Page 1

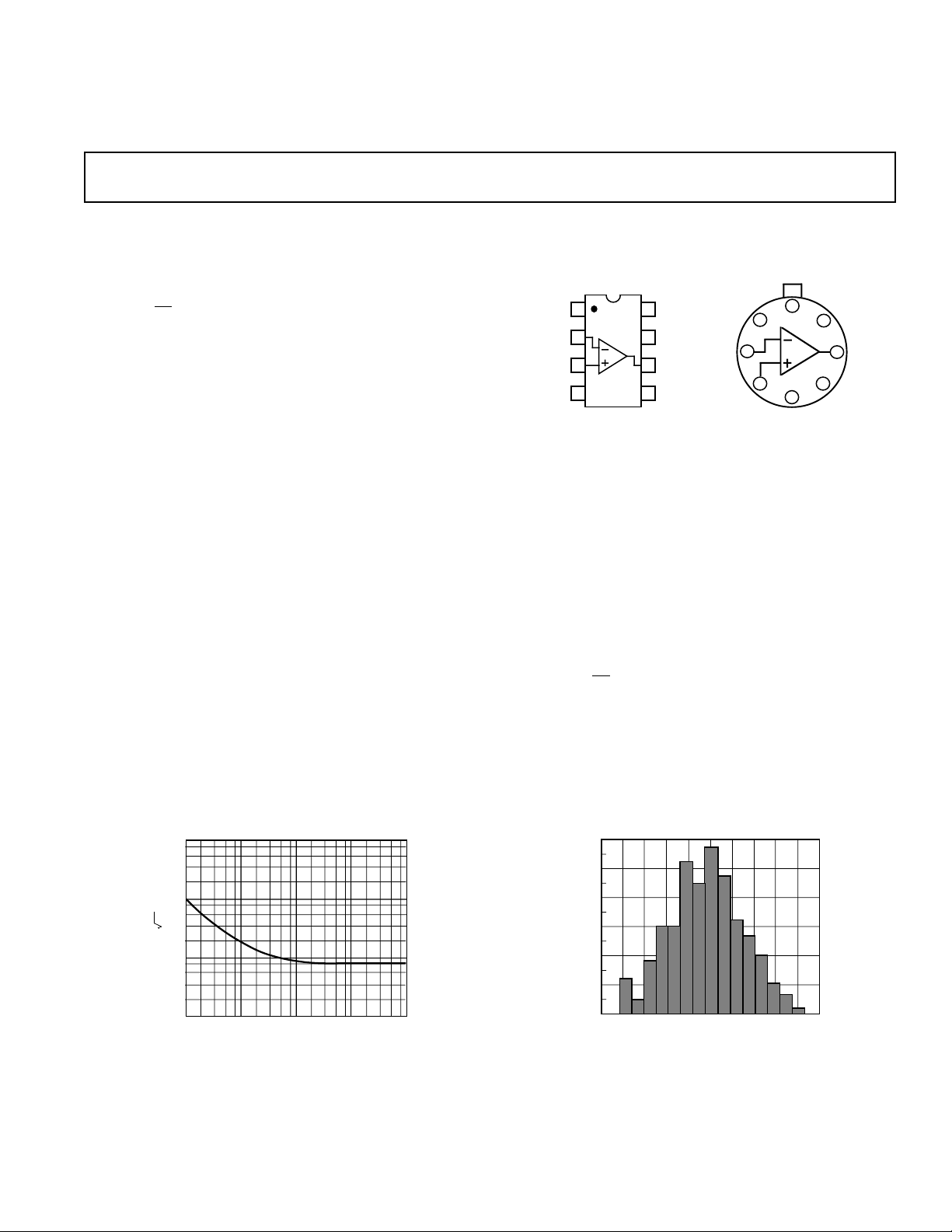

Low Noise, Low Drift

INPUT OFFSET VOLTAGE DRIFT– µV/°C

–0.5–2.0

1.0 1.5 2.5

–2.5 –1.5 –1.0

0.5 2.0

0.0

NUMBER OF UNITS

0

15

5

10

30

25

20

OUTPUT

V

–

NOTE: CASE IS CONNECTED

TO PIN 8

OFFSET

NULL

IN+

IN–

CASE

3

4

5

6

7

8

AD645

1

2

OFFSET

NULL

+V

8

7

6

5

TOP VIEW

AD645

1

4

2

3

NC = NO CONNECT

OFFSET

NULL

–IN

NC

OUTPUT

OFFSET

NULL

–V

S

+IN

+V

S

a

FEATURES

Improved Replacement for Burr-Brown

OPA-111 and OPA-121 Op Amp

LOW NOISE

2 mV p-p max, 0.1 Hz to 10 Hz

10 nV/√

11 fA p-p Current Noise 0.1 Hz to 10 Hz

HIGH DC ACCURACY

250 mV max Offset Voltage

1 mV/8C max Drift

1.5 pA max Input Bias Current

114 dB Open-Loop Gain

Available in Plastic Mini-DIP, 8-Pin Header Packages, or

APPLICATIONS

Low Noise Photodiode Preamps

CT Scanners

Precision I-V Converters

PRODUCT DESCRIPTION

The AD645 is a low noise, precision FET input op amp. It offers the pico amp level input currents of a FET input device

coupled with offset drift and input voltage noise comparable to a

high performance bipolar input amplifier.

The AD645 has been improved to offer the lowest offset drift in

a FET op amp, 1 µV/°C. Offset voltage drift is measured and

trimmed at wafer level for the lowest cost possible. An inherently low noise architecture and advanced manufacturing techniques result in a device with a guaranteed low input voltage

