Page 1

1 MSPS, 12-Bit Impedance

A

V

Data Sheet

FEATURES

Programmable output peak-to-peak excitation voltage

to a maximum frequency of 100 kHz

Programmable frequency sweep capability with

Frequency resolution of 27 bits (<0.1 Hz)

Impedance measurement range from 1 kΩ to 10 MΩ

Capable of measuring of 100 Ω to 1 kΩ with additional

Internal temperature sensor (±2°C)

Internal system clock option

Phase measurement capability

System accuracy of 0.5%

2.7 V to 5.5 V power supply operation

Temperature range: −40°C to +125°C

16-lead SSOP package

APPLICATIONS

Electrochemical analysis

Bioelectrical impedance analysis

Impedance spectroscopy

Complex impedance measurement

Corrosion monitoring and protection equipment

Biomedical and automotive sensors

Proximity sensing

Nondestructive testing

Material property analysis

Fuel/battery cell condition monitoring

2

serial I

circuitry

C interface

Converter, Network Analyzer

AD5933

GENERAL DESCRIPTION

The AD5933 is a high precision impedance converter system

solution that combines an on-board frequency generator with

a 12-bit, 1 MSPS, analog-to-digital converter (ADC). The

frequency generator allows an external complex impedance to

be excited with a known frequency. The response signal from

the impedance is sampled by the on-board ADC and a discrete

Fourier transform (DFT) is processed by an on-board DSP

engine. The DFT algorithm returns a real (R) and imaginary (I)

data-word at each output frequency.

Once calibrated, the magnitude of the impedance and relative

phase of the impedance at each frequency point along the sweep

is easily calculated. This is done off chip using the real and

imaginary register contents, which can be read from the serial

2

I

C interface.

A similar device, also available from Analog Devices, Inc., is the

AD5934, a 2.7 V to 5.5 V, 250 kSPS, 12-bit impedance converter,

with an internal temperature sensor and is packaged in a 16lead SSOP.

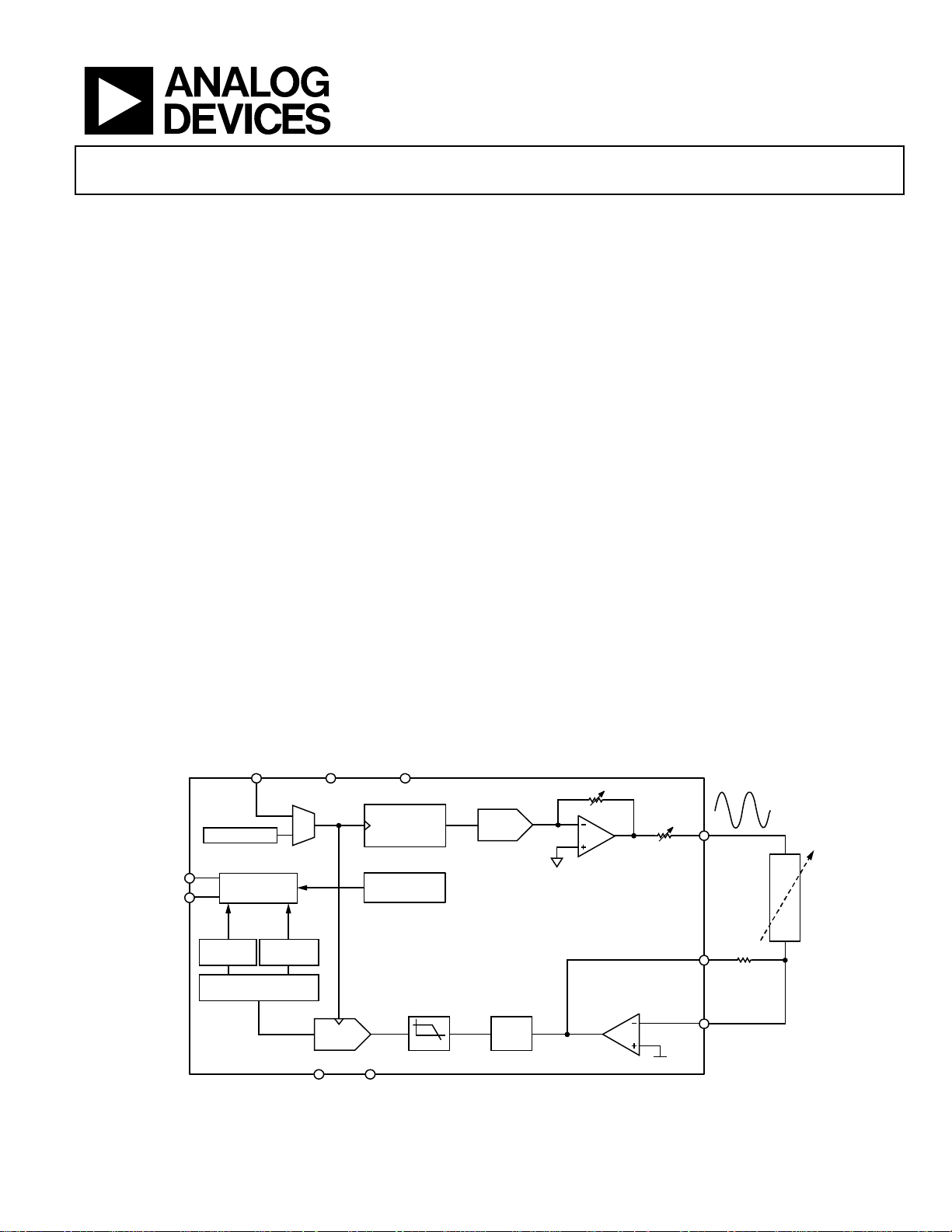

FUNCTIONAL BLOCK DIAGRAM

DDMCLK

OSCILLATOR

SCL

SDA

REGISTER

Rev. D

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

I2C

INTERFACE

REAL

IMAGINARY

REGIS TER

1024-POINT DFT

ADC

(12 BITS)

AGND DGND

DVDD

DDS

CORE

(27 BITS)

TEMPERATURE

SENSOR

AD5933

LPF

DAC

R

OUT

GAIN

VDD/2

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2005–2011 Analog Devices, Inc. All rights reserved.

VOUT

Z(ω)

RFB

VIN

05324-001

Page 2

AD5933 Data Sheet

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description......................................................................... 1

Functional Block Diagram ..............................................................1

Revision History ...............................................................................3

Specifications..................................................................................... 4

I2C Serial Interface Timing Characteristics ..............................6

Absolute Maximum Ratings............................................................ 7

ESD Caution.................................................................................. 7

Pin Configuration and Descriptions.............................................. 8

Typical Performance Characteristics ............................................. 9

Terminology .................................................................................... 12

System Description......................................................................... 13

Transmit Stage............................................................................. 14

Frequency Sweep Command Sequence................................... 15

Receive Stage............................................................................... 15

DFT Operation ...........................................................................15

System Clock............................................................................... 16

Temperature Sensor ...................................................................16

Temperature Conversion Details.............................................. 16

Temperature Value Register ......................................................16

Temperature Conversion Formula........................................... 16

Impedance Calculation.................................................................. 17

Magnitude Calculation.............................................................. 17

Gain Factor Calculation ............................................................17

Impedance Calculation Using Gain Factor............................. 17

Gain Factor Variation with Frequency.................................... 17

Two-Point Calibration ............................................................... 18

Two-Point Gain Factor Calculation......................................... 18

Gain Factor Setup Configuration............................................. 18

Gain Factor Recalculation......................................................... 18

Gain Factor Temperature Variation......................................... 19

Impedance Error......................................................................... 19

Measuring the Phase Across an Impedance ........................... 19

Performing a Frequency Sweep ....................................................22

Register Map ................................................................................... 23

Control Register (Register Address 0x80, Register Address

0x81)............................................................................................. 23

Start Frequency Register (Register Address 0x82, Register

Address 0x83, Register Address 0x84)..................................... 24

Frequency Increment Register (Register Address 0x85,

Register Address 0x86, Register Address 0x87) .....................25

Number of Increments Register (Register Address 0x88,

Register Address 0x89).............................................................. 25

Number of Settling Time Cycles Register (Register Address

0x8A, Register Address 0x8B) ................................................. 25

Status Register (Register Address 0x8F).................................. 26

Temperature Data Register (16 Bits—Register Address 0x92,

Register Address 0x93).............................................................. 26

Real and Imaginary Data Registers (16 Bits—Register

Address 0x94, Register Address 0x95, Register Address 0x96,

Register Address 0x97).............................................................. 26

Serial Bus Interface......................................................................... 27

General I2C Timing.................................................................... 27

Writing/Reading to the AD5933.............................................. 28

Block Write.................................................................................. 28

Read Operations......................................................................... 29

Typical Applications....................................................................... 30

Measuring Small Impedances................................................... 30

Biomedical: Noninvasive Blood Impedance Measurement.. 32

Sensor/Complex Impedance Measurement............................ 32

Electro-Impedance Spectroscopy............................................. 33

Choosing a Reference for the AD5933........................................ 34

Layout and Configuration............................................................. 35

Power Supply Bypassing and Grounding................................ 35

Evaluation Board............................................................................ 36

Using the Evaluation Board ...................................................... 36

Prototyping Area........................................................................ 36

Crystal Oscillator (XO) vs. External Clock............................. 36

Schematics................................................................................... 37

Outline Dimensions....................................................................... 41

Ordering Guide .......................................................................... 41

Rev. D | Page 2 of 44

Page 3

Data Sheet AD5933

REVISION HISTORY

12/11—Rev. C to Rev. D

Changes to Impedance Error Section...........................................19

Removed Figure 26 and Figure 27;

Renumbered Sequentially ..............................................................19

Removed Figure 28, Figure 29, Figure 30, Figure 31..................20

Changes to Figure 39 ......................................................................37

Changes to Figure 40 ......................................................................38

Changes to Figure 41 ......................................................................39

Changes to Figure 42 ......................................................................40

8/10—Rev. B to Rev. C

Changes to Impedance Error Section...........................................19

Changes to Figure 45 ......................................................................38

Changes to U4 Description in Table 19........................................42

2/10—Rev. A to Rev. B

Changes to General Description.....................................................1

5/08—Rev. 0 to Rev. A

Changes to Layout.............................................................. Universal

Changes to Figure 1 ..........................................................................1

Changes to Table 1 ............................................................................4

Changes to Figure 17......................................................................13

Changes to System Description Section ......................................13

Changes to Figure 19......................................................................14

Changes to Figure 24......................................................................18

Changes to Impedance Error Section...........................................19

Added Measuring the Phase Across an Impedance Section .....21

Changes to Register Map Section .................................................24

Added Measuring Small Impedances Section.............................31

Changes to Table 18 ........................................................................35

Added Evaluation Board Section..................................................37

Changes to Ordering Guide...........................................................43

9/05—Revision 0: Initial Version

Rev. D | Page 3 of 44

Page 4

AD5933 Data Sheet

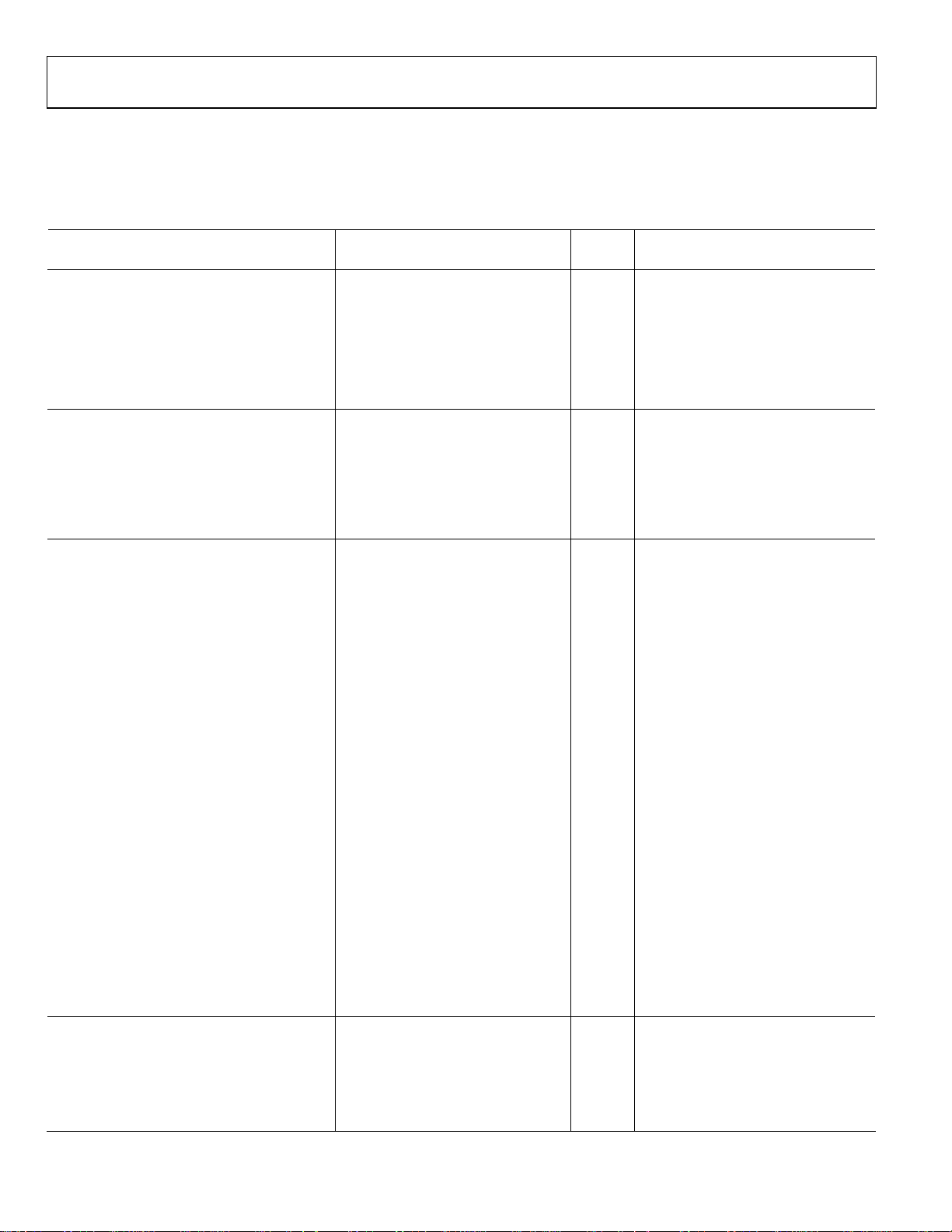

SPECIFICATIONS

VDD = 3.3 V, MCLK = 16.776 MHz, 2 V p-p output excitation voltage @ 30 kHz, 200 kΩ connected between Pin 5 and Pin 6; feedback

