Page 1

Low Cost Monolithic

a

FEATURES

Low Cost

Single or Dual Supply, 5 V to 36 V, 65 V to 618 V

Full-Scale Frequency Up to 500 kHz

Minimum Number of External Components Needed

Versatile Input Amplifier

Positive or Negative Voltage Modes

Negative Current Mode

High Input Impedance, Low Drift

Low Power: 2.0 mA Quiescent Current

Low Offset: 1 mV

PRODUCT DESCRIPTION

The AD654 is a monolithic V/F converter consisting of an input

amplifier, a precision oscillator system, and a high current output stage. A single RC network is all that is required to set up

any full scale (FS) frequency up to 500 kHz and any FS input

voltage up to ±30 V. Linearity error is only 0.03% for a 250 kHz

FS, and operation is guaranteed over an 80 dB dynamic range.

The overall temperature coefficient (excluding the effects of external components) is typically

ates from a single supply of 5 V to 36 V and consumes only

2.0 mA quiescent current.

The low drift (4 µV/°C typ) input amplifier allows operation

directly from small signals such as thermocouples or strain

gauges while offering a high (250 MΩ) input resistance. Unlike

most V/F converters, the AD654 provides a square-wave output,

and can drive up to 12 TTL loads, optocouplers, long cables, or

similar loads.

