V SUPPLY

LOGIC

12/8

CHIP SELECT

BYTE ADDRESS/

CHIP ENABLE

12V/15V SUPPLY

10V REFERENCE

BIPOLAR OFFSET

V

REF OUT

REF IN

V

BIPOFF

10V SPAN INPUT

10V

20V SPAN INPUT

20V

A/D Converters

*

AD674B

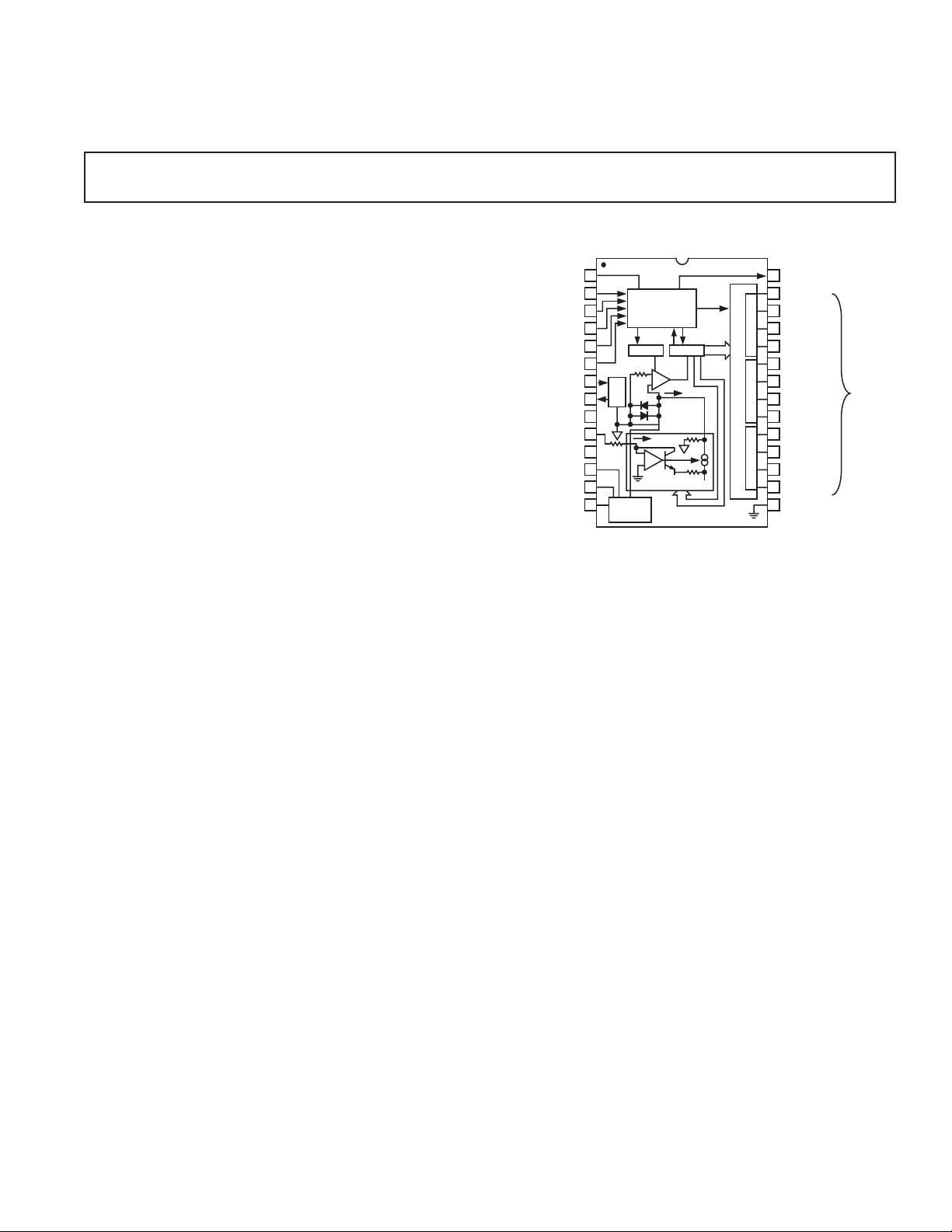

FUNCTIONAL BLOCK DIAGRAM

1

2

3

CS

4

0

5

6

CE

7

CC

8

9

AC

10

11

EE

12

13

IN

14

IN

10V

REF

199.95

k

VO LTAG E

DIVIDER

CONTROL

CLOCK SAR

COMP

–

+

I DAC

I REF

+

–

DAC

N

AD674B/AD774B

V

EE

/AD774B

MSB

N

Y

B

3

B

L

S

E

T

A

12

A

T

E

N

Y

O

B

U

B

T

L

P

E

U

T

B

N

B

Y

U

B

F

B

F

L

E

E

R

S

C

LSB

STATUS

28

STS

27

DB11 (MSB)

26

DB10

25

DB9

24

DB8

23

DB7

22

DB6

21

DB5

20

DB4

19

DB3

18

DB2

17

DB1

16

DB0 (LSB)

DIGITAL

15

COMMON DC

*

DIGITAL

DATA

OUTPUTS

PRODUCT DESCRIPTION

The AD674B and AD774B are complete 12-bit successiveapproximation analog-to-digital converters with three-state

output buffer circuitry for direct interface to 8- and 16-bit

microprocessor busses. A high-precision voltage reference and

clock are included on chip, and the circuit requires only power

supplies and control signals for operation.

The AD674B and AD774B are pin-compatible with the industry standard AD574A, but offer faster conversion time and busaccess speed than the AD574A and lower power consumption.

The AD674B converts in 15 µs (maximum) and the AD774B

converts in 8 µs (maximum).

The monolithic design is implemented using Analog Devices’

BiMOS II process allowing high-performance bipolar analog

circuitry to be combined on the same die with digital CMOS logic.

Offset, linearity, and scaling errors are minimized by active

laser trimming of thin-film resistors.

Five different grades are available. The J and K grades are

specified for operation over the 0°C to 70°C temperature range.

The A and B grades are specified from –40°C to +85°C, the T grade

is specified from –55°C to +125°C. The J and K grades are

available in a 28-lead plastic DIP or 28-lead SOIC. All other grades

are available in a 28-lead hermetically sealed ceramic DIP.

PRODUCT HIGHLIGHTS

1. Industry Standard Pinout: The AD674B and AD774B use

the pinout established by the industry standard AD574A.

2. Analog Operation: The precision, laser-trimmed scaling and

bipolar offset resistors provide four calibrated ranges: 0 V to

10 V and 0 V to 20 V unipolar; –5 V to +5 V and –10 V to

+10 V bipolar. The AD674B and AD774B operate on +5 V

and ± 12 V or ± 15 V power supplies.

3. Flexible Digital Interface: On-chip multiple-mode three-state

output buffers and interface logic allow direct connection to

most microprocessors. The 12 bits of output data can be

read either as one 12-bit word or as two 8-bit bytes (one with

8 data bits, the other with 4 data bits and 4 trailing zeros).

4. The internal reference is trimmed to 10.00 V with 1% maximum error and 10 ppm/°C typical temperature coefficient.

The reference is available externally and can drive up to

2.0 mA beyond the requirements of the converter and bipolar offset resistors.

5. The AD674B and AD774B are available in versions compliant with MIL-STD-883. Refer to the Analog Devices Military Products Databook or current AD674B/AD774B/883B

data sheet for detailed specifications.

