Page 1

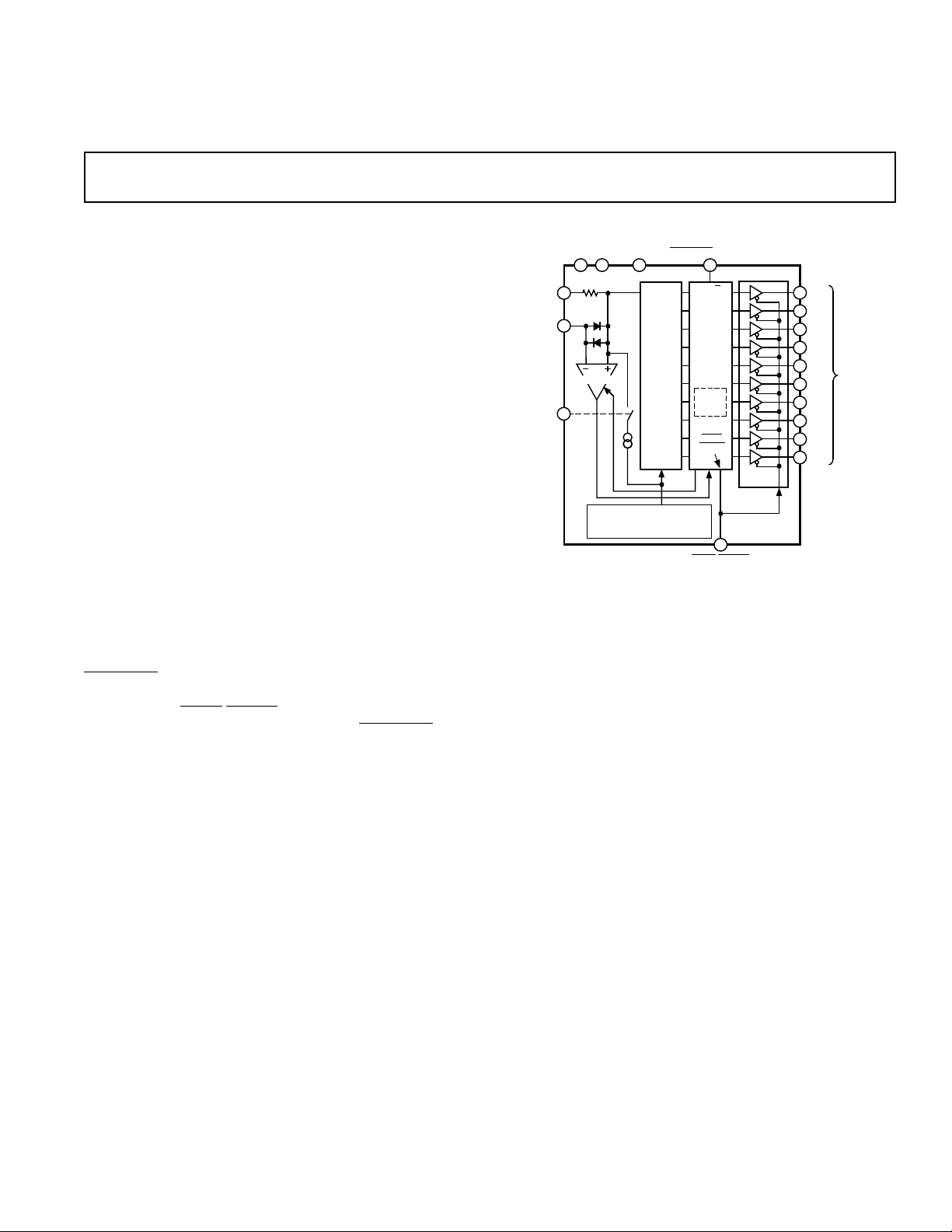

3 STATE

BUFFERS

AUTO BLANK

CONTROL

10-BIT

CURRENT

OUTPUT

DAC

5k

DATA

READY

INT.

CLOCK

10-BIT

SAR

B & C

COMPARATOR

TEMPERATURE COMPENSATED

BURIED ZENER REFERENCE

AND DAC CONTROL

13

14

15

MSB

LSB

17

1610 11

12

BLANK &

CONVERT

CONTROL

V+

V–

DIGITAL

COMMON

ANALOG

IN

ANALOG

COMMON

BIPOLAR

OFFSET

CONTROL

BIT

OUTPUTS

AD571

DATA READY

6

7

8

9

2

3

4

5

18

1

a

10-Bit A/D Converter

AD571*

FEATURES

Complete A/D Converter with Reference and Clock

Fast Successive Approximation Conversion: 40 ms max

No Missing Codes Over Temperature

08C to +708C: AD571K

–558C to +1258C: AD571S

Digital Multiplexing: Three-State Outputs

18-Pin Ceramic DIP

Low Cost Monolithic Construction

PRODUCT DESCRIPTION

The AD571 is an 10-bit successive approximation A/D converter consisting of a DAC, voltage reference, clock, comparator, successive approximation register and output buffers—all

fabricated on a single chip. No external components are required to perform a full accuracy 10-bit conversion in 40 µs.

