Page 1

Voltage-to-Frequency and

C

FEATURES

V/F conversion to 1 MHz

Reliable monolithic construction

Very low nonlinearity

0.002% typ at 10 kHz

0.005% typ at 100 kHz

0.07% typ at 1 MHz

Input offset trimmable to zero

CMOS- or TTL-compatible

Unipolar, bipolar, or differential V/F

V/F or F/V conversion

Available in surface mount

MIL-STD-883 compliant versions available

PRODUCT DESCRIPTION

The AD650 V/F/V (voltage-to-frequency or frequency-to-voltage

converter) provides a combination of high frequency operation

and low nonlinearity previously unavailable in monolithic form.

The inherent monotonicity of the V/F transfer function makes

the AD650 useful as a high-resolution analog-to-digital converter.

A flexible input configuration allows a wide variety of input

voltage and current formats to be used, and an open-collector

output with separate digital ground allows simple interfacing to

either standard logic families or opto-couplers.

The linearity error of the AD650 is typically 20 ppm (0.002% of

full scale) and 50 ppm (0.005%) maximum at 10 kHz full scale.

This corresponds to approximately 14-bit linearity in an analogto-digital converter circuit. Higher full-scale frequencies or

longer count intervals can be used for higher resolution

conversions. The AD650 has a useful dynamic range of six

decades allowing extremely high resolution measurements.

Even at 1 MHz full scale, linearity is guaranteed less than

1000 ppm (0.1%) on the AD650KN, BD, and SD grades.

In addition to analog-to-digital conversion, the AD650 can be

used in isolated analog signal transmission applications,

phased-locked loop circuits, and precision stepper motor speed

controllers. In the F/V mode, the AD650 can be used in

precision tachometer and FM demodulator circuits.

The input signal range and full-scale output frequency are userprogrammable with two external capacitors and one resistor.

Input offset voltage can be trimmed to zero with an external

potentiometer.

Frequency-to-Voltage Converter

AD650

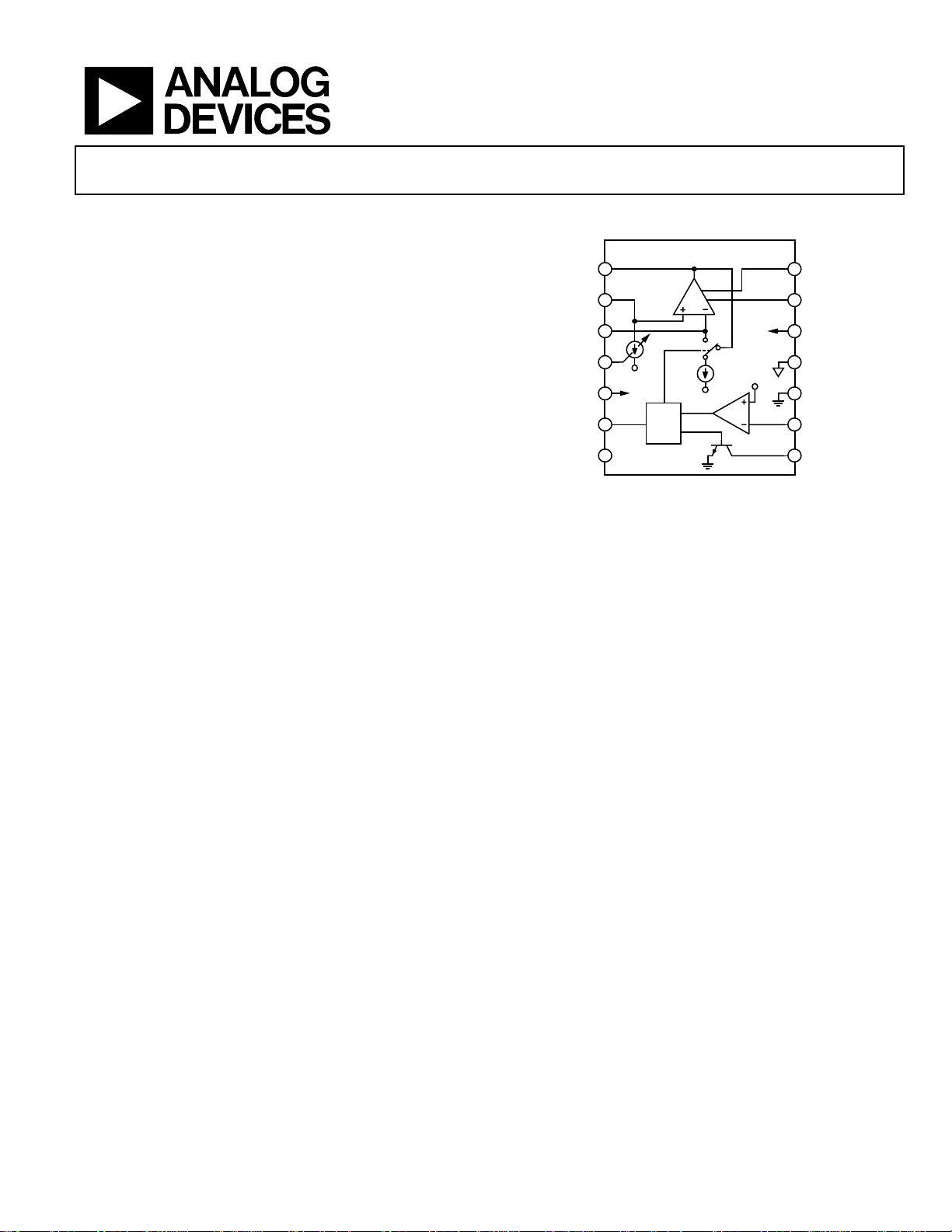

FUNCTIONAL BLOCK DIAGRAM

V

1

OUT

+IN

–IN

BIPOLAR

OFFSET

CURRENT

–V

ONE

SHOT

APACITOR

NC

2

3

4

–V

S

5

S

OUT

FREQ

6

7

NC = NO CONNECT

OP

AMP

ONE

SHOT

IN

OUT

–V

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

S

COMP

Figure 1.

The AD650JN and AD650KN are offered in plastic 14-lead DIP

packages. The AD650JP is available in a 20-lead plastic leaded

chip carrier (PLCC). Both plastic packaged versions of the

AD650 are specified for the commercial temperature range

(0°C to 70°C). For industrial temperature range (−25°C to

+85°C) applications, the AD650AD and AD650BD are offered

in ceramic packages. The AD650SD is specified for the full

−55°C to +125°C extended temperature range.

PRODUCT HIGHLIGHTS

1. Can operate at full-scale output frequencies up to 1 MHz

(in addition to having very high linearity).

2. Can be configured to accommodate bipolar, unipolar, or

differential input voltages, or unipolar input currents.

3. TTL or CMOS compatibility is achieved by using an open

collector frequency output. The pull-up resistor can be

connected to voltages up to 30 V.

4. The same components used for V/F conversion can also be

used for F/V conversion by adding a simple logic biasing

network and reconfiguring the AD650.

5. Separate analog and digital grounds prevent ground loops

in real-world applications.

6. Available in versions compliant with MIL-STD-883.

AD650

OFFSET

14

NULL

OFFSET

13

NULL

+V

12

S

ANALOG

11

GND

DIGITAL

10

GND

COMPARATOR

9

INPUT

F

8

OUTPUT

00797-001

Rev. D

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

Page 2

AD650

TABLE OF CONTENTS

Features.............................................................................................. 1

F/V Conversion .......................................................................... 10

Functional Block Diagram .............................................................. 1

Product Description......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 5

ESD Caution.................................................................................. 5

Pin Configurations and Function Descriptions ........................... 6

Circuit Operation ............................................................................. 7

Unipolar Configuration............................................................... 7

Component Selection................................................................... 8

Bipolar V/F.................................................................................. 10

Unipolar V/F, Negative Input Voltage ..................................... 10

REVISION HISTORY

High Frequency Operation....................................................... 10

Decoupling and Grounding...................................................... 12

Temperature Coefficients .......................................................... 12

Nonlinearity Specification ........................................................ 13

PSRR............................................................................................. 14

Other Circuit Considerations................................................... 14

Applications..................................................................................... 16

Differential Voltage-to-Frequency Conversion...................... 16

Autozero Circuit......................................................................... 16

Phase-Locked Loop F/V Conversion ...................................... 17

Outline Dimensions....................................................................... 19

Ordering Guide .......................................................................... 20

3/06—Rev. C to Rev. D

Updated Format..................................................................Universal

Changes to Product Highlights....................................................... 1

Changes to Table 1............................................................................ 3

Added Pin Function Descriptions Table ...................................... 6

Updated Outline Dimensions....................................................... 18

Changes to Ordering Guide.......................................................... 19

Rev. D | Page 2 of 20

Page 3

AD650

SPECIFICATIONS

T = 25°C, VS = ±15 V, unless otherwise noted.