*Protected by U.S. Patent Nos. 4,250,445; 4,808,908; RE30586.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

(T

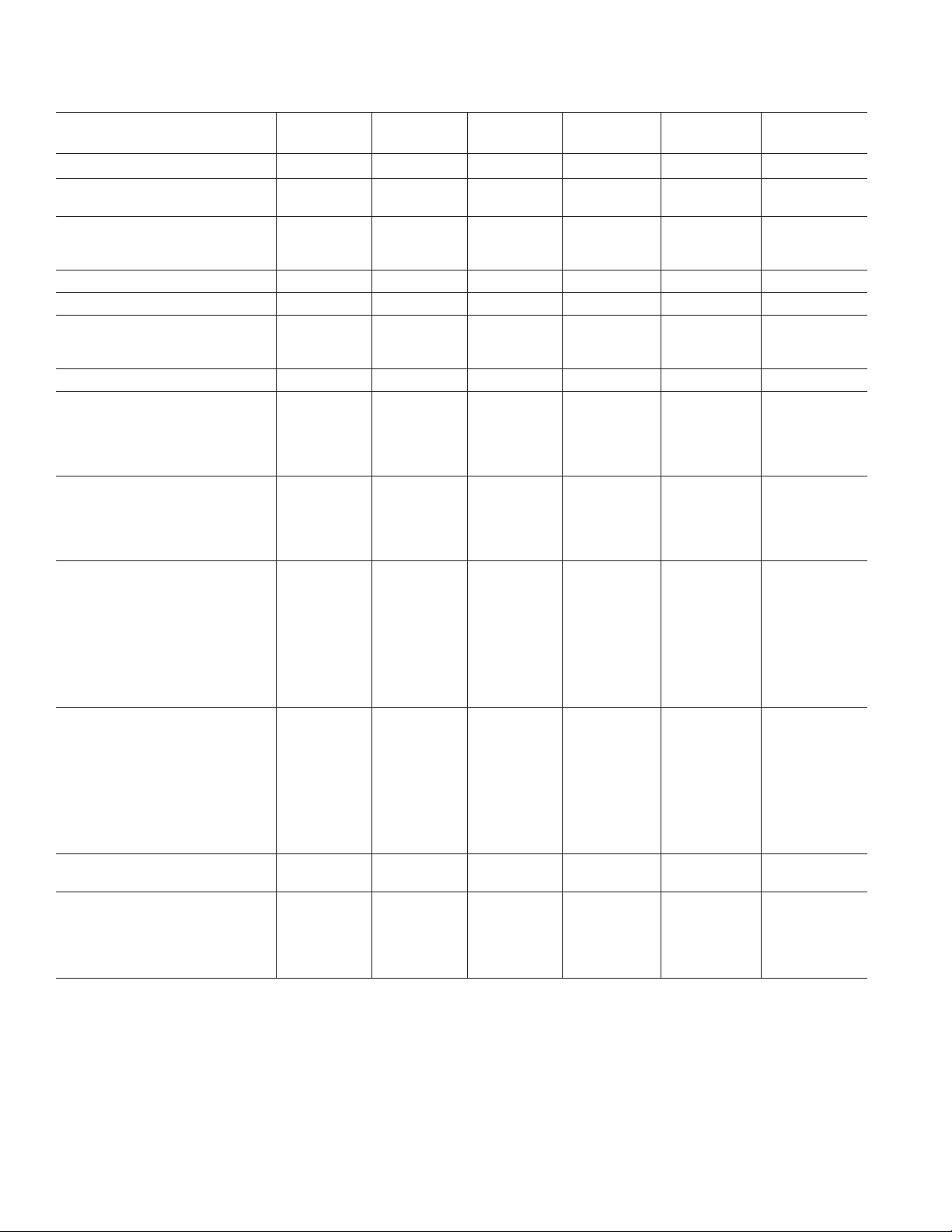

AD674B/AD774B–SPECIFICATIONS

V

= +5 V 10%, VEE = –15 V 10% or –12 V 5%, unless otherwise noted.)

LOGIC

MIN

to T

with VCC = +15 V 10% or +12 V 5%,

MAX

J Grade K Grade A Grade B Grade T Grade

Model (AD674B or AD774B) Min Typ Max Min Typ Max Min Typ Max Min Typ Max Min Typ Max Unit

RESOLUTION 12 12 12 12 12 Bits

LINEARITY ERROR @ 25°C 1 1/2 1 1/2 1/2 LSB

T

MIN

to T

MAX

1 1/2 1 1/2 1 LSB

DIFFERENTIAL LINEARITY ERROR

(Minimum Resolution for Which No

Missing Codes are Guaranteed) 12 12 12 12 12 Bits

UNIPOLAR OFFSET1 @ 25°C 2 2 2 2 2 LSB

BIPOLAR OFFSET1 @ 25°C 6 3 6 3 3 LSB

FULL-SCALE CALIBRATION ERROR

1, 2

@ 25°C (with Fixed 50 Ω Resistor

from REF OUT to REF IN) 0.1 0.25 0.1 0.125 0.1 0.25 0.1 0.125 0.1 0.125 % of FS

TEMPERATURE RANGE 0 70 0 70 –40 +85 –40 +85 –55 +125 °C

TEMPERATURE DRIFT

3

(Using Internal Reference)

Unipolar 2 1 2 1 1 LSB

Bipolar Offset 2 1 2 1 2 LSB

Full-Scale Calibration 6 2 8 5 7 LSB

POWER SUPPLY REJECTION

Max Change in Full-Scale Calibration

VCC = +15 V ± 1.5 V or +12 V ± 0.6 V 2 1 2 1 1 LSB

V

= +5 V ± 0.5 V 1/2 1/2 1/2 1/2 1/2 LSB

LOGIC

VEE = –15 V ± 1.5 V or –12 V ± 0.6 V 2 1 2 1 1 LSB

ANALOG INPUT

Input Ranges

Bipolar –5 +5 –5 +5 –5 +5 –5 +5 –5 +5 V

–10 +10 –10 +10 –10 +10 –10 +10 –10 +10 V

Unipolar 0 10 0 10 0 10 0 10 0 10 V

0 20 0 20 0 20 0 20 0 20 V

Input Impedance

10 V Span 3 5 735 735 735 735 7 kΩ

20 V Span 6 10 14 6 10 14 6 10 14 6 10 14 6 10 14 kΩ

POWER SUPPLIES

Operating Range

V

V

V

LOGIC

CC

EE

4.5 5.5 4.5 5.5 4.5 5.5 4.5 5.5 4.5 5.5 V

11.4 16.5 11.4 16.5 11.4 16.5 11.4 16.5 11.4 16.5 V

–16.5 –11.4 –16.5 –11.4 –16.5 –11.4 –16.5 –11.4 –16.5 –11.4 V

Operating Current

I

LOGIC

I

CC

I

EE

3.5 7 3.5 7 3.5 7 3.5 7 3.5 7 mA

3.5 7 3.5 7 3.5 7 3.5 7 3.5 7 mA

10 14 10 14 10 14 10 14 10 14 mA

POWER CONSUMPTION 220 375 220 375 220 375 220 375 220 375 mW

175 175 175 175 175 mW

INTERNAL REFERENCE VOLTAGE 9.9 10.0 10.1 9.9 10.0 10.1 9.9 10.0 10.1 9.9 10.0 10.1 9.9 10.0 10.1 V

Output Current

(Available for External Loads) 2.0 2.0 2.0 2.0 2.0 mA

(External Load Should Not

Change During the Conversion)

NOTES

1

Adjustable to zero.