Operating on supplies of +5 V to +15 V and –15 V, the

AD571 will accepts analog inputs of 0 V to +10 V unipolar of

±5 V bipolar, externally selectable. When the BLANK and

CONVERT input is driven low, the three-state outputs will be

open and a conversion will commence. Upon completion of the

conversion, the

pears at the output. Pulling the BLANK and

DATA READY line goes low and the data ap-

CONVERT input

high blanks the outputs and readies the device for the next conversion. The AD571 executes a true 10-bit conversion with no

missing codes in 40 µs maximum.

The AD571 is available in two version for the 0°C to +70°C

temperature range, the AD571J and K. The AD571S guarantees

10-bit accuracy and no missing codes from –55°C to +125°C.

*Covered by Patent Nos. 3,940,760; 4,213,806; 4,136,349.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. The AD571 is a complete 10-bit A/D converter. No external

components are required to perform a conversion. Full-scale

calibration accuracy of ± 0.3% is achieved without external

trims.

2. The AD571 is a single chip device employing the most advanced IC processing techniques. Thus, the user has at his

disposal a truly precision component with the reliability and

low cost inherent in monolithic construction,

3. The AD571 accepts either unipolar (0 V to +10 V) or bipolar

(–5 V to +5 V) analog inputs by grounding or opening a

single pin.

4. The device offers true 10-bit accuracy and exhibits no missing codes over its entire operating temperature range.

5. Operation is guaranteed with –15 V and +5 V or +15 V supplies. The device will also operate with a –12 V supply.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