Table 1.

AD650J/AD650A AD650K/AD650B AD650S

Model Min Typ Max Min Typ Max Min Typ Max Units

DYNAMIC PERFORMANCE

Full-Scale Frequency Range 1 1 1 MHz

Nonlinearity

f

f

f

f

Full-Scale Calibration Error

100 kHz ± 5 ± 5 ± 5 %

1 MHz ± 10 ± 10 ± 10 %

vs. Supply

vs. Temperature

BIPOLAR OFFSET CURRENT

Activated by 1.24 kΩ Between

Pin 4 and Pin 5

DYNAMIC RESPONSE

Maximum Settling Time for

Full-Scale Step Input

Overload Recovery Time

Step Input

ANALOG INPUT AMPLIFIER

(V/F CONVERSION)

Current Input Range (Figure 4) 0 +0.6 0 +0.6 0 +0.6 mA

Voltage Input Range (Figure 12) −10 0 −10 0 −10 0 V

Differen tial Impedance 2 MΩ||10 pF 2 MΩ||10 pF 2 MΩ||10 pF

Common-Mode Impedance 1000 MΩ||10 pF 1000 MΩ||10 pF 1000 MΩ||10 pF

Input Bias Current

Noninverting Input 40 100 40 100 40 100 nA

Inverting Input ±8 ±20 ±8 ±20 ±8 ±20 nA

Input Offset Voltage

(Trimmable to Zero) ±4 ±4 ±4 mV

vs. Temperature (T

Safe Input Voltage ±VS ±VS ±VS V

COMPARATOR (F/V CONVERSION)

Logic 0 Level −VS −1 −VS −1 −VS −1 V

Logic 1 Level 0 +VS 0 +VS 0 +VS V

Pulse Width Range4 0.1 (0.3 × tOS) 0.1 (0.3 × tOS) 0.1 (0.3 × tOS) µs

Input Impedance 250 250 250 kΩ

OPEN COLLECTOR OUTPUT

(V/F CONVERSION)

Output Voltage in Logic 0

I

Output Leakage Current in Logic 1 100 100 100 nA

Voltage Range5 0 36 0 36 0 36 V

1

= 10 kHz 0.002 0.005 0.002 0.005 0.002 0.005 %

MAX

= 100 kHz 0.005 0.02 0.005 0.02 0.005 0.02 %

MAX

= 500 kHz 0.02 0.05 0.02 0.05 0.02 0.05 %

MAX

= 1 MHz 0.1 0.05 0.1 0.05 0.1 %

MAX

3

2

% of

−0.015 +0.015 −0.015 +0.015 −0.015 +0.015

FSR/V

A, B, and S Grades

at 10 kHz ±75 ±75 ±75 ppm/°C

at 100 kHz ±150 ±150 ±200 ppm/°C

J and K Grades

at 10 kHz ±75 ±75 ppm/°C

at 100 kHz ±150 ±150 ppm/°C

0.45 0.5 0.55 0.45 0.5 0.55 0.45 0.5 0.55 mA

1 pulse of new frequency plus 1 s 1 pulse of new frequency plus 1 s 1 pulse of new frequency plus 1 s

1 pulse of new frequency plus 1 s 1 pulse of new frequency plus 1 s 1 pulse of new frequency plus 1 s

to T

MIN

) ±30 ±30 ±30 µV/°C

MAX

≤ 8 mA, T

SINK

MIN

to T

0.4 0.4 0.4 V

MAX

Rev. D | Page 3 of 20

Page 4

AD650

AD650J/AD650A AD650K/AD650B AD650S

Model Min Typ Max Min Typ Max Min Typ Max Units

AMPLIFIER OUTPUT (F/V CONVERSION)

Voltage Range

(1500 Ω Min Load Resistance)

Source Current

(750 Ω Max Load Resistance)

Capacitive Load

(Without Oscillation)

POWER SUPPLY

Voltage, Rated Performance ±9 ±18 ±9 ±18 ±9 ±18 V

Quiescent Current 8 8 8 mA

TEMPERATURE RANGE

Rated Performance

N Package 0 +70 0 +70 °C

D Package −25 +85 −25 +85 −55 +125 °C

1

Nonlinearity is defined as deviation from a straight line from zero to full scale, expressed as a fraction of full scale.

2

Full-scale calibration error adjustable to zero.

3

Measured at full-scale output frequency of 100 kHz.

4

Refer to F/V conversion section of the text.

5

Referred to digital ground.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

0 10 0 10 0 10 V

10 10 10 mA

100 100 100 pF

Rev. D | Page 4 of 20

Page 5

AD650

ABSOLUTE MAXIMUM RATINGS

Parameter Rating

Total Supply Voltage 36 V

Storage Temperature Range −55°C to +150°C

Differential Input Voltage ±10 V

Maximum Input Voltage ±VS

Open Collector Output Voltage

Above Digital GND

Current 50 mA

Amplifier Short Circuit to Ground Indefinite

Comparator Input Voltage ±VS

36 V

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Rev. D | Page 5 of 20

Page 6

AD650

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

1

V

OUT

2

+IN

–IN

3

BIBOLAR OFF SET

CURRENT

–V

ONE SHOT

CAPACITOR

AD650

TOP VIEW

4

(Not to Scale)

