Page 1

Four-Channel, 80 MSPS Digital

a

FEATURES

80 MSPS Wide Band Inputs (14 Linear Bits Plus 3 RSSI)

Dual High Speed Data Input Ports

Four Independent Digital Receivers in Single Package

Digital Resampling for Noninteger Decimation Rates

Programmable Decimating FIR Filters

Programmable Attenuator Control for Clip Prevention

and External Gain Ranging via Level Indicator

Flexible Control for Multicarrier and Phased Array

3.3 V I/O, 2.5 V CMOS Core

User-Configurable Built-In Self-Test (BIST) Capability

JTAG Boundary Scan

APPLICATIONS

Multicarrier, Multimode Digital Receivers GSM, IS136,

EDGE, PHS, IS95

Micro and Pico Cell Systems

Wireless Local Loop

Smart Antenna Systems

Software Radios

In-Building Wireless Telephony

PRODUCT DESCRIPTION

The AD6624 is a four-channel (quad) digital receive signal

processor (RSP) with four cascaded signal-processing elements:

a frequency translator, two fixed-coefficient decimating filters,

and a programmable-coefficient decimating filter.

Receive Signal Processor (RSP)

AD6624

The AD6624 is part of Analog Devices’ SoftCell® multicarrier

transceiver chipset designed for compatibility with Analog

Devices’ family of high sample rate IF sampling ADCs (AD6640/

AD6644 12- and 14-bit). The SoftCell receiver comprises a

digital receiver capable of digitizing an entire spectrum of

carriers and digitally selecting the carrier of interest for tuning

and channel selection. This architecture eliminates redundant

radios in wireless base station applications.

High dynamic range decimation filters offer a wide range of

decimation rates. The RAM-based architecture allows easy

reconfiguration for multimode applications.

The decimating filters remove unwanted signals and noise from

the channel of interest. When the channel of interest occupies less

bandwidth than the input signal, this rejection of out-of-band

noise is called “processing gain.” By using large decimation

factors, this “processing gain” can improve the SNR of the

ADC by 30 dB or more. In addition, the programmable RAM

coefficient filter allows antialiasing, matched filtering, and

static equalization functions to be combined in a single, costeffective filter.

The AD6624 is compatible with standard ADC converters such

as the AD664x, AD9042, AD943x, and the AD922x families of

data converters. The AD6624 is also compatible with the AD6600

Diversity ADC, providing a cost and size reduction path.

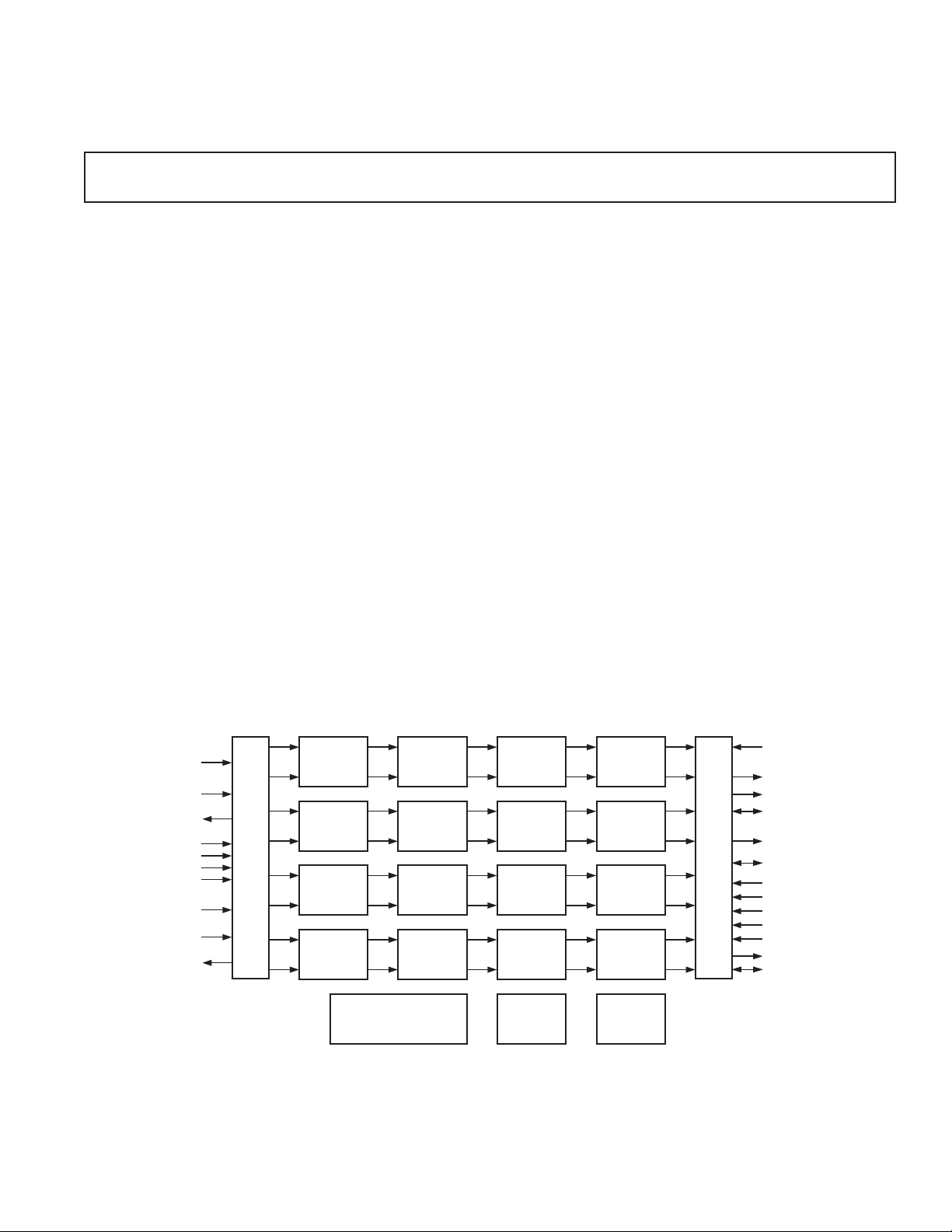

FUNCTIONAL BLOCK DIAGRAM

16 BITS 18 BITS 20 BITS 24 BITS

INA[13:0]

EXPA[2:0]

IENA

LIA-A

LIA-B

SYNCA

SYNCB

SYNCC

SYNCD

INB[13:0]

EXPB[2:0]

IENB

LIB-A

LIB-B

CH A NCO

CH B NCO

INPUT MATRIX

CH C NCO

CH D NCO

EXTERNAL SYNC

RESAMPLER

RESAMPLER

RESAMPLER

RESAMPLER

CIRCUITRY

rCIC2

rCIC2

rCIC2

rCIC2

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

CIC5

CIC5

CIC5

CIC5

JTAG

INTERFACE

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

RAM

COEFFICIENT

FILTER

RAM

COEFFICIENT

FILTER

RAM

COEFFICIENT

FILTER

RAM

COEFFICIENT

FILTER

BUILT-IN

SELF-TEST

SERIAL AND MICROPORT

SDIN[3:0]

SDO[3:0]

DR[3:0]

SDFS[3:0]

SDFE[3:0]

SCLK[3:0]

MODE

DS(RD)

CS

RW (WR)

DTACK(RDY)

A[2:0]

D[7:0]

Page 2

AD6624

TABLE OF CONTENTS

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 1

FUNCTIONAL BLOCK DIAGRAM . . . . . . . . . . . . . . . . . 1

SPECIFICATIONS/CHARACTERISTICS . . . . . . . . . . . . . 3

GENERAL TIMING CHARACTERISTICS . . . . . . . . . . . . 4

ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . 9

PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . 11

ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EXAMPLE FILTER RESPONSE . . . . . . . . . . . . . . . . . . . 14

INPUT DATA PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Input Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Input Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Input Enable Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Gain Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Input Data Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Scaling with Fixed-Point ADCs . . . . . . . . . . . . . . . . . . . . 16

Scaling with Floating-Point or Gain-Ranging ADCs . . . . 16

NUMERICALLY CONTROLLED OSCILLATOR . . . . . 17

Frequency Translation . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

NCO Frequency Hold-Off Register . . . . . . . . . . . . . . . . . 17

Phase Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

NCO Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Phase Dither . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Amplitude Dither . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Clear Phase Accumulator on HOP . . . . . . . . . . . . . . . . . . 17

Input Enable Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mode 00: Blank On IEN Low . . . . . . . . . . . . . . . . . . . . . 17

Mode 01: Clock On IEN High . . . . . . . . . . . . . . . . . . . . 18

Mode 10: Clock on IEN Transition to High . . . . . . . . . . 18

Mode 11: Clock on IEN Transition to Low . . . . . . . . . . . 18

WB Input Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sync Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECOND ORDER rCIC FILTER . . . . . . . . . . . . . . . . . . . 18

rCIC2 Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Example Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Decimation and Interpolation Registers . . . . . . . . . . . . . . 19

rCIC2 Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FIFTH ORDER CASCADED INTEGRATOR COMB

FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CIC5 Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

RAM COEFFICIENT FILTER . . . . . . . . . . . . . . . . . . . . . 20

RCF Decimation Register . . . . . . . . . . . . . . . . . . . . . . . . 21

RCF Decimation Phase . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RCF Filter Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RCF Output Scale Factor and Control Register . . . . . . . . 21

USER-CONFIGURABLE BUILT-IN SELF-TEST (BIST) 22

RAM BIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CHANNEL BIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CHIP SYNCHRONIZATION . . . . . . . . . . . . . . . . . . . . . . 22

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SERIAL OUTPUT DATA PORT . . . . . . . . . . . . . . . . . . . 24

Serial Output Data Format . . . . . . . . . . . . . . . . . . . . . . . 24

Serial Data Frame (Serial Bus Master) . . . . . . . . . . . . . . . 24

Serial Data Frame (Serial Cascade) . . . . . . . . . . . . . . . . . 25

Configuring the Serial Ports . . . . . . . . . . . . . . . . . . . . . . . 25

Serial Port Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Serial Port to DSP Interconnection . . . . . . . . . . . . . . . . . 25

Serial Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Serial Ports Cascaded . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Output Frame Timing (Master and Slave) . . . . . . . 26

Serial Port Timing Specifications . . . . . . . . . . . . . . . . . . . 26

SBM0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SCLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SDIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SDFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SDFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Serial Word Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SDFS Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mapping RCF Data to the BIST Registers . . . . . . . . . . . . 29

0x00–0x7F: Coefficient Memory (CMEM) . . . . . . . . . . . 29

0x80: Channel Sleep Register . . . . . . . . . . . . . . . . . . . . . 30

0x81: Soft_SYNC Register . . . . . . . . . . . . . . . . . . . . . . . 30

0x82: Pin_SYNC Register . . . . . . . . . . . . . . . . . . . . . . . . 30

0x83: Start Hold-Off Counter . . . . . . . . . . . . . . . . . . . . . 30

0x84: NCO Frequency Hold-Off Counter . . . . . . . . . . . . 30

0x85: NCO Frequency Register 0 . . . . . . . . . . . . . . . . . . 30

0x86: NCO Frequency Register 1 . . . . . . . . . . . . . . . . . . 30

0x87: NCO Phase Offset Register . . . . . . . . . . . . . . . . . . 30

0x88: NCO Control Register . . . . . . . . . . . . . . . . . . . . . . 30

0x90: rCIC2 Decimation – 1 (M

0x91: rCIC2 Interpolation – 1 (L

–1) . . . . . . . . . . . . . 31

rCIC2

–1) . . . . . . . . . . . . 31

rCIC2

0x92: rCIC2 Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

0x93: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

0x94: CIC5 Decimation – 1 (M

–1) . . . . . . . . . . . . . . 31

CIC5

0x95: CIC5 Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

0x96: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

0xA0: RCF Decimation – 1 (M

0xA1: RCF Decimation Phase (P

0xA2: RCF Number of Taps Minus One (N

0xA3: RCF Coefficient Offset (CO

–1) . . . . . . . . . . . . . . . 31

RCF

) . . . . . . . . . . . . . . . 31

RCF

) . . . . . . . . . . . . . . 31

RCF

-1) . . . . . 31

RCF

0xA4: RCF Control Register . . . . . . . . . . . . . . . . . . . . . . 31

0xA5: BIST Register for I . . . . . . . . . . . . . . . . . . . . . . . . 32

0xA6: BIST Register for Q . . . . . . . . . . . . . . . . . . . . . . . 32

0xA7: BIST Control Register . . . . . . . . . . . . . . . . . . . . . 32

0xA8: RAM BIST Control Register . . . . . . . . . . . . . . . . 32

0xA9: Serial Port Control Register . . . . . . . . . . . . . . . . . 32

MICROPORT CONTROL . . . . . . . . . . . . . . . . . . . . . . . . 33

External Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Access Control Register (ACR) . . . . . . . . . . . . . . . . . . . . 33

External Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Channel Address Register (CAR) . . . . . . . . . . . . . . . . . . . 34

SOFT_SYNC Control Register . . . . . . . . . . . . . . . . . . . . 34

PIN_SYNC Control Register . . . . . . . . . . . . . . . . . . . . . . 34

SLEEP Control Register . . . . . . . . . . . . . . . . . . . . . . . . . 34

Data Address Registers . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Write Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Read Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Read/Write Chaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Intel Nonmultiplexed Mode (INM) . . . . . . . . . . . . . . . . . 35

Motorola Nonmultiplexed Mode (MNM) . . . . . . . . . . . . 35

Input Port Control Registers . . . . . . . . . . . . . . . . . . . . . . 35

SERIAL PORT CONTROL . . . . . . . . . . . . . . . . . . . . . . . . 36

JTAG BOUNDARY SCAN . . . . . . . . . . . . . . . . . . . . . . . . 36

INTERNAL WRITE ACCESS . . . . . . . . . . . . . . . . . . . . . . 37

Write Pseudocode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

INTERNAL READ ACCESS . . . . . . . . . . . . . . . . . . . . . . . 37

Read Pseudocode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . 38

–2–

REV. B

Page 3

AD6624

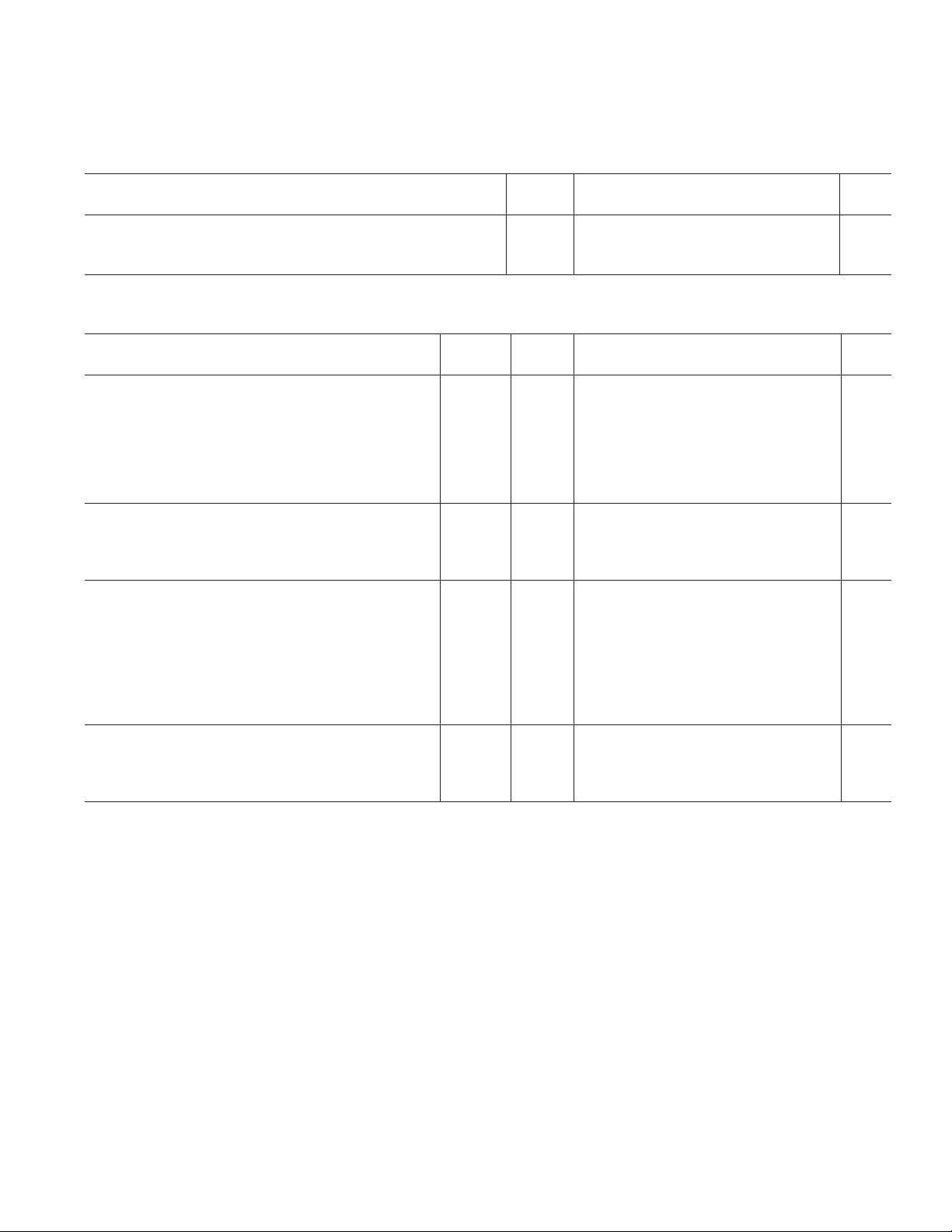

SPECIFICATIONS

(VDD = 2.5 V ⴞ 5%, VDDIO = 3.3 V ⴞ 10%. All specifications TA = T

MIN

to T

, unless otherwise noted.)

MAX

RECOMMENDED OPERATING CONDITIONS

Test AD6624AS

Parameter Level Min Typ Max Unit

VDD IV 2.375 2.5 2.675 V

VDDIO IV 3.0 3.3 3.6 V

T

AMBIENT

IV –40 +25 +70 °C

ELECTRICAL CHARACTERISTICS

Test AD6624AS

Parameter (Conditions) Temp Level Min Typ Max Unit

LOGIC INPUTS

Logic Compatibility Full 3.3 V CMOS

Logic “1” Voltage Full IV 2.0 5.0 V

Logic “0” Voltage Full IV –0.3 +0.8 V

Logic “1” Current Full IV 1 10 µA

Logic “0” Current Full IV 1 10 µA

Input Capacitance 25°CV 4 pF

LOGIC OUTPUTS

Logic Compatibility Full 3.3 V CMOS/TTL

Logic “1” Voltage (I

Logic “0” Voltage (IOL = 0.25 mA) Full IV 0.2 0.4 V

IDD SUPPLY CURRENT

CLK = 80 MHz, (VDD = 2.75 V, VDDIO = 3.6 V) Full IV

I

VDD

I

VDDIO

CLK = GSM Example (65 MSPS, VDD = 2.5 V,

VDDIO = 3.3 V, Dec = 2/10/6 120 Taps 4 Channels) 25°CV

I

VDD

I

VDDIO

POWER DISSIPATION

CLK = 80 MHz TD-SCDMA Full IV 1.1 W

CLK = 65 MHz

Sleep Mode Full IV 287 µW

(5 V TOLERANT)

= 0.25 mA) Full IV 2.4 VDD – 0.2 V

OH

400 mA

60 mA

250 mA

24 mA

GSM/EDGE Example V 700 mW

Specifications subject to change without notice.

REV. B

–3–

Page 4

AD6624–SPECIFICATIONS

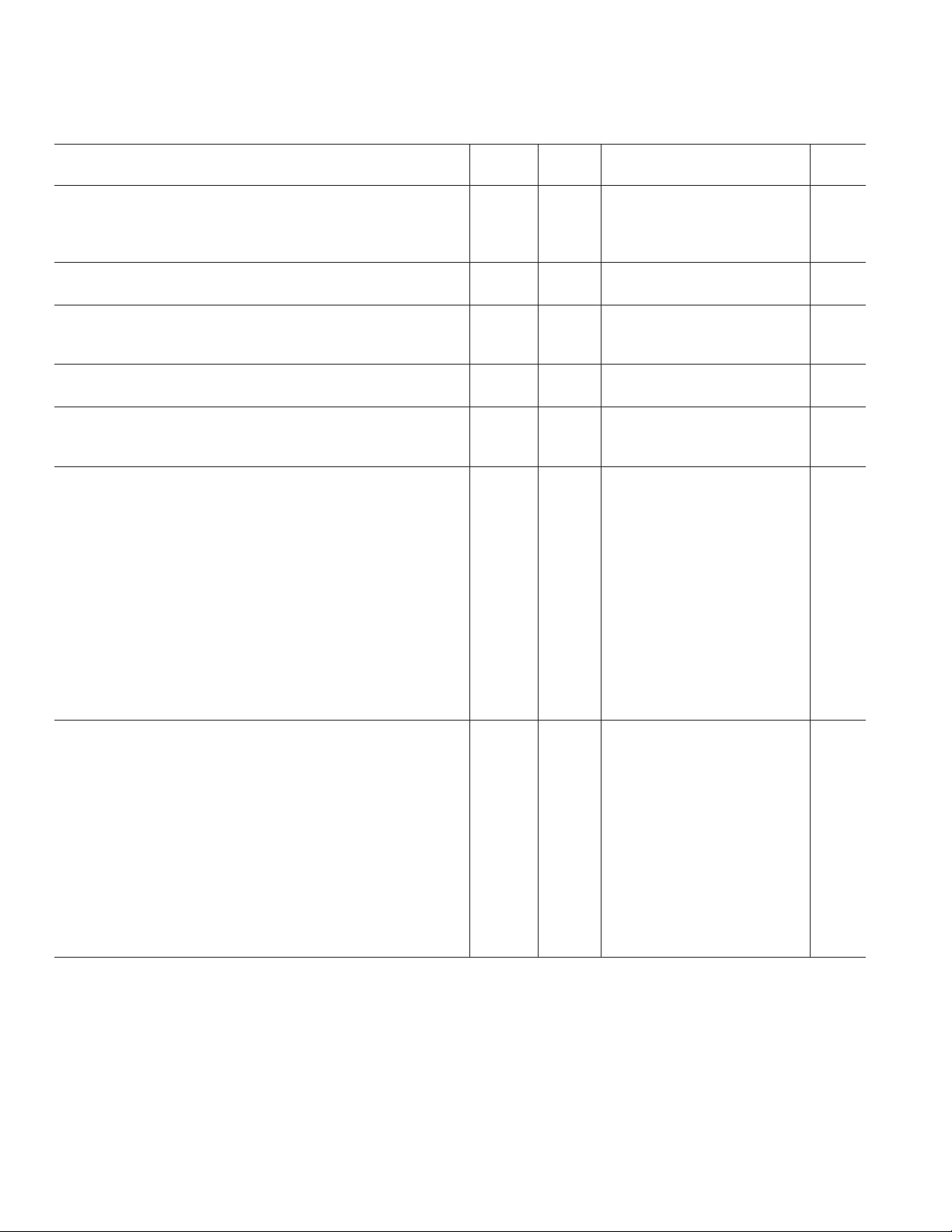

GENERAL TIMING CHARACTERISTICS

1, 2

Test AD6624AS

Parameter (Conditions) Temp Level Min Typ Max Unit

CLK Timing Requirements:

t

CLK

t

CLKL

t

CLKH

CLK Period Full I 12.5 ns

CLK Width Low Full IV 4.5 0.5 × t

CLK Width High Full IV 4.5 0.5 × t

CLK

CLK

ns

ns

RESET Timing Requirement:

t

RESL

RESET Width Low Full I 30.0 ns

Input Wideband Data Timing Requirements:

t

SI

t

HI

Input to ↑CLK Setup Time Full IV 0.8 ns

Input to ↑CLK Hold Time Full IV 2.0 ns

Level Indicator Output Switching Characteristic:

t

DLI

↑CLK to LI (A–A, B; B–A, B) Output Delay Time Full IV 3.8 12.6 ns

SYNC Timing Requirements:

t

SS

t

HS

Serial Port Timing Requirements (SBM = 1):