±50 ppm/°C. The AD654 oper-

Voltage-to-Frequency Converter

AD654

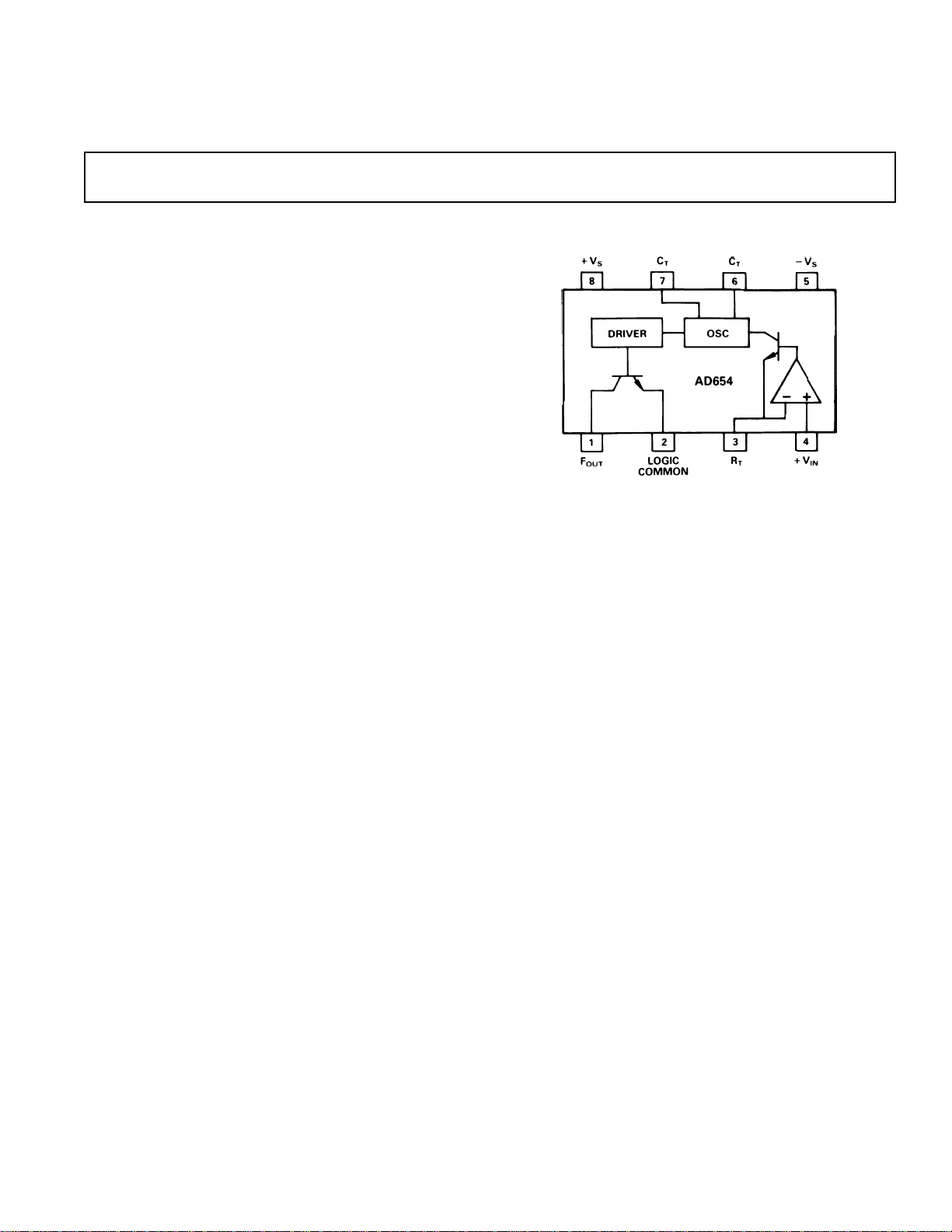

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Packaged in both an 8-pin mini-DIP and an 8-pin SOIC

package, the AD654 is a complete V/F converter requiring

only an RC timing network to set the desired full-scale frequency and a selectable pullup resistor for the open-collector

output stage. Any full scale input voltage range from 100 mV

to 10 volts (or greater, depending on +V

dated by proper selection of the timing resistor. The fullscale frequency is then set by the timing capacitor from the

simple relationship, f = V/10 RC.

2. A minimum number of low cost external components are

necessary. A single RC network is all that is required to set

up any full scale frequency up to 500 kHz and any full-scale

input voltage up to ±30 V.

3. Plastic packaging allows low cost implementation of the standard VFC applications: A/D conversion, isolated signal

transmission, F/V conversion, phase-locked loops, and tuning switched-capacitor filters.

4. Power supply requirements are minimal; only 2.0 mA of quiescent current is drawn from the single positive supply from

4.5 volts to 36 volts. In this mode, positive inputs can vary

from 0 volts (ground) to (+V

easily be connected for below ground operation.

5. The versatile open-collector output stage can sink more than

10 mA with a saturation voltage less than 0.4 volts. The

Logic Common terminal can be connected to any level between ground (or –V

easy direct interface to any logic family with either positive or

negative logic levels.

) and 4 volts below +VS. This allows

S

–4) volts. Negative inputs can

S

) can be accommo-

S

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

(TA = +258C and VS (total) = 5 V to 16.5 V, unless otherwise noted.

AD654–SPECIFICATIONS

All testing done@ VS = +5 V.)

AD654JN/JR

Model Min Typ Max Units

CURRENT-TO-FREQUENCY CONVERTER

Frequency Range 0 500 kHz

Nonlinearity

f

MAX

f

MAX

1

= 250 kHz 0.06 0.1 %

= 500 kHz 0.20 0.4 %

Full-Scale Calibration Error

C = 390 pF, I

vs. Supply (f

V

= +4.75 V to +5.25 V 0.20 0.40 %/V

S

V

= +5.25 V to +16.5 V 0.05 0.10 %/V

S

= 1.000 mA –10 10 %

IN

≤ 250 kHz)

MAX

vs. Temp (0°C to +70°C) 50 ppm/°C

ANALOG INPUT AMPLIFIER

(Voltage-to-Current Converter)

Voltage Input Range

Single Supply 0 (+V

Dual Supply –V

S

– 4) V

S

(+VS – 4) V

Input Bias Current

(Either Input) 30 50 nA

Input Offset Current 5 nA

Input Resistance (Noninverting) 250 MΩ

Input Offset Voltage 0.5 1.0 mV

vs. Supply

V

= +4.75 V to +5.25 V 0.1 0.25 mV/V

S

V

= +5.25 V to +16.5 V 0.03 0.1 mV/V

S

vs. Temp (0°C to +70°C) 4 µV/°C

OUTPUT INTERFACE (Open Collector Output)

(Symmetrical Square Wave)

Output Sink Current in Logic “0”

V

= 0.4 V max, +25°C 10 20 mA

OUT

V

= 0.4 V max, 0°C to +70°C 5 10 mA

OUT

2

Output Leakage Current in Logic “1” 10 100 nA

0°C to +70°C 50 500 nA

Logic Common Level Range –V

Rise/Fall Times (C

I

= 1 mA 0.2 µs

IN

I

= 1 µA1µs

IN

= 0.01 µF)

T

S

(+VS – 4) V

POWER SUPPLY

Voltage, Rated Performance 4.5 16.5 V

Voltage, Operating Range

Single Supply 4.5 36 V

Dual Supply ±5 ± 18 V

Quiescent Current

V

(Total) = 5 V 1.5 2.5 mA

S

VS (Total) = 30 V 2.0 3.0 mA

TEMPERATURE RANGE

Operating Range –40 +85 °C

PACKAGE OPTIONS

3

SOIC (R-8) AD654JR

Plastic DIP (N-8) AD654JN

NOTES

1

At f

= 250 kHz; RT = 1 kΩ, CT = 390 pF, IIN = 0 mA–1 mA.