resistor = 200 kΩ connected between Pin 4 and Pin 5; PGA gain = ×1, unless otherwise noted.

Table 1.

Y Version1

Parameter

Min Typ Max

SYSTEM

Impedance Range 1 K 10 M Ω

Total System Accuracy 0.5 %

System Impedance Error Drift 30 ppm/°C

TRANSMIT STAGE

Output Frequency Range

2

1

100 kHz

Output Frequency Resolution 0.1 Hz

MCLK Frequency 16.776 MHz Maximum system clock frequency

Internal Oscillator Frequency3 16.776 MHz Frequency of internal clock

Internal Oscillator Temperature Coefficient 30 ppm/°C

TRANSMIT OUTPUT VOLTAGE

Range 1

AC Output Excitation Voltage

4

1.98 V p-p

DC Bias5 1.48 V

DC Output Impedance 200 Ω TA = 25°C

Short-Circuit Current to Ground at VOUT ±5.8 mA TA = 25°C

Range 2

AC Output Excitation Voltage4 0.97 V p-p See Figure 6

5

DC Bias

0.76 V

DC Output Impedance 2.4 kΩ

Short-Circuit Current to Ground at VOUT ±0.25 mA

Range 3

AC Output Excitation Voltage

5

DC Bias

4

0.383 V p-p See Figure 8

0.31 V

DC Output Impedance 1 kΩ

Short-Circuit Current to Ground at VOUT ±0.20 mA

Range 4

AC Output Excitation Voltage

5

DC Bias

4

0.198 V p-p See Figure 10

0.173 V

DC Output Impedance 600 Ω

Short-Circuit Current to Ground at VOUT ±0.15 mA

SYSTEM AC CHARACTERISTICS

Signal-to-Noise Ratio 60 dB

Total Harmonic Distortion −52 dB

Spurious-Free Dynamic Range

Wide Band (0 MHz to 1 MHz) −56 dB

Narrow Band (±5 kHz) −85 dB

Unit Test Conditions/Comments

100 Ω to 1 kΩ requires extra buffer

circuitry, see the Measuring Small

Impedances section

2 V p-p output excitation voltage at

30 kHz, 200 kΩ connected between

Pin 5 and Pin 6

<0.1 Hz resolution achievable using

DDS techniques

See Figure 4 for output voltage

distribution

DC bias of the ac excitation signal;

see Figure 5

DC bias of output excitation signal;

see Figure 7

DC bias of output excitation signal;

see Figure 9

DC bias of output excitation signal.

See Figure 11

Rev. D | Page 4 of 44

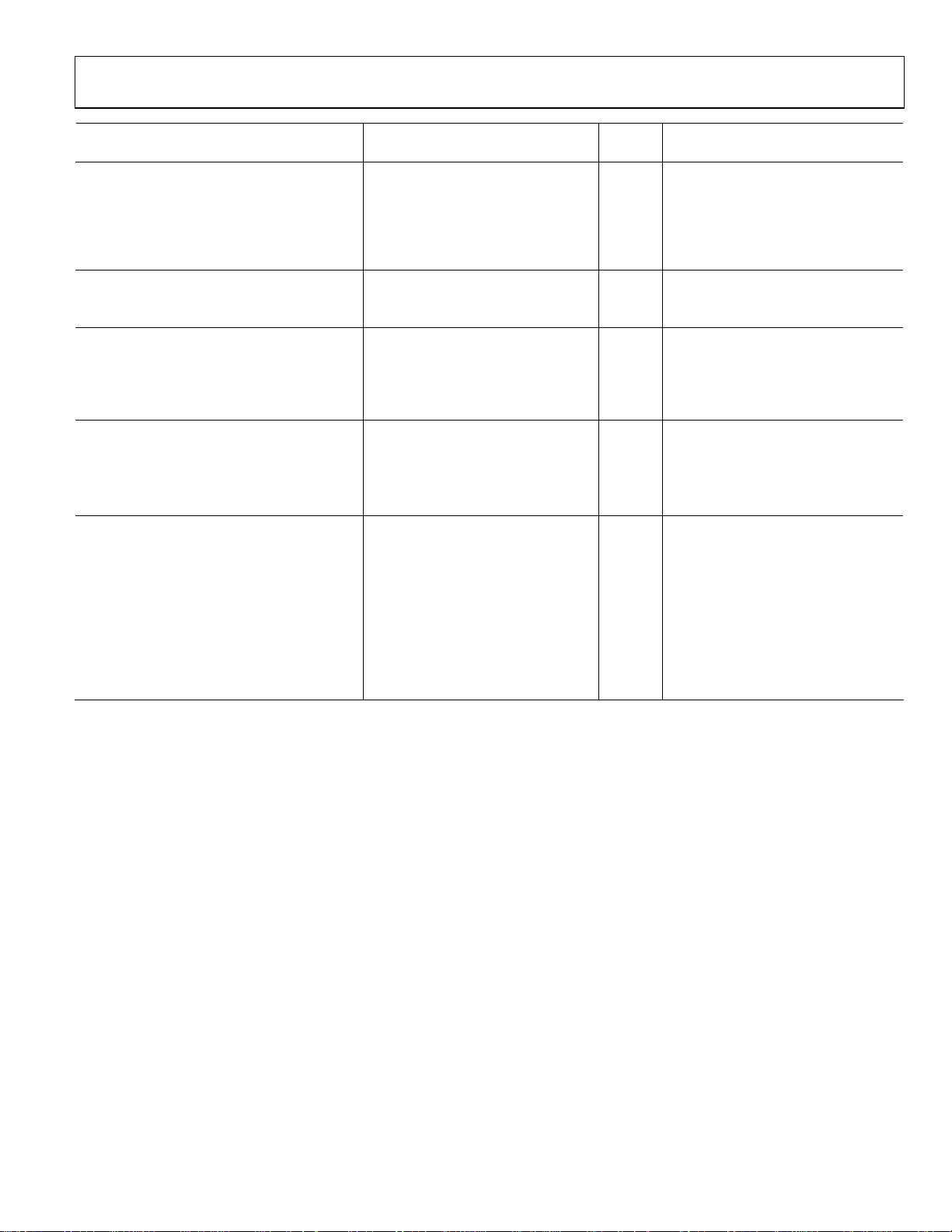

Page 5

Data Sheet AD5933

Y Version1

Parameter

Min Typ Max

RECEIVE STAGE

Input Leakage Current 1 nA To VIN pin

Input Capacitance

6

0.01 pF Pin capacitance between VIN and GND

Feedback Capacitance (CFB) 3 pF

ANALOG-TO-DIGITAL CONVERTER

Resolution

Sampling Rate

6

12 Bits

250 kSPS ADC throughput rate

TEMPERATURE SENSOR

Accuracy ±2.0 °C −40°C to +125°C temperature range

Resolution 0.03 °C

Temperature Conversion Time 800 s

LOGIC INPUTS

Input High Voltage (VIH) 0.7 × VDD

Input Low Voltage (VIL) 0.3 × VDD

Input Current

7

1 µA TA = 25°C

Input Capacitance 7 pF TA = 25°C

POWER REQUIREMENTS

VDD 2.7 5.5 V

IDD (Normal Mode ) 10 15 mA VDD = 3.3 V

17 25 mA VDD = 5.5 V

IDD (Standby Mode) 11 mA

16 mA VDD = 5.5 V

IDD (Power-Down Mode) 0.7 5 µA VDD = 3.3 V

1 8 µA VDD = 5.5 V

1

Temperature range for Y version = −40°C to +125°C, typical at 25°C.

2

The lower limit of the output excitation frequency can be lowered by scaling the clock supplied to the AD5933.

3

Refer to Figure 14, Figure 15, and Figure 16 for the internal oscillator frequency distribution with temperature.

4

The peak-to-peak value of the ac output excitation voltage scales with supply voltage according to the following formula:

Output Excitation Voltage (V p-p) = [2/3.3] × VDD

where VDD is the supply voltage.

5

The dc bias value of the output excitation voltage scales with supply voltage according to the following formula:

Output Excitation Bias Voltage (V) = [2/3.3] × VDD

where VDD is the supply voltage.

6

Guaranteed by design or characterization, not production tested. Input capacitance at the VOUT pin is equal to pin capacitance divided by open-loop gain of current-

to-voltage amplifier.

7

The accumulation of the currents into Pin 8, Pin 15, and Pin 16.

Unit Test Conditions/Comments

Feedback capacitance around currentto-voltage amplifier; appears in

parallel with feedback resistor

Conversion time of single temperature

measurement

VDD = 3.3 V; see the Control Register

(Register Address 0X80, Register

Address 0X81) section

Rev. D | Page 5 of 44

Page 6

AD5933 Data Sheet

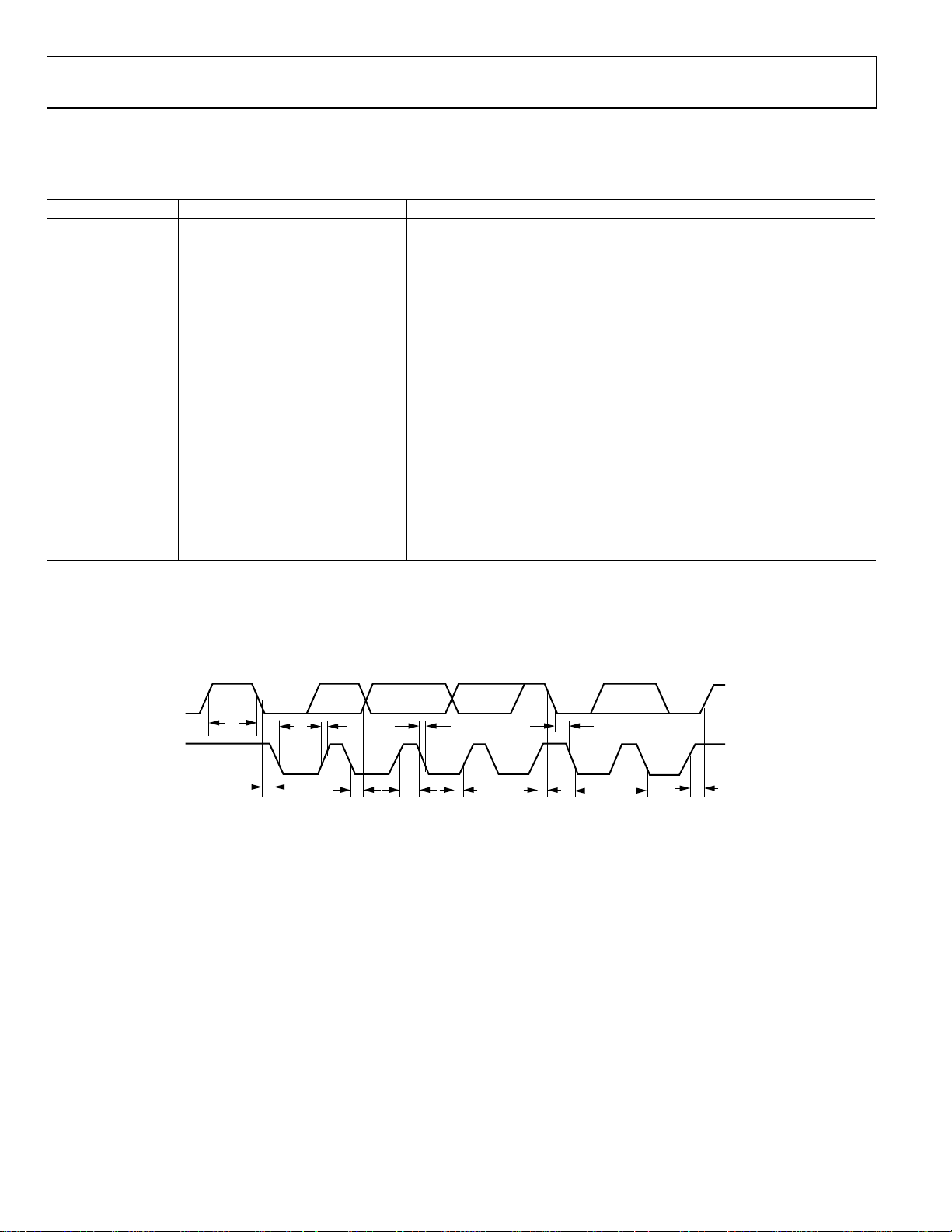

S

I2C SERIAL INTERFACE TIMING CHARACTERISTICS

VDD = 2.7 V to 5.5 V. All specifications T

MIN

to T

, unless otherwise noted.1

MAX

Table 2.