noise of 2 µV p-p, 0.1 Hz to 10 Hz. This level of dc performance

along with low input currents make the AD645 an excellent

choice for high impedance applications where stability is of

prime concern.

Hz max at 10 kHz

Chip Form

1k

IMPROVED

DRIFT

FET Op Amp

AD645

CONNECTION DIAGRAMS

8-Pin Plastic Mini-DIP

(N) Package

The AD645 is available in six performance grades. The AD645J

and AD645K are rated over the commercial temperature range

of 0°C to +70°C. The AD645A, AD645B, and the ultraprecision AD645C are rated over the industrial temperature

range of –40°C to +85°C. The AD645S is rated over the military

temperature range of –55°C to +125°C and is available

processed to MIL-STD-883B.

The AD645 is available in an 8-pin plastic mini-DIP, 8-pin

header, or in die form.

PRODUCT HIGHLIGHTS

1. Guaranteed and tested low frequency noise of 2 µV p-p max

and 20 nV/√

Hz at 100 Hz makes the AD645C ideal for low

noise applications where a FET input op amp is needed.

2. Low V

drift of 1 µV/°C max makes the AD645C an excel-

OS

lent choice for applications requiring ultimate stability.

3. Low input bias current and current noise (11 fA p-p 0.1 Hz to

10 Hz) allow the AD645 to be used as a high precision

preamp for current output sensors such as photodiodes, or as

a buffer for high source impedance voltage output sensors.