Switching Characteristics:

t

DSCLK1

t

DSCLKH

t

DSCLKL

t

DSCLKLL

t

DSDFS

t

DSDFE

t

DSDO

t

DSDR

t

DDR

SYNC (A, B, C, D) to ↑CLK Setup Time Full IV 1.0 ns

SYNC (A, B, C, D) to ↑CLK Hold Time Full IV 2.0 ns

3

↑CLK to ↑SCLK Delay (Divide by 1) Full IV 3.9 13.4 ns

↑CLK to ↑SCLK Delay (For Any Other Divisor) Full IV 4.4 14.0 ns

↑CLK to ↓SCLK Delay (Divide by 2 or Even #) Full IV 3.25 6.7 ns

↓CLK to ↓SCLK Delay (Divide by 3 or Odd #) Full IV 3.8 6.9 ns

↑SCLK to SDFS Delay Full IV 0.2 5.3 ns

↑SCLK to SDFE Delay Full IV –0.4 +4.7 ns

↑SCLK to SDO Delay Full IV –1.0 +4.0 ns

↑SCLK to DR Delay Full IV –0.3 +4.6 ns

↑CLK to DR Delay Full IV 5.4 17.6 ns

Input Characteristics:

t

SSI

t

HSI

Serial Port Timing Requirements (SBM = 0):

Switching Characteristics:

t

SCLK

t

SCLKL

t

SCLKH

t

DSDFE

t

DSDO

t

DSDR

SDI to ↓SCLK Setup Time Full IV 2.4 ns

SDI to ↓SCLK Hold Time Full IV 3.0 ns

3

SCLK Period Full IV 16 ns

SCLK Low Time (When SDIV = 1, Divide by 1) Full IV 5.0 ns

SCLK High Time (When SDIV = 1, Divide by 1) Full IV 5.0 ns

↑SCLK to SDFE Delay Full IV 3.8 15.4 ns

↑SCLK to SDO Delay Full IV 3.7 15.2 ns

↑SCLK to DR Delay Full IV 3.9 15.9 ns

Input Characteristics:

t

SSF

t

HSF

t

SSI

t

HSI

NOTES

1

All timing specifications valid over VDD range of 2.375 V to 2.675 V and VDDIO range of 3.0 V to 3.6 V.

2

C

LOAD

3

The timing parameters for SCLK, SDFS, SDFE, SDO, SDI, and DR apply to all four channels (0, 1, 2, and 3). The slave serial port’s (SCLK) operating frequency is

limited to 62.5 MHz.

Specifications subject to change without notice.

SDFS to ↑SCLK Setup Time Full IV 1.9 ns

SDFS to ↑SCLK Hold Time Full IV 0.7 ns

SDI to ↓SCLK Setup Time Full IV 2.4 ns

SDI to ↓SCLK Hold Time Full IV 2.0 ns

= 40 pF on all outputs unless otherwise specified.

–4–

REV. B

Page 5

AD6624

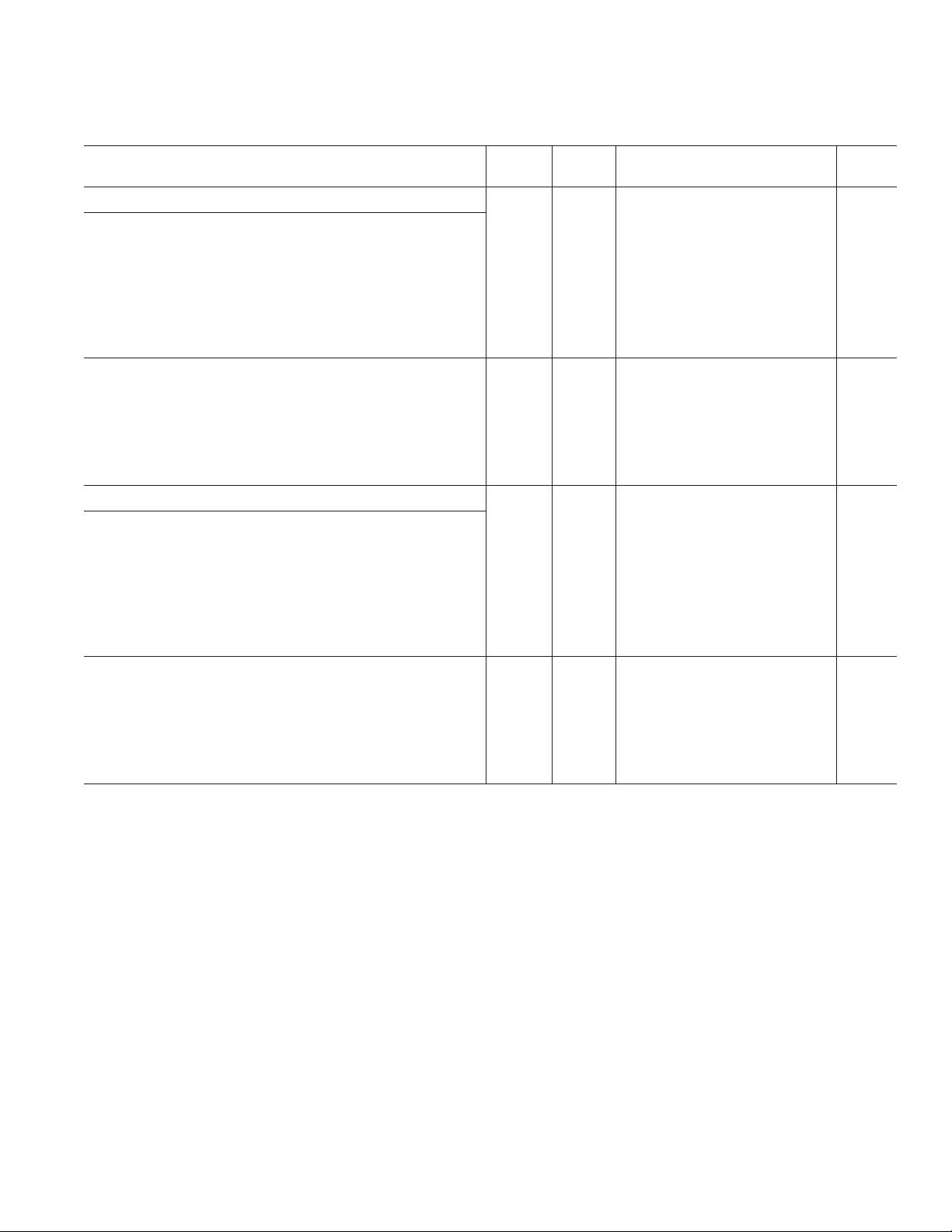

MICROPROCESSOR PORT TIMING CHARACTERISTICS

1, 2

Test AD6624AS

Parameter (Conditions) Temp Level Min Typ Max Unit

MICROPROCESSOR PORT, MODE INM (MODE = 0)

MODE INM Write Timing:

t

SC

t

HC

t

HWR

t

SAM

t

HAM

t

DRDY

t

ACC

Control3 to ↑CLK Setup Time Full IV 5.5 ns

Control3 to ↑CLK Hold Time Full IV 1.0 ns

WR(RW) to RDY(DTACK) Hold Time Full IV 8.0 ns

Address/Data to WR(RW) Setup Time Full IV –0.5 ns

Address/Data to RDY(DTACK) Hold Time Full IV 7.0 ns

WR(RW) to RDY(DTACK) Delay Full IV 4.0 ns

WR(RW) to RDY(DTACK) High Delay Full IV 4 × t

CLK

5 × t

CLK

9 × t

CLK

ns

MODE INM Read Timing:

t

SC

t

HC

t

SAM

t

HAM

t

DRDY

t

ACC

Control3 to ↑CLK Setup Time Full IV 4.0 ns

Control3 to ↑CLK Hold Time Full IV 2.0 ns

Address to RD(DS) Setup Time Full IV 0.0 ns

Address to Data Hold Time Full IV 7.0 ns

RD(DS) to RDY(DTACK) Delay Full IV 4.0 ns

RD(DS) to RDY(DTACK) High Delay Full IV 8 × t

CLK

10 × t

CLK

13 × t

CLK

ns

MICROPROCESSOR PORT, MODE MNM (MODE = 1)

MODE MNM Write Timing:

t

SC

t

HC

t

HDS

t

HRW

t

SAM

t

HAM

t

ACC

Control3 to ↑CLK Setup Time Full IV 5.5 ns

Control3 to ↑CLK Hold Time Full IV 1.0 ns

DS(RD) to DTACK(RDY) Hold Time Full IV 8.0 ns

RW(WR) to DTACK(RDY) Hold Time Full IV 8.0 ns

Address/Data to RW(WR) Setup Time Full IV –0.5 ns

Address/Data to RW(WR) Hold Time Full IV 7.0 ns

RW(WR) to DTACK(RDY) Low Delay Full IV 4 × t

CLK

5 × t

CLK

9 × t

CLK

ns

MODE MNM Read Timing:

t

SC

t

HC

t

SAM

t

HAM

t

ZD

t

ACC

NOTES

1

All timing specifications valid over VDD range of 2.375 V to 2.675 V and VDDIO range of 3.0 V to 3.6 V.

2

C

= 40 pF on all outputs unless otherwise specified.

LOAD

3

Specification pertains to control signals: RW, (WR), DS, (RD), CS.

Specifications subject to change without notice.

Control3 to ↑CLK Setup Time Full IV 4.0 ns

Control3 to ↑CLK Hold Time Full IV 2.0 ns

Address to DS(RD) Setup Time Full IV 8.0 ns

Address to Data Hold Time Full IV 0.0 ns

Data Three-State Delay Full IV 7.0 ns

DS(RD) to DTACK(RDY) Low Delay Full IV 8 × t

CLK

10 × t

CLK

13 × t

CLK

ns

REV. B

–5–

Page 6

AD6624

R

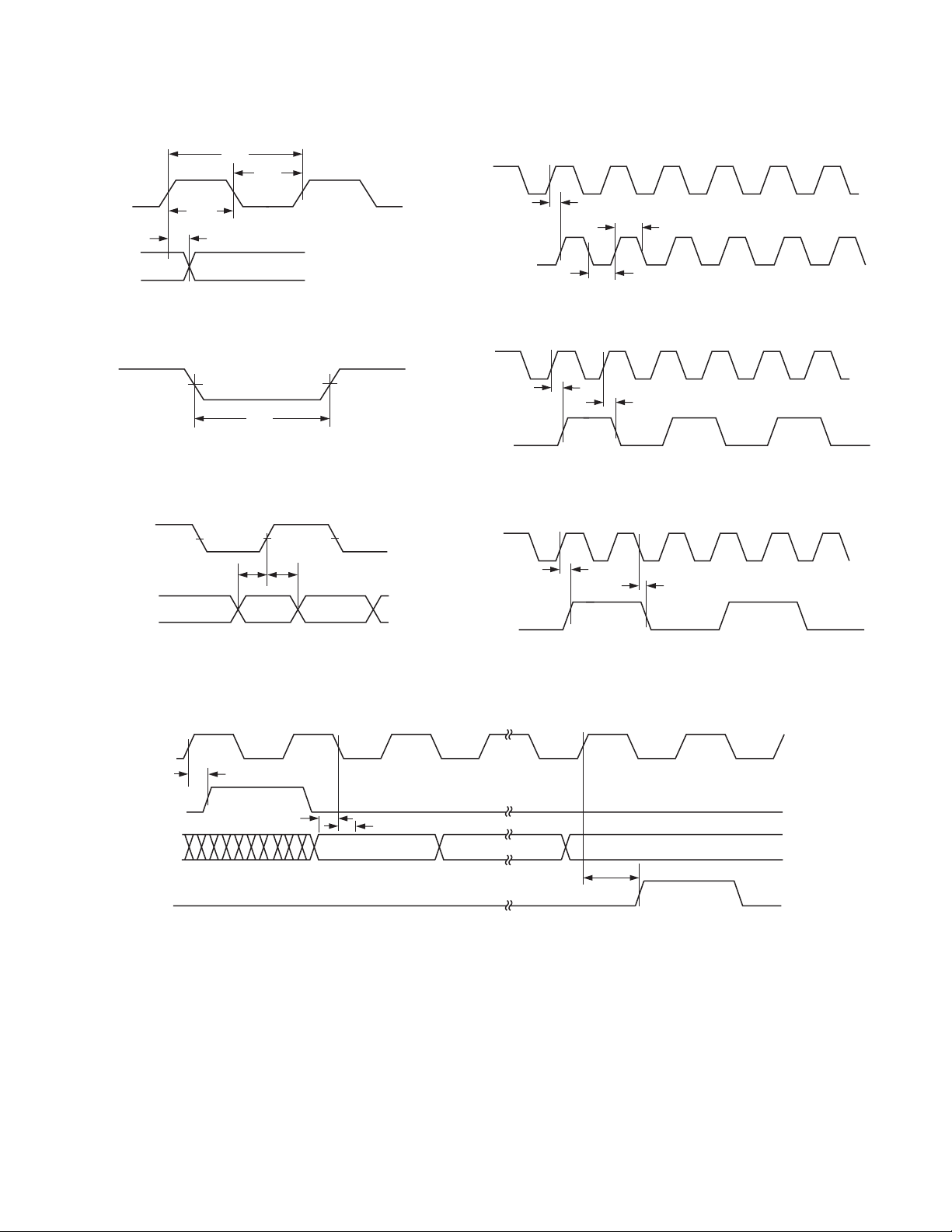

TIMING DIAGRAMS

t

CLK

t

CLKL

CLK

t

CLKH

t

LIA-A

LIA-B

LIB-A

LIB-B

Figure 1. Level Indicator Output Switching Characteristics

DLI

CLK

t

DSCLKH

t

SCLKH

SCLK

t

SCLKL

Figure 4. SCLK Switching Characteristics (Divide by 1)

ESET

t

SSF

Figure 2.