Parameter

f

400 kHz max SCL clock frequency

SCL

2

Limit at T

MIN

, T

MAX

Unit Description

t1 2.5 µs min SCL cycle time

t2 0.6 µs min t

t3 1.3 µs min t

t4 0.6 µs min t

t5 100 ns min t

3

t

6

0.9 µs max t

0 µs min t

t7 0.6 µs min t

t8 0.6 µs min t

t9 1.3 µs min t

, SCL high time

HIGH

, SCL low time

LOW

, start/repeated start condition hold time

HD, STA

, data setup time

SU, DAT

, data hold time

HD, DAT

, data hold time

HD, DAT

, setup time for repeated start

SU, STA

, stop condition setup time

SU, STO

, bus free time between a stop and a start condition

BUF

t10 300 ns max tF, rise time of SDA when transmitting

0 ns min tR, rise time of SCL and SDA when receiving (CMOS compatible)

t11 300 ns max tF, fall time of SCL and SDA when transmitting

0 ns min tF, fall time of SDA when receiving (CMOS compatible)

250 ns max tF, fall time of SDA when receiving

20 + 0.1 C

4

b

ns min tF, fall time of SCL and SDA when transmitting

Cb 400 pF max Capacitive load for each bus line

1

See Figure 2.

2

Guaranteed by design and characterization, not production tested.

3

A master device must provide a hold time of at least 300 ns for the SDA signal (referred to V

4

Cb is the total capacitance of one bus line in picofarads. Note that tR and tF are measured between 0.3 VDD and 0.7 VDD.

of the SCL signal) to bridge the undefined falling edge of SCL.

IH MIN

DA

t

SCL

9

START

CONDITION

t

3

t

4

t

10

t

6

t

11

Figure 2. I

t

2

2

C Interface Timing Diagram

t

t

5

7

t

4

REPEATED

START

CONDITIO N

t

1

t

8

STOP

CONDITIO N

05324-002

Rev. D | Page 6 of 44

Page 7

Data Sheet AD5933

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

DVDD to GND −0.3 V to +7.0 V

AVDD1 to GND −0.3 V to +7.0 V

AVDD2 to GND −0.3 V to +7.0 V

SDA/SCL to GND −0.3 V to VDD + 0.3 V

VOUT to GND −0.3 V to VDD + 0.3 V

VIN to GND −0.3 V to VDD + 0.3 V

MCLK to GND −0.3 V to VDD + 0.3 V

Operating Temperature Range

Extended Industrial (Y Grade) −40°C to +125°C

Storage Temperature Range −65°C to +160°C

Maximum Junction Temperature 150°C

SSOP Package, Thermal Impedance

θJA 139°C/W

θJC 136°C/W

Reflow Soldering (Pb-Free)

Peak Temperature 260°C

Time at Peak Temperature 10 sec to 40 sec

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. D | Page 7 of 44

Page 8

AD5933 Data Sheet

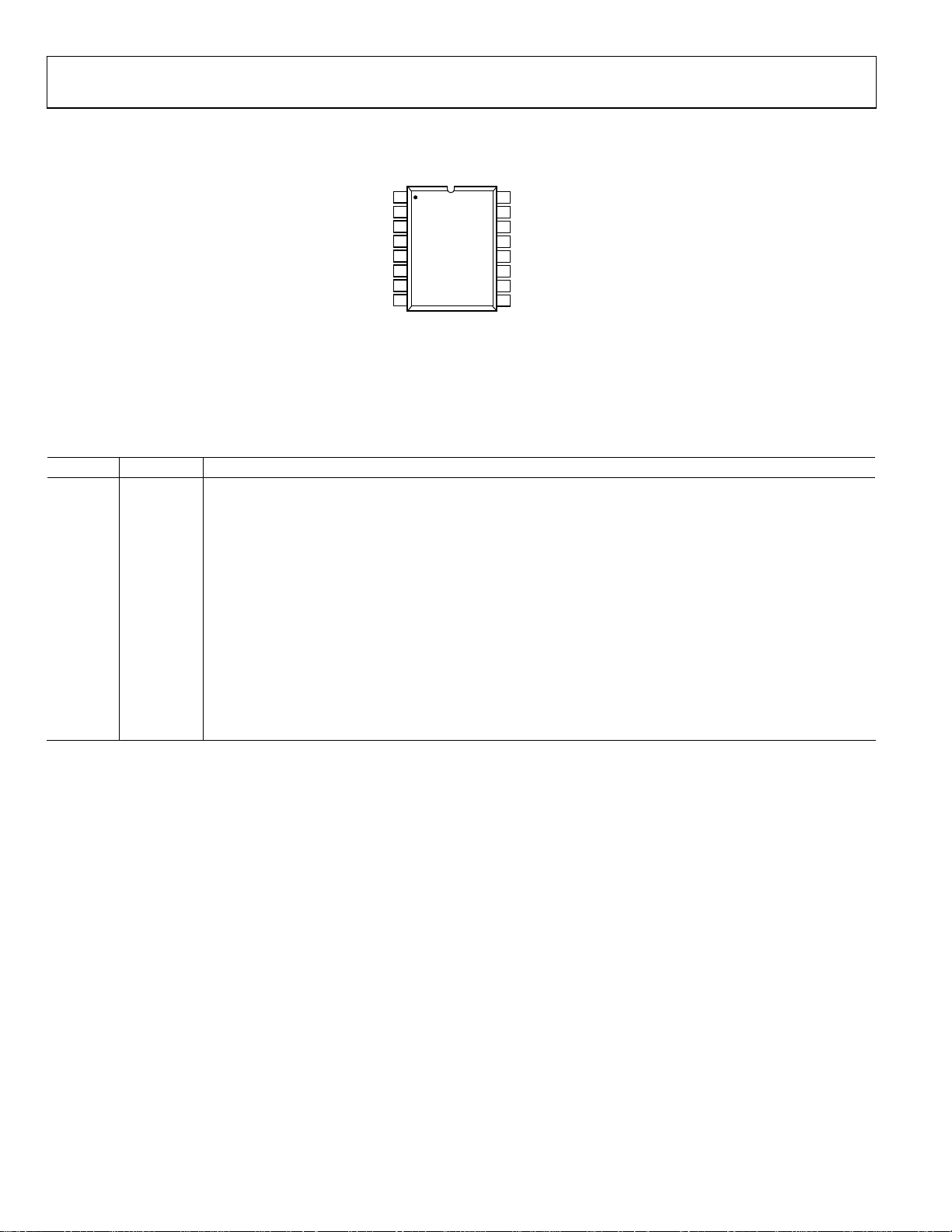

PIN CONFIGURATION AND DESCRIPTIONS

NC

1

NC

2

NC

3

RFB

VIN

VOUT

NC

MCLK

NOTES:

IT IS RECO MMENDED TO TIE ALL SUPPLY

1.

CONNECTIONS (PIN 9, PIN 10, AND PIN 11)

AND RUN FROM A SINGLE SUPPLY BETWEEN

2.7V AND 5.5V. IT IS ALSO RECOMMENDED TO

CONNECT ALL GROUND SIGNALS TOGETHER

(PIN 12, PI N 13, AND PIN 14).

AD5933

4

TOP VIEW

5

(Not to Scale)

6

7

8

NC = NO CONNECT

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1, 2, 3, 7 NC No Connect.

4 RFB

External Feedback Resistor. Connected from Pin 4 to Pin 5 and used to set the gain of the current-to-voltage

amplifier on the receive side.