5

S

6

7

NC

NC = NO CONNECT

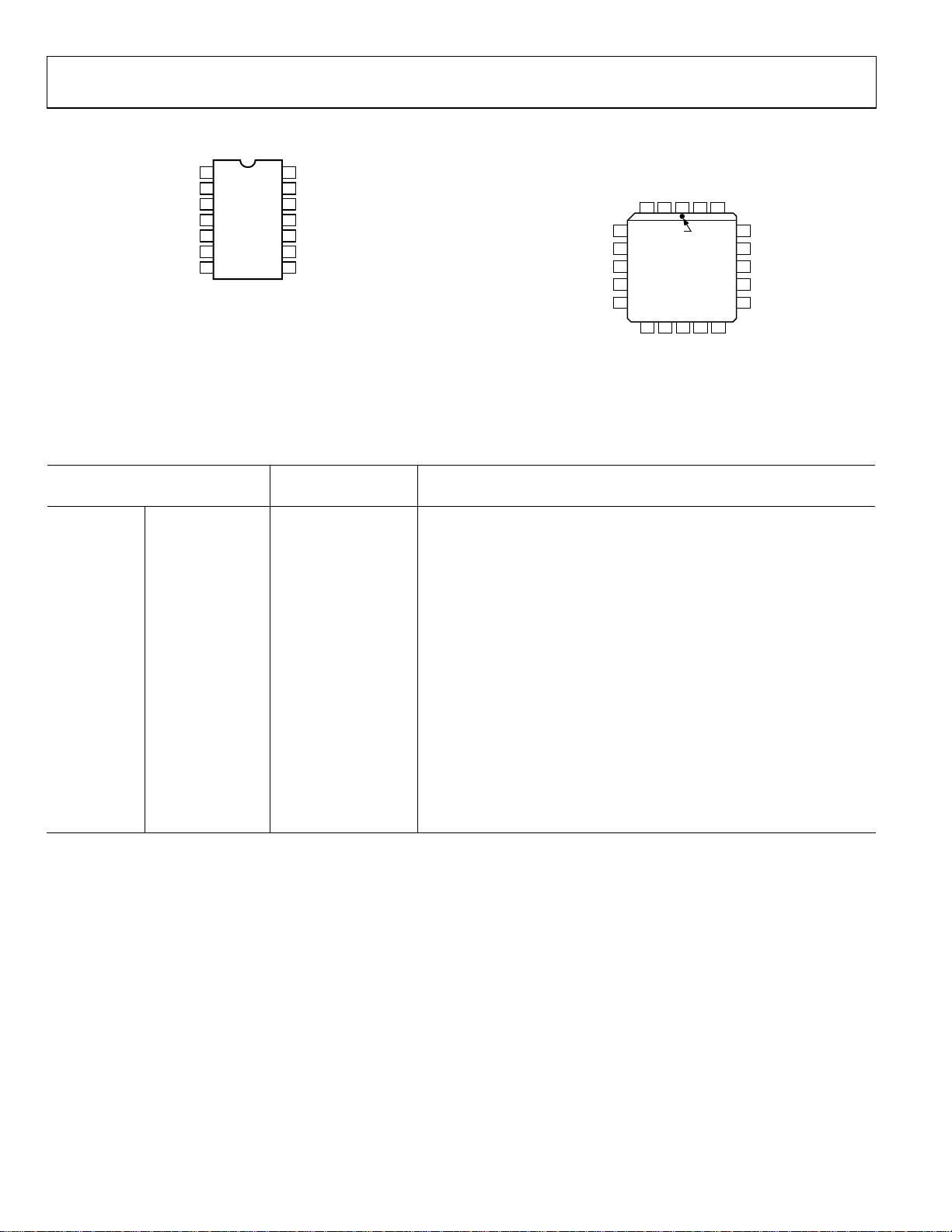

Figure 2. D-14, N-14 Pin Configurations

Table 2. Pin Function Descriptions

Pin No.

D-14, N-14 P-20A Mnemonic Description

1 2 V

2 3 +IN Positive Analog Input.

3 4 –IN Negative Analog Input.

4 6

5 8 –VS Negative Power Supply Input.

6 9

7 1, 5, 7, 10, 11, 15, 17 NC No Connect.

8 12 F

9 13 COMPARATOR INPUT

10 14 DIGITAL GND Digital Ground.

11 16 ANALOG GND Analog Ground.

12 18 +VS Positive Power Supply Input.

13, 14 19, 20 OFFSET NULL

OFFSET NULL

14

13

OFFSET NULL

12

+V

S

ANALOG GND

11

DIGITAL GND

10

COMPARATOR

9

INPUT

8

F

OUTPUT

00797-010

NC = NO CONNECT

OUT

Output of Operational Amplifier. The operational amplifier, along with C

is used in the integrate stage of the V to F conversion.

BIPOLAR OFFSET

CURRENT

ONE-SHOT

CAPACITOR

Frequency Output from AD650.

OUTPUT

On-Chip Current Source. This can be used in conjunction with an external

resistor to remove the operational amplifier’s offset.

The Capacitor, C

OS

for the one shot.

Input to Comparator. When the input voltage reaches −0.6 V, the one shot is

triggered.

Offset Null Pins. Using an external potentiometer, the offset of the

operational amplifier can be removed.

BIPOLAR O FFSET

CURRENT

, is Connected to This Pin. COS determines the time period

OUT

+IN

V

NC

OFFSET

NULL

OFFSET

NC

NULL

18

17

16

15

14

INPUT

OUTPUT

F

COMPARATOR

–V

–IN

NC

NC

4

5

6

7

8

S

1201923

PIN 1

INDENTFIER

AD650

TOP VIEW

(Not to scale)

91011 12 13

NC

ONE SHOT

CAPACITOR

Figure 3. P-20A Pin Configuration

+V

S

NC

ANALOG GND

NC

DIGITAL GND

00797-011

,

INT

Rev. D | Page 6 of 20

Page 7

AD650

+

–

+

–

–

CIRCUIT OPERATION

C

I

IN

–V

1mA

–V

OS

FREQUENCY

OUTPUT

ONE

SHOT

t

OS

IN

1mA

S

00797-005

IN

1mA

S

00797-006

T

1

INT

t

00797-004

t

0797-007

UNIPOLAR CONFIGURATION

The AD650 is a charge balance voltage-to-frequency converter.

In the connection diagram shown in

diagram of

Figure 5, the input signal is converted into an

equivalent current by the input resistance R

exactly balanced by an internal feedback current delivered in

short, timed bursts from the switched 1 mA internal current

source. These bursts of current can be thought of as precisely

defined packets of charge. The required number of charge

packets, each producing one pulse of the output transistor,

depends upon the amplitude of the input signal. Because the

number of charge packets delivered per unit time is dependent

on the input signal amplitude, a linear voltage-to-frequency

transformation is accomplished. The frequency output is

furnished via an open collector transistor.

A more rigorous analysis demonstrates how the charge balance

voltage-to-frequency conversion takes place.

A block diagram of the device arranged as a V-to-F converter is

shown in

Figure 5. The unit is comprised of an input integrator,

a current source and steering switch, a comparator, and a one

shot. When the output of the one shot is low, the current

steering switch S

diverts all the current to the output of the op

1

amp; this is called the integration period. When the one shot

has been triggered and its output is high, the switch S

all the current to the summing junction of the op amp; this is

called the reset period. The two different states are shown in

Figure 6 and Figure 7 along with the various branch currents. It

should be noted that the output current from the op amp is the

same for either state, thus minimizing transients.

S

OUT

AMP

ONE

SHOT

AD650

OP

IN

OUT

C

INT

1 14

2

3

4

–V

5

FREQ

6

C

OS

7

–15V

R

IN

V

IN

R3 R1

0.1µF

Figure 4. Connection Diagram for V/F Conversion, Positive Input Voltage

Figure 4, or the block

IN

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

–V

S

COMP

. This current is

diverts

1

20kΩ

13

12

11

10

9

8

0.1µF

DIGITAL

GROUND

1µF

250kΩ

R2

+15V

ANALOG

GROUND

V

F

LOGIC

OUT

C

INT

COMPARATOR

–0.6V

S1

1mA ± 20%

–V

S

+

V

–

I

IN

R

IN

IN

INTEGRATOR

AD650

Figure 5. Block Diagram

C

INT

I

IN

R

V

IN

IN

1mA

1mA – I

S1

Figure 6. Reset Mode

C

INT

I

IN

R

V

IN

IN

1mA – I

S1

Figure 7. Integrate Mode

RESET INTEGRATE

VOLTS

0797-003

0.6

ΔV

t

OS

Figure 8. Voltage Across C

Rev. D | Page 7 of 20

Page 8

AD650

t

×

−

MAX

The positive input voltage develops a current (IIN = VIN/RIN) that

charges the integrator capacitor C

C

, the output voltage of the integrator ramps downward

INT

towards ground. When the integrator output voltage (Pin 1)

crosses the comparator threshold (–0.6 V) the comparator

triggers the one shot, whose time period, t

the one-shot capacitor C

.

OS

Specifically, the one-shot time period is

Ct (1)

OSOS

The reset period is initiated as soon as the integrator output

voltage crosses the comparator threshold, and the integrator

ramps upward by an amount

dV

tV −=×=Δ mA1

OS

OS

(

C

dt

INT

After the reset period has ended, the device starts another

integration period, as shown in

downward again. The amount of time required to reach the

comparator threshold is given as

t

OS

()

mA1

C

Δ

V

INT

=

= 1

1

T

dV

dt

I

N

C

INT

The output frequency is now given as

f

OUT

15.0

Note that C

1

=

Tt

+

OS

F

Hz

×

A

OS

, the integration capacitor, has no effect on the

INT

I

IN

=

t

×

1

OS

RV

/

104.4

×+

transfer relation, but merely determines the amplitude of the

sawtooth signal out of the integrator.

One-Shot Timing

A key part of the preceding analysis is the one-shot time period

given in Equation 1. This time period can be broken down into

approximately 300 ns of propagation delay and a second time

segment dependent linearly on timing capacitor C

one shot is triggered, a voltage switch that holds Pin 6 at analog

ground is opened, allowing that voltage to change. An internal

0.5 mA current source connected to Pin 6 then draws its

current out of C

, causing the voltage at Pin 6 to decrease

OS

linearly. At approximately –3.4 V, the one shot resets itself,

thereby ending the timed period and starting the V/F

conversion cycle over again. The total one-shot time period can

be written mathematically as

CV

Δ

OS

t +

= (5)

OS

I

DISCHARGE

T

substituting actual values quoted in Equation 5,

. As charge builds up on

INT

is determined by

OS

73 −

sec100.3F/sec108.6

×+××=

)

I

(2)

IN

Figure 8, and starts ramping

I

−

IN

=

mA1

mA1

⎛

⎜

t

OS

⎜

⎝

⎞

⎟

(3)

−=

⎟

I

IN

⎠

(4)

ININ

−

11

FC

. When the

OS

DELAYGATE

Rev. D | Page 8 of 20

V4.3

C

t

=

OS

OS

−

A105.0

×−

93−

sec10300

×+

(6)

This simplifies into the timed period equation (see Equation 1).

