Page 1

Low Cost

a

FEATURES

Easy to Use

Low Cost Solution

Higher Performance than Two or Three Op Amp Design

Unity Gain with No External Resistor

Optional Gains with One External Resistor

(Gain Range 2 to 1000)

Wide Power Supply Range (ⴞ2.6 V to ⴞ15 V)

Available in 8-Lead PDIP and SOIC

Low Power, 1.5 mA max Supply Current

GOOD DC PERFORMANCE

0.15% Gain Accuracy (G = 1)

125 V max Input Offset Voltage

1.0 V/ⴗC max Input Offset Drift

5 nA max Input Bias Current

66 dB min Common-Mode Rejection Ratio (G = 1)

NOISE

12 nV/√Hz @ 1 kHz Input Voltage Noise

0.60 V

EXCELLENT AC CHARACTERISTICS

800 kHz Bandwidth (G = 10)

10 s Settling Time to 0.1% @ G = 1–100

1.2 V/s Slew Rate

APPLICATIONS

Transducer Interface

Low Cost Thermocouple Amplifier

Industrial Process Controls

Difference Amplifier

Low Cost Data Acquisition

p-p Noise (0.1 Hz to 10 Hz, G = 10)

Instrumentation Amplifier

AD622

CONNECTION DIAGRAM

1

R

G

–IN

2

3

+IN

–V

4

S

PRODUCT DESCRIPTION

AD622

The AD622 is a low cost, moderately accurate instrumentation

amplifier that requires only one external resistor to set any gain

between 2 and 1,000. Or for a gain of 1, no external resistor

is required. The AD622 is a complete difference or subtracter

amplifier “system” while providing superior linearity and commonmode rejection by incorporating precision laser trimmed resistors.

The AD622 replaces low cost, discrete, two or three op amp

instrumentation amplifier designs and offers good commonmode rejection, superior linearity, temperature stability, reliability, and board area consumption. The low cost of the AD622

eliminates the need to design discrete instrumentation amplifiers to meet stringent cost targets. While providing a lower cost

solution, it also provides performance and space improvements.

8

7

6

5

R

G

+V

S

OUTPUT

REF

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD622–SPECIFICATIONS

(typical @ +25ⴗC, VS = ⴞ15 V, and RL = 2 k⍀ unless otherwise noted)

AD622

Model Conditions Min Typ Max Units

GAIN G = 1 + (50.5 k/R

Gain Range 1 1000

Gain Error

1

V

OUT

= ±10 V

)

G

G = 1 0.05 0.15 %

G = 10 0.2 0.50 %

G = 100 0.2 0.50 %

G = 1000 0.2 0.50 %

Nonlinearity, V

G = 1–1000 R

G = 1–100 R

Gain vs. Temperature Gain = 1 10 ppm/°C

VOLTAGE OFFSET (Total RTI Error = V

Input Offset, V

OSI

Average TC V

Output Offset, V

OSO

Average TC V

= ±10 V

OUT

= 10 kΩ 10 ppm

L

= 2 kΩ 10 ppm

L

Gain >1

V

V

1

+ V

OSO

/G)

= ±5 V to ±15 V 60 125 µV

S

= ±5 V to ±15 V 1.0 µV/°C

S

= ±5 V to ±15 V 600 1500 µV

S

= ±5 V to ±15 V 15 µV/°C

S

OSI

–50 ppm/°C

Offset Referred to the

Input vs.