5 VIN Input to Receive Transimpedance Amplifier. Presents a virtual earth voltage of VDD/2.

6 VOUT Excitation Voltage Signal Output.

8 MCLK The master clock for the system is supplied by the user.

9 DVDD Digital Supply Voltage.

10 AVDD1 Analog Supply Voltage 1.

11 AVDD2 Analog Supply Voltage 2.

12 DGND Digital Ground.

13 AGND1 Analog Ground 1.

14 AGND2 Analog Ground 2.

15 SDA I2C Data Input. Open-drain pins requiring 10 kΩ pull-up resistors to VDD.

16 SCL I2C Clock Input. Open-drain pins requiring 10 kΩ pull-up resistors to VDD.

16

15

14

13

12

11

10

9

SCL

SDA

AGND2

AGND1

DGND

AVDD2

AVDD1

DVDD

05324-003

Rev. D | Page 8 of 44

Page 9

Data Sheet AD5933

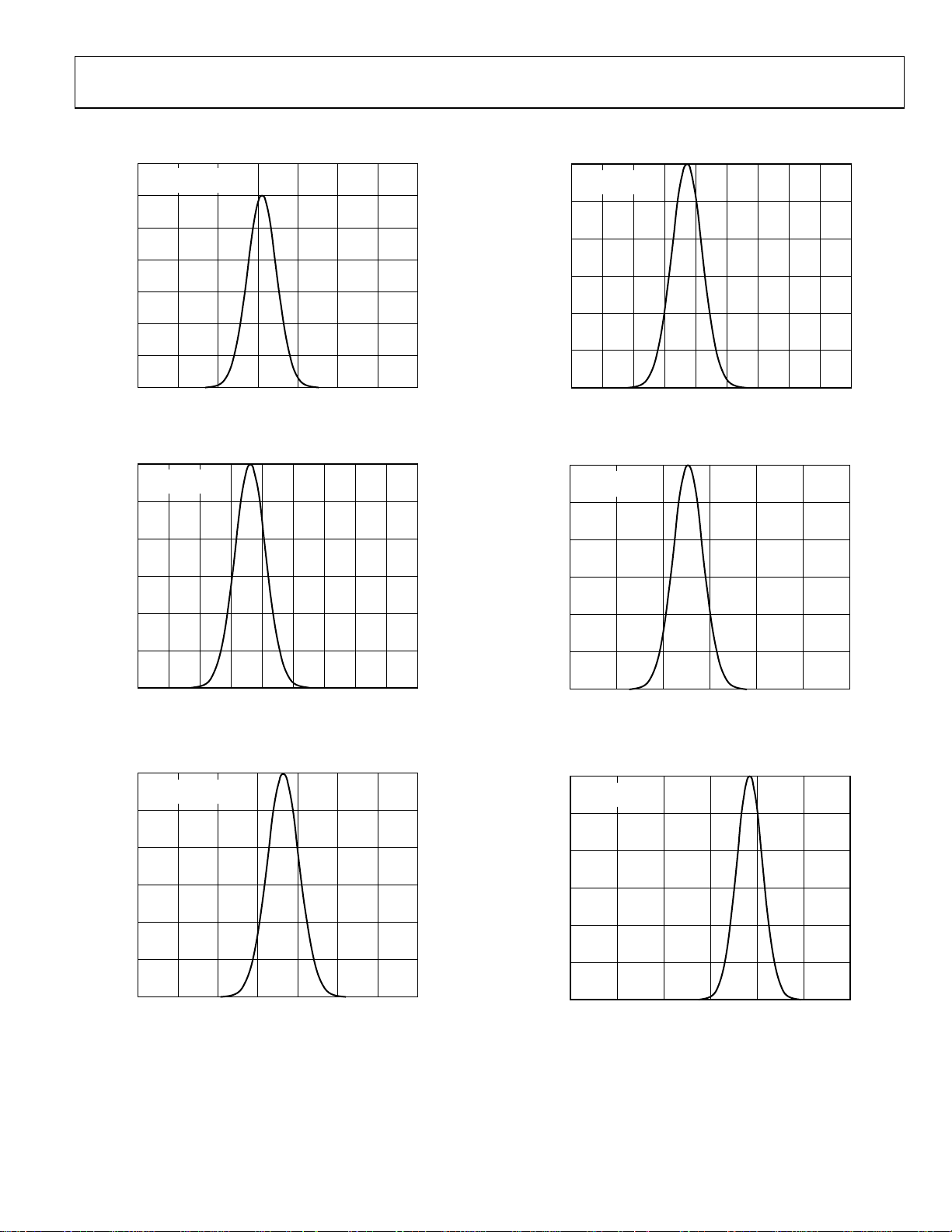

TYPICAL PERFORMANCE CHARACTERISTICS

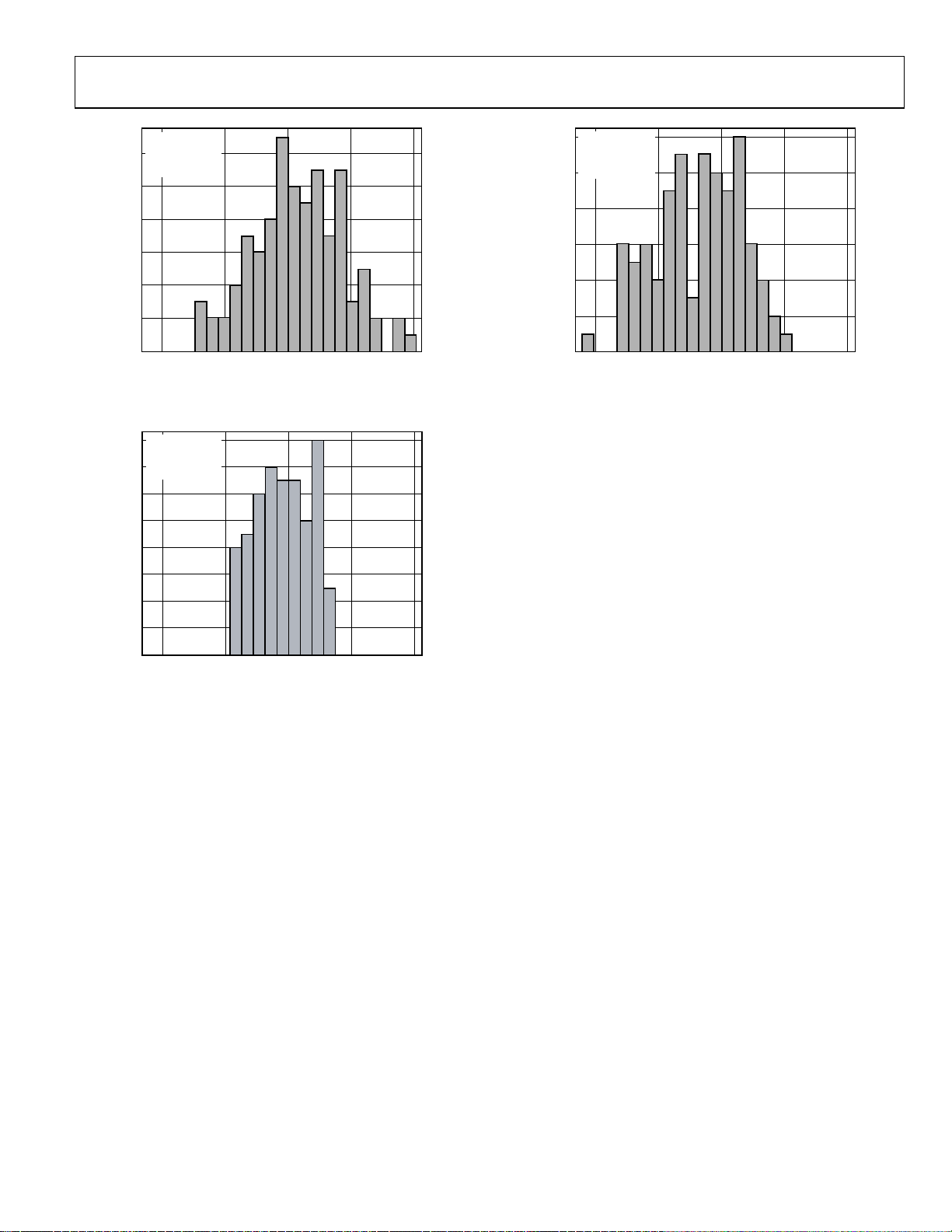

35

30

25

20

15

NUMBER OF DEVICES

10

MEAN = 1.9824

SIGMA = 0.0072

30

25

20

15

10

NUMBER OF DEVI CES

MEAN = 0.7543

SIGMA = 0.0099

5

0

1.92 1.94 1.96 1.98 2.00 2. 02 2.04

VOLTAGE (V)

2.06

Figure 4. Range 1 Output Excitation Voltage Distribution, VDD = 3.3 V

30

MEAN = 1.4807

SIGMA = 0.0252

25

20

15

10

NUMBER OF DEVI CES

5

0

1.30

1.35 1.40 1.45 1.50 1.55 1.60 1.65 1.70

VOLTAGE (V)

1.75

Figure 5. Range 1 DC Bias Distribution, VDD = 3.3 V

30

MEAN = 0.9862

SIGMA = 0.0041

25

5

0

0.68

0.70 0.72 0.74 0.76 0.78 0.80 0.82 0.84

05324-004

VOLTAGE (V)

0.86

05324-007

Figure 7. Range 2 DC Bias Distribution, VDD = 3.3 V

30

MEAN = 0.3827

SIGMA = 0.00167

25

20

15

10

NUMBER OF DEVICES

5

0

0.370

05324-005

0.375 0. 380 0.385 0.390 0.395

VOLTAGE (V)

0.400

05324-008

Figure 8. Range 3 Output Excitation Voltage Distribution, VDD = 3.3 V

30

MEAN = 0.3092

SIGMA = 0.0014

25

20

15

10

NUMBER OF DEVI CES

5

0

0.95 0.96 0.97 0.98 0.99 1. 00 1.01 1.02

VOLTAGE (V)

Figure 6. Range 2 Output Excitation Voltage Distribution, VDD = 3.3 V

05324-006

Rev. D | Page 9 of 44

20

15

10

NUMBER OF DEVI CES

5

0

0.290

0.295 0. 300 0.305 0.310 0.315

VOLTAGE (V)

Figure 9. Range 3 DC Bias Distribution, VDD = 3.3 V

0.320

05324-009

Page 10

AD5933 Data Sheet

30

MEAN = 0.1982

SIGMA = 0.0008

25

20

15

10

NUMBER OF DEVICES

5

0

0.192 0.194 0.196 0.198 0.200 0.202 0.204 0.206

VOLTAGE (V)

Figure 10. Range 4 Output Excitation Voltage Distribution, VDD = 3.3 V

30

MEAN = 0.1792

SIGMA = 0.0024

25

20

15

10

NUMBER OF DEVICES

5

15.8

AVDD1, AVDD2, DVDD CONNECTED TOG ETHER.

OUTPUT EXCITAT ION FREQUENCY = 30kHz

15.3

RFB, Z

14.8

14.3

13.8

13.3

IDD (mA)

12.8

12.3

11.8

11.3

10.8

05324-010

CALIBR AT ION

0

246810121416

= 100kΩ

MCLK FREQUENCY (MHz)

18

05324-012

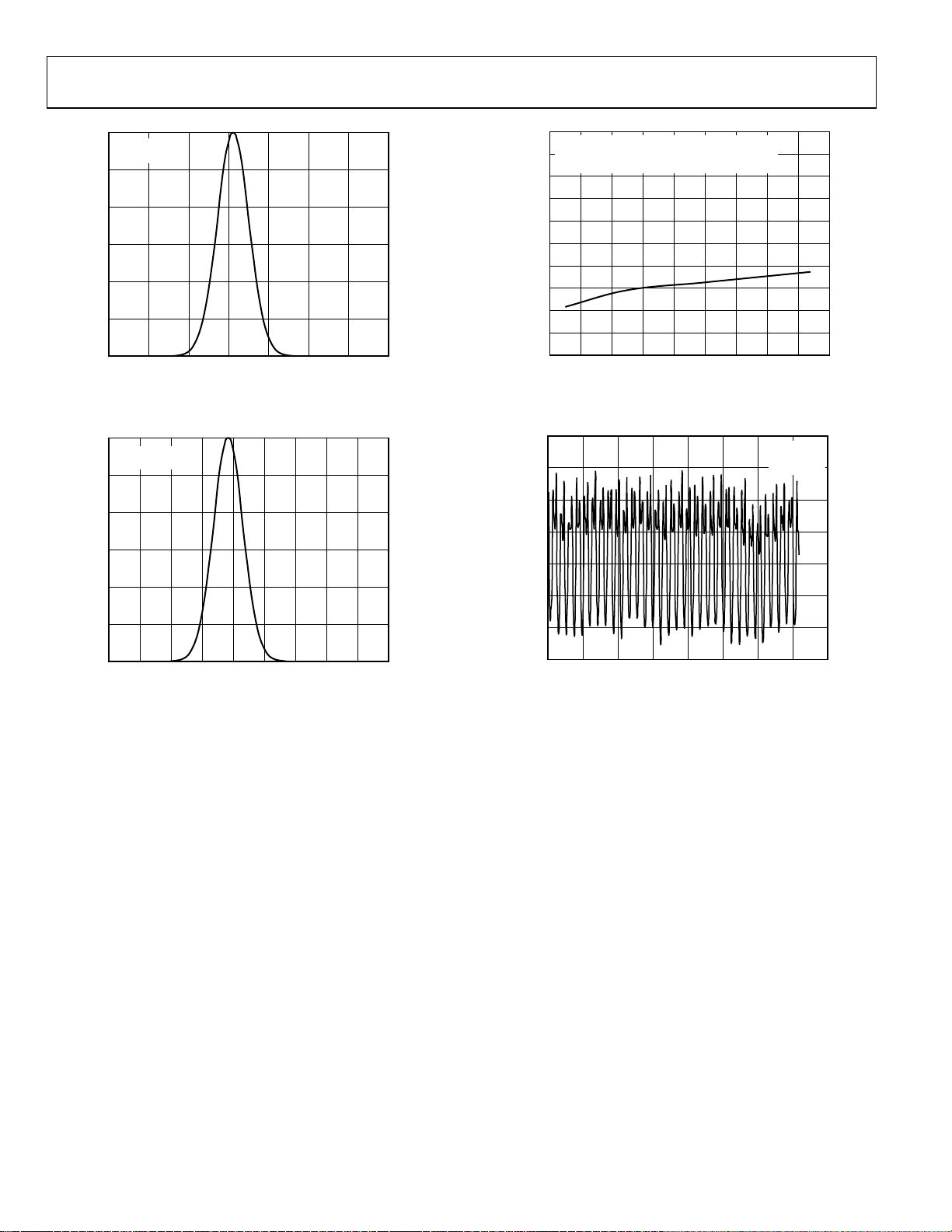

Figure 12. Typical Supply Current vs. MCLK Frequency

0.4

0.2

0

–0.2

–0.4

–0.6

PHASE ERROR (Degrees)

–0.8

VDD = 3.3V

= 25°C

T

A

f = 32kHz

0

0.160

0.165 0.170 0.175 0.180 0.185 0.190 0.195 0. 200

VOLTAGE (V)

Figure 11. Range 4 DC Bias Distribution, VDD = 3.3 V

0.205

–1.0

0

50 100 150 200 250 300 350

05324-011

PHASE (Degrees)

400

05324-013

Figure 13. Typical Phase Error

Rev. D | Page 10 of 44

Page 11

Data Sheet AD5933

12

N = 106

MEAN = 16.8292

12

SD = 0.142904

TEMP = –40°C

10

8

6

COUNT

4

N = 100

MEAN = 16.7257

SD = 0.137633

TEMP = 125°C

10

8

6

COUNT

4

2

0

16.4 16.6 16.8 17. 0

OSCILLATOR FREQUENCY (MHz)

17.2

05324-014

2

0

16.4 16.6 16.8 17. 0

OSCILLATOR FREQUENCY (MHz)

Figure 14. Frequency Distribution of Internal Oscillator at −40°C Figure 16. Frequency Distribution of Internal Oscillator at 125°C

16

N = 100

MEAN = 16.78 11

SD = 0.0881565

14

TEMP = 25°C

12

10

8

COUNT

6

4

2

0

16.4 16.6 16.8 17. 0

OSCILLATOR FREQUENCY (MHz)

17.2

05324-015

Figure 15. Frequency Distribution of Internal Oscillator at 25°C

17.2

05324-016

Rev. D | Page 11 of 44

Page 12

AD5933 Data Sheet

TERMINOLOGY

Tot a l S ys t em A cc ur ac y

The AD5933 can accurately measure a range of impedance

values to less than 0.5% of the correct impedance value for

supply voltages between 2.7 V to 5.5 V.

