Page 1

Per Pin Parametric

Measurement Unit/Source Measure Unit

AD5520

FEATURES

Force/Measure Functions

Force Voltage/Current, Measure Current/Voltage

Force Current/Voltage, Measure Current/Voltage

Force/Measure Voltage Range 11 V

4 Programmable Force/Measure Current Ranges

4 A, 40 A, 400 A, 4 mA

Extended Current Ranges

40 mA and 160 mA with External Driver

Clamp Circuitry and Window Comparators On Board

Guard Amplifier

64-Lead LQFP Package

APPLICATIONS

Automatic Test Equipment

Per Pin PMU, Shared Pin PMU, Device Power Supply

Instrumentation

Source Measure, Parametric Measurement, Precision

Measurement

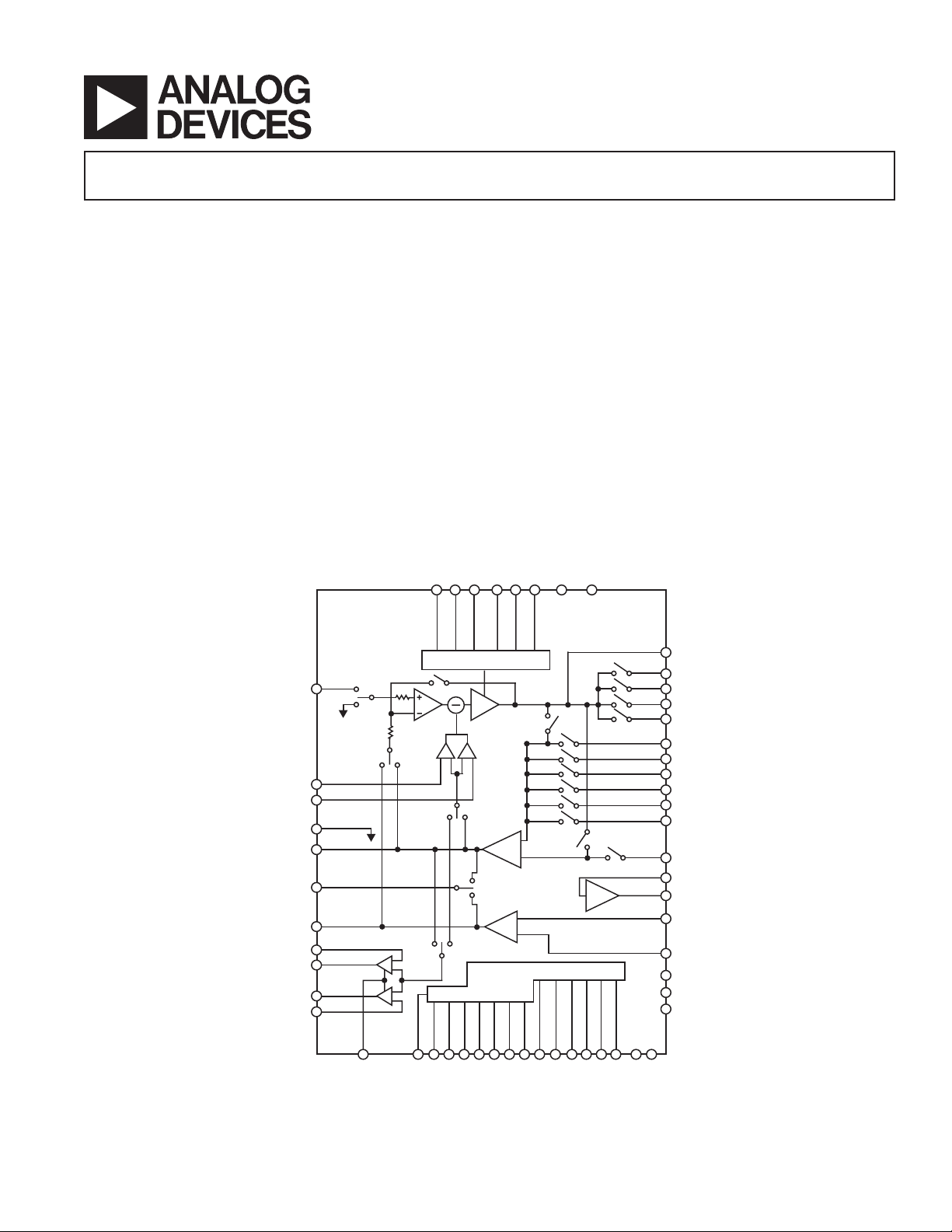

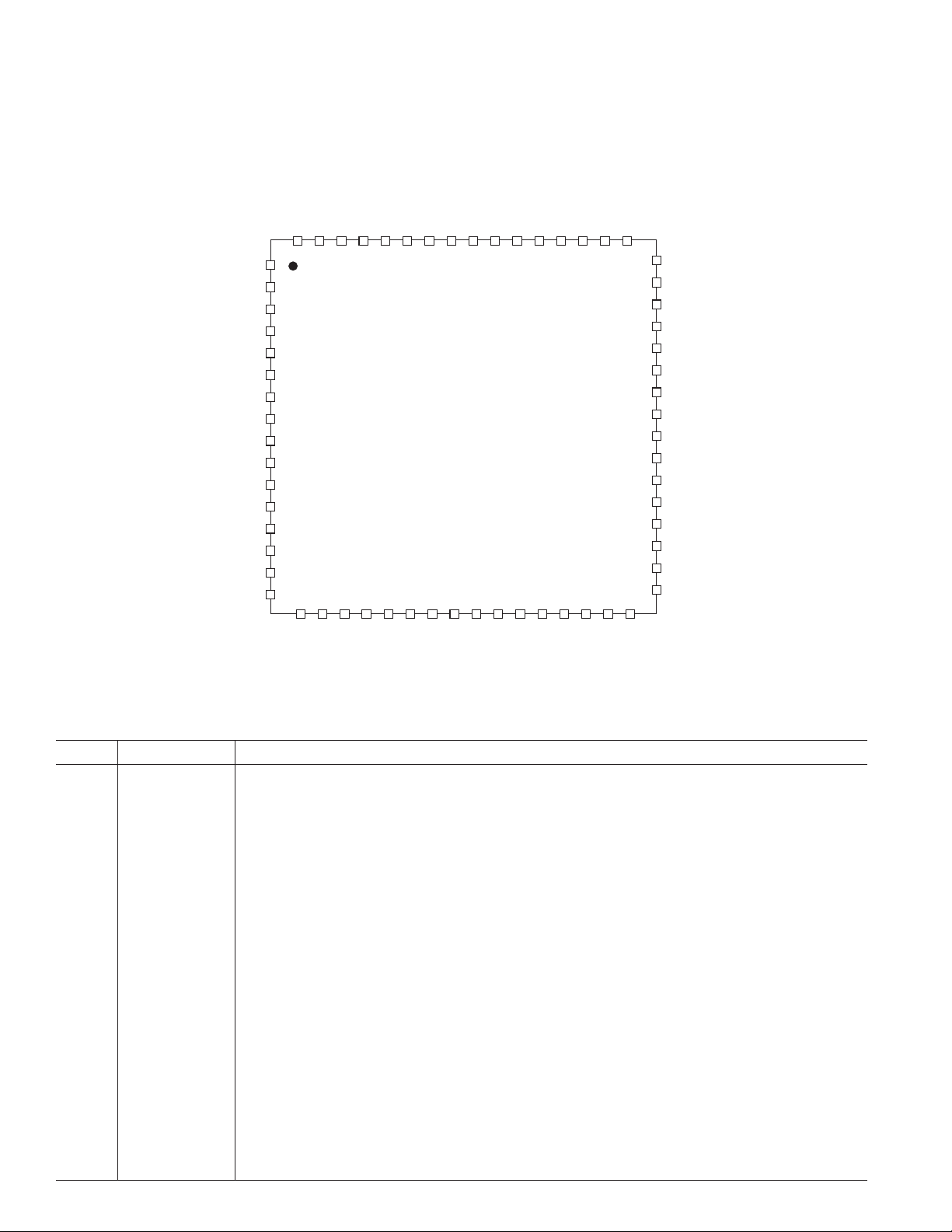

FUNCTIONAL BLOCK DIAGRAM

AD5520

FIN

CLH

CLL

REFGND

MEASIOUT

MEASOUT

MEASVOUT

COMPARATOR

CPH

CPOH

CPOH

CPL

CPCK

REV. A

COMPIN1

COMPIN0

STB

STANDBY

GENERAL DESCRIPTION

The AD5520 is a single channel per pin parametric measurement unit (PPMU) for use in semiconductor automatic test