COMPONENT SELECTION

Only four component values must be selected by the user. These

are input resistance R

and integration capacitor C

input voltage and full-scale frequency, while the last two are

determined by other circuit considerations.

Of the four components to be selected, R2 is the easiest to

define. As a pull-up resistor, it should be chosen to limit the

current through the output transistor to 8 mA if a TTL

maximum V

of 0.4 V is desired. For example, if a 5 V logic

OL

supply is used, R2 should be no smaller than 5 V/8 mA or

625 . A larger value can be used if desired.

R

and COS are the only two parameters available to set the full-

IN

scale frequency to accommodate the given signal range. The swing

variable that is affected by the choice of R

The selection guides of

graphically. In general, larger values of C

input currents (higher values of R

Figure 10, the implications of four different choices of RIN are

shown. Although the selection guide is set up for a unipolar

configuration with a 0 V to 10 V input signal range, the results

can be extended to other configurations and input signal ranges.

For a full-scale frequency of 100 kHz (corresponding to 10 V

input), among the available choices R

gives the lowest nonlinearity, 0.0038%. In addition, the highest

frequency that gives the 20 ppm minimum nonlinearity is

approximately 33 kHz (40.2 k and 1000 pF).

For input signal spans other than 10 V, the input resistance

must be scaled proportionately. For example, if 100 k is called

out for a 0 V to 10 V span, 10 kΩ would be used with a 0 V to 1 V

span, or 200 k with a ±10 V bipolar connection.

The last component to be selected is the integration capacitor

C

. In almost all cases, the best value for C

INT

using the equation

C

= (7)

INT

When the proper value for C

architecture of the AD650 provides continuous integration

of the input signal, therefore, large amounts of noise and

interference can be rejected. If the output frequency is

measured by counting pulses during a constant gate period,

the integration provides infinite normal-mode rejection for

frequencies corresponding to the gate period and its harmonics.

However, if the integrator stage becomes saturated by an

excessively large noise pulse, then the continuous integration of

the signal is interrupted, allowing the noise to appear at the output.

, timing capacitor COS, logic resistor R2,

IN

. The first two determine the

INT

and COS is nonlinearity.

IN

Figure 9 and Figure 10 show this quite

and lower full-scale

OS

) provide better linearity. In

IN

= 20 kΩ and COS = 620 pF

IN

INT

4

−

F

sec/10

(

f

minimumpF1000

is used, the charge balance

INT

)

can be calculated

Page 9

AD650

If the approximate amount of noise that appears on C

(V

), then the value of C

NOISE

can be checked using the following

INT

inequality:

C

INT

OS

>

V3

−−+

(8)

VV

NOISES

−

3

At

101

××

For example, consider an application calling for a maximum

frequency of 75 kHz, a 0 V to 1 V signal range, and supply

voltages of only ±9 V. The component selection guide of

is used to select 2.0 k for R

and 1000 pF for COS. This results

IN

in a one-shot time period of approximately 7 s. Substituting

75 kHz into Equation 7 yields a value of 1300 pF for C

the input signal is near zero, 1 mA flows through the integration

capacitor to the switched current sink during the reset phase,

causing the voltage across C

to increase by approximately 5.5 V.

INT

Because the integrator output stage requires approximately 3 V

headroom for proper operation, only 0.5 V margin remains for

integrating extraneous noise on the signal line. A negative noise

pulse at this time could saturate the integrator, causing an error

in signal integration. Increasing C

to 1500 pF or 2000 pF

INT

provides much more noise margin, thereby eliminating this

potential trouble spot.

is known

INT

Figure 9

. When

INT

100kHz

FREQUENCY FULL-SCALE

1MHz

10kHz

1000

100

50 100 1000

COS (pF)

Figure 9. Full-Scale Frequency vs. COS

INPUT

RESISTOR

16.9k

20k

40.2k

100k

INPUT

RESISTOR

16.9k

20k

40.2k

100k

00797-008

TYPICAL NO NLINEARIT Y (ppm)

20

50 100 1000

ONE SHOT CAPACITOR

C

(pF)

OS

Figure 10. Typical Nonlinearity vs. C

OS

00797-009

Rev. D | Page 9 of 20

Page 10

AD650

V

BIPOLAR V/F

Figure 11 shows how the internal bipolar current sink is used to

provide a half-scale offset for a ±5 V signal range, while providing

a 100 kHz maximum output frequency. The nominally 0.5 mA

(±10%) offset current sink is enabled when a 1.24 k resistor is

connected between Pin 4 and Pin 5. Thus, with the grounded

10 k nominal resistance shown, a −5 V offset is developed at

Pin 2. Because Pin 3 must also be at −5 V, the current through R

is 10 V/40 k = +0.25 mA at V

= +5 V, and 0 mA at VIN = –5 V.

IN

Components are selected using the same guidelines outlined for

t

he unipolar configuration with one alteration. The voltage

across the total signal range must be equated to the maximum

input voltage in the unipolar configuration. In other words, the

value of the input resistor R

is determined by the input voltage

IN

span, not the maximum input voltage. A diode from Pin 1 to

ground is also recommended. This is further discussed in the

Other Circuit Considerations section.

As in the unipolar circuit, R

and COS must have low temperature

IN

coefficients to minimize the overall gain drift. The 1.24 k

resistor used to activate the 0.5 mA offset current should also

have a low temperature coefficient. The bipolar offset current

has a temperature coefficient of approximately −200 ppm/°C.

UNIPOLAR V/F, NEGATIVE INPUT VOLTAGE

Figure 12 shows the connection diagram for V/F conversion of

negative input voltages. In this configuration, full-scale output

frequency occurs at negative full-scale input, and zero output

frequency corresponds with zero input voltage.

A very high impedance signal source can be used because it only

d

rives the noninverting integrator input. Typical input impedance

at this terminal is 1 G or higher. For V/F conversion of positive

input signals using the connection diagram of

enerator must be able to source the integration current

signal g

to drive the AD650. For the negative V/F conversion circuit of

Figure 12, the integration current is drawn from ground

t

hrough R1 and R3, and the active input is high impedance.

Figure 4, the

IN

Circuit operation for negative input voltages is very similar to

ositive input unipolar conversion described in the

p

onfiguration section. For best operating results use Equation 7

C

an

d Equation 8 in the Component Selection section.

Unipo lar

F/V CONVERSION

The AD650 also makes a very linear frequency-to-voltage

converter. Figure 13 shows the connection diagram for F/V

co

nversion with TTL input logic levels. Each time the input

signal crosses the comparator threshold going negative, the one

shot is activated and switches 1 mA into the integrator input for

a measured time period (determined by C

). As the frequency

OS

increases, the amount of charge injected into the integration

capacitor increases proportionately. The voltage across the

integration capacitor is stabilized when the leakage current

through R1 and R3 equals the average current being switched

into the integrator. The net result of these two effects is an

average output voltage that is proportional to the input

frequency. Optimum performance can be obtained by selecting

components using the same guidelines and equations listed in

the

Bipolar V/F section.

For a more complete description of this application, refer to

log Devices’ Application Note AN-279.