Supply (PSR) V

= ±5 V to ±15 V

S

G = 1 80 100 dB

G = 10 95 120 dB

G = 100 110 140 dB

G = 1000 110 140 dB

INPUT CURRENT

Input Bias Current 2.0 5.0 nA

Average TC 3.0 pA/°C

Input Offset Current 0.7 2.5 nA

Average TC 2.0 pA/°C

INPUT

Input Impedance

Differential 10储2GΩ储pF

Common-Mode 10储2GΩ储pF

Input Voltage Range

Over Temperature –V

Over Temperature –V

2

V

= ±2.6 V to ±5 V –V

S

= ±5 V to ±18 V –V

V

S

+ 1.9 +VS – 1.2 V

S

+ 2.1 +VS – 1.3 V

S

+ 1.9 +VS – 1.4 V

S

+ 2.1 +VS – 1.4 V

S

Common-Mode Rejection

Ratio DC to 60 Hz with

1 kΩ Source Imbalance V

= 0 V to ±10 V

CM

G = 1 66 78 dB

G = 10 86 98 dB

G = 100 103 118 dB

G = 1000 103 118 dB

OUTPUT

Output Swing R

Over Temperature –V

Over Temperature –V

= 10 kΩ,

L

= ±2.6 V to ±5 V –V

V

S

V

= ±5 V to ±18 V –V

S

+ 1.1 +VS – 1.2 V

S

+ 1.4 +VS – 1.3 V

S

+ 1.2 +VS – 1.4 V

S

+ 1.6 +VS – 1.5 V

S

Short Current Circuit ±18 mA

–2–

REV. C

Page 3

AD622

AD622

Model Conditions Min Typ Max Units

DYNAMIC RESPONSE

Small Signal –3 dB Bandwidth

G = 1 1000 kHz

G = 10 800 kHz

G = 100 120 kHz

G = 1000 12 kHz

Slew Rate 1.2 V/µs

Settling Time to 0.1% 10 V Step

G = 1–100 10 µs

NOISE

Voltage Noise, 1 kHz

Input, Voltage Noise, e

Output, Voltage Noise, e

ni

no

Total RTI Noise = (e

RTI, 0.1 Hz to 10 Hz

G = 1 4.0 µV p-p

G = 10 0.6 µV p-p

G = 100–1000 0.3 µV p-p

Current Noise f = 1 kHz 100 fA/√Hz

0.1 Hz to 10 Hz 10 pA p-p

REFERENCE INPUT

R

IN

I

IN

V

, V

IN+

= 0 +50 +60 µA

REF

Voltage Range –V

Gain to Output 1 ± 0.0015

POWER SUPPLY

Operating Range

Quiescent Current V

3

= ±2.6 V to ±18 V 0.9 1.3 mA

S

Over Temperature 1.1 1.5 mA

TEMPERATURE RANGE

For Specified Performance –40 to +85 °C

NOTES

1

Does not include effects of external resistor RG.

2

One input grounded. G = 1.

3

This is defined as the same supply range that is used to specify PSR.

Specifications subject to change without notice.

2

) +(e

ni

2

/ G)

no

12 nV/√Hz

72 nV/√Hz

20 kΩ

+ 1.6 +VS – 1.6 V

S

±2.6 ±18 V

REV. C

–3–

Page 4

AD622

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation

2

. . . . . . . . . . . . . . . . . . . . 650 mW

Input Voltage (Common Mode) . . . . . . . . . . . . . . . . . . . ±V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . ±25 V

Output Short Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Storage Temperature Range (N, R) . . . . . . . –65°C to +125°C

Operating Temperature Range

AD622A . . . . . . . . . . . . . . . . . . . . . . . . . . . – 40°C to +85°C

Lead Temperature Range

1

ORDERING GUIDE

Temperature Package

Model Range Option*

S

AD622AN –40°C to +85°C N-8

AD622AR –40°C to +85°C SO-8

AD622AR-REEL –40°C to +85°C 13" Reel

AD622AR-REEL7 –40°C to +85°C 7" Reel

*N = Plastic DIP, SO = Small Outline.