CLK

IN[13:0]

EXP[2:0]

RESET

Timing Requirements

tSIt

HI

DATA

Figure 3. Input Data Timing Requirements

SCLK

t

DSDFS

SDFS

SDI

SDFE

t

SSI

t

DATAn

HSI

CLK

t

DSCLKH

SCLK

t

SCLKL

Figure 5. SCLK Switching Characteristic (Divide by 2 or

EVEN Integer)

CLK

t

DSCLKH

SCLK

t

DSCLKLL

Figure 6. SCLK Switching Characteristic (Divide by 3 or

ODD Integer)

t

DSDFE

Figure 7. Serial Port Switching Characteristics

–6–

REV. B

Page 7

AD6624

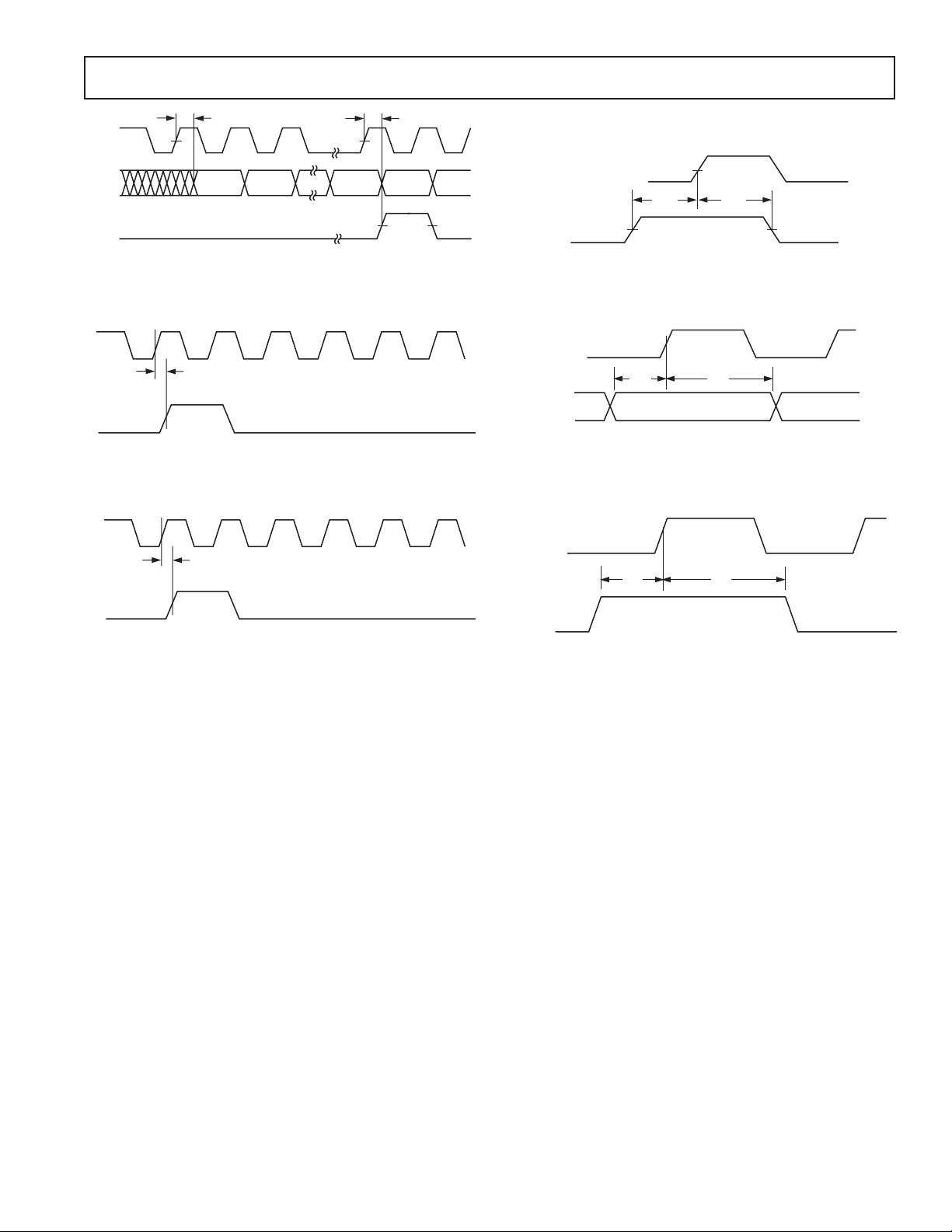

CLK

IN[13:0]

EXP[2:0]

IEN

t

SI

t

HI

t

DSDO

SCLK

SDO

SDFE

I

15

I

14

Q

Figure 8. SDO, SDFE Switching Characteristics

CLK

t

DDR

DR

Figure 9. CLK, DR Switching Characteristics

SCLK

t

DSDR

DR

Figure 10. SCLK, DR Switching Characteristics

t

DSDFE

1

Q

0

SCLK

SDFS

t

SSF

t

HSF

Figure 11. SDFS Timing Requirements (SBM = 0)

Figure 12. Input Timing for A and B Channels

CLK

SYNCA

SYNCB

SYNCC

SYNCD

t

SS

t

HS

Figure 13. SYNC Timing Inputs

REV. B

–7–

Page 8

AD6624

CLK

RD (DS)

WR (RW)

A[2:0]

D[7:0]

DTACK

(RDY)

t

SC

t

SAM

t

ZD

VA LID DATA

VA LID ADDRESS

t

ACC

t

HC

CS

t

ZD

t

HAM

t

DD

t

DDTACK

t

HDS

NOTES

1.

t

ACC

ACCESS TIME DEPENDS ON THE ADDRESS ACCESSED. ACCESS TIME IS

MEASURED FROM FE OF DS TO THE FE OF DTACK.

2.

t

ACC

REQUIRES A MAXIMUM 13 CLK PERIODS.

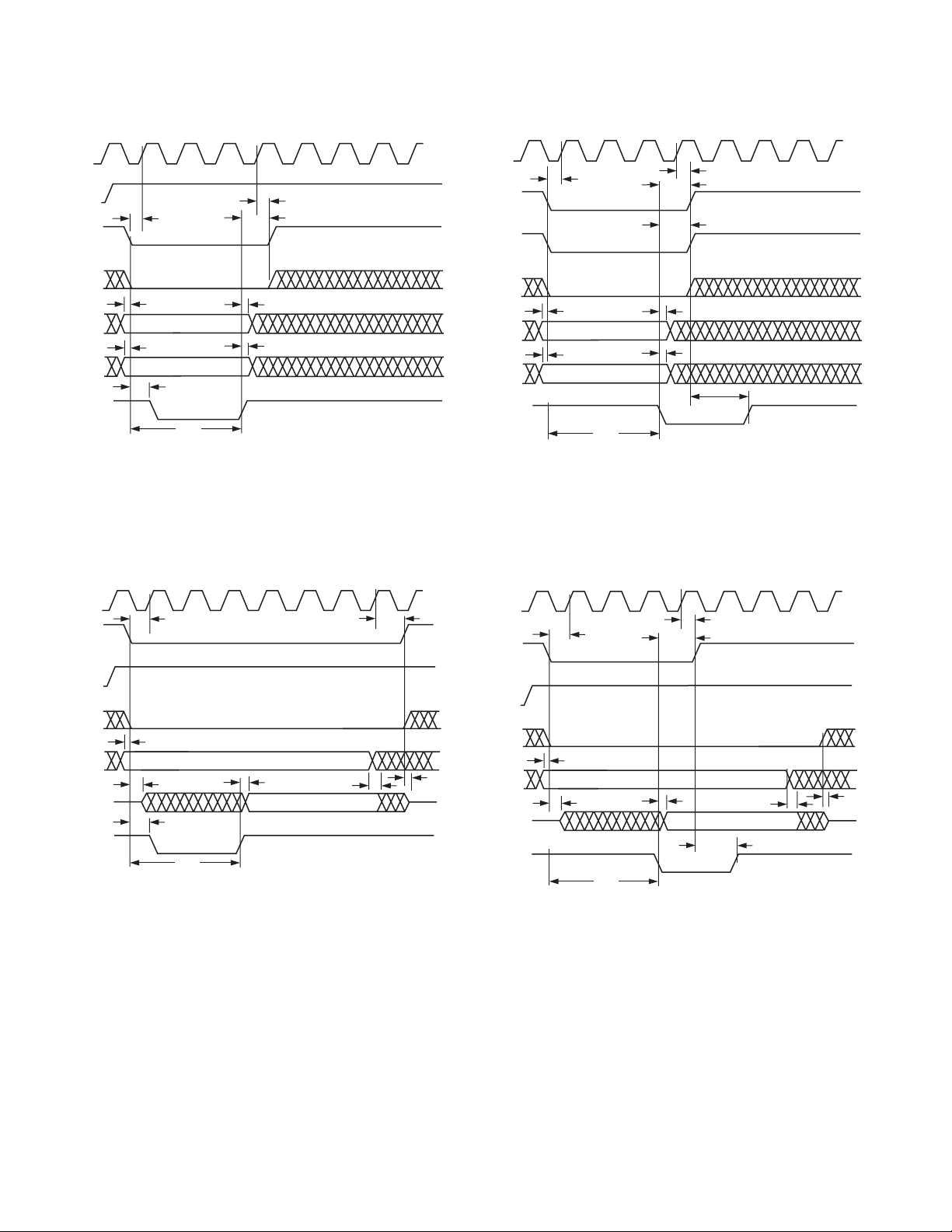

TIMING DIAGRAMS—INM MICROPORT MODE TIMING DIAGRAMS—MNM MICROPORT MODE

CLK

RD (DS)

t

WR (RW)

CS

A[2:0]

D[7:0]

RDY

(DTACK)

NOTES

t

ACCESS TIME DEPENDS ON THE ADDRESS ACCESSED. ACCESS TIME IS

1.

ACC

MEASURED FROM FE OF WR TO THE RE OF RDY.

t

REQUIRES A MAXIMUM 9 CLK PERIODS.

2.

ACC

SC

VAL I D DATA

t

DRDY

t

ACC

t

t

HAM

HAM

t

SAM

VA LID ADDRESS

t

SAM

t

t

HC

HWR

Figure 14. INM Microport Write Timing Requirements

CLK

t

HC

RD (DS)

t

SC

CLK

t

t

SC

t

VAL I D DATA

t

ACC

t

t

HDS

HAM

HAM

DS (RD)

RW (WR)

CS

t

SAM

A[2:0]

D[7:0]

DTACK

(RDY)

NOTES

t

1.

ACC

MEASURED FROM FE OF DS TO THE FE OF DTACK.

t

2.

ACC

VA LID ADDRESS

t

SAM

ACCESS TIME DEPENDS ON THE ADDRESS ACCESSED. ACCESS TIME IS

REQUIRES A MAXIMUM 9 CLK PERIODS.