TO-99 (H) Package

100

nV/ Hz

10

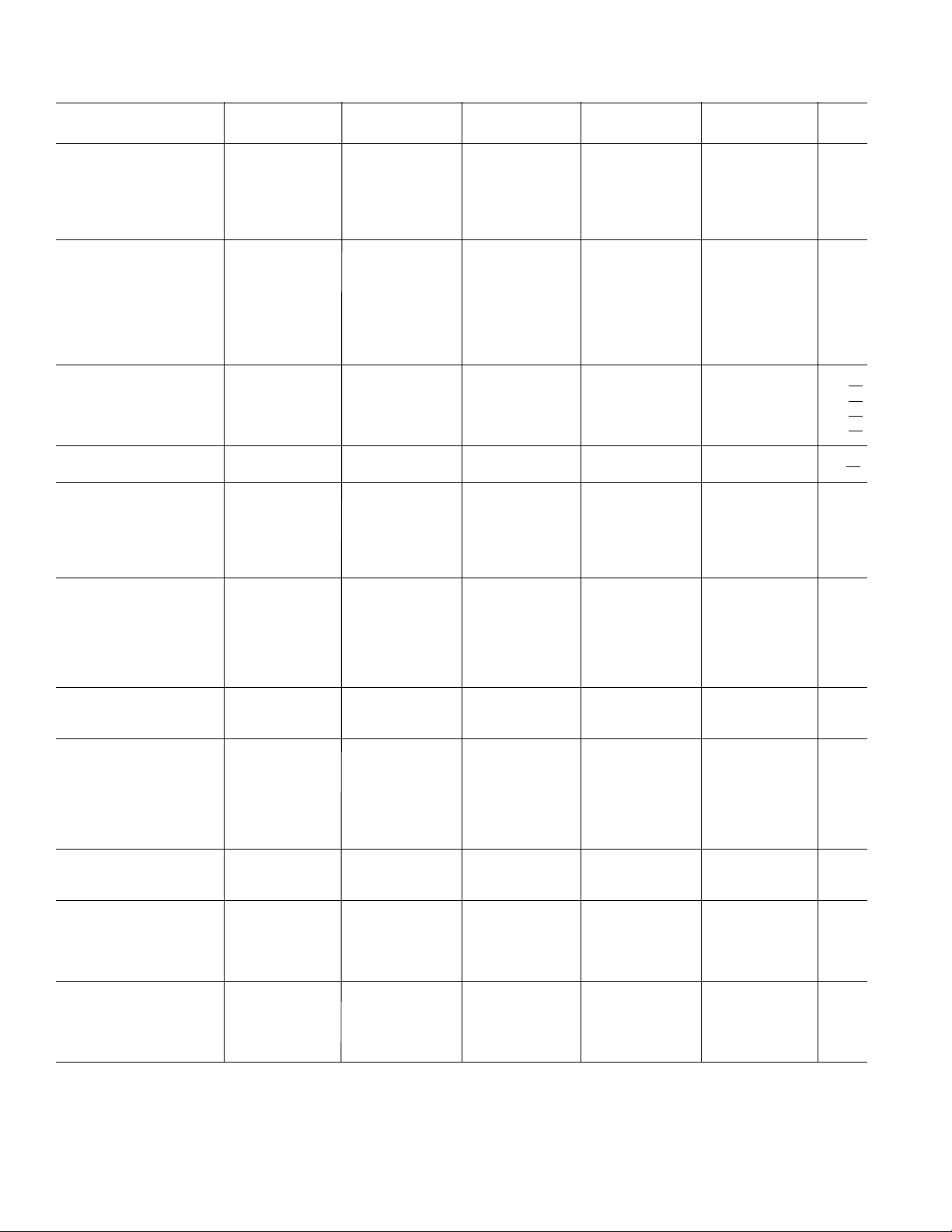

VOLTAGE NOISE SPECTRAL DENSITY

1.0

FREQUENCY – Hz

Figure 1. AD645 Voltage Noise Spectral Density vs.

Frequency

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

1k1 10 100

10k

Figure 2. Typical Distribution of Average Input Offset

Voltage Drift (196 Units)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

AD645–SPECIFICATIONS

(@ +258C, and 615 V dc, unless otherwise noted)