equipment. The part is also suited for use as a source

measurement unit for instrumentation applications. It

contains programmable modes to force a pin voltage and

measure the corresponding current or force a current and

measure the voltage. The AD5520 can force/measure over a

± 11 V range or currents up to ± 4 mA with its on-board

force amplifier. An external amplifier is required for wider

current ranges. The device provides a force sense capability to

ensure accuracy at the tester pin. A guard output is also

available to drive the shield of a force/sense pair. The AD5520

is available in a 64-lead LQFP package.

AVEEAV

CC

COMPIN2

BW SELECT

CLAMP

DETECT

LOGICS

FSEL

CPSEL

COMPOUT1

COMPOUT0

G = 16

I

SENSE

INST AMP

V

SENSE

INST AMP

G = 1

AM1

AM2

MSEL

COMPOUT2

MOE

CLHDETECT

AM0

MEASI5H

MEASI4H

MEASI3H

MEASI2H

MEASI1H

MEASI0H

GUARDIN

G = 1

MEASVH

MEASVL

CLLDETECT

AC0

AC1

FOH

FOH3

FOH2

FOH1

FOH0

MEASIL

GUARD

AGND

QM5

QM4

DVDDCS

DGND

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

Page 2

(AVCC = +15 V 5%, AVEE = –15 V 5%, DVDD = 5 V 10%, AGND = 0 V, REFGND = 0 V,

AD5520–SPECIFICATIONS

DGND = 0 V. All specifications 0C to 70C, unless otherwise noted.)

Parameter Min Typ1Max Unit Test Conditions/Comments

VOLTAGE FORCE MODE

Force Control Output Voltage Range ⫾11 V R

= 10 kΩ, C

LOAD

LOAD

= 50 pF

FOH Output Impedance 70 Ω

FOH0 2.5 kΩ

FOH1 3 kΩ

FOH2 500 Ω

FOH3 60 Ω

Input Offset Error ⫾1 ⫾5mV

Gain Error 1 %

Clamp Voltage Error

2

⫾1% FSof FIN

CURRENT MEASURE/FORCE Set with external sense resistors

FOH0 ± 4 µA MODE0, RS = 125 kΩ

FOH1 ± 40 µA MODE1, R

FOH2 ± 400 µA MODE2, R

= 12.5 kΩ

S

= 12.5 kΩ

S

FOH3 ± 4mAMODE3, RS = 125 Ω

CURRENT MEASURE MODE

High Sense Input Range, V

Linearity

3

Input Bias Current ⫾1 ⫾3nA

Input Bias Current Drift

1

MEASIxH

50 pA/°C

⫾11 V

⫾0.01 % FSR +11 V > V

> –11 V

FOL

Output Offset Error ⫾100 mV MODE0

⫾100 mV MODE1

⫾100 mV MODE2

⫾100 mV MODE3

Gain Error ⫾0.1 ⫾0.35 % Gain of 16

Gain Error Temperature Coefficient

4

30 µV/°C

MEASIOUT Output Load Current ⫾4mA

CMRR 95 dB @ DC

CURRENT FORCE MODE

Input Offset Error ⫾10 mV With MODE0, MODE1, MODE2, MODE3

Gain Error 1 %

Clamp Current Error

2

⫾1% FSof FIN

VOLTAGE MEASURE MODE

Differential Input Range ⫾11 V

Low Sense Input Voltage Range ⫾100 mV MEASVL

Linearity

3

+0.005 % FSR +11 V > V

MEASVH

to V

MEASVL

> –11 V

Input Offset Error ⫾5 ⫾10 mV FIN = 0 V, Measured @ MEASVOUT

Input Offset Error Temperature

Coefficient

Gain Error ⫾0.03 ⫾0.15 % Gain of 1

Gain Error Temperature Coefficient

Input Bias Current ⫾1 ⫾3nA

Input Bias Current Drift

MEASVOUT Output Load Current ⫾4mA

CMRR

AMPLIFIER SETTLING TIME

V

SENSE

I

SENSE

LOOP SETTLING

1

4

4

4

4, 5

⫾15 mV/°C

2 mV/°C

50 pA/°C

73 dB @ DC

Amp 20 µsTo 0.2%

Amp 12 µsTo 0.2%

4, 5

Settling to within 0.024% of 8 V step

COMPIN2 = 100 pF 450 600 µs MODE0

285 390 µs MODE1

170 240 µs MODE2, MODE3

COMPIN1 = 1000 pF 2 2.5 ms MODE0

1.8 2.4 ms MODE1, MODE2, MODE3

COMPIN0 = 3000 pF 5.75 8.7 ms MODE0, MODE1, MODE2, MODE3

REV. A–2–

Page 3

Parameter Min Typ1Max Unit Test Conditions/Comments

SLEW RATE

4, 5

50 mV/µs COMPIN2 = 100 pF

4.3 mV/µs COMPIN1 = 1000 pF

1.28 mV/µs COMPIN0 = 3000 pF

COMPARATOR

CPH, CPL Input Range ⫾11 V V

CPH

> V

CPL

Input Offset ⫾7mV

GUARD DRIVER

Output Voltage ⫾11 V

Output Impedance 130 Ω Capacitive Load Only

Output Offset Voltage 400 mV

Load Current

Output Settling Time

4

4

⫾4mA

0.5 2 µs 100 pF Capacitive Load

ANALOG REFERENCE INPUTS

Force Control Input Range ⫾11 V

Force Control Input Impedance 1 MΩ

Clamp Control Input Range ⫾11 V V

CLH

> V

CLL

Clamp Control Input Impedance 1 MΩ

Comparator Threshold Input Range ⫾11 V

Comparator Threshold Input Impedance 1 MΩ

Input Capacitance

4

3pF

ANALOG MEASUREMENT OUTPUTS

Voltage Measure Output Impedance 2 Ω

Current Measure Output Impedance 3 Ω

Multiplexed Sense Output Impedance 1 kΩ

Input Capacitance

MEASIxH, MEASVH, FOHx 8 pF

LOGIC INPUTS

Input Current ⫾1 µAAll digital inputs together

Input Low Voltage, V

Input High Voltage, V

Input Capacitance

LOGIC OUTPUTS

Output Low Voltage, V

Output High Voltage, V

INL

IHL

4

4

OL

4

OH

POWER REQUIREMENTS

AV

CC

AV

EE

Power Supply Rejection Ratio, PSRR

2.0 V

2.4 V I

+14.25 +15 +15.75 V For specific performance

–14.25 –15 +15.75 V

1

0.8 V

3pF

0.4 V I

= 2 mA

SINK

SOURCE

= 2 mA

6

FOH –25 dB 100 kHz

–16 dB 500 kHz

–15 dB 1 MHz

MEASOUT –55 dB 100 kHz

–10 dB 500 kHz

DC PSR 90 dB

DV

DD

I

AVCC

I

AVEE

I

DVDD

NOTES

1

Typical values are at 25°C and nominal supply, unless otherwise noted.

2

Full-scale = 11 V.

3

Full-scale range = 22 V.

4

Guaranteed by design and characterization but not subject to production test.

5

Force control amplifier dominates slew rate and settling time.