2

Includes internal voltage reference error.

3

Maximum change from 25°C value to the value at T

4

Tested with REF OUT tied to REF IN through 50 Ω resistor, VCC = +16.5 V, VEE = –16.5 V, V

5

Tested with REF OUT tied to REF IN through 50 Ω resistor, VCC = +12 V, VEE = –12 V, V

Specifications subject to change without notice.

Specifications shown in boldface are tested on all devices at final electrical test at T

max specifications are guaranteed, although only those shown in boldface are tested.

MIN

or T

MAX

.

, 25°C, and T

MIN

= +5.5 V, and outputs in high-Z mode.

LOGIC

= +5 V, and outputs in high-Z mode.

LOGIC

. Results from those tests are used to calculate outgoing quality levels. All min and

MAX

4

5

–2–

REV. C

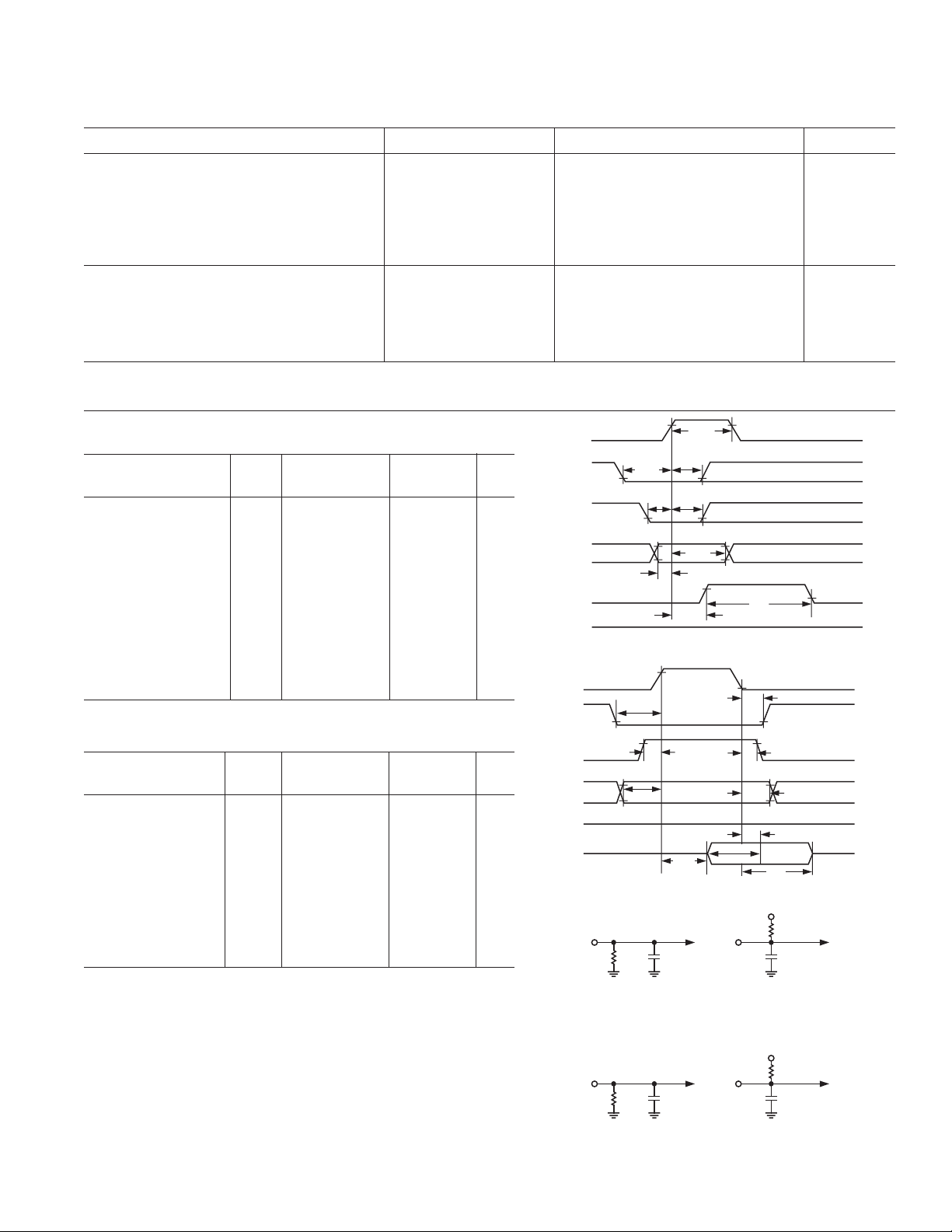

Page 3

t

HEC

t

HSC

t

SSC

t

HRC

t

SRC

t

SAC

t

HAC

t

C

t

DSC

CE

CS

R/C

A

0

STS

DB11 – DB0

HIGH

IMPEDANCE

AD674B/AD774B

(For all grades T

DIGITAL SPECIFICATIONS

VEE = –15 V 10% or –12 V 5%, unless otherwise noted.)

Parameter Test Conditions Min Max Unit

LOGIC INPUTS

V

IH

V

IL

I

IH

I

IL

C

IN

High Level Input Voltage 2.0 V

Low Level Input Voltage –0.5 +0.8 V

High Level Input Current VIN = V

Low Level Input Current VIN = 0 V –10 +10 µA

Input Capacitance 10 pF

LOGIC OUTPUTS

V

OH

V

OL

I

OZ

C

OZ

High Level Output Voltage IOH = 0.5 mA 2.4 V

Low Level Output Voltage IOL = 1.6 mA 0.4 V

High-Z Leakage Current VIN = 0 to V

High-Z Output Capacitance 10 pF

(For all grades T

SWITCHING SPECIFICATIONS

CONVERTER START TIMING (Figure 1)

J, K, A, B Grades T Grade

Parameter Symbol Min Typ Max Min Typ Max Unit

Conversion Time

8-Bit Cycle (AD674B) t

12-Bit Cycle (AD674B) t

8-Bit Cycle (AD774B) t

12-Bit Cycle (AD774B) t

STS Delay from CE t

CE Pulsewidth t

CS to CE Setup t

CS Low During CE High t

R/C to CE Setup t

R/C LOW During CE High t

A0 to CE Setup t

A0 Valid During CE High t

C

C

C

C

DSC

HEC

SSC

HSC

SRC

HRC

SAC

HAC

READ TIMING—FULL CONTROL MODE (Figure 2)

Parameter Symbol Min Typ Max Min Typ Max Unit

Access Time

CL = 100 pF t

Data Valid After CE Low t

Output Float Delay t

CS to CE Setup t

R/C to CE Setup t

A0 to CE Setup t

CS Valid After CE Low t

R/C High After CE Low t

A0 Valid After CE Low t

NOTES

1

tDD is measured with the load circuit of Figure 3a and is defined as the time required

for an output to cross 0.4 V or 2.4 V.

2

0°C to T

3

At –40°C.

4

At –55°C.

5

tHL is defined as the time required for the data lines to change 0.5 V when loaded with

the circuit of Figure 3b.

Specifications shown in boldface are tested on all devices at final electrical test with

MAX

.

worst case supply voltages at T

to calculate outgoing quality levels. All min and max specifications are guaranteed,

although only those shown in boldface are tested.

Specifications subject to change without notice.