(Soldering 10 seconds) . . . . . . . . . . . . . . . . . . . . . . . +300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

8-Lead Plastic Package: θJA = 95°C/Watt

8-Lead SOIC Package: θJA = 155°C/Watt

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD622 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

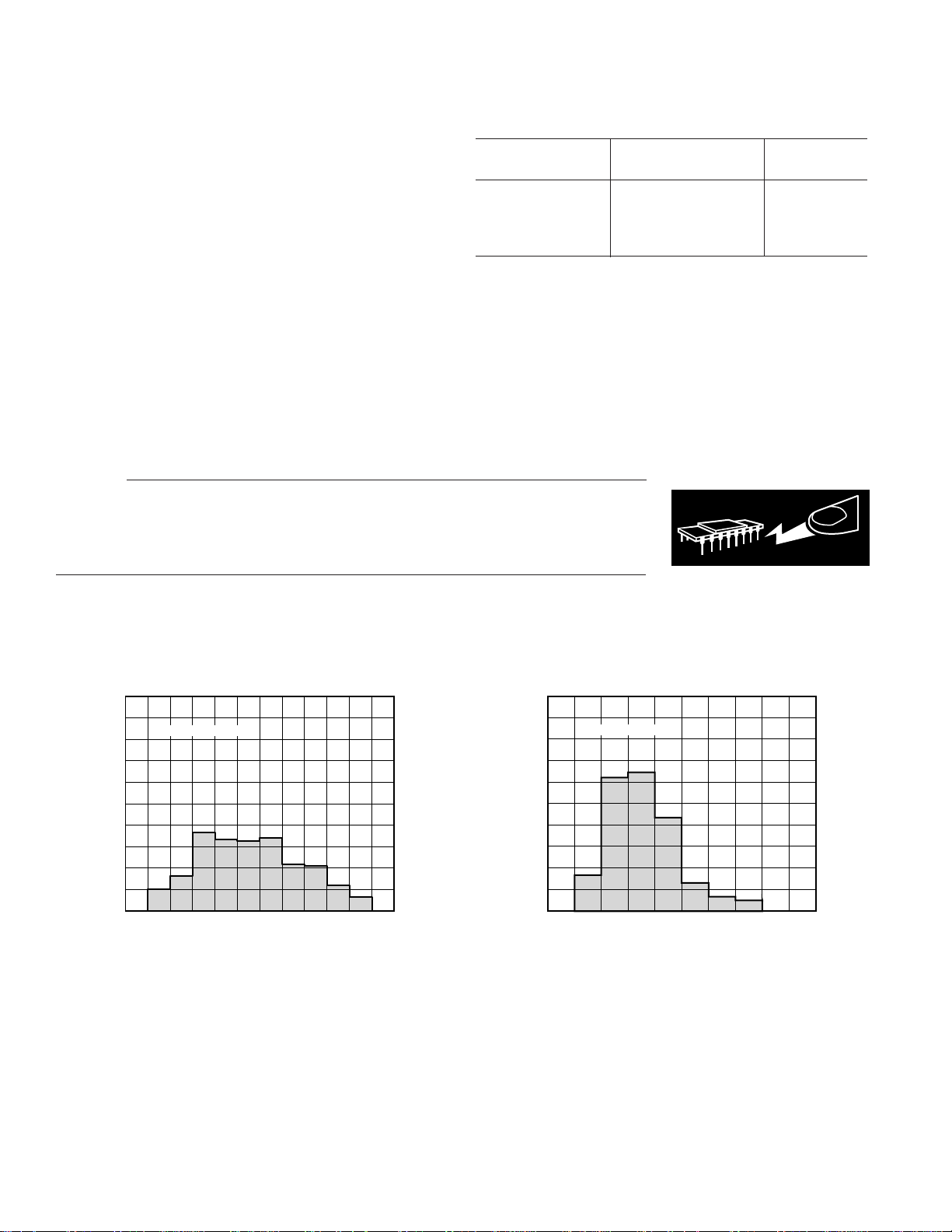

Typical Characteristics

50

SAMPLE SIZE = 191

40

30

20

PERCENTAGE OF UNITS

10

0

–0.40

OUTPUT OFFSET VOLTAGE – mV

(@ +25ⴗC, VS = ⴞ15 V, RL = 2 k⍀, unless otherwise noted)