Ana

HIGH FREQUENCY OPERATION

Proper RF techniques must be observed when operating the

AD650 at or near its maximum frequency of 1 MHz. Lead

lengths must be kept as short as possible, especially on the one

shot and integration capacitors, and at the integrator summing

junction. In addition, at maximum output frequencies above

500 kHz, a 3.6 k pull-down resistor from Pin 1 to −V

required (see Figure 14). The additional current drawn through

t

he pulldown resistor reduces the op amp’s output impedance

and improves its transient response.

is

S

S

OUT

OP

AMP

ONE

SHOT

AD650

–V

IN

OUT

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

S

COMP

20kΩ

13

12

11

10

9

8

0.1µF

DIGITAL

GND

250kΩ

1µF

ANALOG

GND

1kΩ

+15V

+5V

F

OUT

00797-012

C

INT

1000pF

R1

5kΩ

V

IN

±5

–15V

R3

37.4kΩ

1.24kΩ

0.1µF

C

330pF

OS

1 14

2

10kΩ

3

4

–V

5

FREQ

6

7

Figure 11. Connections for ±5 V Bipolar V/F with 0 kHz to 100 kHz TTL Output

Rev. D | Page 10 of 20

Page 11

AD650

V

R3

C

INT

R1

AD650

–V

–15V

1 14

OP

–V

FREQ

S

OUT

AMP

ONE

SHOT

IN

OUT

–V

IN

0.1µF

C

OS

2

3

4

5

6

7

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

S

COMP

20kΩ

13

12

250kΩ

+15V

0.1µF

11

10

DIGITAL

9

GND

8

1µF

ANALOG

GND

R2

+V

F

LOGIC

OUT

00797-013

Figure 12. Connection Diagram for V/F Conversion, Negative Input Voltage

OUT

–15V

R3

R1

1 14

C

INT

2

3

4

–V

0.1µF

C

OS

5

6

7

FREQ

Figure 13. Connection Diagram for F/V Conversion

S

OUT

OP

AMP

ONE

SHOT

AD650

–V

IN

OUT

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

S

COMP

20kΩ

13

250kΩ

12

+15V

0.1µF

11

10

9

1N914

8

500Ω

2kΩ

ANALOG

GND

560pF

500Ω

F

+5V

IN

00797-014

S

OUT

OP

AMP

ONE

SHOT

AD650

–V

IN

OUT

OFFSET

INPUT

OFFSET

TRIM

S1

1mA

–0.6V

S

COMP

ADJUST

20kΩ

13

250kΩ

12

+15V

0.1µF

11

10

1µF

9

8

510Ω

ANALOG

GND PLANE

DIGITAL

GND

+5V

F

OUT

0MHz TO 1MHz

00797-015

V

0V TO 10V

IN

GAIN

ADJUST

5kΩ

14.3kΩ

–15V

1000pF

1 14

2

3

3.6kΩ

4

–V

5

0.1µF

51pF

6

7

FREQ

Figure 14. 1 MHz V/F Connection Diagram

Rev. D | Page 11 of 20

Page 12

AD650

DECOUPLING AND GROUNDING

It is effective engineering practice to use bypass capacitors on

the supply-voltage pins and to insert small-valued resistors

(10 to 100 ) in the supply lines to provide a measure of

decoupling between the various circuits in a system. Ceramic

capacitors of 0.1 F to 1.0 F should be applied between the

supply-voltage pins and analog signal ground for proper

bypassing on the AD650.

In addition, a larger board level decoupling capacitor of 1 F to

10 F should be located relatively close to the AD650 on each

power supply line. Such precautions are imperative in high

resolution, data acquisition applications where users expect to

exploit the full linearity and dynamic range of the AD650.

Although some types of circuits can operate satisfactorily with

power supply decoupling at only one location on each circuit

board, such practice is strongly discouraged in high accuracy

analog design.

Separate digital and analog grounds are provided on the

AD650. The emitter of the open collector frequency output

transistor is the only node returned to the digital ground. All

other signals are referred to analog ground. The purpose of the

two separate grounds is to allow isolation between the high

precision analog signals and the digital section of the circuitry.

As much as several hundred millivolts of noise can be tolerated

on the digital ground without affecting the accuracy of the

VFC. Such ground noise is inevitable when switching the large

currents associated with the frequency output signal.

At 1 MHz full scale, it is necessary to use a pull-up resistor of

about 500 in order to get the rise time fast enough to provide

well defined output pulses. This means that from a 5 V logic

supply, for example, the open collector output draws 10 mA.

This much current being switched causes ringing on long

ground runs due to the self-inductance of the wires. For

instance, 20 gauge wire has an inductance of about 20 nH per

inch; a current of 10 mA being switched in 50 ns at the end of

12 inches of 20 gauge wire produces a voltage spike of 50 mV.

The separate digital ground of the AD650 easily handles these

types of switching transients.

A problem remains from interference caused by radiation of

electromagnetic energy from these fast transients. Typically, a

voltage spike is produced by inductive switching transients;

these spikes can capacitively couple into other sections of the

circuit. Another problem is ringing of ground lines and power

supply lines due to the distributed capacitance and inductance

of the wires. Such ringing can also couple interference into

sensitive analog circuits. The best solution to these problems is

proper bypassing of the logic supply at the AD650 package. A

1 F to 10 F tantalum capacitor should be connected directly

to the supply side of the pull-up resistor and to the digital

ground (Pin 10). The pull-up resistor should be connected

directly to the frequency output (Pin 8). The lead lengths on the

bypass capacitor and the pull-up resistor should be as short as

possible. The capacitor supplies (or absorbs) the current

transients, and large ac signals flows in a physically small loop

through the capacitor, pull-up resistor, and frequency output

transistor. It is important that the loop be physically small for

two reasons: first, there is less self-inductance if the wires are

short, and second, the loop does not radiate RFI efficiently.

The digital ground (Pin 10) should be separately connected to

the power supply ground. Note that the leads to the digital

power supply are only carrying dc current and cannot radiate

RFI. There can also be a dc ground drop due to the difference in

currents returned on the analog and digital grounds. This does

not cause any problem. In fact, the AD650 tolerates as much as

0.25 V dc potential difference between the analog and digital

grounds. These features greatly ease power distribution and

ground management in large systems. Proper technique for

grounding requires separate digital and analog ground returns

to the power supply. Also, the signal ground must be referred

directly to analog ground (Pin 11) at the package. All of the

signal grounds should be tied directly to Pin 11, especially the

one-shot capacitor. More information on proper grounding and

reduction of interference can be found in “Noise Reduction

Techniques in Electronic Systems, 2

nd

edition” by Henry W. Ott,

(John Wiley & Sons, Inc., 1988).

TEMPERATURE COEFFICIENTS

The drift specifications of the AD650 do not include

temperature effects of any of the supporting resistors or

capacitors. The drift of the input resistors R1 and R3 and the

timing capacitor C

stability. In the application of

resistor used with a 100 ppm/°C capacitor can result in a

maximum overall circuit gain drift of:

150 ppm/°C (AD650A) + 100 ppm/°C (C

+ 10 ppm/°C (R

In bipolar configuration, the drift of the 1.24 k resistor used to

activate the internal bipolar offset current source directly affects

the value of this current. This resistor should be matched to the

resistor connected to the op amp noninverting input, Pin 2 (see

Figure 11). That is, the temperature coefficients of these two

resistors should be equal. If this is the case, then the effects of the

temperature coefficients of the resistors cancel each other, and the

drift of the offset voltage developed at the op amp noninverting

input is solely determined by the AD650. Under these conditions,

the TC of the bipolar offset voltage is typically −200 ppm/°C and

is a maximum of −300 ppm/°C. The offset voltage always

decreases in magnitude as temperature is increased.

directly affect the overall temperature

OS

Figure 5, a 10 ppm/°C input

)

OS

) = 260 ppm/°C

IN

Rev. D | Page 12 of 20

Page 13

AD650

Other circuit components do not directly influence the accuracy

of the VFC over temperature changes as long as their actual

values are not as different from the nominal value as to preclude

operation. This includes the integration capacitor C

in the capacitance value of C

simply results in a different rate of

INT

. A change

INT

voltage change across the capacitor. During the integration phase

(see

Figure 8), the rate of voltage change across C

has the

INT

opposite effect that it does during the reset phase. The result is

that the conversion accuracy is unchanged by either drift or

tolerance of C

. The net effect of a change in the integrator

INT

capacitor is simply to change the peak-to-peak amplitude of the

sawtooth waveform at the output of the integrator.

The gain temperature coefficient of the AD650 is not a constant

value. Rather, the gain TC is a function of both the full-scale

frequency and the ambient temperature. At a low full-scale

frequency, the gain TC is determined primarily by the stability of

the internal reference (a buried Zener reference). This low speed

gain TC can be quite effective; at 10 kHz full scale, the gain TC near

25°C is typically 0 ± 50 ppm/°C. Although the gain TC changes

with ambient temperature (tending to be more positive at higher

temperatures), the drift remains within a ±75 ppm/°C window over

the entire military temperature range. At full-scale frequencies

higher than 10 kHz, dynamic errors become much more important

than the static drift of the dc reference. At a full-scale frequency

of 100 kHz and above, these timing errors dominate the gain

TC. For example, at 100 kHz full-scale frequency (R

C

= 330 pF) the gain TC near room temperature is typically

OS

= 40 k and

IN

−80 ±50 ppm/°C, but at an ambient temperature near 125°C, the

gain TC tends to be more positive and is typically 15 ±50 ppm/°C.