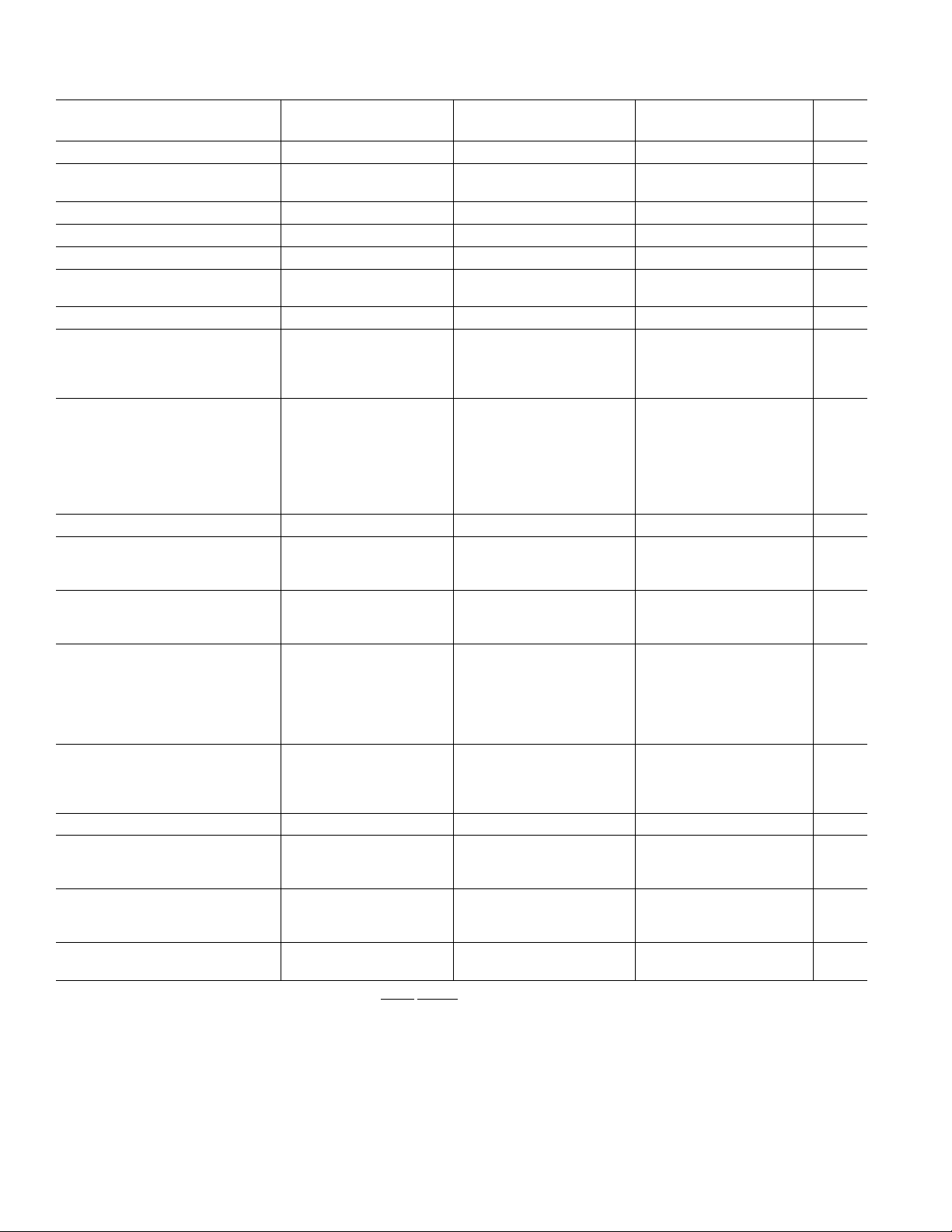

Page 2

AD571–SPECIFICATIONS

(TA = +258C, V+ = +5 V, V– = –12 V or –15 V, all voltages measured with respect to

digital common, unless otherwise noted)

Model Min Typ Max Min Typ Max Min Typ Max Units

AD571J AD571K AD571S

RESOLUTION 10 10 10 Bits

RELATIVE ACCURACY, T

T

to T

MIN

MAX

A

61 61/2 61 LSB

61 61/2 61 LSB

FULL-SCALE CALIBRATION ± 2 ±2 ±2 LSB

UNIPOLAR OFFSET 61 61/2 61 LSB

BIPOLAR OFFSET 61 61/2 61 LSB

DIFFERENTIAL NONLINEAIRTY, TA10 10 10 Bits

T

MIN

to T

MAX

91010Bits

TEMPERATURE RANGE 0 +70 0 +70 –55 +125 °C

TEMPERATURE COEFFICIENTS

Unipolar Offset 62 61 62 LSB

Bipolar Offset 62 61 62 LSB

Full-Scale Calibration

2

64 62 65 LSB

POWER SUPPLY REJECTION

CMOS Positive Supply

+13.5 V ≤ V + ≤ +16.5 V – – – 61 – – – LSB

TTL Positive Supply

+4.5 V ≤ V + ≤ +5.5 V 62 61 62 LSB

Negative Supply

–16.0 V ≤ V – ≤ –13.5 V 62 61 62 LSB

ANALOG INPUT IMPEDANCE 3.0 5.0 7.0 3.0 5.0 7.0 3.0 5.0 7.0 kΩ

ANALOG INPUT RANGES

Unipolar 0 +10 0 +10 0 +10 V

Bipolar –5 +5 –5 +5 –5 +5 V

OUTPUT CODING

Unipolar Positive True Binary Positive True Binary Positive True Binary

Bipolar Positive True Offset Binary Positive True Offset Binary Positive True Offset Binary

LOGIC OUTPUT

Output Sink Current

(V

= 0.4 V max, T

OUT

Output Source Current

(V

= 2.4 V max, T

OUT

to T

MIN

1

MIN

) 3.2 3.2 3.2 mA

MAX

to T

) 0.5 0.5 0.5 mA

MAX

Output Leakage 640 640 640 µA

LOGIC INPUT

Input Current 6100 6100 6100 µA

Logic “1” 2.0 2.0 2.0 V

Logic “0” 0.8 0.8 0.8 V

CONVERSION TIME, T

MIN

to T

MAX

15 25 40 15 25 40 15 25 40 µs

POWER SUPPLY

V+ +4.5 +5.0 +7.0 +4.5 +5.0 +16.5 +4.5 +5.0 +7.0 V

V– –12.0 –15 –16.5 –12.0 –15 –16.5 –12.0 –15 –16.5 V

OPERATING CURRENT

V+ 7 10 7 10 7 10 mA

V– 9 15 9 15 9 15 mA

PACKAGE OPTION

2

Ceramic DIP (D-18) AD571JD AD571KD AD571SD

NOTES

1

The data output lines have active pull-ups to source 0.5 mA. The DATA READY line is open collector with a nominal 6 kΩ internal pull-up resistor.

2

For details on grade and package offerings for SD-grade in accordance with MIL-STD-883, refer to Analog Devices’ Military Products databook or current /883B

data sheet.