REV. C

DD

HD

HL

SSR

SRR

SAR

HSR

HRR

HAR

MIN

6810 6810 µs

91215 91215 µs

456 456 µs

6 7.3 8 6 7.3 8 µs

50 50 ns

50 50 ns

50 50 ns

50 50 ns

50 50 ns

00ns

50 50 ns

J, K, A, B Grades T Grade

1

5

25

20

2

3

50 50 ns

00ns

50 50 ns

00ns

00ns

50 50 ns

, 25°C, and T

V

LOGIC

200 225 ns

75 150 75 150 ns

150 150 ns

. Results from those tests are used

MAX

to T

MIN

with VCC = +15 V 10% or +12 V 5%, V

MAX

LOGIC

to T

MIN

LOGIC

with VCC = +15 V 10% or +12 V 5%,

MAX

–10 +10 µA

–10 +10 µA

LOGIC

+ 0.5 V

LOGIC

= +5 V 10%, VEE = –15 V 10% or –12 V 5%, unless otherwise noted.)

Figure 1. Convert Start Timing

CE

t

HSR

t

HAR

t

HD

DATA

VA LI D

t

DD

25

15

t

CS

R/C

A

0

2

4

ns

ns

STS

DB11 – DB0

SSR

t

SRR

t

HIGH

IMPEDANCE

SAR

Figure 2. Read Cycle Timing

DB

N

3k

100pF

DB

N

HIGH-Z TO LOGIC 0HIGH-Z TO LOGIC 1

High-Z to Logic 1 High-Z to Logic 0

Figure 3a. Load Circuit for Access Time Test

DB

N

3k

LOGIC 1 TO HIGH-Z

100pF

DB

N

LOGIC 0 TO HIGH-Z

Logic 1 to High-Z Logic 0 to High-Z

Figure 3b. Load Circuit for Output Float Delay Test

–3–

= +5 V 10%,

t

HRR

HIGH

IMPEDANCE

t

HL

5V

3k

100pF

5V

3k

100pF

Page 4

AD674B/AD774B

WARNING!

ESD SENSITIVE DEVICE

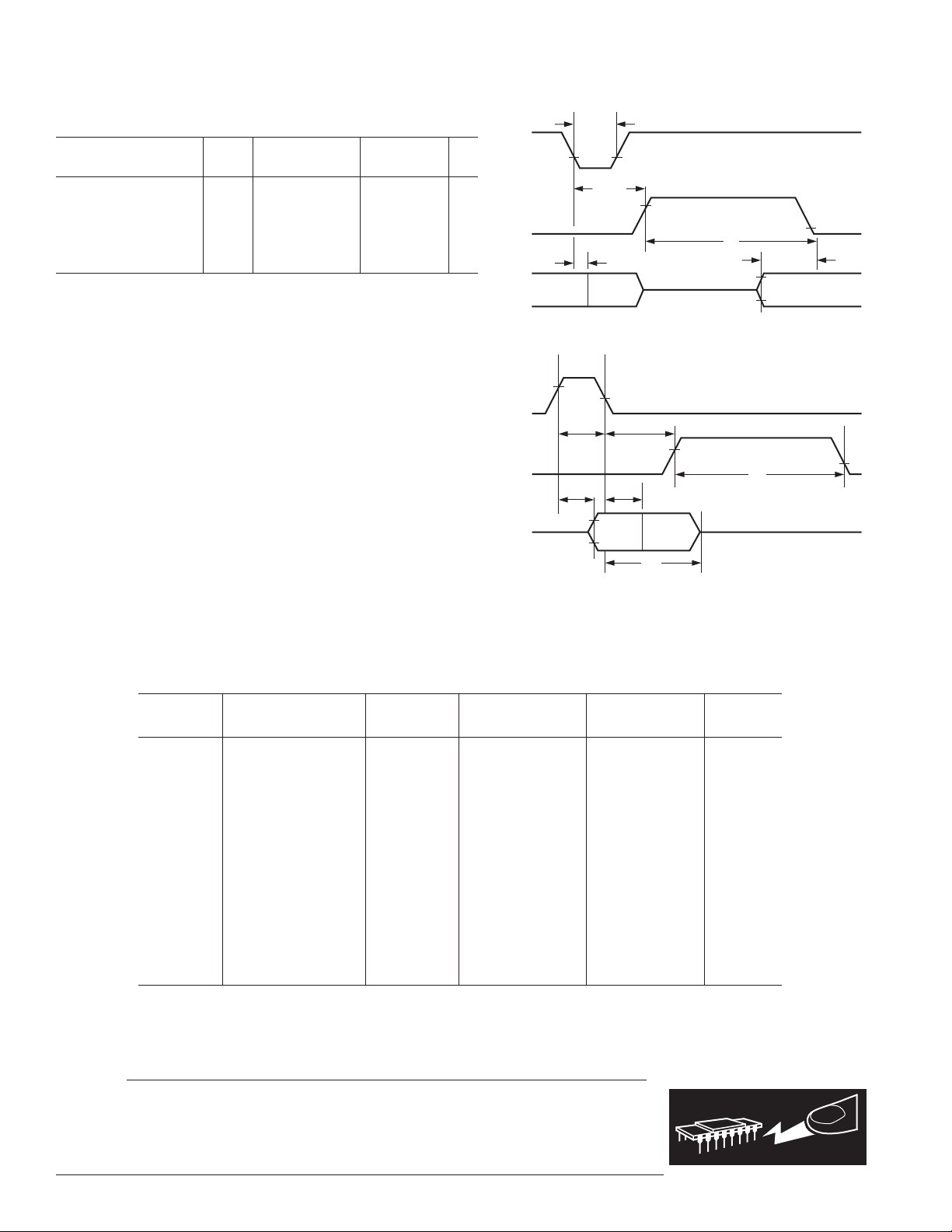

TIMING—STAND ALONE MODE (Figures 4a and 4b)

Parameter Symbol Min Typ Max Min Typ Max Unit

Data Access Time t

Low R/C Pulsewidth t

STS Delay from R/C t

Data Valid After R/C Low t

STS Delay After Data Valid t

High R/C Pulsewidth t

Specifications subject to change without notice.

J, K, A, B Grades T Grade

DDR

HRL

DS

HDR

HS

HRH

50 50 ns

25 25 ns

30 200 600 30 200 600 ns

150 150 ns

150 150 ns

200 225 ns

ABSOLUTE MAXIMUM RATINGS*

VCC to Digital Common . . . . . . . . . . . . . . . . . . . 0 to +16.5 V

to Digital Common . . . . . . . . . . . . . . . . . . . . 0 to –16.5 V

V

EE

V

to Digital Common . . . . . . . . . . . . . . . . . . . 0 to +7 V

LOGIC

Analog Common to Digital Common . . . . . . . . . . . . . . . ± 1 V

Digital Inputs to Digital Common . . . –0.5 V to V

Analog Inputs to Analog Common . . . . . . . . . . . . V

LOGIC

EE

+0.5 V

to V

CC

20 VIN to Analog Common . . . . . . . . . . . . . . . . . . . . . . ±24 V

REF OUT . . . . . . . . . . . . . . . . . . Indefinite Short to Common

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Momentary Short to V

CC

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 175°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . 825 mW