6

Operational with ± 12 V supplies, force/measure range is reduced to ± 8.5 V.

Specifications subject to change without notice.

5V

12 mA

12 mA

0.5 mA Digital inputs at supply rails

AD5520

REV. A

–3–

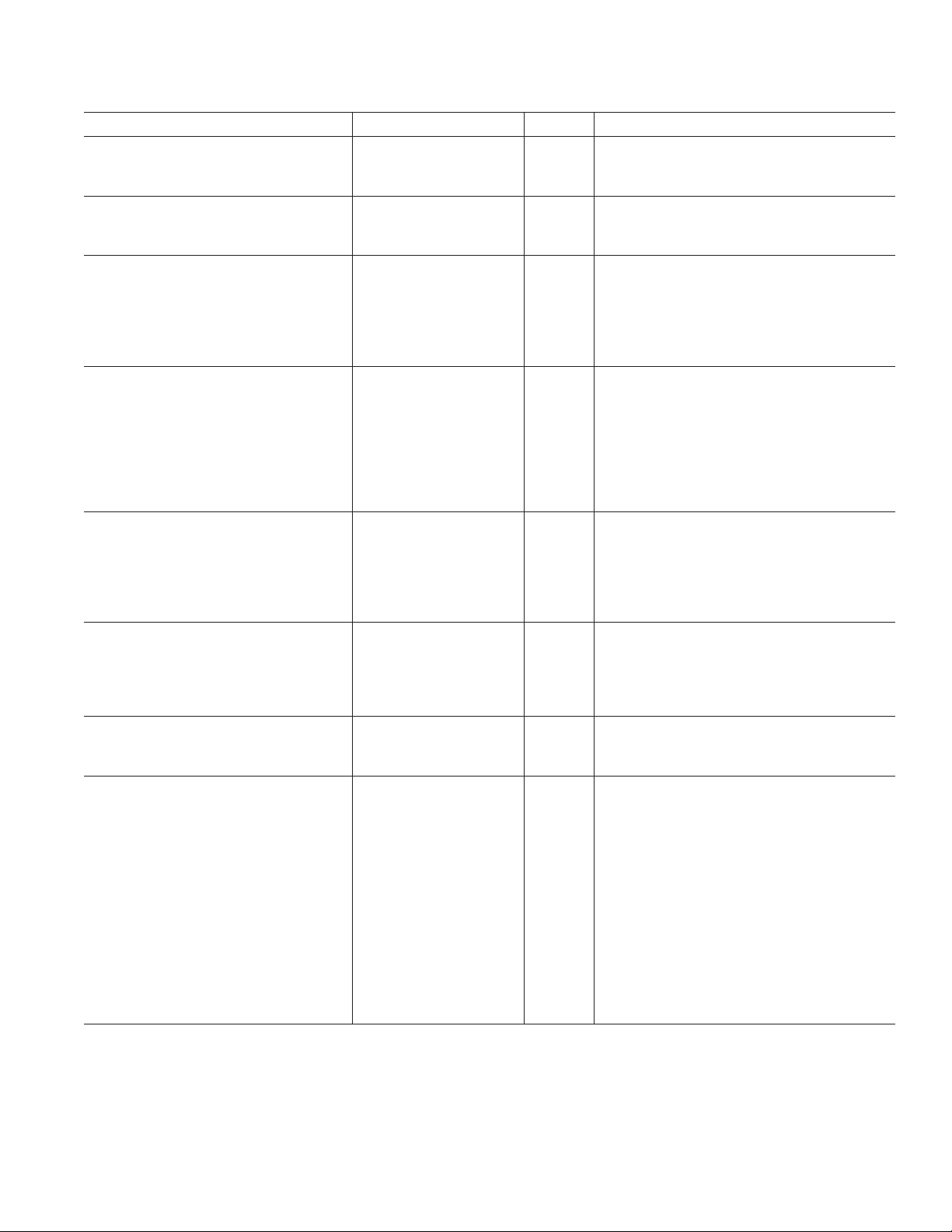

Page 4

AD5520

(AVCC = +15 V 5%, AVEE = –15 V 5%, AGND = 0 V, REFGND = 0 V, DGND = 0 V. All

1, 2

TIMING CHARACTERISTICS

DV

Parameter 5 V 10% 3.3 V Unit Conditions/Comments

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

NOTES

1

See Figure 1.

2

All input signals are specified with tr = tf = 1 ns (10% to 90% of VDD) and timed from a voltage level of (VIL + VIH)/2.

Specifications subject to change without notice.

00ns min CS Falling Edge to STB Falling Edge Setup Time

30 200 ns min STB Pulse Width

40 70 ns min STB Rising Edge to CS Rising Edge Setup Time

040ns min Data Setup Time

550 560 ns min CS Falling Edge to CPCK Rising Edge Setup Time

320 320 ns min CPCK Pulse Width

450 500 ns min CPCK to STB Falling Edge Setup Time

150 800 ns min STB Rising Edge to QMx, CLxDETECT Valid

100 440 ns min STB Rising Edge to CPOH, CPOL Valid

240 240 µs min Comparator Setup Time, MODE2, MODE3 settling

150 500 ns min Comparator Hold Time

100 440 ns min Comparator Output Delay Time

320 320 ns min Comparator Strobe Pulse Width

DD

specifications 0C to 70C, unless otherwise noted.)

STB

AMx, ACx, FSEL,

MSEL, CPSEL

CPCK

QM4, QM5,

CLHDETECT,

CLLDETECT

CPOL, CPOH

CS

t

1

t

4

MEASVOUT

OR MEASIOUT

CPOH, CPOL

t

2

CPCK

t

3

t

5

t

8

Figure 1. Timing Diagram

t

11

t

10

t

12

t

13

t

t

6

7

t

9

Figure 2. Comparator Timing

REV. A–4–

Page 5

AD5520

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C, unless otherwise noted.)

AVCC to AVEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +17 V

AV

CC

AV

to AGND . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V, –17 V

EE

DV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +6 V

DD

Digital Inputs to DGND . . . . . . . . . . –0.3 V to DV

Analog Inputs to AGND . . . . . AV

C

to CLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +34 V

LH

to CPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +34 V

C

PH

REFGND, DGND . . . . . . . . . AV

+ 0.3 V to AVEE – 0.3 V

CC

+ 0.3 V to AVEE – 0.3 V

CC

+ 0.3 V

DD

Operating Temperature Range

Commercial (J Version) . . . . . . . . . . . . . . . . . . 0°C to 70°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature, (T

Package Power Dissipation . . . . . . . . . . . . . (T

Thermal Impedance JA . . . . . . . . . . . . . . . . . . . . . . 47.8°C/W

Lead Temperature (Soldering 10 sec) . . . . . . . . . . . . . . 300°C

IR Reflow, Peak Temperature . . . . . . . . . . . . . . . . . . . . 220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD5520JST 0°C to 70°C 64-Lead LQFP ST-64-2

AD5520JST-REEL 0°C to 70°C 64-Lead LQFP ST-64-2

EVAL-AD5520EB Evaluation Board and Software

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD5520 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

max) . . . . . . . . . 150°C

J

max – TA)/

J

JA

REV. A

–5–

Page 6

AD5520

CPH

CPL

DV

CPOH

CPOL

CPCK

DGND

CLHDETECT

CLLDETECT

QM4

QM5

MOE

CS

STB

AC0

AC1

PIN CONFIGURATION

64-Lead LQFP

COMPIN0

COMPIN1

COMPIN2

REFGND

MEASOUT

REFGND

MEASIOUT

MEASVOUT

FIN

CLH

CLL

1

2

3

DD

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

AD5520

(Not to Scale)

COMPOUT1

COMPOUT2

CC_B

COMPOUT0

AV

49505152535455565758596061626364

FOH

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

AV

EE_B

MEASI5H

MEASI4H

FOH3

MEASI3H

FOH2

MEASI2H

FOH1

MEASI1H

FOH0

MEASI0H

MEASIL

MEASVH

GUARD(NC)

MEASVL

AV

CC_G

DGND

DV

DD

AM2

AM1

AM0

FSEL

STANDBY

NC = NO CONNECT

MSEL

CPSEL

AV

EE

AV

CC

AGND

EE_G

AV

NC

GUARD

GUARDIN

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Description

1 CPH Upper Comparator Threshold Voltage Input, CPH > CPL.

2 CPL Lower Comparator Threshold Voltage Input, CPL < CPH.

3, 18 DV

DD

Digital Supply Voltage.