MAX

1

At f

= 500 kHz; RT = 1 kΩ, CT = 200 pF, IIN = 0 mA–1 mA.

MAX

2

The sink current is the amount of current that can flow into Pin 1 of the AD654 while maintaining a maximum voltage of 0.4 V between Pin 1 and Logic Common.

3

N = Plastic DIP; R = SOIC.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

Specifications subject to change without notice

–2–

REV. A

Page 3

AD654

ABSOLUTE MAXIMUM RATING

Total Supply Voltage +VS to –VS . . . . . . . . . . . . . . . . . . . 36 V

Maximum Input Voltage

(Pins 3, 4) to –V

. . . . . . . . . . . . . . . . . . . . .–300 mV to +V

S

S

Maximum Output Current

Instantaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

Sustained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 mA

Logic Common to –V

. . . . . . . . . . . . . . . –500 mV to (+VS –4)

S

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

CIRCUIT OPERATION

The AD654’s block diagram appears in Figure 1. A versatile

operational amplifier serves as the input stage; its purpose is to

convert and scale the input voltage signal to a drive current in

the NPN follower. Optimum performance is achieved when, at

the full-scale input voltage, a 1 mA drive current is delivered to

the current-to-frequency converter (an astable multivibrator).

The drive current provides both the bias levels and the charging

current to the externally connected timing capacitor. This

“adaptive” bias scheme allows the oscillator to provide low nonlinearity over the entire current input range of 100 nA to 2 mA.

The square wave oscillator output goes to the output driver

which provides a floating base drive to the NPN power transistor. This floating drive allows the logic interface to be referenced to a level other than –V

.

S

for a component having a small tempco. Polystyrene, polypropylene, or Teflon* capacitors are preferred for tempco and dielectric absorption; other types will degrade linearity. The capacitor

should be wired very close to the AD654. In Figure 1, Schottky

diode CR1 (MBD101) prevents logic common from dropping

more than 500 mV below –V

required if –V

V/F CONNECTIONS FOR NEGATIVE INPUT VOLTAGE

OR CURRENT

is equal to logic common.

S

. This diode is not

S

The AD654 can accommodate a wide range of negative input

voltages with proper selection of the scaling resistor, as indicated

in Figure 2. This connection, unlike the buffered positive connection, is not high impedance because the signal source must

supply the 1 mA FS drive current. However, large negative voltages beyond the supply can be handled easily by modifying the

scaling resistors appropriately. If the input is a true current

source, R1 and R2 are not used. Again, diode CR1 prevents

latch-up by insuring Logic Common does not drop more than

500 mV below –V

AD654 input from “below –V

. The clamp diode (MBD101) protects the

S

” inputs.