0 0.40

0.80 1.00–1.00 –0.80

Figure 1. Typical Distribution of Output Offset Voltage

50

40

30

20

PERCENTAGE OF UNITS

10

SAMPLE SIZE = 383

0

60 80 100 120 140

COMMON-MODE REJECTION RATIO – dB

Figure 2. Typical Distribution of Common-Mode Rejection

–4–

REV. C

Page 5

AD622

FREQUENCY – Hz

0.1 1M1 10 100 1k 10k 100k

0

140

80

60

40

20

120

100

CMR – dB

G = 1000

G = 100

G = 10

G = 1

Typical Characteristics

2

1.5

1

0.5

INPUT OFFSET VOLTAGE – mV

0

051234

WARM-UP TIME – Minutes

(@ +25ⴗC, VS = ⴞ15 V, RL = 2 k⍀, unless otherwise noted)

Figure 3. Change in Input Offset Voltage vs. Warm-Up

Time

1000

GAIN = 1

100

Figure 6. CMR vs. Frequency, RTI, Zero to 1 kΩ Source

Imbalance

180

160

140

120

G = 1000

GAIN = 10

10

VOLTAGE NOISE – nV/ Hz

GAIN = 100, 1,000

GAIN = 1000

BW LIMIT

1

1 100k10 100 1k 10k

FREQUENCY – Hz

Figure 4. Voltage Noise Spectral Density vs. Frequency,

(G = 1–1000)

1000

100

CURRENT NOISE – fA/ Hz

10

0 100010

FREQUENCY – Hz

100

Figure 5. Current Noise Spectral Density vs. Frequency

100

80

POSITIVE PSR – dB

60

40

0

0.1 1M1 10 100 1k 10k 100k

FREQUENCY – Hz

G = 100

G = 10

G = 1

Figure 7a. Positive PSR vs. Frequency, RTI (G = 1–1000)

180

160

140

120

100

80

NEGATIVE PSR – dB

60

40

0

0.1 1M1 10 100 1k 10k 100k

FREQUENCY – Hz

G = 1000

G = 100

G = 10

G = 1

Figure 7b. Negative PSR vs. Frequency, RTI (G = 1–1000)

REV. C

–5–

Page 6

AD622–

Typical Characteristics

(@ +25ⴗC, VS = ⴞ15 V, RL = 2 k⍀, unless otherwise noted)

1000

100

10

GAIN – V/V

1

0

100 10M1k 10k 100k 1M

FREQUENCY – Hz

Figure 8. Gain vs. Frequency

30

VS = 615V

G = 10

20

1000

100

10

SETTLING TIME – ms

1

1 100010 100

GAIN

Figure 11. Settling Time to 0.1% vs. Gain, for a 10 V Step

10µV

100

90

ø

2V

10

OUTPUT VOLTAGE SWING – Volts p-p

0

10 10k100 1k

LOAD RESISTANCE – V

Figure 9. Output Voltage Swing vs. Load Resistance

20

15

TO 0.1%

10

SETTLING TIME – ms

5

0

02051015

OUTPUT STEP SIZE – Volts

Figure 10. Settling Time vs. Step Size (G = 1)

10

0%

Figure 12. Gain Nonlinearity, G = 1, RL = 10 k

(20µV = 2 ppm)

1kV

10T

AD622

–V

+V

S

S

INPUT

20V p-p

100kV

0.1%

11kV

0.1%

1kV

100V

0.1%

0.1%

G=1000

G=100

51.1V 511V 5.62kV

G=1

G=10

10kV

0.01%

Figure 13. Settling Time Test Circuit

10kV

0.1%

Ω

V

OUT

–6–

REV. C

Page 7

AD622

THEORY OF OPERATION

The AD622 is a monolithic instrumentation amplifier based on

a modification of the classic three op-amp approach. Absolute

value trimming allows the user to program gain accurately (to

0.5% at G = 100) with only one resistor. Monolithic construction and laser wafer trimming allow the tight matching and

tracking of circuit components, thus insuring its performance.

The input transistors Q1 and Q2 provide a single differentialpair bipolar input for high precision. Feedback through the

Q1-A1-R1 loop and the Q2-A2-R2 loop maintains constant

collector current of the input devices Q1, Q2 thereby impressing

the input voltage across the external gain-setting resistor RG.