Model AD645J/A AD645K/B AD645C AD645S

Conditions

INPUT OFFSET VOLTAGE

1

1

Min Typ Max Min Typ Max Min Typ Max Min Typ Max Units

Initial Offset 100 500 50 250 50 250 100 500 µV

Offset T

MIN–TMAX

300 1000 100 400 75 300 500 1500 µV

Drift (Average) 3 10/5 1 5/2 0.5 1 4 10 µV/°C

vs. Supply (PSRR) 90 110 94 110 94 110 90 110 dB

vs. Supply T

INPUT BIAS CURRENT

2

MIN–TMAX

100 90 100 90 100 86 95 dB

Either Input VCM = 0 V 0.7/1.8 3/5 0.7/1.8 1.5/3 1.8 3 1.8 5 pA

Either Input

@ T

MAX

VCM = 0 V 16/115 16/115 115 1800 pA

Either Input VCM = +10 V 0.8/1.9 0.8/1.9 1.9 1.9 pA

Offset Current VCM = 0 V 0.1 1.0 0.1 0.5 0.1 0.5 0.1 1.0 pA

Offset Current

@ T

MAX

VCM = 0 V 2/6 2/6 6 100 pA

INPUT VOLTAGE NOISE 0.1 to 10 Hz 1.0 3.0 1.0 2.5 1 2 1.0 3.3 µV p-p

f = 10 Hz 20 50 20 40 20 40 20 50 nV/√Hz

f = 100 Hz 10 30 10 20 10 20 10 30 nV/√Hz

f = 1 kHz 9 15 9 12 9 12 9 15 nV/√Hz

f = 10 kHz 8 10 8 10 8 10 8 10 nV/√Hz

INPUT CURRENT NOISE f = 0.1 to 10 Hz 11 20 11 15 11 15 11 20 fA p-p

f = 0.1 thru 20 kHz 0.6 1.1 0.6 0.8 0.6 0.8 0.6 1.1 fA/√Hz

FREQUENCY RESPONSE

Unity Gain, Small Signal 2 2 2 2 MHz

Full Power Response VO = 20 V p-p

R

= 2 kΩ 16 32 16 32 16 32 16 32 kHz

Slew Rate, Unity Gain V

SETTLING TIME

3

LOAD

= 20 V p-p

OUT

R

= 2 kΩ 12 12 12 12 V/µs

LOAD

To 0.1% 6 6 6 6 µs

To 0.01% 8 8 8 8 µs

Overload Recovery

4

50% Overdrive 5 5 5 5 µs

Total Harmonic f = 1 kHz

Distortion R

LOAD

≥ 2 kΩ

VO = 3 V rms 0.0006 0.0006 0.0006 0.0006 %

INPUT IMPEDANCE

Differential V

= ±1 V 1012i110

DIFF

12

i110

12

i110

12

i1 ΩipF

Common-Mode 1014i2.2 1014i2.2 1014i2.2 1014i2.2 ΩipF

INPUT VOLTAGE RANGE

Differential

5

±20 ±20 ±20 ±20 V

Common-Mode Voltage ± 10 +11, –10.4 ±10 +11, –10.4 ±10 +11, –10.4 ±10 +11, –10.4 V

Over Max Oper. Range ±10 ±10 ±10 ±10 V

Common-Mode

Rejection Ratio VCM = ±10 V 90 110 94 110 94 110 90 110 dB

T

MIN–TMAX

100 90 100 90 100 86 100 dB

OPEN-LOOP GAIN VO = ±10 V

R

≥ 2 kΩ 114 130 120 130 120 130 114 130 dB

LOAD

T

MIN–TMAX

114 114 110 dB

OUTPUT CHARACTERISTICS

Voltage R

Current V

≥ 2 kΩ±10 ±11 ±10 ±11 ±10 ±11 ±10 ±11 V

LOAD

T

MIN–TMAX

= ±10 V ±5 ± 10 ±5 ±10 ±5 ±10 ±5 ±10 mA

OUT

±10 ±10 ±10 ±10 V

Short Circuit ±15 ±15 ±15 ±15 mA

POWER SUPPLY

Rated Performance ±15 ±15 ± 15 ±15 V

Operating Range ±5 ±18 ±5 ±18 ±5 ±18 ±5 ±18 V

Quiescent Current 3.0 3.5 3.0 3.5 3.0 3.5 3.0 3.5 mA

Transistor Count # of Transistors 62 62 62 62

NOTES

1

Input offset voltage specifications are guaranteed after 5 minutes of operation at TA = +25°C.

2

Bias current specifications are guaranteed maximum at either input after 5 minutes of operation at T

3

Gain = –1, R

4

Defined as the time required for the amplifier’s output to return to normal operation after removal of a 50% overload from the amplifier input.

5

Defined as the maximum continuous voltage between the inputs such that neither input exceeds ±10 V from ground.

LOAD

= 2 kΩ.

= +25°C. For higher temperature, the current doubles every 10°C.

A

All min and max specifications are guaranteed.

Specifications subject to change without notice.

–2–

REV. B

Page 3

AD645

INPUT VOLTAGE NOISE – µV p-p

25

20

15

10

5

0

NUMBER OF UNITS

0.4 1.0

1.2

1.4

1.6

1.80.6 0.8

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation

2

(@ T

8-Pin Header Package . . . . . . . . . . . . . . . . . . . . . . 500 mW

8-Pin Mini-DIP Package . . . . . . . . . . . . . . . . . . . . 750 mW

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±V

Output Short Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

Storage Temperature Range (H) . . . . . . . . . –65°C to +150°C

Storage Temperature Range (N) . . . . . . . . . –65°C to +125°C

Operating Temperature Range

AD645J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

1

= +25°C)

A

and –V

S

AD645A/B/C . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

AD645S . . . . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Lead Temperature Range

(Soldering 60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . +300°C

NOTES

1

S

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated

S

in the operational section of this specification is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device

reliability.

2

Thermal Characteristics:

8-Pin Plastic Mini-DIP Package: θJA = 100°C/Watt

8-Pin Header Package: θJA = 200°C/Watt

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD645 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

METALIZATION PHOTOGRAPH

Dimensions shown in inches and (mm).

Contact factory for latest dimensions.