S

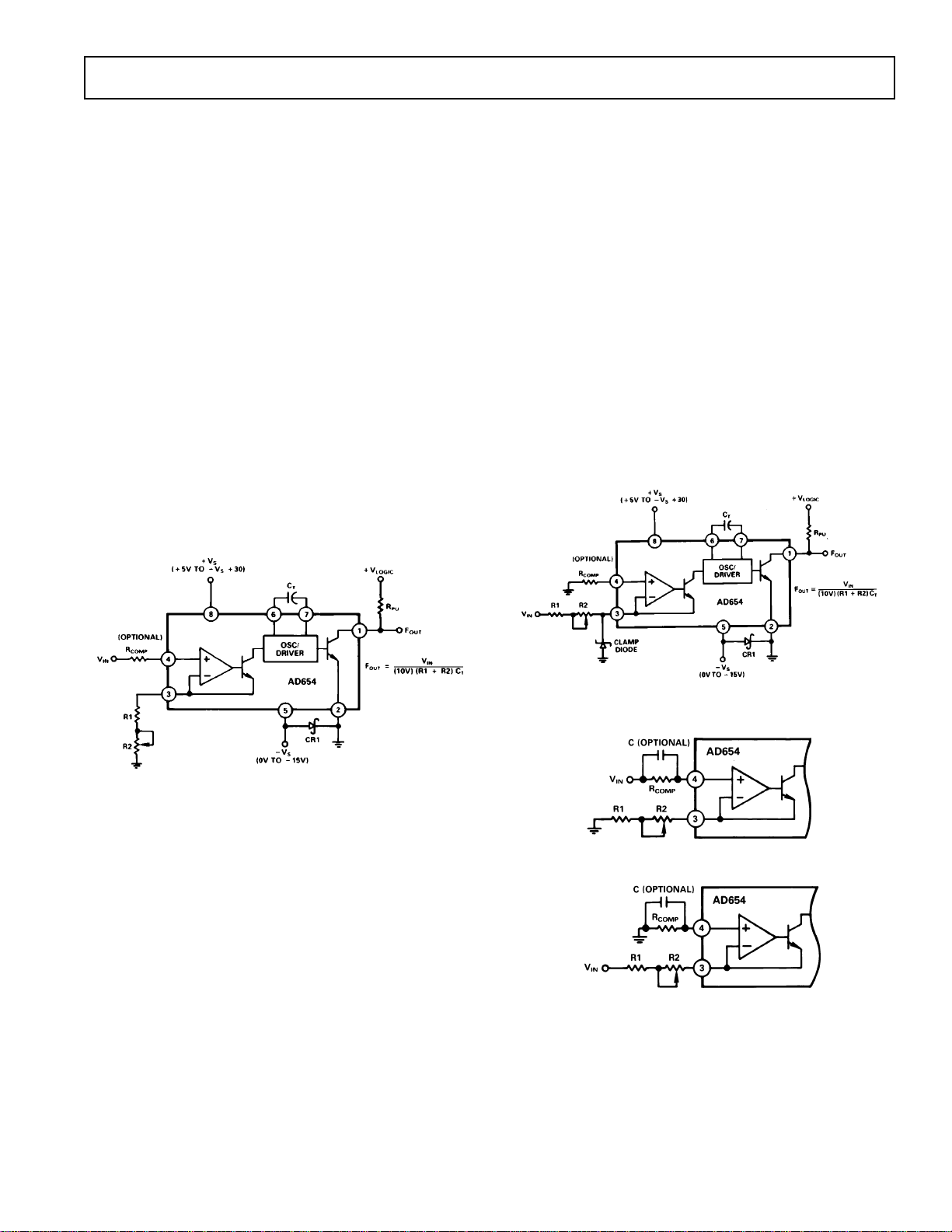

Figure 1. Standard V-F Connection for Positive Input

Voltages

V/F CONNECTION FOR POSITIVE INPUT VOLTAGES

In the connection scheme of Figure 1, the input amplifier presents a very high (250 MΩ) impedance to the input voltage,

which is converted into the proper drive current by the scaling

resistors at Pin 3. Resistors R1 and R2 are selected to provide a

1 mA full-scale current with enough trim range to accommodate

the AD654’s 10% FS error and the components’ tolerances.

Full-scale currents other than 1 mA can be chosen, but linearity

will be reduced; 2 mA is the maximum allowable drive. The

AD654’s positive input voltage range spans from –V

(ground in

S

sink supply operation) to four volts below the positive supply.

Power supply rejection degrades as the input exceeds (+V

3.75 V) and at (+V

– 3.5 V) the output frequency goes to zero.

S

–

S

As indicated by the scaling relationship in Figure 1, a 0.01 µF

timing capacitor will give a 10 kHz full-scale frequency, and 0.001

µF will give 100 kHz with a 1 mA drive current. Good V/F linearity

requires the use of a capacitor with low dielectric absorption

(DA), while the most stable operation over temperature calls

*Teflon is a trademark of E.I. Du Pont de Nemours & Co.

Figure 2. V-F Connections for Negative Input Voltages or

Current

Figure 3a. Bias Current Compensation—Positive Inputs

Figure 3b. Bias Current Compensation—Negative Inputs

If the AD654’s 1 mV offset voltage must be trimmed, the trim

must be performed external to the device. Figure 3c shows an

optional connection for positive inputs in which R

R

add a variable resistance in series with RT. A variable

OFF2

source of ±0.6 V applied to R

then adjusts the offset ±1 mV.

OFF1

Similarly, a ±0.6 V variable source is applied to R

OFF1

OFF

and

in Fig-

ure 3d to trim offset for negative inputs. The ±0.6 V bipolar

source could simply be an AD589 reference connected as shown

in Figure 3e.

REV. A

–3–

Page 4

AD654

Figure 3c. Offset Trim Positive Input (10 V FS)

Figure 3d. Offset Trim Negative Input (–10 V FS)

Figure 4. Current Source FS Trim

resistor R1, and flowing into Pin 3; it constitutes the signal

current I

to be converted. The second path, through another

T

100 Ω resistor R2, carries the same nominal current. Two equal

valued resistors offer the best overall stability, and should be

either 1% discrete film units, or a pair from a common array.