This creates a differential gain from the inputs to the A1/A2

outputs given by G = (R1 + R2)/R

+ 1. The unity-gain sub-

G

tracter A3 removes any common-mode signal, yielding a

single-ended output referred to the REF pin potential.

The value of R

preamp stage. As R

also determines the transconductance of the

G

is reduced for larger gains, the transcon-

G

ductance increases asymptotically to that of the input transistors.

This has three important advantages: (a) Open-loop gain is

boosted for increasing programmed gain, thus reducing gainrelated errors. (b) The gain-bandwidth product (determined by

C1, C2 and the preamp transconductance) increases with programmed gain, thus optimizing frequency response. (c) The

input voltage noise is reduced to a value of 12 nV/√Hz, deter-

mined mainly by the collector current and base resistance of the

input devices.

The internal gain resistors, R1 and R2, are trimmed to an abso-

lute value of 25.25 kΩ, allowing the gain to be programmed

accurately with a single external resistor.

Make vs. Buy: A Typical Application Error Budget

The AD622 offers a cost and performance advantages over

discrete “two op-amp” instrumentation amplifier designs along

with smaller size and less components. In a typical application

shown in Figure 14, a gain of 10 is required to receive and amplify a 0–20 mA signal from the AD694 current transmitter.

The current is converted to a voltage in a 50 Ω shunt. In appli-

cations where transmission is over long distances, line impedance can be significant so that differential voltage measurement

is essential. Where there is no connection between the ground

returns of transmitter and receiver, there must be a dc path from

each input to ground, implemented in this case using two 1 kΩ

resistors. The error budget detailed in Table I shows how to

calculate the effect various error sources have on circuit accuracy.

The AD622 provides greater accuracy at lower cost. The higher

cost of the “homebrew” circuit is dominated in this case by the

matched resistor network. One could also realize a “homebrew”

design using cheaper discrete resistors which would be either

trimmed or hand selected to give high common-mode rejection.

This level of common-mode rejection would however degrade

significantly over temperature due to the drift mismatch of the

discrete resistors.

Note that for the homebrew circuit, the LT1013 specification

for noise has been multiplied by √2. This is because a “two op-

amp” type instrumentation amplifier has two op amps at its

inputs, both contributing to the overall noise.

R

L2

10V

AD694

0–20mA

TRANSMITTER

0–20mA

R

L2

10V

0–20 mA Current Loop

Ω

with 50

Shunt Impedance

50V

1kV

1kV

R

5.62kV

G

AD622

REFERENCE

AD622 Monolithic

Instrumentation Amplifier,

G = 9.986

Figure 14. Make vs. Buy

V

1kV

IN

1kV

9kV*1kV*1kV*9kV*

*0.1% RESISTOR MATCH, 50ppm/ C TRACKING

1/2

LT1013

“Homebrew” In Amp, G = 10

1/2

LT1013

REV. C

–7–

Page 8

AD622

Table I. Make vs. Buy Error Budget

Total Error Total Error

in ppm in ppm

AD622 Circuit “Homebrew” Circuit Relative to 1 V FS Relative to 1 V FS

Error Source Calculation Calculation AD622 Homebrew

ABSOLUTE ACCURACY at T

Total RTI Offset Voltage, µV 250 µV + 1500 µV/10 800 µV × 2 400 1600

Input Offset Current, nA 2.5 nA × 1kΩ 15 nA × 1 kΩ 2.5 15

CMR, dB 86 dB→50 ppm × 0.5 V (0.1% Match × 0.5 V)/10 V 25 50

DRIFT TO +85°C

Gain Drift, ppm/°C (50 ppm + 5 ppm) × 60°C (50 ppm)/°C × 60°C 3300 3000

Total RTI Offset Voltage, µV/°C(2µV/°C + 15 µV/°C/10) × 60°C9µV/°C × 2 × 60°C 210 1080

Input Offset Current, pA/°C 2 pA/°C × 1kΩ × 60°C 155 pA/°C × 1kΩ × 60°C 0.12 9.3

RESOLUTION

Gain Nonlinearity, ppm of Full Scale 10 ppm 20 ppm 10 20

Typ 0.1 Hz–10 Hz Voltage Noise, µV p-p 0.6 µV p-p 0.55 µV p-p × √2 0.6 0.778

= +25°C

A

Total Absolute Error 427.5 1665

Total Drift Error 3510.12 4089.3

Total Resolution Error 10.6 20.778

Grand Total Error 3948 5575

GAIN SELECTION

The AD622’s gain is resistor programmed by RG, or more precisely, by whatever impedance appears between Pins 1 and 8.