4 CPOH Logic Output. When high, indicates MEASVOUT or MEASIOUT > CPH.

5 CPOL Logic Output. When high, indicates MEASVOUT or MEASIOUT < CPL.

6CPCK Logic Input. Used to initiate comparator sampling and update CPOH and CPOL.

7, 17 DGND Digital Ground.

8 CLHDETECT Logic Output. When high, indicates upper clamp active. For details, see the Clamp Function section.

9 CLLDETECT Logic Output. When high, indicates lower clamp active. For details, see the Clamp Function section.

10 QM4 Logic Output. When high, indicates current range Mode 4 is enabled. May be used to drive external

relay or switch. For details, see the High Current Ranges section.

11 QM5 Logic Output. When high, indicates current range Mode 5 is enabled. May be used to drive external

relay or switch. For details, see the High Current Ranges section.

12 MOE Active Low MEASOUT Enable.

13 CS Active Low Logic Input. The device is selected when this pin is low. For details, see the Interface

section.

14 STB Active Low Logic Input. Used in conjunction with CPCK and CS to configure the device for differ-

ent configurations. Rising edge of STB triggers sequence inputs. For details, see the Interface section.

15 AC0 Logic Input. Used in conjunction with AC1 to select one of three external compensation capacitors.

For details, see the Force Control Amplifier section.

16 AC1 Logic Input. Used in conjunction with AC0 to select one of three external compensation capacitors.

For details, see the Force Control Amplifier section.

REV. A–6–

Page 7

AD5520

PIN FUNCTION DESCRIPTIONS (continued)

Pin No. Mnemonic Description

19 AM2 Logic Input. Used in conjunction with AM1 and AM0 to select one of six current ranges or to enable

standby mode. For details, see the Current Ranges section.

20 AM1 Logic Input. Used in conjunction with AM2 and AM0 to select one of six current ranges or to enable

standby mode. For details, see the Current Ranges section.

21 AM0 Logic Input. Used in conjunction with AM2 and AM1 to select one of six current ranges or to enable

standby mode. For details, see the Current Ranges section.

22 STANDBY Logic Input. When high, device is in standby mode of operation. For details, see the Standby

Mode section.

23 FSEL Logic Input. Force mode select. Used to select between current or voltage force operation. For details,

see the Force Voltage or Force Current section.

24 MSEL Logic Input. Measure mode select. Used to connect MEASOUT to either MEASIOUT when high or

MEASVOUT when low.

25 CPSEL Logic Input. Comparator select. Used to compare CPL, CPH to MEASVOUT when low, or to

MEASIOUT when high. For details, see the Comparator Function and Strobing section.

26 AV

27 AV

EE

CC

28 AGND MEASx Input Ground.

29 AV

EE_G

30 GUARD Guard Output.

31 NC No Connect.

32 GUARDIN Guard Input.

33 AV

CC_G

34 MEASVL DUT Voltage Sense Inputs (Low Sense).

35 GUARD(NC) No Connect.

36 MEASVH DUT Voltage Sense Inputs (High Sense).

37 MEASIL DUT Current Sense Inputs (Low Sense).

38 MEASI0H DUT Current Sense Inputs (High Sense).

39 FOH0 Force Control Voltage Output.

40 MEASI1H DUT Current Sense Inputs (High Sense).

41 FOH1 Force Control Voltage Output.

42 MEASI2H DUT Current Sense Inputs (High Sense).

43 FOH2 Force Control Voltage Output.

44 MEASI3H DUT Current Sense Inputs (High Sense).

45 FOH3 Force Control Voltage Output.

46 MEASI4H DUT Current Sense Inputs (High Sense).

47 MEASI5H DUT Current Sense Inputs (High Sense).

48 AV

EE_B

49 FOH External Force Driver Control Voltage Output.

50 AV

CC_B

51 COMPOUT0 Compensation Capacitor 0 Output.

52 COMPOUT1 Compensation Capacitor 1 Output.

53 COMPOUT2 Compensation Capacitor 2 Output.

54 COMPIN0 Compensation Capacitor 0 Input.

55 COMPIN1 Compensation Capacitor 1 Input.

56 COMPIN2 Compensation Capacitor 2 Input.

57, 59 REFGND Analog Input/Output Reference Ground.

58 MEASOUT Multiplexed DUT Voltage/Current Sense Output. For details, see the Measured Parameter section.

60 MEASIOUT DUT Current Sense Output.

61 MEASVOUT DUT Voltage Sense Output.

62 FIN Force Control Voltage Input.

63 CLH Upper Clamp Voltage Input CLH > CLL.

64 CLL Lower Clamp Voltage CLL < CLH.

Most Negative Supply Voltage.

Most Positive Supply Voltage.

Most Negative Supply Voltage.

Most Positive Supply Voltage.

Most Negative Supply Voltage.

Most Positive Supply Voltage.

REV. A

–7–

Page 8

AD5520–Typical Performance Characteristics

0.0030

0.0025

0.0020

0.0015

0.0010

VM LINEARITY (%)

0.0005

0

010203040506070

TEMPERATURE (C)

VDD = +15V

= –15V

V

SS

MODE 3

TPC 1. Voltage Sense Amplifier Linearity vs. Temperature

80

70

60

50

40

30

AMPLITUDE (dB)

20

10

VDD = +15V

= –15V

V

SS

= 25C

T

A

0.0030

VDD = +15V

= –15V

V

SS

MODE 3

0.0025

0.0020

0.0015

0.0010

IM LINEARITY (%)

0.0005

0

010203040506070

TEMPERATURE (C)

TPC 4. Current Sense Linearity vs. Temperature

140

VDD = +15V

V

T

120

100

80

60

CMRR (dB)

40

20

= –15V

SS

= 25C

A

I

SENSE

CMRR

0

110100 1k 10k 100k 1M

FREQUENCY (Hz)

TPC 2. Voltage Sense Amplifier CMRR vs. Frequency

10

C

0

–10

–20

–30

AMPLITUDE (dB)

–40

VDD = +15V

–50

= –15V

V

SS

= 25C

T

A

–60

100 1k 10k 100k

C

= 1.0nF

COMP

C

COMP

FREQUENCY (Hz)

= 3.3nF

COMP

= 0.1nF

TPC 3. Force Amplifier Bandwidth–MODE 0 (4 A)

0

110100 1k 10k 100k 1M

FREQUENCY (Hz)

TPC 5. Current Sense Amplifier CMRR vs. Frequency

5

0

–5

C

–10

–15

C

= 1.0nF

–20

AMPLITUDE (dB)

–25

–30

VDD = +15V

–35

= –15V

V

SS

= 25C

T

A

–40

100 1k 10k 100k

COMP

C

COMP

FREQUENCY (Hz)

= 3.3nF

COMP

= 0.1nF

TPC 6. Force Amplifier Bandwidth–MODE 1 (40 A)

REV. A–8–

Page 9

AD5520

0

VDD = +15V

–5

= –15V

V

SS

= 25C

T

A

–10

–15

–20

C

–25

AMPLITUDE (dB)

–30

–35

–40

–45

100 1k 10k 100k

FREQUENCY (Hz)

COMP

= 1.0nF

C

COMP

C

COMP

= 3.3nF

= 0.1nF

TPC 7. Force Amplifier Bandwidth–MODE 2 (400 A)