Since the 1 mA FS input current is divided into two 500 µA legs

(one to ground and one to Pin 3), the total input signal current

(I

) is divided by a factor of two in this network. To achieve the

S

same conversion scale factor, C

must be reduced by a factor of

T

two. This results in a transfer unique to this hookup:

Figure 3e. Offset Trim Bias Network

FULL-SCALE CALIBRATION

Full-scale trim is the calibration of the circuit to produce the

desired output frequency with a full-scale input applied. In most

cases this is accomplished by adjusting the scaling resistor R

.

T

Precise calibration of the AD654 requires the use of an accurate

voltage standard set to the desired FS value and an accurate frequency meter. A scope is handy for monitoring output waveshape. Verification of converter linearity requires the use of a

switchable voltage source or DAC having a linearity error below

±0.005%, and the use of long measurement intervals to minimize count uncertainties. Since each AD654 is factory tested for

linearity, it is unnecessary for the end-user to perform this tedious

and time consuming test on a routine basis.

Sufficient FS calibration trim range must be provided to accommodate the worst-case sum of all major scaling errors. This includes the AD654’s 10% full-scale error, the tolerance of the

fixed scaling resistor, and the tolerance of the timing capacitor.

Therefore, with a resistor tolerance of 1% and a capacitor tolerance of 5%, the fixed part of the scaling resistor should be a

maximum of 84% of nominal, with the variable portion selected

to allow 116% of the nominal.

If the input is in the form of a negative current source, the scaling resistor is no longer required, eliminating the capability of

trimming FS frequency in this fashion. Since it is usually not

practical to smoothly vary the capacitance for trimming purposes, an alternative scheme such as the one shown in Figure 4

is needed. Designed for a FS of 1 mA, this circuit divides the

input into two current paths. One path is through the 100 Ω

–4–

I

f =

S

(20V ) C

T

For calibration purposes, resistors R3 and R4 are added to the

network, allowing a ±15% trim of scale factor with the values

shown. By varying R4’s value the trim range can be modified to

accommodate wider tolerance components or perhaps the calibration tolerance on a current output transducer such as the

AD592 temperature sensor. Although the values of R1–R4

shown are valid for 1 mA FS signals only, they can be scaled

upward proportionately for lower FS currents. For instance, they

should be increased by a factor of ten for a FS current of 100 µA.

In addition to the offsets generated by the input amplifier’s bias

and offset currents, an offset voltage induced parasitic current

arises from the current fork input network. These effects are

minimized by using the bias current compensation resistor R

OFF

and offset trim scheme shown in Figure 3e.

Although device warm-up drifts are small, it is good practice to

allow the devices operating environment to stabilize before trim,

and insure the supply, source and load are appropriate. If provision

is made to trim offset, begin by setting the input to 1/10,000 of

full scale. Adjust the offset pot until the output is 1/10,000 of

full scale (for example, 25 Hz for a FS of 250 kHz). This is most

easily accomplished using a frequency meter connected to the

output. The FS input should then be applied and the gain pot

should be adjusted until the desired FS frequency is indicated.

INPUT PROTECTION

The AD654 was designed to be used with a minimum of additional hardware. However, the successful application of a precision IC involves a good understanding of possible pitfalls and

the use of suitable precautions. Thus +V

not be driven more than 300 mV below –V

Common should not drop more than 500 mV below –V

and RT pins should

IN

. Likewise, Logic

S

. This

S

would cause internal junctions to conduct, possibly damaging

the IC. In addition to the diode shown in Figures 1 and 2 protecting Logic Common, a second Schottky diode (MBD101)

can protect the AD654’s inputs from “below –V

’’ inputs as

S

REV. A

Page 5

AD654

shown in Figure 5. It is also desirable not to drive +VIN and R

T

above +VS. In operation, the converter will exhibit a zero output

for inputs above (+V

– 3.5 V). Also, control currents above

S

2 mA will increase nonlinearity.

The AD654’s 80 dB dynamic range guarantees operation from a

control current of 1 mA (nominal FS) down to 100 nA (equivalent to 1 mV to 10 V FS). Below 100 nA improper operation of

the oscillator may result, causing a false indication of input amplitude. In many cases this might be due to short-lived noise

spikes which become added to input. For example, when scaled

to accept an FS input of 1 V, the –80 dB level is only 100 µV, so

when the mean input is only 60 dB below FS (1 mV), noise

spikes of 0.9 mV are sufficient to cause momentary malfunction.