Spurious-Free Dynamic Range (SFDR)

Along with the frequency of interest, harmonics of the fundamental frequency and images of these frequencies are present at

the output of a DDS device. The spurious-free dynamic range

refers to the largest spur or harmonic present in the band of

interest. The wideband SFDR gives the magnitude of the largest

harmonic or spur relative to the magnitude of the fundamental

frequency in the 0 Hz to Nyquist bandwidth. The narrow-band

SFDR gives the attenuation of the largest spur or harmonic in a

bandwidth of ±200 kHz, about the fundamental frequency.

Signal-to-Noise Ratio (SNR)

SNR is the ratio of the rms value of the measured output signal

to the rms sum of all other spectral components below the

Nyquist frequency. The value for SNR is expressed in decibels.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of harmonics to the fundamental, where V1 is the rms amplitude of the fundamental

and V2, V3, V4, V5, and V6 are the rms amplitudes of the

second through the sixth harmonics. For the AD5933, THD

is defined as

22222

5

+++

THD

log20(dB)

=

V1

V6VV4V3V2

Rev. D | Page 12 of 44

Page 13

Data Sheet AD5933

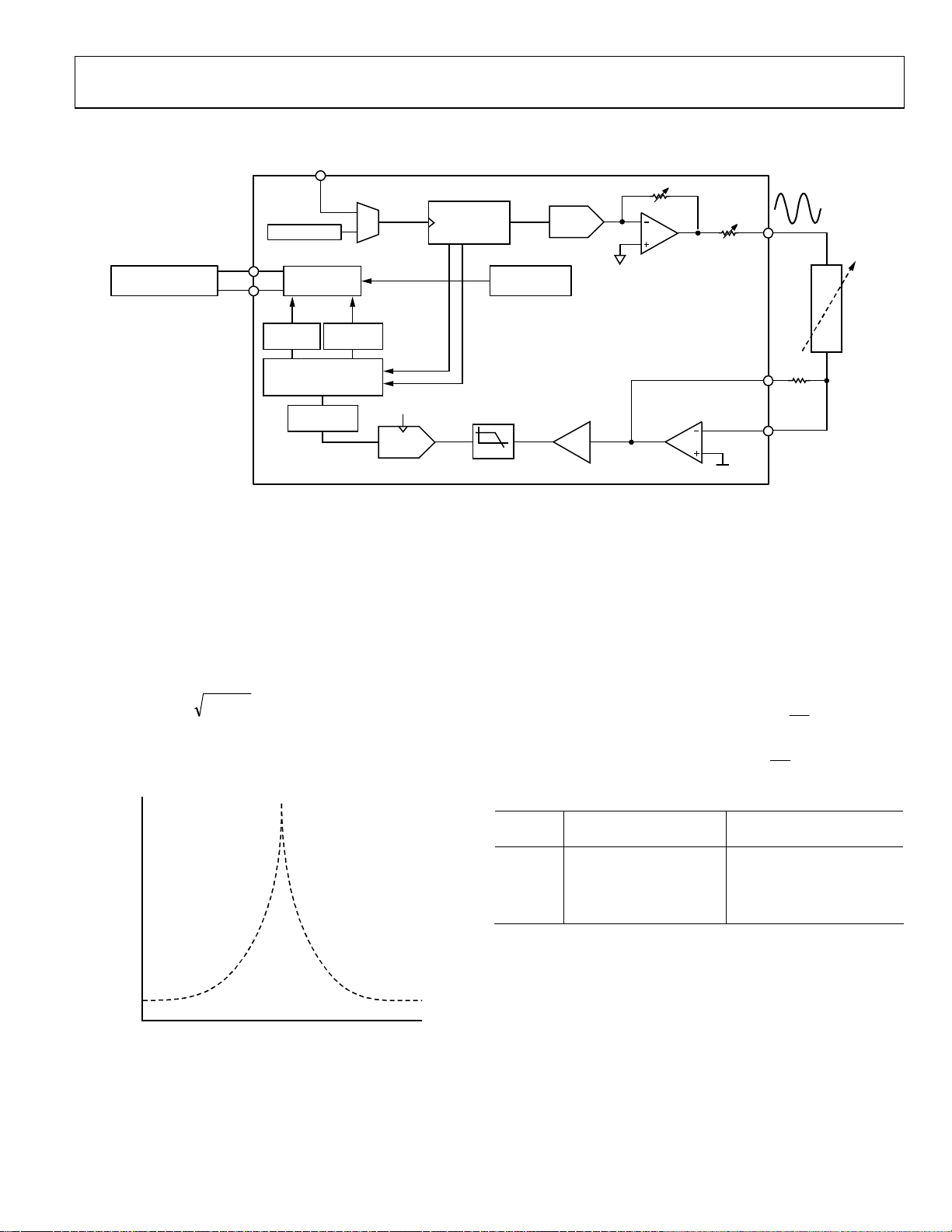

SYSTEM DESCRIPTION

MCLK

DDS

MICROCONTRO LLER

SCL

SDA

OSCILLATOR

I2C

INTERFACE

CORE

(27 BITS)

COS SIN

TEMPERATURE

SENSOR

DAC

R

OUT

VOUT

Z(ω)

REAL

REGISTER

IMAGINARY

REGISTER

MAC CORE

(1024 DFT)

WINDOWI NG

OF DATA

MCLK

ADC

(12 BITS)

Figure 17. Block Overview

The AD5933 is a high precision impedance converter system

solution that combines an on-board frequency generator with a

12-bit, 1 MSPS ADC. The frequency generator allows an external

complex impedance to be excited with a known frequency. The

response signal from the impedance is sampled by the on-board

ADC and DFT processed by an on-board DSP engine. The DFT

algorithm returns both a real (R) and imaginary (I) data-word at

each frequency point along the sweep. The impedance magnitude

and phase are easily calculated using the following equations:

22

IRMagnitude +=

Phase

= tan−1(I/R)

To characterize an impedance profile Z(

ω), generally a frequency

sweep is required, like that shown in Figure 18.

IMPEDANCE

FREQUENCY

Figure 18. Impedance vs. Frequency Profile

05324-018

AD5933

RFB

PROGRAMMABLE

LPF

GAIN AMPLIFIER

×5

×1

VDD/2

VIN

The AD5933 permits the user to perform a frequency sweep with

a user-defined start frequency, frequency resolution, and number

of points in the sweep. In addition, the device allows the user to

program the peak-to-peak value of the output sinusoidal signal as

an excitation to the external unknown impedance connected

between the VOUT and VIN pins.

Table 5 gives the four possible output peak-to-peak voltages and

the corresponding dc bias levels for each range for 3.3 V. These

values are ratiometric with VDD. So for a 5 V supply

98.1 −=×=1RangeforVoltageExcitationOutput

48.1 −=×=1RangeforVoltageBiasDCOutput

0.5

3.3

0.5

3.3

Table 5. Voltage Levels Respective Bias Levels for 3.3 V

Output Excitation

Range

Voltage Amplitude Output DC Bias Level

1 1.98 V p-p 1.48 V

2 0.97 V p-p 0.76 V

3 383 mV p-p

0.31 V

4 198 mV p-p 0.173 V

The excitation signal for the transmit stage is provided on-chip

using DDS techniques that permit subhertz resolution. The receive

stage receives the input signal current from the unknown impedance,

performs signal processing, and digitizes the result. The clock for

the DDS is generated from either an external reference clock,

which is provided by the user at MCLK, or by the internal

oscillator. The clock for the DDS is determined by the status of

Bit D3 in the control register (see Register Address 0x81 in the

Register Map section).

05324-017

ppV3

ppV24.2

Rev. D | Page 13 of 44

Page 14

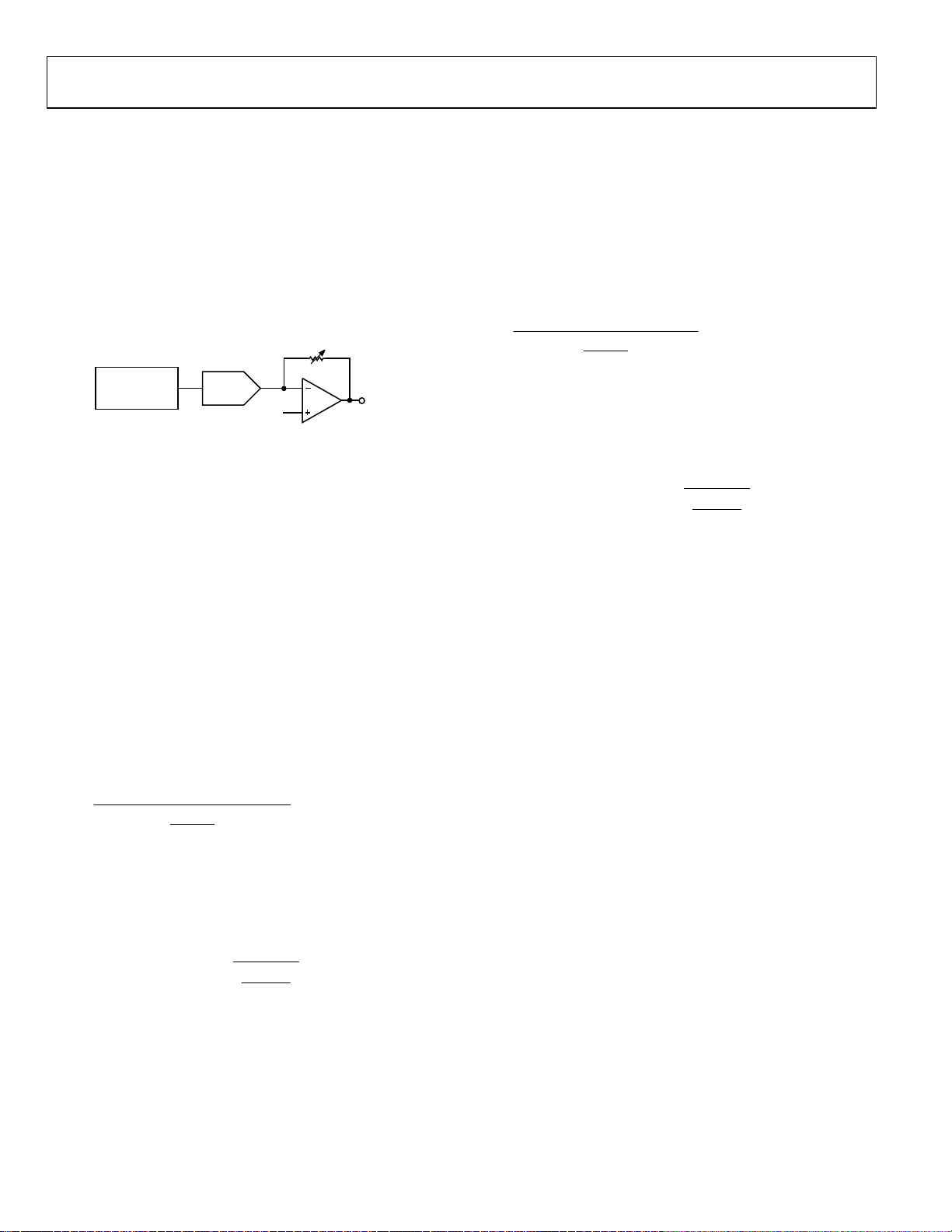

AD5933 Data Sheet

=

TRANSMIT STAGE

As shown in Figure 19, the transmit stage of the AD5933 is made

up of a 27-bit phase accumulator DDS core that provides the

output excitation signal at a particular frequency. The input to

the phase accumulator is taken from the contents of the start

frequency register (see Register Address 0x82, Register Address

0x83, and Register Address 0x84). Although the phase accumulator offers 27 bits of resolution, the start frequency register has

the three most significant bits (MSBs) set to 0 internally; therefore,

the user has the ability to program only the lower 24 bits of the

start frequency register.

R(GAIN)

PHASE

ACCUMULATOR

(27 BITS)

The AD5933 offers a frequency resolution programmable by the

user down to 0.1 Hz. The frequency resolution is programmed

via a 24-bit word loaded serially over the I

frequency increment register.

The frequency sweep is fully described by the programming of

three parameters: the start frequency, the frequency increment,

and the number of increments.

Start Frequency

This is a 24-bit word that is programmed to the on-board RAM

at Register Address 0x82, Register Address 0x83, and Register

Address 0x84 (see the Register Map section). The required code

loaded to the start frequency register is the result of the formula

shown in Equation 1, based on the master clock frequency and the

required start frequency output from the DDS.

⎛

⎜

⎜

⎜

⎜

⎝

⎛

⎜

⎝

For example, if the user requires the sweep to begin at 30 kHz and

has a 16 MHz clock signal connected to MCLK, the code that

needs to be programmed is given by

The user programs the value of 0x0F to Register Address 0x82, the

value of 0x5C to Register Address 0x83, and the value of 0x28 to

Register Address 0x84.