The AD622 is designed to offer gains as close as possible to

popular integer values using standard 1% resistors. Table II

shows required values of R

G = 1, the R

gain R

pins are unconnected (R

G

can be calculated by using the formula

G

for various gains. Note that for

G

50.5 kΩ

R

=

G

G −1

= ∞). For any arbitrary

G

To minimize gain error avoid high parasitic resistance in series

with R

, and to minimize gain drift, RG should have a low

G

TC—less than 10 ppm/°C for the best performance.

Table II. Required Values of Gain Resistors

Desired 1% Std Table Calculated

Gain Value of RG, ⍀ Gain

2 51.1 k 1.988

5 12.7 k 4.976

10 5.62 k 9.986

20 2.67 k 19.91

33 1.58 k 32.96

40 1.3 k 39.85

50 1.02 k 50.50

65 787 65.17

100 511 99.83

200 255 199.0

500 102 496.1

1000 51.1 989.3

–8–

REV. C

Page 9

AD622

C3

0.047mF

R

G

1

3

2

8

6

4

5

V

OUT

7

–V

S

AD622

–IN

+IN

R1

4.02kV 1%

LOCATE C1–C3 AS CLOSE TO

THE INPUT PINS AS POSSIBLE

0.33mF

0.01mF

0.01mF

R2

4.02kV 1%

C2

1000pF 5%

C1

1000pF 5%

0.33mF

+V

S

INPUT AND OUTPUT OFFSET VOLTAGE

The low errors of the AD622 are attributed to two sources,

input and output errors. The output error is divided by G when

referred to the input. In practice, the input errors dominate at

high gains and the output errors dominate at low gains. The

total V

Total Error RTI = input error + (output error/G)

Total Error RTO = (input error × G) + output error

REFERENCE TERMINAL

The reference terminal potential defines the zero output voltage

and is especially useful when the load does not share a precise

ground with the rest of the system. It provides a direct means of

injecting a precise offset to the output, with an allowable range

of 2 V within the supply voltages. Parasitic resistance should be

kept to a minimum for optimum CMR.

INPUT PROTECTION

The AD622 features 400 Ω of series thin film resistance at its

inputs, and will safely withstand input overloads of up to ±25 V

or ±60 mA for up to an hour. This is true for all gains and

power on and off, which is particularly important since the

signal source and amplifier may be powered separately. For

continuous input overload, the current should not exceed 6 mA

(I

IN

clamping the inputs to the supplies (using a diode such as an

IN4148) will reduce the required resistance, yielding lower

noise.

REV. C

for a given gain is calculated as:

OS

≤ VIN/400 Ω). For input overloads beyond the supplies,

RF INTERFERENCE

The circuit of Figure 15 is recommended for AD622 series inamps and provides good RFI suppression at the expense of

reducing the (differential) bandwidth. In addition, this RC input

network also provides additional input overload protection (see

input protection section). Resistors R1 and R2 were selected to

be high enough in value to isolate the circuit’s input from capacitors C1–C3, but without significantly increasing the circuit’s

noise.

Figure 15. RFI Suppression Circuit for AD622 Series In-Amps

R1/R2 and C1/C2 form a bridge circuit whose output appears

across the in-amp’s input pins. Any mismatch between the C1/

R1 and C2/R2 time constant will unbalance the bridge and

reduce common-mode rejection. C3 insures that any RF signals

are common mode (the same on both in-amp inputs) and are

not applied differentially.

This low pass network has a –3 dB BW equal to: 1/(2π (R1 +

R2) (C3 + C1 + C2)). Using a C3 value of 0.047 µF as shown,

the –3 dB signal BW of this circuit is approximately 400 Hz.