This effect can be minimized by using a simple low-pass filter

ahead of the converter or a guard ring around the R

pin. The

T

filter can be assembled using the bias current compensation

resistor discussed in the previous section. For an FS of 10 kHz,

a single-pole filter with a time constant of 100 ms will be suitable, but the optimum configuration will depend on the application and the type of signal processing. Noise spikes are only

likely to be a cause of error when the input current remains near

its minimum value for long periods of time; above 100 nA full

integration of additive input noise occurs. Like the inputs, the

capacitor terminals are sensitive to interference from other signals. The timing capacitor should be located as close as possible

to the AD654 to minimize signal pickup in the leads. In some

cases, guard rings or shielding may be required.

DECOUPLING

It is good engineering practice to use bypass capacitors on the

supply-voltage pins and to insert small-valued resistors (10 to

100 Ω) in the supply lines to provide a measure of decoupling

OUTPUT INTERFACING CONSIDERATION

The output stage’s design allows easy interfacing to all digital

logic families. The output NPN transistor’s emitter and collector are both uncommitted. The emitter can be tied to any voltage between –V

and 4 volts below +VS, and the open collector

S

can be pulled up to a voltage 36 volts above the emitter regardless of +V

. The high power output stage can sink over 10 mA

S

at a maximum saturation voltage of 0.4 V. The stage limits the

output current at 25 mA and can handle this limit indefinitely

without damaging the device.

NONLINEARITY SPECIFICATION

The preferred method of specifying nonlinearity error is in terms

of maximum deviation from the ideal relationship after calibrating the converter at full scale. This error will vary with the full

scale frequency and the mode of operation. The AD654 operates best at a 150 kHz full-scale frequency with a negative

voltage input; the linearity is typically within 0.05%. Operating

at higher frequencies or with positive inputs will degrade the linearity as indicated in the Specifications Table. Typical linearity

at various temperatures is shown in Figure 7.

TWO-WIRE TEMPERATURE-TO-FREQUENCY

CONVERSION

Figure 8 shows the AD654 in a two-wire temperature-to-frequency

conversion scheme. The twisted pair transmission line serves the

dual purpose of supplying power to the device and also carrying

frequency data in the form of current modulation.

The positive supply line is fed to the remote V/F through a

140 Ω resistor. This resistor is selected such that the quiescent

current of the AD654 will cause less than one V

to be dropped.

BE

Figure 5. Input Protection

between the various circuits in the system. Ceramic capacitors

of 0.1 µF to 1.0 µF should be applied between the supply-voltage

pins and analog signal ground for proper bypassing on the AD654.

A proper ground scheme appears in Figure 6.

Figure 6. Proper Ground Scheme

REV. A

–5–

Figure 7. Typical Nonlinearities at Different Full-Scale

Frequencies

Figure 8. Two-Wire Temperature-to-Frequency Converter

Page 6

AD654

As the V/F oscillates, additional switched current is drawn

through R

tional current causes Q1 to saturate, and thus regenerates the

AD654’s output square wave at the collector. The supply voltage to the AD654 then consists of a dc level, less the resistive

line drop, plus a one V

frequency of the AD654. This ripple is reduced by the diode/

capacitor combination.

To set up the receiver circuit for a given voltage, the R

resistances are selected as shown in Table I. CMOS logic stages

can be driven directly from the collector of Q1, and a single

TTL load can be driven from the junction of R

K

°C

°F

At the V/F end, the AD592C temperature transducer is interfaced with the AD654 in such a manner that the AD654 output

frequency is proportional to temperature. The output frequency

can be sealed and offset from K to °C or °F using the resistor

values shown in Table II. Since temperature is the parameter of

interest, an NPO ceramic capacitor is used as the timing capacitor for low V/F TC.

When scaling per K, resistors R1–R3 and the AD589 voltage

reference are not used. The AD592 produces a 1 µA/K current

output which drives Pin 3 of the AD654. With the timing

capacitor of 0.01 µF this produces an output frequency scaled to

10 Hz/K. When scaling per °C and °F, the AD589 and resistors

R1–R3 offset the drive current at Pin 3 by 273.2 µA for scaling

per °C and 255.42 µA for scaling per °F. This will result in fre-

quencies sealed at 10 Hz/°C and 5.55 Hz/°F, respectively.

when Pin 1 goes low. The peak level of this addi-

L

p-p square wave at the output

BE

and R6.

S

Table I.

+V

S

R

S

R

L

10 V 270 Ω 1.8k

15 V 680 Ω 2.7k

Table II.