DAC

V

BIAS

Figure 19. Transmit Stage

=

CodeFrequencyStart

FrequencyStartOutputRequired

MCLK

⎞

⎟

⎠

⎛

⎜

kHz30

⎜

=CodeFrequencyStart

⎜

MHz16

⎛

⎜

⎜

⎜

4

⎝

⎝

VOUT

5324-019

2

C interface to the

⎞

⎟

(1)

27

⎟

24×

⎟

⎟

⎠

⎞

⎟

⎟

27

0x0F5C282

≡×

⎟

⎞

⎟

⎟

⎟

⎠

⎠

Frequency Increment

This is a 24-bit word that is programmed to the on-board RAM

at Register Address 0x85, Register Address 0x86, and Register

Address 0x87 (see the Register Map). The required code loaded

to the frequency increment register is the result of the formula

shown in Equation 2, based on the master clock frequency and the

required increment frequency output from the DDS.

CodeIncrementFrequency

⎛

⎜

Re

⎜

⎜

⎜

⎝

MCLK

⎛

⎜

⎝

IncrementFrequencyquired

⎞

⎟

4

⎠

⎞

⎟

(2)

27

⎟

×

2

⎟

⎟

⎠

For example, if the user requires the sweep to have a resolution

of 10 Hz and has a 16 MHz clock signal connected to MCLK, the

code that needs to be programmed is given by

⎛

⎜

⎜

=CodeIncrementFrequency

⎜

⎛

⎜

⎜

⎜

⎝

⎝

⎞

⎟

Hz10

⎟

0x00014F

≡

⎟

MHz16

⎞

⎟

⎟

⎟

4

⎠

⎠

The user programs the value of 0x00 to Register Address 0x85,

the value of 0x01 to Register Address 0x86, and the value of 0x4F

to Register Address 0x87.

Number of Increments

This is a 9-bit word that represents the number of frequency

points in the sweep. The number is programmed to the on-board

RAM at Register Address 0x88 and Register Address 0x89 (see the

Register Map section). The maximum number of points that can

be programmed is 511.

For example, if the sweep needs 150 points, the user programs

the value of 0x00 to Register Address 0x88 and the value of 0x96

to Register Address 0x89.

Once the three parameter values have been programmed, the

sweep is initiated by issuing a start frequency sweep command to

the control register at Register Address 0x80 and Register Address

0x81 (see the Register Map section). Bit D2 in the status register

(Register Address 0x8F) indicates the completion of the frequency

measurement for each sweep point. Incrementing to the next

frequency sweep point is under the control of the user. The

measured result is stored in the two register groups that follow:

0x94, 0x95 (real data) and 0x96, 0x97 (imaginary data) that should

be read before issuing an increment frequency command to the

control register to move to the next sweep point. There is the

facility to repeat the current frequency point measurement by

issuing a repeat frequency command to the control register. This

has the benefit of allowing the user to average successive readings.

When the frequency sweep has completed all frequency points,

Bit D3 in the status register is set, indicating completion of the

sweep

. Once this bit is set, further increments are disabled.

Rev. D | Page 14 of 44

Page 15

Data Sheet AD5933

V

FREQUENCY SWEEP COMMAND SEQUENCE RECEIVE STAGE

The following sequence must be followed to implement a

frequency sweep:

1. Enter standby mode. Prior to issuing a start frequency sweep

command, the device must be placed in a standby

mode by

issuing an enter standby mode command to the control

register (Register Address 0x80 and Register Address 0x81).

In this mode, the VOUT and VIN pins are connected

internally to ground so there is no dc bias across the external

impedance or between the impedance and ground.

2. Enter initialize

mode. In general, high Q complex circuits

require a long time to reach steady state. To facilitate the

measurement of such impedances, this mode allows the user

full control of the settling time requirement before entering

start frequency sweep

measurement takes place.

mode where the impedance

An initialize with a start frequency command to the control

register enters initialize mode. In this mode the impedance

is excited with the programmed start frequency, but no measurement takes place. The user times out the required settling

time before issuing a start frequency sweep command to the

control register to enter the start frequency sweep mode.

3. Enter start frequency sweep

mode. The user enters this mode

by issuing a start frequency sweep command to the control

register. In this mode, the ADC starts measuring after the

programmed number of settling time cycles has elapsed. The

user can program an integer number of output frequency

cycles (settling time cycles)

to Register Address 0x8A and

Register Address 0x8B before beginning the measurement

at each frequency point (see Figure 28).

The DDS output signal is passed through a programmable gain

stage to generate the four ranges of peak-to-peak output excitation

signals listed in Tabl e 5. The peak-to-peak output excitation voltage is selected by setting Bit D10 and Bit D9 in the control register

(see the Control Register (Register Address 0X80, Register

Address 0X81) section) and is made available at the VOUT pin.

The receive stage comprises a current-to-voltage amplifier,

followed by a programmable gain amplifier (PGA), antialiasing

filter, and ADC. The receive stage schematic is shown in

Figure 20. The unknown impedance is connected between the

VOUT and VIN pins. The first stage current-to-voltage amplifier

configuration means that a voltage present at the VIN pin is a

virtual ground with a dc value set at VDD/2. The signal current

that is developed across the unknown impedance flows into the

VIN pin and develops a voltage signal at the output of the currentto-voltage converter. The gain of the current-to voltage amplifier

is determined by a user-selectable feedback resistor connected

between Pin 4 (RFB) and Pin 5 (VIN). It is important for the user

to choose a feedback resistance value that, in conjunction with the

selected gain of the PGA stage, maintains the signal within the

linear range of the ADC (0 V to VDD).

The PGA allows the user to gain the output of the current-tovoltage amplifier by a factor of 5 or 1, depending upon the status

of Bit D8 in the control register (see the Register Map section,

Register Address 0x80). The signal is then low-pass filtered and

presented to the input of the 12-bit, 1 MSPS ADC.

RFB

R

5 × R

R

LPF

ADC

05324-020

IN

C

R

VDD/2

Figure 20. Receive Stage

The digital data from the ADC is passed directly to the DSP core

of the AD5933, which performs a DFT on the sampled data.

DFT OPERATION

A DFT is calculated for each frequency point in the sweep. The

AD5933 DFT algorithm is represented by

1023

∑

n

=

0

−=

)))sin())(cos((()(

njnnxfX

where:

X(f) is the power in the signal at the Frequency Point f.

x(n) is the ADC output.

cos(n) and sin(n) are the sampled test vectors provided by the

DDS core at the Frequency Point f.

The multiplication is accumulated over 1024 samples for each

frequency point. The result is stored in two, 16-bit registers

representing the real and imaginary components of the result.

The data is stored in twos complement format.

Rev. D | Page 15 of 44

Page 16

AD5933 Data Sheet

SYSTEM CLOCK

The system clock for the AD5933 can be provided in one of two

ways. The user can provide a highly accurate and stable system

clock at the external clock pin (MCLK). Alternatively, the AD5933

provides an internal clock with a typical frequency of 16.776 MHz

by means of an on-chip oscillator.

The user can select the preferred system clock by programming

Bit D3 in the control register (Register Address 0x81, see

Table 11 ). The default clock option on power-up is selected to

be the internal oscillator.

The frequency distribution of the internal clock with temperature

can be seen in Figure 14, Figure 15, and Figure 16.

TEMPERATURE SENSOR

The temperature sensor is a 13-bit digital temperature sensor with

th

a 14

bit that acts as a sign bit. The on-chip temperature sensor

allows an accurate measurement of the ambient device temperature to be made.

The measurement range of the sensor is −40°C to +125°C. At

+150°C, the structural integrity of the device starts to deteriorate

when operated at voltage and temperature maximum specifications. The accuracy within the measurement range is ±2°C.

TEMPERATURE CONVERSION DETAILS

The conversion clock for the part is internally generated; no

external clock is required except when reading from and writing

to the serial port. In normal mode, an internal clock oscillator

runs an automatic conversion sequence.

The temperature sensor block defaults to a power-down state.

To perform a measurement, a measure temperature command

is issued by the user to the control register (Register Address 0x80

and Register Address 0x81). After the temperature operation is

complete (typically 800 s later), the block automatically

powers down until the next temperature command is issued.

The user can poll the status register (Register Address 0x8F) to see

if a valid temperature conversion has taken place, indicating that

valid temperature data is available to read at Register Address

0x92 and Register Address 0x93 (see the Register Map section).

TEMPERATURE VALUE REGISTER

The temperature value register is a 16-bit, read-only register that

stores the temperature reading from the ADC in 14-bit, twos

complement format. The two MSB bits are don’t cares. D13 is the

sign bit. The internal temperature sensor is guaranteed to a low

value limit of –40°C and a high value limit of +150°C. The digital

output stored in Register Address 0x92 and Register Address 0x93

for the various temperatures is outlined in Tabl e 6. The temperature sensor transfer characteristic is shown in Figure 21.

Table 6. Temperature Data Format

Temperature Digital Output D13…D0

−40°C 11, 1011, 0000, 0000

−30°C 11, 1100, 0100, 0000

−25°C 11, 1100, 1110, 0000

−10°C 11, 1110, 1100, 0000

−0.03125°C 11, 1111, 1111, 1111

0°C 00, 0000, 0000, 0000

+0.03125°C 00, 0000, 0000, 0001

+10°C 00, 0001, 0100, 0000

+25°C 00, 0011, 0010, 0000

+50°C 00, 0110, 0100, 0000

+75°C 00, 1001, 0110, 0000

+100°C 00, 1100, 1000, 0000

+125°C 00, 1111, 1010, 0000

+150°C 01, 0010, 1100, 0000

TEMPERATURE CONVERSION FORMULA

Positive Temperature = ADC Code (D)/32

Negative Temperature = (ADC Code (D)

where ADC Code uses all 14 bits of the data byte, including the

sign bit.

Negative Temperature = (ADC Code (D)

where ADC Code (D) is D13, the sign bit, and is removed from the

ADC code.)

01, 0010, 1100, 0000

00, 1001, 0 110, 0000

00, 0000, 0000, 0001

–0.03125°C

–40°C

–30°C

DIGITAL OUT PUT

11, 1111, 1111, 1111

11, 1100, 0100, 0000

11, 1011, 0000, 0000

Figure 21. Temperature Sensor Transfer Function

– 16384)/32

– 8192)/32

75°C

TEMPERATURE (°C)

150°C

05324-021

Rev. D | Page 16 of 44

Page 17

Data Sheet AD5933

IMPEDANCE CALCULATION

1

MAGNITUDE CALCULATION

The first step in impedance calculation for each frequency point

is to calculate the magnitude of the DFT at that point.

The DFT magnitude is given by

22

IRMagnitude +=

where:

R is the real number stored at Register Address 0x94 and

Register Address 0x95.

I is the imaginary number stored at Register Address 0x96 and

Register Address 0x97.

For example, assume the results in the real data and imaginary

data registers are as follows at a frequency point:

Real data register = 0x038B = 907 decimal

Imaginary data register = 0x0204 = 516 decimal

22

=+=Magnitude

506.1043)516907(

To convert this number into impedance, it must be multiplied

by

a scaling factor called the gain factor. The gain factor is

calculated during the calibration of the system with a known

impedance connected between the VOUT and VIN pins.

Once the gain factor has been calculated, it can be used in the

calculation of any unknown impedance between the VOUT and

VIN pins.

GAIN FACTOR CALCULATION

An example of a gain factor calculation follows, with the

following assumptions:

Output excitation voltage = 2 V p-p

Calibration impedance value, Z

CALIBRATION

PGA Gain = ×1

Current-to-voltage amplifier gain resistor = 200 kΩ

Calibration frequency = 30 kHz

Then typical contents of the real data and imaginary data

registers after a frequency point conversion are:

Real data register = 0xF064 = −3996 decimal

Imaginary data register = 0x227E = +8830 decimal

= 200 kΩ

22

=+−=Magnitude

106.9692)8830()3996(

⎛

⎜

⎜

=FactorGain

⎜

⎜

⎝

IMPEDANCE CALCULATION USING GAIN FACTOR

The next example illustrates how the calculated gain factor

derived previously is used to measure an unknown impedance.

For this example, assume that the unknown impedance = 510

kΩ.

After measuring the unknown impedance at a frequency of

30 kHz, assume that the real data and imaginary data registers

contain the following data:

Real data register = 0xFA3F = −1473 decimal

Imaginary data register = 0x0DB3 = +3507 decimal

Then the measured impedance at the frequency point is given

by

Impedance

=

=

GAIN FACTOR VARIATION WITH FREQUENCY

Because the AD5933 has a finite frequency response, the gain

factor also shows a variation with frequency. This variation in

gain factor results in an error in the impedance calculation over

a frequency range. Figure 22 shows an impedance profile based

on a single-point gain factor calculation. To minimize this error,

the frequency sweep should be limited to as small a frequency

range as possible.