When operating at a gain of 1000, the typical dc offset shift over

a frequency range of 1 Hz to 20 MHz will be less than 1.5 µV

RTI and the circuit’s RF signal rejection will be better than

71 dB. At a gain of 100, the dc offset shift is well below 1 mV

RTI and RF rejection better than 70 dB.

The 3 dB signal bandwidth of this circuit may be increased to

900 Hz by reducing resistors R1 and R2 to 2.2 kΩ. The performance is similar to that using 4 kΩ resistors, except that the

circuitry preceding the in-amp must drive a lower impedance

load.

This circuit should be built using a PC board with a ground

plane on both sides. All component leads should be made as

short as possible. Resistors R1 and R2 can be common 1%

metal film units but capacitors C1 and C2 need to be ±5%

tolerance devices to avoid degrading the circuit’s common-mode

rejection. Either the traditional 5% silver micas, miniature size

micas, or the new Panasonic ±2% PPS film capacitors are

recommended.

–9–

Page 10

AD622

GROUNDING

Since the AD622 output voltage is developed with respect to the

potential on the reference terminal, it can solve many grounding

problems by simply tying the REF pin to the appropriate “local

ground.” The REF pin should however be tied to a low impedance point for optimal CMR.

The use of ground planes is recommended to minimize the

impedance of ground returns (and hence the size of dc errors).

In order to isolate low level analog signals from a noisy digital

environment, many data-acquisition components have separate

analog and digital ground returns (Figure 16). All ground pins

from mixed signal components such as analog to digital converters

should be returned through the “high quality” analog ground

plane. Maximum isolation between analog and digital is

achieved by connecting the ground planes back at the supplies.

The digital return currents from the ADC which flow in the

analog ground plane will in general have a negligible effect on

noise performance.

DIGITAL P.S.

V

12

mPROCESSOR

C +5V

0.1mF

GND

DD

0.1mF

AD622

ANALOG P.S.

+5V –5V

V

VIN1

V

0.1mF

DD

2

IN

C

AGND DGND

AD7892-2

Figure 16. Basic Grounding Practice

GROUND RETURNS FOR INPUT BIAS CURRENTS

Input bias currents are those currents necessary to bias the input

transistors of an amplifier. There must be a direct return path

for these currents; therefore when amplifying “floating” input

sources such as transformers, or ac-coupled sources, there must

be a dc path from each input to ground as shown in Figure 17.

Refer to the Instrumentation Amplifier Application Guide (free

from Analog Devices) for more information regarding in amp

applications.

+V

AD622

4

–V

S

S

7

5

REFERENCE

6

LOAD

V

OUT

TO POWER

SUPPLY

GROUND

–INPUT

+INPUT

2

1

R

G

8

3

Figure 17a. Ground Returns for Bias Currents with

Transformer Coupled Inputs

+V

AD622

4

–V

S

S

7

5

REFERENCE

6

LOAD

V

OUT

TO POWER

SUPPLY

GROUND

–INPUT

+INPUT

2

1

R

G

8

3

Figure 17b. Ground Returns for Bias Currents with

Thermocouple Inputs

+V

AD622

–V

S

S

REFERENCE

LOAD

V

OUT

TO POWER

SUPPLY

GROUND

–INPUT

+INPUT

100kV 100kV

R

G

Figure 17c. Ground Returns for Bias Currents with

AC Coupled Inputs

–10–

REV. C

Page 11

0.210 (5.33)

MAX

0.160 (4.06)

0.115 (2.93)

0.022 (0.558)

0.014 (0.356)

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Plastic DIP (N-8) Package

0.430 (10.92)

0.348 (8.84)

8

14

PIN 1

0.100

(2.54)

BSC

5

0.280 (7.11)

0.240 (6.10)

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

SOIC (SO-8) Package

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

AD622

C2118c–0–4/99

0.195 (4.95)

0.115 (2.93)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

PRINTED IN U.S.A.

REV. C

–11–

Loading...

Loading...