(+VS)R1R2R3R4R5

10 V – – – 100k 127k

15 V – – – 100k 127k

10 V 6.49k 4.02k 1k 95.3k 22.6k

15 V 12.7k 4.02k 1k 78.7k 36.5k

10 V 6.49k 4.42k 1k 154k 22.6k

15 V 12.7k 4.42k 1k 105k 36.5k

F = 10 Hz/K

F = 10 Hz/°C

F = 5.55 Hz/°F

and R

S

L

Figure 9. Optoisolator Interface

At the receiver side, the output transistor is operated in the

photo-transistor mode; that is with the base lead (Pin 6) open.

This allows the highest possible output current. For reasonable

speed in this mode, it is imperative that the load impedance be

as low as possible. This is provided by the single transistor stage

current-to-voltage converter, which has a dynamic load impedance of less than 10 ohms and interfaces with TTL at the output.

USING A STAND-ALONE FREQUENCY COUNTER/LED

DISPLAY DRIVER FOR VOLTMETER APPLICATIONS

Figure 10 shows the AD654 used with a stand-alone frequency

counter/LED display driver. With C

the AD654 produces an FS frequency of 100 kHz when V

= 1000 pF and R

T

= 1 kΩ

T

=

IN

+1 V. This signal is fed into the ICM7226A, a universal counter

system that drives common anode LEDs. With the FUNCTION pin tied to D1 through a 10 kΩ resistor the ICM7226A

counts the frequency of the signal at A

. This count period is

IN

selected by the user and can be 10 ms, 100 ms, 1s, or 10 seconds,

as shown on Pin 21. The longer the period selected, the more

resolution the count will have. The ICM7226A then displays

the frequency on the LEDs, driving them directly as shown. Refreshing of the LEDs is handled automatically by the ICM7226.

The entire circuit operates on a single +5 V supply and gives a

meter with 3, 4, or 5 digit resolution.

OPTOISOLATOR COUPLING

A popular method of isolated signal coupling is via optoelectronic isolators, or optocouplers. In this type of device, the signal is coupled from an input LED to an output photo-transistor,

with light as the connecting medium. This technique allows dc

to be transmitted, is extremely useful in overcoming ground

loop problems between equipment, and is applicable over a wide

range of speeds and power.

Figure 9 shows a general purpose isolated V/F circuit using a

low cost 4N37 optoisolator. A +5 V power supply is assumed

for both the isolated (+5 V isolated) and local (+5 V local) supplies. The input LED of the isolator is driven from the collector

output of the AD654, with a 9 mA current level established by

R1 for high speed, as well as for a 100% current transfer ratio.

–6–

Figure 10. AD654 With Stand-Alone Frequency Counter/

LED Display Driver

REV. A

Page 7

AD654

6

2

1

8

OSC

DRIVER

AD 654

V/F OUTPUT

PS = 400MHz

74LS86

A

B

C

R4

1k

+5V

C1

1000pF

C1

500pF

R

T

1k

R3

1k

R3

2k

R1

8.06k

R

PU

2.87k

V

IN

(0 TO + 10V)

TRANSISTOR

OFF

ON

A

B

C

V

V

0

0

0

+5

Longer count periods not only result in the count having more

resolution, they also serve as an integration of noisy analog signals. For example, a normal-mode 60 Hz sine wave riding on

the input of the AD654 will result in the output frequency increasing on the positive half of the sine wave and decreasing on

the negative half of the sine wave. This effect is cancelled by selecting a count period equal to an integral number of noise signal periods. A 100 ms count period is effective because it not

only has an integral number of 60 Hz cycles (6), it also has an

integral number of 50 Hz cydes (5). This is also true of the

1 second and 10 second count period.

AD654-BASED ANALOG-TO-DIGITAL CONVERSION

USING A SINGLE CHIP MICROCOMPUTER

The AD654 can serve as an analog-to-digital converter when

used with a single component microcomputer that has an interval timer/event counter such as the 8048. Figure 11 shows the

AD654, with a full-scale input voltage of +1 V and a full-scale

output frequency of 100 kHz, connected to the timer/counter

input Pin T1 of the 8048. Such a system can also operate on a

single +5 V supply.