HC

t

HRW

t

DDTACK

Figure 16. MNM Microport Write Timing Requirements

WR (RW)

CS

t

SAM

VA LID ADDRESS

t

ZD

t

DRDY

t

ACC

ACCESS TIME DEPENDS ON THE ADDRESS ACCESSED. ACCESS

REQUIRES A MAXIMUM OF 13 CLK PERIODS AND APPLIES TO

t

DD

A[2:0]

D[7:0]

RDY

(DTACK)

NOTES

t

1.

ACC

TIME IS MEASURED FROM FE OF WR TO THE RE OF RDY.

t

2.

ACC

A[2:0] = 7, 6, 5, 3, 2, 1

Figure 15. INM Microport Read Timing Requirements

t

HAM

VA LID DATA

t

ZD

Figure 17. MNM Microport Read Timing Requirements

–8–

REV. B

Page 9

AD6624

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6 V

Input Voltage . . . . . . . . . . . . –0.3 V to +5.3 V (5 V Tolerant)

Output Voltage Swing . . . . . . . . . . –0.3 V to VDDIO + 0.3 V

Load Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 pF

Junction Temperature Under Bias . . . . . . . . . . . . . . . . 125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) . . . . . . . . . . . . . . . . . . . . . . 280°C

*Stresses greater than those listed above may cause permanent damage to the

device. These are stress ratings only; functional operation of the device at these or

any other conditions greater than those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Thermal Characteristics

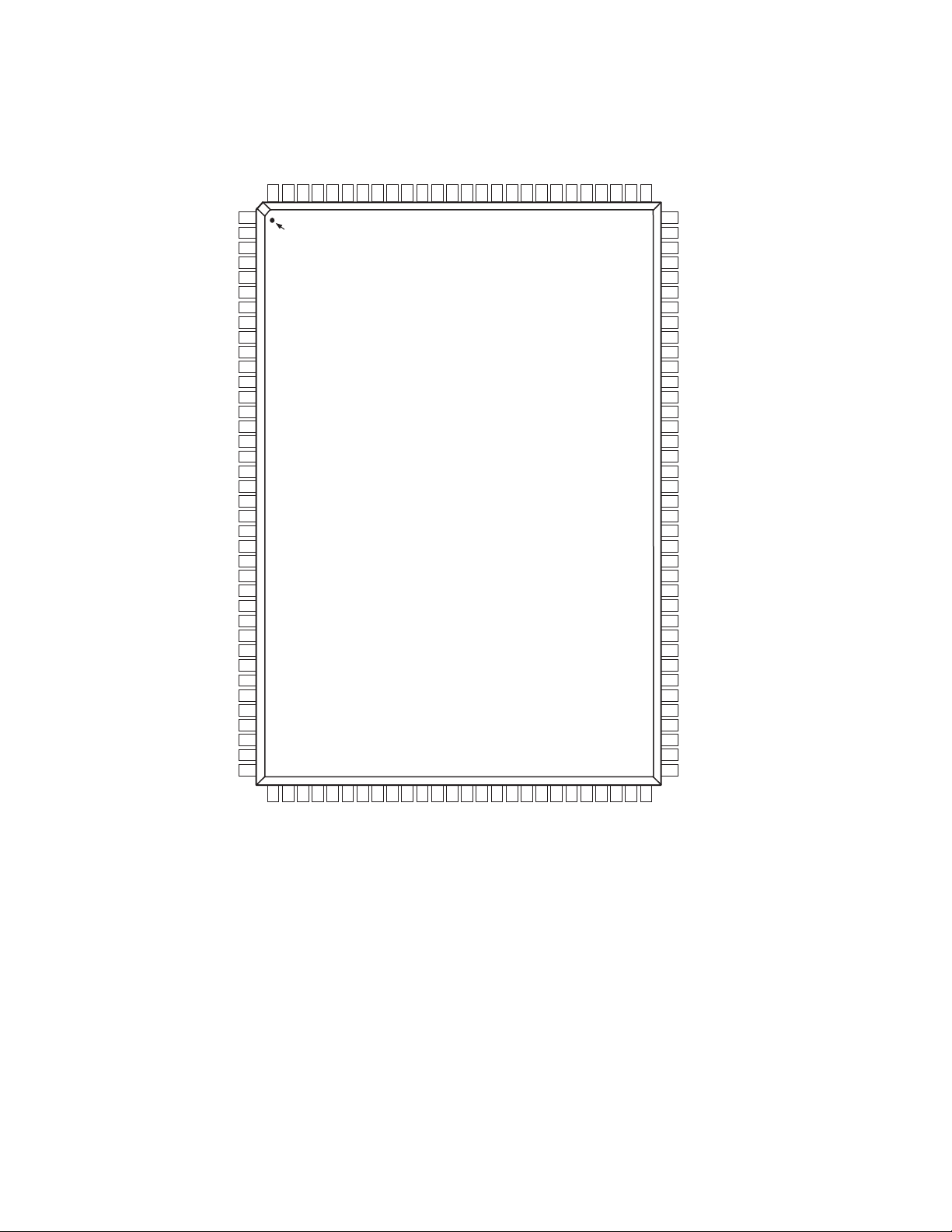

128-Lead Plastic Quad Flatpack:

= 41°C/W, No Airflow

θ

JA

= 39°C/W, 200

θ

JA

θ

= 37°C/W, 400

JA

LFPM Airflow

LFPM Airflow

Thermal measurements made in the horizontal position on

a 4-layer board.

ORDERING GUIDE

Model Temperature Range Package Description Option

AD6624AS –40°C to +70°C (Ambient) 128-Lead MQFP (Plastic Quad Flatpack) S-128-1

AD6624S/PCB Evaluation Board with AD6624 and Software

EXPLANATION OF TEST LEVELS

I. 100% Production Tested.

II. 100% Production Tested at 25°C, and Sample Tested at

Specified Temperatures.

III. Sample Tested Only.

IV. Parameter Guaranteed by Design and Analysis.

V. Parameter is Typical Value Only.

VI. 100% Production Tested at 25°C, and Sample Tested at

Temperature Extremes.

Package

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD6624 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. B

–9–

Page 10

AD6624

IENB

LIB-B

LIB-A

EXPA0

EXPA1

EXPA2

INA13

INA12

INA11

INA10

VDDIO

VSSIO

IENA

LIA-B

LIA-A

VSS

INB5

INB4

INB3

INB2

INB1

VDD

INB0

VSS

CLK

VDD

INA9

INA8

INA7

INA6

INA5

INA4

INA3

INA2

VDD

INA1

INA0

VSS

PIN CONFIGURATION

VSSIO

INB6

INB7

INB8

INB9

VDDIO

INB10

INB11

INB12

INB13

VDD

EXPB2

EXPB1

EXPB0

DR3

VSS

SDFE3

SDIN3

SDO3

SDFS3

VDDIO

SCLK3

DR2

SDFE2

SDIN2

VSSIO

121

122

123

125

126

128

1

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

VSSIO

127

41

40

SYNCD

SYNCC

124

43

42

SYNCB

SYNCA

44

VDD

46

45

D7

RESET

120

47

D6

119

48

D5

116

118

117

AD6624

TOP VIEW

(Not to Scale)

505152

49

D3D2D1

D4

VSS

115

114

53

113

54

VDD

112

55

D0

111

110

565758

DS(RD)

DTACK/RDY

109

RW(WR)

108

107

60

59

MODE

VDDIO

106

61

A2

105

62

A1

104

63

A0

103

102

101

100

98

94

85

83

66

64

VSSIO

99

97

96

95

93

92

91

90

89

88

87

86

84

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

65

VSS

SDO2

SDFS2

SCLK2

DR1

SDFE1

VDD

SDIN1

SDO1

SDFS1

SCLK1

VSSIO

DR0

SDFE0

SDIN0

SDO0

VDDIO

SDFS0

SCLK0

SDIV0

SDIV1

VDD

SDIV2

SDIV3

SBM0

CHIP_ID0

VSS

CHIP_ID1

CHIP_ID2

CHIP_ID3

TDI

VDDIO

TDO

TMS

TCLK

TRST

CS

VSS

–10–

REV. B

Page 11

AD6624

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Type Function

1, 12, 38, 50, 65, 76, 102, 113 VSS G Ground

2–6 INB[5:1]

7, 17, 32, 44, 54, 81, 96, 118 VDD P 2.5 V Supply

8INB0

9 IENB

10 LIB-B O Level Indicator—Input B, Interleaved—Data B

11 LIB-A O Level Indicator—Input B, Interleaved—Data A

13 CLK I Input Clock

14–16 EXPA[0:2]

18–21 INA[13:10]

22, 59, 71, 86, 108, 123 VDDIO P 3.3 V Supply

23–26 INA[9:6]

27, 39, 64, 91, 103, 128 VSSIO G Ground

28–31 INA[5:2]

33–34 INA[1:0]

35 IENA

36 LIA-B O Level Indicator—Input A, Interleaved—Data B

37 LIA-A O Level Indicator—Input A, Interleaved—Data A

40 SYNCD

41 SYNCC

42 SYNCB

43 SYNCA

45 RESET IActive Low Reset Pin

46–49 D[7:4] I/O/T Bidirectional Microport Data

51–53 D[3:1] I/O/T Bidirectional Microport Data

55 D0 I/O/T Bidirectional Microport Data—LSB

56 DS(RD)IActive Low Data Strobe (Active Low Read)

57 DTACK(RDY)

58 RW(WR)IRead Write (Active Low Write)

60 MODE I Intel or Motorola Mode Select

61–63 A[2:0] I Microport Address Bus

66 CS

67 TRST

68 TCLK

69 TMS

70 TDO O/T Test Data Output

72 TDI

73–75 CHIP_ID[3:1]

77 CHIP_ID0

78 SBM0

79–80 SDIV[3:2]

82–83 SDIV[1:0]

84 SCLK0

85 SDFS0

87 SDO0

88 SDIN0

89 SDFE0 O Serial Data Frame End—Channel 0

90 DR0 O Output Data Ready Indicator—Channel 0

1

1

2

1

1

1

1

1

2

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

1

1

IB Input Data (Mantissa)

IB Input Data (Mantissa)—LSB

I Input Enable—Input B

IA Input Data (Exponent)

IA Input Data (Mantissa)

IA Input Data (Mantissa)

IA Input Data (Mantissa)

IA Input Data (Mantissa)

I Input Enable—Input A

IAll Sync Pins Go to All Four Output Channels

IAll Sync Pins Go to All Four Output Channels

IAll Sync Pins Go to All Four Output Channels

IAll Sync Pins Go to All Four Output Channels

2

O/T Active Low Data Acknowledge (Microport Status Bit)

IChip Select

ITest Reset Pin

ITest Clock Input

ITest Mode Select Input

ITest Data Input

IChip ID Selector

IChip ID Selector—LSB

I Serial Bus Master—Channel 0 Only

I Serial Clock Divisor—Channel 0

I Serial Clock Divisor—Channel 0

I/O Bidirectional Serial Clock—Channel 0

I/O Bidirectional Serial Data Frame Sync—Channel 0

O/T Serial Data Output—Channel 0

I Serial Data Input—Channel 0

REV. B

–11–

Page 12

AD6624

PIN FUNCTION DESCRIPTIONS (continued)

Pin No. Mnemonic Type Function

92 SCLK1

93 SDFS1

94 SDO1

95 SDIN1

97 SDFE1 O Serial Data Frame End—Channel 1

98 DR1 O Output Data Ready Indicator—Channel 1

99 SCLK2

100 SDFS2

101 SDO2

104 SDIN2

105 SDFE2 O Serial Data Frame End—Channel 2

106 DR2 O Output Data Ready Indicator—Channel 3

107 SCLK3

109 SDFS3

110 SDO3

111 SDIN3

112 SDFE3 O Serial Data Frame End—Channel 3

114 DR3 O Output Data Ready Indicator—Channel 3

115–117 EXPB[0:2]

119–122 INB[13:10]

124–127 INB[9:6]

NOTES

1

Pins with a pull-down resistor of nominal 70 kΩ.

2

Pins with a pull-up resistor of nominal 70 kΩ.