Model

ORDERING GUIDE

1

Temperature Range Package Option

2

AD645JN 0°C to +70°C N-8

AD645KN 0°C to +70°C N-8

AD645AH –40°C to +85°C H-08A

AD645BH –40°C to +85°C H-08A

AD645CH –40°C to +85°C H-08A

AD645SH/883B –55°C to +125°C H-08A

NOTES

1

Chips are also available.

2

N = Plastic Mini-DIP; H = Metal Can.

+V

S

800

700

600

500

400

300

NUMBER OF UNITS

200

100

0

–1.0 0.8–0.4 –0.2 0.0 0.4 0.6 1.0–0.6 0.2–0.8

Figure 4. Typical Distribution of Input

Offset Voltage (1855 Units)

REV. B

AD645

4

–V

S

7

1

5

10k

V ADJUST

OS

6

2

3

Figure 3. AD645 Offset Null Configuration

120

110

100

90

80

70

60

50

40

NUMBER OF UNITS

30

20

10

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

INPUT OFFSET VOLTAGE – mV

Figure 5. Typical Distribution of Input

Bias Current (576 Units)

INPUT BIAS CURRENT – pA

Figure 6. Typical Distribution of 0.1 Hz

to 10 Hz Voltage Noise (202 Units)

–3–

Page 4

AD645–Typical Characteristics

VOLTAGE NOISE SPECTRAL DENSITY @ 1kHz – nV/

√

Hz

100

1k 10k 100k

1.0

10

100

SOURCE RESISTANCE – Ω

1M 10M 100M

1k

SOURCE

RESISTANCE

NOISE OF AD645

AND RESISTOR

RESISTOR NOISE

ONLY

(@ +258C, 615 V unless otherwise noted)

100

Hz

√

10

1.0

CURRENT NOISE SPECTRAL DENSITY – fA/

0.1

1

100

10

1k 10k 100k

FREQUENCY – Hz

Figure 7. Current Noise Spectral

Density vs. Frequency

1k

100

NOISE BANDWIDTH: 0.1 to 10Hz

1k

100

10

VOLTAGE NOISE SPECTRAL DENSITY – nV/ Hz

0

1M

1 10 100 1k 10k 100k

FREQUENCY – Hz

Figure 8. Voltage Noise Spectral

Density vs. Frequency

1000

R = 10MΩ

Hz

100

10

VOLTAGE NOISE SPECTRAL DENSITY – nV

1

0.1

1.0

10 100

FREQUENCY – Hz

S

R = 1MΩ

S

R = 100kΩ

S

R = 100Ω

S

1k 10k

Figure 9. Voltage Noise Spectral

Density vs. Frequency for Various

100k

Source Resistances

25

f = 1kHz

o

20

Hz

√

nV/

–

15

CURRENT NOISE

100

10

1

Hz

√

10

INPUT VOLTAGE NOISE – µV p-p

1.0

10310

4

5

10

SOURCE RESISTANCE – Ω

7

6

10

8

10

10

Figure 10. Input Voltage Noise vs.

Source Resistance

10

VOLTAGE NOISE

10

5

–

–

9

60

VOLTAGE NOISE

040–20

20 40 60 80 100 120 140

TEMPERATURE – C

Figure 11. Voltage and Current

Noise Spectral Density vs.