Lead Temperature, Soldering (10 sec) . . . . . . . . . . . . . 300°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only and functional operation of

the device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

t

HRL

R/C

t

DS

STS

t

C

t

HDR

DB11–DB0

DATA

VA LI D

HIGH–Z

DATA VAL ID

Flgure 4a. Standalone Mode Timing Low Pulse R/

R/C

STS

DB11–DB0

t

HRH

t

DDRtHDR

HIGH–Z HIGH–Z

DATA

VA LI D

t

DS

t

C

t

HL

Figure 4b. Standalone Mode Timing High Pulse for R/

t

HS

C

C

ORDERING GUIDE

Conversion INL Package Package

MIN

to T

) Description Option

MAX

Model

l

Temperature Time (max) (T

AD674BJN 0°C to 70°C 15 µs ± 1 LSB Plastic DIP N-28

AD674BKN 0°C to 70°C 15 µs ± 1/2 LSB Plastic DIP N-28

AD674BAR –40°C to +85°C 15 µs ± 1 LSB Plastic SOIC R-28

AD674BBR –40°C to +85°C 15 µs ± 1/2 LSB Plastic SOIC R-28

AD674BAD –40°C to +85°C 15 µs ± 1 LSB Ceramic DIP D-28

AD674BBD –40°C to +85°C 15 µs ± 1/2 LSB Ceramic DIP D-28

AD674BTD –55°C to +125°C 15 µs ±1 LSB Ceramic DIP D-28

AD774BJN 0°C to 70°C8 µs ±1 LSB Plastic DIP N-28

AD774BKN 0°C to 70°C8 µs ± 1/2 LSB Plastic DIP N-28

AD774BAR –40°C to +85°C8 µs ±1 LSB Plastic SOIC R-28

AD774BBR –40°C to +85°C8 µs ± 1/2 LSB Plastic SOIC R-28

AD774BAD –40°C to +85°C8 µs ± 1 LSB Ceramic DIP D-28

AD774BBD –40°C to +85°C8 µs ± 1/2 LSB Ceramic DIP D-28

AD774BTD –55°C to +125°C8 µs ± 1 LSB Ceramic DIP D-28

NOTES

1

For details on grade and package offerings screened in accordance with MIL-STD-883, refer to the Analog Devices Military

Products Databook or the current AD674B/ AD774B/883B data sheet.

2

N = Plastic DIP; D = Hermetic DIP; R = Plastic SOIC.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD674B/AD774B features proprietary ESD protection circuitry, permanent damage may occur

on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

2

REV. C–4–

Page 5

AD674B/AD774B

DEFINITION OF SPECIFICATIONS

Linearity Error

Linearity error refers to the deviation of each individual code

from a line drawn from “zero” through “full scale.” The point

used as “zero” occurs 1/2 LSB (1.22 mV for 10 V span) before

the first code transition (all zeroes to only the LSB “on”). “Full

scale” is defined as a level 1 1/2 LSB beyond the last code transition (to all ones). The deviation of a code from the true straight

line is measured from the middle of each particular code.

The K, B, and T grades are guaranteed for maximum nonlinearity of ± 1/2 LSB. For these grades, this means that an analog

value that falls exactly in the center of a given code width will

result in the correct digital output code. Values nearer the upper

or lower transition of the code width may produce the next upper

or lower digital output code. The J and A grades are guaranteed

to ± 1 LSB max error. For these grades, an analog value that

falls within a given code width will result in either the correct

code for that region or either adjacent one.

Note that the linearity error is not user adjustable.

Differential Linearity Error (No Missing Codes)

A specification that guarantees no missing codes requires that

every code combination appear in a monotonic increasing sequence

as the analog input level is increased. Thus every code must have a

finite width. The AD674B and AD774B guarantee no missing codes

to 12-bit resolution, requiring that all 4096 codes must be present

over the entire operating temperature ranges.

Unipolar Offset

The first transition should occur at a level 1/2 LSB above analog

common. Unipolar offset is defined as the deviation of the actual

transition from that point. This offset can be adjusted as discussed

later. The unipolar offset temperature coefficient specifies the

maximum change of the transition point over temperature,

with or without external adjustment.

Bipolar Offset

In the bipolar mode the major carry transition (0111 1111 1111

to 1000 0000 0000) should occur for an analog value 1/2 LSB

below analog common. The bipolar offset error and temperature

coefficient specify the initial deviation and maximum change in

the error over temperature.

Quantization Uncertainty

Analog-to-digital converters exhibit an inherent quantization

uncertainty of ±1/2 LSB. This uncertainty is a fundamental

characteristic of the quantization process and cannot be reduced

for a converter of given resolution.

Left-Justified Data

The output data format is left-justified. This means that the

data represents the analog input as a fraction of full scale, ranging from 0 to 4095/4096. This implies a binary point 4095 to

the left of the MSB.

Full-Scale Calibration Error

The last transition (from 1111 1111 1110 to 1111 1111 1111)

should occur for an analog value 1 1/2 LSB below the nominal

full scale (9.9963 V for 10.000 V full scale). The full-scale calibration error is the deviation of the actual level at the last transition from the ideal level. This error, which is typically 0.05% to

0.1% of full scale, can be trimmed out as shown in Figures 7

and 8. The full-scale calibration error over temperature is given

with and without the initial error trimmed out. The temperature

coefficients for each grade indicate the maximum change in the

full-scale gain from the initial value using the internal 10 V

reference.

Temperature Drift

The temperature drift for full-scale calibration, unipolar offset,

and bipolar offset specifies the maximum change from the initial

(25°C) value to the value at T

Power Supply Rejection

MIN

or T

MAX

.

The standard specifications assume use of +5.00 V and ±15.00 V

or ± 12.00 V supplies. The only effect of power supply error on

the performance of the device will be a small change in the

full-scale calibration. This will result in a linear change in all

low-order codes. The specifications show the maximum fullscale change from the initial value with the supplies at the

various limits.

Code Width

A fundamental quantity for A/D converter specifications is the

code width. This is defined as the range of analog input values for

which a given digital output code will occur. The nominal value

of a code width is equivalent to 1 least significant bit (LSB) of the

full-scale range or 2.44 mV out of 10 V for a 12-bit ADC.

REV. C

–5–

Page 6

AD674B/AD774B

PIN CONFIGURATION

1

V

LOGIC

2

12/8

3

CS

4

A

0

AD674B

5

R/C

CE

V

REF OUT

AGND

REF IN

V

BIP OFF

10 V

20 V

CC

EE

IN

IN

6

AD774B

7

TOP VIEW

(Not to Scale)

8

9

10

11

12

13

14

OR

PIN FUNCTION DESCRIPTIONS

Symbol Pin No. Type* Name and Function

AGND 9 P Analog Ground (Common)

A

0

4 DI Byte Address/Short Cycle. If a conversion is started with A0 Active LOW, a full 12-bit conversion

cycle is initiated. If A

is Active HIGH during a convert start, a shorter 8-bit conversion cycle

0

results. During Read (R/C = 1) with 12/8 LOW, A

= HIGH enables DB3–DB0 and sets DB7–DB4 = 0.

and A

0

BIP OFF 12 AI Bipolar Offset. Connect through a 50 Ω resistor to REF OUT for bipolar operation or to Analog

Common for unipolar operation.

CE 6 DI Chip Enable. Chip Enable is Active HIGH and is used to initiate a convert or read operation.

CS 3 DI Chip Select. Chip Select is Active LOW.

DB11–DB8 27–24 DO Data Bits 11 through 8. In the 12-bit format (see 12/8 and A

4 bits of data. In the 8-bit format, they provide the upper 4 bits when A

disabled when A

is HIGH.

0

DB7–DB4 23–20 DO Data Bits 7 through 4. In the 12-bit format these pins provide the middle 4 bits of data. In the

8-bit format they provide the middle 4 bits when A

DB3–DB0 19–16 DO Data Bits 3 through 0. In both the 12-bit and 8-bit format these pins provide the lower 4 bits of

data when A

is HIGH; they are disabled when A0 is LOW.