5

VDD = +15V

= –15V

V

SS

= 25C

T

A

0

–5

–10

0

VDD = +15V

= –15V

V

–5

SS

= 25C

T

A

–10

–15

–20

–25

AMPLITUDE (dB)

–30

–35

–40

–45

100 1k 10k 100k

C

= 1.0nF

COMP

FREQUENCY (Hz)

C

COMP

C

COMP

= 3.3nF

= 0.1nF

TPC 10. Force Amplifier Bandwidth–MODE 3 (4 mA)

30

20

10

0

I

SENSE

AMPLITUDE (dB)

–15

–20

–25

1101k10k 100k 1M 10M100 100M

FREQUENCY (Hz)

TPC 8. Guard Amplifier Bandwidth

20

VDD = +15V

= –15V

V

SS

10

= 25C

T

A

0

–10

–20

–30

AMPLITUDE (dB)

–40

–50

–60

100k 1M 10M

FREQUENCY (Hz)

TPC 9. Current Sense Amplifier AC PSRR

V

AMPLITUDE (dB)

–10

–20

VDD = +15V

= –15V

V

SS

= 25C

T

A

–30

100 1k 100k 1M10k 10M

SENSE

FREQUENCY (Hz)

TPC 11. Voltage Sense and Current Sense

Amplifier Bandwidths

0

VDD = +15V

= –15V

V

SS

= 25C

T

A

–5

–10

–15

AMPLITUDE (dB)

–20

–25

–30

100k 1M 10M

FREQUENCY (Hz)

TPC 12. Force Amplifier AC PSRR–MODE 3,

= 100 pF

C

COMP

REV. A

–9–

Page 10

AD5520

20

VDD = +15V

= –15V

V

SS

10

= 25C

T

A

0

–10

–20

–30

AMPLITUDE (dB)

–40

–50

–60

100k 1M 10M

FREQUENCY (Hz)

TPC 13. Voltage Sense Amplifier AC PSRR

700

600

500

400

nV/ Hz

300

200

100

0

10 100 1k 10k 100k

FOH

I

SENSE

GUARD

V

SENSE

FREQUENCY (Hz)

TPC 14. Noise Spectral Density

16

14

V

12

10

8

6

VOLTAGE (V)

4

2

0

–2

051015 20 25 30 35 40 45

CC

V

TIME (ms)

TPC 15. Power Up

9

COMPIN2 = 100pF

8

7

6

5

4

3

VOLTAGE (V)

2

1

0

–1

0 0.001 0.002 0.003 0.004 0.005 0.006 0.007

COMPIN1 = 1000pF

COMPIN2 = 3000pF

TIME (s)

TPC 16. Settling Time, Mode 2

DUT

0.008

REV. A–10–

Page 11

THEORY OF OPERATION

The AD5520 is a single channel per pin parametric measurement

unit (PPMU) for use in semiconductor automatic test equipment. It contains programmable modes to force a pin voltage and

measure the corresponding current (FVMI), force current measure voltage (FIMV), force current measure current (FIMI), and

force voltage measure voltage (FVMV). The PPMU can force or

measure a voltage from –11 V to +11 V. It can force or measure a

current over four ranges: 4 µA, 40 µA, 400 µA, and 4 mA. The

addition of an external driver allows two extended ranges.

The device provides a force sense capability to ensure accuracy

at the tester pin. A guard output is also available to drive the

shield of a force/sense pair.

The AD5520 has an on-board window comparator that provides two bits of useful information, DUT too low or too high.

Also provided on the chip is clamp circuitry that will flag via

CLHDETECT and CLLDETECT if the voltage applied to

FIN or across the DUT has exceeded the voltage applied to

CLL and CLH.

On chip is clamp circuitry that clamps the output of the force

amplifier if the voltage at MEASIOUT and MEASVOUT

exceeds CLL and CLH.

INTERFACE

The AD5520 PPMU is controlled via a number of digital inputs,

which are discussed in detail in the following sections. All inputs

are TTL compatible. CS is used to select the device while STB

(active low input) latches data available on the other digital inputs

and updates any required digital outputs. The rising edge of STB

triggers sequence inputs. The remaining digital inputs control the

function of the PMU—which measure mode it is in, which compensation capacitor is used, and the selected current range.

Standby Mode

The AD5520 may be placed into standby mode via the standby

logic input. In this mode, the force amplifier is disconnected from

the force input (FIN), the switch in series with the force output

pins, FOHx, is opened, and the current measure amplifier is disconnected from the sense resistors. The voltage measure amplifier

is still connected across the DUT, so DUT voltage measurements may still be made while in standby mode. Figure 3 shows

the configuration of the PMU while in standby mode.

Table I. Standby Mode

AD5520

DAC

FIN

MEASIOUT

MEASVOUT

G = 16

G = 1

Figure 3. PMU in Standby Mode

Force Voltage or Force Current

FSEL is an input that determines whether the PPMU forces a

voltage or current.

Table II. FSEL Function

FSEL Function

Low Voltage Force and Current Clamp with

MEASIOUT Voltage

High Current Force and Voltage Clamp with

MEASVOUT Voltage

Measured Parameter

MEASOUT is a muxed output that tracks the sensed parameter,

MSEL connects it to the output of either the current sense

amplifier or the voltage sense amplifier, depending on which is

the measured parameter of interest.

The MEASOUT pin will be connected back to an ADC to

allow the measured value to be converted to a digital code.

Table III. MEASOUT Connected to

Voltage or Current

MSEL Function

Low MEASOUT = DUT Voltage

High MEASOUT = DUT Current

The MEASOUT pin may also be made high impedance through

the MOEB logic input.

FOHx

MEASIHx

MEASIL

MEASVH

MEASVL

R

DUT

S

REV. A

STANDBY Function

Low Normal Force Mode

High Standby Mode

Table IV. MOEB Allows MEASOUT

to Go High Impedance

MOEB Function

Low Enable MEASOUT Output

High Hi-Z MEASOUT Output

–11–

Page 12

AD5520

Current Ranges

A number of current ranges are possible with the AD5520. The

AM0, AM1, and AM2 pins are digital inputs used to establish

full-scale current range of the PMU.

Table V. Selection of Current Range

AM0 AM1 AM2 Function

Low Low Low Current Range MODE0 (up to 4 µA)

High Low Low Current Range MODE1 (up to 40 µA)

Low High Low Current Range MODE2 (up to 400 µA)

High High Low Current Range MODE3 (up to 4 mA)

Low Low High Current Range MODE4 (External

Buffer Mode)

High Low High Current Range MODE5 (External

Buffer Mode)

Low High High Standby (same as STANDBY = High)

High High High Standby (same as STANDBY = High)

RS Selection

The AD5520 is designed so that the voltage drop across each of

the R

resistors will be less than ±500 mV when maximum current

S

is flowing through them. To support other current ranges, these

sense resistor values may be changed. A force amplifier can

drive a maximum of 6 mA. It is not recommended to increase

the maximum current above the nominal range.

The two external current ranges use an external buffer to drive the

required current. Our example uses 40 mA and 160 mA ranges.

These ranges can be changed to suit user requirements for a high

current range.

Force Control Amplifier

The force control amplifier requires external capacitors connected

between the COMPOUTx and COMPINx pins. For stability

with large capacitance at the DUT, the largest capacitance value

(3000 pF) should be selected. The force control amplifier should

always contribute the dominant pole in the control loop. Settling times will increase with larger capacitances. ACx inputs

select which external compensation capacitor is used.

Table VI. AC0, AC1 Compensation Capacitor Selection

AC0 AC1 Function

Low Low Select External Compensation Capacitor 0

High Low Select External Compensation Capacitor 1

Low High Select External Compensation Capacitor 2

Comparator Function and Strobing

The AD5520 has an on-board window comparator that provides two bits of useful information, DUT too low or too high.