Specifications subject to change without notice.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

–2–

REV. A

Page 3

AD571

ABSOLUTE MAXIMUM RATINGS

V+ to Digital Common

AD571J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 V to +7 V

AD571K . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 V to +16.5 V

V– to Digital Common . . . . . . . . . . . . . . . . . . . 0 V to –16.0 V

Analog Common to Digital Common . . . . . . . . . . . . . . . ±1 V

Analog Input to Analog Common . . . . . . . . . . . . . . . . . ±15 V

Control Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 V to V+

Digital Outputs (Blank Mode) . . . . . . . . . . . . . . . . . . 0 V to V+

Power Dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 mW

CIRCUIT DESCRIPTION

The AD571 is a complete 10-bit A/D converter which requires

no external components to provide the complete successiveapproximation analog-to-digital conversion function. A block

diagram of the AD571 is shown on front page of this data sheet.

Upon receipt of the

current output DAC is sequenced by the I

CONVERT command, the internal 10-bit

2

L successiveapproximation register (SAR) from its most-significant bit

(MSB) to least-significant bit (LSB) to provide an output current which accurately balances the input signal current through

the 5 kΩ input resistor. The comparator determines whether the

addition of each successively-weighted bit current causes the

DAC current sum to be greater or less than the input current; if

the sum is less the bit is left on, if more, the bit is turned off. After testing all the bits, the SAR contains a 10-bit binary code

which accurately represents the input signal to within ± 1/2 LSB

(0.05%).

Upon completion of the sequence, the SAR sends out a

DATA

READY signal (active low), which also brings the three-state

buffers out of their “open” state, making the bit output lines become active high or low, depending on the code in the SAR.

When the BLANK and

CONVERT line is brought high, the

output buffers again go “open”, and the SAR is prepared for

another conversion cycle. Details of the timing are given in the

Control and Timing section.

The temperature compensated buried Zener reference provides

the primary voltage reference to the DAC and guarantees excellent stability with both time and temperature. The bipolar offset

input controls a switch which allows the positive bipolar offset

current (exactly equal to the value of the MSB less 1/2 LSB)

to be injected into the summing (+) node of the comparator to

offset the DAC output. Thus the nominal 0 V to +10 V unipolar input range becomes a –5 V to +5 V range. The 5 kΩ thinfilm input resistor is trimmed so that with a full-scale input

signal, an input current will be generated which exactly matches

the DAC output with all bits on. (The input resistor is trimmed

slightly low to facilitate user trimming, as discussed on the next

page.)