Temperature

50

T = +25 C

A

V = ±15V

25

0

–

25

CHANGE IN INPUT OFFSET VOLTAGE – µV

–

50

0

1

WARM-UP TIME – Minutes

S

2345

Figure 13. Change in Input Offset

Voltage vs. Warmup Time

150

75

TA = 25°C TO TA = 85°C

0

–

75

CHANGE IN INPUT OFFSET VOLTAGE – µV

150–

012 345

TIME FROM THERMAL SHOCK – Minutes

Figure 14. Change in Input Offset

Voltage vs. Time from Thermal

Shock

CURRENT NOISE – fA/

0.1

0.01

Figure 12. Voltage Noise Spectral

Density @ 1 kHz vs. Source

Resistance

–

9

10

–

10

10

–

11

10

–

12

10

INPUT BIAS CURRENT – Amps

–

13

10

–

14

10

–– –

60 40 20 0 20 40 60

INPUT

BIAS

CURRENT

TEMPERATURE – C

INPUT

OFFSET

CURRENT

80 100

140

120

Figure 15. Input Bias and Offset

Currents vs. Temperature

–

9

10

–

10

10

–

11

10

–

12

10

–

13

INPUT OFFSET CURRENT – Amps

10

–

14

10

–4–

REV. B

Page 5

AD645

100 1k

10k 100k

FREQUENCY – Hz

1M 10M

100

80

60

40

20

0

120

101

COMMON-MODE REJECTION – dB

SLEW RATE – Volts/µs

60 40

20

0

20

40 60 80 100 120 140

1.0

2.0

3.0

4.0

3.0

2.0

1.0

GAIN-BANDWIDTH PRODUCT – MHz

0

TEMPERATURE – 8 C

–––

GAIN-BANDWIDTH

SLEW RATE

35

30

25

20

15

10

5

0

OUTPUT VOLTAGE – Volts p-p

FREQUENCY – Hz

1M1k 10k 100k

10

TA = +25°C

V

= ±15V

S

H PACKAGE

1.0

INPUT BIAS CURRENT – pA

0.1

20–15–10–5

–

51015

0

COMMON MODE VOLTAGE – Volts

Figure 16. Input Bias Current vs.

Common-Mode Voltage

120

110

100

90

COMMON-MODE REJECTION – dB

80

70

–– –

10

15 15

COMMON MODE VOLTAGE – Volts

0510

5

Figure 19. Common-Mode

Rejection vs. Input Common-Mode

Voltage

120

100

80

60

40

POWER SUPPLY REJECTION – dB

20

0

–

PSRR

100 1k 10k 100k

101

FREQUENCY – Hz

+

PSRR

1M 10M

Figure 17. Power Supply Rejection

vs. Frequency

1M 10M

–

45

–

90

–

135

–

180

110

100

80

60

40

OPEN-LOOP GAIN – dB

20

0

–

20

100

10

PHASE

GAIN

1k 10k 100k

FREQUENCY – Hz

Figure 20. Open-Loop Gain and

Phase Shift vs. Frequency

Figure 18. Common-Mode

Rejection vs. Frequency

PHASE SHIFT – Degrees

Figure 21. Gain-Bandwidth Product

and Slew Rate vs. Temperature

4.0

3.0

2.0

GAIN-BANDWIDTH PRODUCT – MHz

1.0

0 5 10 15 20

Figure 22. Gain-Bandwidth and

Slew Rate vs. Supply Voltage

REV. B

SLEW RATE

GAIN-BANDWIDTH

SUPPLY VOLTAGE – ±Volts

160

V = ±15V

4.0

3.0

SLEW RATE – Volts/µs

2.0

150

140

130

120

OPEN-LOOP GAIN – dB

110

100

–– –

60 40 20 0 20 40 60 80 100 120 140

Figure 23. Open-Loop Gain vs.

Temperature

S

V = ±10V

O

RL = 2kΩ

TEMPERATURE –

–5–

8

C

Figure 24. Large Signal Frequency

Response

Page 6

AD645

AD645–Typical Characteristics

10

8

6

4

0.1% 0.01%

2

0

–

2

–

4

–

6

OUTPUT SWING FROM 0V TO ±VOLTS

–

8

–

10

1.0

ERROR

0.1%

2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

0.01%

SETTLING TIME – µs

Figure 25. Output Swing and Error

vs. Settling Time

0.1µF

+

V

S

7

2

V

IN

AD645

3

6

4

0.1µF

–

V

S

RL

2kΩ

V

OUT

C

10pF

100

90

FOR 10V STEP

80

70

60

50

40

SETTLING TIME – µs

30

20

10

0

1

CLOSED-LOOP VOLTAGE GAIN (V/V)

0.01%

0.1%

10

100

1k

Figure 26. Settling Time vs. ClosedLoop Voltage Gain

L

4

3

2

SUPPLY CURRENT – mA

1

0

–60 –40 –20 0 20 40 60 80 100 120 140

TEMPERATURE – 8C

Figure 27. Supply Current vs.

Temperature

Figure 28a. Unity-Gain Follower

5kΩ

0.1µF

+

V

V

IN

5kΩ

2

AD645

3

–

S

7

6

4

0.1µF

V

S

2kΩ

RL

Figure 29a. Unity-Gain Inverter

V

OUT

C

L

10pF

Figure 28b. Unity-Gain Follower

Large Signal Pulse Response

Figure 29b. Unity-Gain Inverter

Large Signal Pulse Response

Figure 28c. Unity-Gain Follower

Small Signal Pulse Response

Figure 29c. Unity-Gain Inverter

Small Signal Pulse Response

–6–

REV. B

Page 7

AD645

V

OUT

=

i

n

2

+

i

f

2

+

i

s

2

Rf

1 + s (Cf ) Rf

2

+

en

2

1 +

Rf

Rd

1 + s (Cd ) Rd

1 + s (Cf ) Rf

2

FREQUENCY – Hz

100 1k 10k 100k101

10nV

100nV

1µV

10µV

SIGNAL BANDWIDTH

NO FILTER

WITH FILTER

e

n

is&i

f

i

n

en

OUTPUT VOLTAGE NOISE – Volts/ Hz

√

Preamplifier Applications

The low input current and offset voltage levels of the AD645 together with its low voltage noise make this amplifier an excellent