0

DGND 15 P Digital Ground (Common)

REF OUT 8 AO 10 V Reference Output

R/C 5 DI Read/Convert. In the full control mode R/C is Active HIGH for a read operation and Active LOW

for a convert operation. In the standalone mode, the falling edge of R/C initiates a conversion.

REF IN 10 AI Reference Input is connected through a 50 Ω resistor to +10 V Reference for normal operation.

STS 28 DO Status is Active HIGH when a conversion is in progress and goes LOW when the conversion is

completed.

V

CC

V

EE

V

LOGIC

10 V

20 V

IN

IN

7 P +12 V/+15 V Analog Supply

11 P –12 V/–15 V Analog Supply

1 P 5 V Logic Supply

13 AI 10 V Span Input, 0 V to +10 V unipolar mode or –5 V to +5 V bipolar mode. When using the

20 V Span, 10 V

should not be connected.

IN

14 AI 20 V Span Input, 0 V to +20 V unipolar mode or –10 V to +10 V bipolar mode. When using the

10 V Span, 20 V

should not be connected.

IN

12/8 2 DI The 12/8 pin determines whether the digital output data is to be organized as two 8-bit words

(12/8 LOW) or a single 12-bit word (12/8 HIGH).

*Types: AI = Analog Input, AO = Analog Output, DI = Digital Input, DO = Digital Output, P = Power

STS

28

DB11 (MSB)

27

DB10

26

25

DB9

24

DB8

23

DB7

22

DB6

21

DB5

20

DB4

19

DB3

18

DB2

17

DB1

16

DB0 (LSB)

15

DGND

= LOW enables the 8 most significant bits,

0

pins) these pins provide the upper

0

is LOW and are

0

is LOW and all zeroes when A0 is HIGH.

0

REV. C–6–

Page 7

AD674B/AD774B

CIRCUIT OPERATION

The AD674B and AD774B are complete 12-bit monolithic A/D

converters that require no external components to provide the

complete successive-approximation analog-to-digital conversion

function. A block diagram is shown in Figure 5.

5V SUPPLY

V

DATA MODE SELECT

READ/CONVERT R/C

ANALOG COMMON

REFERENCE INPUT

LOGIC

12/8

CHIP SELECT

BYTE ADDRESS/

SHORT CYCLE A

CHIP ENABLE

12V/15V SUPPLY

10V REFERENCE

–12V/–15V SUPPLY

BIPOLAR OFFSET

V

REF OUT

REF IN

V

BIPOFF

10V SPAN INPUT

10V

20V SPAN INPUT

20V

1

2

3

CS

4

0

5

6

CE

7

CC

8

9

AC

10

11

EE

12

13

IN

14

IN

REF

199.95

k

10V

VO LTAG E

DIVIDER

CONTROL

CLOCK SAR

COMP

–

+

I DAC

I REF

+

–

DAC

N

AD674B/AD774B

MSB

3

S

T

A

12

T

E

O

U

T

P

U

T

B

U

F

F

E

R

S

V

EE

LSB

N

Y

B

B

L

E

A

N

Y

B

B

L

E

B

N

Y

B

B

L

E

C

STATUS

28

STS

27

DB11 (MSB)

26

DB10

25

DB9

24

DB8

23

DB7

22

DB6

21

DB5

20

DB4

19

DB3

18

DB2

17

DB1

16

DB0 (LSB)

DIGITAL

15

COMMON DC

DIGITAL

DATA

OUTPUTS

Figure 5. Block Diagram of AD674B and AD774B

When the control section is commanded to initiate a conversion

(as described later) it enables the clock and resets the

successive-approximation register (SAR) to all zeroes. Once a

conversion cycle has begun, it cannot be stopped or restarted

and data is not available from the output buffers. The SAR,

timed by the clock, will sequence through the conversion cycle

and return an end-of-convert flag to the control section. The

control section will then disable the clock, bring the output

status flag low, and enable control functions to allow data read

by external command.

During the conversion cycle, the internal 12-bit current output

DAC is sequenced by the SAR from the most significant bit

(MSB) to least significant bit (LSB) to provide an output current that accurately balances the input signal current through

the divider network. The comparator determines whether the

addition of each successively weighted bit current causes the

DAC current sum to be greater or less than the input current; if

the sum is less, the bit is left on; if more, the bit is turned off.

After testing all the bits, the SAR contains a 12-bit binary code

that accurately represents the input signal to within ±1/2 LSB.

The temperature-compensated reference provides the primary

voltage reference to the DAC and guarantees excellent stability

with both time and temperature. The reference is trimmed to

10.00 V ± 1%; it can supply up to 2.0 mA to an external load in

addition to the requirements of the reference input resistor

(0.5 mA) and bipolar offset resistor (0.5 mA). Any external load

on the reference must remain constant during conversion. The

thin-film application resistors are trimmed to match the fullscale output current of the DAC. The input divider network

provides a 10 V or 20 V input range. The bipolar offset resistor

is grounded for unipolar operation and connected to the 10 V

reference for bipolar operation.

DRIVING THE ANALOG INPUT

The AD674B and AD774B are successive-approximation analogto-digital converters. During the conversion cycle, the ADC input

current is modulated by the DAC test current at approximately

a 1 MHz rate. Thus it is important to recognize that the signal

source driving the ADC must be capable of holding a constant

output voltage under dynamically changing load conditions.

FEEDBACK TO AMPLIFIER

V+

R

IN

ADC

I

IN

CURRENT

OUTPUT

I

TEST

COMPARATOR

DAC

SAR

CURRENT

LIMITING

RESISTORS

ANALOG COMMON

I

IS MODULATED BY

IN

CHANGES IN TEST CURRENT.

AMPLIFIER PULSE LOAD

RESPONSE LIMITED BY

OPEN-LOOP OUTPUT IMPEDANCE.

V–

I

DIFF

Figure 6. Op Amp—ADC Interface

The closed-loop output impedance of an op amp is equal to the

open-loop output impedance (usually a few hundred ohms)

divided by the loop gain at the frequency of interest. It is often

assumed that the loop gain of a follower-connected op amp is

sufficiently high to reduce the closed-loop output impedance to

a negligibly small value, particularly if the signal is low frequency. However, the amplifier driving the ADC must either

have sufficient loop gain at 1 MHz to reduce the closed-loop

output impedance to a low value or have low open-loop output

impedance. This can be accomplished by using a wideband op

amp, such as the AD711.

If a sample-hold amplifier is required, the monolithic AD585 or

AD781 is recommended, with the output buffer driving the

AD674B or AD774B input directly. A better alternative is the

AD1674, which is a 10 µs sampling ADC in the same pinout as the

AD574A, AD674A, or AD774B and is functionally equivalent.

SUPPLY DECOUPLING AND LAYOUT

CONSIDERATION

It is critical that the power supplies be filtered, well regulated,

and free from high-frequency noise. Use of noisy supplies will

cause unstable output codes. Switching power supplies is not

recommended for circuits attempting to achieve 12-bit accuracy

unless great care is used in filtering any switching spikes present

in the output. Few millivolts of noise represent several counts of

error in a 12-bit ADC.

Decoupling capacitors should be used on all power supply pins;

the 5 V supply decoupling capacitor should be connected directly

from Pin 1 to Pin 15 (digital common) and the +V

and –V

CC

EE

pins should be decoupled directly to analog common (Pin 9). A

suitable decoupling capacitor is a 4.7 µF tantalum type in paral-

lel with a 0.1 µF ceramic disc type.