CPSEL is the digital input that controls this function, selecting

whether it should compare to the voltage sense or the current

sense amplifier.

Table VII. Comparator Function Select

CPSEL Function

Low Compare CPL, CPH to MEASVOUT

High Compare CPL, CPH to MEASIOUT

After CPSEL has selected which amplifier output is of interest,

logic input CPCK is used to initiate comparator sampling and

update the logic outputs CPOH and CPOL, indicating if the

voltages at MEASIOUT or MEASVOUT have exceeded voltages set at CPL or CPH (thus providing DUT too high or DUT

too low information). A rising edge on STB is required to clock

the CPOH and CPOL data out.

Table VIII. CPCK Synchronous Logic Outputs

CPOH Function

Low MEASVOUT or MEASIOUT < CPH

High MEASVOUT or MEASIOUT > CPH

CPOL Function

Low MEASVOUT or MEASIOUT > CPL

High MEASVOUT or MEASIOUT < CPL

Clamp Function

Clamp circuitry is also included on chip, allowing the output of

the force amplifier to be clamped in the event of the voltage at

MEASIOUT and MEASVOUT exceeding CLL and CLH. The

clamp circuitry play their role in the event of a short or open

circuit. When in force current range, the voltage clamps protect

the DUT in the event of an open circuit. Likewise, when forcing

a voltage and a short circuit occurs, the current clamps will

protect the DUT in this case. The clamps also function to protect the DUT in the event of a transient voltage or current spike

that may occur when changing to a different operating mode or

when programming the device to a different current range.

The digital output flags, which indicate a clamp limit has been

hit, are CLHDETECT for the upper clamp and CLLDETECT

output for the lower clamp.

Table IX. Clamp Detect Outputs

CLHDETECT Function

Low Upper Clamp Inactive

High Upper Clamp Active

CLLDETECT Function

Low Lower Clamp Inactive

High Lower Clamp Active

High Current Ranges

With the use of an external high current amplifier, two high

current ranges are possible. The current range values can be

selected as required in the application through appropriate

selection of the sense resistors connected between MEASI5H,

MEASI4H, and MEASIL. When one of these high current

ranges (MODE 4 or MODE 5) is selected via the AMx control

lines, the appropriate QM4 or QM5 output will be enabled.

These outputs can thus be used to control relays connected in

series with the high current amplifier as shown in Figure 8.

Table X. High Current Range Logic Outputs

QM4 QM5 Function

High Low Current Range MODE 4 Enable Output

Low High Current Range MODE 5 Enable Output

REV. A–12–

Page 13

AD5520

CIRCUIT OPERATION

Force Voltage

Most PMU measurements are performed while in force voltage

and measure current modes, for example, when the device is

used as a device power supply, or in continuity or leakage

testing. In the force voltage mode, the voltage at analog input

FIN is mapped directly to the voltage forced at the DUT.

When in force voltage and measure current modes, the maximum voltage applied to the input corresponds to the maximum

current outputs. Figure 4 shows the transfer function when forcing

a voltage.

V

DUT

R

DUT

V

CLH

R

16

S

V

FIN

R

CLL

V

CLL

RS 16

DUT

R

16

S

V

V

CLH

FIN

V

CLH

RS 16

V

CLH

I

V

DUT

the CLL and CLH levels to ensure the clamp voltages have not

been exceeded. Strobing CPCK and STB will provide information

about the voltage level with respect to the comparator levels,

CPH and CPL.

FIN

FOHx

MEASIHx

MEASIOUT

MEASVOUT

< I

RS 16

DUT

< I

RS 16

DUT

V

= V

DUT

G = 16

G = 1

CLH

V

CLH

V

CLL

MEASIL

MEASVH

MEASVL

> I

DUT

> I

DUT

V

DUT

RS 16

RS 16

= V

CLL

R

S

R

DUT

VFIN

CONDITION

OUTPUT

VCLH

CLH

CLL

VCLL

REFGNDI/V

V

VMEASVOUT

V

VMEASIOUT

V

> I

RS 16

CLH

DUT

< I

CLL

V

DUT

RS 16

DUT

= V

FIN

V

V

CLH

V

CLL

Figure 5. Voltage Force, Measure Current Mode

Force Current

In the force current mode, the voltage at FIN is now converted

to a current through the following relationship:

Force Current V R

= /

FIN SENSE

Figure 6 shows a simplified diagram of the PMU when in

force current mode. The control loop consists of the force

amplifier with the current sense amplifier making up the feedback path. In this case, voltage at the DUT is sensed across

the voltage measure amplifier (Gain = 1) and presented at

the MEASVOUT output.

FIN

FOHx

MEASIHx

Figure 4. Voltage Force Transfer Function

Measure Current

Figure 5 shows a simplified diagram of the PMU when in force

voltage mode. The control loop consists of the force amplifier

with the voltage sense amplifier making up the feedback path.

Current flowing through the DUT is measured by sensing the

current flowing through a selectable sense resistor, which is in

series with the DUT. The current sense amplifier (Gain = 16)

generates a voltage at its output, which is proportional to the

current flowing through the DUT. This voltage is compared to

REV. A

–13–

MEASIOUT

MEASVOUT

V

< V

CLH

DUT

V

< V

CLL

DUT

V

CLH

I

=

DUT

R

G = 16

G = 1

S

V

CLH

V

CLL

I

DUT

VFIN

VCLH

CONDITION

OUTPUT

VCLL

CLH

CLL

REFGNDI/V

V

VMEASVOUT

V

VMEASIOUT

V

CLH

V

CLL

I

DUT

=

> V

< V

DUT

DUT

V

FIN

R

S

Figure 6. Current Force, Voltage Measure Mode

> V

> V

=

MEASIL

MEASVH

MEASVL

DUT

DUT

V

CLL

R

S

R

S

R

DUT

Page 14

AD5520

Figure 7 illustrates the transfer function of the current force mode.

I

DUT

V

CLH

R

DUT

V

FIN

V

CLL

R

DUT

V

DUT

V

CLH

V

CLH

V

CLH

V

CLH

V

FIN

Figure 7. Current Force Transfer Function

Measure Voltage

A DUT voltage is tested via the voltage measure amplifier by a

window comparator to ensure that CPH and CPL levels are not

exceeded. In addition, the DUT voltage is automatically tested

against the voltage levels at the clamp, and clamp flags are

enabled if the DUT voltage exceeds either of the levels.

Short Circuit Protection

The AD5520 is designed to withstand a direct short circuit on

any of the amplifier outputs.

SETTLING TIME CONSIDERATIONS

Fast throughput is a key requirement in automatic test equipment

because it relates directly to the cost of manufacturing the DUT,

thus reducing the time required to make a DAC measurement is of

upmost importance. When taking measurements using a PMU, the

limiting factor is usually the time it takes the output to settle to the

required accuracy so a measurement can be taken. DUT capacitance, measurement accuracy, and the design of the PMU are the

major contributors to this time. Figure 8 shows a simplified block

diagram of the AD5520 PMU. In brief, the device consists of a

force control amplifier, access to a number of selectable sense

resistors, a voltage measure instrumentation amplifier, and a

current measure instrumentation amplifier. To optimize the

performance of the device, there are also nodes provided where

external compensation capacitors are added. As mentioned, making an accurate measurement in the fastest time while avoiding

overshoots and ringing is the key requirement in any ATE system.

This in itself provides challenges. The external compensation

capacitors set up different settling times or bandwidths on the force

control amplifier, and, while one compensation capacitor value

may suit one range, it may not suit other ranges. To optimize

measurement performance and speed, differences in signal behavior on each range and frequency of use of each range need to be

taken into account.

When selecting a faster settling time, there is a trade-off between

the faster settling, overshoots, and ringing. A small compensation value will result in faster settling but may incur penalties in

overshoots or ringing at the DUT. Compensation capacitor

selection should be optimized to ensure minimum overshoots

while still giving good settling time performance.