Pin Types: I = Input, O = Output, P = Power Supply, G = Ground, T = Three-State.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

I/O Bidirectional Serial Clock—Channel 1

I/O Bidirectional Serial Data Frame Sync—Channel 1

O/T Serial Data Output—Channel 1

I Serial Data Input—Channel 1

I/O Bidirectional Serial Clock—Channel 2

I/O Bidirectional Serial Data Frame Sync—Channel 2

O/T Serial Data Output—Channel 2

I Serial Data Input—Channel 2

I/O Bidirectional Serial Clock—Channel 3

I/O Bidirectional Serial Data Frame Sync—Channel 3

O/T Serial Data Output—Channel 3

I Serial Data Input—Channel 3

IB Input Data (Exponent)

IB Input Data (Mantissa)

IB Input Data (Mantissa)

–12–

REV. B

Page 13

AD6624

ARCHITECTURE

The AD6624 has four signal processing stages: a Frequency

Translator, second order Resampling Cascaded Integrator

Comb FIR filters (rCIC2), a fifth order Cascaded Integrator

Comb FIR filter (CIC5), and a RAM Coefficient FIR filter

(RCF). Multiple modes are supported for clocking data into and

out of the chip, and provide flexibility for interfacing to a wide

variety of digitizers. Programming and control is accomplished

via serial and microprocessor interfaces.

Frequency translation is accomplished with a 32-bit complex

Numerically Controlled Oscillator (NCO). Real data entering

this stage is separated into in-phase (I) and quadrature (Q)

components. This stage translates the input signal from a digital

intermediate frequency (IF) to digital baseband. Phase and

amplitude dither may be enabled on-chip to improve spurious

performance of the NCO. A phase-offset word is available to

create a known phase relationship between multiple AD6624s or

between channels.

Following frequency translation is a resampling, fixed-coefficient,

high speed, second order, Resampling Cascade Integrator

Comb (rCIC2) filter that reduces the sample rate based on the

ratio between the decimation and interpolation registers.

WIDEBAND INPUT SPECTRUM (–

SIGNAL OF INTEREST “IMAGE”

The next stage is a fifth order Cascaded Integrator Comb (CIC5)

filter whose response is defined by the decimation rate. The

purpose of these filters is to reduce the data rate to the final

filter stage so it can calculate more taps per output.

The final stage is a sum-of-products FIR filter with programmable 20-bit coefficients, and decimation rates programmable

from 1 to 256 (1–32 in practice). The RAM Coefficient FIR

filter (RCF in the Functional Block Diagram) can handle a

maximum of 160 taps.

The overall filter response for the AD6624 is the composite of

all decimating and interpolating stages. Each successive filter

stage is capable of narrower transition bandwidths but requires

a greater number of CLK cycles to calculate the output. More

decimation in the first filter stage will minimize overall power

consumption. Data from the chip is interfaced to the DSP via a

high-speed synchronous serial port.

Figure 18a illustrates the basic function of the AD6624: to

select and filter a single channel from a wide input spectrum.

The frequency translator “tunes” the desired carrier to baseband.

Figure 18b shows the combined filter response of the rCIC2,

CIC5, and RCF.

f

/2 TO

f

SAMP

/2)

SAMP

SIGNAL OF INTEREST

f

/2

–

S

–

f

/2 –3

S

–3

f

/8

S

f

/8 –5

S

f

/16 –

f

/4 –3

f

/16 –

f

/8 –

–5

S

f

S

S

AFTER FREQUENCY TRANSLATION NCO “TUNES” SIGNAL TO BASEBAND

/16 –

f

S

S

WIDEBAND INPUT SPECTRUM (e.g., 30MHz FROM HIGH-SPEED ADC)

/4 –3

f

/16 –

S

FREQUENCY TRANSLATION (e.g., SINGLE 1MHz CHANNEL TUNED TO BASEBAND)

S

f

/8 –

S

f

S

f

S

/16

/16

DC

DC

f

/16

f

/8 3

f

/16

S

f

S

/16

S

f

/8 3

S

f

f

S

/16

f

S

Figure 18a. Frequency Translation of Wideband Input Spectrum

10

0

–10

–20

–30

–40

–50

–60

–70

dBc

–80

–90

–100

0

–110

–120

–130

–140

–150

–1000

–800 –600 –400 –200 0 200 400 600 800

kHz

1000

Figure 18b. Composite Filter Response of rCIC2, CIC5, and RCF

/4 5

S

/4 5

S

f

/16 3

S

f

/16 3

S

f

/8

f

S

f

S

/2

S

/8

f

/2

S

REV. B

–13–

Page 14

AD6624

EXAMPLE FILTER RESPONSE

10

0

–10

–20

–30

–40

–50

–60

–70

dBc

–80

–90

–100

0

–110

–120

–130

–140

–150

–1000

–800 –600 –400 –200 0 200 400 600 800

kHz

1000

Figure 19. Filter Response

The filter in Figure 19 is based on a 65 MSPS input data rate

and an output rate of 541.6666 kSPS (two samples per symbol

for EDGE). Total decimation rate is 120 distributed between

the rCIC2, CIC5, and RCF.

10

0

–10

–20

–30

–40

–50

–60

–70

dBc

–80

–90

–100

0

–110

–120

–130

–140

–150

–500 –400 –200 0 200 400 500

kHz

Figure 20. Filter Response

The filter in Figure 20 is designed to meet the IS-136 specifications. For this configuration, the clock is set to 61.44 MSPS

with a total decimation rate of 320 providing an output data

rate of 192 kSPS or four samples per symbol.

INPUT DATA PORTS

The AD6624 features dual, high speed ADC input ports, Input

Port A and Input Port B. The dual input ports allow for the

most flexibility with a single tuner chip. These can be diversity

inputs or truly independent inputs such as separate antenna

segments. Either ADC port can be routed to one of four tuner

channels. For added flexibility, each input port can be used to

support multiplexed inputs such as those found on the AD6600

or other ADCs with muxed outputs. This added flexibility

can allow for up to four different analog sources to be processed simultaneously by the four internal channels.

In addition, the front end of the AD6624 contains circuitry that

enables high speed signal level detection and control. This is

accomplished with a unique high speed level detection circuit

that offers minimal latency and maximum flexibility to control

up to four analog signal paths. The overall signal path latency

from input to output on the AD6624 can be expressed in highspeed clock cycles. The equation below can be used to calculate

the latency.

T

LATENCY

M

rC1C2

CIC5 filters, respectively, N

= M

and M

rC1C2(MCIC5

are decimation values for the rC1C2 and

CIC5

+ 7) + N

is the number RCF taps cho-

TAPS

= 4(SDIV + 1) +18

TAPS

sen, and SDIV is the chosen SCLK divisor factor.

Input Data Format

Each input port consists of a 14-bit mantissa and 3-bit exponent. If

interfacing to a standard ADC is required, the exponent bits can

be grounded. If connected to a floating point ADC such as the

AD6600, the exponent bits from that product can be connected

to the input exponent bits of the AD6624. The mantissa data

format is twos complement and the exponent is unsigned binary.

Input Timing

The data from each high speed input port is latched on the

rising edge of CLK. This clock signal is used to sample the

input port and clock the synchronous signal processing stages

that follow in the selected channels.

CLK

tSIt

HI

IN[13:0]

EXP[2:0]

DATA

Figure 21. Input Data Timing Requirements

The clock signals can operate up to 80 MHz and have a 50% duty

cycle. In applications using high-speed ADCs, the ADC sample

clock or data valid strobe is typically used to clock the AD6624.

t

CLK

t

CLKH

CLK

t

CLKL

Figure 22. CLK Timing Requirements

Input Enable Control

There is an IENA and an IENB pin for the Input Port A and

Input Port B, respectively. There are four modes of operation

used for each IEN pin. Using these modes, it is possible to

emulate operation of the other RSPs such as the AD6620, which

offer dual channel modes normally associated with diversity

operations. These modes are: IEN transition to low, IEN transition to high, IEN high, and blank on IEN low.

In the IEN high mode, the inputs and normal operations occur

when the Input Enable is high. In the IEN transition to low

mode, normal operations occur on the first rising edge of the

clock after the IEN transitions to low. Likewise, in the IEN

transition to high mode, operations occur on the rising edge of

the clock after the IEN transitions to high. See the Numerically

Controlled Oscillator section for more details on configuring the

Input Enable Modes. In blank on IEN low mode, the input data

is interpreted as zero when IEN is low.

–14–

REV. B

Page 15

AD6624

A typical application for this feature would be to take the data

from an AD6600 Diversity ADC to one of the inputs of the

AD6624. The A/B_OUT from that chip would be tied to the

IEN. One channel within the AD6624 would be then set so that

IEN transition to low is enabled. Another channel would be

configured so that IEN transition to high is enabled. One of the

serial outputs would be configured as the Serial Bus Master and

the other as a serial bus slave and the output bus configured as

shown in Figure 25. This would allow two of the AD6624 channels to be configured to emulate that AD6620 in diversity mode.

Of course the NCO frequencies and other channel characteristics would need to be set similarly, but this feature allows the

AD6624 to handle interleaved data streams such as found on

the AD6600.

The difference between the IEN transition to high and the IEN

high is found when a system clock is provided that is higher than

the data rate of the converter. It is often advantageous to supply

a clock that runs faster than the data rate so that additional filter

taps can be computed. This naturally provides better filtering.

In order to ensure that other parts of the circuit properly recognize the faster clock in the simplest manner, the IEN transition

to low or high should be used. In this mode, only the first clock

edge that meets the setup and hold times will be used to latch

and process the input data. All other clock pulses are ignored by

front end processing. However, each clock cycle will still produce a new filter computation pair.

Gain Switching

The AD6624 includes circuitry that is useful in applications

where either large dynamic ranges exist or where gain ranging

converters are employed. This circuitry allows digital thresholds to be set such that an upper and a lower threshold can

be programmed.

One such use of this may be to detect when an ADC converter

is about to reach full-scale with a particular input condition.

The results would be to provide a flag that could be used to

quickly insert an attenuator that would prevent ADC overdrive.

If 18 dB (or any arbitrary value) of attenuation (or gain) is

switched in, the signal dynamic range of the system will have

been increased by 18 dB. The process begins when the input

signal reaches the upper programmed threshold. In a typical

application, this may be set 1 dB (user-definable) below fullscale. When this input condition is met, the appropriate LI

(LIA-A, LIA-B, LIB-A, or LIB-B) signal associated with either

the A or B input port is made active. This can be used to switch

the gain or attenuation of the external circuit. The LI signal stays

active until the input condition falls below the lower programmed

threshold. In order to provide hysteresis, a dwell-time register

(see Memory Map for Input Control Registers) is available to

hold off switching of the control line for a predetermined number of clocks. Once the input condition is below the lower

threshold, the programmable counter begins counting highspeed clocks. As long as the input signal stays below the lower

threshold for the number of high speed clock cycles programmed,

the attenuator will be removed on the terminal count. However,

if the input condition goes above the lower threshold with the

counter running, it will be reset and must fall below the lower

threshold again to initiate the process. This will prevent unnecessary switching between states.

This is illustrated in Figure 23. When the input signal goes

above the upper threshold, the appropriate LI signal becomes

active. Once the signal falls below the lower threshold, the

counter begins counting. If the input condition goes above the

lower threshold, the counter is reset and starts again as shown

in Figure 23. Once the counter has terminated to zero, the LI

signal goes inactive.

“HIGH”

DWELL TIME

Figure 23. Threshold Settings for LI

COUNTER RESTARTS

UPPER THRESHOLD

“LOW”

LOWER THRESHOLD

TIME

The LI signal can be used for a variety of functions. It can be

used to set the controls of an attenuator DVGA or integrated and

used with an analog VGA. To simplify the use of this feature,

the AD6624 includes two separate gain settings, one when this

line is inactive (rCIC2_QUIET[4:0]) and the other when active

(rCIC2_LOUD[4:0]). This allows the digital gain to be adjusted

to the external changes. In conjunction with the gain setting, a

variable hold-off is included to compensate for the pipeline delay of

the ADC and the switching time of the gain control element.

Together, these two features provide seamless gain switching.

Another use of these pins is to facilitate a gain range hold-off within

a gain-ranging ADC. For converters that use gain ranging to

increase total signal dynamic range, it may be desirable to prohibit internal gain ranging from occurring in some instances.