The 8748 counter is negative edge triggered; after the STRT

CNT instruction is executed subsequent high to low transitions

on T1 increment the counter. The maximum rate at which the

counter may be incremented is once per three instruction cycles;

using a 6 MHz crystal, this corresponds to once every 7.5 µs, or

a maximum frequency of 133 kHz. Because the counter overflows

every 256 counts (8 bits), the timer interrupt is enabled. Each

overflow then causes a jump to a subroutine where a register is

incremented. After the STOP TCNT instruction is executed,

the number of overflows that have occurred will be the number

in this register. The number in this register multiplied by 256

plus the number in the counter will be the total number of negative edges counted during the count period. The count period is

handled simply by decrementing a register the number of times

necessary to correspond to the desired count time. After the register has been decremented the required number of times the

STOP TCNT instruction is executed.

The total number of negative edges counted during the count

period is proportional to the input voltage. For example, if a 1 V

full-scale input voltage produces a 100 kHz signal and the count

period is 100 ms, then the total count will be 10,000. Scaling

from this maximum is then used to determine the input voltage,

i.e., a count of 5000 corresponds to an input voltage of 0.5 V.

As with the ICM7226, longer count times result in counts having more resolution; and they result in the integration of noisy

analog signals.

FREQUENCY DOUBLING

Since the AD654’s output is a square-wave rather than a pulse

train, information about the input signal is carried on both

halves of the output waveform. The circuit in Figure 12 converts

the output into a pulse train, effectively doubling the output frequency, while preserving the better low frequency linearity of

the AD654. This circuit also accommodates an input voltage

that is greater than the AD654 supply voltage.

Resistors R1–R3 are used to scale the 0 V to +10 V input voltage down to 0 V to +1 V as seen at Pin 4 of the AD654. Recall

that V

must be less than V

IN

–4 V, or in this case less than

SUPPLY

1 V. The timing resistor and capacitor are selected such that this

0 V to +1 V signal seen at Pin 4 results in a 0 kHz to 200 kHz

output frequency.

The use of R4, C1 and the XOR gate doubles this 200 kHz

output frequency to 400 kHz. The AD654 output transistor is

basically used as a switch, switching capacitor C1 between a

charging mode and a discharging mode of operation. The voltages

Figure 12. Frequency Doubler

seen at the input of the 74LS86 are shown in the waveform diagram. Due to the difference in the charge and discharge time

constants, the output pulse widths of the 74LS86 are not equal.

REV. A

Figure 11. AD654 VFC as an ADC

The output pulse is wider when the capacitor is charging due to

its longer rise time than fall time. The pulses should therefore be

counted on their rising, rather than falling, edges.

OPERATION AT HIGHER OUTPUT FREQUENCIES

Operation of the AD654 via the conventional output (Pins 1

and 2) is speed limited to approximately 500 kHz for reasons of

TTL logic compatibility. Although the output stage may become speed limited, the multivibrator core itself is able to oscillate to 1 MHz or more. The designer may take advantage of this

feature in order to operate the device at frequencies in excess

of 500 kHz.

–7–

Page 8

AD654

Figure 13 illustrates this with a circuit offering 2 MHz full scale.

In this circuit the AD654 is operated at a full scale (FS) of

1 mA, with a C

quency of 1 MHz across C

Q2, buffer the differential timing capacitor waveforms to a low

impedance level where the push-pull signal is then ac coupled to

the high speed comparator A2. Hysteresis is used, via R7, for

non-ambiguous switching and to eliminate the oscillations which

would otherwise occur at low frequencies.

The net result of this is a very high speed circuit which does not

compromise the AD654 dynamic range. This is a result of the

FET buffers typically having only a few pA of bias current. The

high end dynamic range is limited, however, by parasitic package

and layout capacitances in shunt with C

each node to ac ground. Minimizing the lead length between

A2–6/A2–7 and Q1/Q2 in PC layout will help. A ground plane

of 100 pF. This achieves a basic device FS fre-

T

. The P channel JFETs, Q1 and

T

, as well as those from

T

Figure 14. Waveforms of 2 MHz Frequency Doubler

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Pin Plastic DIP

C900c–10–6/88

Figure 13. 2 MHz, Frequency Doubling V/F

will also help stability. Figure 14 shows the waveforms V1–V4

found at the respective points shown in Figure 13.

The output of the comparator is a complementary square wave

at 1 MHz FS. Unlike pulse train output V/F converters, each

half-cycle of the AD654 output conveys information about the

input. Thus it is possible to count edges, rather than full cycles

of the output, and double the effective output frequency. The

XOR gate following A2 acts as an edge detector producing a

short pulse for each input state transition. This effectively

doubles the V/F FS frequency to 2 MHz. The final result is a

1 V full-scale input V/F with a 2 MHz full-scale output capability; typical nonlinearity is 0.5%.

8-Pin SOIC

PRINTED IN U.S.A.

–8–

REV. A

Loading...

Loading...