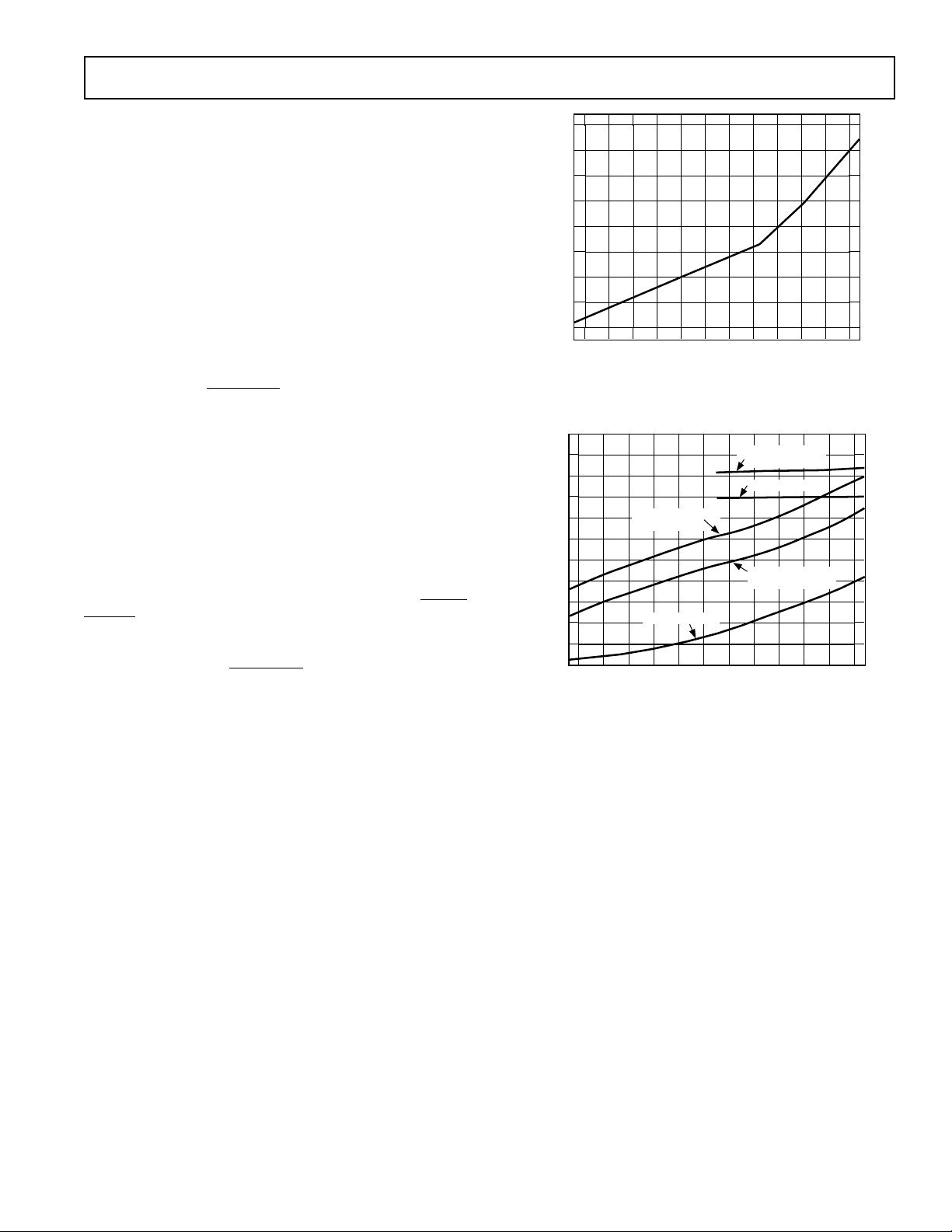

9

8

7

6

5

Volts

–

TH

4

V

3

2

1

5166

7 8 9 101112131415

V+ – Volts

Figure 1. Logic Threshold (AD571K Only)

12

11

10

9

8

7

6

5

4

SUPPLY CURRENT – mA

3

2

1

4.5

516678

I+, CONVERT MODE

V

= 0V

IN

I+, BLANK MODE

9 101112131415

V+/V– – Volts

I–, CONVERT MODE

A

= 0 to +10V

IN

I–, BLANK MODE

I+, CONVERT MODE

V

= +10V

IN

Figure 2. Supply Currents vs. Supply Levels and

Operating Modes

CONNECTING THE AD571 FOR STANDARD OPERATION

The AD571 contains all the active components required to perform a complete A/D conversion. For most situations, all that is

necessary is connection of the power supply (+5 V and –15 V), the

analog input, and the conversion start pulse. However, there are

some features and special connections which should be considered for optimum performance. The functional pinout is shown

in Figure 3.

POWER SUPPLY SELECTION

The AD571 is designed for optimum performance using a +5 V

and –15 V supply, for which the AD571J and AD571S are

specified. AD571K will also operate with up to a +15 V supply,

which allows direct interface to CMOS logic. The input logic

threshold is a function of V+ as shown in Figure 1. The supply

current drawn by the device is a function of both V+ and the

operating mode (BLANK or CONVERT). These supply currents variations are shown in Figure 2. The supply currents

change only moderately over temperature as shown in Figure 6.

REV. A

–3–

Page 4

AD571

BIT 9

BIT 8

BIT 7

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

(MSB) BIT 1

1

2

3

4

AD571

TOP VIEW

5

(Not to Scale)

6

7

8

9

18

BIT 10 (LSB)

17

DATA

16

DIGITAL COM

BIPOLAR OFF

15

ANALOG COM

14

ANALOG IN

13

12

V–

11

BLK AND CONV

10

V+

READY

Figure 3. AD571 Pin Connections

FULL-SCALE CALIBRATION

The 5 kΩ thin-film input resistor is laser trimmed to produce a

current which matches the full-scale current of the internal

DAC—plus about 0.3%—when a full-scale analog input voltage

of 9.990 volts (10 volts—1 LSB) is applied at the input. The input resistor is trimmed in this way so that if a fine trimming potentiometer is inserted in series with the input signal, the input

current at the full-scale input voltage can be trimmed down to

match the DAC full-scale current as precisely as desired. However, for many applications the nominal 9.99 volt full scale can

be achieved to sufficient accuracy by simply inserting a 15 Ω resistor in series with the analog input to Pin 13. Typical full-scale

calibration error will then be about ±2 LSB or ±0.2%. If a more

precise calibration is desired, a 50 Ω trimmer should be used instead. Set the analog input at 9.990 volts, and set the trimmer

so that the output code is just at the transition between

1111111110 and 1111111111. Each LSB will then have a weight

of 9.766 mV. If a nominal full scale of 10.24 volts is desired

(which makes the LSB have a value of exactly 10.00 mV), a

100 Ω resistor in series with a 100 Ω trimmer (or a 200 Ω trimmer with good resolution) should be used. Of course, larger

full-scale ranges can be arranged by using a larger input resistor,

but linearity and full-scale temperature coefficient may be compromised if the external resistor becomes a sizable percentage

of 5 kΩ.