For such converters, the LI (A or B) signals can be used to hold

this off. For this application, the upper threshold would be set

based on similar criteria. However, the lower threshold would

be set to a level consistent with the gain ranges of the specific

converter. The hold-off delay can then be set appropriately for

any number of factors such as fading profile, signal peak to

average ratio, or any other time-based characteristics that might

cause unnecessary gain changes.

Since the AD6624 has a total of four gain control circuits that

can be used if both A and B Input Ports have interleaved data,

each respective LI pin is independent and can be set to different

set points. It should be noted that the gain control circuits are

wideband and are implemented prior to any filtering elements to

minimize loop delay. Any of the four channels can be set to monitor any of the possible four input channels (two in normal mode

and four when the inputs are time-multiplexed).

The chip also provides appropriate scaling of the internal data

based on the attenuation associated with the LI signal. In this

manner, data to the DSP maintains a correct scale value throughout the process, making it totally independent. Since finite

delays are often associated with external gain switching components, the AD6624 includes a variable pipeline delay that can be

used to compensate for external pipeline delays or gross settling

times associated with gain/attenuator devices. This delay may be

set up to seven high speed clocks. These features ensure smooth

switching between gain settings.

REV. B

–15–

Page 16

AD6624

Input Data Scaling

The AD6624 has two data input ports: an A Input Port and a

B Input Port. Each accepts 14-bit mantissa (twos complement

integer) IN[13:0], a 3-bit exponent (unsigned integer) EXP[2:0]

and the Input Enable (IEN). Both inputs are clocked by CLK.

These pins allow direct interfacing to both standard fixed-point

ADCs such as the AD9225 and AD6640, as well as to gainranging ADCs such as the AD6600. For normal operation with

ADCs having fewer than 14 bits, the active bits should be MSBjustified and the unused LSBs should be tied low.

The 3-bit exponent, EXP[2:0], is interpreted as an unsigned

integer. The exponent will subsequently be modified by either of

the 5-bit scale values stored in register 0x92, Bits 4–0 or Bits 9–5.

These 5-bit registers contain the sum of the rCIC2 scale value plus

the external attenuator scale settings and the Exponent Offset

(ExpOff). If no external attenuator is used, these values can only

be set to the value of the rCIC2 scale. If an external attenuator is

used, Bit Position 4–0 (Register 0x92 rCIC2_LOUD[4:0]) contains the scale value for the largest input range. Bit Positions

9–5 (Register 0x92 rCIC2_QUIET[4:0]) are used for the nonattenuated input signal range.

Scaling with Fixed-Point ADCs

For fixed-point ADCs, the AD6624 exponent inputs EXP[2:0]

are typically not used and should be tied low. The ADC outputs

are tied directly to the AD6624 Inputs, MSB-justified. The

ExpOff bits in 0x92 should be programmed to 0. Likewise, the

Exponent Invert bit should be 0.

Thus for fixed-point ADCs, the exponents are typically static

and no input scaling is used in the AD6624.

D11 (MSB)

AD6640

D0 (LSB)

VDD

EXPOFF = 0, EXPINV = 0

IN13

AD6624

IN2

IN1

IN0

EXP2

EXP1

EXP0

IEN

Figure 24. Typical Interconnection of the AD6640 Fixed

Point ADC and the AD6624

Scaling with Floating-Point or Gain-Ranging ADCs

An example of the exponent control feature combines the AD6600

and the AD6624. The AD6600 is an 11-bit ADC with three bits

of gain ranging. In effect, the 11-bit ADC provides the mantissa,

and the three bits of relative signal strength indicator (RSSI) for

the exponent. Only five of the eight available steps are used by

the AD6600. See the AD6600 data sheet for additional details.

For gain-ranging ADCs such as the AD6600,

Exp rCIC

scaled input IN ExpInv ExpWeight

_,,

=× = =

– mod( – , )

210

+

728

(1)

where: IN is the value of IN[13:0], Exp is the value of EXP[2:0],

and rCIC2 is the rCIC scale register value (0x92 Bits 9–5 and 4–0).

The RSSI output of the AD6600 numerically grows with

increasing signal strength of the analog input (RSSI = 5 for a

large signal, RSSI = 0 for a small signal). When the Exponent

Invert Bit (ExpInv) is set to zero, the AD6624 will consider the

smallest signal at the IN[13:0] to be the largest and as the EXP

word increases, it shifts the data down internally (EXP = 5

will shift a 14-bit word right by five internal bits before passing

the data to the rCIC2). In this example, where ExpInv = 0, the

AD6624 regards the largest signal possible on the AD6600 as

the smallest signal. Thus, the Exponent Invert Bit can be used

to make the AD6624 exponent agree with the AD6600 RSSI.

By setting ExpInv = 1, it forces the AD6624 to shift the data

up (left) for growing EXP instead of down. The exponent invert

bit should always be set high for use with the AD6600.

The Exponent Offset is used to shift the data right. For example,

Table I shows that with no rCIC2 scaling, 12 dB of range is lost

when the ADC input is at the largest level. This is undesirable

because it lowers the Dynamic Range and SNR of the system by

reducing the signal of interest relative to the quantization noise floor.

Table I. AD6600 Transfer Function with AD6624 ExpInv = 1,

and No ExpOff

ADC Input AD6600 AD6624 Signal

Level RSSI[2:0] Data Reduction

Largest 101 (5) ⫼ 4 (>> 2) –12 dB

100 (4) ⫼ 8 (>> 3) –18 dB

011 (3) ⫼ 16 (>> 4) –24 dB

010 (2) ⫼ 32 (>> 5) –30 dB

001 (1) ⫼ 64 (>> 6) –36 dB

Smallest 000 (0) ⫼ 128 (>> 7) –42 dB

(ExpInv = 1, ExpOff = 0)

To avoid this automatic attenuation of the full-scale ADC

signal, the ExpOff is used to move the largest signal (RSSI = 5)

up to the point where there is no downshift. In other words,

once the Exponent Invert bit has been set, the Exponent Offset

should be adjusted so that mod(7–5 + ExpOff,8) = 0. This is

the case when Exponent Offset is set to 6 since mod(8,8) = 0.

Table II illustrates the use of ExpInv and ExpOff when used

with the AD6600 ADC.

Table II. AD6600 Transfer Function with AD6624 ExpInv = 1,

and ExpOff = 6

ADC Input AD6600 AD6624 Signal

Level RSSI[2:0] Data Reduction

Largest 101 (5) ⫼ 1 (>> 0) –0 dB

100 (4) ⫼ 2 (>> 1) –6 dB

011 (3) ⫼ 4 (>> 2) –12 dB

010 (2) ⫼ 8 (>> 3) –18 dB

001 (1) ⫼ 16 (>> 4) –24 dB

Smallest 000 (0) ⫼ 32 (>> 5) –30 dB

(ExpInv = 1, ExpOff = 6)

This flexibility in handling the exponent allows the AD6624

to interface with gain-ranging ADCs other than the AD6600.

The Exponent Offset can be adjusted to allow up to seven

RSSI(EXP) ranges to be used as opposed to the AD6600’s five.

–16–

REV. B

Page 17

AD6624

It also allows the AD6624 to be tailored in a system that employs

the AD6600, but does not utilize all of its signal range. For

example, if only the first four RSSI ranges are expected to occur,

the ExpOff could be adjusted to five, which would then make

RSSI = 4 correspond to the 0 dB point of the AD6624.

D10 (MSB)

AD6600

AB_OUT

D0 (LSB)

RSSI2

RSSI1

RSSI0

IN13

AD6624

IN2

IN1

IN0

EXP2

EXP1

EXP0

IEN

Figure 25. Typical Interconnection of the AD6600 GainRanging ADC and the AD6624

NUMERICALLY CONTROLLED OSCILLATOR

Frequency Translation

This processing stage comprises a digital tuner consisting of two

multipliers and a 32-bit complex NCO. Each channel of the

AD6624 has an independent NCO. The NCO serves as a quadrature local oscillator capable of producing an NCO frequency

between –CLK/2 and +CLK/2 with a resolution of CLK/2

32

in

the complex mode. The worst-case spurious signal from the NCO

is better than –100 dBc for all output frequencies.

The NCO frequency value in registers 0x85 and 0x86 are interpreted as a 32-bit unsigned integer. The NCO frequency is

calculated using the equation below.

NCO FREQ

_mod=×

f

32

2

CHANNEL

CLK

(2)

NCO_FREQ is the 32-bit integer (Registers 0x85 and 0x86),

f

CHANNEL

is the desired channel frequency, and

CLK* is the AD6624 master clock rate (CLK).

*See NCO Mode Control section.

NCO Frequency Hold-Off Register

When the NCO Frequency registers are written, data is actually

passed to a shadow register. Data may be moved to the main

registers by one of two methods. The first is to start the chip

using the soft sync feature, which will directly load the NCO

registers. The second allows changes to be pre-written and then

updated through direct software control. To accomplish this,

there is an NCO Frequency Hold-Off Counter. The counter

(0x84) is a 16-bit unsigned integer and is clocked at the master

CLK rate. This hold-off counter is also used in conjunction with

the frequency hopping feature of this chip.

Phase Offset

The phase offset register (0x87) adds an offset to the phase

accumulator of the NCO. This is a 16-bit register and is interpreted as a 16-bit unsigned integer. A 0x0000 in this register

corresponds to a 0 radian offset and a 0xFFFF corresponds to

an offset of 2 π (1–1/(2

16

)) radians. This register allows multiple

NCOs to be synchronized to produce sine waves with a known

and steady phase difference.

NCO Control Register

The NCO control register located at 0x88 is used to configure

the features of the NCO. These are controlled on a per-channel

basis. These are described below.

Bypass

The NCO in the front end of the AD6624 can be bypassed.

Bypass mode is enabled by setting Bit 0 of 0x88 high. When

they are bypassed, down conversion is not performed and the

AD6624 channel functions simply serve as a real filter on complex data. This is useful for passband sampling applications

where the A input is connected to the I signal path within the

filter, and the B input is connected to the Q signal path. This may

be desired if the digitized signal has already been converted to

pass band in prior analog stages or by other digital preprocessing.

Phase Dither

The AD6624 provides a phase dither option for improving the

spurious performance of the NCO. Phase dither is enabled by

setting Bit 1. When phase dither is enabled by setting this bit

high, spurs due to phase truncation in the NCO are randomized. The energy from these spurs is spread into the noise floor

and Spurious Free Dynamic Range is increased at the expense

of very slight decreases in the SNR. The choice of whether

phase dither is used in a system will ultimately be decided by the

system goals. If lower spurs are desired at the expense of a slightly

raised noise floor, it should be employed. If a low noise floor is

desired and the higher spurs can be tolerated or filtered by

subsequent stages, phase dither is not needed.

Amplitude Dither

Amplitude dither can also be used to improve spurious performance of the NCO. Amplitude dither is enabled by setting Bit 2.

Amplitude dither improves performance by randomizing the

amplitude quantization errors within the angular to Cartesian

conversion of the NCO. This option may reduce spurs at the

expense of a slightly raised noise floor. Amplitude dither and

phase dither can be used together, separately, or not at all.

Clear Phase Accumulator on HOP

When Bit 3 is set, the NCO phase accumulator is cleared prior

to a frequency hop. This ensures a consistent phase of the NCO

on each hop. The NCO phase offset is unaffected by this setting

and is still in effect. If phase-continuous hopping is desired, this

bit should be cleared and the last phase in the NCO phase register will be the initiating point for the new frequency.

Input Enable Control

There are four different modes of operation for the input enable.

Each of the high-speed input ports includes an IEN line. Any of

the four filter channels can be programmed to take data from

either of the two A or B Input Ports (see WB Input Select section).

Along with data is the IEN(A,B) signal. Each filter channel can

be configured to process the IEN signal in one of four modes.

Three of the modes are associated with when data is processed

based on a time division multiplexed data stream. The fourth

mode is used in applications that employ time division duplex

such as radar, sonar, ultrasound, and communications that

involve TDD.