101.5

VDD = 3.3V

CALIBRATION FREQUENCY = 60kHz

T

= 25°C

A

101.0

MEASURED CALIBR ATION IMPEDANCE = 100kΩ

100.5

100.0

IMPEDANCE (kΩ)

99.5

⎞

⎟

k200

Ω

⎟

=

⎟

106.9692

⎟

12-

10 × 515.819

⎠

22

1

MagnitudeFactorGain ×

863.3802))3507()1473((

=+−=Magnitude

1

−

12

××

863.380210819273.515

Ω=Ω

k791.509

⎛

⎜

⎜

FactorGain

⎜

Code

⎝

Admittance

⎛

=

⎞

⎝

=

⎟

⎠

Impedance

Magnitude

⎞

1

⎟

⎟

⎠

99.0

98.5

54

Figure 22. Impedance Profile Using a Single-Point Gain Factor Calculation

56 58 60 62 64

FREQUENCY (kHz)

66

05324-022

Rev. D | Page 17 of 44

Page 18

AD5933 Data Sheet

V

TWO-POINT CALIBRATION

Alternatively, it is possible to minimize this error by assuming

that the frequency variation is linear and adjusting the gain

factor with a two-point calibration. Figure 23 shows an

impedance profile based on a two-point gain factor calculation.

101.5

VDD = 3.3V

CALIBRATION F REQUENCY = 60kHz

T

= 25°C

A

101.0

MEASURED CALIBR ATION IMPEDANCE = 100kΩ

100.5

100.0

IMPEDANCE (kΩ)

99.5

99.0

98.5

54

Figure 23. Impedance Profile Using a Two-Point Gain Factor Calculation

56 58 60 62 64

FREQUE NCY (kHz )

66

05324-023

TWO-POINT GAIN FACTOR CALCULATION

This is an example of a two-point gain factor calculation

assuming the following:

Output excitation voltage = 2 V (p-p)

Calibration impedance value, Z

PGA gain = ×1

Supply voltage = 3.3 V

Current-to-voltage amplifier gain resistor = 100 kΩ

Calibration frequencies = 55 kHz and 65 kHz

Typical values of the gain factor calculated at the two calibration

frequencies read

Gain factor calculated at 55 kHz is 1.031224E-09

Gain factor calculated at 65 kHz is 1.035682E-09

Difference in gain factor (∆GF) is 1.035682E-09 −

1.031224E-09 = 4.458000E-12

Frequency span of sweep (∆F) = 10 kHz

Therefore, the gain factor required at 60 kHz is given by

= 100.0 kΩ

UNKNOWN

GAIN FACTOR SETUP CONFIGURATION

When calculating the gain factor, it is important that the receive

stage operate in its linear region. This requires careful selection

of the excitation signal range, current-to-voltage gain resistor,

and PGA gain.

CURRENT-TO-VOLTAGE

GAIN SETTING RESISTOR

RFB

Z

OUT

UNKNOWN

VDD/2

VIN

PGA

(×1 OR ×5)

Figure 24. System Voltage Gain

LPF

ADC

The gain through the system shown in Figure 24 is given by

RangeVoltageExcitationOuput

×

sistorSettingGain

Z

UNKNOWN

Re

GainPGA

×

For this example, assume the following system settings:

VDD = 3.3 V

Gain setting resistor = 200 kΩ

UNKNOWN

= 200 kΩ

Z

PGA setting = ×1

The peak-to-peak voltage presented to the ADC input is

2 V p-p. However, if a PGA gain of ×5 was chose, the voltage

would saturate the ADC.

GAIN FACTOR RECALCULATION

The gain factor must be recalculated for a change in any of the

following parameters:

•

Current-to-voltage gain setting resistor

Output excitation voltage

•

•

PGA gain

05324-024

⎛

⎜

⎜

⎝

12-E458000.4

kHz10

×

⎞

⎟

⎟

⎠

9-

10031224.1kHz5

×+

The required gain factor is 1.033453E-9.

The impedance is calculated as previously described.

Rev. D | Page 18 of 44

Page 19

Data Sheet AD5933

GAIN FACTOR TEMPERATURE VARIATION

The typical impedance error variation with temperature is in

the order of 30 ppm/°C. Figure 25 shows an impedance profile

with a variation in temperature for 100 kΩ impedance using a

two-point gain factor calibration.

101.5

VDD = 3.3V

CALIBRATION F REQUENCY = 60kHz

MEASURED CALIBR ATION IMPEDANCE = 100kΩ

101.0

100.5

100.0

IMPEDANCE (kΩ)

99.5

99.0

98.5

54

Figure 25. Impedance Profile Variation with Temperature Using a Two-Point

56 58 60 62 64

FREQUENCY ( kHz)

Gain Factor Calibration

+125°C

+25°C

–40°C

66

05324-025

IMPEDANCE ERROR

It is important when reading the following section to note that

the output impedance associated with the excitation voltages

was actually measured and then calibrated out for each

impedance error measurement. This was done using a Keithley

current source/sink and measuring the voltage.

R

(for example ,200 specified for a 1.98 V p-p in the

OUT

specification table) is only a typical specification and can vary

from part to part. This method may not be achievable for large

volume applications and in such cases, it is advised to use an

extra low impedance output amplifier, as shown in Figure 4, to

improve accuracy.

Please refer to CN-0217 for impedance accuracy examples on

the AD5933 product web-page.

MEASURING THE PHASE ACROSS AN IMPEDANCE

The AD5933 returns a complex output code made up of separate real and imaginary components. The real component is

stored at Register Address 0x94 and Register Address 0x95 and

the imaginary component is stored at Register Address 0x96

and Register Address 0x97 after each sweep measurement.

These correspond to the real and imaginary components of

the DFT and not the resistive and reactive components of the

impedance under test.

For example, it is a very common misconception to assume

that if a user is analyzing a series RC circuit, the real value

stored in Register Address 0x94 and Register Address 0x95

and the imaginary value stored at Register Address 0x96

and Register Address 0x97 correspond to the resistance and

capacitive reactance, respectfully. However, this is incorrect

because the magnitude of the impedance (|Z|) can be calculated

by calculating the magnitude of the real and imaginary components of the DFT given by the following formula:

22

IRMagnitude +=

After each measurement, multiply it by the calibration term and

invert the product. The magnitude of the impedance is, therefore,

given by the following formula:

Impedance

=

1

MagnitudeFactorGain

×

Where gain factor is given by

⎛

⎜

⎜

Admittance

FactorGain

⎛

=

⎜

Code

⎝

⎞

⎝

=

⎟

⎠

Impedance

Magnitude

⎞

1

⎟

⎟

⎠

The user must calibrate the AD5933 system for a known

impedance range to determine the gain factor before any valid

measurement can take place. Therefore, the user must know the

impedance limits of the complex impedance (Z

UNKNOWN

) for the

sweep frequency range of interest. The gain factor is determined

by placing a known impedance between the input/output of the

AD5933 and measuring the resulting magnitude of the code.

The AD5933 system gain settings need to be chosen to place

the excitation signal in the linear region of the on-board ADC.

Because the AD5933 returns a complex output code made up of

real and imaginary components, the user can also calculate the

phase of the response signal through the AD5933 signal path.

The phase is given by the following formula:

Phase(rads) = tan

−1

(I/R) (3)

The phase measured by Equation 3 accounts for the phase shift

introduced to the DDS output signal as it passes through the

internal amplifiers on the transmit and receive side of the

AD5933 along with the low-pass filter and also the impedance

connected between the VOUT and VIN pins of the AD5933.

The parameters of interest for many users are the magnitude of

the impedance (|Z

|) and the impedance phase (ZØ).

UNKNOWN

The measurement of the impedance phase (ZØ) is a two step

process.

The first step involves calculating the AD5933 system phase.

The AD5933 system phase can be calculated by placing a

resistor across the VOUT and VIN pins of the AD5933 and

calculating the phase (using Equation 3) after each measurement point in the sweep. By placing a resistor across the

VOUT and VIN pins, there is no additional phase lead or lag

introduced to the AD5933 signal path and the resulting phase

is due entirely to the internal poles of the AD5933, that is, the

system phase.

Once the system phase has been calibrated using a resistor, the

second step involves calculating the phase of any unknown

impedance by inserting the unknown impedance between the

VIN and VOUT terminals of the AD5933 and recalculating the

Rev. D | Page 19 of 44

Page 20

AD5933 Data Sheet

–

new phase (including the phase due to the impedance) using

the same formula. The phase of the unknown impedance (ZØ)

is given by the following formula:

systemunknownZ ∇−Φ=

)(Ø

where:

system∇

is the phase of the system with a calibration resistor

connected between VIN and VOUT.

Φ

unknown is the phase of the system with the unknown

impedance connected between VIN and VOUT.

ZØ is the phase due to the impedance, that is, the impedance

phase.

Note that it is possible to calculate the gain factor and to

calibrate the system phase using the same real and imaginary

component values when a resistor is connected between the

VOUT and VIN pins of the AD5933, for example, measuring

the impedance phase (ZØ) of a capacitor.

The excitation signal current leads the excitation signal voltage

across a capacitor by −90 degrees. Therefore, an approximate

−90 degree phase difference exists between the system phase

responses measured with a resistor and that of the system phase

responses measured with a capacitive impedance.

As previously outlined, if the user would like to determine the

phase angle of capacitive impedance (ZØ), the user first has to

determine the system phase response (

system∇) and subtract

this from the phase calculated with the capacitor connected

between VOUT and VIN (Φunknown).

A plot showing the AD5933 system phase response calculated

using a 220 k calibration resistor (R

= 220 k, PGA = ×1)

FB

and the repeated phase measurement with a 10 pF capacitive

impedance is shown in Figure 26.

One important point to note about the phase formula used to

plot Figure 26 is that it uses the arctangent function that returns

a phase angle in radians and, therefore, it is necessary to convert

from radians to degrees.

200

180

160

140

120

100

80

60

SYSTEM P HASE (Degrees)

40

20

0

0 15k 30k 45k 60k 75k 90k 105k 120k

Figure 26. System Phase Response vs. Capacitive Phase

220kΩ RESISTOR

10pF CAPACITOR

FREQUENCY (Hz)

05324-032

The phase difference (that is, ZØ) between the phase response

of a capacitor and the system phase response using a resistor is

the impedance phase of the capacitor, ZØ (see Figure 27).

100

–90

–80

–70

–60

–50

–40

PHASE (Degrees)

–30

–20

–10

0

0 15k 30k 45k 60k 75k 90k 105k 120k

Figure 27. Phase Response of a Capacitor

FREQUENCY (Hz)

05324-033

Also when using the real and imaginary values to interpret

the phase at each measurement point, take care when using

the arctangent formula. The arctangent function returns the

correct standard phase angle only when the sign of the real and

imaginary values are positive, that is, when the coordinates lie

in the first quadrant. The standard angle is the angle taken

counterclockwise from the positive real x-axis. If the sign of the

real component is positive and the sign of the imaginary

component is negative, that is, the data lies in the second

quadrant, then the arctangent formula returns a negative angle

and it is necessary to add a further 180 degrees to calculate the

correct standard angle. Likewise, when the real and imaginary

components are both negative, that is, when the coordinates lie

in the third quadrant, then the arctangent formula returns a

positive angle and it is necessary to add 180 degrees from the

angle to return the correct standard phase. Finally, when the

real component is positive and the imaginary component is

negative, that is, the data lies in the fourth quadrant, then the

arctangent formula returns a negative angle. It is necessary to

add 360 degrees to the angle to calculate the correct phase

angle.

Therefore, the correct standard phase angle is dependent upon

the sign of the real and imaginary component and is summarized in Tab le 7 .

Rev. D | Page 20 of 44

Page 21

Data Sheet AD5933

Once the magnitude of the impedance (|Z|) and the impedance

phase angle (ZØ, in radians) are correctly calculated, it is possible

to determine the magnitude of the real (resistive) and imaginary

(reactive) component of the impedance (Z

UNKNOWN

) by the

vector projection of the impedance magnitude onto the real

and imaginary impedance axis using the following formulas:

The real component is given by

Z

| = |Z| × cos (ZØ)

|

REAL

The imaginary component is given by

Z

| = |Z| × sin (ZØ)

|

IMAG

Table 7. Phase Angle

Real Imaginary Quadrant

Positive Positive First

Positive Negative Second

Negative Negative Third

Positive Negative Fourth

Phase Angle

−

1

×

RI

)/(tan

⎛

−

1

⎜

⎝

⎛

−

1

⎜

⎝

⎛

−

1

⎜

⎝

°180

π

()

/tan°180

×+

RI

π

()

×+

/tan°180

RI

π

()

×+

/tan°360

RI

π

°180

°180

°180

⎞

⎟

⎠

⎞

⎟

⎠

⎞

⎟

⎠

Rev. D | Page 21 of 44

Page 22

AD5933 Data Sheet

PERFORMING A FREQUENCY SWEEP

PROGRAM FREQUENCY SWEEP PARAMETERS

INTO RELEVANT REGIST ERS

(1) START FREQUENCY REGIST ER

(2) NUMBER OF I NCREMENTS REG ISTER

(3) FREQUENCY INCREMENT REGIST ER

PLACE THE AD5933 IN TO STANDBY MODE.