While careful selection of the compensation capacitor is required

to minimize the settling time, another factor can greatly contribute

to the overall settling of the loop if the feedback loop is broken

in some manner and the force control amplifier goes to either

the positive or negative rails. There is a finite amount of time

required for the amplifier to recover from this condition, typically 85 µs, which adds to the settling of the loop. Ensuring that

the force control amplifier never goes into saturation is the best

solution. This solution can be helped by putting the device into

standby mode at any time the operating mode or range selection

is changed. In addition, ensure that the selected output range

can supply the required current needed by the DUT.

PCB LAYOUT AND POWER SUPPLY DECOUPLING

In any circuit where accuracy is important, careful consideration

to the power supply and the ground return layout helps to ensure

the rated performance. The printed circuit board on which

the AD5520 is mounted should be designed so that the analog

and digital sections are separated and confined to certain areas

of the board. If the PMU is in a system where multiple devices

require an AGND-to-DGND connection, the connection should

be made at one point only. The star ground point should be

established as close as possible to the device.

This PMU should have ample supply bypassing of 10 µF in

parallel with 0.1 µF on the supply located as close to the pack-

age as possible, ideally right up against the device. The 0.1 µF

capacitor should have low effective series resistance (ESR) and

effective series inductance (ESI), such as the common ceramic

types that provide a low impedance path to ground at high

frequencies, to handle transient currents due to internal logic

switching. Low ESR, 1 µF to 10 µF, tantalum or electrolytic

capacitors should also be applied at the supplies to minimize

transient disturbance and filter out low frequency ripple.

Fast switching signals, such as clocks, should be shielded with

digital ground to avoid radiating noise to other parts of the

board and should never be run near the reference inputs.

Avoid crossover of digital and analog signals. Traces on opposite sides of the board should run at right angles to each other.

This reduces the effects of feedthrough through the board. A

microstrip technique is by far the best but not always possible

with a double-sided board. In this technique, the component

side of the board is dedicated to the ground plane while signal

traces are placed on the solder side.

REV. A–14–

Page 15

AD5520

It is good practice to employ compact, minimum lead length

PCB layout design. Leads to the input should be as short as

possible to minimize IR drops and stray inductance.

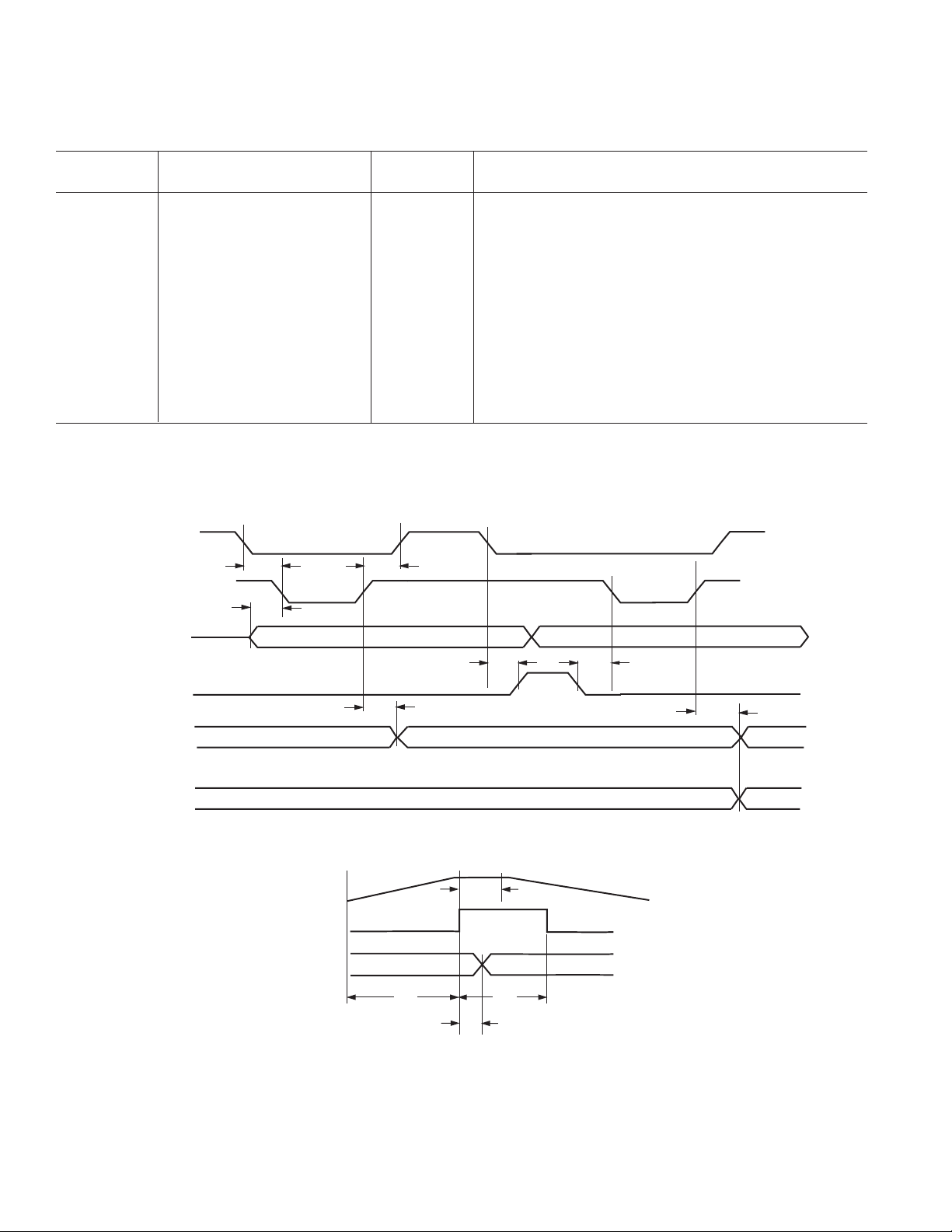

TYPICAL CONNECTION CIRCUIT FOR THE AD5520

Figure 8 shows the AD5520 connected as it would be in a typical

application. The external components required are three compensation capacitors and six sense resistors, depending on how

many ranges are required. If high current ranges > 6 mA are

3000pF

1000pF

100pF

+15V –15V

AVEEAV

CC

AD5520

FIN

CLH

CLL

REFGND

MEASIOUT

MEASOUT

MEASVOUT

COMPARATOR

CPH

CPOH

CPOH

CPL

COMPIN0

COMPIN2

COMPIN1

BW SELECT

COMPOUT1

COMPOUT0

FORCE

AMPLIFIER

CLAMP

DETECT

G = 16

I

SENSE

INST AMP

V

SENSE

INST AMP

G = 1

LOGICS

COMPOUT2

G = 1

MEASI5H

MEASI4H

MEASI3H

MEASI2H

MEASI1H

MEASI0H

GUARDIN

required, an external amplifier must be used with relays to switch

in the different current ranges to the DUT. Other components

are also required to make the PMU function. The PMU requires

a number of discrete voltage levels: five DAC levels for each

PMU used in the system, two levels each for the comparator

and clamps, and one voltage level for the AD5520 force input

voltage. To utilize the information gathered from the DUT, an

ADC (such as the AD7665 16-Bit ADC) must be connected to

the MEASOUT pin to convert the measured current or voltage

to the digital world for analysis.