choice for preamplifiers used in sensitive photodiode applications. In a typical preamp circuit, shown in Figure 30, the output of the amplifier is equal to:

where:

An equivalent model for a photodiode and its dc error sources is

shown in Figure 31. The amplifier’s input current, I

tribute an output voltage error which will be proportional to the

value of the feedback resistor. The offset voltage error, V

cause a “dark” current error due to the photodiode’s finite

shunt resistance, Rd. The resulting output voltage error, V

equal to:

A shunt resistance on the order of 109 ohms is typical for a

small photodiode. Resistance Rd is a junction resistance which

will typically drop by a factor of two for every 10°C rise in temperature. In the AD645, both the offset voltage and drift are

low, this helps minimize these errors.

Minimizing Noise Contributions

The noise level limits the resolution obtainable from any preamplifier. The total output voltage noise divided by the feedback

resistance of the op amp defines the minimum detectable signal

current. The minimum detectable current divided by the photodiode sensitivity is the minimum detectable light power.

REV. B

10pF

9

10 Ω

GUARD

PHOTODIODE

2

AD645

3

6

8

OPTIONAL 26Hz

OUTPUT

FILTERED

OUTPUT

FILTER

Figure 30. The AD645 Used as a Sensitive Preamplifier

V

= ID (Rf) = Rp (P) Rf

OUT

= photodiode signal current (Amps)

I

D

Rp = photodiode sensitivity (Amp/Watt)

Rf = the value of the feedback resistor, in ohms.

P = light power incident to photodiode surface, in watts.

, will con-

B

, will

OS

, is

E

V

= (1 + Rf/Rd) V

E

PHOTODIODE

Rd

I

D

Cd

50pF

I

B

+ Rf I

OS

Cf

10pF

V

OS

Rf

10 Ω

B

9

OUTPUT

Figure 31. A Photodiode Model Showing DC Error

Sources

Sources of noise in a typical preamp are shown in Figure 32.

The total noise contribution is defined as:

Figure 33, a spectral density versus frequency plot of each

source’s noise contribution, shows that the bandwidth of the

amplifier’s input voltage noise contribution is much greater than

its signal bandwidth. In addition, capacitance at the summing

junction results in a “peaking” of noise gain in this configuration. This effect can be substantial when large photodiodes with

large shunt capacitances are used. Capacitor Cf sets the signal

bandwidth and also limits the peak in the noise gain. Each

source’s rms or root-sum-square contribution to noise is obtained by integrating the sum of the squares of all the noise

sources and then by obtaining the square root of this sum. Minimizing the total area under these curves will optimize the

preamplifier’s overall noise performance.

Cf

10pF

Rf

9

10 Ω

PHOTODIODE

Rd

i

S

Cd

i

S

50pF

en

i

f

i

n

OUTPUT

Figure 32. Noise Contributions of Various Sources

Figure 33. Voltage Noise Spectral Density of the Circuit of

Figure 32 With and Without an Output Filter

An output filter with a passband close to that of the signal can

greatly improve the preamplifier’s signal to noise ratio. The photodiode preamplifier shown in Figure 32—without a bandpass

filter—has a total output noise of 50 µV rms. Using a 26 Hz

single pole output filter, the total output noise drops to 23 µV

rms, a factor of 2 improvement with no loss in signal bandwidth.

Using a “T” Network

A “T” network, shown in Figure 34, can be used to boost the effective transimpedance of an I to V converter, for a given feedback resistor value. Unfortunately, amplifier noise and offset

voltage contributions are also amplified by the “T” network

gain. A low noise, low offset voltage amplifier, such as the

AD645, is needed for this type of application.