BIT 9

BIT 8

BIT 7

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

(MSB) BIT 1

1

2

3

4

AD571

TOP VIEW

5

(Not to Scale)

6

7

8

9

BIT 10 (LSB)

18

DATA READY

17

16

DIGITAL COM

BIPOLAR CONTROL

15

14

ANALOG COM

13

–15V

12

BLK AND CONV

11

+5V

10

(SHORT TO COM FOR

UNIPOLAR, OPEN FOR BIPOLAR)

(TOLERATES 200mV TO

DIGITAL COM)

R

IN

15Ω FIXED OR

50Ω VARIABLE

(SEE TEXT)

ANALOG IN

Figure 4. Standard AD571 Connections

BIPOLAR OPERATION

The standard unipolar 0 V to +10 V range is obtained by shorting the bipolar offset control pin to digital common. If the pin is

left open, the bipolar offset current will be switched into the

comparator summing node, giving a –5 V to +5 V range with an

offset binary output code. (–5.00 volts in will give a 10-bit code

of 0000000000; an input of 0.00 volts results in an output code of

1000000000 and 4.99 volts at the input yields the 1111111111).

The bipolar offset control input is not directly TTL compatible,

but a TTL interface for logic control can be constructed as

shown in Figure 5.

+5V

USE ACTIVE

PULL-UP GATE

TTL

GATE

3x IN4148

30kΩ

5V COM

15V COM

B & C

A

IN

A

COM

BIPOLAR

OFFSET

CONTROL

D

COM

AD571

–15V

DR

DATA

10 BITS

Figure 5. Bipolar Offset Controlled by Logic Gate

Gate Output = 1: Unipolar 0 V–10 V Input Range

Gate Output = 0: Bipolar ±5 V Input Range

COMMON-MODE RANGE

The AD571 provides separate analog and digital common connections. The circuit will operate properly with as much as

±200 mV of common-mode range between the two commons.

This permits more flexible control of system common bussing

and digital and analog returns.

In normal operation the analog common terminal may generate

transient currents of up to 2 mA during a conversion. In addition, a static current of about 2 mA will flow into analog common in the unipolar mode after a conversion is complete. An

additional 1 mA will flow in during a blank interval with zero

analog input. The analog common current will be modulated by

the variations in input signal.

The absolute maximum voltage rating between the two commons is ±1 volt. We recommend that a parallel pair of back-toback protection diodes can be connected between the commons

if they are not connected locally.

C = CONVERT MODE

11

10

9

8

7

6

5

4

SUPPLY CURRENTS – mA

3

2

1.5

1

–50 125–25 0 25 50 70 100

TEMPERATURE – °C

B = BLANK MODE

I –15V,C

I +15V,C

I –15V,B

I +15V,B

I +5V,C

I +5V,B

Figure 6. AD571 Power Supply Current vs. Temperature

–4–

REV. A

Page 5

AD571

INPUT VOLTAGE – mV

0

–30

–20 –10 0 +10 +20 +30

10000 00000

01111 11111

01111 11110

10000 00010

10000 00001

OUTPUT

CODE

ZERO OFFSET

The apparent zero point of the AD571 can be adjusted by

inserting an offset voltage between the analog common of the

device and the actual signal return or signal common. Figure 7

illustrates two methods of providing this offset. Figure 7a shows

how the converter zero may be offset by up to ± 3 bits to correct

the device initial offset and/or input signal offsets. As shown, the

circuit gives approximately symmetrical adjustment in unipolar

mode. In bipolar mode R2 should be omitted to obtain a symmetrical range.

A

IN

INPUT

SIGNAL

R1

10ΩR27.5kΩR34.7kΩ

SIGNAL COMMON

+15V

ZERO OFFSET ADJ

±3 BIT RANGE

R4

10kΩ

–15V

AD571

A

COM

Figure 7a.

A

INPUT

SIGNAL

R1

2.7Ω OR

5Ω POT

IN

AD571

A

COM

NOTE: During a conversion transient currents from the analog

common terminal will disturb the offset voltage. Capacitive decoupling should not be used around the offset network. These

transients will settle as appropriate during a conversion. Capacitive decoupling will “pump up” and fail to settle resulting in

conversion errors. Power supply decoupling which returns to

analog signal common should go to the signal input side of the

resistive offset network.

OUTPUT

CODE

0000000100

0000000011

0000000010

0000000001

0000000000

0000000100

0000000011

0000000010

0000000001

0000000000

0V 10mV 30mV 50mV

INPUT VOLTAGE

NORMAL CHARACTERISTICS

REFERRED TO ANALOG COMMON

OUTPUT

CODE

0V 10mV 30mV 50mV

INPUT VOLTAGE

OFFSET CHARACTERISTICS WITH

2.7Ω IN SERIES WITH ANALOG COMMON

SIGNAL COMMON

1/2 BIT ZERO OFFSET

Figure 7b.