Mode 00: Blank On IEN Low

In this mode, data is blanked while the IEN line is low. During the

period of time when the IEN line is high, new data is strobed

on each rising edge of the input clock. When the IEN line is

REV. B

–17–

Page 18

AD6624

lowered, input data is replaced with zero values. During this

period, the NCO continues to run such that when the IEN line

is raised again, the NCO value will be at the value it would have

otherwise been in had the IEN line never been lowered. This

mode has the effect of blanking the digital inputs when the

IEN line is lowered. Back end processing (rCIC2, CIC5, and

RCF) continues while the IEN line is high. This mode is useful

for time division multiplexed applications.

Mode 01: Clock On IEN High

In this mode, data is clocked into the chip while the IEN line is

high. During the period of time when the IEN line is high, new

data is strobed on each rising edge of the input clock. When

IEN line is lowered, input data is no longer latched into the

channel. Additionally, NCO advances are halted. However,

back end processing (rCIC2, CIC5, and RCF) continues during

this period. The primary use for this mode is to allow for a clock

that is faster than the input sample data rate to allow more filter

taps to be computed than would otherwise be possible. In Figure 26, input data is strobed only during the period of time when

IEN is high, despite the fact that the CLK continues to run at a

rate four times faster than the data.

CLK

tHIt

IN[13:0]

E[2:0]

IEN

SI

n

n+1

Figure 26. Fractional Rate Input Timing (4× CLK) in

Mode 01

Mode 10: Clock on IEN Transition to High

In this mode, data is clocked into the chip only on the first clock

edge after the rising transition of the IEN line. Although data is

only latched on the first valid clock edge, the back end processing (rCIC2, CIC5, and RCF) continues on each available clock

that may be present, similar to Mode 01. The NCO phase accumulator is incremented only once for each new input data sample

and not once for each input clock.

Mode 11: Clock on IEN Transition to Low

In this mode, data is clocked into the chip only on the first clock

edge after the falling transition of the IEN line. Although data is

only latched on the first valid clock edge, the back end processing (rCIC2, CIC5, and RCF) continues on each available clock

that may be present, similar to Mode 01. The NCO phase accumulator is incremented only once for each new input data sample

and not once for each input clock.

WB Input Select

Bit 6 in this register controls which input port is selected for

signal processing. If this bit is set high, Input Port B (INB,

EXPB, and IENB) is connected to the selected filter channel. If

this bit is cleared, Input Port A (INA, EXPA, and IENA) is

connected to the selected filter channel.

Sync Select

Bits 7 and 8 of this register determine which external sync pin is

associated with the selected channel. The AD6624 has four sync

pins named SYNCA, SYNCB, SYNCC, and SYNCD. Any of

these sync pins can be associated with any of the four receiver

channels within the AD6624. Additionally, if only one sync

signal is required for the system, all four receiver channels can

reference the same sync pulse. Bit value 00 is Channel A, 01 is

Channel B, 10 is Channel C, and 11 is Channel D.

SECOND ORDER rCIC FILTER

The rCIC2 filter is a second order cascaded resampling integrator comb filter. The resampler is implemented using a unique

technique, which does not require the use of a high-speed clock,

thus simplifying the design and saving power. The resampler

allows for noninteger relationships between the master clock

and the output data rate. This allows easier implementation of

systems that are either multimode or require a master clock that

is not a multiple of the data rate to be used.

Interpolation up to 512, and decimation up to 4096, is allowed

in the rCIC2. The resampling factor for the rCIC2 (L) is a 9-bit

integer. When combined with the decimation factor M, a 12-bit

number, the total rate change can be any fraction in the form of:

L

M

(3)

1=≤

R

R

rCIC

rCIC22

The only constraint is that the ratio L/M must be less than or

equal to one. This implies that the rCIC2 decimates by 1 or more.

Resampling is implemented by apparently increasing the input

sample rate by the Factor L, using zero stuffing for the new data

samples. Following the resampler is a second order cascaded

integrator comb filter. Filter characteristics are determined only

by the fractional rate change (L/M).

The filter can process signals at the full rate of the input port,

80 MHz. The output rate of this stage is given by Equation 4.

Lf

×

rCIC SAMP

f

SAMP

Both L

rate (L

2

rCIC2

rCIC2

2

=

M

rCIC

2

and M

are unsigned integers. The interpolation

rCIC2

) may be from 1 to 512 and the decimation (M

rCIC2

(4)

)

may be between 1 and 4096. The stage can be bypassed by

setting the decimation to 1/1.

The frequency response of the rCIC2 filter is given by Equation 5.

2

M

rCIC

2

−

L

rCIC

2

z

–

1

z

−

1

Mf

rCIC

π

Lf

rCIC SAMP

2

sin

π

f

SAMP

2

×

2

×

f

(5)

Hz

()

=

S

rCIC

2

2

Hf

=

()

S

rCIC

2

2

The scale factor, S

1

L

×

rCIC

1

L

×

rCIC

is a programmable, unsigned 5-bit value

rCIC2

−

1

×

2

sin

×

2

between 0 and 31. This serves as an attenuator that can reduce

the gain of the rCIC2 in 6 dB increments. For the best dynamic

range, S

should be set to the smallest value possible (i.e.,

rCIC2

lowest attenuation) without creating an overflow condition.

This can be safely accomplished using the following equation:

–18–

REV. B

Page 19

AD6624

S ceil M floor

rCIC rCIC

222

OL

CIC

=+

log

2

M

()

rCIC

2

=

2

L

rCIC

2

×

2

S

rCIC

input level

×

2

M

rCIC

L

rCIC

_

2

2

ML floor

21

×× − × +

where input_level is the largest fraction of full-scale possible at

the input to the AD6624 (normally 1). The rCIC2 scale factor

is always used whether or not the rCIC2 is bypassed.

Moreover, there are two scale registers (rCIC2_LOUD[4:0]

Bits 4–0 in x92), and (rCIC2_QUIET[4:0] Bits 9–5 in 0x92)

that are used in conjunction with the computed S

determines the overall rCIC2 scaling. The S

rCIC2

which

rCIC2

value must

be summed with the values in each respective scale register and

ExpOff, to determine the scale value that must be placed in the

rCIC2 scale register. This number must be less than 32 or the

interpolation and decimation rates must be adjusted to validate

this equation. The ceil function denotes the next whole integer

and the floor function denotes the previous whole integer. For

example, the ceil(4.5) is 5 while the floor(4.5) is 4.

The gain and passband droop of the rCIC2 should be calculated

by the equations above, as well as the filter transfer equations

that follow. Excessive passband droop can be compensated

for in the RCF stage by peaking the passband by the inverse

of the roll-off.

Exp rCIC

mod( , )

scaled input IN ExpInv

_,

=× =

scaled input IN ExpInv

_,

=× =

−+

20

mod( , )

−−+

21

28

Exp rCIC

728

(7)

where: IN is the value of IN[15:0], Exp is the value of EXP[2:0],

and rCIC2 is the value of the 0x92 (rCIC2_QUIET[4:0] and

rCIC2_LOUD[4:0]) scale register.

rCIC2 Rejection

Table III illustrates the amount of bandwidth in percent of the

data rate into the rCIC2 stage. The data in this table may be

scaled to any other allowable sample rate up to 80 MHz in

Single Channel Mode or 40 MHz in Diversity Channel Mode.

The table can be used as a tool to decide how to distribute the

decimation between rCIC2, CIC5, and the RCF.

Table III. SSB rCIC2 Alias Rejection Table (f

Bandwidth Shown in Percentage of f

M

/

CIC5

L

–50 dB –60 dB –70 dB –80 dB –90 dB –100 dB

rCIC2

SAMP

SAMP

= 1)

21.79 1.007 0.566 0.318 0.179 0.101

3 1.508 0.858 0.486 0.274 0.155 0.087

4 1.217 0.696 0.395 0.223 0.126 0.071

5 1.006 0.577 0.328 0.186 0.105 0.059

6 0.853 0.49 0.279 0.158 0.089 0.05

7 0.739 0.425 0.242 0.137 0.077 0.044

8 0.651 0.374 0.213 0.121 0.068 0.038

9 0.581 0.334 0.19 0.108 0.061 0.034

10 0.525 0.302 0.172 0.097 0.055 0.031

11 0.478 0.275 0.157 0.089 0.05 0.028

12 0.439 0.253 0.144 0.082 0.046 0.026

13 0.406 0.234 0.133 0.075 0.043 0.024

14 0.378 0.217 0.124 0.07 0.04 0.022

15 0.353 0.203 0.116 0.066 0.037 0.021

16 0.331 0.19 0.109 0.061 0.035 0.02

rCIC rCIC

22

M

rCIC

L

rCIC

2

2

(6)

Example Calculations

Goal: Implement a filter with an Input Sample Rate of 10 MHz

requiring 100 dB of alias rejection for a ±7 kHz pass band.

Solution: First determine the percentage of the sample rate that

is represented by the passband.

BW

FRACTION

=× =100

10

7

MHz

007.

(8)

kHz

Find the –100 dB column in Table III and look down this column

for a value greater than or equal to your passband percentage of

the clock rate. Then look across to the extreme left column and

find the corresponding rate-change factor (M

ring to the table, notice that for a M

rCIC2/LrCIC2

rCIC2/LrCIC2

of 4, the frequency

). Refer-

having –100 dB of alias rejection is 0.071 percent, which is

slightly greater than the 0.07 percent calculated. Therefore, for

this example, the maximum bound on rCIC2 rate change is 4.

A higher chosen M

rCIC2/LrCIC2

means less alias rejection than

the 100 dB required.

An M

rCIC2/LrCIC2

of less than four would still yield the required

rejection; however, the power consumption can be minimized

by decimating as much as possible in this rCIC2 stage. Decimation in rCIC2 lowers the data rate, and thus reduces power

consumed in subsequent stages. It should also be noted that

there is more than one way to determine the decimation by 4. A

decimation of 4 is the same as an L/M ratio of 0.25. Thus any

integer combination of L/M that yields 0.25 will work (1/4, 2/8,

or 4/16). However, for the best dynamic range, the simplest

ratio should be used. For example, 1/4 gives better performance

than 4/16.

Decimation and Interpolation Registers

rCIC2 decimation values are stored in register 0x90. This is a

12-bit register and contains the decimation portion less 1. The

interpolation portion is stored in register 0x91. This 9-bit value

holds the interpolation less one.

rCIC2 Scale

Register 0x92 contains the scaling information for this section of

the circuit. The primary function is to store the scale value

computed in the sections above.

Bits 4–0 (rCIC2_LOUD[4:0]) of this register are used to contain the scaling factor for the rCIC2 during conditions of strong

signals. These five bits represent the rCIC2 scalar calculated above

plus any external signal scaling with an attenuator.

Bits 9–5 (rCIC2_QUIET[4:0]) of this register are used to contain the scaling factor for the rCIC2 during conditions of weak

signals. In this register, no external attenuator would be used

and is not included. Only the value computed above is stored in

these bits.

Bit 10 of this register is used to indicate the value of the external

exponent. If this bit is set LOW, each external exponent represents 6 dB per step as in the AD6600. If this bit is set to HIGH,

each exponent represents a 12 dB step.

REV. B

–19–

Page 20

AD6624

Bit 11 of this register is used to invert the external exponent

before internal calculation. This bit should be set HIGH for

gain-ranging ADCs that use an increasing exponent to represent

an increasing signal level. This bit should be set LOW for gainranging ADCs that use a decreasing exponent for representing

an increasing signal level.

In applications that do not require the features of the rCIC2, it

may be bypassed by setting the L/M ratio to 1/1. This effectively

bypasses all circuitry of the rCIC2 except the scaling, which is still

effectual.

FIFTH ORDER CASCADED INTEGRATOR COMB FILTER

The third signal processing stage, CIC5, implements a sharper,

fixed-coefficient, decimating filter than CIC2. The input rate to

this filter is f

tion 9. N

CH

otherwise N

can be increased, NCH can be reduced, or f

. The maximum input rate is given by Equa-

SAMP2

equals two for Diversity Channel Real input mode;

equals one. In order to satisfy this equation, M

CH

can be increased

CLK

CIC2

(reference fractional rate input timing described in the Input

Timing section).

f

f

SAMP

The decimation ratio, M

CLK

≤

2

N

CH

, may be programmed from 2 to 32

CIC5

(9)

(all integer values). The frequency response of the filter is given

by Equation 10. The gain and passband droop of CIC5 should

be calculated by these equations. Both parameters may be compensated for in the RCF stage.

5

–

M