RESET: BY ISSUING A RESET COMMAND TO

CONTROL REGI STER THE DEVICE IS PL ACED

IN STANDBY MODE.

PROGRAM INITIALIZE WITH START

FREQUENCY CO MMAND TO THE CO NTROL

AFTER A SUFFICIENT AMOUNT OF SETTLING

TIME HAS ELAPSED, PROGRAM START

FREQUENCY S WEEP COMMAND IN T HE

REGISTER.

CONTROL REGISTER.

POLL STATUS REGISTER TO CHECK IF

THE DFT CONVERSION IS COMPLETE.

N

Y

READ VALUES FROM REAL AND

IMAGINARY DATA REGISTER.

Y

POLL STATUS REGISTER TO CHECK IF

FREQUENCY SWEEP IS COMPLETE.

Y

PROGRAM THE AD5933

INTO POWER-DOWN MODE.

PROGRAM THE INCREMENT F REQUENCY O R

THE REPEAT FREQUE NCY COMMAND TO THE

N

CONTRO L REGI STER.

05324-034

Figure 28. Frequency Sweep Flow Chart

Rev. D | Page 22 of 44

Page 23

Data Sheet AD5933

REGISTER MAP

Table 8.

Register Name Register Data Function

0x80 Control D15 to D8 Read/write

0x81 D7 to D0 Read/write

0x82 Start frequency D23 to D16 Read/write

0x83 D15 to D8 Read/write

0x84 D7 to D0 Read/write

0x85 D23 to D16 Read/write

0x86 D15 to D8 Read/write

0x87

0x88 D15 to D8 Read/write

0x89

0x8A D15 to D8 Read/write

0x8B

0x8F Status D7 to D0 Read only

0x92 Temperature data D15 to D8 Read only

0x93 D7 to D0 Read only

0x94 Real data D15 to D8 Read only

0x95 D7 to D0 Read only

0x96 Imaginary data D15 to D8 Read only

0x97 D7 to D0 Read only

Frequency increment

D7 to D0 Read/write

Number of increments

D7 to D0 Read/write

Number of settling time cycles

D7 to D0 Read/write

CONTROL REGISTER (REGISTER ADDRESS 0x80, REGISTER ADDRESS 0x81)

The AD5933 has a 16-bit control register (Register Address 0x80

and Register Address 0x81) that sets the AD5933 control

modes. The default value of the control register upon reset is

as follows: D15 to D0 reset to 0xA000 upon power-up.

The four MSBs of the control register are decoded to provide

control functions, such as performing a frequency sweep,

powering down the part, and controlling various other

functions defined in the control register map.

The user may choose to write only to Register Address 0x80 and

not to alter the contents of Register Address 0x81. Note that the

control register should not be written to as part of a block write

command. The control register also allows the user to program

the excitation voltage and set the system clock. A reset command

to the control register does not reset any programmed values

associated with the sweep (that is, start frequency, number of

increments, frequency increment). After a reset command, an

initialize with start frequency command must be issued to the

control register to restart the frequency sweep sequence (see

Figure 28).

Table 9. Control Register Map (D15 to D12)

D15 D14 D13 D12 Function

0 0 0 0 No operation

0 0 0 1 Initialize with start frequency

0 0 1 0 Start frequency sweep

0 0 1 1 Increment frequency

0 1 0 0 Repeat frequency

1 0 0 0 No operation

1 0 0 1 Measure temperature

1 0 1 0 Power-down mode

1 0 1 1 Standby mode

1 1 0 0 No operation

1 1 0 1 No operation

Table 10. Control Register Map (D10 to D9)

D10 D9 Range No. Output Voltage Range

0 0 1 2.0 V p-p typical

0 1 4 200 mV p-p typical

1 0 3 400 mV p-p typical

1 1 2 1.0 V p-p typical

Rev. D | Page 23 of 44

Page 24

AD5933 Data Sheet

Table 11. Control Register Map (D11, D8 to D0)

Bits Description

D11 No operation

D8 PGA gain; 0 = ×5, 1 = ×1

D7 Reserved; set to 0

D6 Reserved; set to 0

D5 Reserved; set to 0

D4 Reset

D3 External system clock; set to 1

Internal system clock; set to 0

D2 Reserved; set to 0

D1 Reserved; set to 0

D0 Reserved; set to 0

Control Register Decode

Initialize with Start Frequency

This command enables the DDS to output the programmed

start frequency for an indefinite time. It is used to excite the

unknown impedance initially. When the output unknown

impedance has settled after a time determined by the user, the

user must initiate a start frequency sweep command to begin

the frequency sweep.

Start Frequency Sweep

In this mode the ADC starts measuring after the programmed

number of settling time cycles

ability to program an integer number of output frequency cycles

(settling time cycles) to Register Address 0x8A and Register

Address 0x8B

at each frequency point (see Figure 28).

before the commencement of the measurement

has elapsed. The user has the

Increment Frequency

The increment frequency command is used to step to the next

frequency point in the sweep. This usually happens after data

from the previous step has been transferred and verified by the

DSP. When the AD5933 receives this command, it waits for the

programmed number of settling time cycles before beginning

the ADC conversion process.

Repeat Frequency

The AD5933 has the facility to repeat the current frequency

point measurement by issuing a repeat frequency

the control register

average successive readings.

. This has the benefit of allowing the user to

command to

Measure Temperature

The measure temperature command initiates a temperature

reading from the part. The part does not need to be in powerup mode to perform a temperature reading. The block powers

itself up, takes the reading, and then powers down again. The

temperature reading is stored in a 14-bit, twos complement

format at Register Address 0x92 and Register Address 0x93.

Power-Down Mode

The default state on power-up of the AD5933 is power-down

mode. The control register contains the code 1010,0000,0000,0000

(0xA000). In this mode, both the VOUT and VIN pins are

connected internally to GND.

Standby Mode

This mode powers up the part for general operation; in standby

mode the VIN and VOUT pins are internally connected to ground.

Output Voltage Range

The output voltage range allows the user to program the

excitation voltage range at VOUT.

PGA Gain

The PGA gain allows the user to amplify the response signal

into the ADC by a multiplication factor of ×5 or ×1.

Reset

A reset command allows the user to interrupt a sweep. The start

frequency, number of increments, and frequency increment

register contents are not overwritten. An initialize with start

frequency command is required to restart the frequency sweep

command sequence.

START FREQUENCY REGISTER (REGISTER ADDRESS 0x82, REGISTER ADDRESS 0x83, REGISTER ADDRESS 0x84)

The default value of the start frequency register upon reset is

as follows: D23 to D0 are not reset on power-up. After a reset

command, the contents of this register are not reset.

The start frequency register contains the 24-bit digital representation of the frequency from where the subsequent frequency

sweep is initiated. For example, if the user requires the sweep to

start from frequency 30 kHz (using a 16.0 MHz clock), then the

user programs the value of 0x0F to Register Address 0x82, the

value of 0x5C to Register Address 0x83, and the value of 0x28 to

Register Address 0x84. This ensures the output frequency starts

at 30 kHz.

The code to be programmed to the start frequency register is

⎛

⎜

⎜

=

CodeFrequencyStart

⎜

⎛

⎜

⎜

⎜

⎝

⎝

⎞

⎟

kHz30

⎟

27

≡×

⎟

MHz16

⎞

⎟

⎟

⎟

4

⎠

⎠

28C5F0x02

Rev. D | Page 24 of 44

Page 25

Data Sheet AD5933

FREQUENCY INCREMENT REGISTER (REGISTER ADDRESS 0x85, REGISTER ADDRESS 0x86, REGISTER ADDRESS 0x87)

The default value upon reset is as follows: D23 to D0 are not reset

on power-up. After a reset command, the contents of this register

are not reset.

The frequency increment register contains a 24-bit representation of the frequency increment between consecutive frequency

points along the sweep. For example, if the user requires an

increment step of 10 Hz using a 16.0 MHz clock, the user

should program the value of 0x00 to Register Address 0x85, the

value of 0x01 to Register Address 0x86m, and the value of 0x4F

to Register Address 0x87.

The formula for calculating the increment frequency is given by

⎛

⎜

⎜

=

CodeIncrementFrequency

⎜

⎛

⎜

⎜

⎜

⎝

⎝

⎞

⎟

Hz10

⎟

27

≡×

⎟

MHz16

⎞

⎟

⎟

⎟

4

⎠

⎠

F00014x02

The user programs the value 0x00 to Register Address 0x85, the

value 0x01 to Register Address 0x86, and the value 0x4F to

Register Address 0x87.

NUMBER OF INCREMENTS REGISTER (REGISTER ADDRESS 0x88, REGISTER ADDRESS 0x89)

The default value upon reset is as follows: D8 to D0 are not reset

on power-up. After a reset command, the contents of this

register are not reset.

Table 12. Number of Increments Register

Reg Bits Description Function Format

D15 to D9 Don’t care Read or

0x88

D8 Number of

increments

0x89 D8 to D0 Number of

increments

write

Read or

write

Read or

write

Integer number

stored in binary

format

Integer number

stored in binary

format

This register determines the number of frequency points in the

frequency sweep. The number of points is represented by a 9-bit

word, D8 to D0. D15 to D9 are don’t care bits. This register, in

conjunction with the start frequency register and the increment

frequency register, determines the frequency sweep range for

the sweep operation. The maximum number of increments that

can be programmed is 511.

NUMBER OF SETTLING TIME CYCLES REGISTER (REGISTER ADDRESS 0x8A, REGISTER ADDRESS 0x8B)

The default value upon reset is as follows: D10 to D0 are not

reset on power-up. After a reset command, the contents of this

register are not reset (see Tab le 1 3).

This register determines the number of output excitation cycles

that are allowed to pass through the unknown impedance, after

receipt of a start frequency sweep, increment frequency, or

repeat frequency command, before the ADC is triggered to

perform a conversion of the response signal. The number of

settling time cycles register value determines the delay between

a start frequency sweep/increment frequency /repeat frequency

command and the time an ADC conversion commences. The

number of cycles is represented by a 9-bit word, D8 to D0. The

value programmed into the number of settling time cycles

register can be increased by a factor of 2 or 4 depending upon

the status of bits D10 to D9. The five most significant bits, D15

to D11, are don’t care bits. The maximum number of output

cycles that can be programmed is 511 × 4 = 2044 cycles. For

example, consider an excitation signal of 30 kHz. The

maximum delay between the programming of this frequency

and the time that this signal is first sampled by the ADC is ≈

511 × 4 × 33.33 µs = 68.126 ms. The ADC takes 1024 samples,

and the result is stored as real data and imaginary data in

Register Address 0x94 to Register Address 0x97. The conversion

process takes approximately 1 ms using a 16.777 MHz clock.

Table 13. Number of Settling Times Cycles Register

Register Bits Description Function Format

0x8A

0x8B D7 to D0 Number of settling time cycles Read or write

D15 to D11 Don’t care

D10 to D9

D8 MSB number of settling time cycles

2-bit decode

D10 D9 Description

0 0 Default

0 1 No. of cycles × 2

1 0 Reserved

1 1 No. of cycles × 4

Rev. D | Page 25 of 44

Read or write

Integer number stored in

binary format

Page 26

AD5933 Data Sheet

STATUS REGISTER (REGISTER ADDRESS 0x8F)

The status register is used to confirm that particular measurement tests have been successfully completed. Each of the bits

from D7 to D0 indicates the status of a specific functionality of

the AD5933.

Bit D0 and Bit D4 to Bit D7 are treated as don’t care bits These

bits do not indicate the status of any measurement.

The status of Bit D1 indicates the status of a frequency point

impedance measurement. This bit is set when the AD5933 has

completed the current frequency point impedance measurement.

This bit indicates that there is valid real data and imaginary data

in Register Address 0x94 to Register Address 0x97. This bit is

reset on receipt of a start frequency sweep, increment frequency,

repeat frequency, or reset command. This bit is also reset on

power-up.

The status of Bit D2 indicates the status of the programmed

frequency sweep. This bit is set when all programmed increments to the number of increments register are complete. This

bit is reset on power-up and on receipt of a reset command.

Table 14. Status Register (Register Address 0x8F)

Control Word Function

0000 0001 Valid temperature measurement

0000 0010 Valid real/imaginary data

0000 0100 Frequency sweep complete

0000 1000 Reserved

0001 0000 Reserved

0010 0000 Reserved

0100 0000 Reserved

1000 0000 Reserved

Valid Temperature Measurement

The valid temperature measurement control word is set when a

valid temperature conversion is complete indicating that valid