Figure 8 shows the nominal transfer curve near zero for an

AD571 in unipolar mode. The code transitions are at the edges

of the nominal bit weights. In some applications it will be preferable to offset the code transitions so that they fall between the

nominal bit weights, as shown in the offset characteristics. This

offset can easily be accomplished as shown in Figure 7b. At balance (after a conversion) approximately 2 mA flows into the

analog common terminal. A 2.7 Ω resistor in series with this

terminal will result in approximately the desired 1/2 bit offset of

the transfer characteristics. The nominal 2 mA analog common

current is not closely controlled in production. If high accuracy

is required, a 5 Ω potentiometer (connected as a rheostat) can

be used as R1. Additional negative offset range may be obtained

by using larger values of R1. Of course, if the zero transition

point is changed, the full-scale transition point will also move.

Thus, if an offset of 1/2 LSB is introduced, full-scale trimming

as described on previous page should be done with an analog input of 9.985 volts.

Figure 8. AD571 Transfer Curve—Unipolar Operation

(Approximate Bit Weights Shown for Illustration, Nominal

Bit Weights , 9.766 mV)

BIPOLAR CONNECTION

To obtain the bipolar –5 V to +5 V range with an offset binary

output code the bipolar offset control pin is left open.

A –5.0 volt signal will give a 10-bit code of 0000000000; an input of 0.00 volts results in an output code of 1000000000;

+4.99 volts at the input yields 1111111111. The nominal transfer curve is shown in Figure 9.

Figure 9. AD571 Transfer Curve—Bipolar Operation

REV. A

–5–

Page 6

AD571

CONTROL AND TIMING OF THE AD571

There are several important timing and control features on the

AD571 which must be understood precisely to allow optimal

interfacing to microprocessor or other types of control systems.

All of these features are shown in the timing diagram in Figure

10.

The normal standby situation is shown at the left end of the

drawing. The BLANK and

high, the output lines will be “open”, and the

(

DR) line will be high. This mode is the lowest power state of

the device (typically 150 mW). When the (B &

brought low, the conversion cycle is initiated; but the

data lines do not change state. When the conversion cycle is

complete, the

lines become active with the new data.

About 1.5 µs after the B &

line will go high and the data lines will go open. When the

B &

C line is again brought low, a new conversion will begin.

The minimum pulse width for the B &

data and start a new conversion is 2 µs. If the B &

brought high during a conversion, the conversion will stop, and

the

DR and data lines will not change. If a 2 µs or longer pulse

is applied to the B &

will clear and start a new conversion cycle.

DR line goes low, and within 500 ns, the data

CONVERT (B & C) line is held

DATA READY

C ) line is

DR and

C line is again brought high, the DR

C line to blank previous

C line is

C line during a conversion, the converter

BLANK and CONVERT line is driven low and at the end of

conversion, which is indicated by

conversion result will be present at the outputs. When this data

has been read from the 10-bit bus, BLANK and

restored to the blank mode to clear the data bus for other converters. When several AD571s are multiplexed in sequence, a

new conversion may be started in one AD571 while data is

being read from another. As long as the data is read and the first

AD571 is cleared within 15 µs after the start of conversion of the

second AD571, no data overlap will occur.

Figure 11. Convert Pulse Mode

DATA READY going low, the

CONVERT is

Figure 10. AD571 Timing and Control Sequences

CONTROL MODES WITH BLANK AND CONVERT

The timing sequence of the AD571 discussed above allows the

device to be easily operated in a variety of systems with differing

control modes. The two most common control modes, the Convert Pulse Mode and the Multiplex Mode, are illustrated here.

Convert Pulse Mode–In this mode, data is present at the output

of the converter at all times except when conversion is taking

place. Figure 11 illustrates the timing of this mode. The BLANK

and

CONVERT line is normally low and conversions are trig-

gered by a positive pulse. A typical application for this timing

mode is shown in Figure 14, in which µP bus interfacing is

easily accomplished with three-state buffers.

Multiplex Mode—In this mode the outputs are blanked except

when the device is selected for conversion and readout; this timing is shown in Figure 12. A typical AD571 multiplexing application is shown in Figure 15.

This operating mode allows multiple AD571 devices to drive

common data lines. All BLANK and

high to keep the outputs blanked. A single AD571 is selected, its

CONVERT lines are held

Figure 12. Multiplex Mode

SAMPLE-HOLD AMPLIFIER CONNECTION TO THE

AD571

Many situations in high-speed acquisition systems or digitizing

of rapidly changing signals require a sample-hold amplifier

(SHA) in front of the A-D converter. The SHA can acquire and

hold a signal faster than the converter can perform a conversion.