This information is presented in a graphical form in

Figure 15.

The gain TC always tends to become more positive at higher

temperatures. Therefore, it is possible to adjust the gain TC of

the AD650 by using a one-shot capacitor with an appropriate

TC to cancel the drift of the circuit. For example, consider the

100 kHz full-scale frequency. An average drift of −100 ppm/°C

means that as temperature is increased, the circuit produces a

lower frequency in response to a given input voltage. This means

that the one-shot capacitor must decrease in value as temperature

increases in order to compensate the gain TC of the AD650; that

is, the capacitor must have a TC of −100 ppm/°C. Now consider

the 1 MHz full-scale frequency.

100

–50

0

–100

–200

GAIN TC (ppm/°C)

–300

–400

10kHz

100kHz

1MHz

Figure 15. Gain TC vs. Temperature

TEMPERATURE (° C)

–250 255075

100 125

00797-016

Rev. D | Page 13 of 20

It is not possible to achieve much improvement in performance

unless the expected ambient temperature range is known. For

example, in a constant low temperature application such as

gathering data in an Arctic climate (approximately −20°C), a

C

with a drift of −310 ppm/°C is called for in order to compensate

OS

the gain drift of the AD650. However, if that circuit should see

an ambient temperature of 75°C, then the C

capacitor would

OS

change the gain TC from approximately 0 ppm to 310 ppm/°C.

The temperature effects of these components are the same when

the AD650 is configured for negative or bipolar input voltages,

and for F/V conversion as well.

NONLINEARITY SPECIFICATION

The linearity error of the AD650 is specified by the endpoint

method. That is, the error is expressed in terms of the deviation

from the ideal voltage to frequency transfer relation after

calibrating the converter at full scale and zero. The nonlinearity

varies with the choice of one-shot capacitor and input resistor

(see

Figure 10). Verification of the linearity specification

requires the availability of a switchable voltage source (or a

DAC) having a linearity error below 20 ppm, and the use of

very long measurement intervals to minimize count

uncertainties. Every AD650 is automatically tested for linearity,

and it is not usually necessary to perform this verification,

which is both tedious and time consuming. If it is required to

perform a nonlinearity test either as part of an incoming quality

screening or as a final product evaluation, an automated benchtop tester proves useful. Such a system based on Analog

Devices’ LTS-2010 is described in “V-F Converters Demand

Accurate Linearity Testing,” by L. DeVito, (Electronic Design,

March 4, 1982).

The voltage-to-frequency transfer relation is shown in

and

Figure 17 with the nonlinearity exaggerated for clarity. The

first step in determining nonlinearity is to connect the endpoints of

the operating range (typically at 10 mV and 10 V) with a straight

line. This straight line is then the ideal relationship that is desired

from the circuit. The second step is to find the difference between

this line and the actual response of the circuit at a few points

between the endpoints—typically ten intermediate points

suffices. The difference between the actual and the ideal

response is a frequency error measured in hertz. Finally, these

frequency errors are normalized to the full-scale frequency and

expressed either as parts per million of full scale (ppm) or parts

per hundred of full scale (%). For example, on a 100 kHz full

scale, if the maximum frequency error is 5 Hz, the nonlinearity

is specified as 50 ppm or 0.005%. Typically on the 100 kHz

scale, the nonlinearity is positive and the maximum value

occurs at about midscale (

Figure 16). At higher full-scale

frequencies, (500 kHz to 1 MHz), the nonlinearity becomes “S”

shaped and the maximum value can be either positive or negative.

Typically, on the 1 MHz scale (R

= 16.9 k, COS = 51 pF) the

IN

nonlinearity is positive below about 2/3 scale and is negative

above this point. This is shown graphically in

Figure 17.

Figure 16

Page 14

AD650

100k

OUTPUT F REQUENCY (Hz)

100

ACTUAL

50ppm

IDEAL

PSRR

The power supply rejection ratio is a specification of the change

in gain of the AD650 as the power supply voltage is changed.

The PSRR is expressed in units of parts-per-million change of

the gain per percent change of the power supply (ppm/%). For

example, consider a VFC with a 10 V input applied and an

output frequency of exactly 100 kHz when the power supply

potential is ±15 V. Changing the power supply to ±12.5 V is a

5 V change out of 30 V, or 16.7%. If the output frequency changes

to 99.9 kHz, then the gain has changed 0.1% or 1000 ppm. The

PSRR is 1000 ppm divided by 16.7%, which equals 60 ppm/%.

10mV

Figure 16. Exaggerated Nonlinearity at 100 kHz Full Scale

INPUT VOLTAGE

10V

00797-017

The PSRR of the AD650 is a function of the full-scale operating

frequency. At low full-scale frequencies the PSRR is determined

by the stability of the reference circuits in the device and can be

very effective. At higher frequencies, there are dynamic errors

that become more important than the static reference signals,

and consequently the PSRR is not quite as effective. The values

1M

ACTUAL

VOLTAGE TO FREQUENCY

TRANSFER REL ATION

600ppm

600ppm

IDEAL RELATION

of PSRR are typically 0 ± 20 ppm/% at 10 kHz full-scale frequency

(R

= 40 k, COS = 3300 pF). At 100 kHz (RIN = 40 k, COS =

IN

330 pF) the PSRR is typically +80 ± 40 ppm/%, and at 1 MHz

(R

= 16.9 k, COS = 51 pF) the PSRR is +350 ± 50 ppm/%.

IN

This information is summarized graphically in

Figure 18.

OTHER CIRCUIT CONSIDERATIONS

The input amplifier connected to Pin 1, Pin 2, and Pin 3 is not a

OUTPUT FREQUENCY (Hz)

1k

standard operational amplifier. Rather, the design has been

optimized for simplicity and high speed. The single largest

difference between this amplifier and a normal op amp is the lack

10mV

Figure 17. Exaggerated Nonlinearity at 1 MHz Full Scale

INPUT VOLTAGE

10V

00797-018

of an integrator (or level shift) stage. Consequently, the voltage on

the output (Pin 1) must always be more positive than 2 V below the

inputs (Pin 2 and Pin 3). For example, in the F-to-V conversion

mode (

Figure 13) the noninverting input of the op amp (Pin 2)

is grounded, which means that the output (Pin 1) is not able to

go below –2 V. Normal operation of the circuit shown in

Figure 13

never calls for a negative voltage at the output, but users can

1k

imagine an arrangement calling for a bipolar output voltage (for

example, ±10 V) by connecting an extra resistor from Pin 3 to a

positive voltage. However, this does not work.

100

PSRR (ppm/%)

Care should be taken under conditions where a high positive

input voltage exists at or before power up. These situations can

cause a latch up at the integrator output (Pin 1). This is a

10

nondestructive latch and, as such, normal operation can be

restored by cycling the power supply. Latch up can be prevented

by connecting two diodes (for example, 1N914 or 1N4148) as

10k 100k 1M

FULL SCAL E FREQUENCY (Hz )

Figure 18. PSRR vs. Full-Scale Frequency

00797-019

shown in

below Pin 2.

Figure 11, thereby preventing Pin 1 from swinging

Rev. D | Page 14 of 20

Page 15

AD650

A

A second major difference is that the output only sinks 1 mA to

the negative supply. There is no pulldown stage at the output

other than the 1 mA current source used for the V-to-F

conversion. The op amp sources a great deal of current from the

positive supply, and it is internally protected by current limiting.

The output of the op amp can be driven to within 3 V of the

positive supply when it is not sourcing external current. When

sourcing 10 mA the output voltage can be driven to within 6 V

of the positive supply.

A third difference between this op amp and a normal device is

that the inverting input, Pin 3, is bias current compensated and

the noninverting input is not bias-current compensated. The

bias current at the inverting input is nominally zero, but can be

as much as 20 nA in either direction. The noninverting input

typically has a bias current of 40 nA that always flows into the

node (an npn input transistor). Therefore, it is not possible to

match input voltage drops due to bias currents by matching

input resistors.