FOH

FOH3

FOH2

FOH1

FOH0

12.5k⍀

125k⍀

MEASIL

GUARD

MEASVH

MEASVL

AGND

QM5

QM4

AD815

RELAY

<ⴞ11.5V

3.126⍀

12.5⍀

125⍀

1.25k⍀

ⱕⴞ11V

DUT

<ⴞ100mV

REV. A

CPCK

STB

STANDBY

FSEL

CPSEL

MSEL

AM2

AM1

AM0

MOE

CLHDETECT

CLLDETECT

AC0

AC1

DVDDCS

DGND

Figure 8. Typical Configuration of the AD5520 as Used in an ATE Circuit

–15–

Page 16

AD5520

TYPICAL APPLICATION CIRCUIT

Figure 9 shows the AD5520 as it would be used in an ATE

system. This device could be used as a per pin parametric unit

in order to speed up the rate at which testing could be done. It

could also be used as a DUT power supply, as shown in the

application circuit. The central PMU shown in the block

diagram is usually a highly accurate PMU and is shared among a

number of pins in the tester. In general, many discrete levels are

required in an ATE system for the pin drivers, comparators,

clamps, and active loads. DAC devices, such as the AD5379, offer

a highly integrated solution for a number of these levels. The

AD5379 is a dense 40-channel DAC designed with high channel

requirements, like ATE in mind.

The flexible function of the AD5520 also makes it suited for use in

instrumentation applications such as source measure units. Source

measure units are programmable instruments capable of sourcing

and measuring voltage or current simultaneously. The AD5520

provides a more integrated solution in such equipment.

EVALUATION BOARD FOR THE AD5520 PMU

A full featured evaluation kit is available for the AD5520. It

consists of an evaluation board with direct hookup via a 36-way

CENTRAL PMU

TIMING DATA

MEMORY

TIMING

GENERATOR

DLL, LOGIC

DAC

ADC

FORMATTER

DE-SKEW

DAC

DAC

GUARD AMP

DAC

VTERM

VH

DRIVER

VCH

RELAYS

centronics connector to a PC. PC-based software to control the

AD5520 is provided as part of the evaluation kit. The evaluation board schematic is shown in Figure 10. Note that V

must provide sufficient headroom for the force and measure

V

SS

DD

and

voltage range. In addition to the supply voltages for the evaluation board, it is also necessary to provide the following voltage

levels for the clamp, comparator, and the force input pin—CLL,

CLH, CPL, CPH, and FIN. SMB connections are provided

for these voltage inputs. To use the evaluation board, it will also

be necessary to provide a DUT connected via the gold pins.

Both AGND and DGND inputs are provided on the board.

The AGND and DGND planes are connected at one location

close to the AD5520. It is recommended not to connect AGND

and DGND elsewhere in the system to avoid ground loop problems. REFGND is routed back to AGND at the power block to

maintain a clean ground reference for accurate measurements.

Each supply is decoupled to the relevant ground plane with

10 F and 0.1 F capacitors. The device supply pin is again

decoupled with a 10 F and 0.1 F capacitor pair to the relevant

ground plane.

Care should be taken when replacing devices to ensure that

the pins line up correctly with the PCB pads.

PPMU

DAC

ADC

DEVICE UNDER

TEST (DUT)

50 COAX

COMPARE

MEMORY

FORMATTER

DE-SKEW

DAC

DAC

DAC

DAC

DAC

DAC

VCL

VL

DAC

COMP

VTH

VTL

ACT IVE LOAD

IOL

VCOM

IOH

Figure 9. Typical Application ATE Circuit

GND SENSE

DEVICE POWER

SUPPLIES

DAC

ADC

GUARD

AMP

REV. A–16–

Page 17

AD5520

QM5

R9

D2

RL2

10k

B

C

Q1

C16

10pF

E

T1

T3

U5–B

14

15

16

AD815ARB–24

T2

D1

RL1

AD815ARB

59

57

REFGND

REFGND

974210

RELAY–G6H

974210

RELAY–G6H

R11

52

E

R5, 12.4

R4, 124

R3, 1.24k

R2, 12.4k

R1, 124k

54

C9, 3.3nF

QM4

C15

10pF

35

36

NC

MEASVH

COMPIN0

COMPOUT0

51

323130

34

MEASVL

GAURDIN

EE

AV

26

29

C5

LK1

NC

AV

0.1F

C10

–15V

GUARD

EE_G

48

10F

C17

EE_B

AV

C19

R10

C6

20V

DGND AGND

7 17 28

DGND

10F

C11

C18

0.1F

20V

C12

0.1F

AD815ARB–24

12

13

+VS

–VS

U5–C

+15V

20V

C23

10F

C22

0.1F

J11–1

20V

+5VD

C21

10F

C20

0.1F

C13

C25

C24

J11–2

10F

20V

20V

+15V

–15V

10F

0.1F

J11–3

R8

10k

B

C

Q1

R7

R6

5k

C14

49

4746454443424140393837

FOH

16

FOH3

FOH2

MEASI5H

MEASI4H

MEASI3H

MEASI2H

CPOH4CPOL5CHL-DET8CLL-DET9QM410QM5

FOH1

11

FOH0

MEASIL

MEASI1H

MEASIOH

COMPIN256COMPOUT2

53

C8, 1nF

C7, 100pF

COMPIN155COMPOUT1

831

+5VD +5VD

J9

J8

J7

J6

T4

27

C4

T5

CC

CC_G

AV

AV

33

10F

T7

T6

6061626364

58

MEASOUT

MEASIOUT

CC_B

AV

50

20V

J5

J4

J3

J2

C2

C1

20V

10F

0.1F

DD

3

DV

+15V

DD

DV

18

C3

0.1F

+5VD

T11

T10

T9

T8

FIN

CLL

CLH

MEASVOUT

STANDBY22STB14CPCK6MOEB12CSB13AM021AM120AM219FSEL23CPSEL25MSEL24AC015AC1

1

2

CPH

CPL

U5–A

R12

831

5k

T12

U2, U3, U4 BYPASS CAPACITORS

REV. A

18

19

Q0

74HCT573

D0D1D2D3D4D5D6

2

D0D1D2D3D4D5D6

D[0:7]

+5VD

C28

0.1F

C27

0.1F

C26

0.1F

15

16

17

141312

Q1Q2Q3Q4Q5Q6Q7

D7

6

543

789

D7

U2

C

11

J1–14

J10–1

J10–2

1

141312

11

C

D7

OE

U4

74HCT573

J1–19

D7

J1–31

J1–36

J1–23

J1–22

J1–21

J1–20

D0D1D2D3D4D5D6

J1–2

J1–24

J1–3

J1–25

J1–4

J1–26

J1–5

J1–27

J1–28

J1–7

J1–6

J1–29

J1–30

D7

J1–9

J1–8

543

11

U3

C

1

J1–1

OE

2

D0D1D2D3D4D5D6

Q0

19

D0D1D2D3D4D5D6

19

Q0

74HCT573

OE

1

D0D1D2D3D4D5D6

2

D0D1D2D3D4D5D6

141312

Q1Q2Q3Q4Q5Q6Q7

D7

6

543

789

D7

15

16

17

18

789

6

Q1Q2Q3Q4Q5Q6Q7

15

16

17

18

Figure 10. Evaluation Board Schematic

–17–

Page 18

AD5520

OUTLINE DIMENSIONS

64-Lead Low Profile Quad Flat Package [LQFP]

(ST-64-2)

Dimensions shown in millimeters

1.45

1.40

1.35

0.15

0.05

10ⴗ

6ⴗ

2ⴗ

SEATING

PLANE

ROTATED 90ⴗ CCW

VIEW A

0.08 MAX

COPLANARITY

0.75

0.60

0.45

SEATING

PLANE

0.20

0.09

7ⴗ

3.5ⴗ

0ⴗ

COMPLIANT TO JEDEC STANDARDS MS-026BCD

1.60

MAX

1

VIEW A

16

17

PIN 1

0.50

BSC

12.00 BSC

SQ

TOP VIEW

(PINS DOWN)

0.27

0.22

0.17

4964

48

10.00

BSC SQ

33

32

REV. A–18–

Page 19

AD5520

Revision History

Location Page

10/03—Data Sheet changed from REV. 0 to REV. A.

Changes to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Updated ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REV. A

–19–

Page 20

C03701–0–10/03(A)

–20–

Loading...

Loading...