REV. C

–7–

Page 8

AD674B/AD774B

Circuit layout should attempt to locate the ADC, associated

analog input circuitry, and interconnections as far as possible

from logic circuitry. For this reason, the use of wire-wrap circuit

construction is not recommended. Careful printed-circuit layout

and manufacturing is preferred.

UNIPOLAR RANGE CONNECTIONS FOR THE AD674B AND AD774B

The AD674B and AD774B contain all the active components

required to perform a complete 12-bit A/D conversion. Thus,

for most situations, all that is necessary is connection of the

power supplies (+5 V, +12/+15 V, and –12/–15 V), the analog

input, and the conversion initiation command, as discussed on

the next page.

AD674B/AD774B

2

12/8

3

CS

4

A

0

5

R/C

CE

6

REF IN

10

REF OUT

8

BIP OFF

12

10V

13

IN

20V

14

IN

ANA COM

9

STS 28

HIGH BITS

24–27

MIDDLE BITS

20–23

LOW BITS

16–19

+5V 1

+15V 7

–15V 11

DIG COM 15

–12V/

–15V

100k

ANALOG

OFFSET

100k

100

0 TO 10V

INPUTS

0 TO 20V

R1

+12V/

+15V

GAIN

R2

100

Figure 7. Unipolar Input Connections

UNIPOLAR CALIBRATION

The connections for unipolar ranges are shown in Figure 7. The

AD674B or AD774B is trimmed to a nominal 1/2 LSB offset so

that the exact analog input for a given code will be in the middle

of that code (halfway between the transitions to the codes above

and below it). Thus, when properly calibrated, the first transition

(from 0000 0000 0000 to 0000 0000 0001) will occur for an input

level of +1/2 LSB (1.22 mV for 10 V range).

If Pin 12 is connected to Pin 9, the unit will behave in this manner,

within specifications. If the offset trim (R1) is used, it should be

trimmed as above, although a different offset can be set for a

particular system requirement. This circuit will give approximately

± 15 mV of offset trim range.

The full-scale trim is done by applying a signal 1 1/2 LSB below

the nominal full scale (9.9963 for a 10 V range). Trim R2 to

give the last transition (1111 1111 1110 to 1111 1111 1111).

BIPOLAR OPERATION

The connections for bipolar ranges are shown in Figure 8.

Again, as for the unipolar ranges, if the offset and gain specifications are sufficient, one or both of the trimmers shown can be

replaced by a 50 Ω ± 1% fixed resistor. The analog input is

applied as for the unipolar ranges. Bipolar calibration is similar

to unipolar calibration. First, a signal 1/2 LSB above negative

full scale (–4.9988 V for the ±5 V range) is applied and R1 is

trimmed to give the first transition (0000 0000 0000 to 0000

0000 0001). Then a signal 1 1/2 LSB below positive full scale

(+4.9963 V for the ±5 V range) is applied and R2 trimmed to

give the last transition (1111 1111 1110 to 1111 1111 1111).

All of the thin-film application resistors of the AD674B and

AD774B are factory trimmed for absolute calibration. Therefore,

in many applications, no calibration trimming will be required.

The absolute accuracy for each grade is given in the specification

tables. For example, if no trims are used, ±2 LSB max zero offset

error and ± 0.25% (10 LSB) max full-scale error are guaranteed.

If the offset trim is not required, Pin 12 can be connected directly

to Pin 9; the two resistors and trimmer for Pin 12 are then not

needed. If the full-scale trim is not required, a 50 Ω 1% metal

film resistor should be connected between Pin 8 and Pin 10.

The analog input is connected between Pins 13 and 9 for a 0 V

to 10 V input range, between Pins 14 and 9 for a 0 V to 20 V

input range. Input signals beyond the supplies are easily accommodated. For the 10 V span input, the LSB has a nominal value of

2.44 mV; for the 20 V span, 4.88 mV. If a 10.24 V range is

desired (nominal 2.5 mV/bit), the gain trimmer (R2) should be

replaced by a 50 Ω resistor and a 200 Ω trimmer inserted in

series with the analog input to Pin 13 (for a full-scale range of

20.48 V [5 mV/bit] use a 500 Ω trimmer into Pin 14). The

gain trim described below is now done with these trimmers.

The nominal input impedance into Pin 13 is 5 kΩ, and into Pin

14 is 10 kΩ.

AD674B/AD774B

GAIN

OFFSET

ANALOG

INPUTS

5V

10V

R2

R1

100

100

2

12/8

3

CS

4

A

5

R/C

CE

6

REF IN

10

REF OUT

8

BIP OFF

12

10V

13

20V

14

ANA COM

9

0

IN

IN

STS 28

HIGH BITS

24–27

MIDDLE BITS

20–23

LOW BITS

16–19

+5V 1

+15V 7

–15V 11

DIG COM 15

Figure 8. Bipolar Input Connections

GROUNDING CONSIDERATIONS

The analog common at Pin 9 is the ground reference point for

the internal reference and is thus the “high quality” ground for

the ADC; it should be connected directly to the analog reference

point of the system. To achieve the high-accuracy performance

available from the ADC in an environment of high digital noise

content, the analog and digital commons must be connected

together at the package. In some situations, the digital common

at Pin 15 can be connected to the most convenient ground reference point; digital power return is preferred.

REV. C–8–

Page 9

AD674B/AD774B

VALUE OF A0 AT LAST CONVERT COMMAND

CE

CS

R/C

12/8

D

EN

R

Q

S

A

0

READ

Q

D

EN

START CONVERT

S

Q

R

QB

HIGH IF CONVERSION

IN PROGRESS

CLK EN

STATUS

NYBBLE A

ENABLE

NYBBLE B

ENABLE

NYBBLE C

ENABLE

NYBBLE = 0

ENABLE

EOC 12

EOC 8

SAR

RESET

TO

OUTPUT

BUFFERS

Figure 9. Equivalent Internal Logic Circuitry

CONTROL LOGIC

The AD674B and AD774B contain on-chip logic to provide

conversion initiation and data read operations from signals

commonly available in microprocessor systems; this internal

logic circuitry is shown in Figure 9.

The control signals CE, CS, and R/C control the operation of

the converter. The state of R/C when CE and CS are both

asserted determines whether a data read (R/C = 1) or a convert

(R/C = 0) is in progress. The register control inputs, A

and

0

12/8, control conversion length and data format. If a conversion

is started with A

If A

is high during a convert start, a shorter 8-bit conversion

0

cycle results. During data read operations, A

low, a full 12-bit conversion cycle is initiated.

0

determines

0

whether the three-state buffers containing the 8 MSBs of the

conversion result (A

= 0) or the 4 LSBs (A0 = 1) are enabled.

0

The 12/8 pin determines whether the output data is to be organized as two 8-bit words (12/8 tied to DIGITAL COMMON)

or a single 12-bit word (12/8 tied to V

the byte addressed when A

is high contains the 4 LSBs from

0

). In the 8-bit mode,

LOGIC

the conversion followed by four trailing zeroes. This organization allows the data lines to be overlapped for direct interface to

8-bit buses without the need for external three-state buffers.

An output signal, STS, indicates the status of the converter.

STS goes high at the beginning of a conversion and returns low

when the conversion cycle is complete.