The bipolar offset current is activated by connecting a 1.24 k

resistor between Pin 4 and the negative supply. The resulting

current delivered to the op amp noninverting input is nominally

0.5 mA and has a tolerance of ±10%. This current is then used

to provide an offset voltage when Pin 2 is tied to ground through

a resistor. The 0.5 mA that appears at Pin 2 is also flowing

through the 1.24 k resistor. An external resistor is used to

activate the bipolar offset current source to provide the lowest

tolerance and temperature drift of the resulting offset voltage.

It is possible to use other values of resistance between Pin 4 and

−V

to obtain a bipolar offset current different from 0.5 mA.

S

Figure 19 shows the relationship between the bipolar offset

current and the value of the resistor used to activate the source.

µ

1000

800

The op amp has provisions for trimming the input offset

voltage. A potentiometer of 20 k is connected from Pin 13 to

Pin 14 and the wiper is connected to the positive supply

through a 250 k resistor. A potential of about 0.6 V is

established across the 250 k resistor, and the 3 A current is

injected into the null pins. It is also possible to null the op amp

offset voltage by using only one of the null pins and by using a

bipolar current either into or out of the null pin. The amount of

current required is very small—typically less than 3 A. This

technique is shown in the

Applications section of this data

sheet; the autozero circuit uses this technique.

600

400

BIPOLAR OFFSET CURRENT

200

500 4000

1000 1500 2000 2500 3000 3500

EXTERNAL RESI STOR

Figure 19. Bipolar Offset Current vs. External Resistor

Ω

00797-020

Rev. D | Page 15 of 20

Page 16

AD650

T

APPLICATIONS

DIFFERENTIAL VOLTAGE-TO-FREQUENCY CONVERSION

The circuit in Figure 20 accepts a true floating differential input

signal. The common-mode input, V

+15 V to −5 V with respect to analog ground. The signal input,

V

, can be ±5 V with respect to the common-mode input. Both

IN

inputs are low impedance; the source that drives the commonmode input must supply the 0.5 mA drawn by the bipolar offset

current source, and the source that drives the signal input must

supply the integration current.

If less common-mode voltage range is required, then a lower

voltage Zener can be used. For example, if a 5 V Zener is used,

the V

input can be in the range +10 V to −5 V. If the Zener is

CM

not used at all, the common-mode range is ±5 V with respect to

analog ground. If no Zener is used, the 10 k pulldown resistor

is not needed and the integrator output (Pin 1) is connected

directly to the comparator input (Pin 9).

AUTOZERO CIRCUIT

In order to exploit the full dynamic range of the AD650 VFC,

very small input voltages need to be converted. For example, a

six decade dynamic range based on a full scale of 10 V requires

accurate measurement of signals down to 10 V. In these

situations, a well-controlled input offset voltage is imperative. A

constant offset voltage does not affect dynamic range but simply

shifts all of the frequency readings by a few hertz. However, if

the offset should change, it is not possible to distinguish

between a small change in a small input voltage and a drift of

the offset voltage. Therefore, the usable dynamic range is less.

The circuit shown in

of the op amp offset voltage. The circuit uses an AD582 sample-

Figure 21 provides automatic adjustment

, can be in the range

CM

and-hold amplifier to control the offset, and the input voltage to

the VFC is switched between ground and the signal to be

measured via an

AD7512DI analog switch. The offset of the

AD650 is adjusted by injecting a current into—or drawing a

current out of—Pin 13. Note that only one of the offset null pins

is used. During the VFC norm mode, the SHA is in the hold

mode and the hold capacitor is very large, 0.1 F, which holds

the AD650 offset constant for a long period of time.

When the circuit is in the autozero mode, the SHA is in sample

mode and behaves like an op amp. The circuit is a variation of

the classical two amplifier servo loop, where the output of the

device under test (DUT)—here the DUT is the AD650 op

amp—is forced to ground by the feedback action of the control

amplifier—the SHA. Because the input of the VFC circuit is

connected to ground during the autozero mode, the input

current that can flow is determined by the offset voltage of the

AD650 op amp. Because the output of the integrator stage is

forced to ground, it is known that the voltage is not changing (it

is equal to ground potential). Therefore, if the output of the

integrator is constant, its input current must be zero, so the

offset voltage has been forced to be zero. Note that the output of

the DUT could have been forced to any convenient voltage

other than ground. All that is required is that the output voltage

be known to be constant. Note also that the effect of the bias

current at the inverting input of the AD650 op amp is also

mulled in this circuit. The 1000 pF capacitor shunting the

200 k resistor is compensation for the two amplifier servo

loop. Two integrators in a loop require a single zero for

compensation. The 3.6 k resistor from Pin 1 of the AD650 to

the negative supply is not part of the autozero circuit, but rather,

it is required for VFC operation at 1 MHz.

10V ZENER 1N52 40

1 14

C

I

V

CM

INPU

40kΩ

V

IN

330pF

NOTES

1. V

IS THE COMMON MODE INPUT +15V TO –5V WITH RESPECT TO ANALOG GROUND.

CM

IS THE SIGNAL INPUT ±5V WITH RESPECT TO VCM.

2. V

IN

1.24kΩ

C

OS

2

3

4

5

6

7

1000pF

10kΩ

–V

FREQ

S

OUT

AMP

ONE

SHOT

OP

IN

OUT

–V

0kHz TO 100kHz

INPUT

OFFSET

S1

1mA

–0.6V

S

FREQUENCY

OUTPUT

TRIM

COMP

13

12

11

10

9

8

1kΩ

20kΩ

250kΩ

10kΩ

+15V

+

0.1µF

–

GND

+

0.1µF

–

–15V

–

1µF

+

GND

+5V

00797-021

Figure 20. Differential Input

Rev. D | Page 16 of 20

AD650

Page 17

AD650

PHASE-LOCKED LOOP F/V CONVERSION

Although the F/V conversion technique shown in Figure 13 is

quite accurate and uses only a few extra components, it is very

limited in terms of signal frequency response and carrier feedthrough. If the carrier (or input) frequency changes

instantaneously, then the output cannot change very rapidly due

to the integrator time constant formed by C

and RIN. While it

INT

is possible to decrease the integrator time constant to provide

faster settling of the F-to-V output voltage, the carrier

feedthrough then becomes larger. For signal frequency response

in excess of 2 kHz, a phase-locked F/V conversion technique

such as the one shown in

Figure 22 is recommended.

+V

1

2

3

4

1

–V

S

2

3

4

5 10

6 9

7 8

+V

S

CONTROL

INPUT

–5 VOLTS VFC NORMAL

GND AUTO ZERO

AD7512

10

AD582

5

–V

S

S

9

8

7

CAP

6

0.1µF

INPUT

VOLTAGE

14

13

12

11

+V

S

OUTPUT

10kΩ

1000pF

16.9kΩ

+IN

3

–IN

2

Figure 21. Autozero Circuit

1kΩ

200kΩ

NULL

BIPOLAR

OFFSET

In a phase-locked loop circuit, the oscillator is driven to a

frequency and phase equal to an input reference signal. In

applications such as a synthesizer, the oscillator output

frequency is first processed through a programmable “divide by

N” before being applied to the phase detector as feedback. Here

the oscillator frequency is forced to be equal to “N times” the

reference frequency. It is this frequency output that is the

desired output signal and not a voltage. In this case, the AD650

offers compact size and wide dynamic range.