–7–

Page 8

AD645

45

°

BSC

0.100

(2.54)

BSC

0.034 (0.86)

0.027 (0.69)

0.045 (1.14)

0.027 (0.69)

0.160 (4.06)

0.110 (2.79)

0.100

(2.54)

BSC

0.200

(5.08)

BSC

6

8

5

7

1

4

2

3

REFERENCE PLANE

BASE & SEATING PLANE

0.335 (8.51)

0.305 (7.75)

0.370 (9.40)

0.335 (8.51)

0.750 (19.05)

0.500 (12.70)

0.045 (1.14)

0.010 (0.25)

0.050

(1.27)

MAX

0.040 (1.02) MAX

0.019 (0.48)

0.016 (0.41)

0.021 (0.53)

0.016 (0.41)

0.185 (4.70)

0.165 (4.19)

0.250 (6.35)

MIN

10pF

R

G

10kΩ

Rf

R

8

10 Ω

i

1.1kΩ

V

OUT

AD645

PHOTODIODE

R

G

V = I R (1 )

OUT+D

f

R

i

Figure 34. A Photodiode Preamp Employing a “T”

Network for Added Gain

A pH Probe Buffer Amplifier

A typical pH probe requires a buffer amplifier to isolate its 10

9

to 10

Ω source resistance from external circuitry. Just such an

6

amplifier is shown in Figure 35. The low input current of the

AD645 allows the voltage error produced by the bias current

and electrode resistance to be minimal. The use of guarding,

shielding, high insulation resistance standoffs, and other such

standard methods used to minimize leakage are all needed to

maintain the accuracy of this circuit.

The slope of the pH probe transfer function, 50 mV per pH unit

at room temperature, has a +3300 ppm/°C temperature coefficient. The buffer of Figure 35 provides an output voltage equal

to 1 volt/pH unit. Temperature compensation is provided by

resistor RT which is a special temperature compensation resistor, part number Q81, 1 kΩ, 1%, +3500 ppm/°C, available from

Tel Labs Inc.

Guarding the input lines by completely surrounding them with a

metal conductor biased near the input lines’ potential has two

major benefits. First, parasitic leakage from the signal line is

reduced, since the voltage between the input line and the guard

is very low. Second, stray capacitance at the input terminal is

minimized which in turn increases signal bandwidth. In the

header or can package, the case of the AD645 is connected to

Pin 8 so that it may be tied to the input potential (when operating as a follower) or tied to ground (when operating as an inverter). The AD645’s positive input (Pin 3) is located next to

the negative supply voltage pin (Pin 4). The negative input (Pin

2) is next to the balance adjust pin (Pin 1) which is biased at a

potential close to that of the negative supply voltage. Note that

any guard traces should be placed on both sides of the board. In

addition, the input trace should be guarded along both of its

edges, along its entire length.

Contaminants such as solder flux, on the board’s surface and on

the amplifier’s package, can greatly reduce the insulation resistance and also increase the sensitivity to atmospheric humidity.

Both the package and the board must be kept clean and dry. An

effective cleaning procedure is to: first, swab the surface with

high grade isopropyl alcohol, then rinse it with deionized water,

and finally, bake it at 80°C for 1 hour. Note that if either polystyrene or polypropylene capacitors are used on the printed circuit board that a baking temperature of 70°C is safer, since both

of these plastic compounds begin to melt at approximately

+85°C.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

TO-99 Header (H) Package

C1398a–24–9/91

0.1µF

0.1µF

°

C

+15V

COM

–15V

pH

PROBE

GUARD

V ADJUST

OS

100kΩ

–

1

4

3

AD645

2

8

+

+V

S

V

S

–V

S

OUTPUT

5

6

7

V

S

1VOLT/pH UNIT

19.6kΩ

RT

1kΩ

+3500ppm/

Figure 35. A pH Probe Amplifier

Circuit Board Notes

The AD645 is designed for through hole mount into PC boards.

Maintaining picoampere level resolution in that environment

requires a lot of care. Since both the printed circuit board and

the amplifier’s package have a finite resistance, the voltage difference between the amplifier’s input pin and other pins (or

traces on the PC board) will cause parasitic currents to flow into

(or out of) the signal path. These currents can easily exceed the

1.5 pA input current level of the AD645 unless special precautions are taken. Two successful methods for minimizing leakage

are: guarding the AD645’s input lines and maintaining adequate

insulation resistance.

–8–

PIN 1

0.210

(5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

Plastic Mini-DIP (N) Package

8

1

0.430 (10.92)

0.348 (8.84)

0.100

(2.54)

BSC

5

4

0.070 (1.77)

0.045 (1.15)

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

PRINTED IN U.S.A.

REV. B

Loading...

Loading...