Table I. Truth Table

CE CS R/C 12/8 A0 Operation

0XXXXNone

X1 XXXNone

1 0 0 X 0 Initiate 12-Bit Conversion

1 0 0 X 1 Initiate 8-Bit Conversion

1011XEnable 12-Bit Parallel Output

10100Enable 8 Most Significant Bits

10101Enable 4 LSBs + 4 Trailing Zeroes

The ADC may be operated in one of two modes, the full-control

mode and the standalone mode. The full-control mode uses all

the control signals and is useful in systems that address decode

multiple devices on a single data bus. The standalone mode is

useful in systems with dedicated input ports available. In general, the standalone mode is capable of issuing start-convert

commands on a more precise basis and therefore produces

higher accuracy results. The following sections describe these

two modes in more detail.

FULL-CONTROL MODE

Chip Enable (CE), Chip Select (CS), and Read/Convert (R/C)

are used to control Convert or Read modes of operation. Either

CE or CS may be used to initiate a conversion. The state of R/C

when CE and CS are both asserted determines whether a data

Read (R/C = 1) or a Convert (R/C = 0) is in progress. R/C

should be LOW before both CE and CS are asserted; if R/C is

HIGH, a Read operation will momentarily occur, possibly

resulting in system bus contention.

REV. C

–9–

Page 10

AD674B/AD774B

STANDALONE MODE

“Standalone” mode is useful in systems with dedicated input

ports available and thus not requiring full bus interface capability. Standalone mode applications are generally able to issue

conversion start commands more precisely than full-control

mode, resulting in improved accuracy.

CE and 12/8 are wired HIGH, CS and A

are wired LOW, and

0

conversion is controlled by R/C. The three-state buffers are

enabled when R/C is HIGH and a conversion starts when R/C

goes LOW. This gives rise to two possible control signals—a

high pulse or a low pulse. Operation with a low pulse is shown

in Figure 4a. In this case, the outputs are forced into the high

impedance state in response to the falling edge of R/C and

return to valid logic levels after the conversion cycle is completed.

The STS line goes HIGH 200 ns after R/C goes LOW and

returns low 600 ns after data is valid.

If conversion is initiated by a high pulse as shown in Figure 4b,

the data lines are enabled during the time when R/C is HIGH.

The falling edge of R/C starts the next conversion, and the data

lines return to three-state (and remain three-state) until the next

high pulse of R/C.

CONVERSION TIMING

Once a conversion is started, the STS line goes HIGH. Convert

start commands will be ignored until the conversion cycle is

complete. The output data buffers can be enabled up to 1.2 µs

prior to STS going LOW. The STS line will return LOW at the

end of the conversion cycle.

The register control inputs, A

length and data format. If a conversion is started with A

a full 12-bit conversion cycle is initiated. If A

and 12/8, control conversion

0

is HIGH during a

0

LOW,

0

convert start, a shorter 8-bit conversion cycle results.

During data read operations, A

determines whether the three-

0

state buffers containing the 8 MSBs of the conversion result

= 0) or the 4 LSBs (A0 = 1) are enabled. The 12/8 pin

(A

0

determines whether the output data is to be organized as two

8-bit words (12/8 tied LOW) or a single 12-bit word (12/8 tied

HIGH). In the 8-bit mode, the byte addressed when A

is high

0

contains the 4 LSBs from the conversion followed by four trailing zeroes. This organization allows the data lines to be overlapped for direct interface to 8-bit buses without the need for

external three-state buffers.

GENERAL A/D CONVERTER INTERFACE

CONSIDERATIONS

A typical A/D converter interface routine involves several operations. First, a write to the ADC address initiates a conversion.

The processor must then wait for the conversion cycle to complete, since most integrated circuit ADCs take longer than one

instruction cycle to complete a conversion. Valid data can, of

course, only be read after the conversion is complete. The

AD674B and AD774B provide an output signal (STS) which

indicates when a conversion is in progress. This signal can be

polled by the processor by reading it through an external threestate buffer (or other input port). The STS signal can also

generate an interrupt upon completion of conversion if the system timing requirements are critical and the processor has other

tasks to perform during the ADC conversion cycle. Another

possible time-out method is to assume that the ADC will take its

maximum conversion time to convert, and insert a sufficient

number of “no-op” instructions to ensure that this amount of

processor time is consumed.

Once conversion is complete, the data can be read. For converters with more data bits than are available on the bus, a choice of

data formats is required, and multiple read operations are

needed. The AD674B and AD774B include internal logic to

permit direct interface to 8-bit and 16-bit data buses, selected

by the 12/8 input. In 16-bit bus applications (12/8 high) the

data lines (DB11 through DB0) may be connected to either the

12 most significant or 12 least significant bits of the data bus.

The remaining 4 bits should be masked in software. The interface to an 8-bit data bus (12/8 low) is done in a left-justified format. The even address (A

through DB4). The odd address (A

low) contains the 8 MSBs (DB11

0

high) contains the 4 LSBs

0

(DB3 through DB0) in the upper half of the byte, followed by

four trailing zeroes, thus eliminating bit masking instructions.

It is not possible to rearrange the output data lines for right-justified 8-bit bus interface.

D7 D0

DB11

XXX0

(EVEN ADDR)

XXX1

(ODD ADDR)

DB10 DB9 DB8 DB7 DB6 DB5 DB4

(MSB)

DB3 DB2 DB1

DB0

0000

(LSB)

Figure 10. Data Format for 8-Bit Bus

REV. C–10–

Page 11

0.085

0.0125 (0.32)

0.0091 (0.23)

8

0

0.0291 (0.74)

0.0098 (0.25)

45

0.0500 (1.27)

0.0157 (0.40)

SEATING

PLANE

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

0.1043 (2.65)

0.0926 (2.35)

0.0500

(1.27)

BSC

28 15

141

0.7125 (18.10)

0.6969 (17.70)

0.4193 (10.65)

0.3937 (10.00)

0.2992 (7.60)

0.2914 (7.40)

PIN 1

(2.16)

0.017 0.003

28

1

+

–

(0.43)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead Ceramic DIP Package

(D-28)

0.050 (12.83)

15

0.59

+

0.01

–

(14.98)

1.42 (36.07)

1.40 (35.56)

0.1 (2.54)

+

0.047 0.007

–

(1.19)

14

0.095 (2.41)

0.050

+

0.010

–

(1.27)

SEATING

PLANE

28-Lead Plastic DIP Package

(N-28)

o

30

0.010 0.002

(0.254 0.05)

0.6 (15.24)

0.05 (1.27)

0.045 (1.14)

0.08 (2.0)

0.125 MIN (3.17)

0.145 0.02

(3.68)

+

–

+

–

AD674B/AD774B

+

–

PIN 1

0.250

(6.35)

MAX

0.200 (5.05)

0.125 (3.18)

1.565 (39.70)

1.380 (35.10)

28

15

0.580 (14.73)

0.485 (12.32)

114

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

0.060 (1.52)

0.015 (0.38)

0.070

(1.77)

MAX

SEATING

PLANE

0.150

(3.81)

MIN

0.625 (15.87)

0.600 (15.24)

28-Lead Wide Body SOIC Package

(R-28)

0.195 (4.95)

0.125 (3.18)

0.015 (0.381)

0.008 (0.204)

REV. C

–11–

Page 12

AD674B/AD774B

Revision History

Location Page

Data Sheet changed from REV. B to REV. C.

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Add 28-Lead Wide Body SOIC Package Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C00808-0-4/02(C)

PRINTED IN U.S.A.

REV. C–12–

Loading...

Loading...