3.6kΩ

1000pF

14 13 1

OP

AMP

0.5mA

–15V +15V GND

54

NULL

1mA

–V

0.1µF

–V

S

9

COMPARATOR

–0.6 VOLT

+V

S

COMPARATOR

INPUT

ANALOG

GND

S

1112

0.1µF 51 pF

FREQUENCY

ONE

SHOT

AD650

C

6

OUTPUT

DIGITAL

GND

OS

FREQUENCY

OUTPUT

8

500Ω

10

10µF

+

+5V

00797-022

1

D TYPE FLIP FLOP

1012

D

INPUT

CARRIER

INPUT

CARRIER

11

3

1PR1

1/2 7474

CLOCK

1

1

4 12

D2PR

CLEAR

2

1/2 7474

CLOCK

2

AD650

1MHz FULL-SCALE

R

IN

C

OS

FREQ

C

INT

OUT

(UNIPOLAR INPUT)

Figure 22. Phase-Locked Loop F/V Conversion

Q

CLEAR

13

= 16.9k

= 51pF

= 1000pF

9

1

1

NAND XOR

36

1/4 7400

2

5

Q

2

4

7486

125

SD211

DMOSF ET

71.5kΩ

590kΩ

VOLTS INPUT

TO AD650

–15V

51pF

G

D

S

B

Rev. D | Page 17 of 20

C

140kΩ

15pF

AD509

OP AMP

VOLTAGE

OUTPUT

R

F/V

00797-023

Page 18

AD650

×

π

×

In signal recovery applications of a PLL, the desired output

signal is the voltage applied to the oscillator. In these situations,

a linear relationship between the input frequency and the

output voltage is desired; the AD650 makes a superb oscillator

for FM demodulation. The wide dynamic range and

outstanding linearity of the AD650 VFC allow simple

embodiment of high performance analog signal isolation or

telemetry systems. The circuit shown in

phase detector that also provides proper feedback in the event

of unequal frequencies. Such phase-frequency detectors (PFDs)

are available in integrated form. For a full discussion of phaselock loop circuits see “Phase Lock Techniques,” 3

F.M. Gardner, (John Wiley & Sons, Inc., 1979).

An analysis of this circuit must begin at the 7474 Dual D flip

flop. When the input carrier matches the output carrier in both

phase and frequency, the Q outputs of the flip flops rise at

exactly the same time. With two zeros, and then two ones on

the inputs of the exclusive or (XOR) gate, the output remains

low keeping the DMOS FET switched off. Also, the NAND gate

goes low resetting the flip-flops to zero. Throughout this entire

cycle, the DMOS integrator gate remains off, allowing the

voltage at the integrator output to remain unchanged from the

previous cycle. However, if the input carrier leads the output

carrier by a few degrees, the XOR gate is turned on for the short

time span that the two signals are mismatched. Because Q

low during the mismatch time, a negative current is fed into the

integrator, causing its output voltage to rise. This in turn

increases the frequency of the AD650 slightly, driving the

system towards synchronization. In a similar manner, if the

input carrier lags the output carrier, the integrator is forced

down slightly to synchronize the two signals.

Using a mathematical approach, the ±25 A pulses from the

phase detector are incorporated into the phase-detector gain (K

A25

=dK

2

π

6−

×=

Also, the V/F converter is configured to produce 1 MHz in

response to a 10 V input so its gain (Ko) is

6

Hz1012

K (10)

O

××π

=

V10

×=

The dynamics of the phase relationship between the input and

output signals can be characterized as a second order system

with natural frequency (ω

).

n

Figure 22 uses a digital

radian/amperes104

(9)

radians

5

103.6

secvolt

×

rd

Edition, by

is

2

).

d

KK

o

=ω

n

d

(11)

C

and damping factor (ζ) is

KCKR

o

d

=ζ

For the values shown in

(12)

2

Figure 22, these relations simplify to a

natural frequency of 35 kHz with a damping factor of 0.8.

For a simple approach to determine component values for other

PLL frequencies and VFC full-scale voltage, follow these steps:

1.

Determine K

maximum input carrier frequency f

maximum output voltage V

K

=

o

2.

Calculate a value for C based upon the desired loop

bandwidth f

of the output signal. The loop bandwidth (f

maximum carrier frequency (f

(in units of radians per volt second) from the

o

(in hertz) and the

MAX

.

MAX

2

F

MAX

V

(13)

MAX

. Note that this is the desired frequency range

n

n

). The signal can be very

MAX

) is not the

narrow even though it is transmitted over a 1 MHz carrier.

K

o

C

2

f

n

where:

units = farads

C

f

units = hertz

n

K

units = rad/volt × sec

o

−

101

××=

FV

7

(14)

secRad

×

3. Calculate R to yield a damping factor of approximately 0.8

using this equation:

f

n

××=

R

where:

units = ohms

R

f

units = hertz

n

K

units = rad/volt × sec

o

105.2

o

Ω×

Rad

6

(15)

VK

If in actual operation the PLL overshoots or hunts excessively

before reaching a final value, the damping factor can be raised

by increasing the value of R. Conversely, if the PLL is

overdamped, a smaller value of R should be used.

Rev. D | Page 18 of 20

Page 19

AD650

C

R

.

OUTLINE DIMENSIONS

0.005 (0.13) MIN

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

ONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FO

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

Figure 23. 14-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP]

Dimensions shown in inches and (millimeters)

0.775 (19.69)

0.750 (19.05)

0.735 (18.67)

14

1

PIN 1

0.100 (2.54)

BSC

0.210

(5.33)

MAX

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

0.070 (1.78)

0.050 (1.27)

0.045 (1.14)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

CORNER LEADS MAY BE CONFIGURED AS WHOLE OR HALF LEADS.

COMPLIANT TO JEDEC STANDARDS MS-001-AA

Figure 24. 14-Lead Plastic Dual In-Line Package [PDIP]

Dimensions shown in inches and (millimeters)

0.080 (2.03) MAX

14

1

0.100 (2.54)

BSC

0.765 (19.43) MAX

0.070 (1.78)

0.030 (0.76)

8

0.280 (7.11)

0.250 (6.35)

0.240 (6.10)

7

0.015

(0.38)

MIN

SEATING

PLANE

0.005 (0.13)

MIN

8

7

(D-14)

(N-14)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

GAUGE

PLANE

MAX

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.430 (10.92)

MAX

0.195 (4.95)

0.130 (3.30)

0.115 (2.92)

0.014 (0.36)

0.010 (0.25)

0.008 (0.20)

Rev. D | Page 19 of 20

Page 20

AD650

0.048 (1.22 )

0.048 (1.22)

0.042 (1.07)

0.020

(0.51)

0.042 (1.07)

3

4

PIN 1

IDENTIFIER

TOP VIEW

(PINS DOWN)

8

9

0.356 (9.04)

R

0.350 (8.89)

0.395 (10.03)

0.385 (9.78)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

0.056 (1.42)

0.042 (1.07)

19

18

0.050

(1.27)

BSC

14

13

SQ

SQ

COMPLIANT TO JEDEC STANDARDS MO-047-AA

0.180 (4.57)

0.165 (4.19)

0.120 (3.04)

0.090 (2.29)

0.20 (0.51)

MIN

0.021 (0.53)

0.013 (0.33)

0.032 (0.81)

0.026 (0.66)

0.045 (1.14)

0.025 (0.64)

0.020 (0.50)

0.330 (8.38)

0.290 (7.37)

R

R

BOTTOM

VIEW

(PINS UP)

Figure 25. 20-Lead Plastic Leaded Chip Carrier [PLCC]

(P-20A)

Dimensions shown in inches and (millimeters)

ORDERING GUIDE

Gain Tempco

1 MHz

Linearity

Model

ppm/°C

100 kHz

AD650JN 150 typ 0.1% typ 0°C to 70°C 14-Lead Plastic Dual In-Line Package [PDIP] N-14

AD650JNZ

1

150 typ 0.1% typ 0°C to 70°C 14-Lead Plastic Dual In-Line Package [PDIP] N-14

AD650KN 150 typ 0.1% max 0°C to 70°C 14-Lead Plastic Dual In-Line Package [PDIP] N-14

AD650KNZ

1

150 typ 0.1% max 0°C to 70°C 14-Lead Plastic Dual In-Line Package [PDIP] N-14

AD650JP 150 typ 0.1% typ 0°C to 70°C 20-Lead Plastic Leaded Chip Carrier [PLCC] P-20A

AD650JPZ

1

150 typ 0.1% typ 0°C to 70°C 20-Lead Plastic Leaded Chip Carrier [PLCC] P-20A

AD650AD 150 max 0.1% typ −25°C to +85°C 14-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP] D-14

AD650BD 150 max 0.1% max −25°C to +85°C 14-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP] D-14

AD650SD 200 max 0.1% max −55°C to +125°C 14-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP] D-14

AD650SD/883B 200 max 0.1% max −55°C to +125°C 14-Lead Side-Brazed Ceramic Dual In-Line Package [SBDIP] D-14

AD650ACHIPS Die

1

Z = Pb-free part.

Temperature

Range

Package Description

Package

Option

©2006 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

C00797-0-3/06(D)

Rev. D | Page 20 of 20

Loading...

Loading...