A SHA can also be used to accurately define the exact point in

time at which the signal is sampled. For the AD571, a SHA can

also serve as a high input impedance buffer.

Figure 13 shows the AD571 connected to the AD582 monolithic SHA for high speed signal acquisition. In this configuration, the AD582 will acquire a 10 volt signal in less than 10 µs

with a droop rate less than 100 µV/ms. The control signals are

arranged so that when the control line goes low, the AD582 is put

into the “hold” mode, and the AD571 will begin its conversion

cycle. (The AD582 settles to final value well in advance of the

first comparator decision inside the AD571). The

READY line is fed back to the other side of the differential

input control gate so that the AD582 cannot come out of the

“hold” mode during the conversion cycle. At the end of the conversion cycle, the

placing the AD582 back into the sample mode. This feature allows simple control of both the SHA and the A-D converter

with a single line. Observe carefully the ground, supply, and bypass capacitor connections between the two devices. This will

minimizes ground noise and interference during the conversion

cycle to give the most accurate measurements.

DATA READY line goes low, automatically

DATA

–6–

REV. A

Page 7

Figure 13. Sample-Hold Interface to the AD571

INTERFACING THE AD571 TO A MICROPROCESSOR

The AD571 can easily be arranged to be driven from standard

microprocessor control lines and to present data to any standard

microprocessor bus (4-, 8-, 12- or 16-bit) with a minimum of

additional control components. The configuration shown in

Figure 14 is designed to operate with an 8-bit bus and standard

8080 control signals.

AD571

the new data and the control lines will return to the standby

state. The 100 pF capacitor slows down the

be used as a latch signal for data outputs. The new data will

remain active until a new conversion is commanded. The selfpulsing nature of this circuit guarantees a sufficient convert

pulse width.

This new data can now be presented to the data bus by enabling the three-state buffers when desired. A data word

(8-bit or 2-bit) is loaded onto the bus when its decoded address goes low and the

presents data to the bus “left-justified,” with the highest bits in

the 8-bit word; a “right-justified” data arrangement can be set

up by a simple re-wiring. Polling the converter to determine if

conversion is complete can be done by addressing the gate

which buffers the

is no need for additional buffer register storage: the data can be

held indefinitely in the AD571, since the B &

ally held low.

BUS INTERFACING WITH A PERIPHERAL INTERFACE

CIRCUIT

An improved technique for interfacing to a µP bus involves the

use of special peripheral interfacing circuits (or I/O devices),

such as the MC6821 Peripheral Interface Adapter (PIA). Shown

in Figure 15 is a straightforward application of a PIA to multiplex up to 8 AD571 circuits. The AD571 has 3-state outputs,

RD line goes low. This arrangement

DR line, as shown. In this configuration, there

DR line enough to

C line is continu-

Figure 14. Interfacing AD571 to an 8-Bit Bus

(8080 Control Structure)

The input control circuitry shown is required to ensure that the

AD571 receives a sufficiently long B &

converter is ready to start a new conversion, the B &

low, and

dress decode line goes low, followed by

will now go high, followed about 1.5 µs later by

the external flip-flop and brings B &

tiates the conversion cycle. At the end of the conversion cycle,

the

REV. A

DR is low. To command a conversion, the start ad-

DR line goes low, the data outputs will become active with

C input pulse. When the

C line is

WR. The B & C line

DR. This resets

C back to low, which ini-

–7–

Figure 15. Multiplexing 8 AD571s Using Single PIA for

µ

P Interface. No Other Logic Required (6800 Control

Structure)

hence the data bit outputs can be paralleled, provided that only

one converter at a time is permitted to be the active state. The

DATA READY output of the AD571 is an open collector with

resistor pull-up, thus several

allow indication of the status of the selected device. One of the

8-bit ports of the PIA is combined with 2 bits from the other

port and programmed as a 10-bit input port. The remaining 6

bits of the second port are programmed as outputs and along

DR lines can be wire-ored to

Page 8

AD571

with the 2 control bits (which act as outputs), are used to control the 8 AD571s. When a control line is in the “1” or high

state, the ADC will be automatically blanked. That is, its outputs will be in the inactive open state. If a single control line is

switched low, its ADC will convert and the outputs will automatically go active when the conversion is complete. The result

can then be read from the two peripheral ports; when the next

conversion is desired, a different control line can be switched to

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

18-Lead Ceramic Dual-In-Line Package

zero, blanking the previously active port at the same time. Subsequently, this second device can be read by the microprocessor,

and so-forth. The status lines are wire-ored in 2 groups and

connected to the two remaining control pins. This allows a conversion status check to be made after a convert command, if

necessary. The ADCs are divided into two groups to minimize

the loading effect of the internal pull-up resistors on the

READY buffers.

DATA

C457d–4–1/87

–8–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...